Page 1

Instructions

and

Operating Manual

X96S

DENSITY GAGE

60%

Ronan Engineering

Process Setup

Filtering

Low Alarm

High Alarm

Empty Clamp

Linearization

Temp.

Press.

Page 2

Table of Contents

OVERVIEW......................................................................................................................... 1

Advantages 1

Gamma's Advantages..................................................................................................................................................... 1

X96S Advantages........................................................................................................................................................... 1

BASIC CONCEPTS............................................................................................................2

Communications 2

4-20 MA......................................................................................................................................................................... 2

HART............................................................................................................................................................................. 2

Variables 2

Communications Variables............................................................................................................................................2

Device Variables............................................................................................................................................................ 2

THEORY .............................................................................................................................3

Theory of Radiation Gaging 3

Principles of Operation 3

PASSWORD....................................................................................................................... 5

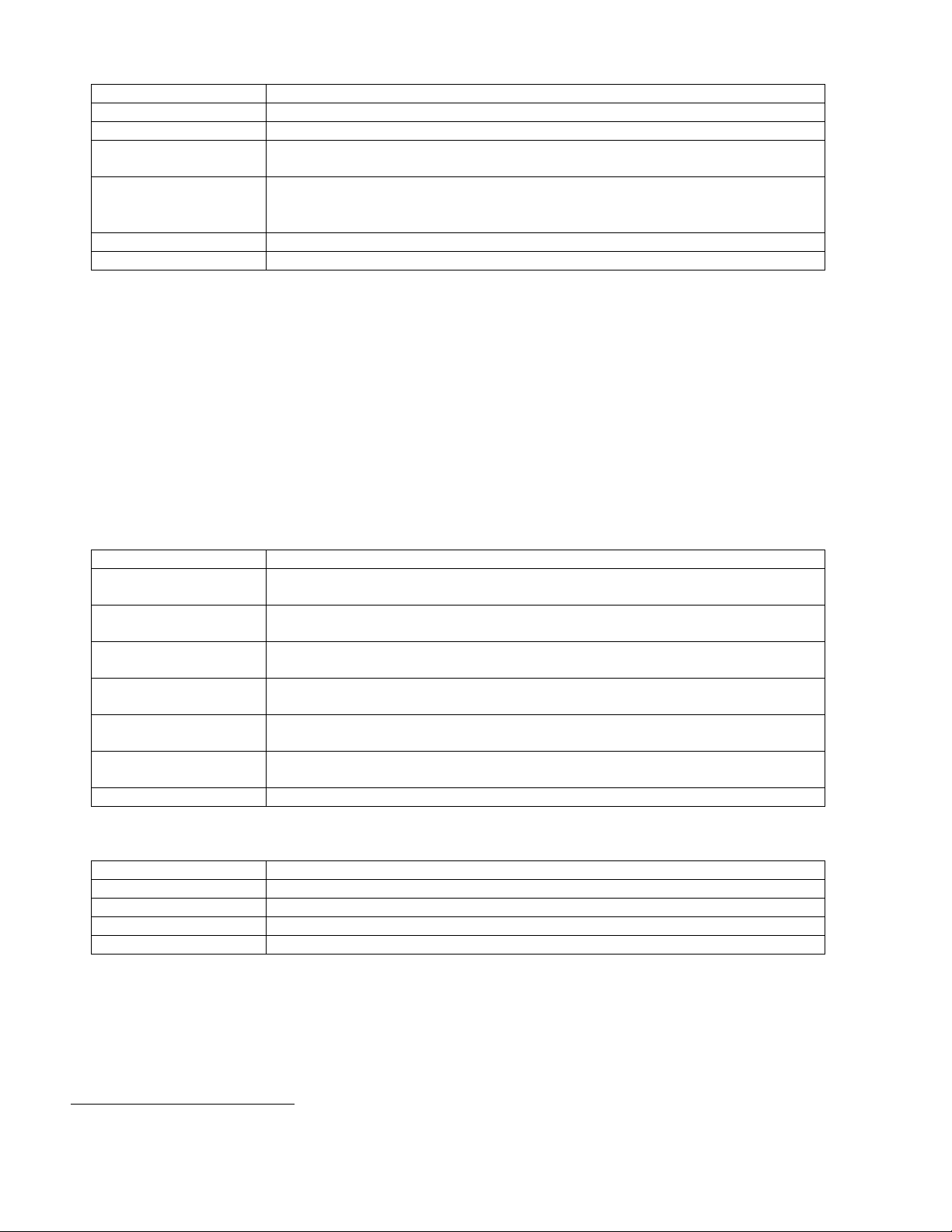

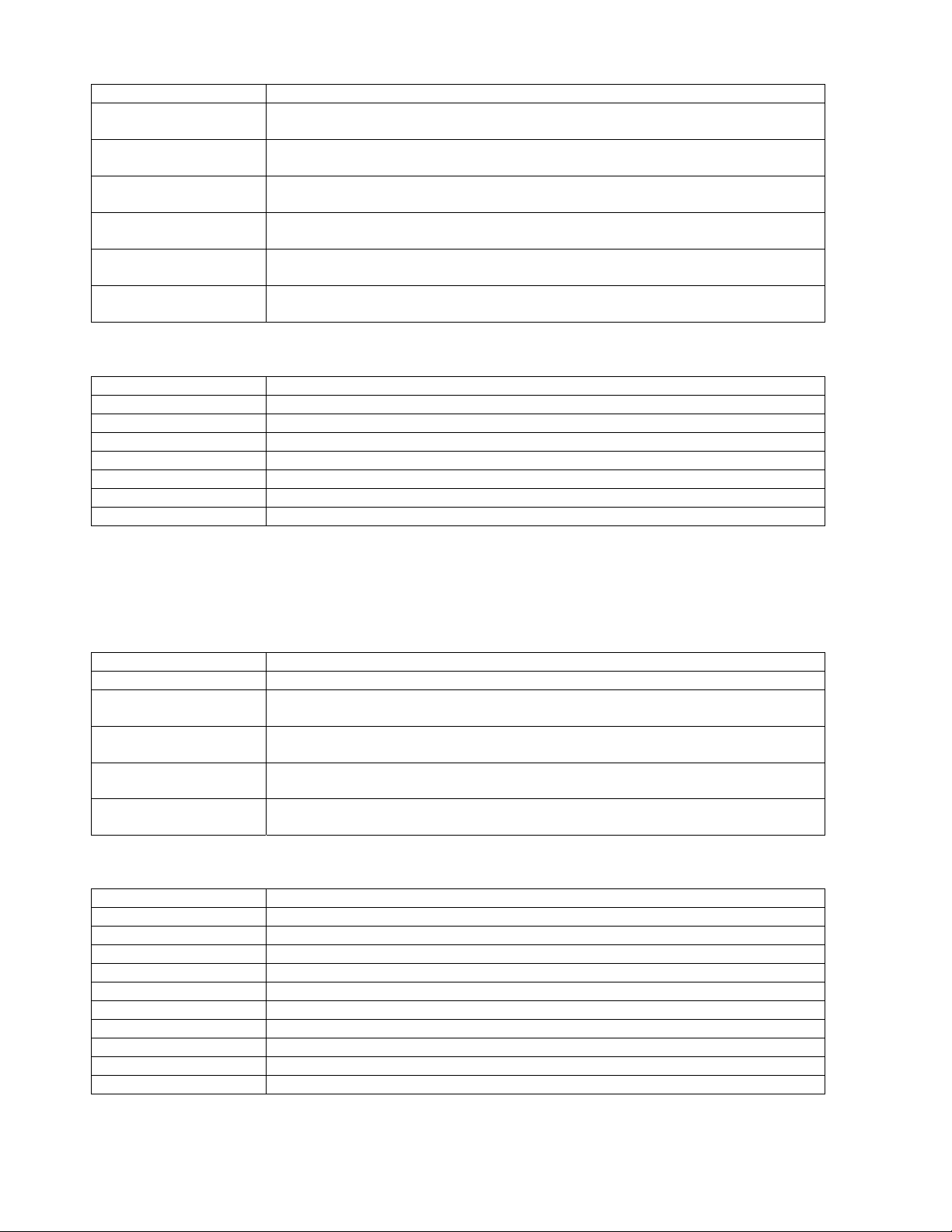

MENUS/OPERATION......................................................................................................... 6

Menu Trees 6

Root Menu 12

Variables Menu............................................................................................................................................................ 12

Variable Mapping Menu ..........................................................................................................................................12

Status Display Menu ....................................................................................................................................................13

Configuration Menu..................................................................................................................................................... 13

Operation Menu ....................................................................................................................................................... 14

Filtering Menu .....................................................................................................................................................14

Empty Clamp Menu............................................................................................................................................. 15

Detector Fault Menu ............................................................................................................................................15

Linearization Menu .............................................................................................................................................. 15

Config Linearize Menu .................................................................................................................................... 15

Temp Comp Menu ............................................................................................................................................... 16

Pressure Comp Menu ........................................................................................................................................... 16

D1 Config Menu ......................................................................................................................................................17

% Solids Variables Menu..................................................................................................................................... 18

% Acids Variables Menu .....................................................................................................................................18

D2 Config Menu ......................................................................................................................................................18

% Solids Variables Menu..................................................................................................................................... 19

% Acids Variables Menu .....................................................................................................................................19

Proc Temp Config Menu.......................................................................................................................................... 19

Pressure Config Menu.............................................................................................................................................. 20

Head Temp Config Menu.........................................................................................................................................20

Alarms...................................................................................................................................................................... 20

Hardware Menu .......................................................................................................................................................21

Source Type Menu............................................................................................................................................... 22

Usr Def Source Menu ..........................................................................................................................................22

Analog Out Config................................................................................................................................................... 22

HART Output Menu ........................................................................................................................................... 23

Density Gage Manual 012407

i

Page 3

Com1 Protocol Menu....................................................................................................................................... 23

HART Menu ............................................................................................................................................................23

System Menu ...........................................................................................................................................................23

Digital Outputs Menu 24

Relay and TTL Menus .................................................................................................................................................25

Digital Inputs Menu 25

Input 1 Menu................................................................................................................................................................ 25

Calibration Menu 26

Ref Constants Menu..................................................................................................................................................... 26

Loop Config Menu....................................................................................................................................................... 27

Aux Loop Cfg Menu.................................................................................................................................................... 27

Calibrate Menu............................................................................................................................................................. 28

Low Reference Menu............................................................................................................................................... 28

High Calibrate Menu................................................................................................................................................ 28

Temp Reference Menu............................................................................................................................................. 28

Pressure Reference Menu......................................................................................................................................... 29

Auto Reference Menu .............................................................................................................................................. 29

Diagnostics............................................................................................................................................................... 29

X96S Local Display 30

Navigating Menus 30

Editing Values 31

Editing Fixed Point Numbers....................................................................................................................................... 31

Editing Floating Point Numbers...................................................................................................................................31

Editing Text Strings ..................................................................................................................................................... 31

Editing Enumerated Values .........................................................................................................................................31

X96 Local Display Vs 275 Calibrator 31

INSTALLATION................................................................................................................ 32

Caution......................................................................................................................................................................... 32

Specific License 32

(SA or GS Series)............................................................................................................................................. 32

General License 32

(RLL Source Holder) ....................................................................................................................................... 32

Unpacking 32

Storage 32

Mechanical Mounting 35

Electrical Installation of Interconnect Wiring 36

Microprocessor Verification 37

Power-up 38

PASSWORD..................................................................................................................... 39

QUICK START REFERENCE – CALIBRATING DENSITY .............................................40

QUICK START REFERENCE – CALIBRATING DENSITY............................................... 41

QUICK START REFERENCE – CALIBRATING DENSITY .............................................43

QUICK START REFERENCE – CALIBRATING DENSITY .............................................44

CALIBRATION .................................................................................................................45

Density Gage Manual 012407

ii

Page 4

Reference Modes 45

Types of Calibration 45

Calibration ................................................................................................................................................................... 45

Low Reference (Single Point Calibration) ............................................................................................................... 45

Calibration Constant ................................................................................................................................................46

Calibration Curve..................................................................................................................................................... 46

High Calibration (Dual Point Calibration) ...............................................................................................................47

Preparation for Calibration........................................................................................................................................... 47

Dual-Point Calibration Procedure................................................................................................................................ 47

Single-Point Calibration Procedure.............................................................................................................................. 48

Temperature Compensation .........................................................................................................................................48

Documentation 49

CONFIGURATION............................................................................................................50

DETECTOR ......................................................................................................................51

Scintillator Detector 51

ION Chamber 53

ELECTRONICS ................................................................................................................58

X96-2001PL 58

X96-2003-01PL 58

X96-2003-02PL 58

X96-2003-03PL 58

X96-2003-04PL 58

X96-2003-05PL 58

X96-2004PL 58

X96-2005PL 58

X96-2008PL 58

X96-2009PL1 59

X96-2009PL2 59

X96-2009PL3 59

X96-2029PL 59

X96C148 59

X96C148-2 59

X96C148-4 59

X96S Mechanical Chassis & LCD Part Numbers 60

X96S Electronic Module Part Numbers 60

Density Gage Manual 012407

iii

Page 5

Overview

The X96S is a family of measurement products that is intended to replace the current X96N and X99 product families. These

products:

• use nuclear measurement techniques,

• support all features of the current X96N and X99 products,

• support up to 32 scintillation or ionization detectors,

• optional HART interface,

• improved user interface options

• more user functionality, and

• more product flexibility.

