Page 1

Quick Start Guide

00825-0100-4377, Rev FB

Rosemount™ 752 Remote Indicator

with FOUNDATION™ Fieldbus Protocol

April 2021

Page 2

Quick Start Guide April 2021

Safety messages

This guide provides basic guidelines for Rosemount 752 Remote Indicator. It does not provide

instructions for configuration, diagnostics, maintenance, service, troubleshooting, Explosion-proof,

Flameproof, or intrinsically safe (I.S.) installations. Refer to the Rosemount 752 Reference Manual for

more instruction. This manual is also available electronically on Emerson.com/Rosemount.

WARNING

Explosions could result in death or serious injury.

Installation of this indicator in an explosive environment must be in accordance with the appropriate

local, national, and international standards, codes, and practices. Review the Product Certifications

section for any restrictions associated with a safe installation.

• Before connecting a communicator in an explosive atmosphere, ensure the instruments in the

segment are installed in accordance with intrinsically safe or non-incendive field wiring practices.

• In an explosion-proof/flameproof installation, do not remove the indicator cover when power is

applied to the unit.

Electrical shock can result in death or serious injury.

• Avoid contact with the leads and terminals. High voltage that may be present on leads can cause

electrical shock.

Conduit/cables entries

• Unless marked, the conduit/cable entries in the housing use a ½–14 NPT thread form. Entries

marked “M20” are M20 × 1.5 thread form. On devices with multiple conduit entries, all entries will

have the same thread form. Only use plugs, adapters, glands, or conduit with a compatible thread

form when closing these entries.

• When installing in a hazardous location, use only appropriately listed or Ex certified plugs, glands,

or adapters in cable/conduit entries.

Contents

Wiring connection........................................................................................................................3

Configure the transducer block.................................................................................................... 7

Product Certification.................................................................................................................... 9

Declaration of Conformity..........................................................................................................16

China RoHS................................................................................................................................ 19

2 Rosemount 752

Page 3

April 2021 Quick Start Guide

1 Wiring connection

1.1 Wiring for FOUNDATION™ Fieldbus protocol

1. Remove the housing cover on terminal compartment side.

Note

Do not remove the cover in explosive atmospheres when the circuit

is live. Signal wiring supplies all power to the indicator.

2. Connect the power leads to the terminals marked “FIELDBUS

WIRING” as shown in Figure 1-1.

Note

The power terminals are not polarity sensitive.

3. Plug and seal unused conduit connections on the indicator housing

to avoid moisture accumulation in the terminal side.

a. If you do not seal unused connections, mount the indicator

with the electrical housing positioned downward for

drainage.

b. Install wiring with a drip loop.

c. Arrange the drip loop so the bottom is lower than the conduit

connections and the indicator housing.

Note

Do not apply high voltage (e.g. ac line voltage) to the indicator terminals.

Abnormally high voltage can damage the unit. Indicator terminals are rated

to 32 Vdc.

Figure 1-1: Fieldbus Terminal Block

Quick Start Guide 3

Page 4

Quick Start Guide April 2021

Electrical considerations

Proper electrical installation is necessary to prevent errors due to improper

grounding and electrical noise. Shielded, twisted pair cable should be used

for best results in electrically noisy environments. Cable type A is

recommended by FOUNDATION™ Fieldbus protocol.

Power supply

The indicator requires between 9 and 32 Vdc (9 and 15 Vdc for FISCO) to

operate and provide complete functionality. The dc power supply should

provide power with less than two percent ripple.

Power conditioner

A Fieldbus segment requires a power conditioner to isolate the power

supply, filter, and decouple the segment from other segments attached to

the same power supply.

Grounding

Signal wiring of the Fieldbus segment cannot be grounded. Grounding out

one of the signal wires will shut down the entire FOUNDATION™ Fieldbus

segment.

Shield wire ground

To protect the Fieldbus segment from noise, grounding techniques for

shield wire usually require a single grounding point for shield wire to avoid

creating a ground loop. The ground point is typically at the power supply.

