Ronan X96S User Manual

Instructions

and

Operating Manual

X96S

DENSITY GAGE

60%

60%

Ronan Engineering

Process Setup

Filtering

Low Alarm

High Alarm

Empty Clamp

Linearization

Temp.

Press.

|

|

|

Table of Contents |

OVERVIEW......................................................................................................................... |

1 |

|

1 |

Advantages |

|

|

|

Gamma's Advantages..................................................................................................................................................... |

|

1 |

|

X96S Advantages........................................................................................................................................................... |

|

1 |

|

BASIC CONCEPTS |

2............................................................................................................ |

2 |

|

Communications |

|

||

4-20 MA......................................................................................................................................................................... |

|

|

2 |

HART............................................................................................................................................................................. |

2 |

|

2 |

Variables |

|

|

|

Communications Variables ............................................................................................................................................ |

2 |

||

Device Variables............................................................................................................................................................ |

|

2 |

|

THEORY ............................................................................................................................. |

|

|

3 |

Theory of Radiation Gaging |

3 |

||

Principles of Operation 3 |

|

||

PASSWORD....................................................................................................................... |

|

|

5 |

MENUS/OPERATION......................................................................................................... |

6 |

||

Menu Trees |

6 |

|

|

Root Menu |

12 |

|

|

Variables Menu............................................................................................................................................................ |

|

12 |

|

Variable Mapping Menu .......................................................................................................................................... |

12 |

||

Status Display Menu .................................................................................................................................................... |

|

13 |

|

Configuration Menu..................................................................................................................................................... |

|

13 |

|

Operation Menu ....................................................................................................................................................... |

|

14 |

|

Filtering Menu ..................................................................................................................................................... |

|

14 |

|

Empty Clamp Menu ............................................................................................................................................. |

15 |

||

Detector Fault Menu ............................................................................................................................................ |

15 |

||

Linearization Menu .............................................................................................................................................. |

15 |

||

Config Linearize Menu .................................................................................................................................... |

15 |

||

Temp Comp Menu |

............................................................................................................................................... |

16 |

|

Pressure Comp Menu ........................................................................................................................................... |

16 |

||

D1 Config Menu ...................................................................................................................................................... |

|

17 |

|

% Solids Variables Menu..................................................................................................................................... |

18 |

||

% Acids Variables Menu ..................................................................................................................................... |

18 |

||

D2 Config Menu ...................................................................................................................................................... |

|

18 |

|

% Solids Variables Menu..................................................................................................................................... |

19 |

||

% Acids Variables Menu ..................................................................................................................................... |

19 |

||

Proc Temp Config Menu.......................................................................................................................................... |

19 |

||

Pressure Config Menu.............................................................................................................................................. |

20 |

||

Head Temp Config Menu......................................................................................................................................... |

20 |

||

Alarms...................................................................................................................................................................... |

|

|

20 |

Hardware Menu ....................................................................................................................................................... |

|

21 |

|

Source Type Menu ............................................................................................................................................... |

|

22 |

|

Usr Def Source Menu .......................................................................................................................................... |

22 |

||

Analog Out Config................................................................................................................................................... |

|

22 |

|

HART Output Menu ........................................................................................................................................... |

23 |

||

Density Gage Manual 012407 |

i |

Com1 Protocol Menu....................................................................................................................................... |

23 |

|

HART Menu ............................................................................................................................................................ |

|

23 |

System Menu ........................................................................................................................................................... |

|

23 |

Digital Outputs Menu |

24 |

|

Relay and TTL Menus ................................................................................................................................................. |

|

25 |

Digital Inputs Menu |

25 |

|

Input 1 Menu................................................................................................................................................................ |

26 |

25 |

Calibration Menu |

|

|

Ref Constants Menu..................................................................................................................................................... |

|

26 |

Loop Config Menu....................................................................................................................................................... |

|

27 |

Aux Loop Cfg Menu.................................................................................................................................................... |

|

27 |

Calibrate Menu............................................................................................................................................................. |

|

28 |

Low Reference Menu |

............................................................................................................................................... |

28 |

High Calibrate Menu................................................................................................................................................ |

|

28 |

Temp Reference Menu............................................................................................................................................. |

28 |

|

Pressure Reference Menu......................................................................................................................................... |

29 |

|

Auto Reference Menu .............................................................................................................................................. |

29 |

|

Diagnostics............................................................................................................................................................... |

|

29 |

X96S Local Display |

30 |

30 |

Navigating Menus |

|

|

Editing Values |

31 |

|

Editing Fixed Point Numbers....................................................................................................................................... |

31 |

|

Editing Floating Point Numbers................................................................................................................................... |

31 |

|

Editing Text Strings ..................................................................................................................................................... |

|

31 |

Editing Enumerated Values ......................................................................................................................................... |

31 |

|

X96 Local Display Vs 275 Calibrator 31 |

||

INSTALLATION................................................................................................................ |

|

|

32 |

|

Caution......................................................................................................................................................................... |

|

32 |

|

32 |

Specific License |

|

|

||

(SA or GS Series)............................................................................................................................................. |

|

32 |

||

General License |

32 |

|

|

|

(RLL Source Holder) ....................................................................................................................................... |

|

32 |

||

Unpacking |

32 |

|

|

|

Storage |

32 |

|

35 |

|

Mechanical Mounting |

|

|||

Electrical Installation of Interconnect Wiring 36 |

|

|||

Microprocessor Verification 37 |

|

|||

Power-up |

38 |

|

|

|

PASSWORD..................................................................................................................... |

|

|

|

39 |

QUICK START REFERENCE – CALIBRATING DENSITY ............................................. |

40 |

|||

QUICK START REFERENCE – CALIBRATING DENSITY............................................... |

41 |

|||

QUICK START REFERENCE – CALIBRATING DENSITY ............................................. |

43 |

|||

QUICK START REFERENCE – CALIBRATING DENSITY ............................................. |

44 |

|||

CALIBRATION ................................................................................................................. |

|

|

45 |

|

Density Gage Manual 012407 |

ii |

Reference Modes |

45 |

45 |

|

Types of Calibration |

|

||

Calibration ................................................................................................................................................................... |

|

|

45 |

Low Reference (Single Point Calibration) ............................................................................................................... |

