Page 1

Direct Drive Technology

Demonstration Machine

Quick Start

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment. Safety Guidelines for the

Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

office or online at http://literature.rockwellautomation.com

) describes some important differences between solid state equipment and

hard-wired electromechanical devices. Because of this difference, and also because of the wide variety of uses for solid state equipment, all

persons responsible for applying this equipment must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or

application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and requirements

associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for actual use based on the

examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software described

in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

available from your local Rockwell Automation sales

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may

lead to personal injury or death, property damage, or economic loss.

Identifies information that is critical for successful application and understanding of the product.

Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or economic

loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may be present.

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach dangerous

temperatures.

Rockwell Automation, Allen-Bradley, TechConnect, PanelView, PowerFlex 4, PowerFlex 40, PowerFlex 40P, PowerFlex 400, RSLogix 500, DriveExplorer, SLC, and MicroLogix are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Install the Direct Drive Technology Demonstration Machine

Table of Contents

Preface

About This Publication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chapter 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Position and Level Machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Remove Shipping Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Install Signs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Assemble Computer and Computer Stand . . . . . . . . . . . . . . . . . . . . . . 13

Make Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Preparing the Direct Drive Technology Demonstration Machine for

Shipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Using the Direct Drive Technology Demonstration Machine

Specifications and Dimensions

Chapter 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Machine Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Start Computer Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Machine Shut Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Using Push Button Switches and Door Interlock to Run the

Machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Emergency Stop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Stop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Front and Back Doors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Using the Application to Control the Machine. . . . . . . . . . . . . . . . . . . 19

Appendix A

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Environmental Specifications for the Direct Drive Technology

Demonstration Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Direct Drive Technology Demonstration Machine Specification . . . . 21

Rockwell Automation Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Installation and Parts Assistance for Direct Drive Technology

Demonstration Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3Publication PMC-QS002B-EN-P - October 2008 3

Page 4

Table of Contents

4 Publication PMC-QS002B-EN-P - October 2008

Page 5

Preface

About This Publication

Audience

Parts List

Use this quick start to setup the Direct Drive Technology Demonstration

Machine. This quick start describes the necessary tasks to install and run this

demonstration machine.

This quick start is for anyone who will be setting up Direct Drive Technology

Demonstration Machine for demonstration purposes only.

This quick start uses the following hardware.that is shipped with the

demonstration machine.

