Rosemount 2051L Specifications

Product Data Sheet

00813-0100-4016, Rev RG

November 2018

Rosemount™ DP Level Transmitters and 1199

Diaphragm Seal Systems

Applications

■

Level, flow, pressure, interface, density

■

Extreme hot and cold temperatures

■

Corrosive, clogging, or viscous processes

■

Hygienic requirements

■

Special process connections

November 2018

Proven, reliable, and innovative DP Level technologies

To meet your application requirements, Rosemount™ DP Level technologies deliver an unsurpassed product offering that is easy to

specify, order, and install. The offering includes a wide variety of process connections, direct mount or capillary connections, and

materials of construction to address almost any application. If you don’t see what you need listed here, ask us. We can create a

custom engineered solution to meet your needs.

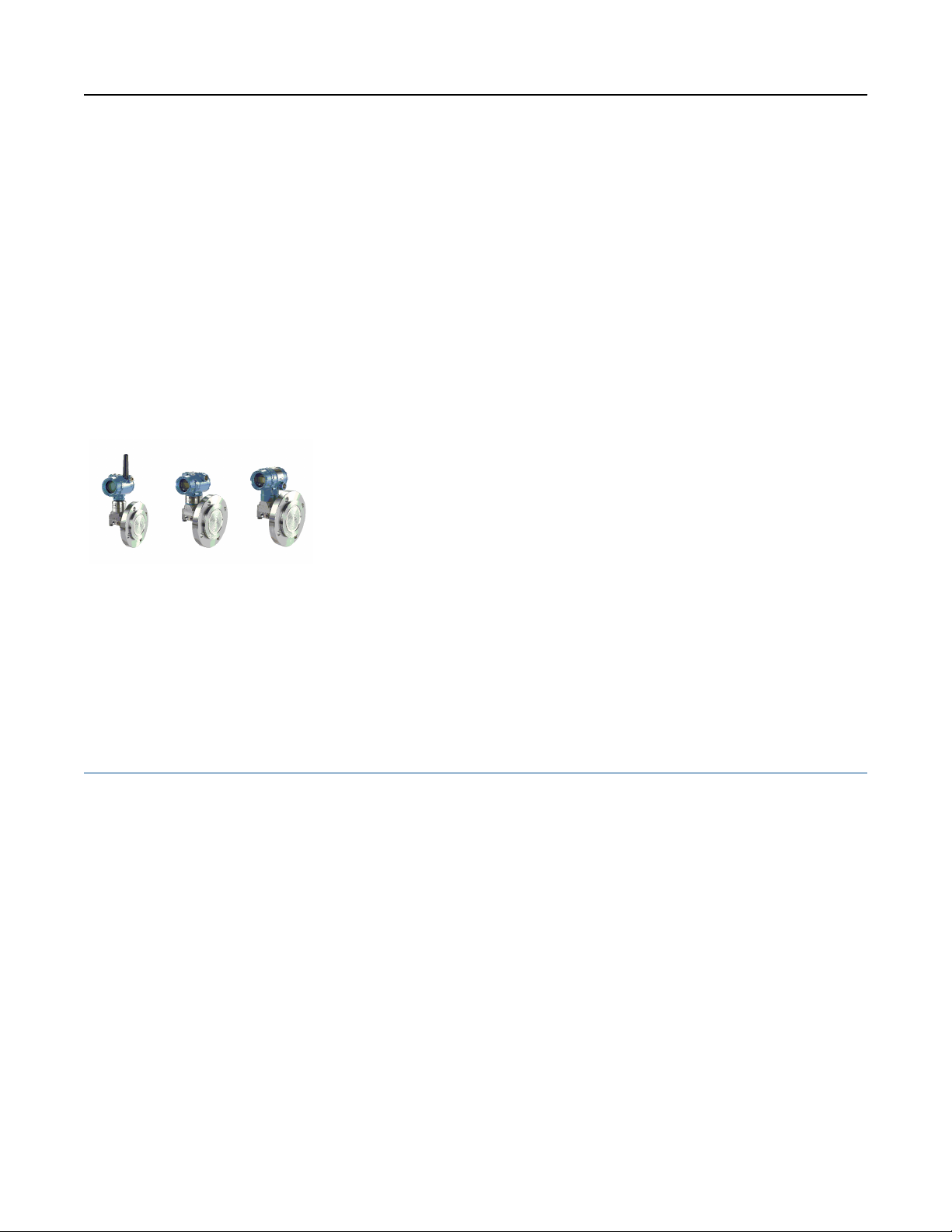

Rosemount Level Transmitters

Level transmitters combine world-class Rosemount pressure instrumentation with direct-mount seals, all in a single integrated

model number.

Rosemount 3051SAL, 3051L, and 2051L Level Transmitters

■

Achieve best-in-class system reliability with all welded systems

■

Wireless configurations provide new data access

■

Connect to virtually any process with a comprehensive offering of

process connections, fill fluids, direct mount or capillary connections,

and materials

■

Quantify and optimize total system performance with QZ option

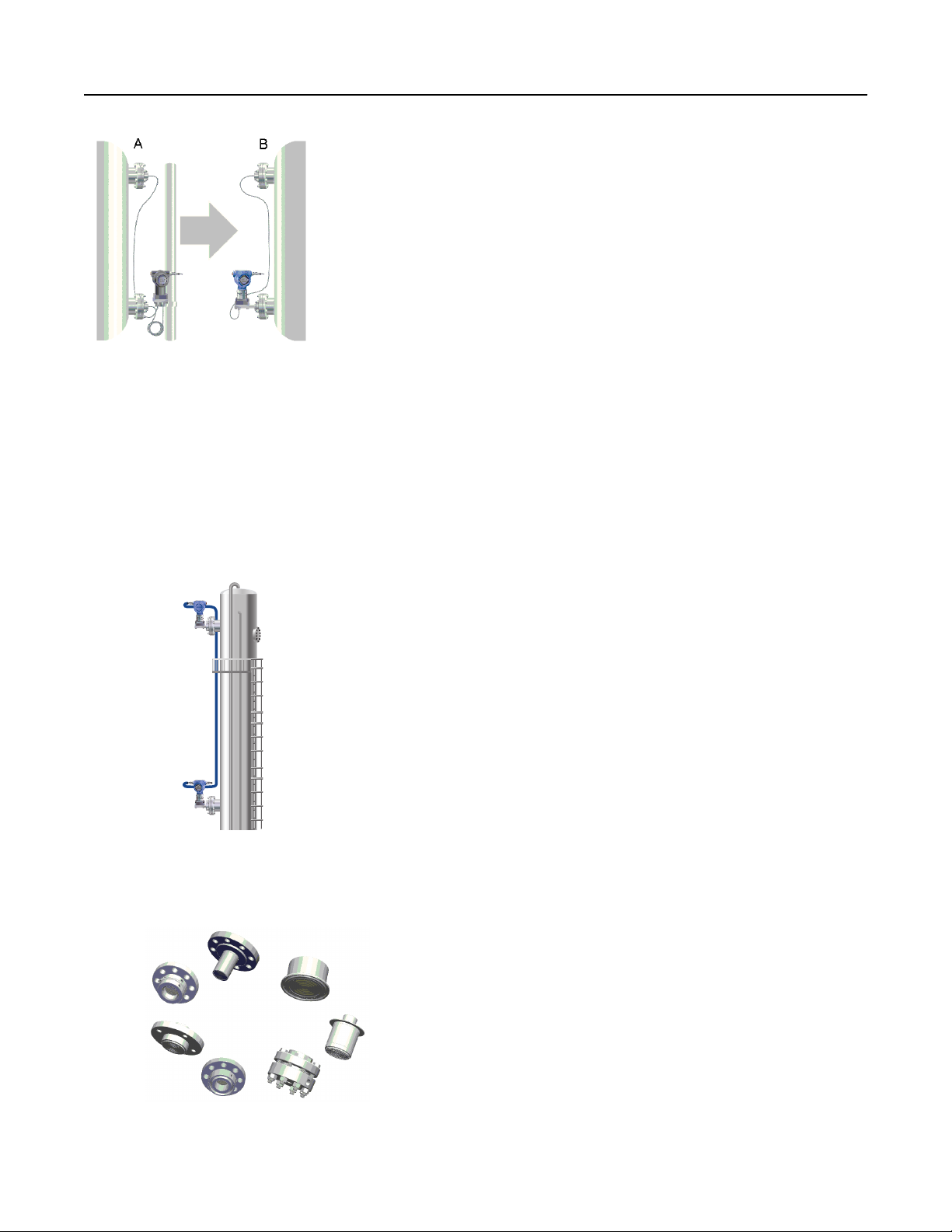

Rosemount Tuned-System™ Assemblies optimize results

Rosemount Tuned-System Assemblies utilize a direct mount seal on the high pressure connection and a remote mount (Capillary)

connection on the low pressure connection. This improves overall performance and installation compared to a traditional Balanced

Seal System.

Contents

Proven, reliable, and innovative DP Level technologies ..................................................................................................................... 2

Rosemount 3051S Electronic Remote Sensor (ERS) System...............................................................................................................5

Rosemount 3051S Scalable™ Level Transmitter................................................................................................................................22

Rosemount™ 3051L Level Transmitter............................................................................................................................................. 51

Rosemount™ 2051L Liquid Level Transmitter................................................................................................................................... 58

Rosemount™ 1199 Direct Mount Seal Systems................................................................................................................................ 65

Rosemount 1199 Remote Mount Seal Systems............................................................................................................................... 71

Flanged seals................................................................................................................................................................................... 77

Threaded seals.................................................................................................................................................................................94

Hygienic seals..................................................................................................................................................................................98

Specialty seals............................................................................................................................................................................... 108

Specifications................................................................................................................................................................................ 113

Product certifications.................................................................................................................................................................... 133

Dimensional Drawings...................................................................................................................................................................175

2 Emerson.com/Rosemount

November 2018

■

Reduce installed costs by 20 percent by eliminating excess capillary and

transmitter mounting hardware

■

Improve performance by up to 30 percent

■

Increase response time by up to 80 percent

■

Reduce risk with up-front quantified performance reports

A. Balanced system with two equal lengths of

capillary

B. Tuned-system assembly with direct mount plus

capillary

Rosemount 3051S Electronic Remote Sensor (ERS)™ System

The Rosemount 3051S ERS System is a digital DP Level architecture that links two Rosemount 3051S Pressure Sensors together

electronically. The pressure sensors are synchronized on a single power loop where the differential pressure, level, and volume are

calculated and transmitted using a standard two-wire 4–20 mA HART® signal.

A digital upgrade to a proven technology

■

■

■

■

Simplified installations and maintenance routines

■

■

■

■

Rosemount 1199 Seal Systems

90 percent improvement in time response

Elimination of temperature effects and measurement drift

Multivariable capabilities including DP, PLO, PHI, volume, and level

Proven Rosemount 3051S Sensor technology

Elimination of wet legs or dry legs

Easy installations without need for heat tracing and insulation

Proactive maintenance and troubleshooting with sensor alerts and diagnostics

Simplified inventories with sensors and standard cable

Seal systems provide a reliable process pressure measurement and

prevent the process medium from contacting the transmitter

diaphragm. Transmitter/diaphragm seal systems should be considered

when:

■

Process temperature is outside of the operating ranges of the

transmitter.

■

Process is corrosive and/or requires specific exotic materials of

construction.

■

Process contains suspended solids or is viscous and is prone to

plugging of connections.

Product Data Sheet 3

November 2018

■

Application requires the use of flush-mount hygienic connections

that facilitates CIP/SIP service.

■

There is a requirement for easier cleaning of the process from the

connections to avoid contamination between batches.

Application flexibility

■

Flanged, threaded, and hygienic process connections

■

Meets industry standards such as EN 1092-1, ANSI/ASME B16.5, JIS B2238, ANSI/ASME B1.20.1, EN 10226-1, GOST 33259-15,

ISO 228-1

■

Variety of fill fluids applications including cold temperature, hot temperature, and hygienic and food grade

■

Three different capillary diameters allow for optimization of accuracy and time response

Reliable system construction

■

Welded design with no threaded connections

■

100 percent helium leak tested

■

Advanced manufacturing techniques ensure air-free, leak-tight system that is stable over time

■

Reliable operation in full vacuum applications

Robust seal design

■

Backup convolutions on the diaphragm protect seal integrity

■

Recessed diaphragms reduce potential for handling damage

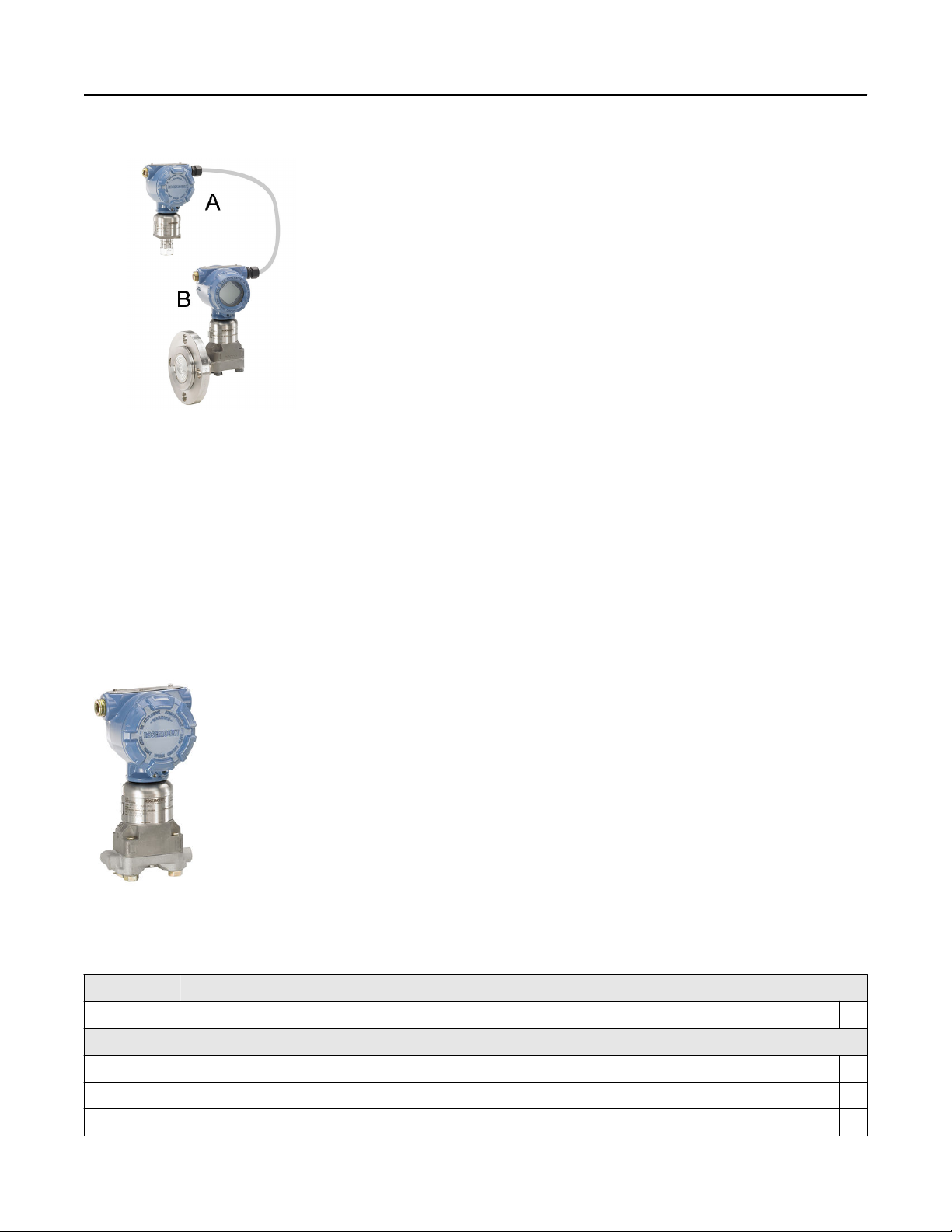

Seal system construction options

Figure 1: Welded-Repairable Construction

■

All connection points welded except gasket between sensor module and transmitter flange

■

Transmitter can be re-used if repair work is required

Figure 2: All Welded (Vacuum) Construction

■

All connection points welded including welded disk over sensor module isolators

■

Ideal for vacuum applications (< 6 psia, 400 mbar-a)

■

Seal system and transmitter are not repairable

4 Emerson.com/Rosemount

November 2018

Rosemount 3051S Electronic Remote Sensor (ERS) System

The Rosemount 3051S ERS System is a flexible, 2-wire 4-20 mA HART architecture that calculates

differential pressure (DP) electronically using two pressure sensors that are linked together with

a non-proprietary electrical wire.

