A

GPIO ICs

Keyencoder IC

BU1852GUW

No.11098EAT04

●Description

Keyencoder IC BU1852GUW can monitor up to 8x12 matrix (96 keys), which means to be adaptable to Qwerty keyboard.

We adopt the architecture that the information of the only key which status is changed, like push or release, is encoded into

the 8 bits data. This can greatly reduce the CPU load which tends to become heavier as the number of keys increase.

(Previously, all key's status is stored in the registers.) When the number of keys is small, the extra ports can be used as

GPIO. Furthermore, auto sleep function contributes to low power consumption, when no keys are pressed. It is also

equipped with the various functions such as ghost key rejection, N-key Rollover, Built-in power on reset and oscillator.

●Features

1) Monitor up to 96 matrix keys.

2) Under 3µA Stand-by Current

3) Built-in Power on Reset.

4) Ghost key rejection.

5) Keyscan / GPIO selectable

6) 3 volt tolerant Input

●Absolute maximum ratings (Ta=25℃)

Parameter Symbol Ratings Unit Conditions

VDD -0.3 ~ +2.5 V VDD≦VDDIO

Supply Voltage

VDDIO -0.3 ~ +4.5 V

1

※

VI1 -0.3 ~ VDD +0.3

V XRST, XI, TW, PORENB

1

Input voltage

VI2 -0.3 ~ VDDIO +0.3

※

V ADR

VIT -0.3 ~ +4.5 V

Storage temperature range Tstg -55 ~ +125 ℃

2

Package power PD 272

※ This IC is not designed to be X-ray proof.

※1 It is prohibited to exceed the absolute maximum ratings even including +0.3 V.

※2 Package dissipation will be reduced each 2.72mW/℃ when the ambient temperature increases beyond 25℃.

※

mW

●Operating conditions

Ratings

Parameter Symbol

Min. Typ. Max.

Supply voltage range

(VDD)

Supply voltage range

(VDDIO)

VDD 1.65 1.80 1.95 V

VDDIO 1.65 1.80 3.60 V

VI1 -0.2 - VDD+0.2 V XRST, XI, TW, PORENB

Input voltage range

VI2 -0.2 - VDDIO+0.2 V ADR

VIT -0.2 - 3.60 V

XINT, SCL, SDA,

COL[11:0], ROW[7:0]

Unit Conditions

XINT, SCL, SDA,

COL[11:0], ROW[7:0]

Operating temperature range Topr -30 25 +85 ℃

www.rohm.com

1/24

© 2011 ROHM Co., Ltd. All rights reserved.

2011.01 - Rev.

BU1852GUW

A

●Electrical characteristics

1. DC characteristics (VDD=1.8V, VDDIO=1.8V, Ta=25℃)

Parameter Symbol

Min. Typ. Max.

Input H Voltage1 V

Input H Voltage2 V

0.8xVDD - 3.6 V

IH1

0.8xVDD - VDD+0.2 V

IH2

Limits

Technical Note

Unit Conditions

1

※

2

※

Input H Voltage3 V

Input H Voltage4 V

Input L Voltage1 V

Input L Voltage2 V

Input H Current1 I

Input H Current2 I

0.8xVDDIO - 3.6 V COL[11:0]

IH3

0.8xVDDIO - VDDIO+0.2 V ADR

IH4

-0.2 - 0.2xVDD V

IL1

-0.2 - 0.2xVDDIO V ADR, COL[11:0]

IL2

-1.0 - 1.0 µA

IH1

-1.0 - 1.0 µA VIN=1.80V

IH2

Input L Current IIL -1.0 - 1.0 µA

Output H Voltage1 V

Output H Voltage2 V

Output L Voltage1 V

Output L Voltage2 V

※1 XINT,SCL,SDA,ROW[7:0]

※2 XRST,XI,TW,PORENB

※3 XINT,SCL,SDA,ROW[7:0],XRST,XI,TW,PORENB

※4 XINT,SCL,SDA,ROW[7:0],COL[11:0]

※5 XRST,XI,TW,PORENB,ADR

※6 XINT,SDA,ROW[7:0]

0.75xVDD - - V IOH=-2mA, ROW[7:0]

OH1

0.75xVDDIO - - V IOH=-2mA, COL[11:0]

OH2

- - 0.25xVDD V IOL=2mA,

OL1

- - 0.25xVDDIO V IOL=2mA, COL[11:0]

OL2

2. Circuit Current (VDD=1.8V, VDDIO=1.8V, Ta=25℃)

Limits

Parameter Symbol

Min. Typ. Max.

3

※

4

※

V

IN

=3.60V

Pull-down/up OFF

5

※

=0V

V

IN

Pull-down/up OFF

6

※

Unit Conditions

Power Down Current

(VDD)

- - 1.0 µA

I

PD

XRST=VSS

Power Down Current

(VDDIO)

Standby Current1

(VDD)

- - 1.0 µA

I

PDIO

I

- - 3.0 µA

STBY1

XRST=VDD,

PORENB=VSS,

Standby Current1

(VDDIO)

Standby Current2

(VDD)

- - 1.0 µA

I

STBYIO1

I

- - 1.0 µA

STBY2

SCL=VDD, SDA=VDD

XRST=VDD,

PORENB=VDD,

Standby Current2

(VDDIO)

Operating Current

(VDD)

I

- - 1.0 µA

STBYIO2

I

- 50 110 µA

OP

SCL=VDD, SDA=VDD

Internal oscillator is used.

one key is pressed.

www.rohm.com

2/24

© 2011 ROHM Co., Ltd. All rights reserved.

2011.01 - Rev.

