Page 1

Rosemount™ 3308 Series Wireless Guided Wave Radar, 3308A

Product Data Sheet

January 2018

00813-0100-4308, Rev DB

World’s first true wireless Guided Wave Radar based on field proven, market leading technologies

Accurate, direct level and interface measurements virtually unaffected by process conditions

Fast and simple commissioning with self-organizing wireless network, intuitive user interface and cut-to-fit

probes

Minimized maintenance with no wires, no moving parts, no re-calibration, long battery life and advanced

diagnostics for better process insight

Page 2

Rosemount 3308 Series

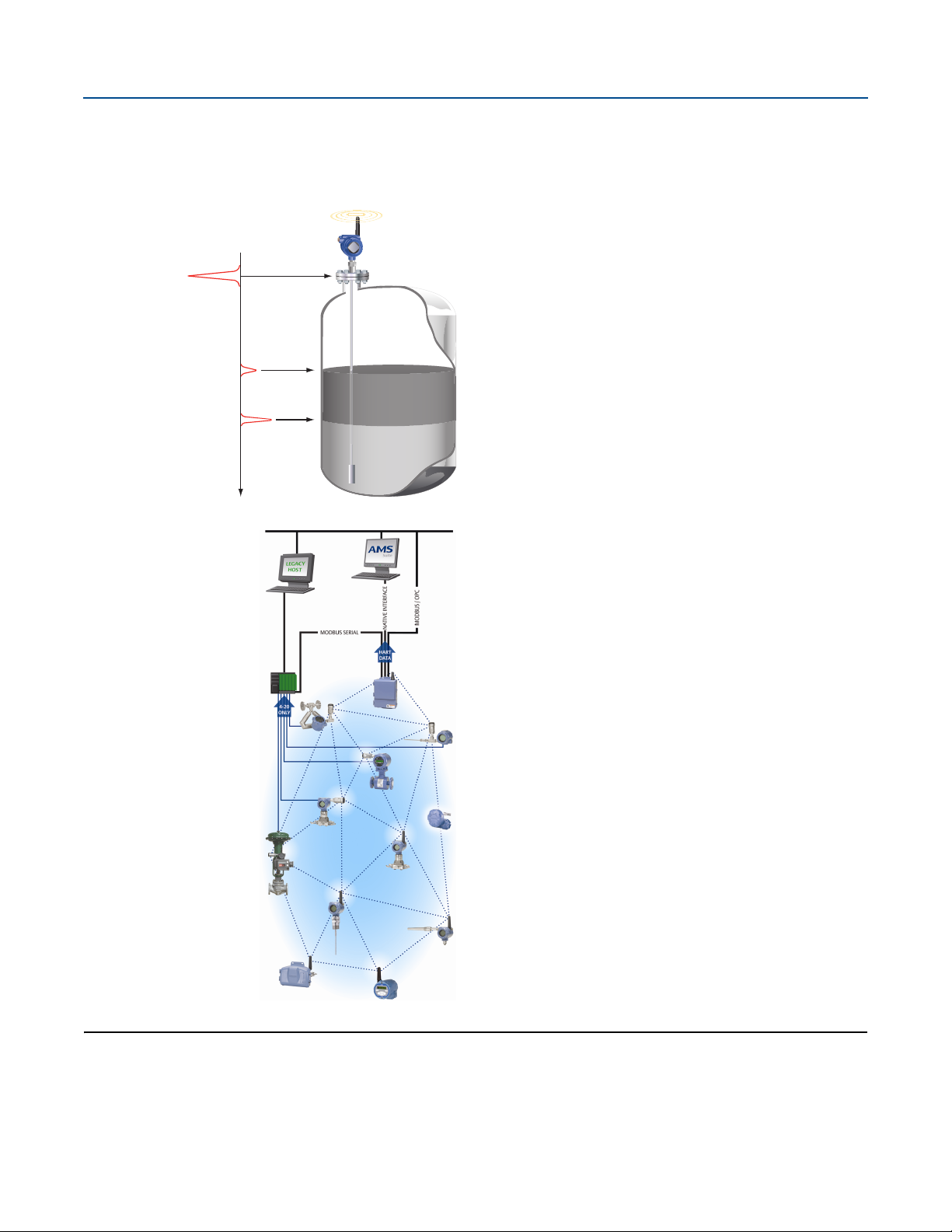

Product level

Interface level

Reference pulse

Introduction

January 2018

Guided wave radar

The Rosemount 3308 Series measurement is based on the Time

Domain Reflectometry (TDR) principle. Low power

nano-second-pulses are guided along a probe submerged in the

process media. When a pulse reaches the surface of the material

it is measuring, part of the energy is reflected back to the

transmitter, and the time difference between the generated and

reflected pulse is converted into a distance from which the total

level or interface level is calculated (see left).

The reflectivity of the product, its dielectric constant, is a key

parameter for measurement performance. A high dielectric

constant of the media gives better reflection and a longer

measuring range.

With innovative technologies inherited from other market

leading Rosemount guided wave radars, Rosemount 3308 Series

delivers reliable measurements without compromising a long

battery life.

Emerson™ Wireless

Emerson Wireless is a self-organizing network solution. Wireless

field instruments send data to a Gateway, directly or routed

through any of the wireless devices in the network. Multiple

communication paths are managed and analyzed in parallel to

assure optimal communication and sustained network reliability

even if obstructions are introduced.

Gateways interface with existing host systems using industry

standard protocols, and native integration into DeltaV

Ovation

Interference from other radios, Wi-Fi

avoided through Time Synchronized Channel Hopping and

Direct Sequence Spread Spectrum (DSSS). Also, a layered

security implementing industry standard Encryption,

Authentication, Verification, Anti-Jamming, and Key

Management ensures that data transmissions are secure and

received only by the Gateway.

The Rosemount 3308 Series is a member of the Emerson

Wireless portfolio, whose wireless network experience totals

billions of operating hours, hundreds of thousands field devices,

and tens of thousands of networks around the world.

™

is transparent and seamless.

®

, and EMC sources is

™

and

Contents

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2

Product Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Dimensional Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Emerson.com/Rosemount

Page 3

January 2018

Oil

Oil

Water

Rosemount 3308 Series

Application examples

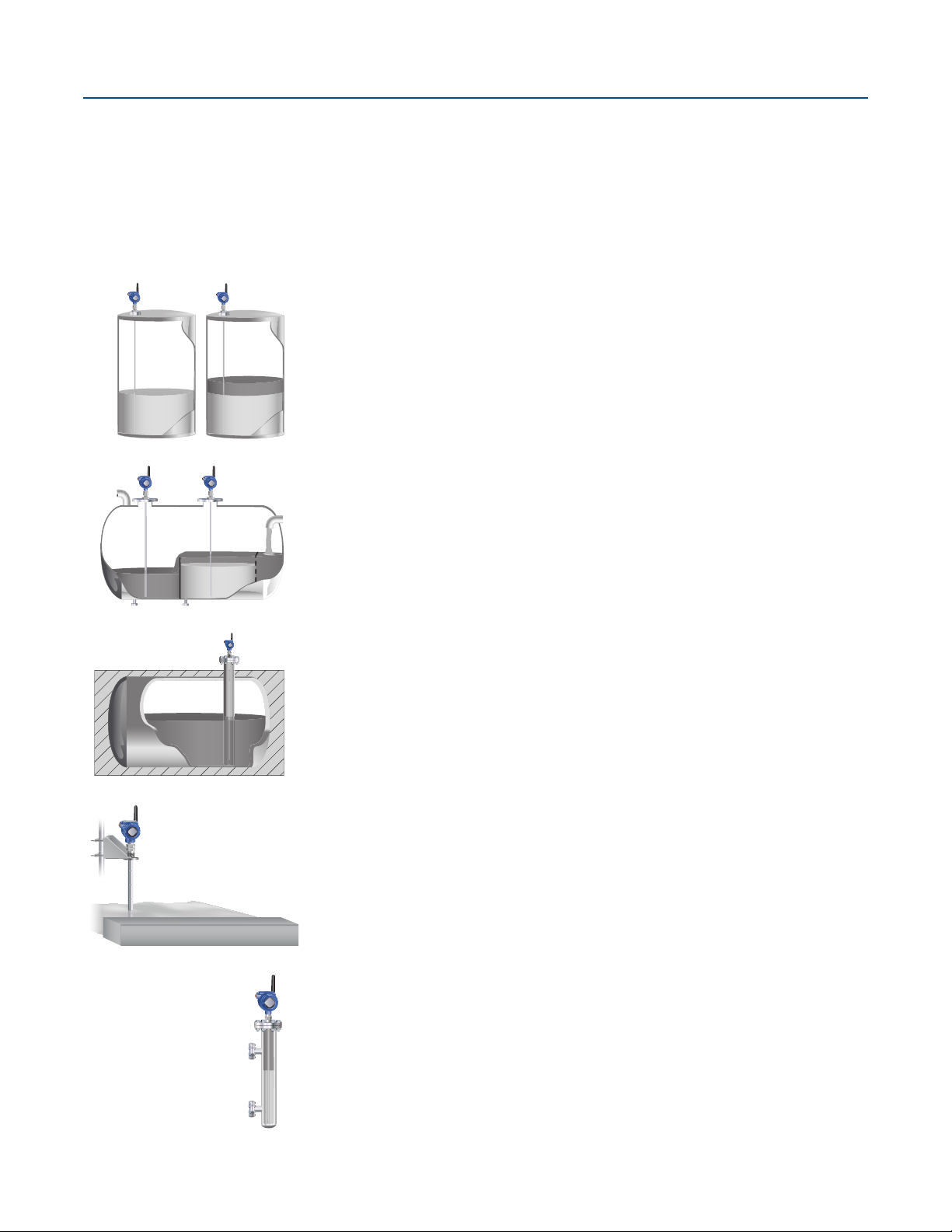

The Rosemount 3308 Series Transmitter is suited for aggregate (total) level measurements on a wide range of liquids, semi-liquids,

and liquid/liquid interfaces.

The quick and easy installation of true wireless transmitters makes the Rosemount 3308 Series an ideal solution to automate

measurements in remote locations or where existing wiring is limited. Moreover, the reliable and accurate nature of guided wave

radar technology offers a versatile solution that is virtually unaffected by process conditions such as temperature, pressure, vapor gas

mixtures, density, turbulence, bubbling/boiling, varying dielectric media, pH, and viscosity.

Storage and buffer tanks

The Rosemount 3308 Series Transmitter is ideal for storage or buffer

tanks for almost any liquid, such as oil, gas condensate, water, or

chemicals.

Low pressure separators

The Rosemount 3308 Series Transmitter can measure both level and

interface level, such as for separator applications.

Waste tanks and sump pits

The Rosemount 3308 Series Transmitter is also a good choice for

waste tanks and underground tanks, such as sump pits.

Open applications—ponds, basins, sumps

The Rosemount 3308 Series Transmitter can be installed in open air

to measure liquids not contained in a tank.

Chamber applications

The Rosemount 3308 Series Transmitter is a good choice for both

chamber and pipe installations.

Emerson.com/Rosemount

3

Page 4

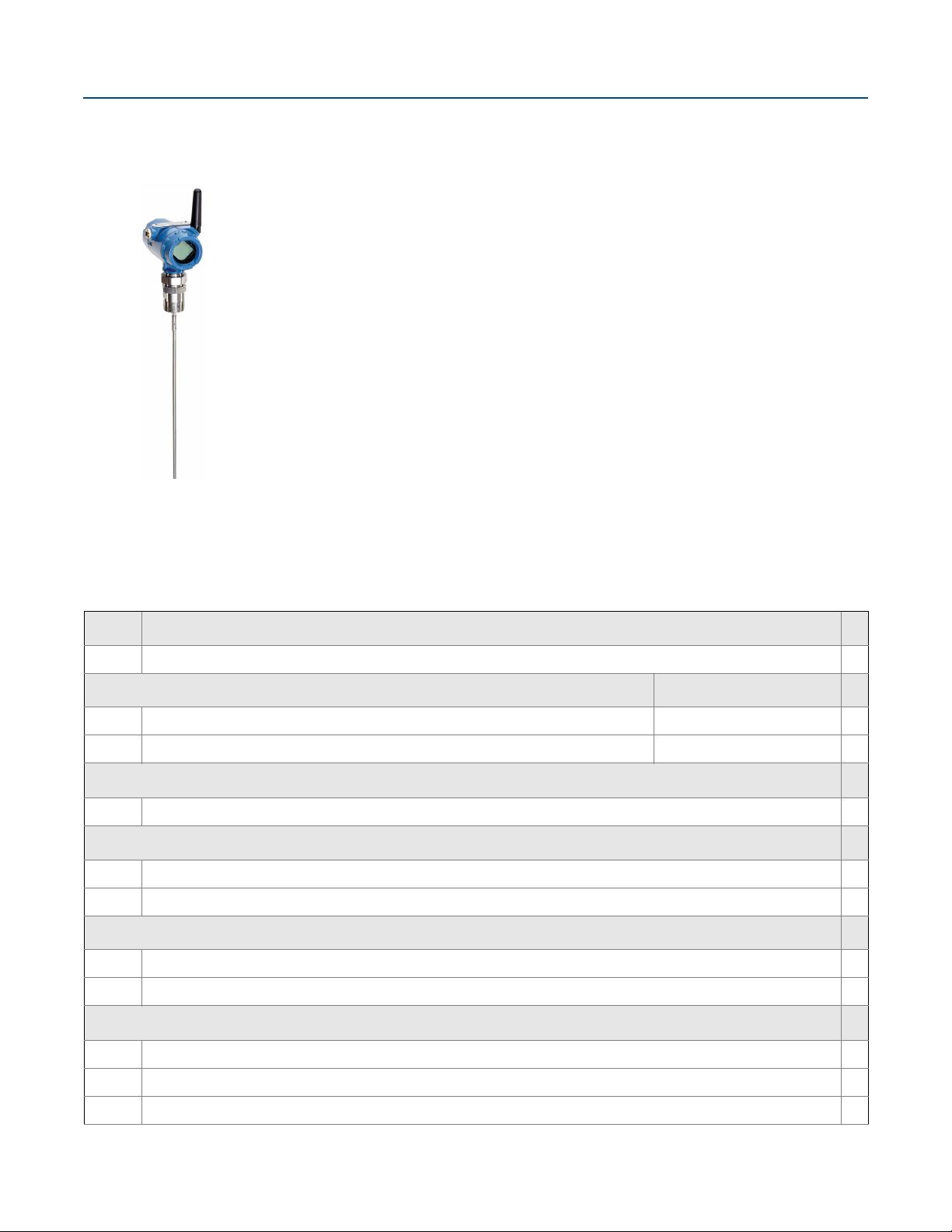

Rosemount 3308 Series

January 2018

Ordering Information

Rosemount 3308 Series Guided Wave Radar Level Transmitters are versatile and easy-to-use with

field proven, market leading technologies. Characteristics include:

• Intrinsically Safe

• Long battery life

®

• IEC 62591 (WirelessHART

• Compatible with AMS Device Manager and AMS Wireless Configurator packages for easy

commissioning and troubleshooting

Additional Information

Specifications: page 14

Interface Measurement: page 21

Mechanical Considerations: page 26

Chamber/Pipe Installations: page 27

Certifications: page 29

Dimensional Drawings: page 32

Specification and selection of product materials, options, or components must be made by the purchaser of the equipment.