Ideal applications for the Rosemount 3051S ERS System include tall vessels and distillation

columns that have traditionally required long lengths of capillary or impulse piping. When used

in these types of applications, the Rosemount 3051S ERS System can deliver:

■

More accurate and repeatable DP measurements

■

Faster time response

■

Simplified installations

■

Reduced maintenance

How to order

Procedure

1. Choose two Rosemount 3051S ERS Transmitter models. These may be any combination of Rosemount 3051SAM and

Rosemount 3051SAL models.

Example

Rosemount 3051SAM

Coplanar

In-line

Example

Rosemount 3051SAL

Coplanar

In-line

2. Decide which model will be the ERS Primary (4–20 mA loop termination and optional LCD display) and which will be the ERS

Secondary. This will be specified by the “Configuration Type” code in each model number.

Product Data Sheet 5

Example

A. Secondary

B. Primary

3. Specify two full model numbers per the desired configuration.

Example

3051SAL1PG4AA1A1020DFF71DA00M5

3051SAM1ST2A2E11A2A

November 2018

Rosemount 3051SAM Transmitter for ERS Applications

■

Coplanar and in-line sensor module platforms

■

Variety of process connections including threaded NPT, flanges, manifolds, and Rosemount

1199 Remote Seals

■

Available with 15-year stability and 15-year limited warranty

Specification and selection of product materials, options, or components must be made by the

purchaser of the equipment. See Material selection for more information.

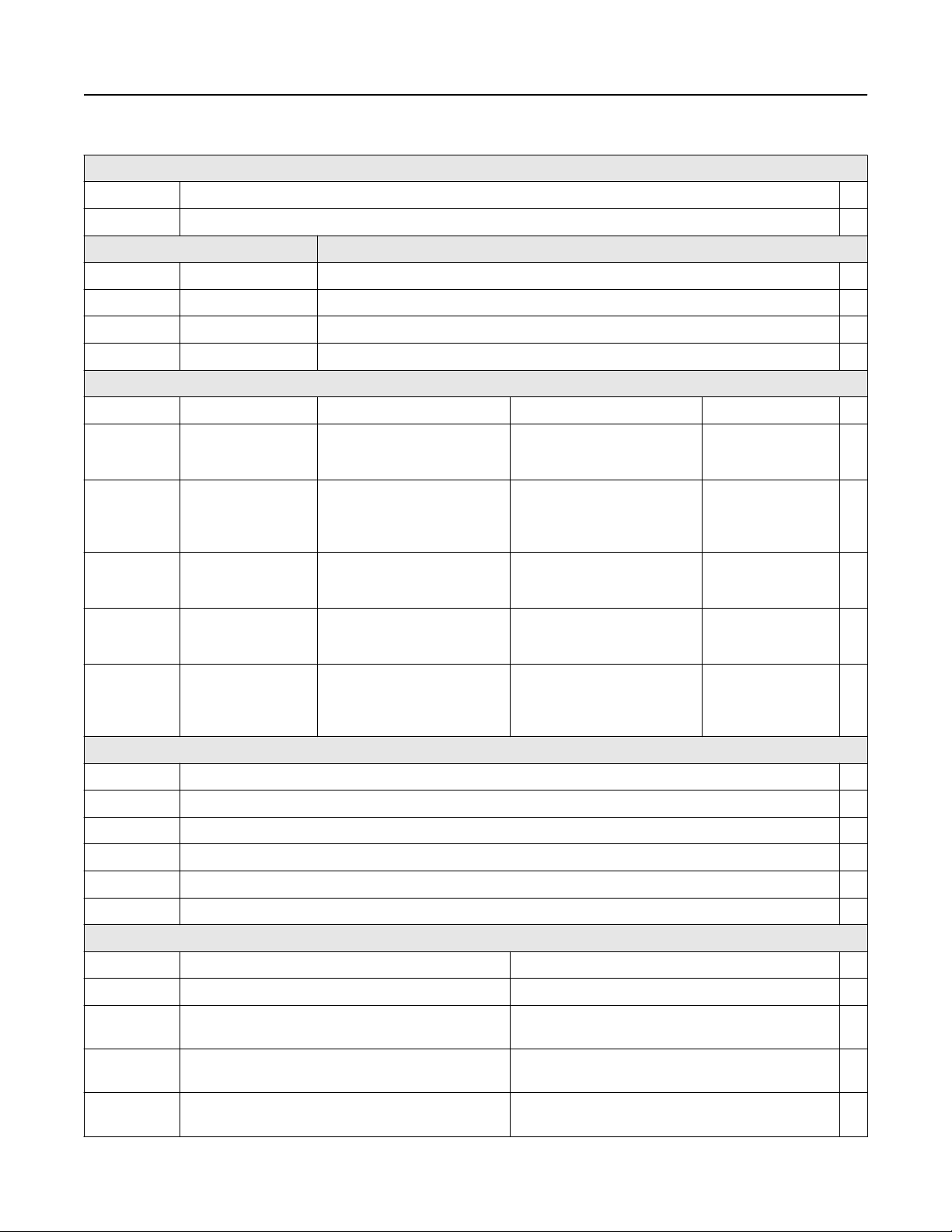

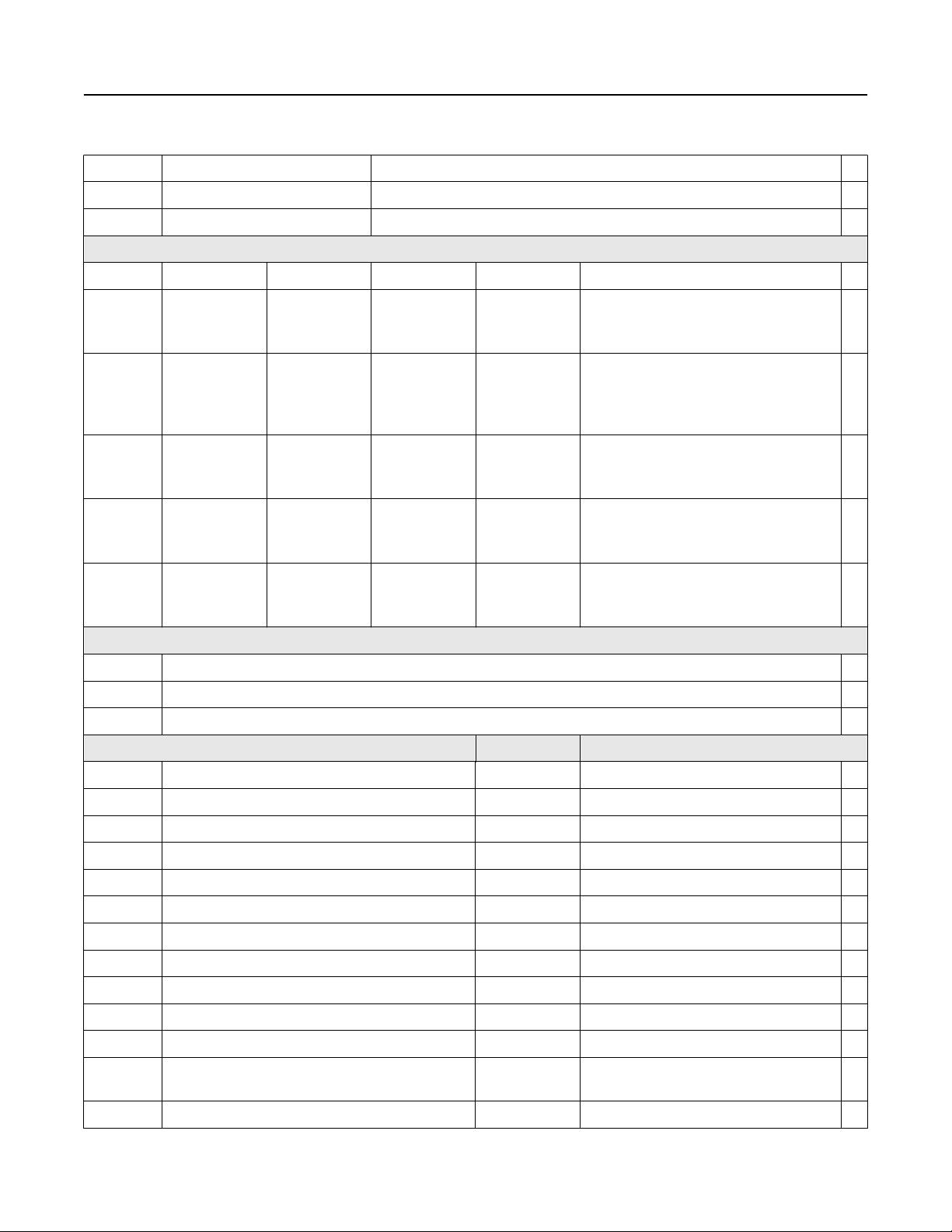

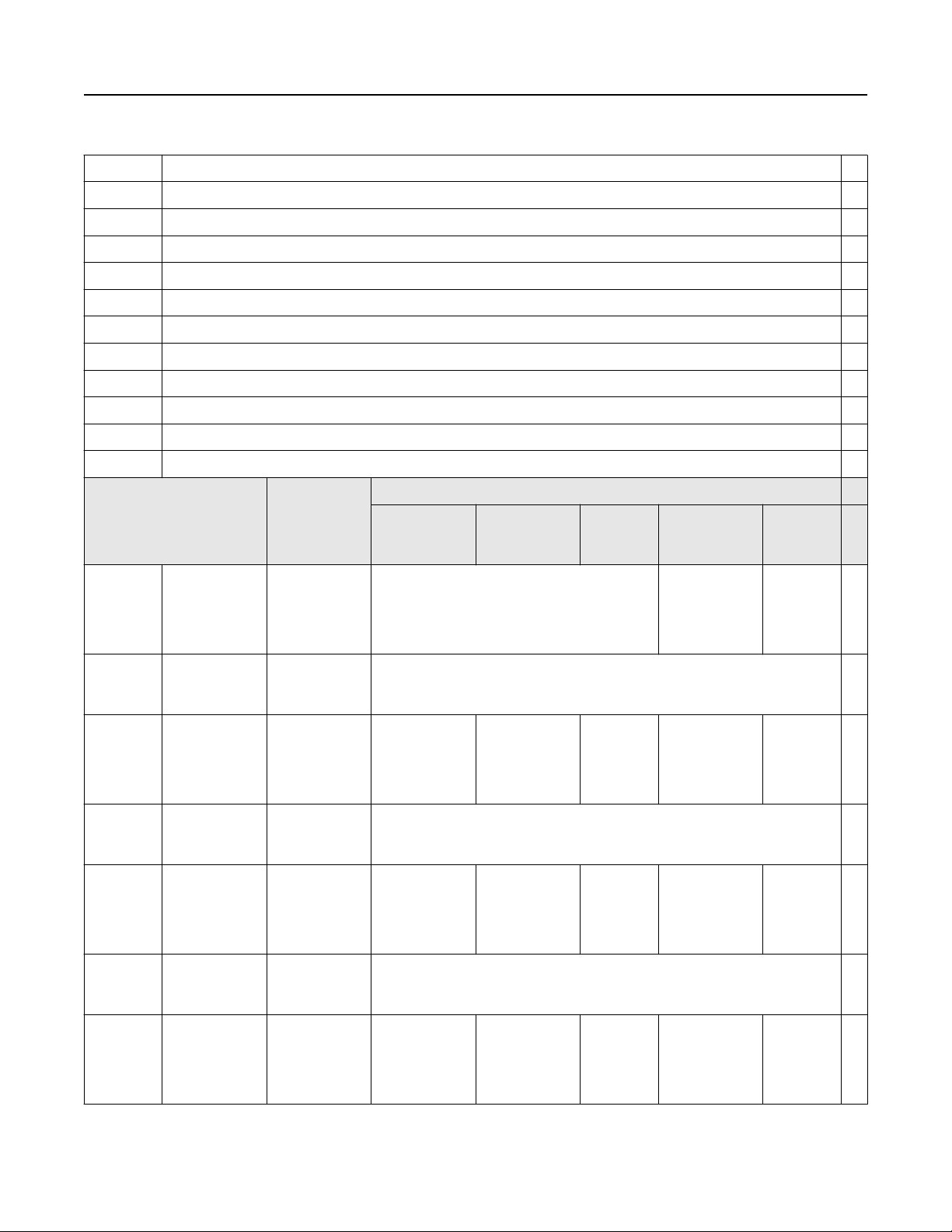

Table 1: Rosemount 3051SAM Transmitter for ERS Applications Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings

are subject to additional delivery lead time.

