Rosemount™ 2240S Multi-Input

Temperature Transmitter

Reference Manual

00809-0100-2240, Rev EA

May 2020

Reference Manual

00809-0100-2240, Rev EA

Contents

1Section 1: Introduction

Contents

May 2020

1.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Manual overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Technical documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3.1 Reference manuals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3.2 Product data sheets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3.3 Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Service support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.5 Product recycling/disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.6 Packing material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.6.1 Reuse and recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.6.2 Energy recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2Section 2: Overview

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 System overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4 Getting started. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.5 Installation procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3Section 3: Sensor Installation

3.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2 Installation considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.3 Multiple Spot Temperature sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.3.1 Installation on fixed roof tanks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.3.2 Installation on floating roof tanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.3.3 Custody transfer applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.4 Water Level Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.5 Installing a temperature sensor tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.6 Rosemount 614 Cryogenic Spot Temperature Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.6.1 Leakage detection on LNG full containment tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Contents

3.6.2 Skin temperature and cool-down monitoring on LNG tank . . . . . . . . . . . . . . . . . . . . . . . 28

i

Contents

May 2020

4Section 4: Rosemount™ 2240S Installation

4.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2 Installation considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.3 Mechanical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.3.1 Mounting on top of a temperature sensor/WLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.3.2 Mounting on a pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.3.3 Wall mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.3.4 Mounting the connection cone and Rosemount 614 sensor . . . . . . . . . . . . . . . . . . . . . . 34

4.4 Electrical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.4.1 Cable/conduit entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.4.2 Power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.4.3 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.4.4 Cable selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.4.5 Hazardous areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.4.6 The Tankbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.4.7 Typical installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.4.8 Rosemount

4.4.9 Tankbus wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.4.10Daisy-chain connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

™

2240S in FOUNDATION Fieldbus system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Reference Manual

00809-0100-2240, Rev EA

4.4.11Temperature element and Water Level Sensor wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5Section 5: Configuration/Operation

5.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.2 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.2.1 Configuration procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.2.2 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.2.3 Configuration tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.3 Basic configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.3.1 Temperature elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.3.2 Water Level Sensor calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.3.3 Water Level Sensor measuring range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.4 LED signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

5.4.1 Status LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

5.4.2 Communication LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.5 Switches and reset buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.5.1 DIP Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.5.2 Reset button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

ii

Contents

Reference Manual

00809-0100-2240, Rev EA

Contents

May 2020

5.6 Configuration using TankMaster WinSetup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

5.6.1 Advanced configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

5.7 F

OUNDATION

5.7.1 Block operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

5.8 Device capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.8.1 Link active scheduler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.8.2 Device addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.8.3 Capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

5.9 General block information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.9.1 Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.9.2 Block instantiation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5.9.3 Factory configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5.10Analog Input block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

5.10.1Configure the AI block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

™

fieldbus overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

5.10.2Factory supplied AI blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

5.10.3Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

5.10.4Simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

5.10.5Filtering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

5.10.6Signal Conversion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

5.10.7Process alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

5.10.8Alarm priority . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

5.11Analog Output block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

5.11.1CHANNEL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

5.11.2XD_SCALE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

5.11.3Application example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

5.12Multiple Analog Input blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

5.12.1Configure the MAI blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

5.12.2Factory Supplied MAI blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

5.13Resource block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

5.13.1FEATURES and FEATURES_SEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

5.13.2MAX_NOTIFY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

5.13.3Field diagnostic alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

5.13.4Recommended actions for alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

5.13.5Alarm priority . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Contents

5.14Configuration using a field communicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

iii

Contents

May 2020

Reference Manual

00809-0100-2240, Rev EA

5.15Configuration using AMS Device Manager. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

5.15.1Starting the Guided Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

5.15.2Temperature sensor setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

5.15.3Water level sensor setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

5.15.4Manual setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

5.16Alert setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

5.16.1Alert default settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

6Section 6: Service and Troubleshooting

6.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

6.2 Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

6.2.1 Viewing input and holding registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

6.2.2 Editing holding registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

6.2.3 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

6.2.4 Ground fault detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

6.2.5 Reset and WLS calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

6.2.6 Device error LED signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

6.2.7 Test and simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

6.2.8 Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

6.3 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

6.3.1 Device status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

6.3.2 Device warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

6.3.3 Device errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

6.3.4 Measurement status for the WLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

6.3.5 Temperature element status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

6.4 Resource block error and status messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

6.5 Transducer block error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

6.6 Analog Input (AI) function block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .132

6.7 Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .133

6.7.1 Viewing active alerts in AMS Device Manager. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

6.7.2 Viewing device status in AMS Device Manager. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

6.7.3 Recommended actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

6.8 Service tools in AMS Device Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

6.8.1 Service tools window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

6.8.2 Device status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

6.8.3 Viewing input and holding registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

iv

Contents

Reference Manual

00809-0100-2240, Rev EA

AAppendix A: Specifications and Reference Data

Contents

May 2020

A.1 Performance specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

A.1.1 Temperature conversion accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

A.1.2 Ambient temperature effect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

A.1.3 Temperature measuring range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .145

A.1.4 Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

A.1.5 Update time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

A.2 General specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

A.2.1 Number of spot elements and wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

A.2.2 Standard temperature sensor types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

A.2.3 Metrology sealing possibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

A.2.4 Write protect switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

A.3 Configuration specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

A.3.1 Configuration tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

A.3.2 Configuration parameters (examples) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

A.3.3 Output variables and units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

A.4 Foundation fieldbus characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

A.4.1 Polarity sensitive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

A.4.2 Quiescent current draw. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

A.4.3 Lift-off minimum voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

A.4.4 Device capacitance / inductance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

A.4.5 Class (Basic or Link Master). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

A.4.6 Number of available VCRs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

A.4.7 Links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

A.4.8 Minimum slot time/maximum response delay/minimum intermessage delay . . . . . 146

A.4.9 Blocks and Execution time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

A.4.10Instantiation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

A.4.11Conforming Foundation fieldbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

A.4.12Field Diagnostics support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

A.4.13Action support wizards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .146

A.4.14Advanced diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .146

Contents

v

Contents

May 2020

Reference Manual

00809-0100-2240, Rev EA

A.5 Electrical specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

A.5.1 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

A.5.2 Internal power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

A.5.3 Bus current draw. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

A.5.4 Tankbus cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

A.5.5 Built-in Tankbus terminator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

A.5.6 Tankbus to sensor isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

A.5.7 Auxiliary sensor input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

A.6 Mechanical specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

A.6.1 Housing material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

A.6.2 Cable entry (connection/glands) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

A.6.3 565/566/765 connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .147

A.6.4 Rosemount 614 cone connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

A.6.5 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

A.6.6 Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

A.7 Environmental specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

A.7.1 Ambient temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

A.7.2 Storage temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

A.7.3 Humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

A.7.4 Ingress protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

A.7.5 Transient / built-in lightning protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

A.8 Dimensional drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

A.9 Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .149

vi

Contents

Contents

May 2020

Reference Manual

00809-0100-2240, Rev EA

BAppendix B: Product Certifications

B.1 European Directive Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

B.2 Ordinary Location Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

B.3 Installing Equipment in North America . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

B.4 USA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

B.5 Canada. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

B.6 Europe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

B.7 International . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .153

B.8 Brazil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

B.9 EAC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

B.10Japan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

B.11Republic of Korea . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

B.12India. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

B.13Conduit plugs and adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

B.13.1Conduit Plug Thread Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

B.13.2Thread Adapter Thread Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .154

B.14Custody Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

B.15Approval Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

vii

Contents

Contents

May 2020

Reference Manual

00809-0100-2240, Rev EA

CAppendix C: FOUNDATION™ Fieldbus Block Information

C.1 Resource block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

C.2 Analog input block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

C.2.1 Simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

C.3 Analog output block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

C.4 Register transducer block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

C.5 Measurement transducer block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

C.5.1 Diagnostic device alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

C.6 Average temperature transducer block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .176

C.7 Supported units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

viii

Contents

Reference Manual

NOTICE

00809-0100-2240, Rev EA

Rosemount™ 2240S

Multi-Input Temperature Transmitter

Read this manual before working with the product. For personal and system safety, and for optimum

product performance, make sure you thoroughly understand the contents before installing, using, or

maintaining this product.

For equipment service or support needs, contact your local Emerson Automation Solutions/Rosemount

Tank Gauging representative.

Spare Parts

Any substitution of non-recognized spare parts may jeopardize safety. Repair, e.g. substitution of

components etc, may also jeopardize safety and is under no circumstances allowed.