See page 23 for more information on Material Selection.

) Communication

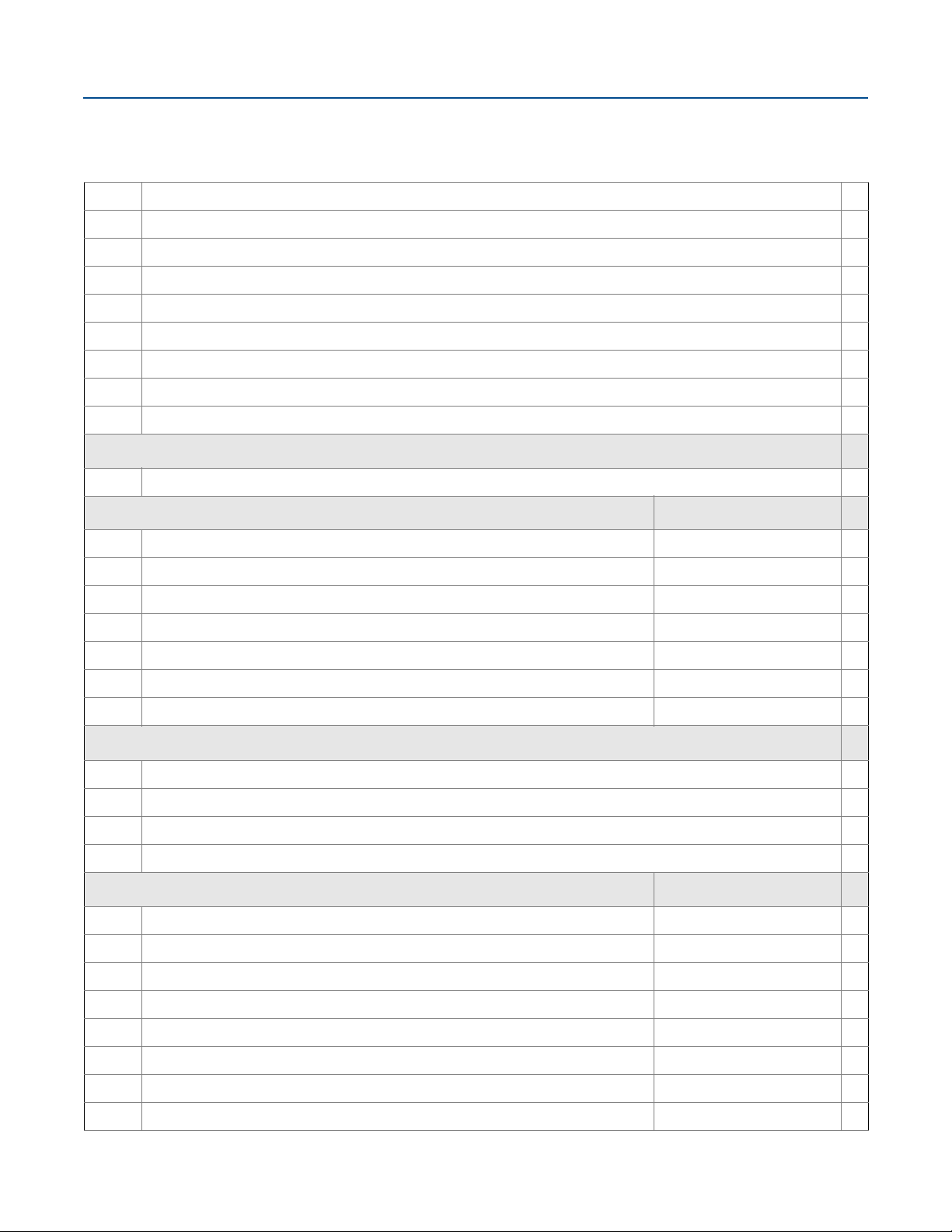

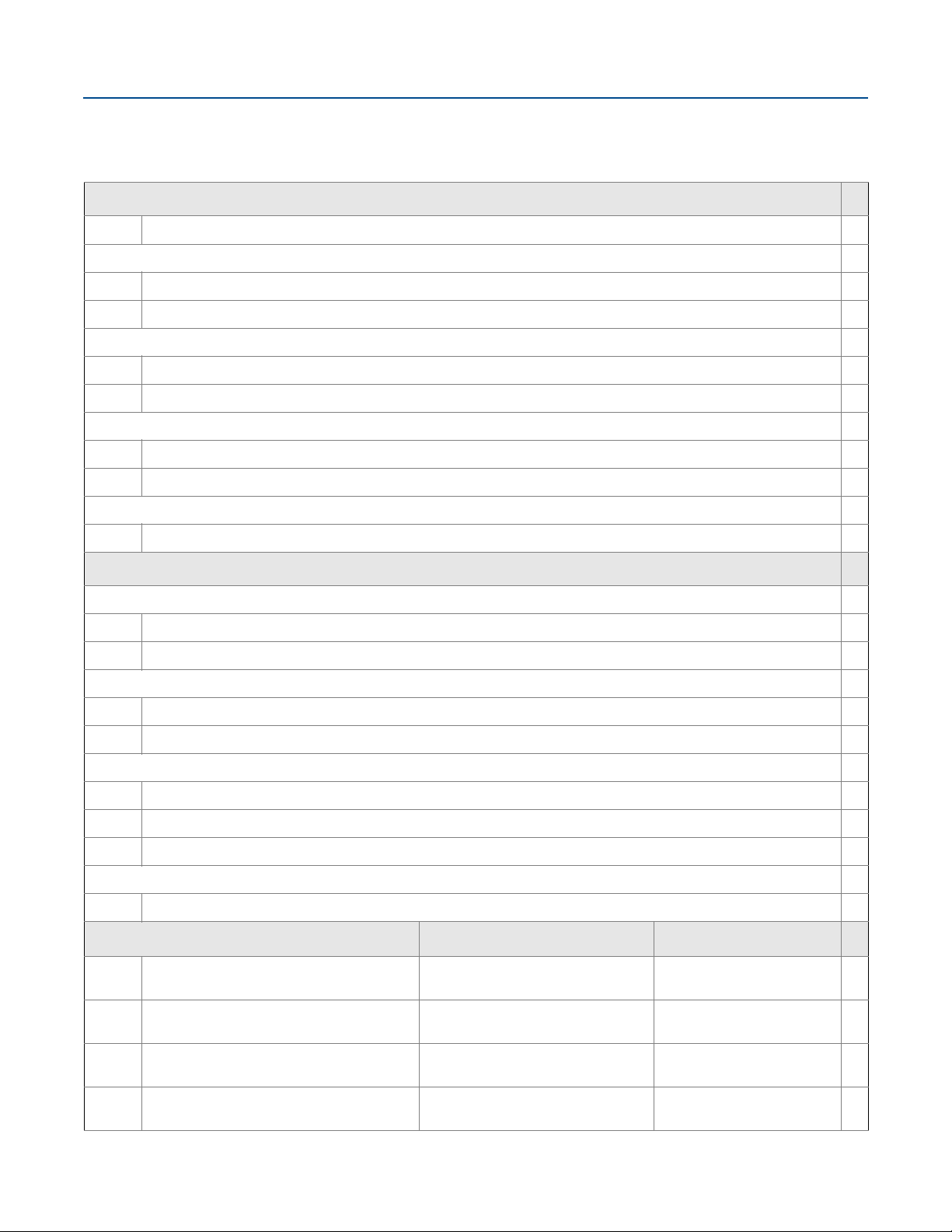

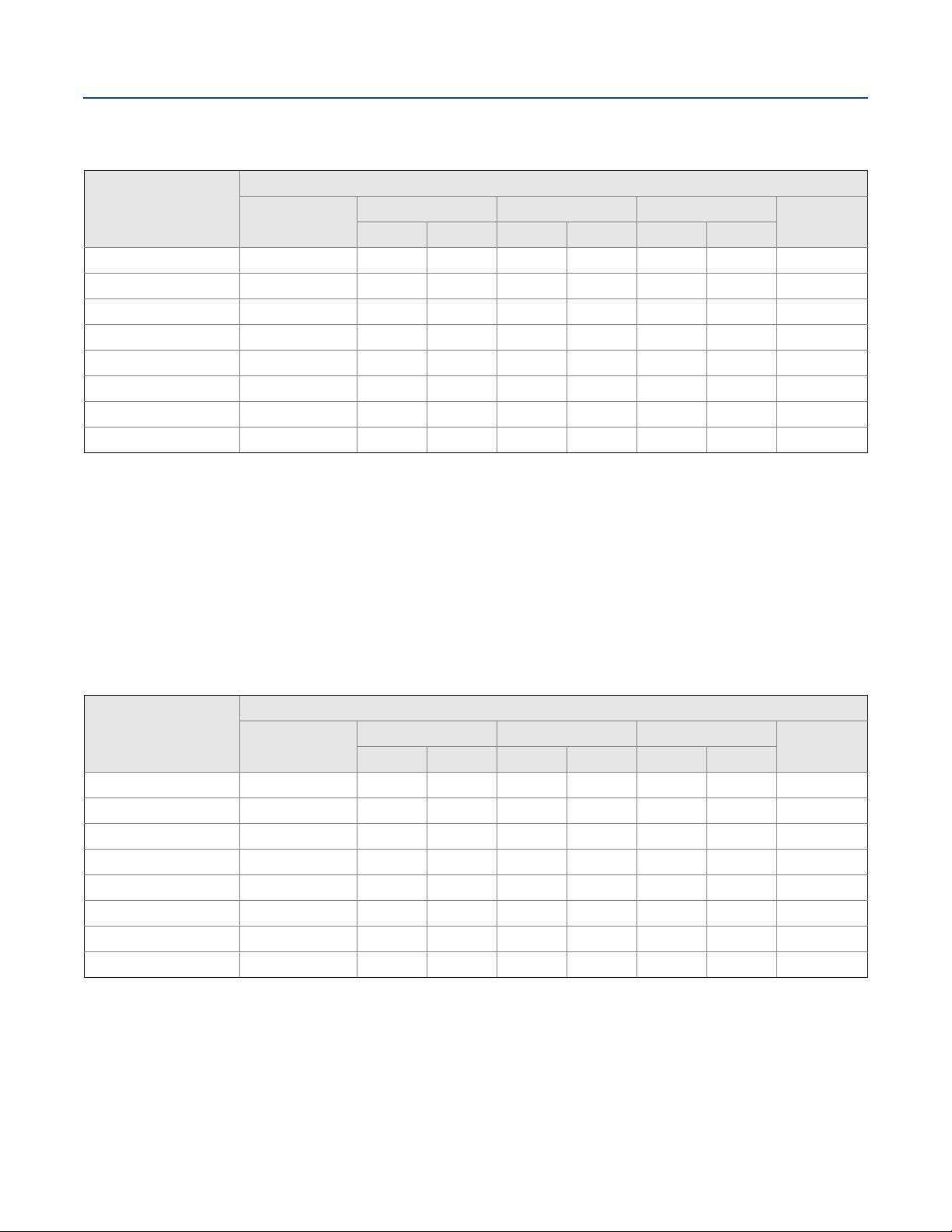

Table 1. Rosemount 3308 Series Level and/or Interface Measurements in Liquids Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Model Product description

3308A Guided Wave Radar Level Transmitter

★

Profile Reference accuracy

(1)(2)

U

S Standard ±0.25 in. (±6 mm)

High Performance ±0.12 in. (±3 mm)

★

★

Signal output (see page 19 for details)

X Wireless

★

Measurement type (see page 21)

2 Level and Interface Transmitter

1 Level or Interface Transmitter (Interface available for fully submerged probe)

★

Housing

D1 Wireless Dual Compartment Housing, Aluminum (with plugged ½-14 NPT conduits)

E1 Wireless Dual Compartment Housing, Stainless steel (with plugged ½-14 NPT conduits)

★

★

Hazardous locations certifications (see page 29-31)

I1 ATEX Intrinsic Safety

I2 INMETRO Intrinsic Safety

I3 NEPSI Intrinsic Safety

4

★

★

★

Emerson.com/Rosemount

Page 5

January 2018

Rosemount 3308 Series

Table 1. Rosemount 3308 Series Level and/or Interface Measurements in Liquids Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

I4 TIIS Intrinsic Safety

★

I5 FM Intrinsically Safe

I6 Canadian Intrinsically Safe

I7 IECEx Intrinsic Safety

IM Technical Regulations Customs Union (EAC) Intrinsic Safety

KD ATEX and Canadian Intrinsic Safety

KE FM and Canadian Intrinsically Safe

KF ATEX and FM Intrinsic Safety

NA No Hazardous Locations Certifications

Operating temperature and pressure (see page 20)

S - 15 psig (-1bar) to 580 psig (40 bar) @ 302 °F (150 °C)

Material of construction; process connection/probe Probe type

1 316L SST (EN 1.4404) All

2 Alloy C-276 (UNS N10276). With plate design if flanged version. 3A, 3B, 4A, 4B, and 5A

3 Alloy 400 (UNS N04400). With plate design if flanged version. 3A, 3B, 4A, 4B, and 5A

7 PTFE covered probe and flange. With plate design. 4A and 5A

8 PTFE covered probe 4A and 5A

★

★

★

★

★

★

H Alloy C-276 (UNS N10276) process connection, flange, and probe 3A, 3B, 4A, 4B, and 5A

D Duplex 2205 (UNS S31803) process connection, flange, and probe 4B and 5A

Sealing O-ring material (see page 20)

V Viton® Fluoroelastomer

E Ethylene Propylene (EPDM)

K Kalrez® 6375 Perfluoroelastomer

B Nitrile Butadiene (NBR)

Process connection size (see Table 2 and Table 3 on page 10 for availability) Process connection type

5 1½-in. Thread/Tri Clamp

2 2-in./DN50/50A NPT Thread/Flange/Tri Clamp

3 3-in./DN80/80A Flange/Tri Clamp

4 4-in./DN100/100A Flange/Tri Clamp

P Proprietary Flanges Proprietary Flange

1 1-in. Thread

6 6-in./DN150/150A Flange

8 8-in./DN200/200A Flange

★

★

★

★

★

★

★

★

★

Emerson.com/Rosemount

5

Page 6

Rosemount 3308 Series

January 2018

Table 1. Rosemount 3308 Series Level and/or Interface Measurements in Liquids Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Process connection rating (see Tab le 2 and Table 3 on page 10 for availability)

NN For use with non-flange process connection type

ASME rating

AA ASME B16.5 Class 150 Flange

AB ASME B16.5 Class 300 Flange

EN rating

DA EN1092-1 PN16 Flange

DB EN1092-1 PN40 Flange

JIS rating

JA JIS B2220 10K Flange

JB JIS B2220 20K Flange

Proprietary

PF Proprietary Flange

Process connection type (see Tabl e 2 and Table 3 on page 10 for availability)

Thread

N NPT thread

G BSPP (G) thread

★

★

★

★

★

★

★

★

★

★

Flange faces

F Flat Face (FF) Flange, available for EN flanges

R Raised Face (RF) Flange, available for ASME and JIS flanges

Proprietary flanges (see page 39 for dimensions)

M Masoneilan™-Proprietary, 316 SST Torque Tube Flange, 316L

P Fisher™-Proprietary, 316 SST, (for 249B and 259B cages) Torque Tube Flange, 316L

Q Fisher-Proprietary, 316 SST, (for 249C cages) Torque Tube Flange, 316L

Tri Cla mp

C Tri Clamp

Probe type Process connection type Probe lengths

3B

Coaxial, perforated. For level and interface

measurement.

