Page 1

SCADA System

Application Guide

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (Publication SGI-1.1

available from your local Rockwell Automation

http://www.ab.com/manuals/gi) describes some important differences

between solid state equipment and hard-wired electromechanical devices.

Because of this difference, and also because of the wide variety of uses for

solid state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is

acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, Rockwell Automation, Inc. cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to

use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation, Inc. is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations.

®

sales office or online at

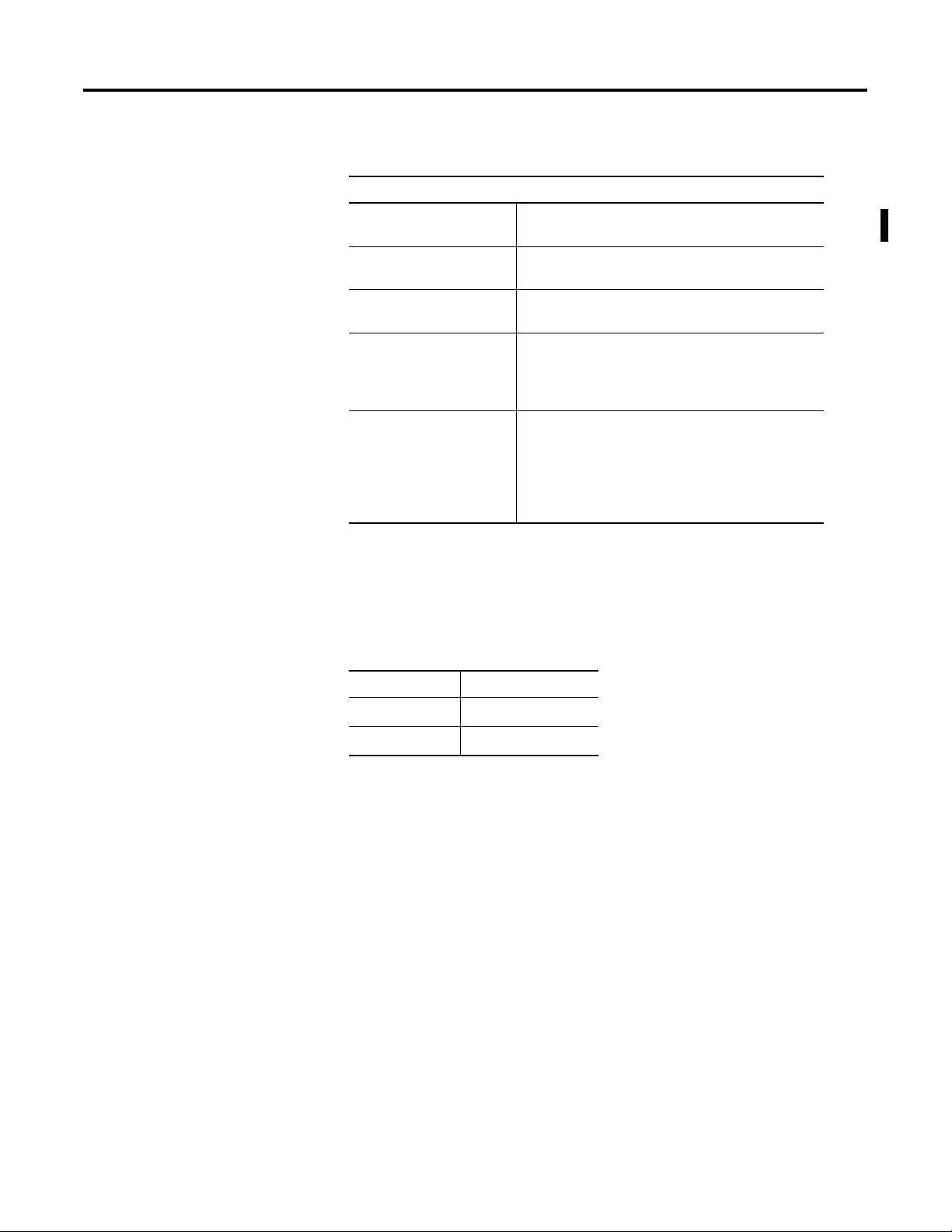

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information about practices or circumstances

that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property

damage, or economic loss.

Identifies information that is critical for successful

application and understanding of the product.