Rosemount Tank Radar AB will not take any responsibility for faults, accidents, etc caused by

non-recognized spare parts or any repair which is not made by Rosemount Tank Radar AB.

Title Page

May 2020

The products described in this document are NOT designed for nuclear-qualified applications.

Using non-nuclear qualified products in applications that require nuclear-qualified hardware or

products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact your local Rosemount Sales

Representative.

WARNING - Substitution of components may impair Intrinsic Safety.

WARNING - To prevent ignition of flammable or combustible atmospheres, disconnect power before

servicing.

AVERTISSEMENT - La substitution de composants peut compromettre la sécurité intrinsèque.

AVERTISSEMENT - Ne pas ouvrir en cas de presence d'atmosphere explosive.

Physical access

Unauthorized personnel may potentially cause significant damage to and/or misconfiguration of

end user’s equipment. This could be intentional or unintentional and needs to be protected against.

Physical security is an important part of any security program and fundamental to protecting your

system. Restrict physical access by unauthorized personnel to protect end user’s assets. This is true

for all systems used within the facility.

Title Page

ix

Title Page

May 2020

Reference Manual

00809-0100-2240, Rev EA

x

Title Page

Reference Manual

00809-0100-2240, Rev EA

Section 1 Introduction

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1

Manual overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2

Technical documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

Service support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5

Product recycling/disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5

Packing material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 6

1.1 Safety messages

Procedures and instructions in this manual may require special precautions to ensure the safety of the

personnel performing the operations. Information that raises potential safety issues is indicated by a

warning symbol ( ). Refer to the safety messages listed at the beginning of each section before

performing an operation preceded by this symbol.

Introduction

May 2020

Failure to follow these installation guidelines could result in death or serious injury.

Make sure only qualified personnel perform the installation.

Use the equipment only as specified in this manual. Failure to do so may impair the protection

provided by the equipment.

Explosions could result in death or serious injury.

Verify that the operating environment of the transmitter is consistent with the appropriate

hazardous locations certifications.

Before connecting a hand held communicator in an explosive atmosphere, make sure the

instruments in the loop are installed in accordance with intrinsically safe or non-incendive field

wiring practices.

Do not remove the gauge cover in explosive atmospheres when the circuit is alive.

Electrical shock could cause death or serious injury.

Use extreme caution when making contact with the leads and terminals.

Any substitution of non-recognized parts may jeopardize safety. Repair, e.g. substitution of

components etc., may also jeopardize safety and is under no circumstances allowed.

Introduction

1

Introduction

May 2020

1.2 Manual overview

This manual provides installation, configuration, and maintenance information for the Rosemount™

2240S Multi-input Temperature Transmitter. The manual is based on a typical Rosemount Tank Gauging

system with a Rosemount 2410 Tank Hub connected to supported devices such as the Rosemount 2240S

Temperature Transmitter. It also includes a brief overview of Foundation

specific information to allow installation of a Rosemount 2240S in Foundation fieldbus networks.

Section 2: Overview provides a brief description of the various components in a Rosemount Tank

Gauging system and recommended installation procedure.

Section 3: Sensor Installation covers installation considerations as well as mechanical installation of

multiple spot temperature and water level sensors.

Section 4: Rosemount

of the Rosemount 2240S.

Section 5: Configuration/Operation describes how to configure the Rosemount 2240S by using tools

such as Rosemount TankMaster, Rosemount 475 Field Communicator, or AMS Device Manager. This

section also provides an overview of F

Section 6: Service and Troubleshooting covers tools, troubleshooting, and various service instructions.

™ 2240S Installation

Reference Manual

00809-0100-2240, Rev EA

™

fieldbus, and provides device

covers installation considerations as well as mechanical installation

OUNDATION fieldbus operation with the Rosemount 2240S.

Appendix A: Specifications and Reference Data contains specifications, dimensional drawings, and

ordering table.

Appendix B: Product Certifications contains information on approvals and certifications.

Appendix C: F

OUNDATION

™ FIELDBUS BLOCK INFORMATION

describes the various function and transducer blocks which

are used for the Rosemount 2240S.

2

Introduction

Reference Manual

00809-0100-2240, Rev EA

1.3 Technical documentation

The Rosemount Tank Gauging System includes the following documentation:

1.3.1 Reference manuals

Rosemount Tank Gauging System Configuration Manual (00809-0300-5100)

Rosemount 2460 System Hub Reference Manual (00809-0100-2460)

Rosemount 2410 Tank Hub Reference Manual (00809-0100-2410)

Rosemount 5900S Radar Level Gauge Reference Manual (00809-0100-5900)

Rosemount 5900C Radar Level Gauge Reference Manual (00809-0100-5901)

Rosemount 5900 Proof Test Manual Supplement (00809-0200-5900)

Rosemount 2240S Temperature Transmitter Reference Manual (00809-0100-2240)

Rosemount 2230 Display Reference Manual (00809-0100-2230)

Rosemount 5300 Series Reference Manual (00809-0100-4530)

Rosemount 5408 Series Reference Manual (00809-0300-4408)

Rosemount TankMaster Software Installation Reference Manual (00809-0400-5110)

Rosemount TankMaster WinView Reference Manual (00809-0300-5110)

Rosemount TankMaster WinOpi Reference Manual (00809-0200-5110)

Rosemount TankMaster WinSetup Reference Manual (00809-0100-5110)

Rosemount Tank Gauging Wireless System Reference Manual (00809-0100-5200)

Rosemount TankMaster Floating Roof Monitoring Reference Manual (00809-0500-5100)

Introduction

May 2020

1.3.2 Product data sheets

Rosemount Tank Gauging System Data Sheet (00813-0100-5100)

Rosemount 2460 System Hub Product Data Sheet (00813-0100-2460)

Rosemount 2410 Product Data Sheet (00813-0100-2410)

Rosemount 5900S Product Data Sheet (00813-0100-5900)

Rosemount 5900C Product Data Sheet (00813-0100-5901)

Rosemount 2240S Product Data Sheet (00813-0100-2240)

Rosemount 2230 Product Data Sheet (00813-0100-2230)

Rosemount 5300 Product Data Sheet (00813-0100-4530)

Rosemount 5408 Product Data Sheet (00813-0100-4408)

Rosemount 565/566/765/614 Product Data Sheet (00813-0100-5565)