Flange/1-, 1½-, 2-in. Thread

4A Rigid Single Lead (d=0.3"/8 mm) Flange/1-, 1½-, 2-in. Thread/Tri Clamp

4B Rigid Single Lead (d=0.5"/13 mm) Flange/1½-, 2-in. Thread/Tri Clamp

5A

Flexible Single Lead (d=0.16"/4 mm).

Refer to page 8 to specify weight or chuck.

Flange/1-, 1½-, 2-in. Thread/Tri Clamp

Min.:1 ft. 4 in. (0.4 m)

Max.: 19 ft. 8 in. (6 m)

Min.:1 ft. 4 in. (0.4 m)

Max.: 9 ft. 10 in. (3 m)

Min.:1 ft. 4 in. (0.4 m)

Max.: 19 ft. 8 in. (6 m)

Min.:3 ft. 4 in. (1 m)

Max.: 55 ft. 9 in. (17 m)

★

★

★

★

★

★

(3)

★

★

(3)

★

6

Emerson.com/Rosemount

Page 7

January 2018

Rosemount 3308 Series

Table 1. Rosemount 3308 Series Level and/or Interface Measurements in Liquids Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

2A Flexible Twin Lead with weight Flange/1½-, 2-in. Thread

Min.:3 ft. 4 in. (1 m)

Max.: 55 ft. 9 in. (17 m)

(4)

3A

Coaxial (for level measurement) Flange/1-, 1½-, 2-in. Thread

4S Segmented Rigid Single Lead (d=0.5"/13 mm) Flange/1½-, 2-in. Thread

Min.:1 ft. 4 in. (0.4 m)

Max.: 19 ft. 8 in. (6 m)

Min.: 1 ft. 4 in. (0.4 m)

Max: 32 ft. 9 in. (10 m)

Probe length units (see page 23 for total probe length)

E English (feet, inches)

M Metric (meters, centimeters)

Probe length (feet/meters)

XXX 0-55 feet or 0-17 meters

Probe length (inches/centimeters)

XX 0-11 inches or 0-99 Centimeters

Update rate, operating frequency and protocol

WA3 User Configurable Update Rate, 2.4 GHz, IEC 62591 (WirelessHART)

Omnidirectional wireless antenna and SmartPower™ solutions (see page 19 for functional specification)

WK1 External Antenna, Adapter for Intrinsically Safe Black Power Module (Power Module Sold Separately)

WN1

High Gain, Remote Antenna (see page 38 for dimensions), Adapter for Intrinsically Safe Black Power Module (Power

Module Sold Separately)

★

★

★

★

★

★

★

Note: Black Power Module must be shipped separately; order Model 701PBKKF (part number 00753-9220-0001).

Options (include with selected model number)

Display

M5 LCD Display (see page 19)

Hydrostatic testing

P1 Hydrostatic Testing, including certificate

Factory configuration

C1 Factory Configuration per Configuration Data Sheet

Special quality assurance

Q4 Calibration Data Certificate

Material traceability certification

(5)

Q8

Material Traceability Certification per EN 10204 3.1

★

★

★

★

★

Emerson.com/Rosemount

7

Page 8

Rosemount 3308 Series

January 2018

Table 1. Rosemount 3308 Series Level and/or Interface Measurements in Liquids Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Welding procedure qualification/specification

Q66 Welding Procedure Qualification Record Documentation

Q67 Welder Performance Qualification Record

Q68 Welding Procedure Specification

Special certifications

QG GOST Certification

Materials certification

(6)

Q15

NACE® material recommendation per NACE MR0175/ISO 15156

Installation options

LS Long Stud for Flexible Single Lead Probes, 25 cm (10 in.) (for use in tall nozzles)

BR Mounting Bracket for 1½-in. NPT Process Connection (see page 37)

Weight and anchoring options for flexible single probes (see page 32 for dimensions)

W1 Small Weight (for narrow tank openings less than 2 in. (50 mm)) (Required for PTFE covered probes)

W3 Heavy weight (for most applications)

W4 Chuck (to tie probe end to tank bottom)

W2 Short weight (when measuring close to the probe end)

Weight assembly options for flexible single probes

WU Weight or chuck not mounted on the probe

Extended product warranty

WR3 3-year limited warranty

WR5 5-year limited warranty

Plantweb™ diagnostic functionality

★

★

★

★

★

★

★

★

DA1 HART® Diagnostics (see page 19)

Centering disc (see page 28 for dimensions and size recommendation)

(8)

S2

S3

S4

2-in. Centering disc

(8)

3-in. Centering disc

(8)

4-in. Centering disc

P2 2-in. Centering disc PTFE

P3 3-in. Centering disc PTFE

P4 4-in. Centering disc PTFE

(8)

S6

S8

6-in. Centering disc

(8)

8-in. Centering disc

8

★

(7)

★

★

★

★

★

★

Emerson.com/Rosemount

Page 9

January 2018

Rosemount 3308 Series

Table 1. Rosemount 3308 Series Level and/or Interface Measurements in Liquids Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

P6 6-in. Centering disc PTFE

P8 8-in. Centering disc PTFE

Assemble/consolidate to chamber (see page 27)

XC Consolidate to Chamber

★

Engineered solutions (see page 26)

Pxxxx Engineered Solutions beyond standard model codes. (Consult factory for details)

1. The Rosemount 3308A with profile code U has two performance modes: Standard and High Performance (default). The performance mode may be reconfigured in

field.

2. Available with hazardous locations certifications I1, I5, I6, and I7.

3. Minimum probe length is 4 ft. 11 in. (1.5 m) for PTFE covered probes (Material of Construction codes 7 and 8).

4. Requires model 3308Axx1.

5. Certificate includes all metallic pressure retaining wetted parts.

6. Available for Probe Type 3A, 3B, 4A, 4B, 4S, and PTFE-coated 5A.

7. Available for SST, Alloy C-276, Alloy 400, and Duplex 2205 probes, type 2A, 4A, 4B, 4S, and 5A. Not available with PTFE covered probes (Material of Construction

codes 7 and 8).

8. Centering disc in same material as probe material of construction.

Emerson.com/Rosemount

9

Page 10

Rosemount 3308 Series

January 2018

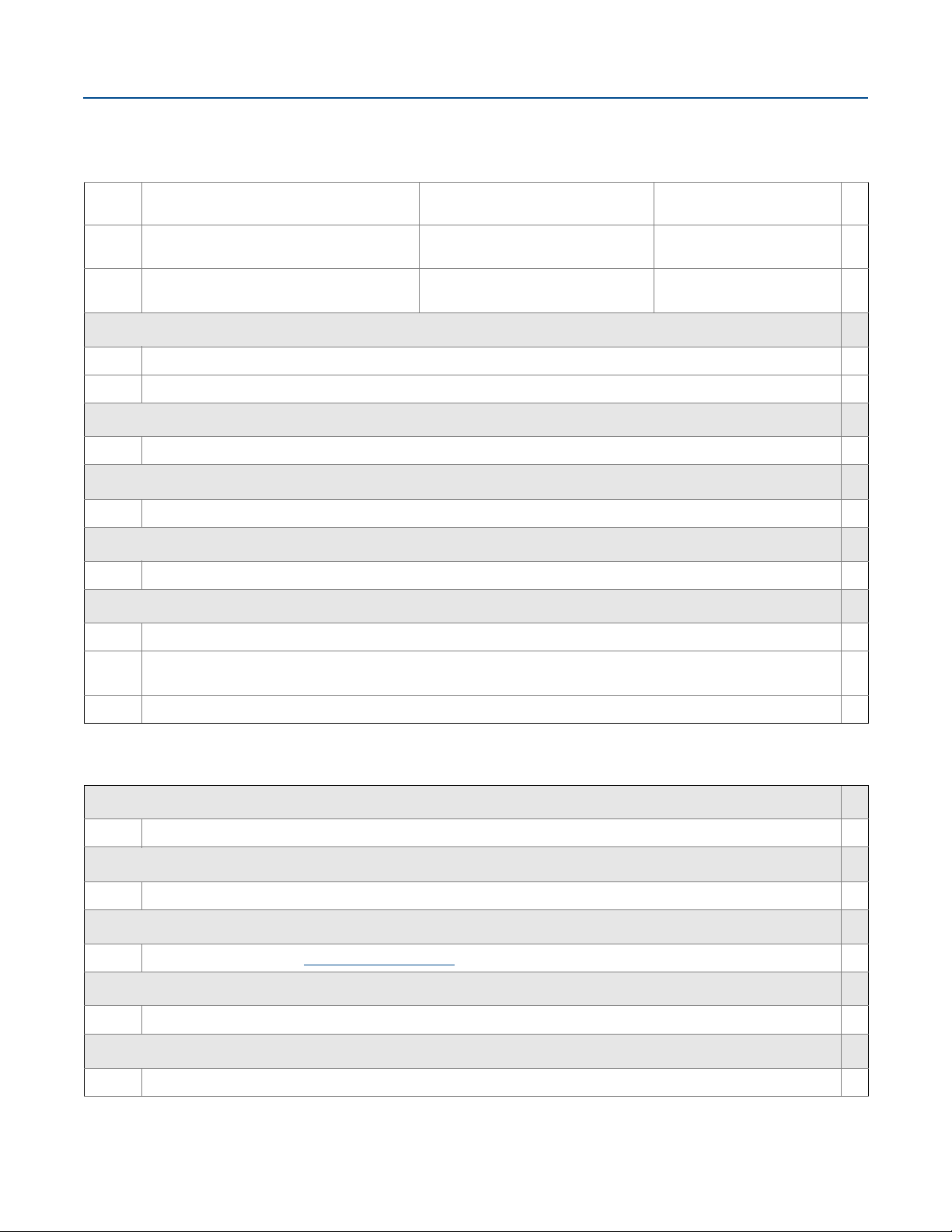

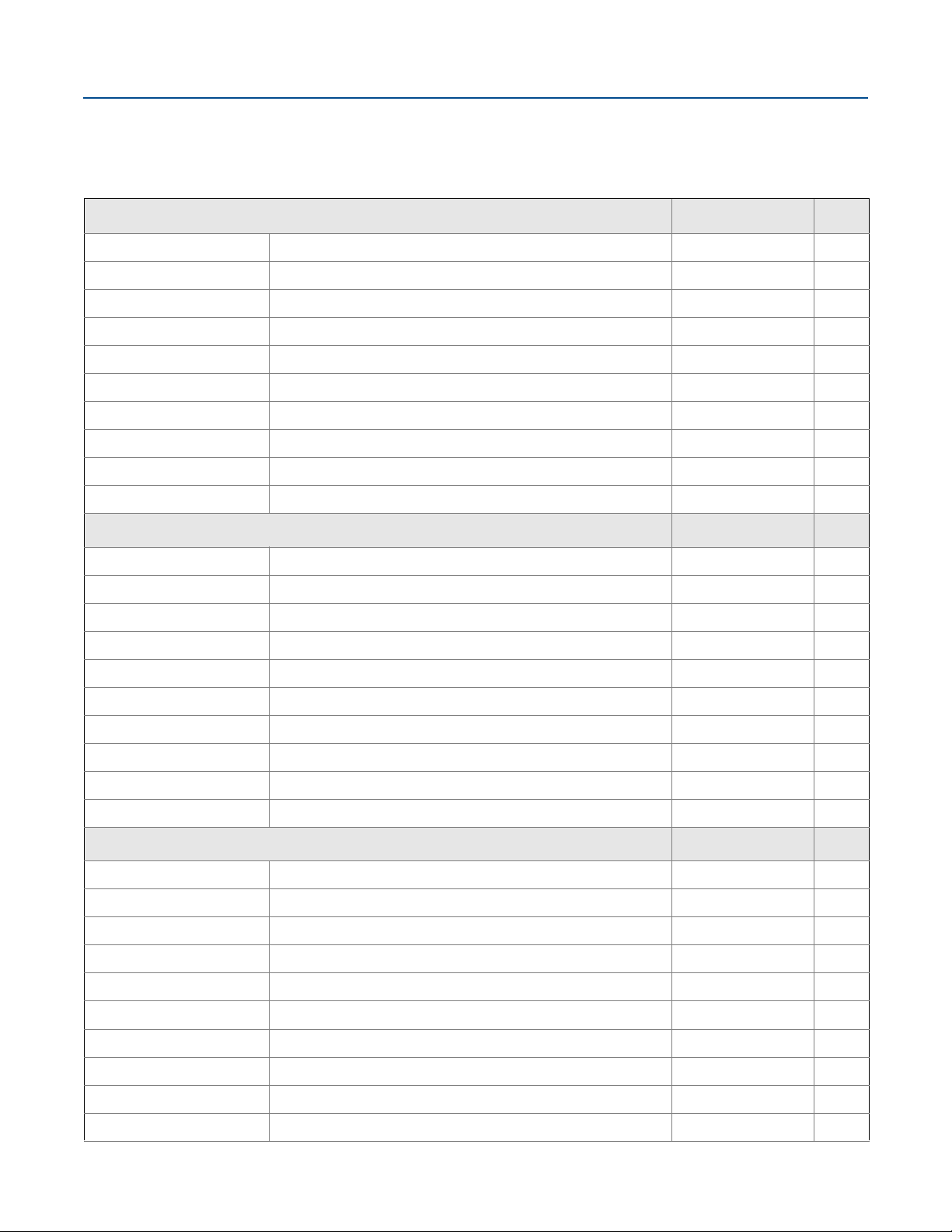

Table 2. Availability of Process Connections - Material of Construction Codes 1, 2, 3, 7, and 8

(Type vs. Size and Rating)

