Page 1

XSD-1000 Scrap Monitoring System

Users Guide

Page 2

Notices............................................................................................................................................................ 2

Overview ........................................................................................................................................................ 3

Operational Overview .............................................................................................................................. 5

Main Screen.................................................................................................................................................... 7

Log File Viewing............................................................................................................................................ 9

User Setup .................................................................................................................................................... 11

Detector Names/Status ........................................................................................................................... 12

Events Logging ....................................................................................................................................... 13

Time Constant......................................................................................................................................... 14

Select Printers ......................................................................................................................................... 15

Manual System Verification .................................................................................................................. 17

Auto System Verification............................................................................................................................. 19

Verify Detectors...................................................................................................................................... 20

Verify Photo-Eyes................................................................................................................................... 22

Verify Relays........................................................................................................................................... 23

Analyzer ....................................................................................................................................................... 24

Administrative Options ................................................................................................................................ 26

History Files ............................................................................................................................................ 27

Log Files Creation .................................................................................................................................. 28

Password Maintenance .......................................................................................................................... 29

Save Current Settings to Disk File ........................................................................................................ 30

Restore Settings from Disk File............................................................................................................. 31

Restore Safe Default Settings................................................................................................................. 32

Background Mode .................................................................................................................................. 33

Detectors.................................................................................................................................................. 34

Detector Locations.................................................................................................................................. 35

Photo-eyes................................................................................................................................................ 37

Relay Output Options ............................................................................................................................ 40

Background Alarms ............................................................................................................................... 42

Speed Alarms .......................................................................................................................................... 43

Quality Assessment ...................................................................................................................................... 46

Reports – Events by Type ...................................................................................................................... 48

Reports – Detector Sensitivity Checks.................................................................................................. 49

Replace Detector..................................................................................................................................... 52

Replace Test Source ............................................................................................................................... 53

No Remote I/O Modules Found............................................................................................................. 58

Remote I/O Failure................................................................................................................................. 59

Detector Failure...................................................................................................................................... 60

Photo-Eye Failure ................................................................................................................................... 61

Adding/Replacing a Remote I/O Module ............................................................................................. 64

Remote I/O Module Addressing................................................................................................................... 65

Printer ........................................................................................................................................................... 68

Events........................................................................................................................................................... 69

Passwords ..................................................................................................................................................... 70

Alarms .......................................................................................................................................................... 71

Appendix ...................................................................................................................................................... 72

Operating System Configuration .......................................................................................................... 72

1

Page 3

Notices

NOTICE

It is illegal to run Microsoft Office Automation and Personal Computing

Functions on this system, except for network/Internet browsing functionality.

2

Page 4

Overview

The Ronan XSD-1000 Series Scrap Detectors are designed to be the most sensitive units

on the market. The units will self-calibrate to the background radiation during power up

and require little maintenance thereafter.

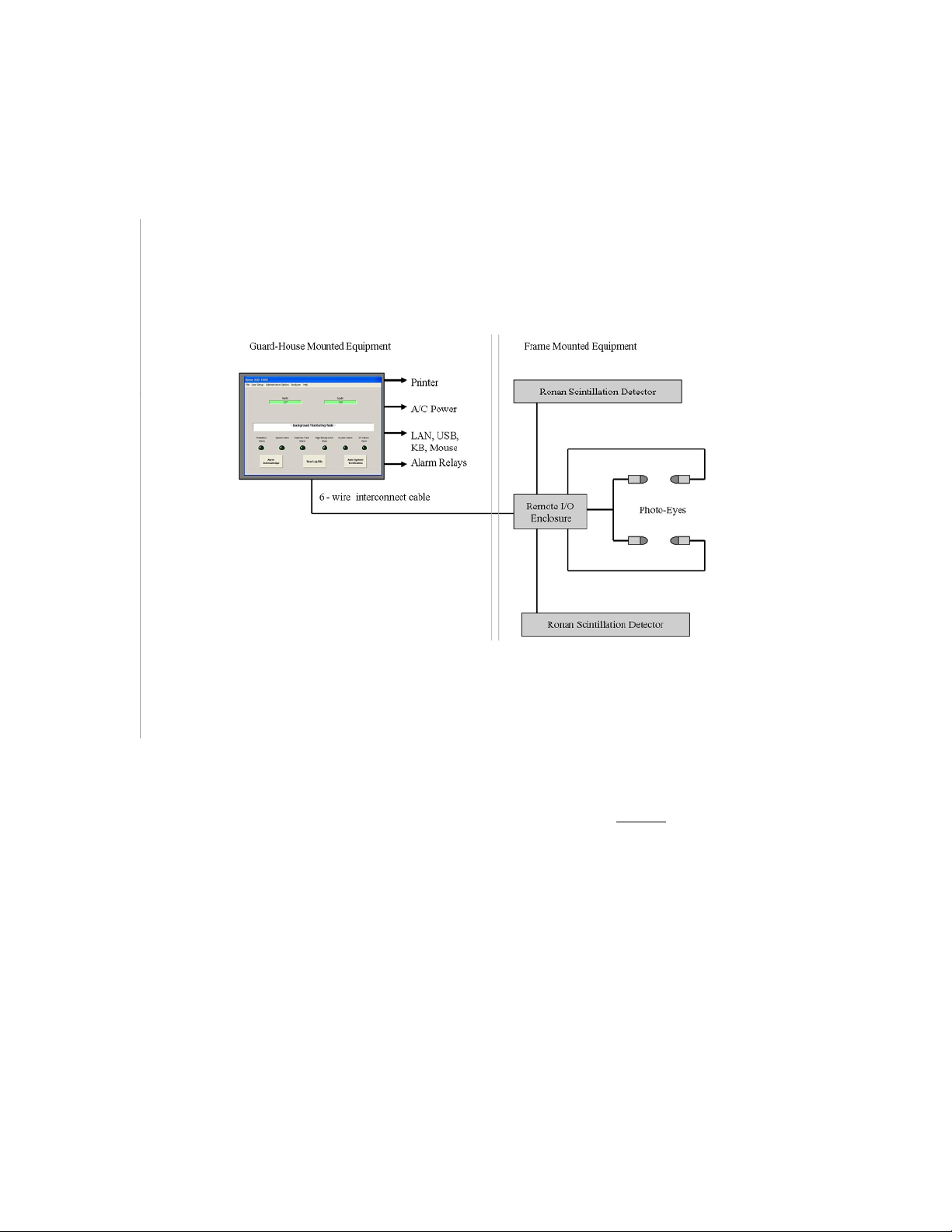

The picture above defines the major components of the Ronan XSD-1000 System:

Monitor Panel – This is the computer, display screen, touch panel, alarm relay, and

communications panel. The touch screen is for acknowledging alarms and performing a

System Verify function. Setup and options selection is via a keyboard and mouse and

requires key-lock access.

6-Wire Interconnect Cable – This cable supplies power and communications to the

Remote I/O modules, detectors, and photo-eyes.

Remote I/O Enclosure – This is a small NEMA 4 enclosure that houses the Remote I/O

modules. There is one module for each detector, and one or two digital modules for the

photo-eyes (depending on how many photo-eyes you have), and one or two relay output

modules for optional controls.

Scintillator Detectors – These are the large, crystal and electronics packages. They detect

nuclear radiation and report the results to the Scintillation Input Remote I/O modules.

3

Page 5

Photo-Eyes – These are in pairs. Each pair has one Transmitter and one Receiver.

Typical systems have two pairs of photo-eyes, one pair at each end of the Scintillation

Detectors. They are wired to the Digital Input Remote I/O modules.

4

Page 6

Operational Overview

The XSD-1000 Monitoring System executes on a Microsoft Windows XP Embedded-

based operating system. The embedded software is intended for use strictly as a

monitoring device. The hard disk is divided into two partitions: one for the operating

system and associated programs (Drive C) and one for the XDS-1000 data files (Log,

Configuration, and History files, Drive D). The primary partition (operating system and

associated program files) is typically write-protected. This ensures that unauthorized reconfiguration of the operating system or unauthorized driver installation will be discarded

at the next system boot (power off and on cycle).

If you wish to configure the system see the appendix section Operating System

Configuration for hard disk access (Drive C: is write-protected and contains Windows

and the XDS-1000 program files). This access will permit you to configure the system

(LAN/WAN connections, Windows printer selection, etc.), then reboot to save your

configuration settings and re-enable the disk-write protection function. For security

reasons, this appendix should be removed and stored separately from the manual to

prevent unauthorized writes to your hard disk.

The system is designed for a no-logon-required boot, and to auto-start the XSD-1000

software. Configuration changes to the XSD-1000 system do not require that the above

procedure be performed, as the configuration settings for the XSD-1000 are stored on the

non-write protected partition. A password is required to exit the XSD-1000 software.

The data files for the XSD-1000 (Log Files, and AssetMgmt file) are stored on the D:

drive of your system. These files are Microsoft Access (.MDB) standard files. If you

plan to access these files over your local network, you may want to configure the D: drive

(and/or just the Log sub-directory) as a shared drive/directory. This will allow you to

consolidate any number of XSD-1000 files into a host system running Microsoft Access.

Make sure you use a unique System ID (set in the XSD-1000 menus) for each system to

identify the file source.

When updates to your XSD-1000 system become available, you will be notified by email. They will be made accessible on the Ronan web site. Following is a typical

scenario for updating your system.

• You will need to download the file (typical file name: Update mm-dd-yy.exe) from

the Ronan web site into the directory: ‘C:\XSD-1000Update’ on the XSD-1000

system.

• Once downloaded, make sure you exit the XSD-1000 software and that no other

programs are running.

• Browse to the C:\XSD-1000Update directory and click on the file you just

downloaded. This will cause the downloaded file to self-extract the contained files.

Allow the system to extract the files into the current directory.

• Exit the extraction windows and explorer.

5

Page 7

• Within one minute, the system will recognize the files, display a prompt, save the

current files, perform the update, then re-boot the system.

• At this point, the XSD-1000 system has been updated and restarted.

Instructions for obtaining a particular update will appear in the e-mail, and be posted on

the web site.

A number of printer support files are included with the system. The XSD-1000 system

will use the printers selected in your Windows setup. Should you need to load additional

printer drivers, follow the instructions in the appendix to first disable the write-protection

manager, then install your files and re-boot the system to re-enable the write-protection

manager.

