Page 1

®

R&S

AREG100A

Automotive Radar Echo

Generator

Getting Started

(>NSÖ2)

1430357202

Version 04

Getting Started

Page 2

This document describes the R&S®AREG100A, stock no. 1430.3508K02.

© 2019 Rohde & Schwarz GmbH & Co. KG

Mühldorfstr. 15, 81671 München, Germany

Phone: +49 89 41 29 - 0

Fax: +49 89 41 29 12 164

Email: info@rohde-schwarz.com

Internet: www.rohde-schwarz.com

Subject to change – Data without tolerance limits is not binding.

R&S® is a registered trademark of Rohde & Schwarz GmbH & Co. KG.

Trade names are trademarks of the owners.

1430.3572.02 | Version 04 | R&S®AREG100A

Throughout this manual, products from Rohde & Schwarz are indicated without the ® symbol , e.g.

R&S®AREG is indicated as R&S AREG.

Page 3

R&S®AREG100A

Contents

1 Safety Information................................................................. 7

2 Preface....................................................................................8

2.1 Key Features......................................................................................... 8

3 Documentation Overview......................................................9

3.1 Getting Started Manual.........................................................................9

3.2 User Manuals and Help........................................................................ 9

3.3 Tutorials............................................................................................... 10

3.4 Service Manual....................................................................................10

Contents

3.5 Instrument Security Procedures....................................................... 10

3.6 Basic Safety Instructions................................................................... 10

3.7 Data Sheets and Brochures............................................................... 10

3.8 Release Notes and Open Source Acknowledgment (OSA).............11

3.9 Application Notes, Application Cards, White Papers, etc...............11

4 Preparing for Use.................................................................12

4.1 Putting into Operation........................................................................ 12

4.1.1 EMI Suppression...................................................................................14

4.1.2 Unpacking and Checking the Instrument.............................................. 14

4.1.3 Accessory List.......................................................................................15

4.1.4 Placing or Mounting the Instrument...................................................... 15

4.1.5 Connecting AC Power...........................................................................17

4.1.6 Cabling of Front End and Base Unit..................................................... 17

4.1.7 Turning the Instrument On and Off....................................................... 19

4.1.8 Functional Check.................................................................................. 21

4.1.9 Checking the Supplied Options and Licenses...................................... 21

3Getting Started 1430.3572.02 ─ 04

Page 4

R&S®AREG100A

4.2 Connecting USB Devices................................................................... 21

4.3 Setting Up a Network (LAN) Connection.......................................... 22

4.3.1 Connecting the Instrument to the Network............................................23

Contents

5 Instrument Tour................................................................... 25

5.1 Front Panel Tour..................................................................................25

5.1.1 Touchscreen..........................................................................................26

5.1.2 Utility Keys............................................................................................ 26

5.1.3 On/Standby........................................................................................... 27

5.1.4 Function Keys....................................................................................... 27

5.1.5 Keypad..................................................................................................27

5.1.6 Navigation Controls...............................................................................28

5.1.6.1 Rotary Knob.......................................................................................... 28

5.1.6.2 Editing Keys.......................................................................................... 28

5.1.6.3 Navigation Keys.................................................................................... 29

5.1.7 Display Keys......................................................................................... 30

5.1.8 [USB] Connector................................................................................... 30

5.1.9 Sensor...................................................................................................30

5.2 Rear Panel Tour...................................................................................31

5.2.1 Connectors............................................................................................31

5.3 Frontend.............................................................................................. 32

5.3.1 Connectors............................................................................................33

6 Trying Out the Instrument...................................................35

6.1 Generating Radar Echo Signals........................................................ 35

6.2 Saving and Recalling Settings...........................................................38

6.3 Use Case Example - Testing Radar Sensors Against Interferers... 40

7 Instrument Control.............................................................. 42

4Getting Started 1430.3572.02 ─ 04

Page 5

R&S®AREG100A

7.1 Possible Ways to Operate the Instrument........................................42

7.2 Means of Manual Interaction..............................................................43

7.3 Understanding the Display Information............................................43

7.3.1 Additional Display Characteristics.........................................................44

7.4 Accessing the Functionality.............................................................. 44

7.5 Entering Data.......................................................................................45

7.5.1 Entering Numeric Parameters...............................................................46

7.5.2 Entering Alphanumeric Parameters...................................................... 47

7.5.3 Undo and Redo Actions........................................................................ 47

7.6 Getting Information and Help............................................................ 47

7.7 Remote Control................................................................................... 49

Contents

7.8 Remote Operation over VNC..............................................................50

Index..................................................................................... 51

5Getting Started 1430.3572.02 ─ 04

Page 6

R&S®AREG100A

Contents

6Getting Started 1430.3572.02 ─ 04

Page 7

R&S®AREG100A

Safety Information

1 Safety Information

The product documentation helps you to use the R&S AREG safely and efficiently. Follow the instructions provided here and in the printed "Basic Safety

Instructions". Keep the product documentation nearby and offer it to other users.

Intended use

The R&S AREG is designated for the development, production and verification of

electronic components and devices in industrial, administrative, and laboratory

environments. Use the R&S AREG only for its designated purpose. Observe the

operating conditions and performance limits stated in the data sheet.

Where do I find safety information?

Safety information is part of the product documentation. It warns you about the

potential dangers and gives instructions how to prevent personal injuries or damage caused by dangerous situations. Safety information is provided as follows:

●

The printed "Basic Safety Instructions" provide safety information in many languages and are delivered with the R&S AREG.

●

Throughout the documentation, safety instructions are provided when you

need to take care during setup or operation.

7Getting Started 1430.3572.02 ─ 04

Page 8

R&S®AREG100A

Key Features

Preface

2 Preface

2.1 Key Features

The R&S AREG Automotive Radar Echo Generator sets standards in RF performance and usability. Outstanding key features are:

●

Remote frontends supporting different frequencies (e.g. 24 GHz) and up to 4

GHz signal bandwidth

●

Simultaneous simulation of up to four objects

– Up to three individually switchable paths for simulation of fixed object dis-

tances from 5 m to 300 m

– One additional switchable path for fixed short object distance of 4m

(including 0.8m air gap)

●

Individually controllable amplitude for each path

●

Frontend available with single antenna (best for testing MIMO radars) or two

antennas (best isolation between Rx/Tx path)

●

Optional Doppler frequency offset for each path for simulation of radial velocity

●

Remote configuration and operation

For a detailed specification refer to the data sheet.

8Getting Started 1430.3572.02 ─ 04

Page 9

R&S®AREG100A

Documentation Overview

User Manuals and Help

3 Documentation Overview

This section provides an overview of the R&S AREG user documentation. Unless

specified otherwise, you find the documents on the R&S AREG product page at:

www.rohde-schwarz.com/manual/areg100a

3.1 Getting Started Manual

Introduces the R&S AREG and describes how to set up and start working with the

product. Includes basic operations, typical measurement examples, and general

information, e.g. safety instructions, etc. A printed version is delivered with the

instrument.

3.2 User Manuals and Help

Separate user manuals are provided for the base unit and the firmware applications:

●

Base unit manual

Contains the description of all instrument modes and functions. It also provides an introduction to remote control, a complete description of the remote

control commands with programming examples, and information on maintenance, instrument interfaces and error messages. Includes the contents of the

getting started manual.