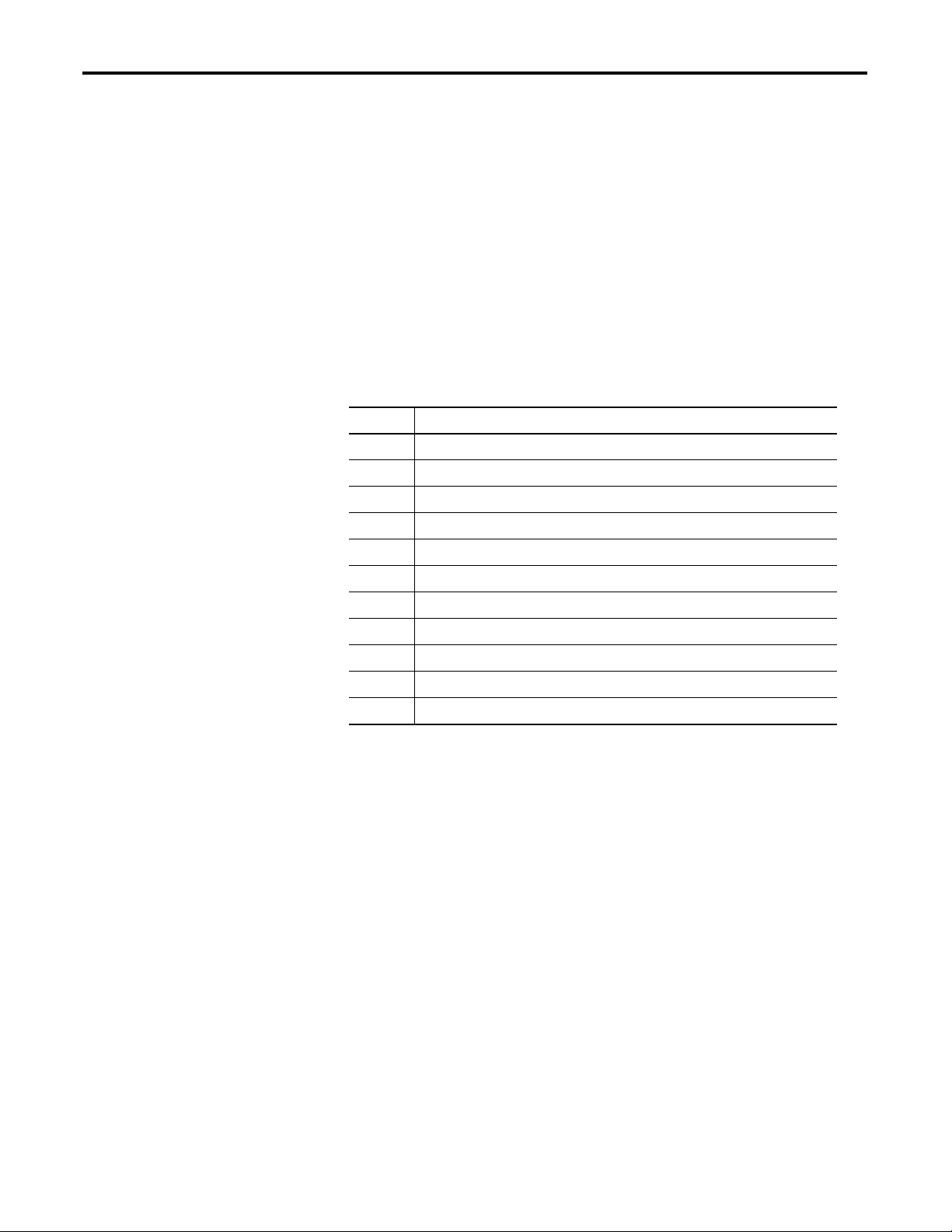

Quantity Description

1 Direct Drive Technology Demonstration Machine

1 Touch screen with computer configured with ControlLogix software

1 Infrared keyboard, mouse with receiver kit

1 Computer power cord

1 Hex wrench set

1 Adjustable crescent wrench

1 Pole with two support clamps

1 Wheel base

1 Keyboard and mouse support assembly

1 Direct Driver Technology sign

1 Build It, Buy It, Customize It sign

5Publication PMC-QS002B-EN-P - October 2008 5

Page 6

Preface

6 Publication PMC-QS002B-EN-P - October 2008

Page 7

Chapter

Install the Direct Drive Technology Demonstration Machine

1

Introduction

Before You Begin

In this chapter, you will install Direct Drive Technology Demonstration

Machine.

Topic Page

Before You Begin 7

What You Need 7

Follow These Steps 8

Position and Level Machine 8

Remove Shipping Clamps 9

Install Signs 12

Assemble Computer and Computer Stand 13

Make Connections 14

Preparing the Direct Drive Technology Demonstration Machine for

Shipment

• The packing material can be saved for use when the machine is

returned.

• Choose an installation location that is within 2 m (6.5 ft) of power

mains and meets the environmental and power specification for

the machine.

• The machine and the boxed contents of the shipping crate should

be brought to the location of the installation.

14

What You Need

7Publication PMC-QS002B-EN-P - October 2008 7

• Utility knife or snip for cutting tie wraps.

• Hex wrench set and an adjustable crescent wrench. These tools

were shipped with the machine.

• Additional tie wraps have been included. Use them to repack the

machine.