45 |

||

Calibration Constant ................................................................................................................................................ |

|

|

46 |

Calibration Curve..................................................................................................................................................... |

|

|

46 |

High Calibration (Dual Point Calibration) ............................................................................................................... |

47 |

||

Preparation for Calibration........................................................................................................................................... |

|

47 |

|

Dual-Point Calibration Procedure ................................................................................................................................ |

47 |

||

Single-Point Calibration Procedure.............................................................................................................................. |

48 |

||

Temperature Compensation ......................................................................................................................................... |

|

48 |

|

Documentation |

49 |

|

|

CONFIGURATION |

............................................................................................................ |

50 |

|

DETECTOR |

...................................................................................................................... |

|

51 |

Scintillator Detector 51 |

|

||

ION Chamber 53 |

|

|

|

ELECTRONICS ................................................................................................................ |

|

58 |

|

X96-2001PL |

58 |

58 |

|

X96-2003-01PL |

|

||

X96-2003-02PL |

58 |

|

|

X96-2003-03PL |

58 |

|

|

X96-2003-04PL |

58 |

|

|

X96-2003-05PL |

58 |

|

|

X96-2004PL |

58 |

|

|

X96-2005PL |

58 |

|

|

X96-2008PL |

58 |

|

|

X96-2009PL1 59 |

|

|

|

X96-2009PL2 59 |

|

|

|

X96-2009PL3 59 |

|

|

|

X96-2029PL |

59 |

|

|

X96C148 |

59 |

|

|

X96C148-2 |

59 |

|

|

X96C148-4 |

59 |

|

60 |

X96S Mechanical Chassis & LCD Part Numbers |

|||

X96S Electronic Module Part Numbers 60 |

|

||

Density Gage Manual 012407 |

iii |

Overview

The X96S is a family of measurement products that is intended to replace the current X96N and X99 product families. These products:

•use nuclear measurement techniques,

•support all features of the current X96N and X99 products,

•support up to 32 scintillation or ionization detectors,

•optional HART interface,

•improved user interface options1,

•more user functionality, and

•more product flexibility.

Advantages

•Mounts external to existing pipe

•Displays in customers units

•Most applications can be solved with low-energy sources

•Not affected by:

-extreme temperatures -caustic processes -violent product flour -sterile processes

-variable product flow velocity

Gamma's Advantages

•Mounts external to pipe or vessel (no components exposed to process material)

•Passes through process material

•Does not make material radioactive

•Does not change the material

•Can be shielded by lead

X96S Advantages

•HART Communications

•Identical interface on local display as via HART

•Blind transmitter in detector on self contained design

•Custom configuration of display

•Surface, panel or rack mount available

•Field mountable

•Push button calibration

•Empty pipe monitor

1 This includes the ability to have a simple or complex user interface a remote user interface or even no user interface.

Density Gage Manual 012407 |

1 |

Basic Concepts

Communications

The Ronan X96S Density gage provides both 4-20 mA current loop and HART communications.

4-20 MA

For many years, the field communication standard for process automation equipment has been a 4-20 mA current loop signal. The current varies in proportion to the process variable being represented. In typical applications, a signal of 4mA will correspond to the lower limit (0%) of the calibrated range and 20mA will correspond to the upper limit (100%) of the calibrated range. Thus, if the system is calibrated for 1 to 3 SGU, then an analog current of 12mA (50% of range) will correspond to a density of 2 SGU.

HART

HART Field Communications Protocol extends the 4-20mA current loop standard to enhance communication with smart field instruments. The HART protocol was designed specifically for use with intelligent measurement and control instruments, which traditionally communicate using 4-20mA analog signals. HART preserves the 4-20mA signal and enables two-way digital communications to occur without disturbing the integrity of the 4-20mA signal. Unlike other digital communication technologies, the HART protocol maintains compatibility with existing 4-20mA systems, and in doing so, provides users with a backward compatible solution. HART Communication Protocol is well established as the "de facto" industry standard for digitally enhanced 4-20mA-field communication.

The enhanced communications capability of intelligent field instruments employing the HART protocol, offers significantly greater functionality and improved performance over traditional 4-20mA analog devices. The HART protocol permits the process variable to continue to be transmitted by the 4-20mA analog signal and additional information pertaining to other variable, parameters, device configuration, calibration, and device diagnostics to be transmitted digitally at the same time. Thus, a wealth of additional information related to plant operation is available to central control or monitoring systems through HART communications.

Variables

There are two types of variables, communications variables and device variables.

Communications Variables

HART defines four device variables, PV (Primary Variable), SV (Secondary Variable), TV, and QV. PV is assigned to the primary 4-20 ma loop. HART is also communicated over this loop. SV is assigned to an optional secondary 4-20 mA loop.

Device Variables

The Ronan X96S Density gage has 5 device variables:

Device Variable |

Value |

D1 |

Density |

D2 |

Density in alternate units |

Proc Temp |

Process Temperature |

Pressure |

Process Pressure |

Head Temp |

Head Temperature |

Density Gage Manual 012407 |

2 |

Theory

Theory of Radiation Gaging

Radiation gages operate on the principle of radiation absorption and transmission.

A beam of gamma radiation is directed from the source holder, through the pipe (or vessel) and its process material, and onto the surface of the detector.

Some amount of radiation is absorbed by the material through which it passes, and some of the radiation is transmitted to the surface of the detector.