6

Page 8

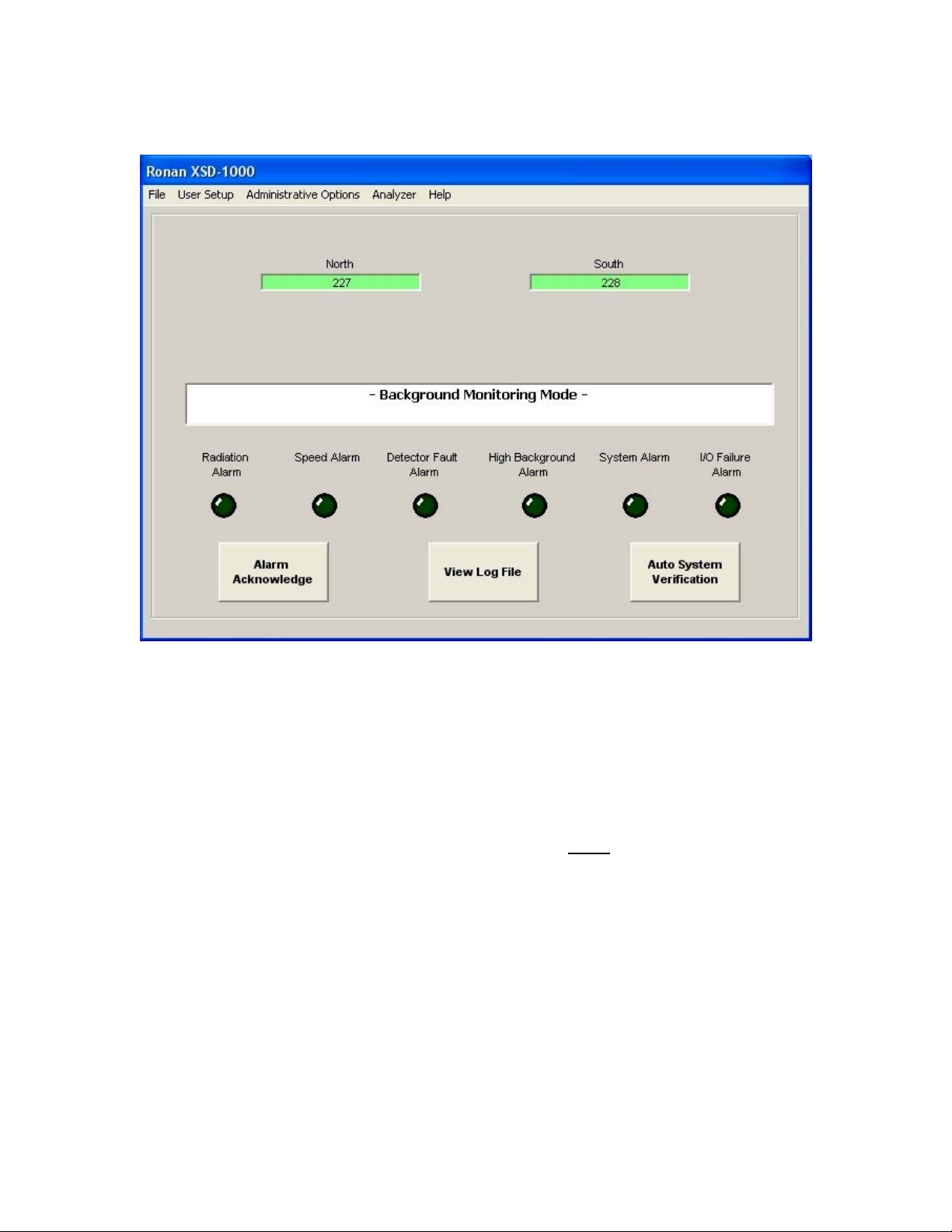

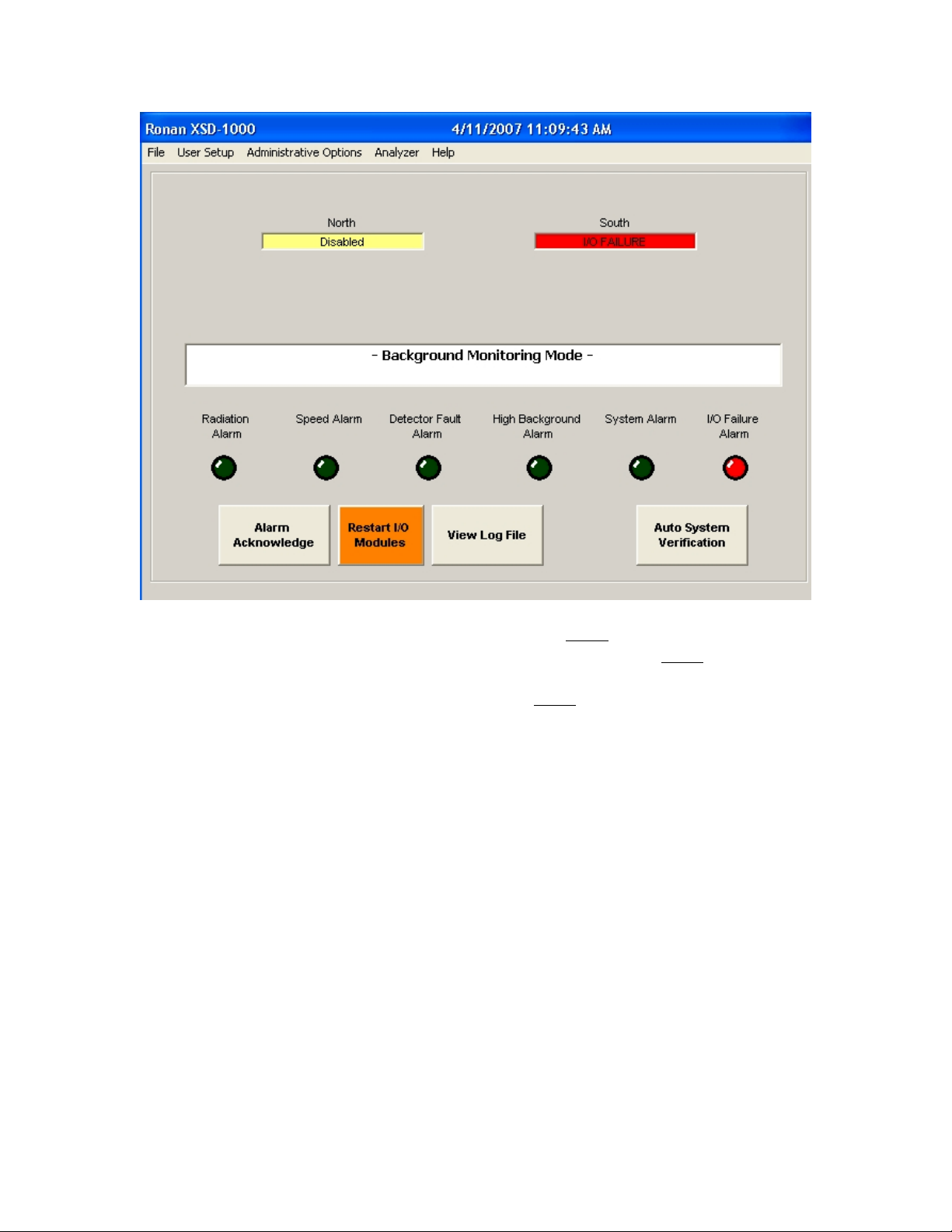

Main Screen

The System Title is displayed at the very top. Below the title is the Main Screen Menu

Bar. This menu bar is only displayed if the key-locked access switch is off. Clicking on

the active menu bar items grants access to the options and software setup.

Below the Menu Bar is the Detector Status box. There is a green box in this area

available for each detector position (up to 12). If a detector is enabled and functional, the

associated box will be green with the average counts displayed during Background mode

or the raw counts during Truck Present mode. If a detector is enabled, but fails, the box

will turn red with a message ‘I/O Failure’, and trigger an alarm. If you disable a detector,

its associated box will display yellow with the message ‘Disabled’ in it.

Below the Detector Status box is the System Status Bar. This bar displays the current

mode (Background or Truck Present), status, error messages, etc. It also acts as a

progress bar during startup and detector stabilization.

7

Page 9

Below the System Status Bar are the Alarm LEDs. If an alarm is triggered, the associated

LED will turn red. Touch the Alarm Acknowledge button to turn the alarm off. Some

alarms, such as Detector Failure, will re-trigger on the next communications cycle, and

will require that you disable that detector to stop the alarm.

The button next to the Alarm Acknowledge is the Restart I/O Modules button. This

button will appear on an I/O failure to permit restarting the communications when the

failure is remedied.

Next is the View Log File. Pressing this button will bring up the current Log File. To

view other Log Files, use the mouse to access the File – View Log File menu item.

The last button is the Auto System Verification touch button. This is for activating the

Automatic System Verification function periodically and performing integrity tests on the

detectors, photo-eyes and alarm relays. This Auto System Verification function will

automatically progress through the tests (if each one is successful) for one-man operation.

8

Page 10

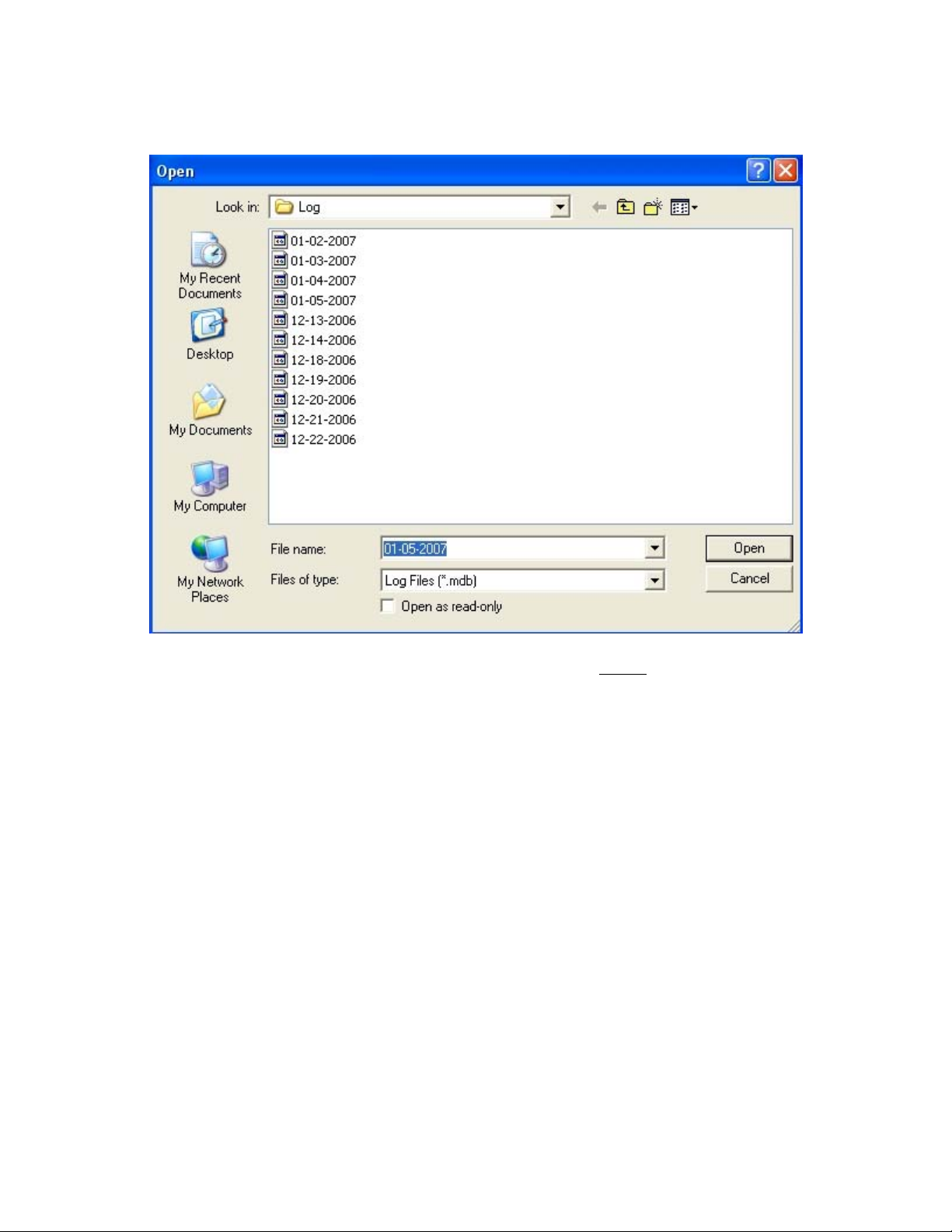

Log File Viewing

The Log File is a hard disk file that is written to based on the events you have enabled in

the User Setup-Events Logging options. All selected events will be written to the file if

and when they occur. This is a Microsoft Access file that can be printed, viewed

outside the XSD-1000 software, and/or sent over a communications line to another

computer.

Selecting the File-View Log File menu entry brings up the above display of all log files

stored on your system. You can select which file to display.

If you select the View Log File hot button on the main screen, only the current active log

file will be displayed.

9

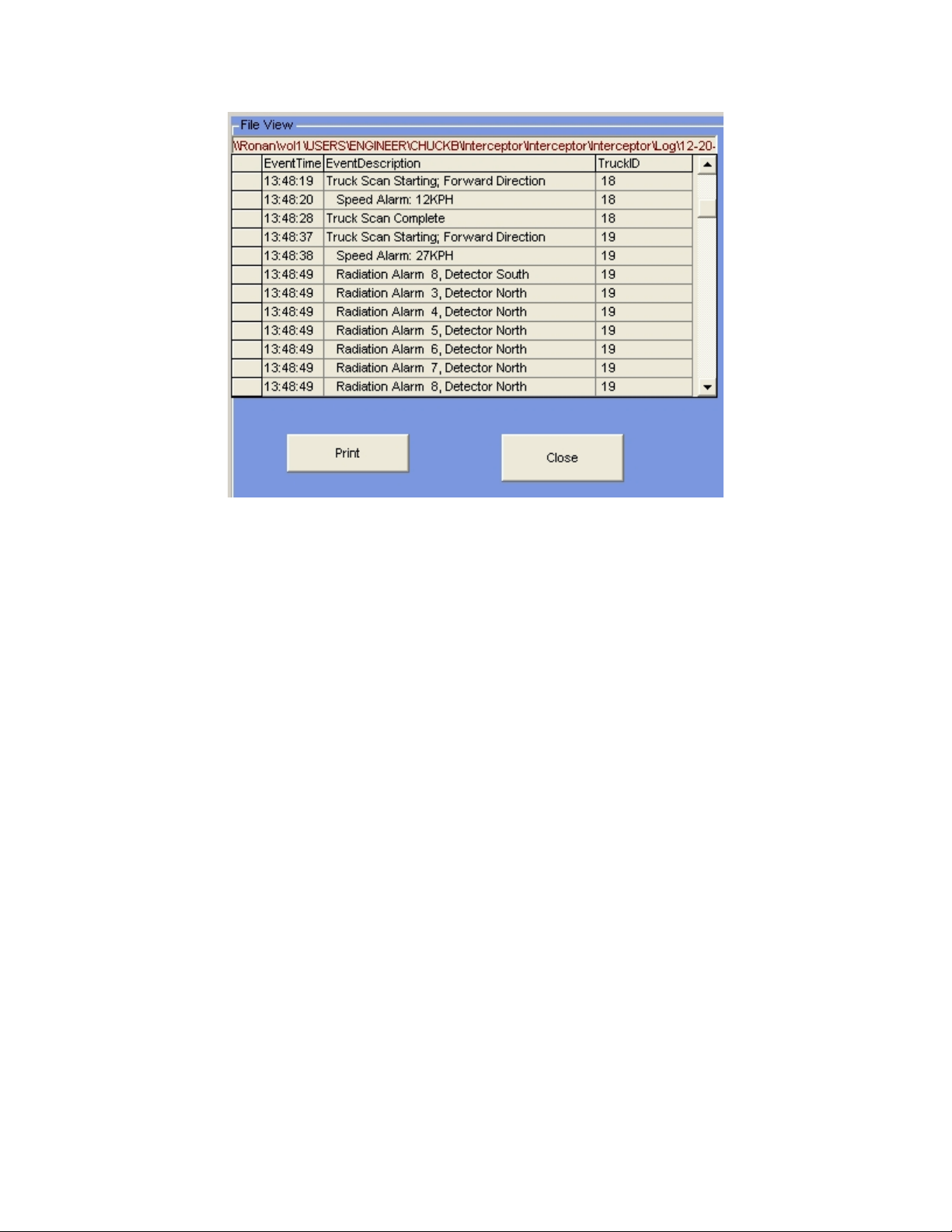

Page 11

The current Log File name will be the current system date. For example: 05-25-

2006.mdb. The file will be created when the system is initially powered up, and when

the expiration time elapses. The expiration time is set up in the Administrative Options –

File – Log Files Creation menu.

