Reference Manual

00809-0100-4308, Rev CD

February 2020

Rosemount™ 3308 Series Wireless Guided

Wave Radar, 3308A

Rosemount™ 3308 Series Wireless Guided Wave Radar Level Transmitter

NOTICE

Read this manual before working with the product. For personal and system safety, and for optimum product performance,

ensure you thoroughly understand the contents before installing, using, or maintaining this product.

For technical assistance, contacts are listed below:

Customer Central

Technical support, quoting, and order-related questions.

• United States - 1-800-999-9307 (7:00 am to 7:00 pm CST)

• Asia Pacific- 65 777 8211

North American Response Center

Equipment service needs.

• 1-800-654-7768 (24 hours a day — includes Canada)

• Outside of these areas, contact your local Emerson representative.

NOTICE

Power module considerations.

• Each Power Module contains two "C" size primary lithium/thionyl chloride batteries. Each battery contains approximately 2.5

grams of lithium, for a total of 5 grams in each pack. Under normal conditions, the battery materials are self-contained and are

not reactive as long as the batteries and the pack integrity are maintained. Care should be taken to prevent thermal, electrical

or mechanical damage. Contacts should be protected to prevent premature discharge.

• Battery hazards remain when cells are discharged.

• Power modules should be stored in a clean and dry area. For maximum battery life, storage temperature should not exceed 86

°F (30 °C).

• The power module may be replaced in a hazardous area. The power module has surface resistivity greater than one gigaohm

and must be properly installed in the wireless device enclosure. Care must be taken during transportation to and from the

point of installation to prevent electrostatic charge build-up.

Shipping considerations for wireless products.

• The unit was shipped to you without the power module installed. Remove the power module prior to shipping.

• Each power module contains two “C” size primary lithium batteries. Primary lithium batteries are regulated in transportation

by the U. S. Department of Transportation, and are also covered by IATA (International Air Transport Association), ICAO

(International Civil Aviation Organization), and ARD (European Ground Transportation of Dangerous Goods). It is the

responsibility of the shipper to ensure compliance with these or any other local requirements. Consult current regulations and

requirements before shipping.

2

WARNING

Explosions could result in death or serious injury.

• Verify that the operating atmosphere of the transmitter is consistent with the appropriate hazardous locations certifications.

• Installation of device in an explosive environment must be in accordance with appropriate local, national, and international

standards, codes, and practices.

• Ensure device is installed in accordance with intrinsically safe or non-incendive field practices.

Electrical shock could cause death or serious injury.

• Ground device on non-metallic tanks (e.g. fiberglass tanks) to prevent electrostatic charge build-up.

• Single lead probes are sensitive for strong electromagnetic fields and therefore not suitable for non-metallic tanks.

• Care must be taken during transportation of power module to prevent electrostatic charge build-up.

• Probes covered with plastic and/or with plastic discs may generate an ignition-capable level of electrostatic charge under

certain extreme conditions. Therefore, when the probe is used in a potentially explosive atmosphere, appropriate measures

must be taken to prevent electrostatic discharge.

Process leaks could result in death or serious injury.

• Only qualified personnel should install the equipment.

• Install transmitter prior to process start-up.

• Install and tighten process connectors before applying pressure.

• Handle the transmitter carefully.

• Do not remove the transmitter while in operation.

• If the process seal is damaged, gas could escape from the tank when removing the transmitter head from the probe.

Failure to follow these installation guidelines could result in death or serious injury.

• Verify that the operating atmosphere of the transmitter is consistent with the appropriate hazardous locations certifications.

• Ensure the transmitter is installed by qualified personnel and in accordance with applicable code of practice.

• Use the equipment only as specified. Failure to do so may impair the protection provided by the equipment.

Electronic boards are electrostatically sensitive. Failure to observe proper handling precautions for static-sensitive components

can result in damage to the electronic components. Do not remove the electronic boards from the transmitter.

To ensure long life for your radar transmitter, and to comply with hazardous location installation requirements, tighten covers on

both sides of the electronics housing.

Any substitution of non-recognized parts may jeopardize safety. Repair (e.g. substitution of components) may also jeopardize

safety and is not allowed under any circumstances.

WARNING

Physical access

Unauthorized personnel may potentially cause significant damage to and/or misconfiguration of end users’ equipment. This could

be intentional or unintentional and needs to be protected against.

Physical security is an important part of any security program and fundamental to protecting your system. Restrict physical access

by unauthorized personnel to protect end users’ assets. This is true for all systems used within the facility.

3

CAUTION

This device complies with Part 15 of the FCC Rules. Operation is subject to the following conditions:

• This device must accept any interference received, including interference that may cause undesired operation.

• This device must be installed to ensure a minimum antenna separation distance of 8 in. (20 cm) from all persons.

Use caution when handling the power module. The Power Module may be damaged if dropped from heights in excess of 20 ft. (6

m).

Changes or modifications to the equipment not expressly approved by Rosemount Inc. could void the user’s authority to operate

the equipment.

CAUTION

The products described in this document are NOT designed for nuclear-qualified applications. Using non-nuclear qualified

products in applications that require nuclear-qualified hardware or products may cause inaccurate readings. For information on

Rosemount nuclear-qualified products, contact your local Emerson Sales Representative.

4

Reference Manual Contents

00809-0100-4308

February 2020

Contents

Chapter 1 Introduction.................................................................................................................. 9

1.1 Using this manual.............................................................................................................................9

1.2 Product recycling/disposal................................................................................................................9

Chapter 2 Transmitter overview...................................................................................................11

2.1 Theory of operation........................................................................................................................11

2.2 Measuring range.............................................................................................................................14

2.3 Emerson Wireless........................................................................................................................... 15

2.4 Application characteristics..............................................................................................................15

2.5 Application examples..................................................................................................................... 17

2.6 Components of the transmitter......................................................................................................18

2.7 Probe selection guide..................................................................................................................... 20

Chapter 3 Installation...................................................................................................................23

3.1 Safety messages.............................................................................................................................23

3.2 Installation procedure.................................................................................................................... 24

3.3 Review mounting considerations....................................................................................................24

3.4 Review mounting preparations.......................................................................................................32

3.5 Centering disc for pipe installations................................................................................................39

3.6 Anchor the probe........................................................................................................................... 44

3.7 Mount device on tank.....................................................................................................................47

3.8 Ground the device..........................................................................................................................69

3.9 Install the power module................................................................................................................70

3.10 Position the antenna.................................................................................................................... 71

3.11 Utilize the device display.............................................................................................................. 72

Chapter 4 Configuration...............................................................................................................75

4.1 Overview........................................................................................................................................ 75

4.2 Safety messages.............................................................................................................................75

4.3 Configuration procedure................................................................................................................ 77

4.4 System readiness............................................................................................................................77

4.5 Get started with your preferred configuration tool......................................................................... 78

4.6 Join device to wireless network.......................................................................................................81

4.7 Configure device using guided setup..............................................................................................91

4.8 Verify level......................................................................................................................................94

Chapter 5 Operation.................................................................................................................... 97

5.1 Safety messages.............................................................................................................................97

5.2 Device display screen messages..................................................................................................... 98

5.3 View measurement data...............................................................................................................101

Reference Manual v

Contents Reference Manual

February 2020 00809-0100-4308

5.4 Device status................................................................................................................................103

Chapter 6 Service and troubleshooting...................................................................................... 105

6.1 Safety messages...........................................................................................................................105

6.2 Alert messages............................................................................................................................. 106

6.3 Troubleshooting guide................................................................................................................. 114

6.4 Service and troubleshooting tools................................................................................................ 118

6.5 Application challenges................................................................................................................. 128

6.6 Replace power module.................................................................................................................135

6.7 Replace the transmitter head....................................................................................................... 137

6.8 Replace the probe........................................................................................................................ 139

6.9 Service support............................................................................................................................ 140

Appendix A Specifications and reference data............................................................................... 141

A.1 Performance specifications.......................................................................................................... 141

A.2 Functional specifications.............................................................................................................. 149

A.3 Physical specifications..................................................................................................................157

A.4 Ordering information................................................................................................................... 162

A.5 Spare parts and accessories..........................................................................................................168

A.6 Dimensional drawings..................................................................................................................178

Appendix B Product Certifications................................................................................................ 187

B.1 European directive information.................................................................................................... 187

B.2 Ordinary location certification...................................................................................................... 187

B.3 Telecommunication compliance.................................................................................................. 187

B.4 FCC and IC.................................................................................................................................... 187

B.5 Installing equipment in North America......................................................................................... 188

B.6 USA.............................................................................................................................................. 188

B.7 Canada.........................................................................................................................................189

B.8 Europe..........................................................................................................................................189

B.9 International.................................................................................................................................190

B.10 Brazil.......................................................................................................................................... 191

B.11 China..........................................................................................................................................191

B.12 Japan.......................................................................................................................................... 191

B.13 Technical Regulations Customs Union (EAC).............................................................................. 191

B.14 Approval drawings......................................................................................................................192

Appendix C High gain remote antenna option...............................................................................195

C.1 Safety messages...........................................................................................................................195

C.2 Functional and physical specifications.......................................................................................... 195

C.3 Review installation considerations................................................................................................196

C.4 Transient/lightning considerations...............................................................................................197

C.5 Install the high gain remote antenna............................................................................................ 197

Appendix D Configuration parameters..........................................................................................201

vi Rosemount 3308 Series

Reference Manual Contents

00809-0100-4308

D.1 Menu overview of the Device Descriptor (DD)..............................................................................201

D.2 Configuration parameters............................................................................................................202

February 2020

Appendix E Alert message mapping..............................................................................................223

E.1 Alert messages and descriptions...................................................................................................223

Reference Manual vii

Contents Reference Manual

February 2020 00809-0100-4308

viii Rosemount 3308 Series

Reference Manual Introduction

00809-0100-4308 February 2020

1 Introduction

1.1 Using this manual

The sections in this manual provide information on installing, configuring, operating, and

maintaining the Rosemount™ 3308 Series Transmitter.

The sections are organized as follows:

Transmitter overview provides an introduction to theory of operation and description of

the transmitter. Information on applications and a probe selection guide are also included.

Installation contains mechanical and electrical installation instructions.

Configuration provides instructions on how to configure and make the transmitter join the

wireless network.

Operation contains operation techniques such as viewing measurement data and display

functionality.

Service and troubleshooting provides troubleshooting techniques for the most common

operating problems, as well as diagnostic and error messages, and service instructions.

Specifications and reference data supplies reference and specification data, as well as

ordering information.

Product Certifications contains hazardous locations certifications and approval drawings.

High gain remote antenna option contains specification and installation information of the

high gain remote antenna option.

Configuration parameters provides a menu overview for the Device Descriptor in AMS

Wireless Configurator and the handheld communicator. Description of the configuration

parameters is also included.

Alert message mapping outlines the most important alerts in the HART® command 48

Additional Status Field for Rosemount 3308 Series.

1.2 Product recycling/disposal

Recycling of equipment and packaging should be taken into consideration and disposed of

in accordance with local and national legislation or regulations.