Page 8

Chapter 1 Install the Direct Drive Technology Demonstration Machine

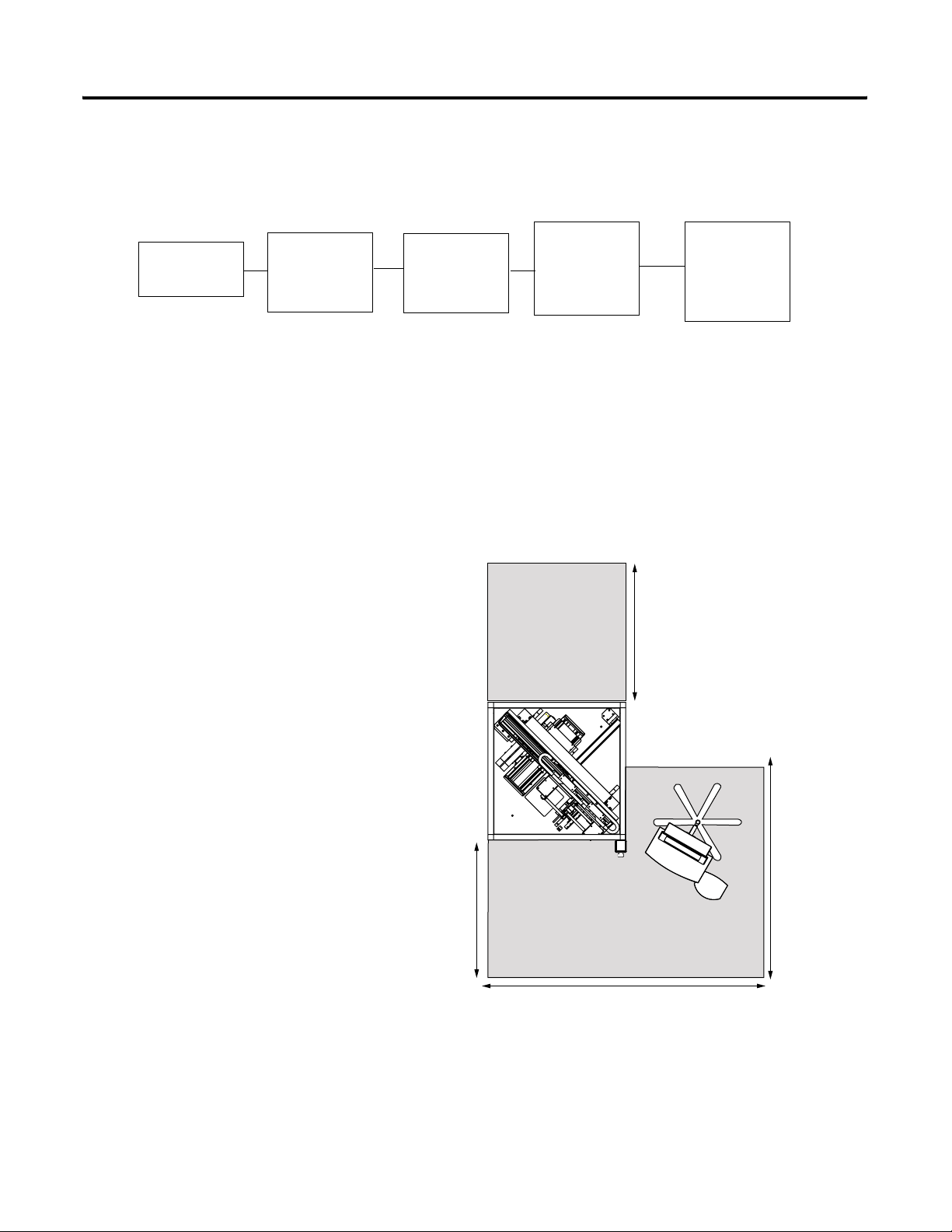

Follow These Steps

Position and

Level Machine

Position and Level Machine

Remove

Shipping

Clamps

Complete the following steps to install the Direct Drive Technology

Demonstration Machine.

Install Signs

Assemble

Computer and

Computer

Stand

Make

Connections

1. Position machine within 2 m (6.6 ft) of power source and with

1 m (3.3 ft) clearance in the front, back and right side of the

machine.

The position can be adjusted while the casters are supporting the

machine.

Dimensions m (ft)

1 (3.3)

1.5 (5)

1 (3.3)

2 (6.6)

2. Extend the four leveling feet so the full weight of the machine is

off the caster and on the leveling feet.

8 Publication PMC-QS002B-EN-P - October 2008

Page 9

Install the Direct Drive Technology Demonstration Machine Chapter 1

3. Adjust the leveling feet so the machine is visually level.

Casters not shown

Remove Shipping Clamps

1. Cut the tie wrap holding the power cable to the back door handle.

2. Remove the 8M Socket Head Cap Screw (SHCS) (X2) and the 6M

SHCS (X4) from the bridge brace and remove brace.

