Page 1

DeviceLogix System

User Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment. Safety Guidelines

for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

Automation sales office or online at http://www.rockwellautomation.com/literature/

between solid state equipment and hard-wired electromechanical devices. Because of this difference, and also because of the

wide variety of uses for solid state equipment, all persons responsible for applying this equipment must satisfy themselves that

each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING

Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

available from your local Rockwell

) describes some important differences

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Allen-Bradley, Rockwell Automation, Rockwell Software, DeviceLogix, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Identifies information that is critical for successful application and understanding of the product.

Identifies information about practices or circumstances that can lead to personal injury or death, property damage,

or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may

be present.

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach

dangerous temperatures.

Page 3

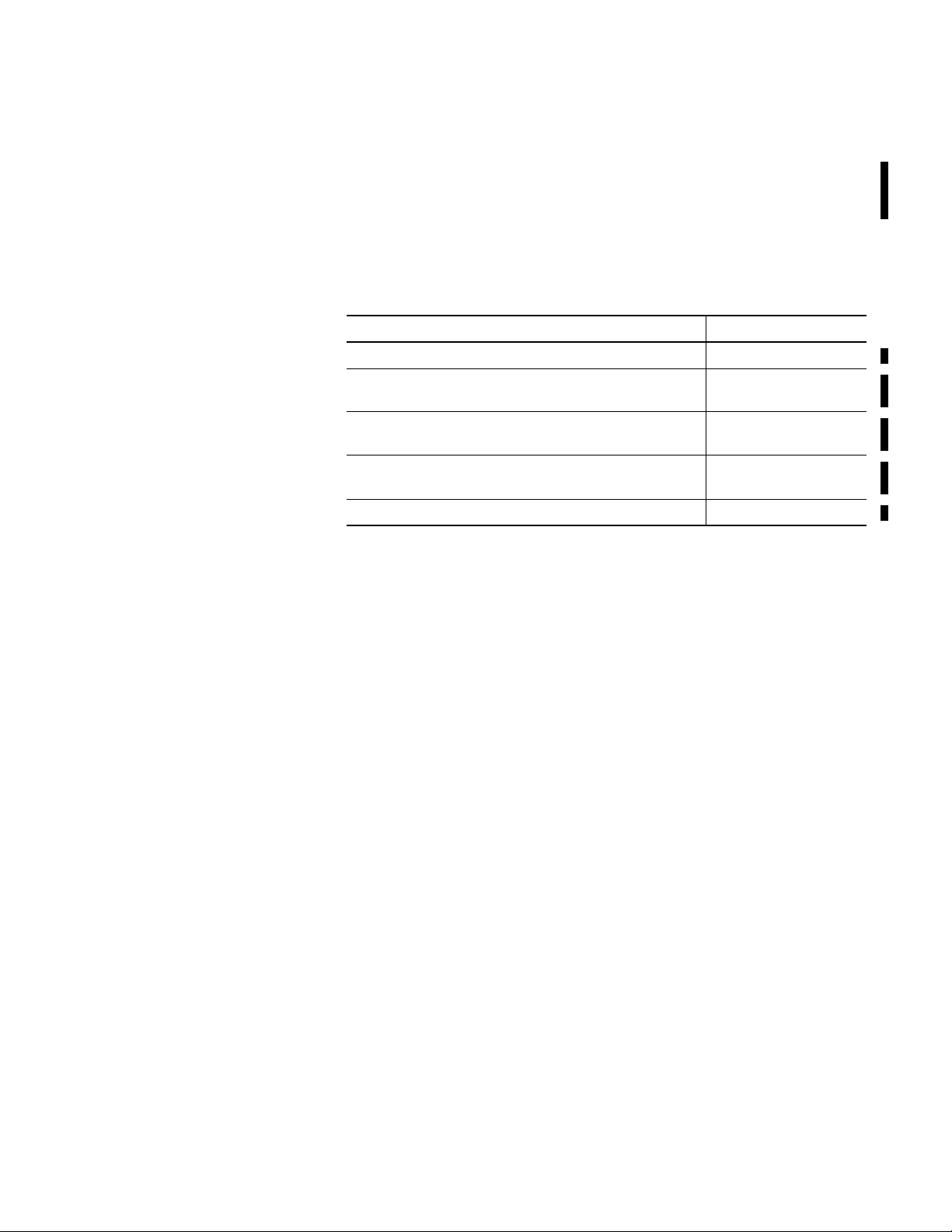

Summary of Changes

Introduction

Updated Information

The release of this document contains new and updated information.

To find new and updated information, look for change bars, as shown

next to this paragraph.

This document contains the following changes.

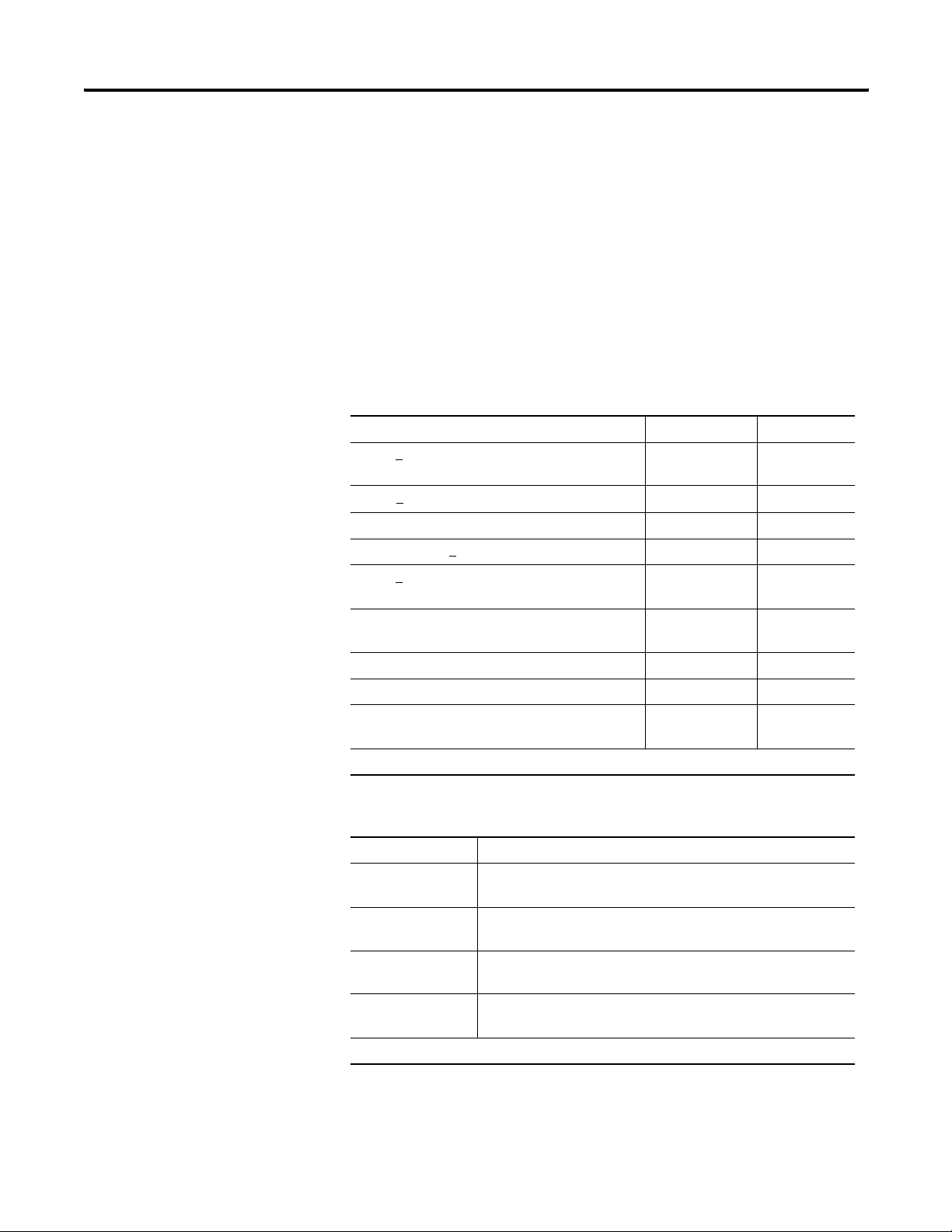

Topic Page

Screen format options for download to device 61, 121

PID instruction supported in Function Block Editor and in New

Ladder Editor

ACC binding for Timer/Counter instructions supported in

Function Block Editor and in New Ladder Editor

Macro function supported in Function Block Editor and in New

Ladder Editor

New Ladder Editor introduced Chapters 6 and 7

Chapters 2, 3, 6, and 7

Chapters 2 and 6

Chapters 3 and 7

3Publication RA-UM003B-EN-P - February 2010 3

Page 4

Chapter 1 Summary of Changes

Notes:

4 Publication RA-UM003B-EN-P - February 2010

Page 5

Table of Contents

Preface

What is DeviceLogix

Functionality?

Navigate the Function Block

Editor Interface

Purpose of This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Who Should Use

This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Related Terms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Common Techniques Used in This Manual. . . . . . . . . . . . . . 10

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Local Function Block Logic . . . . . . . . . . . . . . . . . . . . . . 13

Local Ladder Logic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

DeviceLogix Functionality and Associated Host Software . . . 14

RSNetWorx for DeviceNet Software Operating Modes . . . 15

Drive Tools Software Operating Modes. . . . . . . . . . . . . . 15

DeviceLogix Operating Modes . . . . . . . . . . . . . . . . . . . . 15

Launch the DeviceLogix Editor . . . . . . . . . . . . . . . . . . . . . . 16

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . . 19

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

DeviceLogix Function Block Elements . . . . . . . . . . . . . . . . . 20

I/O Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Function Block Instructions . . . . . . . . . . . . . . . . . . . . . . 23

Enable Line Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Configuration Toolbars . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Standard Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Tabbed Instruction Toolbars. . . . . . . . . . . . . . . . . . . . . . 53

Macro Block Category Toolbar . . . . . . . . . . . . . . . . . . . . 58

Online Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Schematic View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Message Pane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Status Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

File Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Edit Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

View Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Communication Menu . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Tools Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Help Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Bind Function Blocks with I/O

5Publication RA-UM003B-EN-P - February 2010 5

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . . 67

Overview of Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . 68

Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Connect I/O points and function block instructions . . . . . . . 69

Determine the status of a connection . . . . . . . . . . . . . . . . . . 70

Negate Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Set Assume Data Available . . . . . . . . . . . . . . . . . . . . . . . 71

Function Block Properties and Parameters . . . . . . . . . . . 72

Page 6

Table of Contents

Configure the Macro Instruction. . . . . . . . . . . . . . . . . . . . . . 74

Work with the Macro Instruction . . . . . . . . . . . . . . . . . . 74

Edit the Macro Definition and Parameters . . . . . . . . . . . . 80

Offline Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Online Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Go Online . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Online Animation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Change Logic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Enable and Disable Logic . . . . . . . . . . . . . . . . . . . . . . . . 87

Verify Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Compare Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Upload and Download Logic . . . . . . . . . . . . . . . . . . . . . 89

Forcing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Navigate the Old Ladder Editor

Interface

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . . 95

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Ladder Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Rung Element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Bit Element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Latch Element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Counter Element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Timer Element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Configuration Toolbars . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Standard Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Ladder Element Toolbars . . . . . . . . . . . . . . . . . . . . . . . 107

Online Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Ladder Logic View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Message Pane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Status Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

File Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Edit Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

View Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Communication Menu . . . . . . . . . . . . . . . . . . . . . . . . . 114

Tools Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Help Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Create Logic in the Old

DeviceLogix Ladder Editor

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . 117

Understanding and Working With I/O Tags . . . . . . . . . . . . 117

Online Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Communication with Devices . . . . . . . . . . . . . . . . . . . . 118

Go On Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Online Animation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Change Logic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Change the Value of Timers and Counters . . . . . . . . . . 121

Enable and Disable Logic . . . . . . . . . . . . . . . . . . . . . . . 121

6 Publication RA-UM003B-EN-P - February 2010

Page 7

Table of Contents

Verify Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Compare Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Upload and Download Logic . . . . . . . . . . . . . . . . . . . . 123

Forcing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Clear Latched Hardware Faults . . . . . . . . . . . . . . . . . . . 126

Recovery Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Navigate the New Ladder Editor