●

Firmware application manual

Contains the description of the specific functions of a firmware application,

including remote control commands. Basic information on operating the R&S

AREG is not included.

The contents of the user manuals are available as help in the R&S AREG. The

help offers quick, context-sensitive access to the complete information for the

base unit and the firmware applications.

All user manuals are also available for download or for immediate display on the

Internet.

9Getting Started 1430.3572.02 ─ 04

Page 10

R&S®AREG100A

Documentation Overview

Data Sheets and Brochures

3.3 Tutorials

Tutorials offer guided examples and demonstrations on operating the R&S AREG.

They are provided on the product page of the internet.

3.4 Service Manual

Describes the performance test for checking the rated specifications, module

replacement and repair, firmware update, troubleshooting and fault elimination,

and contains mechanical drawings and spare part lists.

The service manual is available for registered users on the global

Rohde & Schwarz information system (GLORIS):

3.5 Instrument Security Procedures

Deals with security issues when working with the R&S AREG in secure areas. It

is available for download on the Internet.

3.6 Basic Safety Instructions

Contains safety instructions, operating conditions and further important information. The printed document is delivered with the instrument.

3.7 Data Sheets and Brochures

The data sheet contains the technical specifications of the R&S AREG. It also

lists the firmware applications and their order numbers, and optional accessories.

The brochure provides an overview of the instrument and deals with the specific

characteristics.

See www.rohde-schwarz.com/brochure-datasheet/areg100a

10Getting Started 1430.3572.02 ─ 04

Page 11

R&S®AREG100A

Application Notes, Application Cards, White Papers, etc.

Documentation Overview

3.8 Release Notes and Open Source Acknowledgment (OSA)

The release notes list new features, improvements and known issues of the current firmware version, and describe the firmware installation.

The open source acknowledgment document provides verbatim license texts of

the used open source software.

See www.rohde-schwarz.com/firmware/areg100a

3.9 Application Notes, Application Cards, White Papers, etc.

These documents deal with special applications or background information on

particular topics.

See www.rohde-schwarz.com/application/areg100a

11Getting Started 1430.3572.02 ─ 04

Page 12

R&S®AREG100A

Preparing for Use

Putting into Operation

4 Preparing for Use

● Putting into Operation..................................................................................... 12

● Connecting USB Devices................................................................................21

● Setting Up a Network (LAN) Connection.........................................................22

4.1 Putting into Operation

This section describes the basic steps to be taken when setting up the R&S

AREG for the first time.

Risk of injury due to disregarding safety information

Observe the information on appropriate operating conditions provided in the

data sheet to prevent personal injury or damage to the instrument. Read

and observe the basic safety instructions provided with the instrument, in

addition to the safety instructions in the following sections. In particular:

●

Do not open the instrument casing.

Risk of injury due to laser radiation

A laser (laser class 1M) is installed in the device.

Do not open the device. The device may only be opened by authorized service personnel.

Risk of instrument damage due to inappropriate operating conditions

Specific operating conditions are required to ensure accurate measurements and to avoid damage to the instrument. Observe the information on

appropriate operating conditions provided in the basic safety instructions

and the instrument's data sheet.

12Getting Started 1430.3572.02 ─ 04

Page 13

R&S®AREG100A

Instrument damage caused by electrostatic discharge

Electrostatic discharge (ESD) can damage the electronic components of the

instrument and the device under test (DUT). Electrostatic discharge is most

likely to occur when you connect or disconnect a DUT or test fixture to the

instrument's test ports. To prevent electrostatic discharge, use a wrist strap

and cord and connect yourself to the ground, or use a conductive floor mat

and heel strap combination.

Risk of instrument damage due to inappropriate operating conditions

An unsuitable operating site or test setup can damage the instrument and

connected devices. Before switching on the instrument, observe the information on appropriate operating conditions provided in the data sheet. In

particular, ensure the following:

Preparing for Use

Putting into Operation

●

All fan openings are unobstructed and the airflow perforations are unimpeded. A minimum distance of 10 cm to other objects is recommended.

●

The instrument is dry and shows no sign of condensation.

●

The instrument is positioned as described in the following sections.

●

The ambient temperature does not exceed the range specified in the

data sheet.

●

Signal levels at the input connectors are all within the specified ranges.

●

Signal outputs are connected correctly and are not overloaded.

13Getting Started 1430.3572.02 ─ 04

Page 14

R&S®AREG100A

Risk of instrument damage due to inappropriate handling

Handle all waveguide components with care.

●

If the R&S AREG is not used, cover the antenna to prevent dust or other

objects from getting into the waveguide.

●

Do not plug or unplug the TRX CTRL cable from the R&S AREG frontend or base unit if the device is running.

●

Do not subject the TRX CTRL or IF cables to a tight bend radius.

Preparing for Use

Putting into Operation

4.1.1 EMI Suppression

Electromagnetic interference (EMI) may affect the measurement results.

To suppress generated Electromagnetic Interference (EMI),

●

Use suitable shielded cables of high quality. For example use double-shielded

RF, BNC and LAN cables (CAT6 STP).

Note: USB cables are of varying and often poor quality. Therefore, check the

quality of each individual USB cable as described in the service manual.

●

Always terminate open cable ends.

Note the EMC classification in the data sheet.

4.1.2 Unpacking and Checking the Instrument

Unpack the R&S AREG carefully and check the contents of the package.

●

Check if all items listed on the delivery note, including this getting started

manual, are included in the delivery.

●

Check the R&S AREG for any damage.

If the contents are damaged, immediately contact the carrier who delivered

the package.

14Getting Started 1430.3572.02 ─ 04

Page 15

R&S®AREG100A

Packing material

Retain the original packing material. If the instrument needs to be transported or shipped later, you can use the material to protect the control elements and connectors.

4.1.3 Accessory List

The instrument comes with the following accessories:

●

Power cable

●

Getting Started printed manual

4.1.4 Placing or Mounting the Instrument

Preparing for Use

Putting into Operation

The R&S AREG is designed for use under laboratory conditions, either on a

bench top or in a rack using the standard rackmount kit.

Bench top operation

If the R&S AREG is operated on a bench top, the surface must be flat. The instrument can be used in horizontal position, standing on its feet, or with the support

feet on the bottom extended.

Risk of injury if feet are folded out

The feet can fold in if they are not folded out completely or if the instrument

is shifted. Collapsing feet can cause injury or damage the instrument.

●

Fold the feet completely in or out to ensure stability of the instrument.

Never shift the instrument when the feet are folded out.

●

When the feet are folded out, do not work under the instrument or place

anything underneath.

●

The feet can break if they are overloaded. The overall load on the folded-out feet must not exceed 500 N.

