Page 1

Instructions

and

Operating Manual

SERIES X90

POINT LEVEL MONITORS

POINT LEVEL MONITORS

SERIES X90

Instructions and Operating Manual

Customer’s Name ____________________

Customer’s P.O. No.

__________________

Ronan Job No. ______________________

Page 2

TABLE OF CONTENTS

1.0

General Description .........................................................................................................

2.0

Specifications (Standard) .................................................................................................

3.0

Theory of Operation .........................................................................................................

4.0

Functional Options ...........................................................................................................

4.1

High-Limit Process Alarm ................................................................................................

4.2

Low-Limit Process Alarm .................................................................................................

4.3

Failure Alarm ...................................................................................................................

5.0

Time Delay Options .........................................................................................................

5.1

Relay Contacts ................................................................................................................

6.0

Circuit Description ...........................................................................................................

7.0

Installation and Electrical Connection—General ...............................................................

7.1

Remote Probe X90-1004 ..................................................................................................

7.2

Model X90GPE ................................................................................................................

7.3

Integral Model X90-1005 ..................................................................................................

8.0

Calibration Controls .........................................................................................................

9.0

Calibration—General .......................................................................................................

9.1

Calibration with Process Material .....................................................................................

9.2

Calibration without Process Material ................................................................................

9.3

Time Delay ......................................................................................................................

9.4

Response Time ...............................................................................................................

10.0

Troubleshooting ...............................................................................................................

11.0

Radiation Safety ..............................................................................................................

11.1

Field Intensity Calculation ................................................................................................

11.2

NRC Regulations .............................................................................................................

11.3

Periodic Leakage Test .....................................................................................................

11.4

Radiation Publications .....................................................................................................

11.5

Abandonment and Disposal .............................................................................................

11.6

Prohibition of Operation ...................................................................................................

11.7

Mounting and Start-up .....................................................................................................

11.8

Well Source Holders SA-4, SA-10, SA-15 ........................................................................

11.9

Standard Sources SA-1, SA-8 ..........................................................................................

11.10

Mandatory Reporting .......................................................................................................

12.0

Leak Test Procedures for Sealed Sources ........................................................................

12.1

Ronan Leak Testing Service ............................................................................................

12.2

Using the Leak Test Kit ....................................................................................................

13.0

Parts Lists

X90-1004 or X90-1004X Probe .........................................................................................

X90-301(V) ......................................................................................................................

X90-1005 .........................................................................................................................

14.0

Drawings and Schematics

Schematic—X90-1005 Point Level Monitor ......................................................................

Schematic—X90-301(V) Relay Circuit .............................................................................

Schematic—X90-301(V) Component Layout ....................................................................

Schematic—X90-1004 Driver Board ................................................................................

Outline Drawing—X90-1004 Component Layout Driver Board ..........................................

Outline Drawing—X90-SM/X90-301(V) Interconnect Wiring .............................................

Outline Drawing—X90 Remote G-M Tube Wiring .............................................................

Schematic—X90-301(V) Terminal Arrangement ..............................................................

Outline Drawing—X90 Explosion-Proof Housing ..............................................................

Outline Drawing—Single-Point Chassis Model X90GPE ...................................................

Outline Drawing—X90 Remote Tube Housing ..................................................................

Outline Drawing—Front and Rear Panels, X90 Gamma Switch ........................................

Outline Drawing—NEMA Type 4 Enclosure ......................................................................

2

2

3

3

3

3

3

4

4

4

4

4

4

5

5

5

5

5

5

5

6

6

7

9

10

10

10

10

10

11

12

12

13

13

13

13

14

16

19

20

21

22

22

23

24

25

26

27

28

29

30

Warranty

workmanship under normal conditions of use and service, and will repair or replace any component

found to be defective, on its return, transportation charges prepaid, within one year of its original purchase. this warranty carries no liability, either expressed or implied, beyond our obligation to replace the

unit which carries the warranty.

Ronan warrants equipment of its own manufacture to be free from defects in material and

Page 3

1.0 GENERAL DESCRIPTION

The Ronan Series X90 Point Level Monitor economically

and reliably solves many process problems in which

noise, temperature, abrasive or corrosive conditions

preclude the effective utilization of sonic, capacitative,

float or other techniques. This is a non-contact system.

Normally, a small Cesium-137 radioisotope source is

housed in a lead-filled shielding enclosure known as the

source holder. This holder is equipped with a shuttering

mechanism and the means for containing the radiation

and collimating or directing the radiated energy toward

the sensor, which is directly opposite the source along a

line or level to be measured. Radiation in all directions is

attenuated to a safe value by the lead shielding. The

source holder is mounted on or adjacent to the vessel

whose content it is desired to monitor.

When the source holder shutter is opened, radiant

energy is directed toward the sensor. In the absence of

the process, this sensor sees only a small amount of

radiation but, when the process is present, a large

percentage of this radiation is absorbed. This absorption

of radiation by the process causes a change in the

radiation at the sensor. When this occurs, a relay

contact signals that the level change has been observed.

The passage of radiant energy through the process

causes no contamination and cannot make the process

or container walls radioactive. These systems may be

used anywhere, including the food processing industries.

For most applications, all components of the system are

externally mounted. Therefore, installation is simple and

requires no major mechanical modification or down-time.

The standard Ronan Model X90-301(V) gamma switch

uses Cesium-137 as the source of gamma rays.

Cesium-137 is a 0.66 MEV gamma ray emitter with a

half-life of 30 years. The radioisotope material is sealed

in a double-welded, stainless steel capsule. The source

type and strength (activity) supplied depends on the

individual application, and is printed on the yellow and

magenta caution label affixed to the 3 source holder.

The standard source holder is lead-filled and equipped

with a two-position ON/OFF shutter mechanism. The

handle and shutter mechanism can, by means of a

combination padlock, be securely locked in the OFF

position during shipping, installation, storage or processdown intervals.

Well sources are supplied with actuator rods, which can

be used to extend the source into the vessel or retract

the source into the storage source holder.

CAUTION: Any malfunction of the source holder must

be immediately reported to Ronan Engineering for repair

or replacement of the source holder. Under no

circumstances may the source holder be taken apart.

Should it be necessary to ship the source holder back to

Ronan, contact Ronan Engineering for detailed shipping

instructions.

A Geiger-Mueller tube is used as the sensor for

detecting the gamma radiation. The G-M tube consists

of a gas-filled cylinder with a central anode. The anode

is connected via a high ohmic resistance to a dc voltage

of 500 V. Conduction occurs when the gamma radiation

ionizes the gas in the tube. Each ionizing event

produces a pulse, the rate of these pulses being

proportional to the field strength of the ionizing radiation,

i.e., incident field intensity. The output of the G-M tube

is processed by an electronic circuit in the X90-301(V)

module and the material level is indicated by either an

ALARM or NORMAL signal.

_____________________________________________

2.0 SPECIFICATIONS (STANDARD)

The X90 is a solid-state instrument available in two

designs. The Model X90 Detector with integral

electronics has a combined detector and switch

assembly located at the vessel. The Model X90-1004

Detector with remote electronics module may be fieldlocated or remotely located in a control room

Detector: Integral: Geiger-Mueller tube Remote:

Geiger-Mueller tube

Radiation at Detector: Integral: 0.1 mR/hr min.

Remote: 0.1 mR/hr min.

Detector Housing: Integral: 4” Schedule 40 carbon

steel pipe (type 304 stainless steel also available);

mount to flat plate bracket Remote: Type 304 stainless

steel; explosion-proof housing; mount with conduit clamp

Housing Classifications:

Groups A, B, C, D; Class II, Division 1, Groups E, F, G

Remote: Class I, Division 1, Groups A, B, C, D; Class

II, Division 1, Groups E, F, G

Ambient Temperature Range:

(-40° to 85°C) Remote: -40° to 185°F (-40° to 85°C)

Overall Length: Integral: 20” (50.80 cm) Remote:

8” (20.32 cm)

Approximate Weight:

Remote: 4.4 lbs. (2 kg)

Power: Integral: 115/230 VAC ± 15%, 40/60 Hz

Remote: 115/230 VAC ± 15%, 50/60 Hz

Power Consumption: Integral: 7 watts per alarm

Remote: 7 watts per alarm point

Relay Output: Integral: DPDT 3 A at 30 VDC; 3 A at

120 VAC Remote: DPDT 3 A at 30 VDC; 3 A at 120

VAC

Analog Output: Remote: 0-1 V

Failure Alarm:

Integral: Included Remote: Included

Integral: Class I, Division 1,

Integral: -40° to 185°F

Integral: 37.4 lbs. (17 kg)

Page 4

Time Delay Range:

20 seconds normal); jumper-selectable Remote: .05 to

20 seconds (10 or 20 seconds normal); jumperselectable

Display: Integral: LED status indicator Remote: LED

status indicator

Accuracy: Integral ± 1/8” Remote: ± 1/8”

All equipment approved by CSA.

—————————————————————————

Integral: 0.5 to 20 seconds (10 or

3.0 THEORY OF OPERATION

The Ronan Series X90 gamma switches provide an

alarm signal whenever the radiation field intensity at the

detector (G-M tube) changes by more than its

predetermined value. The variation in the field intensity

may be due to either a change in the level (at the limit),

or a change in the density of the process material in the

radiation beam path. In a typical arrangement, the X90

detects the level of liquid in a vessel when it has

exceeded a predetermined limit. The level limit is

defined by an imaginary straight line drawn from the

source to the detector.

Figure 1: Source and Detector

When the feed valve is open, liquid is fed into the vessel

and the liquid level rises. The liquid level will rise until it

interrupts the gamma ray beam. There is then a change

in the field intensity at the detector due to absorption by

the process of some of the energy present in the beam,

and the instrument puts out an alarm signal in the form

of a relay contact changeover. This signal may be used

to close the feed valve and/or activate an annunciator.

As the liquid is used from the vessel, the level will fall,

thus again exposing the detector to the gamma radiation

and the feed valve will be opened when the contacts

revert to normal.

This is an example of a high limit switch, i.e., the process

level is not allowed to rise above a certain limit.

Conversely, the source and the detector may be lowered

to below the liquid level and the system functions as a

low limit switch, in which case the system will produce an

alarm when the liquid level falls below this low limit. The

liquid itself may be under pressure at high temperature

or even corrosive, but its characteristics will not affect

the switch, since the system components are outside of

the vessel.

A time delay based on the measurement controls the

interval between radiation level change and alarm. A

hysteresis band about the required level prevents

fluttering and spurious alarm situations.

3.1 Optional Gaging Configurations

3.1.1 Model X90-1004 Remote Probe: The Ronan

Model X90-1004 Remote Probe (located on vessel)

with the X90-301(V) switch electronics may be

located in a general purpose or Division II location.

This is the most widely used configuration. The

X90-1004X is a high-sensitivity tube, which may be

specified for very weak fields (0.1 mR/hr. or less).

3.1.2 Model X90-1005 Integral Switch: The

Ronan Model X90-1005 Integral Switch in a Model

X90-1001XP housing is usually specified when the

X90-301(V) switch electronics cannot be located in

a general purpose or Division II area. It may be

used when the vessel is easily accessible for

calibration and maintenance.

The Model X90-1005 contains the G-M tube sensor

and switch electronics on a single chassis and is

mounted on or just off the vessel wall.

—————————————————————————

4.0 FUNCTIONAL OPTIONS

4.1 High-Limit Process Alarm

The Process alarm relay will change over when the

level of process material rises above the set limit.

4.2 Low-Limit Process Alarm

The process alarm relay will change over when the

process level falls below the set limit.

4.3 Failure Alarm

In the case of the high-limit switch, under normal

conditions the G-M tube receives full radiation and

produces an output. This output will fall, producing

an alarm when either the radiation is interrupted by

the process level rising to above the set limit or the

G-M tube or its power supply fails. However, if the

tube or power supply fails, a failure alarm will be

actuated, indicating the problem is in the unit. If

Page 5

the tube output does not indicate a minimum

background value (due to a malfunction in the G-M

tube or its power supply) the process (and failure, if

used) relay automatically changes over, indicating

an alarm condition.

The failure alarm will occur anytime the output from

the tube is zero.

—————————————————————————

5.0 TIME DELAY OPTIONS

The basic time constant is 0.5 seconds to 40 seconds,

depending upon the span setting. Additional time delays

available are 0.1, 5, 10 and 20 seconds.

For most applications, the 0.1 second jumper is used. If

false alarms occur, the time delay should be increased.

The delay is selected by a plug-in jumper located on the

electronics chassis printed circuit board.

5.1 Relay Contacts

Two Form-C (SPDT) contacts are provided.

Contact ratings are 3 A at 30 Ddc or 120 Vac

resistive. Other forms of contacts may be provided

on request.

If both sets of contacts are to be used for the

process alarm relay, jumper A10, B-11 and C-12

(located on the X90-301(V) printed circuit board or

X90-1005 printed circuit board for the integral

version.) For the integral Model X90-1005, 10A

contacts are provided as standard equipment.

If one set of contacts is to be used for a failure

alarm relay, D10, E-11 and F12 are jumpered.

—————————————————————————

6.0 CIRCUIT DESCRIPTION

The X90-301(V) and X90-1005 circuitry consists of a

stabilized ± 12 V and 500 V power supply, a voltage

integrator, comparator and logic alarms.

The output pulses from the G-M tube are fed through an

emitter follower to the input circuit. The pulses are + 12

V, 200 microseconds wide.

The G-M tube output is integrated and amplified by the

input circuit. The zero and span controls are used to

generate a 0 to 1 V output for low to high level

conditions.

This output is monitored using a simple VTOM across

the test points, AMP and TP GRN. A comparator circuit

will trip the relay circuitry at 0.9 V and reset at 0.2 V.

Jumpers on the circuit board are provided to make the

switch function as a high-level or low-level limit alarm.

Complete circuit schematics and wiring diagrams are

provided at the end of this manual.

7.0 INSTALLATION AND ELECTRICAL

CONNECTION—GENERAL

All equipment manufactured by Ronan Engineering is

carefully packaged and shipped to prevent shipping

damage. Any discrepancies between shipping contents

and invoice should be immediately reported to Ronan or

the Ronan representative.

All Series X90 system components (source holder,

integral switch and remote tube assembly) will tolerate

normal industrial vibration. However, in cases where

vibrators are attached directly to the vessel, the system

components must be mounted on adjacent building

framework or use special supports that provide a degree

of isolation.

When the axis of the G-M tube is placed parallel to the

surface of the process material and its side-facing

source, relay contact changeover will be obtained when

the set limit is exceeded by about one-half inch. When a

coarser level limit is appropriate, a broad band of about

five inches can be obtained by placing the detector axis

perpendicular to the surface of the process material. In

either case, an alarm is produced after the tube is

obscured from (or exposed to) the radiation from the

source.

Whenever possible, separate power sources should be

used for the X90 and the alarm circuit. With this

arrangement, the alarm will operate if the power to the

X90 is interrupted (provided, of course, the alarm circuit

has power available).

Local electrical codes must be followed for all wiring. All

conduit entrances should be sealed to prevent

condensed moisture or water from entering the

enclosures. The cable used to connect the remote G-M

tube should also be run through conduit. All explosionproof housing covers must be replaced when the system

is in operation.

7.1 Remote Probe (X90-1004)

The G-M tube with X90-1004 driver board is placed

in an explosion-proof housing. This assembly is

mounted in position at the required level or point of

measurement and connected to the X90-301(V)

module by a four-conductor, shielded cable

supplied by Ronan Engineering.

Refer to drawing number C-1369-K for wiring of the

remote detector assembly and refer to drawing

number C-1359-K for designation of terminals on

the X90-301(V) module.

7.2 Model X90GPE

The X90-301(V) modules are plugged into X90GPE

surface-mount, single chassis enclosures. Access

to input/output and power connections are from the

front, beneath a convenient, snap-on cover.

Connections are located in a separate

compartment of the chassis and removal of the

Page 6

module is not necessary in order to change wiring.

Grommeted holes are provided on the top and

bottom surfaces of the chassis for cable entry and

exit. Overall dimensions are 7.25” high X 4.5” wide

X 5.75” deep (18.42 cm X 11.43 cm X 14.6 cm).

Refer to drawing number C-1359-K for terminal

designations for power wiring and hook-up to the

remote probe driver board.

7.3 Integral Model X90-1005

Refer to drawing A-1697-K for rear-panel input

power wiring connections and relay contact wiring

connections.

—————————————————————————

8.0 CALIBRATION CONTROLS

The following front-panel controls are used in the set-up

procedure.

ZERO CONTROL is used to provide a zero voltage

signal at TP-AMP with the process level below the point

of measurement, under conditions of maximum radiation

at the G-M tube.

SPAN is used to provide a + 1.0 voltage signal at TPAMP when the process level is above the point of

interest, under conditions of no radiation on the G-M

tube.

Three light-emitting diode (LED) DISPLAYS are

provided. These indicators will signal normal and level

alarm for process conditions and failure alarm.

The AMP TERMINAL is the output of the voltage

integrator. This output increases as the radiation on the

tube decreases and vice versa.

Calibration should be attempted only after all system

components have been securely mounted in position and

power and other connections made where required.

Check also that the correct jumpers have been installed

on the X90-301(V) or X90-1005 printed circuit board.

—————————————————————————

9.0 CALIBRATION—GENERAL

The output at the AMP terminal is a measure of level

present at the detector. This reading will be minimum or

near zero when the detector is fully irradiated (no

process) and the maximum or near 1.0 V when there is

process material between the source and the detector.

Therefore, for calibration any option, two voltage

readings are generated: 0.0 V with no process between

the source and the detector and + 1.0 V with process

between the source and the detector.

9.1 Calibration with Process Material

a) Switch on the power to the X90 and turn the

shutter handle on the source holder to the ON

position. Turn the SPAN control clockwise 20

turns; then 10 turns counterclockwise.

b) Lower the process level below the set limit and

adjust the ZERO control so that the AMP terminal

output is zero.

c) Raise the process level above the set limit and

again measure the voltage at the AMP terminal.

d) Adjust the SPAN control to obtain a reading of +

1.0 V at the AMP terminal.

After the switch has been calibrated using the

above method, the operation of the control relay,

NORMAL and ALARM indicators should be

checked by raising and lowering the process level

about the set limit. If all these operate as required,

the switch is considered calibrated.

9.2 Calibration without Process Material

a) Turn the source holder shutter to the ON

position.

b) Turn the SPAN control clockwise 20 turns; then

10 turns counterclockwise.

c) Take voltage reading at the AMP terminal.

Adjust the zero control to obtain an average 0.0 V

reading at the AMP terminal.

d) Turn the source OFF.

e) Adjust the SPAN control for an average + 1.0 V

reading.

f) Turn the source back ON for operation.

9.3 Time Delay

If false alarms occur, increase the time delay by

moving the delay jumpers on the printed circuit

board to a higher value.

9.4 Response Time

The response time of the amplifier is 0.5 to 40

seconds, depending on the SPAN setting.

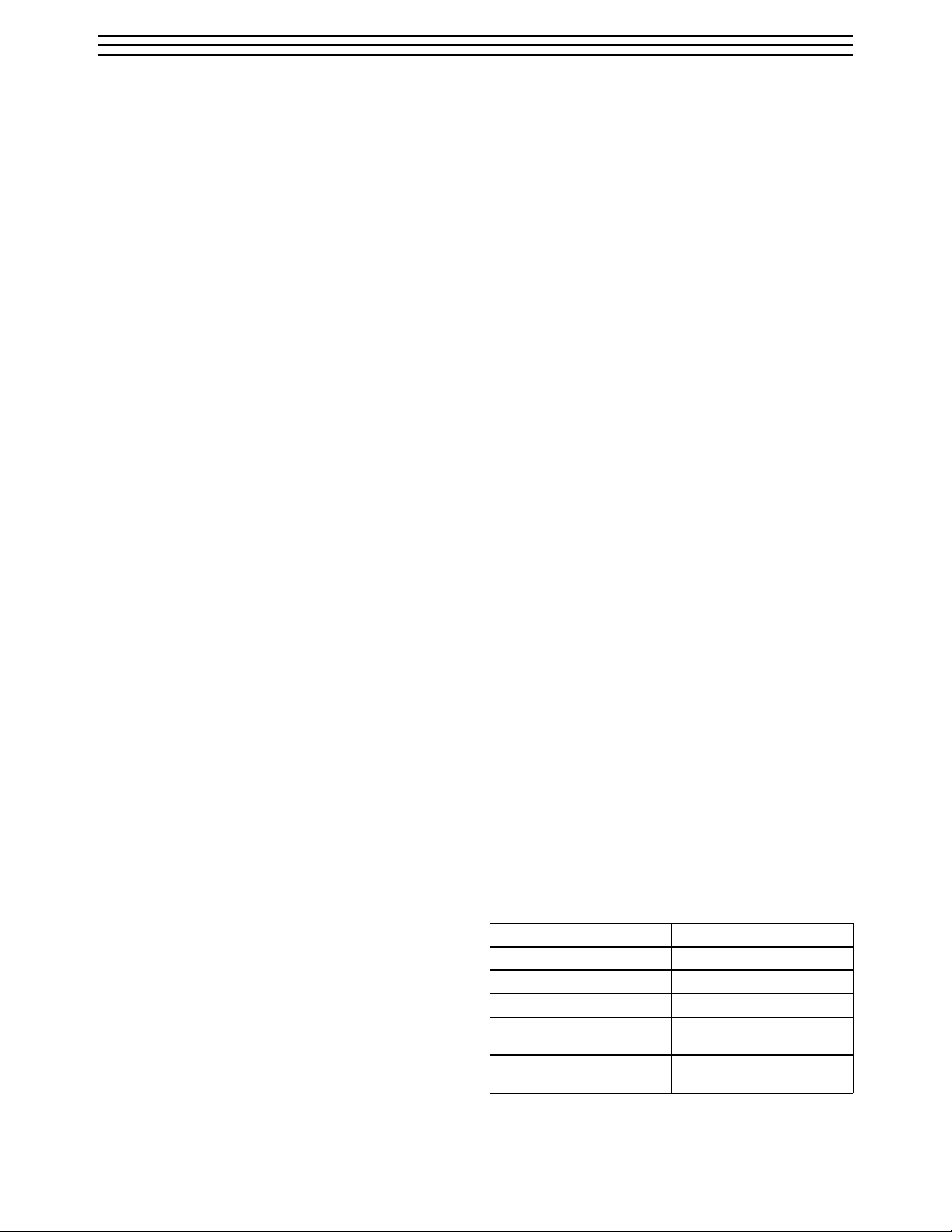

Device

High limit switch

Low limit switch

Process alarm only

Process alarm and failure

alarm

Delays

High and G

Low and G

A-10, B-11, C-12

Failure relay and D-10, E-11,

F-12

Select one: 0.1 sec., 5 sec.,

10 sec., 20 sec.

Install

Page 7

10.0 TROUBLESHOOTING

The X90 is constructed to require the minimum of

maintenance. Operated properly, it should not require

any maintenance for a considerable period of time.

Any necessary troubleshooting should start with the

power supplies. Ronan Engineering suggests that a

voltmeter with a resistance of at least 20 kohm/V be

used for measurement of voltages. Verify that the power

supplies are working before starting with the rest of the

circuitry. The operation of the main circuit may be

checked by adjusting the ZERO control to change the

amplifier voltage at the AMP terminal. Vary the voltage

and check the operation of the relay. Use the circuit

description and circuit schematic D-1357-K or D-1674-K

for reference.

If the relay circuit works properly using the ZERO control,

check the operation of the G-M tube with the source ON

and OFF to see if the tube responds.

For any major faults, we suggest the X90 be returned to

Ronan Engineering for service.

—————————————————————————

11.0 RADIATION SAFETY

The information in this section is intended for specific

licensees. The regulations and instructions pertain to

leak test and other procedures, which specific licensees

are authorized to perform. For general licensees this

section is included for information purposes only.

Most radioactive material used in gaging devices is

regulated by the United States Nuclear Regulatory

Commission (NRC). The NRC issues licenses to users

and manufacturers of gaging devices utilizing radioactive

materials and inspects sites where materials are used to

determine compliance with the terms of the license.

The NRC has issued rules on:

a) instructions to employees (10 CFR part 19);

b) the licensing of radioactive materials and devices (10

CFR part 30); and

c) radiation safety (10 CFR part 20).

During 1962, the NRC began entering into agreements

with individual states to transfer regulatory authority to

them. Known as “agreement states,” their regulations

closely parallel those of the NRC and are essentially

identical, except that the agreement states usually

regulate the use of all radiation-producing devices.

NOTE: Only those individuals specially licensed to

mount, repair, relocate and/or remove the part of the

gage containing the radioactive source may do so. Each

specific licensee should carefully read his particular

license to determine the exact conditions of his license.

Gamma-emitting radioactive material radiates

electromagnetic energy which is similar to light, except

that it readily penetrates opaque materials and is able to

pass through several inches of steel or other dense

material.

The ability to penetrate dense material can be used to

advantage in the measurement of process variables

such as density, level and thickness, where a change in

detected radiation indicates a change in process

variable.

Radiated energy is harmful to the human body when

absorbed at an excessive rate. For example, a glowing

incandescent lamp cannot be held in the hand without

causing severe discomfort or a painful burn. The hand

can be held close to the lamp for seconds, at a few

inches for hours or several feet away continuously. By

use of insulation surrounding the lamp or hand, the lamp

could be held indefinitely without discomfort or injury.

Radioactive energy and radiation is analogous to light

energy and radiation with the radioactive source taking

the place of the incandescent lamp. Permissible human

exposure to a radioactive source is dependent upon:

a) the number of millicuries of radioactive material in the

source (similar to the wattage rating of a lamp);

b) distance from the source;

c) amount of absorber between source and body;

d) amount of portion of the body receiving the radiation.

The term milliroentgen per hour (mR/hr) is a measure of

the radiation field intensity in air. W hen radiation is

absorbed by the body, the term rem or millirem (0.001

rem) is used. This distinction is necessary because not

all radiation affects the body in the same manner. For

gamma radiation, the millirem (mrem) is equal to the

milliroentgen.

The NRC limits the amount of radiation which a person

should receive to 1.25 rem per calendar quarter. This is

an average of about 100 mrem per week.

The 1.25 rem per calendar quarter limitation is a dose at

which there is no possibility of injury. However, since the

use of gamma radiation is relatively new, the history of

injury is not complete. Thus, it is wise to receive as little

radiation as possible. To guard against possible

overexposure and to maintain a record of personnel

routinely exposed to radiation, the NRC requires

monitoring of persons who are apt to receive more than

an average of 25 mrem per week or who are exposed to

a radiation field greater than 100 mr/hr. When personnel

monitoring is required, a record must be kept showing

the dose received. When records are kept, and if an

employee requests it, the employer must furnish a

written report of radiation exposure annually and on

termination of employment.

Page 8

In the majority of Ronan installations, the source is

contained in a lead-filled source holder with an ON/OFF

mechanism. The holder is designed so that the radiation

field is 5 mR/hr or less at a distance of 12 inches from

the surface of the holder when is is in the OFF position.

When the source holder is mounted on the pipe or

vessel and turned to the ON position, the pipe walls,

process material and mounting bracket absorb most of

the radiation. Again, the field intensity is about 5 Mr./hr

at a distance of 12 inches from the surface of the gage.

Thus, a person would have to be within 12 inches of the

gage for 20 hours per week to receive 100 mrem. A

person would have to be within 12 inches of the gage for

five hours per week before he would be required to have

a personnel monitoring device, such as a film badge or a

dosimeter.

Long experience in the nuclear gaging industry with

hundreds of gages, where the source is contained in a

source holder, indicates that the dose received by

operators, maintenance personnel and supervisors

averages less than 25 mrem per week. Thus, for gages

where the source is contained in a source holder, it is

usually not necessary to provide any personnel with

monitors.

Whether or not monitoring devices are needed should be

determined at the gage site at the time of installation in

the form of an occupancy evaluation. Only those

persons specially licensed by the NRC or an agreement

state to install a radioactive device are qualified to make

an occupancy evaluation.

In some installations, it is impossible to mount the source

in a source holder. In these cases the source is usually

mounted in a source well. Installation of the source in

the well should be done as rapidly as possible. All

necessary equipment should be assembled prior to

opening the shipping box containing the source.

A trial installation using a dummy source is

recommended. A dummy source can easily be

fabricated from steel or brass using the outline drawing

of the source supplied by Ronan Engineering. When an

unshielded source is installed in a vessel or when it is

wipe tested, the radiation field is usually greater than 100

mR/hr. Thus, personnel monitoring in the form of film

badges or dosimeters is required. A record of the the

film badge or dosimeter reading must be kept on Form

NRC-5. Since records must be kept, the employer must

furnish to the employee, if requested, a record of the

employee’s radiation exposure annually and on

termination of employment.

Additional precautions are required when a gage is used

on a vessel large enough to permit entry of personnel.

With the source holder in the open position or when the

source is not removed from the source well, the radiation

field intensity inside the vessel can be high. A procedure

must be established so that personnel cannot enter the

vessel until the source holder is in the closed position or

the source is removed from the source well. The use of

padlocks on all man-way and access port covers is

acceptable. The key or combination for the locks should

be kept by the person responsible for radiation safety.

In some cases, when the vessel or pipe is empty, the

radiation field intensity of the outside of the pipe or

vessel will be such that personnel monitoring is required.

For installations using source holders, this problem can

easily be solved by turning the source holder to the OFF

position. For installations using sources in source wells,

where the radiation cannot be turned off, it may be

desirable to remove the source temporarily and return it

to its lead shielded shipping and storage container.

11.1 Field Intensity Calculation

The best method for determining the radiation field

intensity is by measurement with a survey meter.

However, the field intensity can be calculated fairly

accurately without a survey meter.

mCi k

D =

(d)

D = dose rate, mR/hr

mCi = millicurie value of source

d = distance to source in inches

k = constant 0.023 for AM-241

0.5 for CS-137

2.0 for CO-60

Suppose that for a certain installation the estimated

exposure time to the unshielded source is 10

minutes at an average body-to-source distance of

20 inches. The source is 10 millicuries of CS-137.

The dose rate would be:

And the dosage received would be:

2

rate Dose

(20)

dose Total ===

1000 X

10 X 0.5

2

min 10

min/hr 60

The radiation field intensity

can be calculated from:

1000 X

400

5

mr/hr 12.5 1000 X

===

mrem 2.08 mR/hr 12.5

Page 9

Figure 2:

Radiation Transmission CS-137 for Various Materials

9

Page 10

Calculate the radiation field intensity at 12 inches

from the surface of the vessel shown in Figure 3.

Total distance = 12 + 2 + 10 = 24 inches

Dose rate for unshielded source:

10 X 0.5

rate Dose ===

2

(24)

1000 X

476

5

Percent transmission of gamma radiation through

two-inch steel (vessel wall), 0.25-inch source well

wall = .18 X .83 = 0.517. Resultant field intensity =

8.6 X 0.517 = 4.45 mr/hr.

To estimate the dosage received by personnel

working in the vicinity of the source, the occupancy

must be known. Suppose that a man worked 24

hours per week within 12 inches of the vessel. He

would receive a dose in excess of 100 mr. He

would then require a monitoring device.

11.2 NRC Regulations

A current copy of the Title 10 Code of Federal

Regulations, Parts 19, 20 and 30 should be

obtained. These should be read thoroughly to

become familiar with the laws governing the use of

radioactive materials.

a) The “Individual User” listed on the “Application

for By-product Material License” (Form NRC-313) is

responsible for the source. If this person is

transferred or is changed to a position where he is

no longer responsible for the source, the license

must be amended prior to the assignment of the

mr/hr 8.6 1000 X

new user. [30.32, 30.33, 30.34, 30.38]

b) Use of the source is usually licensed for a

particular plant site. If the source is transferred to a

different plant site the license must be amended

prior to the transfer. [30.34 and 30.38]

c) A record of the initial radiation survey must be

kept for reference. [20.40 1 b]

d) Records of the periodic leakage test must be

maintained.

e) A label must be attached to the source holder,

or source well, stating the type and quantity of

radioactive material and the date of manufacture.

The label must bear the conventional radiation

symbol. An NRC-approved label is attached to the

source holder by Ronan Engineering prior to

shipment. For sources in source wells, and NRCapproved tag is placed on the source shipping and

storage contained. [20.203]

SOURCE HOLDER

SOURCE WELL

1/4” WALL

THICKNESS

SOURCE ROD

DETECTOR

SOURCE CS-137

10 MILLICURIE

10.00” 12.00”

304 SS

2” WALL

THICKNESS

Figure 3:

Dosage

Page 11

f) The area in the vicinity of the source must be

posted with a radiation warning sign, if the radiation

field is greater than 5 mr/hr at a distance of 12

inches from the surface of the gage. [20.204a and

20.203]

g) Personnel monitoring is required when personnel

are apt to receive a dose in excess of 23 mrem/wk

or when they enter a radiation field greater than

100 mr/hr. [20.202a]

h) Whenever the source is to be discarded, it must

be returned to Ronan Engineering for proper

disposal. Ronan Engineering must be contacted

for detailed shipping instructions. [20.301a]

i) The regional operations office of the NRC must

be notified of any incident, such as a fire or

explosion, which involves the radioactive material

used in the gage. [20.403] (Ronan Engineering

should also be notified.)

j) If personnel monitoring is required [20.202a], a

record of the radiation exposure must be kept on

Form NRC-5 [20.401a and 20.401c] and, if the

employee requests it, written notification must be

given annually or on termination of employment.

[19.13]

k) If a person receives more than 1.25 rem per

calendar quarter, he must be notified in writing of

the exposure and the NRC must be notified.

[20.405]

l) A restricted area is defined in 10 CRF 20.3A(14)

and the permissible exposure to individuals in a

restricted area is given in 10 CFR 20.101. An

unrestricted area is defined in 10 CFR 20.3A (17)

and the permissible level of radiation in an

unrestricted area is given in 10 CFR 20.105(b).

Any area where an individual, if continuously

present, can receive a dose in excess of 2 mrem in

any one hour or where he can receive more than

100 mrem in any seven consecutive days must be

treated as a restricted area and access thereto be

under the control of the licensee.

m) Employees working in, or frequenting, a

restricted area must be advised of the restricted

area by posting a Form NRC-3 19.11(c). The NRC

regulations state that this form must be posted so

than employees can “observe a copy on the way to

or from their place of employment” in the restricted

area. Thus, Form NRC-3 could be posted at or

near the entry into the restricted area. If personnel

do not work in, or frequent, a restricted area, Form

NRC-3 need not be posted.

11.3 Periodic Leakage Test

Information about the periodic leakage test is

covered in Section 12.

11.4 Radiation Publications

For those who desire further information on

radiation safety and the handling of radioactive

material, the following publications are

recommended:

Radiation Dosimetery, Hine and Brownell

(Academic Press, Inc., 111 Fifth Avenue, New

York, NY 10003)

The following publications and National Bureau of

Standards handbooks are available from the

Superintendent of Documents, Washington, DC

98025:

Number Title

92 Safe Handling of Radioactive Materials

73 Protection Against Radiation from

Sealed Gamma Sources

11.5 Abandonment and Disposal

Abandonment or disposal is prohibited unless

transferred to persons specifically licensed by the

NRC or an agreement state. This means that the

gage cannot be abandoned, sold for scrap, or

placed in the trash bin. If the gage is no longer

needed, it must be shipped to a person or company

specifically licensed by the NRC or an agreement

state to receive the gage for disposal.

11.6 Prohibition of Operation

Operation is prohibited if there is indication of

failure of or damage to shielding or source

containment. If there is any damage to the gage,

or failure of the source rod mechanism, place the

source rod in the OFF position (if possible) and

telephone the field service manager at Ronan

Engineering (606) 342-8500.

Care must be exercised when uncrating the gage.

If the crate is damaged in such a manner that the

gage might be damaged, Ronan Engineering

should be contacted for advice. If the lock is

missing, broken, or not locked, do not uncrate or

mount the gage in position. Call Ronan

Engineering for advice.

11.7 Mounting and Start-up

Anyone may mount the gages in position on the

vessel or pipes, do the electrical wiring, and turn

the electrical power switch ON, if the source holder

is locked in the OFF position.

When mounting the source holder in position, take

the necessary precautions to assure that it is not

dropped or damaged. Refer to the outline drawing

of the source holder in the back of this manual

before mounting it in position.

Only a person specifically licensed by the NRC or

an agreement state is allowed to remove the

source holder from its mounting or to dismantle it.

Page 12

After these preliminary services are performed, a

person specifically licensed by the NRC or an

agreement state must do the start-up of the gage.

This involves unlocking the source holder and

turning it ON; testing for proper operation of the

source holder and position indicator; making the

initial radiation field intensity survey; and initial

testing for leakage of radioactive material. This

specifically licensed person must determine that

the gage is installed in such a manner that

personnel working in the vicinity of the gage will not

receive a radiation dose greater than 0.5 rem/yr.

The gage is shipped from the Ronan factory with

the source holder locked OFF. The combination ill

be given only to the specifically licensed person

performing the start-up and placing the gage in

service.

a copy of the tag attached to the lock follows:

Figure 4: Warning Tag

Device shall be tested for radioactive leakage and

proper functioning of source actuator rod at

installation, at source replacement and thereafter at

no longer than three-year intervals.

11.8 Well Source Holders SA-4, SA-10, SA-15

11.8.1 Source actuator: The actuator should

always move freely. There will be some slight

resistance to movement due to bearing friction of

the gasketed filling, which keeps out moisture and

dirt.

Do not force the source rod actuator.

If a portable radiation survey meter is available, the

radiation field intensity can be measured at the

back of the detector housing. With the source rod

in the STORE position, the field intensity should be

measurable. When the source is placed in the

well, the field intensity should decrease.

11.8.2 Source insertion procedure:

a) Open shutter and pin open with lock pin.

b) Loosen CGB fitting at source rod.

c) Remove handle and attach source extender rod.

e) Push source rod until source bottoms out in

well.

f) Tighten CGB fitting over source extender rod.

11.8.3 Source retraction procedure

a) Loosen CGB filling.

b) Pull source handle back until source rod locates

inside source tube. Source will hit positive stop

inside holder.

c) Push shutter to OFF. Lock with lock pin or

padlock.

d) Remove extender rod.

e) Remove handle from extender rod and attach to

source rod.

11.8.4 Wiping the test points: A wipe test and

radiation survey must be made before the source is

installed onto the vessel wall and before the source

is inserted into the well. The radiation protection

officer (RPO) or licensed personnel must supervise

the installation, source insertion and retraction.

The RPO must also classify the area based on the

radiation survey and personnel occupancy in the

vicinity of the gage.

The RPO must write control procedures for

personnel not to work or occupy the area around

the gage when the process is down, maintenance

on the vessel is performed, or when the vessel is

empty.

Anyone following the instructions of a leak test kit

may perform the wiping procedure, but only a

person or company specifically licensed by the

NRC or an agreement state may do the analysis for

radioactive material.

Using a cotton swab, wipe around the source rod

extending out the top of the source holder and at all

seams as shown in Figure 5. These areas are

most likely to be contaminated if the source leaks.

Do not touch the cotton-tipped end or allow it to

touch other objects, as this would spread

contamination if a leak is present.

After making the wipe test, replace the cotton swab

in the vial with the cotton-tipped end at the bottom.

Replace the cap on the vial, place the vial in the

shipping tube and replace the top on the shipping

tube. Send to: Ronan Engineering Company,

8050 Production Drive, Florence, KY 41042.

Page 13

11.9 Standard Sources SA-1, SA-8

11.9.1 ON/OFF mechanism: To test the ON/OFF

mechanism, move the handle back and forth

several times between the ON and a OFF

positions. The handle should always move freely.

There may be some slight resistance to movement

due to bearing friction.

Do not force the handle.

If a portable radiation survey meter is available, the

radiation field intensity can be measured at points

around the detector housing.

11.9.2 Wiping the test point: Anyone following

the instructions of a leak test kit may perform the

wiping procedure, but only a person or company

specifically licensed by the NRC or an agreement

state may do the analysis for radioactive material.

Using a cotton swab, wipe around the rotor shaft on

the top of the source holder and at all seams, as

shown in Figure 6. These areas are most likely to

be contaminated if the source leaks. Do not touch

the cotton-tipped end or allow it to touch other

objects, as this would spread contamination if a

leak is present.

After making the wipe test, replace the cotton swab

in the vial with the cotton-tipped end at the bottom.

Replace the cap on the vial, place the vial in the

shipping tube and replace the top on the shipping

tube. Send to: Ronan Engineering Company,

8050 Production Drive, Florence, KY 41042.

Figure 5:

Wiping the Test Points (Well Sources)

11.10 Mandatory Reporting

Loss, theft or transfer of this device and failure of or

damage to the shielding or the source containment,

must be reported to the NRC or an agreement

state.

In addition to notifying the NRC or the agreement

state agency, Ronan Engineering should also be

notified, so that proper help can be provided.

If the gage is involved in a fire or explosion, the

area around the gage should be barricaded or

roped-off until the situation can be evaluated by a

specifically licensed person. Telephone Ronan

Engineering at (606) 342-8500.

Figure 6: Wiping the Test Points (Standard

Page 14

12.0 LEAK TEST PROCEDURES FOR

SEALED SOURCES

12.1 Ronan Leak Testing Service

The NRC requires that all sealed sources be tested

for leakage at specified intervals. Only Kr-85,

tritium and certain sources of very small activity (10

CFR 30.18a) are exempted from leak testing.

Ronan Engineering provides for users’ convenience

and safety the “Leak Testing Service.” The leak

testing procedure detailed in these instructions

applies only to the Ronan Model WK Leak Testing

Kit supplied with the Ronan Leak Testing Service.

The Ronan Model WK Leak Testing Kit is intended

for use on all sealed sources that are not exempt

from testing.

This service may be purchased from Ronan on a

contract basis for five years when wipe testing at

six-month intervals is required or on a one-time

basis in the case of three-year wipe test intervals.

The service must be purchased for each individual

source. If the service is retained, Ronan will send

the required number of leak test kits, consisting of:

a) A cotton swab (“Q-tip”) saturated in radiac

wash, contained in a small plastic tube.

b) Special instructions on its use.

c) Leak test forms.

After the sealed sources have been wiped by the

materials, issue a report based on the results and

forward a copy of the results to the customer

immediately.

12.2 Using the Leak Test Kit:

For instructions on using the Leak Test Kit see

section 11.8.4 for well sources or section 11.9.2 for

standard sources.

Return the shipping tube, prepaid, via United

Parcel Services (UPS). Do not send the shipping

tube via conventional mail, as postal regulations

prohibit mailing of radioactive material in this form.

Upon receipt of the wipe, Ronan will perform a

sensitive analysis to determine the presence of

radioactive material. If the wipe is contaminationfree, a notice will be sent via mail that the source is

leak-free. If radioactive material exceeding .005

microcuries is detected on the wipe, an emergency

notification will be sent via telegram or telephone,

advising that the source holder must be taken out

of service and sent back for repair. The emergency

notification will contain detailed instructions for

removal and shipment of source holder.

Ronan will maintain records of each leak test

analysis performed. The records will include the

name and address of the customer; the date the

sample was collected; the individual collecting the

sample; the person performing the analysis; the

date the analysis was performed; the unique

identification of the source being tested; the

radioactive material and mass number contained in

the source; and the results of the test expressed in

PARTS LIST—SERIES X90 POINT LEVEL MONITOR

X90-1004 or X90-1004X Probe

Item

1 1 R1 RC20GF105J Resistor, Carbon, ½ W, 5%, 1.0 Meg Allen-Bradley

2

3

4 1 R4 RC20GF203J Resistor, Carbon, ¼ W, 5%, 20 k Allen-Bradley

5

6 1 R6 RC07GF104J Resistor, Carbon, ½ W, 5%, 100 k Allen-Bradley

7

8

9 1 Q2 2N6725 Transistor, NPN Darlington National

10

11 2

Qty.

1

1

1

1

1

1

ID

R2

R3

R5

C1

Q1

Part No.

RC20GF335J

RC20GF225J

RC20GF183J

DPMS-6D5

2N4392

350-1300-11-07- Terminal Cambion

Description

Resistor, Carbon, ½ W, 5%, 3.3 Meg

Resistor, Carbon, ¼ W, 5%, 2.2 Meg

Resistor, Carbon, ¼ W, 5%, 18 k

Capacitor, 5000 pFd, 600 Vdc

Transistor, N-CH JFET

Circuit Board

Vendor

Allen-Bradley

Allen-Bradley

Allen-Bradley

CDE

National

CCI

Page 15

PARTS LIST—SERIES X90 POINT LEVEL MONITOR

X90-1004 or X90-1004X Probe (continued)

Item

12

Qty.

4

ID

Part No.

350-1246-11-07- Terminal

Description

Vendor

Cambion

13 2

14

15

16

17 1

18 1

19

20

21 1

1

1

1

1

1

A-1106-K Bushing, Mounting Ronan

A-1107-K Bushing, Support Ronan

8404

GM-R-1 or Geiger-Mueller Tube Ronan

PARTS LIST—SERIES X90 POINT LEVEL MONITOR

X90-301(V)

Item

1

2 2 R2,3 RN60C1004 Resistor, Carbon, ½ W, 1%, 1 Meg Allen-Bradley

3 2 R4,5 RN55C2492 Resistor, M.F., ¼ W, 1%, 24.9 k Mepco

4

5 1 R7 RC07GF332J Resistor, Carbon, ¼ W, 5%, 3.3 k Allen-Bradley

6 1 R8 RC07GF562J Resistor, Carbon, ¼ W, 5%, 5.6 k Allen-Bradley

7

8 1 R10 RC07GF101J Resistor, Carbon, ¼ W, 5%, 100 ohms Allen-Bradley

9 1 R11 RN55C3012 Resistor, M.F., ¼ W, 1%, 30.1 k Mepco

10

11

12 2 R13,15 RN55C4993 Resistor, M.F., ¼ W, 1%, 499 k Mepco

13

14 1 R17 RN55C1210 Resistor, M.F., ¼ W, 1%, 121 ohms Mepco

15 2 R18,28 RC07GF472J Resistor, Carbon, ¼ W, 5%, 4.7 k Allen-Bradley

16

17 2 R20,24 RN55C1003 Resistor, M.F., ¼ W, 1%, 100 k Mepco

18 1 R21 RN55C2490 Resistor, M.F., ¼ W, 1%, 249 ohms Mepco

19

20 1 R23 RN55C1001 Resistor, M.F., ¼ W, 1%, 1 k Mepco

21 1 R25 RN55C7502 Resistor, M.F., ¼ W, 1%, 75 k Mepco

22

Qty.

1

1

1

2

ID

R1

R6

R9

R12,16

Part No.

RC32GF913J

RC07GF202J

RN55C8250

89PR10K

1

2

1

1

R14

R19

R22

R26

RN55C3743

RC07GF105J

RN55C4990

68WR10K

Spacer, ¼”, ¾L, 6-32 Thread

Weather-proof box

SST 1” or ¾” Pipe

SST 1” or ¾” Pipe

Aluminum Label

Interconnect Cable, 4 COND/SH

Description

Resistor, Carbon, 1 W, 5%, 91 k

Resistor, Carbon, ¼ W, 5%, 2 k

Resistor, M.F., ¼ W, 1%, 862 ohms

Trim Potentiometer, Cermet, 10 k

Resistor, M.F., ¼ W, 1%, 374 k

Resistor, Carbon, ¼ W, 5%, 10 M

Resistor, M.F., ¼ W, 1%, 499 ohms

Trim Potentiometer, Cermet 10 k

Ronan

Ronan

Ronan

Ronan

Belden

Vendor

Allen-Bradley

Allen-Bradley

Mepco

Beckman

Mepco

Allen-Bradley

Mepco

Beckman

Page 16

PARTS LIST—SERIES X90 POINT LEVEL MONITOR

X90-301(V) (continued)

Item

23

24

25

26 3 R31,32,35 RC07GF680J Resistor, Carbon, ¼ W, 5%, 680 Allen-Bradley

27

28

29 5 C4,7,8,9,10 280AE/A100K Capacitor, Met. Polyester, .1 mfd Phillips

30

31

32 2 C12,13 437ET/G220 Capacitor, Electrolytic, 220 mfd/40 V Phillips

33

34

35 1 C17 344CH/680K Capacitor, Meg. Polycarb., .68 mfd Phillips

36

37 1 C19 199D156X

38

39 2 D1,2 MR250 Diode, Rectifier, HV Motorola

40 2 D10,11 1M200ZS10 Diode, Zener Motorola

41

42 4 D7,8,9,18 1N827A Diode, Reference Zener, 6.2 V Motorola

43 3 D12,13,16 1N457A Diode, General Purpose Fairchild

44

45 1 D15 5082-4650 Light Emitting Diode, Red H.P.

46 1 D17 5082-4550 Light Emitting Diode, Yellow H.P.

47

48 1 Q1 MJE-340 Transistor, NPN Motorola

49 1 Q2 2N3638 Transistor, PNP National

50

51 1 A2 LM307N Operating Amplifier National

52 1 A3 LF355N Operating Amplifier National

53

54

55 1 IC1 7806C Voltage Regulator, 6 V Motorola

56

57 1 IC3 MC14001B Quad 2” NOR Gate Motorola

58 1 IC4 NE555N 555 Timer Signetics

59

60 1 IC6 DS3633N Driver National

61 2 RY1,2 X23DC-24GP Relay, 4 PDT, 24 Vdc Potter &

62

Qty.

3

2

2

2

1

1

2

1

1

4

1

1

1

1

1

2

ID

R27,33,34

R29,30

C1,2

C3,4

C6

C11

C14,15

C16

C18

D3,4,5,6

D14

A1

A4

IC2

IC5

Part No.

RC07GF104J

RC07GF155J

65-DD30-102

280CF/A470K

22263003221

334CH/470K

198D685X

9035K1

719A1GG105K

101SB

UK16-103

0025-DB1

1N4005

5082-4950

LM201AH

LM1458N

7906C

DS3634N

Description

Resistor, Carbon, ¼ W, 5%, 100 k

Resistor, Carbon, ¼ W, 5%, 150 k

Capacitor, .001 mfd/1 kV

Capacitor, Met. Polycarb., .47 mfd/630 V Phillips

Capacitor, 220 pFd

Capacitor, Met. Polycarb., .47 mfd

Capacitor, Tantalum, 6.8 mfd/35 V

Capacitor, Meg. Polyester, 1 mfd/100 V

Capacitor, Ceramic, .01 mfd/16 V

Capacitor, Tantalum, 15 mfd/20 V Sprague

Diode, Rectifier

Light Emitting Diode, Green

Operating Amplifier

Dual Operating Amplifier

Voltage Regulator, 6 V

Driver

Relay Socket

Vendor

Allen-Bradley

Allen-Bradley

Centralab

Phillips

Phillips

Sprague

Mepco

Centralab

Fairchild

H.P.

National

National

Motorola

National

Brumfield

Potter &

Brumfield

Page 17

PARTS LIST—SERIES X90 POINT LEVEL MONITOR

X90-301(V) (continued)

Item

63

64

65

66

67

68 3

69

70

71 1

72

73

74 1

75

76

77 1

78

Qty.

2

1

2

1

1

1

2

1

6

ID

T1

Part No.

1598-102 Test Jack, Red H.H. Smith

1598-103

HLMP-0103 Mounting Clip and Ring, LED H.P.

X90-301

X81-B35

X90-C1348K

461-2871-01-0312

450-3704-01-0300

Description

Relay Holdown

Test Jack, Black

Nuts for Test Jacks

Transformer

Front Panel Ronan

Panel Fastener

Extruded Handle

Engraved Label Ronan

Brackets

Circuit Board

Shorting Plug Cambion

Connector Jack

Vendor

Potter &

Brumfield

H.H. Smith

Tinnerman

MCI Ltd.

Southco

Ronan

Ronan

CCI

Cambion

PARTS LIST—SERIES X90 POINT LEVEL MONITOR

X90-1005

Item

1

2 2 R2,3 RN60C1004 Resistor, Carbon, ½ W, 1%, 1 Meg A.B.

3

4

5 1 R7 RC07GF332J Resistor, Carbon, ¼ W, 5%, 3.3 k A.B.

6

7

8 1 R10 RC07GF101J Resistor, Carbon, ¼ W, 5%, 100 ohms A.B.

9

10

11

12

13 1 R14 RN55C3743 Resistor, M.F., ¼ W, 1%, 374 k Mepco

14

15

16 2 R19 RC07Gf105J Resistor, Carbon, ¼ W, 5%, 10 M A.B.

17

18

19 1 R22 RN55C4990 Resistor, M.F., ¼ W, 1%, 499 ohms Mepco

Qty.

1

2

1

1

1

1

2

ID

R1

R4,5

R6

R8

R9

R11

R12,16

Part No.

RC32GF913J

RN55C2492

RC07GF202J

RC07GF562J

RN55C8250

RN55C3012

89PR10K

Description

Resistor, Carbon, 1 W, 5%, 91 k

Resistor, M.F., ¼ W, 1%, 24.9 k

Resistor, Carbon, ¼ W, 5%, 2 k

Resistor, Carbon, ¼ W, 5%, 5.6 k

Resistor, M.F., ¼ W, 1%, 862 ohms

Resistor, M.F., ¼ W, 1%, 30.1 k

Trim Potentiometer, Cermet, 10 k

Vendor

A.B.

Mepco

A.B.

A.B.

Mepco

Mepco

Beckman

2

1

2

2

1

R13,15

R17

R18,28

R20,24

R21

RN55C4993

RN55C1210

RC07GF472J

RN55C1003

RN55C2490

Resistor, M.F., ¼ W, 1%, 499 k

Resistor, M.F., ¼ W, 1%, 121 ohms

Resistor, Carbon, ¼ W, 5%, 4.7 k

Resistor, M.F., ¼ W, 1%, 100 k

Resistor, M.F., ¼ W, 1%, 249 ohms

Mepco

Mepco

A.B.

Mepco

Mepco

Page 18

PARTS LIST—SERIES X90 POINT LEVEL MONITOR

X90-1005 (continued)

Item

20 1 R23 RN55C1001 Resistor, M.F., ¼ W, 1%, 1 k Mepco

21

22

23

24

25

26 3 R31,32,35 RC07GF680J Resistor, Carbon, ¼ W, 5%, 680 A.B.

27

28

29 1 R39 RC20GF225J Resistor, ¼ W, 5%, 2.2 Meg A.B.

30

31

32 1 R42 RC07GF104J Resistor, ½ W, 5%, 100 k A.B.

33

34

35 5 C5,7,8,9,10 280AE/A100K Capacitor, Met. Polyester, .1 mfd Phillips

36

37

38 2 C12,13 437ET/G220 Capacitor, Electrolytic, 220 mfd/40 V Phillips

39

40 1 C16 719A1GG105K

41

42

43 1 C19 199D156X

44

45 1 C20 453P223-

46

47 2 D10,11 1M200ZS10 Diode, Zener Motorola

48 4 D3,4,5,6 1N4005 Diode, Rectifier Fairchild

49

50 3 D12,13,16 1N457A Diode, General Purpose Fairchild

51 1 D14 5082-4950 Light Emitting Diode, Green H.P.

52

53 1 D17 5082-4550 Light Emitting Diode, Yellow H.P.

54 1 Q3 2N4392 Transistor, N-CH JFET National

55

56 1 Q1 MJE-340 Transistor, NPN Motorola

57 1 Q2 2N3638 Transistor, PNP National

58

59 1 A2 LM307N Operating Amplifier National

60 1 A3 LF355N Operating Amplifier National

61

62

63 1 IC1 7806C Voltage Regulator, 6 V Motorola

Qty.

1

1

3

2

1

1

1

1

1

2

1

1

2

1

1

1

2

4

1

1

1

1

ID

R25

R26

R27,33,34

R29,30

R37

R38

R4

R41

R36

C3,4

C6

C11

C14,15

C17

C18

C21

D1,2

D7,8,9,18

D15

Q4

A1

A4

Part No.

RN55C7502

68WR10K

RC07GF104J

RC07GF155J

RC20GF105J

RC20GF335J

RC20GF203J

RC20GF183J

RC07GF223J

280CG/A470K

22263003221

344CH/470K

198D685X

9035K1

101SB

344CH/680K

UK16-103

0025-DB1

DPMS-6D5

X9400JA3

MR250

1N827A

5082-4650

2N6725

LM201AH

LM1458N

Description

Resistor, M.F., ¼ W, 1%, 75 k

Trim Potentiometer, Cermet 10 k

Resistor, Carbon, ¼ W, 5%, 100 k

Resistor, Carbon, ¼ W, 5%, 150 k

Resistor, ½ W, 5%, 1.0 Meg

Resistor, ½ W, 5%, 3.3 Meg

Resistor, ¼ W, 5%, 20 k

Resistor, ¼ W, 5%, 18 k

Resistor, ½ W, 5%, 22 k

Capacitor, Met. Polycarb., .47 mfd/630 V Phillips

Capacitor, 220 pFd

Capacitor, Met. Polycarb., .47 mfd

Capacitor, Tantalum, 6.8 mfd/35 V

Capacitor, Met. Polyester, 1 mfd/100 V Mepco

Capacitor, Met. Polycarb., .68 mfd

Capacitor, Ceramic, .01 mfd/16 V

Capacitor, Tantalum, 15 mfd/20 V Sprague

Capacitor, 5,000 pFd/600 Vdc

Capacitor, .022 mfd/400 Vdc Sprague

Diode, Rectifier, HV

Diode, Reference Zener, 6.2 V

Light Emitting Diode, Red

Transistor, NPN Darlington

Operating Amplifier

Dual Operating Amplifier

Vendor

Mepco

Beckman

A.B.

A.B.

A.B.

A.B.

A.B.

A.B.

A.B.

Phillips

Phillips

Sprague

Phillips

Centralab

CDE

Motorola

Motorola

H.P.

National

National

National

Page 19

PARTS LIST—SERIES X90 POINT LEVEL MONITOR

X90-1005 (continued)

Item

64 1 IC2 7906C Voltage Regulator, 6 V Motorola

65

66 1 IC4 NE555N 555 Timer Signetics

67 1 IC5 DS3634N Driver National

68

69 2 RY1,2 K10P11D15 Relay, 4 PDT, 24 Vdc Potter &

70

71 2

72

73

74 2

75

76

77 1

78

79

80 2

81

82

83 1

84

85 6

86

87 1

88 1

89

90 1

91 1 F1 MDS-¼ Fuse, ¼ A, Slo-Blo Littlefuse

92

Qty.

1

1

2

1

3

1

1

1

1

2

1

1

1

ID

IC3

IC6

T1

Part No.

MC14001B

DS3633N

1598-102

1598-103

HLMP-0103

X90-301

X90D5 Chassis Ronan

B1615K

X90-B3

10016-B-0256 Handle Amatom

X90-C10

X91-A11

X90-D1316K Circuit Board CCI

461-2871-01-0312

450-3704-01-0300

GM-R-1 or

GM-R-1X

GFT-3 Terminal Strip Curtis

GFT-6 Terminal Strip Curtis

SCU-15D1/4

3420226 Fuse Holder Littlefuse

Description

Quad 2” NOR Gate

Driver

Relay Socket

Relay Holdown Potter &

Test Jack, Red

Test Jack, Black

Nuts for Test Jacks Tinnerman

Mounting Clip and Ring, LED

Transformer

Front Panel

Rear Panel

Bracket

Brackets

Shorting Plug

Connector Jack Cambion

Geiger-Mueller Tube

Connector

Vendor

Motorola

National

Brumfield

Potter &

Brumfield

Brumfield

H.H. Smith

H.H. Smith

H.P.

MCI Ltd.

Ronan

Ronan

Ronan

Ronan

Cambion

Ronan

EDAC

Page 20

Loading...

Loading...