Introduction

3

Introduction

May 2020

1.3.3 Drawings

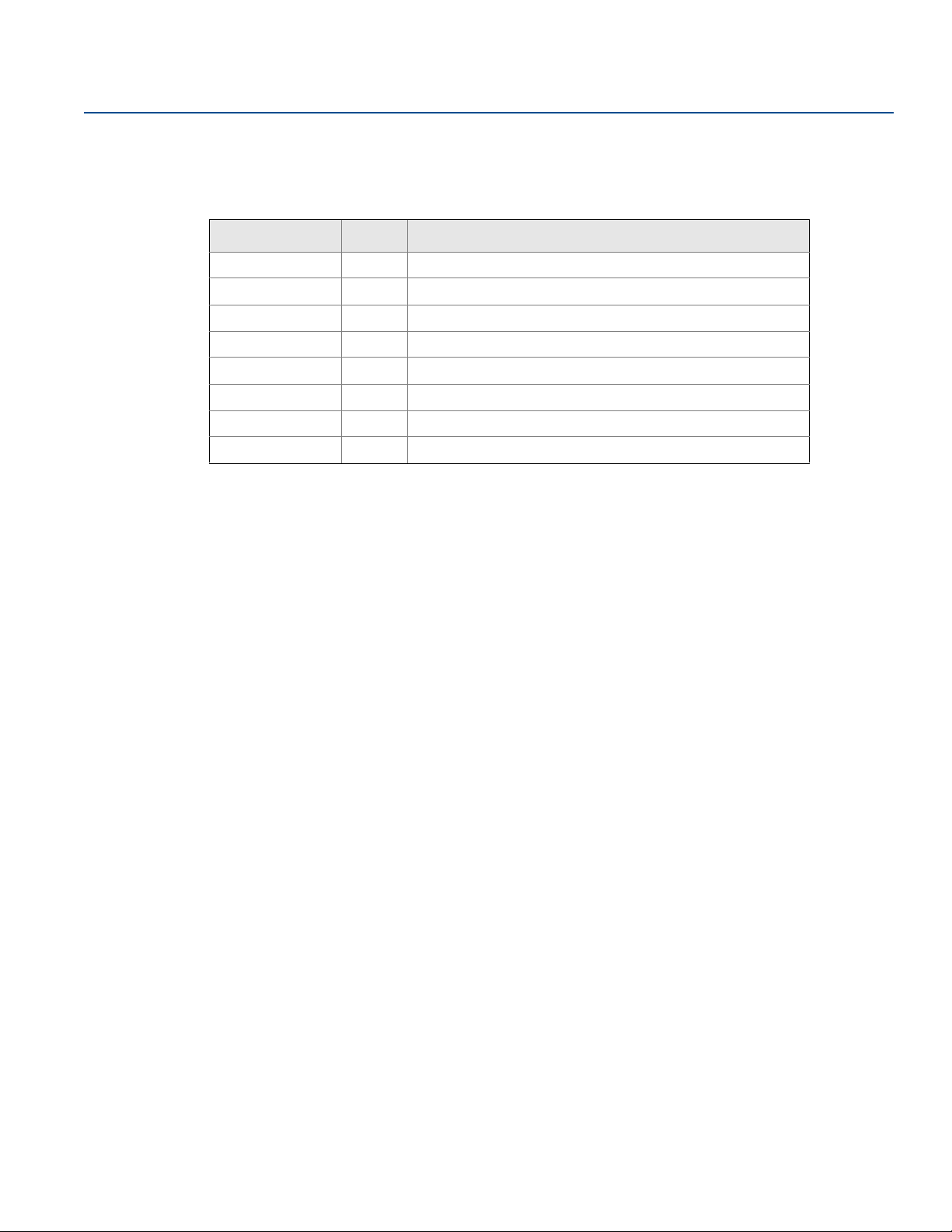

Table 1-1. Installation drawings for the Rosemount 2240 Multi-Input Temperature Transmitter

Drawing Issue Title

D9240 041-912 2 Mechanical Installation Drawing

D9240 041-959 4 Electrical Installation Drawing

D7000 001-798 2 System Installation Drawing Foundation fieldbus FISCO

D7000 001-811 1 System Installation Drawing Foundation fieldbus IS Entity

D7000 005-451 2 Type 614 wiring

D9261 085-035 3 General arrangement - Leak detection temperature sensors

D9261 085-036 3 General arrangement - Cool down temperature sensors

D9261 085-039 2 Rosemount 2240/614 accessory conical connection

Reference Manual

00809-0100-2240, Rev EA

4

Introduction

Reference Manual

S

E

P

A

R

A

T

E

S

T

E

E

L

&

P

L

A

S

T

I

C

00809-0100-2240, Rev EA

1.4 Service support

For service support contact the nearest Emerson Automation Solutions/Rosemount Tank Gauging representative. Contact information can be found on the web site Emerson Automation Solutions/Rosemount

Tank Gauging.

1.5 Product recycling/disposal

Recycling of equipment and packaging should be taken into consideration and disposed of in accordance

with local and national legislation/regulations.

The label below is put on Rosemount Tank Gauging products as a recommendation to customers if

scrapping is considered.

Recycling or disposal should be done following instructions for correct separation of materials when

breaking up the units.

Figure 1-1. A green label is placed on the transmitter housing

Introduction

May 2020

Introduction

5

Introduction

May 2020

1.6 Packing material

Rosemount Tank Radar AB is fully certified according to ISO 14001 environmental standards. By recycling

the corrugated paperboard, or wooden boxes, used for shipping our products you can contribute to take

care of the environment.

1.6.1 Reuse and recycling

Experience has shown that wooden boxes can be used several times for various purposes. After careful

disassembly the wooden parts may be reused. Metal waste may be converted.

1.6.2 Energy recovery

Products which have served their time may be divided into wood and metal components and the wood

can be used as fuel in sufficient ovens.

Due to its low moisture content (approximately 7%) this fuel has a higher calorific value than ordinary

wood fuel (moisture content approximately 20%).

When burning interior plywood the nitrogen in the adhesives may increase emissions of nitrogen oxides

to the air 3-4 times more than when burning bark and splinter.

Reference Manual

00809-0100-2240, Rev EA

Note

Landfill is not a recycling option and should be avoided.

6

Introduction

Reference Manual

Rosemount

TankMaster

Rosemount 2410 Tank Hub

Modem

Rosemount 2460

System Hub

Relay Outputs

Secondary Bus (Non-IS)

Primary Bus

Tankbus

Rosemount 2240S

Temperature

Transmitter

Rosemount 2230

Graphical Field

Host

Zone 1

Zone 0

Rosemount 5900S

Radar Level Gauge

Secondary bus (IS)

