R&S®RTO-K91, R&S®RTO6-K91,

R&S®RTP-K91

DDR3 Compliance Test

User Manual

(;ÜåÕ2)

1178877102

Version 07

This document describes the following DDR3 Compliance Test Procedures:

●

R&S®RTO-K91 (1337.8891.02)

●

R&S®RTO6-K91 (1801.6993.02)

●

R&S®RTP-K91 (1337.8840.02)

© 2021 Rohde & Schwarz GmbH & Co. KG

Mühldorfstr. 15, 81671 München, Germany

Phone: +49 89 41 29 - 0

Email: info@rohde-schwarz.com

Internet: www.rohde-schwarz.com

Subject to change – data without tolerance limits is not binding.

R&S® is a registered trademark of Rohde & Schwarz GmbH & Co. KG.

Trade names are trademarks of the owners.

1178.8771.02 | Version 07 | R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

Throughout this manual, products from Rohde & Schwarz are indicated without the ® symbol , e.g. R&S®ScopeSuite is indicated as

R&S ScopeSuite.

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

Contents

1 R&S ScopeSuite Overview....................................................................7

2 Preparing the Measurements................................................................9

2.1 Test Equipment..............................................................................................................9

2.1.1 Soldering Guide for Modular Probes...............................................................................9

2.2 Installing Software and License.................................................................................. 9

2.3 Setting Up the Network...............................................................................................10

2.4 Starting the R&S ScopeSuite..................................................................................... 11

2.5 Connecting the R&S RTO/RTO6/RTP........................................................................ 11

2.6 Report Configuration.................................................................................................. 13

3 Performing Tests..................................................................................14

Contents

3.1 Starting a Test Session...............................................................................................14

3.2 Configuring the Test................................................................................................... 15

3.2.1 General Test Settings....................................................................................................16

3.2.2 Test Configuration for DDR3......................................................................................... 18

3.3 Initiating the Test.........................................................................................................21

3.4 Getting Test Results....................................................................................................22

3.5 Starting DDR3 Tests....................................................................................................23

4 Timing Tests......................................................................................... 24

4.1 Clock Timing................................................................................................................24

4.1.1 Test Equipment............................................................................................................. 24

4.1.2 Performing the Tests..................................................................................................... 24

4.1.3 Test Setup..................................................................................................................... 25

4.1.4 Measurements.............................................................................................................. 25

4.2 Data Timing..................................................................................................................27

4.2.1 Test Equipment............................................................................................................. 27

4.2.2 Performing the Tests..................................................................................................... 27

4.2.3 Test Setup..................................................................................................................... 28

4.2.4 Measurements.............................................................................................................. 29

4.3 Strobe Timing.............................................................................................................. 30

4.3.1 Test Equipment............................................................................................................. 30

3User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

4.3.2 Performing the Tests..................................................................................................... 30

4.3.3 Test Setup..................................................................................................................... 31

4.3.4 Measurements.............................................................................................................. 32

4.4 Command Timing........................................................................................................34

4.4.1 Test Equipment............................................................................................................. 34

4.4.2 Performing the Tests..................................................................................................... 34

4.4.3 Test Setup..................................................................................................................... 35

4.4.4 Measurements.............................................................................................................. 36

4.5 Address Timing........................................................................................................... 37

4.5.1 Test Equipment............................................................................................................. 37

4.5.2 Performing the Tests..................................................................................................... 37

4.5.3 Measurements.............................................................................................................. 38

4.6 Chip Select Timing......................................................................................................39

Contents

4.6.1 Test Equipment............................................................................................................. 39

4.6.2 Performing the Tests..................................................................................................... 39

4.6.3 Test Setup..................................................................................................................... 40

4.6.4 Measurements.............................................................................................................. 40

4.7 Clock Enable Timing...................................................................................................41

4.7.1 Test Equipment............................................................................................................. 41

4.7.2 Performing the Tests..................................................................................................... 41

4.7.3 Test Setup..................................................................................................................... 42

4.7.4 Measurements.............................................................................................................. 42

5 Electrical Tests..................................................................................... 44

5.1 Single-Ended Signals................................................................................................. 44

5.1.1 Input Slew Rate for ADD and CMD...............................................................................44

5.1.2 Input Slew Rate for DQ and DM....................................................................................46

5.1.3 AC & DC Input Levels for ADD and CMD..................................................................... 48

5.1.4 AC Input Levels for CK and DQS..................................................................................50

5.1.5 Output Slew Rate for DQ.............................................................................................. 52

5.1.6 AC & DC Output Levels for DQ.....................................................................................53

5.1.7 AC Overshoot & Undershoot for ADD and CMD...........................................................55

5.1.8 AC Overshoot & Undershoot for CK, DQ, DQS, and DM..............................................57

5.2 Differential Signals......................................................................................................59

4User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

5.2.1 AC Input Levels for CK and DQS..................................................................................59

5.2.2 AC Differential Cross Point Voltage for CK................................................................... 61

5.2.3 Differential Output Slew Rate for DQS..........................................................................63

5.2.4 Differential AC Output Levels for DQS..........................................................................65

6 Debug Tests..........................................................................................68

6.1 Trigger Write Cycle......................................................................................................68

6.1.1 Test Equipment............................................................................................................. 68

6.1.2 Performing the Tests..................................................................................................... 68

6.1.3 Test Setup..................................................................................................................... 69

6.1.4 Measurements.............................................................................................................. 69

6.2 Trigger Read Cycle......................................................................................................69

6.2.1 Test Equipment............................................................................................................. 69

Contents

6.2.2 Performing the Tests..................................................................................................... 69

6.2.3 Test Setup..................................................................................................................... 70

6.2.4 Measurements.............................................................................................................. 70

5User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

Contents

6User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

1 R&S ScopeSuite Overview

The R&S ScopeSuite software is used with R&S RTO/RTO6/RTP oscilloscopes. It can

be installed on a test computer or directly on the oscilloscope. For system requirements, refer to the Release Notes.

R&S ScopeSuite Overview

The R&S ScopeSuite main panel has several areas:

●

"Settings": connection settings to oscilloscope and other instruments also default

report settings

●

"Compliance Tests": selection of the compliance test

●

"Demo": accesses demo test cases that can be used for trying out the software

without having a connection to an oscilloscope

●

"Help": opens the help file, containing information about the R&S ScopeSuite configuration

●

"About": gives information about the R&S ScopeSuite software

●

"Tile View": allows a personalization of the compliance test selection

You can configure which tests are visible in the compliance test section and which

are hidden, so that only the ones you use are displayed.

► To hide a test from the "Compliance Tests" view, do one of the following:

7User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

a) Right-click on the compliance test you want to hide.

The icon of the test changes, see Figure 1-1. Now with a left click you can hide

the test.

Figure 1-1: Unpin icon

b) Click on "Title View" to show a list of the available test cases. By clicking a test

case in the show list, you can pin/unpin it from the main panel.

R&S ScopeSuite Overview

8User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

2 Preparing the Measurements

2.1 Test Equipment

For DDR3 compliance tests, the following test equipment is needed:

●

R&S RTP with 4 channels and minimum 8 GHz bandwidth, or

R&S RTO2000 with 4 channels and minimum 4 GHz bandwidth

R&S RTO6 with 4 channels and minimum 4 GHz bandwidth

●

R&S RTO/RTO6/RTP-K91 DDR3 compliance test option (required option, installed

on the R&S RTO/RTO6/RTP)

●

4 modular probes, R&S ZM90 with 9 GHz bandwidth. See also Chapter 2.1.1,

"Soldering Guide for Modular Probes", on page 9.

●

4 modular probe tips R&S RT-ZMA10

●

The free-of-charge R&S ScopeSuite software, which can be installed on a computer or directly on the R&S RTO/RTO6/RTP.

Preparing the Measurements

Installing Software and License

2.1.1 Soldering Guide for Modular Probes

All single-ended signals such as ADD, CMD, DQ, DM, CS, CKE should be soldered in

such a way that the signal is connected to the + part on the probe tip. The ground of

the signal is connected to the - part on the same probe tip.

All differential signals such as CK, DQS should be soldered differentially:

●

The + signal is connected to the + part on the probe tip.

●

The - signal is connected to the - part on the same probe tip.

●

The ground of the signal is connected to the ground of the same probe tip.

2.2 Installing Software and License

The preparation steps are performed only once for each computer and instrument that

are used for testing.

Uninstall older versions of the R&S ScopeSuite

If an older version of the R&S ScopeSuite is installed, make sure to uninstall the old

version before you install the new one. You can find the version number of the current

installation in "Help" menu > "About". To uninstall the R&S ScopeSuite, use the Windows " Control Panel" > "Programs".

For best operation results, we recommend that the installed firmware versions of the

R&S ScopeSuite and the oscilloscope are the same.

9User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

To install the R&S ScopeSuite

1. Download the latest R&S ScopeSuite software from the "Software" section on the

Rohde & Schwarz R&S RTO/RTO6/RTP website:

www.rohde-schwarz.com/product/rtp.html

www.rohde-schwarz.com/product/rto.html

2. Install the R&S ScopeSuite software:

● On the computer that is used for testing, or

● On the R&S RTO/RTO6/RTP.

For system requirements, refer to the Release Notes.

To install the license key on the R&S RTO/RTO6/RTP

► When you got the license key of the compliance test option, enable it on the oscil-

loscope using [Setup] > "SW Options".

For a detailed description, refer to the R&S RTO/RTO6/RTP user manual, chapter

"Installing Options", or to the online help on the instrument.

Preparing the Measurements

Setting Up the Network

2.3 Setting Up the Network

If the R&S ScopeSuite software runs on a test computer, the computer and the testing

oscilloscope require a LAN connection.

There are two ways of connection:

●

LAN (local area network): It is recommended that you connect to a LAN with DHCP

server. This server uses the Dynamic Host Configuration Protocol (DHCP) to

assign all address information automatically.

If no DHCP server is available, or if the Tabor WX2182B or WX2182C is used for

automatic testing, assign fixed IP addresses to all devices.

●

Direct connection of the instruments and the computer or connection to a switch

using LAN cables: Assign fixed IP addresses to the computer and the instruments

and reboot all devices.

To set up and test the LAN connection

1. Connect the computer and the instruments to the same LAN.

2. Start all devices.

3. If no DHCP server is available, assign fixed IP addresses to all devices.

4. Ping the instruments to make sure that the connection is established.

5. If VISA is installed, check if VISA can access the instruments.

a) Start VISA on the test computer.

b) Validate the VISA address string of each device.

10User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

See also:

●

Chapter 2.5, "Connecting the R&S RTO/RTO6/RTP", on page 11

2.4 Starting the R&S ScopeSuite

To start the R&S ScopeSuite on the test computer or on the oscilloscope:

► Double-click the R&S ScopeSuite program icon.

To start the R&S ScopeSuite on the instrument, in the R&S RTO/RTO6/RTP firmware:

► In the "Apps" dialog, open the "Compliance" tab.

2.5 Connecting the R&S RTO/RTO6/RTP

Preparing the Measurements

Connecting the R&S RTO/RTO6/RTP

If the R&S ScopeSuite is installed directly on the instrument, the software detects the

R&S RTO/RTO6/RTP firmware automatically, and the "Oscilloscope" button is not

available in the R&S ScopeSuite.

If the R&S ScopeSuite software runs on a test computer, the computer and the testing

oscilloscope require a LAN connection, see Chapter 2.3, "Setting Up the Network",

on page 10. The R&S ScopeSuite software needs the IP address of the oscilloscope to

establish connection.

1. Start the R&S RTO/RTO6/RTP.

2. Start the R&S ScopeSuite software.

3. Click "Settings" > "Oscilloscope".

11User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

Preparing the Measurements

Connecting the R&S RTO/RTO6/RTP

4. Enter the IP address of the oscilloscope.

To obtain the IP address: press the Rohde & Schwarz logo at the top-right corner

of the oscilloscope's display.

5. Click "Get Instrument Information".

The computer connects with the instrument and gets the instrument data.

12User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

If the connection fails, an error message is shown.

2.6 Report Configuration

In the "Report Configuration" menu, you can select the format of the report and the

details to be included in the report. You can also select an icon that is displayed in the

upper left corner of the report.

Also, you can enter common information on the test that is written in the "General Information" section of the test report.

