Page 1

Installation Instructions

MP-Series Integrated Gear Motors

(Catalog Numbers:

MPG-A004-031, MPG-A004-091,

MPG-A010-031, MPG-A010-091, MPG-B010-031, MPG-B010-091,

MPG-A025-031, MPG-A025-091, MPG-B025-031, MPG-B025-091,

MPG-A050-031, MPG-A050-091, MPG-B050-031, MPG-B050-091,

MPG-A110-031, MPG-A110-091, MPG-B110-031, and MPG-B110-091)

These Installation Instructions describe how to install MP-Series

Integrated Gear Motors. Use this document if you are responsible for

designing, installing, or troubleshooting these Allen-Bradley

®

motors.

Please read all instructions before installing your motor.

For: See Page

Receiving and Storage 2

Environmental Ratings 2

Motor Catalog Number Identification 3

Before You Install the Motor 4

Installing Your Motor 5

Guidelines for Installation

Connector Data 9

Mounting Dimensions by Frame Size (MPG-x004-xxx through MPG-x110-xxx) 10 – 21

Housing and Output Flange Connections 22

Motor Load Force Ratings 23

Radial Load Force Ratings

Axial Load Force Ratings (Maximum Radial Load)

Axial Load Force Ratings (Zero Radial Load)

Holding Brake 27

Cables and Connector Kits 28

Building and Installing Cables

Gear Lubricant 29

Related Documentation 30

6

24

25

26

28

Publication MP-IN003C-EN-P — April 2003

Page 2

2 MP-Series Integrated Gear Motor InstallationInstructions

Receiving and Storage

The customer is responsible for inspecting the equipment before

accepting the shipment from the freight company. Check the item(s) you

receive against your purchase order. Notify the carrier of any shipping

damage or missing items immediately.

You may store your motor in a clean and dry location within the following

environmental conditions:

• storage temperature: -30° to 70° C (-22° to 158° F)

• relative humidity: 5% to 95% non-condensing

• atmosphere: non-corrosive

Environmental Ratings

The International Protection Code or IP Rating for environmental

protection of MP gear motors is:

• IP64 dust tight, splashing water

Operational temperature range for MP gear motors is:

• operating temperature: 0° to 40° C (32° to 104° F)

Vibration ratings for the MP gear motors are:

• storage (shock): 20 g peak max, 6 msec duration

• operating (vibration): 2.5 g peak max, 30 to 2000 Hz

Publication MP-IN003C-EN-P — April 2003

Page 3

MP-Series Integrated Gear Motor InstallationInstructions 3

Motor Catalog Number Identification

MP G -A010 -031M 22

BRAKE

22 = No Brake

24 = 24V dcHolding Brake

FEEDBACK

M = Multi-turn High Resolution Encoder

S = Single-turn High Resolution Encoder

GEAR REDUCTION

031 = 31 to 1

091 = 91 to 1

MOTORFRAME SIZE

004 = 004 Frame

010 = 010 Frame

025 = 025 Frame

050 = 050 Frame

110 = 110 Frame

VOLTAGE RATINGOF MOTOR

A=230Vac

B=460Vac

SERIES TYPE

G = IntegratedGear

BULLETIN

Publication MP-IN003C-EN-P — April 2003

Page 4

4 MP-Series Integrated Gear Motor Installation Instructions

Before You Install the Motor

1. Remove the motor carefully from its shipping container.

2. Visually inspect the motor for any damage.

3. Examine the motor frame and mounts, drive flange, mounting holes,

and dowel pin hole for any defects.

ATTENTION

!

Do not open or attempt to open the motor.

Only a qualified Rockwell Automation employee can

service this type of motor.

Failure to observe these safety procedures could result

in personal injury or damage to equipment.

Publication MP-IN003C-EN-P — April 2003

Page 5

MP-Series Integrated Gear Motor Installation Instructions 5

Installing Your Motor

The installation must comply with all local regulations and use of

equipment and installation practices that promote electromagnetic

compatibility and safety.

All motors have a dowel pin hole for precisely aligning the motor output

on a machine. Bolt hole sizes are listed in Mounting Dimensions

beginning on page 10, and bolt torque requirements are listed in Housing

and Output Flange Connections beginning on page 22.

ATTENTION

!

ATTENTION

!

Unmounted motors, disconnected mechanical

connections, and disconnected cables are dangerous if

power is applied.

Disassembled equipment should be appropriately

identified (tagged-out) and access to electrical power

restricted (locked-out).

Before applying power to the motor, remove any

mounting bolts and screws, or other mechanical objects

which could be thrown from the motor.

Failure to observe these safety procedures could result in

personal injury.

Ensure that cables are installed and restrained to prevent

uneven tension or flexing at the cable connectors.

Excessive and uneven lateral force at the cable

connectors may result in the connector’s environmental

seal opening and closing as the cable flexes.

Failure to observe these safety procedures could result in

damage to the motor and its components.

Publication MP-IN003C-EN-P — April 2003

Page 6

6 MP-Series Integrated Gear Motor Installation Instructions

Guidelines for Installation

Observe the following guidelines when installing the motor.

ATTENTION

!

1. Allow sufficient clearances in the area of the motor for it to stay within

its specified operating temperature range 0° to 40° C (32° to 104° F).

Do not enclose the motor unless forced air is blown across the motor

for cooling. A fan blowing air across the motor will improve its

performance. Keep other heat producing devices away from the motor.

ATTENTION

!

Damage may occur to the motor bearings, gearing, and

the feedback device if sharp impact to the shaft is

applied during installation or removal of the motor.

Do not strike the MP gear motor with tools during

installation or removal.

Failure to observe these safety procedures could result in

damage to the motor and its components.

Outer surfaces of motor can reach high temperatures,

125° C (275° F), during motor operation.

Take precautions to prevent accidental contact with hot

surfaces. Consider motor surface temperature when

selecting motor mating connections and cables.

Failure to observe these safety procedures could result in

personal injury or damage to equipment.

2. Always position the motor with the connector housing pointing

downward.

Note: Gearbox input and output rotations are in identical directions.

Publication MP-IN003C-EN-P — April 2003

Page 7

MP-Series Integrated Gear Motor Installation Instructions 7

3. Properly mount and align the motor.

A. Secure the motor to the machine mounting frame. Refer to:

• Mounting Dimensions beginning on page 10 for the bolt hole

pattern of your motor.

• Housing and Output Flange Connections beginning on page 22

for the torque values for connections.

B. Move the output flange so the motor feedback device aligns at its

electronic zero position. Encoder absolute position = 0 occurs when

the dowel pin hole is aligned on the connector side of the motor

and centered on the connectors. Refer to Figure 1 on page 11 for a

visual reference of this alignment.

IMPORTANT

Proper alignment and loading of the motor are critical to

achieving reliable operation throughout the lifetime of

the motor.

When mounting the MP-Series Integrated Gear Motor,

ensure that the connections are properly aligned and

that axial and radial loads are within the specifications of

the motor.

C. Connect the output flange to the machine’s drive assembly.

Mechanical connections to the motor flange must be rigid, secure,

and properly aligned. Refer to:

• Mounting Dimensions beginning on page 10 for the bolt hole

pattern of your motor.

• Housing and Output Flange Connections beginning on page 22

for the torque values for connections.

• Motor Load Force Ratings beginning on page 23 for guidelines to

achieve 20,000 hours of motor bearing life.

4. Apply a high-temperature, medium-strength threadlock adhesive to the

mounting bolts.

Publication MP-IN003C-EN-P — April 2003

Page 8

8 MP-Series Integrated Gear Motor Installation Instructions

5. Attach all power, feedback, and brake cables after the motor is

mounted.

A. Use a drip loop in each cable to keep liquids flowing away from the

connectors.

IMPORTANT

Ensure that proper polarity is maintained when wiring a

brake connector.

The holding brake is designed to hold the motor shaft at

0 rpm and to release when power is applied - it is not

intended to stop motor rotation. Reversing the brake

polarity could cause the brake to be applied while the

motor is running. The section Holding Brake beginning

on page 27 provides information on the electrical

requirements for a brake motor.

Failure to observe proper polarity could result in damage

to the motor and its components.

B. Use Electromagnetic Compatibility (EMC) techniques to reduce

Electromagnetic Interference (EMI), commonly called noise. Noise

adversely impacts motor performance by inducing stray signals.

Effective techniques to counter EMI include filtering the AC power,

shielding and separating signal carrying lines, and practicing good

grounding techniques.

– Filter AC power by using isolated AC power transformers or properly

installed AC line filters.

