Page 1

AIE Adaptive Image Enhancer Series

Real Time

Video Processor IC

BU1574GUW

●Description

BU1574GUW is AIE : Adaptive Image Enhancer (image processing technology by ROHM’s hardware).

●Features

1) Compatible with image data from QCIF size (176 144) up to WVGA+ size (864 480).

2) Compatible with I/O data formats of ITU-R BT.656-4 or YCbCr with synchronizing signals.

3) Multiple operation modes: Image Enhance, Through and Sleep.

4) Registers can be set up through the 2-wire serial interface (I

5) PWM output for image adjustment LCD backlight control.

6) Built-in edge-enhancement and gamma filters.

●Applications

Car camera, Car display, Car navigation system, Mobile phone, and portable DVD etc.

●Absolute maximum ratings

Parameter Symbol Rating Unit

Power supply voltage 1 VDDIO

Power supply voltage 2 VDD

Input voltage VIN

Storage temperature range Tstg

Power dissipation PD 310*1,570*2 mW

*1 IC only. In the case exceeding 25 °C, 3.1 mW should be reduced per 1 °C.

*2 When mounted on a glass epoxy board of 70 x 70 x 1.6 mm. If exceeding 25 °C, 5.7 mW should be reduced per 1 °C.

* Has not been designed to withstand radiation.

* Operation is not guaranteed.

●Operating conditions

Parameter Symbol Rating Unit

Power supply voltage 1 (IO) VDDIO 2.70~3.60(Typ:3.00) V

Power supply voltage 2 (CORE) VDD 1.40~1.60(Typ:1.50) V

Input voltage range VIN-VDDIO 0~VDDIO V

Operating temperature range Topr -40~+85 ℃

* Supply the power source in order of VDD VDDIO.

2

C).

-0.3~+4.2

-0.3~+2.1

-0.3~VDDIO+0.3

-40~+125 ℃

No.09060EAT04

V

V

V

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

1/12

2009.06 - Rev.A

Page 2

BU1574GUW

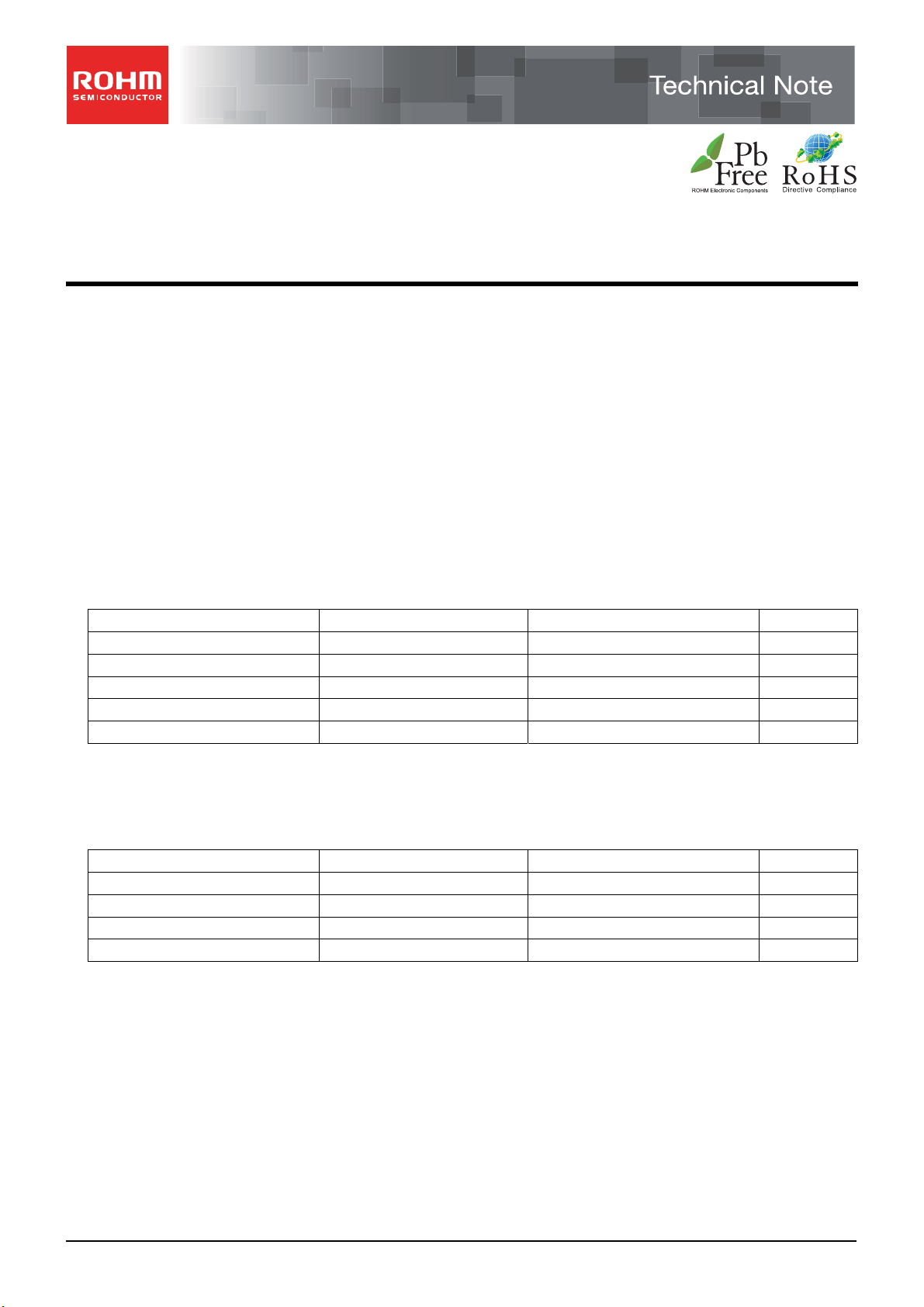

●Electrical characteristics

Parameter Symbol

MIN TYP MAX

Limits

Unit Conditions

Input frequency fIN - - 36.0 MHz CAMCKI (DUTY45%~55%)

Technical Note

Operating current

consumption

Static current consumption IDDst - - 30 uA

IDD1 - 24 - mA At Enhance mode setting (36 MHz).