BU1852GUW

A

Technical Note

2

C AC Characteristics

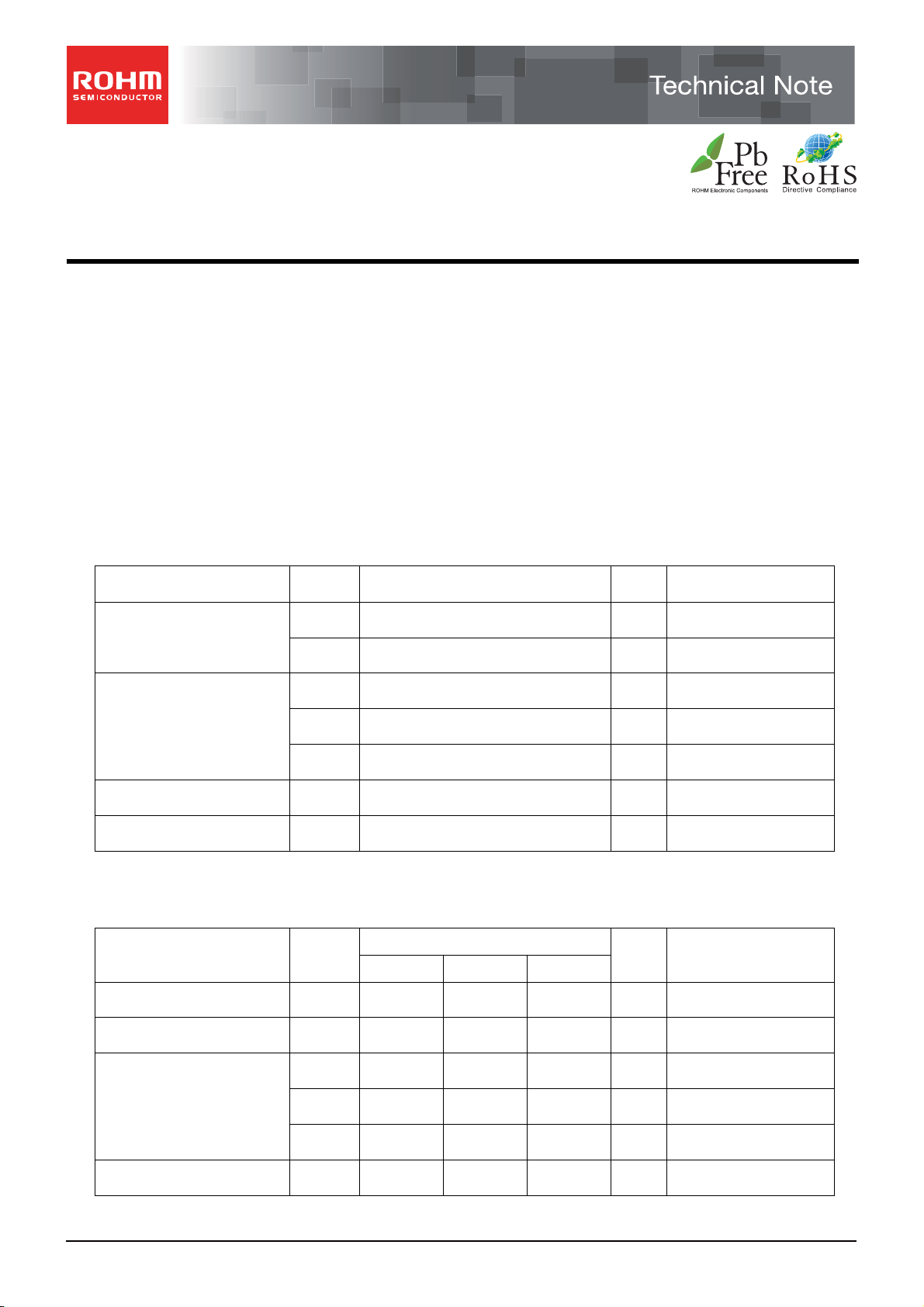

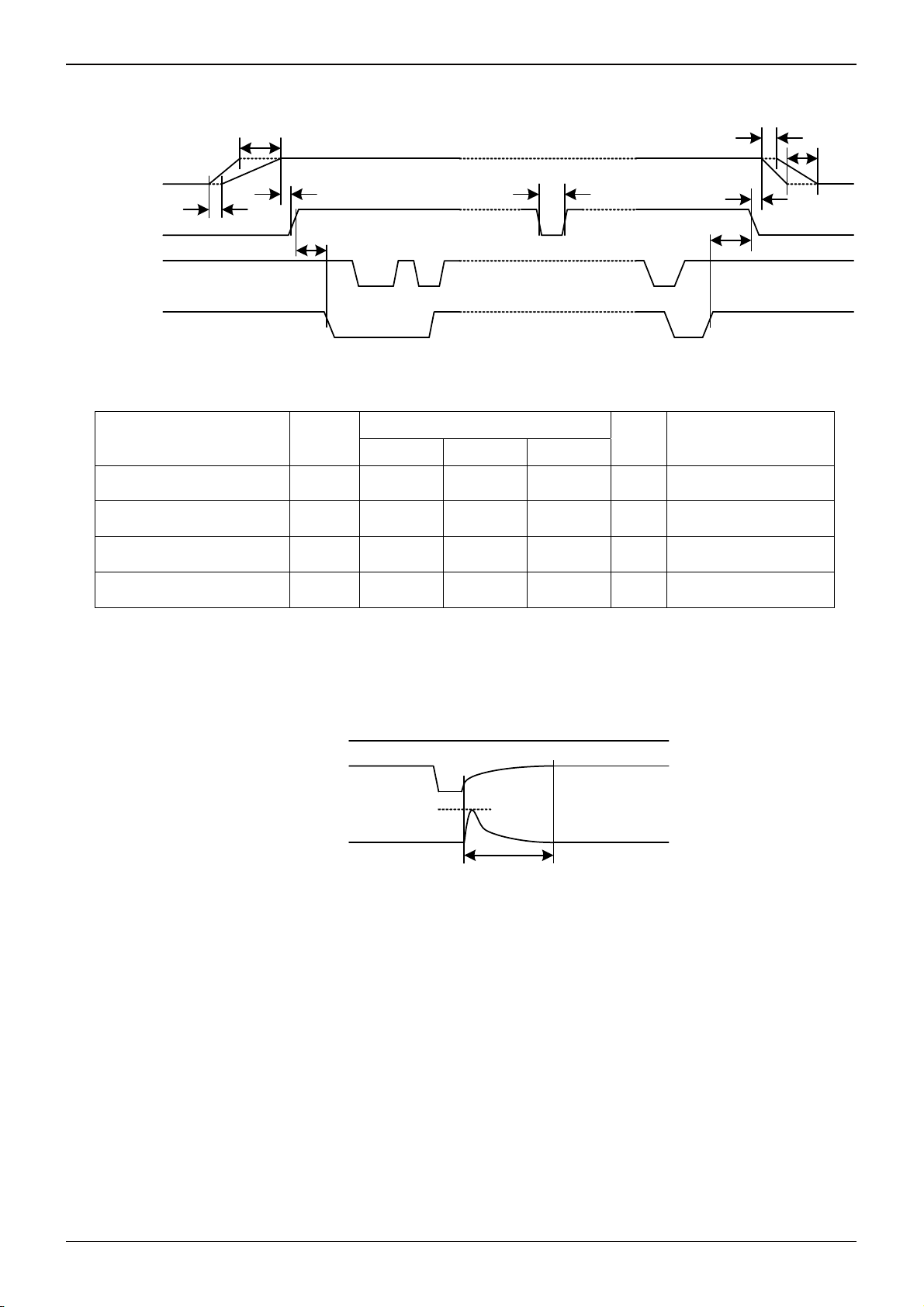

3. I

Condition

(Repeated)

START

tSU;STA

SCL

SDA

tHD;STA

tBUF

VDD=1.8V, VDDIO=1.8V, Topr=25℃, TW=VSS

Parameter Symbol

SCL Clock Frequency f

SCL

t

LOW

BIT7

tHIGH

BIT6

1/fSCLK

tSU;DAT

Fig.1 I

tHD;DAT

2

C AC timing

Ack

STOP

tSU;STO

Limits

Unit Conditions

Min. Typ. Max.

- - 400 kHz

Bus free time t

(Repeated) START Condition

Setup Time

(Repeated) START Condition

Hold Time

SCL Low Time t

SCL High Time t

Data Setup Time t

Data Hold Time t

STOP Condition Setup Time t

1.3 - - µs

BUF

t

0.6 - - µs

SU;STA

0.6 - - µs

t

HD;STA

1.3 - - µs

LOW

0.6 - - µs

HIGH

100 - - ns

SU;DAT

0 - - ns

HD;DAT

0.6 - - µs

SU;STO

www.rohm.com

3/24

© 2011 ROHM Co., Ltd. All rights reserved.

2011.01 - Rev.

BU1852GUW

A

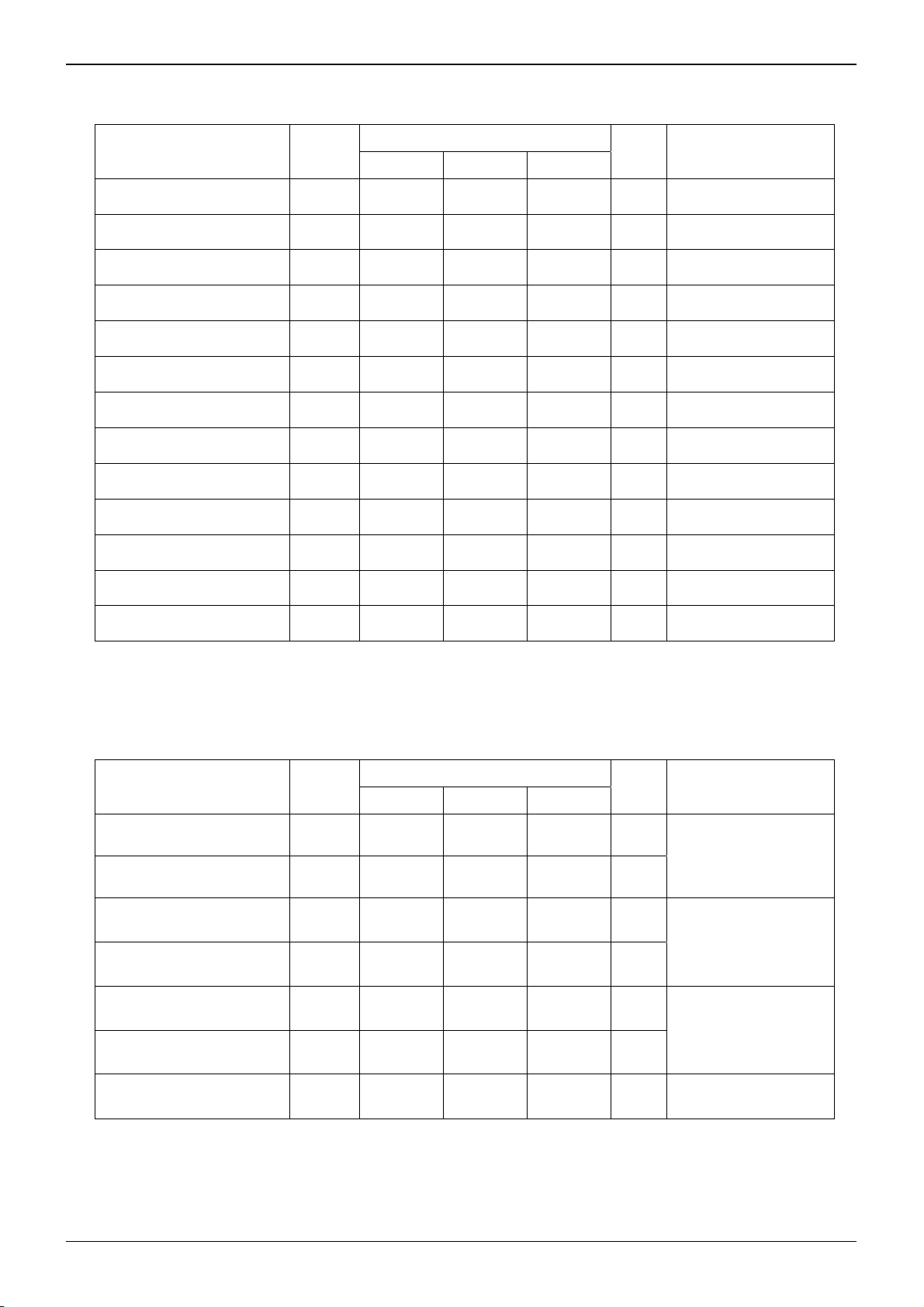

4. GPIO AC Characteristics

GPIO[7:0](Output)

GPIO[7:0](Input)

VDD=1.8V, VDDIO=1.8V, Topr=25℃, TW=VSS

Output Data Valid Time tDV - - 0.8 µs

State

SCL

tIV

XINT

Fig.2 GPIO AC timing

Limits

Parameter Symbol

Min. Typ. Max.