– Physically separate signal lines from motor cabling and power wiring.

Do not route signal wires with motor and power wires, or over the

vent openings of servo drives.

– Ground all equipment using a single-point parallel ground system that

employs ground bus bars or large straps.

Refer to System Design for Control of Electrical Noise

(GMC-SG001x-EN-P) for information on additional electrical noise

reduction techniques.

6. If necessary, home the drive and motor system prior to use. Refer to

your drive instructions for procedures on when and how to do this.

Publication MP-IN003C-EN-P — April 2003

Page 9

MP-Series Integrated Gear Motor Installation Instructions 9

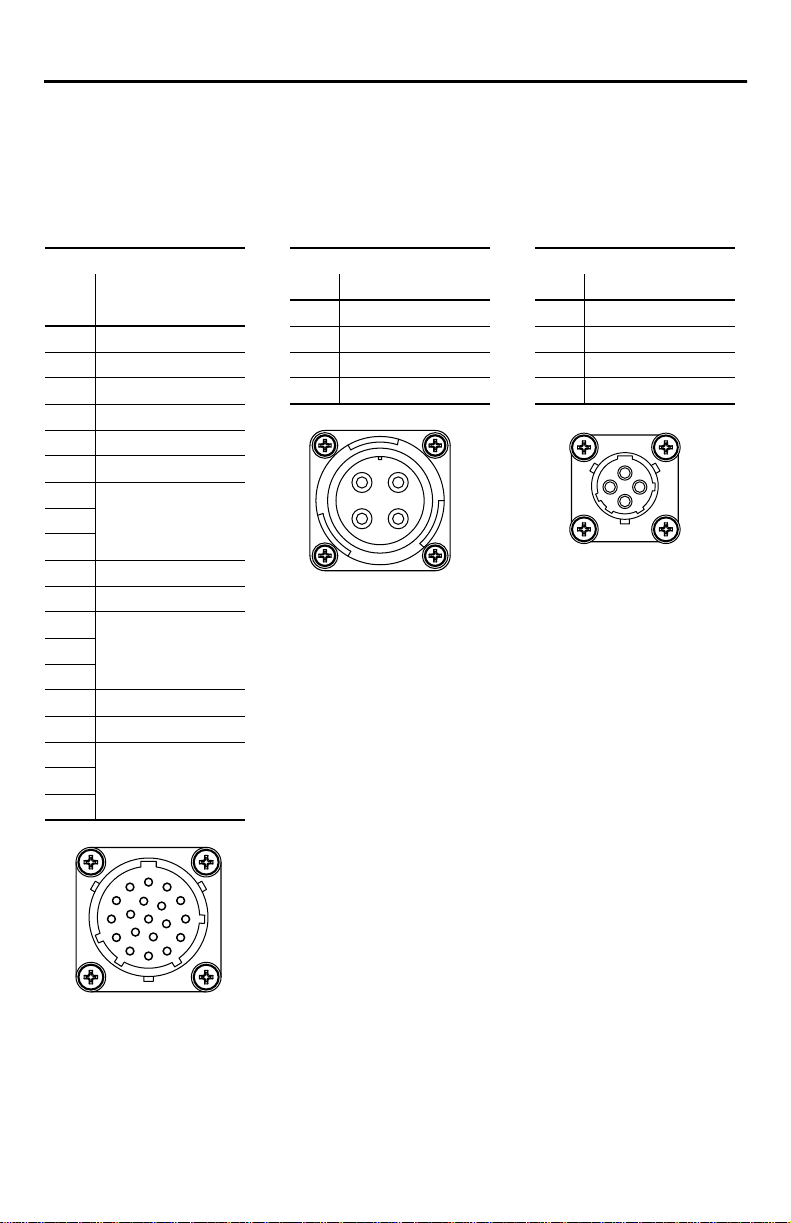

Connector Data

The tables below list the signal descriptions for the feedback, power, and

brake connector pins.

Feedback Connector Power Connector Brake Connector

High Resolution Pin Signal Pin Signal

Pin Encoder

A Sin+ B Phase V B Reserved

B Sin- C Phase W C BRC Cos+ D Ground D Reserved

DCosE Data+

F DataG Reserved

H

J

K +5V dc

LCommon

M Reserved Note: Ensure that proper

N

P

RTS+

STST Reserved

U

V

A Phase U A BR+

A

D

B

C

D

ITT Cannon

ITT Cannon

TNM 10-4

TNM 16-4

polarity is maintained

when wiring a brake

connector.