Advantages

• Mounts external to existing pipe

• Displays in customers units

• Most applications can be solved with low-energy sources

• Not affected by:

-extreme temperatures

-caustic processes

-violent product flour

-sterile processes

-variable product flow velocity

Gamma's Advantages

1

,

• Mounts external to pipe or vessel (no components exposed to process material)

• Passes through process material

• Does not make material radioactive

• Does not change the material

• Can be shielded by lead

X96S Advantages

• HART Communications

• Identical interface on local display as via HART

• Blind transmitter in detector on self contained design

• Custom configuration of display

• Surface, panel or rack mount available

• Field mountable

• Push button calibration

• Empty pipe monitor

1

This includes the ability to have a simple or complex user interface a remote user interface or even no user interface.

Density Gage Manual 012407

1

Page 6

Basic Concepts

Communications

The Ronan X96S Density gage provides both 4-20 mA current loop and HART communications.

4-20 MA

For many years, the field communication standard for process automation equipment has been a 4-20 mA current loop signal. The

current varies in proportion to the process variable being represented. In typical applications, a signal of 4mA will correspond to

the lower limit (0%) of the calibrated range and 20mA will correspond to the upper limit (100%) of the calibrated range. Thus, if

the system is calibrated for 1 to 3 SGU, then an analog current of 12mA (50% of range) will correspond to a density of 2 SGU.

HART

HART Field Communications Protocol extends the 4-20mA current loop standard to enhance communication with smart field

instruments. The HART protocol was designed specifically for use with intelligent measurement and control instruments, which

traditionally communicate using 4-20mA analog signals. HART preserves the 4-20mA signal and enables two-way digital

communications to occur without disturbing the integrity of the 4-20mA signal. Unlike other digital communication technologies,

the HART protocol maintains compatibility with existing 4-20mA systems, and in doing so, provides users with a backward

compatible solution. HART Communication Protocol is well established as the "de facto" industry standard for digitally enhanced

4-20mA-field communication.

The enhanced communications capability of intelligent field instruments employing the HART protocol, offers significantly

greater functionality and improved performance over traditional 4-20mA analog devices. The HART protocol permits the process

variable to continue to be transmitted by the 4-20mA analog signal and additional information pertaining to other variable,

parameters, device configuration, calibration, and device diagnostics to be transmitted digitally at the same time. Thus, a wealth of

additional information related to plant operation is available to central control or monitoring systems through HART

communications.

Variables

There are two types of variables, communications variables and device variables.

Communications Variables

HART defines four device variables, PV (Primary Variable), SV (Secondary Variable), TV, and QV. PV is assigned to the primary

4-20 ma loop. HART is also communicated over this loop. SV is assigned to an optional secondary 4-20 mA loop.

Device Variables

The Ronan X96S Density gage has 5 device variables:

Device Variable Value

D1 Density

D2 Density in alternate units

Proc Temp Process Temperature

Pressure Process Pressure

Head Temp Head Temperature

Density Gage Manual 012407

2

Page 7

Theory

Theory of Radiation Gaging

Radiation gages operate on the principle of radiation absorption and transmission.

A beam of gamma radiation is directed from the source holder, through the pipe (or vessel) and its process material, and onto the

surface of the detector.

Some amount of radiation is absorbed by the material through which it passes, and some of the radiation is transmitted to the

surface of the detector.

Process measurement is possible because the amount of radiation absorbed and transmitted is predictable.

The absorbed radiation is directly related to the density (or mass) of process in the pipe while the transmitted radiation is inversely

related to the density (or mass) of process in the pipe.

Therefore, an increased process density results in a decrease of transmitted radiation.

Since the radiation that's not being absorbed is being transmitted, the process density can be inferred by measuring the amount of

radiation reaching the detector at any point in time. The detector's output signal, in counts, also varies inversely to the process

density.

When the process is light (low density) the detector is exposed to a maximum amount of radiation which produces a HIGH output

of counts. When the process is heavy (high density) the process material "shields" the detector and prevents radiation from

reaching the detector, producing a LOW output of counts.

Ronan’s Density Monitor is used to replace the lab sampling process since the gage output, when accurately calibrated, will

correlate to the density values of process taken from samples near the gage location.

The X96S Microprocessor converts the detector signal to user's measurement units of SGU, percent solids, Baume H, Baume L,

API, or percent steam. The X96S Microprocessor is capable of simultaneously displaying density in two different sets of units.

These different representations of the density value are called density 1 and density 2.

The X96S displays the output measurement range in the selected user units. Channel 1 and Channel 2 can be set independently.

For both channels, the "zero" of the measurement range represents the lowest density of interest, while the "span" of the

measurement range represents the highest density of interest.

Reduction of the signal "noise" due to radiation statistics is handled in the stage of signal processing known as digital filtering.

Digital filtering is a form of statistical averaging used to smooth, or dampen, random radiation as well as process-related noise.

Increasing the digital filter’s “time constant” decreases signal noise.

Dynamic tracking permits the gage response to temporarily by-pass the digital filter. This is helpful in some processes where

sudden or drastic step changes in process must be observed in their true, or unfiltered, state.

Software also compensates for the decay of the radioactive source activity. On-going adjustments are made automatically for the

rate of decay, or source half-life.

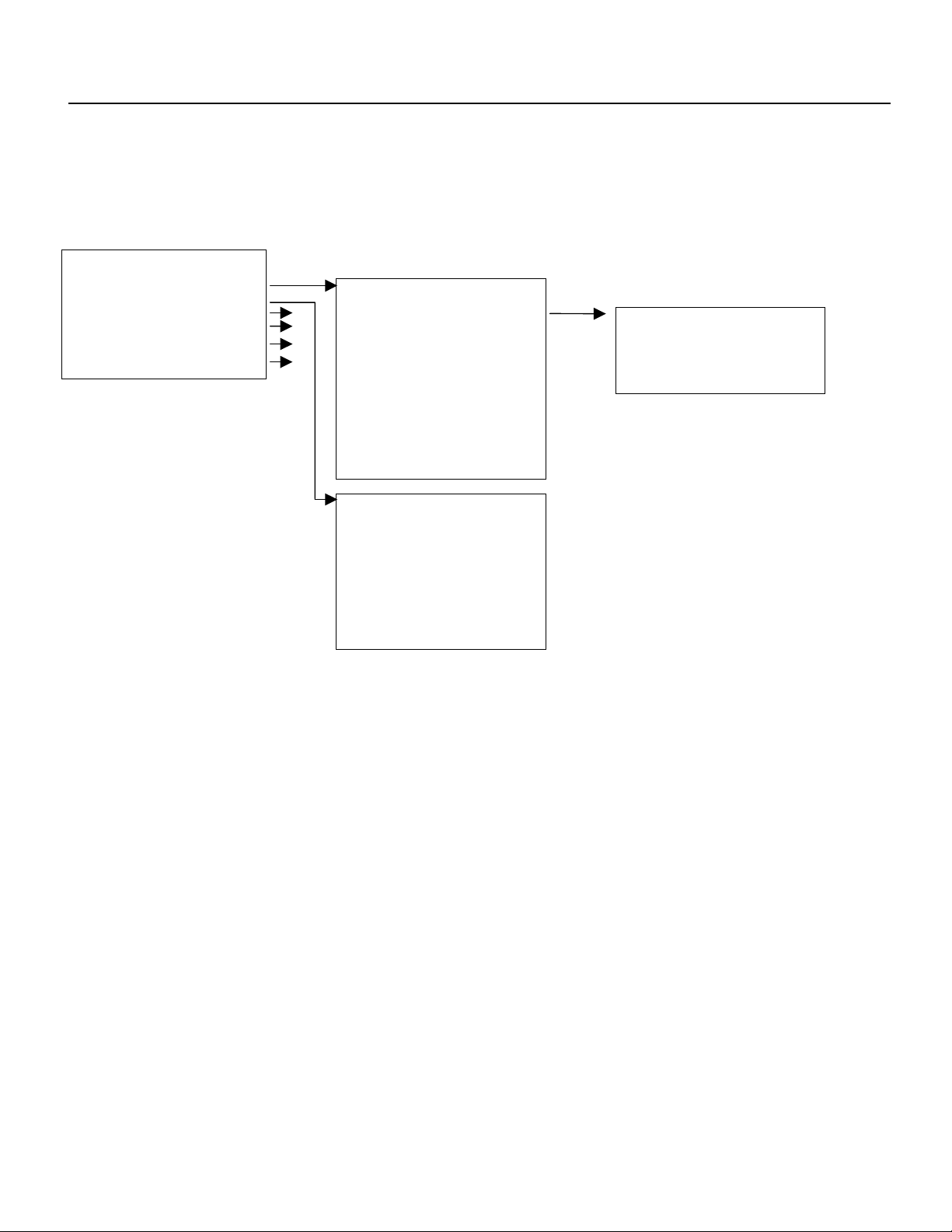

Principles of Operation

The detector's raw output signal is processed through several stages of software in the X96S.

Some of the more significant stages of signal processing are:

• Units Conversion – conversion of density (SpG) into user-selected units

• Measurement Range – 4-20 mA output defined by the user-selected range in user-selected units.

Density Gage Manual 012407

3

Page 8

• Digital Filtering – signal smoothing to reduce statistical radiation noise

• Dynamic Tracking – quick gage response to quick process changes.

• Source Decay Compensation – automatic compensation for the radioisotope decay

• Calibration (Referencing) – calibration of gage to user process.

The Calibration (or Referencing) procedure relates detector output (in counts) to numeric values that accurately represent the actual

process density.

The density algorithm (or curve) used by the X96S software is an exponential function. That is, the relationship between the

detector output and the process density is mathematically expressed as:

Id = Ioe

-ut(d-do)

Where:

Id = detector signal with process density (d)

= detector signal with reference density (do) in pipe

Io

u = the absorption coefficient

t = pipe internal diameter

d = density usually expressed in SpG

d

= reference density

o

The "calibration constant" (1/ut) is used by the X96S software to calculate process density.

Density Gage Manual 012407

4

Page 9

Password

Notice:

To access the Programming Menu, the Password is 101010.

Step 1: Power Up – You should now be on the Status Screen.

Step 2: Press F3 to go back.

Step 3: Now enter the password. (All digits are set at 000000 at this point.)

Press to get the digit to be # one

Press 2 times (The third digit should be highlighted.)

Press to get the digit to be # one

Press 2 times (The fifth digit should be highlighted.)

Press to get the digit to be # one

Press F4 (enter)

Note: If the wrong password was entered, press F1 (ALL0) to set all the digits to the number 0 and

you can begin re-entering the password from the beginning. Pressing F2 (RST0) will set the

individual digit that is highlighted back to the number 0.

Note: For security reasons, each digit will always be displayed as an asterisk.