Preparing the Measurements

Report Configuration

13User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

3 Performing Tests

3.1 Starting a Test Session

Performing Tests

Starting a Test Session

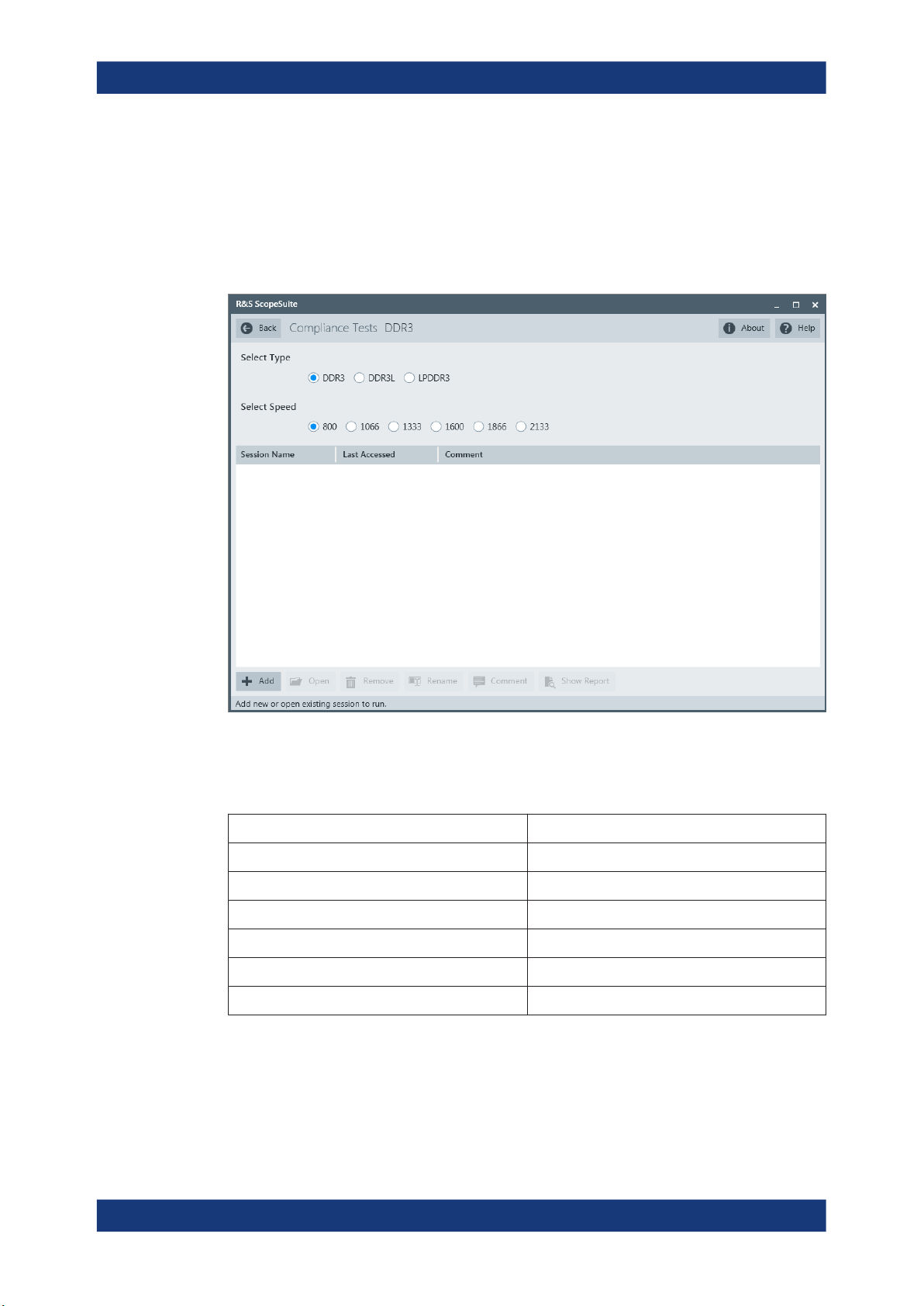

After you open a compliance test, the "Session Selection" dialog appears. In this dialog, you can create new sessions, open or view existing report.

The following functions are available for handling test sessions:

Function Description

"Add" Adds a new session

"Open" Opens the selected session

"Remove" Removes the selected session

"Rename" Changes the "Session Name"

"Comment" Adds a comment

"Show report" Generates a report for the selected session

To add a test session

1. In the R&S ScopeSuite window, select the compliance test.

2. In the "Session Selection" dialog press "Add".

3. If necessary change the "Session Name"

14User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

To open a test session

1. In the R&S ScopeSuite window, select the compliance test.

2. In the "Session Selection" dialog, select the session you want to open and double

click on it.

Alternatively, select the session and press "Open".

To show a report for a test session

1. In the R&S ScopeSuite window, select the compliance test.

2. In the "Session Selection" dialog, select the session you want the report for and

press "Show report".

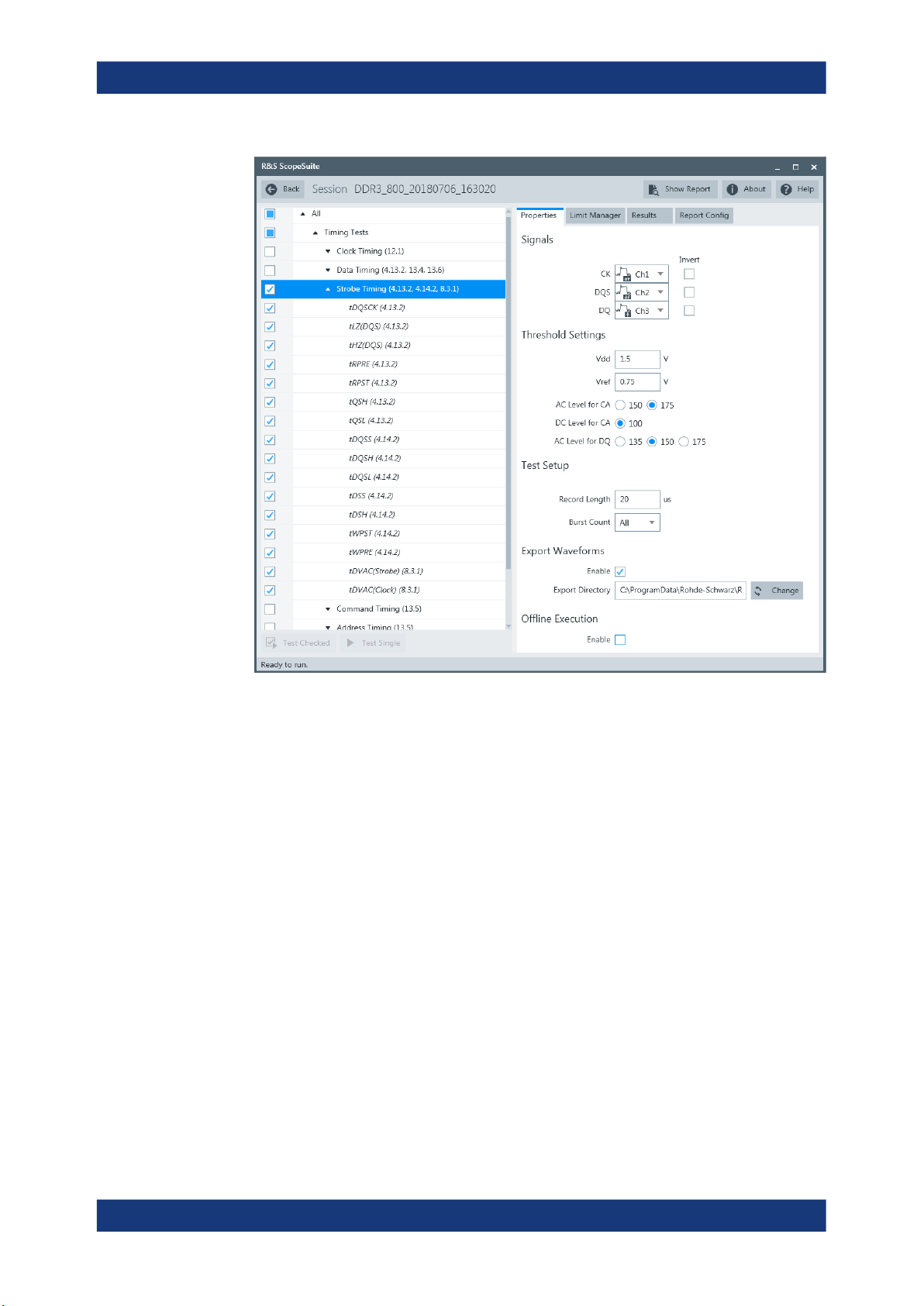

3.2 Configuring the Test

Performing Tests

Configuring the Test

1. In the R&S ScopeSuite window, select the compliance test to be performed:

● "DDR3"

2. Open a test session, see Chapter 3.1, "Starting a Test Session", on page 14.

3. Adjust the "Properties" settings for the test cases you want to perform.

4. Click "Limit Manager" and edit the limit criteria, see Chapter 3.2.1.1, "Limit Man-

ager", on page 17.

5. If you want to use special report settings the "Report Config" tab to define the format and contents of the report. Otherwise the settings defined in "RSScopeSuite" >

"Settings" > "Report" are used. See Chapter 2.6, "Report Configuration",

on page 13.

6. Click "Test Checked"/"Test Single" and proceed as described in the relevant test

case chapter.

15User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

3.2.1 General Test Settings

Performing Tests

Configuring the Test

Each session dialog is divided into several sections:

●

"Properties": shows the settings that can be made for the test case selected on the

left side of the dialog. You can differentiate between the "All" and the sub test properties

In the "All" > "Properties" tab you can configure the settings for all test cases in the

current session. Once you change and save a setting in this tab, the changes will

be done for all test in the sessions. At the same time, there will be a special marking for the functions that have different settings for different sub tests.

●

"Limit Manager": sets the measurement limits that are used for compliance testing,

see Chapter 3.2.1.1, "Limit Manager", on page 17.

●

"Results": shows an overview of the available test results for this session.

●

"Instruments": defines instruments settings for connecting to external devices, that

are specific for this test session.

When a session is first created the global settings ("RSScopeSuite" > "Settings" >

"Instruments") are copied to the session. This "Instruments" tab can be used to

change those copied defaults.

●

"Report Config": defines the format and contents of the report for this session.

16User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

When a session is first created the global settings ("RSScopeSuite" > "Settings" >

"Report") are copied to the session. This "Report Config" tab can be used to

change those copied defaults.

●

"Test Checked"/ "Test Single": starts the selected test group.

3.2.1.1 Limit Manager

The "Limit Manager" shows the measurement limits that are used for compliance testing.

Each limit comprises the comparison criterion, the unit, the limit value A, and a second

limit value B if the criterion requires two limits.

You can set the values to defaults, change the values in the table, export the table in

xml format, or import xml files with limit settings.

► Check and adjust the measurement limits.