At Sleep mode setting input terminal= GND

setting

Input "H" current IIH -10 - 10 uA VIH=VDDIO

Input "L" current IIL -10 - 10 uA VIL=GND

Input "H" voltage 1 VIH1

VDDIO

x0.8

-

Input "L" voltage 1 VIL1 -0.3 -

Input "H" voltage 2 VIH2

VDDIO

x0.85

-

Input "L" voltage 2 VIL2 -0.3 -

Hysteresis voltage width Vhys - 0.7 - V

Output "H" voltage VOH

VDDIO

-0.4

- VDDIO V

Output "L" voltage VOL 0.0 - 0.4 V

(Unless otherwise specified; VDD = 1.50 V, VDDIO = 3.00 V, GND = 0.0 V, Ta = 25 ℃, fIN = 36.0 MHz)

VDDIO

+0.3

VDDIO

x0.2

VDDIO

+0.3

VDDIO

x0.15

Normal input

V

(including the input mode of I/O terminal)

Normal input

V

(including the input mode of I/O terminal)

Hysteresis input

V

(RESETB, CAMCKI, SDA, SDC, I2CDEV0)

Hysteresis input

V

(RESETB, CAMCKI, SDA, SDC, I2CDEV0)

Hysteresis input

(RESETB, CAMCKI, SDA, SDC, I2CDEV0)

IOH = -1.0 mA (DC)

(including the output mode of I/O terminal)

IOL = 1.0 mA (DC)

(including the output mode of I/O terminal)