Identifies information about practices or circumstances

that can lead to personal injury or death, property

damage, or economic loss. Attentions help you:

• identify a hazard

• avoid a hazard

• recognize the consequence

Labels may be located on or inside the drive to alert

people that dangerous voltage may be present.

Labels may be located on or inside the drive to alert

people that surfaces may be dangerous temperatures.

Page 3

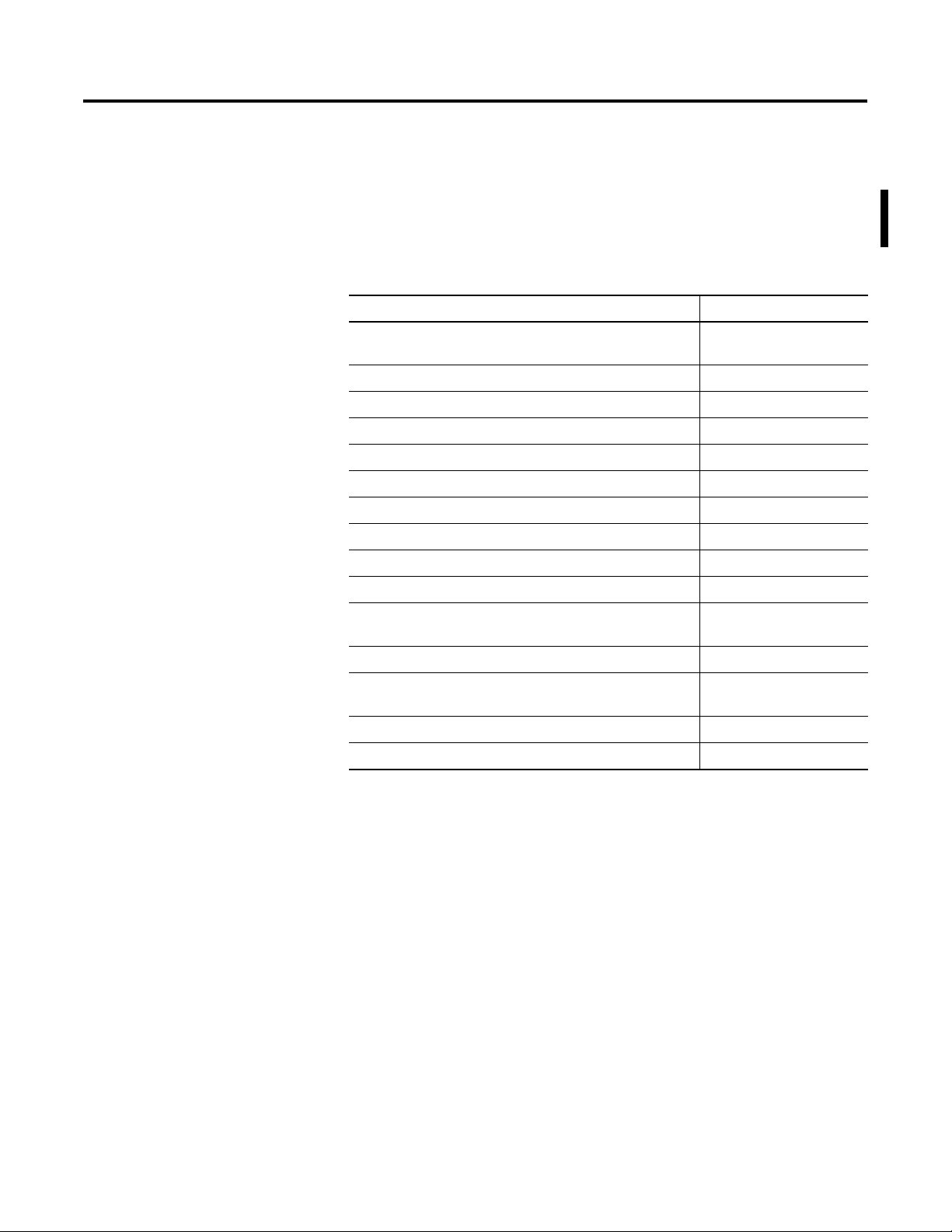

Summary of Changes

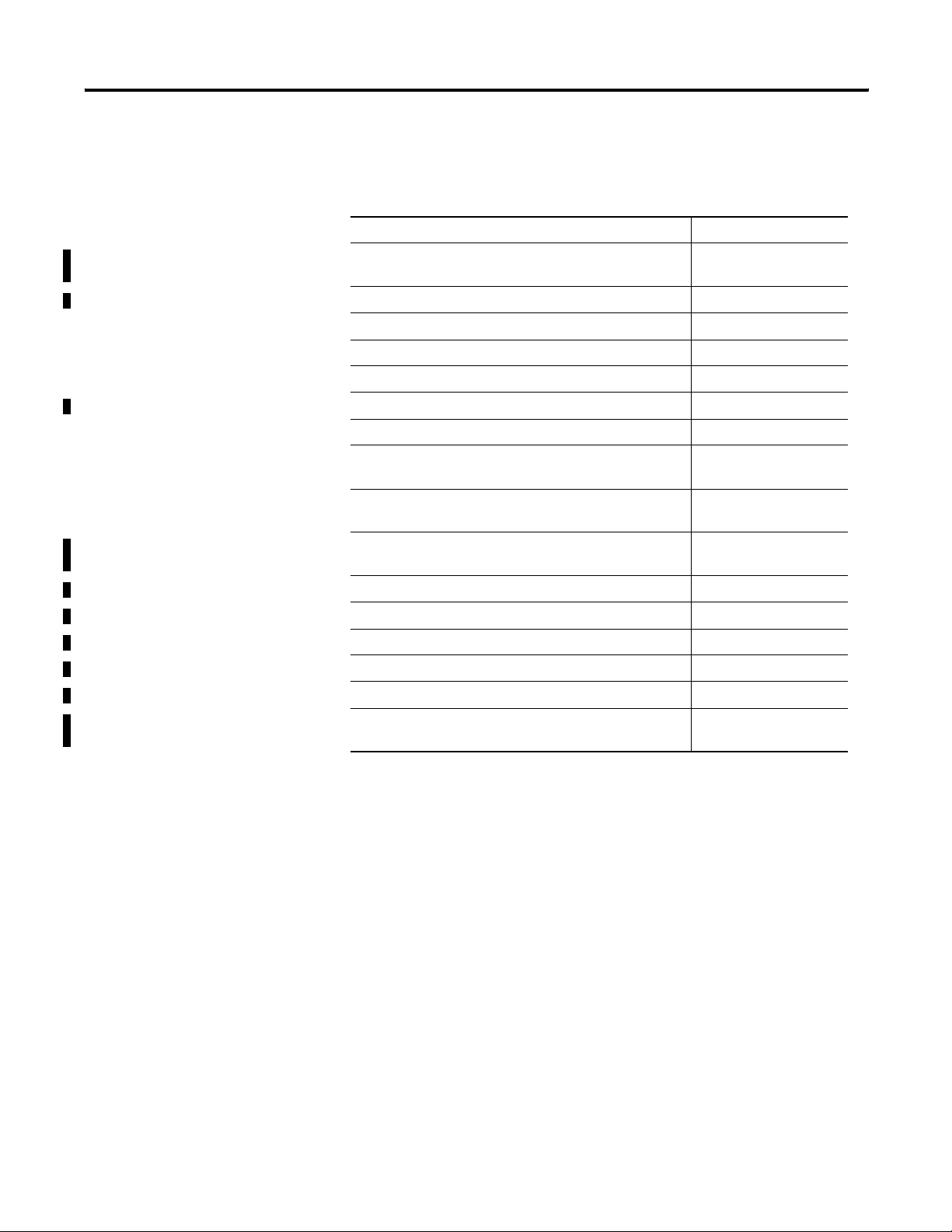

The information below summarizes the changes to this manual since

the last printing.

To help you find new and updated information in this release of the

manual, we have included change bars as shown to the right of this

paragraph.