Model Transmitter type

3051SAM Scalable ERS Measurement Transmitter

Performance class

1 Ultra: 0.025% span accuracy, 200:1 rangedown, 15-year stability, 15-year limited warranty ★

2 Classic: 0.035% span accuracy, 150:1 rangedown, 15-year stability ★

(1)

4 Enhanced ERS System performance, 15-year stability, 15-year limited warranty ★

6 Emerson.com/Rosemount

November 2018

Table 1: Rosemount 3051SAM Transmitter for ERS Applications Ordering Information (continued)

Configuration type

P ERS - primary ★

S ERS - secondary ★

Pressure module type Pressure sensor type

G Coplanar Gage ★

T In-Line Gage ★

E In-Line Absolute ★

A Coplanar Absolute

Pressure range

(2)

Coplanar gage In-line gage In-line absolute Coplanar absolute

1A N/A –14.7 to 30 psig

(–1,01 to 2,06 bar)

2A –250 to 250 inH2O

(–621,60 to 621,60

–14.7 to 150 psig

(–1,01 to 10,34 bar)

mbar)

3A –393 to 1000 inH2O

(–0,97 to 2,48 bar)

4A –14.2 to 300 psig

(–0,97 to 20,68 bar)

5A –14.2 to 2000 psig

(–0,97 to 137,89

–14.7 to 800 psig

(–1,01 to 55,15 bar)

–14.7 to 4000 psig

(–1,01 to 275,79 bar)

–14.7 to 10000 psig

(–1,01 to 689,47 bar)

bar)

Isolating diaphragm

(3)(4)

2

3

4

5

6

7

(3)

(3)(4)

(4)(5)

(3)(4)

(3)(4)

316L stainless steel (SST) ★

Alloy C-276 ★

Alloy 400

Tantalum

Gold-plated Alloy 400 (includes graphite-filled PTFE O-Ring)

Gold-plated 316L SST

0 to 30 psia

(0 to 2,06 bar)

0 to 150 psia

(0 to 10,34 bar)

0 to 800 psia

(0 to 55,15 bar)

0 to 4000 psia (0 to 275,79

bar)

0 to 10000 psia

(0 to 689,47 bar)

0 to 30 psia

(0 to 2,06 bar)

0 to 150 psia

(0 to 10,34 bar)

0 to 800 psia

(0 to 55,15 bar)

0 to 4000 psia

(0 to 275,79 bar)

N/A ★

★

★

★

★

Process connection

Coplanar module type In-line module type

(6)

A11

A12

A15

(6)

(6)

Assemble to Rosemount 305 Manifold Assemble to Rosemount 306 Manifold ★

Assemble to Rosemount 304 or AMF Manifold with

SST traditional flange

Assemble to Rosemount 304 or AMF manifold to SST

Assemble AMF Manifold to ½-14 NPT female process

connection

N/A ★

★

traditional flange with alloy C-276 drain vents

(6)

A22

Assemble to Rosemount 304 or AMF manifold to SST

N/A ★

coplanar flange

Product Data Sheet 7

November 2018

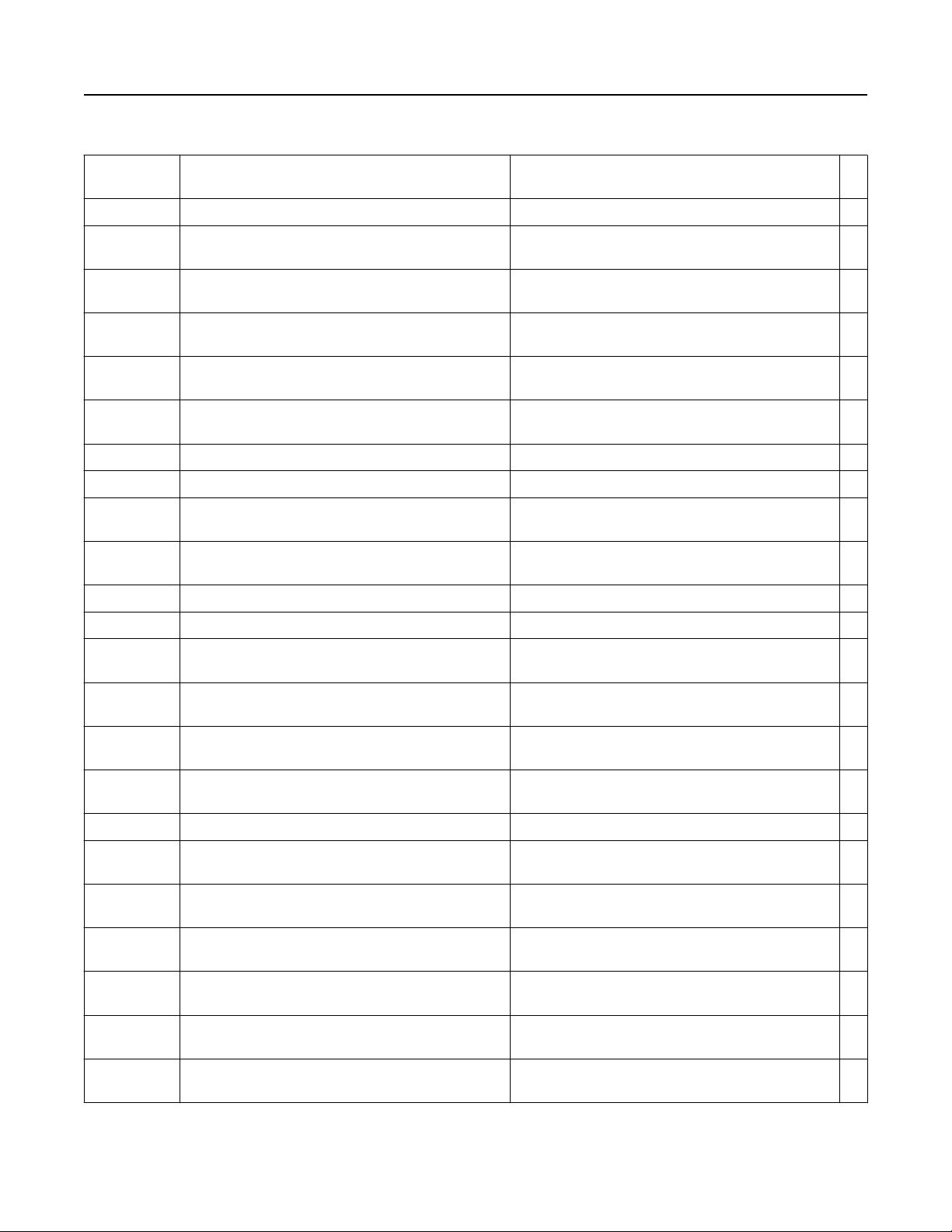

Table 1: Rosemount 3051SAM Transmitter for ERS Applications Ordering Information (continued)

(6)(7)

B11

Assemble to one Rosemount 1199 Remote

Diaphragm Seal with SST transmitter flange

Assemble to one Rosemount 1199 Remote

Diaphragm

E11 Coplanar flange (CS), ¼–18 NPT, 316 SST drain vents ½ –14 NPT female ★

★

E12 Coplanar flange (SST), ¼–18 NPT, 316 SST drain

N/A ★

vents

(3)

E13

Coplanar flange (Cast C-276), ¼–18 NPT, Alloy C-276

N/A ★

drain vents

E14 Coplanar flange (Cast Alloy 400), ¼–18 NPT, Alloy

N/A ★

400/K-500 drain vents

(3)

E15

Coplanar flange (SST), ¼–18 NPT, Alloy C-276 drain

N/A ★

vents

(3)

E16

Coplanar flange (CS), ¼–18 NPT, Alloy C-276 drain

N/A ★

vents

E21 Coplanar flange (CS), RC ¼, 316 SST drain vents N/A ★

E22 Coplanar flange (SST), RC ¼, 316 SST drain vents N/A ★

(3)

E23

Coplanar flange (Cast C-276), RC ¼, Alloy C-276 drain

N/A ★

vents

E24 Coplanar flange (Cast Alloy 400), RC ¼, alloy 400/

N/A ★

K-500 drain vents

(3)

E25

(3)

E26

F12 Traditional flange (SST), ¼–18 NPT, 316 SST drain

Coplanar flange (SST), RC ¼, Alloy C-276 drain vents N/A ★

Coplanar flange (CS), RC ¼, Alloy C-276 drain vents N/A ★

N/A ★

vents

(3)

F13

Traditional flange (Cast C-276), ¼–18 NPT, Alloy

N/A ★

C-276 drain vents

F14 Traditional flange (Cast Alloy 400), ¼–18 NPT, Alloy

N/A ★

400/K-500 drain vents

(3)

F15

Traditional flange (SST), ¼–18 NPT, Alloy C-276 drain

N/A ★

vents

F22 Traditional flange (SST), RC ¼, 316 SST drain vents N/A ★

(3)

F23

Traditional flange (Cast C-276), RC¼, Alloy C-276

N/A ★

drain vents

F24 Traditional flange (Cast Alloy 400), RC¼, Alloy 400/

N/A ★

K500 drain vents

(3)

F25

Traditional flange (SST), RC ¼, Alloy C-276 drain

N/A ★

vents

F52 DIN-compliant traditional flange (SST), ¼–18 NPT,

N/A ★

316 drain vents, 7 to 16-in. bolting

G11 Vertical mount level flange (SST), 2-in. ANSI Class

G½ A DIN 16288 male (range 1–4 only) ★

150, 316 SST drain vents

G12 Vertical mount level flange (SST), 2-in. ANSI Class

N/A ★

300, 316 SST drain vents

8 Emerson.com/Rosemount

November 2018

Table 1: Rosemount 3051SAM Transmitter for ERS Applications Ordering Information (continued)

G21 Vertical mount level flange (SST), 3-in. ANSI Class

150, 316 SST drain vents

G22 Vertical mount level flange (SST), 3-in. ANSI Class

300, 316 SST drain vents

G31 Vertical mount level flange (SST), DIN-DN 50 PN 40,

316 SST drain vents

G41 Vertical mount level flange (SST), DIN-DN 80 PN 40,

316 SST drain vents

P11 N/A Level flange (SST), 2-in. ANSI Class 150 ★

P12 N/A Level flange (SST), 2-in. ANSI Class 300 ★

P21 N/A Level flange (SST), 3-in. ANSI Class 150 ★

P22 N/A Level flange (SST), 3-in. ANSI Class 300 ★

P31 N/A Level flange (SST), DIN-DN 50 PN 40 ★

F11 Traditional flange (CS), ¼–18 NPT, 316 SST drain

vents

F32 Bottom vent traditional flange (SST), ¼–18 NPT, 316

SST drain vents

F42 Bottom vent traditional flange (SST), RC¼, 316 SST

drain vents

F62 DIN-compliant traditional flange (316 SST), ¼–18

NPT, 316 drain vents, M10 bolting

N/A ★

N/A ★

N/A ★

N/A ★

Non-threaded instrument flange (I-Flange)

N/A

N/A

N/A

F72 DIN-compliant traditional flange (316 SST), ¼–18

NPT, 316 drain vents, M12 bolting

Transmitter output

A 4–20 mA with digital signal based on HART protocol ★

Housing style Material Conduit entry size

Housings for ERS primary - configuration type code P

1A Plantweb™ housing Aluminum ½–14 NPT ★

1B Plantweb housing Aluminum M20 x 1.5 (CM 20) ★

1J Plantweb housing SST ½–14 NPT ★

1K Plantweb housing SST M20 x 1.5 (CM 20) ★

2E Junction box with remote display

output

2F Junction box with remote display

output

2M Junction box with remote display

output

1C Plantweb housing Aluminum G½

1L Plantweb housing SST G½

2G Junction box with remote display

output

Aluminum ½–14 NPT ★

Aluminum M20 x 1.5 (CM 20) ★

SST ½–14 NPT ★

Aluminum G½

N/A

Product Data Sheet 9

November 2018

Table 1: Rosemount 3051SAM Transmitter for ERS Applications Ordering Information (continued)

Housings for ERS secondary - configuration type code S

2A Junction box Aluminum ½–14 NPT ★

2B Junction box Aluminum M20 x 1.5 (CM 20) ★

2J Junction box SST ½–14 NPT ★

2C Junction box Aluminum G½

Options (include with selected model number)

Extended product warranty

WR3 3-year limited warranty ★

WR5 5-year limited warranty ★

ERS connection cable

R02 25 ft. (7,62 m) of ERS cable (gray color)

R05 50 ft. (15,2 m) of ERS cable (gray color) ★

R10 100 ft. (30,5 m) of ERS cable (gray color) ★

R15 150 ft. (45,72 m) of ERS cable (gray color) ★

(8)

R20

R22

(9)

200 ft. (60,96 m) of ERS cable (gray color)

225 ft. (68,58 m) of ERS cable (gray color)

R30 300 ft. (91,44 m) of ERS cable (gray color)

R40 400 ft. (121,92 m) of ERS cable (gray color)

R50 500 ft. (152,4 m) of ERS cable (gray color)

H02 25 ft. (7,62 m) of ERS cable (blue color)

H05 50 ft. (15,2 m) of ERS cable (blue color)

H10 100 ft. (30,5 m) of ERS cable (blue color)

H15 150 ft. (45,7 m) of ERS cable (blue color)

(8)

H20

H22

(9)

200 ft. (60,96 m) of ERS cable (blue color)

225 ft. (68,58 m) of ERS cable (blue color)

J02 25 ft. (7,62 m) of ERS armored cable

J05 50 ft. (15,2 m) of ERS armored cable

J07 75 ft. (22,8 m) of ERS armored cable

J10 100 ft. (30,5 m) of ERS armored cable

(9)

J12

125 ft. (38,1 m) of ERS armored cable

Mounting bracket

(4)

B1

B2

B3

(4)

(4)

Traditional flange bracket, CS, 2-in. pipe ★

Traditional flange bracket, CS, panel ★

Traditional flange flat bracket, CS, 2-in. pipe ★

B4 Bracket, all SST, 2-in. pipe and panel ★

(4)

B7

Traditional flange bracket, B1 with SST bolts ★

10 Emerson.com/Rosemount

November 2018

Table 1: Rosemount 3051SAM Transmitter for ERS Applications Ordering Information (continued)

(4)

B8

B9

BA

BC

(4)

(4)

(4)

Traditional flange bracket, B2 with SST bolts ★

Traditional flange bracket, B3 with SST bolts ★

Traditional flange bracket, B1, all SST ★

Traditional flange bracket, B3, all SST ★

Special configuration (software)

(10)