Process connection size Process connection rating

Thread/Tri Clamp ASME B16.5 flanges EN1092-1 flanges JIS B2220 flanges Proprietary

Class 150 Class 300 PN16 PN40 10K 20K

1-in. G

(2)

1½-in. C

2-in./DN50/50A C

, N

(2)

3-in./DN80/80A C

4-in./DN100/100A C

, N

(3)

, N

(2)

(2)

, G

(2)

(3)

N/A N/A N/A N/A N/A N/A N/A

N/A N/A N/A N/A N/A N/A N/A

RRF FRR N/A

RRF FRR N/A

RRF FRR N/A

(2)

(2)

6-in./DN150/150A N/A R R F F R R N/A

8-in./DN200/200A N/A R R F F R R N/A

Proprietary flanges N/A N/A N/A N/A N/A N/A N/A M, P, Q

1. Only available with material of construction codes 1, 7, and 8.

2. Only available with material of construction codes 1 and 8.

3. Only available with material of construction codes 1, 2, 3, and 8.

C = Tri Clamp (process connection type code C)

F = Flat Face (process connect ion type code F)

G = BSPP (G) thread (process connection type code G)

M = Maso neilan (pro cess connec tion typ e code M)

N = NPT thread (process connection type code N)

P = Fisher 249B/259B (process connection type code P)

Q = Fisher 249C (process connection type code Q)

R = Raised Face (process conn ection type code R)

flanges

(1)

Table 3. Availability of Process Connections - Material of Construction Codes H and D (Type vs. Size and Rating)

Process connection size Process connection rating

Thread/Tri Clamp ASME B16.5 flanges EN1092-1 flanges JIS B2220 flanges Proprietary

Class 150 Class 300 PN16 PN40 10K 20K

1-in. N/A N/A N/A N/A N/A N/A N/A N/A

1½-in. G, N N/A N/A N/A N/A N/A N/A N/A

2-in./DN50/50A N/A R R N/A N/A N/A N/A N/A

3-in./DN80/80A N/A R R N/A N/A N/A N/A N/A

4-in./DN100/100A N/A R R N/A N/A N/A N/A N/A

6-in./DN150/150A N/A R

(1)

N/A N/A N/A N/A N/A N/A

8-in./DN200/200A N/A N/A N/A N/A N/A N/A N/A N/A

Proprietary flanges N/A N/A N/A N/A N/A N/A N/A N/A

1. Only available with material of construction code H.

G = BSPP (G) thread (process connection type code G)

N = NPT thread (process connection type code N)

R = Raised Face (process conn ection type code R)

flanges

10

Emerson.com/Rosemount

Page 11

January 2018

Rosemount 3308 Series

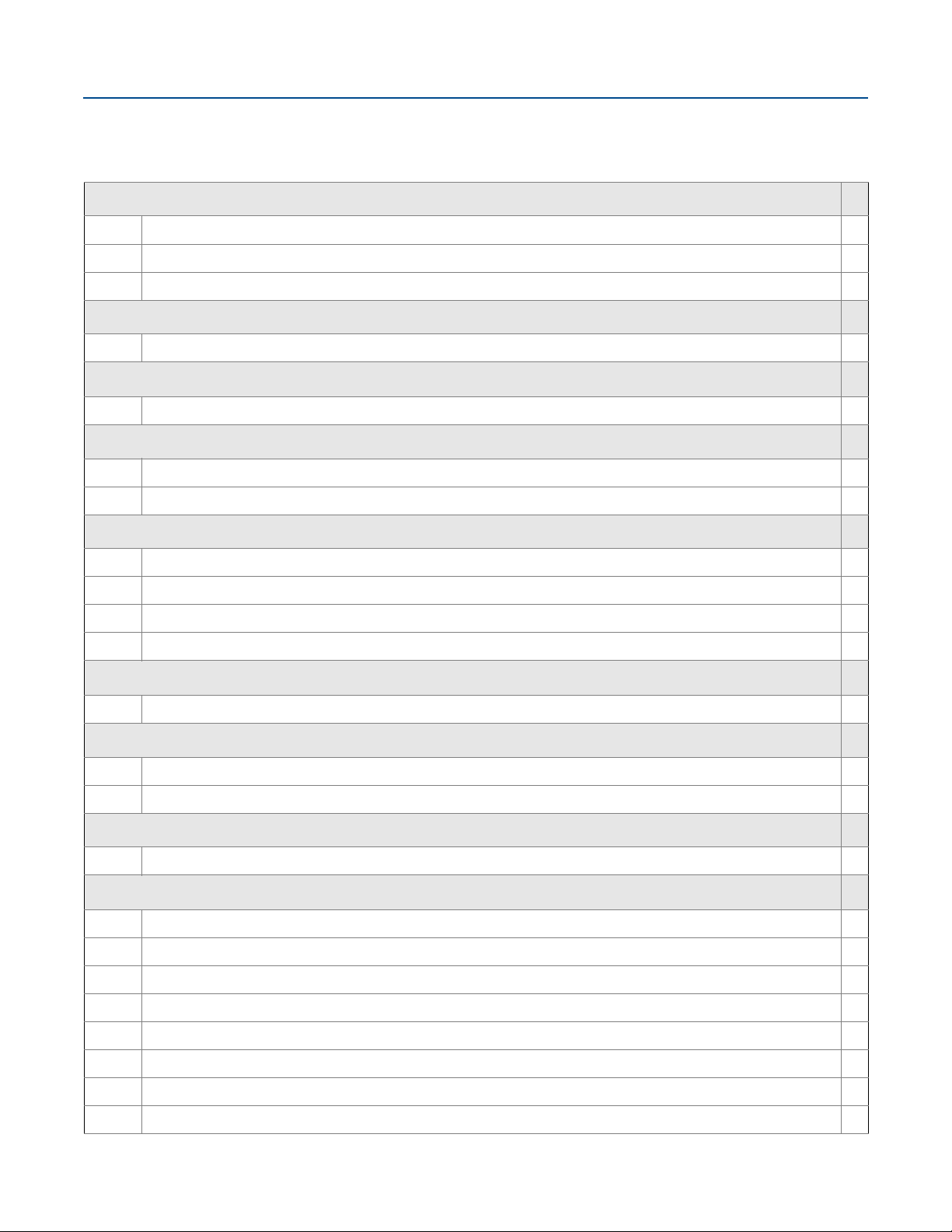

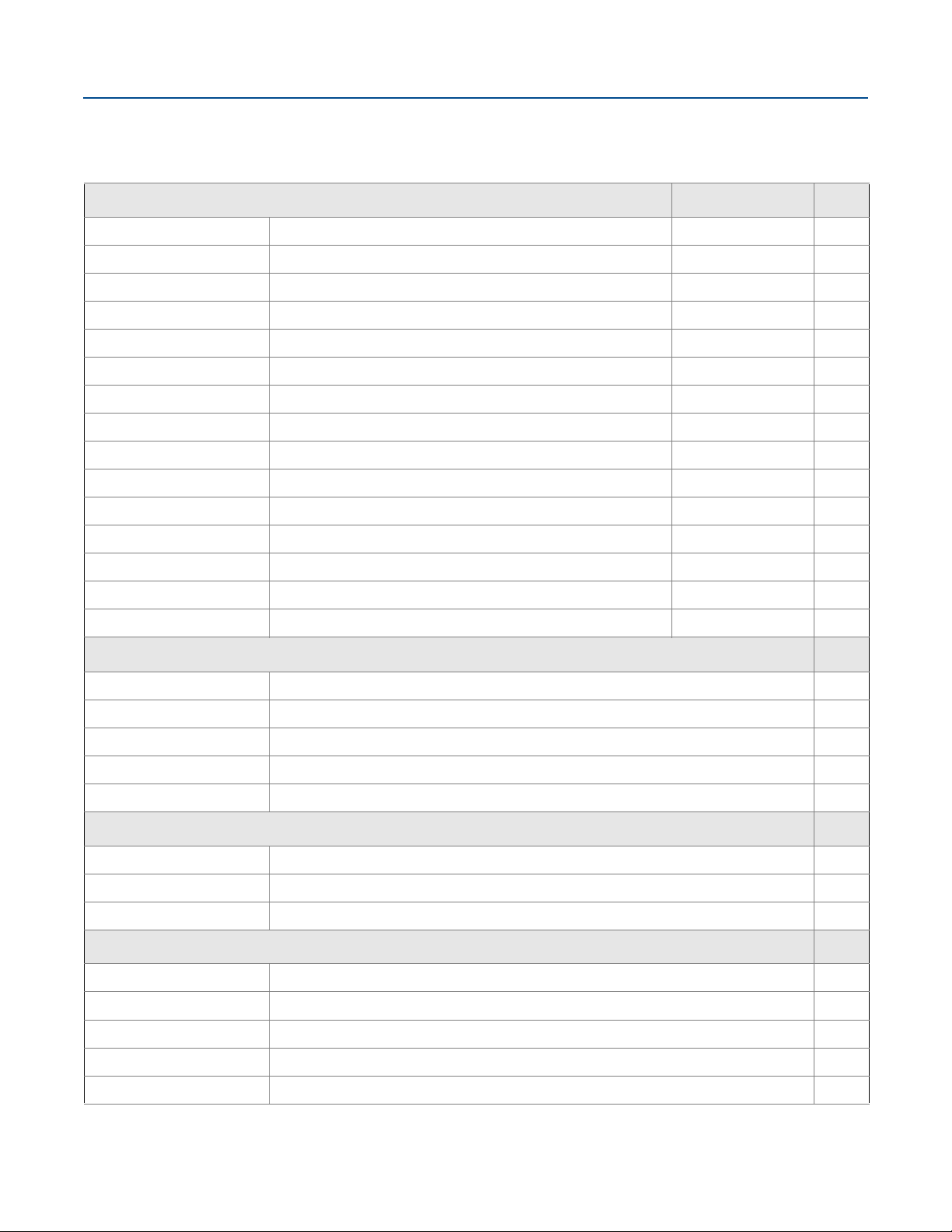

Table 4. Accessories Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Centering discs for rigid single lead probe (d=0.3"/8 mm)

(1)(2)

Outer diameter

03300-1655-0001 Kit, 2-in. Centering Disc, SST 1.8 in. (45 mm)

03300-1655-0006 Kit, 2-in. Centering Disc, PTFE 1.8 in. (45 mm)

03300-1655-0002 Kit, 3-in. Centering Disc, SST 2.7 in. (68 mm)

03300-1655-0007 Kit, 3-in. Centering Disc, PTFE 2.7 in. (68 mm)

03300-1655-0003 Kit, 4-in. Centering Disc, SST 3.6 in. (92 mm)

03300-1655-0008 Kit, 4-in. Centering Disc, PTFE 3.6 in. (92 mm)

03300-1655-0004 Kit, 6-in. Centering Disc, SST 5.55 in. (141 mm)

03300-1655-0009 Kit, 6-in. Centering Disc, PTFE 5.55 in. (141 mm)

03300-1655-0005 Kit, 8-in. Centering Disc, SST 7.40 in. (188 mm)

03300-1655-0010 Kit, 8-in. Centering Disc, PTFE 7.40 in. (188 mm)

Centering discs for rigid single lead probe (d=0.5"/13 mm)

(1)(2)

Outer diameter

03300-1655-0301 Kit, 2-in. Centering Disc, SST 1.8 in. (45 mm)

03300-1655-0306 Kit, 2-in. Centering Disc, PTFE 1.8 in. (45 mm)

03300-1655-0302 Kit, 3-in. Centering Disc, SST 2.7 in. (68 mm)

03300-1655-0307 Kit, 3-in. Centering Disc, PTFE 2.7 in. (68 mm)

03300-1655-0303 Kit, 4-in. Centering Disc, SST 3.6 in. (92 mm)

★

★

★

★

★

★

★

★

★

★

★

03300-1655-0308 Kit, 4-in. Centering Disc, PTFE 3.6 in. (92 mm)

03300-1655-0304 Kit, 6-in. Centering Disc, SST 5.55 in. (141 mm)

03300-1655-0309 Kit, 6-in. Centering Disc, PTFE 5.55 in. (141 mm)

03300-1655-0305 Kit, 8-in. Centering Disc, SST 7.40 in. (188 mm)

03300-1655-0310 Kit, 8-in. Centering Disc, PTFE 7.40 in. (188 mm)

Centering discs for flexible single/twin lead probes

(1)(2)

Outer diameter

03300-1655-1001 Kit, 2-in. Centering disc, SST 1.8 in. (45 mm)

03300-1655-1006 Kit, 2-in. Centering disc, PTFE 1.8 in. (45 mm)

03300-1655-1002 Kit, 3-in. Centering disc, SST 2.7 in. (68 mm)

03300-1655-1007 Kit, 3-in. Centering disc, PTFE 2.7 in. (68 mm)

03300-1655-1003 Kit, 4-in. Centering disc, SST 3.6 in. (92 mm)

03300-1655-1008 Kit, 4-in. Centering disc, PTFE 3.6 in. (92 mm)

03300-1655-1004 Kit, 6-in. Centering disc, SST 5.55 in. (141 mm)

03300-1655-1009 Kit, 6-in. Centering disc, PTFE 5.55 in. (141 mm)

03300-1655-1005 Kit, 8-in. Centering disc, SST, 7.40 in. (188 mm)

03300-1655-1010 Kit, 8-in. Centering disc, PTFE 7.40 in. (188 mm)