4 Rosemount 752

Page 5

I

J

H

H

F

B

C

D

E

A

G

April 2021 Quick Start Guide

Figure 1-2: FOUNDATION Fieldbus Indicator Field Wiring

Intrinsically safe installations may allow fewer devices per I.S. barrier due to

current limitations.

A. Power supply

B. Integrated power conditioner and filter

C. 6234 ft. (1900 m) max (depending upon cable characteristics)

D. Terminators

E. Fieldbus segment

F. Trunk

G. FOUNDATION™ Fieldbus configuration tool

H. Spur

I. Signal wiring

J. Fieldbus devices on segment

(1)

(1) The power supply, filter, first terminator, and configuration tool are typically located

in the control room.

Quick Start Guide 5

Page 6

Quick Start Guide April 2021

Surges/transients

The indicator will withstand electrical transients of the energy level usually

encountered in static discharges or induced switching transients. However,

high-energy transients, such as those induced in wiring from nearby

lightning strikes, can damage the indicator.

Optional transient protection terminal block

The transient protection terminal block can be ordered as an installed option

(option code T1 in the indicator model number) or as a spare part. The spare

part number is 03151-4131-0002. The lightning bolt symbol shown

identifies it as a transient protection terminal block.

Note

The Fieldbus physical layer specification requires indicator communication

during extreme operating conditions of 250 Vrms common mode signal.

The transient terminal block was designed to limit common mode voltages

to 90 V and cannot be used in these extreme operating conditions.

1.2 Grounding the indicator case

Always ground the indicator case in accordance with national and local

electrical codes. The most effective indicator case grounding method is a

direct connection to earth ground with minimal impedance. Methods for

grounding the indicator case include:

Internal ground connection

The internal ground connection screw is inside the terminal side of the

electronics housing. The screw is identified by a ground symbol (

standard on the Rosemount 752 Remote Indicators.

External ground assembly

Ground screw is located at the bottom of the mounting bracket.

Note

Grounding the indicator case using the threaded conduit connection may

not provide a sufficient ground. The transient protection terminal block

(option code T1) will not provide transient protection unless the indicator

case is properly grounded. Use the above guidelines to ground the indicator

case. Do not run transient protection ground wire with signal wiring; the

ground wire may carry excessive current if a lightning strike occurs.

6 Rosemount 752

), and is

Page 7

April 2021 Quick Start Guide

2 Configure the transducer block

The LCD display transducer block can be configured to sequence eight

different process variables. If a function block is scheduled in the Rosemount

752 that links a process variable from another device on the segment, that

process variable can be displayed on the LCD display.

To configure the Rosemount 752 Fieldbus Indicator use any FOUNDATION

Fieldbus configuration tool to modify the configuration parameters for each

value that is to be displayed.

2.1 Configuration parameters

Note

Some host systems may ask for the device's capability level during

commissioning. If prompted, the correct value to enter for the Rosemount

752 is 1.

DISPLAY_PARAM_SEL

The DISPLAY_PARAM_SEL parameter specifies how many process variables

willbe displayed. Select up to eight display parameters.

BLK_TAG_#

Enter the Block Tag of the function block that contains the parameter to be

displayed. The default function block tags from the factory are:

• PID_1200_XXXX

• ISEL_1300_XXXX

• CHAR_1400_XXXX

• ARITH_1500_XXXX

• INTEG_1600_XXXX

™

Note

XXXX represents the last four digits of the device ID.

BLK_TYPE_#

Enter the Block Type of the function block that contains the parameter to be

displayed. (e.g. ISEL PID, etc.)

PARAM_INDEX_#

Choose the parameter to be displayed.

Quick Start Guide 7

Page 8

Quick Start Guide April 2021

CUSTOM_TAG_#

The CUSTOM_TAG_# is an optional user-specified tag identifier that can be

configured to be displayed with the parameter in place of the block tag.