15Getting Started 1430.3572.02 ─ 04

Page 16

R&S®AREG100A

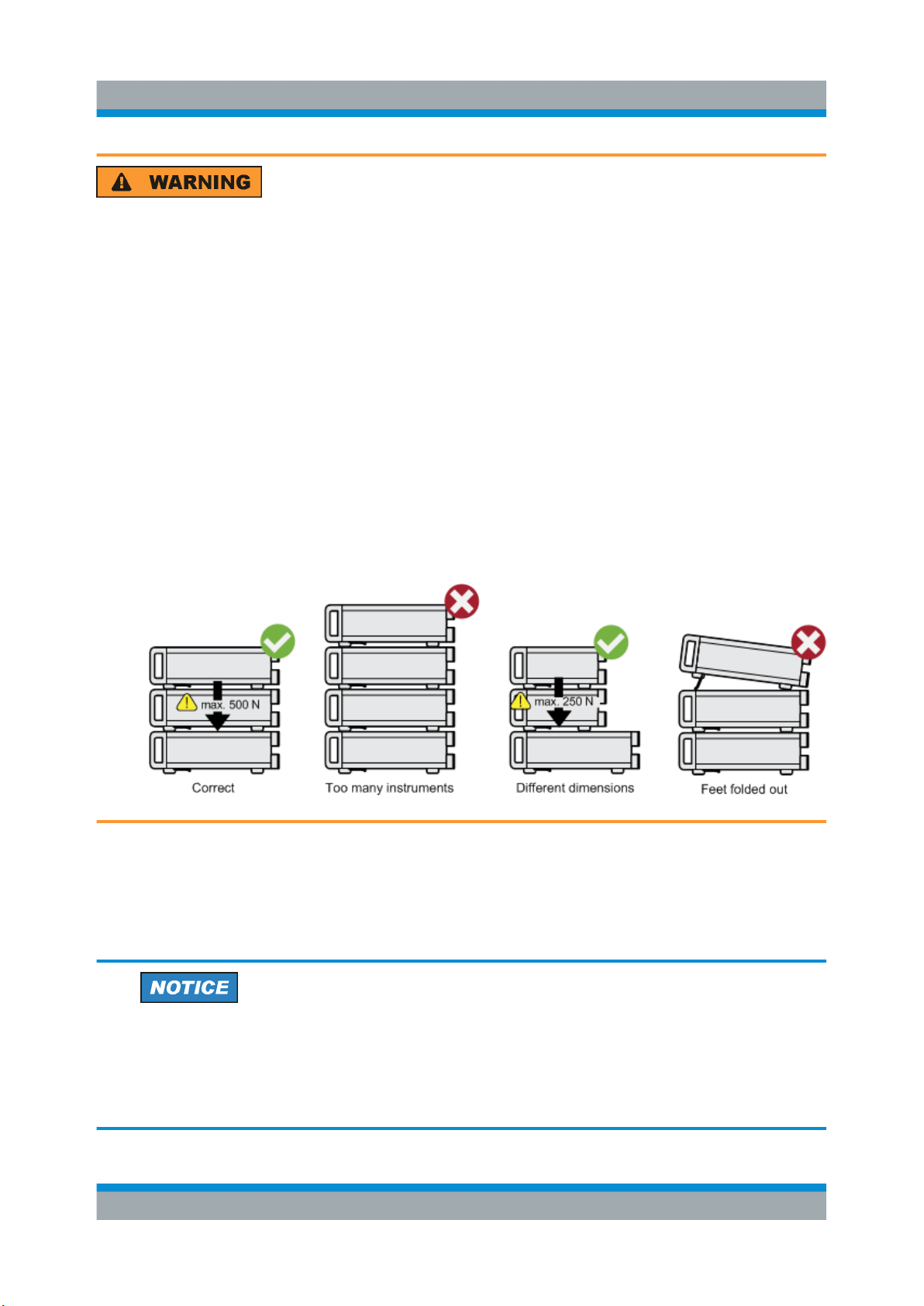

Risk of injury when stacking instruments

A stack of instruments can tilt over and cause injury if not stacked correctly.

Furthermore, the instruments at the bottom of the stack can be damaged

due to the load imposed by the instruments on top.

Observe the following instructions when stacking instruments:

●

Never stack more than three instruments. If you need to stack more

than three instruments, install them in a rack.

●

The overall load imposed on the lowest instrument must not exceed

500 N.

●

It is best if all instruments have the same dimensions (width and length).

If you need to stack smaller instruments on the top, the overall load

imposed on the lowest instrument must not exceed 250 N.

Preparing for Use

Putting into Operation

●

If the instruments have foldable feet, fold them in completely.

Mounting in a rack

The R&S AREG can be installed in a rack using a rack adapter kit (Order No. see

data sheet). The installation instructions are part of the adapter kit.

Risk of instrument damage due to insufficient airflow in a rack

If you mount several instruments in a rack, you need an efficient ventilation

concept to ensure that the instruments do not overheat. Insufficient airflow

for a longer period can disturb the operation and even cause damage.

16Getting Started 1430.3572.02 ─ 04

Page 17

R&S®AREG100A

Preparing for Use

Putting into Operation

4.1.5 Connecting AC Power

The R&S AREG is equipped with an AC power supply connector, that can be

operated with different AC power voltages. Once it is connected, the instrument

automatically adjusts to the given voltage. Refer to the data sheet for the requirements of voltage and frequency. There is no need to set the voltage manually or

change fuses.

To connect the AC supply

► Connect the R&S AREG to the AC power source using the supplied power

cable.

Note: Since the instrument is designed in compliance with standard EN

61010-1 safety class I, it must only be connected to an outlet that has a

ground contact.

Characteristics of the AC power supply:

●

100 V to 240 V AC

4.1.6 Cabling of Front End and Base Unit

To connect the front end

1. Connect the IF cable with the label RX IF OUT to the Rx IF Out connector of

the front end.

2. Connect the IF cable with the label TX IF IN to the Tx IF IN connector of the

front end.

3. Connect the control cable to the Control connector of the front end.

17Getting Started 1430.3572.02 ─ 04

Page 18

R&S®AREG100A

Preparing for Use

Putting into Operation

Figure 4-1: Cabling of front end

1 = Rx IF Out

2 = Tx IF IN

3 = Control

To connect the base unit

1. Connect the IF cable with the label RX IF IN to the RX IF In connector of the

base unit.

2. Connect the IF cable with the label TX IF IOUT to the Tx IF OUT connector of

the base unit.

3. Connect the control cable to the Control connector of the base unit.

18Getting Started 1430.3572.02 ─ 04

Page 19

R&S®AREG100A

Preparing for Use

Putting into Operation

Figure 4-2: Cabling of base unit

1 = Rx IF In

2 = Tx IF Out

3 = Control

4.1.7 Turning the Instrument On and Off

To turn on the R&S AREG

1. Connect the instrument to the AC supply.

2. Turn on the main AC power switch at the rear panel of the R&S AREG (posi-

tion "I" (on)).

The instrument is supplied with AC power.

19Getting Started 1430.3572.02 ─ 04

Page 20

R&S®AREG100A

To start the R&S AREG

Starting the R&S AREG requires that it is connected and turned on.

► At the front panel, press the [On/Standby] key briefly.

The instrument boots the operating system and starts the instrument firmware.

After booting, the instrument is in the state before the last power off (standby

or ready), indicated by the color of the [On/Standby] key's LEDs:

● Green: the R&S AREG is running and ready for operation.

All modules are power-supplied.

● Orange: the R&S AREG is in standby mode (main AC power switch is in

position "I").

To switch between standby and ready state, briefly press the [On/Standby]

key.

If a previous session was terminated regularly, the instrument uses the last setup

with the relevant instrument settings.

Preparing for Use

Putting into Operation

► To set up a new configuration, press the [Preset] key to return the instrument

to its defined reset/preset state.