Servo

gauges

00809-0100-2240, Rev EA

Section 2 Overview

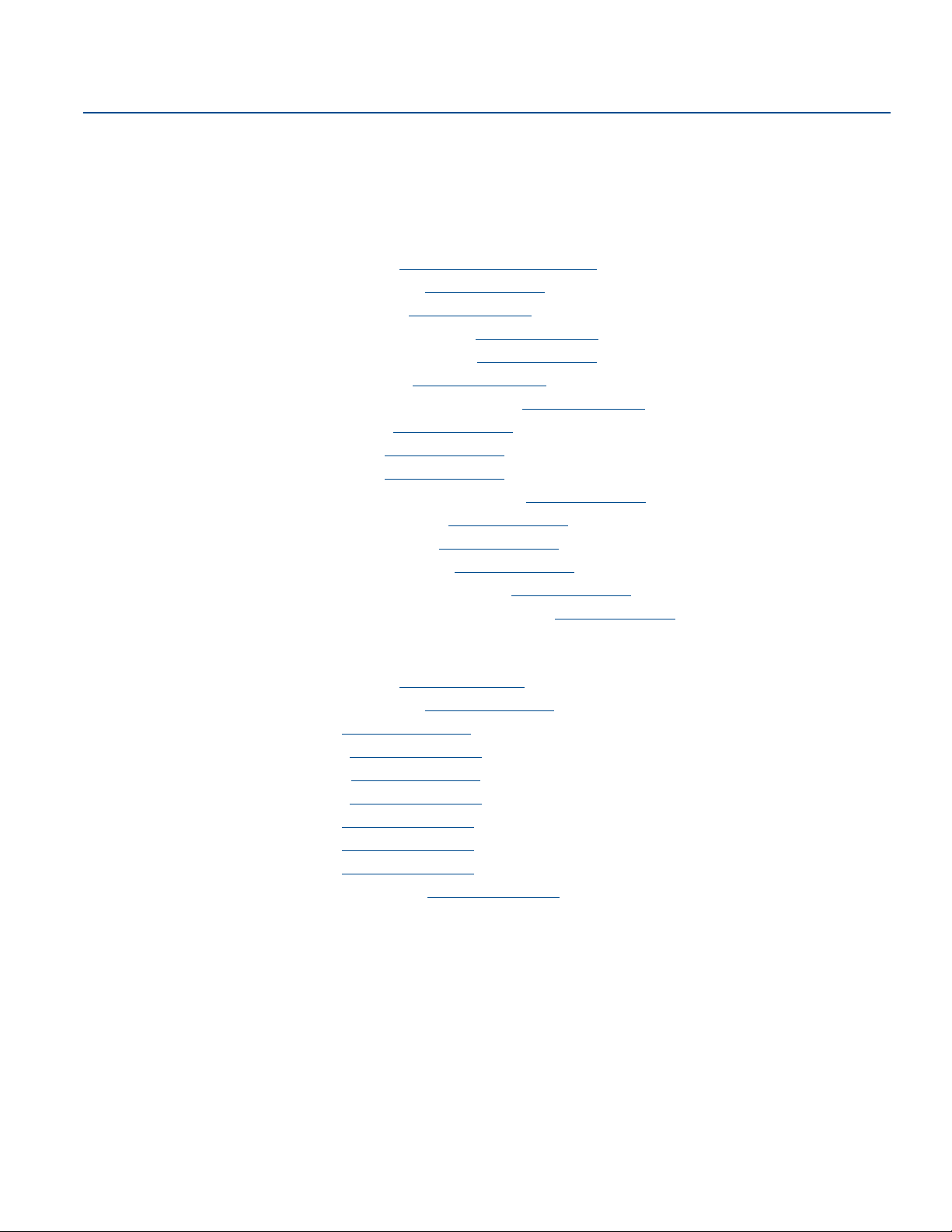

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 7

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

System overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 9

Getting started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 17

Installation procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 18

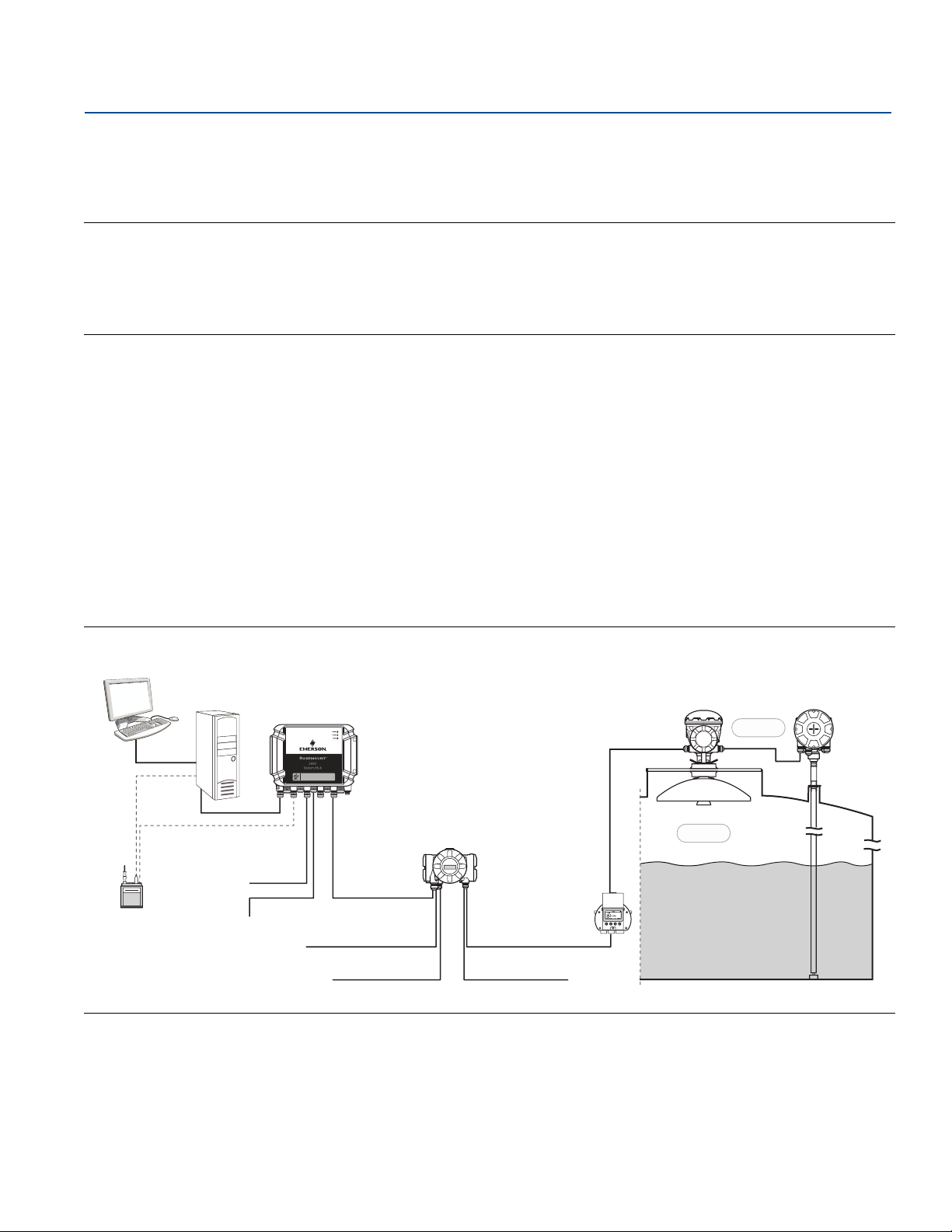

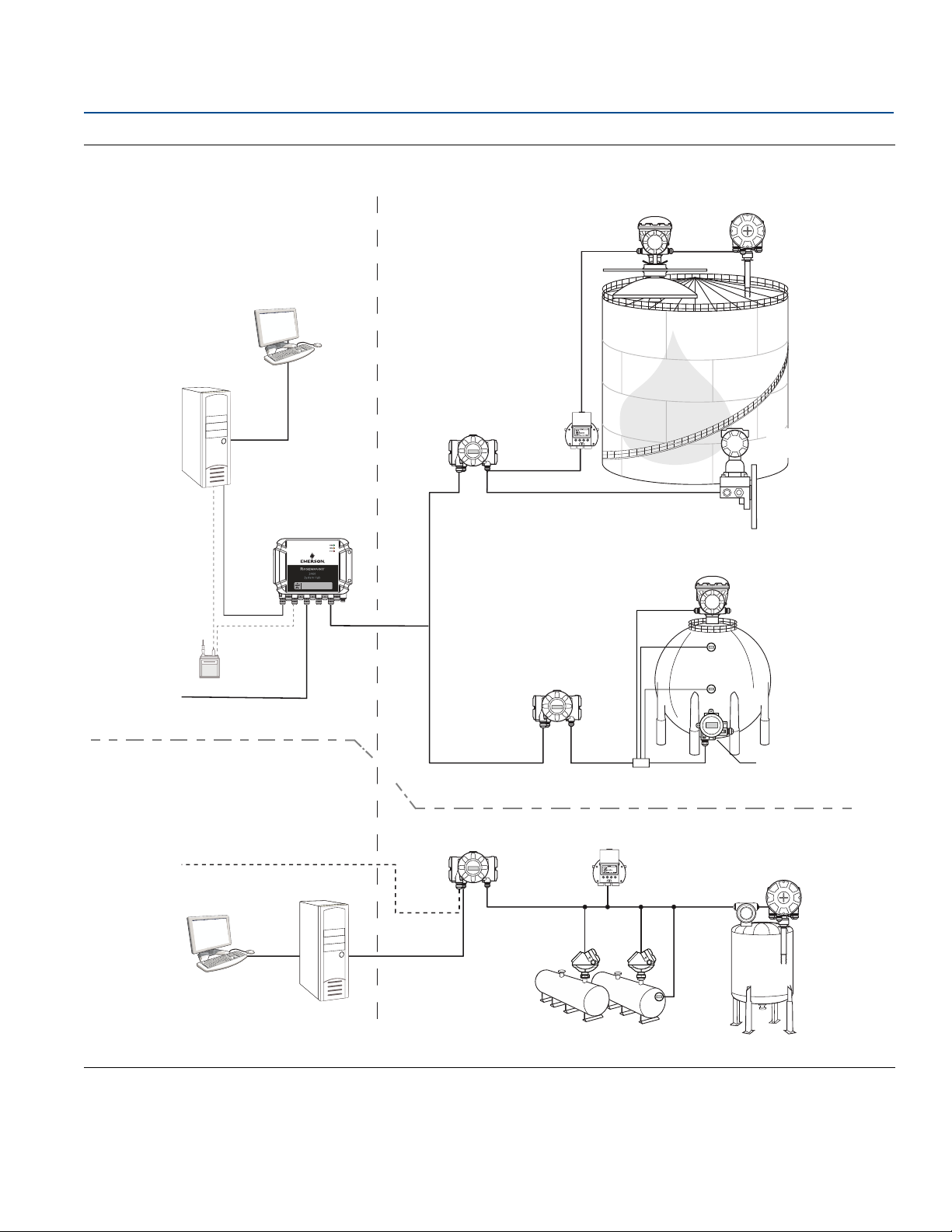

2.1 Introduction

The Rosemount™ 2240S Multi-input Temperature Transmitter can connect up to sixteen 3- or 4-wire

temperature spot elements and an integrated water level sensor. The Rosemount 2240S sends

measurement data, such as temperature and water level, via the intrinsically safe 2-wire Tankbus

Rosemount 2410 Tank Hub. Measurement data and status information can be viewed on a PC with the

Rosemount TankMaster software, as well as on the integral display of the tank hub and the Rosemount

2230 Graphical Field Display.

Data from a group of tanks is buffered by a Rosemount 2460 System Hub, and is distributed to a

Rosemount TankMaster PC, or another host system, whenever the system hub receives a request for

data. In case no system hub is included in the system, the tank hub can communicate directly with the

host computer.