Density Gage Manual 012407

5

Page 10

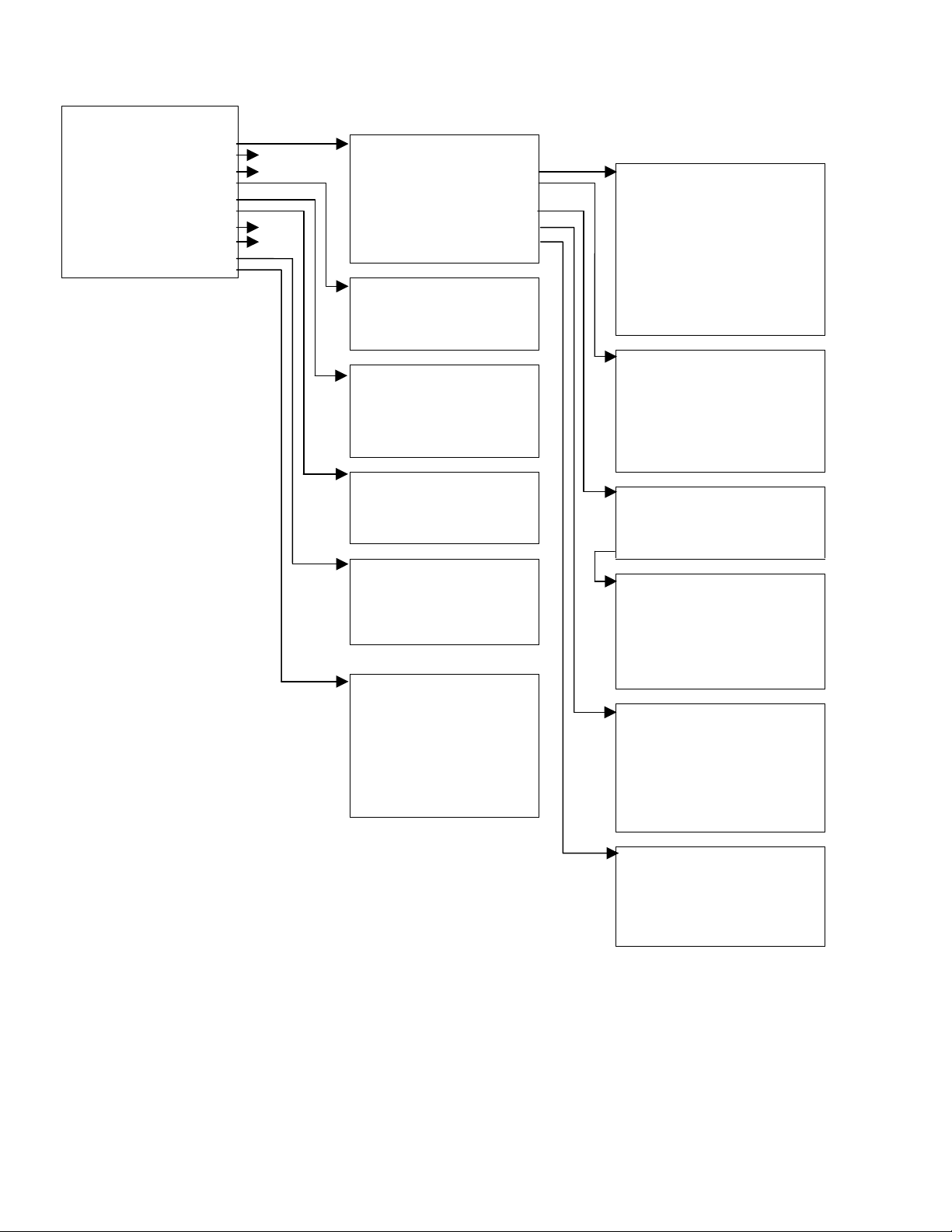

Menus/Operation

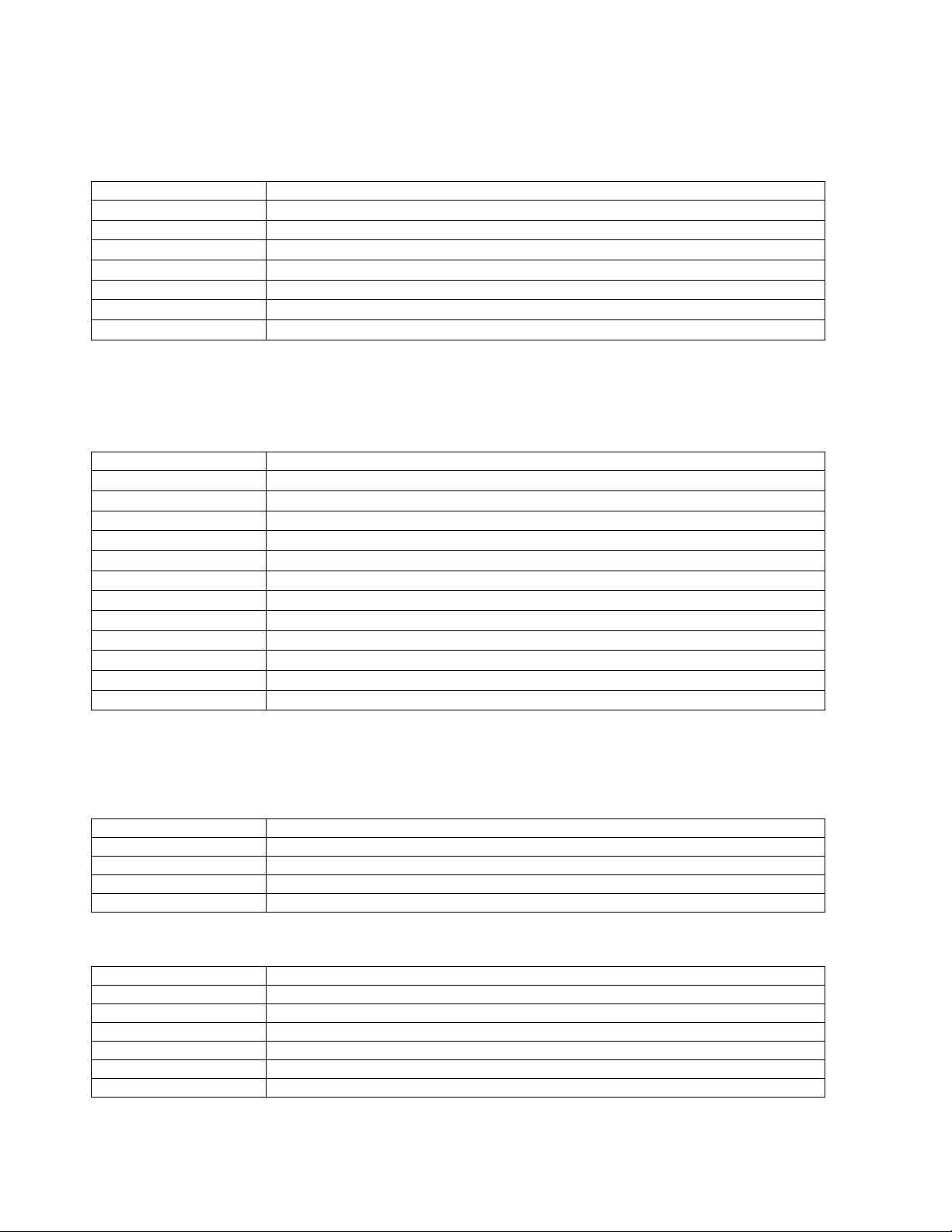

Menu Trees

The Ronan X96S Density Gage uses a tree structured menu system.

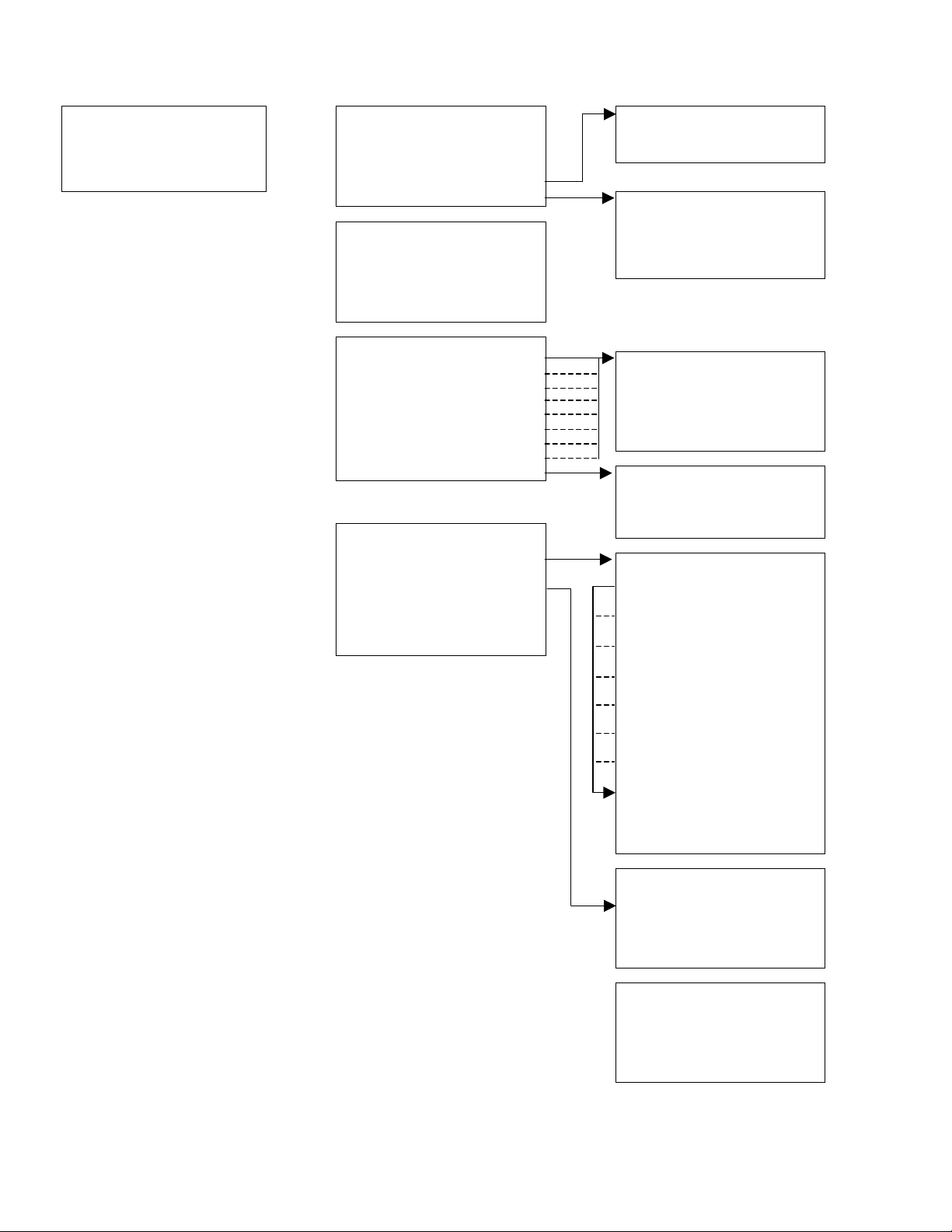

Ronan X96S - Density

Variables Variables

Status Display

Configuration 2 Variable Mapping Variable Mapping

Digital Outputs 4 PV [value units]

Digital Inputs 4 SV [value units] PV is [var mapped to PV]

Calibration 5 TV [value units] SV is [var mapped to SV]

Diagnostic QV [value units] TV is [var mapped to TV]

D1 [value units] QV is [var mapped to TV]

D2 [value units]

Proc Temp [value units]

Pressure [value units]

Head Temp [value units]

Raw Cnts [value]

Filt Cnts [value]

Status Display

Analog Bar [enable]

Line 1: [var]

Line 2: [var]

Line 3: [var]

Line 4: [var]

Line 5: [var]

Line 6: [var]

Line 7: [var]

Line 8: [var]