Reference Manual 9

Introduction Reference Manual

February 2020 00809-0100-4308

10 Rosemount 3308 Series

K

$

%

&

*+

)

,

('

-

Reference Manual Transmitter overview

00809-0100-4308 February 2020

2 Transmitter overview

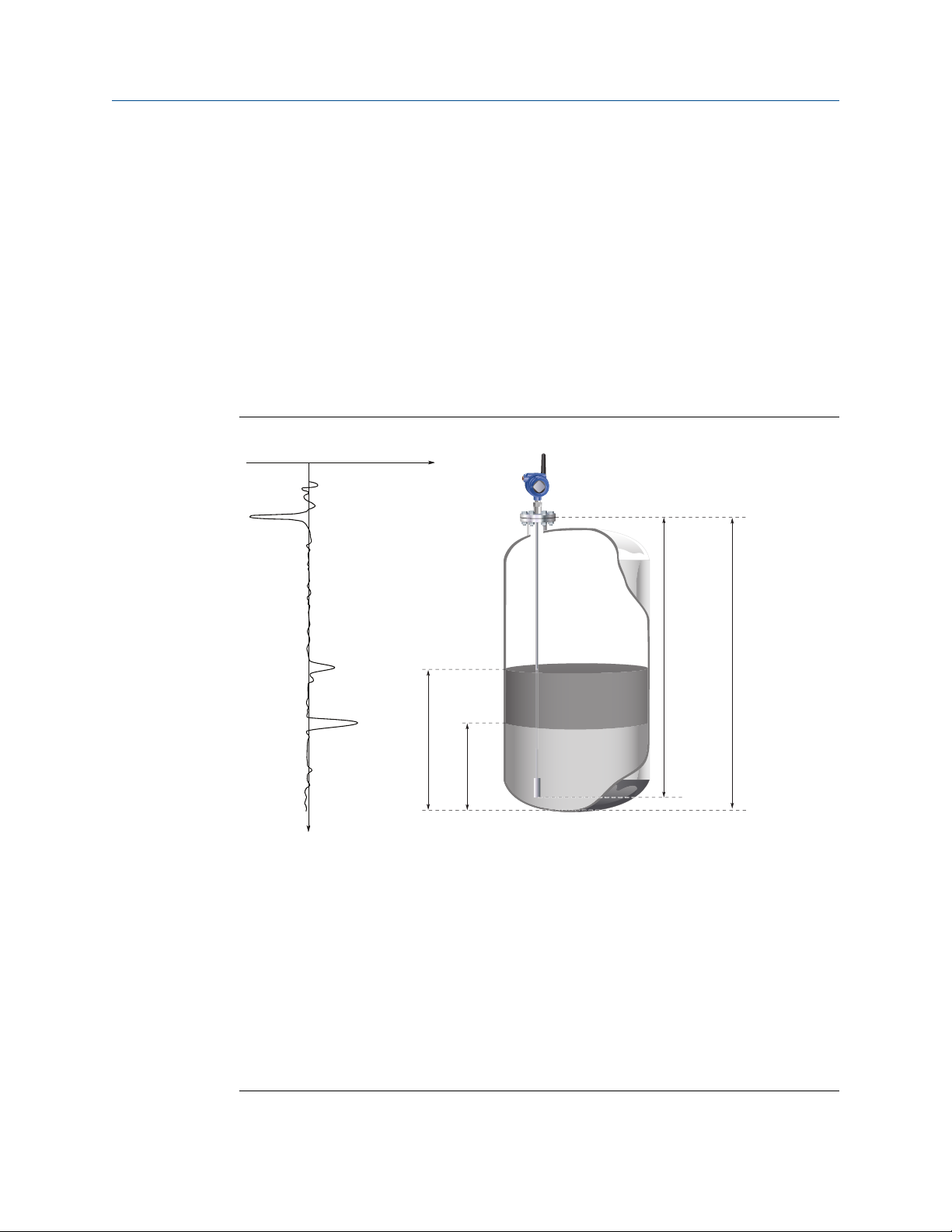

2.1 Theory of operation

The Rosemount™ 3308 Series is the first true wireless level transmitter that is based on the

Time Domain Reflectometry (TDR) principle. Low power nano-second-pulses are guided

along a probe submerged in the process media. When a pulse reaches the surface of the

material it is measuring, part of the energy is reflected back to the transmitter, and the

time difference between the generated and reflected pulse is converted into a distance

from which the total level or interface level is calculated (see Figure 2-1).

Figure 2-1: Guided Wave Radar Operating Principle

A. Reference peak

Reference Manual 11

B. Product surface peak

Product level

C.

D. Interface peak

E. Interface level

F. Upper reference point

G. Probe length

H. Tank height

I. Zero reference point

J. Signal amplitude

K. Time

$

%

&

'

(

)

*

,+-

Transmitter overview Reference Manual

February 2020 00809-0100-4308

The reflectivity of the product is a key parameter for measurement performance. A high

dielectric constant of the media gives better reflection and a longer measuring range.

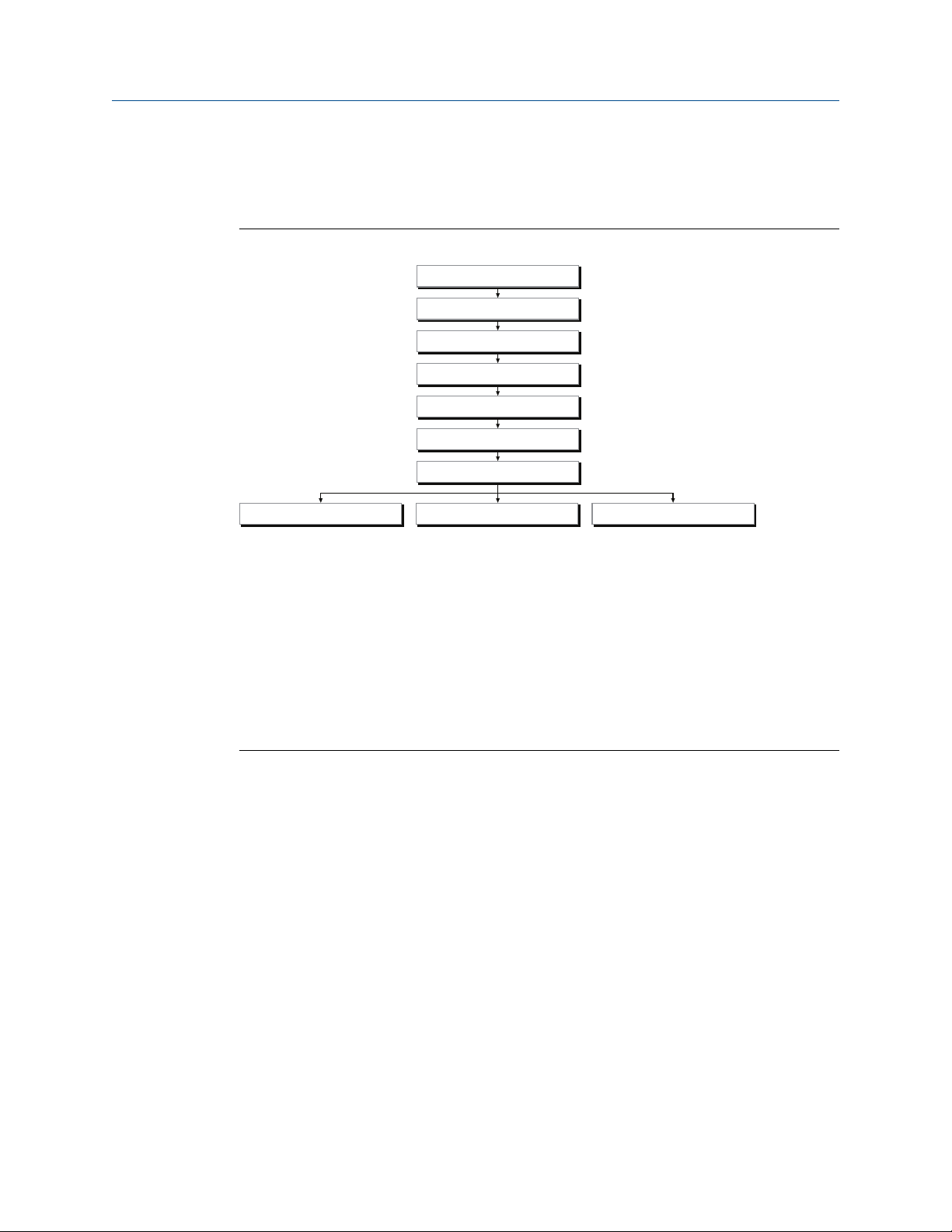

See Figure 2-2 for a schematic overview of the signal processing.

Figure 2-2: Flowchart of the Signal Processing

A. Microwave module

B. A/D converter

C.

Peak search

D. Peak interpolation

E. Echo identifier

F. Distance filtering

G. Variable calculation

H. Aout handler

I. LCD handler

J. HART

®

2.1.1 Reference peak

This peak is caused by the transition between transmitter and the tank vapor space or air.

It is used by the transmitter as a starting reference point for distance to the level surface.

2.1.2 Product surface peak

This peak indicates the product level and is caused by a reflection from the product

surface.

2.1.3 Interface peak

This peak indicates the interface level. The peak is caused by reflection from the interface

between an upper product and a bottom product with a relatively high dielectric constant.

This peak is identified when the measurement mode is set to Product Level and Interface

Level or Interface Level with Submerged Probe.

12 Rosemount 3308 Series

$

(

)

%&'

Reference Manual Transmitter overview

00809-0100-4308 February 2020

2.1.4 Probe end peak

It is caused by reflection from the probe end. If the probe is grounded, the peak will be

positive. If the probe end is submerged in a high dielectric media, such as water, it will not

be visible.

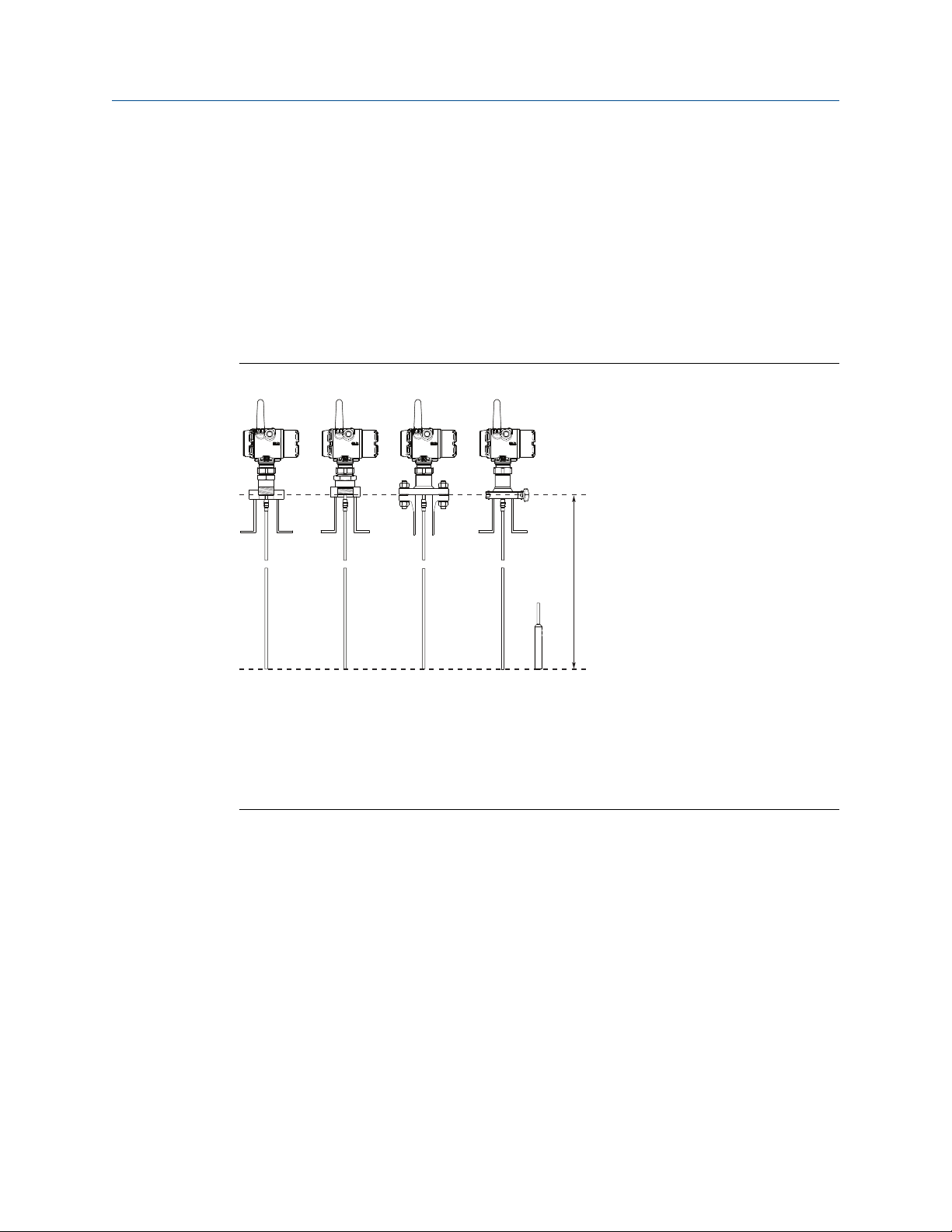

2.1.5 Upper Reference Point

The Upper Reference Point is located at the underside of the threaded adapter,

transmitter flange, or Tri-Clamp®, as illustrated in Figure 2-3.