Performing Tests

Configuring the Test

17User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

Performing Tests

Configuring the Test

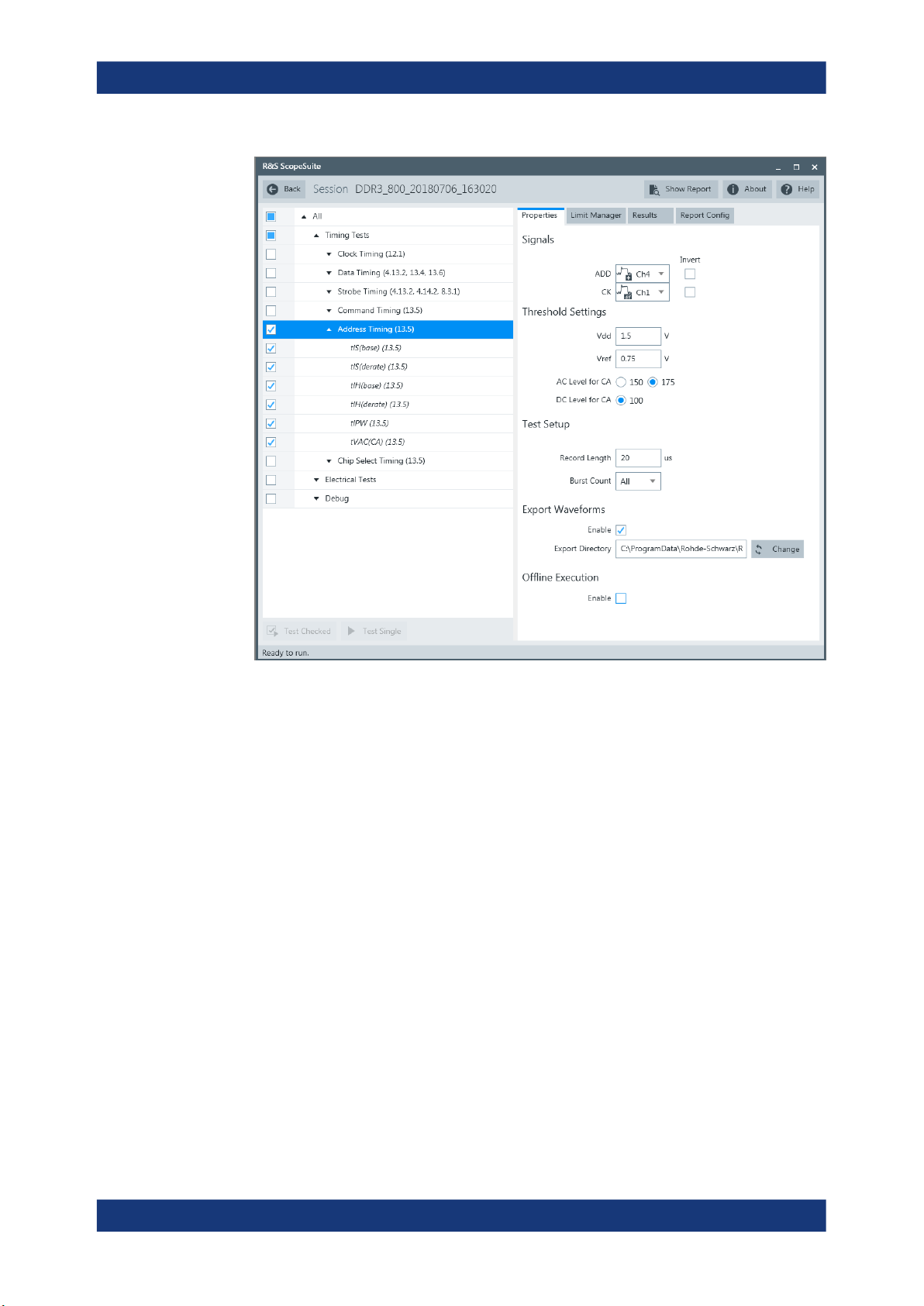

3.2.2 Test Configuration for DDR3

The test configuration consists of some test-specific configuration settings. The values

for the settings in this tab depend on the selected "Speed" and "Type" of standard.

18User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

Performing Tests

Configuring the Test

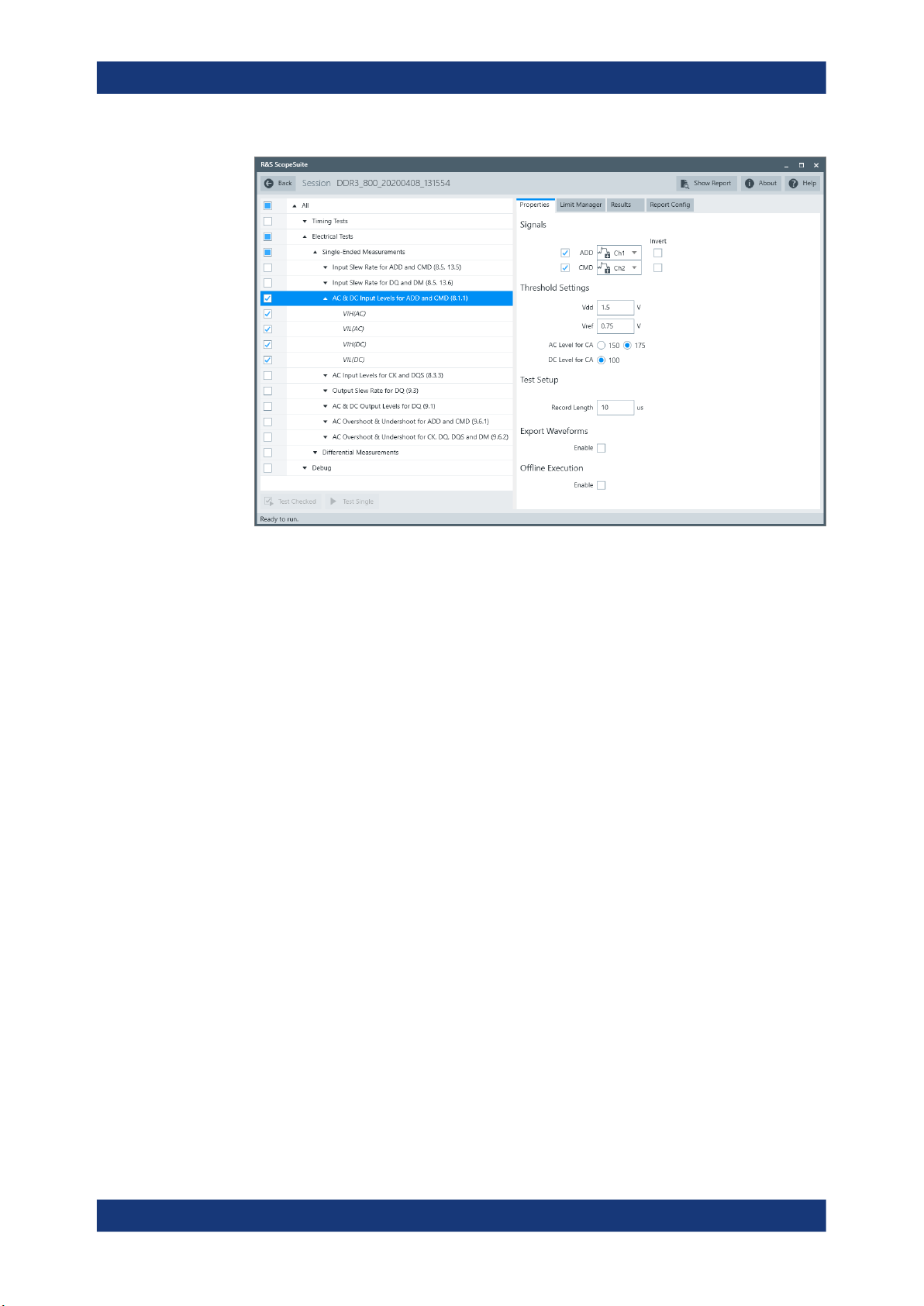

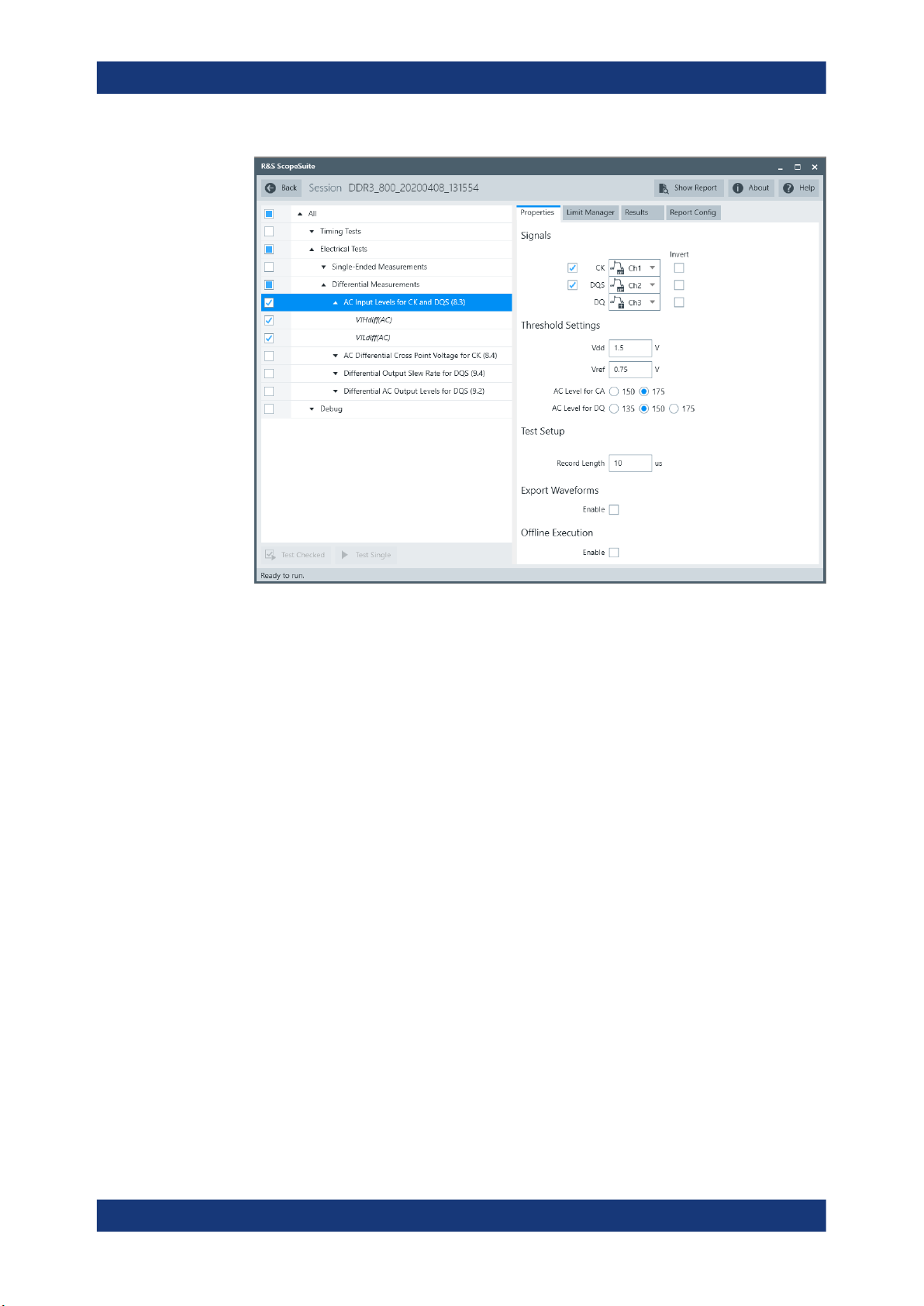

Figure 3-1: Configuration for DDR3 compliance tests

Signals

Selects the channel for the specified signal.

For electrical tests consider also how many test signals are enabled. For example, if

only the ADD/CMD signal is selected, only ADD/CMD signal is used to run the test. If

both the ADD and the CMD signals are selected, test is run using ADD signal first, followed by the CMD signal.

The following signals are available according to the selected test case:

"ADD"

"CMD"

"CK"

"DQS"

"DQ"

"DM"

"CS"

"CKE"

Address signal.

Command signal.

Differential clock input signal.

Data strobe signal.

Data input/output signal.

Data mask signal.

Chip select signal.

Clock enable signal.

19User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

Threshold Settings

The following threshold settings are defined:

"VDD"

Power Supply: 1.5 V +/- 0.075 V

Performing Tests

Configuring the Test

"V

"

REF

"VSS"

"V

"

DDQ

"VTT"

"V

"

SSQ

"AC Level for

Reference voltage

Ground

DQ Power Supply: 1.5 V +/- 0.075 V

VTT = V

DDQ

/2

DQ Ground

AC level for the command address.

CA"

"DC Level for

DC level for the command address.

CA"

"AC Level for

AC level for the data input/output signal.

DQ"

"DC Level for

DC level for the data input/output signal.

DQ"

Average Window

Sets the average window in periods.

Record Length

Sets the number of waveform samples in one waveform record.

Burst Count

Sets the burst count.

Speed Bin

Selects which speed bin is used for the tests.

CAS Latency (CL)

Selects the value for the CAS latency. This is the delay, measured in clock cycles,

between the internal read command and the availability of the first bit of output data.

CAS Write Latency (CWL)

Selects the value for the CAS write latency. This is the delay, measured in clock cycles,

between the internal write command and the availability of the first bit input data.

Export Waveforms

Enables you to export a waveform. You can later load the waveforms to run the tests in

the offline mode, see Offline Execution.

You can define an export directory, or use the default one:

MyDocuments\Rohde-Schwarz\RSScopeSuite\<Version>\Waveforms\

<ComplianceTest>\<SubTest>\<Speed>\<SessionName>

For example:

20User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

MyDocuments\Rohde-Schwarz\RSScopeSuite\4.10.0\Waveforms\DDR3\

DDR3\1333\DDR3_1333_20180413_144116

Offline Execution

Performing Tests

Initiating the Test

If enabled, allows you to use exported waveforms as a source for the execution of the

compliance test.

You can select one waveform for each needed signal.

3.3 Initiating the Test

To perform compliance tests, the device under test is connected to the test board in a

test-specific way. Using a probe, the test board is connected with the R&S RTO/RTO6/

RTP. The probe connections are test-specific. The R&S ScopeSuite guides you stepby-step through the connection setup and the test sequence.