Figure 3-1 – Root, Variables and Displays Menus

Density Gage Manual 012407

6

Page 11

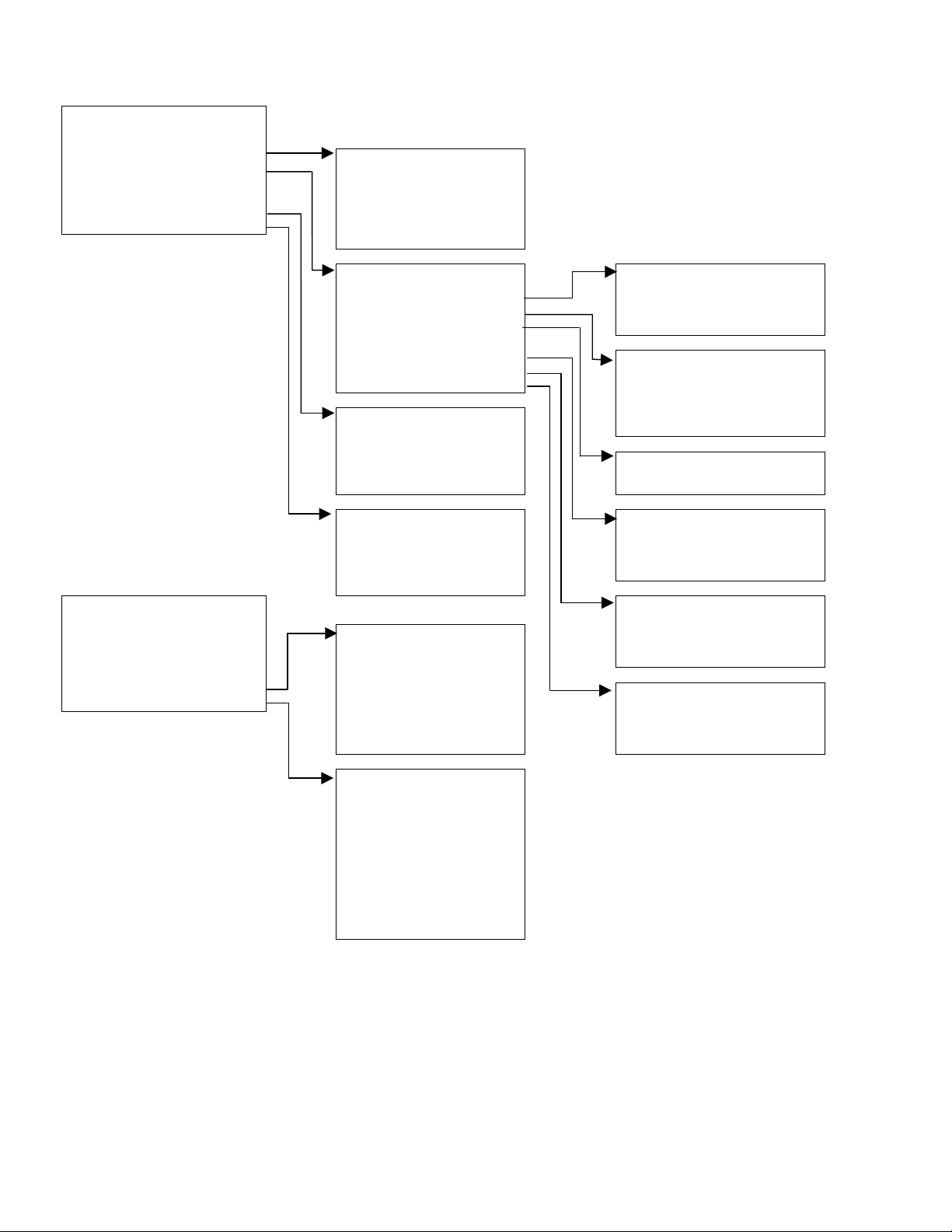

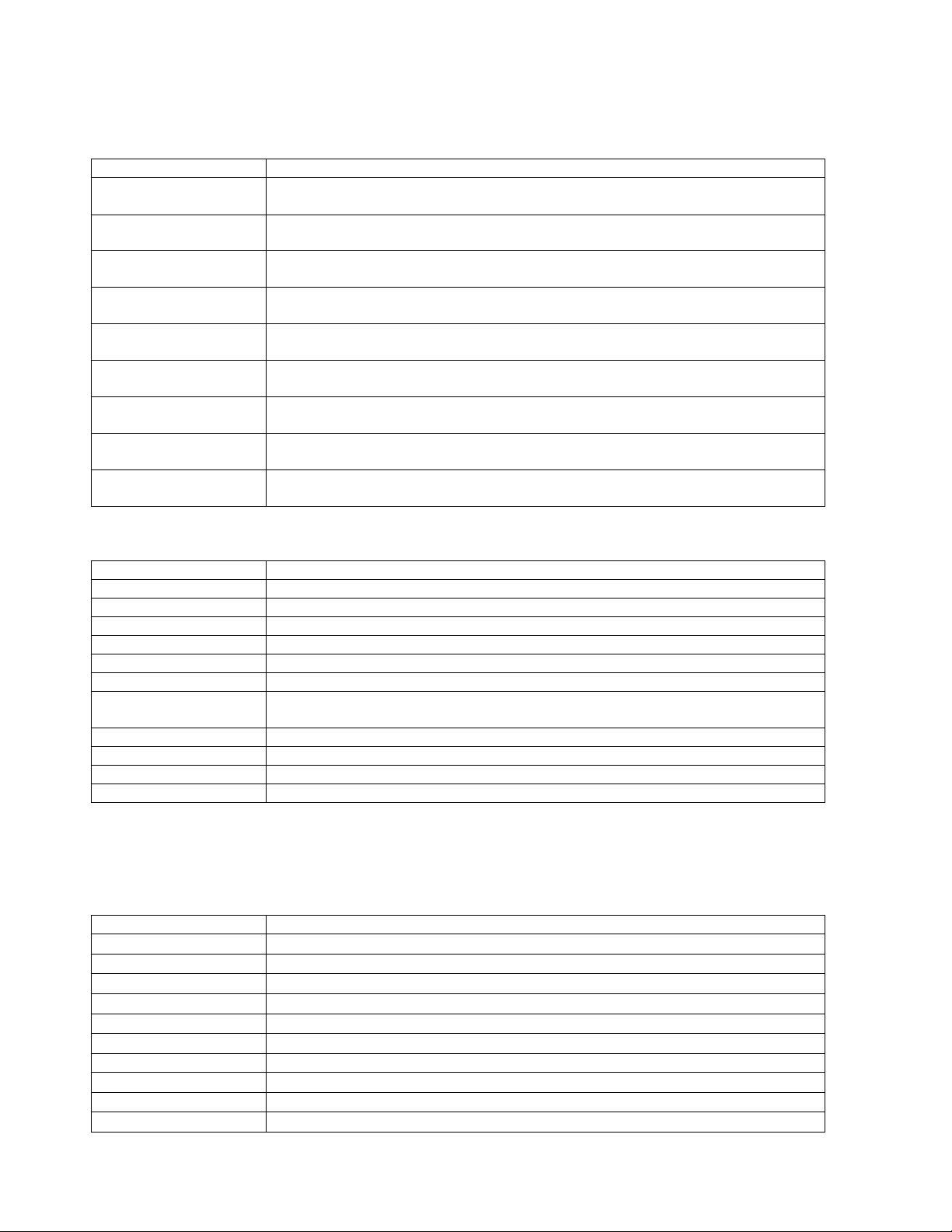

Configuration

Operation Operation

D1 Config 3

D2 Config 3 Filtering Filtering

Proc Temp Config Empty Clamp

Pressure Config Detector Fault Type RC

Head Temp Config Linearization Dyn Track [enable/disable]

Alarms 3 Temp Comp Sigma [value]

Hardware 3 Pressure Comp Fast TC [s]

HART Scan Time [ms] Fast Counter [value]

System Medium TC [s]

Proc Temp Config Slow Counter [value]

Temp Units [°C/F/R/Kelvin] Noise Filter [value]

Low Range [value] Monitor [track value]

High Range[value]

Pressure Config

Pressure Units

[psi;bar;g/Sqcm;kg/Sqcm;pa;kPa

;atm]

Low Range [value] Rcvry Time [seconds]

High Range [value] Min Counts [value]

Head Temp Config

Temp Units [°C/F/R/Kelvin]

Low Range [value] Linearize [enable/disable]

High Range [value] Clear Table

HART

Tag Name [name]

MultiDrop [addr] Table Entry # [number]

Univ Rev [rev] Entry Used [indicator]

Spec Rev [rev] Measured [value]

System Remove Entry

Slow TC [s]

Empty Clamp

Empty Clamp [enable/disable]

Off Time [seconds]

Max Counts [value]

Linearization

Config Linearize

Config Linearize

Actual [value]

Set Entry

Serial # [number] Temp Comp

Hardware Rev [rev]

Software Rev [rev] Temp Comp [enable/disable]

Date [date] Temp Units [units]

Hour (0-23) [hour] A Coeff [value]

Minute [min] B Coeff [value]

Password Enter Temp

Date/Time Format [sel]

Temp Auto Cap [enable/disable]

Last Ref. Temp [°F]

Pressure Comp

Pres Comp [enable/disable]

Pressure Units [units]

A Coeff [value]

Enter Pressure [value]

Pres Auto Cap [enable/disable]

Figure 3-2 – Configuration Menus (1 of 3)

Density Gage Manual 012407

7

Page 12

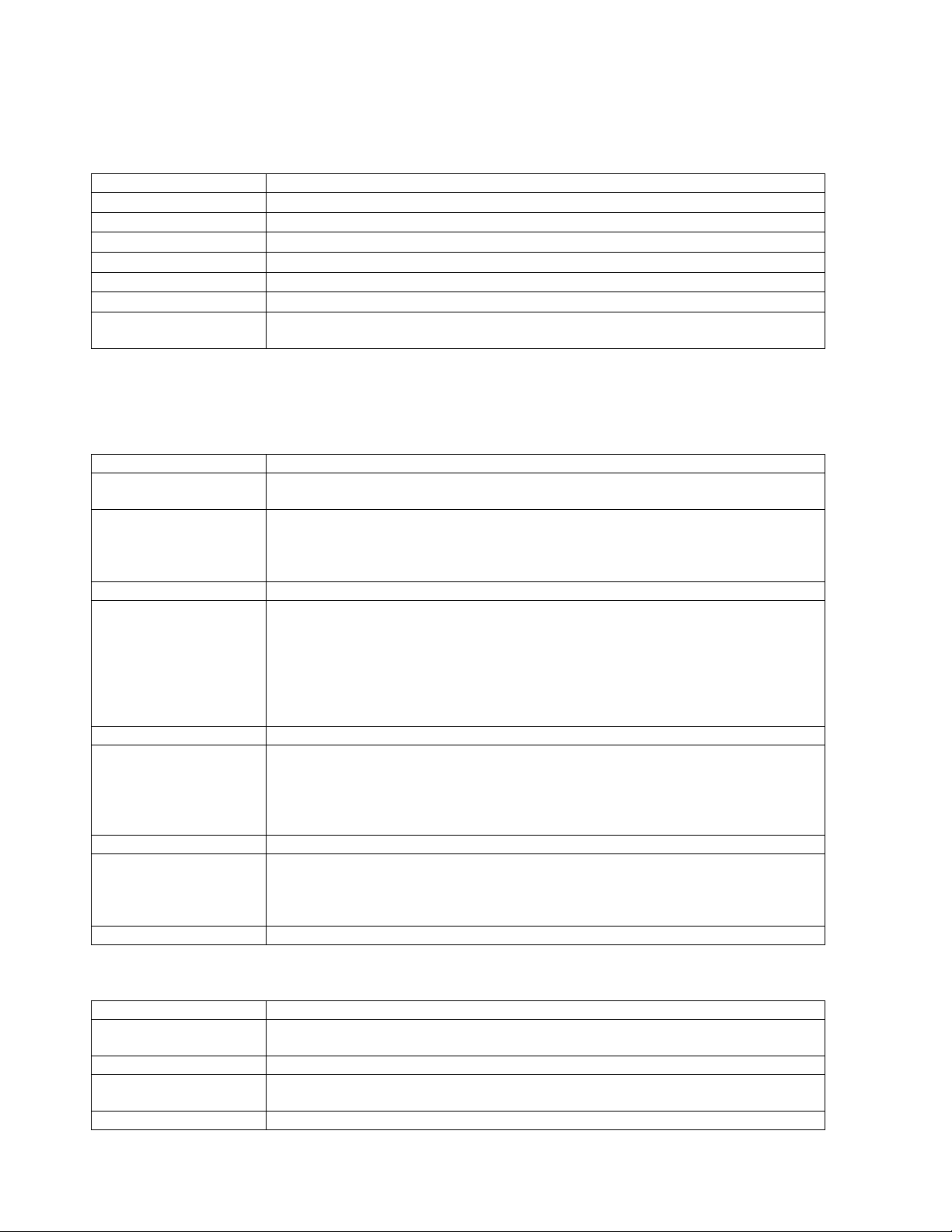

Configuration (Cont’d) Density 1 Config % Solids Variables

D1 Config D1 Units [units] Carrier [value]

D2 Config Low Range [value] Solids [value]

Alarms High Range [value]

Hardware % Solids Variables

% Acids Variables % Acids Variables

Density 2 Config Algorithm

Same Options as Density 1

D2 Units [units] Parameter B

Low Range [value] Parameter C

High Range [value]

% Solids Variables

% Acids Variables

Parameter A

Alarm 1 Alarm (number)

Alarm 2

Alarm 3 Source [variable]

Alarm 4 Alarm Type [variable]

Alarm 5 Setpoint [SGU]

Alarm 6 Setpoint 2 [SGU]

Alarm 7 Hysterisis [%]

Alarm 8

Alarm on 4-20 mA Alarm on 4-20mA

System Hardware System Hardware

Proc Temp [variable] CPU Card [type]

Source Type Slot 1 Details

Pressure Slot 2

Analog Out Config Slot 2 Details

HART Output X96S-20 Slot 3

Com1 Protocol Ronan Slot 3 Details

Alarms

None

Underrange

Overrange

Hardware Freeze

Slot 4

Slot 4 Details

Slot 5

Slot 5 Details

Slot 6

Slot 6 Details

Slot 7

Slot 7 Details

Slot 8

Slot 8 Details

Display X96-2000PL

Display Details

HART X96-2005PL

HART DB Details

Density Gage Manual 012407

Slot Details

Status

Serial Number

SW Major Rev

SW Minor Rev

HW Rev

Source Type

Source Type [type]