★

★

★

★

★

★

★

Emerson.com/Rosemount

11

Page 12

Rosemount 3308 Series

January 2018

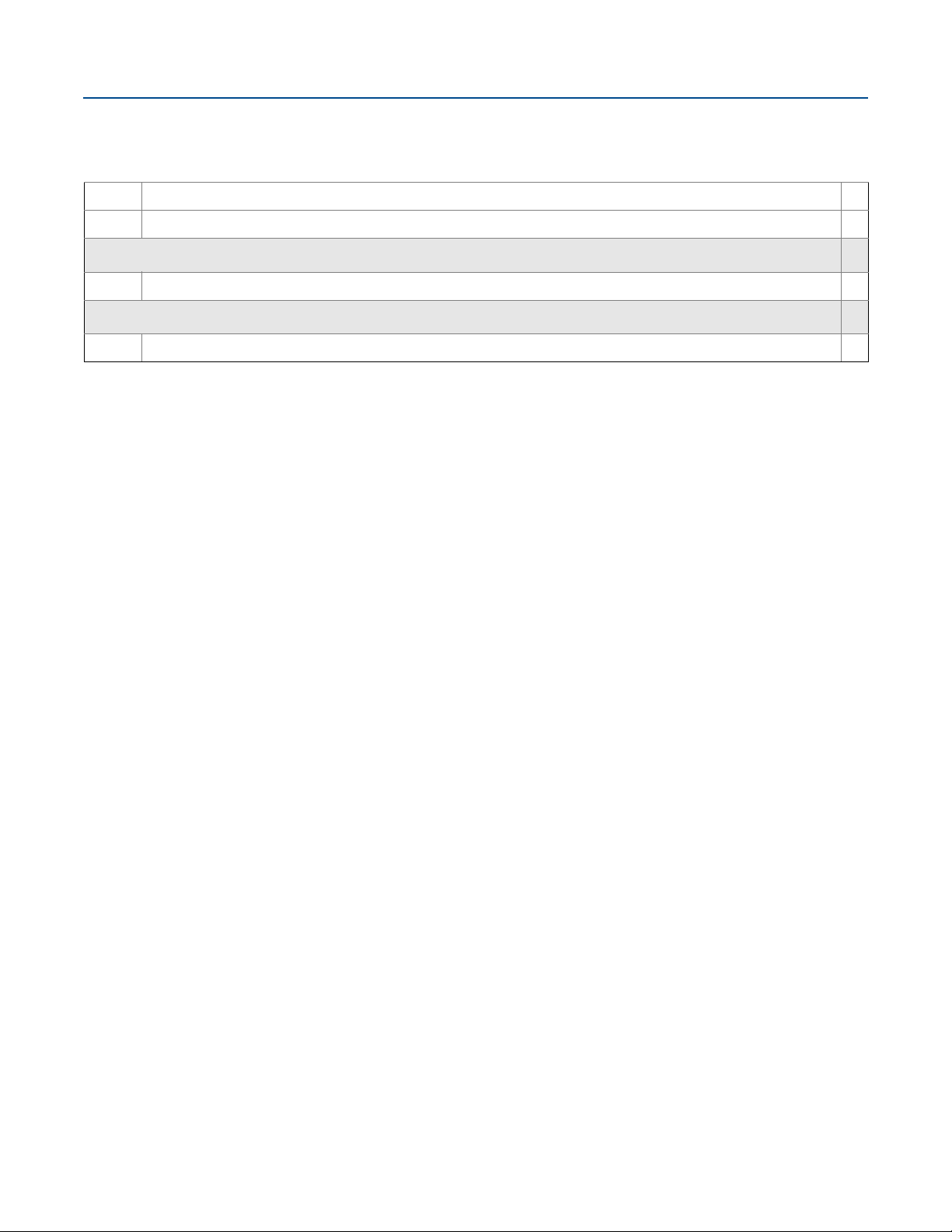

Table 4. Accessories Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

Centering discs for mounting between segments (probe type 4S only) Outer diameter

03300-1656-1002 2-in. Centering Disc (1 pc), PTFE, Segmented Rigid Single Lead 1.8 in. (45 mm)

03300-1656-1003 3-in. Centering Disc (1 pc), PTFE, Segmented Rigid Single Lead 2.7 in. (68 mm)

03300-1656-1004 4-in. Centering Disc (1 pc), PTFE, Segmented Rigid Single Lead 3.6 in. (92 mm)

03300-1656-1006 6-in. Centering Disc (1 pc), PTFE, Segmented Rigid Single Lead 5.55 in. (141 mm)

03300-1656-1008 8-in. Centering Disc (1 pc), PTFE, Segmented Rigid Single Lead 7.40 in. (188 mm)

03300-1656-3002 2-in. Centering Disc (3 pcs), PTFE, Segmented Rigid Single Lead 1.8 in. (45 mm)

03300-1656-3003 3-in. Centering Disc (3 pcs), PTFE, Segmented Rigid Single Lead 2.7 in. (68 mm)

03300-1656-3004 4-in. Centering Disc (3 pcs), PTFE, Segmented Rigid Single Lead 3.6 in. (92 mm)

03300-1656-3006 6-in. Centering Disc (3 pcs), PTFE, Segmented Rigid Single Lead 5.55 in. (141 mm)

03300-1656-3008 8-in. Centering Disc (3 pcs), PTFE, Segmented Rigid Single Lead 7.40 in. (188 mm)

03300-1656-5002 2-in. Centering Disc (5 pcs), PTFE, Segmented Rigid Single Lead 1.8 in. (45 mm)

03300-1656-5003 3-in. Centering Disc (5 pcs), PTFE, Segmented Rigid Single Lead 2.7 in. (68 mm)

03300-1656-5004 4-in. Centering Disc (5 pcs), PTFE, Segmented Rigid Single Lead 3.6 in. (92 mm)

03300-1656-5006 6-in. Centering Disc (5 pcs), PTFE, Segmented Rigid Single Lead 5.55 in. (141 mm)

03300-1656-5008 8-in. Centering Disc (5 pcs), PTFE, Segmented Rigid Single Lead 7.40 in. (188 mm)

Segmented rigid single lead probe spare part kit

03300-0050-0001 15.2-in./385 mm Segment for Top connection (1 pc)

03300-0050-0002 31.5-in./800 mm Segment (1 pc)

03300-0050-0003 31.5-in./800 mm Segment (3 pcs)

03300-0050-0004 31.5-in./800 mm Segment (5 pcs)

03300-0050-0005 31.5-in./800 mm Segment (12 pcs)

Vented flanges

03300-1812-0092 Fisher 249B/259B

03300-1812-0093 Fisher 249C

03300-1812-0091 Masoneilan

(3)

(4)

Flushing connection rings

DP0002-2111-S6 2-in. ANSI, ¼-in. NPT connection

DP0002-3111-S6 3-in. ANSI, ¼-in. NPT connection

DP0002-4111-S6 4-in. ANSI, ¼-in. NPT connection

DP0002-5111-S6 DN50, ¼-in. NPT. connection

DP0002-8111-S6 DN80, ¼-in. NPT. connection

12

Emerson.com/Rosemount

Page 13

January 2018

Rosemount 3308 Series

Table 4. Accessories Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings are subject

to additional delivery lead time.

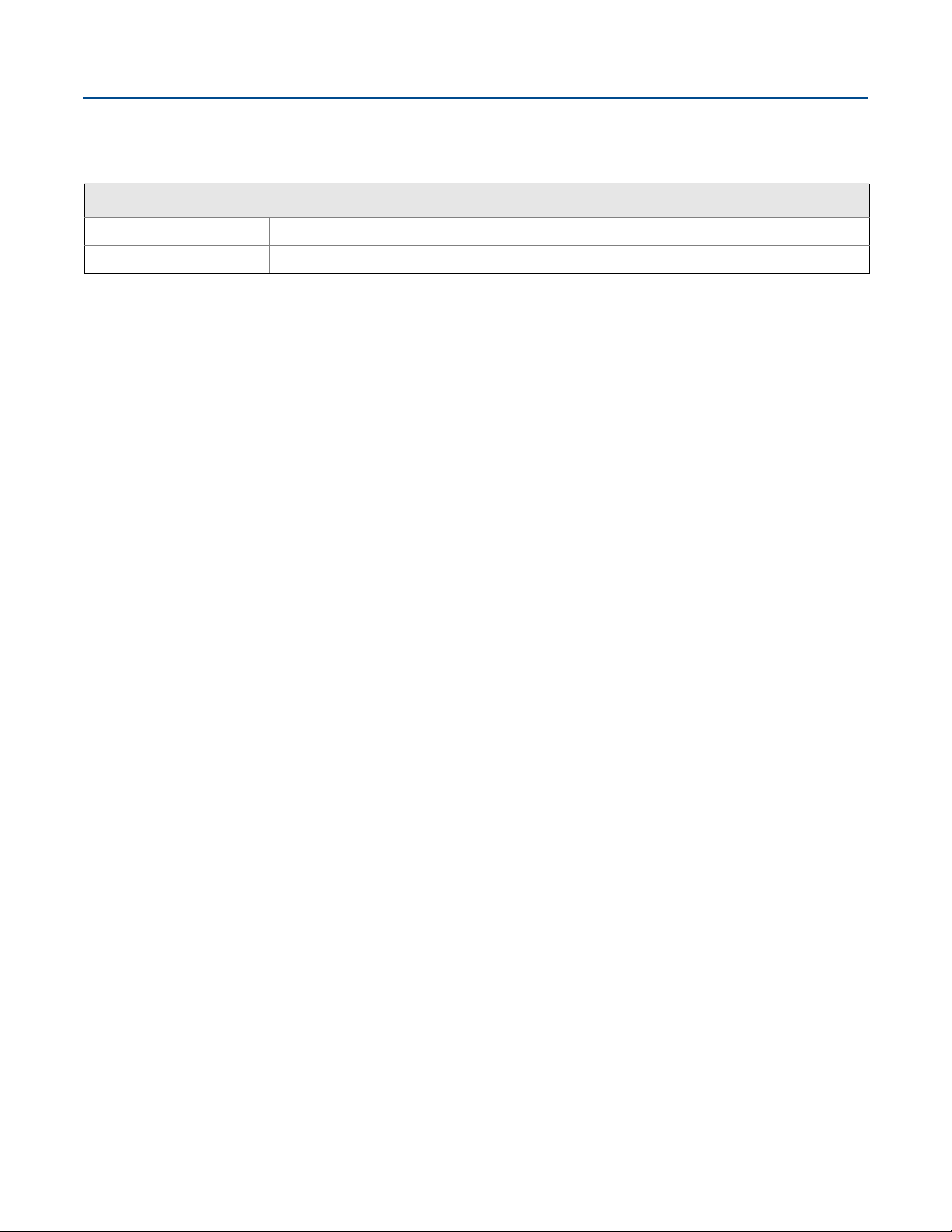

Other

03300-7004-0001 MACTek® VIATOR® HART Modem and cables (RS232 connection)

03300-7004-0002 MACTek VIATOR HART Modem and cables (USB connection)

1. If a centering disc is required for a flanged probe, the centering disc can be ordered with options Sx or Px on page 8 in the model code. If a centering disc is required

for a th read ed co nne cti on o r as a spar e pa rt, it s houl d be orde red usin g th e ite m num ber s li sted in t his t abl e. Ref er to Tab le 20 for centering disc size recommendation

for different pipe schedules.

2. To order a centering disc in a different material, consult the factory.

3. 1½-in. NPT threaded connection is required.

4. For pressure and temperature rating, see “Fisher and Masoneilan” on page 20.

★

★

Emerson.com/Rosemount

13

Page 14

Rosemount 3308 Series

00

±0.25 in.

(6 mm)

±0.98 in.

(25 mm)

33 ft. (10 m)

56 ft. (17 m)

Accuracy

Measuring distance

Specifications

January 2018

Performance specifications

General

Reference conditions

Probe: Flexible single lead

Vessel: 4-in. pipe

Measurement target: Water

Temperature: 68 to 77 °F (20 to 25 °C)

Relative humidity: 30-80%

Reference accuracy

High performance (profile code U):

±0.12 in. (±3 mm), when distance < 33 ft. (10 m)

±0.03% of measured distance, when distance > 33 ft. (10 m)

Standard (profile code S):

Ambient temperature effect

High performance (profile code U): ±0.08 in. (±2 mm)/10 K

Standard (profile code S): < 0.1% of measured distance per 10 K

Electromagnetic interference effect

External antenna (WK1 option): < ±0.25 in. (±6 mm)

Remote (WN1 option): < ±0.2 in. (±5 mm)

Power module battery life

High performance: 5 years at one minute update rate

Standard: 9 years at one minute update rate

(1)

(2)

(3)

Electromagnetic compatibility

Meets EN 61326-1:2013, EN 61326-2-3:2013, and

NE21:2012 if installed in metallic vessels or still pipes.

For optimal single lead probe performance in non-metallic

tanks, the probe must be mounted with a metal flange, or

screwed in to a metal sheet (d > 14 in./350 mm) if a threaded

version is used. See page 26 for more information.

Pressure Equipment Directive (PED)

Complies with 2014/68/EU article 4.3

Radio approvals

Radio Equipment Directive (RED) 2014/53/EU

Part 15 of the FCC Rules

Industry Canada RSS 211

Interface measurement range

The maximum allowable upper product thickness/measuring

range is primarily determined by the dielectric constants of the

two liquids.

Typical applications include interfaces between oil/oil-like and

water/water-like liquids, with a low (<3) dielectric constant for

the upper product and a high (>20) dielectric constant for the

lower product. For such applications, the maximum measuring

range is limited by the length of the coaxial and rigid single lead

probes.

For flexible probes, the maximum measuring range is reduced

by the maximum upper product thickness, according to the

diagram below. However, characteristics may vary between the

different applications.

Environment

Vibration resistance

No effect when tested per the requirements of IEC60770-1

(1999): High Vibration Level - field or pipeline (10-60 Hz 0.21

mm displacement peak amplitude / 60-2000 Hz 3g).

1. Refer to the IEC 60770-1 standard for a definition of radar specific

performance parameters and if applicable corresponding test procedure.

2. Deviation through electromagnetic interference according to EN 61326.

3. Reference conditions are 70 °F (21 °C), and routing data for three

additional network devices.

14

Emerson.com/Rosemount

Page 15

January 2018

1

0

6.6 (2)

13.1 (4)

19.7 (6)

26.2 (8)

32.8 (10)

39.4 (12)

243

567

8910

11

80

80

40

20

10

10

Upper product dielectric constant

Maximum upper product thickness, ft. (m)

Lower product

dielectric constant

Example: With an upper product

dielectric constant of 2, and a

lower product dielectric constant

of 20, the maximum upper product

thickness is 25 ft. (7 m).

25 ft.

(7 m)

DC 2

DC 20

Figure 1. Maximum upper product thickness for

flexible probes

Rosemount 3308 Series

Table 5. Measuring Range and Minimum Dielectric Constant

Probe type Maximum measuring range Minimum dielectric constant

Flexible single lead 55.8 ft. (17 m)

Rigid single lead probe (0.3-in./8 mm) 9.8 ft. (3 m) 2.0

Rigid single lead probe (0.5-in./13 mm) 19.7 ft. (6 m) 2.0

Segmented rigid single lead 32.8 ft. (10 m) 2.0

Flexible twin lead 55.8 ft. (17 m)

Coaxial 19.7 ft. (6 m) 2.0

1. Minimum Dielectric Constant may be lower than 2.0 if one or mor e of the following conditions apply:

- Probe is installed in stilling well or chamber.

- Maximum measuring range is not utilized.

- Noise Threshold is manually adjusted to a lower level.

2. For temperatures above 140 °F (60 °C) manual adjustment of noise threshold may be required for products with low dielectric constant at or close to maximum

measuring range.

Table 6. Maximum Recommended Viscosity and Contamination/Build-up

2.0, when distance < 32.8 ft. (10 m)

10, when distance > 32.8 ft. (10 m)

2.0, when distance < 32.8 ft. (10 m)

10, when distance > 32.8 ft. (10 m)

Probe type Maximum viscosity Contamination/build-up

Single lead 8000 cP

Twin lead 1500 cP Thin build-up allowed, but no bridging

Coaxial 500 cP Not recommended

1. Consult your local Emerson representative in the case of agitation/turbulence and high viscous products.

2. For viscous or sticky applications, it is not recommended to use centering discs mounted along the probe.

Emerson.com/Rosemount

(1)(2)

Build-up allowed

(1)(2)

15

Page 16

Rosemount 3308 Series

Note

Measurements may not be possible in the Blind Zones, and

measurements close to the Blind Zones will have reduced

accuracy. Therefore, the alarm points should be configured

outside these zones.