1. Set the test setup on a nonconductive, static-approved work surface.

2. In the R&S ScopeSuite window, select the compliance test.

3. Open a test session, see Chapter 3.1, "Starting a Test Session", on page 14.

21User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

4. Check the test configuration settings and adjust, if necessary. See: Chapter 3.2,

"Configuring the Test", on page 15.

5. Click "Test Checked" for starting all checked test cases or "Test Single" for starting

only the selected test case.

The R&S ScopeSuite test wizard explains the following individual setup steps. A

detailed test description can be found in the following chapters:

● Chapter 3.5, "Starting DDR3 Tests", on page 23

3.4 Getting Test Results

For each test, the test data - report, diagrams and waveform files - is saved in the following folder:

%ProgramData%\Rohde-Schwarz\RSScopeSuite2\<version>\Sessions\DDR3\

<Session_Name>

Performing Tests

Getting Test Results

If you resume an existing session, new measurements are appended to the report,

new diagrams and waveform files are added to the session folder. Existing files are not

deleted or replaced. Sessions data remain until you delete them in the "Results" tab of

the session.

The report format can be defined in "RSScopeSuite" > "Settings" > "Report" for all

compliance tests (see also Chapter 2.6, "Report Configuration", on page 13). If you

want to use special report settings for a session, you can define the format and contents of the report in the "Report Config" tab of the session.

All test results are listed in the "Results" tab. Reports can be provided in PDF,

MSWord, or HTML format. To view and print PDF reports, you need a PDF viewer, for

example, the Acrobat Reader.

The test report file can be created at the end of the test, or later in the "Session Selection" dialog.

To show a test report

1. In the R&S ScopeSuite window, select the compliance test to be performed.

2. Select the session name in the "Session Selection" dialog and click "Show report".

The report opens in a separate application window, depending on the file format.

You can check the test results and print the report.

To delete the results, diagrams and waveform files of a session

1. In the "Session Selection" dialog select the session and open it.

2. In the "Results" tab, select the result to be deleted.

3. Click "Remove".

22User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

3.5 Starting DDR3 Tests

Before you run the test, complete the following actions:

●

LAN connection of the oscilloscope and the computer running the R&S ScopeSuite, see Chapter 2.5, "Connecting the R&S RTO/RTO6/RTP", on page 11

1. Select "DDR3" in the R&S ScopeSuite start window.

2. In the "Session Selection" dialog, set the "Select Type" standard. The following

"Types" are available:

● "DDR3": Double data rate type three. Used for desktops and servers.

● "DDR3L": DDR3 low voltage. It is used in laptops and low power PCs.

● "LPDDR3": low power DDR3. Consumes very low power and is used for mobile

phones.

3. Set the "Select Speed". There are preset speeds you can select from:

"800"/"1066"/"1333"/"1600"/"1866"/"2133"

Performing Tests

Starting DDR3 Tests

4. Add a new test session. Open it, see Chapter 3.1, "Starting a Test Session",

on page 14.

5. Check the test configuration settings. Adjust, if necessary. See:

● Chapter 3.2.2, "Test Configuration for DDR3", on page 18

● Chapter 3.2.1.1, "Limit Manager", on page 17

6. Select/check the test cases you want to run and click "Test Single"/"Test checked".

7. A step-by step guide explains the following individual setup steps. When you have

finished all steps of the step-by-step guide, the compliance test runs automatically.

23User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

4 Timing Tests

4.1 Clock Timing

4.1.1 Test Equipment

Item Description, model Quantity

Timing Tests

Clock Timing

Rohde & Schwarz oscilloscope R&S RTP with 4 channels and minimum 8 GHz band-

Modular Probe Probe with minimum 9 GHz bandwidth 1

Probe tip R&S RT-ZMA10 1

DUT DDR3 device that supports the selected type 1

4.1.2 Performing the Tests

1. Start the test as described in Chapter 3.5, "Starting DDR3 Tests", on page 23.

2. Select "Timing Tests" > "Clock Timing".

1

width

R&S RTO2000/RTO6 with 4 channels and minimum 4

GHz bandwidth

24User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

Timing Tests

Clock Timing

3. Enable the tests that you want to run.

4. Click "Test Single".

5. Follow the instructions of the step-by step guide.

When you have finished all steps, the compliance test runs automatically.

6. You can also run the test in offline mode, using downloaded waveforms. For

details, see Chapter 3.2.2, "Test Configuration for DDR3", on page 18.

4.1.3 Test Setup

The software guides you to make the proper connections. Follow the steps to conduct

the test.

The software is intended to facilitate the execution of a set of measurements on the relevant signals.

Consider also the soldering guide, see Chapter 2.1.1, "Soldering Guide for Modular

Probes", on page 9.

4.1.4 Measurements

The clock timing measurements consist of up to eight measurements. They test the

limits as defined in the JESD79-3F(DDR3)/JESD79-3-1A-01(DDR3L)/

JESD209-3C(LPDDR3) specifications.

25User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

Timing Tests

Clock Timing

4.1.4.1 Average Clock Period - t

CK(avg)

This test aims to verify that the average clock period tCK(avg) is within the limits

defined in section 12.1.1 (DDR3/DDR3L)/ 11.1.1 (LPDDR3) of the specification. This is

the average clock period calculated across any consecutive 200 cycle window. The

clock period is defined from rising edge to rising edge.

4.1.4.2 Absolute Clock Period - t

CK(abs)

This test aims to verify that the average absolute clock period tCK(abs) is within the

limits defined in section 12.1.2 (DDR3/DDR3L)/ 11.1.2 (LPDDR3) of the specification.

This is the absolute clock period from one rising edge to the next rising edge.

4.1.4.3 Average Low Pulse Width - t

This test aims to verify that the average low pulse width tCL(avg) is within the limits

defined in section 12.1.3 (DDR3/DDR3L)/ 11.1.3 (LPDDR3) of the specification. This is

the average low pulse width, as calculated across any consecutive 200 low pulses.

4.1.4.4 Average High Pulse Width - t

CL(avg)

CH(avg)

This test aims to verify that the average high pulse width tCL(avg) is within the limits

defined in section 12.1.3 (DDR3/DDR3L)/ 11.1.3 (LPDDR3) of the specification. This is

the average low pulse width, as calculated across any consecutive 200 low pulses.

4.1.4.5 Clock Period Jitter - t

JIT(per)

This test aims to verify that the clock period jitter tJIT(per) is within the limits defined in

section 12.1.4 (DDR3/DDR3L)/ 11.1.4 (LPDDR3) of the specification. It is the largest

deviation of any signal tCK from tCK(avg). It defines the single period jitter when the

DLL is already locked.

4.1.4.6 Half Period Jitter - t

JIT(duty)

This test aims to verify that the half period jitter tJIT(duty) is within the limits defined in

section 12.1.4 (DDR3/DDR3L)/ 11.1.4 (LPDDR3) of the specification. This is the largest deviation of any signal tCK from t

4.1.4.7 Cycle to Cycle Period Jitter - t

This test aims to verify that the cycle to cycle period jitter tJIT(cc) is within the limits

defined in section 12.1.5 (DDR3/DDR3L)/ 11.1.5 (LPDDR3) of the specification. This is

the absolute difference in clock period between two consecutive clock cycles. It defines

the cycle to cycle jitter when the DLL is already locked.

JIT(cc)

CK(avg)

.

26User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

Timing Tests

Data Timing

4.1.4.8 Cumulative Error - t

This test aims to verify that the cumulative error tERR(nper) is within the limits defined

in section 12.1.6 (DDR3/DDR3L)/ 11.1.6 (LPDDR3) of the specification. This is the

cumulative error across n multiple consecutive cycles from tCK(avg).

4.2 Data Timing

4.2.1 Test Equipment

Item Description, model Quantity

Rohde & Schwarz oscilloscope R&S RTP with 4 channels and minimum 8 GHz band-

Modular Probe Probe with minimum 9 GHz bandwidth 3

Probe tip R&S RT-ZMA10 3

ERR(nper)

1

width

R&S RTO2000/RTO6 with 4 channels and minimum 4

GHz bandwidth

DUT DDR3 device that supports the selected type 1

4.2.2 Performing the Tests

1. Start the test as described in Chapter 3.5, "Starting DDR3 Tests", on page 23.

2. Select "Timing Tests" > "Data Timing".

27User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

Timing Tests

Data Timing

3. Enable the tests that you want to run.

4. Click "Test Single".

5. Follow the instructions of the step-by step guide.

When you have finished all steps, the compliance test runs automatically.

6. You can also run the test in offline mode, using downloaded waveforms. For

details, see Chapter 3.2.2, "Test Configuration for DDR3", on page 18.

4.2.3 Test Setup

The software guides you to make the proper connections. Follow the steps to conduct

the test.

The software is intended to facilitate the execution of a set of measurements on the relevant signals.

Consider also the soldering guide, see Chapter 2.1.1, "Soldering Guide for Modular

Probes", on page 9.

28User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

4.2.4 Measurements

The data timing measurements consist of up to ten measurements. They test the limits

as defined in the JESD79-3F(DDR3)/JESD79-3-1A-01(DDR3L)/

JESD209-3C(LPDDR3) specifications.

Timing Tests

Data Timing

4.2.4.1 Differential DQ and DM Input Setup Time- t

DS(base)

This test aims to verify that time interval from the data or data mask (DQ/DM rising/

falling edge) setup time to the associated DQS crossing edge is within the limits

defined in section 13.6 of the specification.

4.2.4.2 Differential DQ and DM Input Hold Time - t

DH(base)

This test aims to verify that the time interval from the data or data mask (DQ/DM rising/

falling edge) hold time to the associated DQS crossing edge is within the limits defined

in section 13.6 of the specification.

4.2.4.3 Differential DQ and DM Input Setup Time with Derating Support - t

This test aims to verify that the time interval from data or data mask (DQ/DM rising/

falling edge) setup time to the associated DQS crossing is within the limits defined in

section 13.6 of the specification.

4.2.4.4 Differential DQ and DM Input Hold Time with Derating Support - t

This test aims to verify that the time interval from data or data mask (DQ/DM rising/

falling edge) hold time to the associated DQS crossing is within the limits defined in

section 13.6 of the specification..

DS-Diff(derate)

DH-Diff(derate)

4.2.4.5 DQ Out High Impedance Time From CK/CK# - t

This test aims to verify that the data high impedance time from CK/CK# is within the

limits defined in section 4.13.2 of the specification.

4.2.4.6 DQ Low-Impedance Time from CK/CK# - t

LZ(DQ)

This test aims to verify that the data low impedance time from CK/CK# is within the limits defined in section 4.13.2 of the specification.

4.2.4.7 Data Input Pulse Width - t

DIPW

This test aims to verify that the data and mask input pulse width for each input is within

the limits defined in section 13.4 Note 28 of the specification.

HZ(DQ)

29User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

Timing Tests

Strobe Timing

4.2.4.8 DQS-DQ Skew for DQS and Associated DQ Signals - t

This test aims to verify that the strobe to data skew, per group, per access is within the

limits defined in section 4.13.2 of the specification.

4.2.4.9 DQ/DQS Output Hold Time From DQS - t

QH

This test aims to verify that the data output hold time from strobe is within the limits

defined in section 4.13.2 of the specification.

4.2.4.10 t

Time above V

VAC

This test aims to verify that t

IH(ac) VIL(ac)

is within the limits defined in the specification. This is

VAC

the time to remain above/below V

IH(AC)/VIL(AC)

for a data transition to be considered as

valid.

4.3 Strobe Timing

DQSQ

4.3.1 Test Equipment

Item Description, model Quantity

Rohde & Schwarz oscilloscope R&S RTP with 4 channels and minimum 8 GHz band-

Modular Probe Probe with minimum 9 GHz bandwidth 3

Probe tip R&S RT-ZMA10 3

DUT DDR3 device that supports the selected type 1

4.3.2 Performing the Tests

1. Start the test as described in Chapter 3.5, "Starting DDR3 Tests", on page 23.

2. Select "Timing Tests" > "Strobe Timing".

1

width

R&S RTO2000/RTO6 with 4 channels and minimum 4

GHz bandwidth

30User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

Timing Tests

Strobe Timing

3. Enable the tests that you want to run.

4. Click "Test Single".

5. Follow the instructions of the step-by step guide.

When you have finished all steps, the compliance test runs automatically.

6. You can also run the test in offline mode, using downloaded waveforms. For

details, see Chapter 3.2.2, "Test Configuration for DDR3", on page 18.

4.3.3 Test Setup

The software guides you to make the proper connections. Follow the steps to conduct

the test.

