Page 1

Page 2

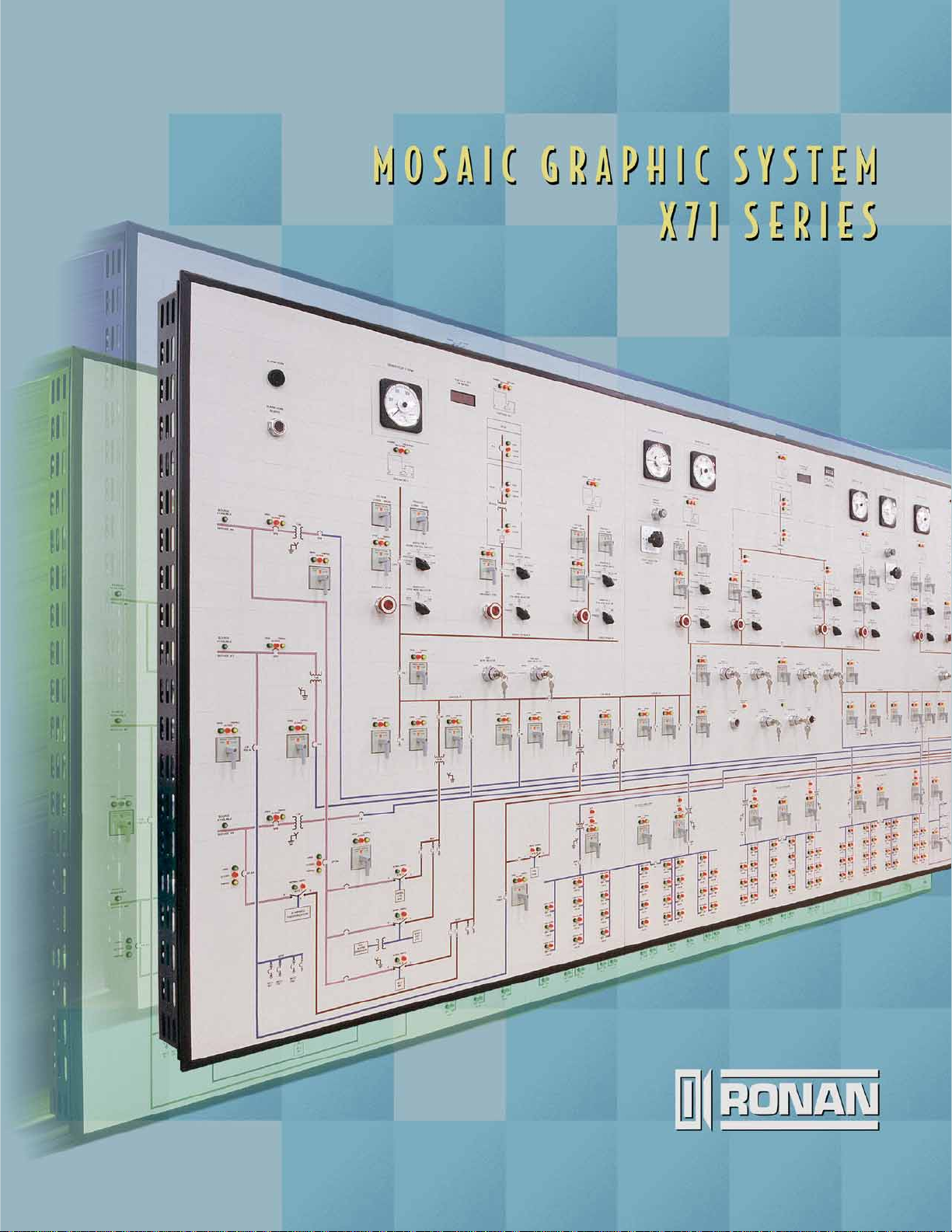

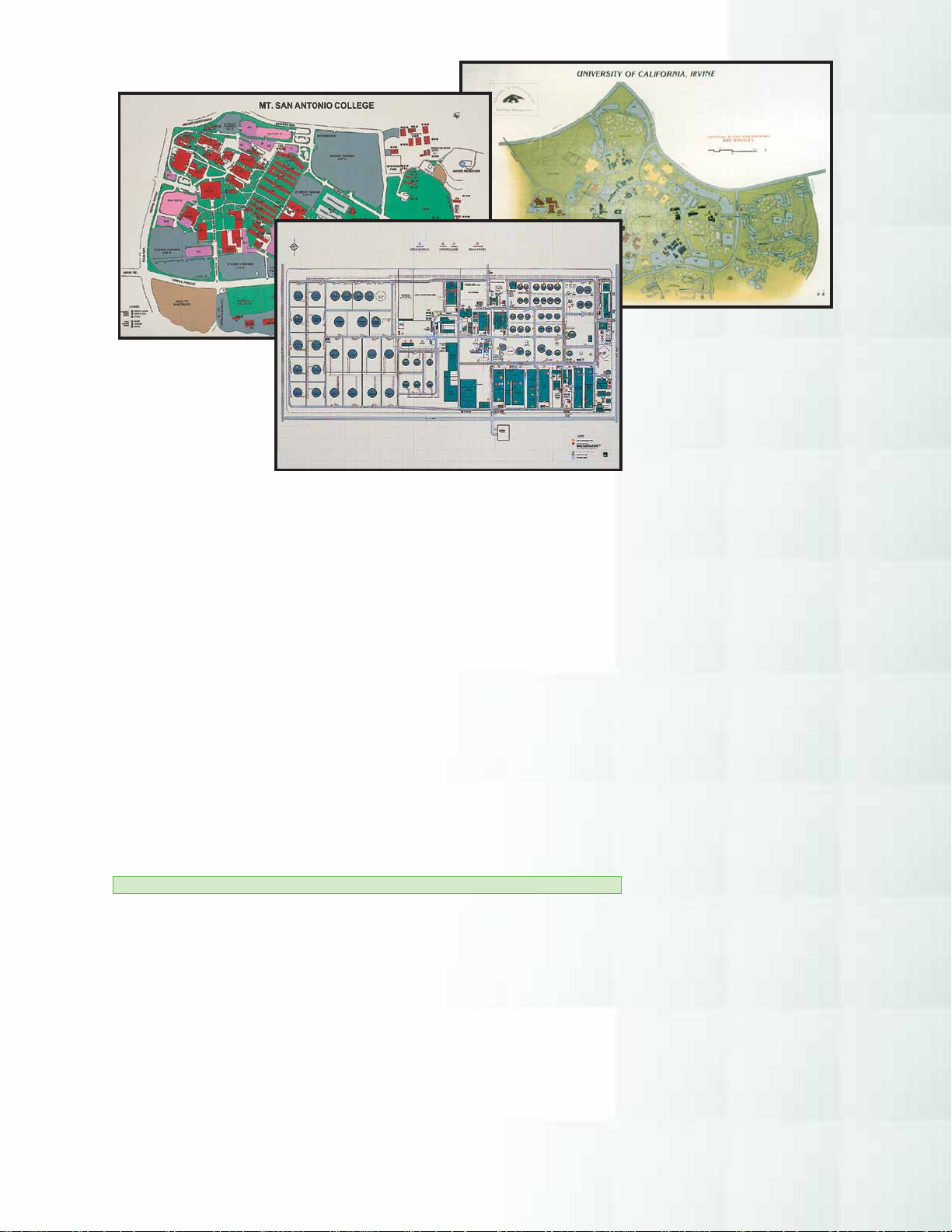

The Ronan Series X71 Mosaic Graphic System is ideally suited for

the graphic display of industrial processes, power distribution networks,

security and fire alarm of buildings in aerial layout, airport runways and

luggage handling facilities, etc. The graphic layout generally includes

status or alarm LED indication, selector and push-button switches,

analog meters, digital and bargraph readouts, annunciators and time

clocks, etc.

The X71 Mosaic Graphic is best suited where applications require

frequent modifications due to plant expansions or process changes.

The surface of the mosaic tiles is silk-screened or engraved with the

customized layout depicting the process or facilities. The panel or wall

mounted graphic provides for a very functional and aesthetically

Plant Security & Fire Alarm Systems

HVAC Systems

Power Plants & Switchyards

Geographical Maps

Industrial Process Plants

Water Treatment & Power Plants

Power Distribution Networks

Information Systems & Data Highway

Gas Distribution Plants

pleasing process or facility annunciator/control system.

Mass Transit & Subway Systems

FEATURES

•High Strength Structural

Mounting Frame

•1″ (25.40 mm) and 2″ (50.80 mm)

Square Tiles

•Multicolor Split Indicators

2

•Conventional and Serial Input

Annunciators

•Smaller and Larger Depth Frames

Available

•Large Number of Colors Available

•Through or Behind Tile Indicators

•Lamp Displays

•Glass Filled Nylon Grid for

Maximum Strength

•Translucent Tiles for Rear-Lit Symbols

•Multifunction Switches and

Push Buttons

•Custom Equipment Integration

•Multicolor Process Lines Outlined

and Non-Outlined

•UL Listed

Three Dimensional Plant Layouts

Airport Luggage Handling Facilities

Material Handling & Conveyor Systems

Emergency Power Switching Systems

Traffic Control Metering

Page 3

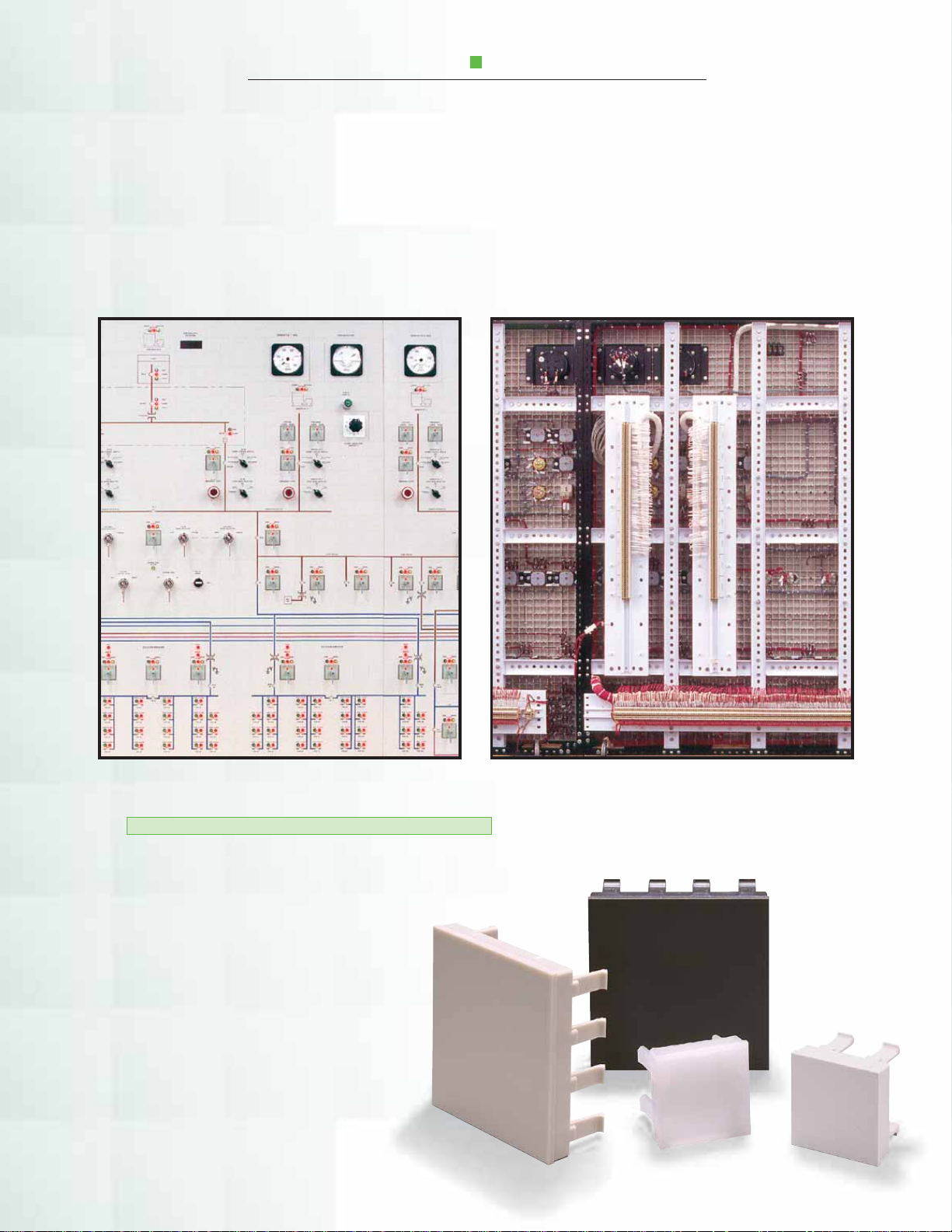

MOSAIC TILES AND GRID

The grid and tile construction allows the highest

flexibility in regard to overall sizing, modification of

display layout and addition or omission of indicators,

control devices, and equipment without the use of

special tools or training. The tile assembly is customized to the specific requirement of an application in

multiples of a single tile size increment. The grid is

supported from the peripheral framework and cross

beam structure for maximum stability. The graphic

assembly is installed through a single panel cutout of

the control panel and secured with clamps provided.

Front View Rear View

TILES AND GRID MATRIX

The high precision 12″ x 12″ (304.80 mm x 304.80 mm)

standard grid is molded from glass-filled nylon 6/6 flameretardant 94V-0 material. The grid is cut in 1″ (25.40 mm)

increments and is assembled to meet size

requirements.

The tiles are molded from polycarbonate

flame-retardant 94V-0 material and are selfextinguishing, highly resistant to ultraviolet

rays, and meet ASTMD648 heat deflection

temperatures of 280° F. The tiles are available

in 1″ x 1″(25.40 mm x 25.40 mm) and

2″ x 2″ (50.80 mm x 50.80 mm). The two

sizes may be mixed on the same grid, with 2″ x 2″

(50.80 mm x 50.80 mm) tiles suitable for larger graphics.

3

Page 4

AUTO RUNNING

MANUAL

M

1600AF

1600AT

ARCHITECTURAL

Mechanical Closet

3

2

1

.1

MOSAIC

200A

PU-801

HI-LO

PRESSURE

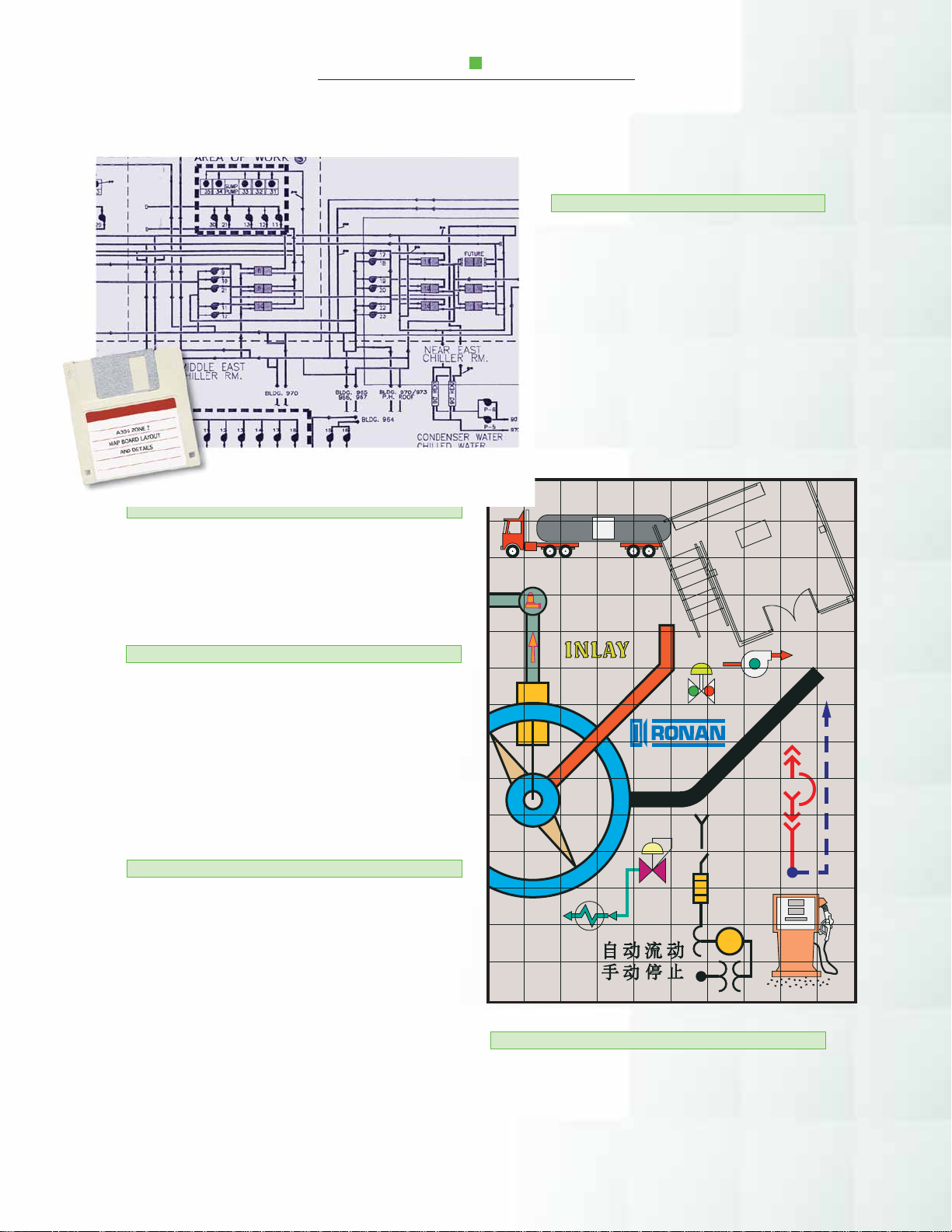

GRAPHIC LAYOUT

LINES

The process line width should be selected based

on the graphic’s overall size and is available outlined

or not outlined (solid). Care should be taken in the

selection of color for contrast in text/process outlines.

DOCUMENTATION

The graphic layout is best transferred via

computer file. If not available, an actual size

drawing will reduce customer approval time

for layouts. Ronan factory personnel will

verify compliance with tile and grid layout

requirements and optional mounting facilities

for special equipment. The customer is requested to select the color for lines, symbols,

and tile background from the color chart.

(See back page)

4

TEXT/LETTERING

The recommended standard lettering style is

gothic, with many other computer generated styles

available. The letters should be sized for easy readability by the operator. Recommended sizes are from

7/16″ (11.11 mm) to 1/2″ (12.70 mm) high. The lettering is centered on symbols or tiles with adjustments

to minimize screening across tile separation.

SYMBOLS AND CUSTOM LOGO

A large number of standard symbols is available.

These can be sized to fit on a single tile or a number

of tiles and placed symmetrically for the best visual

appearance. The standard symbols are available from

Ronan on Auto CAD files to simplify the graphic

layout for the customer. Custom symbols may be generated for specific applications, including customer’s

logo in the graphic layout.

PROTECTIVE COATING

The final graphic display is coated with a nonglare UV resistant acrylic spray for a long-lasting, soil

resistant appearance. The protective coating allows for

cleaning with mild cleaners or soap solution.

Page 5

LIGHTS AND SWITCHES

INDICATOR LIGHTS

All indicator lights utilized are LED type (Light

Emitting Diodes) with current limiting to provide

greater than 100,000 hours of life. The indicators are

available in through-the-tile or behind-the-tile versions.

THROUGH THE TILE

Typical through-the-tile LED indicators are available

in various diameters and light intensity. The size of the

indicators should be based on the size and density of

the graphic. Single or dual color indicators available.

If the customer does not state a preference, Ronan

will select the appropriate type, based on the client’s

application.

BEHIND THE TILE

The Ronan Series X71 LED indicator is a 1″ x 1″

(25.40 mm x 25.40 mm) assembly which attaches to

the grid from the rear behind a translucent tile. The

translucent tile is typically screened with a process

symbol or outline. The X71s are available in single or

multiple colors (up to 3 colors), e.g. green, red or

amber. The three colors are typical for motor or valve

status indication.

PUSH BUTTONS

Push buttons are available in many different sizes

and may occupy a single tile or multiple tiles. The

number of poles and contact ratings are application

based and must be specified by the customer.

Illuminated (LED type) and non-illuminated push

buttons are available with round, square, and rectangular buttons. Momentary or ON/OFF functions with

single or multi-poles are available.

SWITCHES

Proper selection of switches should be made by the

customer based on the application, taking into consideration power requirements, number of poles,

positions (maintain or spring return), actuator (key or

handle), and size. Ronan’s product specialists are

available for technical support.

5

Page 6

ANNUNCIATION AND PROCESS PARAMETER

DISPLAYS

SERIAL INPUT ANNUNCIATORS

The most suitable approach for a larger number

ANNUNCIATORS

The X71 graphic may include conventional

window annunciators mounted into the grid with

special mounting facilities. Due to the annunciators’

inherent heavy weight, there are limitations to their

size. For applications where large numbers of

windows are required, a combination of lamp cabinet,

incandescent or LED type, with remote annunciator

logic is recommended.

of windows or indicators is to utilize the Ronan X110

Serial Input Annunciator Controller driven from a host

such as a PLC, Ronan X120 Field Multiplexer, or an

X500E Sequence of Events Recorder. Each X110

controller provides for 48 outputs with individually

selectable alarm sequence per output. The X110s are

typically mounted in the graphic enclosure or integral

to the rear of the graphic assembly.

DIGITAL/ANALOG METERS AND DISPLAYS

DIGITAL DISPLAYS/BARGRAPHS

Digital Indicators are available in many sizes and

should be selected based on the application. Typical

requirements are AC or DC currents and voltage,

Watt and VAR, frequency, time clock, and process

loop indicators. Typical indicators come with different

size LEDs or LCDs, with any number of digits as

specified by the customer. Digital Indicators typically

span multiple tiles with Ronan providing custom

mounting facilities.

Bargraphs can be utilized as process value indica-

tors with 4-20 mA input and are available with single

or dual channel LED display, with digital indicators

optionally. The bargraphs may be horizontally or

vertically mounted onto Ronan supplied plates.

6

ANALOG DISPLAYS

Analog Meters for specific custom requirements can be supplied. Selection should be

made by the customer with Ronan to supply

special mounting plates sized to the meter’s

dimensions.

Page 7

SPECIFICATIONS

MECHANICAL

The X71 Mosaic Graphic System is assembled from

12″ x 12″(304.80 mm x 304.80 mm) reinforced fiberglass matrix grids to the customer’s specified size. The

assembled grids are mounted into a heavy steel frame

with cross beam support on each corner of each 12″

(304.80 mm) matrix grid. The steel frame is selected

from the two available depths based on the overall size

of the graphic. The accurate panel cutout dimensions

are supplied with the process layout approval drawings

to allow preparation of the control or display panel.

MOUNTING

The X71 graphic assembly is fed through the panel

cutout from the front of the panel and clamped from

the rear with the furnished removable clamp assemblies. The maximum panel thickness allowed with the

standard clamping assemblies is 1″(25.40 mm).

Clearance behind the graphic is based on the depth

of the custom equipment mounted in the graphic as

well as optional termination facilities, connectors, or

serial input annunciators.

3.65"

A Overall

B Cutout

B

Cutout

A

Overall

H Graphic Width

A Overall = Graphic H or W x .0015″ (.0381 mm) + Graphic H or W + 1.50″ (38.10 mm)

B

Cutout

A

Overall

B Cutout = A Overall – .62″ (15.75 mm)

A Overall

B Cutout

(92.71 mm)

H

Graphic

Height

(143.51 mm)

H

Graphic

Height

5.65"

A

A

ELECTRICAL

The indicators, control switches, push buttons,

parameter displays, or other equipment required may

be factory wired to terminals mounted to the rear of

the mechanical structure. The indicators and/or

window type lamp cabinets may be controlled from

conventional solid state alarm logic or X110 Serial

Input Annunciator Controller(s). The X110 may be

integral mounted to the rear of the graphic and factory

wired to the indicators. Optionally, Ronan may provide

multiconductor cables wired to the indicators in the

graphic, and multi-pin connectors for interface to the

remote mounted X110 controllers.

SPECIAL ENCLOSURES

The X71 graphic may be mounted into custom

fabricated enclosures. The enclosures are manufactured

from stainless steel or from cold-rolled steel and

painted to customer specified color. They are sized to

accommodate the graphic, termination facilities and/

or serial input annunciator controllers.

.38" (9.65 mm)

Maximum Thickness

Mounting Panel

Frame

Extrusion

Tile

Grid

H Graphic Width

Mounting Clamp Assembly

Maximum 12.00" (304.80 mm)

Spacing

Detail A

7

Page 8

ORDERING INFORMATION

Color and number selector for symbols and flow lines

100

103

104

106

108

109

114

115

116

117

118

161

162

163

119

120

121

122

123

127

124

125

126

129

130

131

164

165

132

133

134

135

137

138

166

136

139

140

141

142

143

146

144

145

147

150

152

153

154

155

159

160

Complete the information below when

ordering your X71 Mosaic Graphic

Layout Size:

Height ______ Inches ______ (mm)

Width ______ Inches ______ (mm)

Tile Size:

❏ 1″ x 1″ (25.40 mm x 25.40 mm)

❑ 2″ x 2″ (50.80 mm x 50.80 mm)

Tile Color:

❑ Beige ❑ White

❑ Light Gray ❑ Charcoal Gray

Process Layout:

❑ Sketch ❑ Drawing ❑ Auto Cad

❑ 5 Colors or Less ❑ Additional Colors

Indicators:

❑ Through Tile, Number of LEDs _________

❑ Behind Tile, Number of Assemblies ____

(Standard Voltage 24 Vdc, Current 20 mA.

Other Lamp Voltages Available)

Number of Clocks _____________________

Number of Lamp Cabinets _____ Size ______

Number of Annunciators _____ Size _______

❑ Serial Input Annunciator Controller X110

(48 Outputs per Unit)

❑ Terminals: Weidmueller SAK2.5

❑ Terminals with Dual Gating Diodes:

Weidmueller DK4D (Required for Lamp Test)

❑ Analog Display, Model No. ____________

❑ Bargraphs, Model No. _______________

❑ Digital Display, Model No. _____________

Push-Button and Rotary Switches:

Number of Switches ___________________

Number of Poles ______________________

Number of Positions ___________________

Voltage _____ Current Requirement _______

X71 Rev.1 08/01

THREE–YEAR WARRANTY

Ronan warrants equipment of its own manufacture to be free from defects in material and workmanship,

under normal conditions of use and service, and will repair or replace any component found to be defective, on its

return, transportation charges prepaid, within three (3) years of its original purchase. This warranty carries no

liability, either expressed or implied, beyond our obligations to replace the unit which carries the warranty.

RONAN ENGINEERING COMPANY

Display Products Division

21200 Oxnard Street, Woodland Hills, CA 91367 U.S.A. • 800-327-6626 • Fax 818-992-6435

1 Tilley Road, Crowther Industrial Estate, Washington, Tyne & Wear U.K., NE38 OAE • 191-416-1689 • Fax 191-416-5856

32 Bermondsey Road, Toronto, Ontario, Canada M4B 1Z5 • 416-752-0310 • Fax 416-752-8072

http://www.ronan.com E-Mail: sales@ronan.com

Printed in U.S.A.

Loading...

Loading...