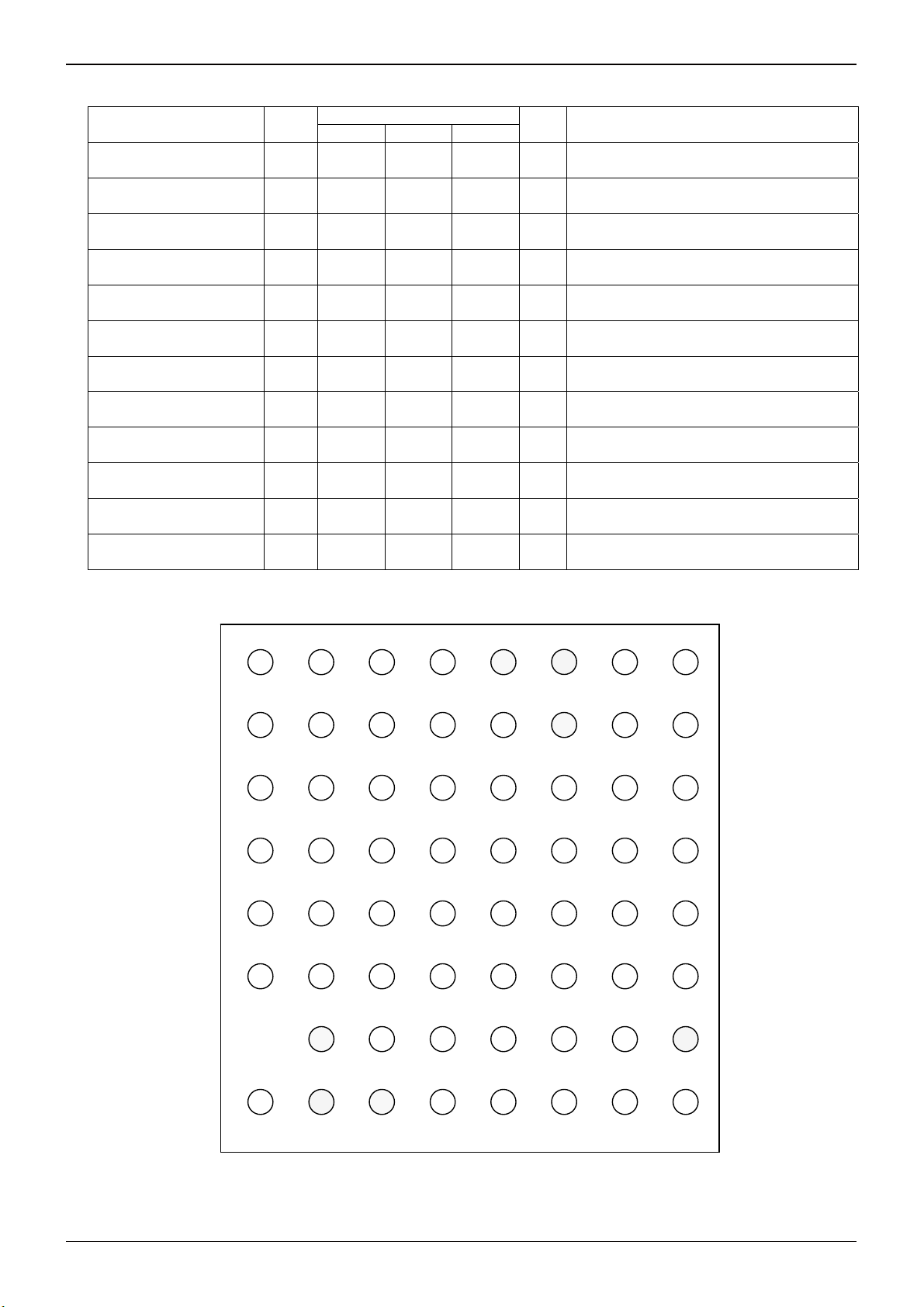

●Terminal Layout

H

17

RESERVEI2

18

RESERVEI3 22RESERVEI724RESERVEI927VDDIO

29

GND

G

15

RESERVEI0

16

RESERVEI1 20RESERVEI521RESERVEI6

25

RESERVEI10

30

VDD

F

13

CAMDI6

14

CAMDI7 19RESERVEI423RESERVEI8

26

RESERVEI1135RESERVEO1136RESERVEO10

E

11

CAMDI49 CAMDI2 10CAMDI312CAMDI528CAMCKI

39

RESERVEO737RESERVEO9

D

8

CAMDI1

5

SDC 7CAMDI060RESETB

44

RESERVEO242RESERVEO441RESERVEO5

C

6

I2CDEV0

4

SDA

3

CAMHSI58CAMHSO55CAMDO051CAMDO4

B

64

VDD 62CAMCKO57RESERVEO1253CAMDO252CAMDO348CAMDO7

A

1

CAMVSI

63

GND

61

VDDIO 59CAMVSO56I2CDEV6B54CAMDO150CAMDO5

1 2 3 4 5 6 7 8

Fig.1 Terminal Layout (Bottom View)