C1

Customer software configuration (Configuration Data Sheet must be completed) ★

C3 Gage pressure calibration on Rosemount 3051SAM A4 only ★

(10)

C4

C5

C6

C7

C8

(10)

(10)

(10)

(10)

NAMUR alarm and saturation levels, high alarm ★

NAMUR alarm and saturation levels, low alarm ★

Custom alarm and saturation levels, high alarm (requires C1 and Configuration Data Sheet) ★

Custom alarm and saturation levels, low alarm (requires C1 and Configuration Data Sheet) ★

Low alarm (standard Rosemount alarm and saturation levels) ★

Special configuration (hardware)

(11)

D2

D4

D5

D7

D9

(12)

(11)

(11)

(11)

¼–14 NPT flange adapters ★

External ground screw assembly ★

Delete transmitter drain/vent valves (install plugs) ★

Coplanar flange without drain/vent ports

RC ½ flange adapters

Product certifications

E1 ATEX Flameproof ★

I1 ATEX Intrinsic Safety ★

N1 ATEX Type n ★

K1 ATEX Flameproof and Intrinsically Safe, Type n, Dust ★

ND ATEX Dust ★

E4 TIIS Flameproof ★

E5 FM Explosion-proof, Dust Ignition-proof ★

I5 FM Intrinsically Safe, Division 2 ★

K5 FM Explosion-proof, Dust Ignition-proof, Intrinsically Safe, Division 2 ★

(13)

E6

CSA Explosion-proof, Dust Ignition-proof, Division 2 ★

I6 CSA Intrinsically Safe ★

(13)

K6

CSA Explosion-proof, Dust Ignition-proof, Intrinsically Safe, Division 2 ★

E7 IECEx Flameproof ★

I7 IECEx Intrinsic Safety ★

N7 IECEx Type n ★

K7 IECEx Flameproof, Intrinsic Safety, Type n ★

E2 INMETRO Flameproof ★

Product Data Sheet 11

November 2018

Table 1: Rosemount 3051SAM Transmitter for ERS Applications Ordering Information (continued)

I2 INMETRO Intrinsically Safe ★

K2 INMETRO Flameproof, Intrinsic Safety, Type n ★

E3 China Flameproof ★

I3 China Intrinsic Safety, Dust Ignition-proof ★

EP Korea Flameproof ★

IP Korea Intrinsic Safety ★

KP Korea Flameproof, Intrinsic Safety ★

EM Technical Regulations Customs Union (EAC) Flameproof ★

IM Technical Regulations Customs Union (EAC) Intrinsic Safety ★

KM Technical Regulations Customs Union (EAC) Flameproof, Intrinsic Safety ★

(13)

KA

KB

(13)

ATEX and CSA Flameproof, Intrinsically Safe, Division 2 ★

FM and CSA Explosion-proof, Dust Ignition-proof, Intrinsically Safe, Division 2 ★

KC FM and ATEX Explosion-proof, Intrinsically Safe, Division 2 ★

(13)

KD

FM, CSA, and ATEX Explosion-proof, Intrinsically Safe ★

Shipboard approvals

SBS American Bureau of Shipping (ABS) Type Approval ★

SBV Bureau Veritas (BV) Type Approval ★

SDN Det Norske Veritas (DNV) Type Approval ★

SLL Lloyds Register (LR) Type Approval ★

Calibration certification

Q4 Calibration certificate ★

QP Calibration certificate and tamper evident seal ★

Material traceability certification

Q8 Material traceability certification per EN 10204 3.1 ★

Quality certification for safety

QS Prior-use certificate of FMEDA Data ★

QT Safety certified to IEC 61508 with certificate of FMEDA data ★

Surface finish certification

Q16 Surface finish certification for hygienic remote seals ★

Toolkit performance reports

(14)

QZ Remote seal system performance calculation report ★

Terminal blocks

(15)

T1 Transient terminal block ★

Sensor fill fluid

(16)

L1 Inert sensor fill fluid ★

12 Emerson.com/Rosemount

November 2018

Table 1: Rosemount 3051SAM Transmitter for ERS Applications Ordering Information (continued)

O-ring

L2 Graphite-filled PTFE O-ring ★

Bolting material

(11)

L4 Austenitic 316 SST bolts ★

(3)

L5

ASTM A 193, Grade B7M bolts ★

L6 Alloy K-500 bolts ★

(3)

L7

ASTM A 453, Class D, Grade 660 bolts ★

L8 ASTM A 193, Class 2, Grade B8M bolts ★

Display type (ERS primary only)

(10)

M5 Plantweb LCD display ★

(17)

M7

Remote mount LCD display and interface, Plantweb housing, no cable, SST bracket ★

M8 Remote mount LCD display and interface, Plantweb housing, 50 ft. (15,2 m) cable, SST bracket ★

M9 Remote mount LCD display and interface, Plantweb housing, 100 ft. (30,5 m) cable, SST bracket ★

Pressure testing

P1 Hydrostatic testing with certificate

Special cleaning

(11)

P2 Cleaning for special services

P3 Cleaning for less than 1 PPM Chlorine/Fluorine

NACE® certificate

(3)

Q15 Certificate of compliance to NACE MR0175/ISO 15156 for wetted materials ★

Q25 Certificate of compliance to NACE MR0103 for wetted materials ★

Typical model number: 3051SAM 1 S T 2A 2 E11 A 2A

See “Specifications” section for more detail. The Rosemount 3051S ERS System offers three performance class options; Classic, Ultra, and

(1)

Enhanced ERS system performance. The Classic and Ultra performance classes are suited to lower static pressure and stable temperature

conditions. The Enhanced ERS system performance class provides better performance across temperature (–40 to 185 °F) with improved

performance at higher static pressure.

The pressure range should be specified based on the maximum static pressure, not differential pressure.

(2)

Materials of construction comply with metallurgical requirements highlighted within NACE MR 0175/ISO 15156 for sour oil field production

(3)

environments. Environmental limits apply to certain materials. Consult latest standard for details. Selected materials also conform to NACE MR

0103 for sour refining environments. Order with Q15 or Q25 to receive a NACE certificate.

Not available with pressure sensor/module codes T or E.

(4)

Tantalum diaphragm material is only available with Pressure Sensor/Module code G.

(5)

“Assemble to” items are specified separately and require a completed model number.

(6)

Consult an Emerson™ representative for performance specifications.

(7)

Maximum cable distance for SIS installations. See Rosemount 3051S ERS Reference Manual for more information.

(8)

Maximum cable distance for IS (Intrinsically safe) installations. Other options may not be valid at longer distances.

(9)

Not available with Configuration Type code S.

(10)

Not available with Process Connection code A11.

(11)

This assembly is included with options E1, N1, K1, ND, E4, E7, N7, K7, E2, KA, KC, KD, K2, T1, EP, and KP.

(12)

Not available with M20 or G½ conduit entry size.

(13)

The QZ report quantifies the performance of the entire ERS system. One report is provided per ERS system. The QZ option is specified on the

(14)

primary transmitter (configuration type code P).

Not available with configuration type code S.

(15)

Silicone fill fluid is standard.

(16)

See the Rosemount 3051S Reference Manual for cable requirements. Contact an Emerson representative for additional information.

(17)

Product Data Sheet 13

November 2018

Rosemount 3051SAL Transmitter for ERS Applications

■

Integrated transmitter and direct mount seal in a single model number

■

Variety of process connections including flanged, threaded, and hygienic remote seals

■

Available with 15-year limited warranty

Specification and selection of product materials, options, or components must be made by the

purchaser of the equipment. See Material selection for more information .

A Rosemount 3051SAL Scalable ERS Level Transmitter consists of three parts. First, specify the transmitter model codes found in

Table 2 . Then, specify a direct mount seal found here: Diaphragm seals for Rosemount 3051SAL. Finish the model number by

specifying all desired options from the "Options" section of Table 2.

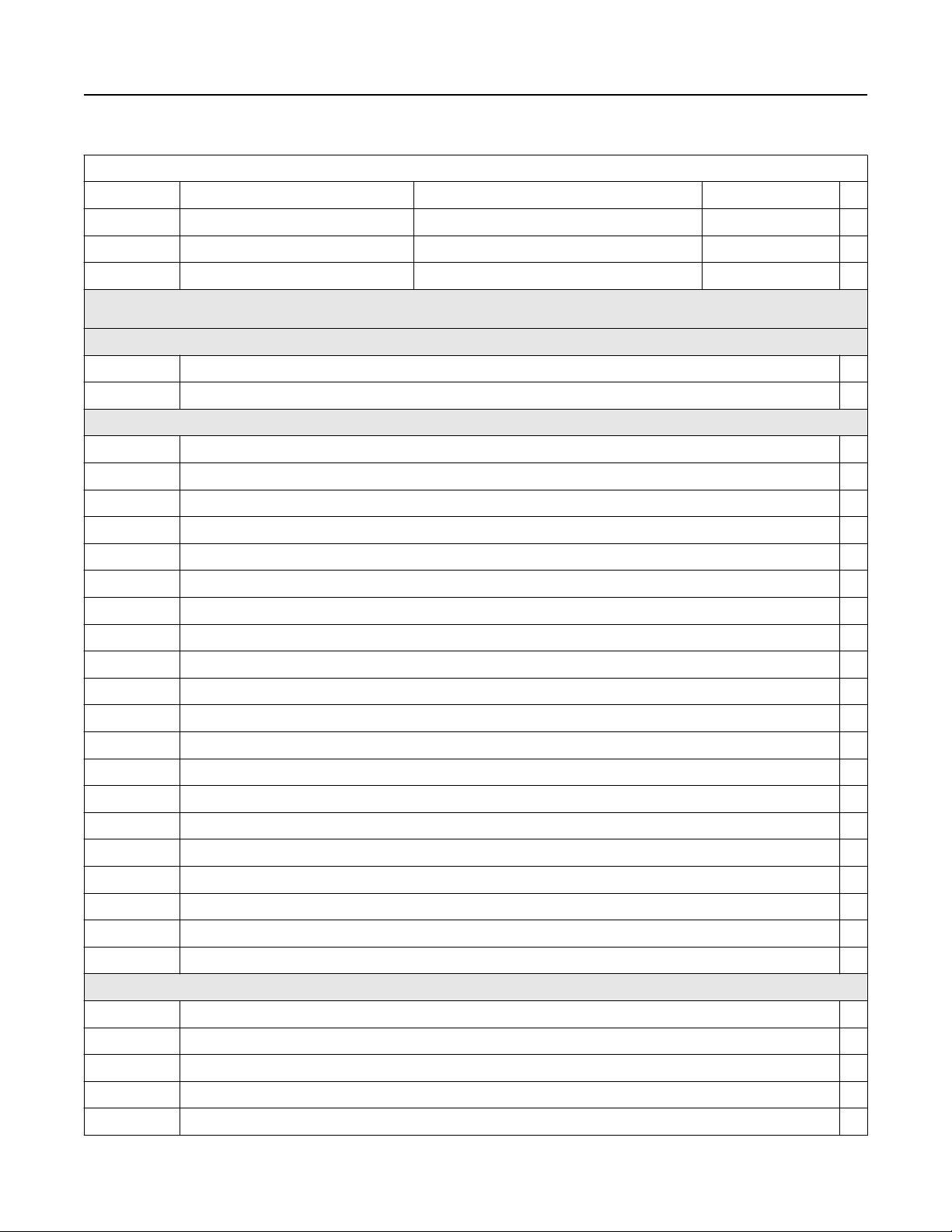

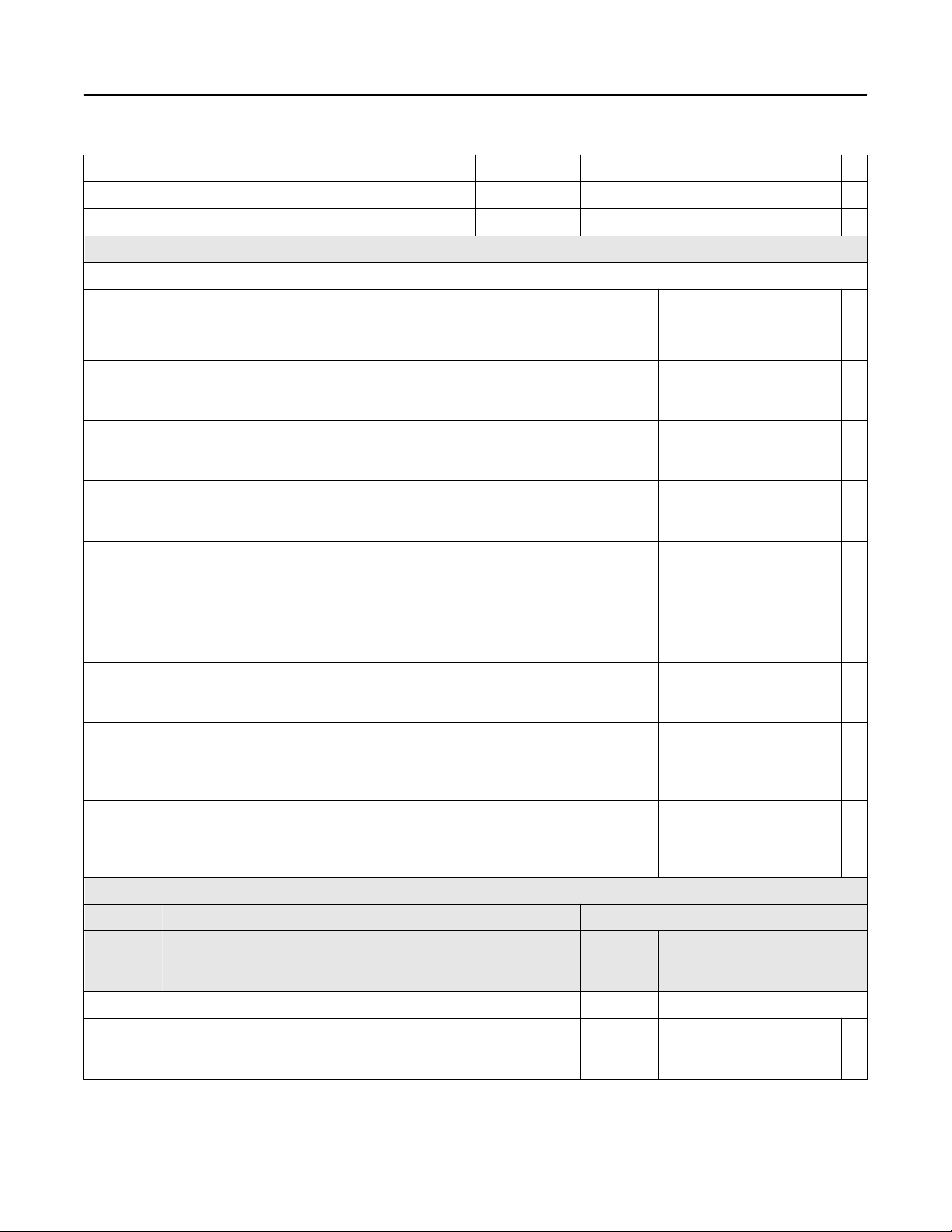

Table 2: Rosemount 3051SAL Transmitter for ERS Applications Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings

are subject to additional delivery lead time.