Figure 2-3: Upper Reference Point

A. NPT

B. BSPP (G)

Flange

C.

D. Tri-Clamp

E. Upper Reference Point

F. Total Probe Length

2.1.6 Zero reference point

The Zero Reference Point is selected by the user and is usually located close to or at the

bottom of the tank. The Zero Reference Point can be set to any position in the tank by

adjusting the Tank Height.

2.1.7 Tank height

The Tank Height is the distance from the Upper Reference Point to the Zero Reference

Point. The transmitter measures the distance to the product surface and subtracts this

value from the Tank Height to determine the level.

Reference Manual 13

$

%

&

%

'

Transmitter overview Reference Manual

February 2020 00809-0100-4308

2.1.8 Probe length

The probe length is the distance between the Upper Reference Point and the end of the

probe. If a weight is used at the end of the probe it shall be included.

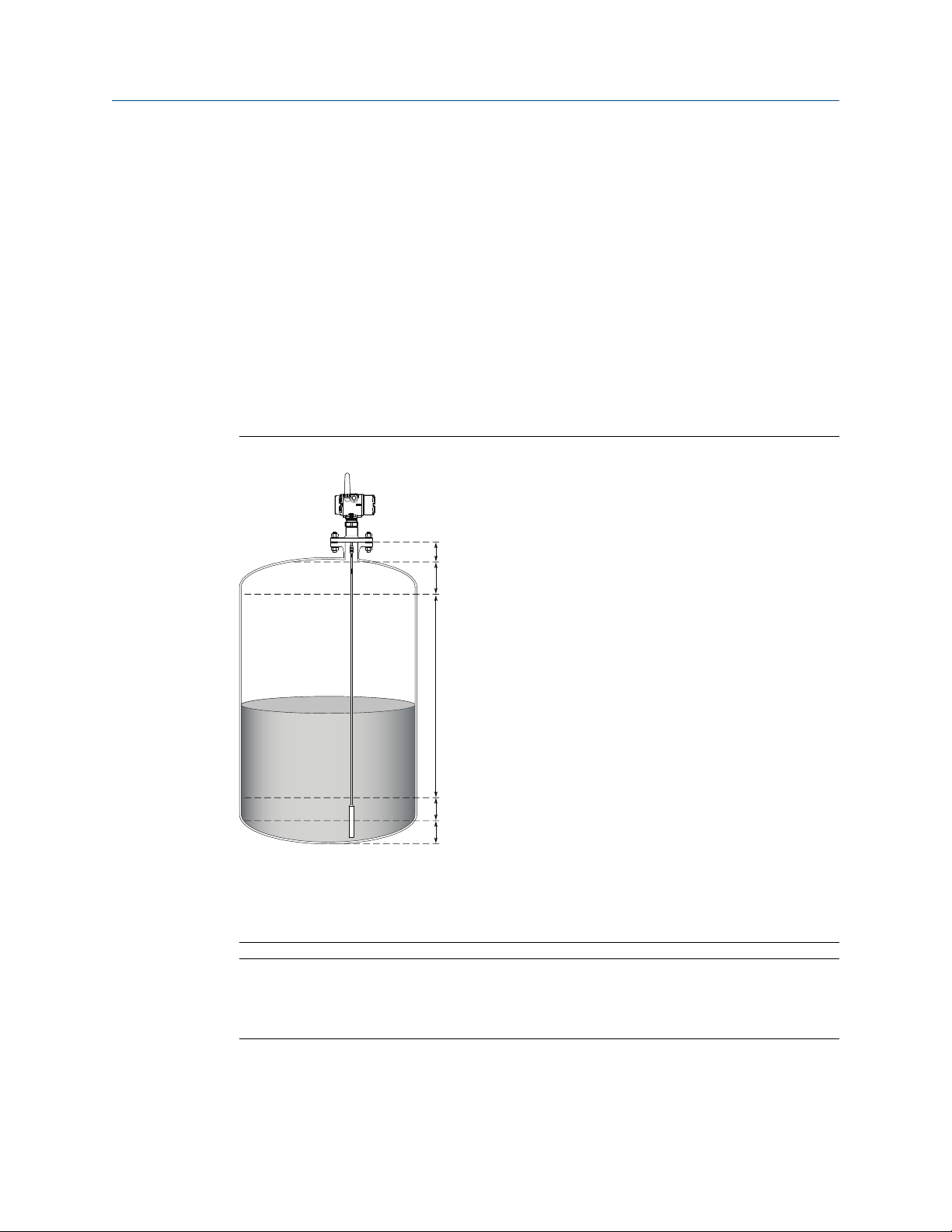

2.2 Measuring range

The measuring range depends on probe type, dielectric constant of the product, and

installation environment, and is limited by the Blind Zones at the very top and bottom of

the probe. In the Blind Zones, the accuracy exceeds ±1.18 in. (30 mm), and measurements

may not be possible. Measurements close to the Blind Zones will have reduced accuracy.

Figure 2-4 illustrates how the measuring range is related to the Blind Zones and the areas

with reduced accuracy.

Figure 2-4: Blind Zones and Areas with Reduced Accuracy

A. Upper Blind Zone

B. Reduced accuracy

Recommended measuring range

C.

14 Rosemount 3308 Series

D. Lower Blind Zone

Note

Measurements may not be possible in the Blind Zones, and measurements close to the

Blind Zones will have reduced accuracy. Therefore, the alarm points should be configured

outside these zones.

Related information

Accuracy over measuring range

Reference Manual Transmitter overview

00809-0100-4308

February 2020

2.3 Emerson Wireless

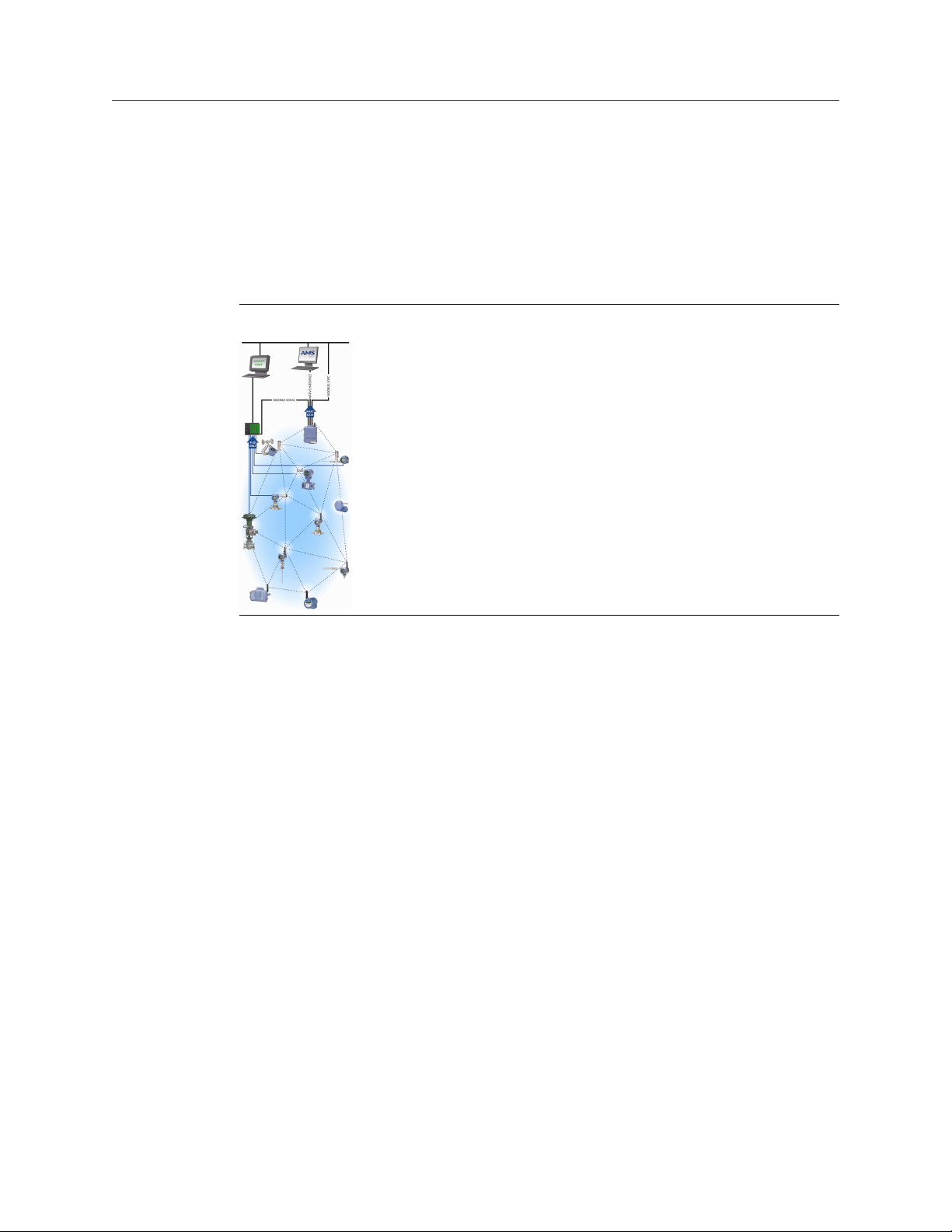

Emerson Wireless is a self-organizing network solution. Wireless field instruments send

data to a Gateway, directly or routed through any of the wireless devices in the network, as

illustrated in Figure 2-5. Multiple communication paths are managed and analyzed in

parallel to assure optimal communication and sustained network reliability even if

obstructions are introduced.

Figure 2-5: Emerson Wireless Network

Gateways interface with existing host systems using industry standard protocols, and

native integration into DeltaV™ and Ovation™ is transparent and seamless.

Interference from other radios, Wi-Fi®, and EMC sources is avoided through Time

Synchronized Channel Hopping and Direct Sequence Spread Spectrum (DSSS). Also, a

layered security implementing industry standard Encryption, Authentication, Verification,

Anti-Jamming, and Key Management ensures that data transmissions are secure and

received only by the Gateway.

The Rosemount 3308 Series is a member of the Emerson Wireless portfolio, whose

wireless network experience totals billions of operating hours, hundreds of thousands of

field devices, and tens of thousands of networks around the world.

2.4 Application characteristics

2.4.1 Tank shape

The guided wave radar transmitter is insensitive to the tank shape. Since the radar signal

travels along a probe, the shape of the tank bottom has no effect on the measurement

performance. The transmitter handles flat or dish-bottom tanks equally well.

2.4.2 In-tank obstructions

The Rosemount 3308 Series Transmitter is relatively insensitive to objects in the tank since

the radar signal is transmitted along a probe.

Reference Manual 15

$

%

%

Transmitter overview Reference Manual

February 2020 00809-0100-4308

Avoid physical contact between probes and agitators as well as applications with strong

fluid movement unless the probe is anchored. If the probe can move within 1 ft. (30 cm)

away from any object, such as an agitator, during operation then probe tie-down is

recommended.

In order to stabilize the probe for side forces, you have the option to either hang a weight

at the probe end (flexible probes only) or fix/guide the probe to the tank bottom.