Interface

Create Logic in the New Ladder

Editor

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . 127

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Ladder Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Rung Element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Configuration Toolbars . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Standard Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Tabbed Instruction Toolbar . . . . . . . . . . . . . . . . . . . . . 130

Online Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Ladder Logic View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Message Pane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Status Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

File Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Edit Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

View Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Communications Menu. . . . . . . . . . . . . . . . . . . . . . . . . 140

Tools Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Help Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . 143

About I/O Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Working with the Tag Database . . . . . . . . . . . . . . . . . . 144

About Screen Format Elements . . . . . . . . . . . . . . . . . . . . . 145

Configure the Macro Instruction. . . . . . . . . . . . . . . . . . . . . 146

Work with the Macro Instruction . . . . . . . . . . . . . . . . . 147

Edit the Macro Definition and Parameters . . . . . . . . . . . 154

Interface Changes Related to Macro Instruction . . . . . . . 158

Online Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Edit Parameter Values When Online . . . . . . . . . . . . . . . 158

Online Animation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Enable and Disable Logic . . . . . . . . . . . . . . . . . . . . . . . 159

Verify Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Upload and Download Logic . . . . . . . . . . . . . . . . . . . . 161

Force Inputs and Outputs. . . . . . . . . . . . . . . . . . . . . . . 162

Publication RA-UM003B-EN-P - February 2010 7

Page 8

Table of Contents

Register EDS Files and Add

Devices Offline/Online

RSNetWorx for DeviceNet

Software and the

DeviceLogix Editors

What This Appendix Contains . . . . . . . . . . . . . . . . . . . . . . 165

EDS Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Unregister EDS files . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Register EDS Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Add Devices offline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Add Devices online. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

What This Appendix Contains . . . . . . . . . . . . . . . . . . . . . . 177

Access Device Properties. . . . . . . . . . . . . . . . . . . . . . . . . . 177

Check General Information . . . . . . . . . . . . . . . . . . . . . 178

Enter Device Parameters . . . . . . . . . . . . . . . . . . . . . . . 180

Understand Parameters . . . . . . . . . . . . . . . . . . . . . . . . 184

Determine Parameters . . . . . . . . . . . . . . . . . . . . . . . . . 188

Access I/O Data Information . . . . . . . . . . . . . . . . . . . . 195

Access EDS Information . . . . . . . . . . . . . . . . . . . . . . . . 196

Launch the DeviceLogix Editor . . . . . . . . . . . . . . . . . . . 198

8 Publication RA-UM003B-EN-P - February 2010

Page 9

Preface

Purpose of This Manual

Who Should Use This Manual

This manual describes how to install and configure devices using

DeviceLogix. It also describes how to navigate and use the old

DeviceLogix Ladder Editor, the new DeviceLogix Ladder Editor, and

the DeviceLogix Function Block Editor.

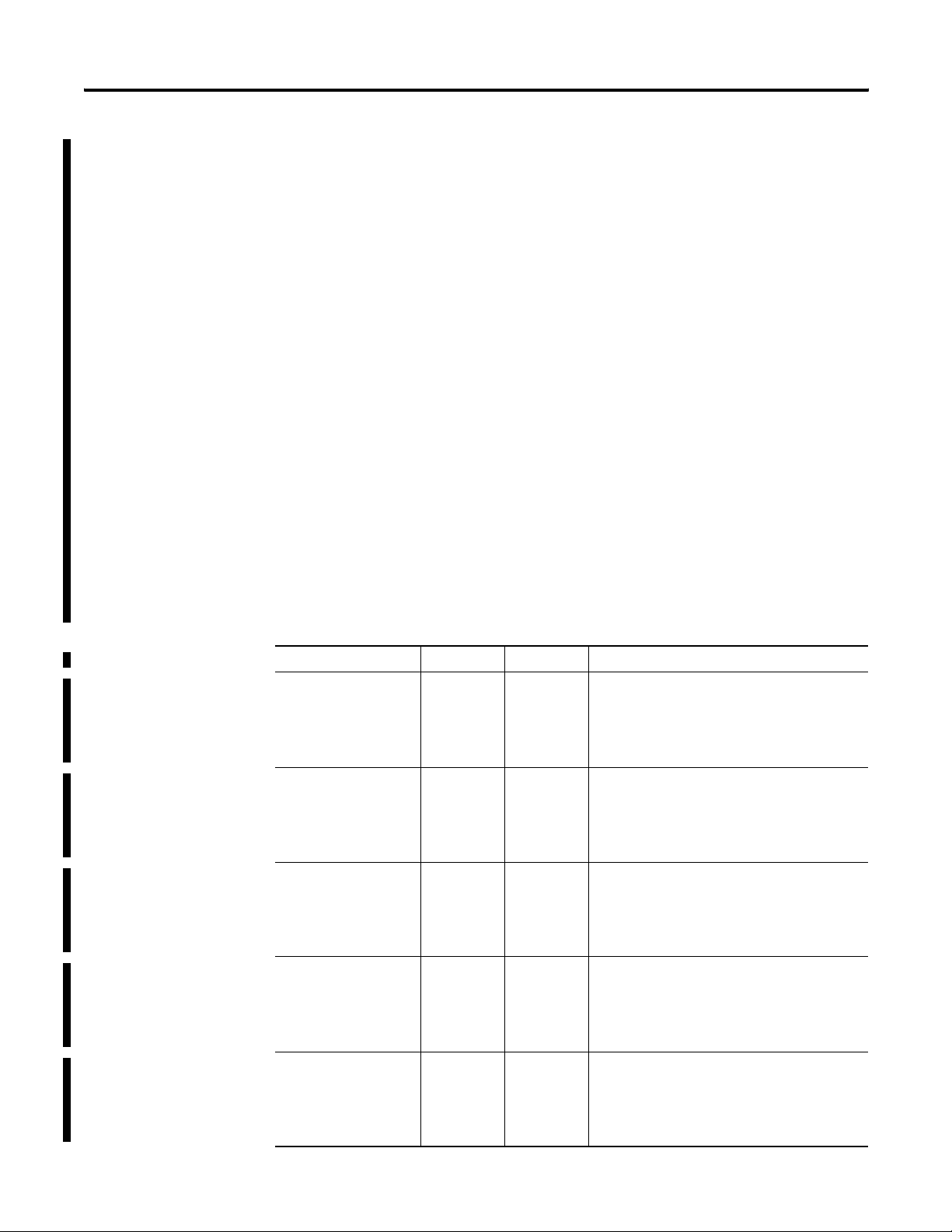

See the Following Sections See Page

Who Should Use This Manual 9

Related Terms 9

Common Techniques Used in This Manual 10

This manual is intended for engineers and technicians who use

DeviceLogix to control outputs and manage information locally within

devices.

This document assumes that you are familiar with one or more of the

following working environments:

• RSNetWorx for DeviceNet software (including the configuration

of distributed I/O devices)

• Drive Tools (including DriveExplorer, DriveTools SP, and Drive

Add-On Profiles)

Related Terms

Refer to the Related Terms table to become familiar with DeviceLogix.

Related Terms

Name Description

Download The transfer of logic from the software memory to the device.

Logic Logic consists of function blocks or ladder logic and their interconnnections

that can reside on a DeviceLogix device.

MAC ID Media Access Control Identifier - An integer identification value assigned to

each node on DeviceNet. This value distinguishes a node among all other

nodes on the same link.

NAN Not a Number - Value that is typically produced as a the result of an

operation on invalid input operands, especially in floating-point calculations.

Upload The transfer of logic from the device memory to the software memory.

9Publication RA-UM003B-EN-P - February 2010 9

Page 10

Chapter 1 Preface

Common Techniques Used in This Manual

The following conventions are used throughout this manual:

• Bulleted lists provide information, not procedural steps.

• Numbered lists provide sequential steps.

• Pictures of keys and/or dialogs represent the actual keys you

press or the dialogs you use.

• Actions you must perform appear in bold and look like the

following example: Select Unregister a device.

• A menu item in this format Network > Online identifies the

menu item (Network) and the submenu item (Online) after the

caret (>).

TIP

Tips contain helpful information.

10 Publication RA-UM003B-EN-P - February 2010

Page 11

Chapter

What is DeviceLogix Functionality?

1

Introduction

DeviceLogix functionality has been added to a number of Rockwell

Automation devices to control outputs and manage status information

locally within the device.

The configuration of the DeviceLogix functionality is accomplished

through the DeviceLogix Editor. The DeviceLogix Editor includes two

kinds of logic configuration tools for DeviceLogix devices to meet

different configuration preferences:

• Function Block Editor - provides a graphical interface for

configuring function blocks to provide local control within

DeviceLogix-capable devices.

• Ladder Editor - provides a ladder-style configuration tool for

DeviceLogix-capable devices. Beginning with firmware

revision 4, two Ladder Editors are available within DeviceLogix.

The Old Ladder Editor supports DeviceLogix, firmware

revision 3 and earlier. The New Ladder Editor supports

DeviceLogix, firmware revision 4.

The DeviceLogix Editor is an applet of RSNetWorx for DeviceNet

software and Drive Tools software, and it can be launched directly

from those hosts.

With DeviceLogix-capable devices, you can enable a logic operation

using the DeviceLogix Editor to provide local control over the device’s

operation. A DeviceLogix device consists of:

• a specific number of inputs and/or outputs.

• local logic that determines its behavior.

11Publication RA-UM003B-EN-P - February 2010 11

Page 12

Chapter 1 What is DeviceLogix Functionality?

Inputs and Outputs

Inputs and outputs can be one of two types.

• Physical - Inputs and outputs realized by physical connections to

the device. These are referred to as Discrete/Analog Inputs or

Discrete/Analog Outputs.

• Networked - Inputs consumed by the device from the network

and outputs produced by the device onto the network.

Input and Output Bits

There are five types of DeviceLogix inputs. Inputs are read from the

Electronic Data Sheet (EDS) file or are created dynamically during

logic configuration. The inputs that are read from the EDS file cannot

be modified. The DeviceLogix inputs are:

•Device Input - A physical input of the device. Device inputs

represent the actual inputs, such as sensors and switches,

attached to a particular device.

• Network Input - Formerly called the Consumed Network Bit

(CNB), network input is data sent from a master that can be

used in the device’s logic.

• Device Status - Status inputs indicate the state of the device. For

example, if an explicit message connection exists between the

device and a master, an input called ‘explicit connection exists’

is set to true and possibly affects the logic the device performs.

• Device Fault - Faults are conditions that report device errors. For

example, if a device detects a short circuit on an output, a fault

input is set to true and possibly affects the logic the device

performs.

12 Publication RA-UM003B-EN-P - February 2010

Page 13

What is DeviceLogix Functionality? Chapter 1

There are two types of DeviceLogix outputs:

• Device Output - Hardware outputs that are the actual outputs,

such as lights and actuators, attached to a particular device.

Without DeviceLogix functionality, the master would normally

control the outputs via consumed data. In fact, if there is no

local logic controlling an output, the master controls the output

as it would if DeviceLogix functionality were not running on the

device. However, within DeviceLogix functionality, if the local

logic controls an output, the master no longer controls the

output. The only way the master can affect the state of an output

that is under local control is to route requests to the local logic

by using network inputs. Some outputs can be under local

control while others can still be controlled by the master.

• Network Output - Formerly called Produced Network Bit (PNB),

Network outputs report the results of the local logic to a master

and are part of the produced data from the device.

Local Function Block Logic

The local logic of a DeviceLogix device consists of function blocks,

inputs, outputs, and connections (wires) between them. Function

blocks contain connection points (called pins) and perform a specific

function. Inputs and outputs also have connection pins and represent

the actual hardware devices, networked data, and fault and status bits

that are available for use in the local logic.

A connection (wire) between function blocks is defined when an

input pin of one function block is bound to an output pin of another

function block. A pin can be bound to a:

• pin of another function block.

• physical input/output.

•networked input/output.

• fault or status bit.

• miscellaneous bit.

• block input enable bit and block output enable bit.

Function blocks may also have attributes that influence their function.

Configuring a DeviceLogix device consists of defining or editing the

local logic that is present on the device along with the EDS parameters

for that device.

Publication RA-UM003B-EN-P - February 2010 13

Page 14

Chapter 1 What is DeviceLogix Functionality?

Local Ladder Logic

The local logic of a DeviceLogix device consists of rung, branch,

contact, output coil, and box instructions. A box instruction performs

a specific function (such as Timer or Counter). Contact and coil

instructions could be hardware data, networked data, and fault and

status bits that are available for use in the local logic. Additionally,

contact could also refer the output of a box instruction.