The software is intended to facilitate the execution of a set of measurements on the relevant signals.

Consider also the soldering guide, see Chapter 2.1.1, "Soldering Guide for Modular

Probes", on page 9.

31User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

4.3.4 Measurements

The strobe measurements consist of up to ten measurements. They test the limits as

defined in the JESD79-3F(DDR3)/JESD79-3-1A-01(DDR3L)/JESD209-3C(LPDDR3)

specifications.

Timing Tests

Strobe Timing

4.3.4.1 DQS Output Access Time from CK/CK # - t

This test aims to verify that the strobe rising edge output access time from rising

CK/CK# is within the limits defined in section 4.13.2 of the specification.

4.3.4.2 Low-Impedance Time from CK/CK# - t

LZ

This test aims to verify that the strobe low-impedance time is within the limits defined in

section 4.13.2 of the specification.

4.3.4.3 High-Impedance Time from CK/CK# - t

HZ

This test aims to verify that the strobe high-impedance time is within the limits defined

in section 4.13.2 of the specification.

4.3.4.4 Differential Read Preamble - t

RPRE

This test aims to verify that the strobe differential READ Preamble is within the limits

defined in section 4.13.2 of the specification.

4.3.4.5 Read Postamble - t

RPST

DQSCK

This test aims to verify that the strobe differential READ Postamble is within the limits

defined in section 4.13.2 of the specification.

4.3.4.6 Differential Output High Time - t

QSH

This test aims to verify that the strobe differential output high time is within the limits

defined in section 4.13.2 of the specification.

4.3.4.7 Differential Output Low Time - t

QSL

This test aims to verify that the strobe differential output low time is within the limits

defined in section 4.13.2 of the specification.

4.3.4.8 DQS Latching Transition to Associated Clock Edge - t

This test aims to verify that the time interval from the strobe rising edge to CK/CK# rising edge is within the limits defined in section 4.14.2 of the specification.

DQSS

32User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

Timing Tests

Strobe Timing

4.3.4.9 DQS Input High Pulse Width - t

DQSH

This test aims to verify that the strobe differential input high pulse width is within the

limits defined in section 4.14.2 of the specification.

4.3.4.10 DQS Input Low Pulse Width - t

DQSL

This test aims to verify that the strobe differential input low pulse width is within the limits defined in section 4.14.2 of the specification.

4.3.4.11 DQS Falling Edge to CK Setup Time - t

This test aims to verify that the time interval from the strobe falling edge setup time to

the CK/CK# rising edge is within the limits defined in section 4.14.2 of the specification.

4.3.4.12 DQS Falling Edge Hold Time from CK - t

This test aims to verify that the strobe falling edge hold time from CK/CK# rising edge

is within the limits defined in section 4.14.2 of the specification.

4.3.4.13 Write Postamble - t

WPST

DSS

DSH

This test aims to verify that the strobe differential WRITE Postamble is within the limits

defined in section 4.14.2 of the specification.

4.3.4.14 Write Preamble - t

WPRE

This test aims to verify that the strobe differential WRITE Preamble is within the limits

defined in section 4.14.2 of the specification.

4.3.4.15 Time before Ringback - t

This test aims to verify that the time before ringback for strobe is within the limits

defined in section 8.3.1 of the specification. This is the "time above AC-level" during a

differential AC-swing.

4.3.4.16 Time before Ringback - t

This test aims to verify that the time before ringback for CK /CK# is within the limits

defined in section 8.3.1 of the specification. This is the "time above AC-level" during a

differential AC-swing.

DVAC(Strobe)

DVAC(Clock)

33User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

4.4 Command Timing

4.4.1 Test Equipment

Item Description, model Quantity

Timing Tests

Command Timing

Rohde & Schwarz oscilloscope R&S RTP with 4 channels and minimum 8 GHz band-

Modular Probe Probe with minimum 9 GHz bandwidth 2

Probe tip R&S RT-ZMA10 2

DUT DDR3 device that supports the selected type 1

4.4.2 Performing the Tests

1. Start the test as described in Chapter 3.5, "Starting DDR3 Tests", on page 23.

2. Select "Timing Tests" > "Command Timing".

1

width

R&S RTO2000/RTO6 with 4 channels and minimum 4

GHz bandwidth

34User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

Timing Tests

Command Timing

3. Enable the tests that you want to run.

4. Click "Test Single".

5. Follow the instructions of the step-by step guide.

When you have finished all steps, the compliance test runs automatically.

6. You can also run the test in offline mode, using downloaded waveforms. For

details, see Chapter 3.2.2, "Test Configuration for DDR3", on page 18.

4.4.3 Test Setup

The software guides you to make the proper connections. Follow the steps to conduct

the test.

The software is intended to facilitate the execution of a set of measurements on the relevant signals.

Consider also the soldering guide, see Chapter 2.1.1, "Soldering Guide for Modular

Probes", on page 9.

35User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

4.4.4 Measurements

The command timing measurements consist of up to six measurements. They test the

limits as defined in section 13.5 (DDR3/DDR3L)/ 4.2 (LPDDR3) of the

JESD79-3F(DDR3)/JESD79-3-1A-01(DDR3L)/JESD209-3C(LPDDR3) specifications.

Timing Tests

Command Timing

4.4.4.1 Address and Control Input Setup Time - t

IS

This test aims to verify that the command and address setup time from CK/CK# is

within the limits defined in the specification.

4.4.4.2 Address and Control Input Setup Time with Derating Support - t

This test aims to verify that the command and address setup time from CK/CK# is

within the limits defined in the specification.

4.4.4.3 Address and Control Input Hold Time - t

IH

This test aims to verify that the command and address hold time from CK/CK# is within

the limits defined in the specification.

4.4.4.4 Address and Control Input Hold Time with Derating Support - t

This test aims to verify that the command and address hold time from CK/CK# is within

the limits defined in the specification.

4.4.4.5 Address and Control Input Pulse Width t

IPW

IS (Derated)

IH (Derated)

4.4.4.6 t

This test aims to verify that the control and address input pulse width for each input is

within the limits defined in the specification.

VAC (CA)

This test aims to verify that t

is the time to remain above/below V

is within the limits defined in the specification. This

VAC (CA)

IH(AC)/VIL(AC)

for a command transition to be consid-

ered as valid.

36User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

4.5 Address Timing

4.5.1 Test Equipment

Item Description, model Quantity

Timing Tests

Address Timing

Rohde & Schwarz oscilloscope R&S RTP with 4 channels and minimum 8 GHz band-

Modular Probe Probe with minimum 9 GHz bandwidth 2

Probe tip R&S RT-ZMA10 2

DUT DDR3 device that supports the selected type 1

4.5.2 Performing the Tests

1. Start the test as described in Chapter 3.5, "Starting DDR3 Tests", on page 23.

2. Select "Timing Tests" > "Address Timing".

1

width

R&S RTO2000/RTO6 with 4 channels and minimum 4

GHz bandwidth

37User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

Timing Tests

Address Timing

3. Enable the tests that you want to run.

4. Click "Test Single".

5. Follow the instructions of the step-by step guide.

When you have finished all steps, the compliance test runs automatically.

6. You can also run the test in offline mode, using downloaded waveforms. For

details, see Chapter 3.2.2, "Test Configuration for DDR3", on page 18.

4.5.3 Measurements

The address timing measurements consist of up to six measurements. They test the

limits as defined in section 13.5 (DDR3/DDR3L)/ 4.2 (LPDDR3) of the

JESD79-3F(DDR3)/JESD79-3-1A-01(DDR3L)/JESD209-3C(LPDDR3) specifications.

For details on the measurements, see Chapter 4.4.4, "Measurements", on page 36.

38User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

4.6 Chip Select Timing

4.6.1 Test Equipment

Item Description, model Quantity

Timing Tests

Chip Select Timing

Rohde & Schwarz oscilloscope R&S RTP with 4 channels and minimum 8 GHz band-

Modular Probe Probe with minimum 9 GHz bandwidth 2

Probe tip R&S RT-ZMA10 2

DUT DDR3 device that supports the selected type 1

4.6.2 Performing the Tests

1. Start the test as described in Chapter 3.5, "Starting DDR3 Tests", on page 23.

2. Select "Timing Tests" > "Chip Select Timing".

1

width

R&S RTO2000/RTO6 with 4 channels and minimum 4

GHz bandwidth

39User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

3. Enable the tests that you want to run.

4. Click "Test Single".

5. Follow the instructions of the step-by step guide.

When you have finished all steps, the compliance test runs automatically.

6. You can also run the test in offline mode, using downloaded waveforms. For

details, see Chapter 3.2.2, "Test Configuration for DDR3", on page 18.

4.6.3 Test Setup

The software guides you to make the proper connections. Follow the steps to conduct

the test.

The software is intended to facilitate the execution of a set of measurements on the relevant signals.

Consider also the soldering guide, see Chapter 2.1.1, "Soldering Guide for Modular

Probes", on page 9.

Timing Tests

Chip Select Timing

4.6.4 Measurements

The chip select timing measurements consist of up to six measurements. They test the

limits as defined in section 13.5 (DDR3/DDR3L)/ 4.2 (LPDDR3) of the

JESD79-3F(DDR3)/JESD79-3-1A-01(DDR3L)/JESD209-3C(LPDDR3) specifications.

4.6.4.1 Address and Control Input Setup Time - t

This test aims to verify that the chip select setup time from CK/CK# is within the limits

defined in the specification.

4.6.4.2 Address and Control Input Setup Time with Derating Support - tIS (Derated)

This test aims to verify that the chip select setup time from CK/CK# is within the limits

defined in the specification.

4.6.4.3 Address and Control Input Hold Time - t

This test aims to verify that the chip select hold time from CK/CK# is within the limits

defined in the specification.

IS

IH

4.6.4.4 Address and Control Input Hold Time with Derating Support - tIH (Derated)

This test aims to verify that the chip select hold time from CK/CK# is within the limits

defined in the specification.

40User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

Timing Tests

Clock Enable Timing

4.6.4.5 t

IPW

This test aims to verify that the chip select input pulse width for each input is within the

limits defined in the specification.