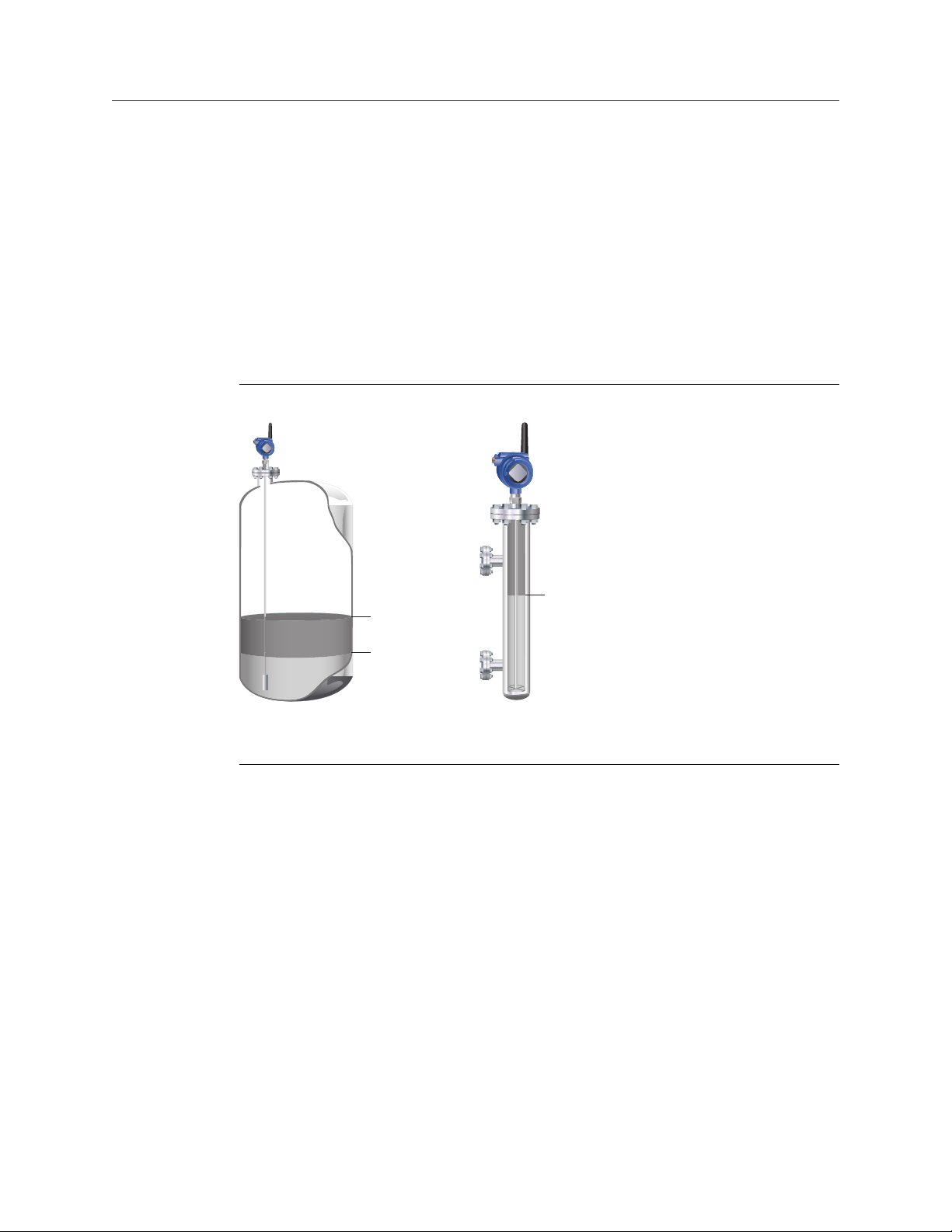

2.4.3 Interface level measurement

Rosemount 3308 Series Transmitter is well suited for measuring the interface of oil and

water, or other liquids with significant dielectric differences.

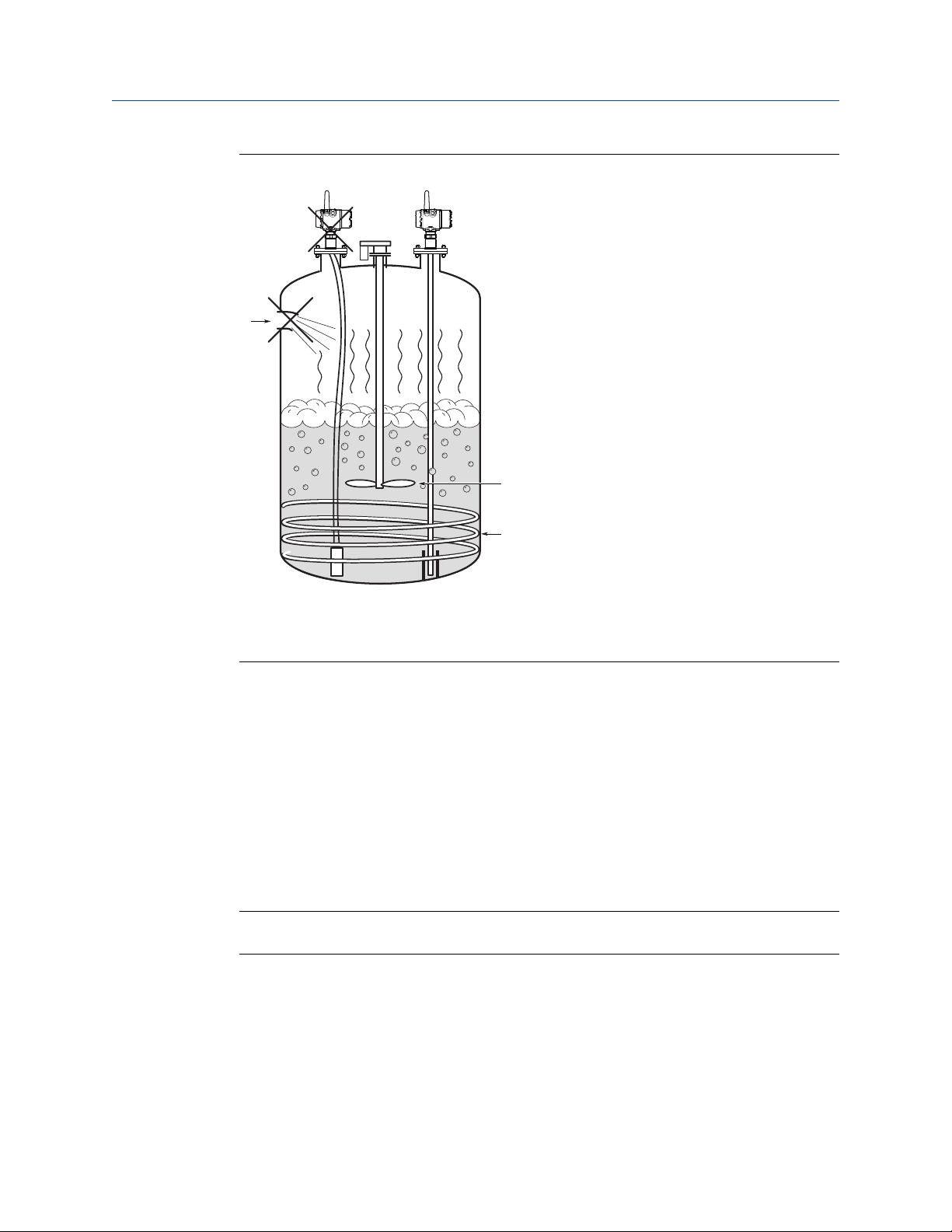

Figure 2-6: Interface Level Measurement

A. Product level

B. Interface level

All probes can be used for measuring interfaces. Single probes are the preferred choice in

almost all applications but depending on the application and installation geometries a

coaxial probe or a twin probe may be a better fit.

For measuring the interface level, the transmitter uses the residual wave of the first

reflection. Part of the wave, which was not reflected at the upper product surface,

continues until it is reflected at the lower product surface. The speed of this wave depends

fully on the dielectric constant of the upper product.

The maximum allowable upper product thickness/measuring range is primarily

determined by the dielectric constants of the two liquids. Target applications include

interfaces between oil/oil-like and water/water-like liquids. For such applications the upper

product dielectric constant is low (<3) and the lower product dielectric constant is high

(>20).

Related information

Interface measurements

16 Rosemount 3308 Series

Reference Manual Transmitter overview

00809-0100-4308 February 2020

Emulsion layers

Sometimes there is an emulsion layer (mix of the products) between the two products

which, depending on its characteristics, will affect interface measurements. For assistance

with emulsion applications, consult your local Emerson representative.

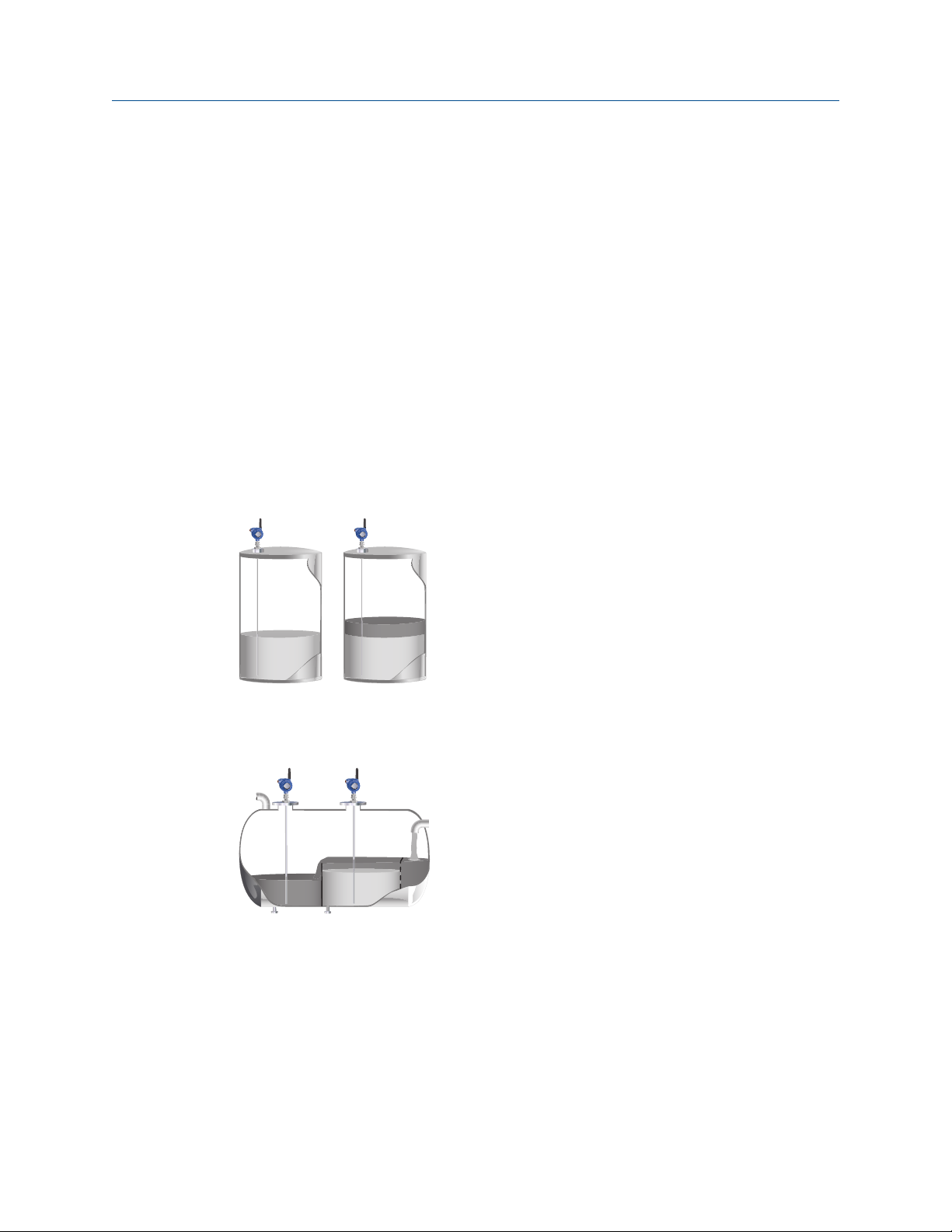

2.5 Application examples

The Rosemount 3308 Series Transmitter is suited for aggregate (total) level

measurements on a wide range of liquids, semi-liquids, and liquid to liquid interfaces.

Moreover, the reliable and accurate guided wave radar technology offers a versatile

solution that is virtually unaffected by process conditions such as temperature, pressure,

vapor gas mixtures, density, turbulence, bubbling/boiling, varying dielectric media, pH,

and viscosity.