A

B

C

M

L

U

K

V

T

J

H

G

ITT Cannon

TNM 16-19

A

B

N

P

C

R

D

S

E

F

Publication MP-IN003C-EN-P — April 2003

Page 10

10 MP-Series Integrated Gear Motor Installation Instructions

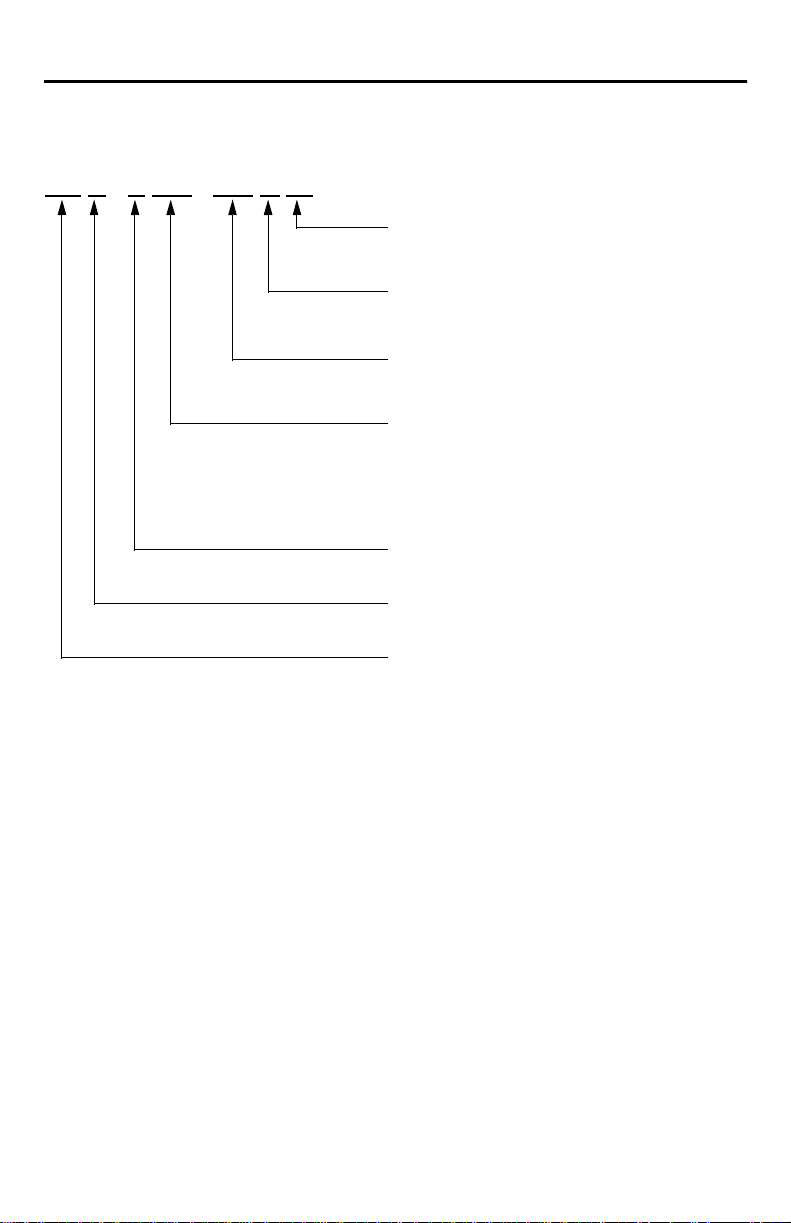

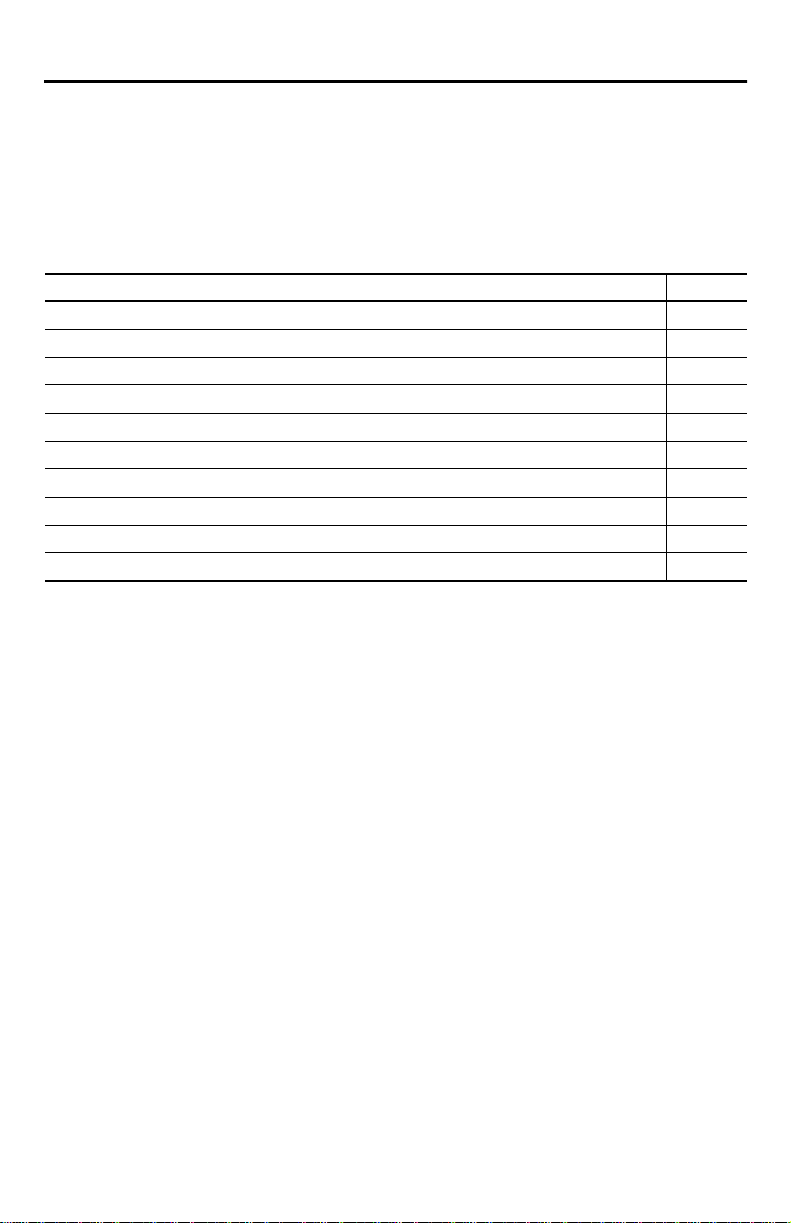

Mounting Dimensions

Dimensions for MP-Series Integrated Gear Motors are provided on the

listed pages. Refer to Figure 1 on page 11 for the dimensional symbol

designations for the motors.

If your motor is one of the following, then go to: Page

MPG-A004-031x22, MPG-A004-031x24 12

MPG-A004-091x22, MPG-A004-091x24 13

MPG-x010-031x22, MPG-x010-031x24 14

MPG-x010-091x22, MPG-x010-091x24 15

MPG-x025-031x22, MPG-x025-031x24 16

MPG-x025-091x22, MPG-x025-091x24 17

MPG-x050-031x22, MPG-x050-031x24 18

MPG-x050-091x22, MPG-x050-091x24 19

MPG-x110-031x22, MPG-x110-031x24 20

MPG-x110-091x22, MPG-x110-091x24 21

Publication MP-IN003C-EN-P — April 2003

Page 11

MP-Series Integrated Gear Motor Installation Instructions 11

Figure 1

References for Motor Mounting Dimensions

L

LB

LE

AE

AF

AG

L-LB

E

T

NB

LA

D

AC

N

LD

MPG-x025-091x22 shown

P

HD

BHP (Bolt Hole Pattern)

AD

BHPA (Auxiliary

Bolt Hole Pattern)

DB

BE

Publication MP-IN003C-EN-P — April 2003

S (diameter of hole)

M (dia. of bolt circle

on motor housing)

MA (thread and depth)

MC (dia. of bolt circle

o n output flange)

MB (diameter of dowel)

Dowel pin hole aligned

at electronic zero

Page 12

12 MP-Series Integrated Gear Motor Installation Instructions

Motor Dimension

Symbol

1, 2

AC

AD

AE

AF

AG

BE

D

DB

E

HD

L

L-LB

LA

LB

LD

LE

M

MA on MC

MB

N

NB

P

S on M

T

Bolt Hole

Patterns:

BHP 45

BHPA N/A N/A

Motor Outline

MPG-A004-031x22 MPG-A004-031x24

mm (in.) mm (in.)

70 (2.76) 70 (2.76)

80 (3.15) 79.1 (3.11)

75 (2.95) 75 (2.95)

N/A N/A

N/A N/A

67.7 (2.67) 88.9 (3.50)

39.975 - 40 (1.5738) - (1.5748) 39.975 - 40 (1.5738) - (1.5748)

20 - 20.021 x 4 DP (0.7874) - (0.7882)

x (0.16) DP

20 - 20.021 x 4 DP(0.7874) - (0.7882)

x (0.16) DP

3 (0.12) 3 (0.12)

123 (4.84) 122.1 (4.81)

156.7 (5.58) 200.2 (7.88)

19.5 (0.77) 19.5 (0.77)

4 (0.16) 4 (0.16)

137.2 (5.40) 180.7 (7.11)

140.9 (5.55) 189.5 (7.46)

N/A N/A

79 (3.11) 79 (3.11)

M5 x 7

on 31.5 BC

5 - 5.012

x 6 DP

M5 x (0.28)

on (1.24) BC

(0.1967) - (0.1973)

x (0.24) DP

M5 x 7

on 31.5 BC

5 - 5.012

x 6 DP

M5 x (0.28)

on (1.24) BC

(0.1967) - (0.1973)

x (0.24) DP

63.97 - 64 (2.5185) - (2.5197) 63.97 - 64 (2.5185) - (2.5197)

63 (2.48) 63 (2.48)

86 (3.39) 86 (3.39)

4.5 on 79 BC (0.18) on (3.11) BC 4.5 on 79 BC (0.18) on (3.11) BC

7 (0.28) 7 (0.28)

o

45o

1

Motors are designed to metric dimensions (inch references are mathematical conversions).

2

Abbreviations: BC = Bolt Circle, BHP/BHPA = Bolt Hole Patterns, DP = Depth.

Publication MP-IN003C-EN-P — April 2003

Page 13

MP-Series Integrated Gear Motor Installation Instructions 13

Motor Dimension

Symbol

1, 2

AC

AD

AE

AF

AG

BE

D

DB

E

HD

L

L-LB

LA

LB

LD

LE

M

MA on MC

MB

N

NB

P

S on M

T

Bolt Hole

Patterns:

BHP 45

BHPA N/A N/A

Motor Outline

MPG-A004-091x22 MPG-A004-091x24

mm (in.) mm (in.)

70 (2.76) 70 (2.76)

80 (3.15) 79.1 (3.11)

75 (2.95) 75 (2.95)

N/A N/A

N/A N/A

67.7 (2.67) 88.9 (3.50)

39.975 - 40 (1.5738) - (1.5748) 39.975 - 40 (1.5738) - (1.5748)

20 - 20.021

x 4 DP

(0.7874) - (0.7882)

x (0.16) DP

20 - 20.021 x 4 DP (0.7874) - (0.7882)

x (0.16) DP

3 (0.12) 3 (0.12)

123 (4.84) 122.1 (4.81)

141.7 (5.58) 185.2 (7.29)

19.5 (0.77) 19.5 (0.77)

4 (0.16) 4 (0.16)

122.2 (4.81) 165.7 (6.52)

125.9 (4.96) 174.5 (6.87)

N/A N/A

79 (3.11) 79 (3.11)

M5 x 7

on 31.5 BC

5 - 5.012

x 6 DP

M5 x (0.28)

on (1.24) BC

(0.1967) - (0.1973)

x (0.24) DP

M5 x 7

on 31.5 BC

5 - 5.012

x 6 DP

M5 x (0.28)

on (1.24) BC

(0.1967) - (0.1973)

x (0.24) DP

63.97 - 64 (2.5185) - (2.5197) 63.97 - 64 (2.5185) - (2.5197)

63 (2.48) 63 (2.48)

86 (3.39) 86 (3.39)

4.5 on 79 BC (0.18) on (3.11) BC 4.5 on 79 BC (0.18) on (3.11) BC

7 (0.28) 7 (0.28)

o

45o

1

Motors are designed to metric dimensions (inch references are mathematical conversions).