Process measurement is possible because the amount of radiation absorbed and transmitted is predictable.

The absorbed radiation is directly related to the density (or mass) of process in the pipe while the transmitted radiation is inversely related to the density (or mass) of process in the pipe.

Therefore, an increased process density results in a decrease of transmitted radiation.

Since the radiation that's not being absorbed is being transmitted, the process density can be inferred by measuring the amount of radiation reaching the detector at any point in time. The detector's output signal, in counts, also varies inversely to the process density.

When the process is light (low density) the detector is exposed to a maximum amount of radiation which produces a HIGH output of counts. When the process is heavy (high density) the process material "shields" the detector and prevents radiation from reaching the detector, producing a LOW output of counts.

Ronan’s Density Monitor is used to replace the lab sampling process since the gage output, when accurately calibrated, will correlate to the density values of process taken from samples near the gage location.

The X96S Microprocessor converts the detector signal to user's measurement units of SGU, percent solids, Baume H, Baume L, API, or percent steam. The X96S Microprocessor is capable of simultaneously displaying density in two different sets of units. These different representations of the density value are called density 1 and density 2.

The X96S displays the output measurement range in the selected user units. Channel 1 and Channel 2 can be set independently. For both channels, the "zero" of the measurement range represents the lowest density of interest, while the "span" of the measurement range represents the highest density of interest.

Reduction of the signal "noise" due to radiation statistics is handled in the stage of signal processing known as digital filtering. Digital filtering is a form of statistical averaging used to smooth, or dampen, random radiation as well as process-related noise. Increasing the digital filter’s “time constant” decreases signal noise.

Dynamic tracking permits the gage response to temporarily by-pass the digital filter. This is helpful in some processes where sudden or drastic step changes in process must be observed in their true, or unfiltered, state.

Software also compensates for the decay of the radioactive source activity. On-going adjustments are made automatically for the rate of decay, or source half-life.

Principles of Operation

The detector's raw output signal is processed through several stages of software in the X96S.

Some of the more significant stages of signal processing are:

•Units Conversion – conversion of density (SpG) into user-selected units

•Measurement Range – 4-20 mA output defined by the user-selected range in user-selected units.

Density Gage Manual 012407 |

3 |

•Digital Filtering – signal smoothing to reduce statistical radiation noise

•Dynamic Tracking – quick gage response to quick process changes.

•Source Decay Compensation – automatic compensation for the radioisotope decay

•Calibration (Referencing) – calibration of gage to user process.

The Calibration (or Referencing) procedure relates detector output (in counts) to numeric values that accurately represent the actual process density.

The density algorithm (or curve) used by the X96S software is an exponential function. That is, the relationship between the detector output and the process density is mathematically expressed as:

Id = Ioe-ut(d-do)

Where:

Id = detector signal with process density (d)

Io = detector signal with reference density (do) in pipe u = the absorption coefficient

t = pipe internal diameter

d = density usually expressed in SpG do = reference density

The "calibration constant" (1/ut) is used by the X96S software to calculate process density.

Density Gage Manual 012407 |

4 |

Password

Notice:

To access the Programming Menu, the Password is 101010.

Step 1: Power Up – You should now be on the Status Screen.

Step 2: Press F3 to go back.

Step 3: Now enter the password. (All digits are set at 000000 at this point.)

Press |

to get the digit to be # one |

Press |

2 times (The third digit should be highlighted.) |

Press |

to get the digit to be # one |

Press |

2 times (The fifth digit should be highlighted.) |

Press |

to get the digit to be # one |

Press F4 (enter) |

|

Note: If the wrong password was entered, press F1 (ALL0) to set all the digits to the number 0 and you can begin re-entering the password from the beginning. Pressing F2 (RST0) will set the individual digit that is highlighted back to the number 0.

Note: For security reasons, each digit will always be displayed as an asterisk.

Density Gage Manual 012407 |

5 |

Menus/Operation

Menu Trees

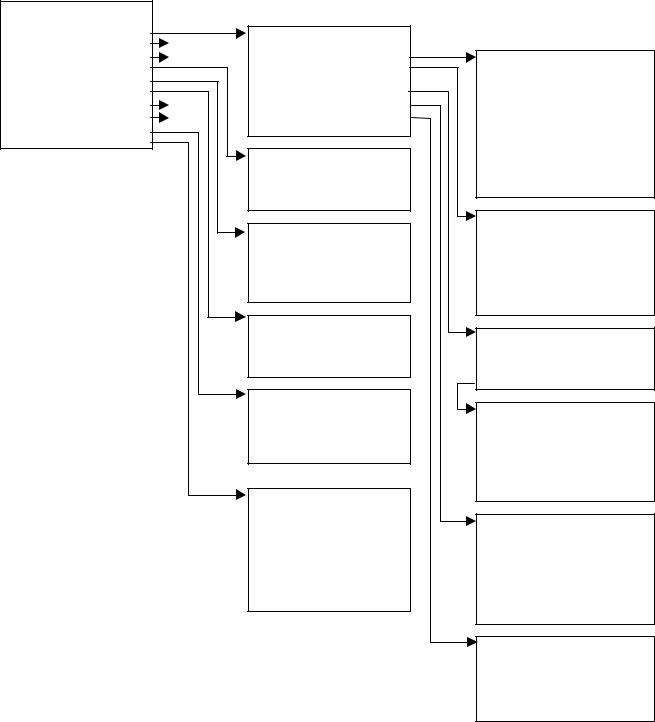

The Ronan X96S Density Gage uses a tree structured menu system.