If the system is powered down, then powered back up in the same day, the system will reopen the same file and append to it. The current Log File is the default.

Use the scroll bar on the right side of the display to view events beyond what the screen

is displaying. If you have the Image Capture option, there will be a window to the right

of the data display. This window is for viewing captured images from a camera when a

particular alarm event has been selected.

If an alarm condition is listed for a particular Truck ID, you can click (or touch) the

Truck Scan Starting entry to display the Approximate Source Location picture as

displayed after a Truck Present Cycle when an alarm occurs.

10

Page 12

User Setup

This set of menus allows non-password protected options. These options (other than the

Detector Status) typically do not affect local system operation.

11

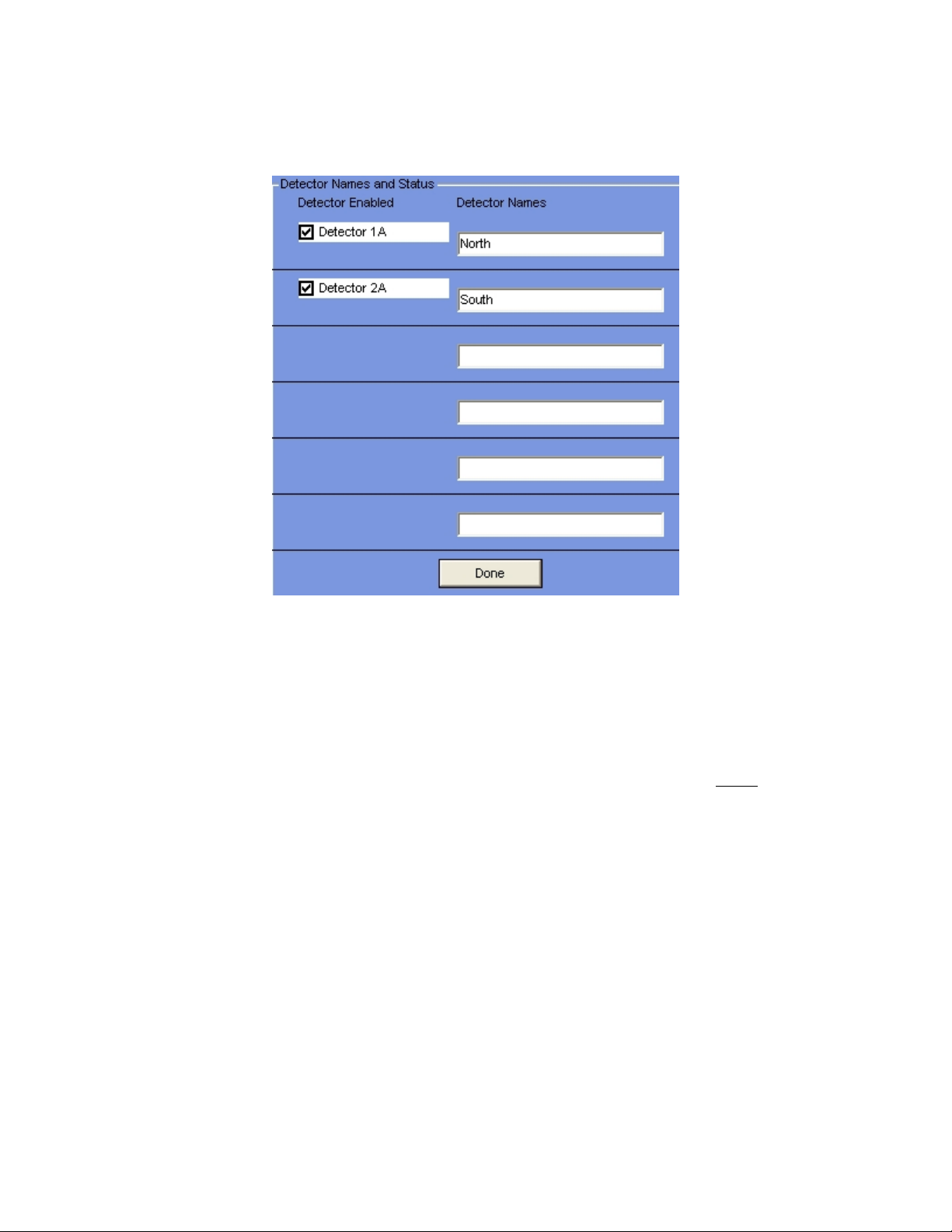

Page 13

Detector Names/Status

NOTE: the number of detectors displayed here is defined in the Administration Menus

under Configure – Detectors. This should be done before enabling any detectors.

Enter the names of each detector for clarity (North, Top, etc.), and each detector’s status

(Enabled/Disabled). Each detector should have a unique name for identification

purposes. The names you select will appear over the green box displaying that detector’s

averaged counts during Background mode, and the raw counts for that detector during

Truck Present mode. The names will also appear in the Log File report if an alarm occurs

for that detector. To change the Detector Names, highlight the name in the box, and type

in the new name.

All operational detectors’ status should be ‘Enabled’. Use the ‘Disable’ function if a

detector fails in order to disable constantly triggering the I/O Failure Alarm, until the

detector problem is resolved.

To change a detector’s status (Enabled/Disabled), click on the box. A check mark means

Enabled, a blank box means Disabled.

The detector values next to each check-box under the ‘Detector Enabled’ column are the

names used to wire the detectors to the proper Remote I/O modules (1A, 2A, etc.).

12

Page 14

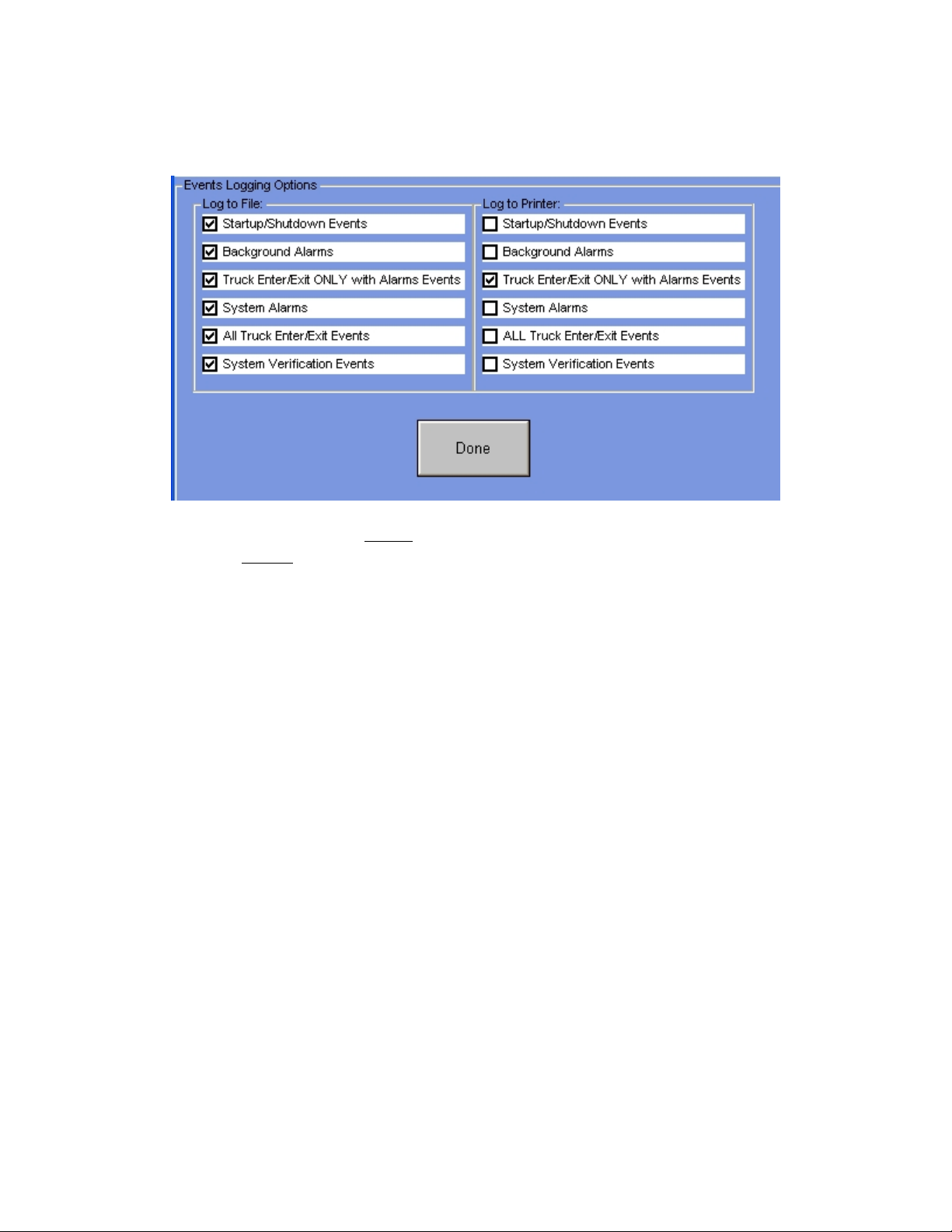

Events Logging

Use this menu to setup which events are to be logged to the Log File and which are to be

logged to the Printer. To change your choices, click on the boxes next to each choice.

A checked box enables logging the selected event to the device.

13

Page 15

Time Constant

This is the Time Constant for Background Averaging. This number is usually about 180

seconds (3 minutes). Background radiation changes are slight and slow, and a long time

constant is required to reduce the statistical noise.

It acts as a digital filter on the raw counts to establish the baseline for all detection

activities. The long time constant value filters the raw signal, yet permits the system to

constantly calibrate itself through background changes between day/night and seasons.

14

Page 16

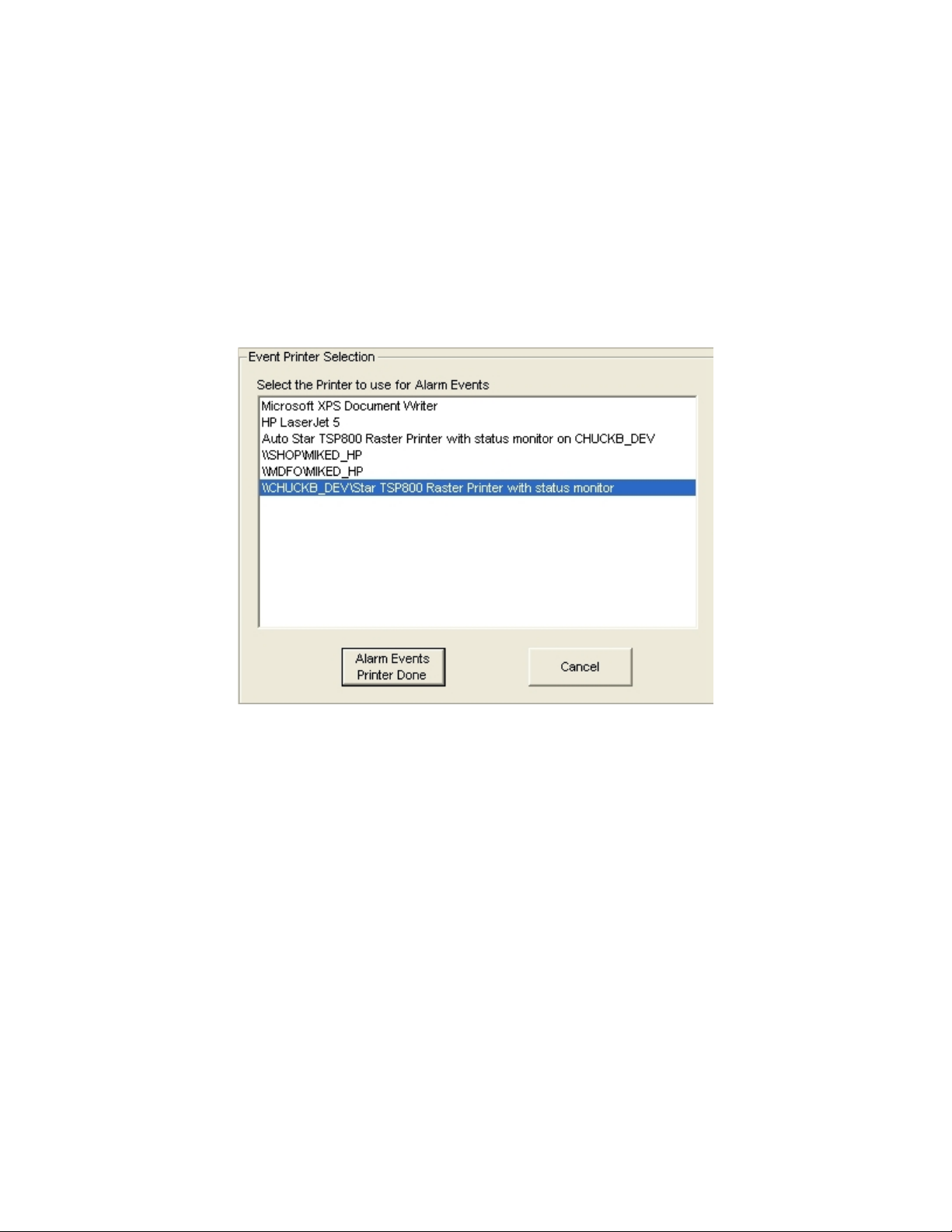

Select Printers

In this menu you can select the printer to be used for Alarm Events, typically during a

Truck Present cycle. This could be a ticket-style printer since each truck event can have

its own ticket. A separate printer can also be selected for your reports. Either of these

selections can use local or networked printers.

