Page 1

Reference Manual

00809-0100-4160, Rev AD

January 2013

Rosemount 2160 Wireless

Vibrating Fork Liquid Level Switch

www.rosemount.com

Page 2

Page 3

Reference Manual

NOTICE

00809-0100-4160, Rev AD

January 2013

Rosemount 2160

Rosemount 2160 Wireless

Vibrating Fork Liquid Level Switch

Rosemount 2160 Hardware Revision 2

®

Device Revision 2

HART

Field Communicator Field Device Dev v1, DD v2

Read this manual before working with the product. For personal and system safety, and for

optimum product performance, make sure you thoroughly understand the contents before

installing, using, or maintaining this product.

For technical assistance, contacts are listed below:

Customer Central

Technical support, quoting, and order-related questions.

United States: 1 800 999 9307 (7:00 am to 7:00 pm CST)

Asia Pacific: 65 777 8211

Europe/ Middle East/ Africa: 49 (8153) 9390

North American Response Center

Equipment service needs.

1 800 654 7768 (24 hours—includes Canada)

Outside of these areas, contact your local Emerson Process Management representative.

The products described in this document are NOT designed for nuclear-qualified

applications.

Using non-nuclear qualified products in applications that require nuclear-qualified hardware

or products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact an Emerson Process

Management Sales Representative.

Replacement equipment or spare parts not approved by Emerson for use as spare

parts could reduce the capabilities of the 2160, and may render the instrument

dangerous.

• Use spare parts supplied or sold by Emerson

www.rosemount.com

Page 4

Rosemount 2160

NOTICE

Reference Manual

00809-0100-4160, Rev AD

January 2013

Failure to follow these installation guidelines could result in death or serious injury

• The Rosemount 2160 is a wireless liquid level switch. It must be installed, connected,

commissioned, operated, and maintained by suitably qualified personnel only , observing

any national and local requirements that may apply

• Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment

Explosions could result in death or serious injury

• Installation of the 2160 in a hazardous environment must be in accordance with the

appropriate local, national, and international standards, codes, and practices.

Please review the approvals section of the 2160 Reference Manual for any restrictions

associated with an installation

• Before connecting a Field Communicator in an explosive atmosphere, ensure the

installation is in accordance with intrinsically safe or non-incendive field wiring practices

• Verify that the operating atmosphere of the level switch is consistent with the

appropriate hazardous locations certifications

External Surface may be hot

• Care must be taken to avoid possible burns

Process leaks could result in death or serious injury

• Install and tighten process connectors before applying pressure

• Do not attempt to loosen or remove process connectors while the 2160 is in service

Electrical shock could cause death or serious injury

• If the liquid level switch is installed in a high voltage environment and a fault condition or

installation error occurs, high voltage may be present on leads and terminals

• Use extreme caution when making contact with the leads and terminals

• Make sure that power to the 2160 is off while making connections

Operation is subject to the following two conditions: (1) This device may not cause

harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

Shipping considerations for wireless products:

The unit was shipped to you without the Black Power Module installed. Please remove the

power module prior to shipping.

Each power module contains two “C” size primary lithium batteries. These batteries are

regulated in transportation by the U. S. Department of Transportation, and are also covered

by IATA (International Air Transport Association), ICAO (International Civil Aviation

Organization), and ARD (European Ground Transportation of Dangerous Goods). It is the

responsibility of the shipper to ensure compliance with these or any other local requirements.

Please consult current regulations and requirements before shipping.

The power module with the wireless unit contains two “C” size primary lithium/thionyl chloride

batteries. Each battery contains approximately 2.5 grams of lithium, for a total of 5 grams in each

pack. Under normal conditions, the battery materials are self-contained and are not reactive as

long as the batteries and the pack integrity are maintained. Care should be taken to prevent

thermal, electrical or mechanical damage. Contacts should be protected to prevent premature

discharge.

Battery hazards remain when cells are discharged.

Batteries should be stored in a clean and dry area. For maximum battery life, storage temperature

should not exceed 86 °F (30 °C).

II

Page 5

Reference Manual

00809-0100-4160, Rev AD

January 2013

Rosemount 2160

Table Of Contents

SECTION 1

OVERVIEW

SECTION 2

CONFIGURATION

Safety Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Using This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Definitions And Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Models Covered. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

About the 2160 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Switch Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Measurement Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Short Fork Technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Special Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Rosemount 2160 Application Examples . . . . . . . . . . . . . . . . . . . . . . . .1-5

Extended Fork Supports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Switchpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Service Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

Product Recycling/Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

Safety Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Required Bench Top Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Squawk Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

AMS Wireless Configurator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Field Communicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Field Communicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Menu Tree. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Device Network Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Join to Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Configure Update Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Operation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Remove Black Power Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Review Configuration Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Review Device Identification Information . . . . . . . . . . . . . . . . . . . . . . . 2-8

Review Radio Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Check Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Basic Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Temperature Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Operation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Sensor Output Delay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Media Density . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Write Protect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Data Logging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

LCD Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

LCD Display Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Detailed Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Configure Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Sensor Stabilization Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

Measurement Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

Allowable Change In Dry Fork Frequency. . . . . . . . . . . . . . . . . . . . . .2-13

III

Page 6

Rosemount 2160

Reference Manual

00809-0100-4160, Rev AD

January 2013

Sensor Fault Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Power Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Power Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Diagnostics and Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

Load User Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

Join Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

Communication Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Join Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

Available Neighbors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

Advertisements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

Join Attempts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

Sensor Frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Temperature Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Uncompensated Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-18

Sensor State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-18

Dry Fork Frequency / Switch Points . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Sensor State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-19

Counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-20

Timers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Dry Fork Frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-21

Sensor Frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Calibrate Dry Fork. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Sensor Calibration Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-22

Calibration Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-22

Reset Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-23

Sensor Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Fork Frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Advanced Functions for HART Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Saving, Recalling, and Cloning Configuration Data . . . . . . . . . . . . . .2-24

SECTION 3

INSTALLATION

IV

Safety Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

General Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Wireless Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Environmental Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Installation Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Installation Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Battery Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Installing the LCD Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Correct Fork Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Tightening the 2160 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Insulation (2160***E Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Page 7

Reference Manual

00809-0100-4160, Rev AD

January 2013

Rosemount 2160

SECTION 4

COMMISSIONING

SECTION 5

OPERATION AND

MAINTENANCE

APPENDIX A

SPECIFICATIONS AND

REFERENCE DATA

Safety Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Verify Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Local Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Field Communicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Smart Wireless Gateway. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

AMS Wireless Configurator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

How to Use Squawk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Safety Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

LCD Screen Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Startup Screen Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Diagnostic Button Screen Sequence . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Network Diagnostic Status Screens . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Device Diagnostic Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

Power Module Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Physical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

Functional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

Dimensional Drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-6

2160 Thread Mounting (Standard Length) . . . . . . . . . . . . . . . . . . . . . .A-6

2160 Thread Mounting (Extended Length) . . . . . . . . . . . . . . . . . . . . . .A-7

2160 Flange Mounting (Standard Length) . . . . . . . . . . . . . . . . . . . . . .A-8

2160 Flange Mounting (Extended Length) . . . . . . . . . . . . . . . . . . . . . .A-9

2160 Hygienic Fitting (Standard Length). . . . . . . . . . . . . . . . . . . . . . .A-10

2160 Hygienic Fitting (Extended Length) . . . . . . . . . . . . . . . . . . . . . .A-12

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-13

Spare Parts and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-15

APPENDIX B PRODUCT

CERTIFICATIONS

European Directive Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

Telecommunication Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

FCC and IC Approvals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

Canadian Registration Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

Hazardous Locations Certifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

American and Canadian Approvals. . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

European Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

Rest Of The World Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-3

V

Page 8

Rosemount 2160

Reference Manual

00809-0100-4160, Rev AD

January 2013

VI

Page 9

Reference Manual

00809-0100-4160, Rev AD

January 2013

Rosemount 2160

Section 1 Overview

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-1

Using This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-2

Definitions And Abbreviations . . . . . . . . . . . . . . . . . . . . . page 1-2

Models Covered . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-2

About the 2160 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-3

Service Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-9

Product Recycling/Disposal . . . . . . . . . . . . . . . . . . . . . . .page 1-9

SAFETY MESSAGES Procedures and instructions in this manual may require special precautions to

ensure the safety of the personnel performing the operations. Infor mation that

raises potential safety issues is indicated by a caution symbol ( ). The

external hot surface symbol ( ) is used when a surface is hot and care must

be taken to avoid possible burns. If there is a risk of an electrical shock the

( ) symbol is used. Refer to the safety messages listed at th e be gin n ing of

each section before performing an operation preceded by this symbol.

Warnings

Failure to follow these installation guidelines could result in death or serious injury

• The Rosemount 2160 is a wireless liquid level switch. It must be installed, connected,

commissioned, operated, and maintained by suitably qualified personnel only , observing

any national and local requirements that may apply

• Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment

Explosions could result in death or serious injury

• Installation of the 2160 in a hazardous environment must be in accordance with the

appropriate local, national, and international standards, codes, and practices.

Please review the approvals section of the 2160 Reference Manual for any restrictions

associated with an installation

• Before connecting a Field Communicator in an explosive atmosphere, ensure the

installation is in accordance with intrinsically safe or non-incendive field wiring practices

• Verify that the operating atmosphere of the level switch is consistent with the

appropriate hazardous locations certifications

External Surface may be hot

• Care must be taken to avoid possible burns

Process leaks could result in death or serious injury

• Install and tighten process connectors before applying pressure

• Do not attempt to loosen or remove process connectors while the 2160 is in service

Electrical shock could cause death or serious injury

• If the liquid level switch is installed in a high voltage environment and a fault condition or

installation error occurs, high voltage may be present on leads and terminals

• Use extreme caution when making contact with the leads and terminals

• Make sure that power to the 2160 is off while making connections

www.rosemount.com

Page 10

Reference Manual

00809-0100-4160, Rev AD

Rosemount 2160

January 2013

USING THIS MANUAL This manual provides information on installing, operating, and maintaining the

Rosemount 2160 Wireless liquid level switch.

• Section 2: Configuration provides instruction on commissioning and

operating the Rosemount 2160. Information on software functions,

configuration parameters, and online variables is also included.

• Section 3: Installation contains mechanical and electrical installation

instructions.

• Section 4: Commissioning contains techniques for properly

commissioning the device.

• Section 5: Operation and Maintenance contains operation and

maintenance techniques.

• Appendix A: Specifications and Reference Data supplies reference

and specification data, as well as ordering information.

• Appendix B: Product Certifications contains approval information.