To shut down and turn off the R&S AREG

Risk of losing data

If you switch off the running instrument using the rear panel switch or by

disconnecting the power cord, the instrument loses its current settings. Furthermore, program data can be lost.

Press the On/Standby key first to shut down the application properly.

1. Press the [On/Standby] key.

The current setup is saved, the operating system shuts down and sets the

instrument to standby state.

The [On/Standby] LED must be orange.

2. Turn off the main AC power switch at the rear panel of the R&S AREG (position "0" (off)).

The instrument is no longer supplied with AC power.

20Getting Started 1430.3572.02 ─ 04

Page 21

R&S®AREG100A

Connecting USB Devices

Turning off the AC power

You can leave the AC power on permanently. Switching off is required only

if the instrument must be disconnected from all power supplies.

Preparing for Use

4.1.8 Functional Check

When the instrument is switched on, it automatically monitors the main functions.

A detected fault is indicated by an "Error" message displayed in the "Info" line of

the instrument together with a brief error description. For an in-depth identification

of the error, tap on the "Info" indication. In response, a description of the errors is

displayed. For more information, refer to the "Troubleshooting and Error Messages" section in the user manual.

4.1.9 Checking the Supplied Options and Licenses

The instrument can be equipped with both, hardware and firmware options. To

check whether the installed options correspond to the options indicated on the

delivery note, proceed as follows:

1. Press the [Setup] key.

2. Select "Instrument Assembly > Hardware Config" and "Software / Options".

A list with hardware and firmware information is displayed.

3. Check the availability of the hardware options as indicated in the delivery

note.

For an overview of the available options, refer to the data sheet.

4.2 Connecting USB Devices

The USB interfaces of the R&S AREG allow you to connect USB devices, including USB hubs directly to the instrument. Due to the large number of available

USB devices, there is almost no limit to the expansions that are possible with the

R&S AREG.

21Getting Started 1430.3572.02 ─ 04

Page 22

R&S®AREG100A

Setting Up a Network (LAN) Connection

The following list shows various USB devices that can be useful:

●

Memory stick for easy transfer of data to/from a computer (for example firmware updates)

●

Keyboard or mouse to simplify the entry of data, comments, filenames, etc.

●

Power sensors of the R&S NRP families

All USB devices can be connected to or disconnected from the instrument during

operation.

Connecting a USB storage device

When a USB storage device like a memory stick, a CD-ROM drive, or a hard disk

is connected, it is detected automatically. The device is made available as a new

drive (/usb). The name of the drive is manufacturer-dependent.

Connecting a keyboard

Preparing for Use

A keyboard is detected automatically when it is connected. The default keyboard

layout is English – US.

Connecting a mouse

A mouse is detected automatically when it is connected.

4.3 Setting Up a Network (LAN) Connection

The R&S AREG is equipped with a network interface and can be connected to an

Ethernet LAN (local area network). Provided the appropriate rights have been

assigned by the network administrator, the interface can be used, for example:

●

To transfer data between a controller and the instrument, for example to run a

remote control program.

●

To access or operate the instrument from a remote computer using the

Ultr@VNC program (or a similar tool, like another VNC client or any Web

browser supporting Java).

●

To transfer data from a remote computer and back, for example using network

folders.

●

To use power sensors with network capability, e.g. the R&S NRP LAN power

sensors.

22Getting Started 1430.3572.02 ─ 04

Page 23

R&S®AREG100A

Setting Up a Network (LAN) Connection

This section describes how to configure the LAN interface.

Accessing operating system

No access to the operating system is required for normal operation.

All necessary system settings can be made in the "Setup" dialog.

Preparing for Use

4.3.1 Connecting the Instrument to the Network

There are two methods to establish a LAN connection to the instrument:

●

A non-dedicated network (Ethernet) connection from the instrument to an

existing network

●

A dedicated network connection (Point-to-point connection) between the

instrument and a single computer

For addressing, both the instrument and the computer require an IP address. The

address information is usually assigned to the devices automatically, depending

on the network capabilities.

If the IP address is not assigned automatically, see "Assigning the IP Address" in

the R&S AREG user manual, for information on how to assign the address manually.

To set up a network (LAN) connection

Risk of network failure

Consult your network administrator before performing the following tasks:

●

Connecting the instrument to the network

●

Configuring the network

●

Changing IP addresses

Errors can affect the entire network.

► Connect the instrument to the network or to a single PC.

If the instrument is connected to the LAN, the operating system automatically

detects the network connection and activates the required drivers.

23Getting Started 1430.3572.02 ─ 04

Page 24

R&S®AREG100A

Setting Up a Network (LAN) Connection

By default, the instrument is configured to use DHCP (dynamic host configuration protocol) configuration and to obtain the whole address information automatically.

When connected, the R&S AREG displays the address information on the

screen.

Risk of network connection failure

Network cables and cable connectors of poor quality, or failures in the autonegotiation process, can cause network connection failures.

If the network connection to the instrument fails, check the network infrastructure and contact your network administrator.

Preparing for Use

For details, see section "Troubleshooting and Error Messages" in the R&S

AREG user manual.

24Getting Started 1430.3572.02 ─ 04

Page 25

R&S®AREG100A

Instrument Tour

Front Panel Tour

5 Instrument Tour

The following topics help you to get familiar with the instrument and perform the

first steps:

●

Chapter 5.1, "Front Panel Tour", on page 25

●

Chapter 5.2, "Rear Panel Tour", on page 31

●

Chapter 5.3, "Frontend", on page 32

This section explains the control elements and the connectors of the R&S AREG

with the aid of the front and rear views. For specifications of the interfaces, refer

to the data sheet.

5.1 Front Panel Tour

This section provides an overview of the control elements at the front panel of the

R&S AREG.

Figure 5-1: Front panel view of the R&S AREG

1 = Touchscreen

2 = Utility keys

3 = [On/Standby]

4 = Function keys

5 = Keypad

6 = Navigation controls

25Getting Started 1430.3572.02 ─ 04

Page 26

R&S®AREG100A

Instrument Tour

Front Panel Tour

7 = Display keys

8 = [USB]

9 = [Sensor]

5.1.1 Touchscreen

The screen at the front panel is the graphical user interface. It shows the settings

dialogs and parameters, and the current configuration at a glance, see Chap-

ter 7.3, "Understanding the Display Information", on page 43.

The touch-sensitive panel provides an alternative means of user interaction for

quick and easy handling of the instrument, see Chapter 7.2, "Means of Manual

Interaction", on page 43.

Risk of touchscreen damage

Inappropriate tools or excessive force can damage the touchscreen.

Observe the following instructions when operating the touchscreen:

●

Never touch the screen with ball point pens or other sharp objects, use

your fingers instead.

As an alternative, you can use a stylus pen with a smooth soft tip.

●

Never apply excessive force to the screen. Touch it gently.

●

Never scratch the screen surface, for example with a finger nail.

●

Never rub the screen surface strongly, for example with a dust cloth.

For instructions on cleaning the screen, see the Maintenance chapter in

the R&S AREG user manual.

5.1.2 Utility Keys

The utility keys set the R&S AREG to a defined state, and provide access to basic

settings and information on assistance.