The DeviceLogix Editor is a graphical tool for building DeviceLogix

functionality in DeviceLogix-enabled products. With the editor, you

can create logic, bind logic input and output, verify logic,

upload/download logic and enable/disable logic in

DeviceLogix-enabled products. When logic is running (in online mode

and when logic is enabled), real-time data is animated in the editor

and you can also implement forces or perform online parameter

modification for some function types.

DeviceLogix Functionality and Associated Host Software

You configure DeviceLogix features through RSNetWorx for DeviceNet

software and Drives Tools software. The DeviceLogix Editor ships as

part of RSNetWorx for DeviceNet software, starting with revision 3.0.

EDS files that enable DeviceLogix functionality are also shipped with

RSNetWorx for DeviceNet software in a separate folder labeled

Additional EDS Files.

For more information on registering EDS files, see Appendix A.

For more information on configuring RSNetWorx for DeviceNet

software for use with the DeviceLogix Editors, see Appendix B.

14 Publication RA-UM003B-EN-P - February 2010

Page 15

What is DeviceLogix Functionality? Chapter 1

RSNetWorx for DeviceNet Software Operating Modes

RSNetWorx for DeviceNet software lets you select online or offline

mode, as described below.

• Offline - RSNetWorx for DeviceNet software is not connected to

the network.

•Online - RSNetWorx for DeviceNet software is connected to the

network and is capable of communicating with devices on the

network.

Drive Tools Software Operating Modes

Drive Tools software lets you select online mode, as described below.

• Online - Drive Tools software is connected to the network and is

capable of communicating with devices on the network.

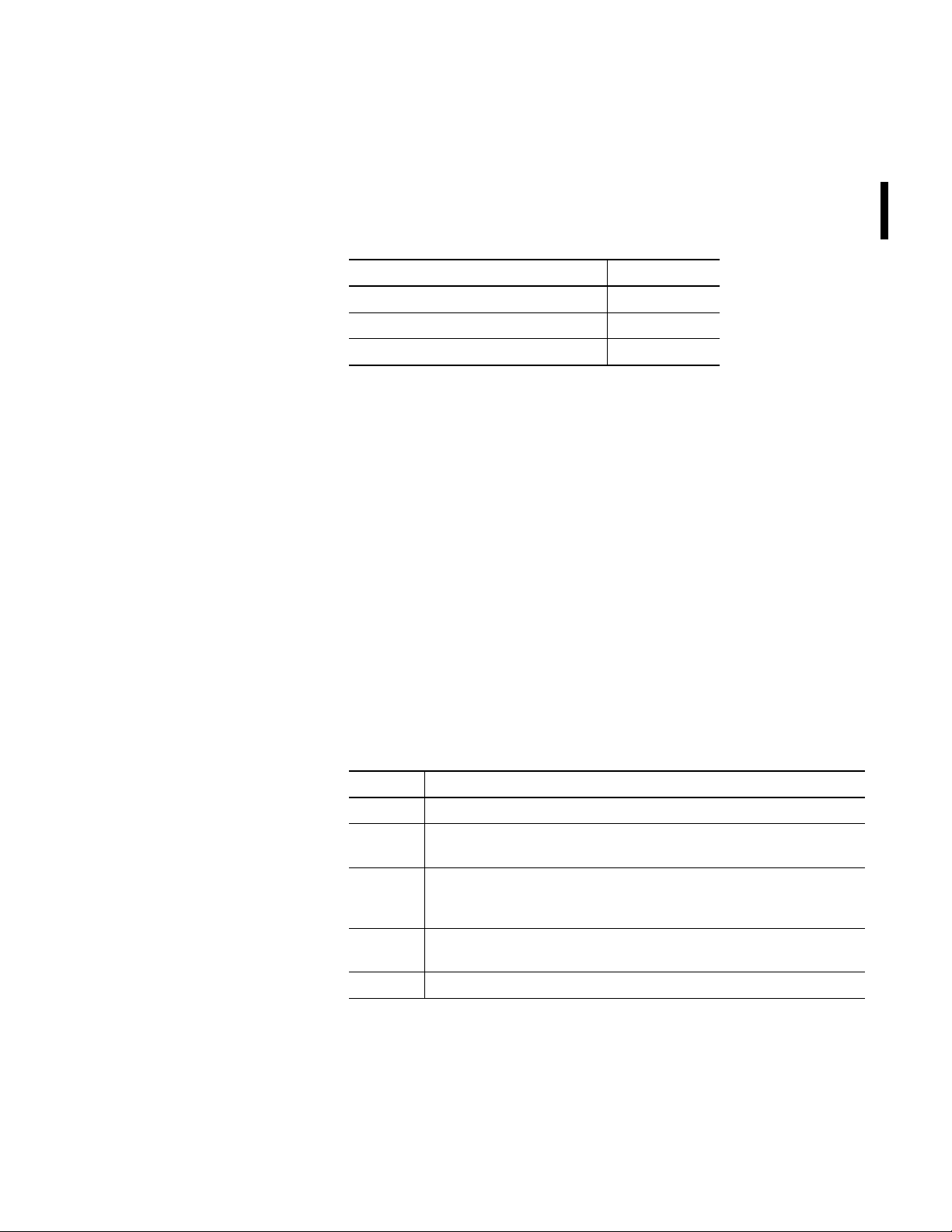

DeviceLogix Operating Modes

The mode that RSNetWorx for DeviceNet software is in directly affects

the way the DeviceLogix Editor behaves when it is launched. When

online with the device, DeviceLogix functionality provides two

alternative states: Pending Edits and Animated.

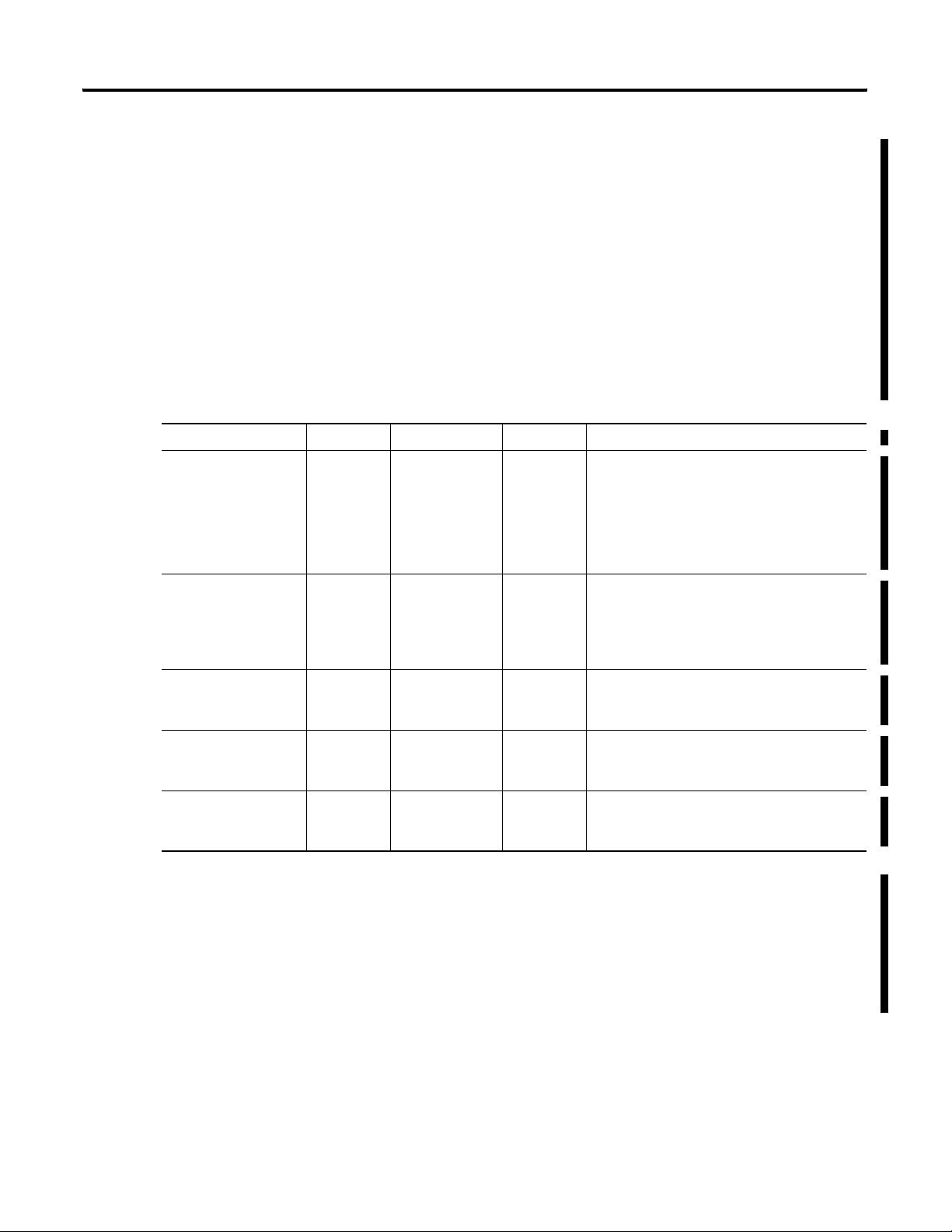

Mode Description

Offline The DeviceLogix Editor does not communicate with the

device. If RSNetWorx software is offline, the DeviceLogix

Editor is also offline. When offline, you can edit existing

DeviceLogix configurations or create new configurations.

Online Pending

Edits

Animated When online and animated, DeviceLogix functionality allows

When online with a device, pressing the edit button or

selecting

allows a device’s configuration to be edited while online.

When your edits are complete, the configuration must be

downloaded to the device.

a device’s configuration to be monitored in “real time”. Real

time includes comms throughput latencies. Depending on the

device, you may be able to change presets and accumulated

values.

Tools > Edit enables Pending Edits. Pending Edits

Publication RA-UM003B-EN-P - February 2010 15

Page 16

Chapter 1 What is DeviceLogix Functionality?

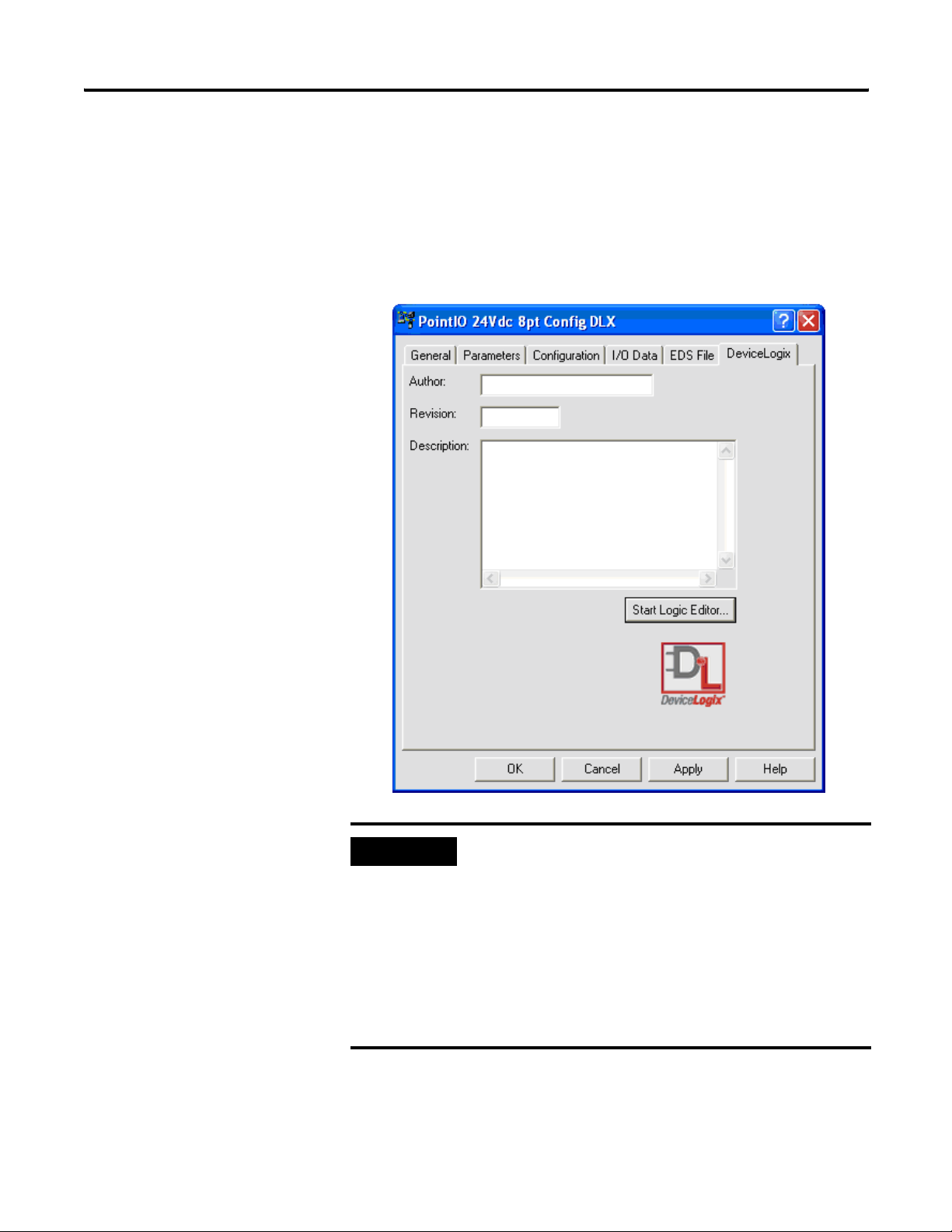

Launch the DeviceLogix Editor

After you configure the properties for your DeviceLogix-enabled

device (for more information, see Appendix A), you can launch the

DeviceLogix Editor. You see an additional tab in the device properties

dialog box for all DeviceLogix-enabled devices. This tab is labeled

DeviceLogix. This tab provides access to the start-up window for the

DeviceLogix Editor. You have the option to fill in your name, a

revision number, and a description of your configuration (all optional

fields)..