DEFINITIONS AND ABBREVIATIONS

The following definitions are used in this manual:

Dry The 2160 fork (sensor) is submerged to a depth of less than 0.5 in. (13 mm)

Wet The 2160 fork (sensor) is submerged to a depth of greater than 0.5 in. (13 mm)

Fault The fork frequency is outside the normal frequency band

Normal

Mode

Enhanced

Mode

The operating mode in which the 2160 considers a 0 Hz fork frequency to

represent a Wet condition (and not a Fault)

The operating mode in which the 2160 considers a 0 Hz fork frequency to

represent a fault condition

The following abbreviations are used in this manual:

DD Device Description

IS Intrinsically Safe

PV Primary Value or Process Value

SV Secondary Value

TV Tertiary Value (Third Value)

QV Quaternary Value (Fourth Value)

MODELS COVERED The following models of the Rosemount 2160 Wireless liquid level switch are

covered in this manual:

• The standard temperature 2160***S

• The extreme temperature 2160***E

1-2

Page 11

Reference Manual

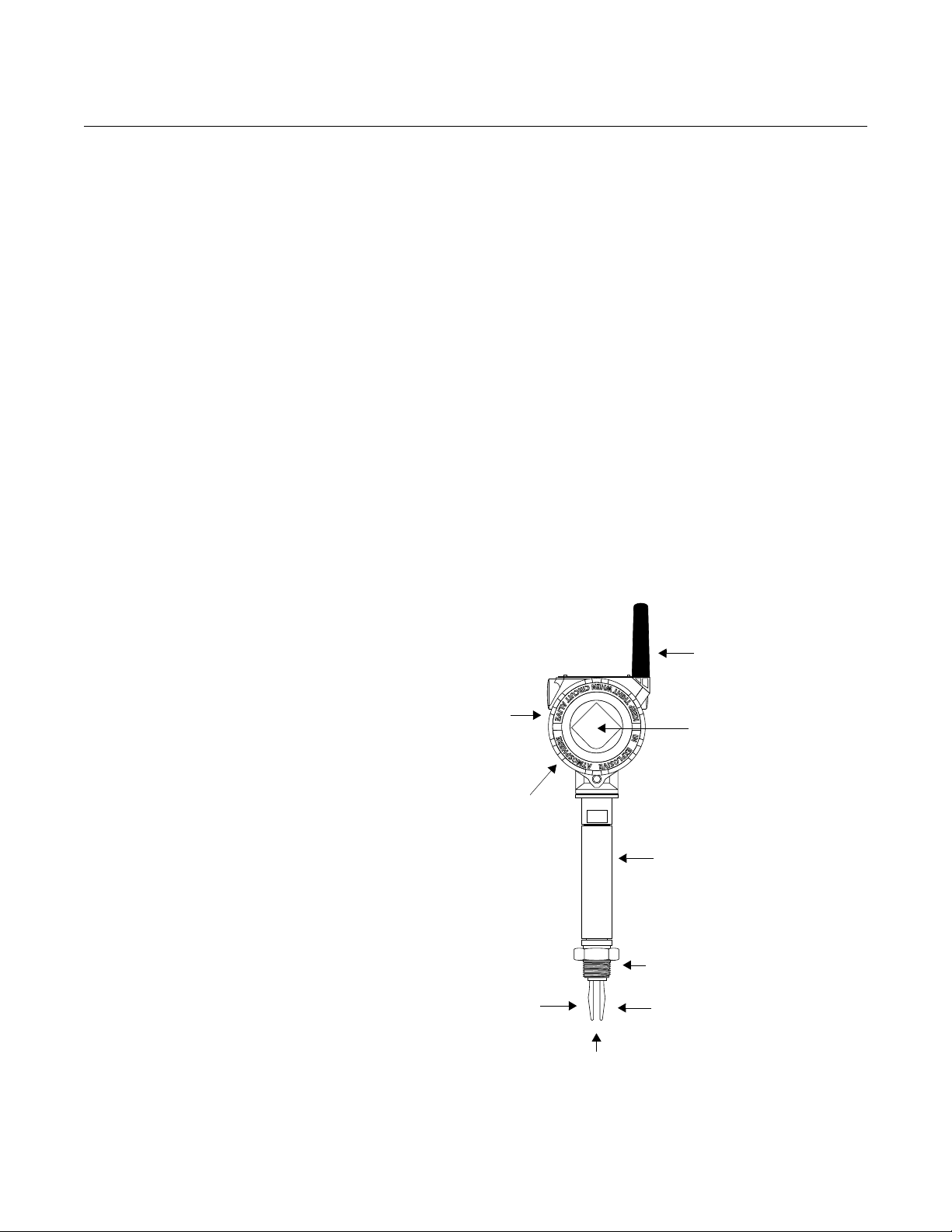

Wetted Materials in 316/316L SST (1.4401/1.4404), or

Alloy C (UNS N10002) and Alloy C-276 (UNS N10276)

NEMA Type 4X (IP66)

Housing in Aluminum.

Removable Covers on

Both Sides

Short Fork Length

with Extensions

up to 118 in. (3 m)

Threaded,

Flanged, or

Hygienic

Connections

Thermal Tube

(2160***E Only)

Fast Drip Design

ATEX, FM, CSA, IECEx, and

NEPSI Intrinsically Safe

Antenna

Optional LCD

Display

00809-0100-4160, Rev AD

January 2013

Rosemount 2160

ABOUT THE 2160

Switch Overview The Rosemount 2160 Wireless is a wireless liquid point level switch.

Based on vibrating short fork technology, the 2160 is suitable for virtually all

liquid applications:

• Vir tually unaf fected by flow, bubbles, turbulence, foam, vibration, solids

content, coating, properties of the liquid, and product variations

• Operation in extreme temperatures of –94 to 500 °F (–70 to 260 °C)

• No need for calibration and requires minimum installation procedures

• No moving p arts or crevices means virtually no maintenance

• Electronic self-checking and condition monitoring

• Programmable switching delay for turbulent or splashing applications

• Short fork length with extensions up to 118 in. (3 m)

• “Fast Drip” fork design gives quick response time

• General area and Intrinsically Safe options

This combination of features makes the 2160 an ideal choice for a wide

variety of challenging applications in the chemical, power generation, and oil

and gas industries.

Figure 1-1. Features of the 2160

1-3

Page 12

Reference Manual

00809-0100-4160, Rev AD

Rosemount 2160

January 2013

Measurement Principle The Rosemount 2160 is designed using the principle of a tuning fork.

A piezo-electric crystal oscillates the forks at their natural frequency . Changes

to this frequency are continuously monitored.

The frequency of the vibrating fork sensor changes depending on the medium

in which it is immersed. The denser the liquid, the lower the frequency.

When used as a low level alarm, the liquid in the tank or pipe drains down

past the fork, causing a change of natural frequency that is detected by the

electronics and switches the output state to a Dry condition.

When the 2160 switch is used as a high level alarm, the liquid rises in the

tank or pipe making contact with the fork, causing the output state to switch to

a Wet condition.

The output state, along with other parameters , are regularly transmitted over

a secure wireless connection to a Smart Wireless Gateway.

Short Fork Technology The natural frequency (~1400Hz) of the fork avoids interference from plant

vibration that may cause false switching. This allows for minimum intrusion

into the tank or pipe through the use of a short fork.

Using Short Fork Technology, the Rosemount 2160 can be used in almost all

liquid applications. Extensive research has maximized the operational

effectiveness of the fork design, making it suitable for most liquids including

coating liquids, aerated liquids, and slurries.

Special Features Instrument Health Monitor and Continuous Self-Check

The 2160 continuously performs instrument health diagnostics to self-check

the condition of the fork and sensor. These diagnostics can detect damage to

the forks including corrosion, internal or external damage to the forks, and

breakages to the internal wiring.

See “Operation Mode” on page 2-9 for further information.

Fork Design

The “fast drip” fork design draws liquid away from the fork tips, and together

with a short switching delay , allows the 2160 to react quickly and with greater

sensitivity to density variations.

Battery Powered

The 2160 is powered by an integral battery. The fork sensor requires very little

power and the battery life remains long even with fast update rates.

See “Battery Installation” on page 3-6 for further information.

Adjustable Time Delay

There is also a user-selectable time de lay to virtually eliminate the risk of false

switching in turbulent or splashing applications.

See “Sensor Output Delay” on page 2-10 for further information.

1-4

Page 13

Reference Manual

00809-0100-4160, Rev AD

January 2013

Rosemount 2160

Rosemount 2160

Application Examples

For most liquids, including coating, aerated liquids and slurries, the fun ction is

virtually unaffected by flow, turbulence, bubbles, foam, vibration, solid

particles, build-up, or properties of the liquid.

See Figure 1-5 on page 1-8 for application examples.

The 2160 switch can be used in hazardous (IS) or non-hazardous (safe)

areas but supports higher process temperatures up to 500 °F (260 °C).

The switch can be mounted in almost any position in an open or closed tank

or pipe. There is a wide range of threaded, flanged, or hygienic connections.

Application Considerations:

• Ensure the process is operating within the instrument op er a ting

temperature and pressure ranges (see “Specifications” on page A-1)

• Ensure the liquid viscosity is within the recommended viscosity range

(see “Specifications” on page A-1)

• Check that the liquid density is higher than 31.2 lb/ft

(see “Specifications” on page A-1)

• Check for risk of build-up on the forks

Avoid situations where drying and coating products may create

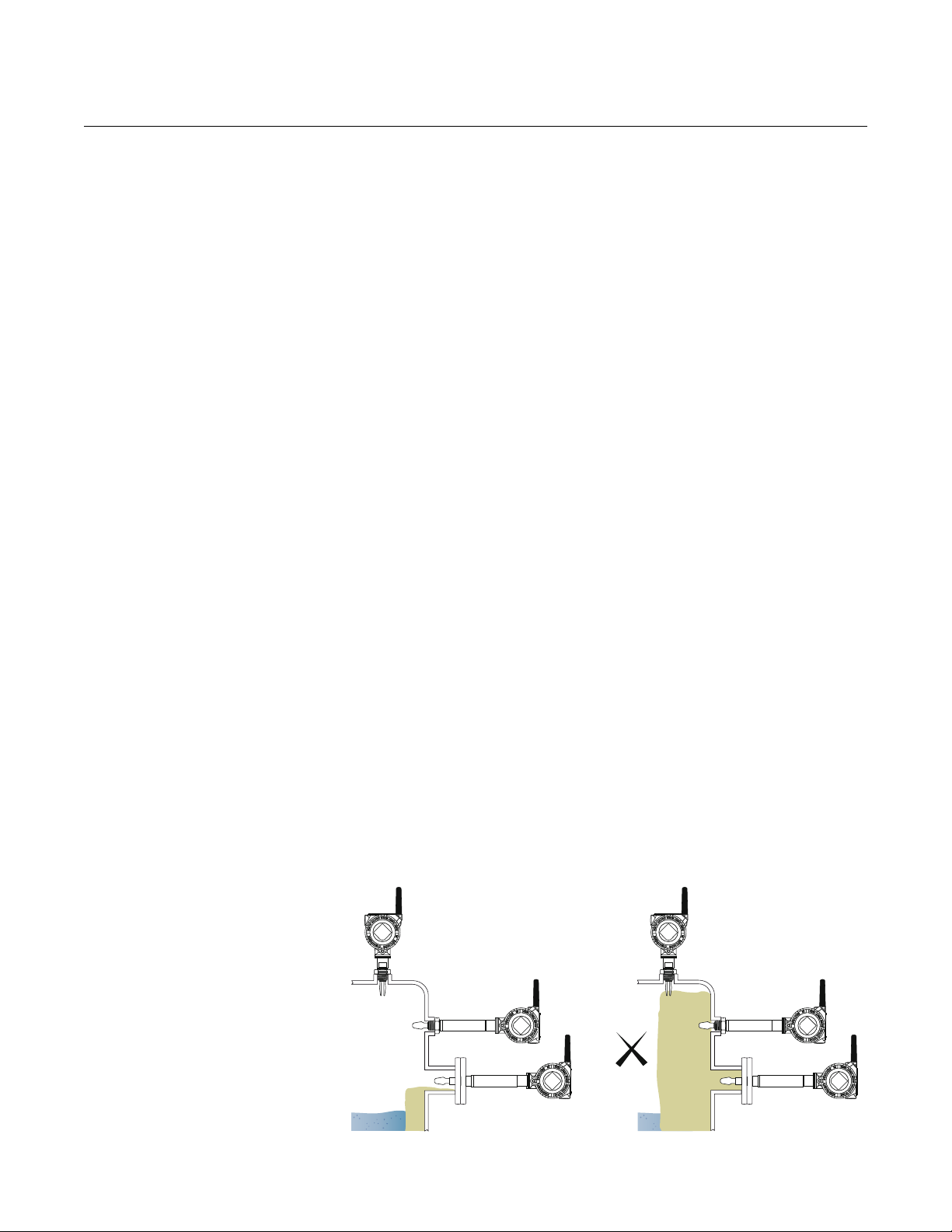

excessive build-up (see Figure 1-2)

• Ensure there is no risk of ‘bridging’ the forks

Examples of products that can create bridgin g of forks are dense p aper

slurries and bitumen

• Check the solids content in the liquid

3

(500 kg/m3)

Figure 1-2.