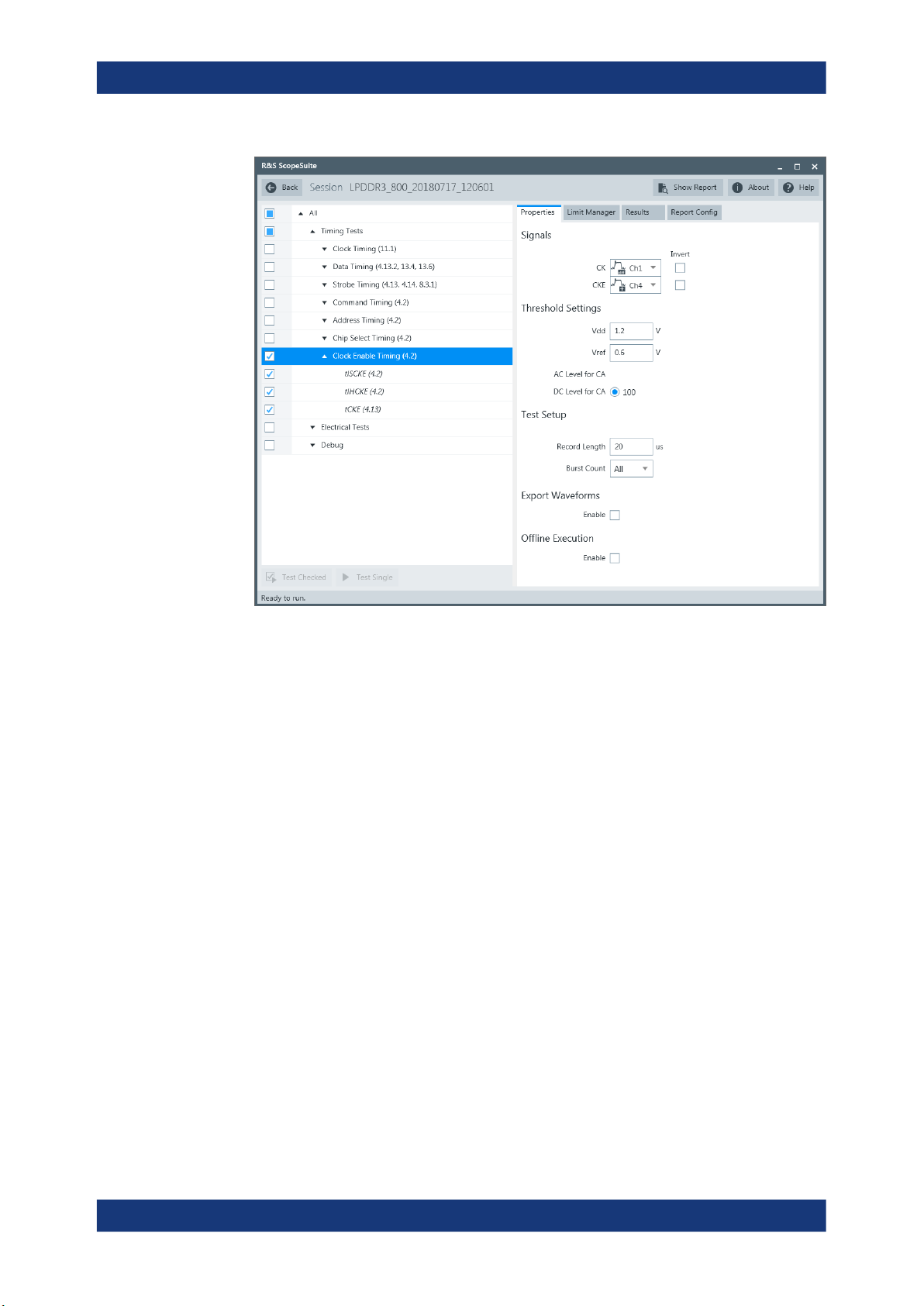

4.7 Clock Enable Timing

4.7.1 Test Equipment

Item Description, model Quantity

Rohde & Schwarz oscilloscope R&S RTP with 4 channels and minimum 8 GHz band-

Modular Probe Probe with minimum 9 GHz bandwidth 2

Probe tip R&S RT-ZMA10 2

DUT DDR3 device that supports the selected type 1

1

width

R&S RTO2000/RTO6 with 4 channels and minimum 4

GHz bandwidth

4.7.2 Performing the Tests

1. Start the test as described in Chapter 3.5, "Starting DDR3 Tests", on page 23.

2. Select "Timing Tests" > "Clock Enable Timing".

41User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

Timing Tests

Clock Enable Timing

3. Enable the tests that you want to run.

4. Click "Test Single".

5. Follow the instructions of the step-by step guide.

When you have finished all steps, the compliance test runs automatically.

6. You can also run the test in offline mode, using downloaded waveforms. For

details, see Chapter 3.2.2, "Test Configuration for DDR3", on page 18.

4.7.3 Test Setup

The software guides you to make the proper connections. Follow the steps to conduct

the test.

The software is intended to facilitate the execution of a set of measurements on the relevant signals.

Consider also the soldering guide, see Chapter 2.1.1, "Soldering Guide for Modular

Probes", on page 9.

4.7.4 Measurements

The clock enable timing measurements consist of up to three measurements. They test

the limits as defined in the JESD209-3C(LPDDR3) specification.

42User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

Timing Tests

Clock Enable Timing

4.7.4.1 Clock Enable Input Setup Time - t

ISCKE

This test aims to verify that the clock enable input setup time from CKE is within the

limits defined in section 4.2 of the specification.

4.7.4.2 Clock Enable Input Hold Time - t

IH

This test aims to verify that the clock enable hold time from CKE is within the limits

defined in section 4.2 of the specification.

4.7.4.3 Clock Enable Minimum Pulse Width t

This test aims to verify that the minimum pulse width for each input is within the limits

defined in section 4.13 of the specification.

CKE

43User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

5 Electrical Tests

5.1 Single-Ended Signals

5.1.1 Input Slew Rate for ADD and CMD

5.1.1.1 Test Equipment

Item Description, model Quantity

Electrical Tests

Single-Ended Signals

Rohde & Schwarz oscilloscope R&S RTP with 4 channels and minimum 8 GHz band-

Modular Probe Probe with minimum 9 GHz bandwidth 2

Probe tip R&S RT-ZMA10 2

DUT DDR3 device that supports the selected type 1

5.1.1.2 Performing the Tests

1. Start the test as described in Chapter 3.5, "Starting DDR3 Tests", on page 23.

2. Select "Electrical Tests" > "Single-Ended Signals" > "Input Slew Rate for ADD and

CMD".

1

width

R&S RTO2000/RTO6 with 4 channels and minimum 4

GHz bandwidth

44User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

Electrical Tests

Single-Ended Signals

3. Enable the "Signals" you want to use.

If only the ADD/CMD signal is selected, only ADD/CMD signal will be used to run

the test.

If both the ADD and the CMD signals are selected, test will be run using ADD signal first, followed by the CMD signal.

4. Enable the tests that you want to run.

5. Click "Test Single".

6. Follow the instructions of the step-by step guide.

When you have finished all steps, the compliance test runs automatically.

7. You can also run the test in offline mode, using downloaded waveforms. For

details, see Chapter 3.2.2, "Test Configuration for DDR3", on page 18.

5.1.1.3 Test Setup

The software guides you to make the proper connections. Follow the steps to conduct

the test.

The software is intended to facilitate the execution of a set of measurements on the relevant signals.

Consider also the soldering guide, see Chapter 2.1.1, "Soldering Guide for Modular

Probes", on page 9.

5.1.1.4 Measurements

The input slew rates for address and command measurements consist of up to four

measurements. It tests the limits as defined in sections 8.5 and 13.5 (DDR3/DDR3L)/

45User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

7.6 and 11.5 (LPDDR3) of the JESD79-3F(DDR3)/JESD79-3-1A-01(DDR3L)/

JESD209-3C(LPDDR3) specifications.

Setup Slew Rate Rising - SR(tIS) Rising

This test aims to verify that the setup slew rate for rising signal is within the limits

defined in the specification.

Setup Slew Rate Falling - SR(tIS) Falling

This test aims to verify that the setup slew rate for falling signal is within the limits

defined in the specification.

Hold Slew Rate Rising - SR(tIH) Rising

This test aims to verify that the hold slew rate for rising signal is within the limits

defined in the specification.

Hold Slew Rate Falling - SR(tIH) Falling

This test aims to verify that the hold slew rate for falling signal is within the limits

defined in the specification.

Electrical Tests

Single-Ended Signals

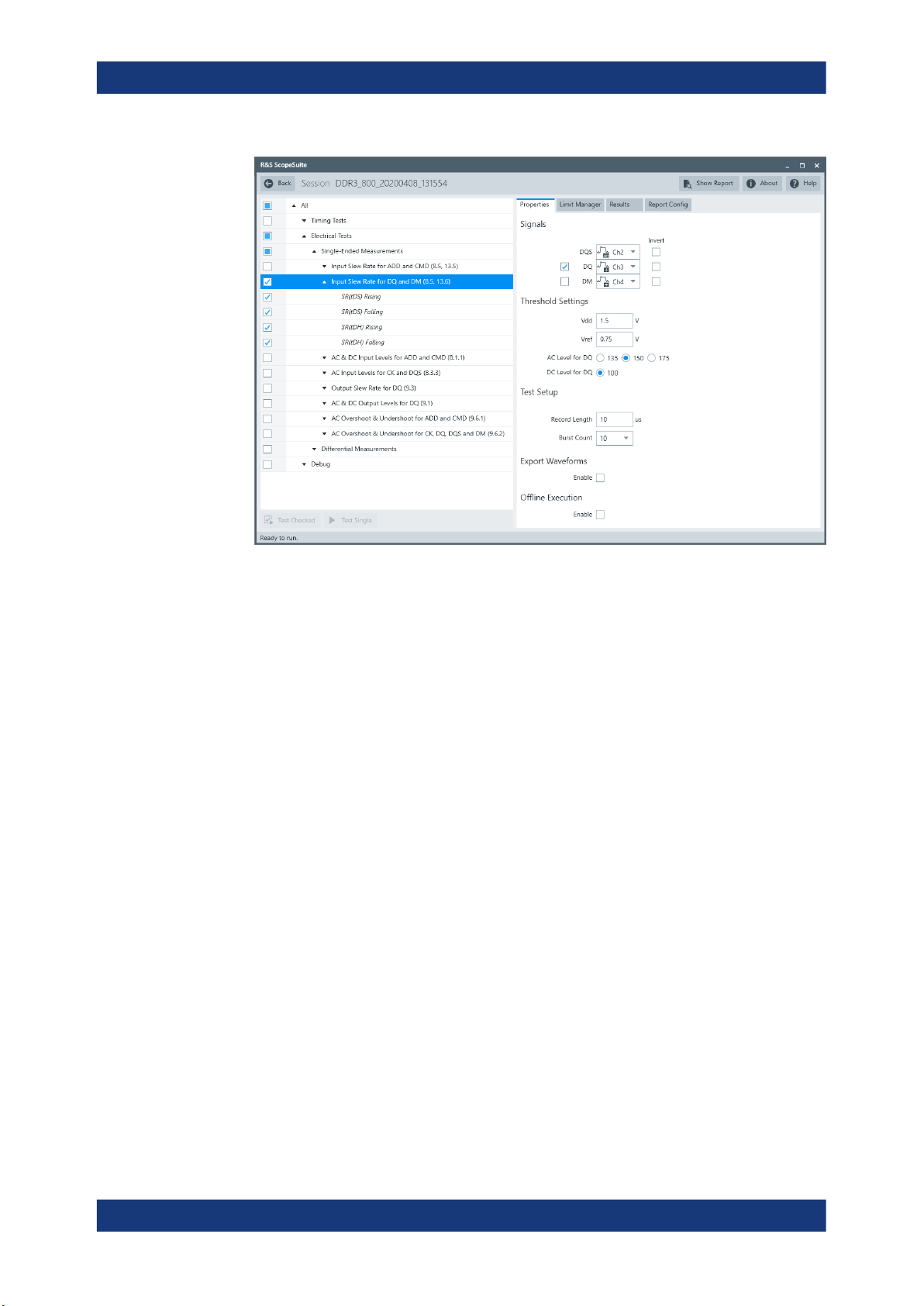

5.1.2 Input Slew Rate for DQ and DM

5.1.2.1 Test Equipment

Item Description, model Quantity

Rohde & Schwarz oscilloscope R&S RTP with 4 channels and minimum 8 GHz band-

width

R&S RTO2000/RTO6 with 4 channels and minimum 4

GHz bandwidth

Modular Probe Probe with minimum 9 GHz bandwidth 2

Probe tip R&S RT-ZMA10 2

DUT DDR3 device that supports the selected type 1

5.1.2.2 Performing the Tests

1. Start the test as described in Chapter 3.5, "Starting DDR3 Tests", on page 23.

2. Select "Electrical Tests" > "Single-Ended Signals" > "Input Slew Rate for DQ and

DM".

1

46User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

Electrical Tests

Single-Ended Signals

3. Enable the tests that you want to run.

4. Click "Test Single".

5. Follow the instructions of the step-by step guide.

When you have finished all steps, the compliance test runs automatically.

6. You can also run the test in offline mode, using downloaded waveforms. For

details, see Chapter 3.2.2, "Test Configuration for DDR3", on page 18.

5.1.2.3 Test Setup

The software guides you to make the proper connections. Follow the steps to conduct

the test.

The software is intended to facilitate the execution of a set of measurements on the relevant signals.

Consider also the soldering guide, see Chapter 2.1.1, "Soldering Guide for Modular

Probes", on page 9.

5.1.2.4 Measurements

The input slew rates for data and mask measurements consist of up to four measurements. It tests the limits as defined in sections 8.5 and 13.6 (DDR3/DDR3L)/ 7.6 and

11.6 (LPDDR3) of the JESD79-3F(DDR3)/JESD79-3-1A-01(DDR3L)/

JESD209-3C(LPDDR3) specifications.

47User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

Setup Slew Rate Rising - SR(tIS) Rising

This test aims to verify that the setup slew rate for rising signal is within the limits

defined in the specification.

Setup Slew Rate Falling - SR(tIS) Falling

This test aims to verify that the setup slew rate for falling signal is within the limits

defined in the specification.

Hold Slew Rate Rising - SR(tIH) Rising

This test aims to verify that the hold slew rate for rising signal is within the limits

defined in the specification.

Hold Slew Rate Falling - SR(tIH) Falling

This test aims to verify that the hold slew rate for falling signal is within the limits

defined in the specification.

Electrical Tests

Single-Ended Signals

5.1.3 AC & DC Input Levels for ADD and CMD

5.1.3.1 Test Equipment

Item Description, model Quantity

Rohde & Schwarz oscilloscope R&S RTP with 4 channels and minimum 8 GHz band-

width

R&S RTO2000/RTO6 with 4 channels and minimum 4

GHz bandwidth

Modular Probe Probe with minimum 9 GHz bandwidth 2

Probe tip R&S RT-ZMA10 2

DUT DDR3 device that supports the selected type 1

5.1.3.2 Performing the Tests

1. Start the test as described in Chapter 3.5, "Starting DDR3 Tests", on page 23.

2. Select "Electrical Tests" > "Single-Ended Signals" > "AC & DC Input Levels for

ADD and CMD".