At power up, if no printers have been selected or your previous selection is not available,

the system will assign the printer(s) to the Windows default printer. A warning block

will appear at startup if your previous selection is no longer available.

On the first frame, you select the printer to use for Alarm Events. This includes all alarm

events enabled in the Events Logging user menu. Click on your choice and then click on

the Alarm Events Printer Done button to continue. Clicking on the Cancel button aborts

with no action being taken.

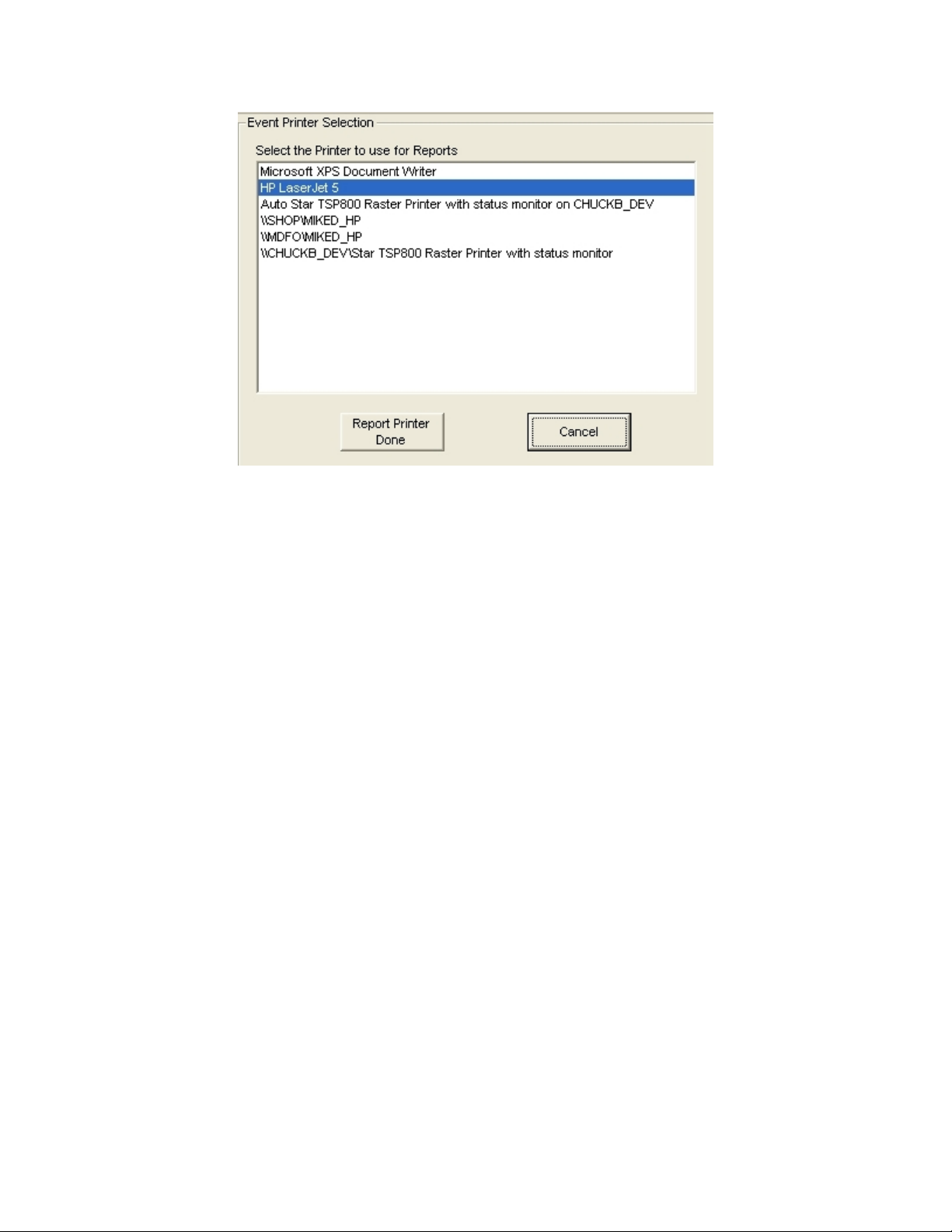

The same menu will appear and but now expect you to select the printer for reporting.

15

Page 17

You can select any printer from the list (including the same one used for Alarm Event

printing). Click on one of the selections in the list then click on the Report Printer Done

button to save your selection.

This selection is used for reports such as the Log Files, Analyzer graphs, and the reports

available in the Quality Assessment section.

16

Page 18

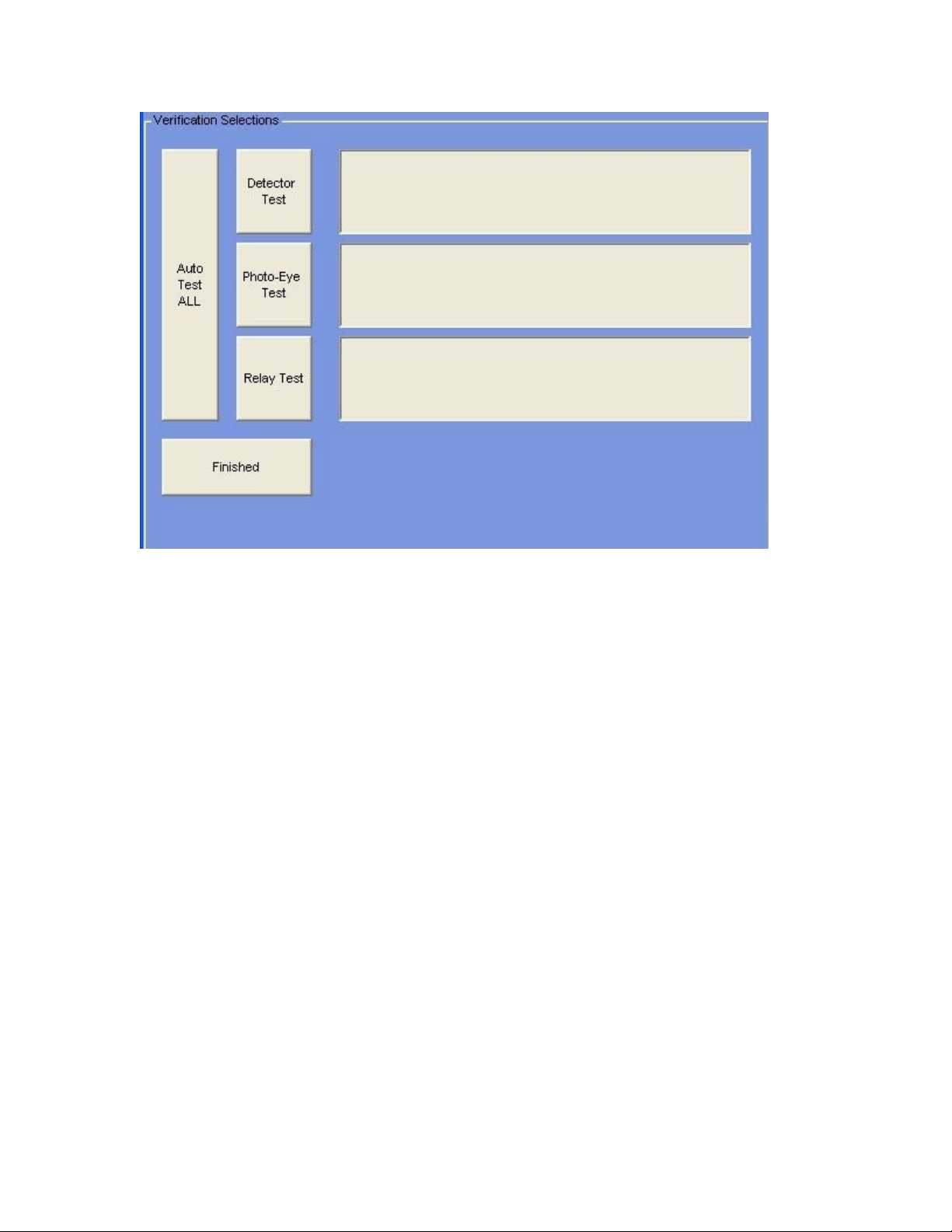

Manual System Verification

The major components of the system can be periodically checked with this function. It

should be performed regularly to ensure the integrity of the monitoring system. This

selection allows you to select the parts of the system you wish to verify:

• Detectors

• Photo-eyes

• Relays and internal beeper

The first screen you encounter is the above with preparation instructions. Clicking on the

Quit option will abort the function.

17

Page 19

This is the selection screen. You can select the parts of the system you wish to verify

here. Each selection will test one of the three functions. Clicking on the Auto Test ALL

button will run an Auto-Test on all three functions (the same as the touch-button

AutoVerify” on the Main Screen).

18

Page 20

Auto System Verification

When you select the Auto Verification function (right-most touch-button on the Main

Screen), the system will auto-finish the Detector and Photo-Eye Verifications if all

functions in these categories pass. This allows you to start the Verification, go to the

Truck Path, test each detector, test each photo-eye, then return to the Monitor Panel, test

the Alarm Relays, and ensure that each function passed.

An optional relay output at the detector frame is available when the detector frame is not

located conveniently to the Monitor Panel. This output will energize for a few seconds

when all detectors have passed, and when all photo-eyes have passed (in Auto

Verification mode), to allow an audible or visual indication of the Auto Verification

process. This output is on the Relay Output Remote I/O Module, Output Number 1.

This screen allows you to continue or abort the Auto Verification process. If you click

(or touch) the Continue button, the system will begin the Detector Stabilization process,

then start the Detector Verification process.

19

Page 21

Verify Detectors

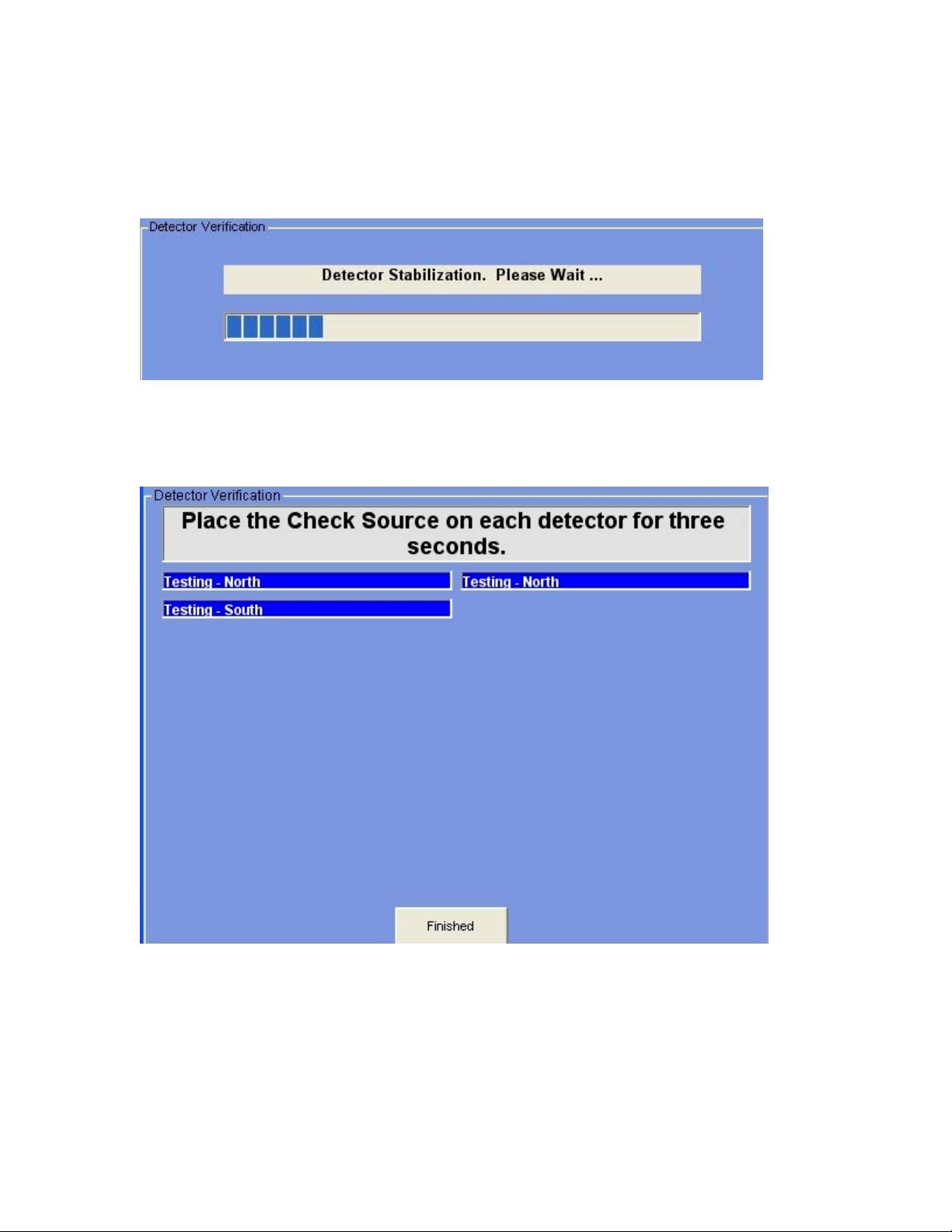

When you select Verify Detectors from the Manual Verify screen, or press the

AutoVerify button on the Main Screen, you will be presented with the following screen:

In order to perform any detector test, the system must get a stabilized value from each

detector. The progress bar will inform you of the time remaining before testing can

begin.