Table 5-1: Utility keys

Utility Key Assigned functions

[Preset] Sets the instrument to a defined state

[Local] Switches from remote control to local (manual) control

26Getting Started 1430.3572.02 ─ 04

Page 27

R&S®AREG100A

Instrument Tour

Front Panel Tour

Utility Key Assigned functions

[Setup] Accesses the general instrument settings

[Help] Displays context-sensitive help text

5.1.3 On/Standby

The [On/Standby] key starts up and shuts down the instrument, and switches

between the standby and the ready state.

●

In the ready state, On/Standby key lights green. The instrument is ready for

operation.

●

In the standby state, the On/Standby key lights orange. The standby power

mode keeps the power switch circuits and the oven-controlled crystal oscillator OCXO active. In this state, it is safe to switch off the AC power and disconnect the instrument from the power supply.

5.1.4 Function Keys

Function keys provide access to the most common generator settings and functions. You can find a detailed description of the corresponding functions in the

user manual.

Table 5-2: Function keys

Function key Assigned functions

[Freq] Activates frequency entry.

[Level] Activates level entry.

[Mod on/off] Switches the modulation on and off.

[RF on/off] Switches the RF output on and off.

5.1.5 Keypad

The keypad enables you to enter alphanumeric parameters, including the corresponding units. It contains the following keys:

27Getting Started 1430.3572.02 ─ 04

Page 28

R&S®AREG100A

Instrument Tour

Front Panel Tour

Table 5-3: Keys on the keypad

Type of key Description

Alphanumeric keys Enter numbers and (special) characters in edit dialog boxes.

Decimal point Inserts a decimal point "." at the cursor position.

Sign key Changes the sign of a numeric parameter. In the case of an

alphanumeric parameter, inserts a "-" at the cursor position.

Unit keys

(G/n dBμV, M/μ μV, k/m mV

and x1 dB(m))

These keys add the selected unit to the entered numeric value

and complete the entry.

In the case of level entries (e.g. in dB) or dimensionless values,

all units have the value "1" as multiplying factor. Thus, they have

the same function as an [Enter] key.

5.1.6 Navigation Controls

The navigation controls include a rotary knob, navigation keys, and the display

keys. They allow you to navigate within the display or within dialog boxes.

5.1.6.1 Rotary Knob

The rotary knob has several functions:

●

Increments (clockwise direction) or decrements (counterclockwise direction)

the instrument parameter at a defined step width in the case of a numeric

entry.

●

Moves the selection, e.g. to a function block in the block diagram

●

Shifts the selection bar within focused areas (e.g. lists).

●

Acts like the [Enter] key, when it is pressed.

5.1.6.2 Editing Keys

Editing keys enable you to confirm an entry, delete individual characters, or exit

the current operation.

28Getting Started 1430.3572.02 ─ 04

Page 29

R&S®AREG100A

Instrument Tour

Front Panel Tour

Table 5-4: Editing keys

Type of key Description

[Esc] key Closes all kinds of dialog boxes, if the edit mode is not active.

Quits the edit mode, if the edit mode is active. In dialog boxes

that contain a "Cancel" button it activates that button.

For "Edit" dialog boxes the following mechanism is used:

●

If data entry has been started, it retains the original value

and closes the dialog box.

●

If data entry has not been started or has been completed, it

closes the dialog box.

[Enter] key

[Backspace] key Deletes the character to the left of the cursor in editing mode.

Has the same effect as pressing the rotary knob

●

Concludes the entry of dimensionless entries. The new value

is accepted.

●

With other entries, this key can be used instead of the

default unit key.

●

In a dialog box, selects the default or focused element.

●

Calls the next dialog level.

●

Confirms and closes open input windows.

5.1.6.3 Navigation Keys

As an alternative to the rotary knob or the touchscreen, you can use the navigation keys to navigate through dialog boxes, diagrams, or tables.

Table 5-5: Navigation keys

Type of key Description

[Up/Down] Key The [Up] and the [Down] key does the following:

●

In a numeric edit dialog box, increase or decrease the instrument parameter.

●

In a list, scroll forward and backward through the list entries.

●

In a table, move the selection bar vertically.

●

In windows or dialog boxes with vertical scrollbar, move the

scrollbar.

[Left/Right] Key The [Left] and the [Right] key does the following:

●

In an alphanumeric edit dialog box, move the cursor.

●

In a list, scroll forward and backward through the list entries.

●

In a table, move the selection bar horizontally.

●

In windows or dialog boxes with horizontal scrollbar, move

the scrollbar.

29Getting Started 1430.3572.02 ─ 04

Page 30

R&S®AREG100A

5.1.7 Display Keys

The display keys arrange different windows on the display.

Table 5-6: Display keys

Display key Assigned functions

[Home] Returns to the initial feature screen.

[Next window] Toggles between the entry fields in the taskbar.

Instrument Tour

Front Panel Tour

[On/Off]

[Undo] Reverts the last operation.

[User] Adds a parameter to the user menu for quick access.

●

Switches highlighted elements or a function block on and off.

●

Switches between two or more settings, e.g. items of selection lists. At the end of a list, the cursor is set on the first

entry again.

5.1.8 [USB] Connector

USB (universal serial bus) interfaces of type A (host USB).

●

Connection of peripherals such as mouse or keyboard

●

Connection of memory stick for file transmission

●

Firmware update

Further USB interface type A (host USB) and a USB interface type B ([USB

In]) are available on the rear panel.

5.1.9 Sensor

Connector for R&S NRP sensors.

The R&S AREG supports the use of R&S NRP power sensors in various ways

including the use as a power viewer.

A power sensor is connected to the R&S AREG by inserting the male connector.

To disconnect, pull the connector by its sleeve. You cannot disconnect the sensor

simply by pulling at the cable or the rear part of the connector.

30Getting Started 1430.3572.02 ─ 04

Page 31

R&S®AREG100A

Instrument Tour

Rear Panel Tour

5.2 Rear Panel Tour

This section provides an overview of the connectors at the rear panel of the

instrument. For technical data of the connectors, refer to the data sheet.

Figure 5-2: Rear panel view of the R&S AREG

1 = IEC 625/IEEE 488 connector

2 = USB In connector (type micro-B)

3 = LAN connector

4 = USB connector (type A)

5 = AC power supply connection and main power switch

6 = Ref In and Ref Out connectors (BNC)

7 = AUX IF In / IF Out connectors (SMA)

8 = Frontend RX IF In / TX IF Out connectors (SMA)

9 = Frontend Control

5.2.1 Connectors

IEC 625/IEEE 488

Option: R&S AREG-B86

GPIB-bus interface for remote control of the instrument.

The IEC 625 interface is in compliance with IEEE488 and SCPI. A computer for

remote control can be connected via this interface. To set up the connection, we

recommend that you use a shielded cable.

Note: To avoid electromagnetic interference (EMI) caused by open lines, always

terminate any connected IEC-bus cable with an instrument or a controller.

31Getting Started 1430.3572.02 ─ 04

Page 32

R&S®AREG100A

USB/USB In

●

Female USB type A connector, to connect devices like a keyboard, a mouse,

a memory stick, or the R&S NRP-Z3/Z4 cable for the R&S NRP power sensors

●

Female USB In connector (USB type B), for example for remote control.

Option: R&S AREG-B86

See also Chapter 4.2, "Connecting USB Devices", on page 21.

LAN

The LAN interface can be used to connect the R&S AREG to a local network for

remote control, remote operation, and data transfer.

