Page 1

DeviceNet System

Quick Reference

Page 2

DeviceNet System Quick Reference

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical

equipment. Safety Guidelines for Application, Installation, and Maintenance of Solid State

Controls (publication SGI-1.1

online at http://literature.rockwellautomation.com

between solid state equipment and hard-wired electromechanical devices. Because of this

difference, and also because of the wide variety of uses for solid state equipment, all persons

responsible for applying this equipment must satisfy themselves that each intended application

of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential

damages resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes.

Because of the many variables and requirements associated with any particular installation,

Rockwell Automation, Inc. cannot assume responsibility or liability for actual use based on the

examples and diagrams. No patent liability is assumed by Rockwell Automation, Inc. with

respect to use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of

Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety

considerations.

WARNING Identifies information about practices or circumstances that can cause an

explosion in a hazardous environment, which may lead to personal injury or

death, property damage, or economic loss.

IMPORTANT Identifies information that is critical for successful application and

understanding of the product.

ATTENTION Identifies information about practices or circumstances that can lead to

personal injury or death, property damage, or economic loss. Attentions help

you identify a hazard, avoid a hazard, and recognize the consequence.

SHOCK HAZARD Labels may be on or inside the equipment, for example, a drive or

motor, to alert people that dangerous voltage may be present.

BURN HAZARD Labels may be on or inside the equipment, for example, a drive or motor,

to alert people that surfaces may reach dangerous temperatures.