Enter a tag of up to five characters.

UNITS_TYPE_#

The UNITS_TYPE_# parameter is generally selected via a drop-down menu

with three options: AUTO, CUSTOM, or NONE. Select CUSTOM and be sure

to configure the CUSTOM_UNITS_# parameter. Select NONE if the

parameter is to be displayed without associated units.

CUSTOM_UNITS_#

Specify custom units to be displayed with the parameter. Enter up to six

characters. To display Custom Units the UNITS_TYPE_# must be set to

CUSTOM.

Note

_# represents the specified parameter number.

8 Rosemount 752

Page 9

April 2021 Quick Start Guide

3 Product Certification

Rev 1.17

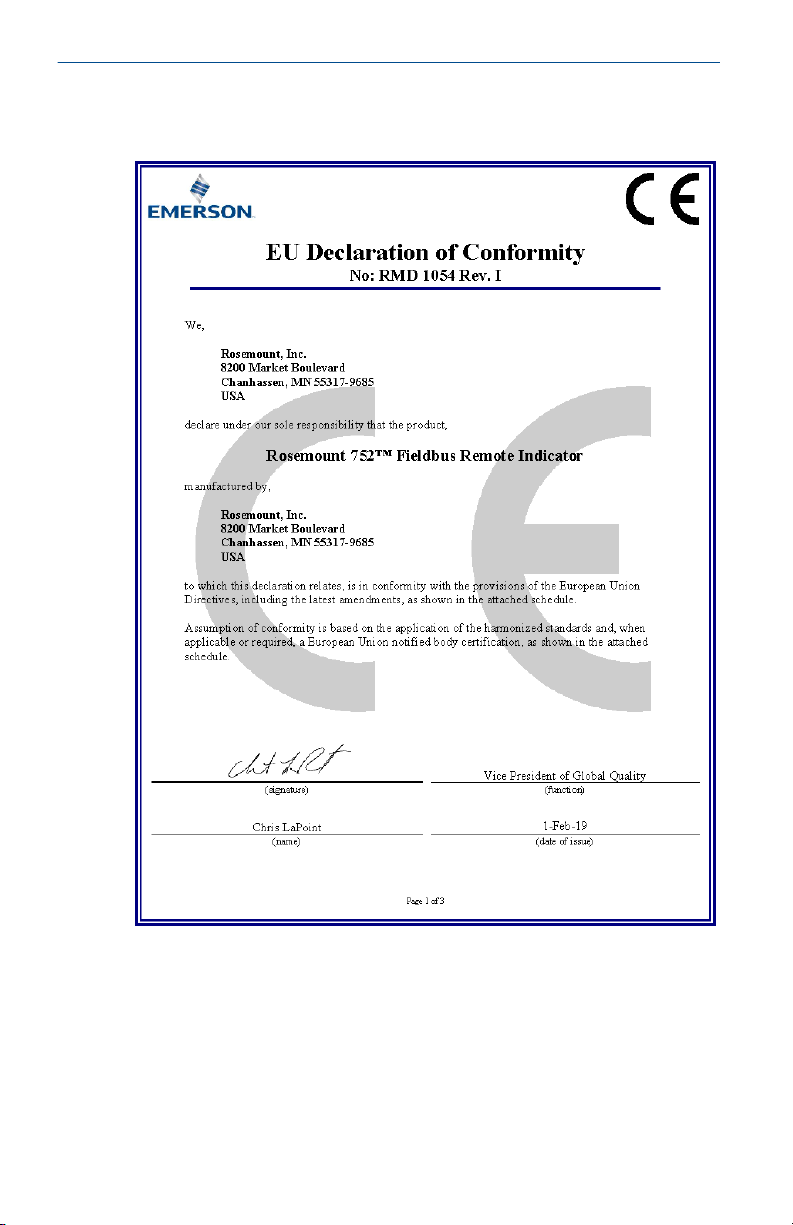

3.1 European Directive Information

A copy of the EU Declaration of Conformity can be found at the end of the

Quick Start Guide. The most recent revision of the EU Declaration of

Conformity can be found at Emerson.com/Rosemount.