31

MSEL0

32

MSEL1

46

RESERVEO0

33

MSEL2

34

PWMO

38

RESERVEO8

40

RESERVEO6

43

RESERVEO3

45

RESERVEO1

47

GND

49

CAMDO6

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

2/12

2009.06 - Rev.A

Page 3

BU1574GUW

Technical Note

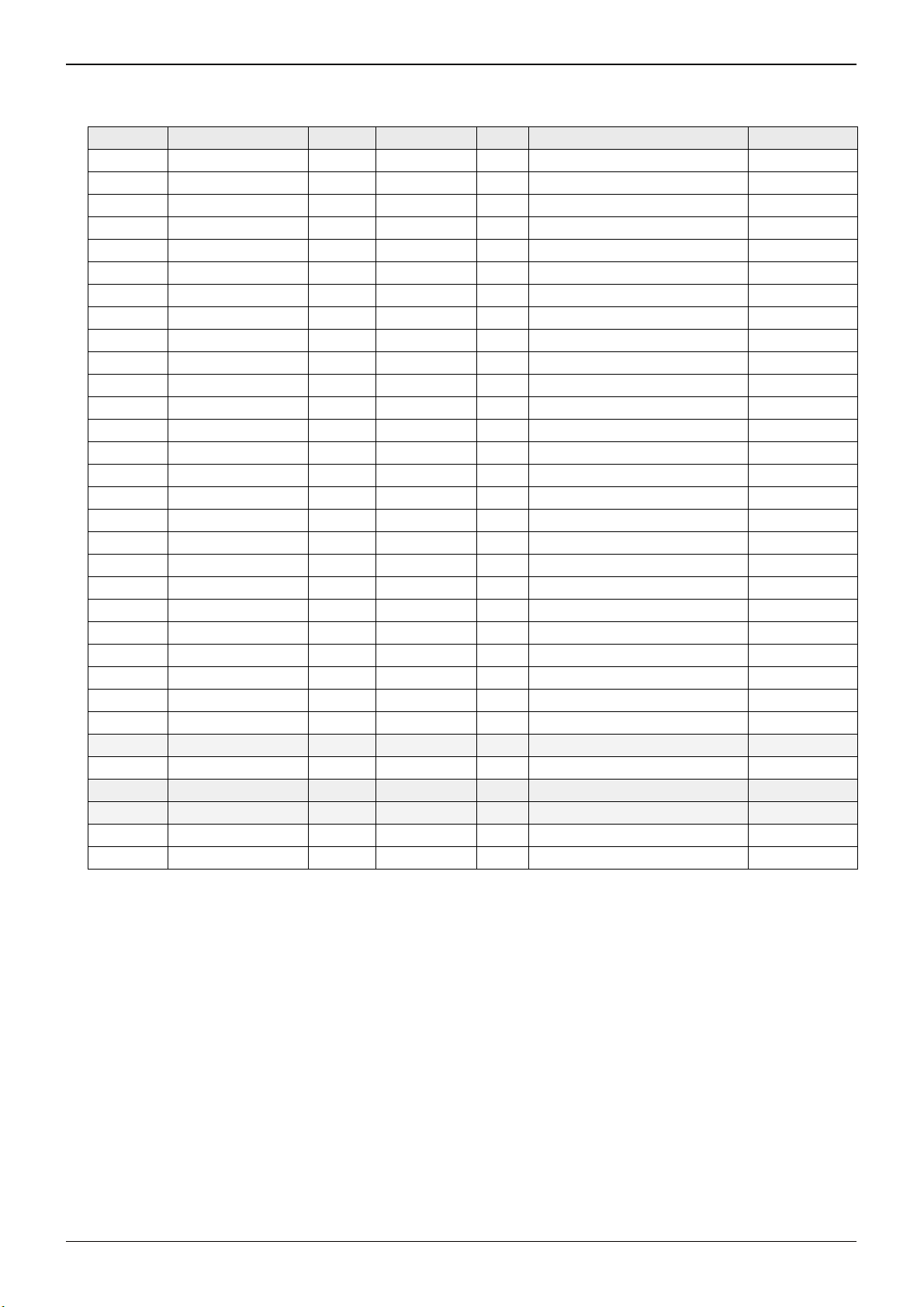

●Terminal functions

PIN No. Pin Name In/Out Active Level Init Descriptions In/Output type

1 CAMVSI In * - Vertical timing input C*1

2 N.C. *2 - - - - -

3 CAMHSI In * - Horizontal timing input C*1

4 SDA In/Out DATA In In/Output serial data F

5 SDC In CLK - In/Output serial clock D*1

6 I2CDEV0 In * - I2C device address setting D*1

7 CAMDI0 In DATA - Data input: bit 0 G*1

8 CAMDI1 In DATA - Data input: bit 1 G*1

9 CAMDI2 In DATA - Data input: bit 2 G*1

10 CAMDI3 In DATA - Data input: bit 3 G*1

11 CAMDI4 In DATA - Data input: bit 4 G*1

12 CAMDI5 In DATA - Data input: bit 5 G*1

13 CAMDI6 In DATA - Data input: bit 6 G*1

14 CAMDI7 In DATA - Data input: bit 7 G*1

15 RESERVEI0 *3 In * - RESERVE C*1

16 RESERVEI1 *3 In * - RESERVE C*1

17 RESERVEI2 *3 In * - RESERVE C*1

18 RESERVEI3 *3 In * - RESERVE C*1

19 RESERVEI4 *3 In * - RESERVE C*1

20 RESERVEI5 *3 In * - RESERVE C*1

21 RESERVEI6 *3 In * - RESERVE C*1

22 RESERVEI7 *3 In * - RESERVE C*1

23 RESERVEI8 *3 In * - RESERVE C*1

24 RESERVEI9 *3 In * - RESERVE C*1

25 RESERVEI10 *3 In * - RESERVE C*1

26 RESERVEI11 *3 In * - RESERVE C*1

27 VDDIO - PWR - DIGITAL IO power source -

28 CAMCKI In CLK - Clock input D*1

29 GND - GND - Common GROUND -

30 VDD - PWR - CORE power source -

31 MSEL0 *3 In * - Mode select 0 A

32 MSEL1 *3 In * - Mode select 1 A

*Change by setup by the register is possible for the "*" display in the column of an Active level. Moreover, Init is a pin state under reset.

*1 : It suspends during reset (initial state)

*2 : Please connect with GND

*3 : Please connect with GND.