Storage and buffer tanks

The Rosemount 3308 Series Transmitter is ideal for storage or buffer tanks for almost any

liquid, such as oil, gas condensate, water, or chemicals.

Low pressure separators

The Rosemount 3308 Series Transmitter can measure both level and interface level, such

as for separator applications.

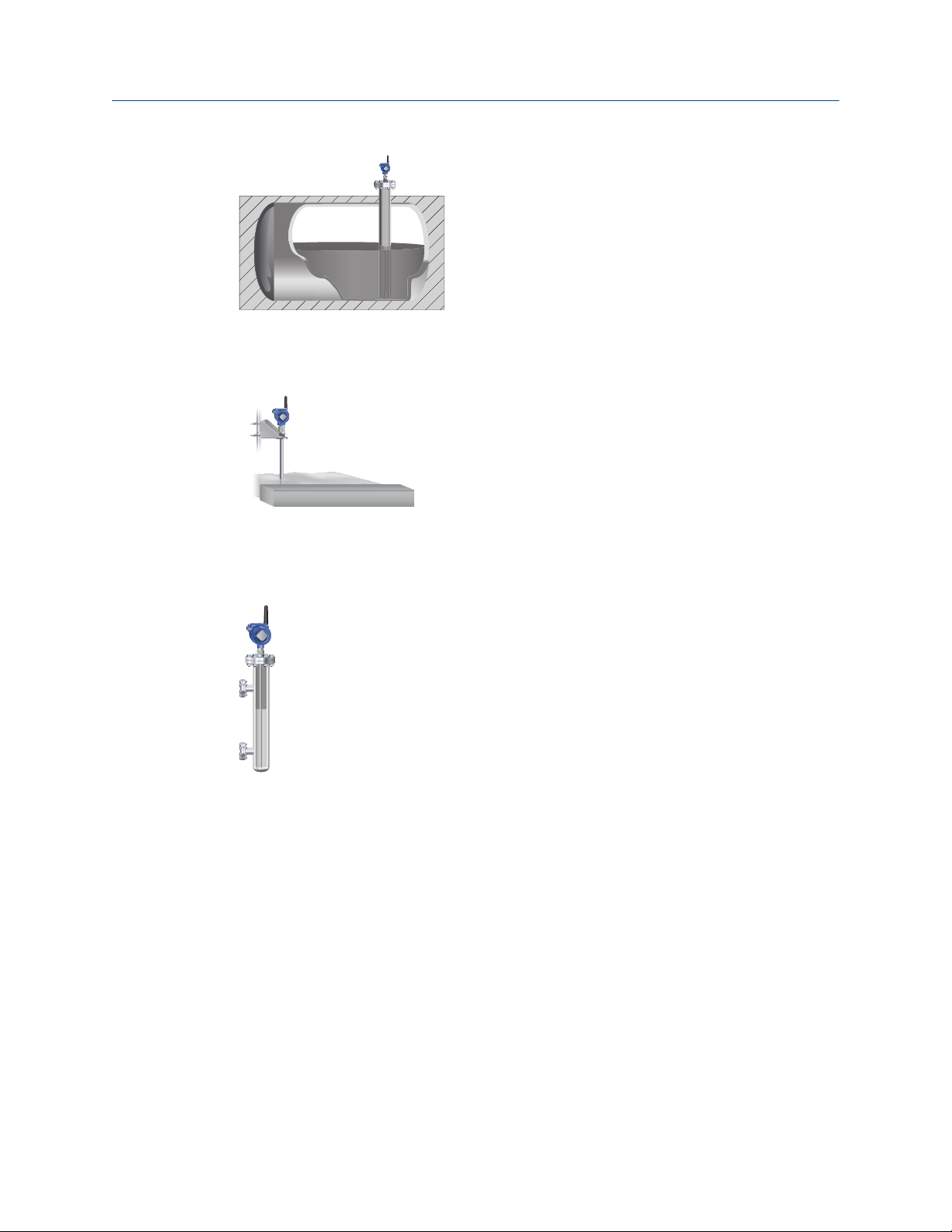

Waste tanks and sump pits

The Rosemount 3308 Series Transmitter is a good choice for waste tanks and

underground tanks, such as sump pits.

Reference Manual 17

Transmitter overview Reference Manual

February 2020

Open applications —ponds, basins, sumps

The Rosemount 3308 Series Transmitter can be installed in open air to measure liquids not

contained in a tank.

00809-0100-4308

Chamber applications

The Rosemount 3308 Series Transmitter is a good choice for both chamber and pipe

installations.

2.6 Components of the transmitter

The Rosemount 3308 Series transmitter housing contains advanced electronics for signal

processing. The transmitter housing is made of aluminum or stainless steel, depending on

specified option code.

The radar electronics produces an electromagnetic pulse, which is guided by the probe.

There are different probe types available for various applications: flexible single lead, rigid

single lead, segmented rigid single lead, flexible twin lead, and coaxial.

18 Rosemount 3308 Series

$

&

%

(

)

+

,-./

*

'

Reference Manual Transmitter overview

00809-0100-4308 February 2020

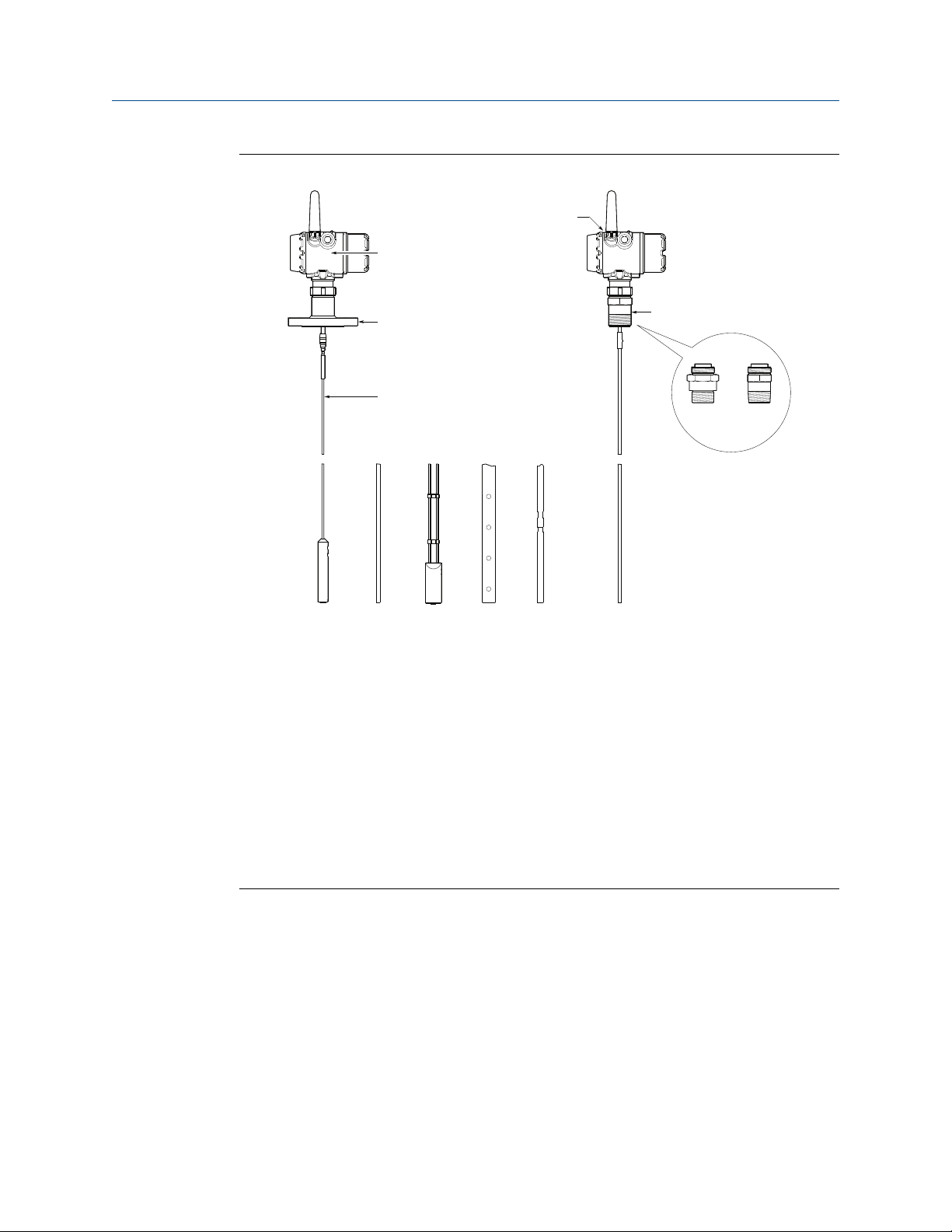

Figure 2-7: Transmitter Components

A. Radar electronics

B. Flanged process connections

C.

Probe

D. Dual compartment housing

E. Threaded process connections

F. BSPP (G)

G. NPT

H. Flexible single lead with weight

I. Rigid single lead

J. Flexible twin lead with weight

K. Coaxial

L. Segmented rigid single lead probe

Reference Manual 19

Transmitter overview Reference Manual

February 2020 00809-0100-4308

2.7 Probe selection guide

Use the following guidelines to choose appropriate probe for your Rosemount 3308 Series

transmitter:

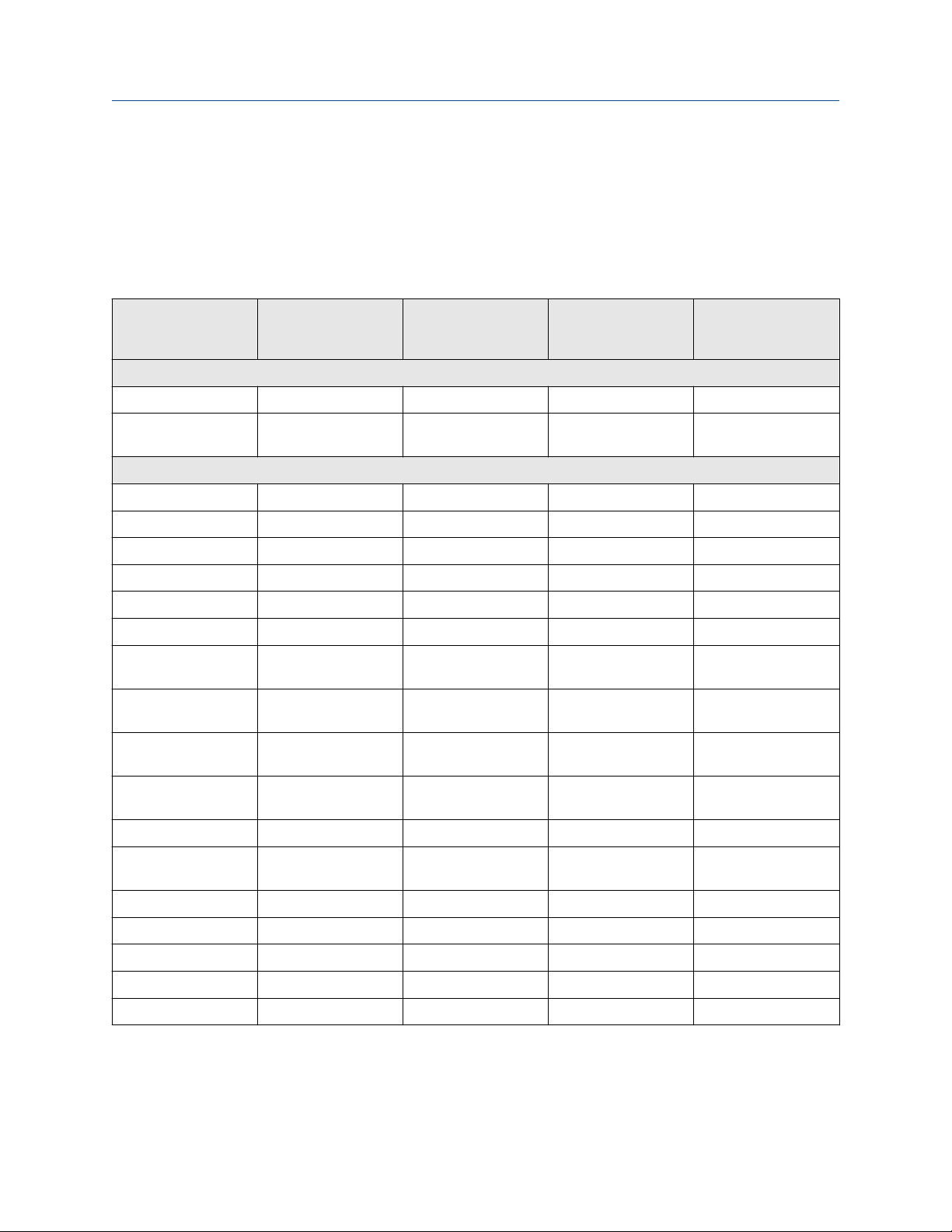

Table 2-1: Probe Selection Guide

G=Good, NR=Not Recommended, AD=Application Dependent (consult factory)