Model Transmitter type

3051SAL Scalable level transmitter

Performance class

(1)

1 Ultra: 0.055% span accuracy, 150:1 rangedown, 15-year limited warranty ★

2 Classic: 0.065% span accuracy, 150:1 rangedown ★

4 Enhanced ERS system performance, 15-year limited warranty ★

Configuration type

P ERS - primary ★

S ERS - secondary ★

Pressure module type Pressure sensor type

G Coplanar Gage ★

T In-line Gage ★

E In-line Absolute ★

A Coplanar Absolute

Pressure range

Coplanar gage In-line gage In-line absolute Coplanar

1A N/A –14.7 to 30 psig (–1,01 to 2,06

2A –250 to 250 inH2O (–

(2)

621,60 to 621,60

mbar)

bar)

–14.7 to 150 psig (–1,01 to

10,34 bar)

absolute

0 to 30 psia (0 to 2,06 bar) 0 to 30 psia (0

to 2,06 bar)

0 to 150 psia (0 to 10,34 bar) 0 to 150 psia

(0 to 10,34

bar)

★

★

3A –393 to 1000 inH2O

(–0,97 to 2,48 bar)

–14.7 to 800 psig (–1,01 to

55,15 bar)

0 to 800 psia (0 to 55,15 bar) 0 to 800 psia

(0 to 55,15

bar)

★

14 Emerson.com/Rosemount

November 2018

Table 2: Rosemount 3051SAL Transmitter for ERS Applications Ordering Information (continued)

4A –14.2 to 300 psig(–

0,97 to 20,68 bar)

–14.7 to 4000 psig (–1,0 to

275,79 bar)

0 to 4000 psia (0 to 275,79 bar) 0 to 4000 psia

(0 to 275,79

bar)

5A –14.2 to 2000 psig (–

0,97 to 137,89 bar)

–14.7 to 10000 psig (–1,01 to

689,47 bar)

0 to 10000 psia (0 to 689,47

bar)

N/A ★

Transmitter output

A 4–20 mA with digital signal based on HART Protocol ★

Housing style Material Conduit entry size

Housings for ERS primary - configuration type code P

1A Plantweb housing Aluminum ½–14 NPT ★

1B Plantweb housing Aluminum M20 x 1.5 (CM 20) ★

1J Plantweb housing SST ½–14 NPT ★

1K Plantweb housing SST M20 x 1.5 (CM 20) ★

2E Junction box with remote display

Aluminum ½–14 NPT ★

output

2F Junction box with remote display

Aluminum M20 x 1.5 (CM 20) ★

output

2M Junction box with remote display

SST ½–14 NPT ★

output

★

1C Plantweb housing Aluminum G½

1L Plantweb housing SST G½

2G Junction box with remote display

Aluminum G½

output

Housings for ERS secondary - configuration type code S

2A Junction box Aluminum ½–14 NPT ★

2B Junction box Aluminum M20 x 1.5 (CM 20) ★

2J Junction box SST ½–14 NPT ★

2C Junction box Aluminum G½

Seal system type

(3)

Coplanar pressure module type

1 Single direct mount

Welded-repairable ★

seal system

2 Single direct mount

All welded ★

seal system

In-line pressure module type

1 Single direct mount

All welded ★

seal system

High side connection type

Single direct mount seal system (between transmitter and remote seal)

0 No extension ★

Product Data Sheet 15

November 2018

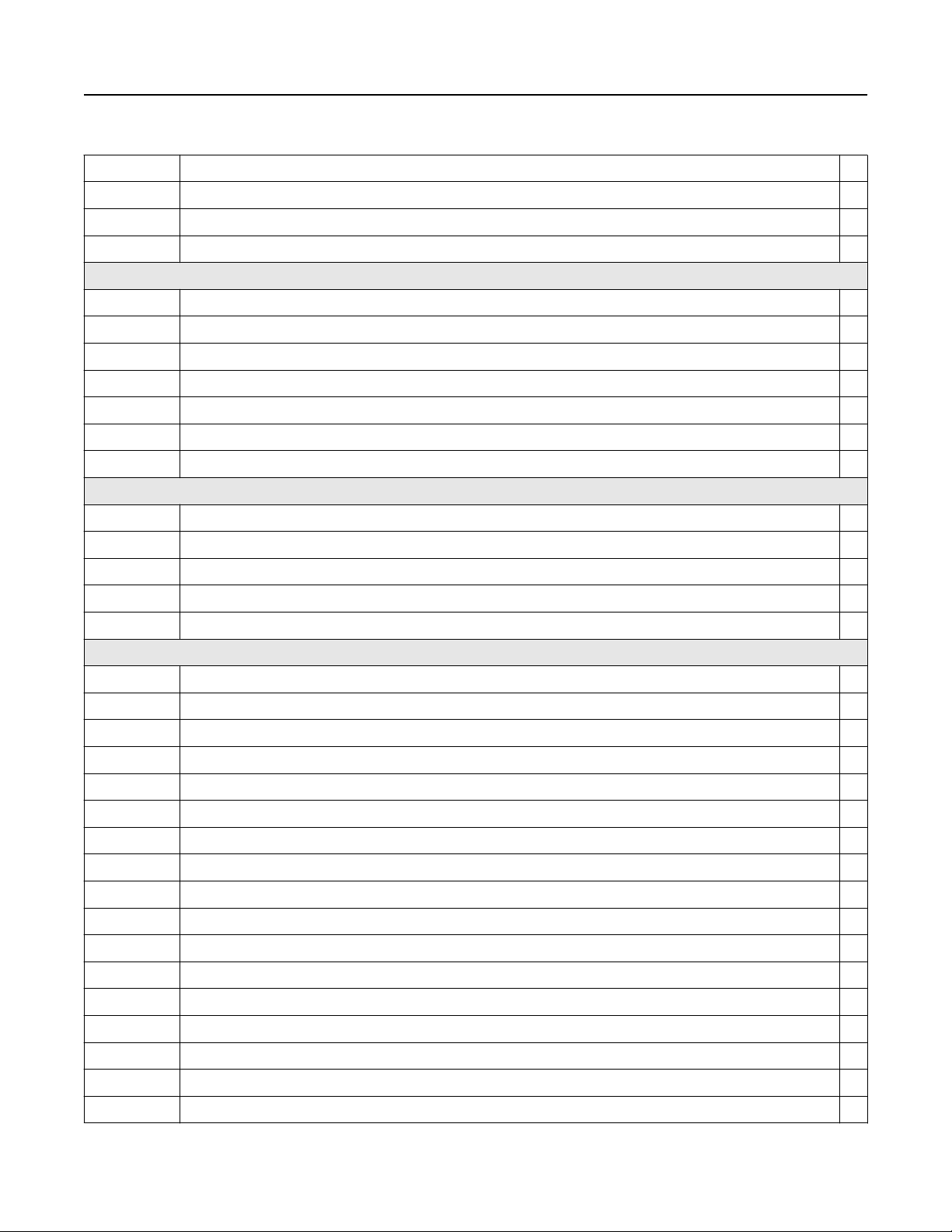

Table 2: Rosemount 3051SAL Transmitter for ERS Applications Ordering Information (continued)

2 2-in. (50 mm) extension ★

4 4-in. (100 mm) extension ★

(4)

5

6

7

(5)

(5)(6)

Thermal Optimizer ★

Thermal Range Expander - Silicone 200 secondary fill fluid ★

Thermal Range Expander - SYLTHERM™ XLT secondary fill fluid ★

Low side connection type (reference pressure connection)

Single direct mount seal system

00 None (In-line style sensor) ★

20 316L SST isolator/SST transmitter flange ★

30 Alloy C-276 isolator/SST transmitter flange ★

Seal fill fluid Specific

gravity at 77

°F (25 °C)

Temperature limits

No extension 2-in. (50 mm)

(7)(8)

extension

4-in. (100

mm)

Thermal Range

Expander

(9)

extension

D Silicone 200 0.934 –49 to 401 °F (–45 to 205 °C) N/A ★

F Silicone 200 for

vacuum applications

0.934 For use in vacuum applications below 14.7 psia (1 bar-a), refer to

vapor pressure curves in Rosemount DP Level Fill Fluid

Specification Technical Note.

(10)

J

(10)

Q

Tri-Therm 300 0.795 –40 to 401 °F

(–40 to 205 °C)

Tri-Therm 300 for

vacuum applications

0.795 For use in vacuum applications below 14.7 psia (1 bar-a), refer to

vapor pressure curves in Rosemount DP Level Fill Fluid

–40 to 464 °F

(–40 to 240 °C)

–40 to 572 °F

(–40 to 300 °C)

N/A ★

Specification Technical Note.

L Silicone 704 1.07 32 to 401 °F (0

to 205 °C)

C Silicone 704 for

vacuum applications

1.07 For use in vacuum applications below 14.7 psia (1 bar-a), refer to

vapor pressure curves in Rosemount DP Level Fill Fluid

32 to 464 °F (0

to 240 °C)

32 to 572 °F (0

to 300 °C)

Up to 599 °F

(315 °C)

Specification Technical Note.

R Silicone 705 1.09 68 to 401 °F

(20 to 205 °C)

V Silicone 705 for

vacuum applications

1.09 For use in vacuum applications below 14.7 psia (1 bar-a), refer to

vapor pressure curves in Rosemount DP Level Fill Fluid

68 to 464 °F

(20 to 240 °C)

68 to 572 °F

(20 to 300 °C)

Up to 698 °F

(370 °C)

Specification Technical Note.

A SYLTHERM XLT 0.85 –157 to 293 °F (–105 to 145 °C) N/A ★

H Inert (Halocarbon) 1.85 –49 to 320 °F (–45 to 160 °C) N/A ★

(10)(11)

G

(10)

N

Glycerin and water 1.13 5 to 203 °F (–15 to 95 °C) N/A ★

Neobee® M-20 0.94 5 to 401 °F (–

5 to 437 °F (–15 to 225 °C) N/A ★

15 to 205 °C)

(10)(11)

P

Propylene glycol and

1.02 5 to 203 °F (–15 to 95 °C) N/A ★

water

(12)

Y

UltraTherm™ 805 1.20 N/A Up to 770 °F

( 410 °C)

(13)

★

★

★

★

★

★

★

16 Emerson.com/Rosemount

November 2018

Table 2: Rosemount 3051SAL Transmitter for ERS Applications Ordering Information (continued)

(12)

Z

UltraTherm 805 for

vacuum applications

1.20 For use in vacuum applications below 14.7 psia (1 bar-a), refer to

vapor pressure curves in Rosemount DP Level Fill Fluid

Specification Technical Note.

Continue specifying a completed model number by choosing a remote seal type below:

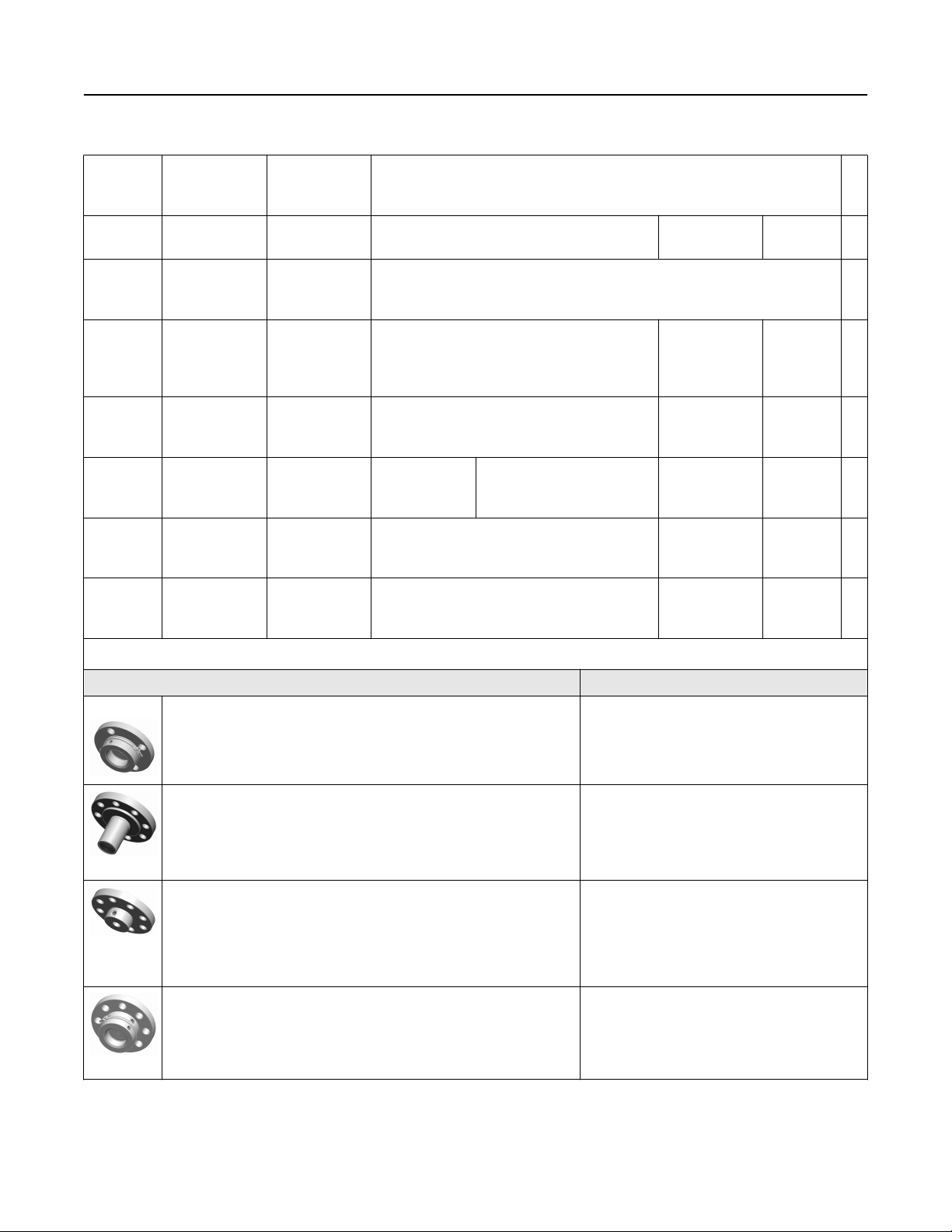

Seal style Process connections

FF Flush Flanged Seal 2-in./DN 50/50A

3-in./DN 80/80A

4-in./ DN 100/100A

EF Extended Flanged Seal 3-in./DN 80/80A

4-in./DN 100/100A

RF Remote Flanged Seal ½-in.