BIT 0BIT 1

tDV

Unit Conditions

Technical Note

A

NA

t

IR

Interrupt Valid Time tIV - - 5 µs

Interrupt Reset Time tIR - - 5 µs

www.rohm.com

4/24

© 2011 ROHM Co., Ltd. All rights reserved.

2011.01 - Rev.

BU1852GUW

A

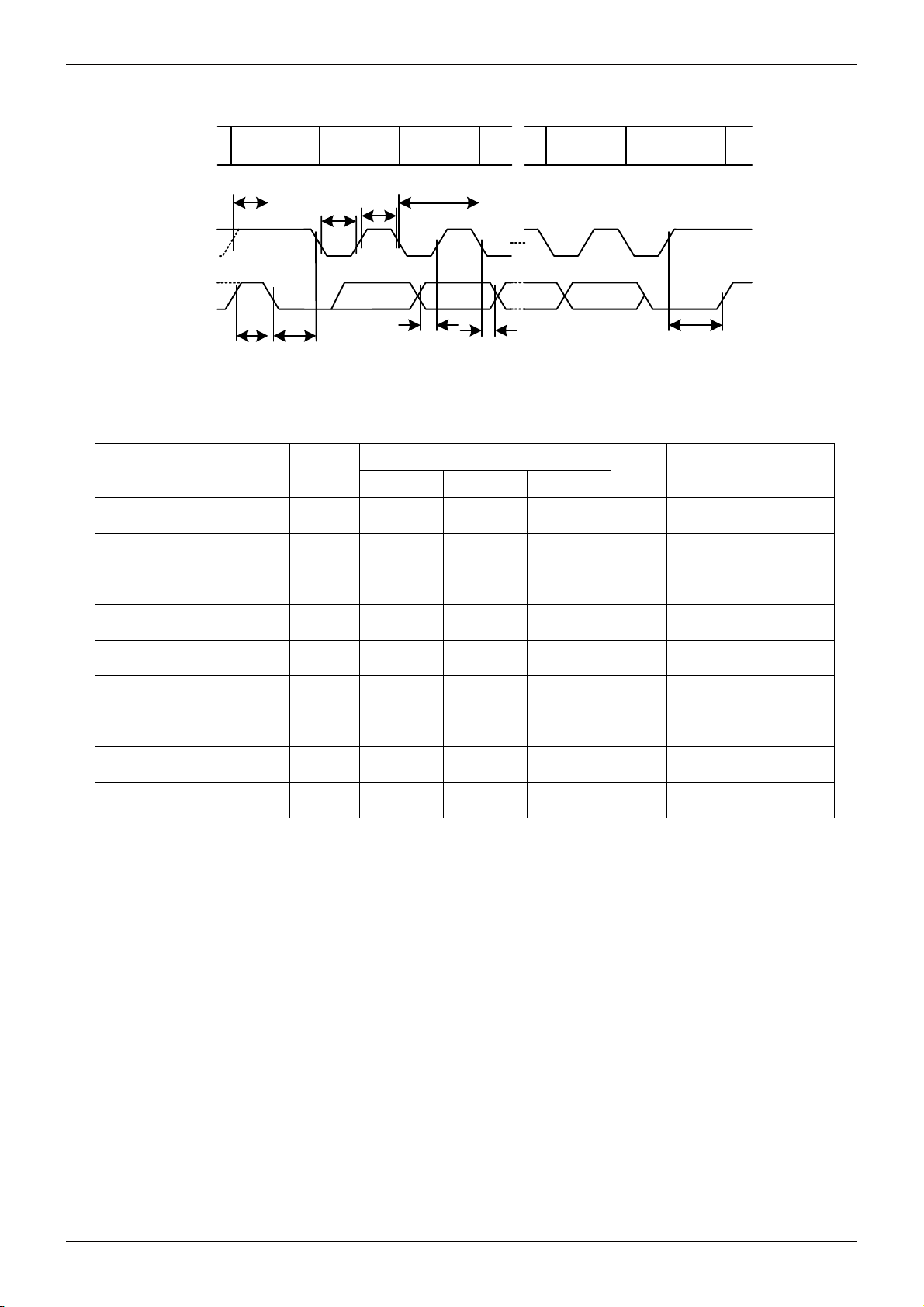

5. Startup sequence

VDD

VDDIO

tVDD

XRST

tVDD

SCL

SDA

VDD=1.8V, VDDIO=1.8V, Topr=25℃, TW=VSS

Parameter Symbol

VDD Stable Time t

Reset Wait Time t

VDD

RWAIT

tVDD

tRWAIT

tI2CWAIT

tRV

tI2CWAIT

Fig.3 Start Sequence timing

Limits

Unit Conditions

Min. Typ. Max.

- - 5 ms

VDD and VDDIO are ON

at the same time.

0 - - µs XRST controlling

Technical Note

tVDD

tRWAIT

1

※

Reset Valid Time tRV 10 - - µs

I2C Wait Time t

※1 Even if XRST port is not used, it operates because Power On Reset is built in.

In this case, connect XRST port with VDD on the set PCB.

10 - - µs

I2CWAIT

Note) At VDD=0V, when SCL port is changed from 0V to 0.5V or more, SCL port pulls the current. It is same in SDA, XINT,

and ROW[7:0] ports of 3V tolerant I/O. (VDDIO=0V in case of COL[11:0] ports)

VDD

Port

Port

0V

3V

0V

0.1~1mA

(~2kΩ Pull-up)

Pull Current

2~3ms

Fig.4 Port operating at VDD=0V

www.rohm.com

5/24

© 2011 ROHM Co., Ltd. All rights reserved.

2011.01 - Rev.

BU1852GUW

A

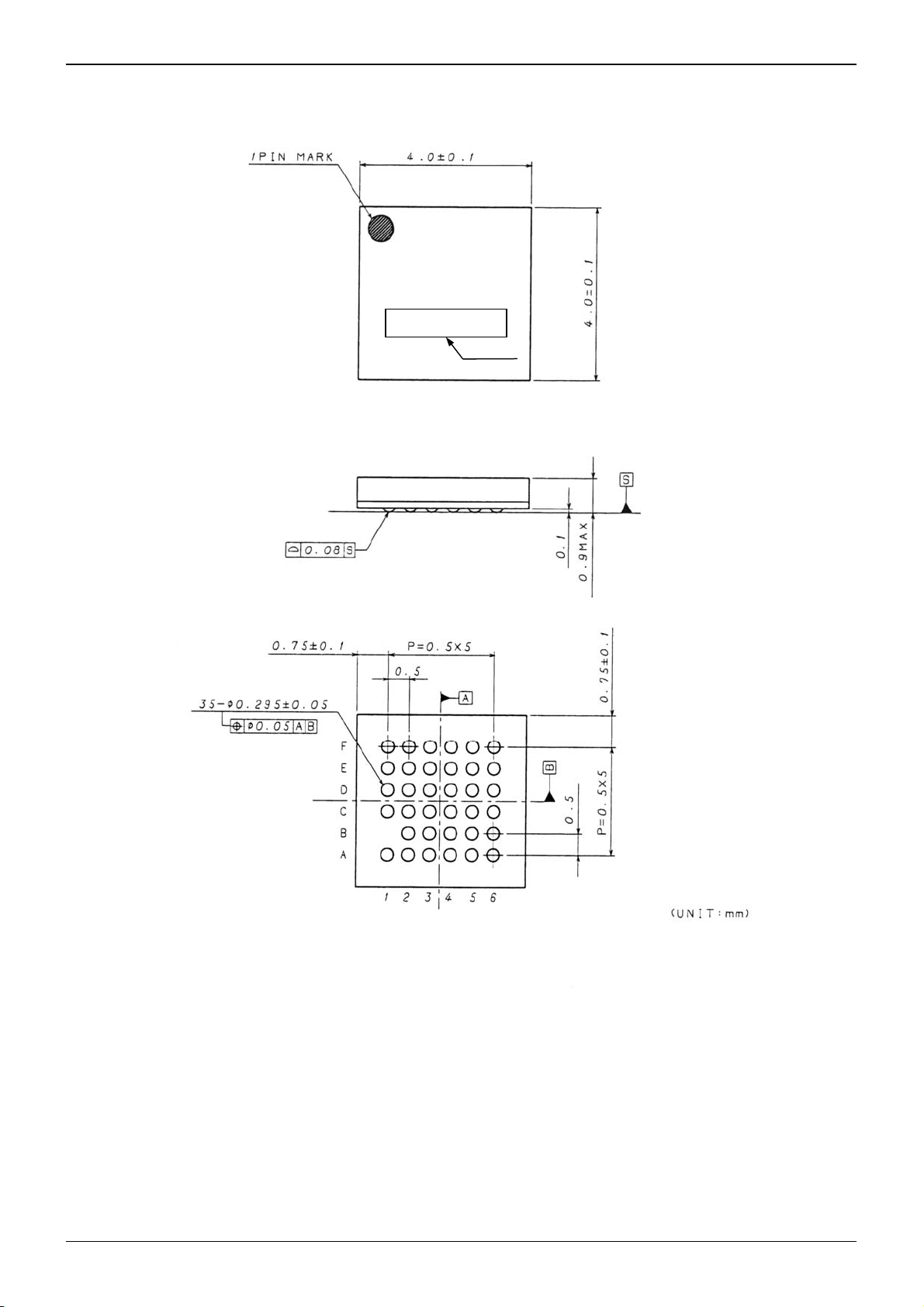

●Package Specification

Technical Note

U1852

Lot No.