Flexible single lead Rigid single lead,

segmented rigid

single lead

Measurements

Level G G G G

Interface (liquid/

liquid)

Process medium characteristics

Changing density G G G G

Changing dielectric

Wide pH variations G G G G

Pressure changes G G G G

Temperature changes G G G G

Condensing vapors G G G G

Bubbling/boiling

surfaces

Foam (mechanical

avoidance)

Foam (top of foam

measurement)

G G G G

(2)

G G G G

G G G G

NR NR NR AD

AD AD AD NR

Flexible twin lead Coaxial

(1)

Foam (foam and liquid

measurement)

Clean liquids G G G G

Liquid with dielectric

(3)

<2.0

Coating liquids

Viscous liquids

Crystallizing liquids AD AD NR NR

Solids/Powders NR NR NR NR

Fibrous liquids G G NR NR

20 Rosemount 3308 Series

(4)

(4)

AD AD AD NR

AD AD AD AD

G G NR NR

G G AD NR

Reference Manual Transmitter overview

00809-0100-4308 February 2020

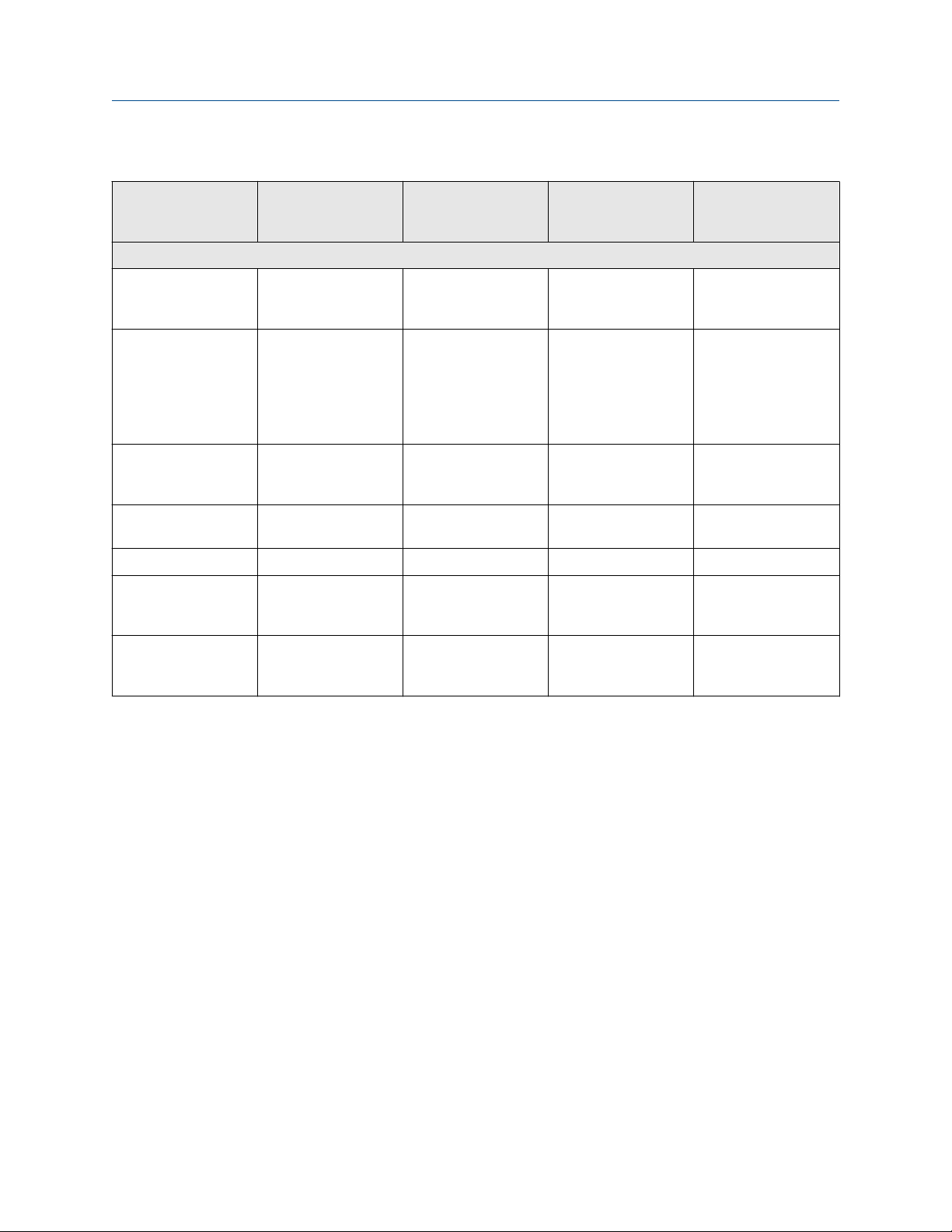

Table 2-1: Probe Selection Guide (continued)

Flexible single lead Rigid single lead,

segmented rigid

single lead

Tank environment considerations

Probe is close (<12

NR NR AD G

in./30 cm) to

disturbing objects

Tall and narrow

AD AD AD G

mounting nozzles

(diameter <6 in./15

cm and

height>diameter + 4

in./10 cm)

Probe might touch

NR NR NR G

nozzle / disturbing

object

Liquid or vapor spray

NR NR NR G

might touch probe

High turbulence AD

Turbulent conditions

(5)

G AD

AD NR AD NR

causing breaking

forces

Non-metallic tanks or

AD

(6)

AD

(6)

open atmosphere

applications

Flexible twin lead Coaxial

AD

(5)

(6)

G

G

(1) Not in fully submerged applications.

(2) For overall level applications a changing dielectric has no effect on the measurement. For interface measurements a

changing dielectric of the top fluid will degrade the accuracy of the interface measurement.

(3) See Table A-2 for more information.

(4) See Table A-1 for more information.

(5) Ok If probe is anchored.

(6) Not suitable in applications with disturbing EMC from nearby equipment.

Reference Manual 21

Transmitter overview Reference Manual

February 2020 00809-0100-4308

22 Rosemount 3308 Series

Reference Manual Installation

00809-0100-4308 February 2020

3 Installation

3.1 Safety messages

Instructions and procedures in this section may require special precautions to ensure the

safety of the personnel performing the operations. Information that potentially raises

safety issues is indicated by a warning symbol ( ). Refer to the following safety messages

before performing an operation preceded by this symbol.

WARNING

Failure to follow safe installation and servicing guidelines could result in death or serious

injury.

• Ensure the transmitter is installed by qualified personnel and in accordance with

applicable code of practice.

• Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment.

Explosions could result in death or serious injury.

• Verify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications.

• Installation of device in an explosive environment must be in accordance with

appropriate local, national, and international standards, codes, and practices.

• Ensure device is installed in accordance with intrinsically safe or non-incendive field

practices.

Electrical shock could cause death or serious injury.

• Ground device on non-metallic tanks (e.g. fiberglass tanks) to prevent electrostatic

charge build-up.

• Single lead probes are sensitive for strong electromagnetic fields and therefore not

suitable for non-metallic tanks.

• Care must be taken during transportation of power module to prevent electrostatic

charge build-up.

• Device must be installed to ensure a minimum antenna separation distance of 8 in. (20

cm) from all persons.

• Probes covered with plastic and/or with plastic discs may generate an ignition-capable

level of electrostatic charge under certain extreme conditions. Therefore, when the

probe is used in a potentially explosive atmosphere, appropriate measures must be

taken to prevent electrostatic discharge.

Reference Manual 23

Installation Reference Manual

February 2020 00809-0100-4308

WARNING

Process leaks could result in death or serious injury.

• Only qualified personnel should install the equipment.

• Install transmitter prior to process start-up.

• Install and tighten process connectors before applying pressure.

• Handle the transmitter carefully.

• Do not remove the transmitter while in operation.

• If the process seal is damaged, gas could escape from the tank when removing the

transmitter head from the probe.

3.2 Installation procedure

Follow these steps for proper installation:

Procedure

1. Review installation considerations.

2.

Review mounting preparations.

a) Measure tank height.

b) Optional: Shorten the probe.

c) Optional: Mount a centering disc for pipe installations.

d) Optional: Anchor the probe.

3. Mount device on tank.

4. Ground the device.

5. Install the power module.

6. Position the antenna.

7. Utilize the display.

3.3 Review mounting considerations

Before installing the Rosemount 3308 Series Transmitter, consider recommendations for

sufficient free space, mounting position, and special needs for non-metallic tanks.

3.3.1 Recommended mounting position for liquids

When finding an appropriate mounting position for the transmitter, the conditions of the

tank must be carefully considered. The transmitter should be mounted so that the

influence of disturbing objects is reduced to a minimum. For easy access to the

transmitter, ensure that it is mounted with sufficient service space.

24 Rosemount 3308 Series

&

%

$

Reference Manual Installation

00809-0100-4308

February 2020

Figure 3-1: Mounting Position

A. Inlet pipe

B. Agitator

Heating coils

C.

The following guidelines should be considered when mounting the transmitter:

• Do not mount close to inlet pipes.

• Do not mount close to agitators. If the probe can move to within 12 in. (30 cm) away

from an agitator, the probe should be anchored.

• If the probe tends to sway due to turbulent conditions in the tank, the probe should be

anchored.

• Avoid mounting close to heating coils.

• Position the probe such that it is subject to a minimum of lateral force.

• The probe should not come into contact with the nozzle or other objects in the tank.

Note

Violent fluid movements causing high sideway forces may break rigid probes.

3.3.2 Free space requirement

If the probe is mounted close to a wall, nozzle or other tank obstruction, noise might

appear in the level signal. Therefore the following minimum clearance, according to Table

3-1, must be maintained.