Avoid Product Build-up

As a guideline, the maximum solid particle diameter in the liquid is

0.2 in. (5 mm). Extra consideration is needed when dealing with

particles bigger than 0.2 in. (5 mm). Consult the factory for advice.

• Problems may occur if product coats and dries causing caking.

• In almost all cases, the 2160 is insensitive to foams (i.e. does not see

the foam).

However in rare occasions, some very dense foams may be seen as

liquid; a known example of this is found in ice-cream and orange juice

manufacturing.

OK

1-5

Page 14

Rosemount 2160

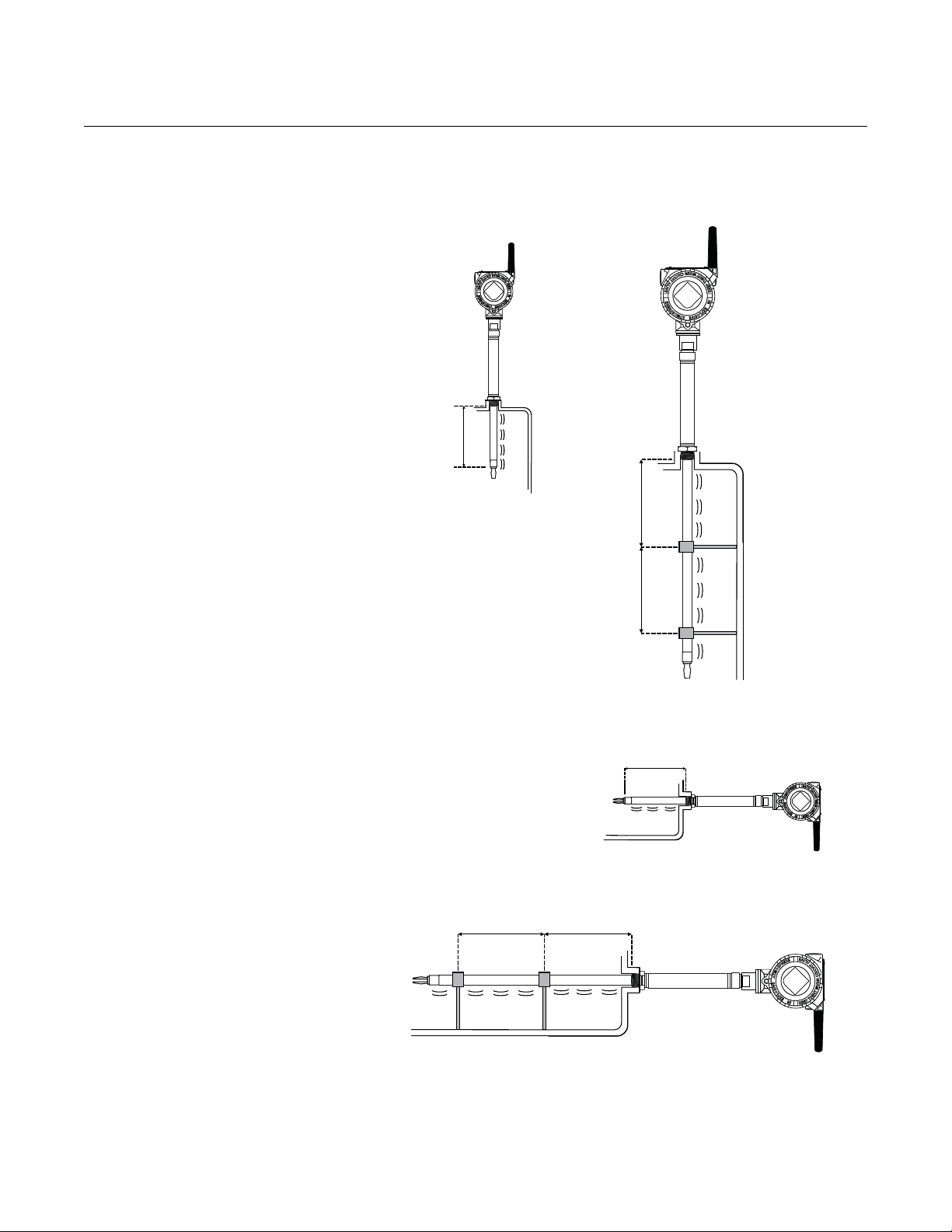

3.28 ft.

(1.0 m)

3.28 ft.

(1.0 m)

3.28 ft.

(1.0 m)

3.28 ft.

(1.0 m)

Maximum

3.28 ft.

(1.0 m)

Maximum

3.28 ft.

(1.0 m)

Extended Fork Supports

Figure 1-3. Supports Needed for

Extended Forks

OK

Reference Manual

00809-0100-4160, Rev AD

January 2013

OK

OK

OK

1-6

Page 15

Reference Manual

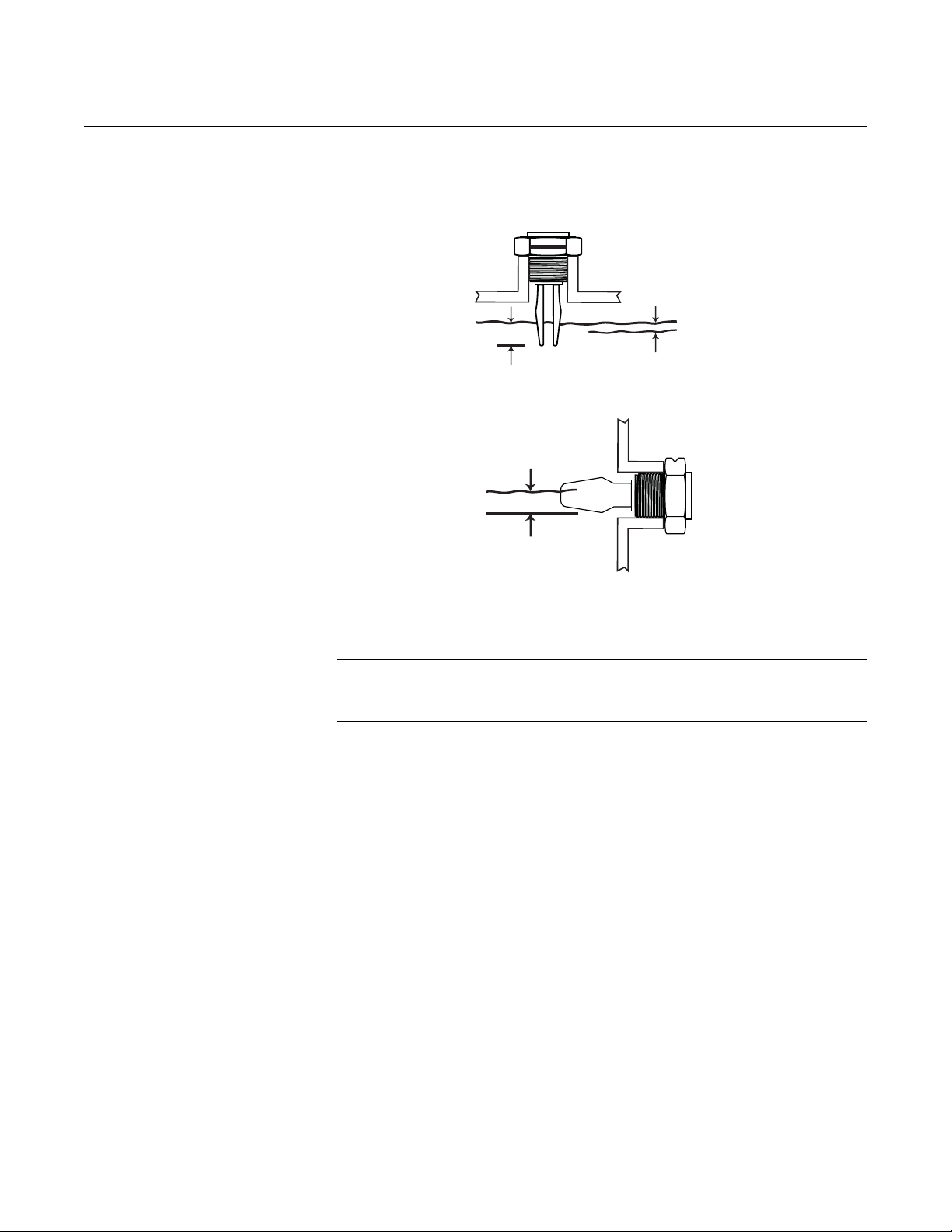

SP = Switchpoint (H20)

HY = Switching Hysteresis

±0.039 in.

(1 mm)

±0.5 in.

(13 mm)

±0.5 in.

(13 mm)

00809-0100-4160, Rev AD

January 2013

Switchpoint

Figure 1-4. Switchpoint

Rosemount 2160

SP

HY

SP

NOTE:

A lower density media will give a switchpoint closer to the connection.

A higher density media will give a switchpoint closer to the fork tip.

1-7

Page 16

Rosemount 2160

Figure 1-5. Rosemount 2160

Application Examples

Overfill Protection

Spillage caused by overfilling can be hazardous to people and the environment, resulting in

lost product and potentially high clean up costs.

High and Low Level Alarm

Maximum and minimum level detection in tanks containing different types of liquids are ideal

applications. The Rosemount 2160 is robust and operates continuously across the

temperature range of –94 to 500 °F (–70 to 260 °C) and operating p ressures of up to 1450 psig

(100 barg), making it perfect for use as a high or low level alarm. It is common practice to have

an independent high level alarm switch as a backup to an installed level device in case of

primary failure.

Reference Manual

00809-0100-4160, Rev AD

January 2013

Pump Control (Limit Detection)

Batch processing tanks often contain stirrers and agitators to ensure mixing and product

‘fluidity’. The standard user-selectable time delay, from 0 to 3600 seconds, virtually eliminates

the risk of false switching from splashing.

Pump Protection or Empty Pipe Detection

With the fork projecting only 2 in. (50 mm) (dependant on connection type), the 2160 can be

installed in small diameter pipes. Short forks mean minimum intrusion on the wetside and

allow for simple, low cost installation at any angle into pipes or tanks. The 2160 is ideal for

reliable pump control and can be used to protect against pumps running dry.

Extreme Temperature Applications

The 2160***E is designed for extreme temperatures and is suitable for continuous operation

within the temperature range of –94 to 500 °F (–70 to 260 °C).

Hygienic Applications

With the highly polished forks option providing a surface finish (Ra) better than 0.4 µm, the

2160 meets the most stringent hygienic requirements used in food and beverage, and

pharmaceutical applications.

1-8

Page 17

Reference Manual

NOTICE

00809-0100-4160, Rev AD

January 2013

Rosemount 2160

SERVICE SUPPORT To expedite the return process outside of North America, contact the nearest

Emerson Process Management representative.

Within the United States, call the Emerson Process Management Response

Center toll-free number 1 800 654 7768. This center, available 24 hours a day,

will assist you with any needed information or materials.

The center will ask for product model and serial numbers, and will provide a

Return Material Authorization (RMA) number. The center will also ask for the

process material to which the product was last exposed.

Individuals who handle products exposed to a hazardous substance can avoid injury if they

are informed of, and understand, the hazard. If the product being returned was exposed to a

hazardous substance as defined by OSHA, a copy of the required Material Safety Data

Sheet (MSDS) for each hazardous substance identified must be included with the returned

goods.

PRODUCT RECYCLING/DISPOSAL

Shipping considerations for wireless products (lithium batteries):

The unit was shipped to you without the power module installed. Please remove the power

module prior to shipping.

Primary lithium batteries (charged or discharged) are regulated in transportation by the U. S.

Department of Transportation. They are also covered by IATA (International Air Transport

Association), ICAO (International Civil Aviation Organization), and ARD (European Ground

Transportation of Dangerous Goods). It is the responsibility of the shipper to ensure

compliance with these or any other local requirements. Please consult current regulations

and requirements before shipping.