For information on See

Removing Configuring Classic PLC-5 Processors with

1785-KE Modules chapter

Add in additional publications Preface

Designing communication for DF1 Radio Modem 1-17 through 1-19

Modbus RTU 3-46 through 3-57

Data Logging 3-58 through 3-69

Conditions that will erase the data retrieval file 3-69

DF1 Radio Modem 4-7 through 4-8

Configuring a Radio Modem station 4-27 through 4-32

Rockwell Automation modems 8-3 through 8-4

Configuring modems for PLC-5, SLC, and Logix processors 10-3

Configuring modems for MicroLogix 1100/1200/1500

controllers

Communicating over the telephone line 10-4 through 10-8

Remotely programming Allen-Bradley processors over a

telemetry network

DF1 Radio Modem B-7

Third party suppliers Appendix C

NA

10-4

Chapter 11

1 Publication AG-UM008C-EN-P - February 2005

Page 4

2 Summary of Changes

Publication AG-UM008C-EN-P - February 2005

Page 5

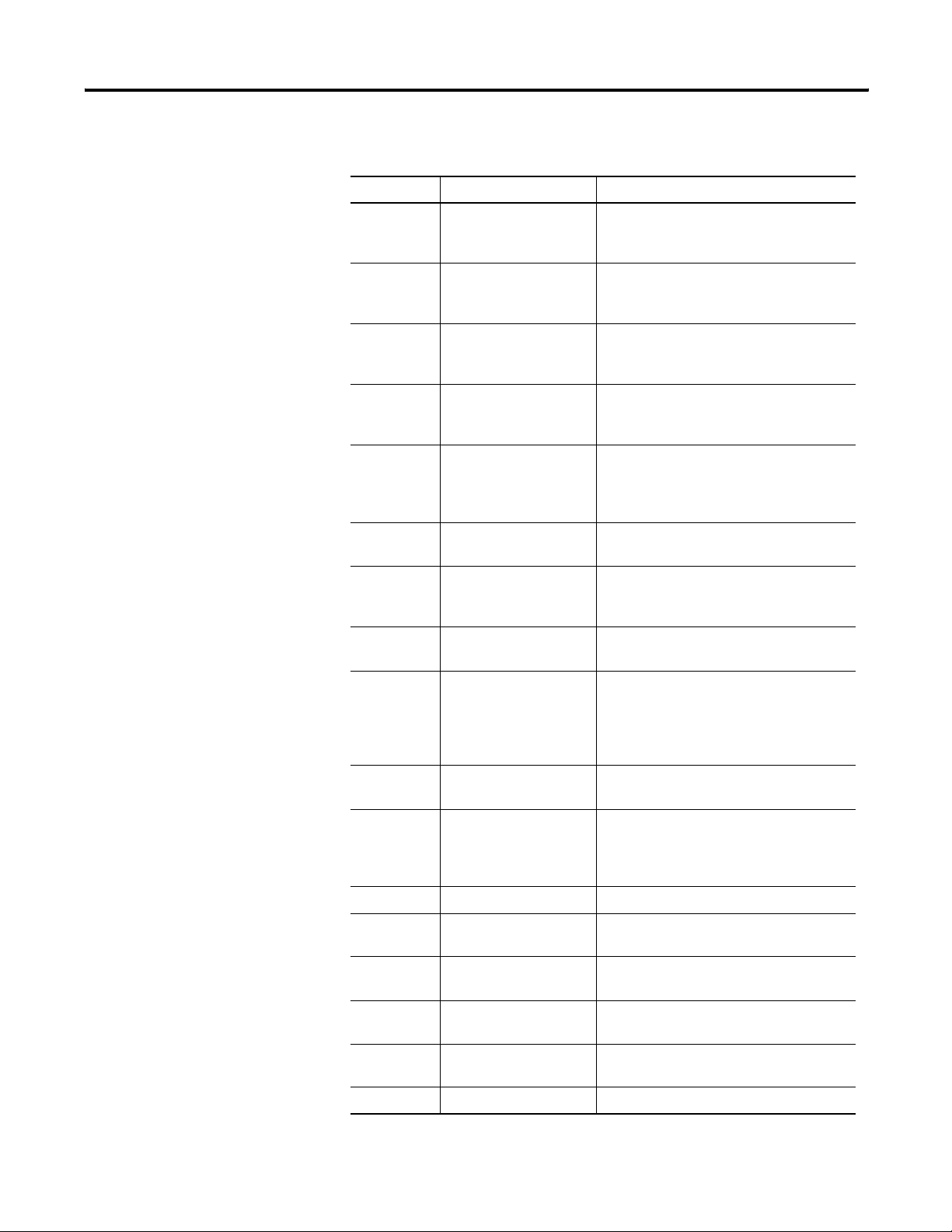

Designing Communication

Table of Contents

Preface

What SCADA Information Is Available?. . . . . . . . . . . . . . . . 1-1

Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Contents of this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Terms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Address Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Related Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Chapter 1