Upper Blind Zone

Lower Blind Zone

Reduced accuracy

Reduced accuracy

±0.12 in.

(3 mm)

3.5 in. (9 cm)

14.6 in. (37 cm)

±1.18 in.

(30 mm)

±0.12 in.

(3 mm)

13.0 in. (33 cm)

±1.18 in.

(30 mm)

5.9 in. (15 cm)

4.3 in. (11 cm)

0.4 in. (1 cm)

8.7 in.

(22 cm)

2 in. (5 cm)

4.3 in.

(11 cm)

3.2 in. (8 cm)

3.2 in. (8 cm)

±0.25 in.

(6 mm)

±1.18 in.

(30 mm)

3.2 in. (8 cm)

9.8 in. (25 cm)

±0.25 in.

(6 mm)

±1.18 in.

(30 mm)

10.6 in. (27 cm)

5.1 in. (13 cm)

Accuracy

Water (DC = 80) Oil (DC = 2.2)

Blind Zone

Accuracy Accurac y

Standard (profile code S)

Water (DC = 80) Oil (DC = 2.2)

High performance (profile code U)

Accuracy over measuring range

The measuring range depends on probe type, dielectric

constant of the product and installation environment, and is

limited by the Blind Zones at the very top and bottom of the

probe. In the Blind Zones, the accuracy exceeds ±1.18 in. (30

mm), and measurements may not be possible. Measurements

close to the Blind Zones will have reduced accuracy.

The following conditions will impact the Blind Zones:

If the single lead probes or twin probes are installed in a

nozzle, the nozzle height shall be added to the specified

Upper Blind Zone.

The measuring range for the PTFE covered flexible single lead

probe includes the weight when measuring on a high

dielectric media.

Figure 2, Figure 3, Figure 4, and Figure 5 illustrate the accuracy

over measuring range at reference condition using the Trim Near

Zone function, with alternating probe types and varying

dielectric constant of the product.

January 2018

Figure 2. Accuracy over Measuring Range for Flexible Single Lead Probe

16

Emerson.com/Rosemount

Page 17

January 2018

3.5 in. (9 cm)

1.2 in. (3 cm)

3.9 in. (10 cm)

18.9 in. (48 cm)

±0.12 in.

(3 mm)

±1.18 in.

(30 mm)

3.9 in. (10 cm)

12.2 in. (31 cm)

0.8 in. (2 cm)

±0.12 in.

(3 mm)

±1.18 in.

(30 mm)

5.1 in.

(13 cm)

4.3 in. (11 cm)

2 in. (5 cm)

4.3 in.

(11 cm)

±0.25 in.

(6 mm)

±1.18 in.

(30 mm)

3.2 in. (8 cm)

9.8 in. (25 cm)

±0.25 in.

(6 mm)

±1.18 in.

(30 mm)

10.6 in. (27 cm)

5.1 in. (13 cm)

Accuracy

Water (DC = 80) Oil (DC = 2.2)

Blind Zone

Accuracy Accurac y

Standard (profile code S)

Water (DC = 80) Oil (DC = 2.2)

High performance (profile code U)

0.4 in. (1 cm)

3.5 in. (9 cm)

2 in. (5 cm)

2.8 in. (7 cm)

0.4 in. (1 cm)

7.9 in. (20 cm)

5.9 in. (15 cm)

9.5 in. (24 cm)

7.9 in.

(20 cm)

3.2 in. (8 cm)

7.9 in. (20 cm)

3.9 in. (10 cm)

12.6 in. (32 cm)

±0.12 in.

(3 mm)

±1.18 in.

(30 mm)

±0.12 in.

(3 mm)

±1.18 in.

(30 mm)

±0.25 in.

(6 mm)

±1.18 in.

(30 mm)

3.2 in. (8 cm)

7.9 in. (20 cm)

±0.25 in.

(6 mm)

±1.18 in.

(30 mm)

Accuracy

Water (DC = 80) Oil (DC = 2.2)

Blind Zone

Accuracy Accurac y

Standard (profile code S)

Water (DC = 80) Oil (DC = 2.2)

High performance (profile code U)

Rosemount 3308 Series

Figure 3. Accuracy over Measuring Range for Rigid Single Lead/Segmented Rigid Single Probes

Figure 4. Accuracy over Measuring Range for Flexible Twin Lead Probe

Emerson.com/Rosemount

17

Page 18

Rosemount 3308 Series

5.5 in. (14 cm)

13.0 in. (33 cm)

5.1 in. (13 cm)

5.9 in. (15 cm)

7.1 in. (18 cm)

7.1 in. (18 cm)

2.0 in. (5 cm)

2.0 in.

(5 cm)

3.2 in. (8 cm)

2.8 in.

(7 cm)

±0.12 in.

(3 mm)

±1.18 in.

(30 mm)

±0.12 in.

(3 mm)

±1.18 in.

(30 mm)

±0.25 in.

(6 mm)

±1.18 in.

(30 mm)

6.3 in. (16 cm)

8.3 in. (21cm)

±0.25 in.

(6 mm)

±1.18 in.

(30 mm)

1.2 in. (3 cm)

2 in. (5 cm)

Accuracy

Water (DC = 80) Oil (DC = 2.2)

Blind Zone

Accuracy Accurac y

Standard (profile code S)

Water (DC = 80) Oil (DC = 2.2)

High performance (profile code U)

Figure 5. Accuracy over Measuring Range for Coaxial Probe

January 2018

18

Emerson.com/Rosemount

Page 19

January 2018

Rosemount 3308 Series

Functional specifications

General

Field of applications

Liquids and semi-liquids level or liquid/liquid interfaces

3308Axx1... for level or submerged probe interface

measurement

3308Axx2... for level and interface measurement

Measurement principle

Time Domain Reflectometry (TDR)

(See “Introduction” on page 2 for a description of how it works)

Microwave output power

Nominal 10 μw, Max <20 mW

Humidity limits

0 to 100% relative humidity

Wireless

Output

IEC 62591 (WirelessHART) 2.4 GHz

Transmit rate

User selectable, 4 seconds to 60 minutes

Frequency rate

2400 - 2483.5 MHz

Radio frequency output from antenna

External antenna (WK1 option): < 10 mW (+10dBm) EIRP

Remote (WN1 option): < 40mW (16dBm) EIRP

Modulation type

QPSK/iEEE 802.15.4 IEC 62591 (WirelessHART)

Number of channels

15

Channel spacing

5 MHz

Emission designation

G1D

Display and configuration

LCD display

Toggles between selected output variables

Shows diagnostic information (alerts)

Display updates at each wireless update

Figure 6. LCD Display

Output units

Level, Interface, and Distance: ft, inch, m, cm, or mm

Volume: ft

Tempera tur e: °F, °C

Table 7. Output Variables

Varia ble LCD display PV, SV, TV, QV

Level

Distance

Surface Signal Strength N/A

Total Volume

Interface Level

Interface Distance

Interface Signal Strength

Upper Product Thickness

Electronics Temperature

Signal Quality

Supply Voltage

% of Range

3

, inch3, US gals, Imp gals, barrels, yd3, m3, or liters

(1)

(1)

(1)

(3)

N/A

(2)

(2)

(2)

(2)

(2)

Emerson.com/Rosemount

1. For 3308Axx1, Interface measurement is only available for fully submerged

probe.

2. Not available as primary variable.

3. Only available with 3308Axx2.

19

Page 20

Rosemount 3308 Series

PTFE covered probe and

flange (model code 7)

Pressure psig (bar)

580 (40)

232 (16)

-14 (-1)

-40

(-40)

302

(150)

Tem per atu re ° F (°C)

January 2018

HART diagnostics

Signal Quality Metrics - Diagnostics package that monitors the

relations between surface, noise and threshold. The function

can be used to detect abnormal conditions in the process such

as probe contamination or sudden loss of signal strength. Signal

Quality is available as Output Variable and it comes with user

configurable alerts through AMS Wireless Configurator or Field

Communicator.

Temperature limits

Verify that the operating atmosphere of the transmitter is

consistent with the appropriate hazardous locations

certifications, see “Product Certifications” on page 29.

Table 8. Ambient Temperature Limits

Description Operating limit Storage limit

With LCD display

Without LCD display

1. LCD display may not be readable and device display updates will be slower at

temperatures below -4 °F (-20 °C).

-40 to 175 °F

(-40 to 80° C)

-40 to 185 °F

(-40 to 85° C)

(1)

-40 to 185 °F

(-40 to 85 °C)

-40 to 185 °F

(-40 to 85 °C)

Process temperature and pressure rating

Figure 7 gives the maximum process temperature (measured at

the lower part of the flange or threaded connection) and

pressure rating.

Table 9. Temperature Ranges for Standard Tank Seals

With Different O-ring Materials

O-ring material

Viton Fluoroelastomer 5 (-15) 302 (150)

Ethylene Propylene (EPDM) -40 (-40) 266 (130)

Kalrez 6375 Perfluoroelastomer 14 (-10) 302 (150)

Nitrile Butadiene (NBR) -31 (-35) 230 (110)

Temperature °F (°C) in air

Min. Max.

Note

Always check the chemical compatibility of the O-ring material

with your application. If the O-ring material is not compatible

with its chemical environment, the O-ring may eventually

malfunction.

Flange rating

ASME

316L SST flanges according to ASME B16.5 Table 2-2.3:

Max. 302 °F/580 psig (150 °C/40 bar)

Alloy C-276 (UNS N10276) flanges according to ASME B16.5

Table 2-3.8:

Max. 302 °F/580 psig (150 °C/40 bar)

Final rating depends on flange, material of construction, and

O-ring selection.

Figure 7. Max. Rating, Standard Tank Connections

Duplex 2205 (UNS S31803) flanges according to ASME B16.5

Table 2-2.8:

Max. 302 °F/580 psig (150 °C/40 bar)

EN

EN 1.4404 according to EN 1092-1 material group 13E0:

Max. 302 °F/580 psig (150 °C/40 bar)

Alloy C-276 (UNS N10276) flanges according to EN 1092-1

material group 12E0:

Max. 302 °F/580 psig (150 °C/40 bar)

Duplex 2205 (EN 1.4462) flanges according to EN 1092-1

material group 16E0:

Max. 580 psig (40 Bar), -22 °F (-30 °C) up to max 302 °F (150 °C)

JIS

316L SST Flanges according to JIS B2220 material group 2.3:

Max. 302 °F/580 psig (150 °C/40 bar)

Fisher and Masoneilan

316L SST Flanges according to ASME B16.5 Table 2-2.3:

Max. 302 °F/580 psig (150 °C/40 bar)

1. Minimum temperature limit due to EN13445-2.

(1)

20

Emerson.com/Rosemount

Page 21

January 2018

Product Level

Interface Level

Interface Level

Interface

measurement

Interface measurement with

fully submerged probe

Rosemount 3308 Series

Table 10. Tri Clamp Rating

Size Maximum pressure (bar)

1½-in. (37.5 mm) 16

2-in. (50 mm) 16

3-in. (75 mm) 10

4-in. (100 mm) 10

1. The final rating depends on the clamp and gasket.

(1)

Plate design

Certain models of flanged alloy and PTFE covered probes have a

tank connection design with a protective flange plate of the

same material as the probe and with a backing flange in 316L/EN

1.4404. The protective flange plate prevents the backing flange

from being exposed to the tank atmosphere.

Flange rating according to SST backing flange ASME B16.5 Table

2-2.3, EN 1092-1 material group 13E0, and JIS B2220 material

group 2.3.

PTFE protective plate:

Max. 302 °F/232 psig (150 °C/16 Bar)

Alloy C-276 and Alloy 400 protective plate:

Max. 302 °F/580 psig (150 °C/40 Bar)

The dielectric constant of the upper product must have a

lower dielectric constant than the lower product to have a

distinct reflection.

The difference between the dielectric constants for the two

products must be larger than 10.

Maximum dielectric constant for the upper product is 10 for

the coaxial probe, and 5 for the single lead and flexible twin

lead probes.

Minimum detectable upper product thickness is 4 in. (10 cm)

when the upper product is oil (DC=2.2) and the lower product

is water (DC=80).

For guidelines on emulsion, consult your local Emerson

representative.

For additional information, see the Guided Wave Radar Interface

Measurement Technical Not e

.

Interface measurements

The Rosemount 3308 Series is well suited for interface

measurements, including applications where the probe is fully

submerged in the liquid.

Figure 8. Interface Measurements

If interface is to be measured, follow these criteria:

The dielectric constant of the upper product should be known

and should not vary. The AMS Wireless Configurator and Field

Communicator have a built-in Dielectric Constant Guide to

assist the user in determining the dielectric constant of the

upper product.

Emerson.com/Rosemount

21

Page 22

Rosemount 3308 Series

January 2018

Conditions used for flange strength calculations

Table 11. 316L SST or Process Connection With Plate Design

Standard Bolting material Gasket Flange material Hub material

ASME Stainless steel SA193 B8M Class 2

EN, JIS EN 1515-1/-2 group 13E0, A4-70

Soft (1a) with min.

thickness 1.6 mm

Soft (EN 1514-1) with

min. thickness 1.6 mm

Stainless steel A182 Gr. F316L

and EN 10222-5-1.4404

Stainless steel SA479M

316L and

EN 10272-1.4404

Table 12. Alloy C-276

Standard Bolting material Gasket Flange material Hub material

ASME

EN, JIS

Soft (1a) with min.

thickness 1.6 mm

UNS N10276

Soft (EN 1514-1) with

min. thickness 1.6 mm

SB462 Gr. N10276 (solution

annealed condition) or

SB575 Gr. N10276 (solution

annealed condition)

SB574 Gr. N10276

Table 13. Duplex 2205

Standard Bolting material Gasket Flange material Hub material

ASME A193 B7 or A320 L7

®

EN, JIS Bumax

88

Soft (1a) with min.

thickness 1.6 mm

Soft (EN 1514-1) with

min. thickness 1.6 mm

Duplex stainless steel

SA/A182 F51 and

EN10222-5-1.4462

or SA/A240 Gr. S31803 and

EN10028-7-1.4462

Stainless steel SA479M

S31803 and

EN, JIS Bumax 88 EN

10272-1.4462

22

Emerson.com/Rosemount

Page 23

January 2018

Protective plate

PTFE covered probe

and protective plate

Alloy probe and

protective plate

Tot al P ro be L eng th

NPT BSPP (G) Flange

Upper

Reference

Point

Tri Clamp

Rosemount 3308 Series

Physical specifications

Material selection

Emerson provides a variety of Rosemount products with various

product options and configurations including materials of

construction that can be expected to perform well in a wide

range of applications. The Rosemount product information

presented is intended as a guide for the purchaser to make an

appropriate selection for the application. It is the purchaser’s

sole responsibility to make a careful analysis of all process

parameters (such as all chemical components, temperature,

pressure, flow rate, abrasives, contaminants, etc.), when

specifying product, materials, options and components for the

particular application. Emerson is not in a position to evaluate or

guarantee the compatibility of the process fluid or other process

parameters with the product, options, configuration or

materials of construction selected.