available from your local Rockwell Automation sales office or

) describes some important differences

DNET-QR001A-EN-E – March 2009 2

Page 3

DeviceNet System Quick Reference

Table of Contents

Topic Page

Design 3

Select 4

Install 5

Configure 6

193-DNCT Handheld Configuration Device 6

Node Commissioning on Your DeviceNet Network 6

Starting the 193-DNCT Terminal 7

Change Node Number 63 to Node Number 1 8

Create the 1756-DNB and 1769-SDN Scanlist by Using AutoScan 9

Example: Configure the E1 Overload

Maintain 13

Diagnostics and Troubleshooting 13

12

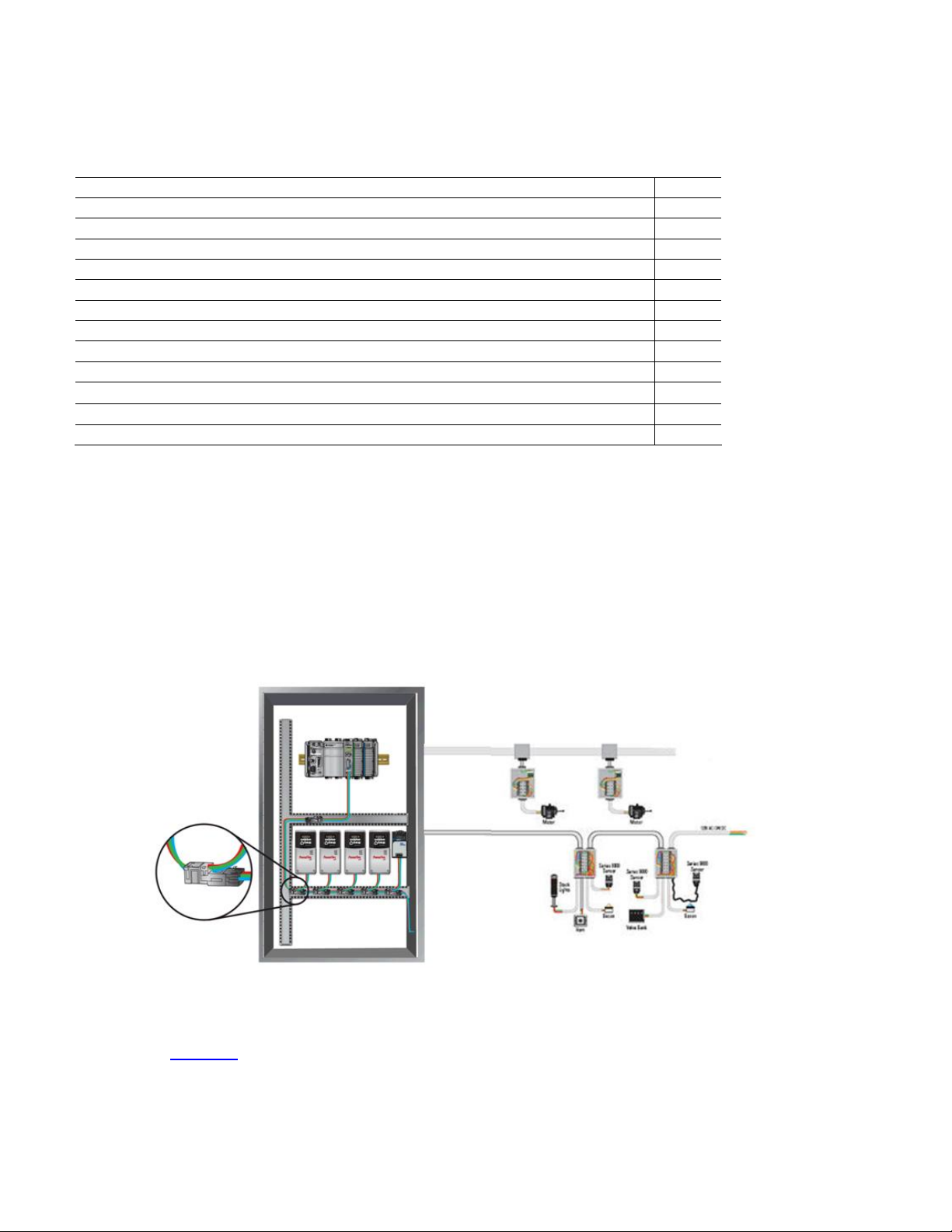

Design

For this manual, we are looking at a system with these constraints. They do not represent network

maximums. The DeviceNet network has these capabilities:

• Cable length of 100 m (328 ft)

• Maximum of 64 nodes

• Power supply limited to 4 A (Class 2)

Example Media Configuration

This example illustrates the layout of a drop system configuration.

For detailed wiring information, refer to the Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

.

DNET-QR001A-EN-E – March 2009 3

Page 4

DeviceNet System Quick Reference

Select

Use this table to select the appropriate media for your system. For other media choices, refer to

Chapter 6 in the On-Machine Connectivity Catalog, publication M116-CA001

.

Description Cat. No.

DeviceNet handheld configuration terminal

IP20 flat media

Trunk-line connector, IDC

Drop-line connector, IDC 1485P-K1DL4

Terminating resistor, IDC 1485P-K1TR4

Terminal block, IDC 1485P-K1TLR4

Flat-to-thin round cable converter, IDC 1485P-K1GK4

5-pin open style connector, IDC 1485P-K1G4-Y5

Manual crimp tool 1485A-KCRIMP

ControlLogix DeviceNet scanner module 1756-DNB

CompactLogix DeviceNet scanner module 1769-SDN

4-in/2-out block I/O 120V AC relay DSA 100-DNY41R

193-DNCT

1485-P1W100

1485P-K1TG4

4-in/2-out block I/O 24V DC relay DSA 100-DNY42R

AC/DC DIN-rail mount power supply, DeviceNet 4 A 1606-XLDNET4

E1 DeviceNet module for 193 E1 plus overload relay 193-EDN

PowerFlex DeviceNet communication interface 22-COMM-D

Thin round cable, 50 m (164 ft) roll 1485-P1C50

Terminating resistor 1485A-C2

DNET-QR001A-EN-E – March 2009 4

Page 5

DeviceNet System Quick Reference

Install

Locate and mount the modules. Follow these steps to crimp the connectors.

For thin round media, refer to the DeviceNet Media Design Installation Guide,

publication DNET-UM072

.

Important:

• Do not crimp the edge of the connector cover.

• Do not crimp at the back of the crimp block.

• Be sure to set the connector in the correct orientation.