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Choosing a Polling Mode for DF1 Half-Duplex Master . . . . 1-2

Message-Based Polling Mode . . . . . . . . . . . . . . . . . . . . 1-2

Standard Polling Mode . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

About Polled Report-by-Exception . . . . . . . . . . . . . . . . 1-4

About Slave-to-Slave Messaging . . . . . . . . . . . . . . . . . . 1-5

Addressing Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Communication Scheme Design Using Standard-Mode . . . . 1-8

Designing a Polling Scheme . . . . . . . . . . . . . . . . . . . . 1-11

Planning for Timing Issues . . . . . . . . . . . . . . . . . . . . . 1-13

Design Considerations . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Communication Scheme Design Using

Message-Based Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Designing Communication

for DF1 Full-Duplex Protocol. . . . . . . . . . . . . . . . . . . . . . . 1-16

Designing Communication for DF1 Radio Modem Protocol. 1-17

Determining When to Use DF1 Radio Modem Protocol . 1-17

What to Do Next? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Chapter 2

Configuring Enhanced PLC-5

Processors

1 Publication AG-UM008C-EN-P - February 2005

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Installing the Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Configuring a DF1 Half-Duplex Standard Mode

Master Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Define the Communication Driver Characteristics . . . . . 2-5

Displaying System (Master) Channel Status . . . . . . . . . . 2-7

Create Station Lists. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Monitor Active Stations . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Configuring a DF1 Half-Duplex Message-based

Mode Master Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Configuring the Processor as a Slave Station. . . . . . . . . . . . 2-15

Displaying Slave System Channel Status . . . . . . . . . . . . 2-18

Page 6

2 Table of Contents

Configuring MicroLogix

1100/1200/1500 Controllers

Configuring the Processor as a Station on a

Point-to-Point Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Displaying Point-to-Point System Channel Status . . . . . . 2-22

Messaging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Master Station to Slave Station . . . . . . . . . . . . . . . . . . . 2-23

Polled Report-by-Exception . . . . . . . . . . . . . . . . . . . . . 2-23

Processor-to-Processor . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Considerations When Configuring MSG Control Blocks . 2-25

Example MSG Control Blocks. . . . . . . . . . . . . . . . . . . . 2-26

Chapter 3

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Installing the Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

MicroLogix 1200/1500 Channel 0 Cable Pinouts - User

Supplied Optical Isolator . . . . . . . . . . . . . . . . . . . . . . . 3-3

MicroLogix 1200/1500 Channel 0 Cable Pinouts -

Allen-Bradley Supplied Optical Isolator. . . . . . . . . . . . . 3-4

MicroLogix 1500 LRP Channel 1 Cable Pinouts . . . . . . . 3-5

Using Modems that Support DF1 Communication Protocols 3-6

Dial-up Phone Modems . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Leased-Line Modems . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Radio Modems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Line Drivers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Modem Control Line Operation . . . . . . . . . . . . . . . . . . . . . 3-8

DF1 Full-Duplex . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

DF1 Half-Duplex Slave. . . . . . . . . . . . . . . . . . . . . . . . . 3-8

DF1 Half Duplex Master. . . . . . . . . . . . . . . . . . . . . . . . 3-9

DF1 Radio Modem. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Configuring DF1 Half-Duplex Channel 0 Parameters. . . . . . 3-11

RTS Send Delay and RTS Off Delay . . . . . . . . . . . . . . . 3-11

Configuring a Standard-Mode DF1 Half-Duplex

Master Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Minimum DF1 Half-Duplex Master Channel 0

ACK Timeout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Determining Minimum Master ACK Timeout . . . . . . . . . 3-15

DF1 Half-Duplex Master Channel Status . . . . . . . . . . . . 3-17

Monitor Active Stations. . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Configuring a Message-based Mode DF1

Half-Duplex Master Station . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Configuring a Slave Station . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Configuring Poll Timeout . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