2

Abbreviations: BC = Bolt Circle, BHP/BHPA = Bolt Hole Patterns, DP = Depth.

Publication MP-IN003C-EN-P — April 2003

Page 14

14 MP-Series Integrated Gear Motor Installation Instructions

Motor Dimension

Symbol

1, 2

AC

AD

AE

AF

AG

BE

D

DB

E

HD

L

L-LB

LA

LB

LD

LE

M

MA on MC

MB

N

NB

P

S on M

T

Bolt Hole/

Patterns:

BHP 45

BHPA N/A N/A

Motor Outline

MPG-x010-031x22 MPG-x010-031x24

mm (in.) mm (in.)

95.00 (3.74) 95 (3.74)

82.60 (3.25) 81.7 (3.22)

83.20 (3.28) 83.20 (3.28)

N/A N/A

N/A N/A

67.70 (2.67) 88.90 (3.50)

62.97 - 63 (2.4791) - (2.4803) 62.97 - 63 (2.4791) - (2.4803)

31.5 - 31.525

x 6 DP

(1.2402) - (1.2411)

x (0.24) DP

31.5 - 31.525

x 6 DP

(1.2402) - (1.2411)

x (0.24) DP

6.00 (0.24) 6 (0.24)

141.60 (5.57) 140.70 (5.54)

184.5 (7.26) 219.50 (8.64)

30.00 (1.18) 30.00 (1.18)

7.00 (0.28) 7.00 (0.28)

154.50 (6.08) 189.50 (7.46)

156.50 (6.16) 197.10 (7.76)

N/A N/A

109.00 (4.29) 109.00 (4.29)

M6 x 10

on 50 BC

6 - 6.012

x 7 DP

M6 x (0.39)

on (1.97) BC

(0.2362) - (0.2367)

x (0.28) DP

M6 x 10

on 50 BC

6 - 6.012

x 7 DP

M6 x (0.39)

on (1.97) BC

(0.2362) - (0.2367)

x (0.28) DP

89.965 - 90 (3.5419) - (3.5433) 89.965 - 90 (3.5419) - (3.5433)

85.00 (3.35) 85.00 (3.35)

118.00 (4.65) 118.00 (4.65)

5.5 on 109 BC (0.22) on (4.29) BC 5.5 on 109 BC (0.22) on (4.29) BC

10.00 (0.39) 10.00 (0.39)

o

45o

1

Motors are designed to metric dimensions (inch references are mathematical conversions).

2

Abbreviations: BC = Bolt Circle, BHP/BHPA = Bolt Hole Patterns, DP = Depth.

Publication MP-IN003C-EN-P — April 2003

Page 15

MP-Series Integrated Gear Motor Installation Instructions 15

Motor Dimension

Symbol

1, 2

AC

AD

AE

AF

AG

BE

D

DB

E

HD

L

L-LB

LA

LB

LD

LE

M

MA on MC

MB

N

NB

P

S on M

T

Bolt Hole/

Patterns:

BHP 45

BHPA N/A N/A

Motor Outline

MPG-x010-091x22 MPG-x010-091x24

mm (in.) mm (in.)

95.00 (3.74) 95 (3.74)

82.60 (3.25) 81.7 (3.22)

83.20 (3.28) 83.20 (3.28)

N/A N/A

N/A N/A

67.70 (2.67) 88.90 (3.50)

62.97 - 63 (2.4791) - (2.4803) 62.97 - 63 (2.4791) - (2.4803)

31.5 - 31.525

x 6 DP

(1.2402) - (1.2411)

x (0.24) DP

31.5 - 31.525

x 6 DP

(1.2402) - (1.2411)

x (0.24) DP

6.00 (0.24) 6 (0.24)

141.60 (5.57) 140.70 (5.54)

169.5 (6.67) 204.5 (8.05)

30.00 (1.18) 30.00 (1.18)

7.00 (0.28) 7.00 (0.28)

139.5 (5.49) 174.5 (6.87)

141.5 (5.57) 182.1 (7.18)

N/A N/A

109.00 (4.29) 109.00 (4.29)

M6 x 10

on 50 BC

6 - 6.012

x 7 DP

M6 x (0.39)

on (1.97) BC

(0.2362) - (0.2367)

x (0.28) DP

M6 x 10

on 50 BC

6 - 6.012

x 7 DP

M6 x (0.39)

on (1.97) BC

(0.2362) - (0.2367)

x (0.28) DP

89.965 - 90 (3.5419) - (3.5433) 89.965 - 90 (3.5419) - (3.5433)

85.00 (3.35) 85.00 (3.35)

118.00 (4.65) 118.00 (4.65)

5.5 on 109 BC (0.22) on (4.29) BC 5.5 on 109 BC (0.22) on (4.29) BC

10.00 (0.39) 10.00 (0.39)

o

45o

1

Motors are designed to metric dimensions (inch references are mathematical conversions).

2

Abbreviations: BC = Bolt Circle, BHP/BHPA = Bolt Hole Patterns, DP = Depth.

Publication MP-IN003C-EN-P — April 2003

Page 16

16 MP-Series Integrated Gear Motor Installation Instructions

Motor Dimension

Symbol

1, 2

AC

AD

AE

AF

AG

BE

D

DB

E

HD

L

L-LB

LA

LB

LD

LE

M

MA on MC

MB

N

NB

P

S on M

T

Bolt Hole

Patterns:

BHP 45

BHPA 22.5

Motor Outline

MPG-x025-031x22 MPG-x025-031x24

mm (in.) mm (in.)

120 (4.72) 120 (4.72)

96.5 (3.80) 95.6 (3.76)

111.2 (4.38) 111.2 (4.38)

85 (3.35) 85 (3.35)

68.6 (2.70) 68.6 (2.70)

67.7 (2.67) 88.9 (3.50)

79.97 - 80 (3.1484) - (3.1496) 79.97 - 80 (3.1484) - (3.1496)

40 - 40.025 x

6 DP

(1.5748) - (1.5758)

x (0.24) DP

40 - 40.025 x

6 DP

(1.5748) - (1.5758)

x (0.24) DP

6.00 (0.24) 6 (0.24)

169.00 (6.65) 168.1 (6.62)

222.50 (8.76) 251.10 (9.88)

29.00 (1.14) 29.00 (1.14)

8.00 (0.31) 8.00 (0.31)

193.50 (7.62) 222.10 (8.74)

161.00 (6.34) 170.90 (6.73)

46.50 (1.83) 46.50 (1.83)

135.00 (5.31) 135.00 (5.31)

M6 x 12

on 63 BC

6 - 6.012

x 7 DP

M6 x (0.47)

on (2.48) BC

(0.2362) - (0.2367)

x (0.28) DP

M6 x 12

on 63 BC

6 - 6.012

x 7 DP

M6 x (0.47)

on (2.48) BC

(0.2362) - (0.2367)

x (0.28) DP

109.965 - 110 (4.3293) - (4.3307) 109.965 - 110 (4.3293) - (4.3307)

105.00 (4.13) 105.00 (4.13)

145.00 (5.71) 145.00 (5.71)

5.5 on 135 BC (0.22) on (5.31) BC 5.5 on 135 BC (0.22) on (5.31) BC

10.00 (0.39) 10.00 (0.39)

o

45o

o

22.5o

1

Motors are designed to metric dimensions (inch references are mathematical conversions).

2

Abbreviations: BC = Bolt Circle, BHP/BHPA = Bolt Hole Patterns, DP = Depth.

Publication MP-IN003C-EN-P — April 2003

Page 17

MP-Series Integrated Gear Motor Installation Instructions 17

Motor Dimension

Symbol

1, 2

AC

AD

AE

AF

AG

BE

D

DB

E

HD

L

L-LB

LA

LB

LD

LE

M

MA on MC

MB

N

NB

P

S on M

T

Bolt Hole

Patterns:

BHP 45

BHPA 22.5

Motor Outline

MPG-x025-091x22 MPG-x025-091x24

mm (in.) mm (in.)