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

3/12

2009.06 - Rev.A

Page 4

BU1574GUW

Technical Note

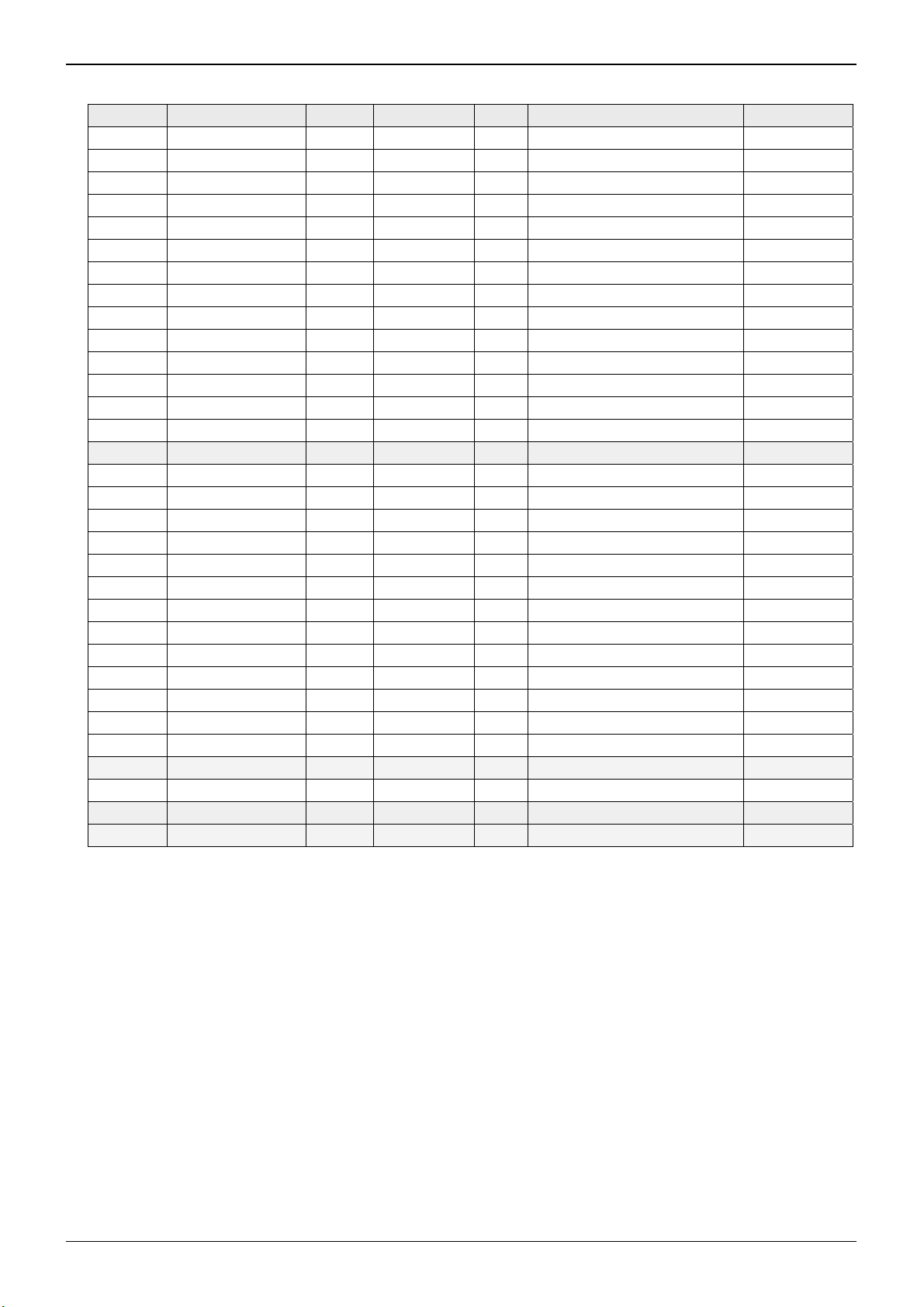

PIN No. Pin Name In/Out Active Level Init Descriptions In/Output type

33 MSEL2 *4 In * - Mode select 2 A

34 PWMO Out * Low PWM output for LCD backlight E

35 RESERVEO11 *5 Out * Low RESERVE E

36 RESERVEO10 *5 Out * Low RESERVE E

37 RESERVEO9 *5 Out * Low RESERVE E

38 RESERVEO8 *5 Out * Low RESERVE E

39 RESERVEO7 *5 Out * Low RESERVE E

40 RESERVEO6 *5 Out * Low RESERVE E

41 RESERVEO5 *5 Out * Low RESERVE E

42 RESERVEO4 *5 Out * Low RESERVE E

43 RESERVEO3 *5 Out * Low RESERVE E

44 RESERVEO2 *5 Out * Low RESERVE E

45 RESERVEO1 *5 Out * Low RESERVE E

46 RESERVEO0 *5 Out * Low RESERVE E

47 GND - GND - Common GROUND -

48 CAMDO7 Out DATA Low Data output: bit 7 E

49 CAMDO6 Out DATA Low Data output: bit 6 E

50 CAMDO5 Out DATA Low Data output: bit 5 E

51 CAMDO4 Out DATA Low Data output: bit 4 E

52 CAMDO3 Out DATA Low Data output: bit 3 E

53 CAMDO2 Out DATA Low Data output: bit 2 E

54 CAMDO1 Out DATA Low Data output: bit 1 E

55 CAMDO0 Out DATA Low Data output: bit 0 E

56 I2CDEV6B *3 In * - RESERVE A

57 RESERVEO12 *5 Out * High RESERVE E

58 CAMHSO Out * Low Horizontal timing output signal E

59 CAMVSO Out * Low Vertical timing output signal E

60 RESETB In Low - System reset signal B

61 VDDIO - PWR - DIGITAL IO power source -

62 CAMCKO Out CLK Low Clock output E

63 GND - GND - Common GROUND -

64 VDD - PWR - CORE power source -

*Change by setup by the register is possible for the "*" display in the column of an Active level. Moreover, Init is a pin state under reset.

*3 : Please connect with GND

*4 : Please connect with VDDIO

*5 : Leave OPEN

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

4/12

2009.06 - Rev.A

Page 5

BU1574GUW

●I/O pins equivalent circuit diagrams

Type Equivalent circuit structure Type Equivalent circuit structure

A

C

E

G

VDDIO

VDDIO

To internal

GND

GND

Input pin

VDDIO

Internal signal

VDDIO

GND

Internal signal

GND

Input pin with the suspend function

VDDIO

VDDIO

Internal signal

GND

GND

Output-pin

VDDIO

Internal signal

VDDIO

GND

To internal

VDDIO

Internal signal

Internal signal

VDDIO

B

GND

Input pin with the hysteresis function

VDDIO

D

GND

Input pin with the hysteresis and suspend functions

VDDIO

To internal

F

GND

In/output pin with the hysteresis function

GND

VDDIO

GND

GND

Internal signal

In/output pin with the suspend function

Fig.2 I/O pins equivalent circuit diagrams

Technical Note

To internal

To internal

Internal signal

Internal signal

Internal signal

Internal signal

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

5/12

2009.06 - Rev.A

Page 6

BU1574GUW

A

●Block diagram

Technical Note

CAMDI[17:0]

SD

SDC

CAMVSI

CAMHSI

CAMCKI

MSEL0/1/2

RESETB

Color correction

Brightness

distinction

Register

I2C interface

Timing generator

Image enhance

Gamma control

Edge

enhancement

PWM control

generation

CAMDO[17:0]

PWMO

CAMVSO

CAMHSO

CAMCKO

Fig.3 Block diagram

●Functional descriptions

1. Brightness distinction

Luminance of the input image is analyzed, and collection coefficient value is calculated. Calculated collection coefficient

value is kept until the next frame is input, and it is reflected on the image enhancement part and the color collection part

when the next frame is processed.

2. Image enhance

The correction operation is done to the luminance element of the input image based on the correction coefficient value

from the luminance distinction part.

It puts the chroma element from the color correction together, and outputs along output format.

It is possible to change correction strength of the output image.

3. Color correction

The correction operation is done to the chroma element of the input image based on the correction coefficient value from

the luminance distinction part. Color correction strength can be changed.

4. Edge enhancement

The edge emphasis filter is built into. The image is corrected to sharp image quality by emphasizing the outline.

Strength of the edge emphasis filter can be adjusted.

5. Gamma control

Gamma control can be given to the luminance element.

A line form is interpolated with a setup point of the gamma curve between the setup point nine points, and output value is

calculated from that curve.

6. PWM control generation

The PWM signal for the LCD backlight control can be output. There is a setup of a manual by the register in the DUTY

control of the PWM signal, and an auto-setup to be controlled automatically by BU1574GUW. As for the auto-setup,

DUTY is calculated from the luminance information of the input image every frame.

7. Register

The image correction parameter, the image size, and the format are set from the register.

The data of the register can be written by the I

2

C interface, and be read.

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

6/12

2009.06 - Rev.A

Page 7

BU1574GUW

8. Data input format

8.1 ITU-R BT.656 input format

8.1.1 Horizontal direction synchronization timing

CAMCKI

Technical Note

CAMDI0

-CAMDI7

1st 2nd 3rd 4th Cb0 Y0 Cr0 Y1 Cb359 Y718 Cr359 Y719 1st 2nd 3rd 4th 1st 2nd 3rd 4th

SAV EAV SAV

8.1.2 Vertical direction synchronization timing

Field 1

H bit

V bit

F bit

Field 2

H bit

V bit

F bit

52452512345 19202122

262 263 264 265 266 267 268 282 283 284 285

Fig.5 ITU-R BT.656 input format for NTSC (vertical direction)

Field 1

H bit

622 623 624 625 1 2 3 22 23 24 25

Valid data section

[NTSC] 1716 clocks / [PAL] 1728 clocks

Y: 720

Cb,Cr: 360

1440 clocks

720pixel

data

data

Fig.4 ITU-R BT.656 input format (horizontal direction)