Fig.5 Package Specification (VBGA035W040)

www.rohm.com

6/24

© 2011 ROHM Co., Ltd. All rights reserved.

2011.01 - Rev.

BU1852GUW

A

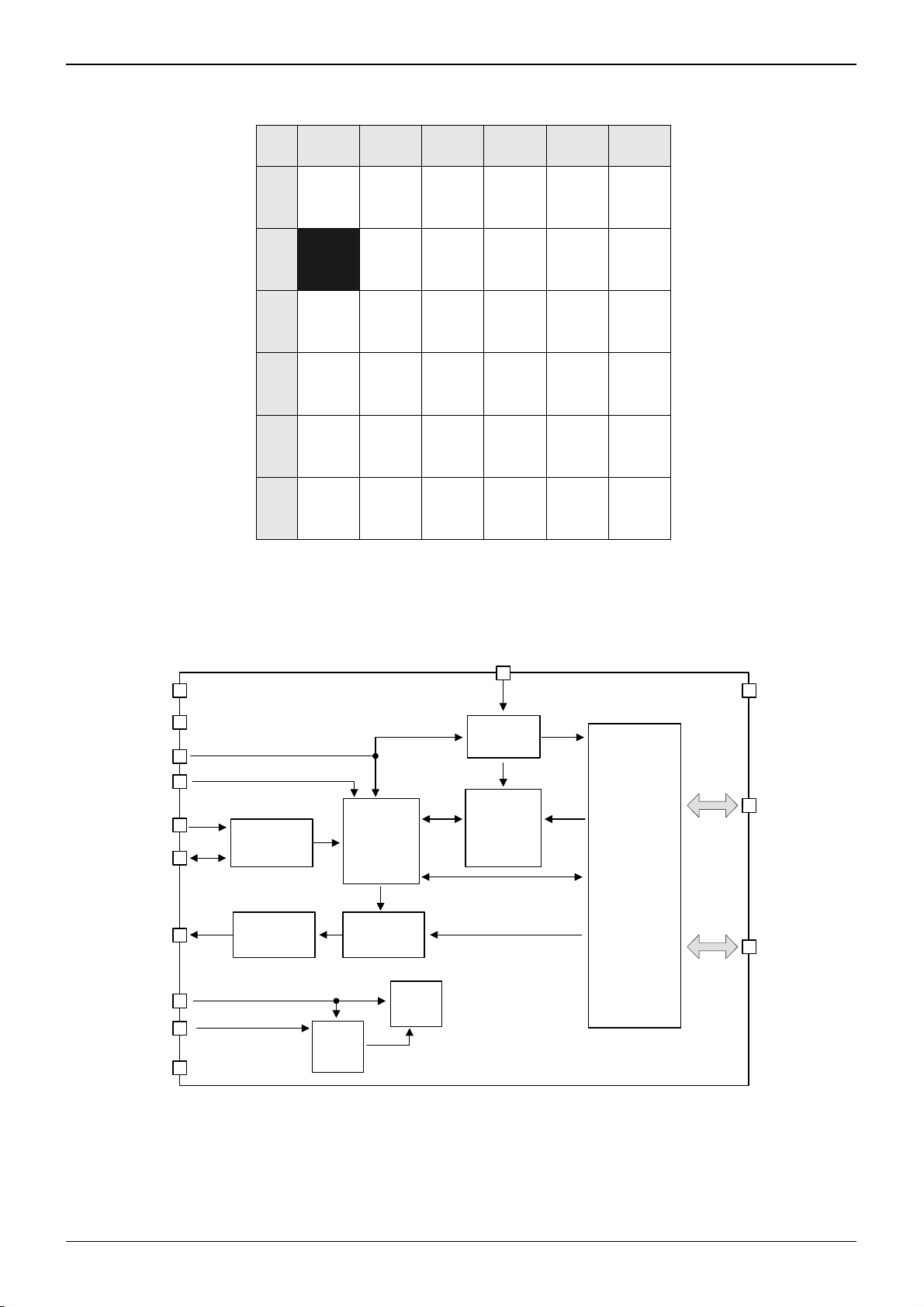

A

●Pin Assignment

Technical Note

●Block diagram

VDD

TESTM[1:0]

ADR

TW

SCL

SDA

XINT

XRST

PORENB

VSS

A

B

C

D

E

F

Input

Filter

Interrupt

Filter

1 2 3 4 5

TESTM 0 XI ROW0 ROW2 ROW4

XRST ROW1 ROW3 ROW6

XINT VDD PORENB VSS ROW 7

SDA VDD VDDIO VSS COL2

SCL COL10 COL8 COL6 COL4

TESTM 1 COL11 COL9 COL7 COL5

Fig.6 Pin Diagram (Top View)

XI

Oscillator

Key

I2C / 3 wire

Control

Interrupt

Logic

Reset

Gen

Power

on

Reset

Fig.7 Functional Block Diagram

Encoder

+

FIFO

6

TW

ROW5

COL0

COL1

COL3

DR

VDDIO

COL[11:0]/

GPIO[19:8]

Key Scan

/

GPIO

Control

ROW[7:0]/

GPIO[7:0]

www.rohm.com

7/24

© 2011 ROHM Co., Ltd. All rights reserved.

2011.01 - Rev.

BU1852GUW

A

●Pin Functional Descriptions

PIN name I/O Function Init Cell Type

VDD - Power supply (Core, I/O except for COL[11:0], ADR) - -

VDDIO - Power supply (I/O for COL[11:0], ADR) - -

VSS - GND - -

XRST I Reset(Low Active) I A

XI I External clock input (32kHz) I I

Select protocol

TW I

H: original 3 wire

L: I

(TW=L) Select Device Address for I

ADR I

(TW=H) H : Key scan rate 1/2

2

C

2

C

I B

I B

L : Key scan rate original

XINT O Key/GPIO Interrupt

H(TW=H)

Hi-z(TW=L)

SCL I Clock for serial interface I D

SDA I/O Serial data inout for serial interface I F

ROW0 I/O ROW0 / GPIO0

Technical Note

E

ROW1 I/O ROW1 / GPIO1

ROW2 I/O ROW2 / GPIO2

ROW3 I/O ROW3 / GPIO3

ROW4 I/O ROW4 / GPIO4

ROW5 I/O ROW5 / GPIO5

ROW6 I/O ROW6 / GPIO6

ROW7 I/O ROW7 / GPIO7

COL0 I/O COL0 / GPIO8

COL1 I/O COL1 / GPIO9

COL2 I/O COL2 / GPIO10

COL3 I/O COL3 / GPIO11

COL4 I/O COL4 / GPIO12

COL5 I/O COL5 / GPIO13

COL6 I/O COL6 / GPIO14

COL7 I/O COL7 / GPIO15

COL8 I/O COL8 / GPIO16

COL9 I/O COL9 / GPIO17

I

[100kΩ Pull-up]

L(TW=H)

I

[150kΩ Pull-down]

(TW=L)

G

H

COL10 I/O COL10 / GPIO18

COL11 I/O COL11 / GPIO19

PORENB I Power on reset enable (Low Active) I B

TESTM0 I

Tes t P in s

1

※

I C

TESTM1 I

※1 Note: All these pins must be tied down to GND in normal operation.

www.rohm.com

8/24

© 2011 ROHM Co., Ltd. All rights reserved.

2011.01 - Rev.

BU1852GUW

A

●I/O equivalence circuit

Technical Note

A B C D

E F G H

I

Fig.8 Equivalent I/O circuit diagram

www.rohm.com

9/24

© 2011 ROHM Co., Ltd. All rights reserved.

2011.01 - Rev.

BU1852GUW

A

●Functional Description

1. Power mode

The device enters the state of Power Down when XRST=”0”. When XRST becomes High after powered, the device

enters the standby state.

Power On Reset

A Power On Reset logic is implemented in this device. Therefore, it will operate correctly even if the XRST port is not

used. In this case, the XRST port must be connected to “1” (VDD), and the PORENB port must be connected to “0”

(VSS). If you don’t want to use Power On reset, you must connect PORENB port to “1” (VDD).