1

48User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

Electrical Tests

Single-Ended Signals

3. Enable the "Signals" you want to use.

If only the ADD/CMD signal is selected, only ADD/CMD signal will be used to run

the test.

If both the ADD and the CMD signals are selected, test will be run using ADD signal first, followed by the CMD signal.

4. Enable the tests that you want to run.

5. Click "Test Single".

6. Follow the instructions of the step-by step guide.

When you have finished all steps, the compliance test runs automatically.

7. You can also run the test in offline mode, using downloaded waveforms. For

details, see Chapter 3.2.2, "Test Configuration for DDR3", on page 18.

5.1.3.3 Test Setup

The software guides you to make the proper connections. Follow the steps to conduct

the test.

The software is intended to facilitate the execution of a set of measurements on the relevant signals.

Consider also the soldering guide, see Chapter 2.1.1, "Soldering Guide for Modular

Probes", on page 9.

5.1.3.4 Measurements

The AC and DC logic input levels for single-ended address and command measurements consist of up to four measurements. It tests the limits as defined in section

49User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

8.1.1(DDR3) / 3.1(DDR3L) / 7.1.1(LPDDR3) of the JESD79-3F(DDR3)/

JESD79-3-1A-01(DDR3L)/JESD209-3C(LPDDR3) specifications.

V

IH(AC)

This test aims to verify that the AC input logic high is within the limits defined in the

specification.

V

IL(AC)

This test aims to verify that the AC input logic low is within the limits defined in the

specification.

V

IH(DC)

This test aims to verify that the DC input logic high is within the limits defined in the

specification.

V

IL(DC)

Electrical Tests

Single-Ended Signals

This test aims to verify that the DC input logic low is within the limits defined in the

specification.

5.1.4 AC Input Levels for CK and DQS

5.1.4.1 Test Equipment

Item Description, model Quantity

Rohde & Schwarz oscilloscope R&S RTP with 4 channels and minimum 8 GHz band-

width

R&S RTO2000/RTO6 with 4 channels and minimum 4

GHz bandwidth

Modular Probe Probe with minimum 9 GHz bandwidth 2

Probe tip R&S RT-ZMA10 2

DUT DDR3 device that supports the selected type 1

5.1.4.2 Performing the Tests

1

1. Start the test as described in Chapter 3.5, "Starting DDR3 Tests", on page 23.

2. Select "Electrical Tests" > "Single-Ended Signals" > "AC Input Levels for CK and

DQS".

50User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

Electrical Tests

Single-Ended Signals

3. Enable the tests that you want to run.

4. Click "Test Single".

5. Follow the instructions of the step-by step guide.

When you have finished all steps, the compliance test runs automatically.

6. You can also run the test in offline mode, using downloaded waveforms. For

details, see Chapter 3.2.2, "Test Configuration for DDR3", on page 18.

5.1.4.3 Test Setup

The software guides you to make the proper connections. Follow the steps to conduct

the test.

The software is intended to facilitate the execution of a set of measurements on the relevant signals.

Consider also the soldering guide, see Chapter 2.1.1, "Soldering Guide for Modular

Probes", on page 9.

5.1.4.4 Measurements

The single-ended AC input levels for clock and strobe measurements consist of up to

two measurements. It tests the limits as defined in section 8.3.3 (DDR3) / 7.4.3

(LPDDR3) of the JESD79-3F(DDR3)/JESD209-3C(LPDDR3) specifications.

V

SEH(AC)

This test aims to verify that the single-ended high level for strobes/clock is within the

limits defined in the specification.

51User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

V

SEL(AC)

This test aims to verify that the single-ended low level for strobes/clock is within the

limits defined in the specification.

5.1.5 Output Slew Rate for DQ

5.1.5.1 Test Equipment

Item Description, model Quantity

Electrical Tests

Single-Ended Signals

Rohde & Schwarz oscilloscope R&S RTP with 4 channels and minimum 8 GHz band-

Modular Probe Probe with minimum 9 GHz bandwidth 2

Probe tip R&S RT-ZMA10 2

DUT DDR3 device that supports the selected type 1

5.1.5.2 Performing the Tests

1. Start the test as described in Chapter 3.5, "Starting DDR3 Tests", on page 23.

2. Select "Electrical Tests" > "Single-Ended Signals" > "Output Slew Rate for DQ".

1

width

R&S RTO2000/RTO6 with 4 channels and minimum 4

GHz bandwidth

3. Enable the tests that you want to run.

52User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

4. Click "Test Single".

5. Follow the instructions of the step-by step guide.

When you have finished all steps, the compliance test runs automatically.

6. You can also run the test in offline mode, using downloaded waveforms. For

details, see Chapter 3.2.2, "Test Configuration for DDR3", on page 18.

5.1.5.3 Test Setup

The software guides you to make the proper connections. Follow the steps to conduct

the test.

The software is intended to facilitate the execution of a set of measurements on the relevant signals.

Consider also the soldering guide, see Chapter 2.1.1, "Soldering Guide for Modular

Probes", on page 9.

Electrical Tests

Single-Ended Signals

5.1.5.4 Measurements

The single-ended output slew rate for data consists of up to two measurements. It tests

the limits as defined in section 9.3 (DDR3) / 8 (DDR3L)/ 8.3 (LPDDR3) of the

JESD79-3F(DDR3)/JESD79-3-1A-01(DDR3L)/JESD209-3C(LPDDR3) specifications.

Slew Rate Query Output Single-Ended Signals Rising- SRQse Rising

This test aims to verify that the single-ended output slew rate for rising edge is within

the limits defined in the specification. It is measured from VOL(AC) to VOH(AC).

Slew Rate Query Output Single-Ended Signals Falling - SRQse Falling

This test aims to verify that the single-ended output slew rate for falling edge is within

the limits defined in the specification. It is measured from VOH(AC) to VOL(AC).

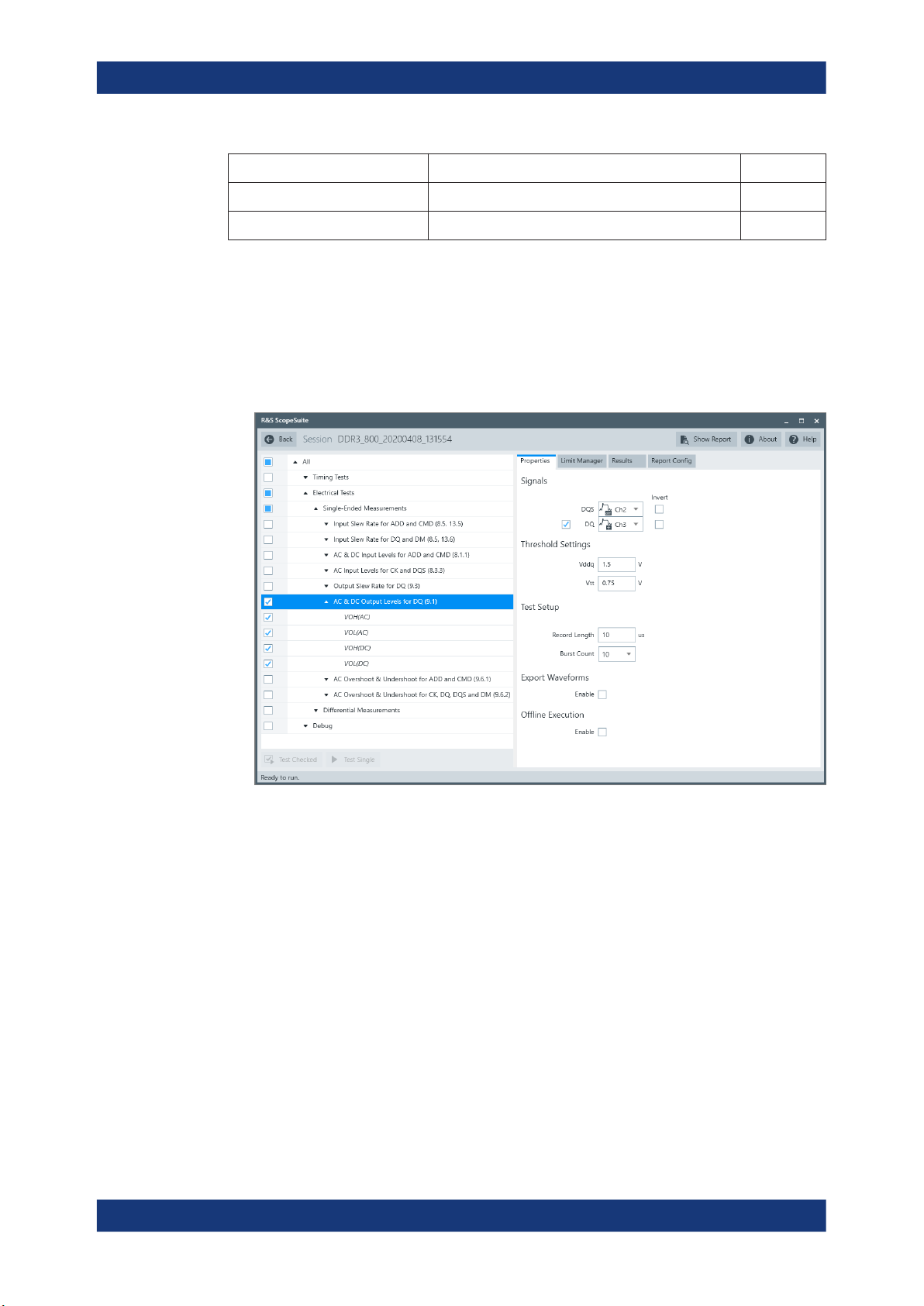

5.1.6 AC & DC Output Levels for DQ

5.1.6.1 Test Equipment

Item Description, model Quantity

Rohde & Schwarz oscilloscope R&S RTP with 4 channels and minimum 8 GHz band-

width

R&S RTO2000/RTO6 with 4 channels and minimum 4

GHz bandwidth

Modular Probe Probe with minimum 9 GHz bandwidth 2

1

53User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

Item Description, model Quantity

Probe tip R&S RT-ZMA10 2

DUT DDR3 device that supports the selected type 1

5.1.6.2 Performing the Tests

1. Start the test as described in Chapter 3.5, "Starting DDR3 Tests", on page 23.

2. Select "Electrical Tests" > "Single-Ended Signals" > "AC & DC Output Levels for

DQ".

Electrical Tests

Single-Ended Signals

3. Enable the tests that you want to run.

4. Click "Test Single".

5. Follow the instructions of the step-by step guide.

When you have finished all steps, the compliance test runs automatically.

6. You can also run the test in offline mode, using downloaded waveforms. For

details, see Chapter 3.2.2, "Test Configuration for DDR3", on page 18.

5.1.6.3 Test Setup

The software guides you to make the proper connections. Follow the steps to conduct

the test.

The software is intended to facilitate the execution of a set of measurements on the relevant signals.

54User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

Consider also the soldering guide, see Chapter 2.1.1, "Soldering Guide for Modular

Probes", on page 9.

5.1.6.4 Measurements

The AC & DC output levels for data measurements consist of up to four measurements. It tests the limits as defined in section 9.1 (DDR3/DDR3L)/ 8.1(LPDDR3) of the

JESD79-3F(DDR3)/JESD79-3-1A-01(DDR3L)/JESD209-3C(LPDDR3) specifications.

V

OH(AC)

This test aims to verify that the AC output high measurement level for the output slew

rate is within the limits defined in the specification.

V

OL(AC)

This test aims to verify that the AC output low measurement level for the output slew

rate is within the limits defined in the specification.

Electrical Tests

Single-Ended Signals

V

OH(DC)

This test aims to verify that the DC output high measurement level for IV curve linearity

is within the limits defined in the specification.

V

OL(DC)

This test aims to verify that the DC output low measurement level for IV curve linearity

is within the limits defined in the specification.