AC supply and power switch

The AC power supply connector and the main power switch are located in a unit

on the rear panel of the instrument.

Instrument Tour

Frontend

Main power switch function:

●

Position 1: The instrument is in operation.

●

Position 0: The entire instrument is disconnected from the AC power supply.

Ref In/Ref Out

Input/output for external reference signal.

Incl. dedicated connectors for the 10 MHz reference signal.

AUX IF In / IF Out connectors (SMA)

Option: R&S AREG-B17

Used as auxiliary IF output ports for signal analysis and for applying an additional

interferer to the generated echo signal.

Frontend RX IF In / TX IF Out connectors (SMA)

Used to connect the frontend with the supplied IF cables.

Frontend Control

Used to connect the frontend with the supplied control cable.

5.3 Frontend

This section provides an overview of the connectors of the frontend of the instrument. For technical data of the connectors, refer to the data sheet.

32Getting Started 1430.3572.02 ─ 04

Page 33

R&S®AREG100A

Instrument Tour

Frontend

Figure 5-3: Frontend of R&S AREG

1 = Control

2 = Rx IF Out / Tx IF IN + REF IN

3 = Rx Power (SMA)

4 = 2 x Waveguide port

5.3.1 Connectors

Control

Used to connect the R&S AREG base unit with the supplied control cable.

Rx IF Out / Tx IF In + REF In

Used to connect to the base unit with the supplied IF cables.

Rx Power (SMA)

Used for NRP connection to perform EIRP power measurements.

Waveguide port (2 x)

Used for antenna connection. These ports support different frequency ranges

(e.g. 24 GHz).

33Getting Started 1430.3572.02 ─ 04

Page 34

R&S®AREG100A

The R&S AREG comes with either one or two antennas mounted to the waveguide ports. Users can detach the included antennas and can connect their own

antennas. If doing so, the gain of the user antennas need to be set in the AREG

configuration. (See user manual, chapt. 4.2.4 AREG Configuration.)

Instrument Tour

Frontend

34Getting Started 1430.3572.02 ─ 04

Page 35

R&S®AREG100A

Trying Out the Instrument

Generating Radar Echo Signals

6 Trying Out the Instrument

This chapter introduces the first steps with the R&S AREG. It shows how to operate and configure the instrument using simple examples. The complete description of the functionality and its usage is given in the R&S AREG user manual.

Basic instrument operation is described in Chapter 7, "Instrument Control",

on page 42.

Prerequisites

The instrument is set up, connected to the power supply, and started up as

described in Chapter 4, "Preparing for Use", on page 12.

The instrument is manually operated via the touchscreen. Try out the following:

● Generating Radar Echo Signals......................................................................35

● Saving and Recalling Settings........................................................................ 38

● Use Case Example - Testing Radar Sensors Against Interferers................... 40

6.1 Generating Radar Echo Signals

The core element of a measurement setup is the R&S AREG base unit with connected frontend.

To generate a radar echo signal

1. Select a radar object to be configured. Use the object with the range that fulfills your test requirement.

35Getting Started 1430.3572.02 ─ 04

Page 36

R&S®AREG100A

Trying Out the Instrument

Generating Radar Echo Signals

2. Modify the attenuation until the appropriate value for the RCS is displayed.

The RCS indicates the size of the simulated radar object.

Examples for RCS values (can vary in reality)

● Truck (RCS =20 dBsm)

● Car (RCS = 5 dBsm)

● Pedestrian (RCS = −4 dBsm)

3. If the attenuation range of the specific radar object is not enough to reach the

appropriate RCS value, you can modify the base attenuation.

36Getting Started 1430.3572.02 ─ 04

Page 37

R&S®AREG100A

Trying Out the Instrument

Generating Radar Echo Signals

4. Switch on your radar object.

5. Switch "RF On".

As a result, the RUT reports the range and the radar cross section of the target, which can be compared with the pre-configured values in the R&S AREG

37Getting Started 1430.3572.02 ─ 04

Page 38

R&S®AREG100A

Trying Out the Instrument

Saving and Recalling Settings

6.2 Saving and Recalling Settings

To restore the results of our measurements later, we save the instrument settings

in a file.

To save the instrument settings in a file

We assume, a test configuration as described in Chapter 6.1, "Generating Radar

Echo Signals", on page 35.

1. Press the [Setup] key on the front panel.

2. In the "Setup" menu, select "Settings > Save/Recall".

3. In the "Save/Recall" dialog, select "Operation Mode > Save".

4. Tap the "Filename", use the on-screen keyboard, and enter MyTestSignal.

5. Tap the "Save" button.

The file MyTestSignal.savrcltxt is stored in the default directory /var/user/.

38Getting Started 1430.3572.02 ─ 04

Page 39

R&S®AREG100A

To load saved instrument settings

You can restore the settings to the instrument at any time using the settings file.

1. Press the [Preset] button to restore the default instrument settings so you can

check that the stored user settings are restored afterwards.

2. Press the [Setup] key on the front panel.

3. In the "Setup" menu, select "Settings > Save/Recall".

4. In the "Save/Recall" dialog, select "Operation Mode > Recall".

Navigate to the directory the file is saved in and select the MyTestSignal

file.

Trying Out the Instrument

Saving and Recalling Settings

5. Tap the "Recall" button.

All instrument settings are restored and the display resembles Chapter 6.1,

"Generating Radar Echo Signals", on page 35, which shows the instrument

display right before the settings were saved.

39Getting Started 1430.3572.02 ─ 04

Page 40

R&S®AREG100A

Use Case Example - Testing Radar Sensors Against Interferers

How to display all parameters with values different to their preset values

When you load a file to your instrument, you do not have enough information on the changed settings. In such case, it is useful to visualize all

parameters that have been changed from their default state.

Try out the following:

●

Touch and hold a spot in the tile diagram for at least 1 second to access the

context-sensitive menu.

●

Select "Mark All Parameters Changed from Preset".

Trying Out the Instrument

●

All changed parameters are highlighted.

6.3 Use Case Example - Testing Radar Sensors

Against Interferers

The R&S AREG provides an input interface in the IF domain (AUX IF In), which

allows in combination with any analog or vector signal generator the simulation of

a wide range of interferers together with the wanted echoes.

40Getting Started 1430.3572.02 ─ 04

Page 41

R&S®AREG100A

Use Case Example - Testing Radar Sensors Against Interferers

Figure 6-1: Testing Radar Sensors Against Interferers

Trying Out the Instrument

1. Connect a R&S SMW200A to the TX_IF_IN port of the R&S AREG base unit.

2. The generated interfering signal is superimposed and upconverted into the Eband together with the delayed echo signal from the simulated radar objects.

3. The influence of the interferer signals can now be oserved and evaluated.

41Getting Started 1430.3572.02 ─ 04

Page 42

R&S®AREG100A

Possible Ways to Operate the Instrument

Instrument Control

7 Instrument Control

This chapter provides an overview on how to work with the R&S AREG.

It covers the following topics:

● Possible Ways to Operate the Instrument....................................................... 42

● Means of Manual Interaction...........................................................................43

● Understanding the Display Information...........................................................43

● Accessing the Functionality.............................................................................44

● Entering Data.................................................................................................. 45

● Getting Information and Help.......................................................................... 47

● Remote Control...............................................................................................49

● Remote Operation over VNC.......................................................................... 50

7.1 Possible Ways to Operate the Instrument

There are three ways to operate the R&S AREG:

●

Manual operation:

Use the touchscreen, hard keys and rotary knob, or an optional mouse and/or

keyboard.