1. Set the center of the connector cover (see arrows) in the center of the crimp block of the crimp tool.

2. Crimp the connector until you hear the connector lock into place.

DNET-QR001A-EN-E – March 2009 5

Page 6

DeviceNet System Quick Reference

Configure

193-DNCT Handheld Configuration Device, Revision 2.1 or Later

The 193-DNCT DeviceNet configuration terminal is a handheld device that can configure, program,

retrieve historical data, and monitor DeviceNet components, while directly connected to the network.

Commissioning is made simple with the capability to upload, store, and download complete device

configurations, while online with the network. This tool also aides in troubleshooting by providing

physical layer diagnostics and network bandwidth statistics.

Node Commissioning on Your DeviceNet Network

Once the DeviceNet media and/or cabling system is installed, you need to assign a unique node

number, between 0 and 63, to every device on the DeviceNet network. You can do this by setting the

rotary or dip switches or by using the Node Commission function via software or a handheld device.

Set each device on the network to the same communication rate: 125, 250, 250, or 500 Kbps.

Important:

The factory default for each device is 125 Kbps, set to node number 63 with autobaud

enabled.

DNET-QR001A-EN-E – March 2009 6

Page 7

DeviceNet System Quick Reference

–

Starting the 193-DNCT Terminal

Attach and connect the 193-DNCT terminal to the DeviceNet network. This display appears for

10 seconds.

Baud = Fixed Baud Rate

Auto = Autobaud

AB

DEVICENET HIM

Actual Terminal Node Address

Baud: 125K Auto: 62

Actual Baud Rate

Adrs = Fixed HIM Mac ID

Auto = Auto Addressing

Important:

The DeviceNet configuration terminal is shipped so that when it is placed on a

DeviceNet network for the first time, it automatically sets its baud rate to that of the

traffic on the network. Auto Addressing automation assigns an unused network node

address to the terminal.

After 10 seconds, a Network Who dialog box similar to the one shown below appears with all nodes

and associated devices on the network.

NETWORK WHO Node: 43

0 -- DeviceNet Scanner

2 -- 100-DNY42

5 -- E1 Plus

6 -- Parker Valve

7 -- E1 Plus

8

100-DNY42

Notice that the node number in the upper right corner constantly changes. This shows the node number

that the 193-DNCT terminal is currently scanning during the active network browse it is performing.

If the Network Who dialog box does not appear after 10 seconds, the 193-DNCT terminal is set to

Autobaud Enabled and cannot determine a communication rate as no communication is currently

occurring on the network.

Follow these steps to disable Autobaud.

1. On the 193-DNCT keypad, press ESC

2. Select AutoBaud and press the <Up Arrow>

DNET-QR001A-EN-E – March 2009 7

.

to choose Disable.

Page 8

Follow these steps to set the communication rate to 125 Kbps.

DeviceNet System Quick Reference

1. Press SEL

2. Select BaudRate and press the Up Arrow

3. Press ESC

to advance to BaudRate.

to exit Setup.

to choose 125 Kbps.

Change Node Number 63 to Node Number 1

No entry exists for node 1 in the Network Who dialog box because the device is currently at node 63.

Follow these steps to change to node number from 63 to 1.

1. On the 193-DNCT keypad, press the Down Arrow

Product Name’.

2. Press Enter

3. Press the Down Arrow

4. Press Enter

A dialog box appears with NodeComm selected.

5. Press Enter

to advance to the configuration dialog box.

to select Tools.

.

again.

to scroll through the list and select ‘63 – No

The Node Commissioning dialog box appears with BaudRate selected.

Node Commissioning

------------------------------------- BaudRate: 125K

Address: 63

6. Press SEL to advance to Address and select it.

7. To change the Address, press 1 and then Enter

An Apply Changes dialog box appears.

Tip:

8. Press SEL

After approximately 2 seconds the 193-DNCT terminal re-initializes. In another 10 seconds, the

terminal again displays the Network Who dialog box with node 1 now visible.

You can use the Up Arrow

and then Enter to complete the node commissioning.

and Down Arrow to scroll through the node numbers.

.

DNET-QR001A-EN-E – March 2009 8

Page 9

DeviceNet System Quick Reference

Create the 1756-DNB and 1769-SDN Scanlist by Using AutoScan

The DeviceNet network AutoScan feature allows a scanner to automatically map a network of slave

devices into its scanlist without the use of RSNetWorx for DeviceNet software. This greatly improves

the ease of setting up a DeviceNet network, especially networks comprised of simple devices.