3.2 Ordinary Location Certification

As standard, the transmitter has been examined and tested to determine

that the design meets the basic electrical, mechanical, and fire protection

requirements by a nationally recognized test laboratory (NRTL) as accredited

by the Federal Occupational Safety and Health Administration (OSHA).

3.3 North America

The US National Electrical Code® (NEC) and the Canadian Electrical Code

(CEC) permit the use of Division marked equipment in Zones and Zone

marked equipment in Divisions. The markings must be suitable for the area

classification, gas, and temperature class. This information is clearly defined

in the respective codes.

3.4 USA

E5 FM Explosion-proof and Dust-Ignition proof

Certificate:

Standards:

Markings:

I5/IE FM Intrinsically Safe, Division 2/FISCO Intrinsically Safe

Certificate:

Standards:

Markings:

Quick Start Guide 9

FM16US0090

FM 3600:2011, FM 3615:2006, FM 3616:2011, FM

3810:2005, ANSI/NEMA®-250:2003

XP CL I, DIV 1, GP B, C, D T5; DIP CL II DIV 1 GP E, F, G; CL III;

(–20 °C ≤ Ta ≤ 80 °C); Seal not required; Type 4X

FM17US0348X

FM 3600:2018, FM 3610:2018, FM 3611:2004, FM

3810:2005, ANSI/NEMA 250:2003, ANSI/ISA-60079-0:2013,

ANSI/ISA-60079-11:2014, ANSI/ISA 61010-1:2004

IS CL I, II, III, DIV 1, GP A, B, C, D, E, F, G T4; IS CL I, ZONE 0,

AEx ia IIC T4; (–20 °C ≤ Ta ≤ 60 °C); NI CL I, DIV 2, GP A, B, C, D

T4; (–20 °C ≤ Ta ≤ 60 °C); Install per 00752-1010; Type 4X

FISCO Field Device; IS CL I, II, III, DIV 1, GP A, B, C, D, E, F, G T4;

Page 10

Quick Start Guide April 2021

IS CL I, ZONE 0, AEx ia IIC T4; (–20 °C ≤ Ta ≤ 60 °C); Install per

00752-1010; Type 4X

3.5 Canada

E6 CSA Explosion-proof and Dust-Ignition proof, Division 2

Certificate:

Standards:

Markings:

I6/IF CSA Intrinsically Safe/FISCO Intrinsically Safe

Certificate:

Standards:

Markings:

3.6 Europe

E1 ATEX Flameproof

Certificate:

Standards:

Markings:

1563767

CSA C22.2 No. 25-1966, CSA C22.2 No. 30-M1986, CAN/CSA

C22.2 No. 94-M91, CSA C22.2 No. 142-M1987, CAN/CSA

C22.2 No. 157-92, CSA C22.2 No. 213-M1987

CL I, DIV 1, GP B, C, D; CL II, DIV 1, GP E,F,G; CL III; (–50 °C ≤ T

≤ 80 °C); CL I, DIV 2 GP A, B, C, D T3C; (–20 °C ≤ Ta ≤ 40 °C);

Seal not required; Type 4X

1563767

CSA C22.2 No. 25-1966, CSA C22.2 No. 30-M1986, CAN/CSA

C22.2 No. 94-M91, CSA C22.2 No. 142-M1987, CAN/CSA

C22.2 No. 157-92, CSA C22.2 No. 213-M1987

CL I, DIV 1, GP A, B, C, D T3C (–20 °C ≤ Ta ≤ 40 °C); Install per

00752-1020; Type 4X FISCO field device; CL I, DIV 1, GP A, B,

C, D T3C (–20 °C ≤ Ta ≤ 40 °C); Install per 00752-1020; Type

4X

KEMA03ATEX2476X

EN 60079-0:2012+A11:2013, EN 60079-1:2014

II 2 G; Ex db IIC T6…T5 Gb, T5 (–60 °C ≤ Ta ≤ 80 °C), T6 (–60

°C ≤ Ta ≤ 70 °C); IP66

a

Special Conditions for Safe Use (X):