Overview

May 2020

(1)

, to a

Figure 2-1. System integration

1. The intrinsically safe Tankbus complies with the FISCO FOUNDATION™ fieldbus standard.

Overview

7

Overview

A

B

C

D

E

F

May 2020

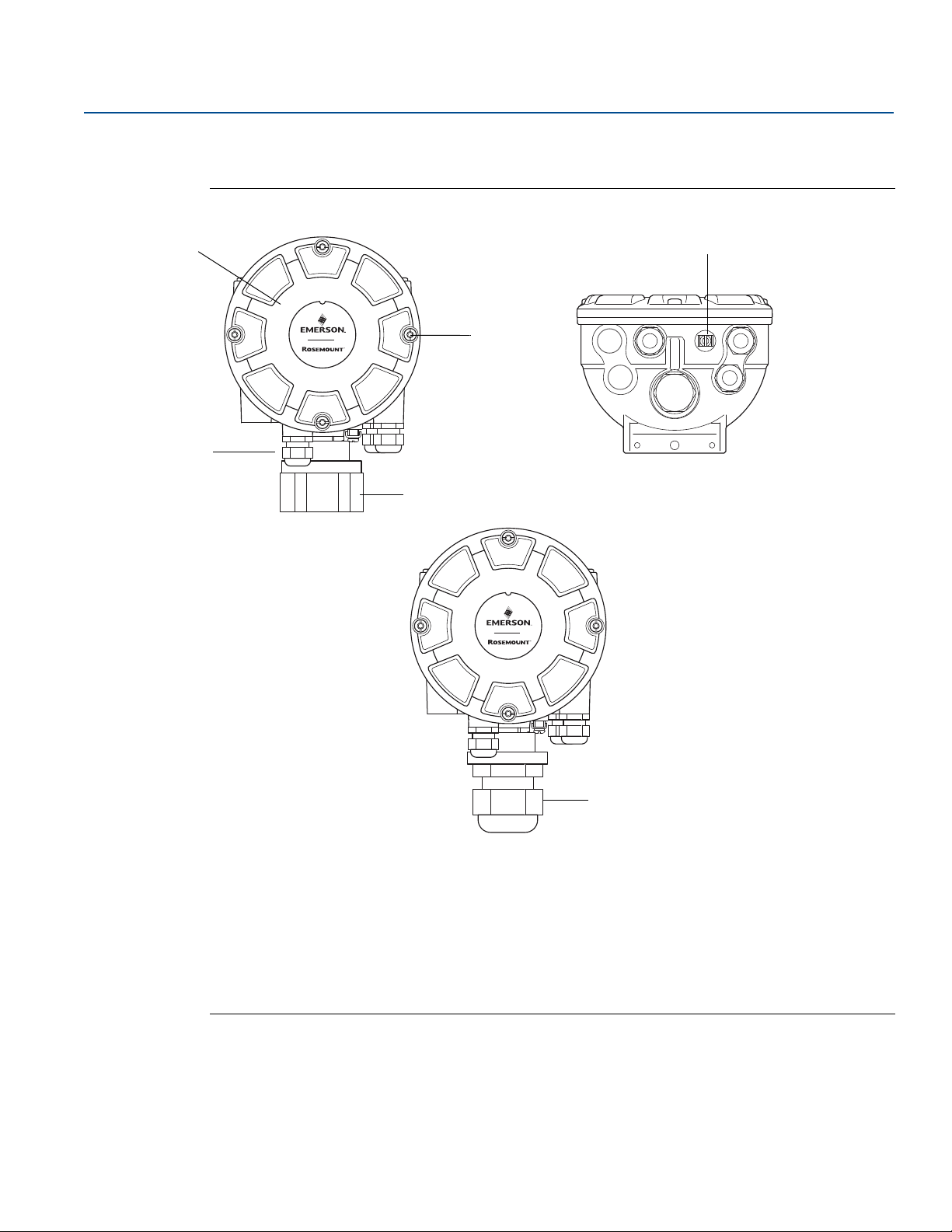

2.2 Components

Reference Manual

00809-0100-2240, Rev EA

Figure 2-2. Rosemount 2240S components

A. Cover.

B. Entries (x 3) of type ½ - 14 NPT.

C. Lock nut for connection of Multi Spot Temperature sensor and Water Level Sensors (MST/WLS).

D. Cover screws (x 4).

E. External ground screw.

F. M32 Cable gland (option for remote mounting).

8

Overview

Reference Manual

00809-0100-2240, Rev EA

2.3 System overview

The Rosemount Tank Gauging system is a state-of-the art inventory and custody transfer radar tank level

gauging system. It is developed for a wide range of applications at refineries, tank farms and fuel depots,

and fulfills the highest requirements on performance and safety.

Overview

May 2020

The field devices on the tank communicate over the intrinsically safe Tankbus. The Tankbus is based on a

standardized fieldbus, the FISCO

supporting that protocol. By utilizing a bus powered 2-wire intrinsically safe fieldbus the power

consumption is minimized. The standardized fieldbus also enables integration of other vendors’

equipment on the tank.

The Rosemount Tank Gauging product portfolio includes a wide range of components to build small or

large customized tank gauging systems. The system includes various devices, such as radar level gauges,

temperature transmitters, and pressure transmitters for complete inventory control. Such systems are

easily expanded thanks to the modular design.

The Rosemount Tank Gauging system is a versatile system that is compatible with and can emulate all

major tank gauging systems. Moreover, the well-proven emulation capability enables step-by-step

modernization of a tank farm, from level gauges to control room solutions.

It is possible to replace old mechanical or servo gauges with modern Rosemount Tank Gauging devices,

without replacing the control system or field cabling. It is further possible to replace old HMI/SCADA-systems and field communication devices without replacing the old gauges.

There is a distributed intelligence in the various system units which continuously collect and process

measurement data and status information. When a request for information is received an immediate

response is sent with updated information.

The flexible Rosemount Tank Gauging system supports several combinations to achieve redundancy,

from control room to the different field devices. Redundant network configuration can be achieved at all

levels by doubling each unit and using multiple control room work stations.

(1)