Once the stabilization has completed, each detector that has been activated and is enabled

will be available for testing. You must place the Test Source supplied with your system

on each detector for three seconds. If the detector is working correctly, the displayed box

for that detector will change to a green color and read “Passed”. In Manual Verification,

you must click on the Finished button to continue, when all detectors have been tested.

In Auto Verification, if all detectors Pass, the system will continue to the Photo-Eye

20

Page 22

Verification automatically. The results of the verifications will also be recorded in the

Log File and Printer if selected in the Events Logging menu.

21

Page 23

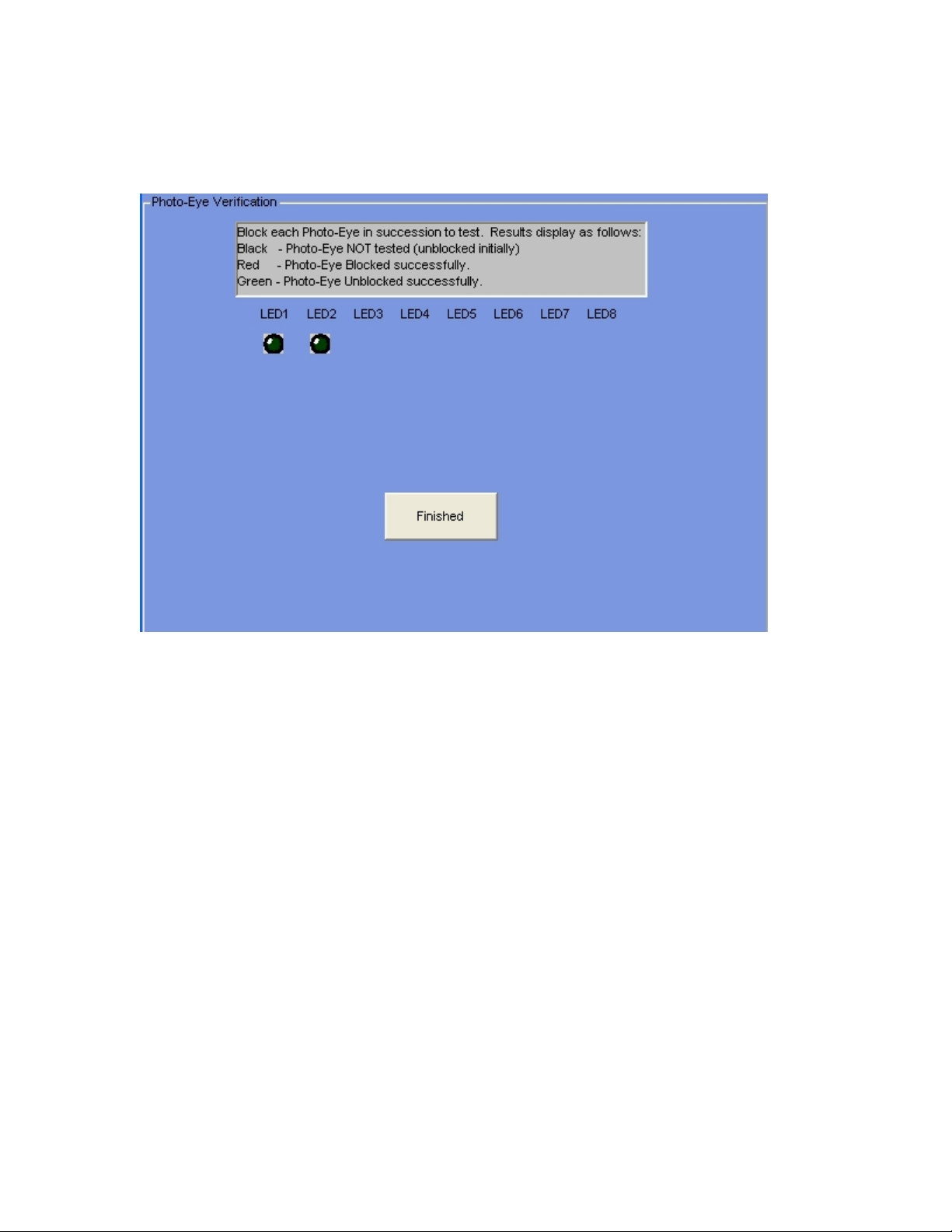

Verify Photo-Eyes

This function ensures the correct operation for each of the Photo-Eyes in your system.

As you walk through the Truck Path, each photo-eye will be blocked, then unblocked.

The blocking and unblocking will be recorded on this screen. When a photo-eye is

blocked, its associated LED on the screen will turn Red. After being blocked, when a

photo-eye is unblocked, its associated LED on the screen will turn Green.

If you are Manually verifying the system, click on the Finish button when done. If you

have selected Auto Verification, the system will move on to the Relay Verification

automatically after toggling the Verification Annunciator relay for a second or two, if all

photo-eyes pass (turn Red, then Green).

22

Page 24

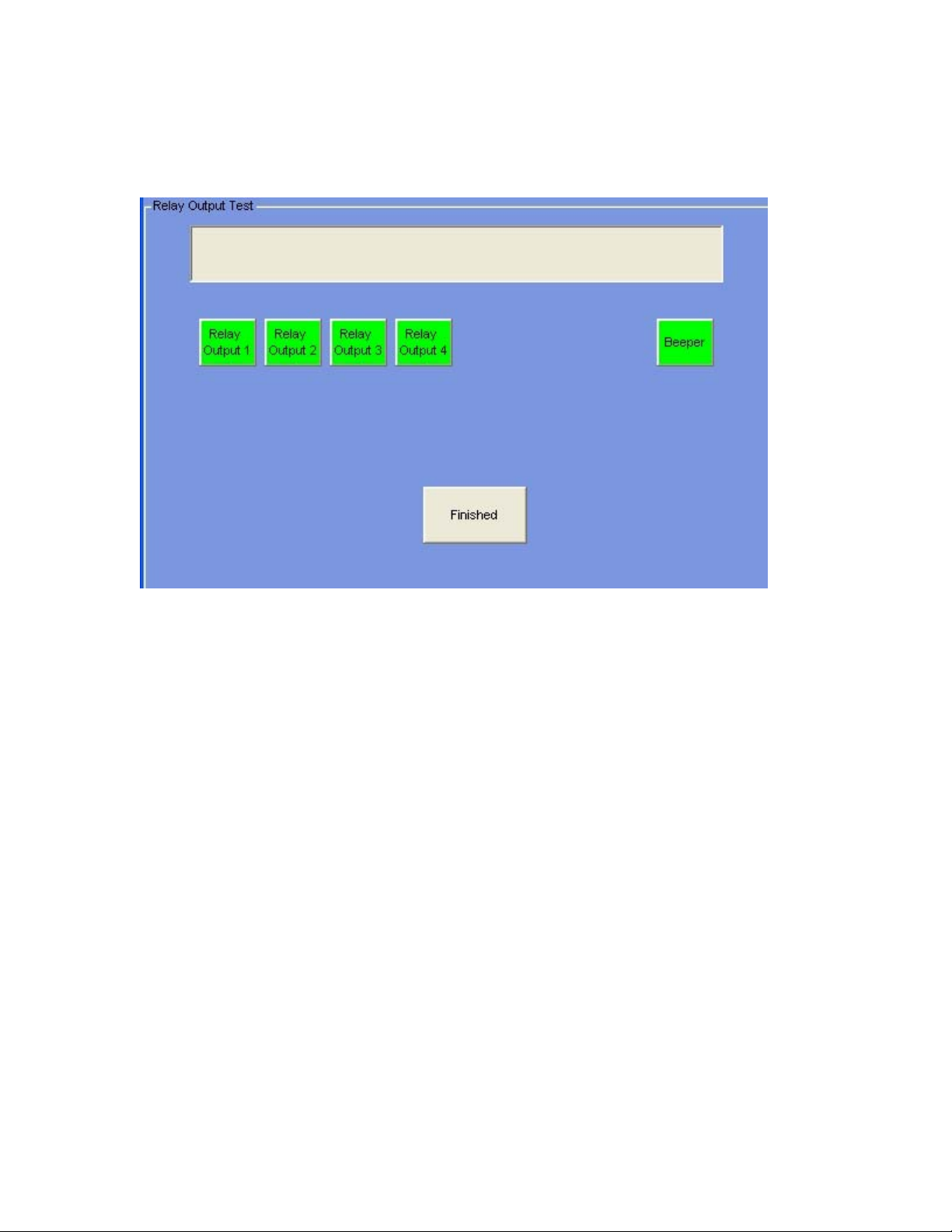

Verify Relays

This verification function will allow you to test each of the relay outputs.

Each Green relay (or beeper) box you click on will initially turn Red (and energize the

relay or internal beeper). Any annunciators you have tied to the relay should also be

activated. Clicking on a Red box will turn the relay (or beeper) box to Green (and deenergize the relay or beeper).

Whether you have selected Manual Verification or Auto Verification, you will need to

click (or touch) the Finished button here to complete the Verification Process (or return to

the Manual Selection screen).

23

Page 25

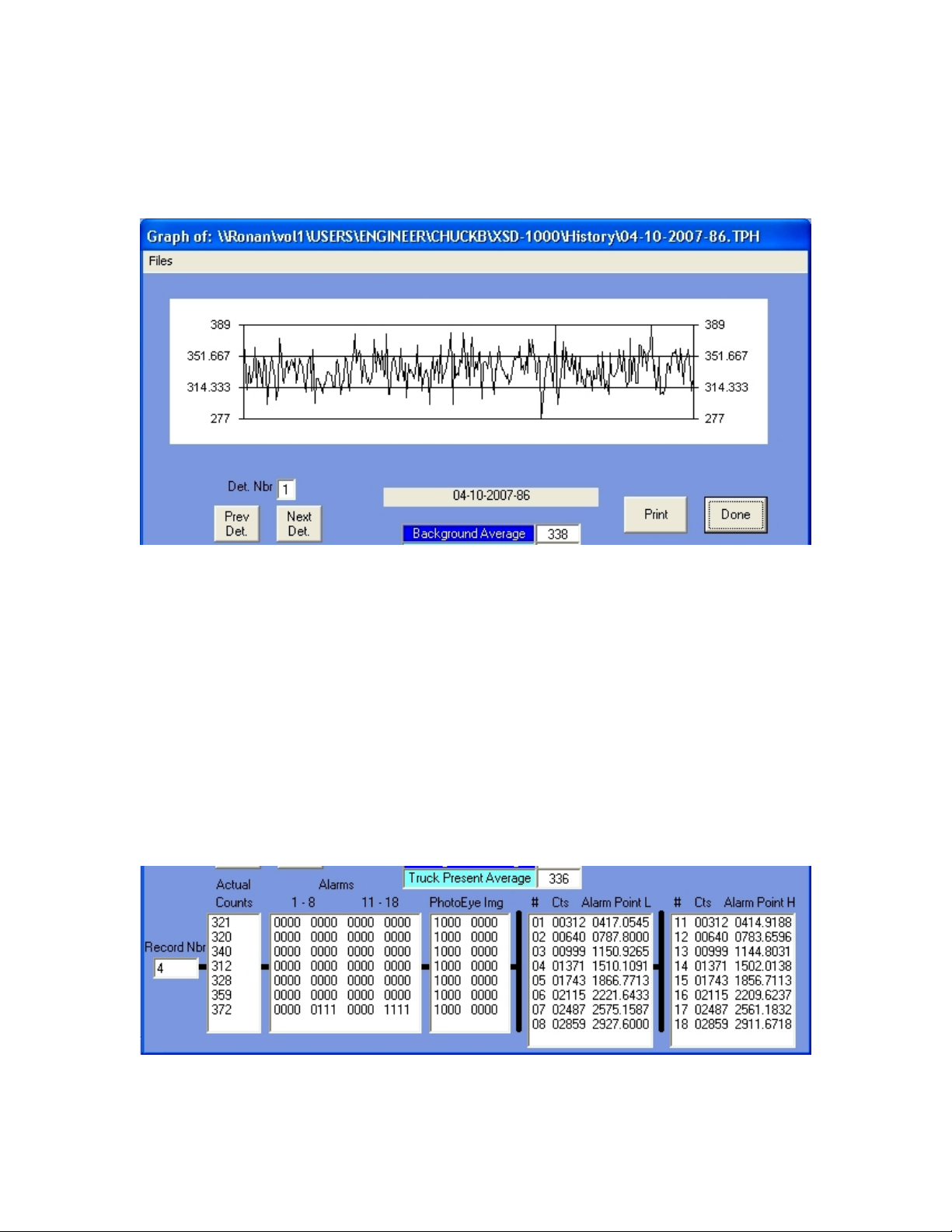

Analyzer

The Analyzer function allows you to graphically view the Truck Present cycle counts

from the detectors. This is primarily used for system tuning on special applications.

When a file is opened (if the Truck Present History is enabled) or the previous Truck

Present cycle is viewed, the counts from the detector (default is Detector 1) are

graphically displayed.

By clicking on specific points on the graph, the bottom list boxes will scroll to that point

(as indicated by the horizontal bar next to the lists). When you click on a point in the

graph, notice the second list box from the left. If any alarms occurred on that point, a ‘1’

will appear under the appropriate alarm (1-8 or 11-18). You can select other detectors by

selecting the Previous Detector button or the Next Detector button. The graph can also

be printed by clicking on the Print button.

There is a natural attenuation in counts due to the truck bed blocking the background

counts, so a Truck Present Average is generally lower than the Background Average.