Power Down State

The device enters Power Down state by XRST=”0”. An internal circuit is initialized, and key encoding and 3wire/I

interface are invalid. Power On Reset becomes inactive during this state.

Stand-by State

The device enters the stand-by state by setting XRST to "1". In this state, the device is waiting for keys pressed or

2

C communication (TW=”0”). When a key is pressed or I2C start condition, the state will change to operation. Power

I

On Reset is active in this state if PORENB = “0”.

Operating State

The device enters the operating state by pressing keys. The device will scan the key matrix and encode the key code,

and then the 3wire/I

After communicating with host device, when no keys are pressed, the device returns to the stand-by state. Power On

Reset is active in this state if PORENB=”0”.

2. Protocol of serial interface

2

C

I

When set to TW=”0”, SCL and SDA are used for I

accessed through I

GPO or key scan, proper register setting should be done through I

3 wire (Original)

When set to TW=”1”, SCL and SDA are used for original 3wire communication, which is not the standard interface.

Any register shown in section 4 cannot be accessed through 3wire. With TW=”1”, only keyscan and key encoding

are supposed to be performed. GPIO function is inactive. When the application needs kind of complex system (for

instance, GPO+keyscan or GPIO+keyscan…), I2C mode is recommended.

See appendix for the details.

Technical Note

2

2

C interface tries to start communication by driving XINT “0”. See next section for the details.

2

2

C. Initially, all GPIO ports are set to GPI and pull-up/down ON. When the application requires

C communication. Any register shown in section 4 can be

2

C.

C

www.rohm.com

10/24

© 2011 ROHM Co., Ltd. All rights reserved.

2011.01 - Rev.

BU1852GUW

A

r

Technical Note

2

C Bus Interface (TW=”0”)

3. I

Each function of GPIO is controlled by internal registers. The I

registers. The device supports 400kHz Fast-mode data transfer rate.

Slave address

Two device addresses (Slave address) can be selected by ADR port.

2

C Slave interface is used to write or read those internal

ADR=0 0 0 0 1 0 1 0

ADR=1 0 0 0 1 1 0 1

Data transfer

One bit of data is transferred during SCL = “1”. During the bit transfer SCL = “1” cycle, the signal SDA should keep

the value. If SDA changes during SCL = “1”, START condition or STOP condition occur and it is interpreted as a

control signal.

A7 A6 A5 A4 A3 A2 A1 R/W

1/0

SDA

SCL

Data is valid

when SDA is stable

Fig.9 Data transfer

START・STOP・Repeated START conditions

When SDA and SCL are “1”, the data isn’t transferred on the I2C bus. If SCL remains “1” and SDA transfers from “1”

to “0”, it means “Start condition” is occurred and access is started. If SCL remains “1” and SDA transfers from “0” to

“1”, it means “Stop condition” is occurred and access is stopped. It becomes repeated START condition (Sr) the

START condition enters again although the STOP condition is not done.

SDA is

variable

SDA

SCL

START Condition Repeated START Condition

S S

P

STOP Condition

Fig.10 START・STOP・Repeated START conditions

www.rohm.com

11/24

© 2011 ROHM Co., Ltd. All rights reserved.

2011.01 - Rev.

BU1852GUW

A

AAA

r

A

A

A

Acknowledge

After start condition is occurred, 8 bits data will be transferred. SDA is latched by the rising edge of SCL. After 8 bits

data transfer is finished by the “Master”, “Master” opens SDA to “1”. And then, “Slave” de-asserts SDA to “0” as

“Acknowledge”.

Writing protocol

Register address is transferred after one byte of slave address with R/W bit. The 3rd byte data is written to internal

register which defined by the 2

be reset to (00h) after the byte transfer.

S

SDA output

from “Master”

Not acknowledge

SDA output

from “Slave”

SCL 1 2 8 9

S

START condition

Acknowledge

Clock pulse

For Acknowledgs

Fig.11 Acknowledge

nd

byte. However, when the register address increased to the final address (18h), it will

D7 D6 D5D4D3D2 D1 D0 D 7 D 6 D 5D4D3D2 D1D0XXXA4A3A2A1A0XXXX XX 0X

data

Technical Note

P

data Register addressSlave address

R / W=0(write )

Transmit from maste

Transmit from slave

= acknowledge

= not acknowledge

S= Start condition

P= Stop condition

Register address

increment

Register address

increment

Fig.12 Writing protocol

www.rohm.com

12/24

© 2011 ROHM Co., Ltd. All rights reserved.

2011.01 - Rev.

BU1852GUW

A

Reading protocol

After Writing the slave address and Read command bit, the next byte is supposed to be read data. The reading

register address is the next of the previous accessed address. Reading address is incremented one by one. When

the incremented address reaches the last address, the following read address will be reset to (00h).

Technical Note

XXX X X X X D7D6D5D4D3D2D1D0 D7D6D5D4D3D2D1D0

Salve address

Transmit from master

Transmit from slave

1S A P

data

R/W=1(Read)

Register Address

A

increment

A=acknowledge

=not acknowledge

A

S=Start condition

P=Stop condition

A

data

Register address

increment

Fig.13 Readout protocol

Complex reading protocol

There is the complex reading protocol to read the specific address of registers that master wants to read.

After the specifying the internal register address as writing command, master occurs repeated START condition with

read command. Then, the reading access of the specified registers is supposed to start. The register address

increment is the same as normal reading protocol. If the address is increased to the last, it will be reset to (00h).

S A A A

XXXX XX0X

Slave address

R/W=0(write)

X X X A4 A3 A2 A1 A0

Register address

Sr 1

XXXX XXX

Slave address

R/W=1(read)

D7 D6 D5 D4 D3 D2 D1 D0

data

Transmit from master

Transmit from slave

A

Register address

increment

D7 D6 D5 D4 D3 D2 D1 D0 A

data

Register address

A=acknowledge

A

=not aclnowledge

S=Start condition

P=Stop condition

Sr=Repeated Start condition

increment

P

Fig.14 Complex reading protocol

Illegal access of I

2

C

When illegal access happens, the data is annulled.

The illegal accesses are as follows.

・The START condition or the STOP condition is continuously generated.

・When the Slave address and the R/W bit are written, repeated START condition or the STOP condition are

generated.

・Repeated START condition or the STOP condition is generated while writing data.

www.rohm.com

13/24

© 2011 ROHM Co., Ltd. All rights reserved.

2011.01 - Rev.