FOUNDATION™ fieldbus, and allows integration of any device

1. See documents IEC 61158-2 and IEC/TS 60079-27

Overview

9

Overview

Rosemount 2230

Display

Rosemount 2240S

Temperature Transmitter

Rosemount 5900S

Radar Level Gauge

Tankbus

Rosemount 5300

Level Transmitter

Rosemount 5408

Level Transmitter

Rosemount 3051S

Pressure Transmitter

TRL2 Modbus

Rosemount 2180

Field Bus Modem

Rosemount 2460 System Hub

Rosemount

TankMaster PC

Plant Host Computer

Rosemount 644

644

Plant Host Computer

NON-HAZARDOUS AREA HAZARDOUS AREA

Rosemount 2410 Tank Hub

Rosemount 5900S

Radar Level Gauge

Tankbus

Segment coupler

CUSTODY TRANSFER / INVENTORY TANK GAUGINGOPERATIONAL CONTROL

Rosemount 644

Temperature

Transmitter

Rosemount 2410 Tank Hub

Rosemount 2410 Tank Hub

Rosemount 2240S

Temperature Transmitter

Rosemount

TankMaster PC

Rosemount 644

Rosemount 2230 Display

Ethernet

May 2020

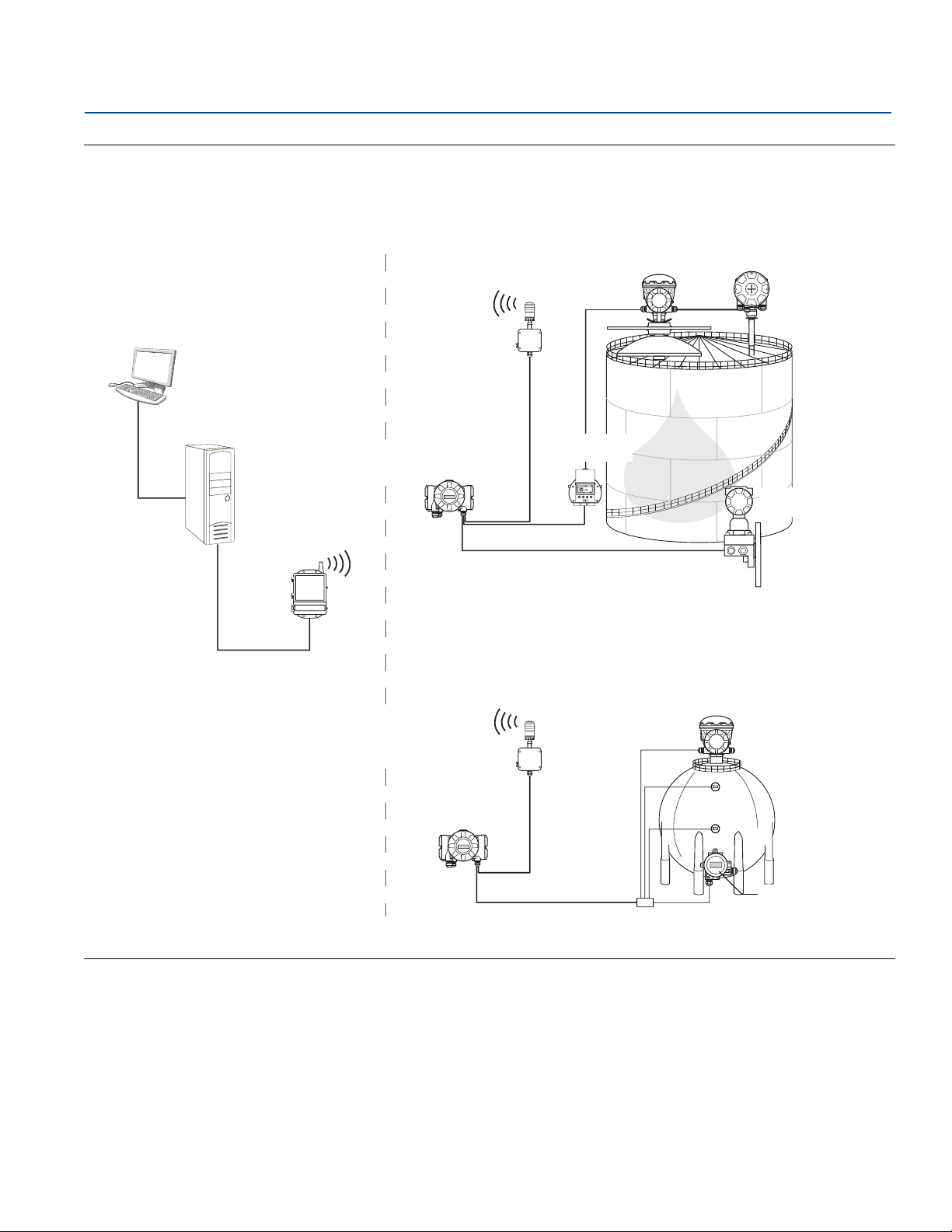

Figure 2-3. Rosemount Tank Gauging System Architecture

Reference Manual

00809-0100-2240, Rev EA

Overview

10

Reference Manual

NON-HAZARDOUS AREA HAZARDOUS AREA

Emerson Wireless

Gateway

Tankbus

Segment coupler

Emerson Wireless

775 THUM Adapter

Rosemount 5900S

Radar Level Gauge

Rosemount 2240S

Temperature Transmitter

Rosemount 2230

Display

Rosemount 3051S

Pressure Transmitter

Rosemount 2410 Tank Hub

Rosemount 5900S

Radar Level Gauge

Rosemount

TankMaster PC

Rosemount 644

Temperature Transmitter

Rosemount 644

Rosemount 644

Emerson Wireless

775 THUM Adapter

Rosemount 2410 Tank Hub

00809-0100-2240, Rev EA

Figure 2-4. Rosemount Tank Gauging System Architecture for Wireless Systems

Overview

May 2020

Overview

11

Overview

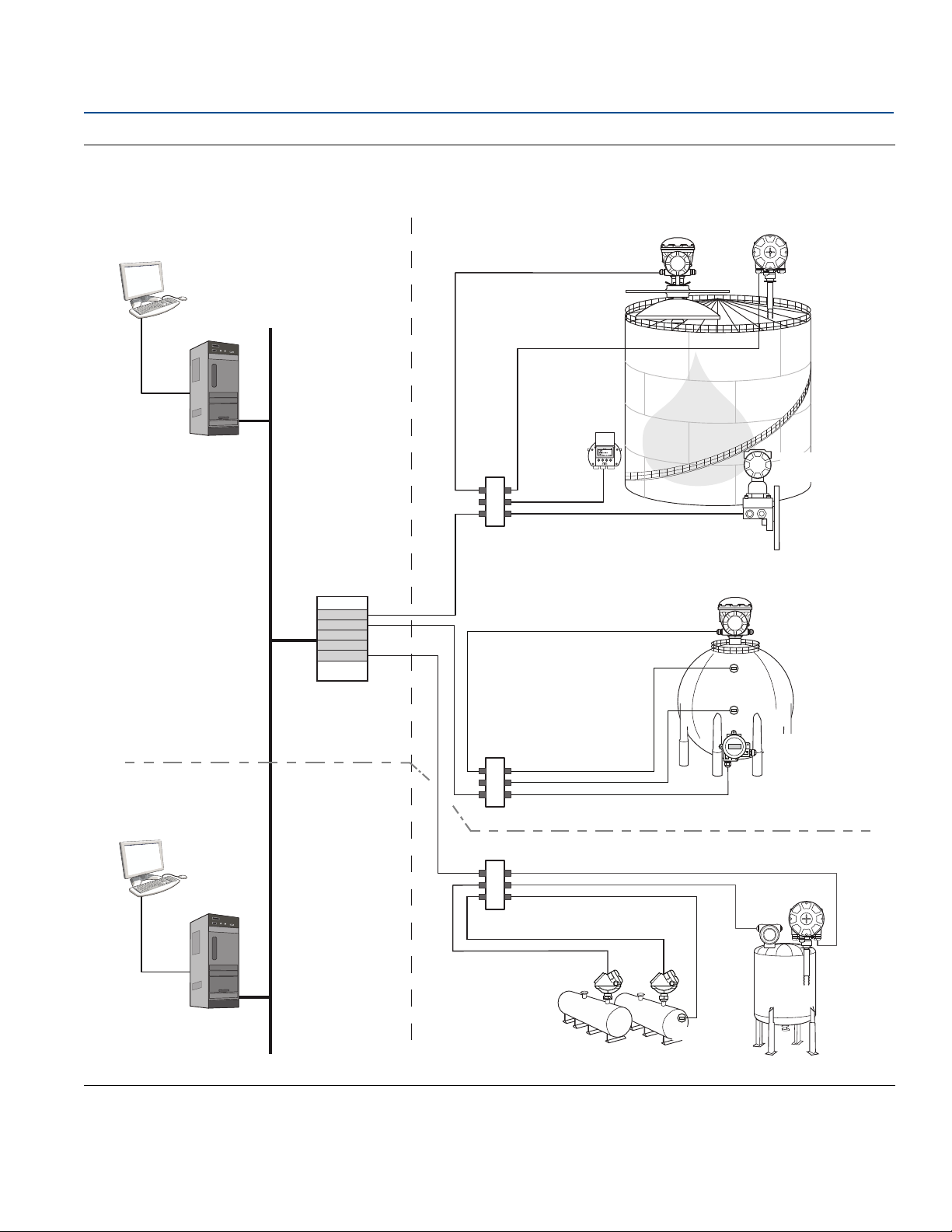

NON-HAZARDOUS AREA HAZARDOUS AREA

CUSTODY TRANSFER

INVENTORY TANK GAUGING

OPERATIONAL CONTROL

PC

644

644

Segment coupler

Segment coupler

FOUNDATION Fieldbus

Power Supply

Rosemount 644

PC

Rosemount 5900S

Radar Level

Rosemount 2240S

Temperature Transmitter

Rosemount 3051S

Pressure Transmitter

Rosemount 5900S

Radar Level Gauge

Rosemount 644

Temperature

Transmitter

Rosemount 5300

Level Transmitter

Rosemount 5408

Rosemount 2240S

Rosemount 2230 Display

May 2020

Figure 2-5. Rosemount Tank Gauging System Architecture in a FOUNDATION Fieldbus Network