24

Page 26

As you select different points on the graph, the record number in the far left of the bottom

portion will change. A record represents one sample period of time. The actual counts

for this detector is listed next.

There are 16 possible alarms per detector. The first 8 alarms are based on the

Background Average, and the next 8 are based on the Truck Present Average. A ‘1’ in

any row in the Alarms box represents the level of alarm in that column.

The next box represents the photo-eye image from the photo-eyes. A ‘1’ in a column

represents that photo-eye being blocked, and a ‘0’ represents the photo-eye unblocked.

The leftmost digit is photo-eye number 1.

The last box lists the alarm number (1-8 and 11-18), the counts from the detector (and the

summed counts over time for alarms greater than 1 or 11), and the alarm point for each

alarm. Obviously, a count greater than its alarm point is an alarm condition.

25

Page 27

Administrative Options

These menus are password protected. Entering a valid password will gain you access to

the Administrative options.

These options are primarily used for initial setup or system upgrades. Once setup, there

is little need for future access.

The Administrative Options permit changing the number of detectors, photo-eye

configuration, background and truck present alarm functions, passwords, speed alarm

options and the Quality Assessment functions. The history sampling can also be changed

from the Administrative Options menus.

One important function in the Administrative Options is saving your current

configuration. After setting up the User Options and the Administrative Options, you

should access the Administrative Options – File – Save Current Settings to Disk File and

save the current configuration settings. This can be important for later use in upgrades,

repairs, restoration, etc.

The default passwords for the Administrative Functions are:

• admin

• password

• access

These can be changed and managed in the Administrative Options menus.

26

Page 28

History Files

These selections determine if the system will record the files of counts received during

Background and/or Truck Present mode. This is normally a diagnostic function used by

field service in the event of a problem. Enabling these options will require substantial

disk space over time. Click on the box to enable (checked) or disable (unchecked) the

option.

If you do not know if you need these options, disable them. If you plan to use the

Analyzer function described elsewhere, you will need the Truck Present History function

enabled. With the Truck Present History function disabled, you can still use the Analyzer

function, but you can only display the last Truck Present cycle activity. When the next

Truck Present cycle begins, the previous contents will be lost.

27

Page 29

Log Files Creation

You can select when the system should create new log files here. If you select:

• Never – the system will create a Log File at initial startup, and never create another as

long as the original one exists. Note: this file can get very large over time.

• Day – a new Log File will be created daily.

• Week – a new Log File will be created weekly

• Month – a new Log file will be created at a change of month.

• Year – a new Log file will be created at a change of year.

28

Page 30

Password Maintenance

This menu allows you to set up to 3 passwords for Administrative Options access and up

to 3 passwords for user-logout (system shutdown). The passwords can be letters and/or

numbers and can be up to 15 characters long. The passwords are case sensitive and must

be input exactly as listed in the password boxes above.

The Log Out passwords permit the user to exit the XSD-1000 software package (File –

Exit), and the Administrative passwords permit access to the Administrative Options in

the menus.

The passwords listed in the example above are the system default passwords.

29

Page 31

Save Current Settings to Disk File

This menu permits you to store your current User and Administrative options to a disk

file. Once saved, you can use the File – Restore Settings from Disk File menu item to

retrieve these settings.

You can save multiple configurations by using unique file names for each one.

Note: Do NOT overwrite the Factory.CFG file. This is the factory setup file and allows

you to recover the safe values stored by the factory.

30

Page 32

Restore Settings from Disk File

This function will restore a previously saved configuration from a disk file. Caution: the

current settings in the system will be overwritten by these values.

The Factory.CFG file contains the settings for the system that was set at the Ronan

Facility before being shipped to you.

31

Page 33

Restore Safe Default Settings

Use this option if all else fails. Initially, try restoring the settings you saved. If this fails,

restore the factory settings (Factory.CFG file). If the Factory.CFG file is not present or

fails, you can use this option (Safe Defaults).

Caution: this option will over-write any settings you have changed including the Factory

settings.

32

Page 34

Background Mode

You set the Power Up Stabilization Time here. When you start up the XSD-1000

software, the system will average the detector counts for a period of time. This is the

Power Up Stabilization Period that the system calibrates to. This value should be at least

3 minutes (180 seconds) to allow proper statistical averaging and a stable value for each

detector.

The Number of .2 Second Period Samples value should NOT be changed unless you

consult the factory first. This value represents how often the system samples the detector

readings. This value also affects the overall detector sensitivity and the number of

‘looks’ the detector has during a Truck Present cycle.

33

Page 35

Detectors

You can select which detectors you have in your system with this screen. Each detector

number is associated with a Remote I/O Module Address. If you activate a detector that

has no Remote I/O Module currently active, the system will warn you. Unless you are

upgrading your system, you should not activate detectors with no Remote I/O Module

present.

The Dual Option means that you have two detectors at that position. This is normally a

special detector with two electronic heads that act as one (or two detectors end-to-end).

Do not enable this option if you do not have actual Dual Detectors with your system.

34

Page 36

Detector Locations

In this menu, you position the detectors as they are mounted around the Truck Path. This

will permit the system to approximate where on the truck a Radiation Alarm occurred.

Initially, the detectors are listed in the upper left corner of the screen. As you view the

back of a truck in the ‘Incoming’ direction through the Truck Path. Move the mouse over

one of the detector boxes, hold down the left mouse button, and ‘drag’ the detector to its

position around the truck. It is not important how close to the truck you get (stay within

the dotted boxes). If you have a two detector system, try to get the detector boxes as

close to the vertical center of the dotted box as possible. For top or bottom-mounted

detectors, try to get as close as you can horizontally to the center of the box. A four

detector system will mean that you should try to get each detector box about 1/3 of the

way away from the top or bottom of the dotted boxes.

The following is an illustration of a two detector system:

35

Page 37

36

Page 38

Photo-eyes

The top section of this menu has three options. The first is the Total Number of pairs of

Photo-eyes (remember that photo-eyes come in pairs: one transmitter and one receiver

per pair). Most systems have 2: one at each end of the detectors. Up to 8 photo-eye pairs

can be accommodated.

The next option is the distance between the photo-eye pairs. This distance is in Feet (if

MPH speed is selected in the Admin – Alarms Setup - Speed Alarms Menu) or Meters (if

Km/Hr is selected) and is measured along the vehicle path (not across it). The typical

distance is 6 - 10 feet.

The final option at the top is the selection of Unidirectional or Bi-directional operation.

If you are only checking vehicles in one direction (for instance: coming into the facility

only), then select unidirectional. If you plan to check vehicles in both directions (for

instance: entering and exiting the facility), then select bi-directional. Note: if you have

only one photo-eye pair, do not select Bi-directional. The system cannot distinguish both

directions with a single photo-eye pair.

You must now determine your directions for clarity. If you selected a unidirectional

system, the right side of the above display will be blank. Facing the XSD-1000 Frame

and Detectors from the Monitor Panel location, determine which direction vehicles will

pass through the system and define a name for that direction (ie: Incoming, Entrance,

etc). For instance, as you face the XSD-1000 Frame and Detectors, if vehicles enter the

system from left to right as they enter your facility, you could call this direction

‘Entrance’, or ‘Forward’. Whatever name you choose will be used on-screen and in the

Log Files and Printer Logs to determine the direction of a Truck Present cycle.

37

Page 39

There are 5 boxes below the photo-eyes that display the functions of the photo-eyes. The

first one is highlighted initially. To select other functions, click on the definition boxes

and the photo-eyes enabled for that function will be shown.

The number of photo-eyes you selected previously determines how many lights are

available below the name you select. Each light represents a photo-eye. A ‘black’ light

means it is not selected; a ‘green’ light means it is selected. The light with the box

around it represents photo-eye number 1. The others are numbered from left to right. As

you click on the boxes below the lights, the lights will change to show the ones selected

and unselected. To change a photo-eye from selected to unselected or unselected to

selected, click on the photo-eye you wish to change. The photo-eye numbers on the

screen match the numbers on the Remote I/O Digital Input card. If you wired the leftmost photo-eye into Input #1, then number one on the screen represents the left-most

photo-eye.

You must determine which photo-eyes perform the following functions:

• Truck Present Photo-Eye: Only one light should be green here and should be an ‘end’

light (first or last). The direction the vehicle travels for the Forward Direction Name

cycle will determine which photo-eye starts the Truck Present cycle. The first photoeye blocked by the truck will start the Truck Present cycle. Click on any light to

toggle it from on to off to on.

• Photo-Eye(s) ON to Maintain Truck Presence: These are the photo-eyes that must be

on to maintain the Truck Present cycle. If any of the lights defined here remain

blocked, the Truck Present cycle will continue. All the photo-eyes selected here must

be off during a Truck Present Cycle to end a Truck Present cycle.

• Photo-Eyes for Speed Checking: Any photo-eye not used to start the Truck Present

cycle for this direction should be used for speed checking.

• Photo-Eye at Starting end of Detector: This could be the same photo-eye that starts a

Truck Present cycle (if you only have two photo-eyes on your system). There is one

photo-eye at each end of the detector. The one the vehicle will block first in this

direction should be selected here. This gives the system the knowledge it needs to

calculate the Alarm Points properly.

• Photo-Eye at Far End of Detector: This is the photo-eye at the other end of the

detector used for Alarm Point calculations.

If you have a bi-directional system, you will need to set the Reverse Direction Name

section up like you did the Forward Direction Name section. Keep in mind that the

vehicle is now moving in the opposite direction, and the photo-eye settings for the

Forward section should be a mirror image of this section.

38

Page 40

Now you must select the picture that represents which way the vehicle will be moving in

the Forward Direction Name direction. Click below the picture to change the direction.

This picture will be displayed in the event of a vehicle alarm, and an approximate

location of any source material will be displayed.

39

Page 41

Relay Output Options

You have 4 relays and an internal beeper available on each XSD-1000 system. This

option allows you to select the relay that will trip on the alarm specified. You can select

the same relay for all alarms, or split them up. Click on a blank box to check it, or on a

check mark to deselect it. Any relay can be set to activate on any, all, or none of the

events listed.

Each relay is a Form ‘C’ type contact arrangement (N.O., N.C., Common).

The beeper (located on the underside of the Monitor Panel) can also be programmed to

alarm on any, all, or none of the events.

40

Page 42

System ID

This is the title displayed at the top of the main screen. It is also used in the

communications function to identify this XSD-1000 system. If you have multiple XSD1000 systems communicating to a host (or server), the System Identification for each

must be unique.

The value here can be anything you decide, up to a maximum of 50 characters.

The Log Files from each XSD-1000 system can be uploaded to a host system over the

Ethernet link and ‘linked’ into a Microsoft Access file. The unique System ID will

help organize this combined file.

41

Page 43

Background Alarms

The default values for this menu should not be changed without consulting the factory.

The Detector Low Count Failure is the lowest number of counts you can receive from an

active detector. This value is typically 1.

The Consecutive Failures till Alarm ensures that you do not get false alarms in a very low

background radiation area.

The High Background Alarm Multiplier should always be 3. If the detector counts

suddenly peak above the background average by this amount (3 times background

average), then the detector will fault after the Consecutive Number of Faults. This alarm

is to ensure that radioactivity introduced to the detectors during Background mode does

not affect the sensitivity or calibration of the system.

The Consecutive Failures till Alarm behaves the same as above, except here it applies to

a High Background Alarm.

42

Page 44

Speed Alarms

The top item in this menu is the speed units. Select either MPH or KPH for your use.

Notice that the Maximum Speed will be automatically changed based on your selection.

After your units selection, type in the correct speed in the second section.

The maximum speed for vehicles is typically 5 MPH (8 KPH). Unless otherwise

instructed by Ronan factory personnel, this value should remain at 5 MPH (8 KPH).

Speed detection is performed using photo-eyes. In a single photo-eye pair system, speed

checking cannot be performed.

43

Page 45

Truck Present Alarms

The first box defines whether alarms are enabled during a Truck Present cycle. This

option should always be selected.

The Truck Present ‘ON’ Delay is for delaying the start of Truck Present cycles and is

primarily for applications where trucks may stop on a weight scale after triggering the

Truck Present Photo-eye. This value will delay the start of the cycle. Normally, the

value here is zero.

The Maximum Truck Present Time should always be 60 seconds. This value minimizes

false alarms due to the statistical algorithms used.

The Truck Present ‘OFF’ Delay value is used to maintain a Truck Present cycle when the

photo-eyes may become unblocked between the cab and trailer of a truck. If the gap

between a cab and trailer exceeds the distance between your photo-eyes, use this value to

compensate such that at least one photo-eye is blocked during the truck cycle.

44

Page 46

The bottom section should never be changed except under factory direction. The Sigma

Values and Reduction Factors directly control the sensitivity of the XSD-1000 system.

45

Page 47

Quality Assessment

The Quality Assessment functions of the XSD-1000 is intended for users requiring

periodic assessment of the system’s functionality for ISO or insurance purposes. This

functionality will allow you to track initial installation of the detectors and their output

values, then track them periodically and compare any differences. The system will

automatically calculate a valid differential from period to period including the Test

Source decay.

Multiple reports are available to check all replacement activities and dates of detectors

and Test Sources.

If you plan to use this feature, you should ensure that immediately after installation and

before commissioning the system, that your detectors and Test Source are listed in the

activity report. This information will be required after the first period to enable the

system to compare the results and determine the validity of the detectors.

You also need to set up the interval for this periodic test. After the interval time elapses,

a warning box will appear on the Main Screen reminding you that your periodic

assessment is due.

46

Page 48

Reports – Events by Date

This report will list all Detector or Test Source replacements (or installments) and all

Detector Sensitivity Checks by the date they were performed. The data is identical to the

report of Events by Type, except arranged by date.