Tank connection

The tank connection consists of a tank seal, a flange, Tri Clamp,

or NPT or BSPP (G) threads. See “Dimensional Drawings” on

page 32.

Certain models of flanged alloy and PTFE covered probes have a

tank connection design with a protective plate of the same

material as the probe (see Figure 9). This is to prevent the

316L/EN 1.4404 SST flange from being exposed to the tank

atmosphere.

Probes

Probe versions

Flexible single lead, rigid single lead, segmented rigid single

lead, flexible twin lead, and coaxial.

Total probe length

This is defined from the Upper Reference Point to the end of the

probe (weight included, if applicable).

Figure 10. Total Probe Length

Figure 9. Probe and Protective Plate

Housing and enclosure

Ingress protection

IP66/67 and NEMA

Flange dimensions

Follows ASME B16.5, JIS B2220, and EN 1092-1 standards for

blind flanges. For Proprietary Fisher and Masoneilan flanges, see

“Proprietary Flanges” on page 39.

®

4X

Select the probe length according to the required measuring

range (the probe must be hung and fully extended through the

entire distance where level readings are desired).

Cut-to-fit probes

All probes can be cut in field except for the PTFE covered probe.

However, there are some restrictions for the coaxial probe: Probes

over 4.1 ft. (1.25 m) can be cut up to 2 ft. (0.6 m). Shorter probes

can be cut to the minimum length of 1.3 ft. (0.4 m).

Table 14. Minimum and Maximum Probe Length

Probe type Probe length

Flexible single lead 3.3 to 55.8 ft. (1 to 17 m)

Rigid single lead (0.3-in./8 mm) 1.3 to 9.8 ft. (0.4 to 3 m)

Rigid single lead (0.5-in./13 mm) 1.3 to 19.7 ft. (0.4 to 6 m)

Segmented rigid single lead 1.3 to 32.8 ft. (0.4 to 10 m)

Flexible twin lead 3.3 to 55.8 ft. (1 to 17 m)

Coaxial 1.3 to 19.7 ft. (0.4 to 6 m)

Probe angle

0 to 90 degrees from vertical axis

Emerson.com/Rosemount

23

Page 24

Rosemount 3308 Series

January 2018

Tensile strength

Flexible single lead SST: 2698 lb (12 kN)

Flexible single lead Alloy C-276: 1798 lb (8 kN)

Flexible single lead Alloy 400: 1124 lb (5 kN)

Flexible single lead Duplex 2205: 1349 lb (6 kN)

Flexible twin lead: 2023 lb (9 kN)

Collapse load

Flexible single lead SST: 3597 lb (16 kN)

Flexible single lead Alloy C-276: 2023 lb (9 kN)

Flexible single lead Alloy 400: 1349 lb (6 kN)

Flexible single lead Duplex 2205: 1574 lb (7 kN)

Sideway capacity

Rigid single lead/segmented rigid single lead:

4.4 ft. lbf, 0.44 lb at 9.8 ft. (6 Nm, 0.2 kg at 3 m)

Coaxial: 73.7 ft. lbf, 3.7 lb at 19.7 ft. (100 Nm, 1.67 kg at 6 m)

Material exposed to tank atmosphere

Material of

construction code

1

2

3

7 PTFE (1 mm PTFE cover)

8

H

D

1. For flexible single/twin lead probes only.

Material

316 SST

(1)

, 316L SST (EN 1.4404), PTFE,

PFA, and O-ring materials

Alloy C-276 (UNS N10276), PTFE, PFA,

and O-ring materials

Alloy 400 (UNS N04400), PTFE, PFA, and

O-ring materials

PTFE, 316L SST (EN 1.4404), and O-ring

materials

Alloy C-276 (UNS N10276), PTFE, PFA,

and O-ring materials

Duplex 2205 (UNS S31803/EN 1.4462),

Duplex 2507 (UNSS32750/EN 1.4410),

PTFE, PFA, and O-ring materials

Weight

Table 15. Flange and Probes

Item Weight

Flange Depends on flange size

Flexible single lead probe 0.05 lb/ft. (0.07 kg/m)

Rigid single lead probe

(0.3-in./8 mm)

Rigid single lead probe

(0.5-in./13 mm)

Segmented rigid single

lead probe

0.27 lb/ft. (0.4 kg/m)

0.71 lb/ft. (1.06 kg/m)

0.71 lb/ft. (1.06 kg/m)

Flexible twin lead probe 0.09 lb/ft. (0.14 kg/m)

Coaxial probe 0.67 lb/ft. (1 kg/m)

Table 16. End Weight

Item

Small weight (code W1)

Short weight (code W2) 0.88 lb (0.40 kg)

Heavy weight (code W3) 2.43 lb (1.10 kg)

Flexible twin lead probe 1.3 lb (0.60 kg)

Weight

SST probe: 0.88 lb (0.40 kg)

PTFE covered probe: 2.20 lb (1 kg)

End weight and anchoring options

There are in total four weight and anchoring options for flexible

single lead probes. See Figure 15 on page 32 for dimensions.

Small weight (code W1)

A small weight is recommended for narrow tank openings less

than 1.5 in. (38 mm). Required weight option for PTFE covered

probes.

Short weight (code W2)

A short weight is available for the single flexible stainless steel

probe. It is recommended for maximized measuring ranges with

measurements close to the probe end.

Heavy weight (code W3)

A heavy weight is the recommended choice for most

applications.

Chuck (code W4)

To tie probe end to tank bottom.

24

Emerson.com/Rosemount

Page 25

January 2018

Nozzle diameter

Nozzle height

Clearance to tank wall

Table 17. Minimum Clearance

Rosemount 3308 Series

Description Flexible single lead Rigid single lead/

Flexible twin lead Coaxial

segmented rigid single lead

Recommended

nozzle diameter

4 in. (100 mm) or more 4 in. (100 mm) or more 4 in. (100 mm) or more > probe diameter

1.5 in. (38 mm)

Min. nozzle

diameter

(1)

1.5 in. (38 mm)

for probe type 4A

2 in. (50 mm) > probe diameter

2 in. (50 mm)

for probe type 4B and 4S

Maximum nozzle

height

Min. clearance to

tank wall or

obstruction

Min. pipe/bypass

diameter

1. The Trim Near Zone (TNZ) function may be necessary or an Upper Null Zone (UNZ) setup may be required to mask the nozzle.

2. For nozzles taller than 4 in. (100 mm), the Long Stud version is recommended (option code LS) to prevent the flexible portion from tou ching the edge of the nozz le.

4 in. (100 mm) +

nozzle diameter

(2)

4 in. (100 mm) if smooth

metallic wall.

16 in. (400 mm) if

disturbing objects or

rugged metallic.

Consult your local Emerson

representative.

4 in. (100 mm) +

nozzle diameter

4 in. (100 mm) if smooth

metallic wall.

16 in. (400 mm) if disturbing

objects or rugged metallic.

2 in. (50 mm)

4 in. (100 mm) +

nozzle diameter

4 in. (100 mm) if smooth

metallic wall.

16 in. (400 mm) if

disturbing objects or

rugged metallic.

Consult your local Emerson

representative.

N/A

0 in. (0 mm)

1.5 in. (38 mm)

Figure 11. Mounting in Nozzles and Free Space Requirement

Emerson.com/Rosemount

25

Page 26

Rosemount 3308 Series

Metal flange Metal sheet

(d > 14 in./350 mm)

Flexible single lead

probe with chuck

January 2018

Installation in non-metallic tanks and open-air

applications

Avoid major sources of electrical disturbance in proximity of

the installation, e.g. electrical motors, stirrers, servo

mechanisms.

For clean liquids, use a coaxial probe to reduce effect of

potential electrical disturbances.

Other mechanical considerations

To get best possible performance, the following must be

considered before installing the transmitter:

Inlets should be kept at a distance in order to avoid product

filling on the probe.

Avoid physical contact between probes and agitators, as well

as applications with strong fluid movement unless the probe

is anchored.

Probe tie-down is recommended if the probe can move to

within 1 ft. (30 cm) of any object during operations.

In order to stabilize the probe for side forces, it is possible to

fix or guide the probe to the tank bottom

For optimal single lead probe performance in non-metallic

tanks, the probe must be mounted with a metal flange, or

screwed in to a metal sheet (d > 14 in./350 mm) if a threaded

version is used.

Make sure the nozzle does not extend into the tank.

See the Rosemount 3308 Series Wireless Guided Wave Radar,

3308A Reference Manual

for more mechanical installation

information.

Engineered solutions

When standard model codes are not sufficient to fulfill

requirements, please consult the factory to explore possible

Engineered Solutions. This is typically, but not exclusively,

related to the choice of wetted materials or the design of a

process connection. These Engineered Solutions are part of the

expanded offerings and may be subject to additional delivery

lead time. For ordering, factory will supply a special P-labeled

numeric option code that should be added at the end of the

standard model string.

26

Emerson.com/Rosemount

Page 27

January 2018

Centre-to-centre

Side-and-bottom

dimension

Side-and-side

dimension

Centre-to-centre

Replace chamber flange

Displacer

length

Probe

length

Rosemount 3308 Series

Chamber/pipe installations

General chamber considerations

A chamber or pipe installation is the preferred option due to the

increase in stability and performance of the transmitter. When

selecting a smaller diameter chamber or pipe (such as 2-in.) a

flexible probe is not suitable due to the chance of it coming into

contact with the walls, and relatively large side inlets may

interfere with the signal.

When gas lift and/or turbulence may occur (e.g. boiling

hydrocarbons), a 3- or 4-in. chamber/pipe diameter is

recommended for maximum measurement reliability. This is

especially true in high pressure and high temperature

installations.

Rosemount 9901 Chamber

Rosemount 9901 allows external mounting of process level

instrumentation. It supports a variety of process connections,

and optional drain and vent connections. The Rosemount 9901

chamber is designed to the ASME B31.3 standard, and is

Pressure Equipment Directive (PED) compliant. Use option code

XC to order together with the Rosemount 3308 Series

Transmitters.

Figure 12. Rosemount 9901 Chamber

For additional information, see the Rosemount 9901 Chamber

for Process Level Instrumentation Product Data Sheet

.

Existing chamber

A Rosemount 3308 Series Transmitter is the perfect

replacement in an existing displacer chamber. Proprietary

flanges are offered, enabling use of existing chambers to make

installation easy.

Figure 13. Existing Displacer Chamber

Considerations when changing to Rosemount 3308 Series:

The Rosemount 3308 Series flange choice and probe length

must be correctly matched to the chamber. Both standard

ANSI and EN (DIN), as well as proprietary chamber flanges, are

available. See “Proprietary Flanges” on page 39 to identify the

proprietary flanges.

See Table 20 on page 28 for guidelines on which disc size to use.

See Table 18 for guidelines on the required probe length.

The probe length to use for a Rosemount 9901 chamber can be

calculated with this formula:

Side-and-side dimension:

Probe length = Centre-to-centre dimension + 19 in. (48 cm)

Side-and-bottom dimension:

Probe length = Centre-to-centre dimension + 4 in. (10 cm)

Use a centering disc the same diameter as the chamber if the

probe length >3.3 ft. (1 m). See Table 20 on page 28 for which

disc to use.

Emerson.com/Rosemount

Table 18. Required Probe Length in Chambers

Chamber manufacturer Probe length

Major torque-tube manufacture

(249B, 249C, 249K, 249N, 259B)

Masoneilan (Torque tube

operated), proprietary flange

Other - torque tube

(2)

Displacer + 9 in. (229 mm)

Displacer + 8 in. (203 mm)

Displacer + 8 in. (203 mm)

Displacer + between

Magnetrol

®

(spring operated)

(3)

7.8 in. (195 mm) to 15 in.

(383 mm)

Others - spring operated

1. If flushing ring is used, add the ring height to the probe length.

2. For other manufac turers, there are small variations. This is an approximate

value, actual length should be verified.

3. Lengths vary depending on model, SG and rating, and should be verified.

(2)

Displacer +

19.7 in. (500 mm)

For additional information, see the Replacing Displacers with

Guided Wave Radar Tech nic al No te.

(1)

27

Page 28

Rosemount 3308 Series

D

January 2018

Probe type in chamber considerations

When installing a Rosemount 3308 in a chamber, the single lead

probe is recommended. The probe length determines if a single

rigid or single flexible probe should be used:

Less than 19.7 ft. (6.0 m):

Rigid single probe is recommended. Use a centering disc for

probe > 3.3 ft. (1 m). When mounting space is limited, use a

flexible single probe with a weight and centering disc.

More than 19.7 ft. (6.0 m):

Use flexible single probe with a weight and centering disc.

PTFE covered probes are not recommended for chamber/pipe

installations.

Centering discs

To prevent the probe from contacting the chamber or pipe wall,

centering discs are available for rigid single, flexible single, and

flexible twin lead probes. The disc is attached to the end of the

probe. Discs are made of stainless steel, Alloy C-276, Duplex

2205, or PTFE.

Figure 14. Actual Disc Diameter (D)

Table 20. Centering Disc Size Recommendation for

Different Pipe Schedules

Pipe size Pipe schedule

5s, 5 and

10s,10

2-in. 2-in. 2-in. N/A

3-in. 3-in. 3-in. N/A

4-in. 4-in. 4-in. 4-in. 3-in.

5-in. 4-in. 4-in. 4-in. 4-in.

6-in. 6-in. 6-in. 4-in. 4-in.

7-in. N/A

8-in. 8-in. 8-in. 6-in. 6-in.

1. Schedule is not available for pipe size.

2. No centering disc is available.

(1)

40s, 40 and

80s, 80

6-in. N/A

120 160

(1)

(1)

(1)

N/A

2-in.

N/A

(2)

(1)

For the segmented rigid single lead probe, up to five PTFE

centering discs can be mounted along the probe, but keep a

minimum distance of two segments between the discs.

Additionally, a disc in SST or PTFE (part number

03300-1655-xxxx) can be attached to the end of the probe.

When mounting a centering disc, it is important that it fits

correctly in the chamber/pipe. See Table 19 for Dimension D.

Table 20 shows which centering disc diameter to choose for a

particular pipe.