V bit

F bit

Field 2

H bit

V bit

F bit

309 310 311 312 313 314 315 335 336 337 338

Fig.6 ITU-R BT.656 input format for PAL (vertical direction, bottom view)

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

7/12

2009.06 - Rev.A

Page 8

BU1574GUW

Technical Note

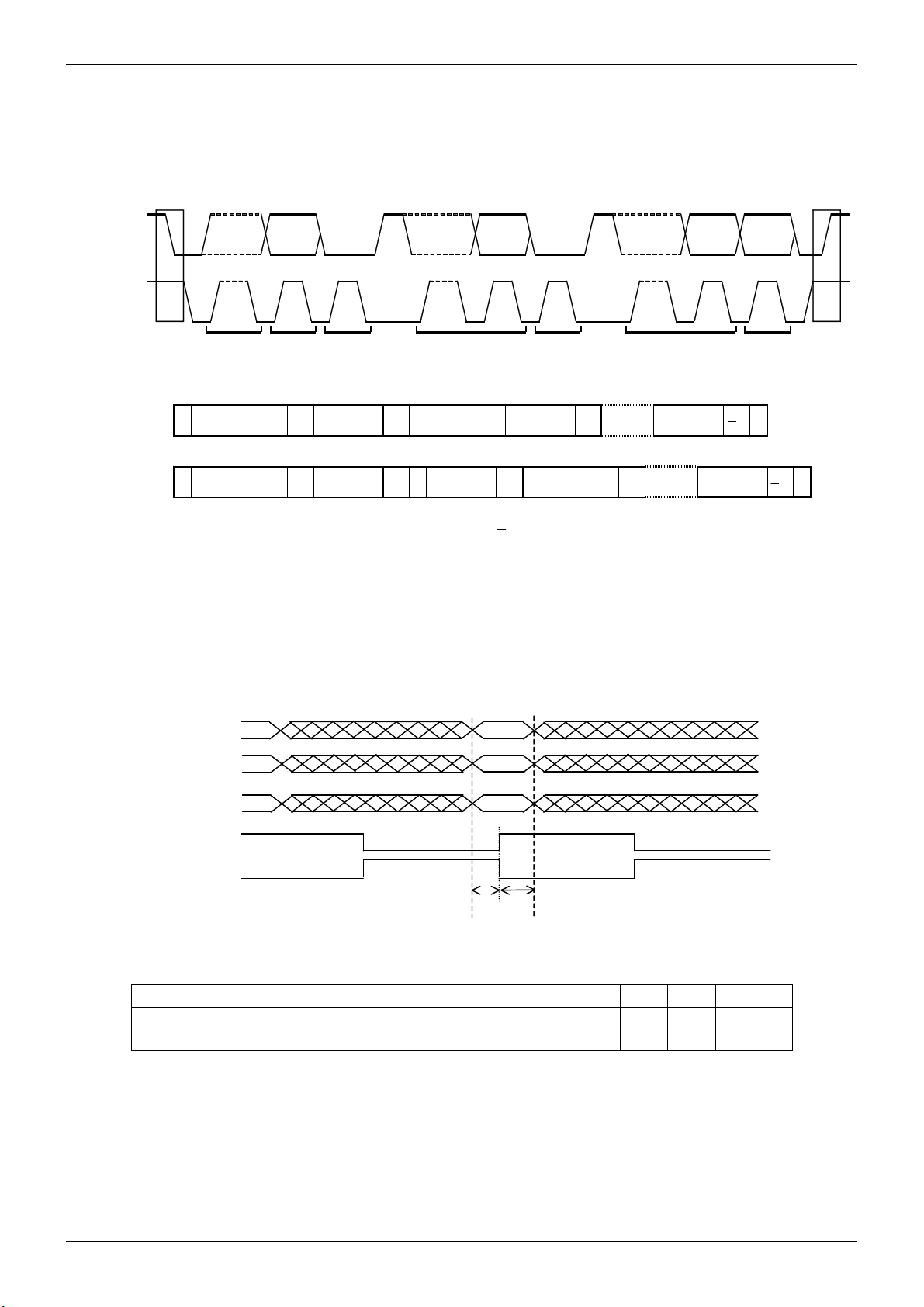

8.2. YCbCr with synchronizing signals 8-bit input format

8.2.1. Horizontal direction synchronization timing

CAMCKI

(*1)

YUV_XST

AIE_XST

×2

XSIZE ×2

AIE_XSIZE ×2

Image area

AIE varid area

CAMDI0

-CAMDI7

(*3)

CAMHSI

Y0 Cb0 Y1 Cr0 Y2 Cb1 Cr1Y3 Cr158 Y318 Y317 Cr158

Y0 Cb0 Y1 Cr0 Y2 Cb1 Cr1Y3 Cr158 Y318 Cb158

(*2)

(*2)

Y318 Cb159 Y319 Cr159Y318

Fig.7 Horizontal direction synchronization timing

(Note)

* YUV_XST, XSIZE x 2, AIE_XST x 2 and AIE_XSIZE×2, which are described in the figures and the notes, are set by the registers.

(*1) By changing the setting of the POL register (INDEX Address: E1h), the polarities of CAMCKI, CAMVSI and CAMHSI can be set independently.

The figure above shows the timing in the case that the data are fetched at the CAMCKI falling edge (CKPOL = 1 setting) and the polarity of

HSYNC is low active (HSPOL = 0 setting).

(*2) Set CAMHSI so as not to become 'L' in other sections than the sync section (CAMHSI = 'L' section in the figure shown above).

(*3) Do not change the frequency of CAMCKI during the operation.

(*4) Take note of the items described above to input each signal.

8.2.2. Vertical direction synchronization timing

YSIZE

AIE_YST line

AIE_YSIZE line

CAMHSI

CAMVSI

CAMDIO

-CAMDI7

Original image

Invalid area

Line.