120 (4.72) 120 (4.72)

96.5 (3.80) 95.6 (3.76)

111.2 (4.38) 111.3 (4.38)

85 (3.35) 85 (3.35)

68.6 (2.70) 68.6 (2.70)

67.7 (2.67) 88.9 (3.50)

79.97 - 80 (3.1484) - (3.1496) 79.97 - 80 (3.1484) - (3.1496)

40 - 40.025 x

6 DP

(1.5748) - (1.5758)

x (0.24) DP

40 - 40.025 x

6 DP

(1.5748) - (1.5758)

x (0.24) DP

6 (0.24) 6 (0.24)

169 (6.65) 168.1 (6.62)

192.5 (7.58) 221.1 (8.70)

29 (1.14) 29 (1.14)

8 (0.31) 8 (0.31)

163.50 (6.44) 192.1 (7.56)

131.00 (5.16) 140.9 (5.55)

46.50 (1.83) 46.50 (1.83)

135.00 (5.31) 135.00 (5.31)

M6 x 12

on 63 BC

6 - 6.012

x 7 DP

M6 x (0.47)

on (2.48) BC

(0.2362) - (0.2367)

x (0.28) DP

M6 x 12

on 63 BC

6 - 6.012

x 7 DP

M6 x (0.47)

on (2.48) BC

(0.2362) - (0.2367)

x (0.28) DP

109.965 - 110 (4.3293) - (4.3307) 109.965 - 110 (4.3293) - (4.3307)

105.00 (4.13) 105.00 (4.13)

145.00 (5.71) 145 (5.71)

5.5 on 135 BC (0.22) on (5.31) BC 5.5 on 135 BC (0.22) on (5.31) BC

10.00 (0.39) 10.00 (0.39)

o

45o

o

22.5o

1

Motors are designed to metric dimensions (inch references are mathematical conversions).

2

Abbreviations: BC = Bolt Circle, BHP/BHPA = Bolt Hole Pattern/Auxiliary BHP, DP = Depth.

Publication MP-IN003C-EN-P — April 2003

Page 18

18 MP-Series Integrated Gear Motor Installation Instructions

Motor Dimension

Symbol

1, 2

AC

AD

AE

AF

AG

BE

D

DB

E

HD

L

L-LB

LA

LB

LD

LE

M

MA on MC

MB

N

NB

P

S on M

T

Bolt Hole

Patterns:

BHP 30

BHPA N/A N/A

Motor Outline

MPG-x050-031x22 MPG-x050-031x24

mm (in.) mm (in.)

152 (5.98) 152 (5.98)

127 (5.00) 126.1 (4.96)

171 (6.73) 171 (6.73)

N/A 120 (4.72)

N/A 104 (4.09)

67.7 (2.67) 88.9 (3.50)

99.965 - 100 (3.9356) - (3.9370) 99.965 - 100 (3.9356) - (3.9370)

50 - 50.025

x 6 DP

(1.9685) - (1.9695)

x (0.24) DP

50 - 50.025

x 6 DP

(1.9685) - (1.9695)

x (0.24) DP

6 (0.24) 6 (0.24)

216.2 (8.51) 215.6 (8.49)

274.0 (10.79) 346 (13.63)

38 (1.50) 38 (1.50)

10 (0.39) 10 (0.39)

236 (9.29) 308 (12.13)

230.7 (9.08) 236.6 (9.31)

N/A 41 (1.61)

168.0 (6.61) 168.0 (6.61)

M8 x 15 DP on

80 BC

8.0 - 8.015

x 7 DP

(M8 x (0.59) DP on

(3.15) BC

(0.3150) - (0.3156)

x (0.28) DP

M8 x 15 DP on

80 BC

8.0 - 8.015

x 7 DP

(M8 x (0.59) DP on

(3.15) BC

(0.3150) - (0.3156)

x (0.28) DP

139.96 - 140 (5.5102) - (5.5118) 139.96 - 140 (5.5102) - (5.5118)

136 (5.35) 136 (5.35)

179 (7.05) 179 (7.05)

6.6 on 168 BC (0.26) on (6.61) BC 6.6 on 168 BC (0.26) on (6.61) BC

14.6 (0.57) 14.6 (0.57)

o

30o

1

Motors are designed to metric dimensions (inch references are mathematical conversions).

2

Abbreviations: BC = Bolt Circle, BHP/BHPA = Bolt Hole Patterns, DP = Depth.

Publication MP-IN003C-EN-P — April 2003

Page 19

MP-Series Integrated Gear Motor Installation Instructions 19

Motor Dimension

Symbol

1, 2

AC

AD

AE

AF

AG

BE

D

DB

E

HD

L

L-LB

LA

LB

LD

LE

M

MA on MC

MB

N

NB

P

S on M

T

Bolt Hole

Patterns:

BHP 30

BHPA N/A N/A

Motor Outline

MPG-x050-091x22 MPG-x050-091x24

mm (in.) mm (in.)

152 (5.98) 152 (5.98)

116.5 (4.59) 115.6 (4.55)

150.5 (5.93) 151 (5.94)

86 (3.39) 86 (3.39)

72 (2.83) 72 (2.83)

67.7 (2.67) 88.9 (3.50)

99.965 - 100 (3.9356) - (3.9370) 99.965 - 100 (3.9356) - (3.9370)

50 - 50.025

x 6 DP

(1.9685) - (1.9695)

x (0.24) DP

50 - 50.025

x 6 DP

(1.9685) - (1.9695)

x (0.24) DP

6 (0.24) 6 (0.24)

206 (8.11) 205.1 (8.07)

227 (8.94) 256.5 (10.10)

38 (1.50) 38 (1.50)

10 (0.39) 10 (0.39)

189 (7.44) 218.5 (8.60)

156 (6.14) 161.9 (6.37)

42 (1.65) 42 (1.65)

168.0 (6.61) 168.0 (6.61)

M8 x 15 DP on

80 BC

8.0 - 8.015

x 7 DP

M8 x (0.59) DP on

(3.15) BC

(0.3150) - (0.3156)

x (0.28) DP

M8 x 15 DP on

80 BC

8.0 - 8.015

x 7 DP

M8 x (0.59) DP on

(3.15) BC

(0.3150) - (0.3156)

x (0.28) DP

139.96 - 140 (5.5102) - (5.5118) 139.96 - 140 (5.5102) - (5.5118)

136 (5.35) 136 (5.35)

179 (7.05) 179 (7.05)

6.6 on 168 BC (0.26) on (6.61) BC 6.6 on 168 BC (0.26) on (6.61) BC

14.6 (0.57) 14.6 (0.57)

o

30o

1

Motors are designed to metric dimensions (inch references are mathematical conversions).

2

Abbreviations: BC = Bolt Circle, BHP/BHPA = Bolt Hole Patterns, DP = Depth.

Publication MP-IN003C-EN-P — April 2003

Page 20

20 MP-Series Integrated Gear Motor Installation Instructions

Motor Dimension

Symbol

1, 2

AC

AD

AE

AF

AG

BE

D

DB

E

HD

L

L-LB

LA

LB

LD

LE

M

MA on MC

MB

N

NB

P

S on M

T

Bolt Hole

Patterns:

BHP 30

BHPA N/A N/A

Motor Outline

MPG-x110-031x22 MPG-x110-031x24

mm (in.) mm (in.)

212 (8.35) 212 (8.35)

127 (5.0) 126.1 (4.96)

171 (6.73) 171 (6.73)

N/A 120 (4.72)

N/A 106 (4.17)

67.7 (2.67) 88.9 (3.50)

159.96 - 160 (6.2976) - (6.2992) 159.96 - 160 (6.2976) - (6.2992)

80 - 80.03

x 8 DP

(3.1496) - (3.1508)

x (0.31) DP

80 - 80.03

x 8 DP

(3.1496) - (3.1508)

x (0.31) DP

8 (0.31) 8 (0.31)

250.5 (9.86) 249.6 (9.83)

300.0 (11.81) 372 (14.65)

50 (1.97) 50 (1.97)

12 (0.47) 12 (0.47)

250 (9.84) 322 (12.68)

244.7 (9.63) 250.6 (9.87)

N/A 41 (1.61)

233 (9.17) 233 (9.17)

M10 x 20 on

125 BC

10 - 10.015

x 10 DP

(M10 x (0.79) on

(4.92) BC

(0.3937) - (0.3943)

x (0.39) DP

M10 x 20 on

125 BC

10 - 10.015

x 10 DP

(M10 x (0.79) on

(4.92) BC

(0.3937) - (0.3943)

x (0.39) DP

199.954 - 200 (7.8722) - (7.8740) 199.954 - 200 (7.8722) - (7.8740)

196 (7.72) 196 (7.72)

247 (9.72) 247 (9.72)

9 on 233 BC (0.35) on (9.17) BC 9 on 233 BC (0.35) on (9.17) BC

15 (0.59) 15 (0.59)

o

30o

1

Motors are designed to metric dimensions (inch references are mathematical conversions).