The following description shows how to operate the instrument manually.

●

Remote control:

Create programs to automatize repeating settings, tests and measurements.

The instrument is connected to a computer running the program.

This way of operation is described in the user manual, chapter "Network and

Remote Control Operation".

●

Remote operation from a computer:

Remote monitoring and control of the instrument from a connected computer

is based on the common cross-platform technology VNC (Virtual Network

Computing). On the remote computer, any standard web browser (supporting

Java) or a dedicated VNC client (like Ultr@VNC) can be used. See also Chap-

ter 7.8, "Remote Operation over VNC", on page 50.

42Getting Started 1430.3572.02 ─ 04

Page 43

R&S®AREG100A

Understanding the Display Information

Instrument Control

7.2 Means of Manual Interaction

For the manual interaction with the R&S AREG, you have several methods that

you can use as an alternative to perform a task:

●

Touchscreen:

Touchscreen operation is the most direct way to interact. Almost all control

elements and actions on the screen are based on the standard operating system concept. You can tap any user interface element to set parameters in dialog boxes, enter data, scroll within a dialog etc., as if you work with a mouse

pointer.

Tapping the screen works like clicking mouse buttons:

– Touch quickly = click: Selects a parameter or provokes an action.

– Touch and hold = right-click: Opens a context-sensitive menu.

– Touch and swipe = drag: Scrolls through the contents of a display element

larger than the screen, e.g. a list or a table.

●

Function keys and rotary knob:

The front panel provides nearly all functions and controls to operate the instrument in the classic way, without touchscreen.

●

Optional mouse and/or keyboard:

These devices work like known from PCs. The navigation keys on the front

panel correspond to the keys on the keyboard.

This manual describes the manual interaction with the instrument via the touchscreen. It mentions the alternative methods using the keys on the instrument or

the on-screen keypads if it deviates from the standard operating procedures. The

usage of the touchscreen and navigation keys is described in Chapter 7.4,

"Accessing the Functionality", on page 44.

Throughout the manual, the term "select" refers to any of the described methods,

i.e. using a finger on the touchscreen, a mouse pointer in the display, or a key on

the instrument or on a keyboard.

7.3 Understanding the Display Information

The home screen of the R&S AREG displays all main settings and generator

states, divided into three main operation areas.

● Additional Display Characteristics...................................................................44

43Getting Started 1430.3572.02 ─ 04

Page 44

R&S®AREG100A

Accessing the Functionality

Instrument Control

7.3.1 Additional Display Characteristics

The following section provides a short insight on the indication of the screen in

general, and significant elements that you see under specific operating modes, in

dialogs or settings.

●

Appearance of active elements

– Active elements like On/Off switches, state buttons have a blue back-

ground.

– Selected elements are framed or highlighted orange.

– Inactive elements are gray.

●

On-Screen keypads

As additional means of interacting with the instrument without having to connect an external keyboard, either a numerical or alphanumerical on-screen

keypad appears when you activate an entry field (see Chapter 7.5, "Entering

Data", on page 45).

●

Info line

The "Info line" shows brief status information and error messages. It appears

when an event generates a message.

●

Key parameters indicated in tab labels

Most dialogs are divided into tabs with logically grouped parameters. The tab

label expresses the content and can also contain status indicators or the set

value of a key parameter.

●

Scroll bar handle

An arrow icon that appears when you touch a scroll bar helps you to scroll in a

dialog or list.

●

Context-sensitive menus

Within the entire screen display, including single parameters, you can access

context-sensitive menus that provide some additional functions.

7.4 Accessing the Functionality

All functionalities are provided in dialog boxes as known from computer programs. You can control the instrument intuitively with the touchscreen. This section provides an overview of the accessing methods.

44Getting Started 1430.3572.02 ─ 04

Page 45

R&S®AREG100A

The instrument's functions and settings can be accessed by selecting one of the

following elements:

●

System and function keys on the front panel of the instrument

●

Taskbar/softkeys on the touchscreen

●

Context-sensitive menus for specific elements on the touchscreen

●

Elements on the status bar in the touchscreen

●

Displayed setting on the touchscreen, that means block diagram and all settings available in dialogs.

To open a dialog box

► Perform one of the following actions:

● Tap the required tile, and then the menu entry.

● Tap the minimized view (button) on the taskbar.

Instrument Control

Entering Data

Some of the utility keys access a dedicated dialog, too.

To minimize a dialog box

► To return to the home screen, tap the "Home" button.

To close a dialog box

To close a dialog box, you have the same controls as you know from computers

or devices with touchscreen.

► Perform one of the following actions:

● Tap the "Close" icon in the upper right corner.

● Press the [Esc] key on the front panel.

● Drag and drop a minimized dialog from the taskbar to the tile diagram.

To select an option in a dialog box

► Tap the required option.

7.5 Entering Data

Some parameters have their own key on the front panel.

45Getting Started 1430.3572.02 ─ 04

Page 46

R&S®AREG100A

For data input in dialog boxes, the instrument provides on-screen keypads for

entering numeric and alphanumeric values. Thus, you can always set the parameters via the touchscreen, the front panel, or an external keyboard.

Correcting an entry

1. Using the arrow keys, move the cursor to the right of the entry you want to

delete.

2. Press the [Backspace] key.

3. Deletes the entry to the left of the cursor.

4. Enter your correction.

Completing the entry

Instrument Control

Entering Data

► Press the [Enter] key or the rotary knob.

Aborting the entry

► Press the [Esc] key.

The dialog box closes without changing the settings.

7.5.1 Entering Numeric Parameters

To enter values with the on-screen keypad

For numeric settings, the instrument displays the numeric keypad. The units

specified correspond to the units of the parameter.

1. Enter the numeric value.

2. Tap the unit button to complete the entry.

The unit is added to the entry.

3. If the parameter does not require a unit, confirm the entered value by pressing

"Enter".

To enter values by using the front panel controls

1. Change the currently used parameter value by using the rotary knob or the

[Up/Down] keys.

46Getting Started 1430.3572.02 ─ 04

Page 47

R&S®AREG100A

Getting Information and Help

2. If the parameter does not require a unit, confirm the entered value by pressing

the [Enter] key or any of the unit keys.

The instrument highlights the editing line to confirm the entry.

If you edit numeric data in tables, the entry field must be in edit mode: Press

[Enter], or the rotary knob to activate the edit mode.

Instrument Control

7.5.2 Entering Alphanumeric Parameters

If a field requires alphanumeric input, you can use the on-screen keyboard to

enter letters and (special) characters.

7.5.3 Undo and Redo Actions

Accessed via the context-sensitive menus, "Undo" allows you to restore one or

more actions on the instrument. Depending on the available memory, the "Undo"

steps can restore all actions.

"Redo" restores a previously undone action.

7.6 Getting Information and Help

In some dialog boxes, graphics are included to explain the way a setting works.

For further information, you can use the following sources:

●

Tooltips give the value range of the parameter.

●

The context help provides functional description on a setting.

●

The general help explains a dialog box, provides instructions, and general

information.