Reference Manual

00809-0100-2240, Rev EA

12

Overview

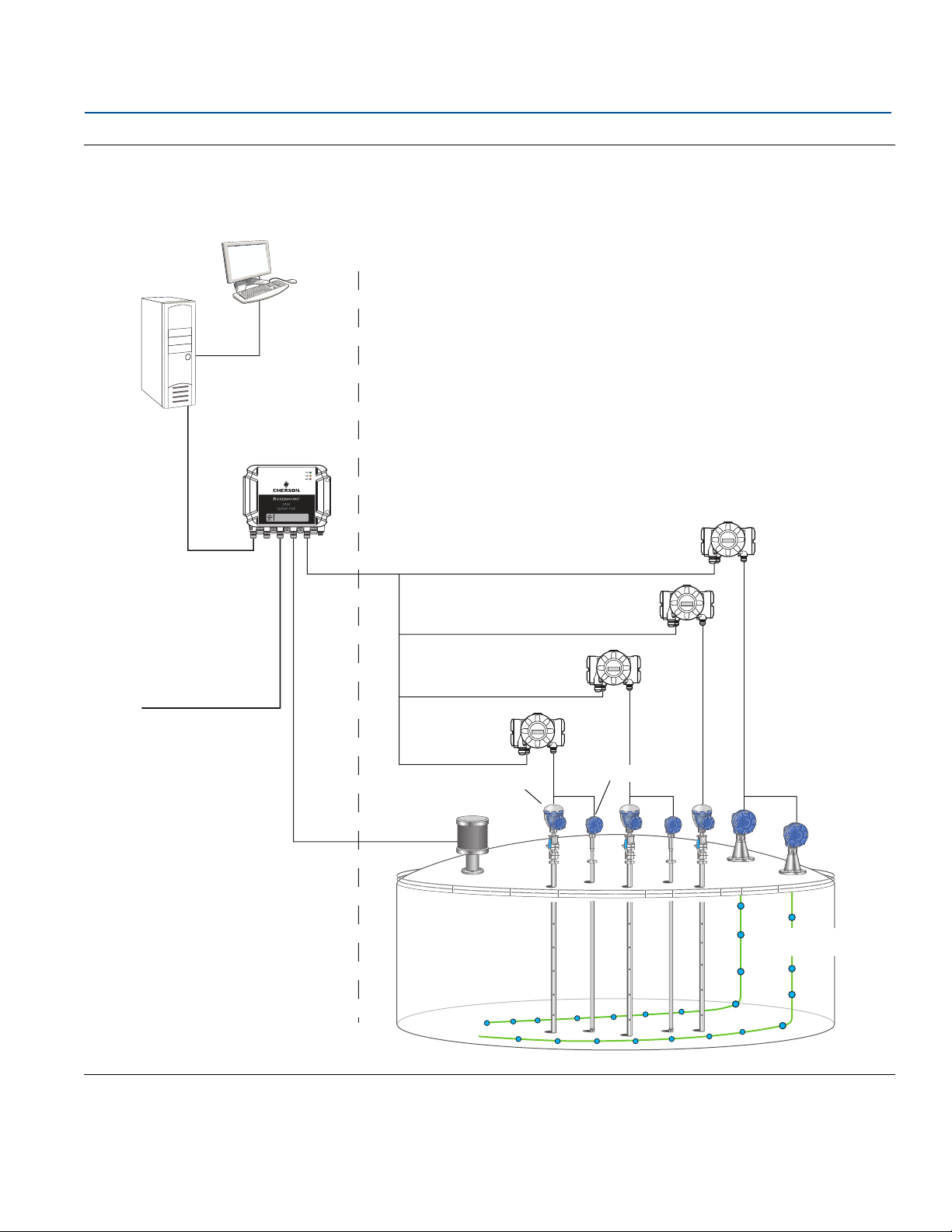

Reference Manual

TRL2 Modbus

Rosemount 2460 System Hub

Rosemount

TankMaster PC

Plant Host Computer

NON-HAZARDOUS AREA HAZARDOUS AREA

Rosemount 2410 Tank Hub

Rosemount 2240S

Temperature Transmitters

Ethernet

Rosemount 614

Temperature Sensor

LTD

Tankbus

Rosemount 5900S

Rosemount 2240S

00809-0100-2240, Rev EA

Figure 2-6. LNG Tank in Rosemount Tank Gauging System

Overview

May 2020

Overview

13

Overview

May 2020

Reference Manual

00809-0100-2240, Rev EA

TankMaster HMI Software

Rosemount TankMaster is a powerful Windows-based Human Machine Interface (HMI) for complete tank

inventory management. It provides configuration, service, set-up, inventory, and custody transfer

functions for Rosemount Tank Gauging systems and other supported instruments.

TankMaster is designed to be used in the Microsoft

measurement data from your Local Area Network (LAN).

The TankMaster WinOpi program lets the operator monitor measured tank data. It includes alarm

handling, batch reports, automatic report handling, historical data sampling as well as inventory

calculations such as Volume, Observed Density and other parameters. A plant host computer can be

connected for further processing of data.

The TankMaster WinSetup program is a graphical user interface for installation, configuration and service

of devices in the Rosemount Tank Gauging system.

®

Windows environment providing easy access to

Rosemount 2460 System Hub

The Rosemount 2460 System Hub is a data concentrator that continuously polls and stores data from

field devices such as radar level gauges and temperature transmitters in a buffer memory. Whenever a

request for data is received, the system hub can immediately send data from the updated buffer memory

for a group of tanks.

Measured and calculated data from one or more tanks is communicated via the Rosemount 2410 Tank

Hub to the system hub buffer memory. Whenever a request is received, the system hub can immediately

send data from a group of tanks to a TankMaster PC, or a host.

The Rosemount 2460 can be used to connect devices from other vendors as well, such as Honeywell

Enraf and Whessoe.

The Rosemount 2460 has eight slots for communication interface boards. These boards can be

individually configured for communication with hosts or field devices. They can be ordered for various

interfaces, for example TRL2, RS485, Enraf BPM, and Whessoe 0-20 mA/RS485 communication. Two

slots can also be configured for RS232 communication.

One of the system hub’s three Ethernet ports is used for Modbus TCP connection to host systems. By

simply connecting the system hub to the existing LAN network, communication over Ethernet is

established.

The system hub can provide redundancy for critical operations, by using two identical devices. The

primary system hub is active and the other one is in passive mode. If the primary unit stops working

properly, the secondary unit is activated and a failure message is sent to TankMaster (or a DCS system).

®

14

Overview

Reference Manual

00809-0100-2240, Rev EA

Rosemount 2410 Tank Hub

The Rosemount 2410 Tank Hub acts as a power supply to the connected field devices in the hazardous

area using the intrinsically safe Tankbus.

The tank hub collects measurement data and status information from field devices on a tank. It has two

external buses for communication with various host systems.

There are two versions of the Rosemount 2410 Tank Hub; one for single tank operation and one for

multiple tanks operation. The multiple tanks version of the Rosemount 2410 supports up to 10 tanks

and 16 devices. With the Rosemount 5300 the Rosemount 2410 supports up to 5 tanks.

The Rosemount 2410 is equipped with two relays which support configuration of up to 10 “virtual” relay

functions allowing you to specify several source signals for each relay.

The Rosemount 2410 supports Intrinsically Safe (IS) and Non-Intrinsically Safe (Non-IS) analog 4-20 mA

inputs/outputs. By connecting an Emerson

output, the tank hub is capable of wireless communication with an Emerson Wireless Gateway in a

WirelessHART

Rosemount 5900S Radar Level Gauge

The Rosemount 5900S Radar Level Gauge is an intelligent instrument for measuring the product level

inside a tank. Different antennas can be used in order to meet the requirements of different applications.

The Rosemount 5900S can measure the level of almost any product, including bitumen, crude oil,

refined products, aggressive chemicals, LPG and LNG.

®

network.

Overview

May 2020

™

Wireless 775 THUM™ Adapter to the IS HART 4-20 mA

The Rosemount 5900S sends microwaves towards the surface of the product in the tank. The level is

calculated based on the echo from the surface. No part of the Rosemount 5900S is in actual contact with

the product in the tank, and the antenna is the only part of the gauge that is exposed to the tank

atmosphere.

The 2-in-1 version of the Rosemount 5900S Radar Level Gauge has two radar modules in the same

transmitter housing allowing two independent level measurements using one antenna and one tank

opening.

Rosemount 5300 Guided Wave Radar

The Rosemount 5300 is a premium 2-wire guided wave radar for level measurements on liquids, to be

used in a wide range of medium accuracy applications under various tank conditions. Rosemount 5300

includes the Rosemount 5301 for liquid level measurements and the Rosemount 5302 for liquid level and

interface measurements.

Rosemount 5408 Radar Level Transmitter

The Rosemount 5408 is a non-contacting level transmitter for accurate and reliable level measurement

on small storage and buffer tanks.

The Rosemount 5408 provides accurate and reliable level measurements for metallic and non-metallic

vessels. It is suitable for almost any liquid and is ideal for challenging applications with agitators, foam,

high temperatures, and pressures. It is also an excellent choice for level measurement in tanks with small

diameter (2- to 4-inch) stiling wells.

The narrow beam makes the Rosemount 5408 the ideal solution for bulk solids in small to medium sized

silos with rapid level changes.

Overview

Rosemount 2240S Multi-Input Temperature Transmitter

The Rosemount 2240S Multi-input Temperature Transmitter can connect up to 16 temperature spot

sensors and an integrated water level sensor.

15

Overview

May 2020

Reference Manual

00809-0100-2240, Rev EA

Rosemount 2230 Graphical Field Display

The Rosemount 2230 Graphical Field Display presents inventory tank gauging data such as level,

temperature, and pressure. The four softkeys allow you to navigate through the different menus to

provide all tank data, directly in the field. The Rosemount 2230 supports up to 10 tanks. Up to three

Rosemount 2230 displays can be used on a single tank.

Rosemount 644 Temperature Transmitter

The Rosemount 644 is used with single spot temperature sensors.