IMPORTANT

16 Publication RA-UM003B-EN-P - February 2010

If you are on line and you click on either the Parameters or the

DeviceLogix tab, you may be prompted to upload or download

the device. When you are on line, the dialog checks the

configuration in the device and compares it to the current

configuration. If the configurations are not the same, you must

upload from or download to the device to make the

configurations the same before you can make changes. If you

need to make changes without uploading or downloading, you

can exit the dialog box, go off line and re-enter the dialog box

to make the desired changes.

Page 17

What is DeviceLogix Functionality? Chapter 1

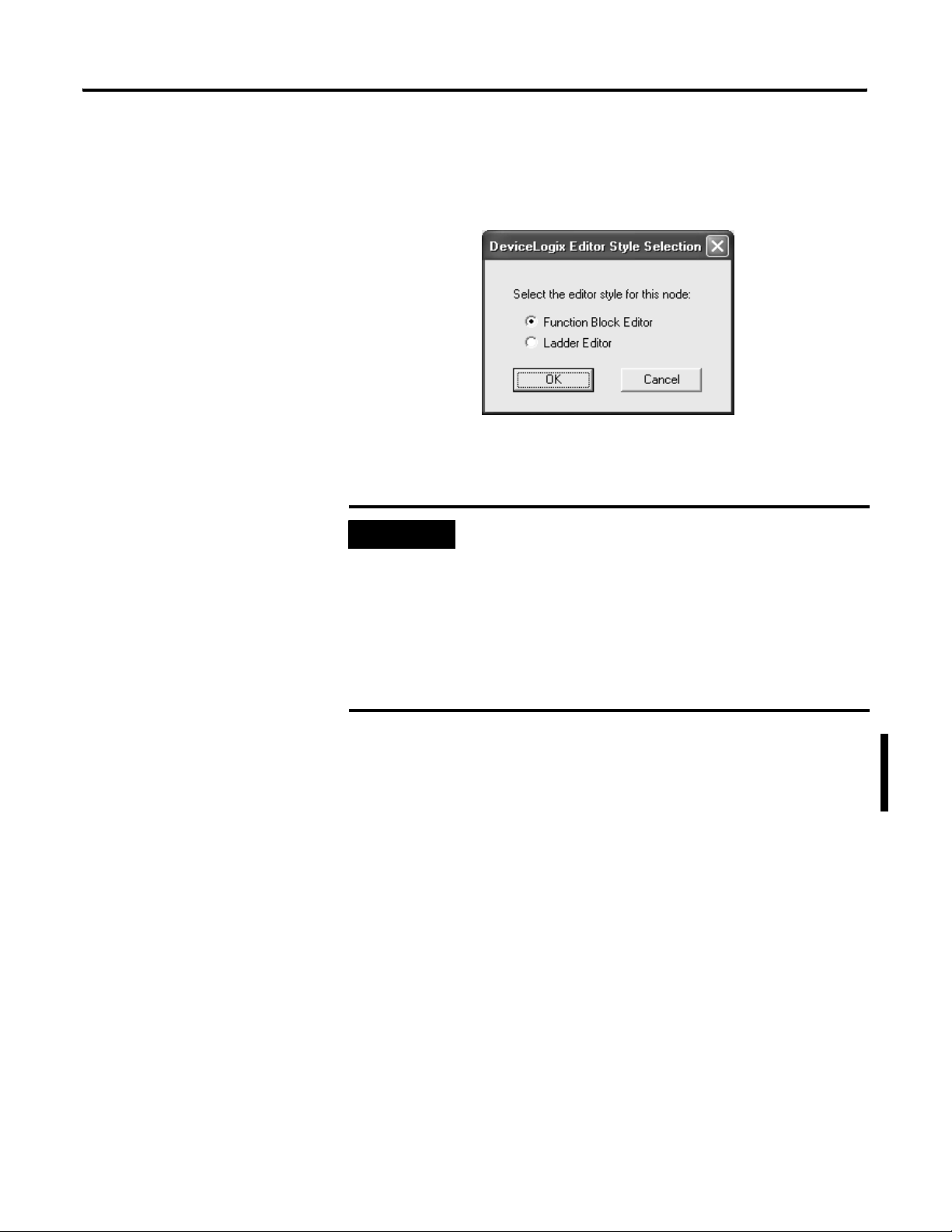

To start the DeviceLogix Editor for a DeviceLogix-enabled device,

click Start Logic Editor. On the DeviceLogix Editor Style Selection

dialog, you are prompted to select the editor type that you want to

launch. After selecting an editor type, click OK.

If the current device does not support one of the editor types, that

editor type will be grayed out.

IMPORTANT

If you select an editor type for a particular device and that type

is committed to the .dnt file (clicking OK or Apply), that editor

style is registered. Therefore, you cannot switch to another

editor style in that same .dnt file (the next time you launch the

DeviceLogix Editor Style Selection dialog, the other editor style

is grayed out). If you want to change the editor type (and a

device supports both editor types), you must create a new

project file, add this device again, and then select the other

editor type.

For more information on the Function Block Editor, refer to Chapters

2 and 3. For more information on the Old Ladder Editor, refer to

Chapters 4 and 5. For more information on the New Ladder Editor,

refer to Chapters 6 and 7.

Publication RA-UM003B-EN-P - February 2010 17

Page 18

Chapter 1 What is DeviceLogix Functionality?

Notes:

18 Publication RA-UM003B-EN-P - February 2010

Page 19

Chapter

2

Navigate the Function Block Editor Interface

What This Chapter Contains

Components

Read this chapter to learn more information about the Function Block

Editor interface. The following table lists what this chapter contains

and where to find specific information.

To help you configure your logic, the Function Block Editor consists

of:

Topic Page

Components 19

DeviceLogix Function Block Elements 20

I/O Components 21

Function Block Instructions 23

Configuration Toolbars 52

Schematic View 59

Message Pane 60

Status Bar 60

Menus 61

• Function Block Elements

• Configuration toolbars

• Schematic view

•Message pane

•Status bar

•Menus

19Publication RA-UM003B-EN-P - February 2010 19

Page 20

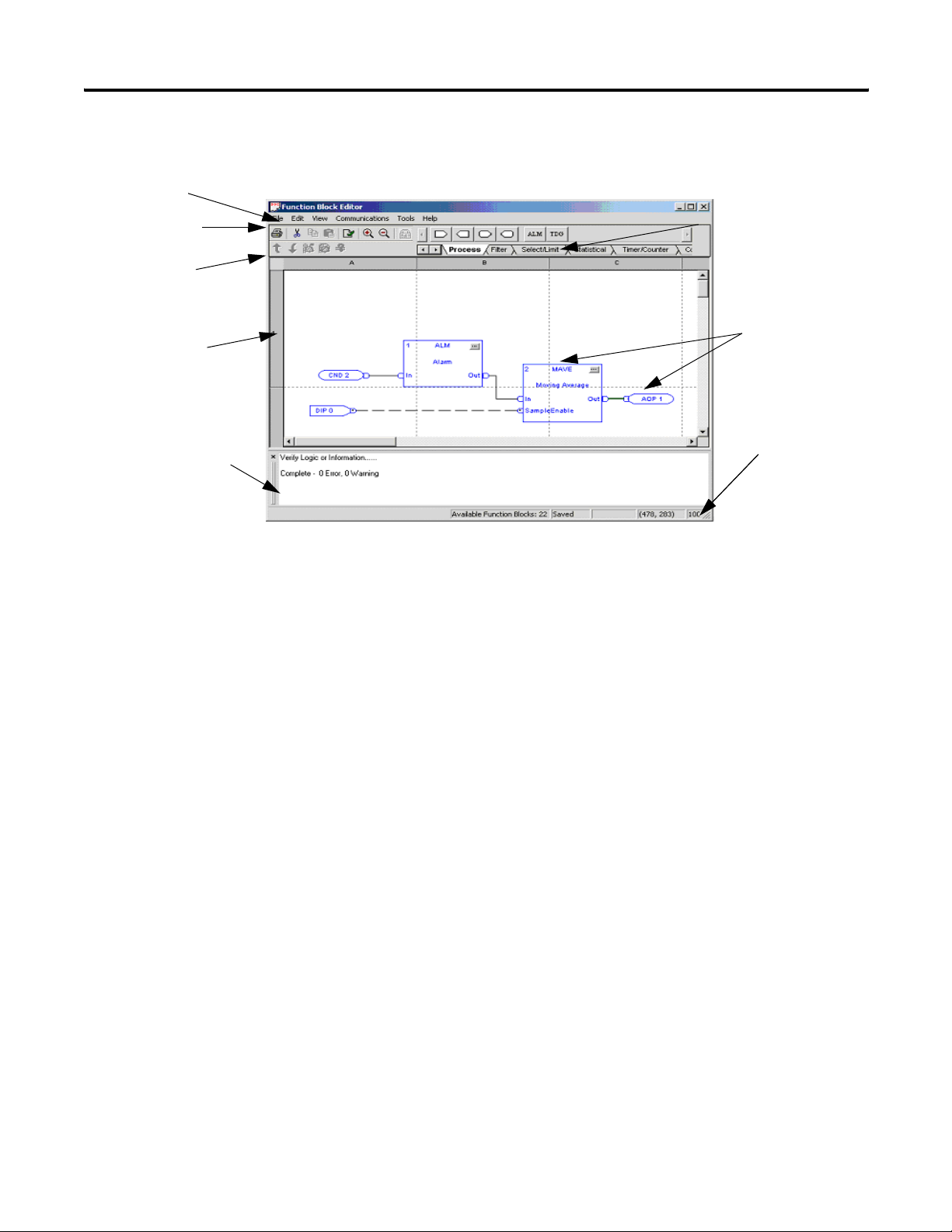

Chapter 2 Navigate the Function Block Editor Interface

Menus

Standard toolbar

Online toolbar

Schematic view

Message pane

DeviceLogix Function Block Elements

Tabbed Instruction

toolbar

Function block

elements

Status barStatus bar

Function Block elements consist of:

• I/O components: the input and output source of the product, or

I/O information from the network

• Function block instructions: all types of DeviceLogix

instructions. An instruction’s I/O path needs to be bound with

I/O components or the inputs and outputs of another

instruction.