Ronan X96S - Density |

|

|

|

|

|

|

|

|

Variables |

|

|

|

|

|

|

|

|

|

|

|

|

Variables |

|

|

||

|

|

|

|

|

|

|||

Status Display |

|

|

|

|

|

|

|

|

Configuration |

|

|

2 |

|

Variable Mapping |

|

Variable Mapping |

|

Digital Outputs |

4 |

|

PV [value |

units] |

|

|

||

Digital Inputs |

|

|

4 |

|

SV [value |

units] |

|

PV is [var mapped to PV] |

|

|

|

||||||

Calibration |

5 |

|

TV [value |

units] |

|

SV is [var mapped to SV] |

||

Diagnostic |

|

|

|

|

QV [value |

units] |

|

TV is [var mapped to TV] |

|

|

|

|

|

D1 [value |

units] |

|

QV is [var mapped to TV] |

|

|

|

|

|

D2 [value |

units] |

|

|

|

|

|

|

|

Proc Temp |

[value units] |

|

|

|

|

|

|

|

Pressure [value units] |

|

|

|

|

|

|

|

|

Head Temp |

[value units] |

|

|

|

|

|

|

|

Raw Cnts [value] |

|

|

|

|

|

|

|

|

Filt Cnts |

[value] |

|

|

Status Display

Analog Bar [enable]

Line 1: [var]

Line 2: [var]

Line 3: [var]

Line 4: [var]

Line 5: [var]

Line 6: [var]

Line 7: [var]

Line 8: [var]

Figure 3-1 – Root, Variables and Displays Menus

Density Gage Manual 012407 |

6 |

Configuration

Operation

D1 Config

D2 Config

Proc Temp Config

Pressure Config

Head Temp Config

Alarms

Hardware

HART

System

3 |

3 |

3 |

3 |

Operation

Filtering

Empty Clamp

Detector Fault

Linearization

Temp Comp

Pressure Comp

Scan Time [ms]

Proc Temp Config

Temp Units [°C/F/R/Kelvin]

Low Range [value] High Range[value]

Pressure Config

Pressure Units

[psi;bar;g/Sqcm;kg/Sqcm;pa;kPa

;atm]

Low Range [value] High Range [value]

Head Temp Config

Temp Units [°C/F/R/Kelvin]

Low Range [value] High Range [value]

HART

Tag Name [name]

MultiDrop [addr]

Univ Rev [rev]

Spec Rev [rev]

System

Serial # [number] Hardware Rev [rev] Software Rev [rev] Date [date]

Hour (0-23) [hour] Minute [min] Password

Date/Time Format [sel]

Filtering

Type RC

Dyn Track [enable/disable]

Sigma [value]

Fast TC [s]

Fast Counter [value]

Medium TC [s]

Slow Counter [value]

Slow TC [s]

Noise Filter [value]

Monitor [track value]

Empty Clamp

Empty Clamp [enable/disable]

Off Time [seconds]

Rcvry Time [seconds]

Min Counts [value]

Max Counts [value]

Linearization

Linearize [enable/disable]

Clear Table

Config Linearize

Config Linearize

Table Entry # [number]

Entry Used [indicator]

Measured [value]

Actual [value]

Set Entry

Remove Entry

Temp Comp

Temp Comp [enable/disable]

Temp Units [units]

A Coeff [value]

B Coeff [value]

Enter Temp

Temp Auto Cap [enable/disable]

Last Ref. Temp [°F]

Pressure Comp

Pres Comp [enable/disable]

Pressure Units [units]

A Coeff [value]

Enter Pressure [value]

Pres Auto Cap [enable/disable]

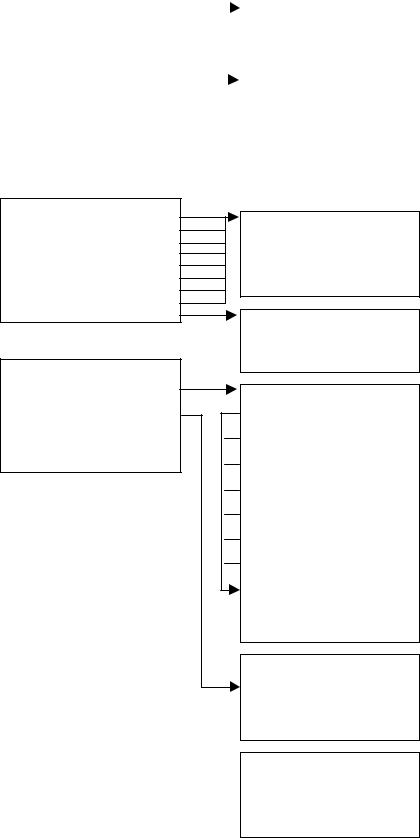

Figure 3-2 – Configuration Menus (1 of 3)

Density Gage Manual 012407 |

7 |

Configuration (Cont’d) |

|

Density 1 Config |

|

|

|

|

% Solids Variables |

|

|

|

|

|

|

||||

D1 Config |

|

D1 Units [units] |

|

|

|

|

Carrier [value] |

|

D2 Config |

|

Low Range [value] |

|

|

|

|

Solids [value] |

|

Alarms |

|

High Range [value] |

|

|

|

|

|

|

Hardware |

|

% Solids Variables |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

% Acids Variables |

|

|

|

|

|

% Acids Variables |

|

|

|

|

|

|

|

|

Algorithm |

|

|

Density 2 Config |

|

|

|

|

||

|

|

Same Options as Density 1 |

|

|

|

|

Parameter A |

|

|

|

D2 Units [units] |

|

|

|

|

Parameter B |

|

|

|

Low Range [value] |

|

|

|

|

Parameter C |

|

|

|

High Range [value] |

|

|

|

|

|

|

|

|

% Solids Variables |

|

|

|

|

|

|

|

|

% Acids Variables |

|

|

|

|

|

|

Alarms

Alarm 1

Alarm 2

Alarm 3

Alarm 4

Alarm 5

Alarm 6

Alarm 7

Alarm 8

Alarm on 4-20 mA

Hardware

System Hardware

Proc Temp [variable] Source Type

Pressure

Analog Out Config HART Output X96S-20

Com1 Protocol Ronan

Alarm (number)