2

Abbreviations: BC = Bolt Circle, BHP/BHPA = Bolt Hole Patterns, DP = Depth.

Publication MP-IN003C-EN-P — April 2003

Page 21

MP-Series Integrated Gear Motor Installation Instructions 21

Motor Dimension

Symbol

1, 2

AC

AD

AE

AF

AG

BE

D

DB

E

HD

L

L-LB

LA

LB

LD

LE

M

MA on MC

MB

N

NB

P

S on M

T

Bolt Hole

Patterns:

BHP 30

BHPA N/A N/A

Motor Outline

MPG-x110-091x22 MPG-x110-091x24

mm (in.) mm (in.)

212 (8.35) 212 (8.35)

127 (5.0) 126.1 (4.96)

171 (6.73) 171 (6.73)

N/A 120 (4.72)

N/A 106 (4.17)

67.7 (2.67) 88.9 (3.50)

159.96 - 160 (6.2976) - (6.2992) 159.96 - 160 (6.2976) - (6.2992)

80 - 80.03 x

8 DP

(3.1496) - (3.1508)

x (0.31) DP

80 - 80.03 x

8 DP

(3.1496) - (3.1508)

x (0.31) DP

8 (0.31) 8 (0.31)

250.5 (9.86) 249.6 (9.83)

285 (11.22) 357 (14.06)

50 (1.97) 50 (1.97)

12 (0.47) 12 (0.47)

235 (9.35) 307 (12.09)

229.7 (9.04) 235.6 (9.28)

N/A 41 (1.61)

233 (9.17) 233 (9.17)

M10 x 20 on

125 BC

10 - 10.015

x 10 DP

(M10 x (0.79) on

(4.92) BC

(0.3937) - (0.3943)

x (0.39) DP

M10 x 20 on

125 BC

10 - 10.015

x 10 DP

(M10 x (0.79) on

(4.92) BC

(0.3937) - (0.3943)

x (0.39) DP

199.954 - 200 (7.8722) - (7.8740) 199.954 - 200 (7.8722) - (7.8740)

196 (7.72) 196 (7.72)

247 (9.72) 247 (9.72)

9 on 233 BC (0.35) on (9.17) BC 9 on 233 BC (0.35) on (9.17) BC

15 (0.59) 15 (0.59)

o

30o

1

Motors are designed to metric dimensions (inch references are mathematical conversions).

2

Abbreviations: BC = Bolt Circle, BHP/BHPA = Bolt Hole Patterns, DP = Depth.

Publication MP-IN003C-EN-P — April 2003

Page 22

22 MP-Series Integrated Gear Motor Installation Instructions

Housing and Output Flange Connections

The following table provides ISO 898-1 mounting bolt strength class

requirements for the motor housing, and tightening torques for

connecting the motor housing and the ISO 9409 compliant output flange

to your assembly. Apply a high-temperature, medium-strength threadlock

adhesive to the mounting bolts.

IMPORTANT

A loose or slipping connection will cause system

instability and may damage the MP gear motor.

All connections between the assembly and the MP gear

motor must be rigid to achieve acceptable response from

both the motor and the system.

Periodically inspect connections to verify their rigidity.

Motor Bolt Strength

Grade

ISO 898-1

MPG-A004 10.9 4.1 (36.3) 8.1 (72)

MPG-A010, MPG-B010 10.9 8.1 (72) 14.0 (124)

MPG-A025, MPG-B025 10.9 8.1 (72) 14.0 (124)

MPG-A050, MPG-B050 10.9 14.0 (124) 34.0 (301)

MPG-A110, MPG-B110 10.9 34.0 (301) 67.0 (593)

1

Refer to Mounting Dimensions beginning on page 10 for hole dimensions.

Tor qu e

Motor Housing

Nm (lb-in.) Nm (lb-in.)

1

Output Flange

1

Publication MP-IN003C-EN-P — April 2003

Page 23

MP-Series Integrated Gear Motor Installation Instructions 23

Motor Load Force Ratings

Motors are capable of operating with a sustained shaft load. The radial

and axial load force location is shown in the figure, and maximum values

for motors are in the following tables.

Figure 2

Load Forces on Shaft

Radial load force applied at mounting end of output flange

Axial load force applied at shaft centerline

The following tables represent 20,000 hour L10 bearing fatigue life at

various loads and speeds. This 20,000 hour life does not account for

possible application-specific life reduction that may occur due to bearing

grease contamination from external sources, improper alignment, or

excessive loading.

Publication MP-IN003C-EN-P — April 2003

Page 24

24 MP-Series Integrated Gear Motor Installation Instructions

Radial Load Force Ratings

Motor 40 rpm 60 rpm 100 rpm 156 rpm 194 rpm

kg (lb) kg (lb) kg (lb) kg (lb) kg (lb)

MPG-A004-031 179 (393) —— 162 (356) 139 (307) 130 (286)

1

MPG-A004-091

MPG-A010-031

MPG-A010-091

MPG-A025-031

MPG-A025-091

MPG-A050-031

MPG-A050-091

MPG-A110-031

MPG-A110-091

MPG-B010-031

MPG-B010-091

MPG-B025-031

MPG-B025-091

MPG-B050-031

MPG-B050-091

MPG-B110-031

MPG-B110-091

1

Measurement speeds: 40, 66 rpm.

2

Measurement speeds: 40, 100, 157 rpm.

3

Measurement speeds: 40, 65 rpm.

4

Measurement speeds: 40, 100, 158 rpm.

5

Measurement speeds: 40, 62 rpm.

6

Measurement speeds: 20, 50, 81 rpm.

7

Measurement speeds: 20, 41 rpm.

8

Measurement speeds: 20, 50, 93 rpm.

9

Measurement speeds: 20, 38 rpm.

179 (393) 179 (393) —— —— ——

2

337 (743) —— 286 (631) 246 (543) ——

3

337 (743) 330 (728) —— —— ——

4

478 (1053) —— 406 (895) 342 (753) ——

5

478 (1053) 476 (1050) —— —— ——

6

1724 (3801) 1509 (3325) 1305 (2877) —— ——

7

1724 (3801) 1602 (3530) —— —— ——

8

3144 (6930) 2751 (6062) 2283 (5032) —— ——

9

3144 (6930) 2987 (6583) —— —— ——

10

337 (743) —— 286 (631) 246 (543) 224 (494)

11

337 (743) 321 (707) —— —— ——

12

478 (1053) —— 406 (895) 350 (772) ——

13

478 (1053) 469 (1033) —— —— ——

14

1724 (3801) 1509 (3325) 1305 (2877) —— ——

15

1724 (3801) 1509 (3325) —— —— ——

16

3144 (6930) 2751 (6062) 2407 (5305) —— ——

17

3144 (6930) 2987 (6583) —— —— ——

10

Measurement speeds: 40, 100, 157, 208 rpm.

11

Measurement speeds: 40, 71 rpm.

12

Measurement speeds: 40, 100, 156 rpm.

13

Measurement speeds: 40, 65 rpm.

14

Measurement speeds: 20, 50, 81 rpm.

15

Measurement speeds: 20, 50 rpm.

16

Measurement speeds: 20, 50, 78 rpm.

17

Measurement speeds: 20, 38 rpm.

Publication MP-IN003C-EN-P — April 2003

Page 25

MP-Series Integrated Gear Motor Installation Instructions 25

Axial Load Force Ratings (Maximum Radial Load)

Motor 40 rpm 60 rpm 100 rpm 156 rpm 194 rpm

kg (lb) kg (lb) kg (lb) kg (lb) kg (lb)

MPG-A004-031 166 (366) 102 (225) —— 88 (194) 82 (180)

1

MPG-A004-091

MPG-A010-031

MPG-A010-091

MPG-A025-031

MPG-A025-091

MPG-A050-031

MPG-A050-091

MPG-A110-031

MPG-A110-091

MPG-B010-031

MPG-B010-091

MPG-B025-031

MPG-B025-091

MPG-B050-031

MPG-B050-091

MPG-B110-031

MPG-B110-091

1

Measurement speeds: 40, 66 rpm.

2

Measurement speeds: 40, 100, 157 rpm.

3

Measurement speeds: 40, 65 rpm.

4

Measurement speeds: 40, 100, 158 rpm.

5

Measurement speeds: 40, 62 rpm.

6

Measurement speeds: 20, 50, 81 rpm.

7

Measurement speeds: 20, 41 rpm.

8

Measurement speeds: 20, 50, 93 rpm.

9

Measurement speeds: 20, 38 rpm.