Recycling of equipment and packaging should be taken into consideration

and disposed of in accordance with local and national legislation/regulations.

1-9

Page 18

Rosemount 2160

Reference Manual

00809-0100-4160, Rev AD

January 2013

1-10

Page 19

Reference Manual

00809-0100-4160, Rev AD

January 2013

Section 2 Configuration

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 2-2

Required Bench Top Configuration . . . . . . . . . . . . . . . . .page 2-2

Device Network Configuration . . . . . . . . . . . . . . . . . . . . . page 2-7

Field Communicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-4

Review Configuration Data . . . . . . . . . . . . . . . . . . . . . . . . page 2-8

Check Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-9

Basic Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 2-9

LCD Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 2-11

Detailed Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 2-12

Diagnostics and Service . . . . . . . . . . . . . . . . . . . . . . . . . .page 2-15

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-21

Simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-23

Advanced Functions for HART Protocol . . . . . . . . . . . . .page 2-24

Rosemount 2160

SAFETY MESSAGES Procedures and instructions in this section may require special precautions to

ensure the safety of the personnel performing the operations. Infor mation that

raises potential safety issues is indicated by a warning symbol ( ). Refer to

the following safety messages before performing an operation preceded by

this symbol.

Warnings

Failure to follow these installation guidelines could result in death or serious injury

• The Rosemount 2160 is a wireless liquid level switch. It must be installed, connected,

commissioned, operated, and maintained by suitably qualified personnel only,

observing any national and local requirements that may apply

• Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment

Explosions could result in death or serious injury

• Installation of the 2160 in a hazardous environment must be in accordance with the

appropriate local, national, and international standards, codes, and practices.

Please review the approvals section of the 2160 Reference Manual for any restrictions

associated with an installation

• Before connecting a Field Communicator in an explosive atmosphere, ensure the

installation is in accordance with intrinsically safe or non-incendive field wiring

practices

• Verify that the operating atmosphere of the level switch is consistent with the

appropriate hazardous locations certifications

External Surface may be hot

• Care must be taken to avoid possible burns

Process leaks could result in death or serious injury

• Install and tighten process connectors before applying pressure

• Do not attempt to loosen or remove process connectors while the 2160 is in service

www.rosemount.com

Page 20

Reference Manual

00809-0100-4160, Rev AD

Rosemount 2160

Electrical shock could cause death or serious injury

• If the liquid level switch is installed in a high voltage environment and a fault condition

or installation error occurs, high voltage may be present on leads and terminals

• Use extreme caution when making contact with the leads and terminals

• Make sure that power to the 2160 is off while making connections

January 2013

OVERVIEW This section contains information on commissioning and verification that

should be performed prior to installation.

Field Communicator and AMS

functions. For convenience, Field Communicator fast key sequences are

labeled “Fast Keys” for each software function below the appropriate

headings.

Example Software Function

Fast Keys

1, 2, 3, etc.

®

instructions are given to perform configuration

REQUIRED BENCH TOP CONFIGURATION

Bench top configuration requires a Field Communicator, AMS, or any

Wireless Communicator.

Bench top configuration consists of testing the transmitter and verifying

transmitter configuration data. The 2160 can be configured before or after

installation (field hook-up). However, configuring the 2160 on the bench

before installation ensures that all network settings are working correctly.

When using a Field Communicator , any configuration ch anges made must be

sent to the 2160 by using the “Send” key (F2). AMS configuration changes are

implemented when the “Apply” button is clicked.

Squawk Feature The 2160 feature called “Squawk” can be used to visually identify an

individual 2160 in a wireless network. This can be a useful check during the

configuration and commissioning of multiple 2160 transmitters.

To find out more about this feature, see “How to Use Squawk” on page 4-4.

AMS Wireless

Configurator

AMS is capable of connecting to devices either directly using a HART®

modem or wirelessly via the Smart Wireless Gateway.

When configuring on the bench with a HART modem, double click the device

icon, then choose the Configure/Setup tab (or right click and select

Configure/Setup).

When configuring with the Gateway, dou ble click the device icon and then

choose the Configure/Setup tab (or right click and select Configure/Setup).

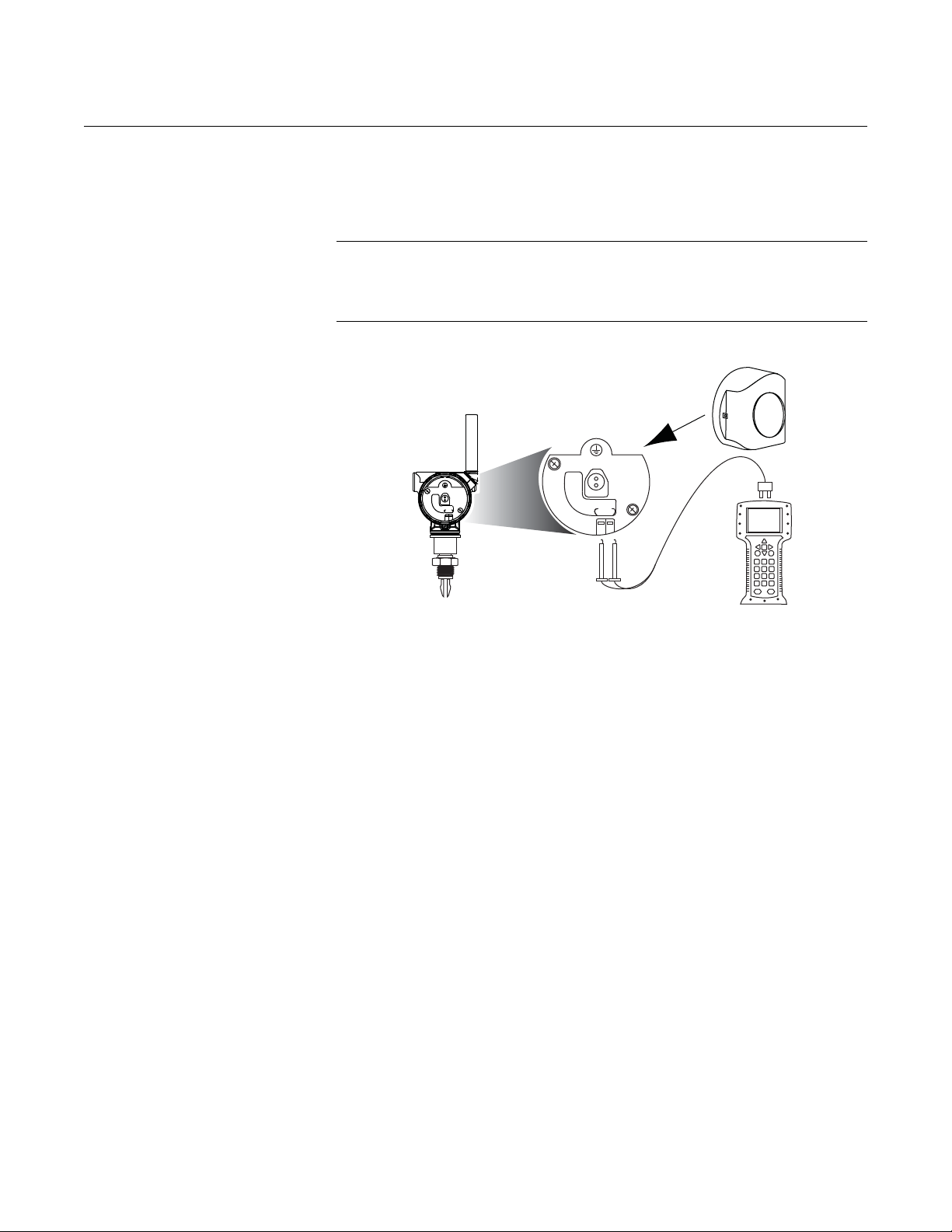

Field Communicator Remove the power mod ule-side housing cover to expose the terminal block

and HART communication terminals, then connect the Black Power Module to

power the unit for configuration. Connect the Field Communicator leads to the

terminals labeled “COMM” on the terminal block. See Figure 2-1 on page 2-3.

Turn on the Field Communicator by pre ssing the ON/OFF key.

2-2

Page 21

Reference Manual

COMM

P/N 00753-9200-0010

00809-0100-4160, Rev AD

January 2013

Figure 2-1.

Field Communicator Connection

Rosemount 2160

The Field Communicator will search for a HART-compatible device and

indicate when the connection is made. If the Field Communicator fails to

connect, it indicates that no device was found and you should re-check the

connections.

NOTE

Before connecting a Field Communicator in an explosive atmosphere, make

sure the instruments are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

P/N 00753-9200-0010

COMM

P/N 00753-9200-0010

COMM

A 2160 DD (Device Description) is required for HART communication.

To obtain the latest DD, visit the Emerson Process Management Easy

Upgrade Site at:

http://www2.emersonprocess.com/en-US/documentation/deviceinstallkits

2-3

Page 22

Rosemount 2160

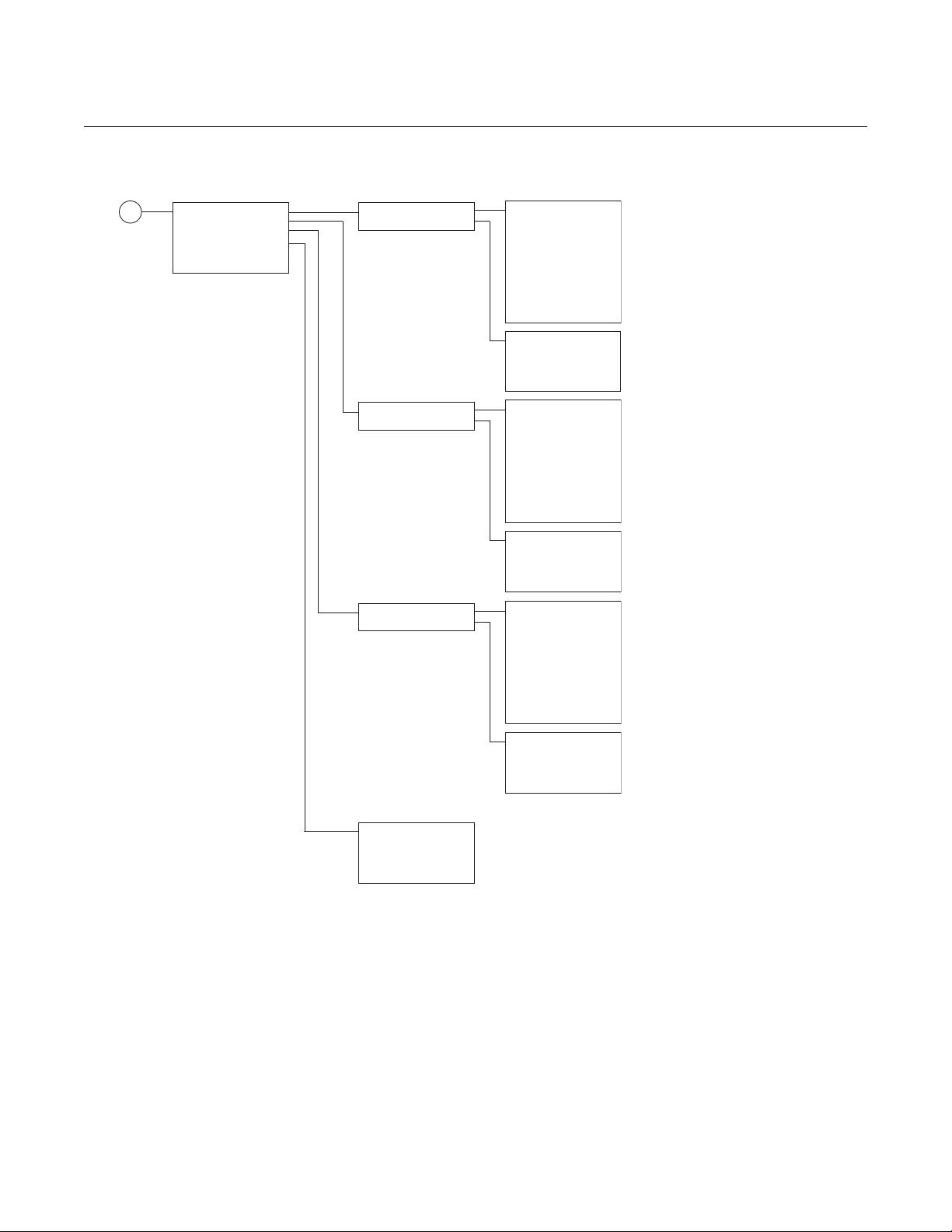

FIELD COMMUNICATOR

Field Communicator Menu Tree

Reference Manual

00809-0100-4160, Rev AD

January 2013

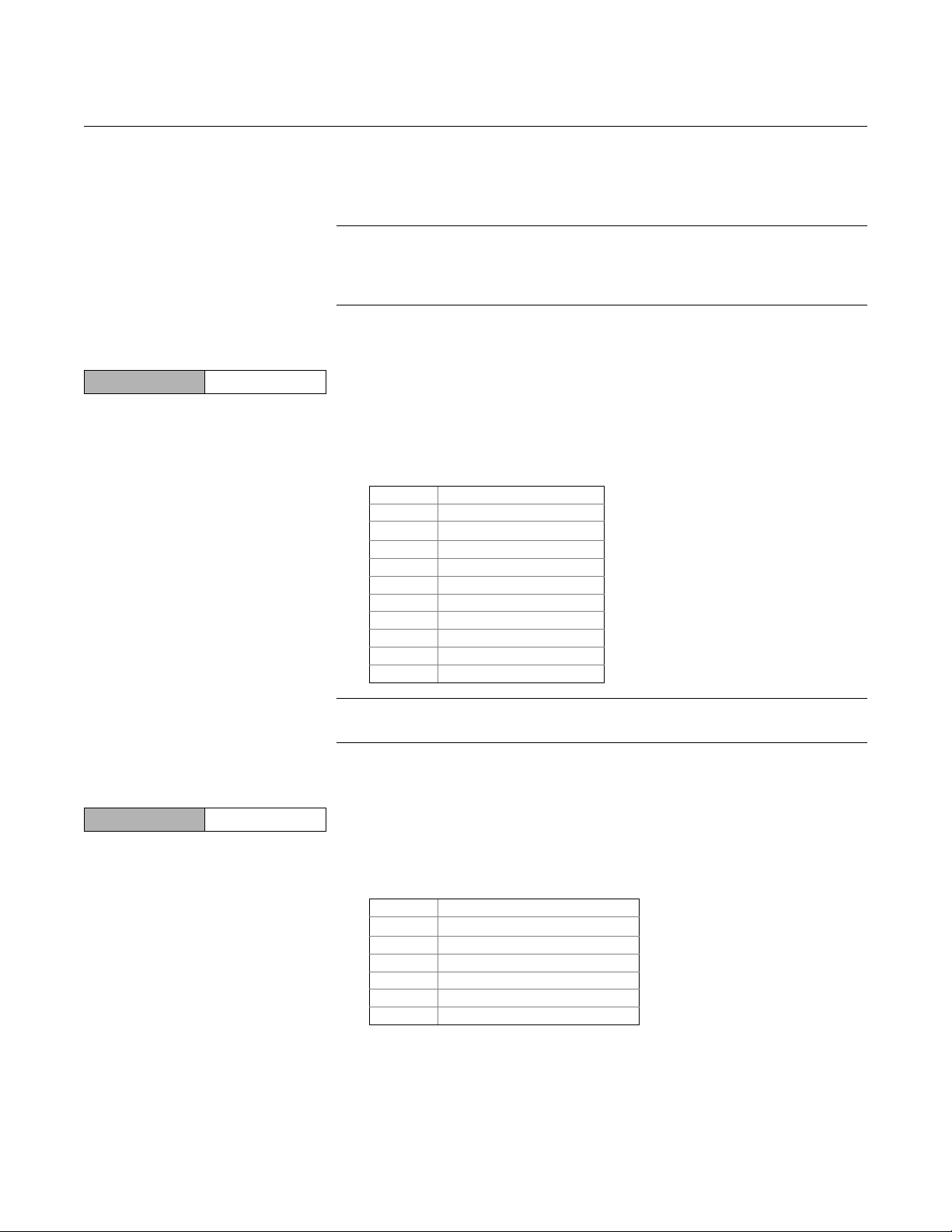

1. Overview

2. Configure

3. Service Tools

1. Device Status 1. Identification

2. Comm Status 2. Revisions

3. PV – 1.0=Wet/0.0=Dry

4. PV Status 4. Security

5. Update Rate

6. Device information

1. Guided Setup

2. Manual Setup

3. Alert Setup

3. Radio

1. Basic Setup

2. Join to Network

3. Configure Update Rate (*1)

4. Configure Device Display

5. Configure Alerts

1. Wireless

2. Operation

3. Display

4. Data Logging

5. Security

6. Device Temperature

7. Device Information

8. Power

1. Alert 1

2. Alert 2

3. Alert 3

4. Alert 4

See Page 2-7

1. Device Image

2. Tag

3. Long Tag

4. Model

5. Serial Number

6. Device ID

7. Date

8. Descriptor

9. Message

10. Model number I

11. Model number II

1. HART

2. Field Device

3. Software

4. Hardware

5. DD

1. Manufacture

2. Device Type

3. Device Revision

4. Software Revision

5. Hardware Revision

6. Transmit Pwr. Lvl

7. Min Brdcst Updt Rt

1. Write Protect

2. Over The Air Upgrade

1. Network ID

2. Join To Network

3. Broadcast Info

1. Application

2. Sensor

1. Display Mode

2. Display Item

1. Meas Status Log

2. Primary Variable, PV

3. 2nd Variable, SV

4. 3rd Variable, TV

5. 4th Variable, QV

6. Configure Data Hist

1. Write Protect

2. Over The Air Upgrade

1. Electronics Temp

2. Elect Temp Status

3. Unit

4. Maximum

5. Minimum

1. Tag

2. Long Tag

3. Descriptor

4. Message

5. Date

6. Country

7. SI Unit Control

1. Power Mode

2. Power Source

1. Configure Alert 1

2. Mode

3. Variable

4. Direction

5. Limit

6. Band

1. Configure Alert 2

2. Mode

3. Variable

4. Direction

5. Limit

6. Band

1. Config Adv Brdcsg

2. Message 1 Content (*2)

3. Message 2 Content (*2)

4. Message 3 Content (*2)

(*1) Config Adv Brdcsg will be displayed if Advanced

Broadcasting is enabled; same menus as under

Configure - Manual Setup - Wireless - Broadcast Info.

(*2) Only visible if Bursting message is enabled.

1. Operation Mode

2. Sensor Output Delay

3. Media Density

1. Sensor Stabilization Time

2. Measurement Time

3. Allowable Change in

Dry Fork Frequency

4. Sensor Fault Delay

1. Configure Alert 3

2. Mode

3. Variable

4. Direction

5. Limit

6. Band

1. Configure Alert 4

2. Mode

3. Variable

4. Direction

5. Limit

6. Band

A

See next page

2-4

Page 23

1. Configure Message 1

2. Configure Message 2

3. Configure Message 3

4. Event Notification

5. Disable Advanced

Broadcasting

A

1. Broadcast Configuration

2. Update Rate

1. Enable Burst Msg 1

2. Message 1 Content

3. First & Trigger Var (*3)

4. 2nd Variable (*3)

5. 3rd Variable (*3)

6. 4th Variable (*3)

7. 5th Variable (*4)

8. 6th Variable (*4)

9. 7th Variable (*4)

10. 8th Variable (*4)

1. Trigger Mode

2. Trigger Level (*3)

3. First & Trigger Var (*3)

4. Update Rate

5. Default Update Rate

1. Trigger Mode

2. Trigger Level (*3)

3. First & Trigger Var (*3)

4. Update Rate

5. Default Update Rate

1. Broadcast Configuration

2. Update Rate

1. Enable Burst Msg 2

2. Message 2 Content

3. First & Trigger Var (*3)

4. 2nd Variable (*3)

5. 3rd Variable (*3)

6. 4th Variable (*3)

7. 5th Variable (*4)

8. 6th Variable (*4)

9. 7th Variable (*4)

10. 8th Variable (*4)

1. Trigger Mode

2. Trigger Level (*3)

3. First & Trigger Var (*3)

4. Update Rate

5. Default Update Rate

1. Broadcast Configuration

2. Update Rate

1. Enable Burst Msg 3

2. Message 3 Content

3. First & Trigger Var (*3)

4. 2nd Variable (*3)

5. 3rd Variable (*3)

6. 4th Variable (*3)

7. 5th Variable (*4)

8. 6th Variable (*4)

9. 7th Variable (*4)

10. 8th Variable (*4)

(*3) Only visible if Message Content is “Selectable Process Variables/Status” or “Selectable Process Variables”.

(*4) Only visible if Message Content is “Selectable Process Variables/Status”.

1. Refresh Following Info

2. Failed

3. Maintenance

4. Advisory

5. Event Notification

From previous page

Reference Manual

00809-0100-4160, Rev AD

January 2013

Field communicator menu tree continued...

Rosemount 2160

2-5

Page 24

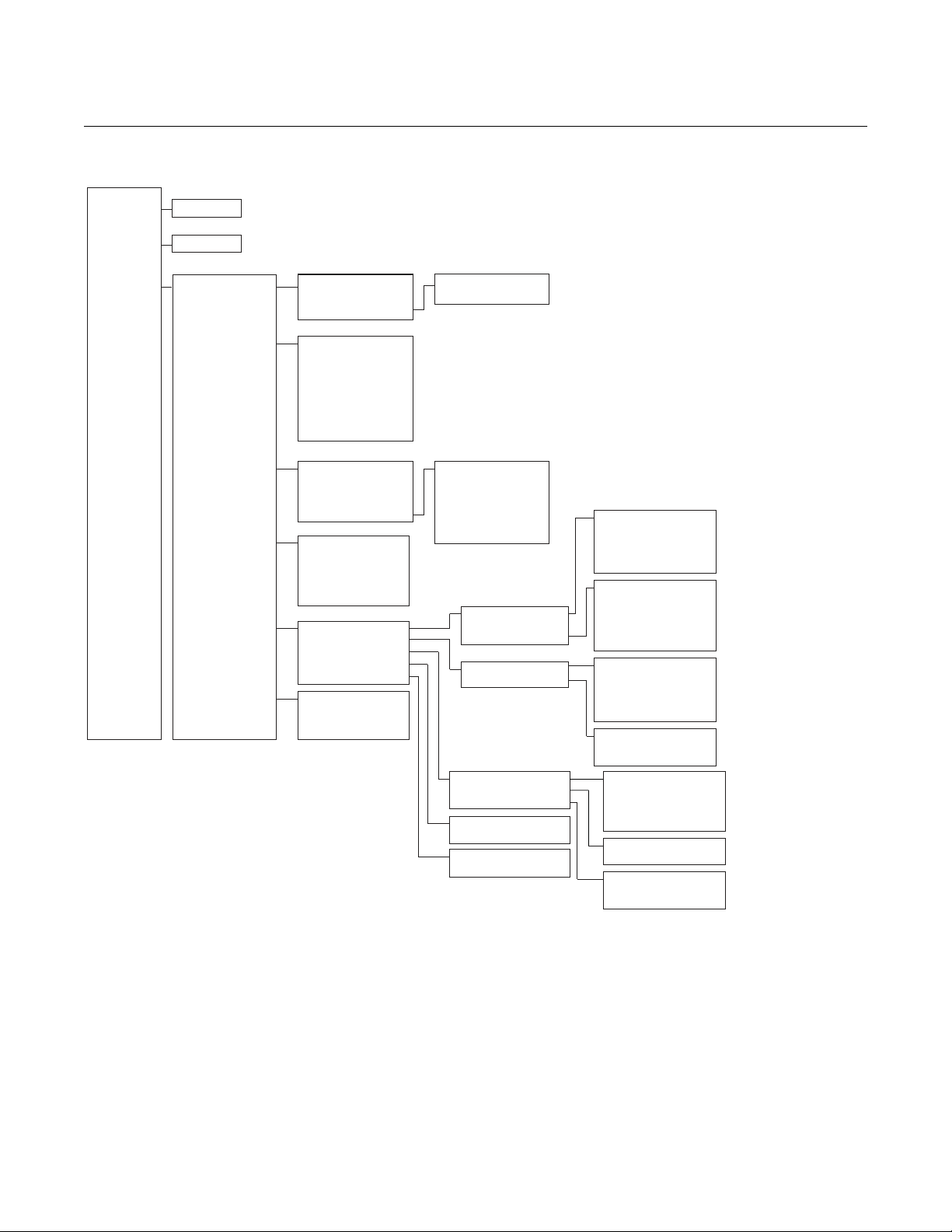

Rosemount 2160

Field communicator menu tree continued...