Reference Manual 25

/

Installation Reference Manual

February 2020 00809-0100-4308

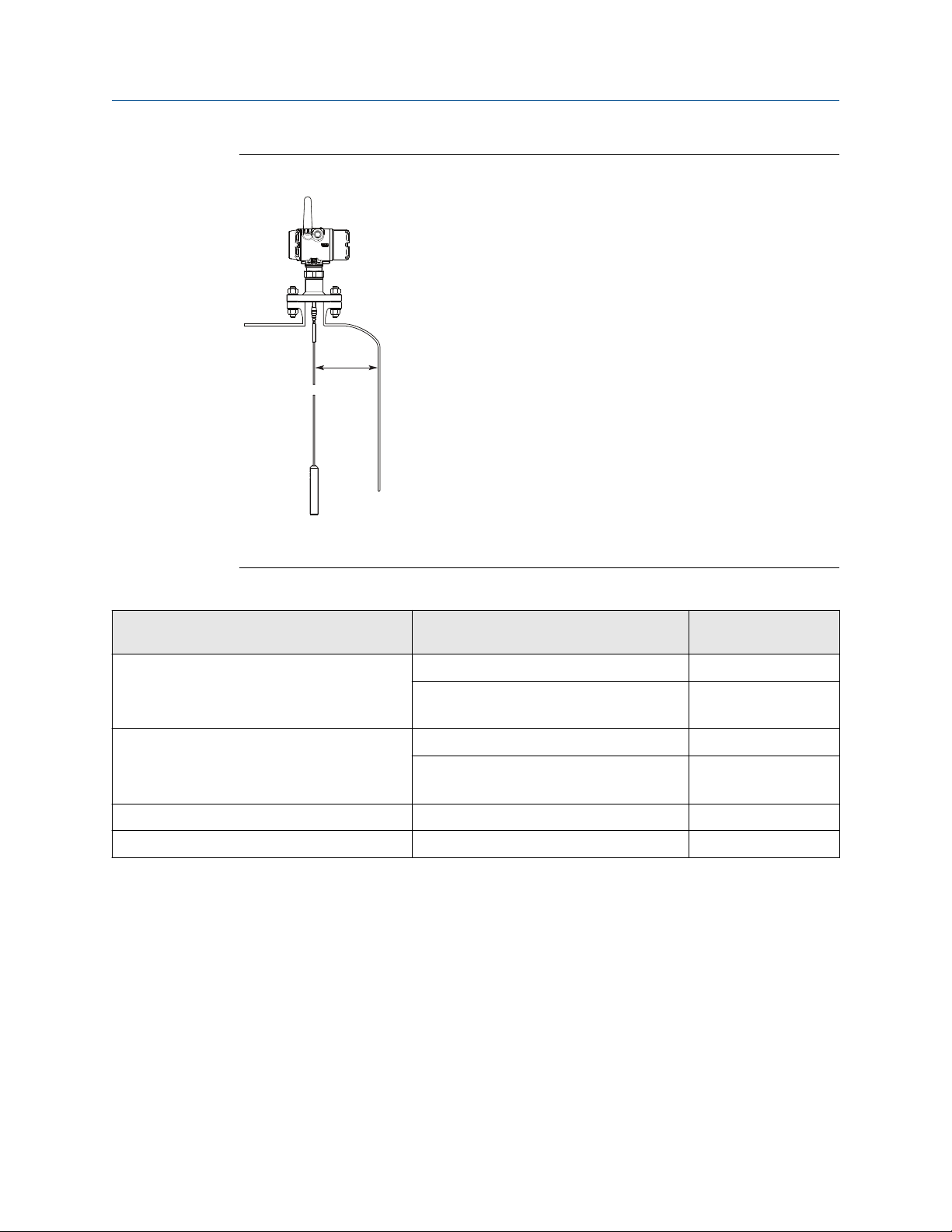

Figure 3-2: Free Space Requirement

L. Clearance to tank wall

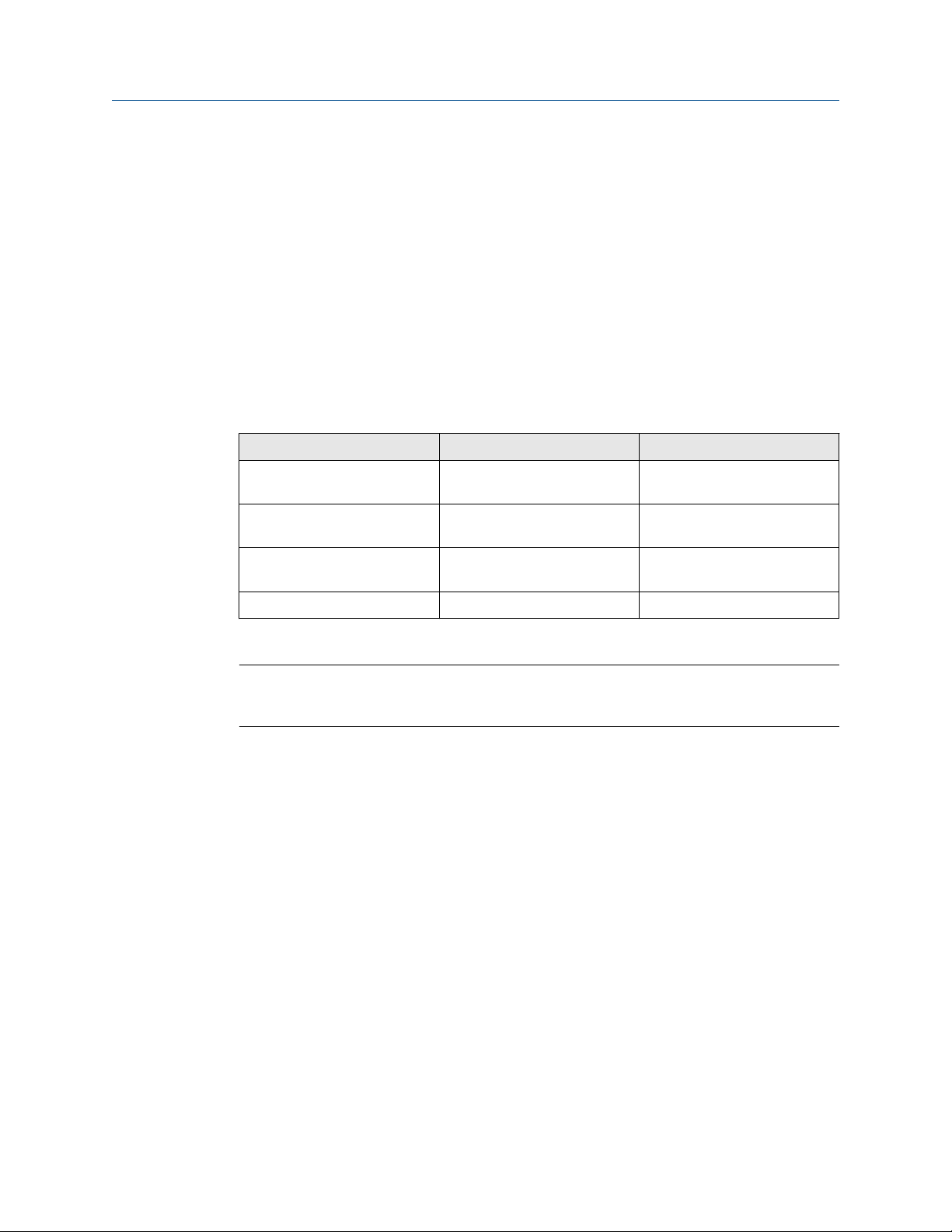

Table 3-1: Recommended Minimum Free Space to Tank Wall or Other Objects in the Tank

Probe type Condition Minimum clearance

(L)

Rigid single lead/Segmented rigid single lead

Flexible single Smooth metal tank wall 4 in. (100 mm)

(1)

Coaxial

Flexible twin N/A 4 in. (100 mm)

(1) Minimum clearance from tank bottom for the coaxial and rigid single probes is 0.2 in. (5 mm).

(1)

Smooth metal tank wall 4 in. (100 mm)

Disturbing objects such as pipes and beams

16 in. (400 mm)

Plastic, concrete or rugged metal tank wall

Disturbing objects such as pipes and beams

16 in. (400 mm)

Plastic, concrete or rugged metal tank wall

N/A 0 in. (0 mm)

26 Rosemount 3308 Series

$

%

&

Reference Manual Installation

00809-0100-4308

February 2020

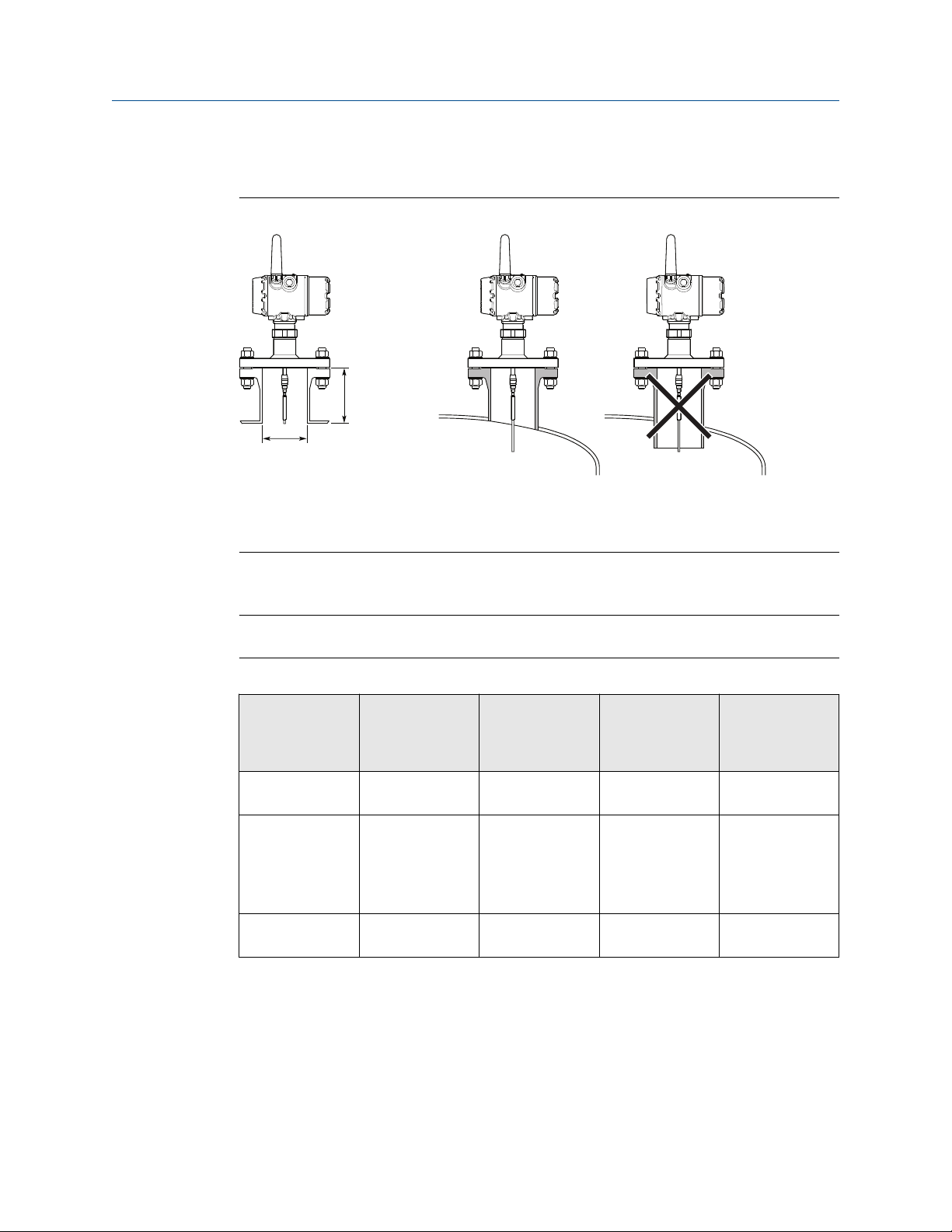

3.3.3 Flange connection on nozzles

Figure 3-3: Mounting in Nozzles

A. Maximum nozzle height

B. Minimum nozzle diameter

Confirm the nozzle does not extend into the tank.

C.

The transmitter can be mounted in nozzles by using an appropriate flange. It is

recommended that the nozzle size is within the dimensions given in Table 3-2.

Note

The probe must not be in contact with the nozzle (except for the coaxial probe).

Table 3-2: Nozzle Considerations

Description Flexible single

lead probe

Recommended

nozzle diameter

Minimum nozzle

diameter

Maximum nozzle

height

(1) The Trim Near Zone (TNZ) function may be necessary or an Upper Null Zone (UNZ) setup may be

(2) Recommended maximum nozzle height. For coaxial probes there is no limitation on nozzle

(3) For nozzles taller than 4 in. (100 mm), the long stud version is recommended (option code LS) to

(1)

(2)

required to mask the nozzle.

height.

prevent the flexible portion from touching the edge of the nozzle.