8M SHCS (X2)

6M SHCS (X4)

Publication PMC-QS002B-EN-P - October 2008 9

Page 10

Chapter 1 Install the Direct Drive Technology Demonstration Machine

3. Remove the cantilever axis shipping brackets at each end of the

stage.

a. Remove the 8M SHCS and washers from the bridge riser.

b. Loosen but don’t remove the 6M SHCS from the stage.

c. Push the stage forward and slide the bracket off the stage.

10 Publication PMC-QS002B-EN-P - October 2008

Page 11

Install the Direct Drive Technology Demonstration Machine Chapter 1

3M SHCS

6M SHCS

A

B

4. Remove the shipping bracket from each carriage on the dual stage

and from the cantilevered axis carriage.

a. Loosen but don’t remove the 3M SHCS.

b. Back off the 6M SHCS until they clear the carriage.

c. Slide the shipping bracket off the end of the stage.

There are two tie wraps that secure the LEU stage. One through the last hole in the magnet channel and one through the loop created by the tie wrap and around the motor assembly.

5. Carefully cut and remove the tie wraps.

Publication PMC-QS002B-EN-P - October 2008 11

Page 12

Chapter 1 Install the Direct Drive Technology Demonstration Machine

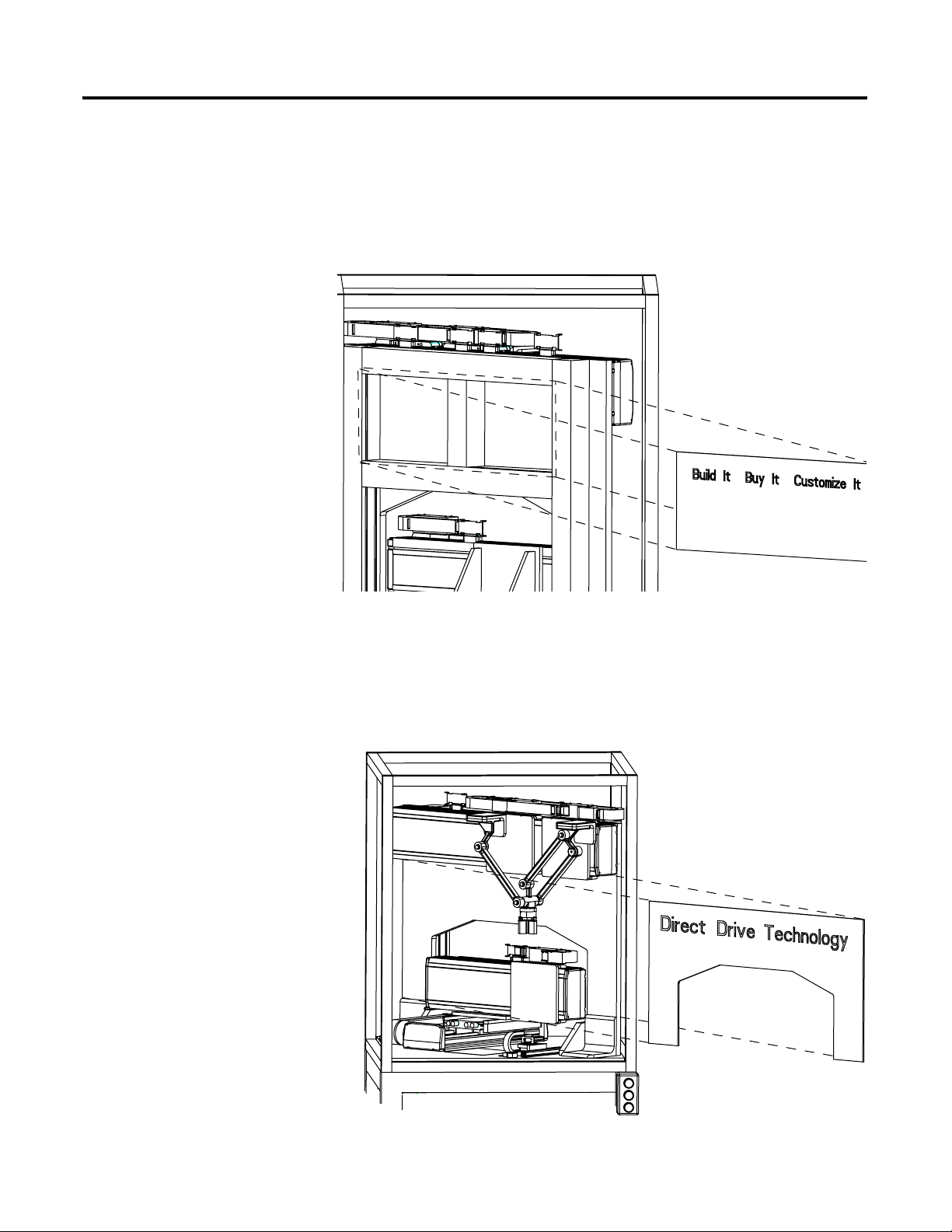

Install Signs

1. Attach the Build It, Buy It, Customize It sign to the back of the

bridge by aligning the Velcro strips.

If adjustment is necessary do not bend the sign. It could be permanently damaged.

2. Attach the Direct Drive Technology sign to the front of the

bridge by aligning the sign to the edge of the bridge.

If adjustment is necessary do not bend the sign. It could be

permanently damaged.

12 Publication PMC-QS002B-EN-P - October 2008

Page 13

Install the Direct Drive Technology Demonstration Machine Chapter 1

Assemble Computer and Computer Stand

1. Insert the uncapped end of pole in wheel base.

50 mm (2 in.) Pole

Wheel Base

2. Loosen the 4M BHCS on the back of the computer monitor and

slide into the keyholes of the Centris bracket and tighten all four

screw.

Centris Bracket

M4 BHCS (X4)

3. Attach the swing arm keyboard assembly on to the post of the

pole clamp.

Swing Arm

Keyboard Tray

Pole Clamp

Publication PMC-QS002B-EN-P - October 2008 13

Assy

Page 14

Chapter 1 Install the Direct Drive Technology Demonstration Machine

Make Connections

1. Attach the keyboard USB and mouse infrared receiver to the

Velcro on the support arm with the sensor side towards the

keyboard.