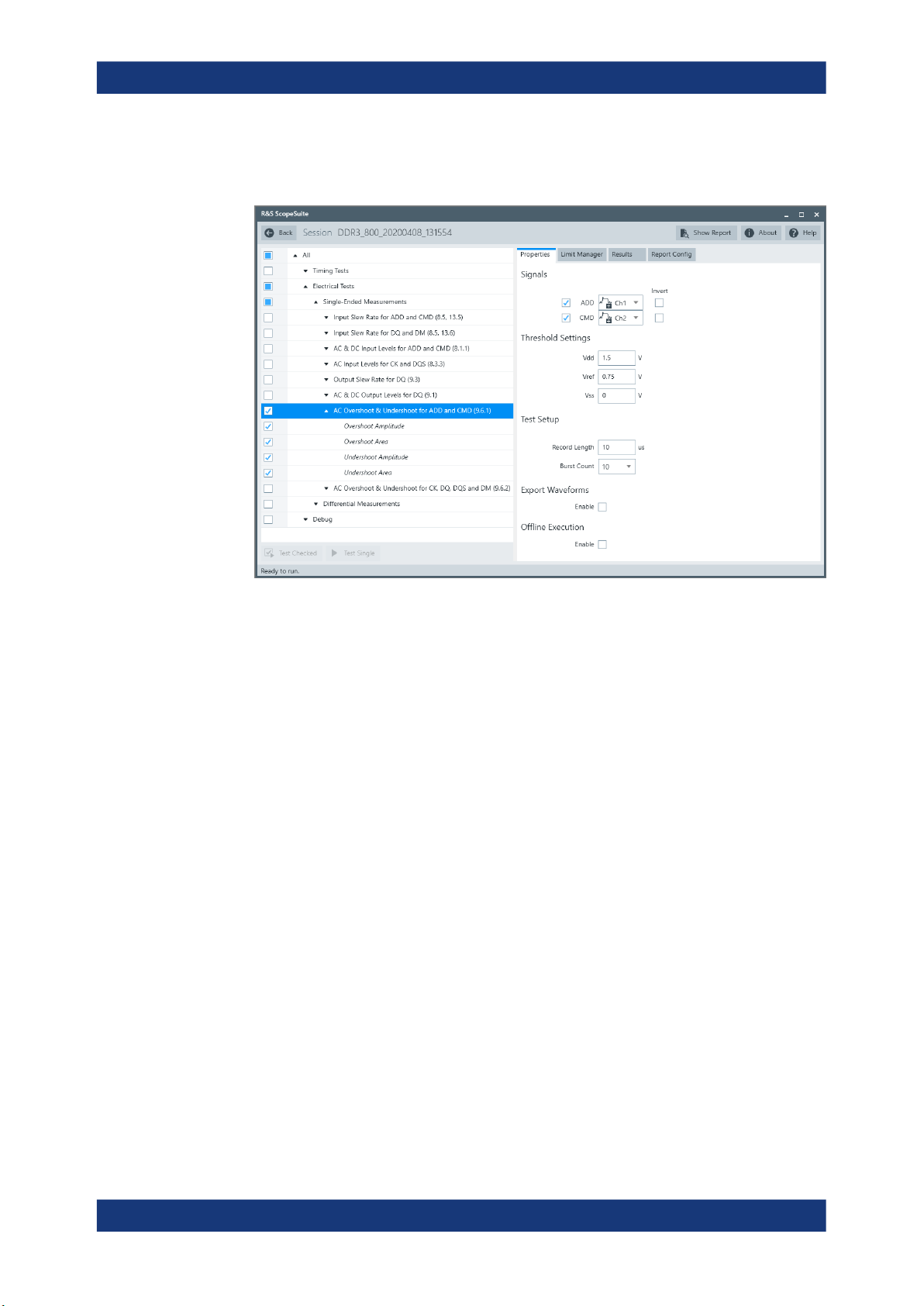

5.1.7 AC Overshoot & Undershoot for ADD and CMD

5.1.7.1 Test Equipment

Item Description, model Quantity

Rohde & Schwarz oscilloscope R&S RTP with 4 channels and minimum 8 GHz band-

width

R&S RTO2000/RTO6 with 4 channels and minimum 4

GHz bandwidth

Modular Probe Probe with minimum 9 GHz bandwidth 2

1

Probe tip R&S RT-ZMA10 2

DUT DDR3 device that supports the selected type 1

5.1.7.2 Performing the Tests

1. Start the test as described in Chapter 3.5, "Starting DDR3 Tests", on page 23.

55User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

2. Select "Electrical Tests" > "Single-Ended Signals" > "AC Overshoot & Undershoot

for ADD and CMD".

Electrical Tests

Single-Ended Signals

3. Enable the "Signals" you want to use.

If only the ADD/CMD signal is selected, only ADD/CMD signal will be used to run

the test.

If both the ADD and the CMD signals are selected, test will be run using ADD signal first, followed by the CMD signal.

4. Enable the tests that you want to run.

5. Click "Test Single".

6. Follow the instructions of the step-by step guide.

When you have finished all steps, the compliance test runs automatically.

7. You can also run the test in offline mode, using downloaded waveforms. For

details, see Chapter 3.2.2, "Test Configuration for DDR3", on page 18.

5.1.7.3 Test Setup

The software guides you to make the proper connections. Follow the steps to conduct

the test.

The software is intended to facilitate the execution of a set of measurements on the relevant signals.

Consider also the soldering guide, see Chapter 2.1.1, "Soldering Guide for Modular

Probes", on page 9.

56User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

5.1.7.4 Measurements

The overshoot and undershoot for address and control measurements consist of up to

four measurements. It tests the limits as defined in section 9.6.1 (DDR3/DDR3L)/

8.5(LPDDR3) of the JESD79-3F(DDR3)/JESD79-3-1A-01(DDR3L)/

JESD209-3C(LPDDR3) specifications.

Overshoot Amplitude

This test aims to verify that the maximum peak amplitude allowed for overshoot area is

within the limits defined in the specification.

Overshoot Area

This test aims to verify that the maximum overshoot area above VDD is within the limits defined in the specification.

Undershoot Amplitude

This test aims to verify that the maximum peak amplitude allowed for undershoot area

is within the limits defined in the specification.

Electrical Tests

Single-Ended Signals

Undershoot Area

This test aims to verify that the maximum undershoot area below VSS is within the limits defined in the specification.

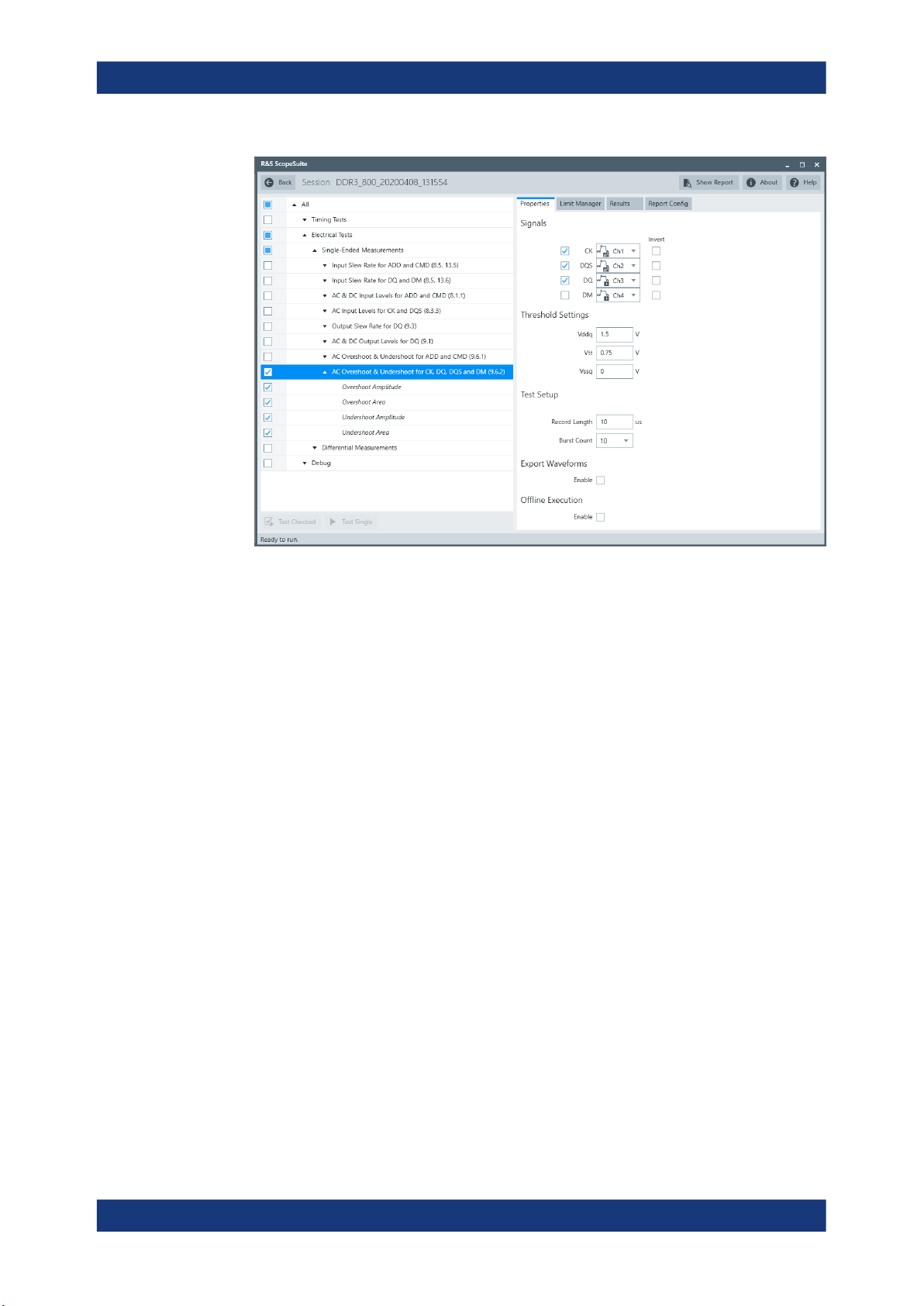

5.1.8 AC Overshoot & Undershoot for CK, DQ, DQS, and DM

5.1.8.1 Test Equipment

Item Description, model Quantity

Rohde & Schwarz oscilloscope R&S RTP with 4 channels and minimum 8 GHz band-

width

R&S RTO2000/RTO6 with 4 channels and minimum 4

GHz bandwidth

Modular Probe Probe with minimum 9 GHz bandwidth 4

Probe tip R&S RT-ZMA10 4

DUT DDR3 device that supports the selected type 1

1

5.1.8.2 Performing the Tests

1. Start the test as described in Chapter 3.5, "Starting DDR3 Tests", on page 23.

2. Select "Electrical Tests" > "Single-Ended Signals" > "AC Overshoot & Undershoot

for CK, DQ, DQS, and DM".

57User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

Electrical Tests

Single-Ended Signals

3. Enable the tests that you want to run.

4. Click "Test Single".

5. Follow the instructions of the step-by step guide.

When you have finished all steps, the compliance test runs automatically.

6. You can also run the test in offline mode, using downloaded waveforms. For

details, see Chapter 3.2.2, "Test Configuration for DDR3", on page 18.

5.1.8.3 Test Setup

The software guides you to make the proper connections. Follow the steps to conduct

the test.

The software is intended to facilitate the execution of a set of measurements on the relevant signals.

Consider also the soldering guide, see Chapter 2.1.1, "Soldering Guide for Modular

Probes", on page 9.

5.1.8.4 Measurements

The overshoot and undershoot for clock, data, strobe and mask measurements consist

of up to four measurements. It tests the limits as defined in section 9.6.2 (DDR3/

DDR3L)/ 8.5(LPDDR3) of the JESD79-3F(DDR3)/JESD79-3-1A-01(DDR3L)/

JESD209-3C(LPDDR3) specifications.

58User Manual 1178.8771.02 ─ 07

R&S®RTO-K91, R&S®RTO6-K91, R&S®RTP-K91

Overshoot Amplitude

This test aims to verify that the maximum peak amplitude allowed for overshoot area is

within the limits defined in the specification.

Overshoot Area

This test aims to verify that the maximum overshoot area above VDDQ is within the

limits defined in the specification.

Undershoot Amplitude

This test aims to verify that the maximum peak amplitude allowed for undershoot area

is within the limits defined in the specification.

Undershoot Area

This test aims to verify that the maximum undershoot area below VSSQ is within the

limits defined in the specification.

Electrical Tests

Differential Signals

5.2 Differential Signals

5.2.1 AC Input Levels for CK and DQS

5.2.1.1 Test Equipment

Item Description, model Quantity

Rohde & Schwarz oscilloscope R&S RTP with 4 channels and minimum 8 GHz band-

width

R&S RTO2000/RTO6 with 4 channels and minimum 4

GHz bandwidth

Modular Probe Probe with minimum 9 GHz bandwidth 2

Probe tip R&S RT-ZMA10 2