1

Line.2Line.

3

AIE_YSIZE

-1

AIE_YSIZE

Fig.8 Vertical direction synchronization timing

(Note)

* Y_SIZE, AIE_YST and AIE_YSIZE, which are described in the figures and the notes, are set by the registers.

(*1) The figure above shows the timing in the case that the polarity of VSYNC is low active (VSPOL = 0 setting) and also the polarity of

HSYNC is low active (HSPOL = 0 setting).

(*2) Take note of the items described above to input each signal.

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

8/12

2009.06 - Rev.A

Page 9

BU1574GUW

2

C Interface format

9. I

Technical Note

The slave address is 42h when I2CDEV0 = 0 and 43h when I2CDEV0 = 1.

When both of the write and read accesses are respectively executed successively 2 times or more, the sub-address is

automatically incremented.

SDA

SDC

START

condition

Write

sequence

Read

sequence

Slave address

S

(42h or 43h)W(0)

Slave address

S

(42h or 43h)

S = START condition A(S) = acknowledge by slave A(S) = not acknowledge by slave

P = STOP condition A(M) = acknowledge by master A(M) = not acknowledge by master

●Timing chart

1. Data input interface timing

CAMVSI

CAMHSI

CAMDI0

-CAMDI7

CAMCKI

(CKPOL-“0”)

CAMCKI

(CKPOL-“1”)

Symbol Descriptions MIN TYP MAX Unit

tDS Setup time to CAMCKI rising / falling edge 8 - - ns

tDH Hold time to CAMCKI rising / falling edge 8 - - ns

Slav e

address

1-7 8S 1-789

R/W

91-789P

Data transfer

A(S) Sub address A(S) Data A(S) Data A(S) Data

W

A(S) Sub address A(S) S

(0)

Fig.9 I

Slave address

(42h or 43h)

2

C Interface format

R

(1)

t

DStDH

Fig.10 Data input interface timing

ACKACK ACKSub address Data

STOP

condition

A(S)/

P

A(S)

A(M)/

A(M) DataA(S) Data

A(M)

P

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

9/12

2009.06 - Rev.A

Page 10

BU1574GUW

I

C

2. Data output interface timing

CAMCKO

t

PCLK

Technical Note

CAMVSO

t

OCD

t

OCD

CAMHSO

t

ODD

CAMDO[7:0]

Fig.11 Data output interface timing

Symbol Descriptions MIN TYP MAX Unit

tPCLK Clock cycle 27.7 - - ns

dPCLK Clock duty 40 50 60 %

tODD CAMDO is defined from CAMCKO - - 5 ns

tOCD CAMVSO and CAMHSO are defined from CAMCKO - - 5 ns

2

C interface timing

3. I

SDA

t

SU;D AT

t

HD;DATtHIGH

Fig.12 I

t

SU;S TA

2

C interface timing

t

HD;ST

t

SU;S TO

t

BUF

SDC

t

HD;STA

t

LOW

Symbol Descriptions MIN TYP MAX Unit

fSCL SDC clock frequency 0 - 400 kHz

tHD;STA

Hold time (repeat) "START" condition

The first clock pulse is generated after this period

0.6 - - µs

fLOW SDC clock "L" period 1.3 - - µs

tHIGH SDC clock "H" period 0.6 - - µs

tSU;STA Repeat "START" condition setup time 0.6 - - µs

tHD;DAT Data hold time 0 µs

tSU;DAT Data setup time 100 - - ns

tSU;STO "STOP" condition setup time 0.6 - - µs

tBUF Bus free period between the "STOP" condition and "START" condition 1.3 - - µs

●Application example

CAMDO[7:0]

AMHSO

CAMVSO

CAMCKO

Image

pro cess ing

C

Camera

module

CAMDI[7:0]

CAMHSI

CAMVSI

CAMCKI

SDA

SDC

CAMDOI[7:0]

CAMHSI

BU15 74GUW

CAMVSI

CAMCKI

CAMDO[7:0]

CA MHS O

CA MVS O

CA MCK O

Fig.13 Application example

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

10/12

2009.06 - Rev.A

Page 11

BU1574GUW

Technical Note

●Notes for use

(1) Absolute Maximum Ratings

An excess in the absolute maximum ratings, such as supply voltage, temperature range of operating conditions, etc., can break

down devices, thus making impossible to identify breaking mode such as a short circuit or an open circuit. If any special mode

exceeding the absolute maximum ratings is assumed, consideration should be given to take physical safety measures including

the use of fuses, etc.

(2) Operating conditions

These conditions represent a range within which characteristics can be provided approximately as expected. The electrical

characteristics are guaranteed under the conditions of each parameter.

(3) Reverse connection of power supply connector

The reverse connection of power supply connector can break down ICs. Take protective measures against the breakdown due

to the reverse connection, such as mounting an external diode between the power supply and the IC’s power supply terminal.

(4) Power supply line

Design PCB pattern to provide low impedance for the wiring between the power supply and the GND lines.

In this regard, for the digital block power supply and the analog block power supply, even though these power supplies has the

same level of potential, separate the power supply pattern for the digital block from that for the analog block, thus suppressing

the diffraction of digital noises to the analog block power supply resulting from impedance common to the wiring patterns. For

the GND line, give consideration to design the patterns in a similar manner.

Furthermore, for all power supply terminals to ICs, mount a capacitor between the power supply and the GND terminal. At the

same time, in order to use an electrolytic capacitor, thoroughly check to be sure the characteristics of the capacitor to be used

present no problem including the occurrence of capacity dropout at a low temperature, thus determining the constant.

(5) GND voltage

Make setting of the potential of the GND terminal so that it will be maintained at the minimum in any operating state.

Furthermore, check to be sure no terminals are at a potential lower than the GND voltage including an actual electric transient.