1. Flameproof joints are not intended for repair.

2. Non-standard paint options may cause risk from electrostatic

discharge. Avoid installations that could cause electrostatic build-up

on painted surfaces, and only clean the painted surfaces with a damp

cloth. If paint is ordered through a special option code, contact the

manufacturer for more information.

10 Rosemount 752

Page 11

April 2021 Quick Start Guide

I1/IA ATEX Intrinsic Safety/FISCO Intrinsic Safety

Certificate:

Standards:

Markings:

Baseefa03ATEX0239X

EN 60079-0:2012+A11:2013, EN 60079-11:2012

II 1 G, Ex ia IIC T4 Ga; (–20 °C ≤ Ta ≤ +60 °C); IP66

See Table 3-1 for entity parameters.

Special Conditions for Safe Use (X):

1. When fitted with the transient protection option, the apparatus is

not capable of withstanding the 500 V test as defined in Clause

6.3.13 of EN 60079-11:2012. This must be taken into account during

installation.

2. The Rosemount™ 752 enclosure may be made of aluminum alloy and

given a protective polyurethane paint finish; however, care should be

taken to protect it from impact or abrasion if located in a zone 0 area.

N1 ATEX Type n

Certificate:

Standards:

Markings:

Baseefa03ATEX0240X

EN 60079-0:2012+A11:2013, EN 60079-15:2010

II 3 G; Ex nA IIC T5 Gc (–20 °C ≤ Ta ≤ 70 °C); IP66

Special Condition for Safe Use (X):

The equipment is not capable of withstanding the 500 V insulation test

required by Clause 6.5 of EN 60079-15:2010. This must be taken into

account when installing the apparatus.

ND ATEX Dust

Certificate:

Standards:

Markings:

KEMA03ATEX2476X

EN 60079-0:2012+A11:2013, EN 60079-31:2014

II 2 D; Ex tb IIIC T105 °C Db (–60 °C ≤ Ta ≤ 80 °C); IP66

Special Conditions for Safe Use (X):

1. Flameproof joints are not intended for repair.

2. Non-standard paint options may cause risk from electrostatic

discharge. Avoid installations that could cause electrostatic build-up

on painted surfaces, and only clean the painted surfaces with a damp

cloth. If paint is ordered through a special option code, contact the

manufacturer for more information.

Quick Start Guide 11

Page 12

Quick Start Guide April 2021

3.7 International

E7 IECEx Flameproof

Certificate:

Standards:

Markings:

Special Conditions for Safe Use (X):

1. Flameproof joints are not intended for repair.

2. Non-standard paint options may cause risk from electrostatic

I7/IG IECEx Intrinsic Safety/FISCO Intrinsic Safety

Certificate:

Standards:

Markings:

Special Conditions for Safe Use (X):

1. When fitted with the transient option, the apparatus is not capable of

IECEx KEM 10.0066X

IEC 60079-0:2011, IEC 60079-1:2014-06

Ex db IIC T6…T5 Gb, T5 (–60 °C ≤ Ta ≤ 80 °C), T6 (–60 °C ≤ Ta ≤

70 °C); IP66

discharge. Avoid installations that could cause electrostatic build-up

on painted surfaces, and only clean the painted surfaces with a damp

cloth. If paint is ordered through a special option code, contact the

manufacturer for more information.

IECEx BAS 04.0029X

IEC 60079-0:2011, IEC 60079-11:2011

Ex ia IIC T4 Ga; T4(–20 °C ≤ Ta ≤ 60 °C) IP66 See Table 3-1 for

entity parameters.

withstanding the 500 V test as defined in Clause 6.3.13 of IEC

60079-11:2011. This must be taken into account during installation.