Table 19. Centering Disc Dimensions

Disc size Actual disc diameter (D)

2-in. 1.8 in. (45 mm)

3-in. 2.7 in. (68 mm)

4-in. 3.6 in. (92 mm)

6-in. 5.55 in. (141 mm)

8-in. 7.40 in. (188 mm)

28

Emerson.com/Rosemount

Page 29

January 2018

Product Certifications

Rosemount 3308 Series

European Union directive information

The EU Declaration of Conformity for all applicable European

directives for this product can be found on

Emerson.com/Rosemount. A hard copy may be obtained by

contacting your local sales representative.

Telecommunication compliance

All wireless devices require certification to ensure that they

adhere to regulations regarding the use of the RF spectrum.

Nearly every country requires this type of product certification.

Emerson is working with governmental agencies around the

world to supply fully compliant products and remove the risk of

violating country directives or laws governing wireless device

usage.

FCC and IC

This device complies with Part 15 of the FCC Rules. Operation is

subject to the following conditions: This device may not cause

harmful interference that may cause undesired operation

This device must be installed to ensure a minimum antenna

separation distance of 20 cm from all persons.

This radio transmitter has been approved by Industry Canada to

operate with the antenna types listed below with the maximum

permissible gain indicated. Antenna types not included in this

list, having a gain greater than the maximum gain indicated for

that type, are strictly prohibited for use with this device.

Antenna model

option

WK1 Integral Omni-directional 2

WN1 Remote Omni-directional 8

This device complies with Industry Canada license-exempt RSS

standard(s). Operation is subject to the following two

conditions: (1) This device may not cause interference, and (2)

this device must accept any interference, including any

interference that may cause undesired operation of the device.

Caution

Changes or modifications to the equipment not expressly approved by

Emerson could void the user’s authority to operate the equipment.

Antenna type Max gain

(dBi)

Ordinary location certification for FM

approvals

As standard, the transmitter has been examined and tested to

determine that the design meets basic electrical, mechanical,

and fire protection requirements by FM Approvals, a nationally

recognized testing laboratory (NRTL) as accredited by the

Federal Occupational Safety and Health Administration (OSHA).

Hazardous locations certificates

U.S.A.

I5 U.S.A Intrinsically Safe

Certificate: FM17US0014X

Standards: FM Class 3600 – 2011, FM Class 3610 – 2015,

FM Class 3810 – 2005, NEMA 250 – 2003,

ANSI/ISA 60079-0:2013,

ANSI/UL 60079-11:2014,

ANSI/ISA 60529:2004, ANSI/ISA 61010-1:2004

Markings: IS CL I, DIV 1, GP A, B, C, D:

IS CL I Zone 0, AEx ia IIC T4 Ga;

T4 Ta = -55 to +70 °C

Type 4X; IP66; IP67

WHEN INSTALLED PER ROSEMOUNT DRAWING

03308-1010

Special Conditions of Certification:

1. The Model 3308 transmitter housing contains aluminum;

protect the enclosure to avoid a potential risk of ignition

due to impact or friction.

2. The surface resistivity of the polymeric antenna is greater

than 1G. To avoid electrostatic charge buildup, it must

not be rubbed or cleaned with solvents or a dry cloth.

3. For use only with the Emerson Process Management Model

701PBKKF SmartPower Option or the Computational

Systems, Inc Model MHM-89004 battery module.

4. Only the Emerson Process Management 375 or 475 Field

Communicator is approved for use with this transmitter.

5. The maximum permitted operating temperature of the

Rosemount 3308A transmitter is 70 °C. To avoid the

effects of process temperature and other thermal effects

care shall be taken to ensure that the “Electronics

Temperature” does not exceed 70 °C.

Canada

I6 Canada Intrinsically Safe

Certificate: FM17CA0007X

Standards: CSA Std. C22.2 No. 61010-1:2004,

CSA Std. 22.2 No. 94-M91,

CAN/CSA-C22.2 NO. 60079-0:15,

CAN/CSA-C22.2 NO. 60079-11:14,

C22.2 No. 60529:2016

Emerson.com/Rosemount

29

Page 30

Rosemount 3308 Series

January 2018

Markings: INTRINSICALLY SAFE Ex ia

CLASS I, GP A, B, C, D;

CLASS I, Zone 0, Ex ia IIC T4 Ga;

TEMP CODE T4 (-55 °C

Type 4X; IP66; IP67

WHEN INSTALLED PER ROSEMOUNT DRAWING

03308-1010

Special Conditions of Certification:

1. The Model 3308 transmitter housing contains aluminum;

protect the enclosure to avoid a potential risk of ignition

due to impact or friction.

2. The surface resistivity of the polymeric antenna is greater

than 1G. To avoid electrostatic charge buildup, it must

not be rubbed or cleaned with solvents or a dry cloth.

3. For use with the Emerson Process Management 701PBKKF

SmartPower Option or the Computational Systems, Inc

Model MHM-89004 battery module only.

4. Only the Emerson Process Management 375 or 475 Field

Communicator is approved for use with this transmitter.

5. The maximum permitted operating temperature of the

Rosemount 3308A transmitter is 70 °C. To avoid the

effects of process temperature and other thermal effects

care shall be taken to ensure that the “Electronics

Temperature” does not exceed 70 °C.

Ta +70 °C)

Europe

I1 ATEX Intrinsic Safe

Certificate: FM 12ATEX0072X

Standards: EN 60079-0:2012+A11:2013, EN

60079-11:2012; EN 60529:1991+A2:2013

Markings: Category II 1 G, Ex ia IIC T4 Ga

(-55 °C

1180

2460

Special Conditions of Certification:

1. The Model 3308 transmitter housing contains aluminum;

protect the enclosure to avoid a potential risk of ignition

due to impact or friction.

2. The surface resistivity of the polymeric antenna is greater

than 1G. To avoid electrostatic charge buildup, it must

not be rubbed or cleaned with solvents or a dry cloth.

3. For use only with the ATEX certified

(Baseefa11ATEX0042X) Emerson Process Management

Model 701PBKKF SmartPower Option or the ATEX certified

(SIRA 15ATEX2332X) Computational Systems, Inc Model

MHM-89004 battery Module.

4. Only an ATEX certified (BVS03ATEXE347,

BVS09ATEXE023) Emerson Process Management 375 or

475 Field Communicator is approved for use with this

transmitter.

Ta +70 °C);

5. The maximum permitted operating temperature of the

Rosemount 3308A transmitter is 70 °C. To avoid the

effects of process temperature and other thermal effects

care shall be taken to ensure that the “Electronics

Temperature” does not exceed 70 °C.

International

I7 IECEx Intrinsic Safety

Certificate: IECEx FMG 12.0029X

Standards: IEC 60079-0: 2011, IEC 60079-11: 2011

Markings: Ex ia IIC T4 Ga (-55 °C

Special Conditions of Certification:

1. The Model 3308 transmitter housing contains aluminum;

protect the enclosure to avoid a potential risk of ignition

due to impact or friction.

2. The surface resistivity of the polymeric antenna is greater

than 1G. To avoid electrostatic charge buildup, it must

not be rubbed or cleaned with solvents or a dry cloth.

3. For use with only the an IECEx certified (IECEx FMG

12.0029X) Emerson Process Management Model

701PBKKF SmartPower Option or the IECEx certified (IECEx

CSA 15.0045X) Computational Systems, Inc Model

MHM-89004 battery pack.

4. Only the Emerson Process Management 375 or 475 Field

Communicator is approved for use with this transmitter.

5. The maximum permitted operating temperature of the

Rosemount 3308A transmitter is 70 °C. To avoid the

effects of process temperature and other thermal effects

care shall be taken to ensure that the “Electronics

Temperature” does not exceed 70 °C.

Ta +70 °C)

Brazil

I2 INMETRO Intrinsic Safety

Certificate: UL-BR 13.0463X

Standards: ABNT NBR IEC 60079-0:2008 + Errata 1:2011,

ABNT NBR IEC 60079-11:2009,

ABNT NBR IEC 60079-26:2008

Markings: Ex ia IIC T4 Ga (-55 °C <

Special Conditions of Certification:

1. The Model 3308 transmitter housing contains aluminium;

protect the enclosure to avoid a potential risk of ignition

due to impact or friction.

2. The surface resistivity of the polymeric antenna is greater

than 1 G. To avoid electrostatic charge buildup, it must

not be rubbed or cleaned with solvents or a dry cloth.

3. For use with the Emerson Process Management 701PB

SmartPower Option only.

4. Only the Emerson Process Management 375 or 475 Field

Communicator is approved for use with this transmitter.

T

amb

< +70 °C)

30

Emerson.com/Rosemount

Page 31

January 2018

Rosemount 3308 Series

5. The maximum permitted operating temperature of the

Rosemount 3308A transmitter is 70 °C. To avoid the

effects of process temperature and other thermal effects

care shall be taken to ensure that the “Electronics

Temperature” does not exceed 70 °C.

China

I3 NEPSI Intrinsic Safety

Certificate: GYJ13.1443X

Standards: GB 3836.1-2010, GB 3836.4-2010,

GB 3836.20-2010

Markings: Ex ia IIC T4 Ga (-55°C

Special Conditions of Certification:

See certificate for details.

+70°C)

~

Japan

I4 TIIS Intrinsic Safety

Certificate: TC20746

Markings: Ex ia IIC T4 -20°~+60°C

Special Conditions of Certification:

See certificate for details.

EAC – Belarus, Kazakhstan, Russia

IM Technical Regulation Customs Union (EAC) Intrinsic Safety

Certificate: RU C-US.Gb05.B.00530

Markings: 0Ex ia IIC T4 Ga X (-55°C

Special Conditions of Certification:

See certificate for details.

Ta +70 °C)

Combinations

KD ATEX and Canadian Intrinsic Safety

KE FM and Canadian Intrinsically Safe

KF ATEX and FM Intrinsic Safety

Other certifications

U1 Overfill protection

Certificate: Z-65.16-536

TÜV-tested and approved by DIBt for overfill protection

according to the German WHG regulations

Ta iwa n

注意!

依據 低功率電波輻射性電機管理辦法

第十二條

經型式認證合格之低功率射頻電機,非經

許可,公司、商號或使用者均不得擅自變更頻

率、加大功率或變更原設計之特性及功能。

第十四條

低功率射頻電機之使用不得影響飛航安全

及干擾合法通信;經發現有干擾現象時,應立

即停用,並改善至無干擾時方得繼續使用。

前項合法通信,指依電信法規定作業之無

線電通信。

低功率射頻電機須忍受合法通信或工業、科學

及醫療用電波輻射性電機設備之干擾。

Emerson.com/Rosemount

31

Page 32

Rosemount 3308 Series

12 (297.2)

3.9 (100.2)

2.8 (71.3)

External antenna

(option WK1)

L 56 ft.

(17 m)

Ø 0.16 (4): SST probe

Ø 0.28 (7): PTFE covered probe

5.5

(140)

Ø 0.9 (22)

BSPP (G) 1-in., s52

BSPP (G) 1½-in., s60

Short weight

(option W2)

2 (50)

Ø 1.5 (38)

Heavy weight

(option W3)

5.5

(140)

Ø 1.5 (38)

Chuck

(option W4)

Ø 1 (24.5)

1 (26)

4.3 (110)

7.8 (198)

Min. 8 (200)

Chamber/pipe

Min. Ø 2 (50)

The probe must be

in the center of the

probe/chamber

PTFE covered probe and

protective plate

Small weight

(option W1)

Weight for PTFE

covered probe

(option W1)

17.1

(435)

Ø 0.88 (22.5)

Thread sealing

NPT 1-in., s52

NPT 1½-in., s52

NPT 2-in., s60

Protective plate

2.4 (62)

1.9 (47)

2.4 (62)

3.4 (86)

Min. 4 (100) if smooth metallic wall.

Min. 16 (400) if disturbing objects or

rugged metallic wall.

H (Nozzle height)

H < 4 (100) + D

Tri Clamp

connection

12 (297.2)

4 (100): Standard length

10 (250): Long stud (option LS)

0.6 (15)

Alloy probe and

protective plate

Protective plate

Recommended: D > 4 (100)

Minimum: D=1.5 (38)

(1)

Ø D (Nozzle diameter)

Dimensional Drawings

Figure 15. Flexible Single Lead Probe

January 2018

1. The Trim Near Zone (TNZ) function may be necessary or an Upper Null Zone (UNZ) setup may be required to mask the nozzle.

Dimensions are in inches (millimeters).

32

Emerson.com/Rosemount

Page 33

January 2018

PTFE covered probe and

protective plate

Tri Clamp

connection

Recommended: D > 4 (100)

Minimum: D=1.5 (38) for probe type 4A

(1)

D=2 (50) for probe type 4B

(1)

Ø D (Nozzle diameter)

12 (297.2)

3.9 (100.2)2.8 (71.3)

External antenna

(option WK1)

Ø 0.31 (8) or Ø 0.51 (13): SST probe

Ø 0.47 (12): PTFE covered probe

BSPP (G) 1-in., s52

BSPP (G) 1½-in., s60

2.4 (62)

Thread sealing

Min. 8 (200)

Chamber/pipe

Min. Ø 2 (50)

NPT 1-in., s52

NPT 1½-in., s52

NPT 2-in., s60

1.9 (47)

2.4 (62)

3.4 (86)

4.3 (110)

L 10 ft. (3 m)

for Ø 0.31 (8)

L 20 ft. (6 m)

for Ø 0.51 (13)

Protective plate

Min. 0.2 (5)

The probe must be

in the center of the

probe/chamber

Min. 4 (100) if smooth metallic wall.

Min. 16 (400) if disturbing objects or

rugged metallic wall.

7.8 (198)

Nozzle height (H)

H < 4 (100) + D

12 (297.2)

Protective plate

Alloy probe and

protective plate

Figure 16. Rigid Single Lead Probe

Rosemount 3308 Series

1. The Trim Near Zone (TNZ) function may be necessary or an Upper Null Zone (UNZ) setup may be required to mask the nozzle.

Dimensions are in inches (millimeters).

Emerson.com/Rosemount

33

Page 34

Rosemount 3308 Series

Recommended: D > 4 (100)

Minimum: D=2 (50)

(1)

Ø D (Nozzle diameter)

12 (297.2)

3.9 (100.2)2.8 (71.3)

External antenna

(option WK1)

Ø 0.51 (13)

BSPP (G) 1½-in., s60

2.4 (62)

Thread sealing

Min. 8 (200)

Chamber/pipe

Min. Ø 2 (50)

NPT 1½-in., s52

NPT 2-in., s60

1.9 (47)

2.4 (62)

3.4 (86)

4.3 (110)

L 33 ft.

(10 m)

Min. 0.2 (5)

The probe must be

in the center of the

probe/chamber

Min. 4 (100) if smooth metallic wall.

Min. 16 (400) if disturbing objects or

rugged metallic wall.

7.8 (198)

Nozzle height (H)

H < 4 (100) + D

15.2 (385)

0.6 (15)

31.5 (800)