Source [variable] Alarm Type [variable] Setpoint [SGU] Setpoint 2 [SGU] Hysterisis [%]

Alarm on 4-20mA

None Underrange Overrange Freeze

System Hardware CPU Card [type]

Slot 1 Details Slot 2

Slot 2 Details Slot 3

Slot 3 Details Slot 4

Slot 4 Details Slot 5

Slot 5 Details Slot 6

Slot 6 Details Slot 7

Slot 7 Details Slot 8

Slot 8 Details Display X96-2000PL Display Details HART X96-2005PL HART DB Details

Slot Details

Status

Serial Number

SW Major Rev

SW Minor Rev

HW Rev

Source Type

Source Type [type] User Def Source

Next Reference[date] Next Wipe Test

Next Shutter Test

Figure 3-2 – Configuration Menus (2 of 3)

Density Gage Manual 012407 |

8 |

Configuration (Cont’d) |

Hardware (Cont’d) |

|

|

|

|

|

Hardware (Cont’d) |

System Hardware |

|

|

|

|

|

|

Proc Temp [variable] |

|

|

|

|

|

|

Source Type |

|

|

|

|

|

|

Pressure |

|

|

|

|

|

|

Analog Out Config |

|

|

|

|

Analog Out Config |

|

|

|

|

|

||

|

HART Output |

|

|

|

Loop 1 (PV) [variable] |

|

|

Com1 Protocol Ronan |

|

|

|

Loop 2 (SV) [variable] |

|

|

|

|

|

|

|

Loop 3 (TV) [variable] |

|

|

|

|

|

|

Power Source [int/ext] |

|

|

|

|

|

|

|

|

|

|

|

|

|

HART Output |

|

|

|

|

|

|

None |

|

|

|

|

|

|

X96S-2005 |

|

|

|

|

|

|

Ser. Port 1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Com1 Protocol |

|

|

|

|

|

|

None |

|

|

|

|

|

|

Hart |

|

|

|

|

|

|

Ronan Setup |

Figure 3-2 – Configuration Menus (3 of 3)

Density Gage Manual 012407 |

9 |

Digital Outputs

Output [Relay 1-4/TTL 1-4]

Select Sources [variable] Polarity [variable]

Digital Inputs

Input 1

Output

Relay 1

Relay 2

Relay 3

Relay 4

TTL 1

TTL 2

TTL 3

TTL 4

Select Sources

Output [selected relay or TTL]

Alarm 1 [yes/no] Alarm 2 [yes/no] Alarm 3 [yes/no] Alarm 4 [yes/no] Alarm 5 [yes/no] Alarm 6 [yes/no] Alarm 7 [yes/no] Alarm 8 [yes/no]

Auto Cal Ref [yes/no] Auto Cal Err [yes/no] Ref Prompt [yes/no] Wipe Test [yes/no] Shutter Test [yes/no] Empty Clamp [yes/no] Detector Flt [yes/no] System Alarm [yes/no]

Polarity

No/Not Driven

NC/Driven

Open/Not Driven

Closed/Driven

Input 1

Use [not used/auto ref] Polarity [high/low]

Figure 4-1– Digital Output and Digital Input Menus

Density Gage Manual 012407 |

10 |

Calibration |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

State [state] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ref Constants |

|

|

|

|

|

|

Ref Constants |

|

|

|

|

|

|

|

|

||

Calibrate |

|

|

|

|

|

|

Ref Mode [variable] |

|

|

|

|

|

|

|

|

||

Last Ref Date [date] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Last Ref Time [time] |

|

|

|

|

|

|

Calibr. Mode [variable] |

|

|

|

|

|

|

|

|

||

Loop Config |

|

|

|

|

|

|

Ref Time [time] |

|

|

|

|

|

|

|

|

||

Aux Loop Cfg |

|

|

|

|

|

|

Min Ref Cnts [counts] |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

Max Ref Cnts [counts] |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Calibrate |

Low Reference |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

Low Reference |

|

|

|

|

|

|

|

|

Reference |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

High Calibrate |

|

|

|

|

|

|

|

Ref Density [value units] |

||

|

|

|

|

|

|

|

Manual Entry |

|

|

|

|

|

|

|

|

|

Ref Cap [counts] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

Clear Ref/Cal |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

Temp Ref |

|

|

|

|

|

|

|

High Calibrate |

||

|

|

|

|

|

|

|

Pressure Ref |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

Auto Reference |

|

|

|

|

|

|

|

Calibrate |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cal Density [value units] |

|

|

|

|

|

|

|

Loop Config |

|

|

|

|

|

|

|

Cal Cap [counts] |

||

|

|

|

|

|

|

|

PV is [variable] |

|

|

|

|

|

|

|

1/uT [slope] |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

Loop test |

|

|

|

|

|

|

|

Manual Entry |

||

|

|

|

|

|

|

|

Damping |

|

|

|

|

|

|

|

1/uT [slope] |

||

|

|

|

|

|

|

|

D/A trim |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Aux Loop Config |

|

|

|

|

|

|

|

Temp Reference |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

SV is [variable] |

|

|

|

|

|

|

|

Temp Ref |

||

|

|

|

|

|

|

|

Aux 1 Test |

|

|

|

|

|

|

|

Temp Cap Low [counts] |

||

|

|

|

|

|

|

|

Aux 1 Trim |

|

|

|

|

|

|

|

Temp Cap High [counts] |

||

|

|

|

|

|

|

|

TV is [variable] |

|

|

|

|

|

|

|

|

||

Diagnostic |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pressure Reference |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Raw Counts |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pressure Ref |