2. Connect the USB and mouse cable to computer.

3. Connect computer power and network cable to the side of the

machine.

4. Place mouse and keyboard on stand.

Emergency Stop,

Stop, Run Buttons

Main Power

Switch

Computer

Power Cord

Preparing the Direct Drive Technology Demonstration Machine for Shipment

Keyboard and Mouse

Infrared Receiver

5. Connect the machine to a 230V AC, 10 A minimum single phase

power main.

To prepare the Direct Drive Technology Demonstration Machine for

shipment pack the machine following the installation instructions in

reverse. Reuse the packing material and the tie wraps that were sent with

the machine.

Network Cable

14 Publication PMC-QS002B-EN-P - October 2008

Page 15

Chapter

Using the Direct Drive Technology Demonstration Machine

2

Introduction

Before You Begin

In this chapter, you will start the Direct Drive Technology

Demonstration Machine and learn how to control it using the hardware

buttons and the RSLogix Software application.

Topic Page

Before You Begin 15

What You Need 15

Follow These Steps 16

Machine Start Up 16

Start Computer Application 17

Using Push Button Switches and Door Interlock to Run the Machine 18

Using the Application to Control the Machine 19

Complete installation instruction in Chapter 1. Check that back door is

secured.

What You Need

15Publication PMC-QS002B-EN-P - October 2008 15

The personal computer user names and passwords are on labels located

on the left side of the combination computer monitor chassis and listed

here:

User Name: Rockwell

Password: Rock1234

or

User Name: Administrator

Password: An0rad1

Page 16

Chapter 2 Using the Direct Drive Technology Demonstration Machine

Follow These Steps

Machine Start Up

Complete the these steps to start the machine and the application

software.

Start

Machine Start

Up

Computer

Application

Machine Shut

Down

Follow these sequence to start the machine.

1. Close the back door.

1. Open the front door.

a. Turn the laser pointer so the ON button is perpendicular to the

carriage.

b. Push the laser pointer down to turn it on.

c. Tighten the hold down screw.

d. Close front door.

2. Pull the emergency stop (E-stop) switch.

3. Turn the power ON.

4. Press Run (green button) on front side of machine.

Wait for the amplifiers count up to 4. It will take approximately 30

seconds for 3 to process.

5. Press Run again.

After the axis homes the machine will start cycling.