Reference Manual

00809-0100-4160, Rev AD

January 2013

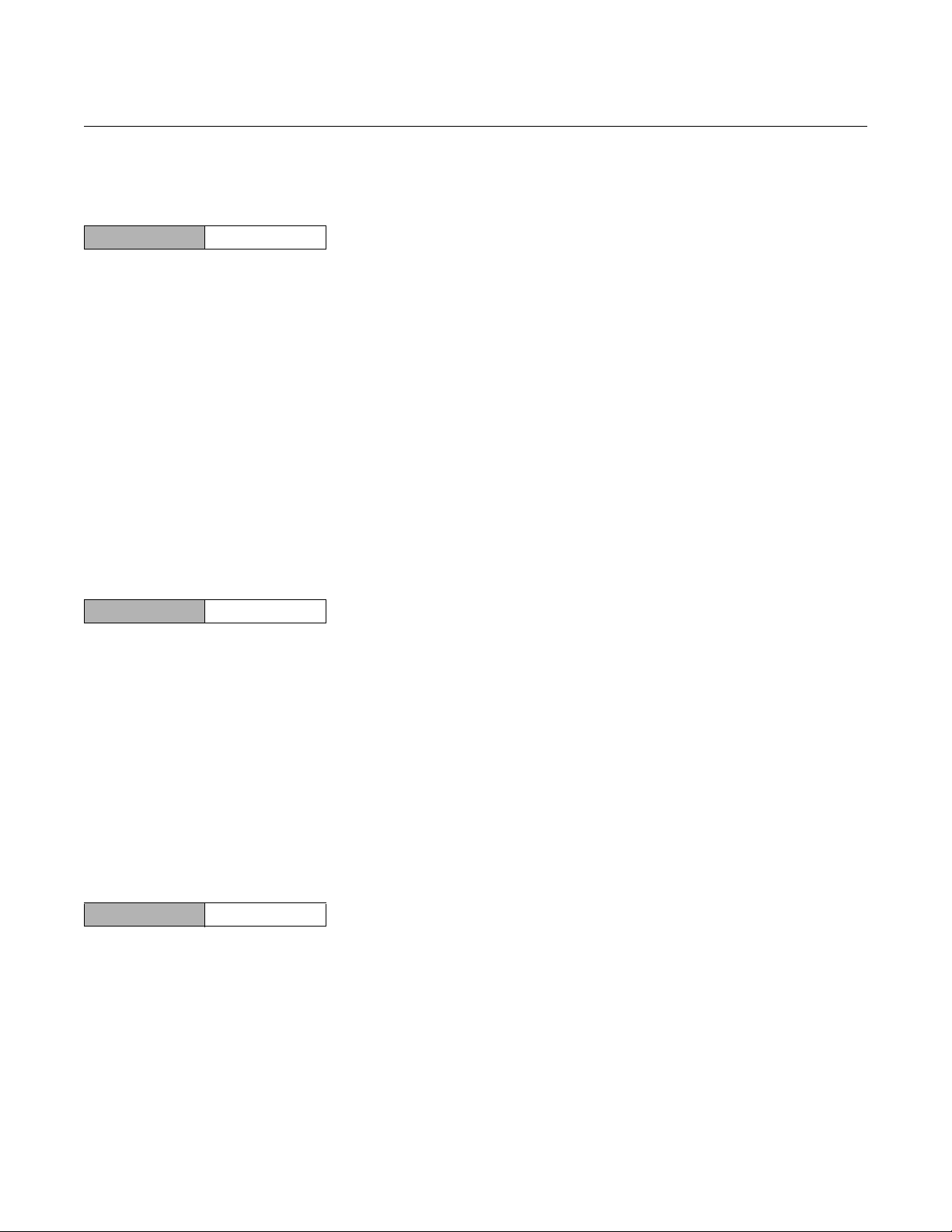

1. Overview

2. Configure

3. Service Tools

(*1) Only visible when there is a history.

(*2) Only one option is visible and it is dependent on whether

Factory Calibration or Site Calibration has been selected.

(*3) Only visible when data logging is enabled.

See Page 2-5

See Page 2-5

1. Alerts

2. Variables

3. Trends

4. Communications

5. Maintenance

6. Simulate

1. Refresh Alerts

2. No Active Alerts

3. History

1. PV – 1.0=Wet/0.0=Dry

2. PV Status

3. Sensor Frequency

4. Sensor Frequency Status

5. Electronics Temp

6. Electronics Temp Status

7. Supply Voltage

8. Supply Voltage Status

9. Last Update Time

1. Output State

2. Sensor Frequency

3. Electronics Temp

4. Supply Voltage

5. Data History

1. Join Status

2. Comm Status

3. Join Mode

4. Available Neighbors

5. Advertisements

6. Join Attempts

1. Diagnostics

2. Counters / Timers

3. Calibrate

4. Routine Maintenance

5. Reset / Restore

1. Output State

2. Sensor Frequency

3. Electronics Temperature

4. Supply Voltage

1. Clear Alert History

2. View Alert History (*1)

1. Device Variable

2. Variable Units

3. Sample Inteval

4. Time of First Value

5. Date of First Value

6. View Data History (*3)

7. Refresh (*3)

1. Sensor

2. Dry Fork Frequency /

Switch Points

1. Counters

2. Timers

1. Sensor Calibration

2. Reset Sensor Calibration

3. Sensor Compensation

1. Locate Device

2. Install New Power Module

1. Device Reset

2. Load User Defaults

1. Sensor Frequency

2. Temperature Compensation

3. Uncompensated Frequency

4. Sensor State

5. Sensor Status

1. Dry Fork Frequency

2. Dry to Too Dry

3. Dry to Indeterminate

4. Wet to Indeterminate

5. Wet to Too Wet

6. Zero

1. Sensor Wet Count

2. Reset/Preset Wet Count

3. Calibration Count

4. Fault Control

5. Reset Fault Count

1. Time Since Output Change

2. Total Time Dry

3. Total Time Wet

1. Dry Fork Frequency

2. Sensor Frequency

3. Calibrate Dry Fork

4. Sensor Calibration Status

5. Calibration Count

1. Restore Factory Calibration

2. Restore Site Calibration

1. Calibration Temperature

2. Temperature Compensation

3. Process Temperature

(*2)

2-6

Page 25

Reference Manual

00809-0100-4160, Rev AD

January 2013

Rosemount 2160

DEVICE NETWORK CONFIGURATION

Join to Network To communicate with the Smart Wireless Gateway, and ultimately the

Fast Keys

2, 1, 2

Information System, the 2160 must be configured to communicate with the

wireless network. This step is the wireless equivalent of connecting wires from

a transmitter to the host system.

1. From the Home screen, select 2: Configure.

2. Select 1: Guided Setup.

3. Select 1: Join to Network.

Using AMS or a Field Communicator, enter the Network ID and Join Key so

they match the Network ID and Join Key of the Gateway and the other

devices in the network. If the Network ID and Join Key are not identical, the

2160 will not communicate with the network.

When using a Field Communicator, the Network ID can be configured by

entering Fast Key sequence: 2, 2, 1, 1. The Join Key can also be configured

using a Field Communicator with the Fast Key sequence: 2, 2, 1, 2.

NOTE

The Network ID and Join Key may be obtained from the

Setup>Network>Settings page on the Gateway’s web server.

Configure Update Rate The final device network configuration piece is the Update Rate which, by

Fast Keys

2, 2, 3

default, is 1 minute. It can be changed at commissioning, or at any time, by

using AMS or the Gateway’s web server. The Update Rate should be

between 1 second and 60 minutes.

1. From the Home screen, select 2: Configure.

2. Select 1: Guided Setup.

3. Select 3: Configure Update Rate.

Operation Mode To view or cha nge th e op er ation mode:

Fast Keys

2, 2, 2, 1, 1

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 2: Operation.

4. Select 1: Application.

5. Select 1: Operation Mode.

The default operating mode is Normal Mode. Other options are Enhanced

Operation Mode (Fault=Wet) or Enhanced Operation Mode (Fault=Dry).

Remove Black Power

Module

After the bench top and network device configuration is completed, you can

remove the Black Power Module and replace the housing cover. The Black

Power Module should be inserted only when the device is ready to be

installed.

Use caution when handling the Black Power Module. The Black Power

Module may be damaged if dropped from heights in excess of 20 ft. (6,1 m).

When the device is installed, re-insert the Black Power Module and close the

housing cover securely. Always ensure a proper seal but do not over tighten.

2-7

Page 26

Rosemount 2160

Reference Manual

00809-0100-4160, Rev AD

January 2013

REVIEW CONFIGURATION DATA

Review Device

Identification Information

Fast Keys

1, 6, 1, 3

The following is a list of factory default configurations that can be viewed by

using the Field Communicator or AMS. Follow the steps below to review the

level switch configuration information.

NOTE

Information and procedures in this section that make use of Field

Communicator fast key sequences and AMS assume that the 2160 and

communication equipment are connected, powered, and operating correctly.

To view device identification information:

1. From the Home screen, select 1: Overview.

2. Select 6: Device Information.

3. Select 1: Identification.

4. Select 3: Device.

5. Select from the corresponding number to view each field:

1 Device Image

2 Tag

3 Long Tag

4 Model

5 Serial Number

6 Device ID

7Date

8 Descriptor

9 Message

10 Model Number I

11 Model Number II

Review Radio

Information

Fast Keys

1, 6, 3

NOTE

Other device information can also be found at Fast Key sequence 2, 2, 7.

To view radio information:

1. From the Home screen, select 1: Overview.

2. Select 6: Device Information.

3. Select 3: Radio.

4. Select from the corresponding number to view each field:

1 Manufacturer

2 Device Type

3 Device Revision

4 Software Revision

5 Hardware Revision

6 Transmit Power Level

7 Minimum Broadcast Update Rate

2-8

Page 27

Reference Manual

00809-0100-4160, Rev AD

January 2013

Rosemount 2160

CHECK OUTPUT Before performing other level switch operations, ensure the 2160 is oper ating

properly by checking the process variables.

Variables To view the Variables menu:

Fast Keys

3, 2

1. From the Home screen, select 3: Service Tools.

2. Select 2: Variables.

The variable menu displays the following process var iab le s:

• PV – level switch output state of 0.0 (Dry) or 1.0 (Wet)

• PV Status – valid or fault status (see “Troubleshooting” on page 6-2)

• Sensor Frequency – the frequency of the vibrating fork

• Sensor Frequency Status – valid or fault status

• Electronics Temp – the temperature inside the 2160 housing

• Electronics Temp Status – valid or fault status

• Supply Voltage – the input voltage to the level switch

• Supply Volt Status – valid or fault status

• Last Update Time – elapsed time since the last data update

BASIC SETUP

Temperature Units The Unit setting allows the Electronics Temperature process variable to be

Fast Keys

2, 2, 6

displayed in Farenheit (°F) or Celsius (°C).