|

|

|

|

|

|

Ref/Cal Data |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

Filt. Counts |

|

|

|

|

|

|

Last Ref Date [date] |

|

|

|

|

|

|

|

Pres Cap Low [counts] |

||

Raw Dens. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Pres Cap High [counts] |

|||

Current |

|

|

|

|

|

|

Ref Density 0 |

|

|

|

|

|

|

|

|

||

Ref/Cal Data |

|

|

|

|

|

|

Cal Density 2 |

|

|

|

|

|

|

|

Auto Reference |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

Alarms |

|

|

|

|

|

|

Ref Cap |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

Cal Cap |

|

|

|

|

|

|

|

Auto Ref [enable] |

||

|

|

|

|

|

|

|

Last Ref Temp |

|

|

|

|

|

|

|

Ref Delay [s] |

||

|

|

|

|

|

|

|

1/uT |

|

|

|

|

|

|

|

Auto Ref Density [SGU] |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Alarms |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

Sys. Alarm |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

Empty Clamp |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

Det. Fault |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

AutoCal Ref |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

AutoCal Error |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

Ref. Prompt |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

Wipe Test |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

Shutter Test |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

Alarms |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

Output |

|

|

|

|

|

|

|

|

||

Figure 3-5 – Calibration Menus

Density Gage Manual 012407 |

11 |

Root Menu

The root menu is titled “Ronan X96S – Density”. It contains the following items:

ITEM |

FUNCTION |

Variables |

Selecting this takes the user to the Variables menu |

Displays |

Selecting this takes the user to the Displays menu |

Configuration |

Selecting this takes the user to the Configuration menu |

Digital Outputs |

Selecting this takes the user to the Digital Outputs menu |

Digital Inputs |

Selecting this takes the user to the Digital Inputs menu |

Calibration |

Selecting this takes the user to the Calibration menu |

Diagnostic |

Selecting this takes the user to the Diagnostic menu |

Variables Menu

The menu titled “Variables” contains the following items:

ITEM |

FUNCTION |

Variable Mapping |

Selecting this takes the user to the Variable Mapping menu |

PV |

Shows the current value of PV (the Primary Variable) |

SV |

Shows the current value of SV (the Secondary Variable) |

TV |

Shows the current value of TV (the Third Variable) |

QV |

Shows the current value of QV (the Fourth Variable) |

D1 |

Shows the current value of D1 (the Density Variable) |

D2 |

Shows the current value of D2 (the Density Variable in alternate units) |

Proc Temp |

Shows the current value of Proc Temp (the Process Temperature) |

Pressure |

Shows the current value of Pressure (the Process Pressure) |

Head Temp |

Shows the current value of Head Temp (the Head Temperature) |

Raw Counts |

Shows the current Raw Counts value from the detector |

Filt Counts |

Shows the current Filtered Counts value from the detector |

Variable Mapping Menu

The “Variable Mapping” menu allows the user to select the device variable to be mapped to PV, SV, TV, and QV. It contains the following items:

ITEM |

FUNCTION |

PV is |

Shows the device variable assigned to PV and allows the user to change the selection |

SV is |

Shows the device variable assigned to SV and allows the user to change the selection |

TV is |

Shows the device variable assigned to TV and allows the user to change the selection |

QV is |

Shows the device variable assigned to QV and allows the user to change the selection |

Each PV, SV, TV, and QV may each select one of the following:

SELECTION |

MEANING |

D1 |

Density represented in units that are used locally |

D2 |

Density represented in alternate units |

Proc Temp |

Process temperature |

Pressure |

Process pressure (if available) |

Head Temp |

Head temperature (if available) |

Not Assigned |

Blank line |

Density Gage Manual 012407 |

12 |

Status Display Menu

The menu titled “Status Display” is used to configure the device status display. It contains the following items

ITEM |

FUNCTION |

Analog Bar |

Shows the current state of the analog bar display (enabled or disabled) and allows the |

|

user change the state. |

Line 1: |

Shows the data to be displayed on line 1 of the status display and allows the user to |

|

change the selection |

Line 2: |

Shows the data to be displayed on line 2 of the status display and allows the user to |

|

change the selection |

Line 3: |

Shows the data to be displayed on line 3 of the status display and allows the user to |

|

change the selection |

Line 4: |

Shows the data to be displayed on line 4 of the status display and allows the user to |

|

change the selection |

Line 5: |

Shows the data to be displayed on line 5 of the status display and allows the user to |

|

change the selection |

Line 6: |

Shows the data to be displayed on line 6 of the status display and allows the user to |

|

change the selection |

Line 7: |

Shows the data to be displayed on line 7 of the status display and allows the user to |

|

change the selection |

Line 8: |

Shows the data to be displayed on line 8 of the status display and allows the user to |

|

change the selection |

Each line can select one of the following:

SELECTION |

MEANING |

D1 |

Density represented in units that are used locally |

D2 |

Density represented in alternate units, |

Proc Temp |

Process temperature |

Pressure |

Process pressure (if available) |

Head Temp |

Head temperature (if available) |

4-20 mA |

4-20 mA output level |

Raw Cnts |

Raw counts (from scintillation detector) or raw analog measurement (from ionization |

|

detector |

Filt. Cnts |

Filtered counts (from scintillation detector) or (from ionization detector) |

Date & Time |

Current date and time |

Diagnostic |

Selecting this takes the user to the Diagnostic Menu |

Not Assigned |

Blank line |

Configuration Menu

The Configuration menu is used to access area configuration menus. It contains the following items:

ITEM |

FUNCTION |

Operation |

Selecting this takes the user to the Operation menu |

D1 Config |

Selecting this takes the user to the D1 Config menu |

D2 Config |

Selecting this takes the user to the D2 Config menu |

Proc Temp Config |

Selecting this takes the user to the Proc Temp Config menu |

Pressure Config |

Selecting this takes the user to the Pressure Config menu |

Head Temp Config |

Selecting this takes the user to the Head Temp Config menu |

Alarms |

Selecting this takes the user to the Alarm menu |

Hardware |

Selecting this takes the user to the Hardware menu |

HART |

Selecting this takes the user to the HART menu |

System |

Selecting this takes the user to the System menu |

Density Gage Manual 012407 |

13 |

Operation Menu

The Operation menu is used to access the menus and variables that control the processing of the density data. It contains the following items:

ITEM |

FUNCTION |

Filtering |

Selecting this takes the user to the Filtering menu |

Empty Clamp |

Selecting this takes the user to the Empty Clamp menu |

Detector Fault |

Selecting this takes the user to the Detector Fault menu |

Linearization |

Selecting this takes the user to the Linearization menu |

Temp Comp |

Selecting this takes the user to the Temp Comp menu |

Pressure Comp |

Selecting this takes the user to the Pressure Comp menu |

Scan Time |

Shows the amount of time to accumulate each density sample and allows the user |

|

change the time value. |

Filtering Menu

The Filtering menu is used to configure the parameters associated with the mold level measurement filter, utilizing the standard scan rate. It contains the following items:

ITEM |

FUNCTION |

Dyn Track |

Shows the current state of the dynamic tracking filter (enabled or disabled) and allows |

|

the user to change the state |

Sigma |

Shows the (sigma) multiplier used to determine maximum number of raw count |

|

variation (for scintillation) or raw analog value (for ion chamber) that the input can |

|

vary from the current filtered counts before changing to the dynamic filter. Sigma is |

|

the square root of the current filtered counts. Also allows user to change this number. |

Fast TC |

Fast Time Constant value to be used when the Fast Counter reaches zero |

Fast Counter |

Shows the fast count down counter value. If gage has been in dynamic tracking long |

|

enough to be using Medium filter and the raw counts continued to exceed the sigma |

|

value, the fast counter value is decreased each consecutive scan. The Fast counter |

|

value resets and returns back to the original value if the raw counts do not continue to |

|

exceed the sigma value. Once the Fast TC is triggered, it will continue to be used until |

|

the counts are within the sigma value for the Fast counter number of times |

|

consecutively. Also allows user to change this number |

Medium TC |

Medium Time Constant value to be used when the Slow Counter reaches zero |

Slow Counter |

Shows the slow count down counter value. If gage is in dynamic tracking, and the raw |

|

counts continue to exceed the sigma value, the slow counter value is decreased each |

|

consecutive scan. The Slow counter value resets and returns back to the original value |

|

if the raw counts do not continue to exceed the sigma value. Also allows user to |

|

change this number |

Slow TC |

Slow Time Constant value to be used if the Slow Counter has not reached zero |

Noise Filter |

Shows the maximum number of potentially erroneous measurements in a row to |

|

bridge before deciding that a step change has occurred in the mold level value. Also |

|

allows user to change this number. Erroneous measurement is defined when the raw |

|

signal is 4 times the pre-selected sigma multiplier |

Monitor |

Shows the current state of the filtering mechanism |

Monitor (filter state) one of the following:

ITEM |

MEANING |

ERROR |

Filter is not initialized (this state should not occur during normal operation of the |

|

X96S Density Gage) |

FILL |

The walking average buffer is filling |

TRACK |

The walking average buffer is filled and the filter is tracking changes in the density |

|

value |

REFILL |

A step change has occurred and the walking average buffer is refilling |

Density Gage Manual 012407 |

14 |

Empty Clamp Menu

The X96S uses a mechanism called empty clamp to protect detectors (particular scintillation detectors) from saturation conditions.

i.e.: Material being processed is lower than detector range, causing too much radiation to reach the detector, possibly damaging the electronics. The Min Counts and the Max Counts parameters set the threshold (in raw counts2) for activation of the empty clamp function. These Count values should be set above (Max Counts) the Reference Counts, and below (Min Counts) the Calibrate Counts, and beyond your normal measurement range.

The Empty Clamp menu is used to configure the parameters associated with the mechanism that shuts off power to the detector if the detector receives more radiation than it is capable of measuring. It contains the following items:

ITEM |

FUNCTION |

Empty Clamp |

Shows the current state of the empty clamp mechanism (enabled or disabled) and |

|

allows the user change the state. |

Off Time |

Shows and allows the user to change the number of seconds that power to the detector |

|

be shut off when the empty clamp mechanism activates before turning the detector on |

|

to see if the radiation level has dropped to a value that the detector is capable of |

|

measuring. Typical value ranges from 15 to 30 minutes. |

Rcvry Time |

Shows and allows the user to change the number of seconds that power will be applied |

|

to the detector when the empty clamp mechanism has activated to see if the radiation |

|

level has dropped to a value that the detector is capable of measuring. Typical value |

|

here is 30 seconds. |

Min Counts |

Shows and allows the user to change the number minimum number of counts that are |

|

used to determine that the detector is saturated (exposed to more radiation than it is |

|

capable of measuring). |

Max Counts |

Shows and allows the user to change the number maximum number of counts that are |

|

used to determine that the detector is exposed to more radiation than it is capable of |

|

measuring. |

Detector Fault Menu

The Detector Fault menu is used to configure a window in which the detector counts must fall within, in order to complete a reference/calibration.

Linearization Menu

The X96S is capable of performing a multi-point linearization of the density data when required by an application. The linearization table contains ten entries, numbered 1 through 10. Each entry consists of a measured value, an actual value, and a flag that indicates if the entry is used3.