2. The Rosemount 752 enclosure may be made of aluminum alloy and

given a protective polyurethane paint finish; however, care should be

taken to protect it from impact of abrasion if located in a zone 0 area.

N7 IECEx Type n

Certificate:

Standards:

Markings:

Special Condition for Safe Use (X):

When fitted with the transient option, the apparatus is not capable of

withstanding the 500 V test as defined in Clause 6.5 of IEC 60079-15:2010.

This must be taken into account during installation.

12 Rosemount 752

IECEx BAS 04.0030X

IEC 60079-0:2011, IEC 60079-15:2010

Ex nA IIC T5 Gc (–40 °C ≤ Ta ≤ 70 °C); IP66

Page 13

April 2021 Quick Start Guide

NF IECEx Dust

Certificate:

Standards:

Markings:

Special Conditions for Safe Use (X):

1. Flameproof joints are not intended for repair.

2. Non-standard paint options may cause risk from electrostatic

3.8 Brazil

E2 INMETRO Flameproof

Certificate:

Standards:

Markings:

Special Condition for Safe Use (X):

For information on the dimensions of the flameproof joints the

manufacturer shall be contacted.

IECEx KEM 10.0066X

IEC 60079-0:2011, EN 60079-31:2013

Ex tb IIIC T105 °C Db (–60 °C ≤ Ta ≤ 80 °C); IP66

discharge. Avoid installations that could cause electrostatic build-up

on painted surfaces, and only clean the painted surfaces with a damp

cloth. If paint is ordered through a special option code, contact the

manufacturer for more information.

UL-BR 15.1054X

ABNT NBR IEC 60079-0:2008 + corrigendum 1:2011, ABNT

NBR IEC 60079-1:2009 + corrigendum 1:2011

Ex db IIC T6... T5 Gb; T6 (–60 °C ≤ T

T

≤ +80 °C)

amb

≤ +70 °C); T5 (–60 °C ≤

amb

I2/IB INMETRO Intrinsic Safety/FISCO Intrinsic Safety

Certificate:

Standards:

UL-BR 16.0078X

ABNT NBR IEC 60079-0:2008 + Errata 1:2011, ABNT NBR IEC

60079-11:2009, ABNT NBR IEC 60079-26:2008 + Errata

1:2008

Markings:

Ex ia IIC T4 (-20 °C ≤ Ta ≤ +60 °C) Ga; IP66

3.9 EAC

EM Technical Regulation Customs Union TR CU 012/2011 (EAC)

Flameproof

Markings:

Quick Start Guide 13

1Ex db IIC T6…T5 Gb X; IP66; T5(-60 °C ≤ Ta ≤ +80 °C), T6(-60

°C ≤ Ta≤ +70 °C)

Page 14

Quick Start Guide April 2021

See certificate for Special Conditions for Safe Use

IM Technical Regulation Customs Union TR CU 012/2011 (EAC) Intrinsic

Safety

Markings:

IN Technical Regulation Customs Union TR CU 012/2011 (EAC) Intrinsic

Safety

Markings:

NM Technical Regulation Customs Union TR CU 012/2011 (EAC) Type n

Markings:

KM Technical Regulation Customs Union TR CU 012/2011 (EAC)

Flameproof, Intrinsic Safety, Type n, and Dust-Ignitionproof

Markings:

3.10 Combinations

K1 Combination of E1, I1, N1, and ND

K2 Combination of E2 and I2

0Ex ia IIC T4 Ga X; IP66; T4(-20 °C ≤ Ta ≤ +60 °C)

See certificate for Special Conditions for Safe Use

0Ex ia IIC T4 Ga X; IP66; T4(-20 °C ≤ Ta ≤ +60 °C)

