Rockwell Automation DeviceNet Communications for PanelView Plus and PanelView Plus CE User Manual

Page 1

DeviceNet Communications

For PanelView Plus and

PanelPlus CE Terminals

2711P

User Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (publication SGI-1.1

available from your local Rockwell Automation sales office or online at

http://literature.rockwellautomation.com

differences between solid state equipment and hard-wired electromechanical

devices. Because of this difference, and also because of the wide variety of

uses for solid state equipment, all persons responsible for applying this

equipment must satisfy themselves that each intended application of this

equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, Rockwell Automation, Inc. cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to

use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware

of safety considerations.

) describes some important

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information about practices or circumstances that can cause

an explosion in a hazardous environment, which may lead to personal

injury or death, property damage, or economic loss.

Identifies information that is critical for successful application and

understanding of the product.

Identifies information about practices or circumstances that can lead

to personal injury or death, property damage, or economic loss.

Attentions help you identify a hazard, avoid a hazard, and recognize

the consequence

Labels may be on or inside the equipment, for example, a drive or

motor, to alert people that dangerous voltage may be present.

Labels may be on or inside the equipment, for example, a drive or

motor, to alert people that surfaces may reach dangerous

temperatures.

Page 3

Table of Contents

Preface

DeviceNet Overview

Configure the Terminal as a Slave

Device

Configure the Terminal as a

Scanner

About This Publication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Topics Covered. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Hardware and Software Requirements . . . . . . . . . . . . . . . . . . 5

Additional Resources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 1

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

DeviceNet Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Supported Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

DeviceNet Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Module Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Chapter 2

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Sample Network Configuration . . . . . . . . . . . . . . . . . . . . . . 15

Configure Communications . . . . . . . . . . . . . . . . . . . . . . . . . 16

Configure RSNetWorx for DeviceNet Software . . . . . . . . . . . 31

Use RSLogix 5000 Software . . . . . . . . . . . . . . . . . . . . . . . . . 44

Chapter 3

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Configure Communications . . . . . . . . . . . . . . . . . . . . . . . . . 49

Configure RSNetWorx for DeviceNet . . . . . . . . . . . . . . . . . . 60

Use RSLogix 5000 Software . . . . . . . . . . . . . . . . . . . . . . . . . 69

Restore Configuration to Local Tab

Index

Appendix A

Copy Configuration to Local Tab . . . . . . . . . . . . . . . . . . . . . 71

3 Publication 2711P-UM004B-EN-P - March 2007

Page 4

4 Table of Contents

Publication 2711P-UM004B-EN-P - March 2007

Page 5

Preface

About This Publication

Topics Covered

PanelView Plus and PanelView Plus CE terminals with a DeviceNet

communications module support DeviceNet scheduled I/O

communications. This guide will show you how to configure

DeviceNet communications between a PanelView Plus terminal and a

ControlLogix controller.

The PanelView Plus and PanelView Plus CE terminals can operate as a

slave or a scanner on the DeviceNet network. You will learn how to

configure a PanelView Plus terminal as a slave and a scanner using

RSView Studio Machine Edition, RSNetWorx for DeviceNet software,

and RSLogix 5000 programming software.

Chapter 1 Overview of DeviceNet module

Provides an overview of the DeviceNet communication module for

PanelView Plus and PanelView Plus CE devices including supported

controllers and DeviceNet I/O messaging.

Chapter 2 Configure Terminal as a Slave Device

Shows how to configure your PanelView Plus terminal to operate as a

slave device on a DeviceNet network using I/O messaging. The

procedures in this chapter build on the configurations defined in

Chapter 1.

Hardware and Software Requirements

Chapter 3 Configure Terminal as a Scanner

Shows how to configure your PanelView Plus terminal to operate as a

scanner on a DeviceNet network using I/O messaging.

Appendix A Restore Configuration to Local Tab

Shows how to copy the Target tab configuration to the Local tab.

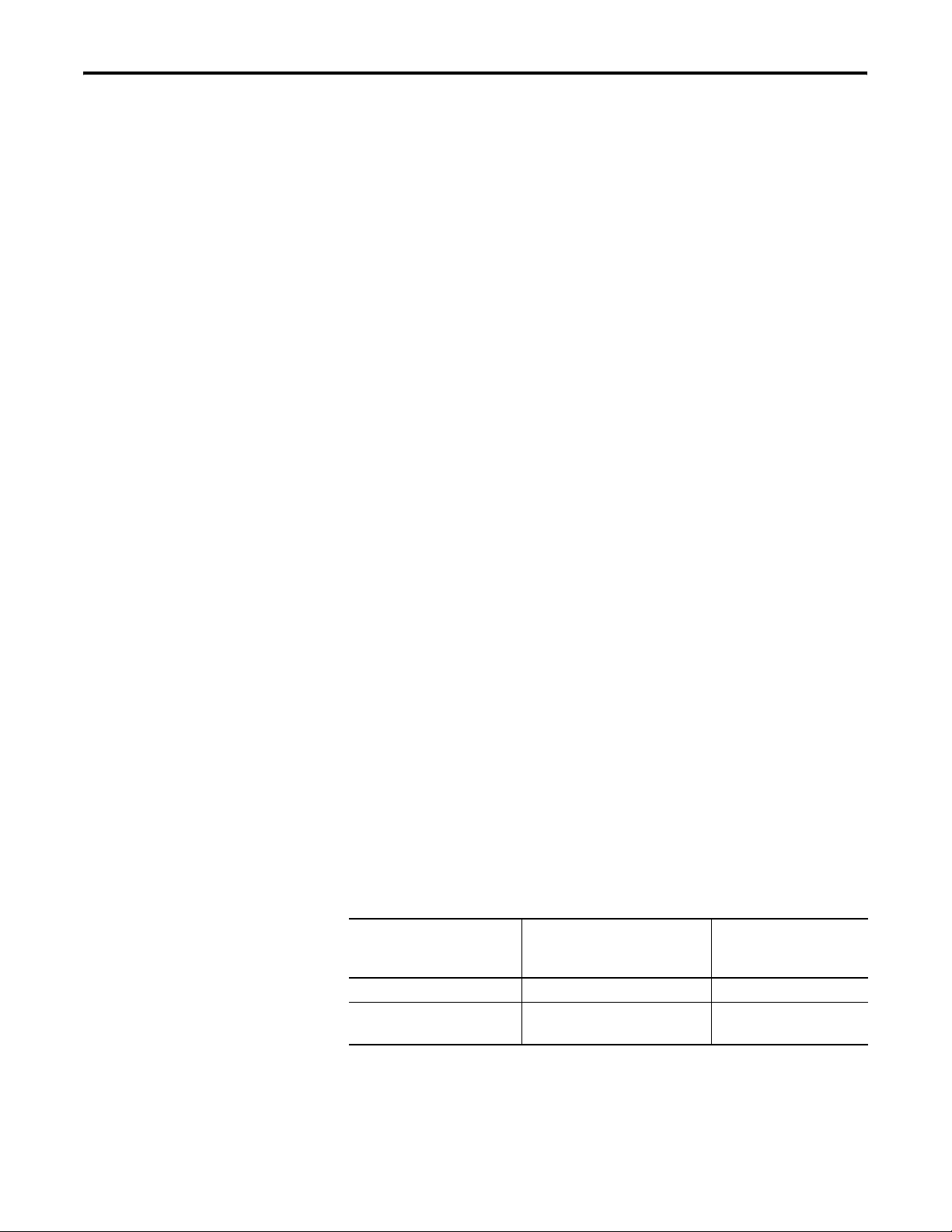

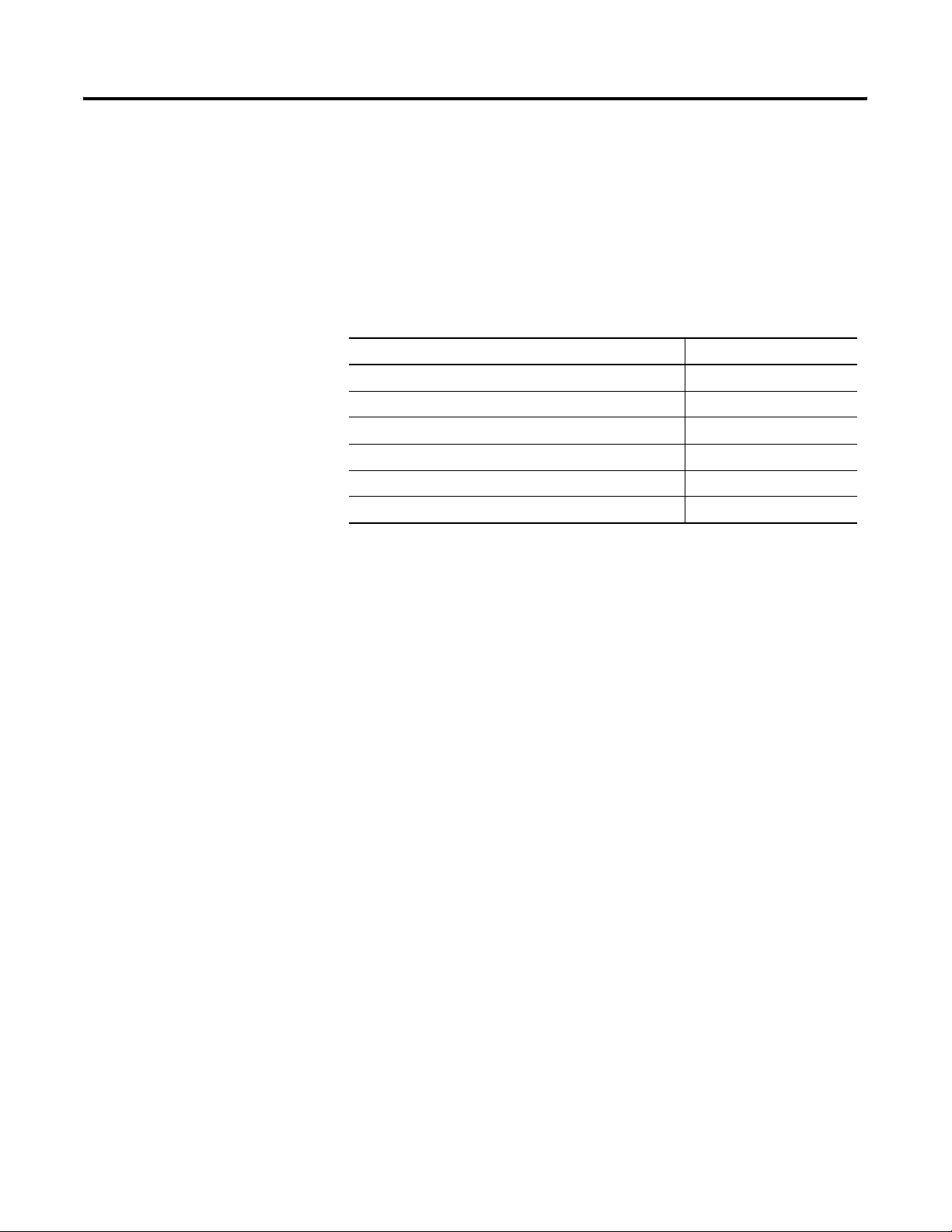

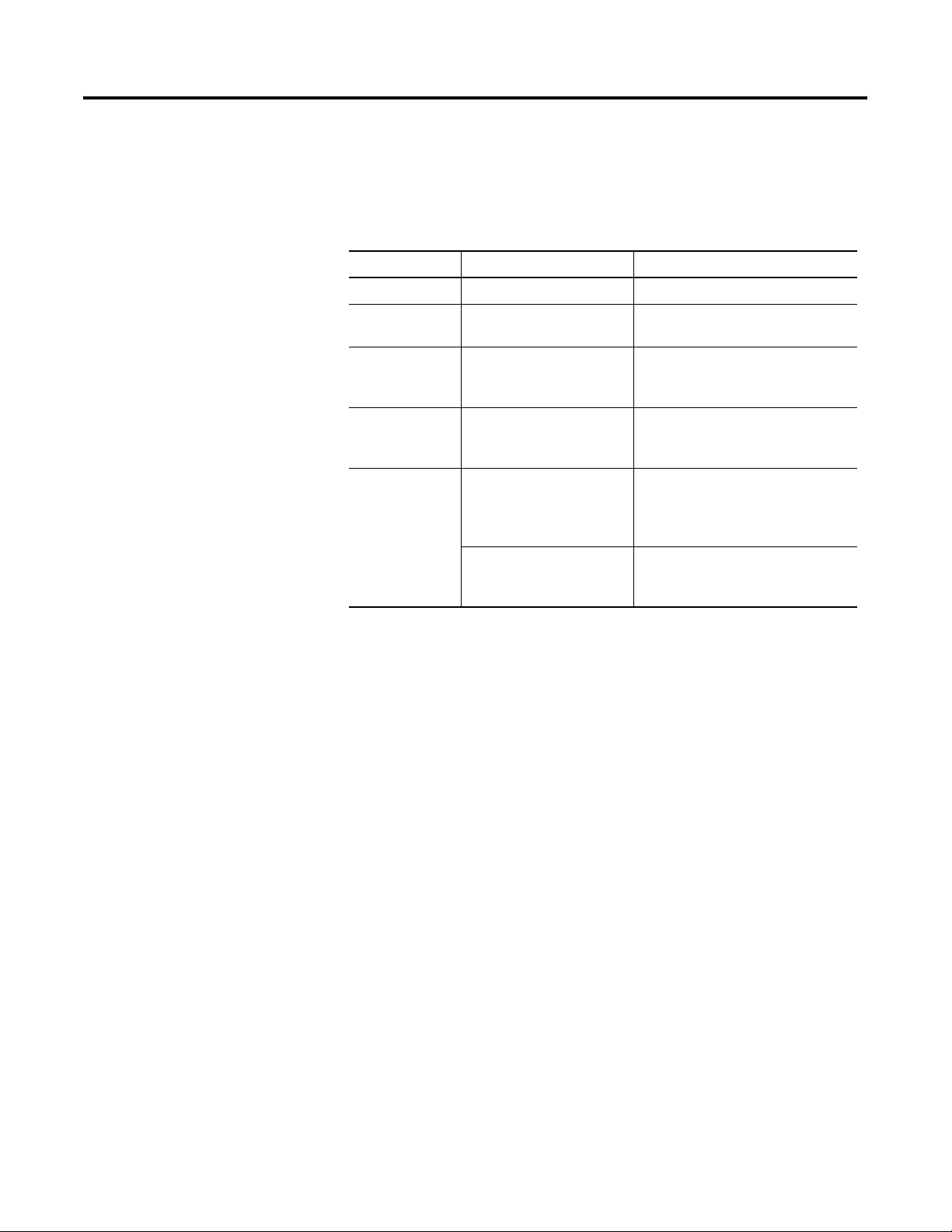

To configure applications for DeviceNet communications, you must

install the appropriate communication module on your PanelView

Plus or PanelView Plus CE terminal. You must also verify that the

correct software and firmware is installed on the development

computer.