16 Publication PMC-QS002B-EN-P - October 2008

Page 17

Using the Direct Drive Technology Demonstration Machine Chapter 2

Start Computer Application

Machine Shut Down

Machine motion can run without running the PC. To control the

machine using the computer interface follow these steps.

1. Apply power to the computer.

2. Enter appropriate user name and password combination.

3. Click the RSLogix5000 icon: MPAS-Hbot_V1.04

4. Minimize MPAS-Hbot_V1.04

5. Click the HMI with Anorad_Hbot_Demo icon.

Follow these steps to shut down the machine if the computer is being

used.

1. Press Pause and wait for motion cycle to complete.

2. Press the E-stop (red push button) switch to remove power to the

drives.

3. Log off and shut down computer.

4. Turn the power OFF.

Follow these steps to shut down machine if computer is not being used.

1. Press Stop. Motion will coast to a stop.

2. Press the E-stop switch to remove power to the drives.

3. Turn the power OFF.

Publication PMC-QS002B-EN-P - October 2008 17

Page 18

Chapter 2 Using the Direct Drive Technology Demonstration Machine

Using Push Button Switches and Door Interlock to Run the Machine

The Run, Stop (yellow), Emergency Stop push button switches and the

front door interlock can control this machine without the use of the

computer interface.

Emergency Stop (E-stop)

To stop the machine immediately push the E-stop switch. Using the

E-stop switch requires you to follow the Machine Start procedure to

start motion.

Stop

Pressing Stop stops motion after the current motion cycle. Press Start to

restart.

Run

Press Run to initialize, run, and re-start the machine. The first time it is

pressed after power is applied the amplifiers are powered up and

initialized with motion parameters. The second time it is pressed after

initialization the axis homes and then runs through it’s cycle

continuously. Pressing Run while the machine is paused starts motion

immediately.

Front and Back Doors

Opening the front or back door is the same as using the E-stop switch.

The interlock opens and all motion coasts to a stop. To re-start machine

follow Machine Start procedure.

18 Publication PMC-QS002B-EN-P - October 2008

Page 19

Using the Direct Drive Technology Demonstration Machine Chapter 2

Using the Application to Control the Machine

Once the machine is initialized using the hardware buttons it can be

controlled with the computer touch screen. The machine must be

connected to the computer via the ethernet cable and the computer

must be running the RSLogix Software application.

There are two virtual buttons displayed on the touch screen: Run and

Pause. Run will start the motion immediately. Pause will stop motion

after the current motion cycle.

Publication PMC-QS002B-EN-P - October 2008 19

Page 20

Chapter 2 Using the Direct Drive Technology Demonstration Machine

20 Publication PMC-QS002B-EN-P - October 2008

Page 21

Specifications and Dimensions

Appendix

A

Introduction

Environmental Specifications for the Direct Drive Technology Demonstration Machine

This appendix provides power and environmental specifications for the Direct

Drive Technology Demonstration Machine.

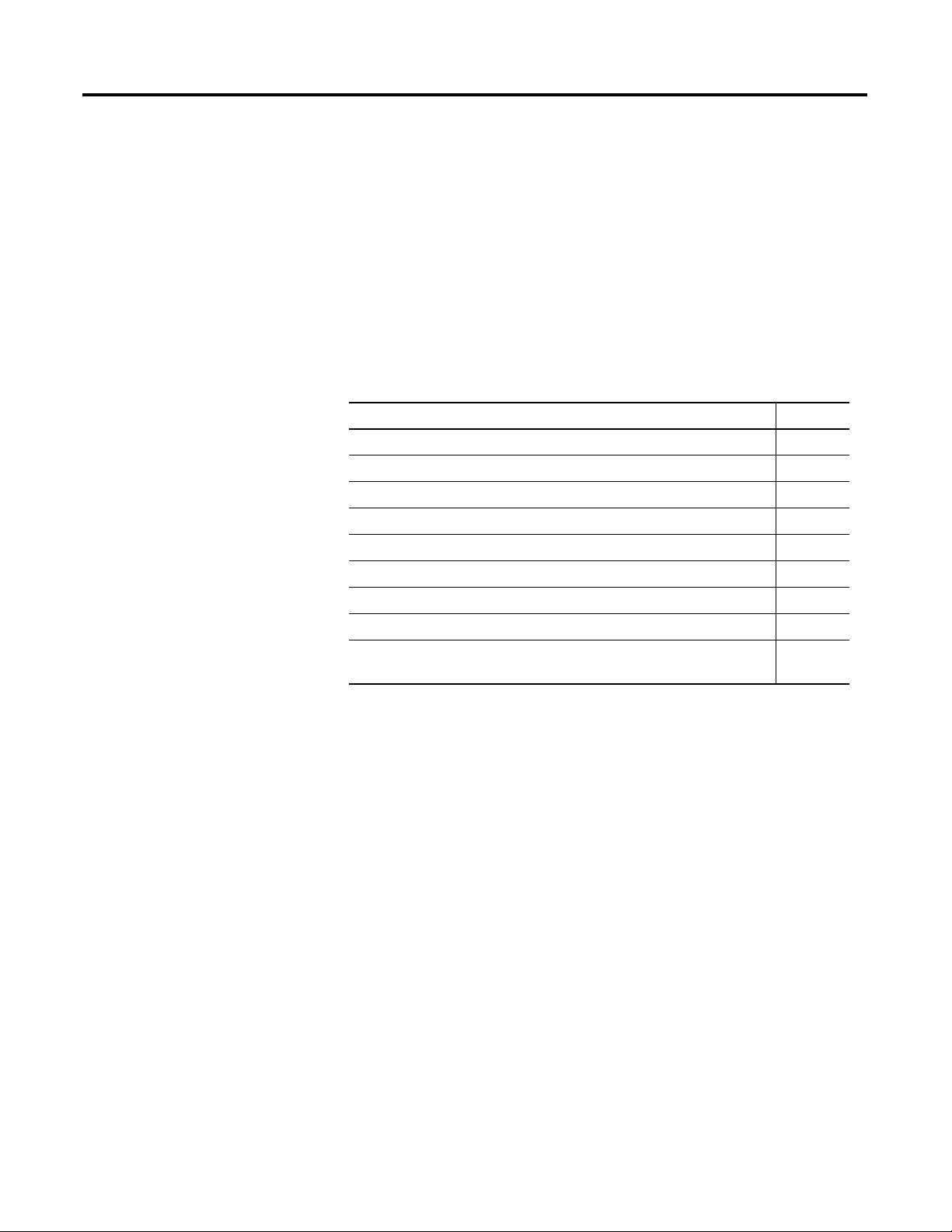

Topic Page

Environmental Specifications for the Direct Drive Technology Demonstration

Machine

Direct Drive Technology Demonstration Machine Specification 21

The following table show the environmental specifications for the

Direct Drive Technology Demonstration Machine.

Attribute Value

Temperature, ambient 0...40 °C (32...104 °F)

Temperature, storage -30...70 °C (-22...158 °F)

Relative humidity 5%…95% noncondensing

Shock 20 g peak, 6 ms duration

Vibration 0.1 grms @ 30…2000 Hz

Cable carrier lifetime 10,000,000 cycles

21

Direct drive linear stages require lubrication every 6 months

or 5,000 km of travel. Use the MP-Series Integrated Linear

Stage grease pump kit, and additional grease cartridges if

needed.

Direct Drive Technology Demonstration Machine Specification

21Publication PMC-QS002B-EN-P - October 2008 21

The follow table shows the specification for the Direct Drive Technology

Demonstration Machine.

Specification Unit Value

Motion System (H x W x D), approx. cm (in.) 188 x 100 x 116 (74 x 39.5 x 46)

Computer and Computer Stand (H x W x D),

approx.

Weight, approx. kg (lb) 465 (1025)

cm (in.) 122 x 61 x 61 (48 x 24 x 24)

Page 22

Appendix A Specifications and Dimensions

22 Publication PMC-QS002B-EN-P - October 2008

Page 23

Page 24

Rockwell Automation Support

If you experience a problem with a Direct Drive Technology Demonstration

Machine, please review the information that's contained in this quick start.

You can also contact the following customer support number for help in

getting machine up and running.

United States 1.631.344.6600

Monday – Friday, 8 a.m. – 5 p.m. EST

Publication PMC-QS002B-EN-P - October 2008 24

Supersedes PMC-QS002A-EN-P May 2008 Copyright © 2008 Rockwell Automation, Inc. Printed in the USA.

Loading...

Loading...