• Text comments

20 Publication RA-UM003B-EN-P - February 2010

Page 21

Navigate the Function Block Editor Interface Chapter 2

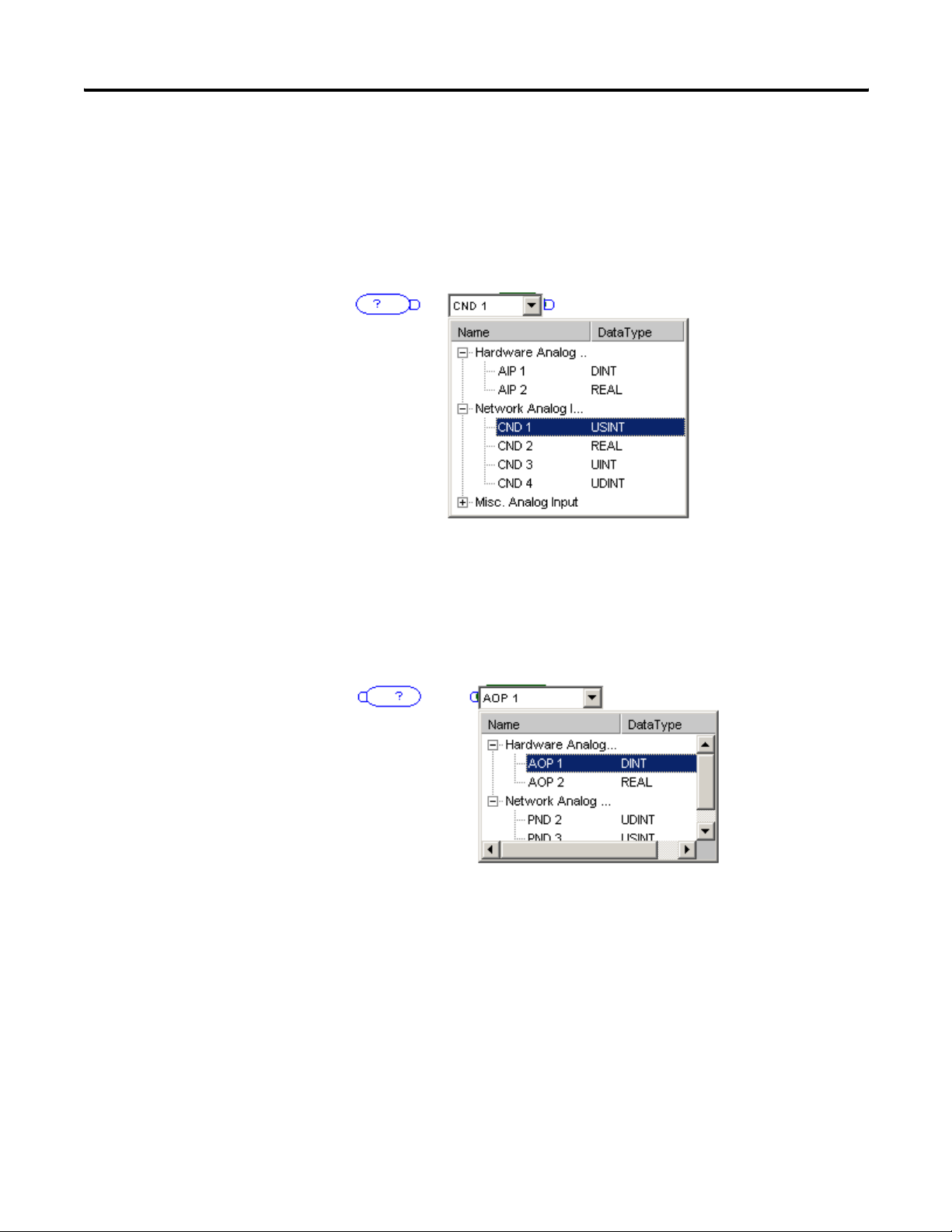

I/O Components

In the following sections, we will briefly describe each of the I/O

components and include their graphic from the Function Block Editor.

You can drag each of these I/O components from the instruction

toolbar, or click the icon and have it added into the current schematic,

or select Edit > Add Element to add the I/O component. Each newly

added I/O component does not have a binding name; you can click it

to display a drop down list related to this component type, and then

select the one you needed.

Digital Input Point (DIP)

The following kinds of digital inputs are supported:

• physical local Boolean input point

• local Boolean fault status

• network Boolean input point

• local Boolean miscellaneous point

Digital Output Point (DOP)

The following kinds of digital outputs are supported:

• physical local Boolean output point

• network Boolean output point

Publication RA-UM003B-EN-P - February 2010 21

Page 22

Chapter 2 Navigate the Function Block Editor Interface

Analog Input Point (AIP)

The following kinds of analog inputs are supported:

• physical local analog input point

• network analog input point

• local analog miscellaneous point

Analog Output Point (AOP)

The following kinds of analog outputs are supported:

• physical local analog output point

• network analog output point

22 Publication RA-UM003B-EN-P - February 2010

Page 23

Navigate the Function Block Editor Interface Chapter 2

Function Block Instructions

The DeviceLogix Function Block Editor has several categories of

function block types:

•Process

•Filter

• Select/Limit

•Statistical

• Timer/Counter

•Compare

•Compute/Math

•Move/Logical

•Macro Block

Each function block type has the following tabs on its property pages:

• General tab - displays general information about this function

block instruction. You can also select the function data type (if

available) and input a comment for this block. Once any

changes have been applied, a sequence number is allocated for

this block.

• Parameter tab - Lists all of the parameters available for this

function block type. Preset data can be entered in all editable

fields. Once logic runs, the real-time value will be updated in

the Value column. Note the read-only data is grayed out and

cannot be edited.

Process Category

The Process category includes the following instruction types:

•Alarm

• Timing Diagnosis

•PID

Publication RA-UM003B-EN-P - February 2010 23

Page 24

Chapter 2 Navigate the Function Block Editor Interface

Alarm

The Alarm function block initiates an alert based on the comparison

between the input value and the threshold. The output of the

DeviceLogix Alarm function block contains these alerts.

The details of the Alarm function block are outlined in the table.

Condition Output Fault State

INPUT >

HLimit==HHLimit)

HLimit <

LLimit < INPUT < HLimit 0x0000 0

• High-High alarm

•High alarm

• Low alarm

• Low-Low alarm

HHLimit (including the case when

INPUT < HHLimit 0x0004 0

0x000C 0

LLLimit < INPUT <

INPUT <

LLLimit (including the case when

LLimit==LLLimit)

INPUT is NAN* Keep the output

INPUT is positive infinity 0x000C 2

INPUT is negative infinity 0x0003 2

Input value from binding source is out of the

object's range

*The condition is only possible when Operation Data Type is REAL.

LLimit 0x0002 0

0x0003 0

unchanged

Keep the output

unchanged

The valid parameter range is shown below:

Parameters Data Range

HHLimit -2147483648 ~ 2147483647 (DINT)

-3.402823466e+38F ~ 3.402823466e+38F (REAL)

HLimit -2147483648 ~ 2147483647 (DINT)

-3.402823466e+38F ~ 3.402823466e+38F (REAL)

LLimit -2147483648 ~ 2147483647 (DINT)

-3.402823466e+38F ~ 3.402823466e+38F (REAL)

LLLimit -2147483648 ~ 2147483647 (DINT)

-3.402823466e+38F ~ 3.402823466e+38F (REAL)

Note: HHLimit >=HLimit >=LLimit >=LLimit

2

1

24 Publication RA-UM003B-EN-P - February 2010

Page 25

Navigate the Function Block Editor Interface Chapter 2

IMPORTANT

When data values are large, switching between REAL and DINT

data types may cause a minimal loss of accuracy. For example,

a value of 99999999 DINT will be rounded up to 100000000

REAL when you switch to a REAL data type and then back to a

DINT data type.

Timing Diagnosis

The DeviceLogix Timing Diagnosis function block object determines

whether the occurrence of the expected event is within the preset

timing interval.

The following is an operation example:

The rising edge of the Trig Start input indicates the occurrence of a

Trig Start event. The rising edge of the Trig Finish input indicates the

occurrence of a Trig Finish event.

When the Trig Start event occurs, the Timing Diagnosis function block

is started. The internal timer starts timing from 0 as shown below.

Meanwhile, the function block reports the triggered status as the

output.

The events that occur in the illustration are as follows.

• If the Trig Finish event occurs before the Minimum Time, that is,

at the time slot (1), then the function block returns an early

finish status. If the occurrence of the Trig Finish event is within

the range of Min time and Min time + Range time, as shown in

time slot (2), then the Trig Finish event happens within the

expected timing slot. Therefore, a normal finish status is

returned. If no Trig Finish event occurs at the interval 0 and Min

time + Range time, then the Late Finish status is returned, as

shown in the time slot (4).

• Within the time interval 0 and Min time + Range time, if the Trig

Start event occurs again, that is as shown in the time slot (3),

then the Retrigger status is reported as the function block

output.

Publication RA-UM003B-EN-P - February 2010 25

Page 26

Chapter 2 Navigate the Function Block Editor Interface

Parameters Data Range

MinTime 0 ~ 65535

RangeTime 0 ~ 65535

ElapsedTime 0 ~ 65535

PID

• Once the Trig Finish event occurs, or if a Retrigger event is

detected, or the Late Finish status is reported, the function block

stops operation, and the internal timer stops timing. The

function requires a reset event to perform another operation.

• In all cases, the Reset signal overrides all other function block

functionality. If the Reset Binding attribute is not supported or it

is not bound, the function block behaves as if it is tied low.

• All input edges that occur during reset are ignored.

• The Elapsed Time attribute should be clear at the time that the

Trig Start event triggers the function block.

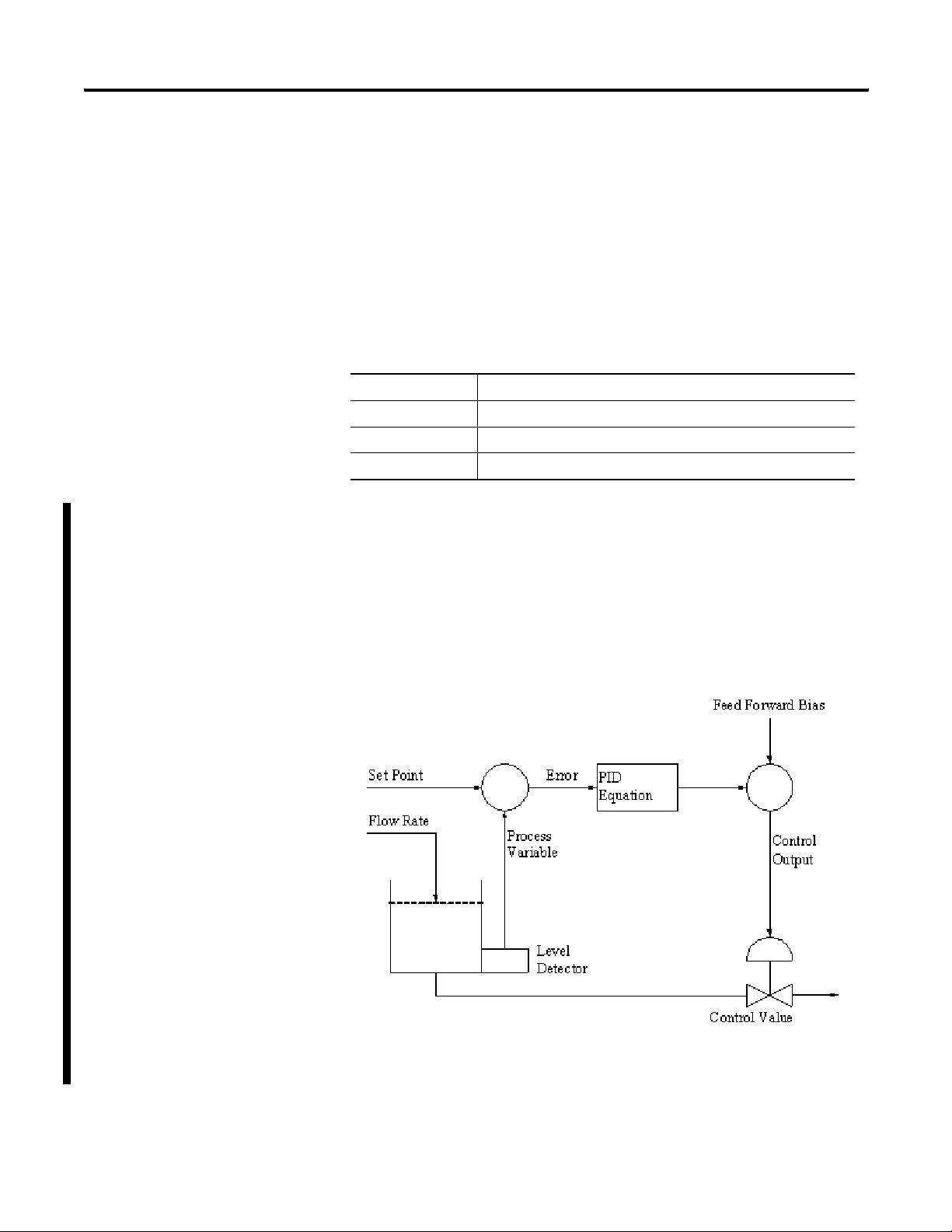

Use the PID function block to control a closed single analog loop.