¾-in

1-in./DN 25/25A

1½-in./DN 40/40A

★

PF Pancake Seal 2-in./DN 50/50A

3-in./DN 80/80A

FC Flush Flanged Seal - Ring Type Joint (RTJ) gasket surface 2-in.

3-in.

RC Remote Flanged Seal - Ring Type Joint (RTJ) gasket surface ½-in.

¾-in

1-in.

1½-in.

RT Remote Threaded Seal ¼ –18 NPT

½ –14 NPT

¾ –14 NPT

1–11.5 NPT

1¼–11.5 NPT

SC Hygienic Tri-Clamp Seal 1½-in.

2-in.

3-in.

Product Data Sheet 17

November 2018

Table 2: Rosemount 3051SAL Transmitter for ERS Applications Ordering Information (continued)

SS Hygienic Tank Spud Seal 4-in.

Options (include with selected model number)

Extended product warranty

WR3 3-year limited warranty ★

WR5 5-year limited warranty ★

ERS connection cable

(14)

R02 25 ft. (7,62 m) of ERS cable (gray color)

R05 50 ft. (15,2 m) of ERS cable (gray color) ★

R10 100 ft. (30,5 m) of ERS cable (gray color) ★

R15 150 ft. (45,72 m) of ERS cable (gray color) ★

(15)

R20

R22

(16)

200 ft. (60,96 m) of ERS cable (gray color)

225 ft. (68,58 m) of ERS cable (gray color)

R30 300 ft. (91,44 m) of ERS cable (gray color)

R40 400 ft. (121,92 m) of ERS cable (gray color)

R50 500 ft. (152,4 m) of ERS cable (gray color)

H02 25 ft. (7,62 m) of ERS cable (blue color)

H05 50 ft. (15,2 m) of ERS cable (blue color)

H10 100 ft. (30,5 m) of ERS cable (blue color)

H15 150 ft. (45,7 m) of ERS cable (blue color)

(15)

H20

H22

(16)

200 ft. (60,96 m) of ERS cable (blue color)

225 ft. (68,58 m) of ERS cable (blue color)

J02 25 ft. (7,62 m) of armored ERS cable

J05 50 ft. (15,2 m) of armored ERS cable

J07 75 ft. (22,8 m) of armored ERS cable

J10 100 ft. (30,5 m) of armored ERS cable

(16)

J12

Software configuration

125 ft. (38,1 m) of armored ERS cable

(17)

C1 Custom software configuration (requires Configuration Data Sheet) ★

Gage pressure calibration

C3 Gage pressure calibration on Rosemount 3051SAL A4 only ★

Alarm limit

(17)

C4 NAMUR alarm and saturation levels, high alarm ★

C5 NAMUR alarm and saturation levels, low alarm ★

18 Emerson.com/Rosemount

November 2018

Table 2: Rosemount 3051SAL Transmitter for ERS Applications Ordering Information (continued)

C6 Custom alarm and saturation levels, high alarm (requires C1 and Configuration Data Sheet) ★

C7 Custom alarm and saturation levels, low alarm (requires C1 and Configuration Data Sheet) ★

C8 Low alarm (standard Rosemount alarm and saturation levels) ★

Ground screw

(18)

D4 External ground screw assembly ★

Conduit plug

DO 316 SST conduit plug ★

Product certifications

E1 ATEX Flameproof ★

I1 ATEX Intrinsic Safety ★

N1 ATEX Type n ★

K1 ATEX Flameproof and Intrinsically Safe, Type n, Dust ★

ND ATEX Dust ★

E4 TIIS Flameproof ★

E5 FM Explosion-proof, Dust Ignition-proof ★

I5 FM Intrinsically Safe, Division 2 ★

K5 FM Explosion-proof, Dust Ignition-proof, Intrinsically Safe, Division 2 ★

(19)

E6

CSA Explosion-proof, Dust Ignition-proof, Division 2 ★

I6 CSA Intrinsically Safe ★

(19)

K6

CSA Explosion-proof, Dust Ignition-proof, Intrinsically Safe, Division 2 ★

E7 IECEx Flameproof ★

I7 IECEx Intrinsic Safety ★

N7 IECEx Type n ★

K7 IECEx Flameproof, Intrinsic Safety, Type n ★

E2 INMETRO Flameproof ★

I2 INMETRO Intrinsically Safe ★

K2 INMETRO Flameproof, Intrinsic Safety, Type n ★

EP Korea Flameproof ★

E3 China Flameproof ★

I3 China Intrinsic Safety, Dust Ignition-proof ★

IP Korea Intrinsic Safety ★

KP Korea Flameproof, Intrinsic Safety ★

EM Technical Regulations Customs Union (EAC) Flameproof ★

IM Technical Regulations Customs Union (EAC) Intrinsic Safety ★

IN Technical Regulations Customs Union (EAC) FISCO Intrinsic Safety ★

KM Technical Regulations Customs Union (EAC) Flameproof, Intrinsic Safety ★

Product Data Sheet 19

November 2018

Table 2: Rosemount 3051SAL Transmitter for ERS Applications Ordering Information (continued)

(19)

KA

KB

(19)

ATEX and CSA Flameproof, Intrinsically Safe, Division 2 ★

FM and CSA Explosion-proof, Dust Ignition-proof, Intrinsically Safe, Division 2 ★

KC FM and ATEX Explosion-proof, Intrinsically Safe, Division 2 ★

(19)

KD

FM, CSA, and ATEX Explosion-proof, Intrinsically Safe ★

Shipboard approvals

SBS American Bureau of Shipping (ABS) Type Approval ★

SBV Bureau Veritas (BV) Type Approval ★

SDN Det Norske Veritas (DNV) Type Approval ★

SLL Lloyds Register (LR) Type Approval ★

Sensor fill fluid

(20)

L1 Inert sensor fill fluid ★

O-ring

L2 Graphite-filled PTFE O-ring ★

Bolting material

L4 Austenitic 316 SST bolts ★

Display type (ERS primary only)

(17)

M5 Plantweb LCD display ★

(21)

M7

Remote mount LCD display and interface, Plantweb housing, no cable, SST bracket ★

M8 Remote mount LCD display and interface, Plantweb housing, 50 ft. (15,2 m) cable, SST bracket ★

M9 Remote mount LCD display and interface, Plantweb housing, 100 ft. (30,5 m) cable, SST bracket ★

Pressure testing

P1 Hydrostatic testing with certificate

Special cleaning

P2 Cleaning for special services

P3 Cleaning for Less than 1 PPM Chlorine/Fluorine

Calibration certification

Q4 Calibration certificate ★

QP Calibration certificate with tamper evident seal ★

Material traceability certification

Q8 Material traceability certification per EN 10204 3.1 ★

Quality certification for safety

QS Prior-use certificate of FMEDA Data ★

QT Safety certified to IEC 61508 with certificate of FMEDA data ★

Toolkit performance reports

(22)

QZ Remote seal system performance calculation report ★

20 Emerson.com/Rosemount

November 2018

Table 2: Rosemount 3051SAL Transmitter for ERS Applications Ordering Information (continued)

Transient protection

(17)

T1 Transient terminal block ★

NACE® certificate

(23)

Q15 Certificate of compliance to NACE MR0175/ISO 15156 for wetted materials ★

Q25 Certificate of compliance to NACE MR0103 for wetted materials ★

Typical model number: 3051SAL 1 P G 4A A 1A 1 0 20 D FF 7 1 DA 0 0 M5

See “Specifications” section for more detail. The Rosemount 3051S ERS System offer three performance class options; Classic, Ultra, and

(1)

Enhanced ERS system performance. The Classic and Ultra performance classes are suited to lower static pressure and stable temperature

conditions. The Enhanced ERS system performance class provides better performance across temperature (–40 to 185 °F) with improved

performance at higher static pressure.

Not suitable for vacuum applications.

(2)

See Seal system type in Rosemount DP Level Product Data Sheet for more detail.

(3)

Maximum working pressure (MWP) of the Thermal Optimizer is 4000 psi (275 bar). See Figure 6, Figure 7, or Table 52 for Thermal Optimizer

(4)

temperature limits.

Maximum working pressure (MWP) of the Thermal Range Expander is 3750 psi (258,6 bar).

(5)

Thermal Range Expander with SYLTHERM XLT secondary fill fluid is not recommended for use in vacuum applications below 6 psia (400 mbar-a).

(6)

At ambient pressure of 14.7 psia (1 bar-a) and ambient temperature of 70 °F (21 °C). Temperature limits are reduced in vacuum service and may

(7)

be limited by seal selection.

Due to heat transfer to the transmitter, the maximum process temperature of the transmitter will be de-rated if ambient or process temperatures

(8)

exceed 185 °F (85 °C). Consult Instrument Toolkit™ to verify the application.

For complete process and ambient temperature limits, see Thermal Range Expander temperature operating range.

(9)

This is a food grade fill fluid.

(10)

Not suitable for vacuum applications.

(11)

Only available with Thermal Range Expander.

(12)

UltraTherm 805 supports maximum design temperature of 454 °C (850 °F). Design temperature rating is for non-continuous use with a

(13)

cumulative exposure time less of than 12 hours.

The pressure range should be specified based on the maximum static pressure, not differential pressure.

(14)

Maximum cable distance for SIS installations. See "Safety Instrumented Systems (SIS) Certification" section of Rosemount 3051S ERS Reference

(15)

Manual for more information.

Maximum cable distance for IS (Intrinsically safe) installations. Other options may not be valid at longer distances.

(16)

Not available with configuration type code S.

(17)

This assembly is included with options EP, KP, E1, N1, K1, ND, E4, E7, N7, K7, E2, KA, KC, KD, K2, T1, E3, EM, KM.

(18)

Not available with M20 or G½ conduit entry size.

(19)

Silicone fill fluid is standard.

(20)

See the Rosemount 3051S Reference Manual for cable requirements. Contact an Emerson representative for additional information.

(21)

The QZ report quantifies the performance of the entire ERS system. One report is provided per ERS system. The QZ option is specified on the

(22)

primary transmitter (configuration type code P).

Materials of construction comply with metallurgical requirements highlighted within NACE MR 0175/ISO 15156 for sour oil field production

(23)

environments. Environmental limits apply to certain materials. Consult latest standard for details. Selected materials also conform to NACE MR

0103 for sour refining environments. UltraTherm 805 supports maximum design temperature of 850 °F (454 °C). Design temperature rating is for

non-continuous use with a cumulative exposure time less of than 12 hours.

Product Data Sheet 21

November 2018

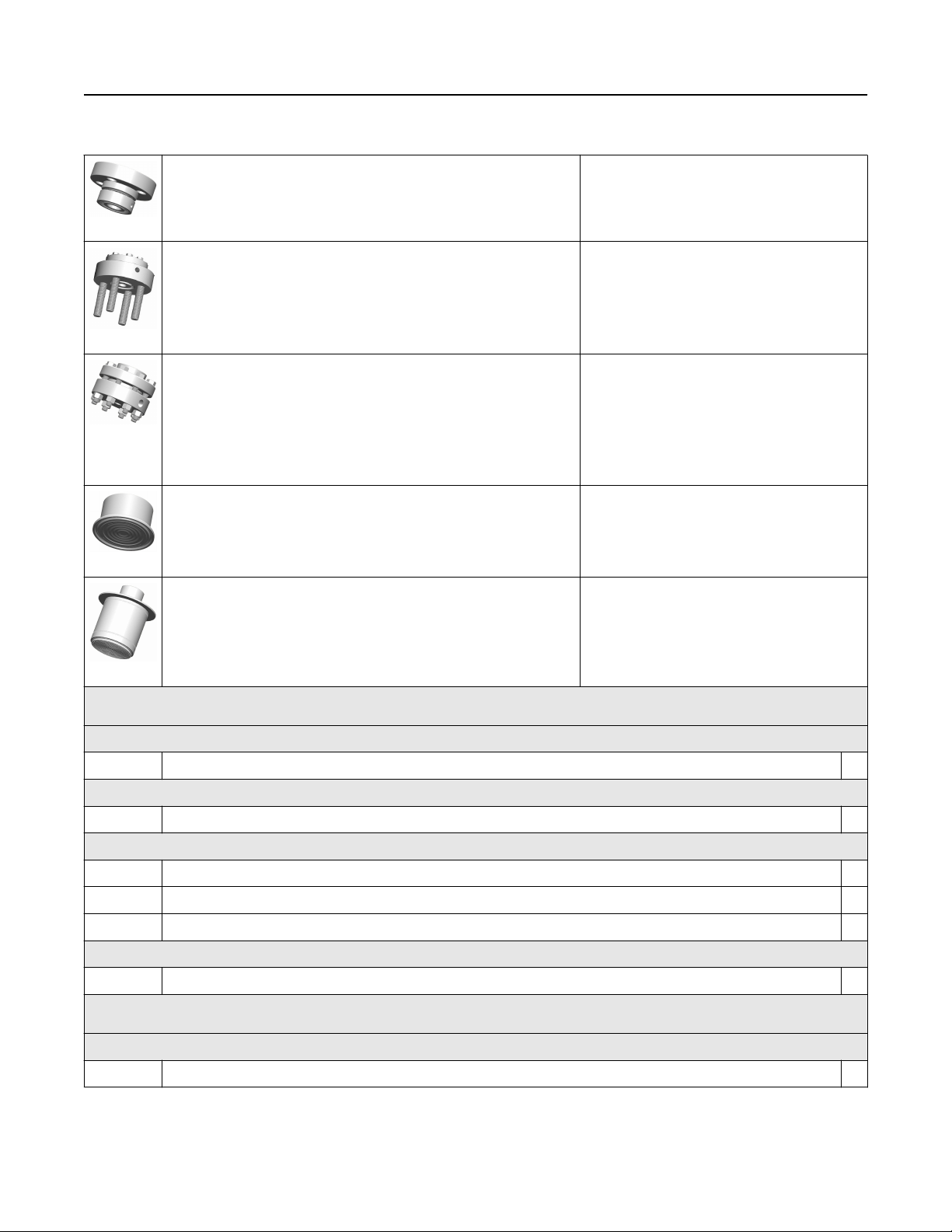

Rosemount 3051S Scalable™ Level Transmitter

Rosemount 3051S Scalable Level Transmitters combine the features and benefits of a high-performance Rosemount 3051S with

the durability and reliability of diaphragm seals all in a single model number.