BU1852GUW

A

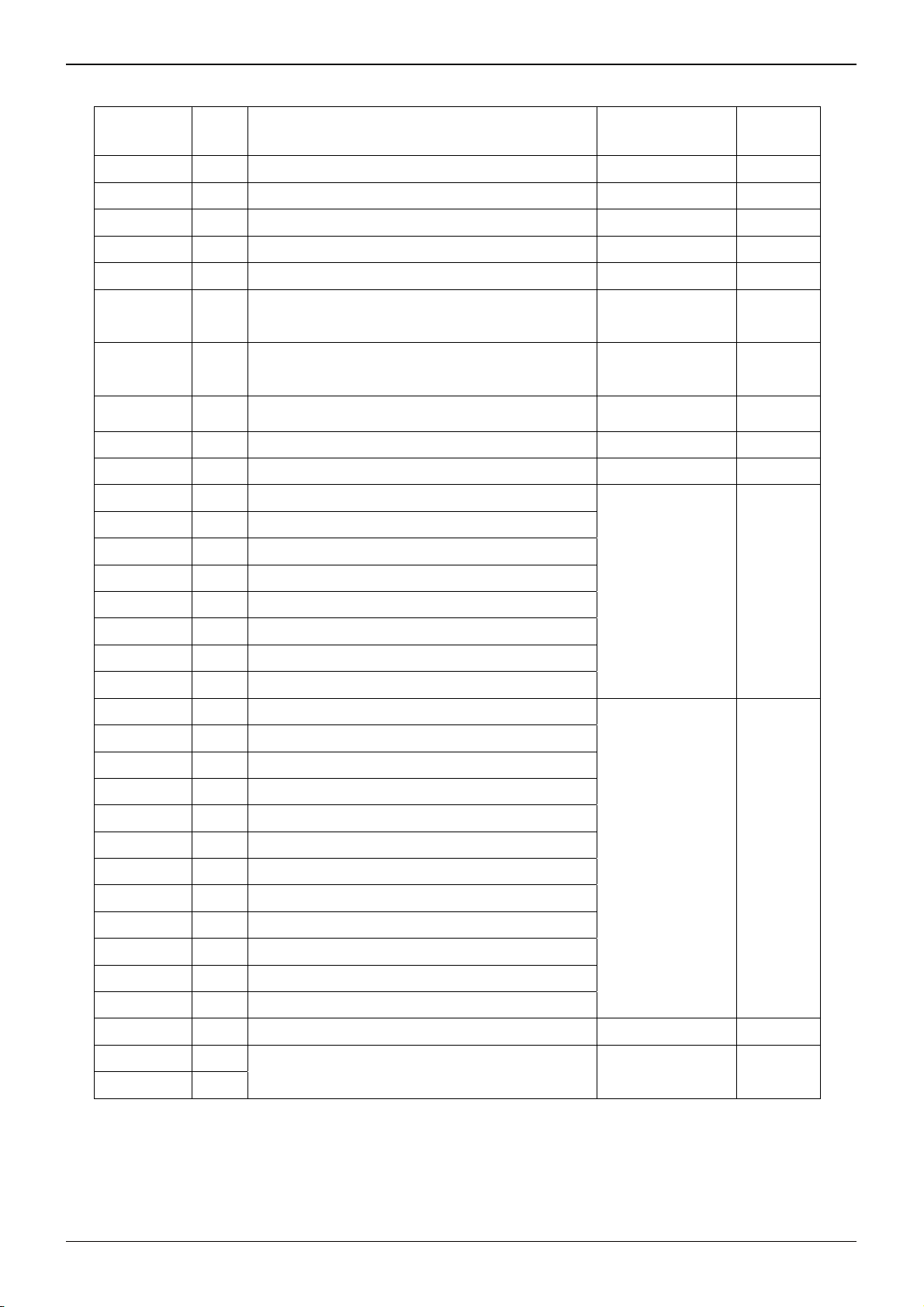

4. Register configuration

Table1 shows the register map and Table2 indicates each function in the corresponding bit. Only when TW is “0”, these

registers can be accessed with I

register map.

Table1 Register map

Address Init Type D7 D6 D5 D4 D3 D2 D1 D0

00h 00h R/W RESET reserved reserved reserved reserved reserved reserved reserved

01h 00h R/W reserved reserved reserved reserved reserved reserved reserved CLKSEL

02h 11h R/W reserved KS_RATE *1

03h 00h R/W reserved reserved reserved reserved KS_C11 KS_C10 KS_C9 KS_C8

04h 00h R/W KS_C7 KS_C6 KS_C5 KS_C4 KS_C3 KS_C2 KS_C1 KS_C0

05h 00h R/W KS_R7 KS_R6 KS_R5 KS_R4 KS_R3 KS_R2 KS_R1 KS_R0

06h 00h R/W reserved reserved reserved reserved IOD19 IOD18 IOD17 IOD16

Technical Note

2

C. By making XRST “0”, the setting register value will be initialized shown in following

07h 00h R/W IOD15 IOD14 IOD13 IOD12 IOD11 IOD10 IOD9 IOD8

08h 00h R/W IOD7 IOD6 IOD5 IOD4 IOD3 IOD2 IOD1 IOD0

09h 00h R/W reserved reserved reserved reserved INTEN19 INTEN18 INTEN17 INTEN16

0Ah 00h R/W INTEN15 INTEN14 INTEN13 INTEN12 INTEN11 INTEN10 INTEN9 INTEN8

0Bh 00h R/W INTEN7 INTEN6 INTEN5 INTEN4 INTEN3 INTEN2 INTEN1 INTEN0

0Ch 00h R/W reserved reserved reserved reserved GPO19 GPO18 GPO17 GPO16

0Dh 00h R/W GPO15 GPO14 GPO13 GPO12 GPO11 GPO10 GPO9 GPO8

0Eh 00h R/W GPO7 GPO6 GPO5 GPO4 GPO3 GPO2 GPO1 GPO0

0Fh 00h R/W reserved reserved reserved reserved XPD19 XPD18 XPD17 XPD16

10h 00h R/W XPD15 XPD14 XPD13 XPD12 XPD11 XPD10 XPD9 XPD8

11h 00h R/W XPU7 XPU6 XPU5 XPU4 XPU3 XPU2 XPU1 XPU0

12h 00h R/W reserved reserved reserved reserved reserved reserved reserved INTFLT

13h 00h - reserved reserved reserved reserved reserved reserved reserved reserved

14h 00h R keycode

15h 00h R reserved reserved reserved Reserved reserved reserved fifo_ovf fifo_ind

16h 00h R reserved reserved reserved Reserved GPI19 GPI18 GPI17 GPI16

17h 00h R GPI15 GPI14 GPI13 GPI12 GPI11 GPI10 GPI9 GPI8

18h FFh R GPI7 GPI6 GPI5 GPI4 GPI3 GPI2 GPI1 GPI0

*1 Do not write more than 0x7F in KS_RATE

※ Do not write “1” in the reserved resisters. The write commands to 13h-18h addresses’ registers are ignored.

www.rohm.com

14/24

© 2011 ROHM Co., Ltd. All rights reserved.

2011.01 - Rev.

BU1852GUW

A

Table2 Register function

Symbol Address Description

RESET 00h

Technical Note

Software reset. All registers are initialized by writing "1".

This register value is returned to "0" automatically.

Exceptionally, GPIn register is not initialized.

CLKSEL 01h

KS_RATE 02h Key scan rate control

KS_Cx 03h-04h

KS_Ry 05h

IODn 06h-08h

INTENn 09h-0Bh Interrupt of GPIOn port is enabled by "1". It is masked by "0".

GPOn 0Ch-0Eh Output value of GPIOn port.

XPDn 0Fh-10h Pull-down of GPIOn port is on by "0" and off by "1". GPIOn should be input.

XPUn 11h Pull-up of GPIOn port is on by "0" and off by "1". GPIOn should be input.

“1” : External clock from XI is used.

“0” : Internal CR oscillator is used.

When set to “1”, port is used as COLx for key scan.

When set to “0”, it is used as GPIO port.

When set to “1”, port is used as ROWy for key scan.

When set to “0”, it is used as GPIO port.

GPIOn’s IO direction.

When set to “1”, GPIOn direction is output. When set to “0”, GPIOn direction is input.

INTFLT 12h

keycode 14h Keycode that Host can read currently

fifo_ind 15h When there are keycode data in FIFO, fifo_ind is set to “1”. “0” means fifo empty.

fifo_ovf 15h When FIFO overflow happens, fifo_ovf is set to “1”. Initially “0” is stored.

GPIn 16h-18h

※"n" is the number of GPIO[19:0] ports. “x” is the number of COL[11:0]. “y” is the number of ROW[7:0].

“1” : interrupt filter ON (1us pulse rejection)

“0” : interrupt filter OFF (bypass)

Input value of GPIOn port. Write command is ignored.

When interrupt happens, these registers must be read.

www.rohm.com

15/24

© 2011 ROHM Co., Ltd. All rights reserved.

2011.01 - Rev.

BU1852GUW

A

5. GPIO function

GPIO configuration

When some ports of COL[11:0] and ROW[7:0] are needed to be used as GPIO, TW must be “0”. Then, set the proper

value in the appropriate registers through I2C. ROW[7:0] and COL[11:0] correspond to GPIO[7:0] and GPIO[19:8],

respectively. By default, GPIO[19:0] ports are set to input(IODn=0) and Pull-up/down ON(XPUn/XPDn=0).

(n is the number of GPIO[19:0] ports.)

Refer to the following for the configuration of GPIO.

Table3 GPIO configuration

Input, Pull-up/down ON * 0 0

Input, Pull-up/down OFF * 0 1

Output, H drive 1 1 *

Output, L drive 0 1 *

Output, Hi-Z

※1 It is required to pull-up to more than VDD potential.

How to deal with GPIO ports which are not using

When set to output, GPIO port must be open.

When set to input, don’t make GPIO port open. It must be forced by "0" or Pull-up/down on.

Interrupt configuration

The initial XINT output is Hi-Z, so it should be pull-up. When interrupt is generated, XINT port outputs L. By default,

interrupt is masked with INTEN register "0". The bit to be used is made "1", and then the mask is released. In this

case, IOD register should be "0"(input).

Write to GPIO port

After master sets the internal register address for write, the data is sent from MSB.

After Acknowledge is returned, the value of each GPIO port will be changed.

Write Configuration Pulse, which is trigger of changing registers, is generated at the timing of Acknowledge.

State of GPIO

Register

GPOn IODn XPDn/XPUn

1

※

0 0 1

Technical Note

SDA

Write Configuration

Write Configuration

Pulse

GPIO[7:0]

SCL

S X X X X X X X 0 Ack AckReg AddressMSB LSB AckData1 (GPO[7:0])MSB LSB AckWRSEL = Write ModeMSB LSB P

SDA

Start Condition

Pulse

GPIO[7:0]

123456789SCL

S X X X X X X X 0 Ack AckReg AddressMSB LSB AckData1 (GPO[7:0])MSB LSB P

Start Condition

Write Acknowledge From Slave

Acknowledge From Sla ve

Stop Condition

tDV

123456789

Write Acknowledge From Slave

Acknowledge From Slave

Acknowledge From Slave

Stop Condition

tDV

Fig.15 Write to GPIO port

Data1

Valid

Data1

Valid

www.rohm.com

16/24

© 2011 ROHM Co., Ltd. All rights reserved.

2011.01 - Rev.