There are three event types that can be presented:

• Replace Detector

• Replace Check Source

• Detector Sensitivity Check

47

Page 49

Reports – Events by Type

This report will list all Detector or Test Source replacements (or installments) and all

Detector Sensitivity Checks by the Event Type. The data is identical to the report of

Events by Type, except the event types are grouped together.

There are three event types that can be presented:

• Replace Detector

• Replace Check Source

• Detector Sensitivity Check

48

Page 50

Reports – Detector Sensitivity Checks

This report will list the last Sensitivity Check performed compared to the one previous to

it, and give an assessment of pass or fail by comparing the percent difference between

these two readings. The ‘First’ value will also be listed as a reference.

Note that if you replace a detector, it becomes the current with no history when a

Detector Sensitivity Check is performed. Immediately after replacing a detector, a

Sensitivity Check should be done for that detector to establish a reference for the normal

periodic Sensitivity Check to determine its validity.

The report has two halves: the left half is based on background averages (or Norm).

This test verifies the low-level sensitivity of the detector. The right half is an assessment

with your Test Source, and validates the gain of the detector. It is important to perform a

‘Replace Test Source’ at system installation so the system can determine the amount of

source decay to apply when performing the periodic Sensitivity checks.

The above report shows that only one Detector Sensitivity Check has been performed.

Therefore, there is no ‘Delta%’ nor ‘Allow%’ nor ‘Passed?’.

49

Page 51

Note the above Detector Sensitivity Report has 2 entries for each detector. You can see

slight differences between the Now and the Prev values on the Test Source half of the

report (Now is the last Detector Sensitivity Check). The Delta% if the percent difference

between the Now and Prev readings. The Allow% is the allowance percentage difference

the Now and Prev readings. In the P? (Passed?) column, both detectors passed both the

Background and Test Source Checks.

If your checks produce an N value (not passed), call Ronan Service to get the detector in

question serviced. The Passed? Column has the following possibilities:

• Y = Yes, this detector passed both the current test, and the longevity test

• N = No, this detector failed the current test (Now compared to Prev)

• ? = Not enough data to evaluate this detector

• R = The detector has failed the longevity test. Contact Ronan Engineering to get this

detector Refurbished.

50

Page 52

Set Sensitivity Check Interval

This menu allows you to establish your periodic interval for the Detector Sensitivity

Checks. After the number of Days from the Start Date, the system will prompt you (on

the Main Screen) daily as a reminder to perform the Detector Sensitivity Check. When

you perform the Detector Sensitivity Check, the Start Date will automatically be updated

to that date.

51

Page 53

Replace Detector

At initial installation, or when a detector is replaced (new or after service), you should

perform a Replace Detector function. The detectors available according to the

Administrative Options – Configure Detectors setup will determine which detectors are

listed. Note that on initial installation, you may not have Serial Numbers listed for the

detectors. This is normal.

To log replacing (or installing) a detector, you click on one of the detectors in the left

box, and it will be displayed in the box under the ‘Replace’ label. You must then supply

the Serial Number (or S.O. number) listed on the detector. Next supply your initials and

click the ‘Done’ button and this detector will then be added to the Quality Assessment

Events, and will be used (instead of the replaced detector) for future Detector Sensitivity

Checks.

52

Page 54

Replace Test Source

To initially install (or eventually replace) a Test Source, you use this menu. Typically,

the information required here is listed on a tag on the Test Source. This information is

necessary for the system to determine the amount of source activity decay between

Detector Sensitivity Checks to determine a proper Allowance Percent for the check.

• Click on the arrow (on the top box) and select the type (isotope) of Test Source you

are installing (or replacing with).

• Type in the Test Source Field Strength in uCi (micro-Curies).

• Enter the date on the Test Source.

• Enter the Serial Number from the label on the Test Source.

• Finally, enter your initials, then click on the ‘Done’ button

The information you entered will be entered into the Quality Assessment Event log.

53

Page 55

Perform Detector Sensitivity Check

The Detector Sensitivity Check is a check on the quality of the measurement and the

sensitivity of the detectors in your system. Tracability and performance checks are

typically required by ISO and insurance organizations. The Detector Sensitivity Check

function will check the detectors attached to your system and maintain a log of the checks

performed for tracability.

The first screen is informational only. If you choose to Continue, the next screen will

appear.

On the second screen, a list of enabled detectors is presented. You may select any or all

of the detectors to perform the Sensitivity Check on. If done on the interval specified in

the Set Sensitivity Check Interval menu, all detector should be checked. If you have just

54

Page 56

Replaced a Detector, you can select only the one you just replaced. If you click the ‘All’

box, all detectors will be selected automatically.

You must enter your initials before the system will accept the Continue button. Note:

clicking on the ‘Quit’ or ‘Abort’ button at any screen during the Detector Sensitivity

Check function will quit the function and write nothing to the Quality Assessment Event

log file.

After selecting the detector(s) to check, click on the Continue button and the next screen

will appear.

The system is preparing to perform a Background Radiation test on the detector(s) you

selected. Ensure that the Test Source and any vehicles or trucks are not near the detectors

before clicking on the Continue button.

During this time, the system is obtaining a Background Radiation average for each

detector you selected previously. Upon completion, the next screen will appear

automatically.

55

Page 57

The system will automatically select the detector to check. Place the Test Source on the

target on the selected detector (the one with the arrow pointing to it), and press the

Continue button. The check for this detector will run. At the conclusion of that test, the

next detector will be selected, and you then move the Test Source to the newly selected

detector. This procedure will repeat until all detectors you selected have been checked.

After the last detector has been checked, a message will appear telling you that all tests

are complete, and to press the Continue button. Pressing the Continue button will cause

the system to write the test results to the Quality Assessment Event log file and display

the Detector Sensitivity report on the screen. Today’s date will also replace the previous

date in the Sensitivity Check Interval.

56

Page 58

TroubleShooting Guide

This troubleshooting guide will help you troubleshoot problems based on the failure you

receive from the system. Refer to the Overview section for system component definitions

such as Monitor Panel, Remote I/O Enclosure, etc, as the Troubleshooting Guide will use

these definitions to refer to the components of the system

57

Page 59

No Remote I/O Modules Found

Normally when starting the XSD-1000 System, the System Status bar reads ‘Verifying

Connected I/O Modules’ for a few seconds, then starts the ‘Power Up Stabilization’. If

during the initial verification function, the system cannot locate any Remote I/O

Modules, a large orange button appears and asks you to check the modules and cabling,

then click the orange button to restart.

• Check the voltage on TB-2 terminals 4 & 5 on the bottom of the Monitor Panel. It

should read between 4.75 VDC and 5.25 VDC. If not, remove the wire from pins 4 &

5, and recheck the voltage at the terminals. If the voltage is between 4.75 VDC and

5.25 VDC, check the cable for a short or miswiring (see diagram below). Click on

the large orange button on the screen, and verify that the green LED on the bottom of

the Monitor Panel is flashing while the “Verifying Connected I/O Modules” status is

displayed. If not, disconnect the Remote I/O Cable from TB-2 terminals 2 & 3 and

re-check the green LED (you will probably have to click on the Orange ‘Restart’

button on the screen). If the LED is then flashing, there is a short in the Remote I/O

Cable, an open wire in the Cable, is miswired, or there is a problem in the Remote I/O

Enclosure. If the LED is still not flashing, replace the Communications board in the

Montor Panel.

• The following wiring diagram illustrates the correct wiring between the Monitor

Panel and the Remote I/O Enclosure:

58

Page 60

Remote I/O Failure

There is one I/O module for each detector in your system, plus one module for photoeyes 1 – 4, and another for photo-eyes 5 – 8. For instance, if you have 2 detectors and 2

photo-eyes (typical system), you will have 4 Remote I/O Modules (the fourth is the Relay

Output for Auto Verification Notification). The Remote I/O Module numbers listed in

the Log File are defined in the Remote I/O Module Addressing section.

• Check the Monitor Panel screen and the current Log File to determine if only one

Remote I/O Module has failed, or if ALL Remote I/O Modules have failed. If all have

failed, go to Step 1 in the ‘No Remote I/O Modules Found’ section.

• Open the Remote I/O Enclosure and notice the red LED’s on each of the Remote I/O

Modules. Any that are NOT flashing, but are on, are NOT communicating. Any

LED’s that are constantly off have lost power, have totally failed, or have an address

conflict. If you have recently added or replaced a Remote I/O Module, refer to the

‘Remote I/O Module Addressing’ section to verify the module’s address.

• Make sure the terminal screws on the Remote I/O Modules are tight and there are no

loose wires.

• Remove the power from the Monitor Panel for about 5 seconds, then restore it. All

LED’s on Remote I/O Modules should begin flashing within a few seconds.

• If a Module (or Modules) still cannot communicate or power up, replace the Remote

I/O Module. Refer to the ‘Remote I/O Module Addressing’ section for proper

addressing.

59

Page 61

Detector Failure

Detector Failures can come from two areas:

• Actual detector failure

• Failure of Scintillator Input Remote I/O Module power supply

(You can refer to the chart in the ‘Remote I/O Module Addressing’ for the correct I/O

Module address if you are not sure which I/O Module to look for).

• Check the Scintillator Input Remote I/O Module in the Remote I/O Enclosure to

ensure its red LED is flashing. If not, refer to the ‘Remote I/O Failure’ section.

Check the voltage at the Remote I/O Modules pins +24V & Com. You should see at

least 15VDC at these terminals. If so, proceed to the section ‘Troubleshooting the

Detector’.

• If there is no voltage at these pins, disconnect the wires to the +24V and Com

terminals and recheck the voltage.

• If you read a low voltage (less than 15VDC) or have no voltage, replace the

Scintillator Input Module.

• If the voltage is greater than 15VDC, proceed to the ‘Troubleshooting the Detector’

section.

60

Page 62

Photo-Eye Failure

Check the 12VDC (TB-2 terminals 6 & 7) on the bottom of the Monitor Panel. If there is

no voltage at these pins, remove the Remote I/O Cable from TB-2 terminals 6 & 7, and

recheck the voltage at the terminals. If there is now 12VDC at the terminals, then the

Remote I/O Cable is miswired or broken and needs replaced. If there is voltage on the

terminals, check the wires at the terminal block on the Communications board inside the

Monitor Panel. If they are intact, replace the 12VDC power supply.

To use the system with a failed Photo-eye (assuming you have more than two Photo-eyes

on your system), do the following:

If you have more than 2 photo-eyes, and a failure occurred on a photo-eye at the

beginning or end of the detector, replace it with one of the others such that the photo-eyes

at both ends of the detector are functional. Go to the Administrative Options – Configure

– PhotoEyes, click on each of the photo-eye configuration boxes, and click off the photoeye you took out. This, in effect, disables that photo-eye until you can get the failed one

repaired or replaced.

Note that it will help if you first go to Administrative Options – File – Save Current

Settings to Disk File and save your settings first. Then when the failed photo-eye is

repaired/replaced, you can go to Administrative Options – File – Restore Settings from

Disk File and retrieve you last setup before the photo-eye configuration was changed.

If you only have 2 photo-eyes, you will need to switch the system to Uni-Directional in

the Administrative Options – Configure – PhotoEyes menu. If the failed photo-eye is the

Truck Present Start photo-eye for the direction you need, you can physically swap the

photo-eyes on the frame. Unfortunately, with only one photo-eye available, the system’s

sensitivity it affected and you may get an increase in false alarms. It is imperative that

you get the photo-eye repaired/replaced as soon as possible.

As above, the failed photo-eye can be turned off using the Administrative Options –

Configure – PhotoEyes menu. Click on each of the photo-eye configuration boxes and

click off the failed photo-eye, until it is repaired/replaced.

61

Page 63

Relay Failure

This failure will probably become apparent during a System Verify (Manual or

Automatic). If a failure occurs with an Alarm Relay, go to the Administrative Options –

Configure – Configure Relay Output Assignments, and re-assign the failed relay to

another working relay. The Alarm Relays are located in the Monitor Panel and will

require repair/replacement of the printed circuit board inside the unit.

If the relay failure is a Verification Notification relay, Speed Notification relay, or a Gate

Control relay, these are located on the frame in the Remote I/O Enclosure. See the

section on Remote I/O Failure for help here.

62

Page 64

Troubleshooting the Detector

NOTE: Make sure the wiring from the detector to the Scintillator Input Remote I/O

Module is correct. If you have just replaced (or added) a Scintillator Input Remote I/O

Module when the Detector Failure occurred, refer to the Remote I/O Module Addressing

section to ensure you have properly addressed the Remote I/O Module.

• Remove the cable from the detector. This is a military style twist-off connector

located at the top of the detector.

• Make sure the Remote I/O Modules are powered up; the red LED on the Scintillator

Remote I/O Modules needs to be On or Flashing.

• Check the voltage at pins A & J of the twist-off connector. If you have greater than

14VDC at these pins, the detector needs to be repaired or replaced. Otherwise,

replace or repair the detector cable.

63

Page 65

Adding/Replacing a Remote I/O Module

When replacing a Remote I/O Module, there are two important things to check:

• Replace with the same module type (Scintillator Input, 3-30VDC Input, etc.)

• Make sure the address on the new board is correct.

You do not have to remove the field wiring to replace a Remote I/O Module, unless the

module’s connector is faulty. Pull the connector up, press the plastic release tab on the

I/O Module, remove the module and replace with a new one, and push on the connector.

When upgrading (adding additional features, detectors, etc.) follow the installation

instructions for proper addressing and wiring.