Rosemount

3051SAL In-line

with “FF” Flanged

Seal

Product features and capabilities include:

■

Variety of process connections including flanged, threaded, and hygienic seals

■

Quantified performance for the entire transmitter/seal assembly (QZ option)

■

HART, FOUNDATION™ Fieldbus, and wireless protocols

Rosemount

3051SAL Coplanar

with “SS” Hygienic

Tank Spud Seal

Rosemount 3051SAL Tuned-System

™

Assembly with Thermal Range Expander

Rosemount 3051SAL Balanced System

Rosemount 3051SAL Scalable Level Transmitter

Specification and selection of product materials, options, or components must be made by the purchaser of the equipment. See

Material selection for more information.

A Rosemount 3051SAL Transmitter consists of three parts. First, specify the transmitter model codes found in Table 3. Then, specify

a direct mount seal found here: Diaphragm seals for Rosemount 3051SAL. Finish the model number by specifying all desired

options from the "Options" section of Table 3.

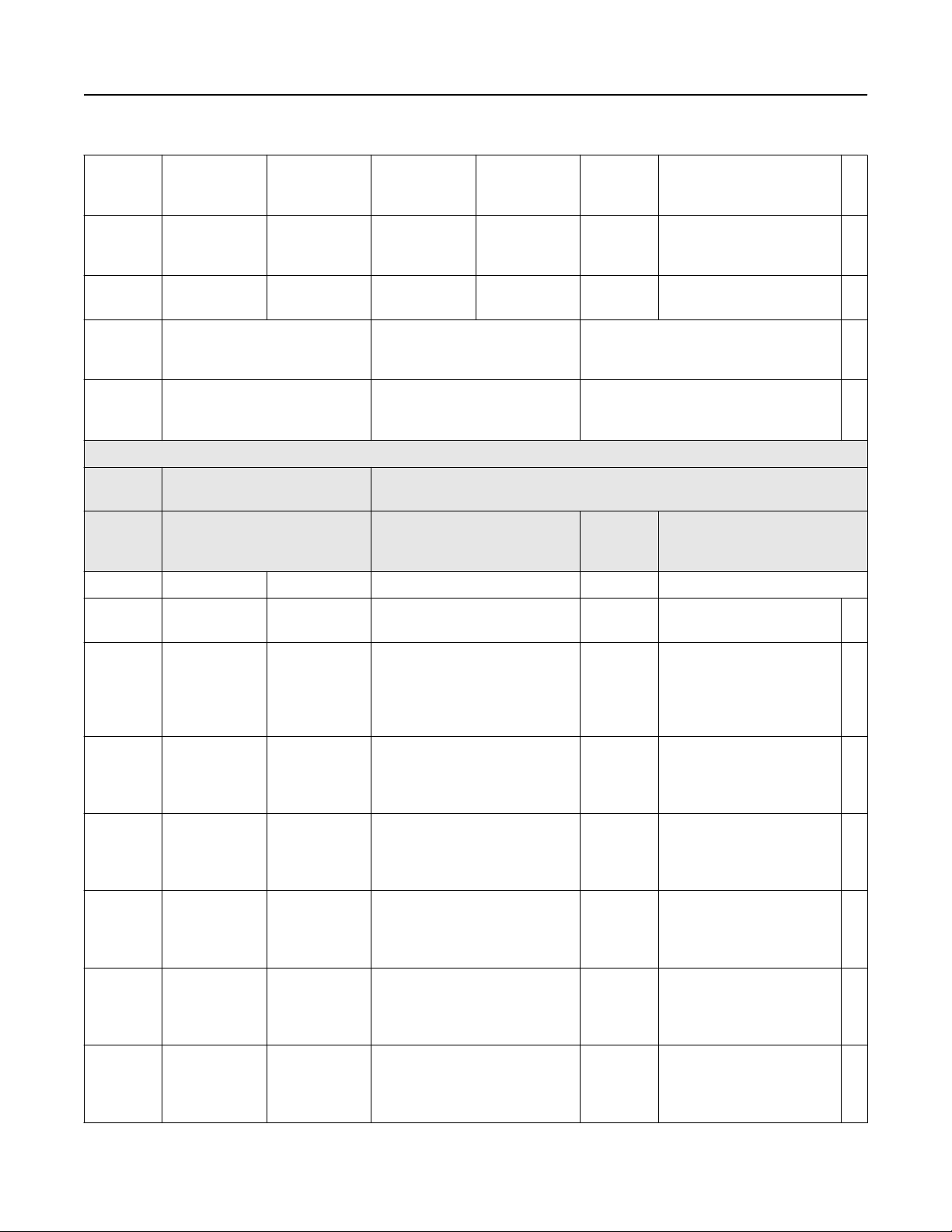

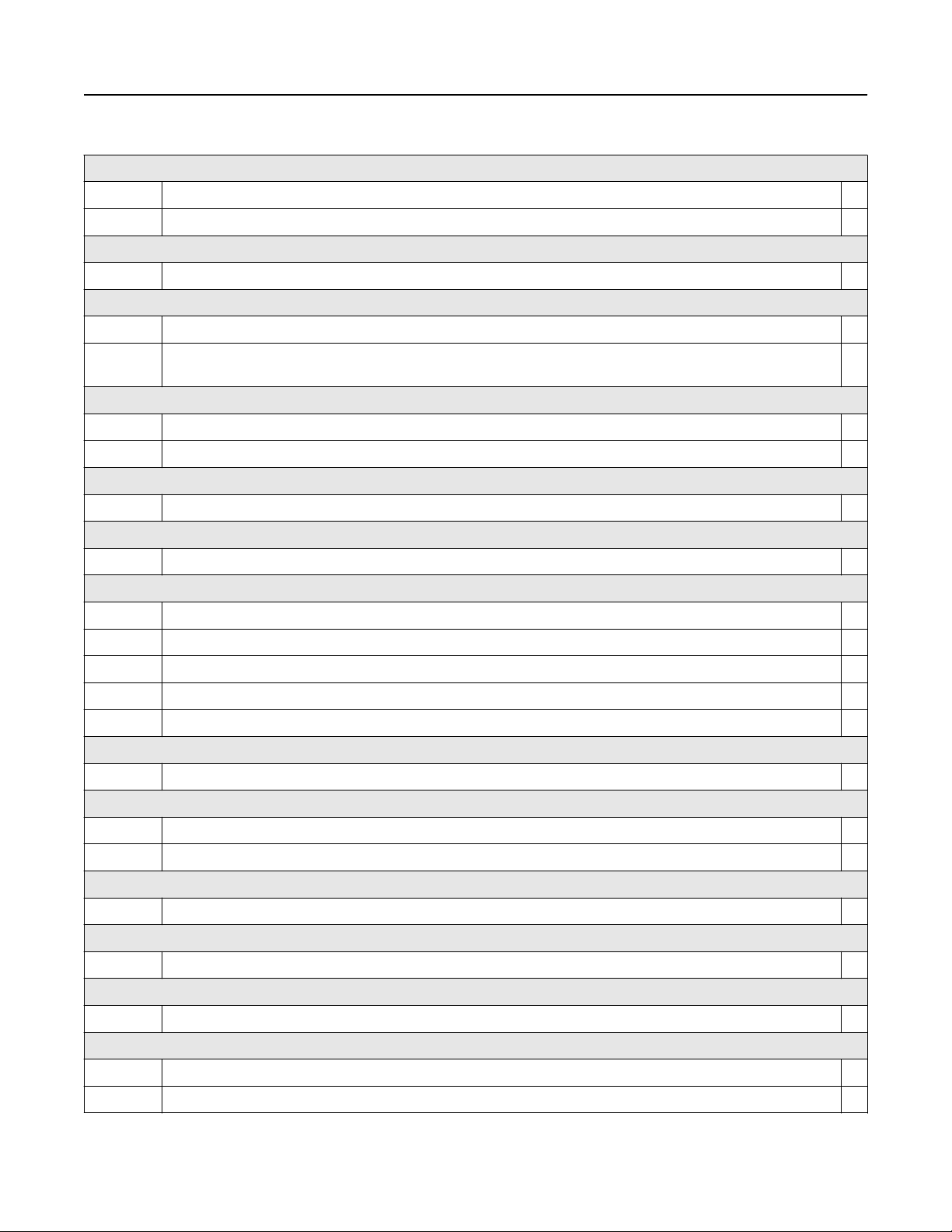

Table 3: Rosemount 3051SAL Scalable Level Transmitter Ordering Information

The starred offerings (★) represent the most common options and should be selected for best delivery. The non-starred offerings

are subject to additional delivery lead time.

Model Transmitter type

3051SAL Scalable level transmitter

Performance class

(1)

1 Ultra: 0.055% span accuracy, 150:1 rangedown, 15-year limited warranty ★

2 Classic: 0.065% span accuracy, 150:1 rangedown ★

Configuration type

C Liquid level transmitter ★

Pressure module type

D Coplanar Differential ★

G Coplanar Gage ★

22 Emerson.com/Rosemount

November 2018

Table 3: Rosemount 3051SAL Scalable Level Transmitter Ordering Information (continued)

T In-line Gage ★

E In-line Absolute ★

A Coplanar Absolute

Pressure range

Coplanar DP Coplanar Gage In-line Gage In-line Absolute Coplanar Absolute

1A N/A N/A –14.7 to 30

psig (–1,01 to

0 to 30 psia (0

to 2,06 bar)

0 to 30 psia (0 to 2,06 bar) ★

2,06 bar)

2A –250 to 250

inH2O (–

621,60 to

621,60 mbar)

3A –1000 to 1000

inH2O (–2,48

to 2,48 bar)

4A –300 to 300 psi

(–20,68 to

20,68 bar)

5A –2000 to 2000

psi (–137,89 to

137,89 bar)

–250 to 250

inH2O (–

621,60 to

621,60 mbar)

–393 to 1000

inH2O (–0,97

to 2,48 bar)

–14.2 to 300

psig (–0,97 to

20,68 bar)

–14.2 to 2000

psig (–0,97 to

137,89 bar)

–14.7 to 150

psig (–1,01 to

10,34 bar)

–14.7 to 800

psig (–1,01 to

55,15 bar)

–14.7 to 4000

psig (–1,01 to

275,79 bar)

–14.7 to 10000

psig (–1,01 to

689,47 bar)

0 to 150 psia (0

to 10,34 bar)

0 to 800 psia (0

to 55,15 bar)

0 to 4000 psia

(0 to 275,79

bar)

0 to 10000 psia

(0 to 689,47

bar)

0 to 150 psia (0 to 10,34 bar) ★

0 to 800 psia (0 to 55,15 bar) ★

0 to 4000 psia (0 to 275,79 bar) ★

N/A ★

Transmitter output

A 4–20 mA with digital signal based on HART protocol ★

(2)

F

(3)

X

FOUNDATION Fieldbus™ protocol ★

Wireless (requires wireless options and wireless Plantweb housing) ★

Housing style Material Conduit entry

1A Plantweb housing Aluminum ½–14 NPT ★

1B Plantweb housing Aluminum M20 x 1.5 ★

1J Plantweb housing SST ½–14 NPT ★

1K Plantweb housing SST M20 x 1.5 ★

2A Junction box housing Aluminum ½–14 NPT ★

2B Junction box housing Aluminum M20 x 1.5 ★

2E Junction box with output for remote interface Aluminum ½–14 NPT ★

2F Junction box with output for remote interface Aluminum M20 x 1.5 ★

2J Junction box housing SST ½–14 NPT ★

(4)

5A

5J

7J

(4)

(5)

Wireless Plantweb housing Aluminum ½–14 NPT ★

Wireless Plantweb housing SST ½–14 NPT ★

Quick connect (a size mini, 4-pin male

SST N/A ★

termination)

1C Plantweb housing Aluminum G½

Product Data Sheet 23

November 2018

Table 3: Rosemount 3051SAL Scalable Level Transmitter Ordering Information (continued)

1L Plantweb housing 316L SST G½

2C Junction box housing Aluminum G½

2G Junction box with output for remote interface Aluminum G½

Seal system type

Coplanar pressure module type In-line pressure module type

1 Direct mount single seal system Welded-

repairable

Direct mount single seal

system

Welded- repairable ★

2 Direct mount single seal system All welded N/A N/A ★

(6)

3

Tuned-system assembly - one

direct mount and one remote

Weldedrepairable

N/A N/A ★

mount seal with capillary

(6)

4

Tuned-system assembly - one

All welded N/A N/A ★

direct mount and one remote

mount seal with capillary

(6)

5

Balanced system - two remote

mount seals with equal lengths

Weldedrepairable

N/A N/A ★

of capillary

(6)

6

Balanced system - two remote

All welded N/A N/A ★

mount seals with equal lengths

of capillary

7 Remote mount single seal

system with capillary - 316L low

Weldedrepairable

Remote mount single seal

system with capillary

All welded ★

side transmitter isolator

8 Remote mount single seal

All welded N/A N/A ★

system with capillary - 316L low

side transmitter isolator

9 Remote mount single seal

system with capillary - Alloy

Weldedrepairable

N/A N/A ★

C-276 low side transmitter

isolator

A Remote mount single seal

All welded N/A N/A ★

system with capillary - Alloy

C-276 low side transmitter

isolator

High side connection type (select based on seal system type chosen)

Single seal system Dual seal system

Direct mount Remote mount with capillary Tuned-

Balanced system

system

assembly

Coplanar In-line Coplanar In-line Coplanar Coplanar

0 No extension Standard Standard No

Standard ★

extension/

Standard

24 Emerson.com/Rosemount

November 2018

Table 3: Rosemount 3051SAL Scalable Level Transmitter Ordering Information (continued)

2 2-in. (50 mm)

extension

N/A N/A N/A 2-in. (50

mm)

N/A

extension

4 4-in. (100 mm)

extension

4-in. (100 mm)

extension

(7)

N/A N/A 4-in. (100

mm)

N/A ★

extension

5 N/A Thermal

N/A N/A N/A N/A ★

optimizer

(8)

6

Thermal Range Expander Silicone 200 secondary fill

Thermal Range Expander Silicone 200 secondary fill fluid

Thermal Range Expander - Silicone 200

secondary fill with low side capillary

single capillary

(8)

7

Thermal Range Expander SYLTHERM™ XLT secondary fill

fluid

Thermal Range Expander SYLTHERM XLT secondary fill

fluid single capillary

Thermal Range Expander - SYLTHERM XLT

secondary fill with low side capillary

Low side connection type or capillary I.D.