166 (366) 123 (272) —— —— ——

2

219 (483) —— 201 (443) 173 (381) ——

3

219 (483) 219 (483) —— —— ——

4

407 (897) —— 254 (559) 213 (471) ——

5

407 (897) 298 (656) —— —— ——

6

625 (1378) 456 (1004) 394 (868) —— ——

7

625 (1378) 483 (1066) —— —— ——

8

1025 (2259) 862 (1899) 715 (1577) —— ——

9

1025 (2259) 936 (2063) —— —— ——

10

219 (483) —— 201 (443) 173 (381) 157 (347)

11

219 (483) 219 (483) —— —— ——

12

407 (897) —— 254 (559) 219 (482) ——

13

407 (897) 293 (645) —— —— ——

14

625 (1378) 456 (1004) 394 (868) —— ——

15

625 (1378) 456 (1004) —— —— ——

16

1025 (2259) 862 (1899) 754 (1662) —— ——

17

1025 (2259) 936 (2063) —— —— ——

10

Measurement speeds: 40, 100, 157, 208 rpm.

11

Measurement speeds: 40, 71 rpm.

12

Measurement speeds: 40, 100, 156 rpm.

13

Measurement speeds: 40, 65 rpm.

14

Measurement speeds: 20, 50, 81 rpm.

15

Measurement speeds: 20, 50 rpm.

16

Measurement speeds: 20, 50, 78 rpm.

17

Measurement speeds: 20, 38 rpm.

Publication MP-IN003C-EN-P — April 2003

Page 26

26 MP-Series Integrated Gear Motor Installation Instructions

Axial Load Force Ratings (Zero Radial Load)

Motor Full rpm range

kg (lb)

MPG-A004-031 1 166 (366)

2

MPG-A004-091

MPG-A010-031

MPG-A010-091

MPG-A025-031

MPG-A025-091

MPG-A050-031

MPG-A050-091

MPG-A110-031

MPG-A110-091

MPG-B010-031

MPG-B010-091

MPG-B025-031

MPG-B025-091

MPG-B050-031

MPG-B050-091

MPG-B110-031

MPG-B110-091

1

Measurement speeds: 40, 100, 156, 194 rpm.

2

Measurement speeds: 40, 66 rpm.

3

Measurement speeds: 40, 100, 157 rpm.

4

Measurement speeds: 40, 65 rpm.

5

Measurement speeds: 40, 100, 158 rpm.

6

Measurement speeds: 40, 62 rpm.

7

Measurement speeds: 20, 50, 81 rpm.

8

Measurement speeds: 20, 41 rpm.

9

Measurement speeds: 20, 50, 93 rpm.

10

Measurement speeds: 20, 38 rpm.

11

Measurement speeds: 40, 100, 157, 208 rpm.

12

Measurement speeds: 40, 71 rpm.

13

Measurement speeds: 40, 100, 156 rpm.

14

Measurement speeds: 40, 65 rpm.

15

Measurement speeds: 20, 50, 81 rpm.

16

Measurement speeds: 20, 50 rpm.

17

Measurement speeds: 20, 50, 78 rpm.

18

Measurement speeds: 20, 38 rpm.

166 (366)

3

219 (483)

4

219 (483)

5

423 (933)

6

423 (933)

7

625 (1378)

8

625 (1378)

9

1025 (2259)

10

1025 (2259)

11

219 (483)

12

219 (483)

13

423 (933)

14

423 (933)

15

625 (1378)

16

625 (1378)

17

1025 (2259)

18

1025 (2259)

Publication MP-IN003C-EN-P — April 2003

Page 27

MP-Series Integrated Gear Motor Installation Instructions 27

Holding Brake

A 24V dc holding brake is an option on the MP-Series Integrated Gear

Motor. The following tables provide specifications on the brake.

IMPORTANT

Ensure that proper polarity is maintained when wiring a

brake connector.

Description Gear

Ratio

Type Permanent Magnet

Holding Torque -031 25 Nm (221 lb-in.) 68 Nm (602 lb-in.) 68 Nm (602 lb-in.)

-091 32 Nm (283 lb-in.) 80 Nm (708 lb-in.) 205 Nm (

Backlash None with brake engaged

Voltage Input 21.6 to 25.4V dc

Current Input 24V dc,

o

to 30o C (68o to 86o F)

20

Coil Resistance at 20

Coil Resistance at 40

at maximum continuous stall torque

Release Time Delay

(when voltage is applied)

Engage Time

(when voltage is removed)

o

C (68o F) 67 to 77 Ohms 48.7 to 56 Ohms 48.7 to 56 Ohms

o

C (104o F), operating

Description Gear

Ratio

Type Permanent Magnet

Holding Torque -031 193 Nm (1711 lb-in.) 693 Nm (6137 lb-in.)

-091 500 Nm (4425 lb-in.) 1300 Nm (11506 lb-in.)

Backlash None with brake engaged

Voltage Input 21.6 to 25.4V dc

Current Input 24V dc,

o

to 30o C (68o to 86o F)

20

Coil Resistance at 20

Coil Resistance at 40

at maximum continuous stall torque

Release Time Delay

(when voltage is applied)

Engage Time

(when voltage is removed)

o

C (68o F) 44.7 to 51.3 Ohms 22.4 to 25.6 Ohms

o

C (104o F), operating

MPG-A004-xxx MPG-A010-xxx,

MPG-B010-xxx

~0.33 A ~0.45 A ~0.45 A

72 to 83 Ohms 52 to 61 Ohms 48 to 55 Ohms

22 ms 25 ms 25 ms

7 ms 6 ms 6 ms

MPG-A050-xxx,

MPG-B050-xxx

~0.5 A ~1.0 A

48 to 55 Ohms 24 to 28 Ohms

35 ms 35 ms

7 ms 7 ms

MPG-A110-xxx,

MPG-B110-xxx

MPG-A025-xxx,

MPG-B025-xxx

1819

lb-in.)

Publication MP-IN003C-EN-P — April 2003

Page 28

28 MP-Series Integrated Gear Motor Installation Instructions

Cables and Connector Kits

Factory manufactured feedback and power cables are available in

standard cable lengths. They provide environmental sealing and proper

shield termination to an IP66 rating, which exceeds the MP gear motor’s

IP64 rating. For a complete listing of available cables refer to your drive’s

installation manual, contact your nearest Rockwell Automation sales

office, or access the information from the web sites referenced in Related

Documentation on page 30.

Building and Installing Cables

Knowledgeable cable routing and careful cable construction improves

system electromagnetic compatibility (EMC).

To build and install cables, perform the following steps:

1. Keep wire lengths as short as physically possible.

2. Route signal cables (encoder, serial, analog, and brake) away from

motor and power wiring.

3. Separate cables by 0.3 m (1 ft) minimum for every 9 m (30 ft) of

parallel run.

4. Ground both ends of the encoder cable shield and twist the signal wire

pairs to prevent electromagnetic interference (EMI) from other

equipment.

ATTENTION

!

Publication MP-IN003C-EN-P — April 2003

High voltage can be present on the shield of a power

cable, if the shield is not grounded.

Ensure there is a connection to ground for any power

cable shield.

Failure to observe these safety procedures could result in

personal injury or damage to equipment.