User Def Source

Next Reference[date]

Next Wipe Test

Next Shutter Test

Figure 3-2 – Configuration Menus (2 of 3)

8

Page 13

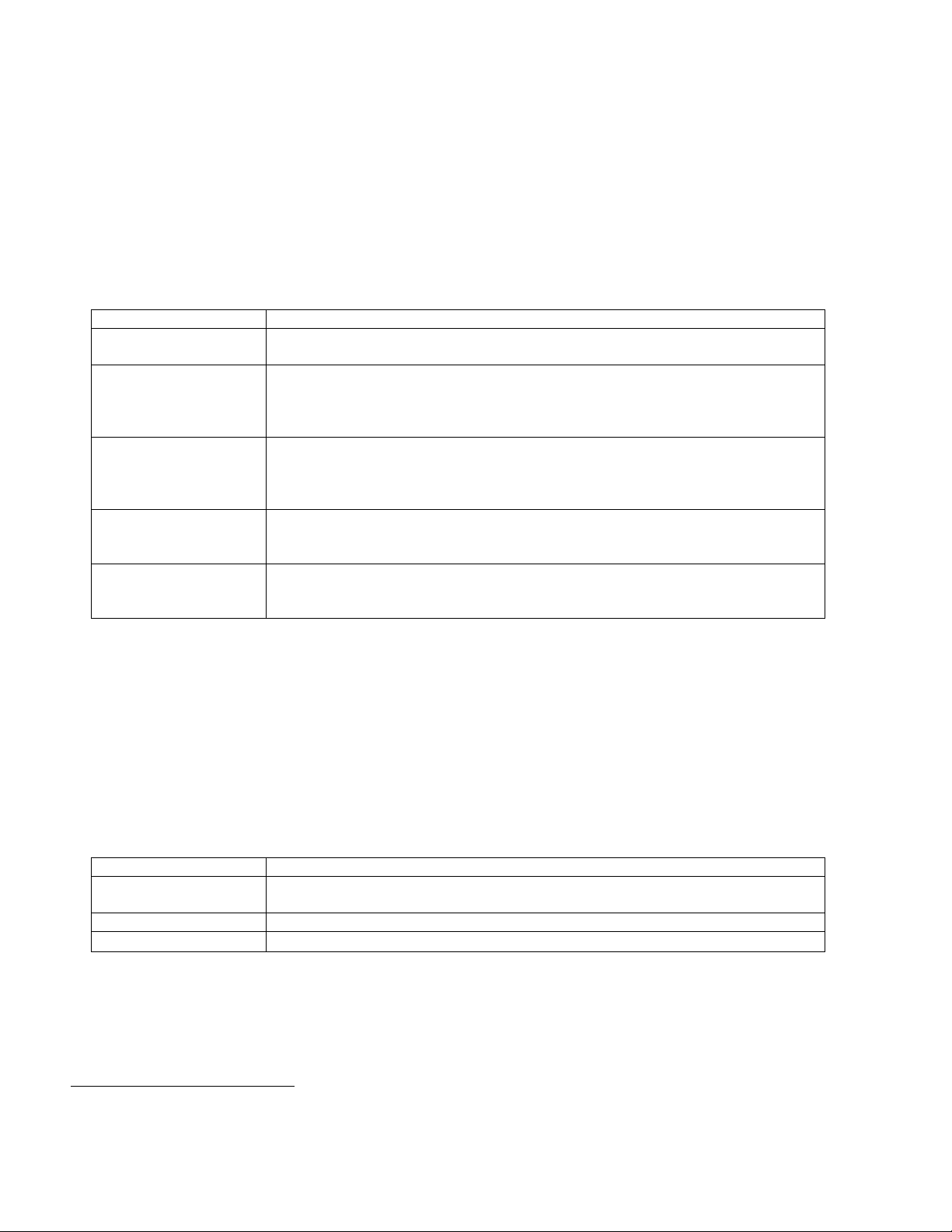

Configuration (Cont’d) Hardware (Cont’d)

Hardware (Cont’d) System Hardware

Proc Temp [variable]

Source Type

Pressure

Analog Out Config Analog Out Config

HART Output Loop 1 (PV) [variable]

Com1 Protocol Ronan Loop 2 (SV) [variable]

Figure 3-2 – Configuration Menus (3 of 3)

Loop 3 (TV) [variable]

Power Source [int/ext]

HART Output

None

X96S-2005

Ser. Port 1

Com1 Protocol

None

Hart

Ronan Setup

Density Gage Manual 012407

9

Page 14

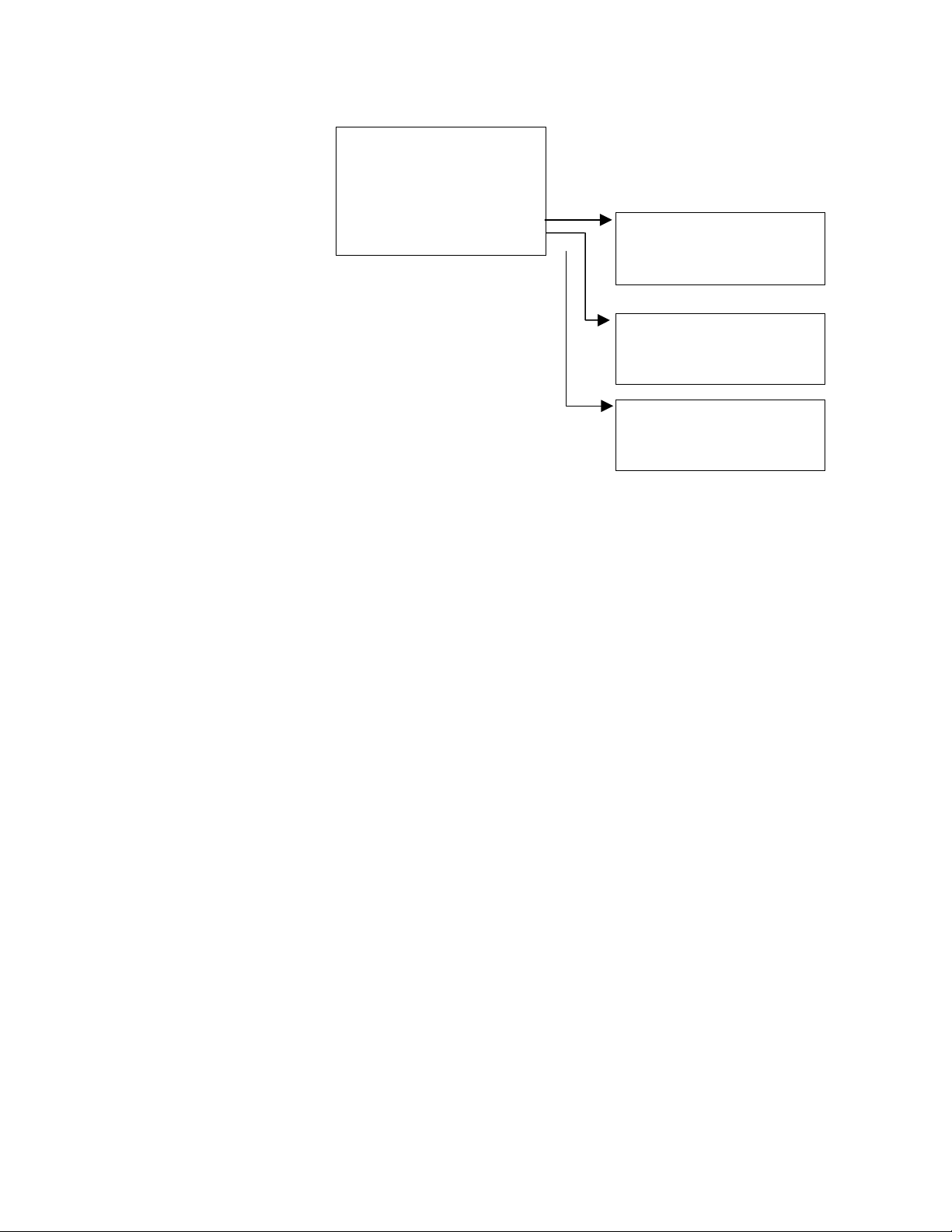

Digital Outputs Output

Output [Relay 1-4/TTL 1-4] Relay 1

Select Sources [variable] Relay 2

Polarity [variable] Relay 3

Relay 4

TTL 1

TTL 2

TTL 3

TTL 4

Output [selected relay or TTL]

Alarm 1 [yes/no]

Alarm 2 [yes/no]

Alarm 3 [yes/no]

Alarm 4 [yes/no]

Alarm 5 [yes/no]

Alarm 6 [yes/no]

Alarm 7 [yes/no]

Alarm 8 [yes/no]

Auto Cal Ref [yes/no]

Auto Cal Err [yes/no]

Ref Prompt [yes/no]

Wipe Test [yes/no]

Shutter Test [yes/no]

Empty Clamp [yes/no]

Detector Flt [yes/no]

System Alarm [yes/no]

Select Sources

Polarity

No/Not Driven

NC/Driven

Open/Not Driven

Closed/Driven

Digital Inputs Input 1

Input 1 Use [not used/auto ref]

Polarity [high/low]

Figure 4-1– Digital Output and Digital Input Menus

Density Gage Manual 012407

10

Page 15

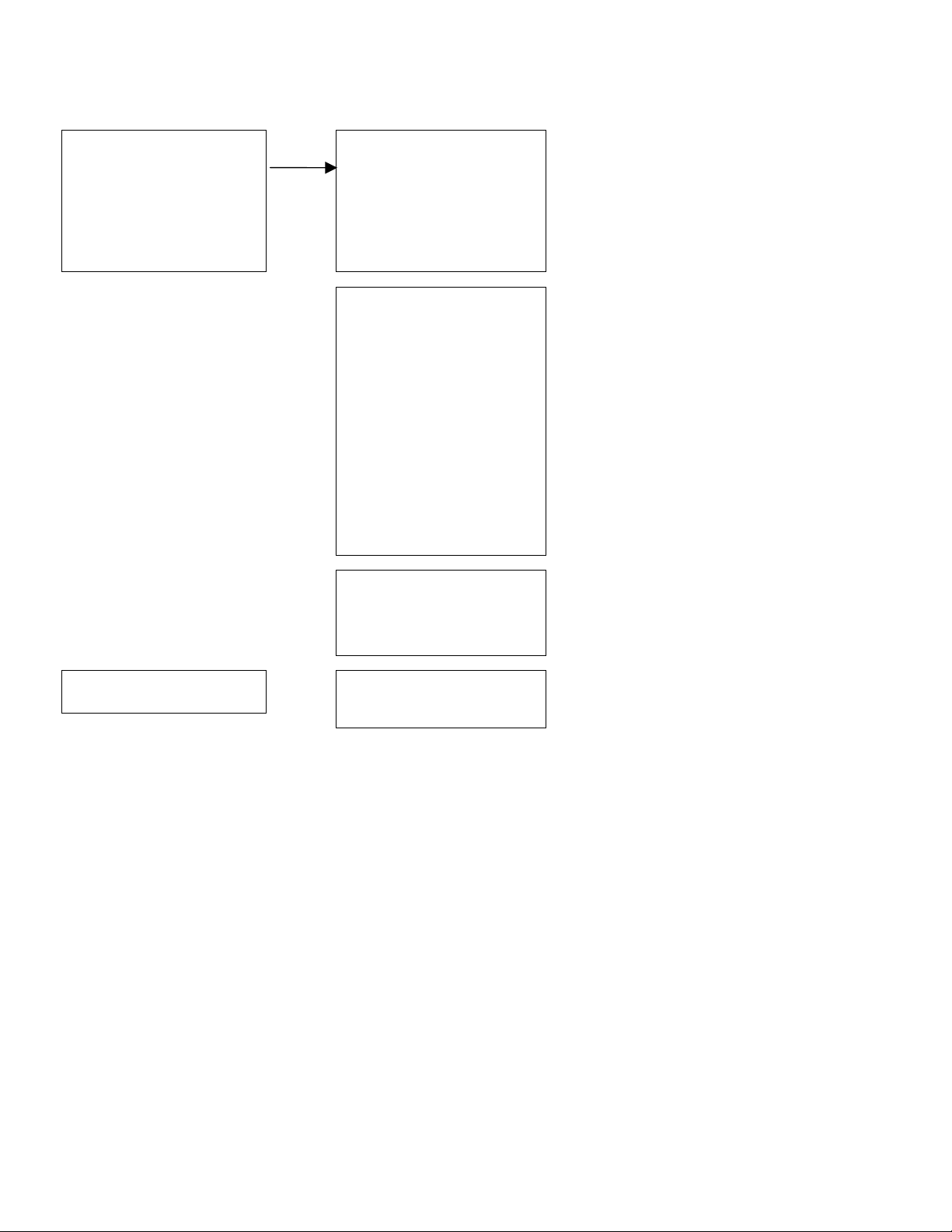

Calibration

State [state]