4 in. (100 mm) or

more

1.5 in. (38 mm) 1.5 in. (38 mm)

4 in. (100 mm) +

nozzle diameter

Rigid single lead

probe/

Segmented rigid

single lead

4 in. (100 mm) or

more

for probe type 4A

2 in. (50 mm) for

probe type 4B and

4S

4 in. (100 mm) +

(3)

nozzle diameter

Flexible twin

lead probe

4 in. (100 mm) or

more

2 in. (50 mm) > probe diameter

4 in. (100 mm) +

nozzle diameter

Coaxial probe

> probe diameter

N/A

Reference Manual 27

Installation Reference Manual

February 2020 00809-0100-4308

3.3.4 Installation in still pipe/chamber

General chamber considerations

Dimensioning the chamber/pipe correctly and selecting the appropriate probe is key to

the success in these applications. When selecting a smaller chamber/pipe diameter, such

as 2-in., a flexible probe is not suitable due to the chance of it coming into contact with the

walls. Also, relatively large side inlets may interfere with the signal.

When gas lift and/or turbulence may occur (e.g. boiling hydrocarbons), a 3- or 4-in.

chamber/pipe diameter is recommended for maximum measurement reliability. This is

especially true in high pressure and high temperature installations.

Table 3-3: Recommended and Minimum Chamber/Still Pipe Diameters for Different

Probes

Probe type Recommended diameter Minimum diameter

Rigid single/segmented rigid

single

Flexible single 4 in. (100 mm) Consult your local Emerson

Flexible twin

Coaxial 3 or 4 in. (75 or 100 mm) 1.5 in. (37.5 mm)

(1) The center rod must be placed more than 0.6 in. (15 mm) away from the pipe wall.

(1)

3 or 4 in. (75 or 100 mm) 2 in. (50 mm)

representative

4 in. (100 mm) Consult your local Emerson

representative

Note

Metal pipes are preferred, especially in applications with low dielectric constant, to avoid

disturbances from objects near the pipe.

Related information

Dimensional drawings

Rosemount chamber

A Rosemount chamber allows external mounting of process level instrumentation. It

supports a variety of process connections, and optional drain and vent connections. The

standard Rosemount chambers are designed according to ASME B31.3. Rosemount

chambers compliant with the Pressure Equipment Directive (PED) are available. Customer

specific engineered solutions for Rosemount chambers are available upon request. Use

option code XC to order together with the Rosemount 3308A Series Transmitters.

28 Rosemount 3308 Series

'

&

&

(

$$

%

Reference Manual Installation

00809-0100-4308 February 2020

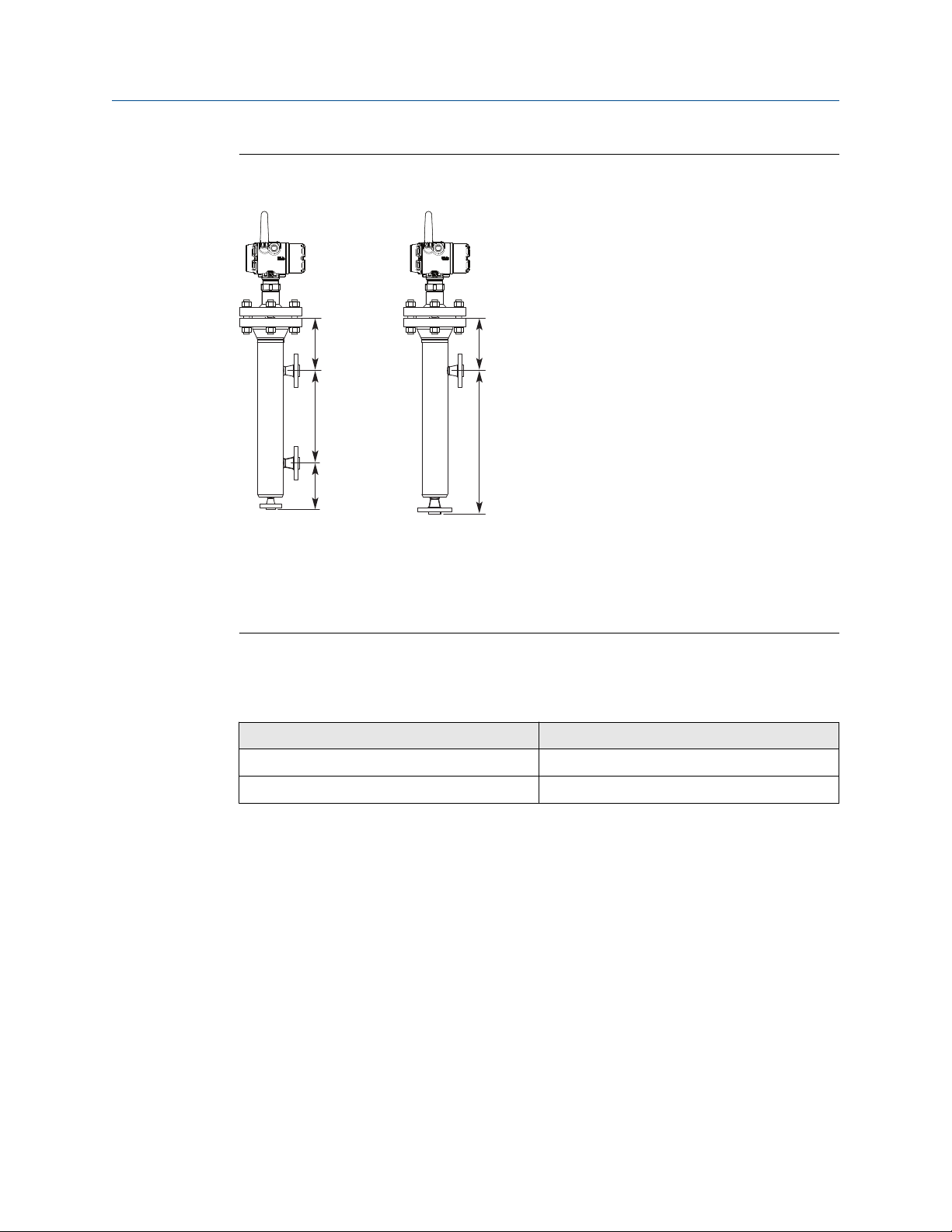

Figure 3-4: Side-to-Side and Side-to-Bottom Chambers

A. Dimension A

B. Dimension B

C.

Dimension CC

D. Side-to-side chamber

E. Side-to-bottom chamber

When mounting in a Rosemount chamber, see Table 3-4 for information on probe length

determination.

Table 3-4: Probe Length Determination for Rosemount CMB Chambers

Chamber type Probe length

Side-to-side chamber A + CC + B - 80 mm

Side-to-bottom chamber A + CC - 80 mm

Use a centering disc the same diameter as the chamber if the probe length >3.3 ft. (1 m).

See Table 3-8 for which disc to use.

Existing chamber

A Rosemount 3308 Series Transmitter is the perfect replacement in an existing displacer

chamber. Proprietary flanges are offered, enabling use of existing chambers to make

installation easy.

Reference Manual 29

$

&

%

Installation Reference Manual

February 2020

00809-0100-4308

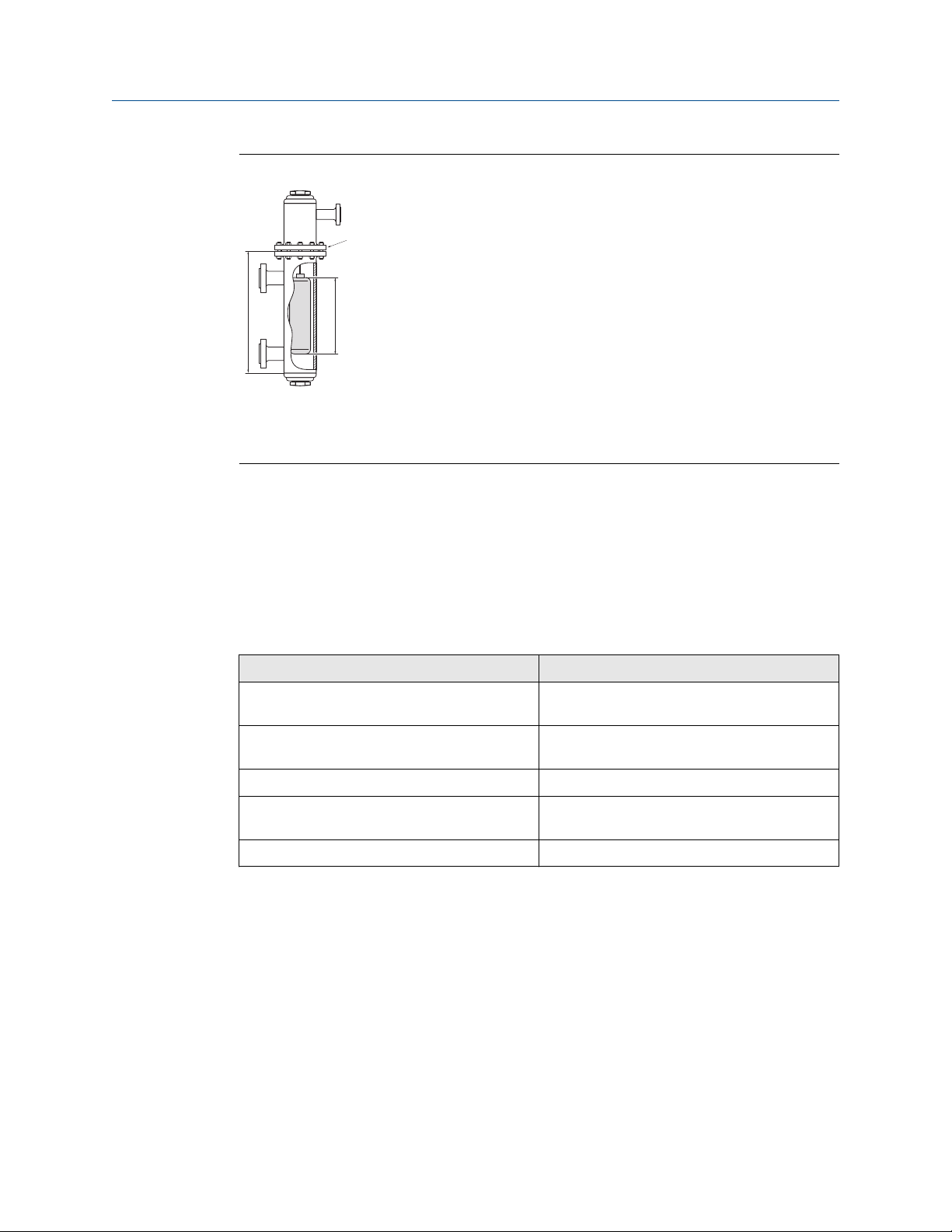

Figure 3-5: Existing Displacer Chamber

A. Replace chamber flange

B. Probe length

Displacer length

C.

Considerations when changing to Rosemount 3308 Series:

• The Rosemount 3308 Series flange choice and probe length must be correctly matched

to the chamber. Both standard ASME and EN (DIN), as well as proprietary chamber

flanges, are available. See Proprietary flanges to identify the proprietary flanges.

• See Table 3-8 for guidelines on which disc size to use.

• See Table 3-5 for guidelines on the required probe length.

Table 3-5: Required Probe Length in Chambers

Chamber manufacturer Probe length

Major torque-tube manufacture (249B, 249C,

249K, 249N, 259B)

Masoneilan™ (torque tube operated),

proprietary flange

Other - torque tube

Magnetrol® (spring operated)

Others - spring operated

(1) If flushing ring is used, add the ring height to the probe length.

(2) For other manufacturers, there are small variations. This is an approximate value; actual length

should be verified.

(3) Lengths vary depending on model, SG, and rating, and should be verified.

(2)

(3)

(2)

Displacer + 9 in. (229 mm)

Displacer + 8 in. (203 mm)

Displacer + 8 in. (203 mm)

Displacer + between 7.8 in. (195 mm) to 15 in.

(383 mm)

Displacer + 19.7 in. (500 mm)

(1)

For additional information, see the Replacing Displacers with Guided Wave Radar

Technical Note.

Probe type in chamber considerations

When installing a Rosemount 3308A in a chamber, the single lead probe is recommended.

The probe must not touch the chamber wall, should extend the full height of the chamber,

but not touch the bottom of the chamber.

30 Rosemount 3308 Series

Loading...

Loading...