Page 29

MP-Series Integrated Gear Motor Installation Instructions 29

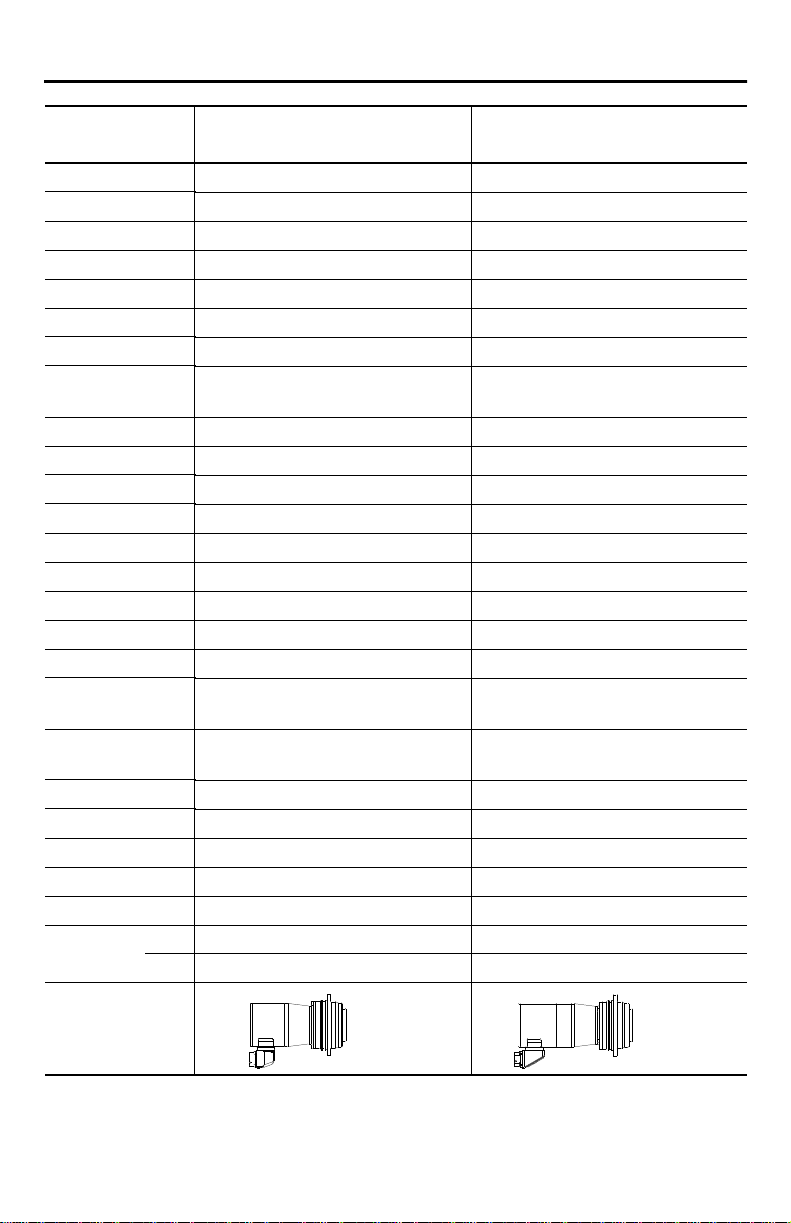

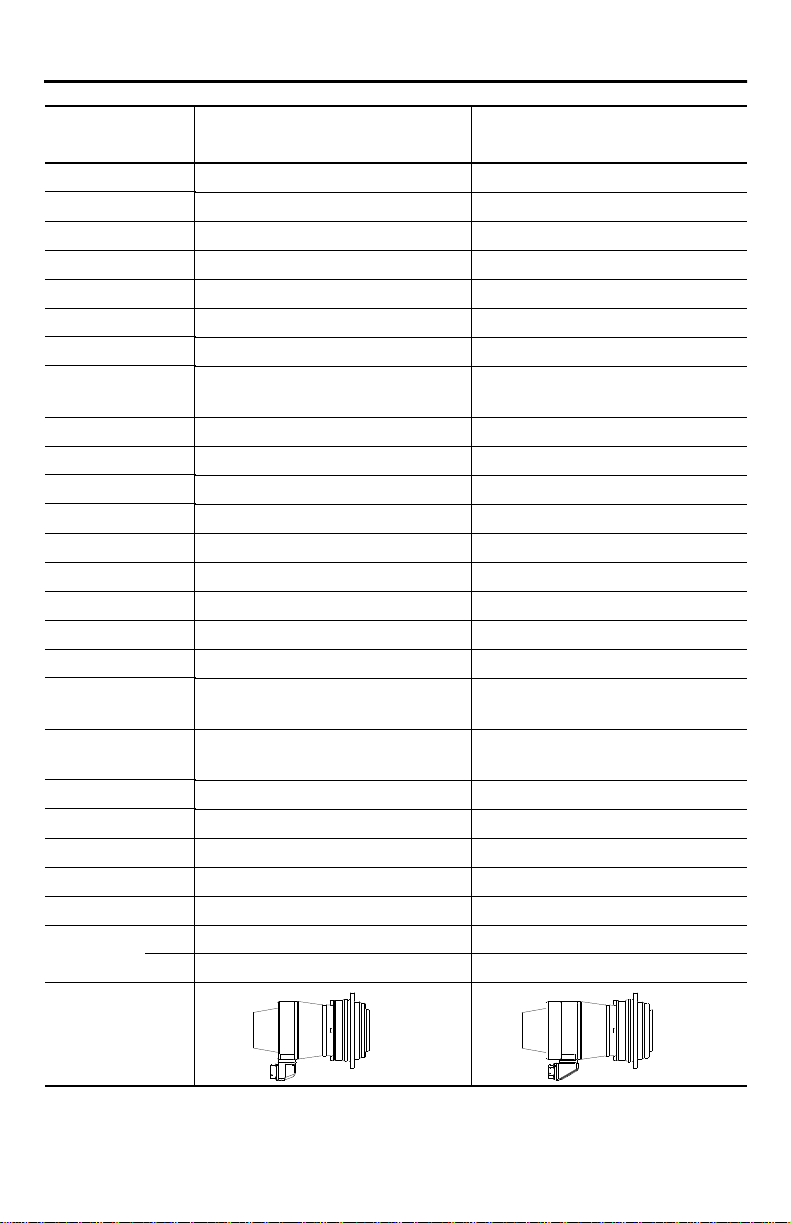

If you choose to build your own cables, the following connector kits are

available for MP-Series Integrated Gear Motors. These solder-type

connectors mate with the motor-mounted connectors and provide

environmental sealing with shield termination.

Each connector kit includes the requisite number and size of solder-type

contact pins, a connector housing, and a connector backshell. As an

example, finished and exploded views of the connector kit are shown

below.

Catalog Number Connector

Ty pe

Accepts

Wire Gauge

2

mm

1

(AWG)

Accepts

Cable Diameter Gauge

mm2 (in.)

2090-MPPC-S Power - Straight 2.5-4.0 (14-12) 7.9-12.4 (0.31-0.49)

2090-MPFC-S Feedback - Straight 0.08-2.5 (28-14)

2090-MPBC-S Brake - Straight 4.3-7.4 (0.17-0.29)

1

Refer to your drive’s installation manual for recommended wire gauges.

EndbellConnector Coupling Ring

Connector Housing

O-Ring

InstallO-Ring

on groove in

Connector Housing

Bushing

Ring Cone

Snap Ring Cone

onto Bushing

Sealing Grommet

Cable Clamp Ring

Clamp Nut

Gear Lubricant

Gear units are permanently lubricated at the factory.

Publication MP-IN003C-EN-P — April 2003

Page 30

MP-Series Integrated Gear Motor Installation Instructions 30

Related Documentation

The following documents contain additional information concerning

related Allen-Bradley products. To obtain a copy, contact your local

Rockwell Automation office or distributor, or access on-line at:

www.theautomationbookstore.com

For information about: Read this document: Publication Number

Small Frame (<

Large Frame (>

Connecting to an Ultra5000™ drive Ultra5000 Intelligent

Connecting to an Ultra3000™ drive Ultra3000 Digital Servo

Connecting to an Kinetix™ 6000 drive Kinetix 6000 Multi-Axis

A glossary of industrial automation

terms and abbreviations

How to minimize and control

system-level noise

An overview of Allen-Bradley motion

controls and systems, including

information about MP-Series motors.

165 mm) MP Motors

215 mm) MP Motors

or

www.ab.com/manuals/gmc

MP-Series Brushless Servo

Motor Manuals

Positioning Drives

Installation Manual

Drives Installation Manual

Servo Drive Installation

Manual

Allen-Bradley Industrial

Automation Glossary

System Design for Control of

Electrical Noise

Motion Control Selection

Guide

.

MP-IN001x-EN-P

MP-IN002x-EN-P

2098-IN001x-EN-P

2098-IN003x-EN-P

2094-IN001x-EN-P

AG-7.1

GMC-RM001x-EN-P

GMC-SG001x-EN-P

Publication MP-IN003C-EN-P — April 2003

Page 31

Notes

MP-Series Integrated Gear Motor Installation Instructions 31

Publication MP-IN003C-EN-P — April 2003

Page 32

For more information refer to our web site:

For Allen-Bradley Technical Support information refer to:

Allen-Bradley is a registered trademark of Rockwell Automation, Inc.

Kinetix, Ultra3000 and Ultra5000 are trademarks of Rockwell Automation, Inc.

www.ab.com/ motion

www.ab.com/support

or Tel: (1) 440.646.5800

Publication MP-IN003C-EN-P — April 2003 PN 0013-2052-003-01

Supersedes Publication MPG-IN003B-EN-P April 2 002 Copyright © 2003 Rockwell Automation, Inc. All rights reserved. Print ed in the USA.

Loading...

Loading...