See certificate for Special Conditions for Safe Use

2Ex nA IIC T5 Gc X; IP66; T5(-40 °C ≤ Ta ≤ +70 °C)

See certificate for Special Conditions for Safe Use

Ex tb IIIC T105 °C Db X along with markings for EM, IM,

and NM above

See certificate for Special Conditions for Safe Use

K5 Combination of E5 and I5

K6 Combination of E6 and I6

KA Combination of E1, E6, I1, and I6

KB Combination of E5, E6, I5, and I6

KC Combination of E5, E1, I5, and I1

KM Combination of EM, IM, and NM

Table 3-1: Entity Parameters

Parameters Fieldbus FISCO

U

i

14 Rosemount 752

30 V 17.5 V

Page 15

April 2021 Quick Start Guide

Table 3-1: Entity Parameters (continued)

Parameters Fieldbus FISCO

I

i

P

i

C

i

L

i

300 mA 380 mA

1.3 W 5.32 W

0 nF 0 nF

0 µH 0 µH

Quick Start Guide 15

Page 16

Quick Start Guide April 2021

4 Declaration of Conformity

16 Rosemount 752

Page 17

April 2021 Quick Start Guide

Quick Start Guide 17

Page 18

Quick Start Guide April 2021

18 Rosemount 752

Page 19

ᴹ

China RoHS

㇑᧗⢙䍘䎵䗷ᴰབྷ⎃ᓖ䲀٬Ⲵ䜘Ԧරࡇ㺘

Rosemount 752

List of Rosemount 752 Parts with China RoHS Concentration above MCVs

䜘Ԧ〠

Part Name

ᴹᇣ⢙䍘Hazardous Substances

䫵

Lead

(Pb)

⊎

Mercury

(Hg)

䭹

Cadmium

(Cd)

ޝԧ䬜

Hexavalent

Chromium

(Cr +6)

ཊⓤ㚄㤟

Polybrominated

biphenyls

(PBB)

ཊⓤ㚄㤟䟊

Polybrominated

diphenyl ethers

(PBDE)

⭥ᆀ㓴Ԧ

Electronics

Assembly

X O O O O

O

༣փ㓴Ԧ

Housing

Assembly

O O O X O

O

Րᝏಘ㓴Ԧ

Sensor

Assembly

X O O O O

O

ᵜ㺘Ṭ㌫ᦞ

SJ/T11364

Ⲵ㿴ᇊ㘼ࡦ

This table is proposed in accordance with the provision of SJ/T11364.

O:

Ѫ䈕䜘ԦⲴᡰᴹ൷䍘ᶀᯉѝ䈕ᴹᇣ⢙䍘Ⲵ䟿൷վҾ

GB/T 26572

ᡰ㿴ᇊⲴ䲀䟿㾱≲

O: Indicate that said hazardous substance in all of the homogeneous materials for this part is below the limit requirement of

GB/T 26572.

X:

Ѫ൘䈕䜘Ԧᡰ֯⭘Ⲵᡰᴹ൷䍘ᶀᯉ䟼ˈ㠣ቁᴹа㊫൷䍘ᶀᯉѝ䈕ᴹᇣ⢙䍘Ⲵ䟿儈Ҿ

GB/T 26572

ᡰ㿴ᇊⲴ䲀䟿㾱≲

X: Indicate that said hazardous substance contained in at least one of the homogeneous materials used for this part is above

the limit requirement of GB/T 26572.

April 2021 Quick Start Guide

5 China RoHS

Quick Start Guide 19

Page 20

*00825-0100-4377*

00825-0100-4377, Rev. FB

Quick Start Guide

April 2021

For more information:

©

2021 Emerson. All rights reserved.

Emerson Terms and Conditions of Sale are

available upon request. The Emerson logo

is a trademark and service mark of

Emerson Electric Co. Rosemount is a mark

of one of the Emerson family of

companies. All other marks are the

property of their respective owners.

www.emerson.com

Loading...

Loading...