BU1852GUW

A

k

A

r

Read from GPIO port

After writing of the Slave address and R/W bits by master, reading GPIO port procedure begins.

All ports’ status that is set to the input by IOD registers are taken into the GPI register when ACK is sent.

Technical Note

SCL

SDA

GPI [7: 0 ] Reg

[ 7: 0] D 1

GPIO

123456789

S X X X X X X X 1Ac

Start Condition

Read

D1

[7]D1[6]D1[5]

cknowledge From Slave

D1

[4]D1[3]D1[2]D1[1]

D1

D 1

[0]

D2

P

NA

Stop Condition

No Acknowledge From Maste

Fig.16 Read from GPIO port

Interrupt Valid/Reset

When the GPIO interrupt is used, some of INTEN registers are required to be written to "1".

When current GPIO port status becomes different from the value of the GPIn registers, XINT port is changed from

"1" to "0". After reading GPI register, it will return to "1".

When Master detects interrupt, Master must read all GPI registers that is set to input(IODn=0), even if XINT is

changed while reading. It is because BU1852GUW does not latch the XINT status. Fig.13 shows one of the example

of using only ROW[7:0] as GPI. In this case, Master reads only 18h register immediate after detecting XINT.

XINT cannot distinguish whether just one port is different or multi ports are different from the previous value. Master

is necessary to store the previous GPI register value and compare it with the current value after XINT is asserted.

SCL

SDA

GPIOn

XINT

123456789

S X X X X X X X 1 Ack NA

Start Condition

Data1 Data2

Data1 Data2GPIn Reg

Read Acknowledge From Slave

Data2 (GPI[7:0])MSB LSB

tIV tIR

P

Stop Condition

No Acknowledge From Master

Data3 Data2

tIV tIR

Fig.17 Interrupt Valid/Reset (Example : ROW[7:0] as GPI with interrupt)

www.rohm.com

17/24

© 2011 ROHM Co., Ltd. All rights reserved.

2011.01 - Rev.

BU1852GUW

A

A

A

A

A

A

A

A

A

A

A

6. Key code Assignment

Table 4 shows the key code assignment. These key codes are sent through 3wire or I2C corresponding to the pushed

or released keys.

Table4 Key codes

COL 0

COL 1

Technical Note

ROW 0 ROW 1ROW2ROW3ROW 4 ROW 5ROW 6ROW7

0x01 0x11 0x21 0x31 0x41 0x51 0x 61 0x71M

0x81 0x91 0xA1 0xB1 0xC1 0xD1 0xE1 0xF1B

M

0x02 0x12 0x22 0x32 0x42 0x52 0x 62 0x72

0x82 0x92 0xA2 0xB2 0xC2 0xD2 0xE2 0xF2

B

COL 2

COL 3

COL 4

COL 5

COL 6

COL 7

COL 8

M

B

M

B

M

B

M

B

M

B

M

B

M

B

0x03 0x13 0x23 0x33 0x43 0x53 0x

0x83 0x93 0xA3 0xB3 0xC3 0xD3 0xE3 0xF3

0x04 0x14 0x24 0x34 0x44 0x54 0x

0x84 0x94 0xA4 0xB4 0xC4 0xD4 0xE4 0xF4

0x05 0x15 0x25 0x35 0x45 0x55 0x

0x85 0x95 0xA5 0xB5 0xC5 0xD5 0xE5 0xF5

0x06 0x16 0x26 0x36 0x46 0x56 0x

0x86 0x96 0xA6 0xB6 0xC6 0xD6 0xE6 0xF6

0x07 0x17 0x27 0x37 0x47 0x57 0x

0x87 0x97 0xA7 0xB7 0xC7 0xD7 0xE7 0xF7

0x08 0x18 0x28 0x38 0x48 0x58 0x

0x88 0x98 0xA8 0xB8 0xC8 0xD8 0xE8 0xF8

0x09 0x19 0x29 0x39 0x49 0x59 0x

0x89 0x99 0xA9 0xB9 0xC9 0xD9 0xE9 0xF9

63 0x73

64 0x74

65 0x75

66 0x76

67 0x77

68 0x78

69 0x79

B

B

B

0x0

0x8

0x0B 0x

0x8B 0x

0

x0C 0x 1C 0x2C 0x3C 0x4C 0x5C 0x6 C0x7C

x8C 0x 9C 0xAC 0xBC 0xCC 0xDC 0 xEC 0xFC

0

0x 1

0x2

0x 9

0xAA 0xBA 0xCA 0xDA 0xEA 0xFA

0x3

0x4

0x5

0x6

1B 0x2B0x3B0x4B 0x5B 0x6B 0x7B

9B 0xAB 0xBB 0xCB 0xDB 0xEB 0xFB

0x7

M

COL 9

M

COL 10

M

COL 11

M : Make Key (the code when the key is pressed)

B : Break Key (the code when the key is released)

www.rohm.com

18/24

© 2011 ROHM Co., Ltd. All rights reserved.

2011.01 - Rev.

BU1852GUW

A

7. Ghost Key Rejection

Ghost key is an inevitable phenomenon as long as key-switch matrices are used. When three switches located at the

corners of a certain matrix rectangle are pressed simultaneously, the switch that is located at the last corner of the

rectangle (the ghost key) also appears to be pressed, even though the last key is not pressed. This occurs because the

ghost key switch is electrically shorted by the combination of the other three switches (Fig.18). Because the key

appears to be pressed electrically, it is impossible to distinguish which key is the ghost key and which key is pressed.

The BU1852GUW solves the ghost key problem to use the simple method. If BU1852GUW detects any three-key

combination that generates a fourth ghost key, and BU1852GUW does not report anything, indicating the ghost keys

are ignored. This means that many combinations of three keys are also ignored when pressed at the same time.

Applications requiring three-key combinations (such as <Ctrl><Alt><Del>) must ensure that the three keys are not

wired in positions that define the vertices of a rectangle (Fig. 19). There is no limit on the number of keys that can be

pressed simultaneously as long as the keys do not generate ghost key events.

Technical Note

PRESSED KEY

EVENT

GHOST-KEY

EVENT

KEY-SWITCH MATRIX

Fig.18 Ghost key phenomenon

EXAMPLES OF VALID THREE-KEY COMBINATIONS

KEY-SWITCH MATRIX KEY-SWITCH MATRIX

Fig.19 Valid three key combinations

www.rohm.com

19/24

© 2011 ROHM Co., Ltd. All rights reserved.

2011.01 - Rev.

BU1852GUW

A

8. Recommended flow

Fig.20 shows the recommended flow when TW=0(I2C protocol is selected).

Sequence

power on

Reset release

Technical Note

Related registers

clock select

determine key scan rate

assign each port

to key scan and GPIO

detemine GPIO direction

GPI interrupt setting

Control GPO port

or

01h : CLKSEL

02h : KS_RATE

03h-04h : KS_C[11:0]

05h : KS_R[7:0]

06h-08h : IOD[19:0]

09h-0Bh : INTEN[19:0]

12h : INTFLT

0Ch-0Eh : GPO[19:0]

14h-18h : Read registers

Monitor “XINT”

Fig.20 Recommended flow and related registers

Forbidden operation:

--- Dynamic change of TW (I

--- Dynamic assignment change of keyscan and GPIO (should be determined initially)

--- Dynamic change of keyscan rate (should be determined initially)

--- Dynamic change of CLKSEL (should be determined initially)

2

C/3wire protocol should be fixed)

www.rohm.com

20/24

© 2011 ROHM Co., Ltd. All rights reserved.

2011.01 - Rev.

BU1852GUW

A

●Application circuit example

1.8V

VDD

INT XINT

MPU

SCL

SDA

VSS

1.8V

XRST

XI

SCL

SDA

0.1uF

VDD

Technical Note

TW

ADR

3.0V

VDDIO

COL11

COL10

COL9

COL8

COL7

COL6

COL5

COL4

COL3

COL2

COL1

COL0

GPO

from/to 3.0V device

GPI

0.1uF

VSS

PORENB

TESTM[1:0]

to Other I2C Devices

BU1852GUW

ROW0

ROW1

ROW2

ROW3

ROW4

ROW5

ROW6

ROW7

Fig.21 Application circuit example

www.rohm.com

21/24

© 2011 ROHM Co., Ltd. All rights reserved.

2011.01 - Rev.

BU1852GUW

A

●Appendix

1. 3wire Interface (TW=”1”)

XINT

SCL

Technical Note

SDA

Start bit

Bit7 Bit6 Bit5 Bit0invalid

sent by BU1852 sent by host device

Fig.22 3wire protocol

Figure 22 shows the original 3wire protocol of BU1852GUW. When this 3wire protocol is used, TW must be “1”. Note

that this 3wire interface is completely different from I

2

C and other standard bus interface.

Procedure

1. When BU1852GUW detects key events, XINT interrupt is generated to host with driving Low.

2. After the host detects XINT interrupt, the host is supposed to send start bit.

3. After BU1852GUW detects start bit, the 8bit data (key code) transmission on SDA will start synchronized with

the rising edge of SCL clock signal, which is sent from the host.