Material for low side reference

Capillary I.D.

connection

Direct mount Remote mount with capillary Tuned-

Balanced system

system

assembly

Coplanar In-line Coplanar or In-line Coplanar Coplanar

0 N/A No reference

N/A N/A N/A ★

connection

(9)(10)

1

Assemble to

N/A N/A N/A N/A ★

one

Rosemount

1199 remote

seal

★

★

★

2 316L SST

N/A N/A N/A N/A ★

isolator and

SST transmitter

flange

3 Alloy C-276

N/A N/A N/A N/A ★

isolator and

SST transmitter

flange

B N/A N/A 0.03-in. (0,711 mm) ID capillary 0.03-in.

(0,711

0.03-in. (0,711 mm) ID

capillary

★

mm) ID

capillary

C N/A N/A 0.04-in. (1,092 mm) ID capillary 0.04-in.

(1,092

0.04-in. (1,092 mm) ID

capillary

★

mm) ID

capillary

D N/A N/A 0.075-in. (1,905 mm) ID capillary 0.075-in.

(1,905

0.075-in. (1,905 mm) ID

capillary

★

mm) ID

capillary

Product Data Sheet 25

Table 3: Rosemount 3051SAL Scalable Level Transmitter Ordering Information (continued)

(11)

E

N/A N/A 0.03-in. (0,711 mm) ID capillary,

PVC coated with closed end

0.03-in.

(0,711

mm) ID

capillary,

PVC

coated

with closed

end

(11)

F

N/A N/A 0.04-in. (1,092 mm) ID capillary,

PVC coated with closed end

0.04-in.

(1,092

mm) ID

capillary,

PVC

coated

with closed

end

(11)

G

N/A N/A 0.075-in. (1,905 mm) ID

capillary, PVC coated with closed

end

0.075-in.

(1,905

mm) ID

capillary,

PVC

coated

with closed

end

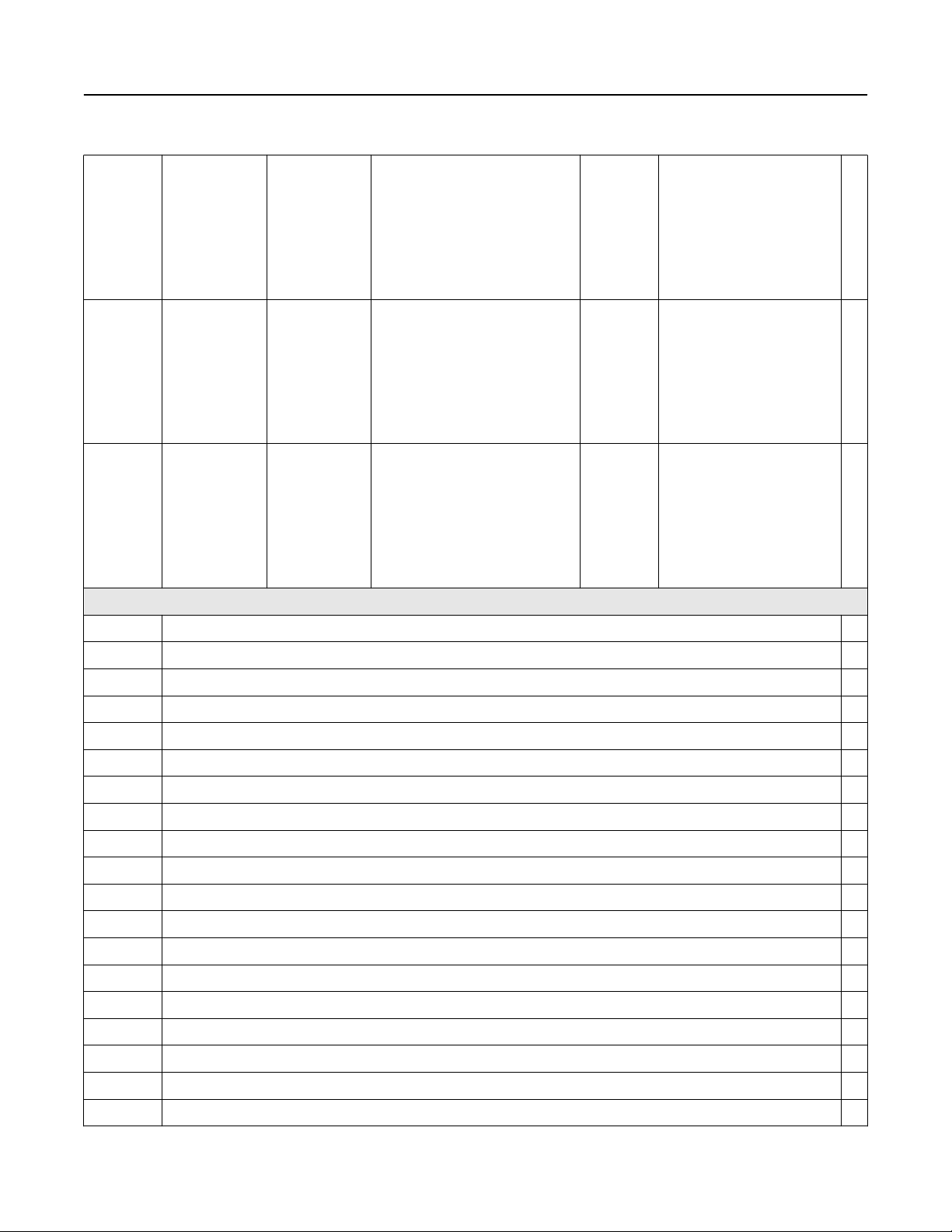

Capillary length

(12)

November 2018

0.03-in. (0,711 mm) ID

capillary, PVC coated with

closed end

0.04-in. (1,092 mm) ID

capillary, PVC coated with

closed end

0.075-in. (1,905 mm) ID

capillary, PVC coated with

closed end

★

★

★

0 No capillary (required for direct mount single seal system) ★

A 1 ft. (0,3 m) ★

B 5 ft. (1,5 m) ★

C 10 ft. (3,0 m) ★

D 15 ft. (4,5 m) ★

E 20 ft. (6,1 m) ★

F 25 ft. (7,6 m) ★

G 30 ft. (9,1 m) ★

H 35 ft. (10,7 m) ★

J 40 ft. (12,2 m) ★

K 45 ft. (13,7 m) ★

L 50 ft. (15,2 m) ★

M 1.6 ft. (0,5 m) ★

N 3.3 ft. (1,0 m) ★

P 4.9 ft. (1,5 m) ★

R 6.6 ft. (2,0 m) ★

T 8.2 ft. (2,5 m) ★

U 9.8 ft. (3,0 m) ★

V 11.5 ft. (3,5 m) ★

26 Emerson.com/Rosemount

November 2018

Table 3: Rosemount 3051SAL Scalable Level Transmitter Ordering Information (continued)

W 13.1 ft. (4,0 m) ★

Y 16.4 ft. (5,0 m) ★

Z 19.7 ft. (6,0 m) ★

1 23 ft. (7,0 m) ★

2 26.2 ft. (8,0 m) ★

3 29.5 ft. (9,0 m) ★

4 32.8 ft. (10,0 m) ★

5 36.1 ft. (11,0 m) ★

6 39.4 ft. (12,0 m) ★

7 42.6 ft. (13,0 m) ★

8 45.9 ft. (14,0 m) ★

9 49.2 ft. (15,0 m) ★

Seal fill fluid Specific

gravity at 77 °F

(25 °C)

Temperature limits

No extension 2-in. (50 mm)

(13)(14)

extension

4-in. (100

mm)

Thermal range

expander

(15)

Capillary

extension

D Silicone 200 0.934 –49 to 401 °F (–45 to 205 °C) N/A –49 to 401

°F

(–45 to

205 °C)

F Silicone 200 for

vacuum

applications

(16)

J

Tri-Therm 300 0.795 –40 to 401 °F (–

0.934 For use in vacuum applications below 14.7 psia (1 bar-a), refer to vapor

pressure curves in Rosemount DP Level Fill Fluid Specification Technical

Note.

40 to 205 °C)

–40 to 464 °F (–

40 to 240 °C)

–40 to 572

°F (–40 to

300 °C)

N/A -40 to 572

°F

(-40 to 300

°C)

(16)

Q

L Silicone 704 1.07 32 to 401 °F (0

Tri-Therm 300

for vacuum

applications

0.795 For use in vacuum applications below 14.7 psia (1 bar-a), refer to vapor

pressure curves in Rosemount DP Level Fill Fluid Specification Technical

Note.

to 205 °C)

32 to 464 °F (0

to 240 °C)

32 to 572

°F (0 to 300

°C)

Up to 599 °F

( 315 °C)

-32 to 599

°F

(0 to 315

°C)

C Silicone 704 for

vacuum

applications

R Silicone 705 1.09 68 to 401 °F (20

1.07 For use in vacuum applications below 14.7 psia (1 bar-a), refer to vapor

pressure curves in Rosemount DP Level Fill Fluid Specification Technical

Note.

to 205 °C)

68 to 464 °F (20

to 240 °C)

68 to 572

°F (20 to

300 °C)

Up to 698 °F

( 370 °C)

68 to 698

°F

(20 to 370

°C)

★

★

★

★

★

★

★

Product Data Sheet 27

Table 3: Rosemount 3051SAL Scalable Level Transmitter Ordering Information (continued)

November 2018

V Silicone 705 for

vacuum

applications

(17)

Y

UltraTherm

805

(17)

Z

UltraTherm

805 for vacuum

applications

1.09 For use in vacuum applications below 14.7 psia (1 bar-a), refer to vapor

pressure curves in Rosemount DP Level Fill Fluid Specification Technical

Note.

™

1.20 N/A Up to 770 °F

( 410 °C)

1.20 For use in vacuum applications below 14.7 psia (1 bar-a), refer to vapor

pressure curves in Rosemount DP Level Fill Fluid Specification Technical

Note.

(18)

N/A ★

A SYLTHERM XLT 0.85 –157 to 293 °F (–105 to 145 °C) N/A -157 to

293 °F

(-105 to

145 °C)

H Inert

(Halocarbon)

1.85 –49 to 320 °F (–45 to 160 °C) N/A -49 to 320

°F (-45 to

160 °C)

(16)

N

Neobee® M-20 0.94 5 to 401 °F (–15

to 205 °C)

5 to 437 °F (–15 to 225 °C) N/A 5 to 437 °F

(-15 to 225

°C)

(10)(16)

G

Glycerin and

water

1.13 5 to 203 °F (–15 to 95 °C) N/A 5 to 437 °F

(-15 to 225

°C)

(10)(16)

P

Propylene

glycol and

water

1.02 5 to 203 °F (–15 to 95 °C) N/A 5 to 203 °F

(-15 to 95

°C)

★

★

★

★

★

★

★

Continue specifying a completed model number by choosing a remote seal type below:

Seal style Process connections

FF Flush Flanged Seal

2-in./DN 50/ 50A

3-in./DN 80/80A

4 in./DN 100/100A

EF Extended Flanged Seal 3-in./DN 80/80A

4-in./DN 100/100A

Remote Flanged (RF) Seal ½-in.

¾-in.

1-in./DN 25/25A

1½-in./DN 40/40A

PF Pancake Seal 2-in./DN 50/50A

3-in./DN 80/80A

28 Emerson.com/Rosemount

November 2018

Table 3: Rosemount 3051SAL Scalable Level Transmitter Ordering Information (continued)

FC Flush Flanged Seal - Ring Type Joint (RTJ) gasket surface 2-in.

3-in.

RC Remote Flanged Seal - Ring Type Joint (RTJ) gasket surface ½-in.

¾-in.

1 in.

1½-in.

RT Remote Threaded Seal ¼–18 NPT

½–14 NPT

¾–14 NPT

1–11.5 NPT

1¼–11.5 NPT

SC Hygienic Tri-Clamp Seal 1½-in.

2-in.

3-in.

SS Hygienic Tank Spud Seal 4-in.

Wireless options (requires option code X and wireless Plantweb housing)

Update rate

(4)

WA User configurable update rate ★

Operating frequency and protocol

3 2.4 GHz DSSS, IEC 62591 (WirelessHART) ★

Omni-directional wireless antenna

(4)

WK

WM

(4)

External antenna ★

Extended range, external antenna ★

WN High-gain, remote antenna

™

SmartPower

(19)(20)

1 Adapter for Black Power Module (I.S. Power Module sold separately) ★

Other options (include with selected model number)

HART Revision configuration (requires HART Protocol output code A)

HR7 Configured for HART Revision 7 ★

Product Data Sheet 29

November 2018

Table 3: Rosemount 3051SAL Scalable Level Transmitter Ordering Information (continued)

Extended product warranty

WR3 3-year limited warranty ★

WR5 5-year limited warranty ★

Plantweb control functionality

(20)(21)(22)

A01 FOUNDATION Fieldbus advanced control function block suite ★

Diagnostics suite

(20)(21)

D01

DA2

(23)

FOUNDATION Fieldbus diagnostics suite (Process Intelligence, Plugged Impulse Line diagnostic) ★

Advanced HART diagnostics suite (Process Intelligence, Loop Integrity, Plugged Impulse Line diagnostic, Process

Alerts, Service Alerts, Variable Log, Event Log)

Mounting bracket

B4 Bracket, all SST, 2-in. pipe panel ★

BE Bracket, 316 SST, B4-style with 316 SST bolting ★

Software configuration

(24)

C1 Custom software configuration (requires Configuration Data Sheet) ★

Gage pressure calibration

★

C3 Gage pressure calibration on Rosemount 3051SAL_ _A4 only ★

Alarm limit

(21)(24)

C4 NAMUR alarm and saturation levels, high alarm ★

C5 NAMUR alarm and saturation levels, low alarm ★

C6 Custom alarm and saturation signal levels, high alarm (requires C1 and Configuration Data Sheet) ★

C7 Custom alarm and saturation signal levels, low alarm (requires C1 and Configuration Data Sheet) ★

C8 Low alarm (standard Rosemount alarm and saturation levels) ★

Hardware adjustments

(24)(25)(26)

D1 Hardware adjustments (zero, span, alarm, security) ★

Flange adapter

D2 ½–14 NPT flange adapter ★

D9 RC½ SST flange adapter

Ground screw

(27)

D4 External ground screw assembly ★

Drain/vent valve

D5 Delete transmitter drain/vent valves (install plugs) ★

Conduit plug

(28)

DO 316 SST conduit plug ★

Product certifications

(29)

E1 ATEX Flameproof ★

I1 ATEX Intrinsic Safety ★

30 Emerson.com/Rosemount

Loading...

Loading...