PanelView Plus 700 to1500

Hardware and Software

RSView Studio Version 4.0 or later Version 4.0 or later

RSView Machine Edition

Runtime

PanelView Plus CE 700 to

1500

Version 4.0 or later Version 4.0 or later

PanelView Plus

400/600

5 Publication 2711P-UM004B-EN-P - March 2007

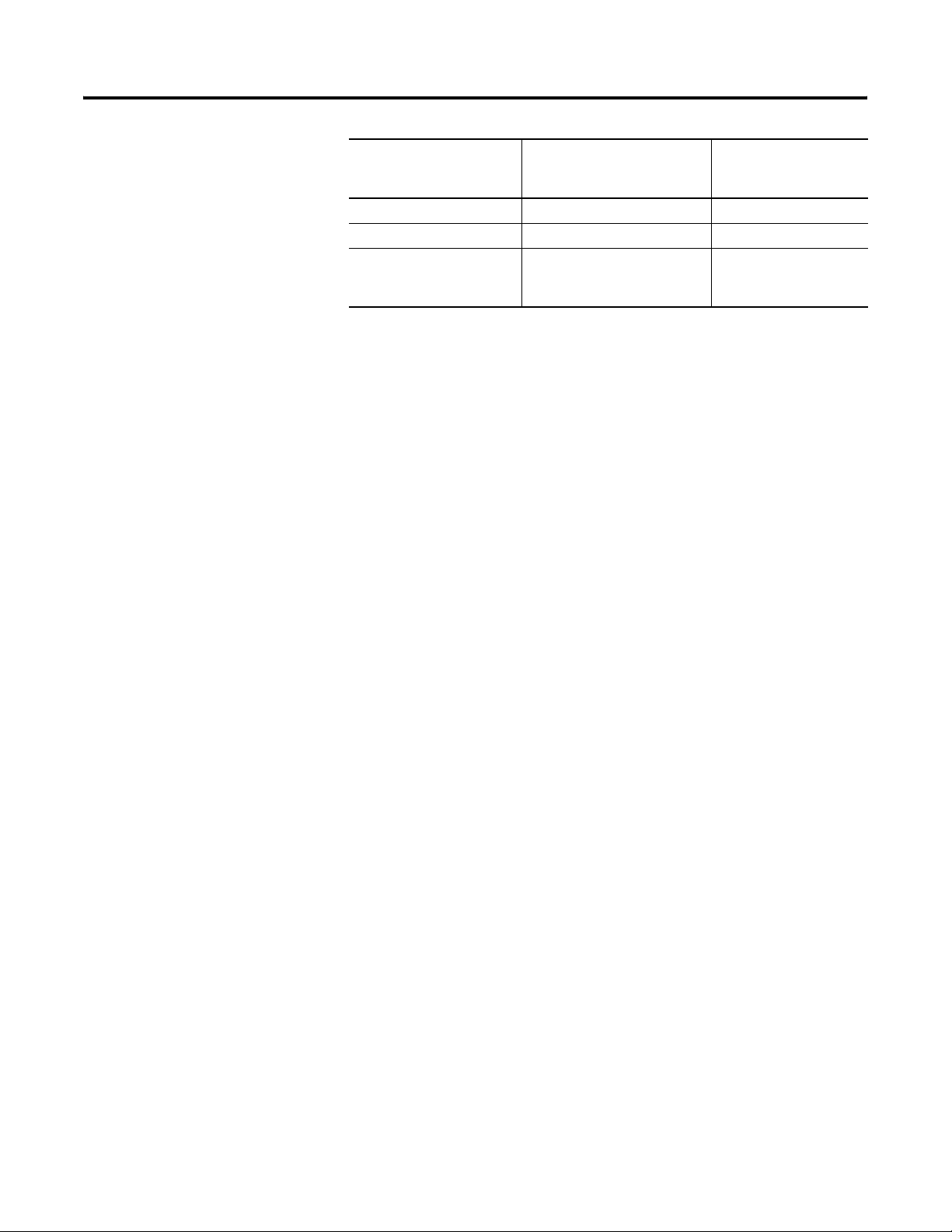

Page 6

6

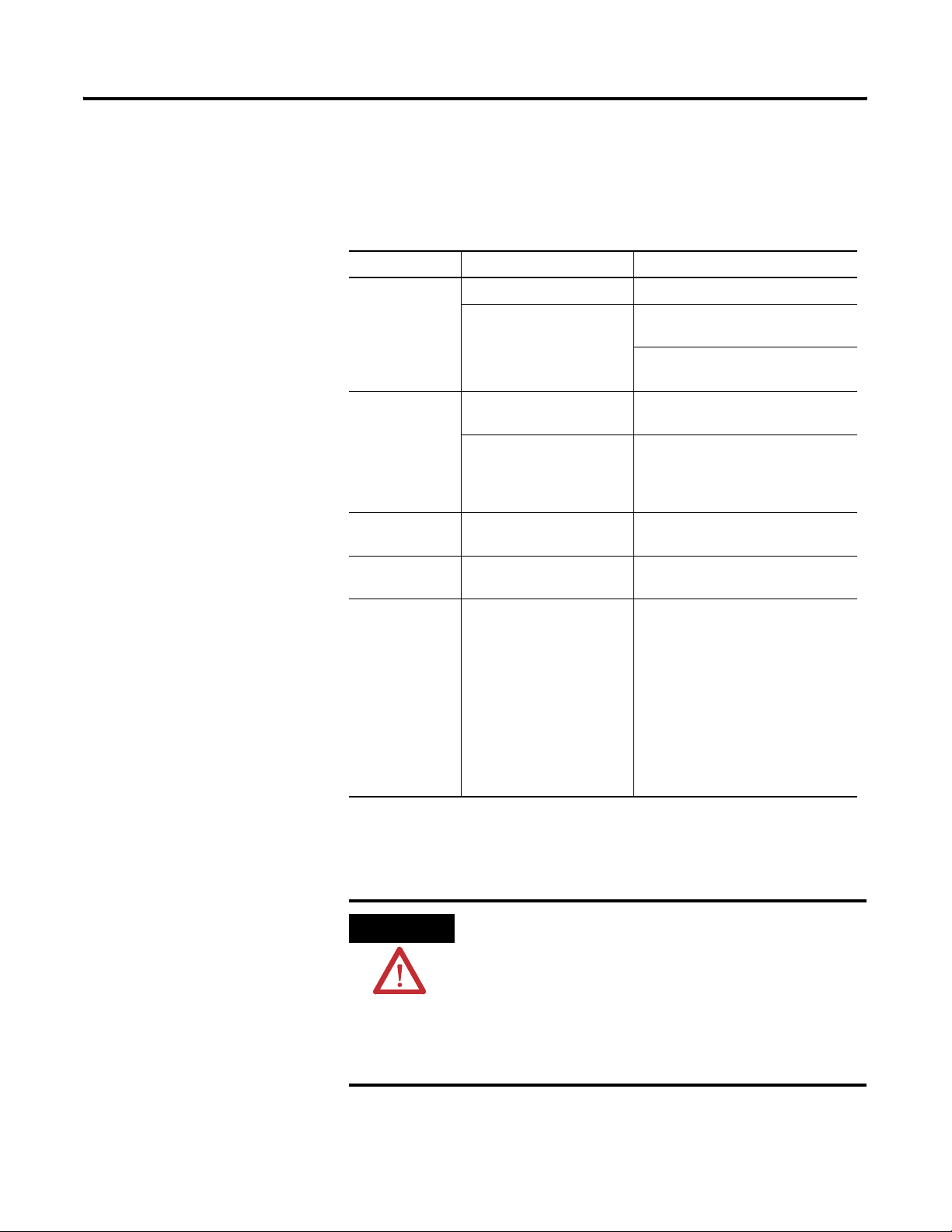

Hardware and Software

PanelView Plus 700 to1500

PanelView Plus CE 700 to

1500

PanelView Plus

400/600

RSNetWorx for DeviceNet Version 6.0 or later V6.0 or later

RSLogix 5000 15.0 or later 15.0 or later

Terminal Communication

Module and Firmware

2711P-RN10H

firmware version 3.16 or later

2711P-RN10C

firmware version 3.16

or later

Publication 2711P-UM004B-EN-P - March 2007

Page 7

7

Additional Resources

For more information on RSView Enterprise or RSView Studio

programming software, refer to the online help.

You can download electronic versions of these publications from the

Rockwell Automation website:

http://www.literature.rockwellautomation.com

Publication Publication Number

PanelView Plus User Manual 2711P-UM001

RSView Machine Edition User Manual ViewME-UM003

DeviceNet Selection Guide DNET-SG001

DeviceNet Media Design Installation Guide DNET-UM072

DeviceNet Tips & Tricks DNET-BR003

Communication Module Installation Instructions 2711P-IN003

Publication 2711P-UM004B-EN-P - March 2007

Page 8

8

Publication 2711P-UM004B-EN-P - March 2007

Page 9

DeviceNet Overview

Chapter

1

Chapter Objectives

DeviceNet Protocol

Supported Controllers

This chapter provides an overview of:

• DeviceNet protocol

• Controller support

• DeviceNet modules

• DeviceNet module indicators

The PanelView Plus or PanelView Plus CE terminals support

DeviceNet I/O only. DeviceNet allows direct connection of devices. It

also provides a control architecture that supports multiple processors.

DeviceNet is a trunk/drop or bus-based network that supports up to

64 nodes and operates at 125, 250, or 500 Kbps.

A PanelView Plus or PanelView Plus CE terminal with a DeviceNet

communication module can connect with other devices. Typical

controllers supported include:

• 1756-DNB module for the Control Logix network

• 1771-SDN module for the PLC-5 network

• 1747-SDN module for the SLC 5/03 to SLC 5/05 network

DeviceNet Module

9 Publication 2711P-UM004B-EN-P - March 2007

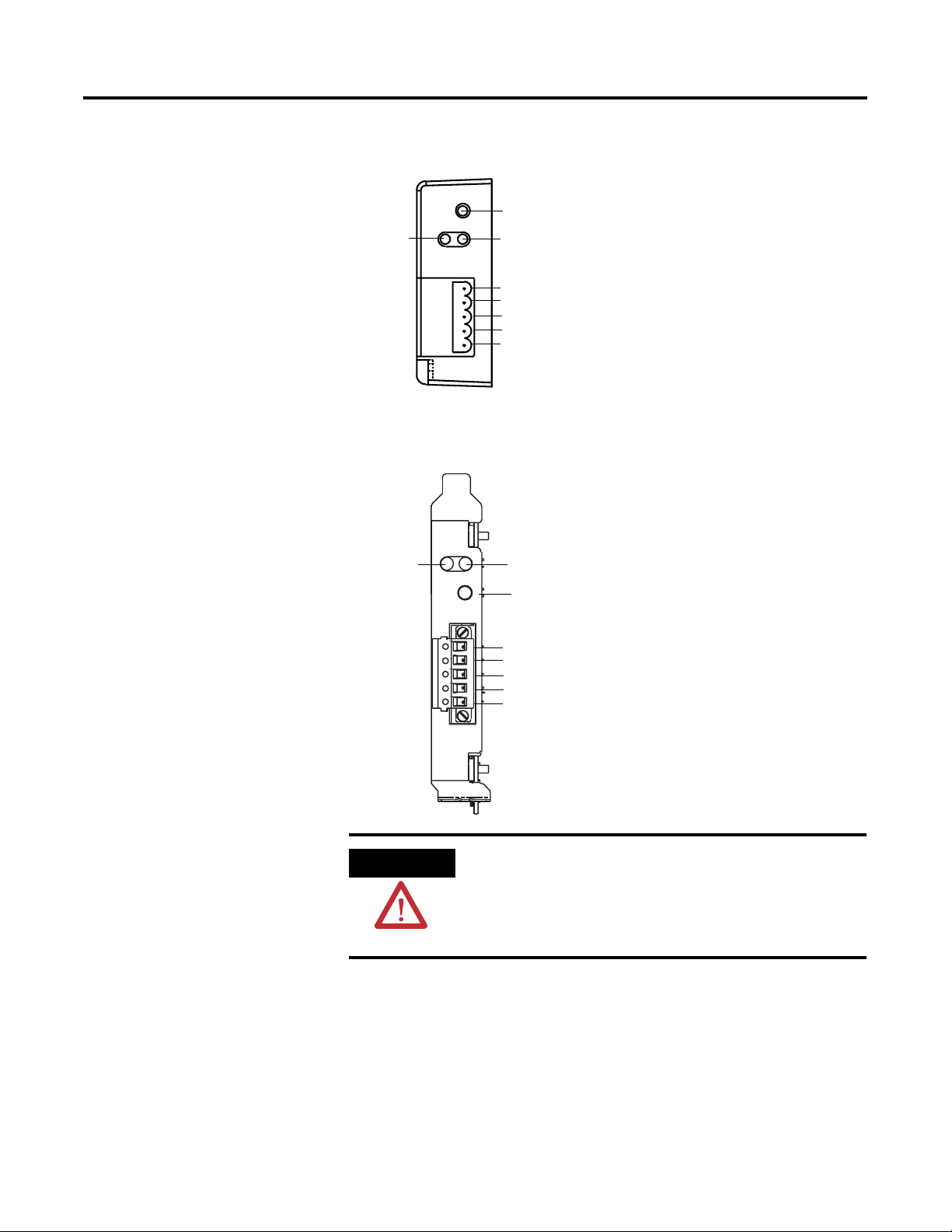

There are two DeviceNet communication modules:

• 2711P-RN10C for PanelView Plus 400 and 600 terminals

• 2711P-RN10H for PanelView Plus and PanelView Plus CE 700

to 1500 terminals

For details how to install the modules on the terminals, refer to the

2711P-IN003 installation instructions that ship with the module.

ATTENTION

The DeviceNet network is not supported on a personal

computer running RSView Machine Edition software.

Page 10

10 DeviceNet Overview

2711P-RN10C DeviceNet Module for 400 and 600 Terminals

I/O Status Indicator

NET Status

Indicator

MOD Status Indicator

Red

White

Shield

Blue

Black

2711P-RN10H DeviceNet Module for 700 to 1500 Terminals

NET Status

Indicator

WARNING

MOD Status Indicator

I/O Status Indicator

Red

White

Shield

Blue

Black

Do not connect or disconnect any communication cable with

power applied to this device or any device on the network. An

electrical arc could cause an explosion in hazardous location

installations. Be sure that power is removed or the area is

nonhazardous before proceeding.

Publication 2711P-UM004B-EN-P - March 2007

Page 11

DeviceNet Overview 11

Module Indicators

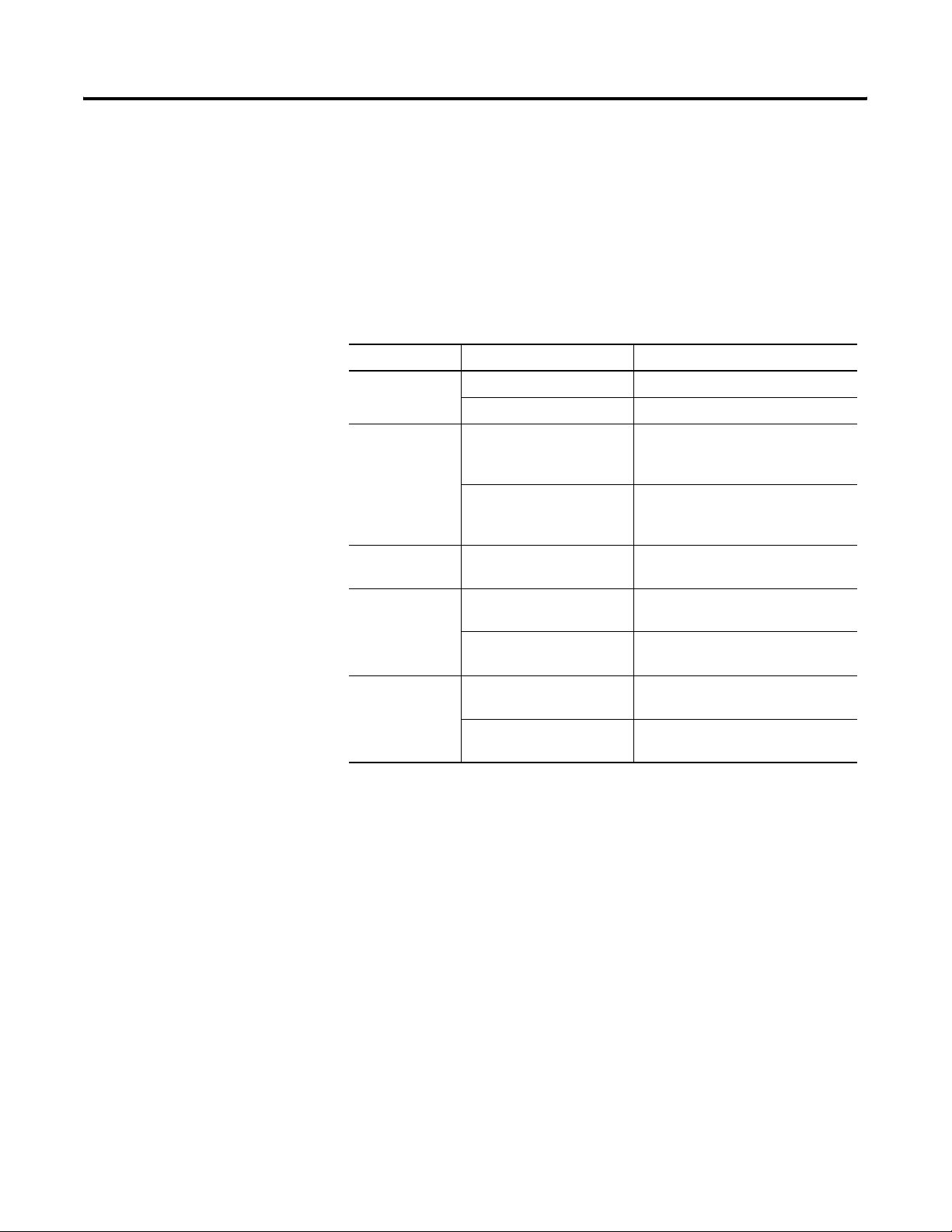

The DeviceNet communication modules have three indicators:

Network Status, I/O Status, Module Status.

DeviceNet I/O Status Indicator

This bi-color (green/red) LED provides information on the states of

inputs and outputs.

Condition Status Indication

Off Outputs active All outputs are active.

Inputs active All inputs are active.

Green Outputs active One or more outputs are active and

under control, and no outputs are

faulted.

Inputs active One or more inputs are active and

producing data, and no inputs are

faulted.

(1)

Flashing green

Flashing red

Outputs idle One or more outputs are idle, and no

outputs are active or faulted.

(1)

Outputs faulted One or more outputs are faulted, and

may be in the fault state.

Inputs faulted One or more inputs are faulted, and

may be in the fault state.