(6) Short circuit between terminals and erroneous mounting

In order to mount ICs on a set PCB, pay thorough attention to the direction and offset of the ICs. Erroneous mounting can break

down the ICs. Furthermore, if a short circuit occurs due to foreign matters entering between terminals or between the terminal

and the power supply or the GND terminal, the ICs can break down.

(7) Operation in strong electromagnetic field

Be noted that using ICs in the strong electromagnetic field can malfunction them.

(8) Inspection with set PCB

On the inspection with the set PCB, if a capacitor is connected to a low-impedance IC terminal, the IC can suffer stress.

Therefore, be sure to discharge from the set PCB by each process. Furthermore, in order to mount or dismount the set PCB

to/from the jig for the inspection process, be sure to turn OFF the power supply and then mount the set PCB to the jig. After the

completion of the inspection, be sure to turn OFF the power supply and then dismount it from the jig. In addition, for protection

against static electricity, establish a ground for the assembly process and pay thorough attention to the transportation and the

storage of the set PCB.

(9) Input terminals

In terms of the construction of IC, parasitic elements are inevitably formed in relation to potential. The operation of the parasitic

element can cause interference with circuit operation, thus resulting in a malfunction and then breakdown of the input terminal.

Therefore, pay thorough attention not to handle the input terminals, such as to apply to the input terminals a voltage lower than

the GND respectively, so that any parasitic element will operate. Furthermore, do not apply a voltage to the input terminals when

no power supply voltage is applied to the IC. In addition, even if the power supply voltage is applied, apply to the input terminals

a voltage lower than the power supply voltage or within the guaranteed value of electrical characteristics.

(10) Ground wiring pattern

If small-signal GND and large-current GND are provided, It will be recommended to separate the large-current GND pattern

from the small-signal GND pattern and establish a single ground at the reference point of the set PCB so that resistance to the

wiring pattern and voltage fluctuations due to a large current will cause no fluctuations in voltages of the small-signal GND. Pay

attention not to cause fluctuations in the GND wiring pattern of external parts as well.

(11) External capacitor

In order to use a ceramic capacitor as the external capacitor, determine the constant with consideration given to a degradation

in the nominal capacitance due to DC bias and changes in the capacitance due to temperature, etc.

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

11/12

2009.06 - Rev.A

Page 12

BU1574GUW

●Ordering part number

B U 1 5 7 4 G U W - E 2

ROHM model

name

●Package specification

VBGA063W050

1PIN MARK

0.08 S

63-φ0.295±0.05

M

φ

0.05

Product number Package type

5.0±0.1

5.0± 0.1

0.10

S

0.9MAX

0.75±0.1

P=0.5×7

0.5

ABS

A

H

G

F

E

D

C

B

A

B

0.5

51

3

762

4

P=0.5×7

8

0.75±0.1

(Unit : mm)

<Tape and Reel information>

Quantity

Direction

of feed

Taping model name

GUW: VBGA063W050

Embossed carrier tape (with dry pack)Tape

2500pcs

E2

The direction is the 1pin of product is at the upper left when you hold

()

reel on the left hand and you pull out the tape on the right hand

Reel

1pin

Order quantity needs to be multiple of the minimum quantity.

∗

E2: Embossed reel tape

Technical Note

Direction of feed

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

12/12

2009.06 - Rev.A

Page 13

Notes

No copying or reproduction of this document, in part or in whole, is permitted without the

consent of ROHM Co.,Ltd.

The content specied herein is subject to change for improvement without notice.

The content specied herein is for the purpose of introducing ROHM's products (hereinafter

"Products"). If you wish to use any such Product, please be sure to refer to the specications,

which can be obtained from ROHM upon request.

Examples of application circuits, circuit constants and any other information contained herein

illustrate the standard usage and operations of the Products. The peripheral conditions must

be taken into account when designing circuits for mass production.

Great care was taken in ensuring the accuracy of the information specied in this document.

However, should you incur any damage arising from any inaccuracy or misprint of such

information, ROHM shall bear no responsibility for such damage.

The technical information specied herein is intended only to show the typical functions of and

examples of application circuits for the Products. ROHM does not grant you, explicitly or

implicitly, any license to use or exercise intellectual property or other rights held by ROHM and

other par ties. ROHM shall bear no responsibility whatsoever for any dispute arising from the

use of such technical information.

Notice

The Products specied in this document are intended to be used with general-use electronic

equipment or devices (such as audio visual equipment, ofce-automation equipment, communication devices, electronic appliances and amusement devices).

The Products specied in this document are not designed to be radiation tolerant.

While ROHM always makes efforts to enhance the quality and reliability of its Products, a

Product may fail or malfunction for a variety of reasons.

Please be sure to implement in your equipment using the Products safety measures to guard

against the possibility of physical injury, re or any other damage caused in the event of the

failure of any Product, such as derating, redundancy, re control and fail-safe designs. ROHM

shall bear no responsibility whatsoever for your use of any Product outside of the prescribed

scope or not in accordance with the instruction manual.

The Products are not designed or manufactured to be used with any equipment, device or

system which requires an extremely high level of reliability the failure or malfunction of which

may result in a direct threat to human life or create a risk of human injury (such as a medical

instrument, transpor tation equipment, aerospace machinery, nuclear-reactor controller,

fuel-controller or other safety device). ROHM shall bear no responsibility in any way for use of

any of the Products for the above special purposes. If a Product is intended to be used for any

such special purpose, please contact a ROHM sales representative before purchasing.

If you intend to export or ship overseas any Product or technology specied herein that may

be controlled under the Foreign Exchange and the Foreign Trade Law, you will be required to

obtain a license or permit under the Law.

Thank you for your accessing to ROHM product informations.

More detail product informations and catalogs are available, please contact us.

ROHM Customer Support System

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

http://www.rohm.com/contact/

R0039

A

Loading...

Loading...