4. 8 bit data are followed by “0” (9

th

bit is always “0”), and then BU1852GUW drives High on XINT line.

See also section “3wire interface AC characteristics”.

www.rohm.com

22/24

© 2011 ROHM Co., Ltd. All rights reserved.

2011.01 - Rev.

BU1852GUW

A

f

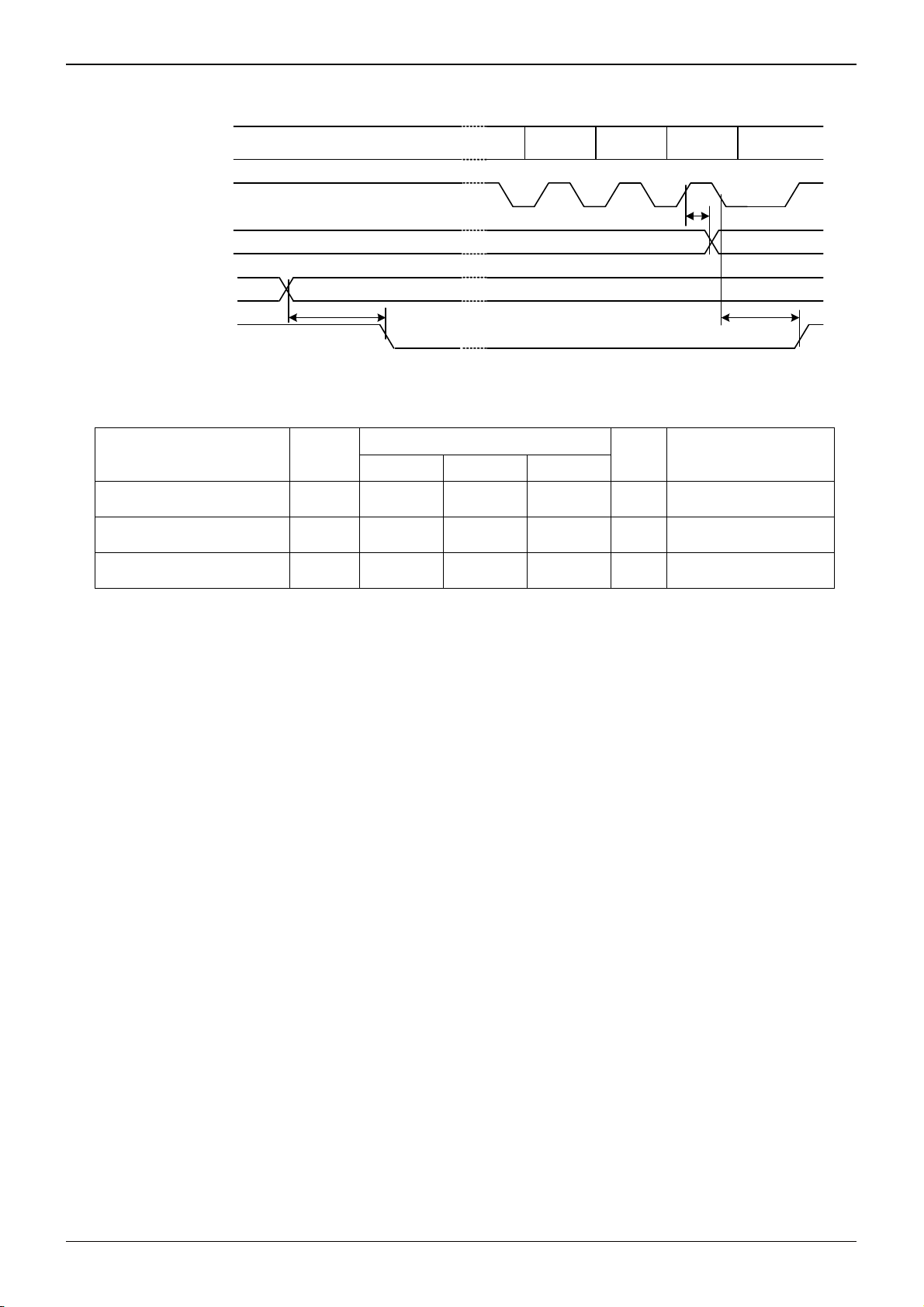

2. 3wire Interface AC characteristics

Technical Note

XINT

State

START BIT 7 BIT 6 "0 "

t

1/

TWLOW ;INT

TWS CLK

t

TWS U ;STA

t

TWL OW ;

CLK

t

TWH IGH ;

CLK

BIT 0

t

TWHD ; INTE

SCL

SDA

t

t

TWH D ;STA

VDD=1.8V, VDDIO=1.8V,Topr=25℃,TW=VDD

Parameter Symbol

SCL Clock Frequency f

START Condition

Setup Time

START Condition

Hold Time

TWH D ;DAT

Fig.23 3wire interface AC timing

Limits

Min. Typ. Max.

- - 21.5 kHz

TWSCLK

t

TWSU;STA

t

TWHD;S TA

0.030 - 500 ms

20 - - µs

Unit Conditions

SCL Low Time t

SCL High Time t

Data Hold Time t

XINT End Hold t

XINT Low Time t

TWLOW;CLK

TWHIGH;CLK

TWHD;D AT

TWHD;INTE

TWLOW;INT

23 - - µs

23 - - µs

0.1 - 1.0 µs

1.35 - 10.2 µs

500 800 1350 ms

www.rohm.com

23/24

© 2011 ROHM Co., Ltd. All rights reserved.

2011.01 - Rev.

BU1852GUW

A

●Ordering part number

Technical Note

B U 1 8 5 2 G U W - E 2

Part No. Part No.

VBGA035W040

35-φ0.295±0.05

Package

GUW: VBGA035W040

1PIN MARK

φ

0.05

0.08 S

0.75 ± 0.1

M

ABS

F

E

D

C

B

A

4.0 ± 0.1

P=0.5×5

0.5

123456

4.0 ± 0.1

0.9MAX.

0.10

S

A

0.75 ± 0.1

B

P=0.5×5

(Unit : mm)

<Tape and Reel information>

Embossed carrier tape (with dry pack)Tape

Quantity

Direction

of feed

2500pcs

E2

The direction is the 1pin of product is at the upper left when you hold

()

reel on the left hand and you pull out the tape on the right hand

Reel

1pin

Order quantity needs to be multiple of the minimum quantity.

∗

Packaging and forming specification

E2: Embossed tape and reel

Direction of feed

www.rohm.com

24/24

© 2011 ROHM Co., Ltd. All rights reserved.

2011.01 - Rev.

Notes

No copying or reproduction of this document, in part or in whole, is permitted without the

consent of ROHM Co.,Ltd.

The content specied herein is subject to change for improvement without notice.

The content specied herein is for the purpose of introducing ROHM's products (hereinafter

"Products"). If you wish to use any such Product, please be sure to refer to the specications,

which can be obtained from ROHM upon request.

Examples of application circuits, circuit constants and any other information contained herein

illustrate the standard usage and operations of the Products. The peripheral conditions must

be taken into account when designing circuits for mass production.

Great care was taken in ensuring the accuracy of the information specied in this document.

However, should you incur any damage arising from any inaccuracy or misprint of such

information, ROHM shall bear no responsibility for such damage.

The technical information specied herein is intended only to show the typical functions of and

examples of application circuits for the Products. ROHM does not grant you, explicitly or

implicitly, any license to use or exercise intellectual property or other rights held by ROHM and

other parties. ROHM shall bear no responsibility whatsoever for any dispute arising from the

use of such technical information.

The Products specied in this document are intended to be used with general-use electronic

equipment or devices (such as audio visual equipment, ofce-automation equipment, communication devices, electronic appliances and amusement devices).

The Products specied in this document are not designed to be radiation tolerant.

While ROHM always makes effor ts to enhance the quality and reliability of its Products, a

Product may fail or malfunction for a variety of reasons.

Please be sure to implement in your equipment using the Products safety measures to guard

against the possibility of physical injur y, re or any other damage caused in the event of the

failure of any Product, such as derating, redundancy, re control and fail-safe designs. ROHM

shall bear no responsibility whatsoever for your use of any Product outside of the prescribed

scope or not in accordance with the instruction manual.

The Products are not designed or manufactured to be used with any equipment, device or

system which requires an extremely high level of reliability the failure or malfunction of which

may result in a direct threat to human life or create a risk of human injury (such as a medical

instrument, transportation equipment, aerospace machinery, nuclear-reactor controller, fuelcontroller or other safety device). ROHM shall bear no responsibility in any way for use of any

of the Products for the above special purposes. If a Product is intended to be used for any

such special purpose, please contact a ROHM sales representative before purchasing.

If you intend to export or ship overseas any Product or technology specied herein that may

be controlled under the Foreign Exchange and the Foreign Trade Law, you will be required to

obtain a license or permit under the Law.

Notice

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

Thank you for your accessing to ROHM product informations.

More detail product informations and catalogs are available, please contact us.

ROHM Customer Support System

http://www.rohm.com/contact/

R1120

A

Loading...

Loading...