Red Outputs forced off One or more outputs are forced off

(may be an unrecoverable fault).

Input unrecoverable fault One or more inputs has an

unrecoverable fault.

(1)

The flash rate of the LED is approximately 1 flash per second. The LED should be on for approximately 0.5

seconds and off for approximately 0.5 seconds.

Publication 2711P-UM004B-EN-P - March 2007

Page 12

12 DeviceNet Overview

DeviceNet Module (MOD) Status Indicator

This bi-color (green/red) LED provides device status. It indicates

whether or not the device has power and is operating properly.

Condition Status Indication

Off No power No power applied to device.

Green Device operational Device is operating in a normal

condition.

(1)

Flashing green

Device in standby

(device needs

commissioning)

(1)

Flashing red

Recoverable fault For example, the device’s scan list

Red Unrecoverable fault Device has an unrecoverable fault.

Device needs commissioning due to

configuration missing, incomplete, or

incorrect.

configuration does match the actual

network configuration.

Cycle power to your computer. If the

problem persists, the device may

need to be replaced.

Device self testing Device is in self test. Refer to the

DeviceNet Specification, Volume II,

Identity Object.

(1)

The flash rate of the LED is approximately 1 flash per second. The LED should be on for approximately 0.5

seconds and off for approximately 0.5 seconds.

Publication 2711P-UM004B-EN-P - March 2007

Page 13

DeviceNet Overview 13

DeviceNet Network (NET) Status Indicator

This bi-color (green/red) LED indicates the status of the

communication link.

Condition Status Indication

Off Not powered Device is not online.

Not online The device has not completed the

Dup_MAC_ID test yet.

The device may not be powered; look

at the Module Status LED.

(1)

Flashing green

Green Link okay, online, connected The device is online and has

Flashing red

Red Critical link failure Failed communication device. The

Online Device is online, but has no

connections in the established state.

Not connected The device has passed the

Dup_MAC_ID test, is online, but has

no established connections to other

nodes.

connections in the established state.

(1)

Connection timeout One or more I/O connections are in

the timed-out state.

device has detected an error that has

rendered it incapable of

communicating on the network

(Duplicate MAC ID or Bus-off).

Check network integrity and

communication rate of all devices.

Then cycle power to the card by

shutting down and cycling power to

your computer.

(1)

The flash rate of the LED is approximately 1 flash per second. The LED should be on for approximately 0.5

seconds and off for approximately 0.5 seconds.

ATTENTION

Extensive use of change-of-state connections, particularly with

rapidly changing data, can adversely impact the available

DeviceNet network bandwidth. If the network bandwith

becomes consumed, some devices may only be able to

communicate intermittently. This can result in timeout errors

and possible loss of data. If timeouts occur, consider changing

the connection type for some of the change-of-state

connections to cyclic or polled.

Publication 2711P-UM004B-EN-P - March 2007

Page 14

14 DeviceNet Overview

Publication 2711P-UM004B-EN-P - March 2007

Page 15

Chapter

Configure the Terminal as a Slave Device

2

Chapter Objectives

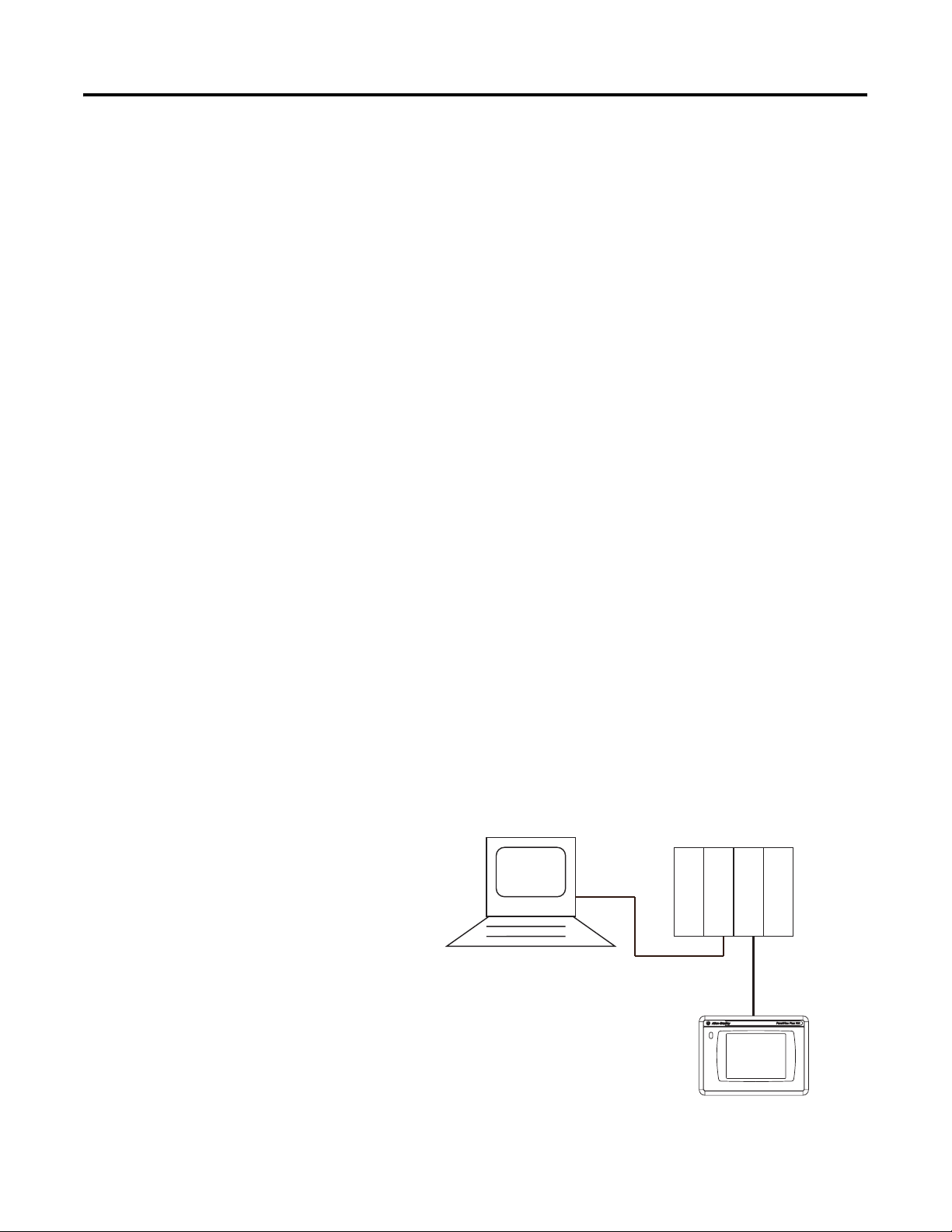

Sample Network Configuration

The procedures in this chapter will show you how to configure a

PanelView Plus terminal to operate as a slave device on a DeviceNet

network. A ControlLogix processor with a 1756-DNB DeviceNet

module will scan inputs and outputs from the PanelView Plus

terminals.

You will learn how to:

• configure communications for the PanelView Plus terminal and

1756-DNB module using RSLinx Enterprise software in RSView

Studio software.

• create a DeviceNet configuration using RSNetWorx for

DeviceNet software.

• add the DeviceNet module I/O configuration to the ControlLogix

tag database using RSLogix 5000 software.

The example configures DeviceNet I/O messaging for a numeric input

and numeric output from a PanelView Plus terminal to a 1756-L63

ControlLogix processor, version 15.0.

• The PanelView Plus terminal has a network node address of 2.

• 1756-L63 ControlLogix processor, version 15.0, in slot 0

communicates via the 1756-DNB DeviceNet scanner module at

network node address 1 in slot 2.

1756-DNB Scanner

Node 2

L

6

3

PanelView Plus with

DeviceNet module

Ethernet

Network

RSLogix 5000 network

RSNetWorx network

RSView Studio network

15 Publication 2711P-UM004B-EN-P - March 2007

Node 1

E

N

B

T

D

N

B

DeviceNet

Cable

Page 16

16 Configure the Terminal as a Slave Device

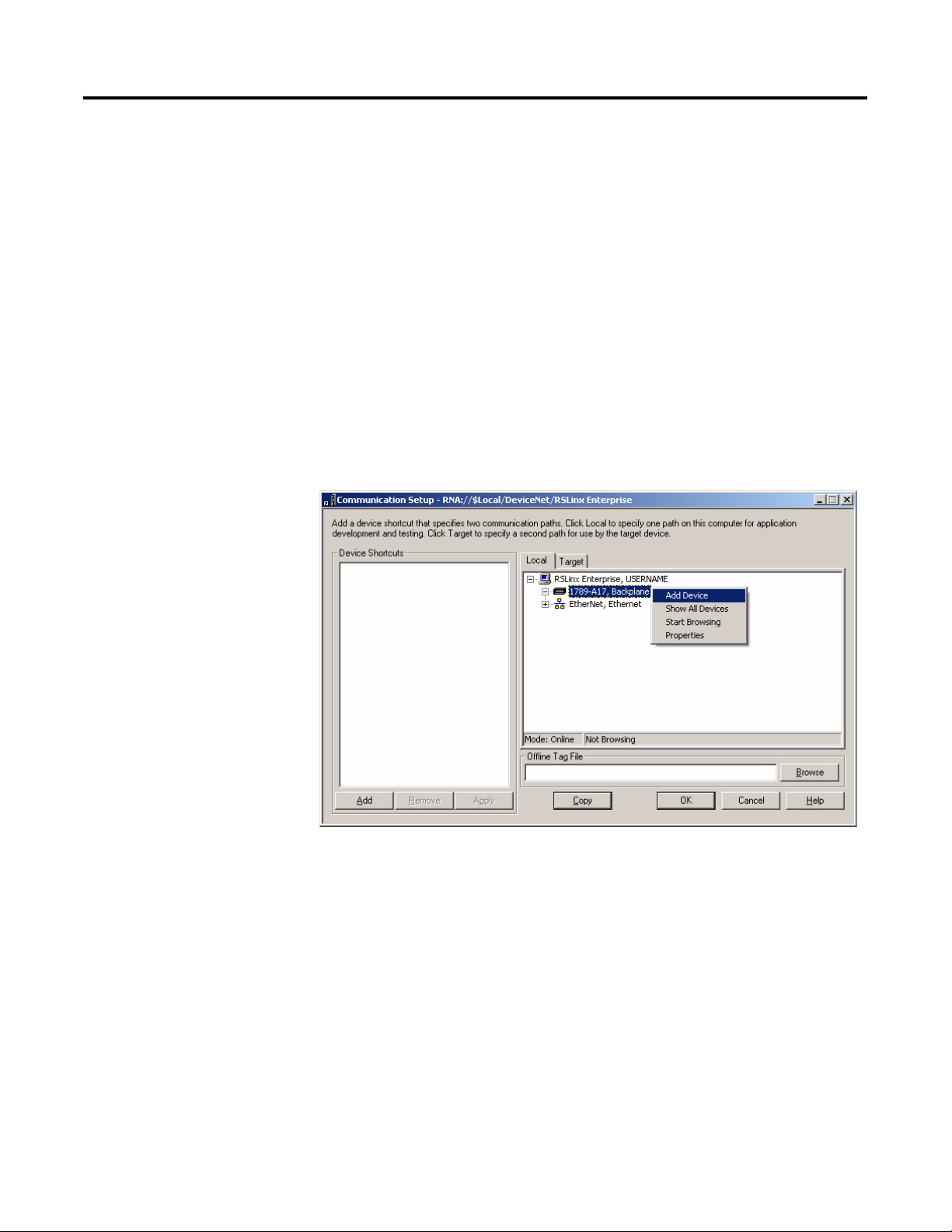

Configure Communications

After creating your Machine Edition application, you are ready to

configure communications using RSLinx Enterprise software.

1. Open RSView Studio software.

2. In the Application Explorer dialog, double-click RSLinx

Enterprise software to expand the tree.

3. Double-click Communication Setup.

4. If prompted, select Create a New Configuration and click Finish.

5. On the Local tab, right-click the 1789-A17 Backplane icon and

select Add Device.

This is the virtual backplane of the PanelView Plus or PanelView

Plus CE device.

Publication 2711P-UM004B-EN-P - March 2007

Page 17

Configure the Terminal as a Slave Device 17

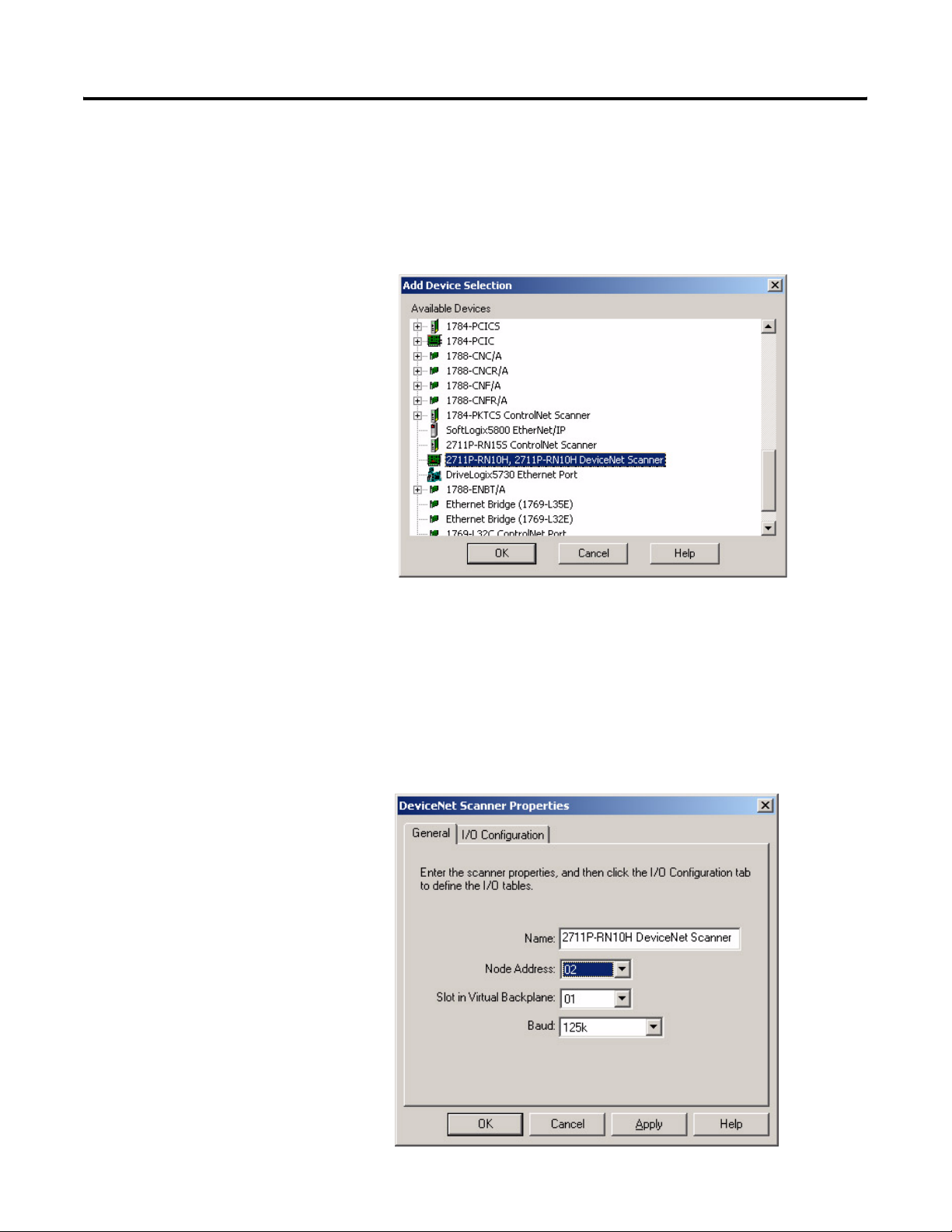

6. In the Add Device Selection dialog, select the communications

card appropriate for your terminal size and click OK.

• The correct card for the PanelView Plus 400 and 600 terminals

is 2711P-RN10C.

• The correct card for the PanelView Plus 700-1500 terminals is

2711P-RN10H.

7. Set the node address to 2, the communication rate to match the

1756-DNB DeviceNet module, and click OK.

The General tab of the DeviceNet Scanner Properties dialog

specifies the name, node address, virtual backplane slot, and

communication rate of the DeviceNet scanner. The virtual

backplane of the PanelView Plus has two slots. Because the

terminal resides in slot 0, the DeviceNet scanner is automatically

assigned to slot 1.