The Linearization menu is used to control the linearization mechanism. It contains the following items:

ITEM |

FUNCTION |

Linearize |

Shows the current state of the Linearization mechanism (enabled or disabled) and |

|

allows the user change the state. |

Clear Table |

This invokes a method that clears all entries in the linearization table |

Config Linearize |

Selecting this takes the user to the Config Linearize menu |

Config Linearize Menu

The Config Linearize menu is used to configure the parameters associated with linearization of the measured data. It contains the following items:

2The threshold is in raw counts since the overload is a function of the radiation effect on the detector and not related to any corrected or converted data.

3Not all of the entries need to be used and the entries do not need to be used in any particular order.

Density Gage Manual 012407 |

15 |

ITEM |

FUNCTION |

Table Entry # |

Shows and allows the user to select an entry in the linearization table |

Entry Used |

Shows if the entry is used or not. |

Measured |

Shows and allows the user to set the measured value associated with this linearization |

|

table entry. This is a value calculated by the X96S. |

Actual |

Shows and allows the user to set the actual value associated with this linearization |

|

table entry. This value is the result of a lab sample, and compares to the Measured |

|

value above. |

Set Entry |

This invokes a method that sets a table entry |

Remove Entry |

This invokes a method that removes a table entry |

Temp Comp Menu

Temperature compensation in the X96s is calculated as a quadratic function4. If temperature compensation is to be used, the process temperature can be captured automatically for you during Referencing by enabling Temp Auto Cap. If you choose to enter the temperature manually, the entered value should be the temperature of the process material during the Referencing function.

Process temperature is typically read via platinum or nickel, 2 or 3-wire RTD attached to the X96S. In these cases, the X96S needs no temperature calibration. You can optionally feed a 0-10volt or 4-20mA signal into the X96S from another source that represents the range of temperature for your process. In this case, you will need to perform a Temp Ref to set the range of measurement. You will also need to define the type of temperature device you are using in the Hardware Menu, Proc Temp menus.

The Temp Comp menu is used to control the temperature compensation mechanism4. It contains the following items:

|

ITEM |

FUNCTION |

|

Temp Comp |

Shows the current state of the temperature compensation mechanism (enabled or |

|

|

disabled) and allows the user change the state. |

|

Temp Units |

Shows and allows the user to set the temperature units used to by the temperature |

|

|

compensation mechanism. |

|

A Coeff |

Shows and allows the user to set the “A” coefficient that relates temperature to |

|

|

changes in density. |

|

B Coeff |

Shows and allows the user to set the “B” coefficient that relates temperature to |

|

|

changes in density. |

|

Enter Temp |

Shows and allows the user to set the process temperature at the time that the gage was |

|

|

Referenced (if Auto Cap was ‘enabled’ during Referencing). |

|

Temp Auto Cap |

This invokes a method that captures the process temperature automatically during gage |

|

|

Referencing. |

|

Last Ref Temp |

Shows the temperature of the process at the time the last reference was completed |

Temp Units is one of the following: |

||

ITEM |

MEANING |

degC |

degrees Celsius |

degF |

degrees Fahrenheit |

degR |

degrees Rankine |

Kelvin |

degrees Kelvin |

Pressure Comp Menu

Pressure compensation is calculated based on the pressure input. The pressure-input range is selected in the Pressure Config Menu, Hardware Menu, and the Pressure Reference Menu.

The Pressure Comp menu is used to control pressure compensation mechanism5. It contains the following items:

4compensated density = uncompensated density + (A Coeff * temperature delta) + (B Coeff * temperature delta2)

5compensated density = uncompensated density + (A Coeff * pressure delta)

Density Gage Manual 012407 |

16 |

|

ITEM |

FUNCTION |

|

Pres Comp |

Shows the current state of the pressure compensation mechanism (enabled or disabled) |

|

|

and allows the user change the state |

|

Pressure Units |

Shows and allows the user to se, the pressure units used to by the pressure |

|

|

compensation mechanism |

|

A Coeff |

Shows and allows the user to set the “A” coefficient that relates pressure to changes in |

|

|

density |

|

Enter Pressure |

Shows, and allows the user to set, the process pressure at the time that the gage was |

|

|

Referenced (if Auto Cap was ‘enabled’ during Referencing). |

|

Pres Auto Cap |

This invokes a method that captures the process temperature automatically during gage |

|

|

Referencing |

|

Scan Time |

Shows the amount of time to accumulate each density sample and allows the user to |

|

|

change the time value |

Pressure Units is one of the following: |

||

ITEM |

MEANING |

PSI |

Pounds per square inch |

Bar |

Bar |

G/Sqcm |

Grams/square centimeter |

Kg/Sqcm |

Kilograms/square centimeter |

Pa |

Pascal |

KPa |

Kilopascal |

atm |

Atmosphere |

D1 Config Menu

The D1 Config menu is used to configure the parameters associated with the density measurement. It contains the following items:

ITEM |

FUNCTION |

|

D1 |

Units |

Shows and allows the user to set the density units used |

D1 |

Low Range |

Shows and allows the user to set the density value to be mapped to 4ma on the current |

|

|

loop output, if D1 is selected to control that current loop. |

D1 |

High Range |

Shows and allows the user to set the density value to be mapped to20ma on the current |

|

|

loop output, if D1 is selected to control that current loop. |

% Solids |

Selecting this takes the user to the % Solids Variables menu |

|

Variables |

|

|

% Acids |

Selecting this takes the user to the % Acids Variables menu |

|

Variables |

|

|

D1 Units is one of the following:

ITEM |

MEANING |

SGU |

specific gravity |

degTwad |

degrees twaddle |

degBrix |

degrees brix |

degBaum_hv |

degrees baume heavy |

degBaum_lt |

degrees baume light |

degAPI |

degrees API |

Percent_sol_wt |

percent solids by weight |

degBall |

degrees balling |

percent_StmQual |

percent steam quality |

% Acids |

percent acids |

Density Gage Manual 012407 |

17 |

Loading...

Loading...