To view the electronics temperature menu:

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 6: Device Temperature.

The electronics temperature menu displays the following:

• Electronics Temp – the live electronics temperature measurement

• Electronics Temp Status – valid or fault status

• Unit – change/view measurement units for Electronics Temperature

• Maximum – view the highest measured electronics temperature

• Minimum – view the lowest measured electronics temperature

Operation Mode The 2160 has three operation modes (see Table A-2 on page A-3):

Fast Keys

2, 2, 2, 1, 1

• Standard – Default operation mode for no sensor fault detection

• Enhanced (Fault=WET) – Output is forced to Wet when fault detected

• Enhanced (Fault=DRY) – Output is forced to Dry when fault detected

To change or view the operation mode:

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 2: Operation.

4. Select 1: Application.

5. Select 1: Operation Mode.

2-9

Page 28

Reference Manual

00809-0100-4160, Rev AD

Rosemount 2160

January 2013

Sensor Output Delay When the 2160 detects a change in process conditions from wet-to-dry or

Fast Keys

2, 2, 2, 1, 2

dry-to-wet, the Sensor Output Delay parameter causes a delay of up to 3600

seconds before a new process condition is indicated in the process variables.

If, for example, there are waves in a tank, then the 2160 may intermittently

detect a change in process conditions. The sensor output delay ensures that

the 2160 fork is dry or wet for a period before switching.

Depending on the application, a suitable delay can prevent const ant switching

of the output state.

NOTE

The delay re-starts each time a change in process conditions is detected.

To change or view the sensor output delay:

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 2: Operation.

4. Select 1: Application.

5. Select 2: Sensor Output Delay.

Media Density The frequency of the vibrating fork sensor can be affected by the process

Fast Keys

2, 2, 2, 1, 3

liquid density. Use Media Density to select one of the following options:

• Normal – Select when the liquid specific gravity is between 0.7 and 2.0

• Low – Select when the liquid specific gravity is less than 0.7

• High – Select when the liquid specific gravity is greater than 2.0

NOTE

If the liquid specific gravity is unknown, keep the default setting of Normal.

Write Protect The 2160 has a software write protect security feature.

Fast Keys

2, 2, 5, 1

The change or view write protect security settings:

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 5: Security.

4. Select 1: Write Protect.

Data Logging Data logging records previous measurement values.

Fast Keys

2, 2, 4, 6

To enable or disable the logging:

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 4: Data Logging.

4. Select 6: Configure Data Hist.

2-10

Follow on-screen instructions to enable or disable the logging.

Page 29

Reference Manual

00809-0100-4160, Rev AD

January 2013

LCD DISPLAY

Rosemount 2160

LCD Display

Configuration

Fast Keys

2, 1, 4

The LCD display indicates output and abbreviated diagnostic messages.

NOTE

Use Rosemount Wireless LCD Part Number: 00753-9004-0002.

The LCD display features a four-line display and a bar graph. The first line of

five characters displays the output description, the second line of seven digits

displays the actual value, the third line of six characters displays engineering

units, and the fourth line displays “Error” when there is an alarm condition.

The LCD display can also display diagnostic messages. The bar graph

represents the network connectivity status.

See “LCD Screen Messages” on page 5-3 for more information on LCD

messages.

To change or view LCD display options:

1. From the Home screen, select 2: Configure.

2. Select 1: Guided Setup.

3. Select 4: Configure Device Display.

Alternatively, to manually change or view LCD display options:

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 3: Display.

4. Follow the on-screen instructions to configure Display Mode and

Display Item parameters.

2-11

Page 30

Reference Manual

Deadband

Assigned Value

Alert Set Point

Alert “OFF” Alert “ON” Alert “OFF”

Units of Measurement

Time

Deadband

Assigned Value

Alert Set Point

Alert “OFF” Alert “ON” Alert “OFF”

Units of Measurement

Time

00809-0100-4160, Rev AD

Rosemount 2160

January 2013

DETAILED SETUP

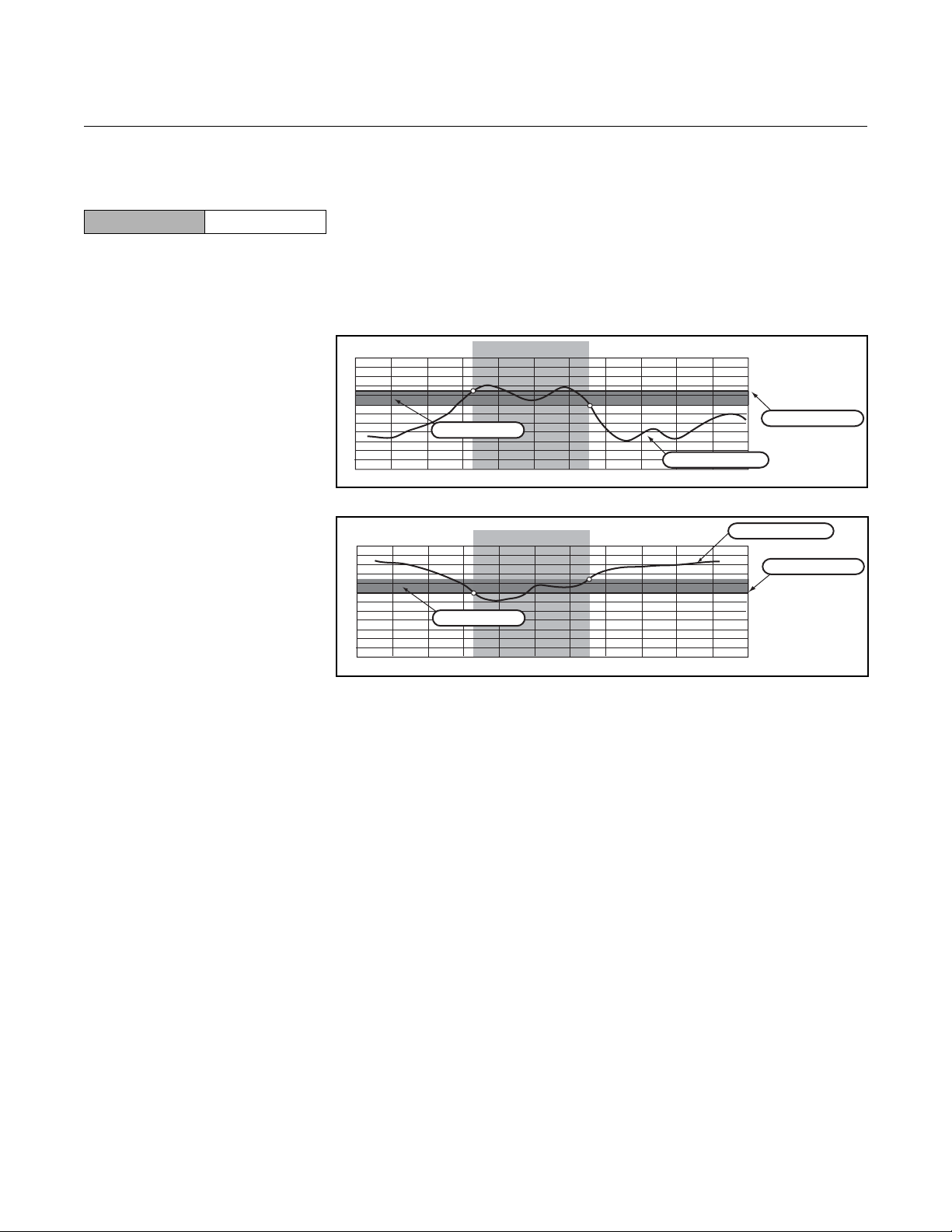

Configure Alerts Alerts can be configured to output a HART message when a configured data

Fast Keys

2, 1, 5

point is exceeded. A process alert is transmitted continuously if a set point for

a process variable is exceeded and the alert mode is enabled.

An alert is displayed on a Field Communicator, AMS status screen, or in the

error section of the optional LCD display. The alert is reset when the assigned

value (process variable) returns within its normal range.

Example 1: Rising Alert

Example 2: Falling Alert

To change or view the process alerts:

1. From the Home screen, select 2: Configure.

2. Select 1: Guided Setup.

3. Select 5: Configure Alerts.

4. Follow the on-screen instructions to configure up to four alerts (Alert 1,

Each alert requires the following information:

To view active or previous alerts:

1. From the Home screen, select 3: Service Tools.

2. Select 1: Alerts.

3. Select Refresh Alerts to repor t new alerts since the last update,

Alert 2, Alert 3, and Alert 4).

•Mode – Disabled (default) or enabled alert

• Variable – Select Output State, Sensor Frequency,

Electronics Temperature, or Supply Voltage

• Direction – Rising or falling alert

• Limit – Alert set point (in same units as the variable)

• Dead Band – Hysteresis data point (in same units as the variable)

for transition from deadband zone to new alert state

Active Alerts to view active alerts, or History to view previous alerts.

2-12

Page 31

Reference Manual

00809-0100-4160, Rev AD

January 2013

Rosemount 2160

Sensor Stabilization

Time

Fast Keys

2, 2, 2, 2, 1

The time needed for the fork sensor to reach a stable vibration may vary

depending on the process conditions. Sensor Stabilization Time sets a

delay before taking a frequency measurement.

The default setting is 60 ms. It can be set to a time in the range 20 to 1000 ms

and is adjustable in 20 ms steps. Alternatively, the setting AUTO is for the

Rosemount 2160 to automatically calculate a delay.

To change or view the sensor stabilization time:

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 2: Operation.

4. Select 2: Sensor.

5. Select 1: Sensor Stabilization Time.

6. Follow the on-screen instructions to configure a delay.

Measurement Time The time needed for the fork sensor to take an accurate measurement after

Fast Keys

2, 2, 2, 2, 2

reaching a stable vibration may vary depending on the process condi tions.

Measurement Time sets a delay before taking a frequency measurement.

The default setting is 60 ms. It can be set to a time in the range 20 to 1000 ms

and is adjustable in 20 ms steps. Alternatively, the setting AUTO is for the

Rosemount 2160 to automatically calculate a delay.

To change or view the measurement time:

Allowable Change In

Dry Fork Frequency

Fast Keys

2, 2, 2, 2, 3

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 2: Operation.

4. Select 2: Sensor.

5. Select 2: Measurement Time.

6. Follow the on-screen instructions to configure a delay.

When the 2160 is re-calibrated in the field, a co mparison is made between the

new dry fork frequency and original factory-set Dry Fork Frequency value.

If the difference is greater than the allowable change value, the re-calibration

is rejected. Check the fork for damage, corrosion, or coating, and clean the

fork if necessary before re-trying.

The default setting is 100 Hz. It can be set to a value in the range 1 to 254 Hz.

NOTE

Fast Key sequence is 3, 5, 1, 2 for the original factory-set Dry Fork Frequency.

To change or view the allowable change:

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 2: Operation.

4. Select 2: Sensor.

5. Select 3: Allowable Change In Dry Fork Frequency.

6. Follow the on-screen instructions to configure the allowable change.

2-13

Page 32

Reference Manual

00809-0100-4160, Rev AD

Rosemount 2160

January 2013

Sensor Fault Delay When the 2160 is operating in Enhanced Mode and detects a fork sensor

Fast Keys

2, 2, 2, 2, 4

fault, Sensor State (page 2-18) indicates a Fault state after a delay set by

Sensor Fault Delay.

The default setting is 600 seconds. It can be a maximum of 3600 seconds.

NOTE

When the 2160 is operating in Normal Mode, a fork sensor fault is not

detected and Sensor State (page 2-18) continues to indicate a Valid state.

To change or view the sensor fault delay:

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 2: Operation.