Ref Constants Ref Constants

Calibrate

Last Ref Date [date] Ref Mode [variable]

Last Ref Time [time] Calibr. Mode [variable]

Loop Config Ref Time [time]

Aux Loop Cfg Min Ref Cnts [counts]

Max Ref Cnts [counts]

Calibrate Low Reference

Low Reference Reference

High Calibrate Ref Density [value units]

Manual Entry Ref Cap [counts]

Clear Ref/Cal

Temp Ref High Calibrate

Pressure Ref

Auto Reference Calibrate

Loop Config Cal Cap [counts]

PV is [variable]

Loop test Manual Entry

Damping

D/A trim 1/uT [slope]

Aux Loop Config Temp Reference

SV is [variable] Temp Ref

Aux 1 Test Temp Cap Low [counts]

Aux 1 Trim Temp Cap High [counts]

TV is [variable]

Diagnostic Pressure Reference

Cal Density [value units]

1/uT [slope]

Raw Counts Ref/Cal Data Pressure Ref

Filt. Counts Pres Cap Low [counts]

Raw Dens. Last Ref Date [date] Pres Cap High [counts]

Current Ref Density 0

Ref/Cal Data Cal Density 2 Auto Reference

Alarms Ref Cap

Cal Cap Auto Ref [enable]

Last Ref Temp Ref Delay [s]

1/uT Auto Ref Density [SGU]

Alarms

Sys. Alarm

Empty Clamp

Det. Fault

AutoCal Ref

AutoCal Error

Ref. Prompt

Wipe Test

Shutter Test

Alarms

Output

Density Gage Manual 012407

Figure 3-5 – Calibration Menus

11

Page 16

Root Menu

The root menu is titled “Ronan X96S – Density”. It contains the following items:

ITEM FUNCTION

Variables

Displays

Configuration

Digital Outputs

Digital Inputs

Calibration

Diagnostic

Variables Menu

The menu titled “Variables” contains the following items:

ITEM FUNCTION

Variable Mapping

PV

SV

TV

QV

D1

D2

Proc Temp

Pressure

Head Temp

Raw Counts

Filt Counts

Selecting this takes the user to the Variables menu

Selecting this takes the user to the Displays menu

Selecting this takes the user to the Configuration menu

Selecting this takes the user to the Digital Outputs menu

Selecting this takes the user to the Digital Inputs menu

Selecting this takes the user to the Calibration menu

Selecting this takes the user to the Diagnostic menu

Selecting this takes the user to the Variable Mapping menu

Shows the current value of PV (the Primary Variable)

Shows the current value of SV (the Secondary Variable)

Shows the current value of TV (the Third Variable)

Shows the current value of QV (the Fourth Variable)

Shows the current value of D1 (the Density Variable)

Shows the current value of D2 (the Density Variable in alternate units)

Shows the current value of Proc Temp (the Process Temperature)

Shows the current value of Pressure (the Process Pressure)

Shows the current value of Head Temp (the Head Temperature)

Shows the current Raw Counts value from the detector

Shows the current Filtered Counts value from the detector

Variable Mapping Menu

The “Variable Mapping” menu allows the user to select the device variable to be mapped to PV, SV, TV, and QV. It contains

the following items:

ITEM FUNCTION

PV is

SV is

TV is

QV is

Each PV, SV, TV, and QV may each select one of the following:

SELECTION

D1

D2

Proc Temp

Pressure

Head Temp

Not Assigned

Density Gage Manual 012407

Shows the device variable assigned to PV and allows the user to change the selection

Shows the device variable assigned to SV and allows the user to change the selection

Shows the device variable assigned to TV and allows the user to change the selection

Shows the device variable assigned to QV and allows the user to change the selection

MEANING

Density represented in units that are used locally

Density represented in alternate units

Process temperature

Process pressure (if available)

Head temperature (if available)

Blank line

12

Page 17

Status Display Menu

The menu titled “Status Display” is used to configure the device status display. It contains the following items

ITEM FUNCTION

Analog Bar

Line 1:

Line 2:

Line 3:

Line 4:

Line 5:

Line 6:

Line 7:

Line 8:

Each line can select one of the following:

Shows the current state of the analog bar display (enabled or disabled) and allows the

user change the state.

Shows the data to be displayed on line 1 of the status display and allows the user to

change the selection

Shows the data to be displayed on line 2 of the status display and allows the user to

change the selection

Shows the data to be displayed on line 3 of the status display and allows the user to

change the selection

Shows the data to be displayed on line 4 of the status display and allows the user to

change the selection

Shows the data to be displayed on line 5 of the status display and allows the user to

change the selection

Shows the data to be displayed on line 6 of the status display and allows the user to

change the selection

Shows the data to be displayed on line 7 of the status display and allows the user to

change the selection

Shows the data to be displayed on line 8 of the status display and allows the user to

change the selection

SELECTION

D1

D2

Proc Temp

Pressure

Head Temp

4-20 mA

Raw Cnts

Filt. Cnts

Date & Time

Diagnostic

Not Assigned

MEANING

Density represented in units that are used locally

Density represented in alternate units,

Process temperature

Process pressure (if available)

Head temperature (if available)

4-20 mA output level

Raw counts (from scintillation detector) or raw analog measurement (from ionization

detector

Filtered counts (from scintillation detector) or (from ionization detector)

Current date and time

Selecting this takes the user to the Diagnostic Menu

Blank line

Configuration Menu

The Configuration menu is used to access area configuration menus. It contains the following items:

ITEM FUNCTION

Operation

D1 Config

D2 Config

Proc Temp Config

Pressure Config

Head Temp Config

Alarms

Hardware

HART

System

Selecting this takes the user to the Operation menu

Selecting this takes the user to the D1 Config menu

Selecting this takes the user to the D2 Config menu

Selecting this takes the user to the Proc Temp Config menu

Selecting this takes the user to the Pressure Config menu

Selecting this takes the user to the Head Temp Config menu

Selecting this takes the user to the Alarm menu

Selecting this takes the user to the Hardware menu

Selecting this takes the user to the HART menu

Selecting this takes the user to the System menu

Density Gage Manual 012407

13

Page 18

Operation Menu

The Operation menu is used to access the menus and variables that control the processing of the density data. It contains the

following items:

ITEM FUNCTION

Filtering

Empty Clamp

Detector Fault

Linearization

Temp Comp

Pressure Comp

Scan Time

Selecting this takes the user to the Filtering menu

Selecting this takes the user to the Empty Clamp menu

Selecting this takes the user to the Detector Fault menu

Selecting this takes the user to the Linearization menu

Selecting this takes the user to the Temp Comp menu

Selecting this takes the user to the Pressure Comp menu

Shows the amount of time to accumulate each density sample and allows the user

change the time value.

Filtering Menu

The Filtering menu is used to configure the parameters associated with the mold level measurement filter, utilizing the

standard scan rate. It contains the following items:

ITEM FUNCTION

Dyn Track

Sigma

Fast TC

Fast Counter

Medium TC

Slow Counter

Slow TC

Noise Filter

Monitor

Shows the current state of the dynamic tracking filter (enabled or disabled) and allows

the user to change the state

Shows the (sigma) multiplier used to determine maximum number of raw count

variation (for scintillation) or raw analog value (for ion chamber) that the input can

vary from the current filtered counts before changing to the dynamic filter. Sigma is

the square root of the current filtered counts. Also allows user to change this number.

Fast Time Constant value to be used when the Fast Counter reaches zero

Shows the fast count down counter value. If gage has been in dynamic tracking long

enough to be using Medium filter and the raw counts continued to exceed the sigma

value, the fast counter value is decreased each consecutive scan. The Fast counter

value resets and returns back to the original value if the raw counts do not continue to

exceed the sigma value. Once the Fast TC is triggered, it will continue to be used until

the counts are within the sigma value for the Fast counter number of times

consecutively. Also allows user to change this number

Medium Time Constant value to be used when the Slow Counter reaches zero

Shows the slow count down counter value. If gage is in dynamic tracking, and the raw

counts continue to exceed the sigma value, the slow counter value is decreased each

consecutive scan. The Slow counter value resets and returns back to the original value

if the raw counts do not continue to exceed the sigma value. Also allows user to

change this number

Slow Time Constant value to be used if the Slow Counter has not reached zero

Shows the maximum number of potentially erroneous measurements in a row to

bridge before deciding that a step change has occurred in the mold level value. Also

allows user to change this number. Erroneous measurement is defined when the raw

signal is 4 times the pre-selected sigma multiplier

Shows the current state of the filtering mechanism

Monitor (filter state) one of the following:

ITEM

ERROR

FILL

TRACK

REFILL

Density Gage Manual 012407

MEANING

Filter is not initialized (this state should not occur during normal operation of the

X96S Density Gage)

The walking average buffer is filling

The walking average buffer is filled and the filter is tracking changes in the density

value

A step change has occurred and the walking average buffer is refilling

14

Page 19

Empty Clamp Menu

The X96S uses a mechanism called empty clamp to protect detectors (particular scintillation detectors) from saturation conditions.

i.e.: Material being processed is lower than detector range, causing too much radiation to reach the detector, possibly damaging

the electronics. The Min Counts and the Max Counts parameters set the threshold (in raw counts

2

) for activation of the empty

clamp function. These Count values should be set above (Max Counts) the Reference Counts, and below (Min Counts) the

Calibrate Counts, and beyond your normal measurement range.

The Empty Clamp menu is used to configure the parameters associated with the mechanism that shuts off power to the detector

if the detector receives more radiation than it is capable of measuring. It contains the following items:

ITEM FUNCTION

Empty Clamp

Shows the current state of the empty clamp mechanism (enabled or disabled) and

allows the user change the state.

Off Time

Shows and allows the user to change the number of seconds that power to the detector

be shut off when the empty clamp mechanism activates before turning the detector on

to see if the radiation level has dropped to a value that the detector is capable of

measuring. Typical value ranges from 15 to 30 minutes.

Rcvry Time

Shows and allows the user to change the number of seconds that power will be applied

to the detector when the empty clamp mechanism has activated to see if the radiation

level has dropped to a value that the detector is capable of measuring. Typical value

here is 30 seconds.

Min Counts

Shows and allows the user to change the number minimum number of counts that are

used to determine that the detector is saturated (exposed to more radiation than it is

capable of measuring).

Max Counts

Shows and allows the user to change the number maximum number of counts that are

used to determine that the detector is exposed to more radiation than it is capable of

measuring.

Detector Fault Menu

The Detector Fault menu is used to configure a window in which the detector counts must fall within, in order to complete a

reference/calibration.

Linearization Menu

The X96S is capable of performing a multi-point linearization of the density data when required by an application. The

linearization table contains ten entries, numbered 1 through 10. Each entry consists of a measured value, an actual value, and a flag

that indicates if the entry is used

The Linearization menu is used to control the linearization mechanism. It contains the following items:

ITEM FUNCTION

Linearize

Clear Table

Config Linearize

Config Linearize Menu

The Config Linearize menu is used to configure the parameters associated with linearization of the measured data. It contains

the following items:

2

The threshold is in raw counts since the overload is a function of the radiation effect on the detector and not related to any

corrected or converted data.

3

Not all of the entries need to be used and the entries do not need to be used in any particular order.

3

.

Shows the current state of the Linearization mechanism (enabled or disabled) and

allows the user change the state.

This invokes a method that clears all entries in the linearization table

Selecting this takes the user to the Config Linearize menu

Density Gage Manual 012407

15

Page 20

ITEM FUNCTION

Table Entry #

Entry Used

Measured

Shows and allows the user to select an entry in the linearization table

Shows if the entry is used or not.

Shows and allows the user to set the measured value associated with this linearization

table entry. This is a value calculated by the X96S.

Actual

Shows and allows the user to set the actual value associated with this linearization

table entry. This value is the result of a lab sample, and compares to the Measured

value above.

Set Entry

Remove Entry

This invokes a method that sets a table entry

This invokes a method that removes a table entry

Temp Comp Menu

Temperature compensation in the X96s is calculated as a quadratic function4. If temperature compensation is to be used, the

process temperature can be captured automatically for you during Referencing by enabling Temp Auto Cap. If you choose to

enter the temperature manually, the entered value should be the temperature of the process material during the Referencing

function.

Process temperature is typically read via platinum or nickel, 2 or 3-wire RTD attached to the X96S. In these cases, the X96S needs

no temperature calibration. You can optionally feed a 0-10volt or 4-20mA signal into the X96S from another source that

represents the range of temperature for your process. In this case, you will need to perform a Temp Ref to set the range of

measurement. You will also need to define the type of temperature device you are using in the Hardware Menu, Proc Temp

menus.