To display context help

► To access a help topic, perform one of the following:

47Getting Started 1430.3572.02 ─ 04

Page 48

R&S®AREG100A

Getting Information and Help

a) Tap and hold the parameter for which you need information and tap "Help"

in the context menu.

b) Tap the parameter and press the [Help] key.

The "Help" dialog opens. You can browse the help for further information.

Instrument Control

Contents of the help dialog box

The help dialog box covers two main areas:

●

"Contents" - contains a table of help contents

●

"Topic" - contains a specific help topic

The help system also provides an "Index" and a "Find" area, and "Zoom" functions that are accessed via the corresponding buttons.

To open general help

► Press the yellow [Help] key on the front panel.

If a dialog box is opened, the help topic for the current tab is shown. Otherwise the "Contents" page appears.

Navigating in the table of contents and in the help topics

1. To move through the displayed contents entries, tap on an entry and scroll or

use a connected mouse or the [Up/Down] keys.

48Getting Started 1430.3572.02 ─ 04

Page 49

R&S®AREG100A

Entries with a plus sign contain further entries.

2. To display a help topic, tap on the topic name or double click on the topic

name or press the [Enter] key.

3. To follow a cross-reference, tap on the link text.

4. To return to the previous page, select "Back".

This function scrolls back all steps you have performed before.

5. Use the "scroll bars" to shift the visible section of content shown.

6. To maximize the "Topics" area, tap the "Hide Contents Tree" button to hide the

contents tree.

Using the index

1. Select the "Index" button.

Instrument Control

Remote Control

2. Enter the first characters of the topic you are interested in.

The entries starting with these characters are displayed.

3. Tap on the index entry.

The corresponding help topic is displayed.

7.7 Remote Control

In addition to working with the R&S AREG interactively, located directly at the

instrument, it is also possible to operate and control it from a remote PC.

The R&S AREG supports various methods for remote control:

●

Connecting the instrument to a (LAN) network (see Chapter 4.3, "Setting Up a

Network (LAN) Connection", on page 22)

●

Using the LXI browser interface in a LAN network

●

Connecting a PC via the IEC-bus (IEEE 488) interface

●

Remote control via the USB interface

For remote control over LAN or USB, you can use the R&S VISA (Virtual

Instrument Software Architecture) library provided for download at the

Rohde & Schwarz website http://www.rohde-schwarz.com/rsvisa.

49Getting Started 1430.3572.02 ─ 04

Page 50

R&S®AREG100A

Remote Operation over VNC

How to configure the remote control interfaces is described in the user manual,

chapter "Network and Remote Control Operation".

Instrument Control

7.8 Remote Operation over VNC

The VNC is an application which can be used to access and control the instrument from a remote computer through a LAN connection. While the instrument is

in operation, the instrument screen contents are displayed on the remote computer, and VNC provides access to all applications, files, and network resources

of the instrument. Thus, remote operation of the instrument is possible.

Instrument control from a remote computer

To access the basic utility functions of the R&S AREG, perform a right

mouse click on the block diagram and select "Key Emulation".

A key panel to the right of the block diagram gives access to the utility functions provided by the front panel keys.

The VNC is an add-on program, included in operating system Linux/Unix, and

available as a free-of-charge download on the internet.

For more information, refer to the R&S AREG user manual, chapter "How to Set

Up Remote Operation via VNC".

50Getting Started 1430.3572.02 ─ 04

Page 51

R&S®AREG100A

Index

Index

A

AC supply ................................................ 17

Active elements ....................................... 44

Alphanumeric parameters ....................... 47

Application cards ..................................... 11

Application notes ..................................... 11

Auto-negotiation

see Autonegotiation ............................ 24

Autonegotiation

Failure .................................................24

B

Brochures ................................................ 10

C

Connector

AC power supply .................................32

GPIB ................................................... 31

IEC/IEEE .............................................31

LAN .....................................................32

Ref In .................................................. 32

Ref Out ............................................... 32

Sensor ................................................ 30

USB .................................................... 32

USB In ................................................ 32

Context-sensitive menu ...........................44

D

Data entry ................................................45

Data sheets ............................................. 10

Dialog boxes ............................................44

Display

Active elements .................................. 44

Context-sensitive menu ...................... 44

Info line ............................................... 44

Information ..........................................43

On-screen keypad .............................. 44

Overview .............................................26

Tab labels ............................................44

E

Electrostatic discharge ............................ 13

EMI suppression ......................................14

Emulating front panel keys ...................... 50

ESD ......................................................... 13

F

Failure

Network connection ............................ 24

Front panel tour ....................................... 25

Function check ........................................ 21

Function keys

Details - see user manual ................... 27

Overview .............................................27

G

Getting started ...........................................9

H

Help ..................................................... 9, 47

I

Info line ....................................................44

Instrument control ....................................42

Instrument security procedures ............... 10

Instrument tour ........................................ 25

K

Key

Access on a remote computer ............ 50

Arrow .................................................. 29

Backspace .......................................... 28

Down ...................................................29

Emulation ............................................50

Enter ................................................... 28

Esc ......................................................28

Freq .................................................... 27

Help .................................................... 26

Home .................................................. 30

Left ......................................................29

Level ................................................... 27

Local ................................................... 26

Mod on/off ...........................................27

Next window ....................................... 30

On/Off ................................................. 30

On/Standby .........................................27

Preset ................................................. 26

Resize window ....................................30

RF on/off ............................................. 27

Right ................................................... 29

Setup .................................................. 26

51Getting Started 1430.3572.02 ─ 04

Page 52

R&S®AREG100A

Index

Up ....................................................... 29

User .................................................... 30

Keyboard

On-screen ........................................... 45

Usage ................................................. 43

Keypad

On-screen ........................................... 45

Overview .............................................27

L

LAN configuration ....................................22

LAN connection

Not working .........................................24

Loading

Trying out ............................................39

M

Manual interaction ................................... 43

Mounting

Rack ....................................................16

Mouse

Usage ................................................. 43

N

Navigation

Keys ....................................................29

Network connection

Error ....................................................24

Numeric data entry .................................. 45

Numeric parameters ................................46

O

On-screen keyboard ................................47

On-screen keypad ................................... 44

Open source acknowledgment (OSA) ..... 11

Operation

Manual ................................................ 43

P

Release notes ..........................................11

Remote access

see Remote operation from a computer

............................................................42

Remote connection

Not working .........................................24

Remote control ........................................ 49

Remote operation ....................................50

Rotary knob ............................................. 28

S

Safety instructions ................................... 10

Security procedures ................................ 10

Service manual ........................................10

Shutting down ..........................................20

Standby ............................................. 20, 27

Starting .................................................... 20

T

Tab labels ................................................ 44

Text entry ................................................. 45

Tooltips

Show ...................................................47

Touchscreen ............................................ 26

Compared with mouse ........................43

Usage ................................................. 43

Turn on .................................................... 19

Tutorials ...................................................10

U

User manual .............................................. 9

V

VNC

Using in a LAN ....................................50

W

White papers ........................................... 11

Parameters

Entering ........................................ 46, 47

Power On ................................................ 27

Power supply

Connector ........................................... 32

Power switch ........................................... 19

R

Rack

Mounting ............................................. 16

Ready state ............................................. 20

52Getting Started 1430.3572.02 ─ 04

Loading...

Loading...