Rosemount 565/566/765 Multiple Spot Temperature Sensors

These multiple spot sensors offer precise measurements for liquid temperature in a wide range of

applications. The Rosemount 565 provides a temperature profile by using up to sixteen Pt-100 spot

elements. The Rosemount 566 is used for cryogenic applications. The Rosemount 765 has an integrated

water level sensor available in open and closed versions for crude oil and lighter fuels, respectively.

Rosemount 614 Cryogenic Spot Temperature Sensor

The Rosemount 614 Cryogenic Spot Temperature Sensor is designed for temperature measurements in

cryogenic and refrigerated full containment storage tanks. It is used with Rosemount 2240S Multi-Input

Temperature Transmitters for applications such as leak detection between inner and outer tank, as well

as skin temperature and/or cool-down monitoring.

The spot elements are wired through a mineral-insulated flexible steel cable up to 300 m (980 ft). This

allows temperature measurements inside a full containment tank during the cool-down procedure and

for leak detection and corner protection in the insulation space.

Rosemount 614 temperature sensors are easily integrated through a conical connection or a junction

box to the Rosemount 2240S Multi-input Temperature Transmitter. Each 2240S Transmitter supports up

to 16 Rosemount 614 temperature sensors.

Rosemount 3051S Pressure Transmitter

The Rosemount 3051S series consists of transmitters and flanges suitable for all kinds of applications,

including crude oil tanks, pressurized tanks and tanks with / without floating roofs.

By using a Rosemount 3051S Pressure Transmitter near the bottom of the tank as a complement to a

Rosemount 5900S Radar Level Gauge, the density of the product can be calculated and presented. One

or more pressure transmitters with different scalings can be used on the same tank to measure vapor

and liquid pressure.

Rosemount 2180 Field Bus Modem

The Rosemount 2180 Field Bus Modem (FBM) is used for connecting a TankMaster PC to the TRL2

communication bus. The Rosemount 2180 is connected to the PC using either the USB or the RS232

interface.

Emerson Wireless Gateway and Emerson Wireless 775 THUM™

Adapter

16

An Emerson Wireless 775 THUM Adapter allows wireless communication between a Rosemount 2410

Tank Hub and an Emerson Wireless Gateway. The gateway is the network manager that provides an

interface between field devices and the TankMaster inventory software or host / DCS systems.

See the Rosemount Tank Gauging System Data Sheet (Document No. 00813-0100-5100) for more

information on the various devices and options.

Overview

Reference Manual

00809-0100-2240, Rev EA

2.4 Getting started

To start up a Rosemount Tank Gauging system do the following:

1. Install the TankMaster software on the control room PC.

2. Prepare the start-up by recording the information that will be needed for configuration of the various

devices as described in the Rosemount Tank Gauging System Configuration Manual

3. Connect the Rosemount 2460 System Hub to the TankMaster PC. The system hub may be connected

via Modbus TCP, a Rosemount 2180 Field Bus Modem, or directly via RS232 or RS485 interface.

4. Connect the Rosemount 2410 Tank Hub to the Rosemount 2460 System Hub.

5. Connect the field devices, such as a Rosemount 5900S Radar Level Gauge and a Rosemount 2240S

Multi-input Temperature Transmitter, to the Rosemount 2410 Tank Hub via the Tankbus.

6. Configure the Rosemount 2460 System Hub (if included in the system) by using the TankMaster

WinSetup configuration software.

7. Configure the Rosemount 2410 Tank Hub by using the TankMaster WinSetup configuration software.

8. Configure field devices, such as the Rosemount 5900S and the Rosemount 2240S, by using the

TankMaster WinSetup configuration software.

Overview

May 2020

.

To start up Rosemount Tank Gauging devices in a F

1. Prepare the start-up by recording the information that will be needed for configuration of the various

field devices as described in the Rosemount Tank Gauging System Configuration Manual

2. Connect the field devices, such as the Rosemount 5900S Radar Level Gauge and Rosemount 2240S

Multi-input Temperature Transmitter, to the F

3. Configure the field devices by using the AMS Device Manager.

See see the Rosemount Tank Gauging System Configuration Manual

configure the various Rosemount Tank Gauging devices.

OUNDATION fieldbus system:

.

OUNDATION fieldbus network.

for more information on how to

Overview

17

Overview

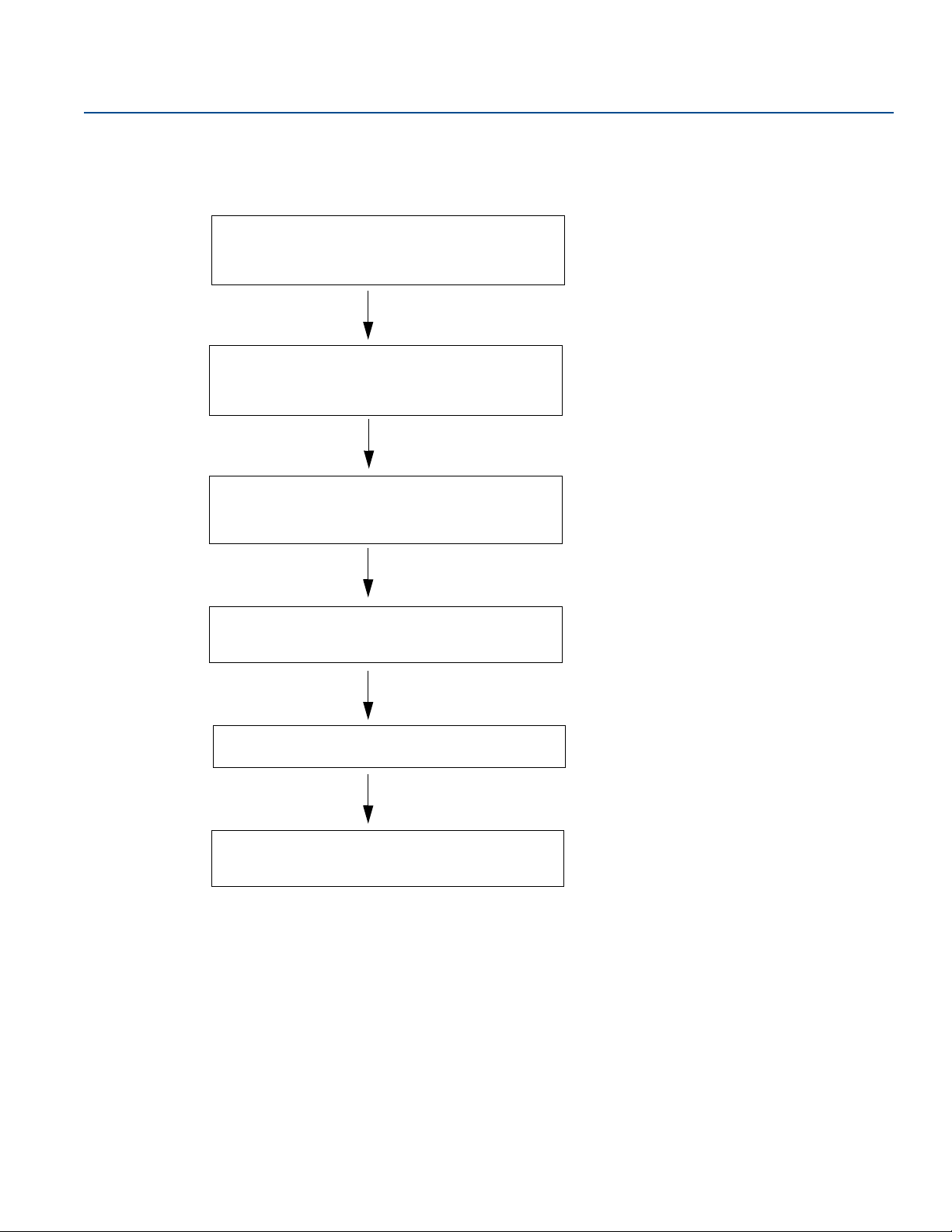

2. Review mounting considerations for the 2240S

(“Installation considerations” on page 30).

5. Power up the 2240S transmitter.

4. Wire the 2240S transmitter

(“Electrical installation” on page 37).

3. Install the 2240S transmitter

(“Mechanical installation” on page 31).

1. Install the temperature sensor/WLS

(Section 3: Sensor Installation).

6. Configure the 2240S transmitter.

(Section 5: Configuration/Operation).

May 2020

2.5 Installation procedure

Follow these steps for proper installation of the Rosemount 2240S:

Reference Manual

00809-0100-2240, Rev EA

18

Overview

Loading...

Loading...