Publication 2711P-UM004B-EN-P - March 2007

Page 18

18 Configure the Terminal as a Slave Device

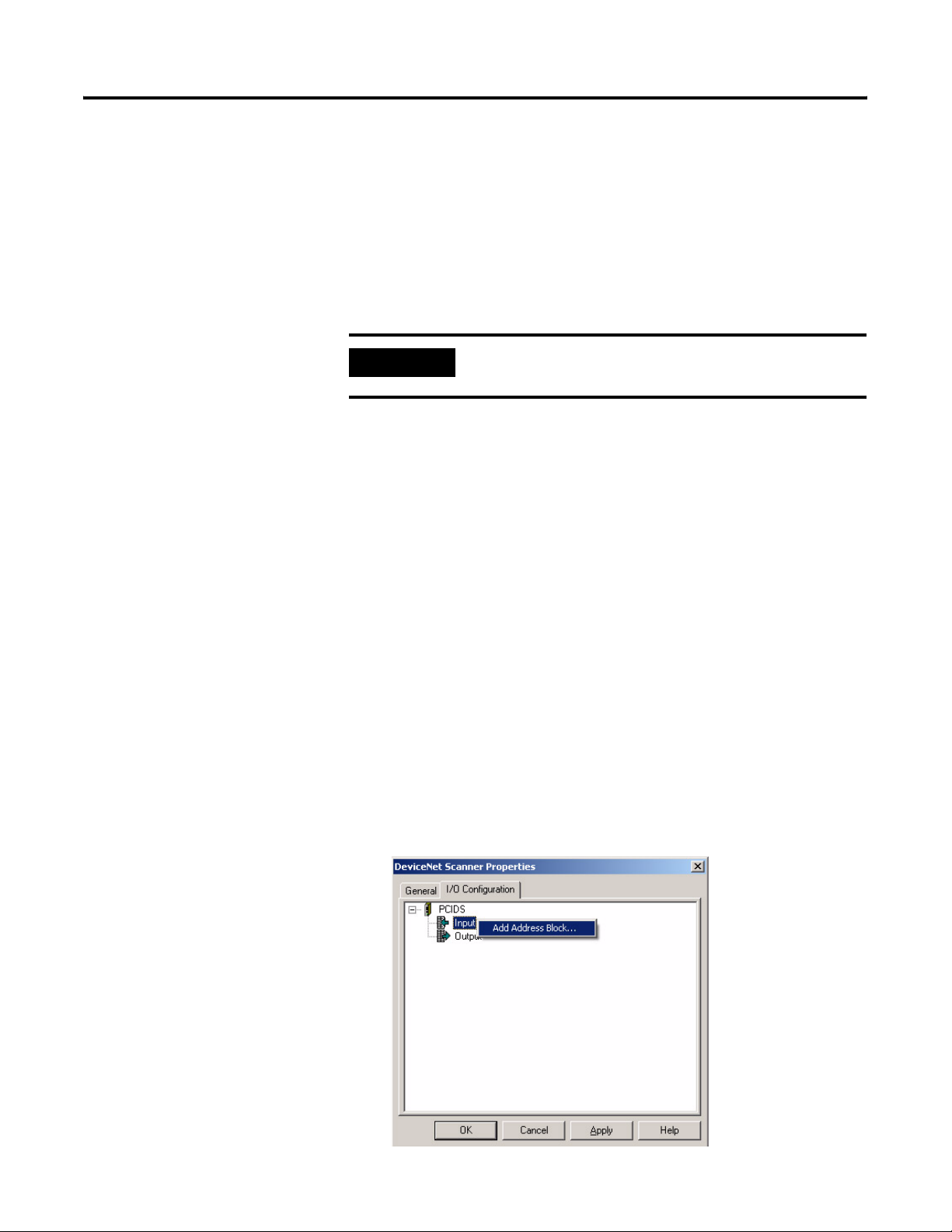

Configure the Slave Inputs and Outputs

You are now ready to configure the slave inputs and outputs in the

PanelView Plus terminal. For the example used in this chapter, the

1756-DNB DeviceNet module will scan these inputs and outputs.

• One DINT or 4 bytes of input data

• One DINT or 4 bytes of output data

IMPORTANT

What differentiates the PanelView Plus terminal as a slave or a scanner

is the node you specify for each block of data. The device you

configure data for via the I/O Configuration tab is the slave on the

network. If the device node matches the node address for the

PanelView Plus terminal, then it will operate as a slave. In this

example, the node address is 2.

Typically these address blocks will be larger. Minimize the

number of address blocks going to a single device.

Definition of Inputs and Outputs

Inputs and outputs are in reference to the PanelView Plus DeviceNet

module and correspond to RSNetWorx terminology. In other words,

the output of a controller is an input to the PanelView Plus terminal.

RSView ME software can read inputs and outputs, but only write to

outputs configured in the PanelView Plus terminal.

Configure the Slave Input Data

Publication 2711P-UM004B-EN-P - March 2007

1. On the I/O Configuration tab, right-click the Input icon and

select Add Address Block.

Page 19

Configure the Terminal as a Slave Device 19

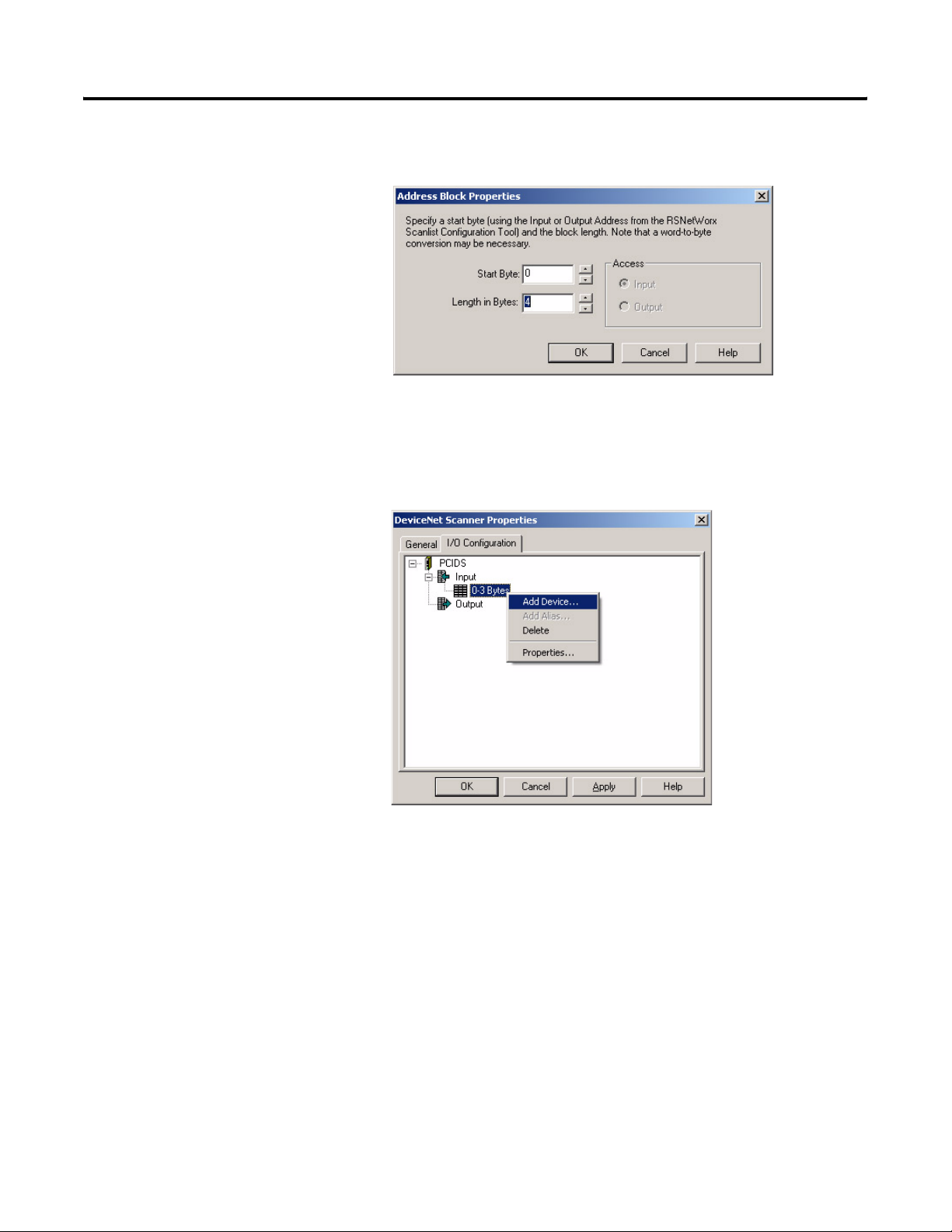

2. In the Address Block Properties dialog, set the Start Byte to 0,

Length in Bytes to 4, and click OK.

The address block 0-3 Bytes is added under Inputs.

3. Right-click on the new address block 0-3 Bytes and select Add

Device to define the PanelView Plus terminal as the slave for the

input address block.

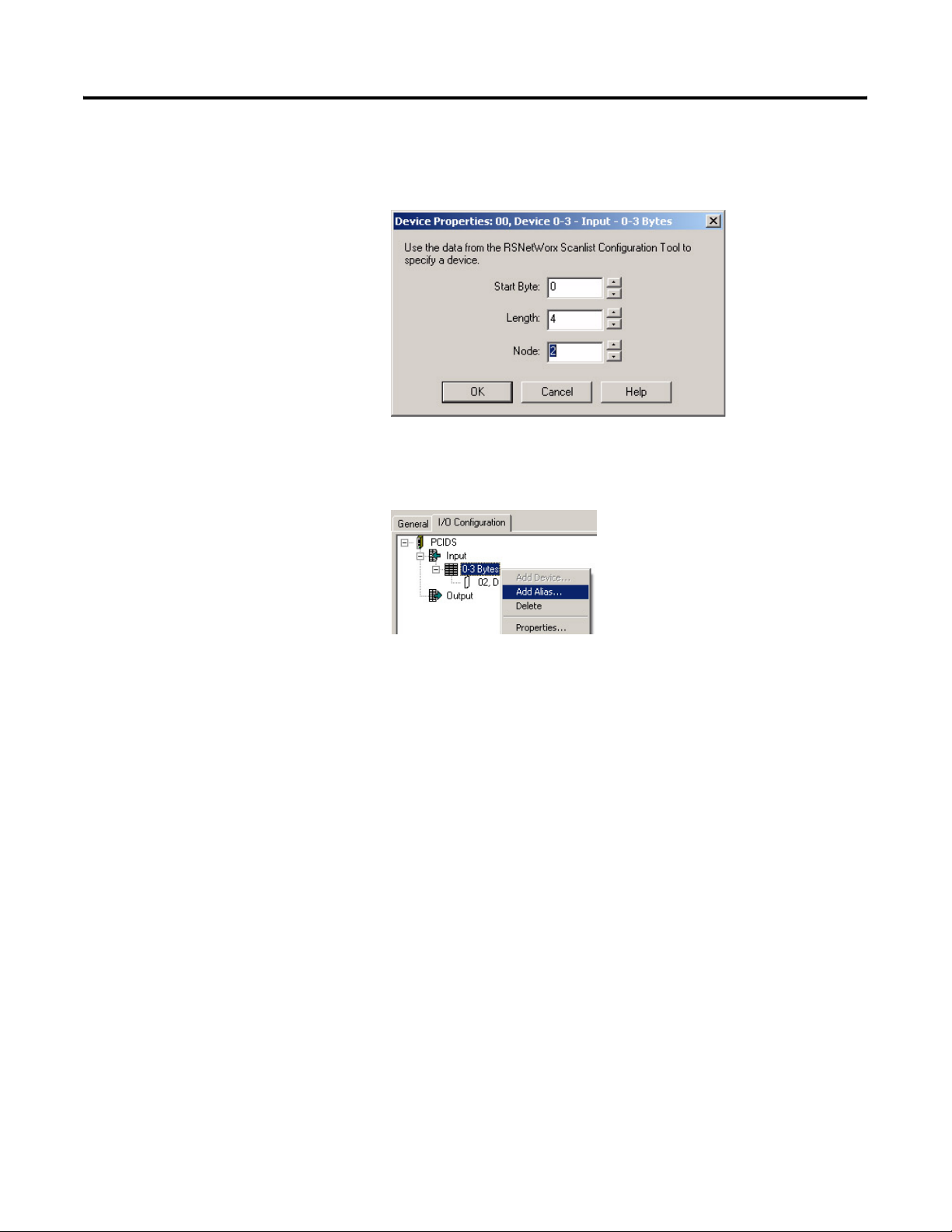

4. In the Device Properties dialog of the input address block, select

Node 2 and click OK.

Publication 2711P-UM004B-EN-P - March 2007

Page 20

20 Configure the Terminal as a Slave Device

Because the device node is the same node as the PanelView

Plus terminal, Node 2 will operate as a slave for the input data.

The 1756-DNB scanner will scan this data.

A dimmed icon appears under the Input address block for

Device 02. This indicates the PanelView Plus terminal is the

slave.

Publication 2711P-UM004B-EN-P - March 2007

Page 21

Configure the Terminal as a Slave Device 21

Create an Input Alias

To make connections to objects, aliases are required. You must create

an alias for the input address block. The aliases serve as the

connection reference you select in RSView Studio software.

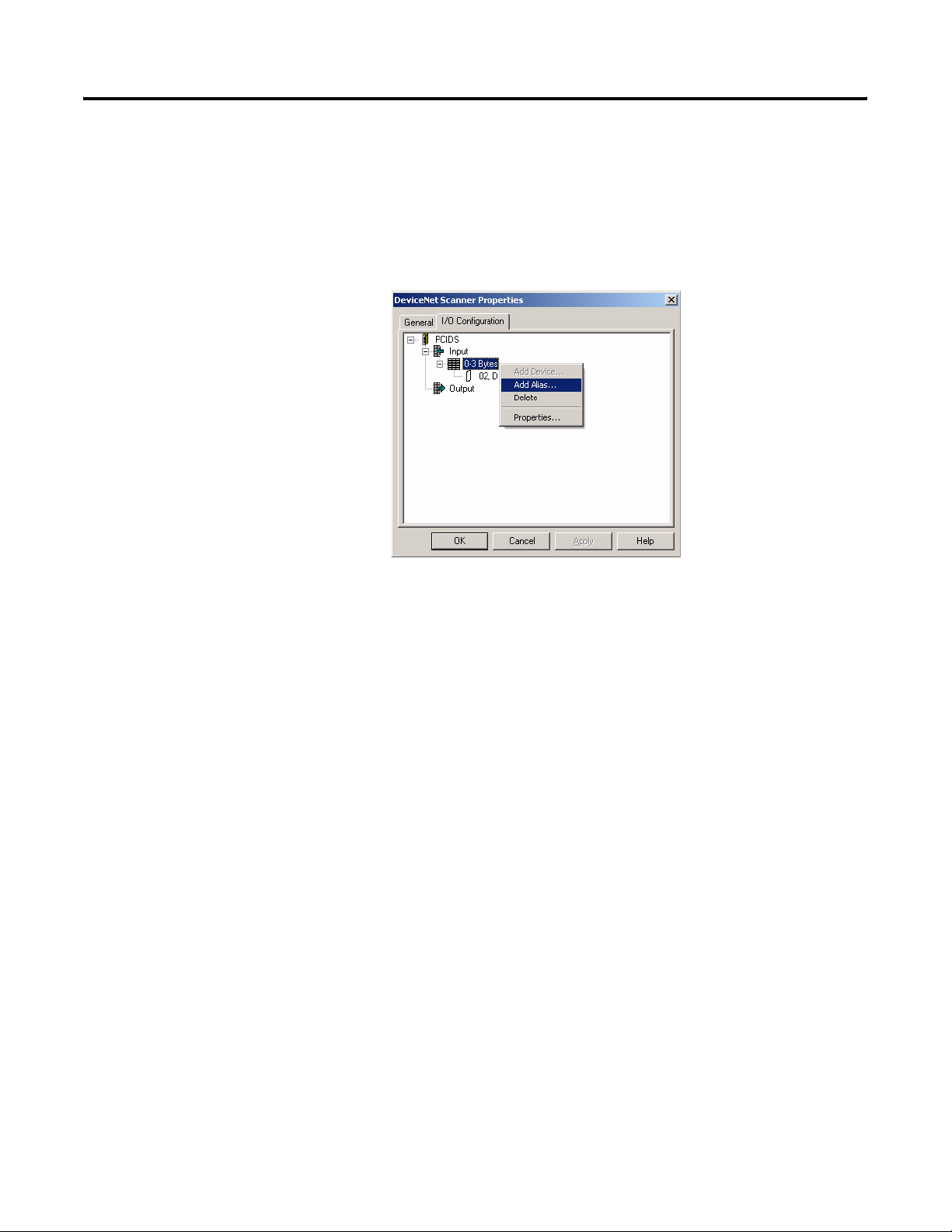

1. Right-click the 0-3 Bytes icon and select Add Alias.

2. In the Alias Properties dialog, select these properties and click

OK to add the alias to the input address block:

• Alias Data Type = DINT

• Alias Name = Slave_Input

• Start Byte = 0

• Array Count = 1

Publication 2711P-UM004B-EN-P - March 2007

Page 22

22 Configure the Terminal as a Slave Device

The Array Count lets you quickly configure multiple aliases with

the same prefix.

Swapping of bytes or words is necessary for some controllers

such as SLC controller. Refer to Help for more information.

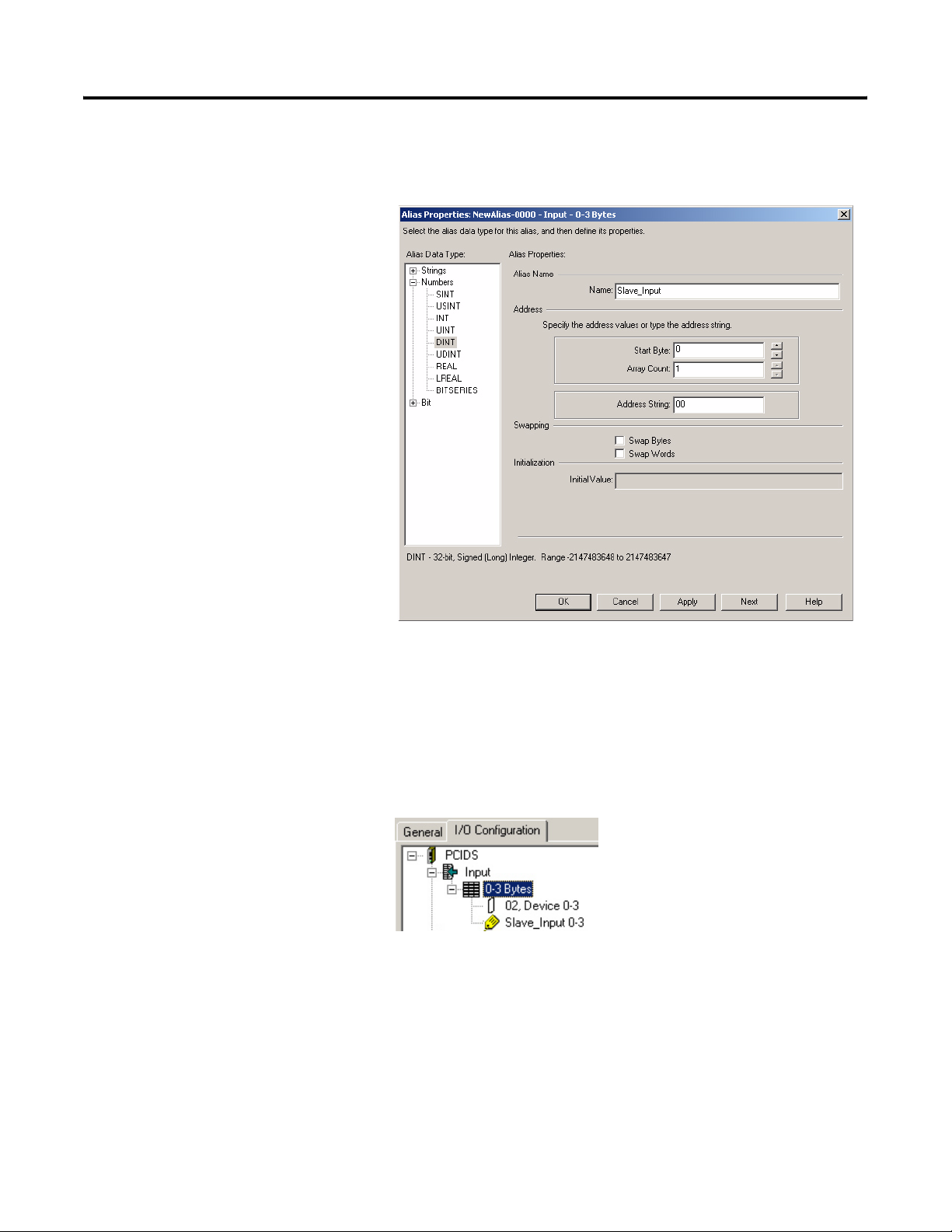

The slave input is now configured with:

• Address length of 4 bytes, starting at byte 0

• Slave device at node 2, which is the PanelView Plus terminal

• Alias of Slave_Input for the input address block

Publication 2711P-UM004B-EN-P - March 2007

Page 23

Configure the Terminal as a Slave Device 23

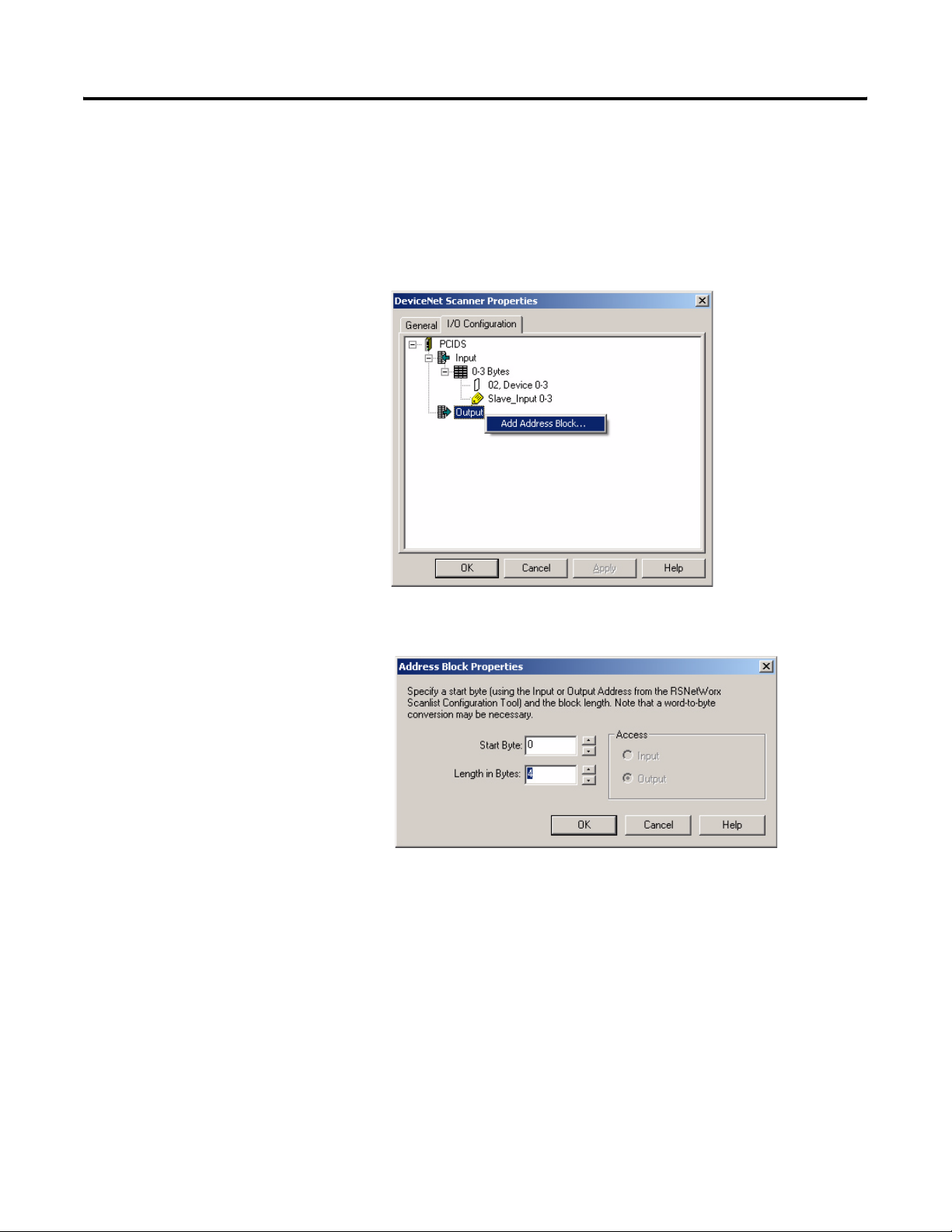

Configure the Slave Output Data

Follow the same procedure to add a slave output block to the I/O

configuration. The 1756-DNB DeviceNet scanner will scan this output.

1. On the I/O Configuration tab, right-click the Output icon and

select Add Address Block.

2. In the Address Block Properties dialog, set the Start Byte to 0,

Length in Bytes to 4, and click OK.

The address block 0-3 Bytes is added under Outputs.

Publication 2711P-UM004B-EN-P - March 2007

Page 24

24 Configure the Terminal as a Slave Device

3. Right-click the new address block 0-3 Bytes and select Add

Device to define the PanelView Plus terminal as the slave for the

output address block.

4. In the Device Properties dialog for the output address block,

select Node 2 and click OK.

Similar to the input data, the PanelView Plus terminal will

operate as a slave for the output data. The 1756-DNB scanner

will scan this output data.

A dimmed icon appears under the Output address block for

Device 02 . This indicates the PanelView Plus terminal is the

slave.

Publication 2711P-UM004B-EN-P - March 2007

Page 25

Configure the Terminal as a Slave Device 25

Create an Output Alias

To make connections to objects, aliases are required. Similar to the

input alias, you must create an alias for the output block.

1. Right-click the 0-3 Bytes icon under Output and select Add Alias.

2. In the Alias Properties dialog, select these properties and then

click OK to add the alias to the output address block:

• Alias Data Type = DINT

• Alias Name = Slave_Output

• Start Byte = 0

• Array Count = 1

• Initial Value = 0

If you do not enter an initial value, a warning message

indicates that default values will be used.

Publication 2711P-UM004B-EN-P - March 2007

Page 26

26 Configure the Terminal as a Slave Device

The slave output is now configured with the following information:

• Address length of 4 bytes, starting at byte 0.

• Slave device on node 2, which is the PanelView Plus terminal.

• Alias of Slave_Output for the output address block.

3. Click OK to save the configuration.

Create a Shortcut

The Local tab in the Communciation Setup allows the aliases you

created to be browsed from within RSView Studio software. It also lets

you to test run the application on a PC with a 1784-PCIDS DeviceNet

PCI Communication Interface card.

ATTENTION

Create a shortcut for the PanelView Plus communication setup and

apply it the DeviceNet driver that was added to the backplane.

1. From the Communication Setup dialog click Add.

DeviceNet network is not supported on a PC running

RSView Machine Edition software.

Publication 2711P-UM004B-EN-P - March 2007

2. For this example, enter DNET as the name of the shortcut.

Page 27

Configure the Terminal as a Slave Device 27

3. With the new shortcut selected and while on the Local tab,

select the 2711P-RN10H DeviceNet Scanner.

4. Click Apply.

The shortcut has been applied to the DeviceNet driver.

Publication 2711P-UM004B-EN-P - March 2007

Page 28

28 Configure the Terminal as a Slave Device

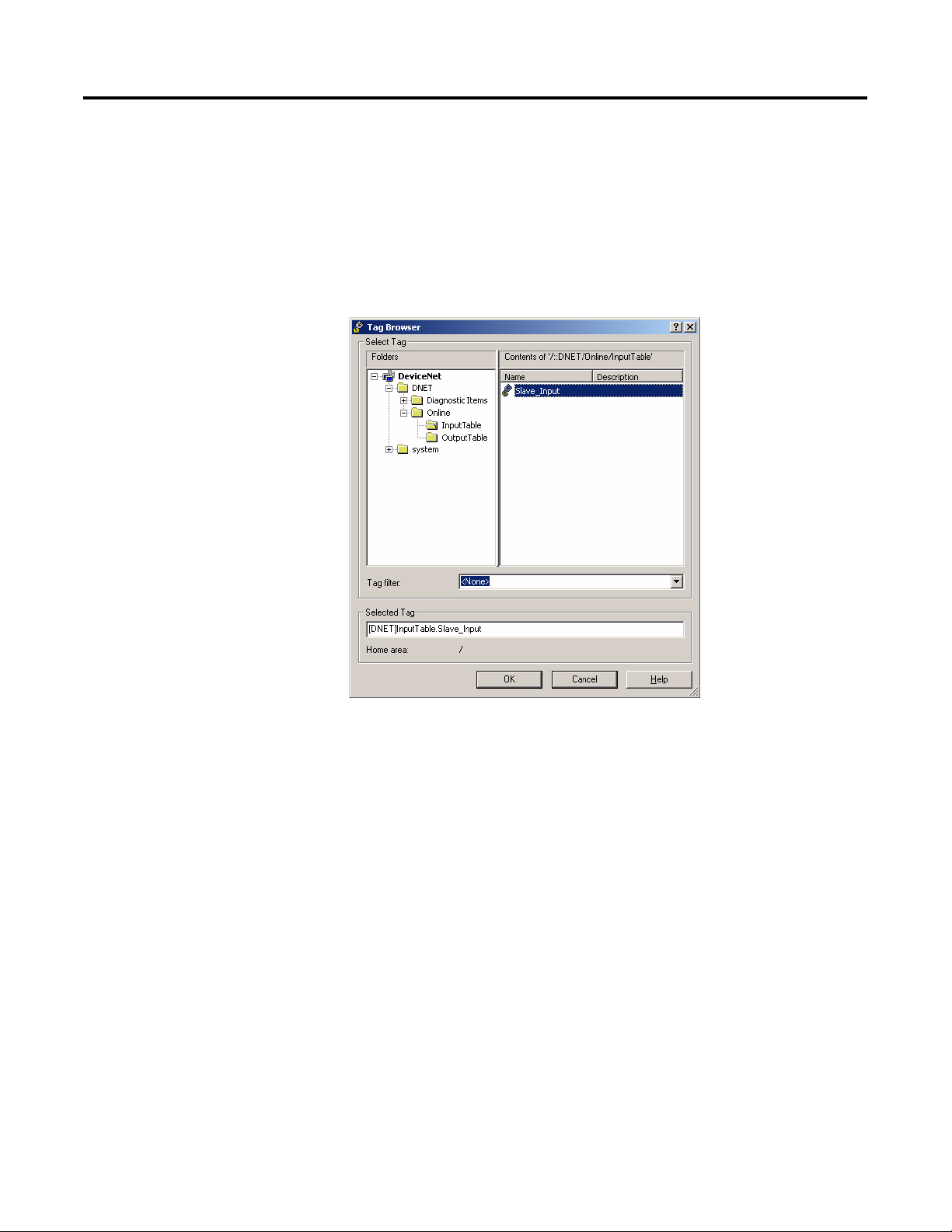

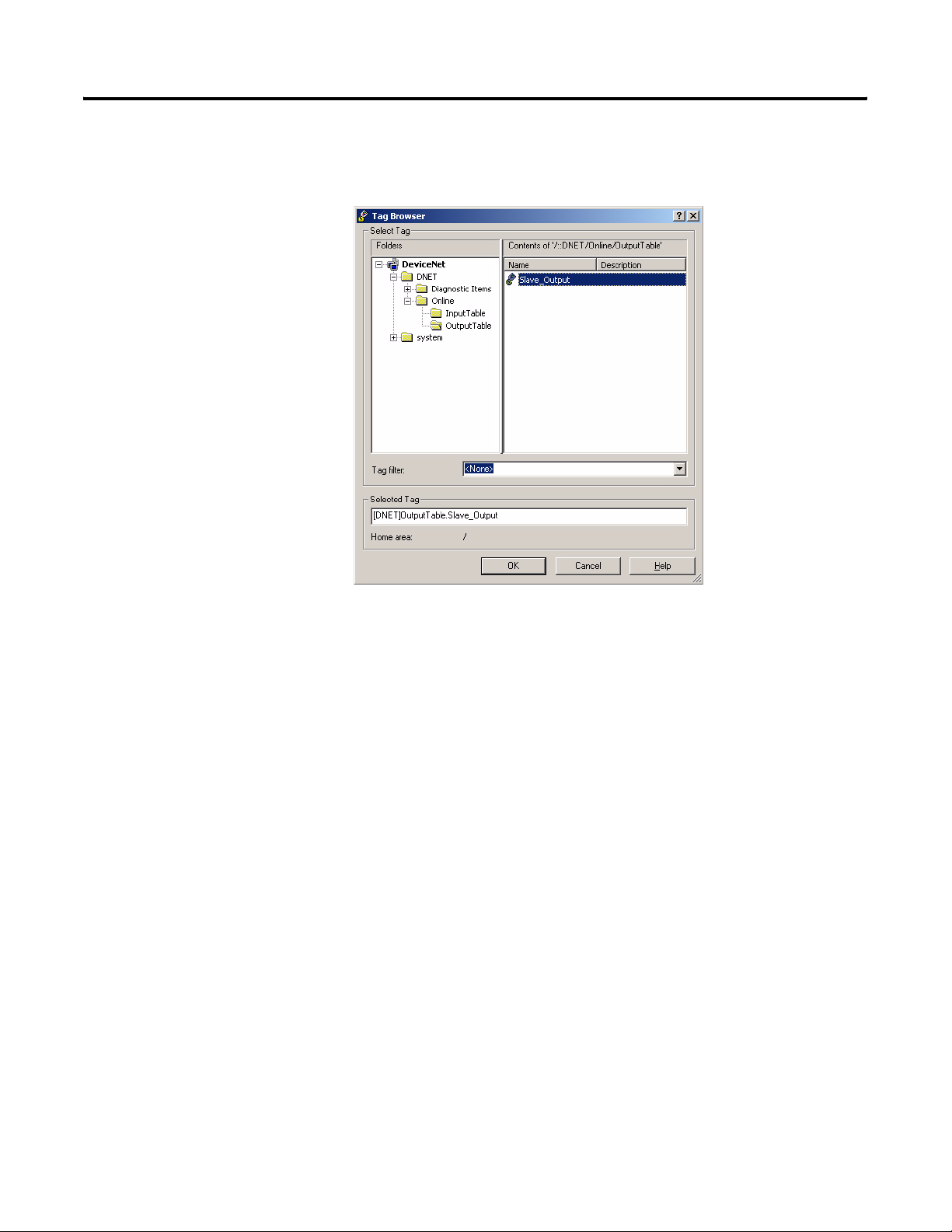

Browse for Tags

While you are creating an RSView Machine Edition application, you

will be creating objects and assigning tags in the Connection tab.

The structure of the DeviceNet Input Table looks like this when

browsing for tags.

Publication 2711P-UM004B-EN-P - March 2007

Page 29

Configure the Terminal as a Slave Device 29

The structure of the DeviceNet Output Table looks like this when

browsing for tags.

Copy RSLinx Configuration to the Target Tab

When the application is complete, you must copy the RSLinx

configuration from the Local tab to the Target tab before you compile

the .mer file.

The Target tab contains the configuration the PanelView Plus terminal

uses to run the application. For I/O network configurations such as

DeviceNet, the shortcut configurations should be the same. For other

protocols, it is not necessary to have identical configurations.

Publication 2711P-UM004B-EN-P - March 2007

Page 30

30 Configure the Terminal as a Slave Device

1. Click Copy in Communication Setup.

The following dialog opens.

2. Click Yes.

The Communications Setup dialog will appear.

3. Click OK from the Communications Setup dialog to save the

configuration and close the dialog.

Create a runtime .mer file and download it to the PanelView

Plus terminal. Load the application in the terminal but do not

run the application. You must map the data between the

PanelView Plus terminal and the 1756-DNB scanner using

RSNetWorx for DeviceNet software.

Publication 2711P-UM004B-EN-P - March 2007

Page 31

Configure the Terminal as a Slave Device 31

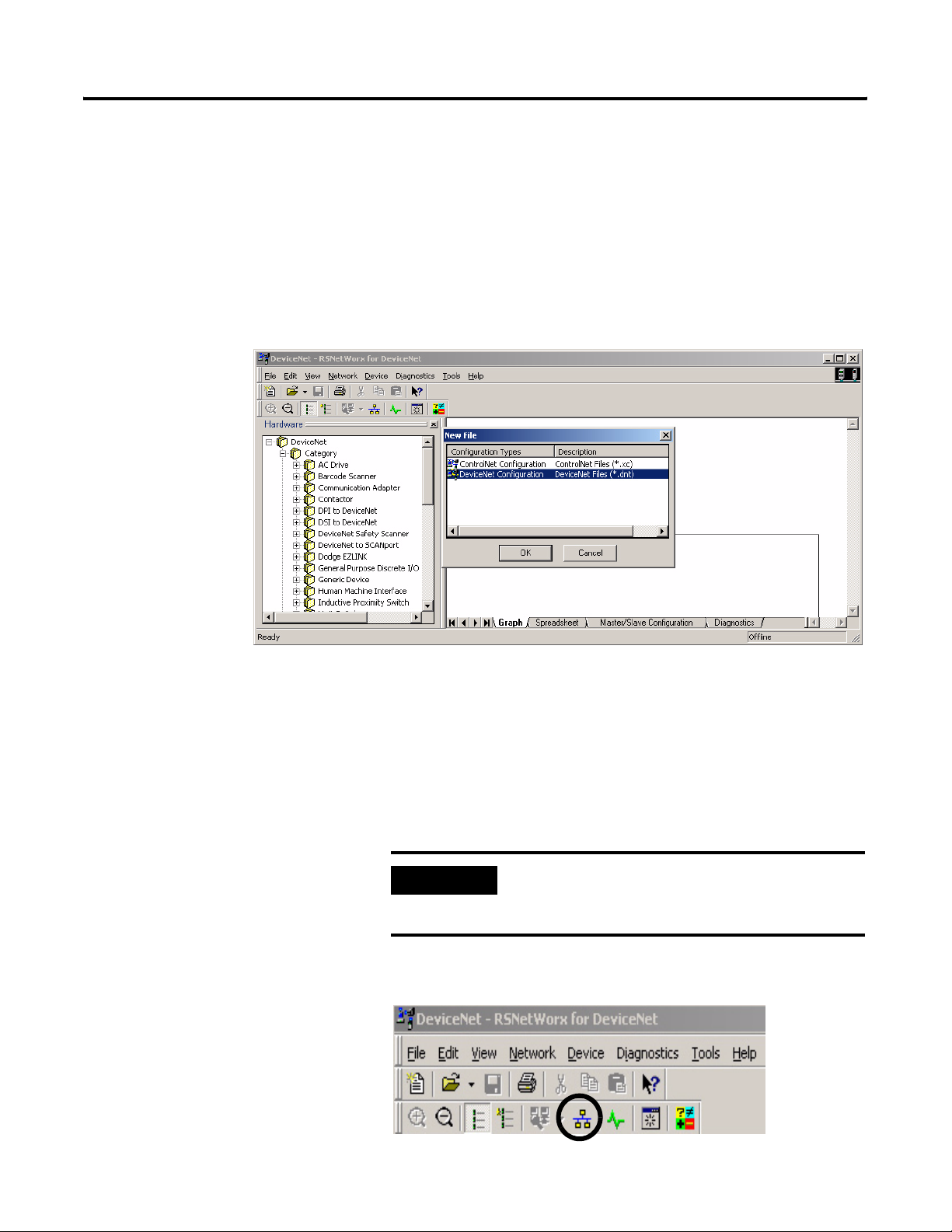

Configure RSNetWorx for DeviceNet Software

This section shows how to create a DeviceNet configuration using

RSNetWorx for DeviceNet software. You must now map the

PanelView Plus I/O configuration to the 1756-DNB DeviceNet

module.

1. Open RSNetWorx for DeviceNet software by selecting Start >

Menu > Programs > Rockwell Software > RSNetWorx >

RSNetworx for DeviceNet.

2. Create a new DeviceNet configuration and click OK.

The example configuration uses online browsing for devices on

the DeviceNet network.

3. Make sure all connections are made and that the communication

rates match on all devices.

4. On the PanelView Plus, load the runtime .mer application in

RSView Machine Edition, but do not run it as this time.

IMPORTANT

5. When the network and devices are ready, go online by clicking

the icon on the toolbar.

Do not run the application until the scanlist is

downloaded to the terminal. A scanlist will not

download to the terminal if the application is running.

Publication 2711P-UM004B-EN-P - March 2007

Page 32

32 Configure the Terminal as a Slave Device

The Browse for Network dialog opens.

6. Select the path of the DeviceNet network and click OK.

Publication 2711P-UM004B-EN-P - March 2007

Page 33

Configure the Terminal as a Slave Device 33

When the network is scanned, the devices display in the

network dialog. The dialog shows an icon for both the

1756-DNB module and the PanelView Plus/PanelView Plus CE

DeviceNet.

PV Plus/PV Plu s CE

DeviceNet

Configure Slave I/O for the PanelView Plus Terminal

You must configure the slave I/O before adding it to the 1756-DNB

scanlist. This section shows how to configure slave I/O for the

PanelView Plus terminal.

Publication 2711P-UM004B-EN-P - March 2007

Page 34

34 Configure the Terminal as a Slave Device

1. Double-click the PanelView Plus/PanelView Plus CE DeviceNet

icon to view the general properties.

2. Select the Module tab.

Because you are editing the configuration online, you are

prompted to:

• upload the current configuration in the module.

• download the configuration from the software.

Publication 2711P-UM004B-EN-P - March 2007

Page 35

Configure the Terminal as a Slave Device 35

3. Click the Upload button to edit the configuration.

When the upload is complete the Module tab appears.

4. Click Slave Mode.

The Slave Mode configuration dialog appears.

5. Check the Enable Slave Mode checkbox to enable Slave mode

and edit the Slave mode configuration.

Publication 2711P-UM004B-EN-P - March 2007

Page 36

36 Configure the Terminal as a Slave Device

6. Under Change of State / Cyclic, set these parameters to use

Cyclic I/O messaging:

• Select Cyclic

• Input Size = 4

• Output Size = 4

The configuration will transfer 4 bytes of input data and 4 bytes

of output data using cyclic I/O messaging.

TIP

The input size should match the size of the input address block

in RSView Machine Edition software. Similarly, the output size

of the output address block in RSView Machine Edition should

also match.

7. Click OK to save the data.

Map the I/O to the PanelView Plus Image Table

You must map the I/O data to the PanelView Plus image table so that

it can be scanned by the 1756-DNB DeviceNet module.

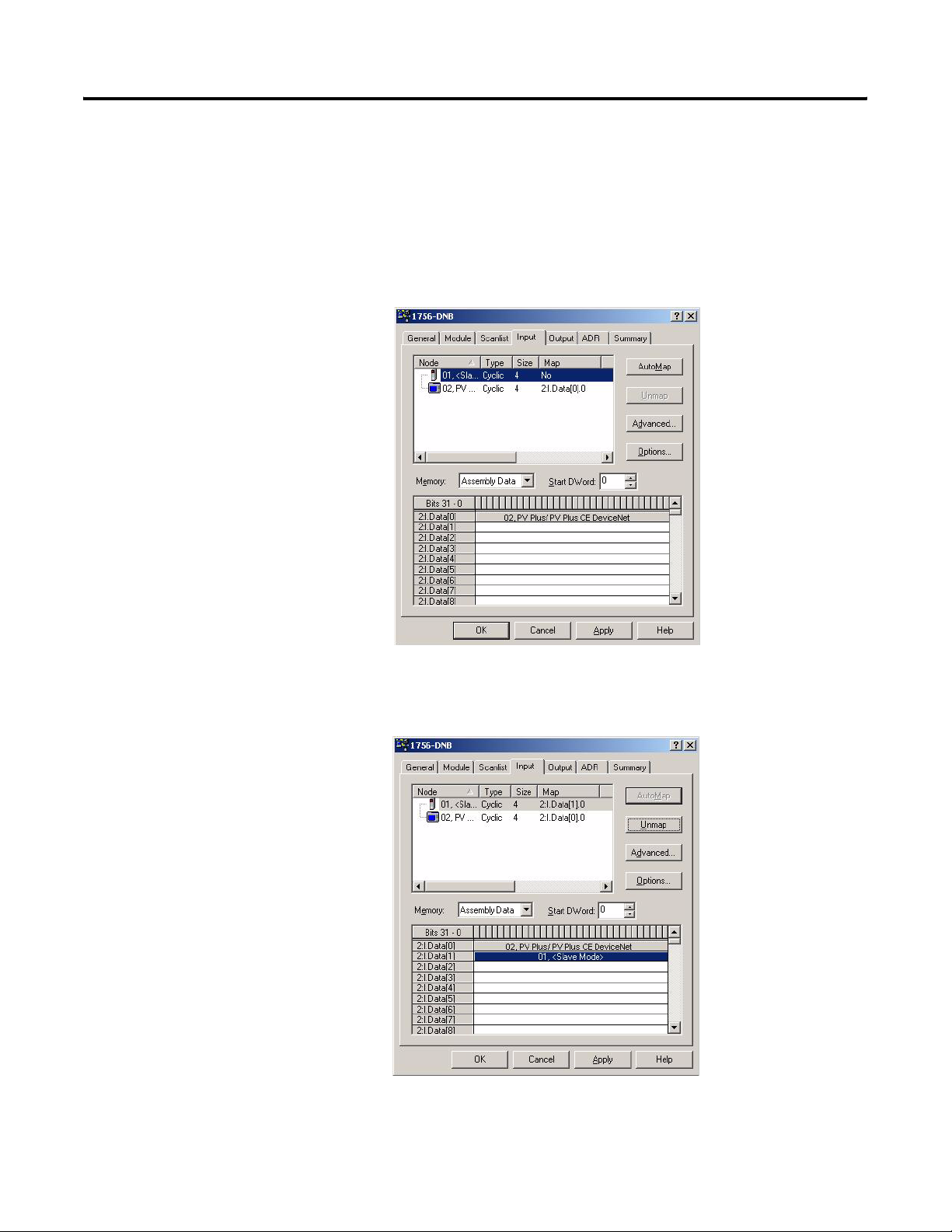

1. Select the Input tab to map the input data to the image table.

Publication 2711P-UM004B-EN-P - March 2007

Page 37

Configure the Terminal as a Slave Device 37

The input data you just configured appears in the top window.

2. Click AutoMap to map the data to the least significant word in

the PanelView Plus input image table.

Publication 2711P-UM004B-EN-P - March 2007

Page 38

38 Configure the Terminal as a Slave Device

3. Select the Output tab to view the output table.

4. Click AutoMap to map the output data to the least significant

word in the PanelView Plus output image table.

Publication 2711P-UM004B-EN-P - March 2007

5. Click OK to save the configuration.

Page 39

Configure the Terminal as a Slave Device 39

You are prompted to download the I/O configuration to the

PanelView Plus terminal.

6. Click Yes to download the I/O configuration.

Publication 2711P-UM004B-EN-P - March 2007

Page 40

40 Configure the Terminal as a Slave Device

Map the PanelView Plus I/O to the 1756-DNB Scanlist

You can now add the PanelView Plus I/O data to the scanlist of the

1756-DNB DeviceNet module.

1. In the network dialog, double-click the 1756-DNB icon to access

the 1756-DNB properties.

Publication 2711P-UM004B-EN-P - March 2007

2. Select the Module tab.

Because you are editing the configuration online, you are

prompted to:

• upload the current configuration in the module.

• download the configuration from the software.

3. Click Upload to edit the current configuration.

Page 41

Configure the Terminal as a Slave Device 41

When the upload is complete, the module tab will open.

4. From the Module tab, select Slot 2 which is the location of the

1756-DNB module in the ControlLogix rack.

5. Select the Scanlist tab to view and edit the 1756-DNB scanlist.

The PanelView Plus terminal appears as an available device.

This means you can add it to the scanlist.

Publication 2711P-UM004B-EN-P - March 2007

Page 42

42 Configure the Terminal as a Slave Device

6. Select the PanelView Plus device and click > to add the device

to the scanlist.

The Automap on Add checkbox is selected. When you add the

device to the scanlist, the slave inputs and outputs are

automatically added to the input and output tables.

TIP

If the Automap on Add checkbox was not checked, you

would need to manually map the data on the Input tab.

7. Select the Input tab to verify that the PanelView Plus I/O is

mapped to the Input Assembly Data file.

Publication 2711P-UM004B-EN-P - March 2007

The DINT slave output (Slave_Output) created for the

PanelView Plus terminal in RSLinx Enterprise software resides in

the first 4 bytes of the 1756-DNB input table.

Page 43

Configure the Terminal as a Slave Device 43

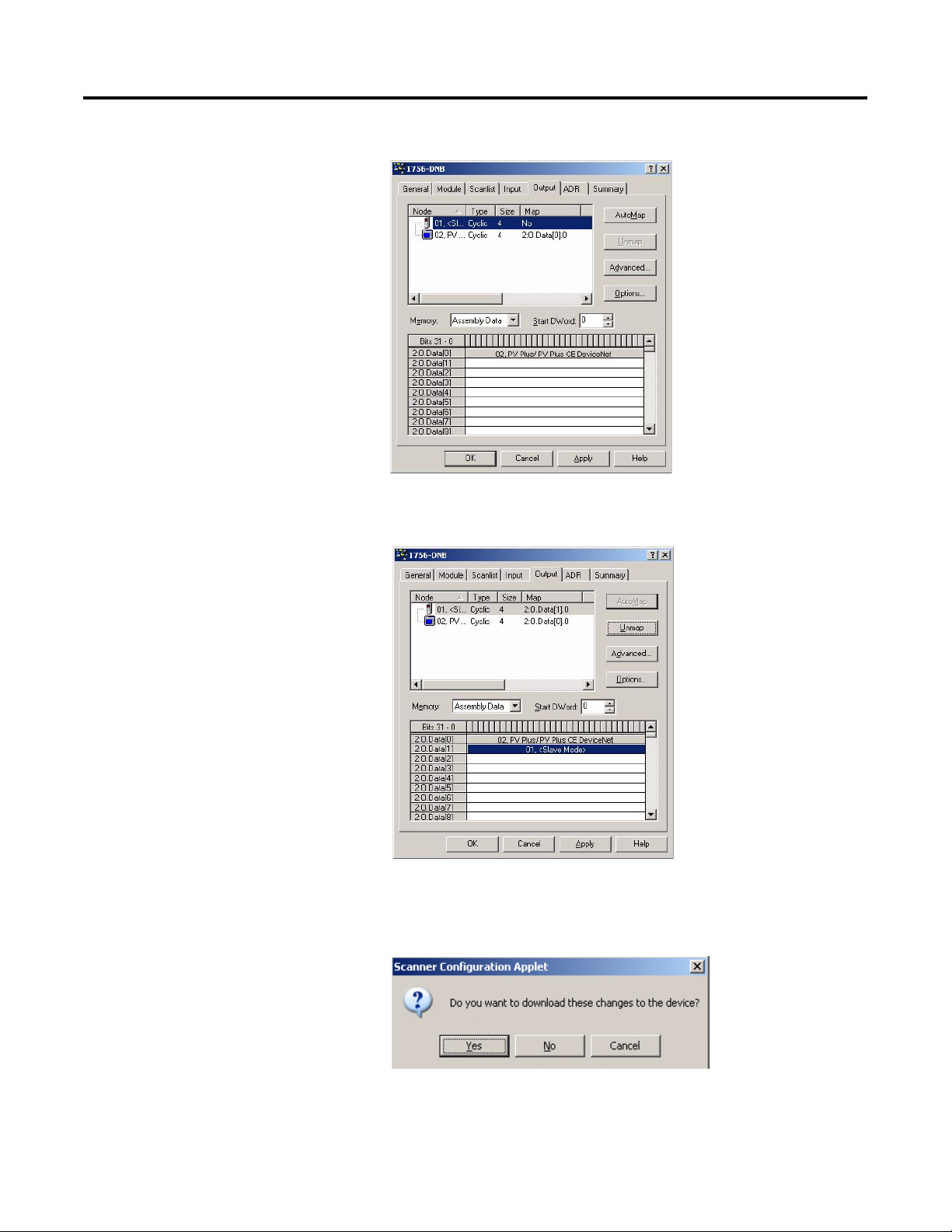

8. Select the Output tab to verify that the PanelView Plus I/O is

mapped to the 1756-DNB output image file.

The DINT slave input (Slave_Input alias) created for the

PanelView Plus slave in RSLinx Enterprise software resides in the

first 4 bytes of the 1756-DNB output table.

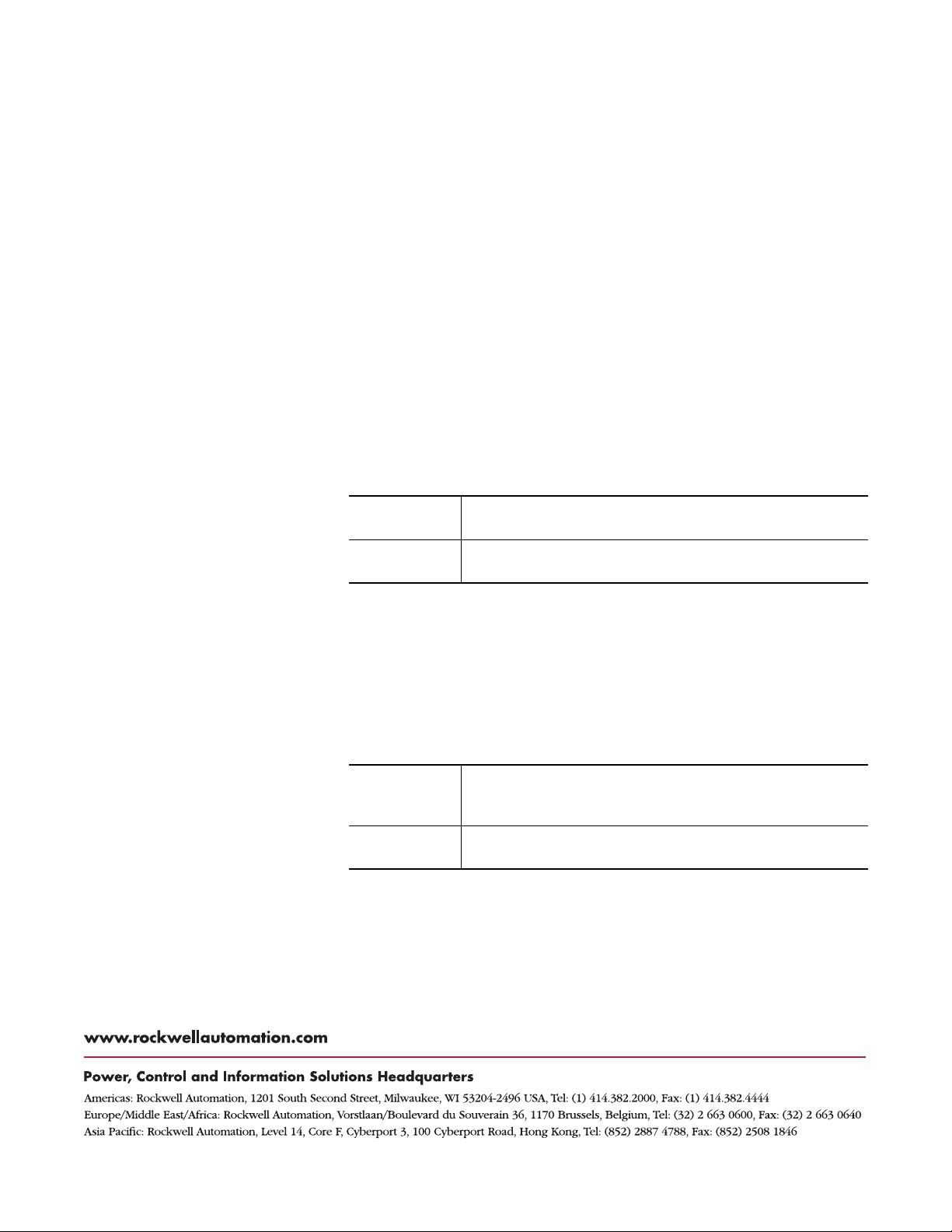

9. Click OK.

You are prompted to download the changes to the 1756-DNB

module.

10. Click Yes to download the configuration.

The 1756-DNB module is now configured to scan the slave I/O

in the PanelView Plus terminal.

Publication 2711P-UM004B-EN-P - March 2007

Page 44

44 Configure the Terminal as a Slave Device

Summary

The scanlists are now configured for both the 1756-DNB DeviceNet

module and the PanelView Plus terminal.

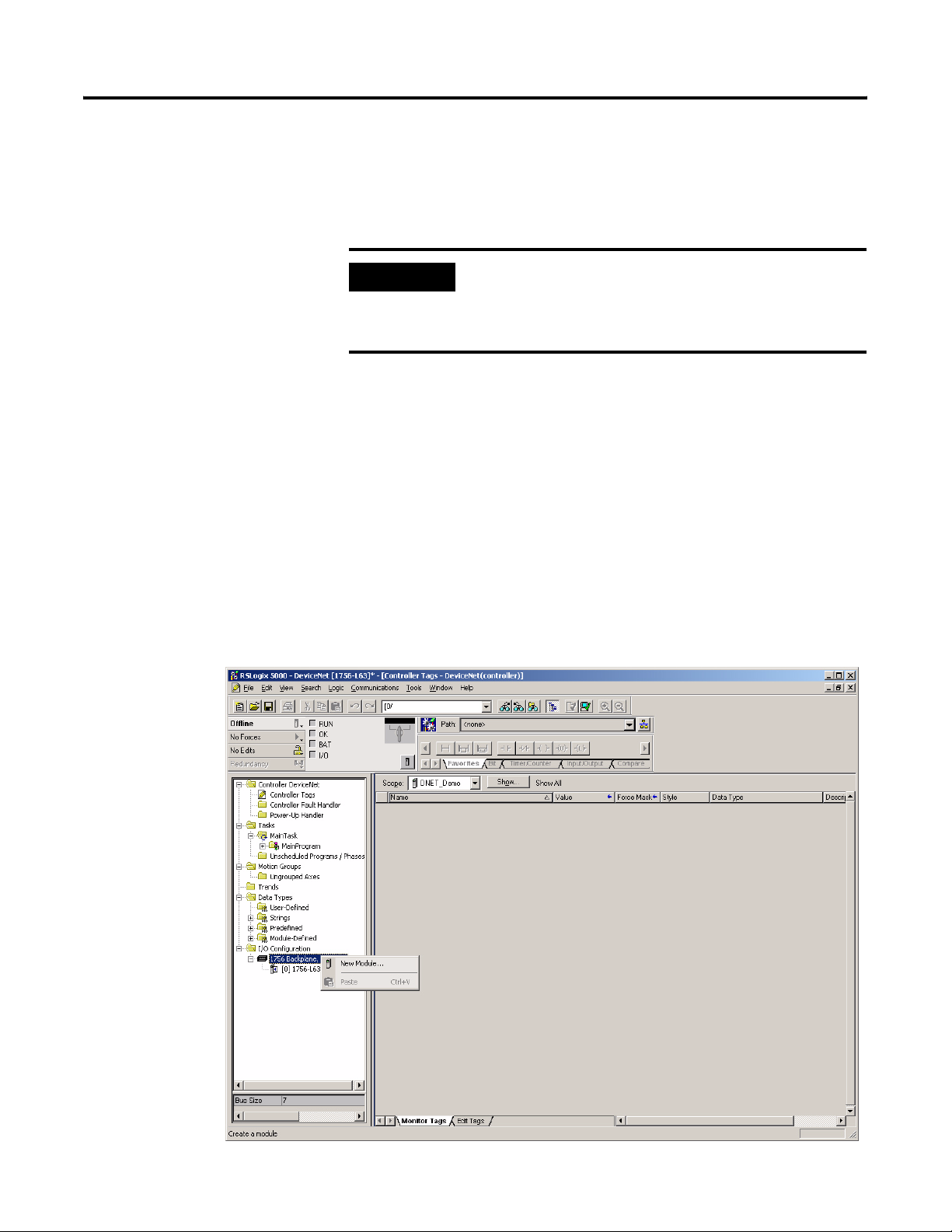

Use RSLogix 5000 Software

IMPORTANT

You must now add the DeviceNet I/O configuration in the 1756-DNB

module to the controller tags database in RSLogix 5000 software. You

can then put the 1756-DNB module in Run mode and initiate data

transfer.

For these examples, the module is in slot 0.

1. Verify that the 1756-L63 ControlLogix processor is in slot 0.

2. Open a new application.

3. Right-click the I/O Configuration icon and select New Module.

To change the scanlist for a device on the network, you must

place the device in Idle mode before downloading the changes.

On the PanelView Plus terminal, you can load the application

but not run it.

Publication 2711P-UM004B-EN-P - March 2007

Page 45

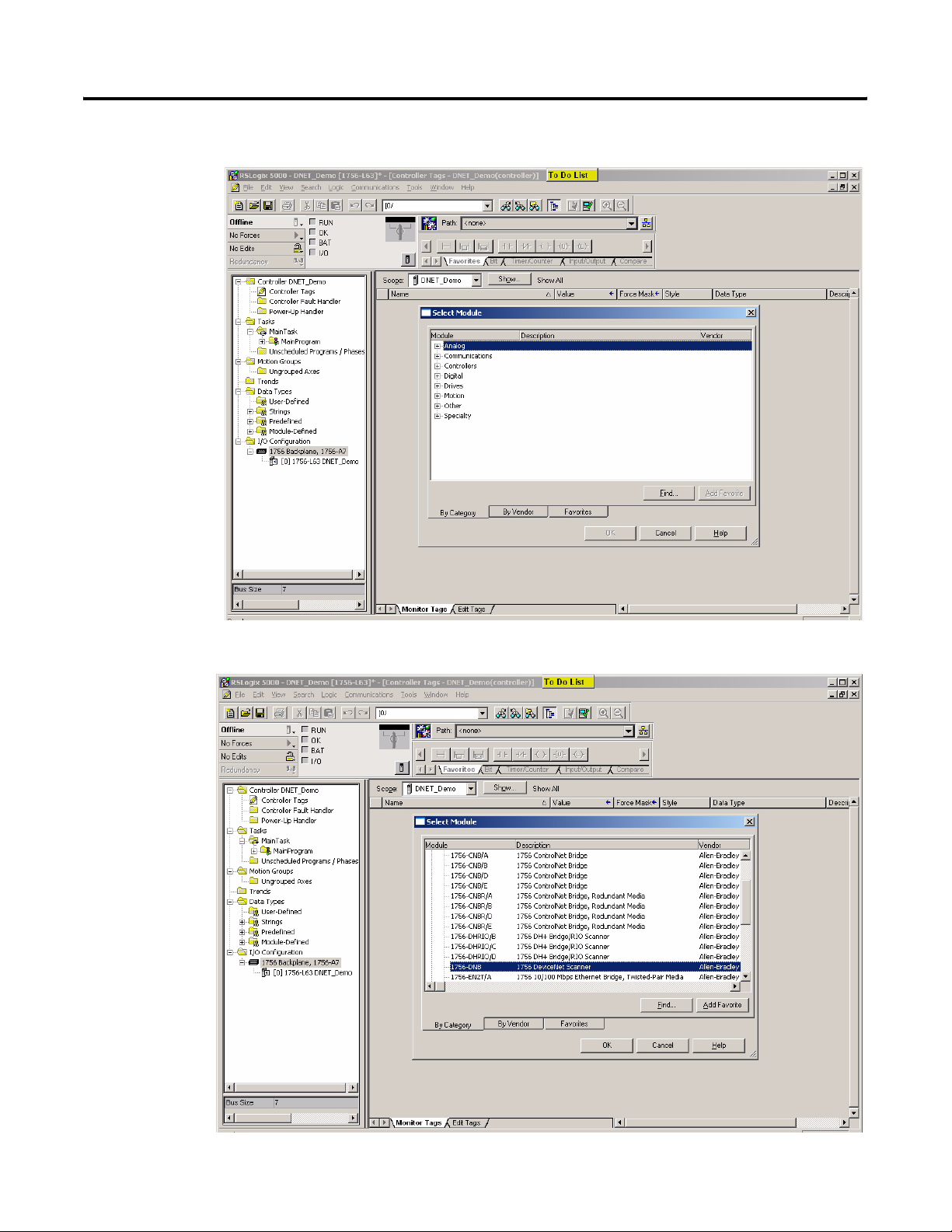

Configure the Terminal as a Slave Device 45

The By Category tab displays a list of module types.

4. Expand Communications and select 1756-DNB.

Publication 2711P-UM004B-EN-P - March 2007

Page 46

46 Configure the Terminal as a Slave Device

After selecting the module, you are prompted to select the Major

Revision of the 1756-DNB module.

5. Select the Major Revision of the module installed in the

ControlLogix rack and select OK.

Publication 2711P-UM004B-EN-P - March 2007

Page 47

Configure the Terminal as a Slave Device 47

6. In the New Module dialog, enter these parameters:

• name for the module.

• slot location of the 1756-DNB module in the ControlLogix rack,

in this case, slot 2.

7. Click OK.

You have just added the 1756-DNB module I/O configuration to

the ControlLogix controller tag database.

Publication 2711P-UM004B-EN-P - March 2007

Page 48

48 Configure the Terminal as a Slave Device

8. To view the tags, double-click the Controller Tags icon in the

tree.

Notice that the input, output, and status tags are specific to the

slot the 1756-DNB module resides in, which is slot 2. The inputs

and outputs mapped in RSNetWorx software now reside in:

• Local:2:I.Data array for inputs.

• Local:2:O:Data array for outputs.

9. To enable DeviceNet communications, put the DeviceNet

1756-DNB module in Run mode by setting the run mode bit in

the output command register.

Local:2:O.Command.Register.Run.

You can do this in the ladder logic or by accessing the tag

directly.

10. Download the program to the ControlLogix processor and put

the program in run mode.

Publication 2711P-UM004B-EN-P - March 2007

Page 49

Configure the Terminal as a Scanner

Chapter

3

Chapter Objectives

Configure Communications

The procedures in this chapter build on the example configuration in

Chapter 2. In this chapter, you will configure the PanelView Plus as a

scanner and the 1756-DNB DeviceNet module as the slave device. The

PanelView Plus will scan I/O from the 1756-DNB DeviceNet module.

In this section, you will learn how to:

• configure slave input and output data for the 1756-DNB module.

• view the structure of the DeviceNet input and output table when

browsing for tags.

• copy the RSLinx software configuration to the Target tab.

Configure the Slave Inputs and Outputs

IMPORTANT

To change the scanlist for a device on the network, you must

place the device in Idle mode before downloading the changes.

For the PanelView Plus, you can load the application but not run

it. For the 1756-DNB module, put the ControlLogix processor in

Program mode.

To place the device in Idle mode:

• For the PanelView Plus, load the application but do not run it.

• For the 1756-DNB module, put the ControlLogix 1756-L63

processor in Program mode. This action will clear the run bit

Local:2:O.CommandRegister.Run.

You are now ready to configure the slave inputs and outputs in the

1756-DNB module. The PanelView Plus terminal will scan these

inputs and outputs.

• One DINT or four bytes of input data, starting at byte 4.

• One DINT or four bytes of output data, starting at byte 4.

The PanelView Plus can scan 2048 bytes of input data and 2048 bytes

of output data. The number of input and output bytes is minus any

slave I/O data configured in the PanelView Plus.

49 Publication 2711P-UM004B-EN-P - March 2007

Page 50

50 Configure the Terminal as a Scanner

For each block of data, you will enter the node address of the

1756-DNB DeviceNet module to indicate that the module is the slave

device. The node address of the 1756-DNB module for the sample

configuration is node 1.

Configure the Scanner Input Data

You are now ready to configure the scanner input data. You will do

this in Communications Setup in RSView Machine Edition under

RSLinx Enterprise software.

The example used in this chapter builds from the Slave configuration

example. You can configure a PanelView Plus terminal as both a

scanner and slave for the same application.

1. On the I/O Configuration Tab, right-click the Input icon and

select Add Address Block.

Publication 2711P-UM004B-EN-P - March 2007

2. In the Address Block Properties dialog set the Start Byte to 4,

Length in Bytes to 4, and click OK.

The address block 4-7 Bytes is added under Inputs.

Page 51

Configure the Terminal as a Scanner 51

3. Right-click the new 4-7 address block Bytes and select Add

Device to define the 1756-DNB DeviceNet module as the slave

device for the input address block.

4. In the Device Properties dialog for the input address block,

select the node of the slave device, in this example Node 1, and

click OK.

Node 1 indicates that the 1746-DNB module will operate as the

slave for the input data. The PanelView Plus will scan this data

from the module.

Create an Input Alias

To make connections to objects, aliases are required. You must create

an alias for the input address block.

Publication 2711P-UM004B-EN-P - March 2007

Page 52

52 Configure the Terminal as a Scanner

1. Right-click the 4-7 Bytes icon and select Add Alias.

Publication 2711P-UM004B-EN-P - March 2007

Page 53

Configure the Terminal as a Scanner 53

2. In the Alias Properties dialog, select these properties and then

click OK to add the alias to the input address block:

• Alias Data Type = DINT

• Alias Name = Scanner_Input

• Start Byte = 4

• Array Count = 1

The slave input is now configured with:

• Address block of four bytes, starting at byte 4

• Slave device on node 1, which is the 1756-DNB module

• Alias of Scanner_Input for the input address block

Publication 2711P-UM004B-EN-P - March 2007

Page 54

54 Configure the Terminal as a Scanner

Configure the Scanner Output Data

You are now ready to configure the scanner output data. You will do

this in Communications Setup in RSView Machine Edition under

RSLinx Enterprise software.

You can configure a PanelView Plus terminal as both a scanner and

slave for the same application. Add a scanner output block to the I/O

configuration. The PanelView Plus terminal will scan this output

block.

1. Right-click the Output icon to add an Address Block.

Publication 2711P-UM004B-EN-P - March 2007

2. In the Address Block Properties dialog, set the Start Byte to 4,

Length in Bytes to 4, and click OK.

The address block 4-7 Bytes is added under Outputs.

Page 55

Configure the Terminal as a Scanner 55

3. Right-click the new address block 4-7 Bytes and select Add

Device to define the 1756-DNB module as the slave device for

the output block.

4. In the Device Properties dialog for the output address block,

select Node 1 and click OK.

Similar to the input data, the 1756-DNB module will operate as a

slave for the output data. The PanelView Plus will scan this

output data from the module.

Publication 2711P-UM004B-EN-P - March 2007

Page 56

56 Configure the Terminal as a Scanner

Create an Output Alias

Similar to the input alias, you need to create an alias for the output

block.

1. Right-click the 4-7 Bytes icon under Output and select Add Alias.

2. In the Alias Properties dialog, select these properties and then

click OK to add the alias to the address block:

• Alias Data Type = DINT

• Alias Name = Scanner_Output

• Start Byte = 4

• Array Count = 1

• Initial Value = 0

If you do not enter an initial value, a warning message indicates

that default values will be used.

Publication 2711P-UM004B-EN-P - March 2007

Page 57

Configure the Terminal as a Scanner 57

The scanner output is now configured with:

• Address block of four bytes, starting at byte 4

• Slave device on node 1, which is the 1756-DNB module

• Alias of Scanner_Output for the output address block

3. Click OK to save the configuration.

4. To exit Communications Setup, click OK to save the

configuration and close the dialog.

Publication 2711P-UM004B-EN-P - March 2007

Page 58

58 Configure the Terminal as a Scanner

Browse for Tags

The structure of the DeviceNet Input Table looks like this when

browsing for tags.

Both slave and scanned alias are listed together. It is important to

create an alias that will be meaningful to you when you are

developing your RSView Machine Edition application.

Publication 2711P-UM004B-EN-P - March 2007

Page 59

Configure the Terminal as a Scanner 59

The structure of the DeviceNet Output Table looks like this when

browsing for tags.

Copy RSLinx Enterprise Configuration to the Target Tab

When all the object connections are made and the application is

complete, click Copy in Communication Setup to copy the RSLinx

Enterprise configuration from the Local tab to the Target tab.

Create a runtime .mer file and download to the PanelView Plus

terminal. Load the application in the terminal but do not run the

application. You must first map the data between the PanelView Plus

and the 1756-DNB scanner using RSNetWorx for DeviceNet software.

Publication 2711P-UM004B-EN-P - March 2007

Page 60

60 Configure the Terminal as a Scanner

Configure RSNetWorx for DeviceNet

In this section, you will use RSNetWorx for DeviceNet to configure

slave I/O for the 1756-DNB DeviceNet module and map the I/O to the

PanelView Plus terminal.

Before downloading the scanlists to the PanelView Plus and

1756-DNB module, the devices must be in Idle mode.

• For the PanelView Plus, load the application but do not run it.

• For the 1756-DNB module, put the ControlLogix 1756-L63

processor in Program mode. This action will clear the run bit

Local:2:O.CommandRegister.Run.

Configure Slave I/O for the 1756-DNB Module

To configure the slave inputs and outputs in the 1756-DNB module

you must be online.

1. In the RSNetWorx for DeviceNet dialog, double-click the

1756-DNB icon to open the 1756-DNB properties dialog.

Publication 2711P-UM004B-EN-P - March 2007

Page 61

Configure the Terminal as a Scanner 61

The 1756-DNB properties dialog opens.

2. Select the Module tab and verify that the slot number is 2.

Slot 2 is the location of the 1756-DNB module in the

ControlLogix rack.

Publication 2711P-UM004B-EN-P - March 2007

Page 62

62 Configure the Terminal as a Scanner

3. Click Slave Mode button.

The Slave Mode configuration dialog appears.

4. Check the Enable Slave Mode checkbox to enable Slave mode

and edit the Slave mode configuration.

5. Under Change of State / Cyclic, set these parameters to use

Cyclic I/O messaging:

• Select Cyclic

• Input Size = 4

• Output Size = 4

The configuration will transfer 4 bytes of input data and 4 bytes

of output data using cyclic I/O messaging.

TIP

The input size should match the size of the input address block

in RSView Machine Edition. Similarly, the output size of the

output address block in RSView Machine Edition should also

match.

Publication 2711P-UM004B-EN-P - March 2007

6. Click OK to save the data.

Page 63

Configure the Terminal as a Scanner 63

Map the I/O to the 1756-DNB Image Table

You must now map the I/O data to the image table of the 1756-DNB

module so that it can be scanned by the PanelView Plus terminal.

1. Select the Input tab to map the input data to the image table.

The input data just configured appears in the top window.

2. Select node 1, which represents the 1756-DNB slave mode I/O

and click AutoMap to map the data to the next least significant

DWord in the 1756-DNB input image table.

Publication 2711P-UM004B-EN-P - March 2007

Page 64

64 Configure the Terminal as a Scanner

3. Select the Output tab to view the output table.

4. Select node 1 and click AutoMap to map the output data to the

least significant DWord in the 1756-DNB output image table.

Publication 2711P-UM004B-EN-P - March 2007

5. Click OK to save the configuration.

You are prompted to download the I/O configuration to the

1756-DNB module.

6. Select Yes to download the configuration.

Page 65

Configure the Terminal as a Scanner 65

Map the 1756-DNB I/O to the PanelView Plus Scanlist

You are now ready to add the I/O configuration in the 1756-DNB

module to the scanlist of the PanelView Plus terminal. The PanelView

Plus can then scan this data.

1. In the Network dialog, double-click the PanelView

Plus/PanelView Plus CE DeviceNet icon.

The PanelView Plus/PanelView Plus CE DeviceNet dialog

opens.

Publication 2711P-UM004B-EN-P - March 2007

Page 66

66 Configure the Terminal as a Scanner

2. Select the Scanlist tab to view and edit the PanelView Plus

scanlist.

The 1756-DNB module appears as an available device. This

means you can add it to the Scanlist.

3. Select the 1756-DNB device and click > to add the device to the

Scanlist.

The Automap on Add checkbox is checked. When you add the

device to the Scanlist, the slave inputs and outputs are

automatically added to the input and output image tables.

TIP

If the Automap on Add checkbox was not checked, you

would need to manually map the data on the Input tab.

Publication 2711P-UM004B-EN-P - March 2007

Page 67

Configure the Terminal as a Scanner 67

4. Select the Input tab to verify that the 1756-DNB data is mapped

to the PanelView Plus input image file.

The DINT slave output (Scanner_Output) created in RSLinx

Enterprise software resides in the first 4 bytes of the PanelView

Plus Input table. The Input tab shows the data mapped

correctly.

5. Select the Output tab to verify that the 1756-DNB data is

mapped to the PanelView Plus output image file.

The DINT slave input (Scanner_Input) created in RSLinx

Enterprise software resides in the first 4 bytes of the PanelView

Publication 2711P-UM004B-EN-P - March 2007

Page 68

68 Configure the Terminal as a Scanner

Plus output table. The Output tab shows the data mapped

correctly.

TIP

If the Automap on Add checkbox was not checked, you

would need to manually map the data on the Output tab.

6. Click OK.

You are prompted to download the changes to the PanelView

Plus terminal.

7. Click Yes to download the configuration.

The PanelView Plus is now configured to scan the slave I/O data

in the 1756-DNB DeviceNet module.

Summary

The scanlists are now configured for both the 1756-DNB DeviceNet

module and the PanelView Plus terminal.

IMPORTANT

To change the scanlist for a device on the network, you must

place the device in Idle mode before downloading the changes.

For the PanelView Plus, you can load the application but not run

it. For the 1756-DNB module, put the ControlLogix processor in

Program mode.

You are now ready to put each device in Run mode.

• For the PanelView Plus, run the Machine Edition .mer

application in the terminal.

• For the 1756-DNB module, enable the run bit in the ladder

program using RSLogix 5000 software.

Publication 2711P-UM004B-EN-P - March 2007

Page 69

Configure the Terminal as a Scanner 69

Use RSLogix 5000 Software

During the first part of the example configuration in Chapter 2:

• you added the 1756-DNB I/O configuration to the 1756-L63

controller tags database using RSLogix 5000 software.

• you then set the run bit Local:2:O.CommandRegister.Run in the

output command register

You did this to enable communications between the PanelView

Plus and the 1756-DNB DeviceNet module.

In the Configure RSNetWorx for DeviceNet software section of this

chapter, you put the processor in Program mode to clear the

Command Register run bit. Because the 1756-DNB was in Idle mode,

you were able to download the scanlist to the 1756-DNB module. You

can now put 1756-DNB module in Run mode. In the 1756-DNB

command register set the run bit Local:2:O.CommandRegister.Run.

Summary

The PanelView Plus is now ready to operate as a scanner on the

DeviceNet network. The terminal can scan the configured slave I/O

data from the 1756-DNB module.

Publication 2711P-UM004B-EN-P - March 2007

Page 70

70 Configure the Terminal as a Scanner

Publication 2711P-UM004B-EN-P - March 2007

Page 71

Appendix

A

Restore Configuration to Local Tab

In some cases, it may be necessary to edit an application after the

DeviceNet configuration on the Local tab has changed or has been

moved to a different computer. The RSLinx Enterprise Local tab

configuration stays resident on the desktop computer, regardless of

which application is being edited.

Copy Configuration to Local Tab

The following procedure shows how to copy the Target tab

configuration for an application to the Local tab to allow for browsing

for tags.

IMPORTANT

Make sure that the DeviceNet configuration is saved, make sure the

application is backed up using Application Manager.

When you are ready to resume editing, restore the application using

the Application Manager. This will create an XML file with the

restored I/O configuration. For RSView Studio software, you must

complete the following steps.

1. Close RSView Studio software.

2. Disable the RSLinx Enterprise service within the Service Control

Manager (Control Panel>Administrative Tools>Services).

3. Double-click RSLinx Enterprise.

This procedure will overwrite all driver configurations on the

Local tab with all of the driver configurations that were on the

Target tab when the application was backed up.

4. Make a backup copy of the current RSLinxNG.xml file in

C:\Documents and Settings\All Users\Application

Data\Rockwell\RSLinx Enterprise.

5. Rename the Restored_restoredAppNAme_RSLinxNG.xml to

RSLinxNG.xml.

6. Re-enable and restart the RSLinx Enterprise software.

71 Publication 2711P-UM004B-EN-P - March 2007

Page 72

72 Restore Configuration to Local Tab

To allow browsing for tags, open the Communication Setup under the

RSLinx Enterprise tree and apply the shortcut to the DeviceNet driver

on the Local tab. If changes are made to the driver configuration on

the Local tab, be sure to copy this configuration to the Target tab

using the Copy button on the Communication Setup dialog.

Publication 2711P-UM004B-EN-P - March 2007

Page 73

Index

Numerics

2711P-RN10C 9

2711P-RN10H 9

A

alias

input

21, 51

output 25

B

browsing for 58

C

communications 16, 49

scanner 49

slave device 16

configuration

copy

71

network 15

PanelView Plus 33

restore 71

RSLinx 29

RSLogix 5000 69

RSNetWorx 31, 60

scanner 49, 50, 54

slave 23

slave device 15

slave inputs 18

slave outputs 18

D

DeviceNet module 9

2711P-RN10C 9

2711P-RN10H 9

I

I/O 36

I/O mapping 36, 40

I/O status indicators 11

image table 36

input alias 21, 51

inputs 18

M

MOD 12

module status indicators 11

N

NET 13

network 15

network configuration 15

network status indicators 11

O

output alias 25

outputs 18

P

PanelView Plus

1756-DNB

configuration 33

I/O mapping 36

image table 36

slave I/O 33

protocol 9

40

1756-DNB 40

R

RSLinx 29

configuration 29

RSLogix 5000 44, 69

RSNetWorx 31, 60

configuration 31

S

scanlist 40

scanner 54

configuration 54

input data 50

output data 54

shortcut 26

slave device 15

communications 16

configuration 15

slave outputs

configuration

status indicators

I/O

11

module (MOD) 12

network (NET) 13

supported controllers 9

18

T

tags 28, 58

browsing for 28

Publication 2711P-UM004B-EN-P - March 2007

Page 74

74 Index

Publication 2711P-UM004B-EN-P - March 2007

Page 75

Page 76

Rockwell Automation

Support

Rockwell Automation provides technical information on the web to assist you

in using its products. At http://support.rockwellautomation.com, you can find

technical manuals, a knowledge base of FAQs, technical and application

notes, sample code and links to software service packs, and a MySupport

feature that you can customize to make the best use of these tools.

For an additional level of technical phone support for installation,

configuration and troubleshooting, we offer TechConnect Support programs.

For more information, contact your local distributor or Rockwell Automation

representative, or visit http://support.rockwellautomation.com.

Installation Assistance

If you experience a problem with a hardware module within the first 24

hours of installation, please review the information that's contained in this

manual. You can also contact a special Customer Support number for initial

help in getting your module up and running:

United States 1.440.646.3223

Monday – Friday, 8am – 5pm EST

Outside United

States

Please contact your local Rockwell Automation representative for any

technical support issues.

New Product Satisfaction Return

Rockwell tests all of its products to ensure that they are fully operational

when shipped from the manufacturing facility. However, if your product is

not functioning and needs to be returned:

United States Contact your distributor. You must provide a Customer Support case

number (see phone number above to obtain one) to your distributor in

order to complete the return process.

Outside United

States

PanelView Plus, VersaView, ControlLogix, TechConnect, RSView Studio, RSView Machine Edition, RSNetWorx

for DeviceNet, RSLogix 5000, RSView, PLC-5, SLC, RSLinx, RSLinx Enterprise, RSNetWorx, Allen-Bradley, and

Rockwell Automation are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Please contact your local Rockwell Automation representative for

return procedure.

Publication 2711P-UM004B-EN-P - April 2007 76

Supersedes Publication 2711P-UM004A -EN-P - March 2006 Copyright © 2007 Rockwell Automatio n, Inc. All rights reserved. Printed in the U.S.A.

Loading...

Loading...