The PID function block operates only in the timed mode. In this

mode, the function block is calculated and updates its output

periodically at a user-selectable rate. PID closed loop control holds a

process variable at a desired set point. A flow rate/fluid level example

is shown in the following figure.

Σ

Σ

26 Publication RA-UM003B-EN-P - February 2010

Page 27

Navigate the Function Block Editor Interface Chapter 2

The PID equation controls the process by sending an output to the

actuator device. The greater the error between the setpoint and

process variable input, the greater the output will be. An additional

value (feedforward or bias) can be added to the control output as an

offset. The PID result (control variable) drives the process variable

toward the setpoint.

The PID function block monitors and controls the process loop for

analog process parameters such as pressure, temperature, flow rate,

and fluid level. Features of the PID function block include:

• PID equations expressed in Dependent Gains (ISA standard)

• Input scaling in engineering units

• Zero-crossing deadband

• Derivative term acts on PV

• Direct or reverse acting control

•Output alarms

• Output limiting with anti-reset windup

• Manual mode (with bumpless transfer)

• Feedforward or output biasing

The PID function block uses the following equation with dependent

gains:

Where:

K

is Control Gain

c

T

is Reset Term

i

T

is Rate Term

d

SP is Set Point

PV is Process Variable

E is (SP-PV) or (PV-SP)

CV is Output Control Variable

Δt is Loop Update Time

Publication RA-UM003B-EN-P - February 2010 27

Page 28

Chapter 2 Navigate the Function Block Editor Interface

The PID function has Enable In and Process Variable as inputs, and

Enable Out and Control Variable as outputs, as described in the

following tables.

Input Type Default Description

Enable In BOOL 1 Enable In

PV REAL 0.0 Process Variable

Output Type Default Description

Enable Out BOOL 0 Enable Out

CV REAL 0.0 Control Variable

The PID function also provides four parameters that you can modify

as needed:

• Tuning

•Configuration

•Scaling

•Status

Tuning Parameters

Tuning Parameters allow you to set the PID algorithm parameters.

Parameter Type Range Default Description

Setpoint (SP) REAL 0.0 Desired control point of the process variable. It

should be scaled in the engineering unit.

Set Output % REAL 0.0 ~ 100.0 0.0 PID output for the manual set output mode. Use

this value to prevent bumps in control when

switching control mode back to automatic.

Output Bias % REAL 0.0 ~ 100.0 0.0 Output bias percentage

Control Gain (K

Reset Time (T

Rate Time (T

Station Mode BOOL 0 Indicates the station mode:

) REAL 0.0 Controller gain

c

)REAL 0.0 Reset time

i

) REAL 0.0 Rate time

d

• 0 = Manual

• 1= Automatic

28 Publication RA-UM003B-EN-P - February 2010

Page 29

Navigate the Function Block Editor Interface Chapter 2

Manual and Automatic Modes

The PID function block automatically provides bumpless

transfer from manual mode to auto mode. The PID function

block back-calculates the value of the integral accumulation

term required to make the CV output track the set output value

in manual mode. In this manner, when the loop switches to auto

mode, the CV output starts off from the set output value and no

"bump" in output value occurs.

Configuration Parameters

Configuration parameters allow you to set control loop features.

Parameter Type Range Default Description

Control Action BOOL 0 Indicates the direction of control:

• 0 is E=SP-PV

• 1 is E=PV-SP

This parameter cannot be configured when the

DeviceLogix logic is in the Run mode.

Loop Update Time UDINT 0 Periodical time interval in microseconds for

output update.

This parameter cannot be configured when the

DeviceLogix logic is in the Run mode.

CV High Limit % REAL 0.0 ~ 100.0 0.0 System's maximum allowable value for the

Control Variable. The PID function block does

not output a CV that exceeds the High Limit.

CV Low Limit % REAL 0.0 ~ 100.0 0.0 Sytem's minimum allowable value for the

Control Variable. The PID function block does

not output a CV less than the Low Limit.

Deadband Value REAL 0.0 Error range above and below the setpoint. Enter

"0" to inhibit the deadband. The deadband has

the same scaled units as the setpoint.

Deadband

The adjustable deadband is used to select an error range above

and below the setpoint where output does not change as long as

the error remains within this range. This deadband controls how

closely the process variable matches the set point without

changing the output.

Publication RA-UM003B-EN-P - February 2010 29

Page 30

Chapter 2 Navigate the Function Block Editor Interface

Zero-crossing is deadband control that lets the function block

use the error for computational purposes as the process variable

crosses into the deadband until the process variable crosses the

setpoint. Once the process variable crosses the setpoint (error

crosses zero and changes sign), and as long as the process

variable remains in the deadband, the function block considers

the error value to be zero. The deadband has the same scaled

units as the setpoint.

Output Limit

An output limit (percent of output) can be set on the control

output. When the function block detects that the output has

reached a limit, the PID function block automatically avoids

reset windup by preventing the integral term from accumulating

whenever the CV output reaches its maximum or minimum

values. The accumulated integral term remains frozen until the

CV output drops below its maximum limit or rises above its

minimum limit. Normal integral accumulation automatically

resumes.

Scaling Parameters

Scaling parameters allow you to set the output scale.

Parameter Type Default Description

PV Max REAL 0.0 Maximum value for the unscaled Process

Variable (PV).

This parameter cannot be configured when the

DeviceLogix logic is in the Run mode.

PV Min REAL 0.0 Minimum value for the unscaled Process

Variable (PV).

This parameter cannot be configured when the

DeviceLogix logic is in the Run mode.

EU Max REAL 0.0 Maximum engineering unit for the Process

Variable (PV).

This parameter cannot be configured when the

DeviceLogix logic is in the Run mode.

EU Min REAL 0.0 Minimum engineering unit for the Process

Variable (PV).

This parameter cannot be configured when the

DeviceLogix logic is in the Run mode.

CV Max (at 100%) REAL 0.0 Maximum value for the unscaled Control

Variable (CV).

This parameter cannot be configured when the

DeviceLogix logic is in the Run mode.

30 Publication RA-UM003B-EN-P - February 2010

Page 31

Navigate the Function Block Editor Interface Chapter 2

CV Min (at 0%) REAL 0.0 Minimum value for the unscaled Control

Variable (CV).

This parameter cannot be configured when the

DeviceLogix logic is in the Run mode.

Positive Deviation

Alarm Limit

REAL 0.0 High deviation alarm from the set point.

Negative Deviation

Alarm Limit

Status Parameters

Status parameters allow you to monitor the control algorithm running

status, using the Alarm parameter's bit field as described here:

• Bit 0: CV is below minimum output limit (0=no; 1=yes)

• Bit 1: CV is above maximum output limit (0=no; 1=yes)

• Bit 2: Error is within deadband (0=no; 1=yes)

• Bit 3: Deviation is alarmed high (0=no; 1=yes)

• Bit 4: Deviation is alarmed low (0=no; 1=yes)

• Bit 5: SP is out of range (0=no; 1=yes)

• Bit 6: PV is out of range (0=no; 1=yes)

• Bit 7~15: Reserved

REAL 0.0 Low deviation alarm from the set point.

The PID function block scales the process variable, using the

following formula:

The setpoint and zero-crossing deadband should be scaled to

engineering units.

Publication RA-UM003B-EN-P - February 2010 31

Page 32

Chapter 2 Navigate the Function Block Editor Interface

Filter Category

The Filter category includes a single instruction type: Low Pass Filter.

Low Pass Filter

The DeviceLogix Low Pass Filter (LPF) function block provides a filter

to attenuate input frequency above the cutoff frequency.

Let W

value of the sampling period. Therefore, the sampling frequency f

According to W

stand for the value of the attribute WLag and T

lag

the expected analog cutoff frequency fp is:

,

lag

sample

is the

s

is:

With the basic equation between the analog input frequency f and the

digital frequency

we can obtain the digital frequency

Ω

corresponding to f

Ω

p

p

The bilinear transformation method is applied to convert the analog

filter into the digital filter. The bilinear transformation is defined as

follows.

To adjust the frequency shift due to the bilinear transformation, you

must use the prewarping equation to calculate the prewarping analog

frequency. The prewarping equation is as follows.

Then the value of w

substitute for w

32 Publication RA-UM003B-EN-P - February 2010

is taken as the real analog cutoff frequency and

p

..

lag

Page 33

Navigate the Function Block Editor Interface Chapter 2

The above discussion outlined the general process of low-pass

filtering. Specifically, the filter discussed order 1 LPF and order 2 LPF.

Order 1 LPF

The target analog filter is as follows.

When bilinear transformation is applied, we take the w

as the actual

p

cutoff frequency. That is, the target transform function is as follows.

Then we apply the bilinear transformation.

Therefore, the corresponding difference equation is as follows.

Order 2 LPF

The target analog filter is as follows.

This is the same derivation process that is in order 1 LPF. Finally, the

corresponding difference equation is as follows.

where

Publication RA-UM003B-EN-P - February 2010 33

Page 34

Chapter 2 Navigate the Function Block Editor Interface

The valid parameter range is shown below.

Parameters Data Range

Initialize 0,1

WLag 0 < WLag = 3.402823466e+38F

Order 1,2

Flotation 0, 1, 2, 3

FaultOption -3.402823466e+38F ~ 3.402823466e+38F

Select/Limit Category

The Select/Limit category includes the following instruction types:

Select

•Select

• High Low Limit

The DeviceLogix Select function block identifies one input within the

selected two function block inputs as the output according to the

value of the selector. The Select function block is outlined in detail

below.

IF Selector = 1

Output = value of Input 2

IF Selector = 0

Output = value of Input 1

END

The valid data ranges are as follows.

Parameters Data Range

In1 -2147483648 ~ 2147483647 (DINT)

-3.402823466e+38F ~ 3.402823466e+38F (REAL)

In2 -2147483648 ~ 2147483647 (DINT)

-3.402823466e+38F ~ 3.402823466e+38F (REAL)

SelectorIn 0, 1

FaultOption 0, 1, 2, 3

FaultStateValue -2147483648 ~ 2147483647 (DINT)

-3.402823466e+38F ~ 3.402823466e+38F (REAL)

34 Publication RA-UM003B-EN-P - February 2010

Page 35

Navigate the Function Block Editor Interface Chapter 2

IMPORTANT

When data values are large, switching between REAL and DINT

data types may cause a minimal loss of accuracy. For example,

a value of 99999999 DINT will be rounded up to 100000000

REAL when you switch to a REAL data type and then back to a

DINT data type.

High/Low Limit

The DeviceLogix High/Low Limit function block limits the input value

within the specified data range.The High/Low Limit function block is

outlined in detail below.

IF value of Input > HighLimit

Output = HighLimit

ELSE IF value of Input < LowLimit

Output = LowLimit

ELSE

Output = Input

END

Output

Condition

INPUT in NAN NAN Value of the Fault

If Use Fault Checking

is RESET

If Use Fault

Checking is SET

state value

Fault Status

1

INPUT is the Positive

Infinity

INPUT is the Negative

Infinity

HighLimit 0

LowLimit 0

The valid data ranges are as follows.

Parameters Data Range

HighLimit 2147483648 ~ 2147483647 (DINT)

-3.402823466e+38F ~ 3.402823466e+38F (REAL)

LowLimit 2147483648 ~ 2147483647 (DINT)

-3.402823466e+38F ~ 3.402823466e+38F (REAL)

FaultOption 0, 1, 2, 3, 4, 5

FaultStateValue -2147483648 ~ 2147483647 (DINT)

-3.402823466e+38F ~ 3.402823466e+38F (REAL)

Note: HighLimit > LowLimit.

Publication RA-UM003B-EN-P - February 2010 35

Page 36

Chapter 2 Navigate the Function Block Editor Interface

IMPORTANT

When data values are large, switching between REAL and DINT

data types may cause a minimal loss of accuracy. For example,

a value of 99999999 DINT will be rounded up to 100000000

REAL when you switch to a REAL data type and then back to a

DINT data type.

Statistical Category

The Statistical category includes a single instruction type: Moving

Average.

Moving Average

The DeviceLogix Moving Average function block calculates a time

average value for the input signal.

When sampling is enabled, the object executes this formula as the

main function.

When the object starts executing, the moving average is initialized, as

shown in the example that follows.

Example

Number of samples = 3

Scan 1: Output1 = Input1

Scan 2: Output2 = (Input2+Input1)/2

Scan 3: Output3 = (Input3+Input2+Input1)/3

The table lists the conditions and corresponding output with special

input values.

Output

Condition

INPUT in NAN NAN Hold last output Value of instance

INPUT is the Positive

Infinity

INPUT is the Negative

Infinity

Input value from

binding source is out

of range for the object

Fault Option = 1 Fault Option = 2 Fault Option = 3

Positive Infinity 2

Negative Infinity 2

The calculated result

using the truncated input

value

attribute Fault State

Value

Fault Code

2

1

36 Publication RA-UM003B-EN-P - February 2010

Page 37

Navigate the Function Block Editor Interface Chapter 2

The valid data ranges are as follows.

Parameters Data Range

SampleEnable 0, 1

NumberOfSamples 1 ~ 65535

SampleRate 0 ~ 65535

FaultOption 0, 1, 2, 3

FaultStateValue -2147483648 ~ 2147483647 (DINT)

-3.402823466e+38F ~ 3.402823466e+38F (REAL)

IMPORTANT

When data values are large, switching between REAL and DINT

data types may cause a minimal loss of accuracy. For example,

a value of 99999999 DINT will be rounded up to 100000000

REAL when you switch to a REAL data type and then back to a

DINT data type.

Timer/Counter Category

The Timer/Counter category includes the following instruction types:

• Timers - The Timer controls the state of a single output based on

the value of an Accumulator and a Preset. The Timer has two

inputs called Input and Reset which control the counting of the

Accumulator. The three timers available are:

– On-Delay Timer

– Off-Delay Timer

– Pulse Timer

All three timers have a selectable time base of either 1

millisecond or 10 milliseconds. The timers are non-retentive.

Only the output status is available. No Timer Timing or Timer

Done bits are available. The different timers are described in the

next sections.

• Counters - There are two kinds of Counters:

– Up Counter

– Up/Down Counter

The difference is the Up/Down Counter has two input path: one

for up counting and the other for down counting. The Reset

path binding is optional for Counters. You can also change

element type by editing the name field.

Publication RA-UM003B-EN-P - February 2010 37

Page 38

Chapter 2 Navigate the Function Block Editor Interface

On Delay Timer

The On Delay Timer delays the output response to an input by a

desired amount of time. When the input is TRUE, the timer increments

the accumulator and when the input goes FALSE the timer resets the

accumulator. For each time base unit of time, the timer increments the

accumulator. When the accumulator reaches the preset value, the

timer sets the output to TRUE. The timer maintains the output TRUE

status as long as the input remains TRUE.

When the input changes from TRUE to FALSE, the timer resets both

the output and the accumulator. If the input goes FALSE before the

time period specified by the time base and preset, the output remains

FALSE and the accumulator is cleared, essentially ignoring the input.

If the device supports retentive type Timer or Ccounter, then the

accumulate value of the Timer/Counter will be retained during

power-down. When the power is cycled and the logic resumes

running, it updates based on the previous accumulate value.

If the timer senses a TRUE level on the reset input at any time during

the operation of the timer, it resets the output to FALSE and clears the

accumulator. Because the reset line is level sensitive, the timer

remains reset until the timer detects a FALSE on the reset input. Also,

because the input is level sensitive, the timer again begins to

increment the accumulator if the reset line goes FALSE while the input

remains TRUE.

The valid data ranges are as follows.

Parameters Data Range

PRE 0 ~ 65535

ACC 0 ~ 65535

Time Base 0 (1 ms), 1 (10 ms)

38 Publication RA-UM003B-EN-P - February 2010

Page 39

Navigate the Function Block Editor Interface Chapter 2

Off Delay Timer

The Off-Delay Timer works the same way as the On-Delay Timer but

instead of delaying the TRUE status of the output, it delays the FALSE

status of the output. The input to this timer is a level sensitive FALSE

with an edge-triggered reset on the FALSE to TRUE transition. This

means that when the input is FALSE, the timer increments the

accumulator and when the input goes TRUE the timer resets the

accumulator. For each time base unit of time, the timer increments the

accumulator.

When the accumulator reaches the preset value, the timer sets the

output to FALSE. The timer maintains the output FALSE status as long

as the input remains FALSE. When the input changes from FALSE to

TRUE, the timer sets the output to TRUE and resets the accumulator. If

the input goes TRUE before the time period specified by the time base

and preset, the output remains TRUE, and the accumulator is cleared,

essentially ignoring the input.

If the timer senses a TRUE level on the reset input at any time during

the operation of the timer, it resets the output to FALSE and clears the

accumulator. Because the reset line is level sensitive, the timer

remains reset until the timer detects a FALSE on the reset input. Also,

because the input is level sensitive, the timer again begins to

increment the accumulator if the reset line goes FALSE while the input

remains FALSE. However, because the reset logic already set the

output to FALSE, the time delay causes no effect because the output is

already FALSE. If the input is TRUE when the reset goes FALSE, the

timer sets the output to TRUE.

Publication RA-UM003B-EN-P - February 2010 39

Page 40

Chapter 2 Navigate the Function Block Editor Interface

The valid data ranges are as follows.

Parameters Data Range

PRE 0 ~ 65535

ACC 0 ~ 65535

Time Base 0 (1 ms), 1 (10 ms)

Pulse Timer

The Pulse Timer generates a TRUE value on its output for a fixed

amount of time. The duration of the TRUE pulse is determined by the

preset value along with the time base of the timer. When the input to

the timer changes from FALSE to TRUE, it sets the output to TRUE and

starts the accumulator counting. It then increments the accumulator

each time the time base number of milliseconds has expired. When

the accumulator reaches the preset value, the timer resets the output

to FALSE.

In the Pulse Timer, the input acts only as a trigger to start the

accumulator counting. Once the accumulator starts timing, it continues

to rise regardless of the state of the input. As long as the output is

TRUE and the accumulator is counting, additional triggers of the input

do not affect the state of the output or the count of the accumulator.

Once the accumulator reaches the preset value and the timer resets

the output to FALSE, the Pulse Timer can again trigger the process by

sensing a FALSE to TRUE transition on the input pin. Even if the input

remains on the entire time the accumulator is counting, when the

accumulator reaches the preset value, the timer resets the output to

FALSE.

At any point during the operation of the timer, if it detects a TRUE

level on the reset input, it will disable the timer and set the output to

FALSE. The timer must again be triggered by a FALSE to TRUE

transition on the input. This means that if the input is TRUE and the

timer is reset, the timer will remain inactive. Even if the reset changes

back to FALSE while the input is TRUE, the timer remains inactive. In

order to start a new pulse operation, the input must change to FALSE

and then back to TRUE.

40 Publication RA-UM003B-EN-P - February 2010

Page 41

Navigate the Function Block Editor Interface Chapter 2

The valid data ranges are as follows.

Parameters Data Range

PRE 0 ~ 65535

ACC 0 ~ 65535

Time Base 0 (1 ms), 1 (10 ms)

Publication RA-UM003B-EN-P - February 2010 41

Page 42

Chapter 2 Navigate the Function Block Editor Interface

Up Counter

The Up Counter has two inputs called Input and Reset and one output

called Output. The Up counter simply counts up on a FALSE to TRUE

transition and sets its output to TRUE when the accumulator reaches

the preset value. The accumulator continues to count up until the

counter is reset or it reaches 65,535. A TRUE value on the reset input

zeros the accumulator and sets the output to FALSE.

An illustration of the counter function with a preset value set to 3 is

below.

The valid data ranges are as follows.

Parameters Data Range

PRE 0 ~ 65535

ACC 0 ~ 65535

Up/Down Counter

The Up/Down counter has three inputs called Input, Reset, and Count

Down Input and one output called Output. The counter increments

the accumulator any time the Input changes from FALSE to TRUE and

decrements the counter any time the Count Down Input changes from

FALSE to TRUE. When the accumulator is above or equal to the preset

value, the counter sets its output to TRUE. When the accumulator falls

below the preset, the counter resets its output to FALSE. Like the Up

Counter, the Up Down Counter resets when a TRUE level is detected

on the Reset input. When a reset occurs, the counter zeros the

accumulator and sets the output to FALSE.

42 Publication RA-UM003B-EN-P - February 2010

Page 43

Navigate the Function Block Editor Interface Chapter 2

An illustration of the Up Down counter function with a preset value

set to 3 is below:

The valid data ranges are as follows.

Parameters Data Range

PRE 0 ~ 65535

ACC 0 ~ 65535

Publication RA-UM003B-EN-P - February 2010 43

Page 44

Chapter 2 Navigate the Function Block Editor Interface

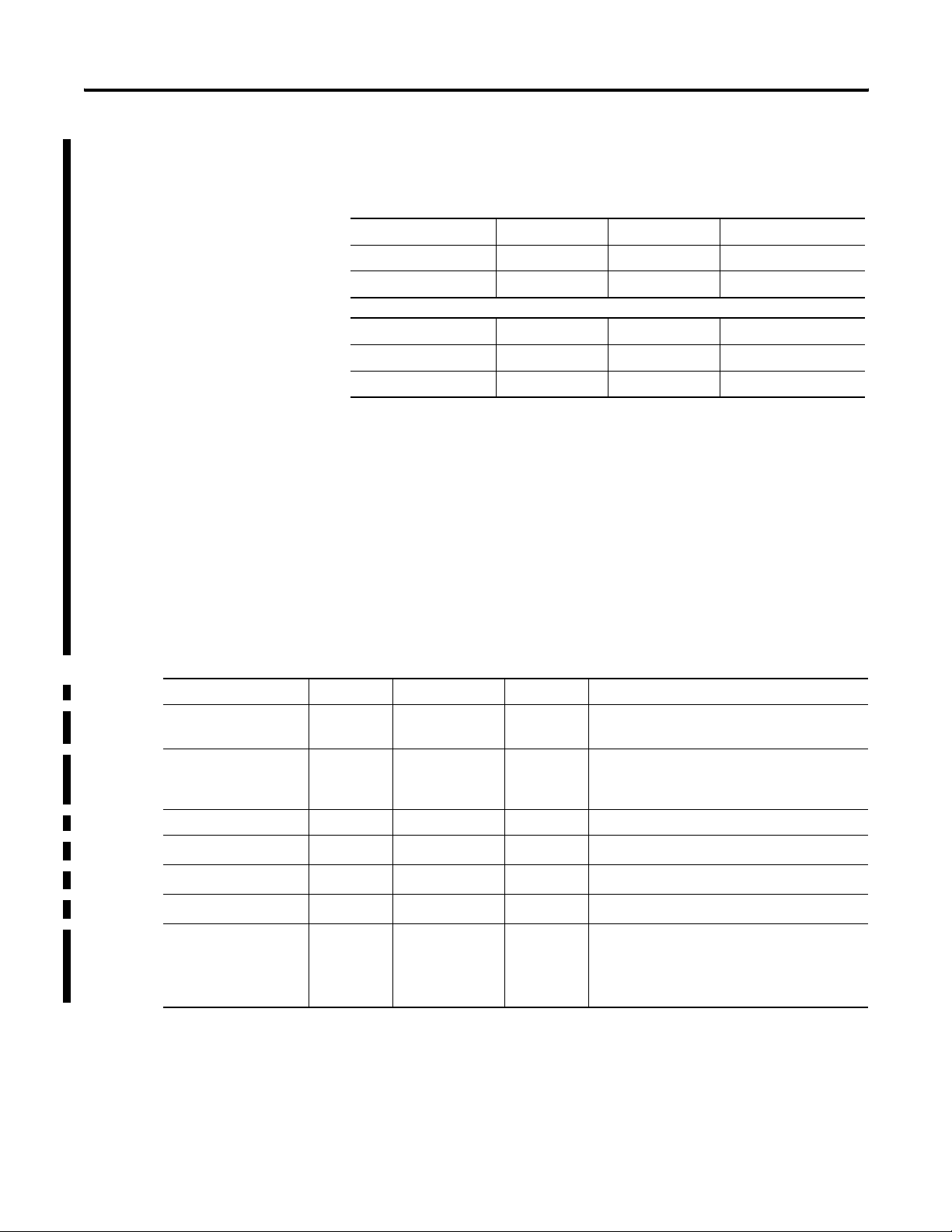

Compare Category

The Compare category includes basic comparison functions, including

the the instruction types:

Operation rules [all except Mask (MEQ)]

The conditions and outputs of each function block are described

below.

• Greater Than (GRT)

• Greater Than or Equal To (GEQ)

•Equal (EQU)

• Not Equal (NEQ)

• Less Than (LES)

• Less Than or Equal (LEQ)

•Mask (MEQ)

Function Block

Ty pe

Greater Than (GRT) Source A > Source B 1

Greater Than or

Equal (GEQ)

Equal (EQU) Source A == Source B 1

Not Equal (NEQ) Source A != Source B 1

Less Than (LES) Source A < Source B 1

Less Than or Equal

(LEQ)

Condition Output

Source A <= Source B 0

Source A >= Source B 1

Source A < Source B 0

Source A != Source B 0

Source A == Source B 0

Source A >= Source B 0

Source A <= Source B 1

Source A > Source B 0

Data ranges

The valid data ranges for all of these instructions are as follows.

Parameters Data Range

Source A -2147483648 ~ 2147483647 (DINT)

-3.402823466e+38F ~ 3.402823466e+38F (REAL)

Source B -2147483648 ~ 2147483647 (DINT)

-3.402823466e+38F ~ 3.402823466e+38F (REAL)

FaultOption 0, 1, 2

44 Publication RA-UM003B-EN-P - February 2010

Page 45

Navigate the Function Block Editor Interface Chapter 2

IMPORTANT

When data values are large, switching between REAL and DINT

data types may cause a minimal loss of accuracy. For example,

a value of 99999999 DINT will be rounded up to 100000000

REAL when you switch to a REAL data type and then back to a

DINT data type.

Comparison output for Infinity Input

Value of

Source A

(+) Infinity(+) Infinity011001

(+) Infinity(-) Infinity110100

(+) Infinity Any finite

(-) Infinity(+) Infinity000111

(-) Infinity(-) Infinity011001

(-) Infinity Any finite

Any finite

number

Any finite

number

Any finite

number

Value of

Source B

number

number

(+) Infinity000111

(-) Infinity110100

Any finite

number

Comparison Output

GRT GEQ EQU NEQ LES LEQ

110100

000111

Refer to operation rules

Operation rules [Mask (MEQ) only]

The Mask process is outlined below.

IF (Source AND Mask) == (Compare AND Mask)

Output is Set

ELSE

Output is Clear

END

Data ranges [Mask (MEQ) only]

The valid data ranges for the MEQ instructions are as follows.

Parameters Data Range

Source 16#0 ~ 16#FFFFFFFF

Mask 16#0 ~ 16#FFFFFFFF

Compare 16#0 ~ 16#FFFFFFFF

Publication RA-UM003B-EN-P - February 2010 45

Page 46

Chapter 2 Navigate the Function Block Editor Interface

Compute/Math Category

The Compute/Math category includes fundamental arithmetic

operations, including the instructions types:

Operation rules

•Add (ADD)

•Multiply (MUL)

• Subtract (SUB)

• Divide (DIV)

• Modulus (DINT)

• Modulus (REAL)

• Absolute (ABS)

• Negative (NEG)

• Square Root (SQR)

• Power (XPY)

The conditions and outputs of each function block are described

below.

Function Block

Ty pe

Add (ADD) = Source A + Source B

Multiply (MUL) = Source A x Source B

Subtract (SUB) = Source A - Source B

Divide (DIV) = Source A / Source B

Modulus (DINT) = Source A - (Source A/ Source B) x Source B

Modulus (REAL) = Source A - (DINT)(Source A/ Source B) x Source B

Absolute (ABS) = Absolute value of (Source A)

Negative (NEG) = - Source A

Square Root (SQR) = Square root of (Source A) *

Power (XPY) = Source A * * Source B

* If Source A is negative, the operation takes the absolute value of the Source A before

calculating the square root and no fault is reported.

Output

46 Publication RA-UM003B-EN-P - February 2010

Page 47

Navigate the Function Block Editor Interface Chapter 2

Fault State Conditions and Rules

Fault state conditions and rules are listed below.

Operation

Data Type

DINT The result from

REAL (±) Infinity x (±)

Condition Output Fault

the operations

ADD, SUB or

MUL exceeds

the range of the

DINT data type

(Any DINT) / 0 = Dividend 3

Input data from

the binding path

is out of range

Infinity

(±) Nonzero / 0 (±) Infinity 3

Infinity + Infinity Infinity 3

0 / 0 Infinity 3

Infinity - Infinity NAN 3

(±) Infinity / (±)

Infinity

(±) Infinity x 0 NAN 3

Fault Option

= 1

Truncates Hold last

Use the

Tr un ca te s

input value

(±) Infinity Hold last

NAN 3

Fault

Option = 2

output

output

Fault

Option = 3

Value of

instance

attribute

Fault State

value

Value of

instance

attribute

Fault State

value

Code

3

1

3

Sqrt ((±) Infinity) Infinity 3

0 x x 0 NAN 3

In XPY

operation,

source A is

negative while

source B is not

an integer value

NAN operand

for any

operation

Input data from

the binding path

is out of range

NAN 3

NAN 3

Use the

Tr un ca te s

input value

1

Publication RA-UM003B-EN-P - February 2010 47

Page 48

Chapter 2 Navigate the Function Block Editor Interface

Data ranges

The valid data ranges for the compute instructions are as follows.

Parameters Data Range

SourceA -2147483648 ~ 2147483647 (DINT)

Source B -2147483648 ~ 2147483647 (DINT)

FaultOption 0, 1, 2, 3

FaultStateValue -2147483648 ~ 2147483647 (DINT)

-3.402823466e+38F ~ 3.402823466e+38F (REAL)

-3.402823466e+38F ~ 3.402823466e+38F (REAL)

-3.402823466e+38F ~ 3.402823466e+38F (REAL)

IMPORTANT

When data values are large, switching between REAL and DINT

data types may cause a minimal loss of accuracy. For example,

a value of 99999999 DINT will be rounded up to 100000000

REAL when you switch to a REAL data type and then back to a

DINT data type.

Move/Logical Category

The Move/Logical category includes fundamental bit type logic

operations, including the instructions types:

•Boolean

– AND (BAND)

– Not AND (BNAND)

– OR (BOR)

– Not OR (BNOR)

– Exclusive OR (BXOR)

– Exclusive Not OR (BXNOR)

– NOT (BNOT)

•Latch

– Set Latch (SETD)

– Reset Latch (RESD)

48 Publication RA-UM003B-EN-P - February 2010

Page 49

Navigate the Function Block Editor Interface Chapter 2

Boolean Functions

The Boolean functions are as follows. Note that the number of inputs

can be changed on some functions and is product-specific.

Function Block

Ty pe

AND (BAND 0 0 0

Not AND (BNAND) 0 0 1

OR (BOR) 0 0 0

Not OR (BNOR) 0 0 1

Exclusive OR (BXOR) 0 0 0

Set Reset Output Value

010

100

111

011

101

110

011

101

111

010

100

110

011

101

110

Exclusive Not OR

(BXNOR)

NOT (BNOT) * 0 N/A 1

Note: The Input number can be set in a property page; the default

number is 2. BNOT has only one input.

Publication RA-UM003B-EN-P - February 2010 49

001

010

100

111

1N/A0

Page 50

Chapter 2 Navigate the Function Block Editor Interface

Latch Functions

There are two kinds of Latch functions: Set Dominant Latch (SR) and

Reset Dominant Latch (RS). Unlike the Latch in RS Logix 5000,

DeviceLogix Latch requires the Reset binding. So the Set/Reset

appears in pair and the RS type and SR type have different element

order. See its truth table below.

Function Block

Ty pe

SETD (Set

Dominant)

RS (Reset

Dominant)

Input 1 Input 2 Value at time +

t

0

000 0

010 1

100 0

110 1

001 1

011 1

101 0

111 1

000 0

010 1

100 0

110 0

001 1

011 1

101 0

111 0

Value at time +

t

0+1

Enable Line Feature

Enable Line can be supported by each instruction type in the Function

Block Editor. When an instruction supports the Enable Line feature,

that particular instruction can only be executed when the Enable Line

feature is on; otherwise, that instruction maintains the data from the

last data scan. Each instruction that uses Enable Line must configure

both an input and an output; the output has the same real time data as

the input, passing the enable information to the next instruction.

50 Publication RA-UM003B-EN-P - February 2010

Page 51

Navigate the Function Block Editor Interface Chapter 2

The Enable Line feature can have two data sources:

• If an input uses Enable Line to bind with an input point or other

function block’s output, the input retains this point’s data value.

• If an input uses Enable Line in an unbound capacity, the input

uses the default constant value (which you can set on each

instruction’s property page).

TIP

The EDS file for a device must explicitly specify support for this

functionality to be available. If a device’s EDS file does not

support this feature, this functionality will not be available.

Publication RA-UM003B-EN-P - February 2010 51

Page 52

Chapter 2 Navigate the Function Block Editor Interface

Configuration Toolbars

The Function Block Editor toolbars are:

• Standard - Lets you perform general editing functions, verify

logic, and toggle edit mode.

• Tabbed Instruction - Lets you enter Boolean or Analog type I/O,

and add functional elements to the schematic.

• Online - Lets you perform online functions. This toolbar is

enabled only when you are working on line.

Standard Toolbar

Standard Toolbar

Function Description

Sends the logic schematic to a printer.

Removes the selected element.

Duplicates the selected element and send it to the

clipboard.

Places the element in the clipboard at current cursor

position.

Verifies the logic you have configured on the schematic

sheet.

Makes the configuration smaller.

Makes the configuration bigger.

Toggles between the DeviceLogix Function Block Editor

software being in the Edit mode or not being in the Edit

mode. In the Edit mode, you can modify the logic but you

cannot communicate with the device. That is, you cannot

upload or download logic or turn the logic On or Off. When

you are not in Edit mode, you can perform online animation,

if the device is online. You can set the preset value, force

I/O, or accumulator value of counters or timers, and

download to a device, but you cannot modify logic.

52 Publication RA-UM003B-EN-P - February 2010

Page 53

Navigate the Function Block Editor Interface Chapter 2

Tabbed Instruction Toolbars

The tabbed instruction toolbars are:

•Process

•Filter

• Select/Limit

•Statistical

• Timer/Counter

•Compare

•Compute/Math

•Move/Logical

•Macro Block

Independent of what instruction type you have selected, the following

I/O components toolbar icons are always available.

I/O Components Toolbar

Function Description

Boolean bit input

Boolean bit output

Analog bit input

Analog bit output

Publication RA-UM003B-EN-P - February 2010 53

Page 54

Chapter 2 Navigate the Function Block Editor Interface

Process Category Toolbar

Process Category Toolbar

Function Description

Filter Category Toolbar

Filter Category Toolbar

Function Description

Alarm Instruction

Timing Diagnosis Instruction

PID Instruction

Low Pass Filter Instruction

Select/Limit Category Toolbar

Select/Limit Category Toolbar

Function Description

Select Instruction

High Low Limit Instruction

Low Pass Filter Instruction

Statistical Category Toolbar

Statistical Category Toolbar

Function Description

Moving Average Instruction

54 Publication RA-UM003B-EN-P - February 2010

Page 55

Navigate the Function Block Editor Interface Chapter 2

Timer/Counter Category Toolbar

Timer/Counter Category Toolbar

Function Description

Pulse Timer Instruction

On-Delay Timer Instruction

Off-Delay Timer Instruction

Up Counter Instruction

Up Down Counter Instruction

TIP

When using the ACC feature, you may notice some minor

differences in the Timer/Counter instructions. Depending on the

firmware implementation, some devices consider this an output

and bind it to an analog output tag, while other devices

consider it a parameter.

Compare Category Toolbar

Compare Category Toolbar

Function Description

Greater Than Instruction

Greater Than or Equal To Instruction

Equal Instruction