When you enable AutoScan, the 1756-DNB or 1769-SDN scanner module searches for devices on the

network that are not yet mapped. Once a qualifying device is found, the scanner adds the device to its

scanlist and maps its I/O data into a predefined location in the scanner’s I/O memory table. This

location is based on the device’s node address and the mapping size.

AutoScan is not enabled initially. You must enable AutoScan so that devices are automatically added to

the scanlist whenever the scanner module is in Idle mode. The mapping size provides the scanner

module with the number of bytes per node to allocate in the I/O tables. Set the mapping size so that it is

higher than the maximum input or output size of every device on the network. If a device found on the

network has an input or output size larger than the mapping size you set, it will not be added to the

scanlist.

In this example, the mapping size is set to 32 bytes per node. The 193-DNCT terminal configures and

originates AutoScan from a special menu, created specifically for that purpose.

1. Turn the key on the front of the 1756-L63 controller (in slot 2) completely clockwise.

This puts the ControlLogix controller into Program mode, which also puts the scanner module into

Idle mode.

2. In the Network Who dialog box, press the Up Arrow

(0 – 1756-DNB DeviceNet Scanner).

3. Press Enter

4. Press the Down Arrow

5. Press the Down Arrow

This AutoScan Setup dialog box appears.

to go to its configuration dialog box.

to navigate to and select Scanner and press Enter .

to navigate to and select AutoScan and press Enter .

to navigate to and select the first line

AutoScan Setup

AutoScan: Disable

Mapping: 32

Idle Mode

Active Nodes: 0

DNET-QR001A-EN-E – March 2009 9

Page 10

DeviceNet System Quick Reference

6. If AutoScan is selected and set to Disable, press the Up Arrow

7. Press SEL

8. Press SEL

AutoScan begins and the Active Nodes value increments. When the value reaches a node count

of 6, AutoScan is finished and found all 6 nodes on the network.

9. Select AutoScan and press the Up Arrow

10. Press SEL

AutoScan is disabled in the scanner.

11. Press ESC

12. Turn the key on the front of the 1756-L63 controller (in slot 2) completely counter-clockwise.

This puts the ControlLogix controller back into Run mode, which will also put the scanner module

into Run mode, provided that the scanner run bit is set by the logic or data table.

to select Mapping and press 3, 2, and then Enter .

and then Enter to save your changes.

to change to Disable.

twice and then press Enter to save your changes.

three times to return to the Network Who dialog box on the 193-DNCT terminal.

to change to Enable.

View the I/O Mapping Information

Once all of the devices have been added to the scanlist via AutoScan, you can check the I/O data

mapping that was generated by AutoScan. The 193-DNCT terminal can view the input and output data

sizes along with the input and output data mapping assignments for each device.

1. In the Network Who dialog box, press the Up Arrow

(0 – 1756-DNB DeviceNet Scanner).

2. Press Enter

3. Press the Down Arrow to navigate to and select Scanner and press Enter .

4. Press the Down Arrow

This ScanList dialog box appears.

to go to its configuration dialog box.

to navigate to and select ScanList and press Enter .

to navigate to and select the first line

ScanList

0 -- DeviceNet Scanner

2 -- 100-DNY42

5 -- E1 Plus

6 -- Parker Valve

7 -- E1 Plus

8 – 100-DNY42

62 – This DeviceNet HIM

DNET-QR001A-EN-E – March 2009 10

Page 11

DeviceNet System Quick Reference

5. Press the Down Arrow

A dialog box appears with the mapping details of the E1 Plus devices scanlist entry. You can

temporarily disable the 1756-DNB scanner scanlist entry.

6. Press SEL

This entry lets you modify the size of the native data location for the controller you are using.

For example, the Logix-based controllers use a 32 bit Dword for each location in their data table

while some other controllers may use only a 16 bit word. Depending on the native data size of the

controller you are using, you may need to modify this entry, to accurately view the data mapping

assignments for a device in the scanlist.

• The input mapping line displays an 8 to signify an input size of 8 bytes of data going back to

the scanner.

• The next line displays D40:0 --- D41:31 to signify that the data starts at Dword 40, bit 0 of

the input table and continues contiguously to Dword 41, bit 31. Therefore the mapping takes

two complete, 32 bit, Dword locations in the data table. The output mapping line displays a 1

to signify an output size of 1 byte of data coming from the scanner.

• The last line displays D40:0 --- D40:7 to signify that the data starts at Dword 40, bit 0 of the

output table and continues contiguously to Dword 40, bit 7.

7. Press the Down Arrow

to select Mapping.

to navigate to and select 5 – E1 Plus and press Enter .

to change the mapping value.

Notice the effect this change has on the mapping details.

8. Press ESC

four times to return to the Network Who dialog box on the 193-DNCT terminal.

DNET-QR001A-EN-E – March 2009 11

Page 12

DeviceNet System Quick Reference

Example: Configure the E1 Overload

With your fully wired and operational network, there is usually some configuration required for one or

more of the devices, including how the device will behave on the DeviceNet network or how the device

will act as its main function. The 193-DNCT terminal can configure and monitor parameters in the

devices connected to the network. In this example, the 193-DNCT terminal changes the OverLoad

Warning Level parameter in the E1 Plus overload unit.

1. In the Network Who dialog box, press the Down Arrow to navigate to and select 5 – E1 Plus.

2. Press Enter

3. Press the Down Arrow

Device parameters can be viewed by Groups of similar functions or as a Numerical Listing.

4. Press the Down Arrow

The 193-DNCT terminal now displays parameter 1, the Average %FLA parameter.

Important:

to go to the E1 Plus configuration dialog box.

to navigate to and select Params and press Enter .

to navigate to and select Num List and press Enter .

Additional information is provided at the bottom of the display for each parameter

display, including the parameter description (that scrolls continuously), minimum and

maximum values, and if the parameter is read only.

5. Press 1, then 7, and press Enter to display parameter 17 (the OL Warning Level configuration).

The OL Warning Level parameter 17 displays with a value of 80%.

6. Press the SEL

Notice how the configuration value changes to 90% on the display. This value was actually written

to the E1 Plus and has been stored into nonvolatile memory within the device.

, then press 9, 0, and Enter to change the value to 90%.

DNET-QR001A-EN-E – March 2009 12

Page 13

DeviceNet System Quick Reference

Maintain

Diagnostics and Troubleshooting

The 193-DNCT terminal has some diagnostics built in that can be used to troubleshoot a DeviceNet

network. These diagnostics include bus voltages, bandwidth utilization percentage, and CAN error

counts.

1. Press the Down Arrow

2. Press Enter

3. Press the Down Arrow

This dialog box, with similar values, appears on the 193-DNCT terminal.

to select the HIM.

to navigate to Node 62 This DeviceNet HIM.

to navigate to and select the Network group and press Enter .

Baud Rate: 125K

Bus Voltage: 23.90

Bus Voltage Hi: 24.02

Bus Voltage Low: 23.81

Bus % Load: 9.4

Max Bus % Load 16.9

CAN Errors/Sec: 0

The Max Bus % Load and CAN Errors/Sec parameters are not easily measured by other means

and are valuable for troubleshooting the network. The Max Bus % Load parameter shows the

maximum network bandwidth that has ever been used. If this value goes too high, communication

anomalies could occur on the network due to devices being ‘starved’ for bandwidth. The CAN

Errors/Sec parameter is generated if packets are being corrupted on the network, such as due to

electrical noise or a bad device. This value, which should be zero on a healthy network, is a good

barometer of the general health of the DeviceNet packet-delivery mechanism.

DNET-QR001A-EN-E – March 2009 13

Page 14

DeviceNet System Quick Reference

Allen-Bradley, Rockwell Automation, PowerFlex, ControlLogix, CompactLogix, and RSNetWorx for DeviceNet are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication DNET-QR001A-EN-E – March 2009

DNET-QR001A-EN-E – March 2009 14

Copyright©2009 Rockwell Automation, Inc. All rights Reserved. Printed in USA.

Loading...

Loading...