NOTE: If two Remote I/O Modules have the same address, either one or both will not

communicate properly! See the section on ‘Remote I/O Module Addressing’.

64

Page 66

Remote I/O Module Addressing

In the following illustrations, the slider on each switch position 1 – 7, should match the

black portion of each switch. For instance:

in this illustration, switch position 1 is On (up), positions 2 through 7 are Off (down).

This chart illustrates the proper addressing for each Remote I/O Module:

Module

Module Type Description Switch Positions

Address

1 3-30VDC Input Photo-eyes 1 - 4

2 3-30VDC Input Photo-eyes 5 - 8

5 Relay Output Auto Verification

Annunciator

7 Scintillator Input Detector 1A

8 Scintillator Input Detector 2A

9 Scintillator Input Detector 3A

10 Scintillator Input Detector 4A

11 Scintillator Input Detector 5A

65

Page 67

12 Scintillator Input Detector 6A

13 Scintillator Input Detector 7A

14 Scintillator Input Detector 8A

15 Scintillator Input Detector 9A

16 Scintillator Input Detector 10A

17 Scintillator Input Detector 11A

18 Scintillator Input Detector 12A

19 Scintillator Input Detector 1B (Dual

Detector ONLY)

20 Scintillator Input Detector 2B (Dual

Detector ONLY)

21 Scintillator Input Detector 3B (Dual

Detector ONLY)

22 Scintillator Input Detector 4B (Dual

Detector ONLY)

23 Scintillator Input Detector 5B (Dual

Detector ONLY)

66

Page 68

24 Scintillator Input Detector 6B (Dual

Detector ONLY)

25 Scintillator Input Detector 7B (Dual

Detector ONLY)

26 Scintillator Input Detector 8B (Dual

Detector ONLY)

27 Scintillator Input Detector 9B (Dual

Detector ONLY)

28 Scintillator Input Detector 10B

(Dual Detector

ONLY)

29 Scintillator Input Detector 11B

(Dual Detector

ONLY)

30 Scintillator Input Detector 12B

(Dual Detector

ONLY)

67

Page 69

Printer

You have the option to select which events will be printed to the printer. These options

are found in the User Setup - Events Logging menu. The same events available for the

Log File are available for the Printer. Any event checked, if it occurs, will be printed.

You may select different events for the Printer and Log File.

The optional printer supplied by Ronan is a thermal 4” wide printer with graphics

capability. Its primary purpose is to log alarm events on hard copy. Truck Present Alarm

events will be printed on an individual ‘ticket’ of paper, while other system and

background alarms will be printed when a truck arrives or when the system is shut down.

The cable interface at the monitor panel is a 25-pin male D-sub-style connector.

68

Page 70

Events

The following events can be selected for printing or logging in the User Setup menus:

• Startup/Shutdown Events: XSD-1000 program startup/shutdown

• Background Alarms: Alarms occurring during Background Mode. These include

High Background Alarms, Detector Failure Alarms.

• Truck Present Alarms: Alarms occurring during Truck Present Mode. Including

Radiation Alarms, Vehicle Speed Alarms. The Truck ID will also be printed with

these events.

• System Alarms: Program failure, Remote I/O Module failure, Communications

failure.

• Truck Enter/Exit Events: Vehicles triggering the Truck Present photo-eye(s), and

exiting the system. The Truck ID will also be printed with these events.

• System Verification Events: Summary when the System Verification is performed

either manually or automatically.

69

Page 71

Passwords

The XSD-1000 system requires a password to access the Administrative menus, and to

shut down the software. There are three passwords for each function. The default

Administrative access password is ‘admin’. Once accessed, the Administrative

Passwords should be changed for security reasons.

The default Exit password (to shut down the XSD-1000 software) is ‘exit’. This

password should also be changed during the Administrative session.

70

Page 72

Alarms

Radiation Alarm – These alarms are only detected during a Truck Present cycle. If a

radioactive source has been detected in a vehicle during a Truck Present cycle or the

vehicle has blocked the photo-eyes for longer than the Maximum Truck Present Time

(defined in Administrative Options – Alarms Setup – Truck Present Alarms), this alarm

will be activated.

Speed Alarm – This alarm is only detected during a Truck Present cycle. The Photo-Eyes

for Speed Checking (defined in Administrative Options – Configuration – PhotoEyes)

will detect the vehicle’s speed and report any speed violations. A speed violation

requires that the vehicle be re-scanned through the system. Numerous speed violations

could mean that a photo-eye has failed and the system thinks it is blocked, causing

spurious speed violations. Periodically run the System Verification to check for proper

photo-eye operation.

Truck Present Time-Out Alarm – This alarm is only detected during a Truck Present

cycle and triggers a Radiation Alarm. (See Radiation Alarm above). If you receive a

Truck Present Time-Out Alarm and the vehicle had already exited the system, run the

System Verification to check the photo-eye operation. A failed photo-eye can look like a

blocked photo-eye to the system.

Detector Fault Alarm – This alarm is triggered by the counts (value displayed in the

green boxes on the Main Screen for each detector) received by a detector being below the

Detector Low Count Failure value defined in the Administrative Options – Alarms Setup

– Background Alarms menu. The box under this setting is the consecutive number of

times this condition must be met before actually issuing the alarm. This value should

always be 3. The Low Count Failure value is normally set to 1.

High Background Alarm – This alarm can occur only during Background Mode (when no

photo-eyes are blocked). If a large radioactive source is exposed to the detectors, the

instantaneous counts are compared against the background average (displayed during

Background Mode in the green boxes on the Main Screen). If the instantaneous counts

exceed the background average by a factor defined in the High Background Alarm

Multiplier (Administrative Options – Alarms Setup – Background Alarm menu), and it

occurs on consecutive samples (as defined by the High Background Consecutive Failures

till Alarm menu), this alarm will be triggered. If this alarm occurs, the background

averaging will cease until the condition is remedied.

I/O Failure Alarm

– These alarms can occur anytime a Remote I/O Module fails to

communicate properly.

71

Page 73

Appendix

Operating System Configuration

It may be necessary to reconfigure your Windows XP operating system from time to

time. These reasons can be adding printers, configuring your LAN access, setting up

shared directories, etc. The system will allow this, but will discard any changes the next

time it boots. The reconfiguration mentioned here is to the operating system stored on

Drive C. Changes you make in the menus of the XSD-1000 are stored on Drive D, which

is NOT write-protected.

Also note that there is no typical ‘Shut Down’ function on the Windows menu. This

feature is not required normally since the hard disk is write-protected. For normal

shutdown, you can simply unplug the unit.

There are two methods for disabling the write-protection on Drive C: temporary and

permanent. Is it advised to NEVER use the permanent write-protect disable function

unless you are the owner and operator of the system, or you have qualified personnel

operating the system. This system can have access to your LAN/WAN, internet, and

numerous other sites. The system also depends on minimal network traffic to maintain

its communications speed to the Remote I/O modules and maintain its sensitivity.

The two methods are described here. To temporarily disable the write-protect feature of

Drive C, select the Start button, then the Run function. In the Open: box, type

‘ProtectionOff.bat’, then click on the OK button. This will disable the write-protection

function until you reboot the system. After reboot, the write-protection function will

automatically be enabled. To reboot the system after making any changes, you should

again select the Start button, then the Run function. In the Open: box, type ‘Restart.bat’

and the OK button. This will ensure that any settings you have made are saved before

actually shutting down.

The second method is similar to the first. Select the Start button, then the Run function.

In the Open: box, type ‘PProtectionOff.bat’, then click on the OK button. This

permanently disables the write-protection function, even after rebooting. If at some point

later you decide to re-enable the write-protect function, do the following: Select the Start

button, then the Run function. In the Open: box, type ‘ProtectionOn.bat’, then click the

OK button. The system must be rebooted to enable the write protect function. This need

not be immediately, but keep in mind that you are not protected until you reboot. This is

done by selecting the Start button, then the Run function. In the Open: box, type

‘Restart.bat’ and click the OK button.

72

Page 74

Electrical

Environmental

Mechanical

Electrical

Environment

Mechanical

Computer

XSD-1000 Specifications

Frame Components

Supply + 5 VDC @ 7.5A max

+12 VDC @ 4.5A max

Optional 120 VAC @ 6A max /220 VAC @3A max

Signal RS-485 Communications

Connections 6 Position Terminal Block for cable from Monitor

Panel (See chart for maximum cable lengths)

All scintillator/photo-eye connections local to frame.

Operating Temp -20C to +60C normal

-40C to +60C with Heaters

Storage Temp -40C to +60C

Humidity 0 – 100%

Classifications NEMA 4

Frame Material Steel – Painted

Frame Weight

Detector Mat’l Steel – Painted

Detector Weight

Options Detectors – 1 to 12 (Single or Dual)

Photo-eyes – 1 to 8

Monitor Panel Components

Supply 85 – 265 VAC @ 2A max, 50/60Hz

Signal RS-485 Communications to/from Frame,

Ethernet, USB

Connections AC Power, 6 Position Terminal block for

Power/Communications to Frame, 4 Alarm Relays

(Form ‘A’), Beeper, Keyboard, Mouse, Printer,

Ethernet, USB.

Operating Temp 0C to +50C

Storage Temp -20C to +60C

Humidity 0% to 95% non-condensing

Classification None

Material Steel – Painted enclosure

Glass – Touch Screen

Aluminum – Screen Bezel, Terminal Cover

Size Enclosure – 300mm x 300mm x 120mm

LCD Panel – 8.4” Color w/Touch-screen

Weight 20 lbs., 9.07 kgs

Type Fan-less Single Board VIA 733 MHZ with Low

Power C3 Processor

Operating Sys.

Hard Disk 40G hard disk for file storage

Windows XP Embedded

Page 75

Options

System Options

Remote Camera Capturing Vehicle Images when Alarms Occur

RFID Reader Capturing Rail Car identification when Alarms

Occur

Ticket Printer Thermal ticket printer for alarm notifications

SNM Detection Special Nuclear Materials detection includes

Gamma and Neutron detection

Isotope

Identification

Permits the identification of isotopes detected and

reduces nuisance alarms

Page 76

Max Cable Lengths (feet) for XSD-1000 Monitor Panel to Remote I/O Panel

Supply

Nbr of

Remote I/O

Cards

3-11

Voltage from

Monitor Panel

1

(VDC)

22 ga - Max

Length

20 ga - Max

Length

3 12 426.1 673.4

4 12 319.6 505.1

5 12 255.6 404.0

6 12 213.0 336.7

7 12 182.6 288.6

8 12 159.8 252.5

9 12 142.0 224.5

10 12 127.8 202.0

11 12 116.2 183.7

6

5 + 12 N/A 25 25 25 25

18 ga - Max

Length

1065.2 1378.5

798.9 1033.9

639.1 827.1

532.6 689.2

456.5 590.8

399.4 516.9

355.1 459.5

319.6 413.5

290.5 376.0

16 ga - Max

Length

14 ga - Max

Length

Notes:

1. Minimum is 3 cards: 1 Digital Input for Photo-eyes, 2 Scintillator Input cards.

2. All new installations will require a 4-wire cable with overall shield and a 12VDC to 5VDC

Power supply

5

in the Remote I/O Panel.

3. Cable lengths are calculated using wire resistances for 19/?? stranding.

4. 18 AWG and 16 AWG are the standard wire gages for XSD-1000 systems.

5. For retrofits of Interceptor 500, if cable length is < 25 ft., use 6 wire cable without power

supply card.

2169.8

1627.4

1301.9

1084.9

929.9

813.7

723.3

651.0

591.8

Page 77

- New Installation User Software Setup XDS-1000 Monitoring System

07 June 2007

These steps, at a minimum must be performed to use the XSD-1000 System:

Administrative Options – File – Log File Creation

Set the interval for Log File Creation. (‘Daily’ will create a new Log File every day, etc.)

Administrative Options – Configure – Detectors

Select the number of detectors and their availability here. This menu determines the total

number of detectors for your system, and their basic configuration (Single/Dual).

User Setup – Detector Names Status

Type the names of each detector to identify them (North, East, Top-Left, etc.)

Administrative Options – Configure – Detector Locations

Move the detector boxes around the truck at their appropriate locations. Remember that

Detector 1 is tied to Remote I/O Module Address 7, Detector 2 is tied to Address 8, etc.

Administrative Options – Configure - System ID

Type in a unique ID for this system. If you are using multiple systems linked together

over your LAN system, each system MUST have a unique ID (Lower Gate, North

Entrance, etc).

Perform the following if you plan to use the Quality Assessment Package:

Administrative Options – Quality Assessment – Replace Components – Set

Sensitivity Check Interval

Normally this is 365 days, but can be whatever you set as your standard (a value of 0

disables the warning).

Administrative Options – Quality Assessment – Replace Components – Replace

Detectors

You will need to ‘replace’ (first time is install) the detectors to put them into the

database.

Administrative Options – Quality Assessment – Replace Components – Replace Test

Source

This also must be done to determine the Sensitivity Check Allowances.

Administrative Options – Quality Assessment – Replace Components – Perform

Detector Sensitivity Check

This must be done to establish a reference base of values for future Sensitivity Checks.

Page 78

Microsoft Software License Terms for:

Windows® XP Embedded Runtime

These license terms are an agreement between you and Ronan Engineering Company. Please read them.

They apply to the software included on this device. The software also includes any separate media on which

you received the software.

The software on this device includes software licensed from Microsoft Corporation or its affiliate.

The terms also apply to any Microsoft

• Updates,

• Supplements,

• Internet-based services, and

• Support services

for this software, unless other terms accompany those items. If so, those terms apply. If you obtain