4. Select 2: Sensor.

5. Select 4: Sensor Fault Delay.

6. Follow the on-screen instructions to configure the sensor fault delay.

Power Mode For configuration and diagnostic purposes, the 2160 can be put into an

Fast Keys

2, 2, 8, 1

Always On power mode. The fork sensor is energized cont inuously and a new

measurement is completed, typically, every 500 ms.

The Always On power mode causes a much higher drain on the battery, and

so the 2160 reverts to the default Normal power mode after a settable period

of up to 10 minutes.

In Normal power mode, the fork sensor is energized for the period set by the

update rate (see “Configure Update Rate” on page 2-7).

To view or change Power Mode:

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 8: Power.

4. Select 1: Power Mode.

5. Follow the on-screen instructions to configure the power mode.

Power Source A wireless device may be attached to a source of continuous power or to a

Fast Keys

2, 2, 8, 2

power source that drains over time (e.g. a battery). The 2160 is always

powered by Battery Power.

To view the Power Source:

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 8: Power.

4. Select 2: Power Source.

2-14

Page 33

Reference Manual

00809-0100-4160, Rev AD

January 2013

Rosemount 2160

DIAGNOSTICS AND SERVICE

Diagnostics and service functions listed below are primarily for use after field

installation.

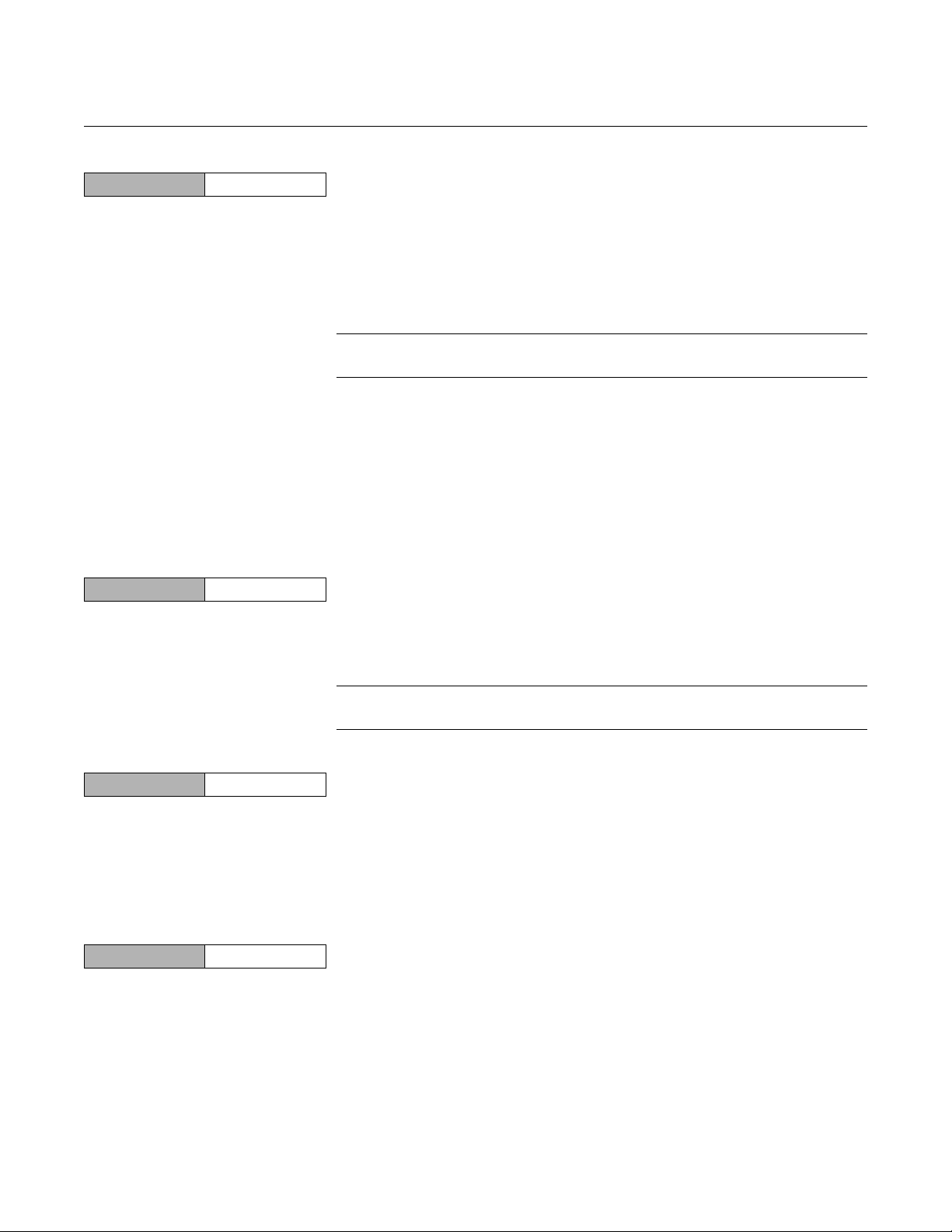

Load User Defaults The master reset function is used to reset the electronics and reset

Fast Keys

Table 2-1. User Defaults

3, 5, 2

parameters to their factory-set defaults (see Ta ble 2-1 ) .

To perform a master reset:

1. From the Home screen, select 3: Service Tools.

2. Select 5: Maintenance

3. Select 2: Load User Defaults.

4. Follow on-screen instructions to perform the reset.

Parameter Names Defaults

Operation Mode

Media Density

Sensor Output Delay

Sensor Stabilisation Time

Sensor Frequency Measurement Time

Sensor Fault Delay

Process Temperature

Burst Message 0: Burst Mode Control

Burst Variable Slot 0

Burst Variable Slot 1

Burst Variable Slot 2

Burst Variable Slot 3

Burst Variable Slot 4

Burst Variable Slot 5

Burst Variable Slot 6

Burst Variable Slot 7

Burst Ext. Cmd Number

Triggered Update Rate

Default Update Rate

Trigger Mode

Trigger Variable Classification

Trigger Units

Trigger Level

Alerts: Alert Variable Assignment

Alert Mode

Alert Direction

Alert Set Point

Alert Dead Band

Alert Units

Alert Name

Data Trending: Trend Number

Trend Control

Device Variable Code

Sample Period

Sensor Wet Count

Fault Count

Total Time Wet

Total Time Dry

Time Since Output Change

Sensor Calibration Status

Allowable Dry Fork Frequency Shift

Temperature Coefficient

Normal

Normal

0 s

60 ms

60 ms

600 ms

20 °C

Wireless

2

3

0

1

246

247

248

249

178

(1)

60 s

(1)

60 s

Continuous

0

251

0.5

(1)

2

(1)

Off

Rising

(1)

0.0

(1)

0.0

(1)

251

ALERT X

0

Off

Not Used

60 s

0

0

00, 00:00:00

00, 00:00:00

00, 00:00:00

Factory Calibrated

100 Hz

-0.019 %/°C

(1)

(1)

(1)

(1)

(1)

2-15

Page 34

Reference Manual

00809-0100-4160, Rev AD

Rosemount 2160

(1) Where this parameter was factory-configured with a user-defined value, that same value is re-loaded

when using the Load User Defaults function. P arameters without a user-def ined value are re stored to

the default value shown in this table.

January 2013

Join Status Wireless devices join the secure network through a four step process:

Fast Keys

3, 4, 1

• Step 1. Network Found

• Step 2. Network Security Clearance Granted

• Step 3. Network Bandwidth Allocated

• Step 4. Network Join Complete

To view the join status of the Rosemount 2160:

1. From the Home screen, select 3: Service Tools.

2. Select 4: Communications.

3. Select 1: Join Status.

Communication Status This indicates whether or not the 2160 is connected to the secure network.

Fast Keys

3, 4, 2

To view the communication status of the 2160:

1. From the Home screen, select 3: Service Tools.

2. Select 4: Communications.

3. Select 2: Comm Status.

Join Mode This mode configures how the device attempts to join the secure network.

Fast Keys

3, 4, 3

Settable options are:

• Do Not Attempt to Join

•Join Now

• Attempt to Join immediately on Power Up or Reset

To change or view the join mode:

1. From the Home screen, select 3: Service Tools.

2. Select 4: Communications.

3. Select 3: Join Mode.

2-16

Page 35

Reference Manual

00809-0100-4160, Rev AD

January 2013

Rosemount 2160

Available Neighbors In a self-organizing network, the more neighbors a device has, the more

Fast Keys

3, 4, 4

robust the network will be.

To view the number of available neighbors:

1. From the Home screen, select 3: Service Tools.

2. Select 4: Communications.

3. Select 4: Available Neighbors.

Advertisements To view the number of advertising packets heard from other wireless devices:

Fast Keys

3, 4, 5

1. From the Home screen, select 3: Service Tools.

2. Select 4: Communications.

3. Select 5: Advertisements.

Join Attempts Too many join attempts result in the device considering the join attempt as

Fast Keys

3, 4, 6

failed. If this happens, re-check the Join Key and Network ID.

To view the number of attempts made to join a secure network:

1. From the Home screen, select 3: Service Tools.

2. Select 4: Communications.

3. Select 6: Join Attempts

Sensor Frequency The vibrating fork frequency is indicated in Sensor Frequency after process

Fast Keys

3, 5, 1, 1, 1

condition adjustments.

NOTE

See “Sensor Stabilization Time” on page 2-13 and “Measurement Time” on

page 2-13 for process condition adjustments.

Sensor Frequency is the HART dynamic variable SV (Secondary Variable)

and can be indicated instead of the variable PV on the optional LCD display.

To view the vibrating fork frequency (sensor frequency):

1. From the Home screen, select 3: Service Tools.

2. Select 5: Maintenance.

3. Select 1: Diagnostics.

4. Select 1: Sensor.

5. Select 1: Sensor Frequency.

NOTE

The Fast Key sequence 3, 2, 3 also indicates Sensor Frequency.

2-17

Page 36

Rosemount 2160

Reference Manual

00809-0100-4160, Rev AD

January 2013

Temperature

Compensation

Fast Keys

Uncompensated

Frequency

Fast Keys

3, 5, 3, 3, 2

3, 5, 1, 1, 3

The frequency of the vibrating fork sensor may be affected by a varying

process temperature. If the 2160 knows the process temperature, it can

compensate accordingly and provide an improved frequency switching point

(page 2-19) and trend calculation.

Use Temperature Compensation to set the temperature coefficient of the

vibrating fork sensor in units of %/°F (%/°C).

To change or view the temperature coefficient:

1. From the Home screen, select 3: Service Tools.

2. Select 5: Maintenance.

3. Select 3: Calibrate.

4. Select 3: Sensor Compensation.

5. Select 2: Temperature Compensation.

Uncompensated Frequency indicates the vibrating fork frequency before

compensating for a varying process temperature.

To view the uncompensated frequency:

1. From the Home screen, select 3: Service Tools.

2. Select 5: Maintenance.

3. Select 1: Diagnostics.

4. Select 1: Sensor.

5. Select 3: Uncompensated Frequency.

Sensor State Sensor State indicates the present state of the vibrating fork.

Fast Keys

3, 5, 1, 1, 4

As the vibrating fork sensor becomes immersed in the process liquid, the

vibration frequency changes and the sensor state changes to Wet.

When the process liquid falls away from the fork, the vibration frequency

changes and the sensor state changes to Dry.

If the vibrating fork sensor is damaged, the frequency moves outside normal

operating limits and the sensor state changes to Too Dry, Too Wet, or Zero.

(See “Dry Fork Frequency / Switch Points” on page 2-19 for band limits.)

To view the sensor state:

1. From the Home screen, select 3: Service Tools.

2. Select 5: Maintenance.

3. Select 1: Diagnostics.

4. Select 1: Sensor.

5. Select 4: Sensor State.

2-18

Page 37

Reference Manual

00809-0100-4160, Rev AD

January 2013

Rosemount 2160

Dry Fork Frequency /

Switch Points

Fast Keys

3, 5, 1, 2

The hysteresis for Sensor State transitions can be viewed in the dry fork

frequency and switch points menu: