Page 1

USER'S MANUAL

Page 2

For the USA

FEDERAL COMMUNICATIONS COMMISSION

RADIO FREQUENCY INTERFERENCE

STATEMENT

This equipment has been tested and found to comply with the

limits for a Class B digital device, pursuant to Part 15 of the

FCC Rules.

These limits are designed to provide reasonable protection

against harmful interference in a residential installation.

This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance

with the instructions, may cause harmful interference to radio

communications.

However, there is no guarantee that interference will not

occur in a particular installation.

If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and

receiver.

- Connect the equipment into an outlet on a circuit different

from that to which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician

for help.

Unauthorized changes or modification to this system can void

the users authority to operate this equipment.

The I/O cables between this equipment and the computing

device must be shielded.

NOTICE

Grounding Instructions

Do not modify the plug provided - if it will not fit the outlet,

have the proper outlet installed by a qualified electrician.

Check with qualified electrician or service personnel if the

grounding instructions are not completely understood, or if in

doubt as to whether the tool is properly grounded.

Use only 3-wire extension cords that have 3-prong

grounding plugs and 3-pole receptacles that accept the tool’s

plug.

Repair or replace damaged or worn out cord immediately.

Operating Instructions

KEEP WORK AREA CLEAN. Cluttered areas and benches

invites accidents.

DON’T USE IN DANGEROUS ENVIRONMENT. Don’t

use power tools in damp or wet locations, or expose them to

rain. Keep work area well lighted.

DISCONNECT TOOLS before servicing; when changing

accessories, such as blades, bits, cutters, and like.

REDUCE THE RISK OF UNINTENTIONAL STARTING.

Make sure the switch is in off position before plugging in.

USE RECOMMENDED ACCESSORIES. Consult the

owner’s manual for recommended accessories. The use of

improper accessories may cause risk of injury to persons.

NEVER LEAVE TOOL RUNNING UNATTENDED.

TURN POWER OFF. Don’t leave tool until it comes to a

complete stop.

For Canada

CLASS B NOTICE

This digital apparatus does not exceed the Class B limits for

radio noise emissions set out in the Radio Interference

Regulations of the Canadian Department of Communications.

KEEP HANDS AWAY WHEN CUTTING TOOL IS IN MOTION.

REGARDEZ BIEN OU VOUS METTEZ LES MAINS LORSQUE

L' OUTIL DE DECOUPE FONCTIONNE.

`

CLASSE B AVIS

Cet appareil numérique ne dépasse pas les limites de la

classe B au niveau des émissions de bruits radio électriques fixés dans le Réglement des signaux parasites

par le ministère canadien des Communications.

ROLAND DG CORPORATIONROLAND DG CORPORATION

ROLAND DG CORPORATION

ROLAND DG CORPORATIONROLAND DG CORPORATION

1227 Ohkubo-cho, Hamamatsu-shi, Shizuoka-ken, JAPAN 432

MODEL NAME : See the MODEL given on the rating plate.

RELEVANT DIRECTIVE : EC MACHINERY DIRECTIVE (89/392/EEC)

EC LOW VOLTAGE DIRECTIVE (73/23/EEC)

EC ELECTROMAGNETIC COMPATIBILITY DIRECTIVE (89/336/EEC)

YEARS OF

MANUFACTURE

WARNING

This is a Class A product. In a domestic environment this product may cause radio interference in

which case the user may be required to take adequate measures.

1996

Page 3

Table of Contents

Thank you very much for purchasing the <Color CAMM> Model PNC-5000.

• To ensure correct and safe usage with a full understanding of this product's performance, please be sure to read through this

manual completely and store it in a safe location.

• Unauthorized copying or transferal, in whole or in part, of this manual is prohibited.

• The contents of this operation manual and the specifications of this product are subject to change without notice.

• The operation manual and the product have been prepared and tested as much as possible. If you find any misprint or error,

please inform us.

Table of Contents

Typographic Conventions ..........................................................................................................................2

To Ensure Safe Use................................................................................................................2

About the Labels Affixed to the Unit ...............................................................2

To Ensure Correct Use .............................................................................................................................2

1 Checking Supplied Items......................................................................................................................3

2 Part Names and Functions ...................................................................................................................3

2-1 Front View .......................................................................................................................................3

2-2 Rear View........................................................................................................................................3

2-3 Operation Panel .............................................................................................................................4

3 Set-up and Connections .......................................................................................................................5

4 What the PNC-5000 Can Do..................................................................................................................5

5 Basic Operation.......................................................................................................................................6

5-1 DIP Switch Settings .......................................................................................................................6

5-2 Powering On ...................................................................................................................................6

5-3 Installing/Removing a Blade.........................................................................................................7

5-4 Installing a Ribbon Cartridge........................................................................................................8

5-5 Loading/Removing the Material...................................................................................................9

5-6 Downloading Printing/Cutting Data .............................................................................................9

5-7 Pausing Operations .................................................................................................................... 10

5-8 Removing and Reloading a Printed Material for Cutting ...................................................... 10

5-9 Cutting Test to Check Cutter Force ...........................................................................................11

5-10 Performing a Self-test .................................................................................................................11

5-11 Powering Off .................................................................................................................................11

6 Printing and Cutting Samples .......................................................................................................... 12

7 About the Printing/Cutting Area....................................................................................................... 13

8 About the Blade.................................................................................................................................... 13

9 Care and Maintenance ........................................................................................................................ 14

10 What to Do If... ...................................................................................................................................... 14

11 Specifications of PNC-5000............................................................................................................... 17

Clipart used this manual is from CorelDRAW

Copyright © 1995 ROLAND DG CORPORATION

TM

1

Page 4

ON

3

2

1

Typographic Conventions / To Ensure Safe Use

This indicates a point requiring particular care to ensure safe use of the product.

Typographic

Conventions

This manual uses typographic conventions

which are outlined at the right.

NOTICE

To Ensure Safe Use

:

Failure to heed this message will result in serious injury or death.

:

Failure to heed this message may result in serious injury or death.

:

Failure to heed this message may result in minor injury.

:

Indicates important information to prevent machine breakdown or

malfunction and ensure correct use.

:

Indicates a handy tip or advice regarding use.

Never disassemble or

modify this product.

Do not allow liquids, metal

objects or flammables

inside the machine.

Fire or breakdown may result.

Handle the power cord with care.

Do not step on or damage the power

cord, or allow heavy objects to be placed

atop it. Failure to heed may result in

electrocution

or fire.

Do not install in an

unstable or high location.

Do not install the machine on

the edge of a table, or it may

fall.

About the Labels

Affixed to the Unit

Ensure the safety of the area

around the platen before

switching on the power.

The carriage moves simultaneously

when the power is switched on.

Handle the blade

with care.

Do not inadvertently

allow the hands, hair, or

necktie near the carriage

while in operation.

When pulling the

power cord from an

electrical socket, be

sure to grip the plug.

Do not place hands

near the platen while

in operation.

These labels are affixed to the body of this product.

The following figure describes the location.

Do not allow the hands near

the platen while in operation.

Rating plate

To Ensure Correct Use

NOTICE

This product is a

precision instrument and

must be handled with

care.

2

NOTICE

Do not install in an area

subject to dust, high

humidity or poor

ventilation.

NOTICE

Do not connect to an AC

outlet that supplies other

than the specified

voltage.

100 V 117 V 220 V

240 V

240 V

NOTICE

When the unit is not in use

for an extended period,

detach the electrical plug

from the AC outlet.

Page 5

1 Checking Supplied Items / 2 Part Names and Functions

1 Checking Supplied Items

Check the following to make sure that you received all the items that were shipped along with the unit.

• Power Cord : 1 • Thermal transfer ribbon cartridge : 1

• Blade (Carbide) : 1 • Blade Holder : 1

• Roller Base : 1 • Cutter Tool : 1

• Material for Test Cuts : 1 • Alignment Tool : 1

• Head Cleaner : 1 • Cleaning Sheet for Printing Head : 1

• Hexagonal Screw Driver : 1 • User's Manual : 1

2 Part Names and Functions

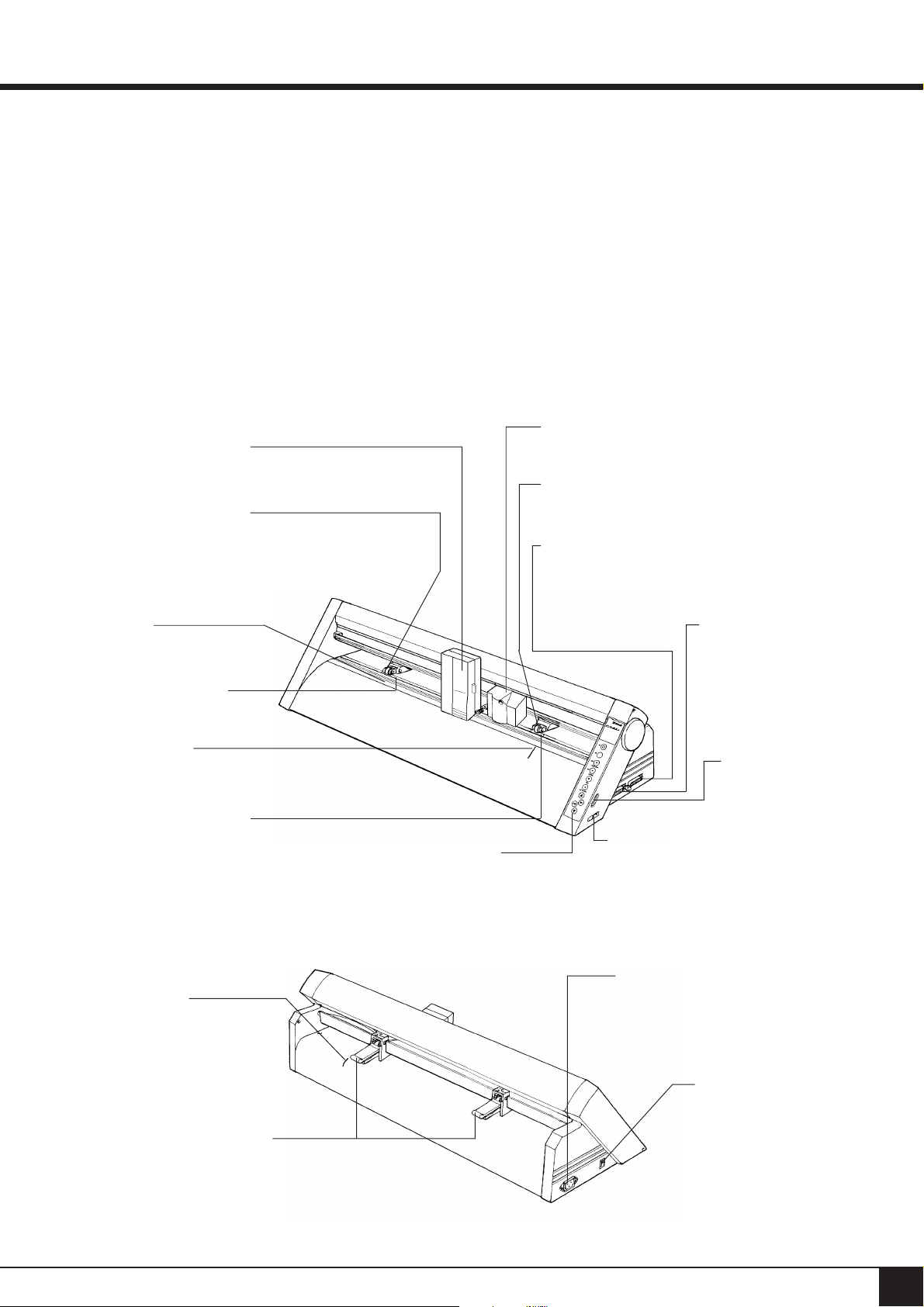

2-1 Front View

Cutting Carriage

Printing Carriage

The ribbon cartridge is mounted here.

Pinch Roller (Left)

Press material against the grit roller. When loading

material, place the left roller inside the left edge of the

material to correctly track it through the machine.

The blade holder is mounted here.

Pinch Roller (Right)

This presses the material against the grit roller.

Serial (RS-232C) Input Connector

In a serial configuration, connect the serial cable here.

This cable carries data to your computer.

Platen

Grit Roller (Left)

Guide Line

Align the material with these lines when loading.

Grit Roller (Right)

2-2 Rear View

Guide Line

Align the material with

these lines when loading.

Operation Panel

Parallel (Centronics)

Input Connector

In a parallel configuration,

connect the parallel cable

here. This cable carries

data to your computer.

DIP Switches

Used to make various

settings.

Cutter Force Control Slider

Sets the down force for the cutting tool.

Power Connector (AC IN)

This connector accepts standard AC

power cord.

Sheet Loading Lever

Used to raise or lower the pinch rollers

when loading or unloading material.

Power Switch

3

Page 6

2 Part Names and Functions

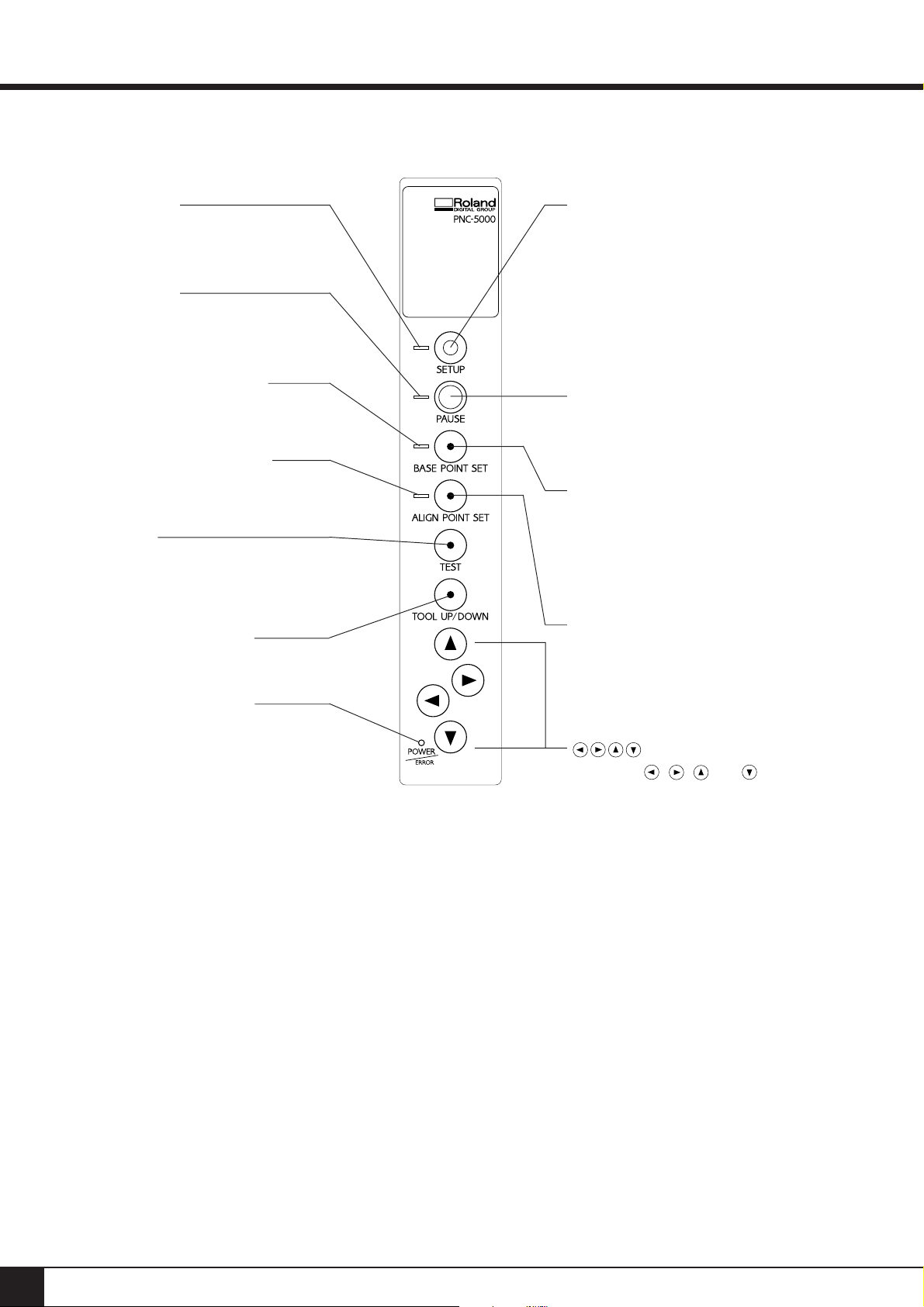

2-3 Operation Panel

SETUP LED

Lights when the SETUP key is pressed.

Operations can be performed when lighted.

PAUSE LED

Lights when the PAUSE key is pressed to stop

the PNC-5000 temporarily.

BASE POINT SET LED

Lights when the base point is set.

ALIGN POINT SET LED

Lights when the align point is set.

TEST Key

Executes a cutting test to check material

characteristics, cut quality, and suitable

pressure for the blade.

TOOL UP/DOWN Key

Moves the tool move up or down.

POWER/ERROR LED

Lights when the power is switched on and

flashes when an error is generated.

SETUP Key

Pressing this key after loading material detects

the position of the pinch rollers and automatically determines the area for printing or cutting.

Also, pressing this key after using the PAUSE

key to temporarily stop an operation in progress

will delete the data that has been sent to the

PNC-5000 from the computer. This key must be

pressed in order to begin printing or cutting.

PAUSE Key

When pressed once, this key temporarily halts

operation in progress. Pressing this key again

releases the paused state.

BASE POINT SET Key

When material has been reloaded, pressing this

key sets the base point (the crop-mark position

at the front-right edge of the material). For

more details, see section “5-8 Removing and

Reloading Printed Material for Cutting.”

ALIGN POINT SET Key

When material has been reloaded, pressing this

key sets the align point (the crop-mark

position at the front-left edge of the material).

For more details, see section “5-8 Removing

and Reloading Printed Material for Cutting.”

(Cursor Keys)

Pressing the , , , and keys causes

the tool or material to move in the specified

direction.

The SETUP LED and POWER/ERROR LED blink simultaneously.

The SETUP LED and POWER/ERROR LED blink simultaneously if material is not loaded correctly. See “5-5 Loading/Removing

Material” for an explanation of how to load material.

The PAUSE LED and POWER/ERROR LED blink simultaneously.

The PAUSE LED and POWER/ERROR LED blink simultaneously if no ribbon cartridge is installed, or if the ink ribbon has run out.

For more details, see “5-4 Installing a Ribbon Cartridge.”

4

Page 7

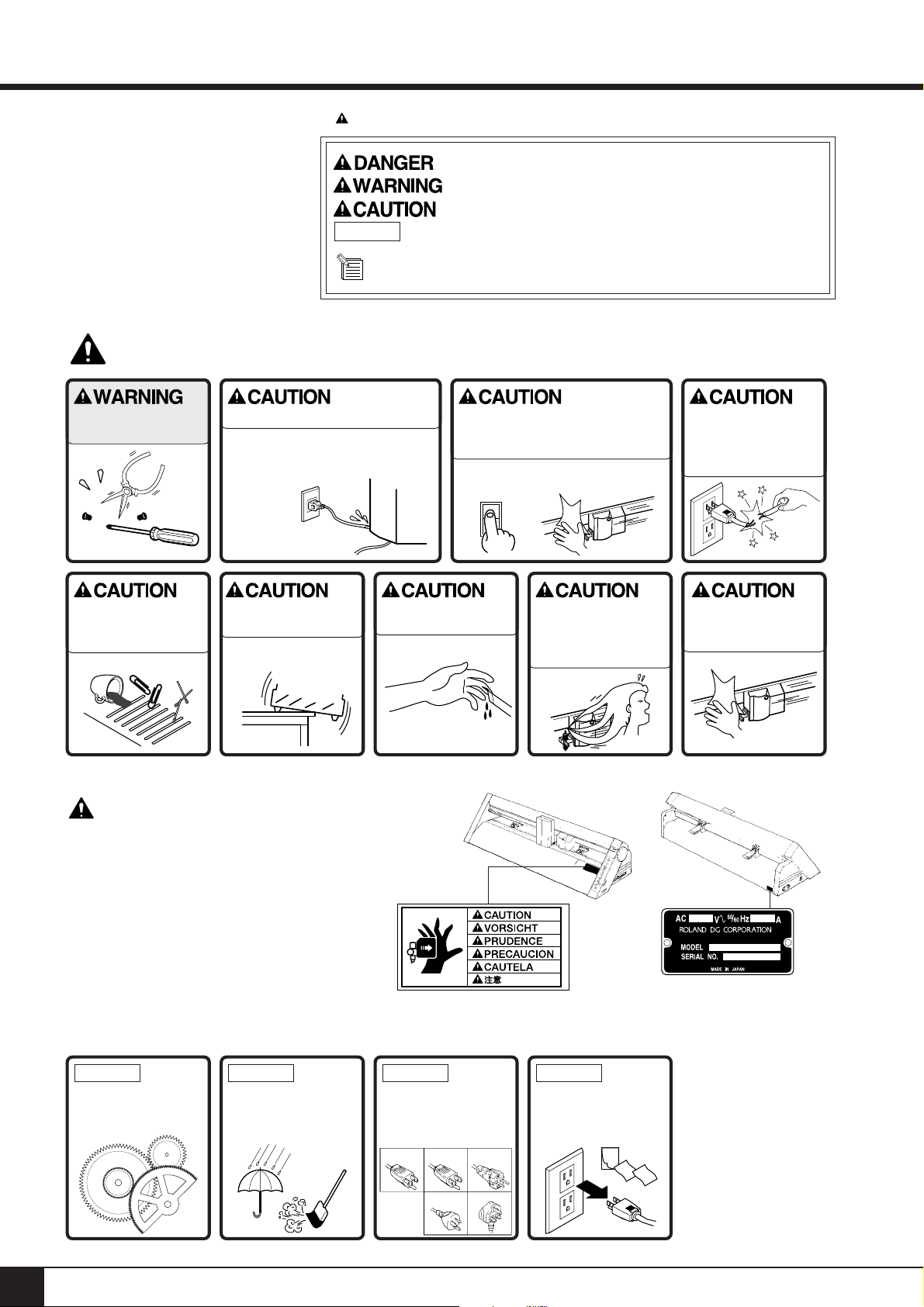

3 Set-up and Connections / 4 What the PNC-5000 Can Do

3 Set-up and Connections

When arranging setup space for the PNC-5000, make sure you have a space that is at least 905 mm (35-11/16") wide, 500 mm (19-11/

16") in depth, and 220 mm (8-11/16") in height. Since the material moves during printing and cutting, make sure the unit is placed on a

stable, sturdy surface. Also make sure there is nothing that can block the material at both front and rear.

NOTICE

• Avoid installing the PNC-5000 in the following conditions, as this may result in damage to the machine.

Avoid places subject to strong electrical noise.

Avoid excessively dusty or damp places.

Never leave the unit in a place that is subject to direct sunlight or extreme temperatures.

Because it is normal for this device to emit heat when in operation, never place it in an area with poor ventilation.

• Do not try to pick up or move the PNC-5000 by grasping the top area of the unit. Be sure to use both hands to grip the PNC-5000

securely on the left and right sides.

• Always make sure that the power is off on both the computer and the PNC-5000 whenever any cables are connected or discon-

nected.

• Ensure that the power supply voltage in within ±10% of the machine's rated voltage.

Cables are available separately. One which you are sure matches

the model of computer being used should be selected.

Serial interface cable

Power outlet

Power

connector

Power cord

Parallel input connector

Serial input connector

Parallel interface cable

Serial connector

parallel connector

4 Here’s What the PNC-5000 Can Do

• Print color graphics on vinyl film and other materials.

• Custom cut vinyl film and other materials.

• Print color graphics on vinyl film and other materials, and then immediately custom cut the material.

or

5

Page 8

5 Basic Operation

5 Basic Operation

5-1 DIP Switch Settings

DIP switch Function OFF ON

SW-1 Baud rate 9600 19200

SW-2 Parity Disable Enable

SW-3 Parity ODD EVEN

SW-4 Handshake Hardwire XON/XOFF

SW-5 Front edge sense Disable Enable

SW-6 Cut sheet mode Disable Enable

SW-7 Blade offset 0.25 0.5*

SW-8 Long output mode Light Heavy

SW-9 Crop mark mode OFF ON

SW-10 (Not Used) ––

* Option required; please consult your dealer.

All DIP switches are set to OFF when shipped from the factory.

The DIP switches are located on the right face of the unit, near the bottom.

SW-1–4 : Sets the communication parameters for a serial connection. When the PNC-5000 is connected to the computer through the

serial port, be sure that the communication parameters for SW-1 to SW-4 are set correctly, matching the computer port

settings.

(Data length is fixed to 8 bits.)

SW-5 : Detects automatically the front edge of loaded material. To detect the front edge of loaded material, set SW-5 to ON (en-

abled).

SW-6 : Detects length of cut material automatically. Switch to ON (enabled) when loading sheet material, and OFF (disabled) when

loading roll material.

SW-7 : Sets the amount of offset for the cutter blade. Set to OFF when using a tool with a blade offset of 0.25 mm, or to ON when

using a tool with a blade offset of 0.5 mm.

SW-8 : Sets the weight of the material. SW-8, which controls the material weight, should normally be set to OFF (light). Cutting

speed slows down when switch is turned ON, but the force used to move the material and the blade increases.

SW-9 : Switch on if wish for crop marks to be printed automatically. Switch off to avoid crop marks.

NOTICE

DIP switches settings must be made only

when the power is turned off.

5-2 Powering On

Press the side of the

switch marked “ | ”.

6

When the power switch is pressed to power on the unit, the

tool carriage moves. Use caution to ensure that your hands or

other objects do not become caught in the moving parts.

Page 9

5-3 Installing/Removing a Blade

NOTICE

Do not touch the tip of the blade. This could impair the cutting performance of the blade.

Installation

5 Basic Operation

1

Adjusting the

Cutter Blade

Blade adjustment may be necessary when:

- cutting material whose carrier paper is thinner than the material itself

- cutting material with no carrier paper

1)

Insert blade into the blade holder until it

snaps into place with an audible click.

Push-pin

Blade holder

Blade

When stock vinyl film is to

be cut, tighten the cap all

the way (2.5 mm (about

0.1") of blade extension).

Gap

Amount of cutter blade

extension: 0 mm

Turn the cap as shown by the

arrow to align the tip of the

blade with the tip of the cap

2

2)Support the tool-securing screw from below and install the blade

holder.

* Insert the blade holder until the collar is flush with the carriage.

Cutting carriage

1) Loosen

Tool-securing screw

Turn the cap as

shown by the arrow

2)

Thickness of the

sheet portion

Turn the cap as

shown by the arrow

3) Tighten

Tighten the cap until

gap is eliminated

Amount of cutter blade

extension: 2.5 mm (about

0.1") (maximum length)

Amount of cutter

blade extension

Thickness of the carrier paper

NOTICE

When cutting is performed after printing, the cap tip of the blade holder may scratch the printed surface. If this is the case,

lengthen the cutter blade extension.

Removal

1

1) Loosen

Leave the tool-securing screw loose. Tightening the screw makes

it more difficult to install the blade holder.

2)Remove the blade holder from

the cutting carriage.

Cutting carriage

Tool-securing screw

2

Blade holder

Blade

If a blade was used, wipe the blade with a soft cloth to

remove any material that may cling to it.

Push-pin

Press the push-pin and

remove the blade from

the blade holder.

7

Page 10

5 Basic Operation

5-4 Installing a Ribbon Cartridge

NOTICE

• A used ribbon cartridge cannot be reused. Do not attempt to turn over and reinstall a used ribbon cartridge, or to rewind the ink

ribbon and reuse the cartridge.

• If a single-color ink ribbon has been used for printing, do not attempt to print overtop of this with a four-color ink ribbon or an ink

ribbon of a different color.

• Before starting to print, make sure that a ribbon cartridge of the desired color has been installed.

2)Install the ribbon

cartridge.

Remove Excess Slack from the Ink Ribbon

The ink ribbon may show some slack when the stopper

has been removed from the ribbon cartridge. If this is the

case, the slack should be taken up before the ribbon

cartridge is installed.

1) Open the

cover.

3) Close the

cover.

Take care to ensure

that the ink ribbon is

not pinched when the

cover is closed.

Printing head

Ink ribbon

Take care to ensure that the

ink ribbon does not catch on

the printing head.

Remove the stopper

Use your finger or a

pen to take up excess

slack in the ink ribbon.

Changing the ribbon cartridge while printing is in progress

1) Press the PAUSE key to stop operation of the PNC-5000.

2) Remove the ribbon cartridge.

3) Install the second ribbon cartridge, then press the PAUSE key again.

The PAUSE LED and POWER/ERROR LED will blink simultaneously.

If the ink ribbon runs out while printing

1) If the ink ribbon runs out during printing, operation stops.

The PAUSE LED and POWER/ERROR LED will blink simultaneously.

2) Remove the old ribbon cartridge.

3) Install a new ribbon cartridge, then press the PAUSE key. (Be sure to install an ink ribbon of the same type as the old one.)

If the PAUSE LED and POWER/ERROR LED blink simultaneously

These two LEDs will blink simultaneously if the ink ribbon has been removed, or if the ink ribbon has been used up.

In this case, remove the old ink ribbon (if one is present) and install a new ink ribbon, then press the PAUSE key.

8

Page 11

5 Basic Operation

5-5 Loading/Removing the Material

Loading the Material

Material with a width (horizontal dimension) of 279.4 mm (11") to 406.4 mm (16") can be loaded.

Any length (vertical dimension) of 110 mm (4-3/8") or more is acceptable.

• The tool carriage moves when the SETUP key is pressed. Take care to ensure that your hands or other objects do not

get caught in the moving parts.

• A soiled material may impair printing accuracy. If dirt or oils from the hand are transferred to the material when it is

loaded, use a cloth moistened with alcohol to wipe the material clean before printing.

NOTICE

Never move the tool carriage by hand. Damage and poor performance may result.

1

1) Lower the sheet loading levers to raise the

pinch rollers.

2) Makes sure the right-hand pinch roller is

positioned above the right-hand grit roller.

If it is not, move the right-hand pinch roller

to the right until the two rollers touch.

3) Pass the material between the pinch rollers

and the grit roller.

* Before attempting to move the pinch roller, be

sure to lower the sheet loading lever.

When using roll material

1) Set the accessory roller base in back of the unit.

2) Pass the end of the material between the pinch rollers and

the grit rollers so that it extends from the front of the unit.

* Place the Roller base parallel to the unit.

2 3

Sheet loading lever

Raise

5) Move the left-hand pinch roller to align

it with the edge of the materials.

Inner side of the material

4) Align with the guide lines

Pull out the length to be used

from the roll material

Roll material

Roller base FrontRear

Press the SETUP key.

The SETUP LED

lights up

Removal

* To remove a portion that has been print or cut on roll material, use the cutter tool included with the PNC-5000.

1 2

The carriages moves to the left edge of

the printing/cutting area.

Press the SETUP key.

Lower

The SETUP LED

goes out

Sheet loading lever

Remove the material.

5-6 Downloading Printing/Cutting Data

The unit will begin printing/cutting when it receives printing/cutting data sent from the computer.

For further details, refer to the user's manual provided with your software.

9

Page 12

5 Basic Operation

5-7 Pausing Operations

If you want to stop the PNC-5000 momentarily while it is printing or cutting, follow the procedure described below.

1 2

The PAUSE LED

lights up

Press the PAUSE key.

Printing or cutting is paused.

To resume printing or cutting

Press the PAUSE key.

The PAUSE LED

goes out

Printing or cutting is resumes.

To Terminate printing or cutting

1) Halt transmission of printing or cutting instructions

from the computer.

2) Press the SETUP key.

The SETUP LED goes out

Printing or cutting instructions already sent

from the computer to the PNC-5000 are

deleted, and operation stops.

5-8Removing and Reloading Printed Material for Cutting

1

Switch off the power,

and set DIP switch

SW-9 to ON.

Switch on the power, load the

2

alignment tool, ribbon

cartridge, and material, then

press the SETUP key.

(The alignment tool is installed

on the cutting carriage in the

same way as a blade holder.)

3

4

Send the printing data from

the computer.

Before data output begins, two crop

marks are automatically printed on the

left and right areas at the front edge of

the material.

When printing is finished press the SETUP key, remove the material and carry

out lamination (or whatever further processing needs to be done).

When done, reload the material in the same position used for printing, and press

the SETUP key. (The SETUP LED goes out.)

Rear

Front

5

2) Set the align point

Use the cursor keys to

move the tip of the

alignment tool to the

square crop mark at the

lower left area of the

material, then press the

ALIGN POINT SET key.

The ALIGN POINT SET LED lights up The BASE POINT SET LED lights up

Rear

Front

1)2)

6

7

When reloading material, be sure to make the settings described above. Crop marks or other marks that have been set with

application software cannot be used.

Remove the alignment tool from the cutting carriage and install a blade.

Send the cutting data from the computer.

NOTICE

1) Set the base point

Use the cursor keys to

move the tip of the

alignment tool to the

square crop mark at the

lower right area of the

material, then press the

BASE POINT SET key.

10

Page 13

5 Basic Operation

5-9 Cutting Test to Check Cutter Force

Before cutting, you may wish to perform a “cutting test” to learn whether the unit cut satisfactorily. If cutting is to be continued on the

same material, there is no need to perform a cutting test.

Move the cutter force control slider all the way to the left (minimum cutter force).

1 2

* Note that an area of approximately 2 square centimeters (a little less than a square inch) is

required to make a test cut.

3

1) First peel off the round section (shaded as shown ).

When it can be peeled by itself, without disturbing the square, the cutter force is set

appropriately.

2) Next, peel off the square, and look at the backing behind it.

The optimum blade pressure is correct if you can clearly make out the lines left by the blade.

Adjust the cutter force control slider until results as shown above are obtained.

(Gradually increase the cutter force until you reach the optimum level.)

Use the , , , and

keys to move the tool

carriage to the position on

the material where the

cutting test is to be executed.

Peel off first

Then peel

this off

Press the TEST key.

Cutting test starts.

Origin (when

using roll material)

5-10 Performing a Self-test

The PNC-5000 is equipped with a “self-test” function to allow you to check whether or not it is capable of operating normally. If the

PNC-5000 is not performing correctly, follow the steps below to perform a self-test.

A computer is not required in order to carry out the self-test.

1

Install a blade and ribbon cartridge

in the PNC-5000.

Performing a cutting test.

3

Load the material, and press the SETUP key.

Operations is normal if the figure shown at below.

2

Hold down the key on the panel

while you turn the power on.

+

5-11 Powering

Off

Press the side of

the switch marked

with “

”.

NOTICE

• Do not switch off the power while the

printing head is lowered. Doing so

may damage the head and impair

printing performance.

• When the unit is not in use, keep the pinch rollers raised. The pinch rollers may be

deformed if left engaged.

• If you do not intend to use the unit for an extended period of time, disconnect the

unit from the power outlet.

Printing head is lowered

PlatenRibbon cartridge

11

Page 14

6 Printing and Cutting Samples

6 Printing and Cutting Samples

Removing the blank space surrounding a picture

Cutting outline

Material

Adding color to a border

Cutting outline

Material

Correcting Line Pitch

Stick

Stick

12

Line pitch: Correct Line pitch is too narrow, and ink

How to Correct Line Pitch

Hold down the SETUP key and switch on the

power.

Pressing the or key changes the pattern

in which the PAUSE LED, BASE POINT SET

LED, and ALIGN POINT SET LED light up.

This pattern indicates the current line pitch.

Use the table at right as a reference to press the

and keys and make the desired linepitch setting. After making the setting, press

the SETUP key (the SETUP LED will light

up). (If material is not loaded, be sure to load

one before pressing the SETUP key.) The

setting that has been made is stored in memory

even after the power is switched off. To

change the setting, simply repeat the procedure

just described.

* Distance accuracy cannot be guaranteed when

line-pitch correction has been performed.

overlaps.

Line-pitch correction:

Set to “Wide” or “Extra Wide”

Line-pitch

correction

LED

Extra wide

Lighted

Dark Dark

display

pattern

Dark Dark Dark

Line pitch is too wide, and spaces

appear between lines.

Line-pitch correction:

Set to “Narrow” or “Extra Narrow”

Default

(

no correction

Blinking

Blinking Blinking

Dark Dark Dark

Lighted

)

NarrowWide

Blinking

Extra narrow

Lighted

Page 15

6 Printing and Cutting Samples / 7 About the

Printing/Cutting Area / 8 About the Blade

Printing with a width of 210 mm or more (using a 4-color ribbon cartridge)

381 mm (15") (maximum printing/cutting width)

210 mm (8-1/4") (length of the ink ribbon)

171 mm (6-11/16")

OK

No good

Ink-ribbon seam

Take steps to ensure that the

printing data does not overlap

with the ink-ribbon seam

7 About the Printing/Cutting Area

Factory default

6.5 mm

(5/16")

25 mm (1") or more

..... Printing/Cutting area

12.5

mm

(1/2")

When DIP switch SW-5 (front

edge sense) is ON (enabled)

Pinch roller (left)Pinch roller (left)

12.5

mm

(1/2")

6.5 mm

(5/16")

25 mm (1")

When DIP switch SW-6 (cut

sheet mode) is ON (enabled)

Pinch roller

(left)

6.5 mm

(5/16")

50 mm (2")

25 mm (1")

110 mm (4-3/8")

12.5

mm

(1/2")

8 About the Blade

If the blade becomes dull

When the blade starts to lose its sharpness, try gradually increasing the cutter force.

Increasing the cutter force temporarily allows the blade to perform better. However, once the blade is dull, it is time to replace it.

or more

Average blade life

The life of a blade varies, depending on the amount of cutting it performs.

The total cutting length can vary considerably, depending on the thickness, toughness, and type of adhesive of the cut material. Set an

appropriate cutter force, one that is well matched to the material and the hardness of the blade. This will extend the life of the blade.

Excessive cutter forces can cause the blade to wear out quickly. Care should be taken.

13

Page 16

9 Care and Maintenance / 10 What to Do If...

9 Care and Maintenance

NOTICE

• Be sure to turn off the power to the PNC-5000 before cleaning.

• Never attempt to oil or lubricate the mechanism.

Cleaning the main unit

For routine cleaning, use a soft piece of cloth.

Cleaning the printing head

NOTICE

Drops of cleaning fluid may spray out when the cap is opened. Hold away from the

platen when opening the cap. The platen may be discolored by any cleaning fluid

that comes in contact with it. (The cleaning fluid is non-toxic.)

Open the cover and remove the ribbon cartridge.

To remove any soiling on the printing head, use a head cleaner included with the PNC-5000.

After cleaning, refer to “5-10 Performing a Self-test” to check operation and make

sure that the PNC-5000 is working correctly.

* If high-quality printing is desired, the printing head should always be kept

clean to prevent buildup of grime.

Printing head

Cleaning the platen

If the platen becomes soiled, wipe it clean with a dry, soft cloth.

Do not wipe with a head cleaner or alcohol.

Use care when cleaning to avoid damaging the surface of the platen. Damage to the platen may impair the accuracy of printing.

10 What to Do If...

If you want to completely stop the operation of the PNC-5000, turn off the power switch.

If the PNC-5000 doesn't run...

Is the PNC-5000 power on? Turn on the power. (See “5-2 Powering On” .)

Is the unit in SETUP status (the

SETUP LED is lit)?

Is the PAUSE LED illuminated? If the PAUSE key has been pressed and the PAUSE LED is lighted, the unit has

PNC-5000

If connected via the serial port, do the

communication parameters for the

PNC-5000 match those of the

computer?

Is the computer set up correctly? Check the following items:

Computer

If the SETUP LED is not illuminated, make sure the material is loaded correctly

and press the SETUP key to illuminate the SETUP LED.

been paused (see “5-7 Pausing Operations” ).

To resume printing or cutting, press the PAUSE key again. The PAUSE LED is

extinguished, and printing or cutting resumes.

To terminate printing or cutting, first stop the transmission of printing or cutting

instructions from the computer to the PNC-5000. Then press the SETUP key.

This deletes the printing or cutting instructions that have already been sent from

the computer to the PNC-5000, and printing or cutting is stopped.

If operation is still not correct when the next batch of data is sent after printing or

cutting, or cutting has been stopped, switch the power off and then on again.

Set the DIP switches correctly (see “5-1 DIP Switch Settings” .)

• DIP switches • Memory switches • Interface board

• Communication parameters • Other settings

Read the computer user’s manual and set it up correctly.

14

Page 17

10 What to Do If...

Are the computer and the PNC-5000

linked with the right cable?

Is the cable making a secure connection?

Connection cable

Is the OS set up correctly? Check the following items:

Are the application software settings

correct?

Software

Are the settings for the driver software

correct?

The type of cable you need is determined by your computer and the software you

are using. Even if the computer is the same, running different software may require

a different cable. Use the cable specified in your software.

Connect securely. (See “3 Set-up and Connections” .)

• Output port selection • Output device selection

• Output port open • Communication parameters

• Other settings

Check the OS user’s manual and set it up correctly.

Check the following items:

• Output device specifications (select a device name that matches the instruction system. If the wrong device is selected an incorrect instruction may be

output, resulting in an error).

• Communication parameters • Other settings

Check the software user’s manual and set it up correctly.

If you are using driver software for output on the PNC-5000, then make the

settings for the correct driver in the computer. Select the PNC-5000 as the output

device.

Clean, attractive printing is impossible

Clean the printing head (see “9 Care and Maintenance”).Is the printing head dirty?

NOTICE

If cleaning will not improve the printing quality, the printing head might

reach to the end of its life.

Contact your dealer for replacement of the printing head.

Is the surface of the platen dirty or

scratched?

Is the material dirty? Remove superficial soiling, then load the material.

Is the material damaged?

Clean the platen (see “9 Care and Maintenance”).

Clean, attractive printing is not possible if the material is damaged or warped.

Use care to keep materials from being damaged while in storage.

The Material is not cut properly

Are the blade and blade holder installed

correctly and securely?

Is the blade chipped? If it is, replace it with a new one (see “5-3 Installing/Removing a Blade” ).

Check if there are any dirty deposits on the

blade.

Make sure you are using an appropriate

cutter force setting.

Install these so that there is no looseness (see “5-3 Installing/Removing a Blade” ).

If dirty, remove and clean the blade.

Perform a “cutting test,” then adjust the cutter force slider as necessary to obtain

the optimum cutter force (see “5-9 Cutting Test to Check Cutter force”).

When cutting a thick material, set DIP switch SW-7 to ON (heavy). (See “5-1 DIP Switch Settings” .)

15

Page 18

10 What to Do If...

The material slips away from the pinch rollers during operation

Are the sheet loading levers on both the

left and right sides raised?

Make sure the material is parallel with the grit roller.

If the front edge of the material rests at an angle, cut off the odd-shaped part to make it straight. Then align it so that it is parallel with

the grit roller.

If the material is to be advanced over a long distance, moving the movable pinch roller inward slightly can help prevent the material

from becoming dislodged. Also, after loading the material, it is recommended that you carry out an alignment test by using the

key to advance the material by the amount that will be used for printing or cutting. Make sure that the material travels correctly

through the machine.

If roll material is used, print or cut only after first pulling out the amount of material that is to be used. The PNC-5000 is not designed

to pull material off rolls.

Make sure that the left and right edges of the material do not touch the inner surfaces of the PNC-5000 during operation. Such contact

may damage the material, and could also make it impossible to advance the material–thus causing it to slip.

If a sheet loading lever has not been raised, then the material has not been secured

in place. Make sure that the pinch rollers on the left and right sides are within the

boundaries of the material, and raise the sheet loading levers. (See “5-5 Loading/

Removing the Material” .)

The POWER/ERROR LED is blinking

Are the application software settings

correct?

Check the following items:

• Output device specifications (select a device name that matches the instruction system. If the wrong device is selected an incorrect instruction may be

output, resulting in an error).

• Communication parameters • Other settings

Check the software user’s manual and set it up correctly.

If connected via the serial port, do the

communication parameters for the PNC5000 match those of the computer?

Set the DIP switches correctly (see “5-1 DIP Switch Settings” .)

PAUSE LED and POWER/ERROR LED blink simultaneously

Is the ribbon cartridge installed correctly? Install the ribbon cartridge correctly on the printing carriage (see “5-4 Installing a

Ribbon Cartridge”).

Has the ink ribbon been used up? If there is no more ink ribbon left for printing, replace the ribbon cartridge with a

new one (see “5-4 Installing a Ribbon Cartridge”).

SETUP LED and POWER/ERROR LED blink simultaneously

Is the material loaded correctly?

Does the front of the material stick out to

the front surface of the PNC-5000?

Is the length of the loaded material too

short?

Load the material correctly (see “5-5 Loading/Removing the Material”).

16

Page 19

B3010896BE R3-1

Loading...

Loading...