The Temp Comp menu is used to control the temperature compensation mechanism

ITEM FUNCTION

Temp Comp

Shows the current state of the temperature compensation mechanism (enabled or

disabled) and allows the user change the state.

Temp Units

Shows and allows the user to set the temperature units used to by the temperature

compensation mechanism.

A Coeff

Shows and allows the user to set the “A” coefficient that relates temperature to

changes in density.

B Coeff

Shows and allows the user to set the “B” coefficient that relates temperature to

changes in density.

Enter Temp

Shows and allows the user to set the process temperature at the time that the gage was

Referenced (if Auto Cap was ‘enabled’ during Referencing).

Temp Auto Cap

This invokes a method that captures the process temperature automatically during gage

Referencing.

Last Ref Temp

Shows the temperature of the process at the time the last reference was completed

Temp Units is one of the following:

ITEM MEANING

degC

degF

degR

Kelvin

degrees Celsius

degrees Fahrenheit

degrees Rankine

degrees Kelvin

4

. It contains the following items:

Pressure Comp Menu

Pressure compensation is calculated based on the pressure input. The pressure-input range is selected in the Pressure Config

Menu, Hardware Menu, and the Pressure Reference Menu.

The Pressure Comp menu is used to control pressure compensation mechanism

4

compensated density = uncompensated density + (A Coeff * temperature delta) + (B Coeff * temperature delta2)

5

compensated density = uncompensated density + (A Coeff * pressure delta)

Density Gage Manual 012407

16

5

. It contains the following items:

Page 21

ITEM FUNCTION

Pres Comp

Pressure Units

A Coeff

Enter Pressure

Pres Auto Cap

Scan Time

Pressure Units is one of the following:

ITEM MEANING

PSI

Bar

G/Sqcm

Kg/Sqcm

Pa

KPa

atm

Shows the current state of the pressure compensation mechanism (enabled or disabled)

and allows the user change the state

Shows and allows the user to se, the pressure units used to by the pressure

compensation mechanism

Shows and allows the user to set the “A” coefficient that relates pressure to changes in

density

Shows, and allows the user to set, the process pressure at the time that the gage was

Referenced (if Auto Cap was ‘enabled’ during Referencing).

This invokes a method that captures the process temperature automatically during gage

Referencing

Shows the amount of time to accumulate each density sample and allows the user to

change the time value

Pounds per square inch

Bar

Grams/square centimeter

Kilograms/square centimeter

Pascal

Kilopascal

Atmosphere

D1 Config Menu

The D1 Config menu is used to configure the parameters associated with the density measurement. It contains the following

items:

ITEM FUNCTION

D1 Units

D1 Low Range

D1 High Range

% Solids

Variables

% Acids

Variables

D1 Units is one of the following:

ITEM MEANING

SGU

degTwad

degBrix

degBaum_hv

degBaum_lt

degAPI

Percent_sol_wt

degBall

percent_StmQual

% Acids

Shows and allows the user to set the density units used

Shows and allows the user to set the density value to be mapped to 4ma on the current

loop output, if D1 is selected to control that current loop.

Shows and allows the user to set the density value to be mapped to20ma on the current

loop output, if D1 is selected to control that current loop.

Selecting this takes the user to the % Solids Variables menu

Selecting this takes the user to the % Acids Variables menu

specific gravity

degrees twaddle

degrees brix

degrees baume heavy

degrees baume light

degrees API

percent solids by weight

degrees balling

percent steam quality

percent acids

Density Gage Manual 012407

17

Page 22

% Solids Variables Menu

The % Solids Variables menu is used to configure the parameters associated with the percent of solids measurement. It

contains the following items:

ITEM FUNCTION

Carrier

Solids

Shows and allows the user to set the density of the carrier

Shows and allows the user to set the density of the solids

% Acids Variables Menu

The % Acids Variables menu is used to configure the parameters associated with the percent of acids measurement. It

contains the following items:

ITEM FUNCTION

Algorithm

Parameter A

Parameter B

Parameter C

Allows the user to select the desired algorithm

Allows the user to adjust the Parameter A value

Allows the user to adjust the Parameter B value

Allows the user to adjust the Parameter C value

Algorithm Menu

The Algorithm menu allows the user to select the calculation associated with the percent of acids measurement.

ITEM MEANING

Linear

Log

Quadratic pos/neg

None

A (Y) + B

In (Y) + A

A (Y)^2 + B (Y) + C

Not used

D2 Config Menu

The D2 Config menu is used to configure the parameters associated with the alternate representation of the density

measurement. It contains the following items:

ITEM FUNCTION

D2 Units

D2 Low Range

D2 High Range

% Solids

Variables

% Acids

Variables

D2 Units is one of the following:

ITEMS MEANING

SGU

degTwad

degBrix

degBaum_hv

degBaum_lt

degAPI

Percent_sol_wt

Shows and allows the user to set the density units used for the alternate representation

of the density measurement

Shows and allows the user to set the density value to be mapped to 4ma on the current

loop output, if D2 is selected to control that current loop.

Shows and allows the user to set the density value to be mapped to20ma on the current

loop output, if D2 is selected to control that current loop.

Selecting this takes the user to the % Solids Variables menu

Selecting this takes the user to the % Acids Variables menu

specific gravity

degrees twaddle

degrees brix

degrees baume heavy

degrees baume light

degrees API

percent solids by weight

Density Gage Manual 012407

18

Page 23

ITEMS MEANING

degBall

Percent_StmQual

Percent Acids

degrees balling

percent steam quality

percent acids

% Solids Variables Menu

The % Solids Variables menu is used to configure the parameters associated with the percent of solids measurement. It

contains the following items:

ITEM FUNCTION

Carrier

Solids

Shows and allows the user to set the density of the carrier

Shows and allows the user to set the density of the solids

% Acids Variables Menu

The % Acids Variables menu is used to configure the parameters associated with the percent of acids measurement. It

contains the following items:

ITEM

Algorithm

Parameter A

Parameter B

Parameter C

FUNCTION

Allows the user to select the desired algorithm

Allows the user to adjust the Parameter A value

Allows the user to adjust the Parameter B value

Allows the user to adjust the Parameter C value

Algorithm Menu

The Algorithm menu allows the user to select the calculation associated with the percent of acids measurement.

ITEM MEANING

Linear

Log

Quadratic

positive/negative

None

A (Y) + B

In (Y) + A

A (Y)^2 + B (Y) + C

Not used

Proc Temp Config Menu

The Proc Temp Config menu is used to configure the parameters associated with the process temperature measurement. It

contains the following items:

ITEM FUNCTION

Temp Units

Low Range

High Range

Shows and allows the user to set the units to be used for process temperature

Shows and allows the user to set the temperature value to be mapped to 4ma on the

current loop output, if process temperature is selected to control that current loop.

Shows and allows the user to set the temperature value to be mapped to20ma on the

current loop output, if process temperature is selected to control that current loop.

Temp Units is one of the following:

ITEM MEANING

degC

degF

degR

Kelvin

Density Gage Manual 012407

degrees Celsius

degrees Fahrenheit

degrees Rankine

degrees Kelvin

19

Page 24

Pressure Config Menu

The Pressure Config menu is used to configure the parameters associated with the process pressure measurement. It contains

the following items:

ITEM FUNCTION

Pressure Units

Low Range

High Range

Pressure Units is one of the following:

ITEM MEANING

PSI

Bar

G/Sqcm

Kg/Sqcm

Pa

KPa

atm

Shows and allows the user to set the units to be used for process pressure

Shows and allows the user to set the pressure value to be mapped to 4ma on the

current loop output, if process pressure is selected to control that current loop.

Shows and allows the user to set the pressure value to be mapped to20ma on the

current loop output, if process pressure is selected to control that current loop.

Pounds per square inch

Bar

Grams/square centimeter

Kilograms/square centimeter

Pascal

Kilopascal

Atmosphere

Head Temp Config Menu

The Head Temp Config menu is used to configure the parameters associated with the detector electronics temperature

measurement. It contains the following items:

ITEM FUNCTION

Temp Units

Low Range

High Range

Shows and allows the user to set the units to be used for head temperature

Shows and allows the user to set the temperature value to be mapped to 4ma on the

current loop output, if head temperature is selected to control that current loop.

Shows and allows the user to set the temperature value to be mapped to20ma on the

current loop output, if head temperature is selected to control that current loop.

Alarms

The Alarms menu is used to configure the parameters associated with the analog alarms. This applies to alarms 1-8 as well as the

4-20mA alarm.

ITEM FUNCTION

Alarm Type

Setpoint

Setpoint2

Hysterisis

Alarm Type is one of the following:

ITEM

None

Low

High

Range

Shows and allows the user to set the alarm type

Shows and allows the user to set the alarm set point

Shows and allows the user to set the second alarm set point

Shows and allows the user to set the alarm hysterisis percent

MEANING

Alarm not yet set

Alarm when the source is equal to or lower than Setpoint

Alarm when the source is equal to or higher than Setpoint

Alarm when the source is equal to or lower than Setpoint OR the source is equal

to or higher than Setpoint2

6

6

The second alarm set point is only used when the alarm type is range.

Density Gage Manual 012407

20

Page 25

Hardware Menu

The Hardware menu is used to define the type of hardware used to provide measurements and radiation. It contains the

following items:

ITEM FUNCTION

System Hardware

Proc Temp

Source Type

Pressure

Analog Out Config

HART Output

Com1 Protocol

The System Hardware menu takes the user to a list of the hardware modules in the system and the status of these modules:

ITEM FUNCTION

CPU Card

CPU Status

DIO Card

DIO Status

Slot 3 Card

Slot 3 Status

Slot 4 Card

Slot 4 Status

Slot 5 Card

Slot 5 Status

Slot 6 Card

Slot 6 Status

Slot 7 Card

Slot 7 Status

Slot 8 Card

Slot 8 Status

Display X96-2002

Display Status

HART X96-2005

HART Status

Shows the user the list of hardware modules in the system and the status of these

modules

Shows and allows the user to set the type of device used to read process temperature

Selecting this item takes the user to the Source Type menu

Shows and allows the user to set the type of device used to read process pressure

Shows and allows the user to set the source of power as internal or external

Shows and allows the user to adjust the HART output functions

Shows and allows the user to adjust the Com1 Protocols [None/Hart/Ronan Setup]

Shows the type of CPU card installed (in slot 1)

Status of the CPU card

Shows the type of DIO (Digital Input/Output) card installed (in slot 2)

Status of the DIO card

Shows the type of card (if any) installed in slot 3

If a card is installed in slot 3, shows the status of the card, else shows None

Shows the type of card (if any) installed in slot 4

If a card is installed in slot 4, shows the status of the card, else shows None

Shows the type of card (if any) installed in slot 5

If a card is installed in slot 5, shows the status of the card, else shows None

Shows the type of card (if any) installed in slot 6

If a card is installed in slot 6, shows the status of the card, else shows None

Shows the type of card (if any) installed in slot 7

If a card is installed in slot 7, shows the status of the card, else shows None

Shows the type of card (if any) installed in slot 8

If a card is installed in slot 8, shows the status of the card, else shows None

Shows the type of display module (if any attached)

Shows the status of the display module if attached, or else shows None

Shows the type of the HART interface (if any) present

Shows the status of the HART interface, if the interface is present, else shows None

Proc Temp is one of the following:

ITEM

None

pt100_a_385

pt100_a_392

ni120

0-10 volts

4-20 ma

Density Gage Manual 012407

MEANING

No temperature measurement device configured

Platinum RTD with an alpha of 885 (commonly used in USA)

Platinum RTD with an alpha of 892 (commonly used in Europe)

Nickel RTD

Temperature measurement device that provides a 0 to 10 volt signal

Temperature measurement device that provides a 4-20 ma signal

21

Page 26

Source Type Menu

The Source Type menu is used to define the type of radiation source used. It contains the following items:

ITEM FUNCTION

Source Type

Usr Def Source

Next Reference

Next Wipe Test

Next Shutter

Test

Source Type is one of the following:

Shows and allows the user to set the source type

Selecting this takes the user to the Usr Def Source menu

Shows the date of when the next Reference should be completed

Shows the date of when the next Wipe Test should be completed

Shows the date of when the next Shutter Test should be completed

ITEM

Unknown

co_60

cs_137

am_241

Usr Def

MEANING

Source type not known

Cobalt 60

Cesium 137

Americium 241

Any source type other than the ones listed above OR a source of the nominal type

listed above with a different half-life

Usr Def Source Menu

The Usr Def Source menu is used to define the type of radiation source used. It contains the following items:

ITEM FUNCTION

Name

Half Life

Pressure is one of the following:

ITEM

None

0-10 volts

4-20 ma

Shows, and allows the user to set, the source type name

Shows, and allows the user to set, the source half life

MEANING

No pressure measurement device configured

Pressure measurement device that provides a 0 to 10 volt signal

Pressure measurement device that provides a 4-20 ma signal

Analog Out Config

The analog Out Config menu is used to set where the source of power is. It contains the following items:

ITEM FUNCTION

Loop 1

Loop 2

Loop 3

Power Source

Loops 1-3 contain the following selections:

ITEM FUNCTION

X96S-2005

X96S-2004, chan 1

X96S-2004, chan 2

None

Density Gage Manual 012407

Shows and allows the user to assign a source to Loop 1

Shows and allows the user to assign a source to Loop2

Shows and allows the user to assign a source to Loop 3

Shows and allows the user to set whether the source of power is internal or

external, to power the AO modules outputs

Selecting this will assign the HART card to the desired loop

Selecting this will allow the user to assign channel 1 to the desired loop

Selecting this will allow the user to assign channel 2 to the desired loop

No card selected

22

Page 27

HART Output Menu

The HART Output menu is used to define the type of HART Output desired.

ITEM FUNCTION

X96S-2005

Serial Port 1

None

Selecting this will assign the HART card

Selecting this will allow the user to use Serial Port 1

No HART Output desired

Com1 Protocol Menu

Com1 Protocol contains the following items:

ITEM MEANING

HART HART protocol

Ronan Setup Ronan Setup protocol

HART Menu

The Hardware menu is used to provide information about the HART interface. It contains the following items:

ITEM FUNCTION

Tag Name

MultiDrop

Univ Rev

Spec Rev

Shows and allows the user to set the device tag name

Shows and allows the user to set the multi-drop address for a device (or 0 if the device

is not used on a multi-drop loop)

Shows the HART universal command revision to which this device is conferment

Shows the HART specification revision to which this device is conferment

System Menu

The System menu is used to provide information about the X96S. It contains the following items:

ITEM FUNCTION

Serial #

Hardware Rev

Software Rev

Date

Hour (0-23)

Minute

Password

Date/Time Format

Date/Time Format is one of the following:

ITEM

mm/dd/yy hh:mm:ss

mm/dd/yyyy hh:mm:ss

mm/dd/yy hh:mm:ss

am/pm

dd-mm-yy hh:mm:ss

dd-mm-yyyy hh:mm:ss

dd/mm/yy hh:mm:ss

dd/mm/yyyy hh:mm:ss

Shows the device serial number

Shows the device hardware revision

Shows the device software revision

Shows and allows the user to set the date

Shows and allows the user to set the hour

Shows and allows the user to set the minute

Shows and allows the user to set a password from the main display to allow access to

all menus

Shows and allows the user to set the date/time format used on the status display

MEANING

North American date and 24 hour time

North American Y2K date and 24 hour time,

North American date and 12 hour time with am/pm indication

European date and 24 hour time,

European Y2K date and 24 hour time

European date and 24 hour time

European Y2K date and 24 hour time

Density Gage Manual 012407

23

Page 28

Digital Outputs Menu

This menu is used to view and configure the digital outputs. It contains the following items:

ITEM FUNCTION

Output

Select Sources

Polarity

Select Sources has the following option to assign:

ITEM FUNCTION

Alarm 1 [yes/no]

Alarm 2 [yes/no]

Alarm 3 [yes/no]

Alarm 4 [yes/no]

Alarm 5 [yes/no]

Alarm 6 [yes/no]

Alarm 7 [yes/no]

Alarm 8 [yes/no]

Auto Cal Ref [yes/no]

Auto Cal Err [yes/no]

Ref Prompt [yes/no]

Wipe Test [yes/no]

Shutter Test [yes/no]

Empty Clamp [yes/no]

Detector Flt [yes/no]

System Alarm [yes/no]

Shows and allows the user to select and configure a specific digital output

TTL 1-4)

Selecting this allows the user to assign an array sources to the above digital output

Shows and allows the user to set the above digital output

Allows the user to assign Alarm 1 to the selected digital output

Allows the user to assign Alarm 2 to the selected digital output

Allows the user to assign Alarm 3 to the selected digital output

Allows the user to assign Alarm 4 to the selected digital output

Allows the user to assign Alarm 5 to the selected digital output

Allows the user to assign Alarm 6 to the selected digital output

Allows the user to assign Alarm 7 to the selected digital output

Allows the user to assign Alarm 8 to the selected digital output

Allows the user to assign Auto Cal Ref to the selected digital output

Allows the user to assign Auto Cal Err to the selected digital output

Allows the user to assign Ref Prompt to the selected digital output

Allows the user to assign Wipe Test to the selected digital output

Allows the user to assign Shutter Test to the selected digital output

Allows the user to assign Empty Clamp to the selected digital output

Allows the user to assign Detector Flt to the selected digital output

Allows the user to assign System Alarm to the selected digital output

(Relay 1-4 or

Polarity has the following option to assign:

ITEM FUNCTION

NO/Not Driven

NC/Driven

Open/Not Driven

Allows the user to configure the selected digital output as non-fail safe mode

Allows the user to configure the selected digital output as fail safe mode

Allows the user to force the selected digital output open or not driven (relay deenergized) or driven (TTL not driven) regardless of the state of the source

Closed/Driven

Allows the user to force the selected digital output closed (relay energized) or driven

(TTL driven) regardless of the state of the source

Density Gage Manual 012407

24

Page 29

Relay and TTL Menus

The Relay and TTL menus are used to configure the X96S Relay Outputs and the 4 TTL Outputs. The Relay and TTL menus

show the settings of the corresponding 4 Relay Outputs and 4 TTL Outputs, allowing the characteristics of the outputs to be

changed. Each menu contains the following items:

Output (Cont’d.)

ITEM FUNCTION

Relay 1

Relay 2

Relay 3

Relay 4

TTL 1

TTL 2

TTL 3

TTL 4

Selecting this takes the user to the Relay 1 menu

Selecting this takes the user to the Relay 2 menu

Selecting this takes the user to the Relay 3 menu

Selecting this takes the user to the Relay 4 menu

Selecting this item takes the user to the TTL 1 menu

Selecting this takes the user to the TTL 2 menu

Selecting this takes the user to the TTL 3 menu

Selecting this takes the user to the TTL 4 menu

Digital Inputs Menu

This menu is used to view and configure the digital input(s). It contains the following item:

ITEM FUNCTION

Input 1

Selecting this takes the user to the Input 1 menu

Input 1 Menu

The Input 1 menus (is used to configure the X96S digital input. It contains the following items:

ITEM FUNCTION

Use

Polarity

Use is one of the following:

ITEM

Not Used

Auto Ref

Polarity is one of the following:

ITEM

Low

High

Shows, and allows the user to set, the use of the digital input

Shows, and allows the user to set, the active state of the digital input

MEANING

This digital input is not used

A “true” on this digital input indicates that the X96S should perform the auto reference

procedure

MEANING

A “true” is represented by a low signal on the digital input

A “true” is represented by a high signal on the digital input

Density Gage Manual 012407

25

Page 30

Calibration Menu

This menu is used to view and control the calibration of the X96S Density Gage. It contains the following items:

ITEM FUNCTION

State

Ref Constants

Calibrate

Last Ref Date

Last Ref Time

Loop Config

Aux Loop Cfg

State is one of the following:

Shows the state of the density configuration process

Selecting this takes the user to the Ref Constants menu

Selecting this takes the user to the Calibrate menu

Shows the date on which the gage was most recently Low Referenced.

Shows the time on which the gage was most recently Low Referenced

Selecting this takes the user to the Loop Config menu

Selecting this takes the user to the Aux Loop Cfg menu

ITEM

Uncalibrated

Referenced

Partial Cal

Need Ref Density

Need Cal Density

Fully Calibrated

Invalid Data

MEANING

Needs reference and calibrate or slope.

Needs calibrate or slope

Needs reference or slope

Reference density must be entered

Calibration density must be entered

Calibration complete

Reference and calibrate data is inconsistent

Ref Constants Menu

This menu is used to view and control the reference constants used in the reference and calibration procedures. It contains the

following items:

ITEM FUNCTION

Ref Mode

Calib. Mode

Ref Time

MinRefCnts

MaxRefCnts

Shows and allows the user to set the reference mode

Shows and allows the user to set the Calibrate Mode

Shows and allows the user to set the number of seconds of data to collect for a

reference or calibrate sample

Shows and allows the user to set the minimum raw value to use for a reference or

calibrate sample

Shows and allows the user to set the maximum raw value to use for a reference or

calibrate sample

Ref Mode and Calib. Mode has to be selected to one of the following:

ITEM

Empty

Water

Process

Absorber

Density Gage Manual 012407

MEANING

Nothing (just air) in measuring area.

Measuring area filled with water.

Process material in measuring area (density must be provided).

Absorber placed in radiation path.

26

Page 31

Loop Config Menu

This menu is used to access the primary 4-20ma loop calibration procedures. It contains the following items:

ITEM FUNCTION

PV

Loop test

Damping

D/A trim

The PV menu allows you to select one of the following:

Shows and allows the user to set the variable assigned to the primary 4-20ma current

loop

This invokes a method that performs a test on the primary 4-20ma current loop

Shows and allows the user to set the damping constant for the primary 4-20ma current

loop

This invokes a method that performs the D/A trimming of the primary 4-20ma current

loop

ITEM

D1 Density represented in units that are used locally

D2 Density represented in alternate units

Proc Temp Process temperature

Pressure Process pressure (if available)

Head Temp Head temperature (if available)

Not Assigned Blank line

MEANING

Aux Loop Cfg Menu

This menu is used to access the secondary 4-20ma loop calibration procedures. It contains the following items:

ITEM FUNCTION

SV is

Aux 1 Test

Aux 1 Trim

TV is

Aux 2 Test

Aux 2 Trim

Shows and allows the user to set the variable assigned to the SV (secondary variable)

4-20ma current loop

This invokes a method that performs a test on the secondary 4-20ma current loop

This invokes a method that performs the D/A trimming of the secondary 4-20ma

current loop

Shows and allows the user to set the variable assigned to the TV (the Third Variable)

4-20ma current loop

This invokes a method that performs a test on the TV 4-20ma current loop

This invokes a method that performs the D/A trimming of the TV 4-20ma current loop

Density Gage Manual 012407

27

Page 32

Calibrate Menu

This menu is used to access the various calibration procedures. It contains the following items:

ITEM FUNCTION

Low Reference

High Calibrate

Manual Entry

Clear Ref/Cal

Temp Ref

Pressure Ref

Auto Reference

Low Reference Menu

This menu is used to perform the low reference procedure. It contains the following items:

ITEM FUNCTION

Reference

Ref Density

Ref Cap

High Calibrate Menu

Selecting this takes the user to the Low Reference menu

Selecting this takes the user to the High Calibrate menu

Shows and allows the user to set the density slope value

This invokes a method that clears the density reference

This invokes a method that performs the process temperature calibration

This invokes a method that performs the process pressure calibration

Selecting this takes the user to the Auto Reference menu

This invokes a method that performs the low reference procedure

Shows and allows the user to set the reference density value

Shows the raw captured density counts

This menu is used to perform the high calibrate procedure. It contains the following items:

ITEM FUNCTION

Calibrate

Cal Density

Cal Cap

1/uT

This invokes a method that performs the high calibrate procedure

Shows and allows the user to set, the calibrate density value

Shows the raw captured density counts

Shows the calculated slope value (Same value as in Calibrate Menu, Manual Entry)

Temp Reference Menu

(This menu is ONLY used if the Hardware Menu, Proc Temp value is set for 0-10 volts or 4-20 ma.)

This menu is used to perform the process temperature reference procedure. It contains the following items:

ITEM FUNCTION

Temp LoRef

Temp HighCal

Temp Cal Low

Temp Cal High

Temp Cap Low

Temp Cap High

RTD Slope

RTD Offset

This invokes a method that performs the low temp reference

This invokes a method that performs the high temp calibration

Temperature value during the Temp Lo Ref procedure

Temperature value during the Temp High Cal procedure

Shows the raw captured temperature counts during the low temp reference

Shows the raw captured temperature counts during the high temp calibration

Factory value for RTD Slope

Factory value for RTD Offset

Density Gage Manual 012407

28

Page 33

Pressure Reference Menu

This menu is used to perform the process pressure reference procedure. You will be asked to provide real or simulated pressure

input conditions, and then enters the pressures relating to these conditions. It contains the following items:

ITEM FUNCTION

Pressure Ref

Pres Cap Low

Pres Cap High

This item invokes a method that performs the two point process pressure reference