DF1 Half-Duplex Slave Channel Status . . . . . . . . . . . . . 3-25

Configuring a Radio Modem Station. . . . . . . . . . . . . . . . . . 3-27

DF1 Radio Modem Channel Status . . . . . . . . . . . . . . . . 3-30

Configuring the Store & Forward Table. . . . . . . . . . . . . 3-31

Publication AG-UM008C-EN-P - February 2005

Page 7

Table of Contents 3

Configuring a Station on a Point-to-Point Link . . . . . . . . . . 3-33

DF1 Full-Duplex Channel Status . . . . . . . . . . . . . . . . . . 3-35

DF1 Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

Master Station to Slave Station . . . . . . . . . . . . . . . . . . . 3-36

Polled Report-by-Exception . . . . . . . . . . . . . . . . . . . . . 3-36

Processor-to-Processor . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

Considerations When Configuring MSG

Control Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

Example MSG Control Blocks . . . . . . . . . . . . . . . . . . . . . . 3-42

Modbus RTU Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

Modbus RTU Master. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

Modbus RTU Slave. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-47

Modbus RTU Master Configuration . . . . . . . . . . . . . . . . 3-48

Modbus RTU Master Configuration . . . . . . . . . . . . . . . . 3-49

Modbus RTU Slave Configuration . . . . . . . . . . . . . . . . . 3-50

Modbus Slave Memory Map . . . . . . . . . . . . . . . . . . . . . 3-51

Modbus Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-53

Modbus Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . 3-54

Configuring a Modbus Message . . . . . . . . . . . . . . . . . . 3-56

Data Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-58

Queues and Records . . . . . . . . . . . . . . . . . . . . . . . . . . 3-58

Example Queue 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-59

Example Queue 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-60

Configuring Data Log Queues . . . . . . . . . . . . . . . . . . . 3-62

DLG - Data Log Instruction. . . . . . . . . . . . . . . . . . . . . . 3-64

Data Log Status File . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-64

Retrieving (Reading) Records . . . . . . . . . . . . . . . . . . . . 3-66

Accessing the Retrieval File . . . . . . . . . . . . . . . . . . . . . 3-67

Retrieval Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-67

Information for Creating Your Own Application . . . . . . 3-68

Conditions that Will Erase the Data Retrieval File . . . . . . . . 3-69

Configuring SLC 5/03, 5/04, and

5/05 Processors

Chapter 4

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Installing the Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Using Modems that Support DF1 Communication Protocols 4-3

Dial-up Phone Modems . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Leased-Line Modems . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Radio Modems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Line Drivers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Modem Control Line Operation . . . . . . . . . . . . . . . . . . . . . 4-5

DF1 Full-Duplex . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

DF1 Half-Duplex Slave. . . . . . . . . . . . . . . . . . . . . . . . . 4-6

DF1 Half Duplex Master. . . . . . . . . . . . . . . . . . . . . . . . 4-6

DF1 Radio Modem. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Publication AG-UM008C-EN-P - February 2005

Page 8

4 Table of Contents

Configuring DF1 Half-Duplex Channel 0 Parameters. . . . . . 4-8

RTS Send Delay and RTS Off Delay . . . . . . . . . . . . . . . 4-8

Configuring a Standard-Mode DF1 Half-Duplex

Master Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Minimum DF1 Half-Duplex Master Channel 0

ACK Timeout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Determining Minimum Master ACK Timeout . . . . . . . . . 4-14

DF1 Half-Duplex Master Channel Status . . . . . . . . . . . . 4-16

Monitor Active Stations. . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Configuring a Message-based Mode DF1 Half-Duplex

Master Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Configuring a Slave Station . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Configuring Channel 0 Poll Timeout . . . . . . . . . . . . . . . . . 4-25

DF1 Half-Duplex Slave Channel Status . . . . . . . . . . . . . 4-25

Configuring a Radio Modem Station. . . . . . . . . . . . . . . . . . 4-27

DF1 Radio Modem Channel Status . . . . . . . . . . . . . . . . 4-30

Configuring the Store & Forward Table. . . . . . . . . . . . . 4-31

Configuring a Station on a Point-to-Point Link . . . . . . . . . . 4-33

DF1 Full-Duplex Channel Status . . . . . . . . . . . . . . . . . . 4-35

Messaging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

Master Station to Slave Station . . . . . . . . . . . . . . . . . . . 4-37

Polled Report-by-Exception . . . . . . . . . . . . . . . . . . . . . 4-37

Processor-to-Processor . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

Considerations When Configuring MSG

Control Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

Example MSG Control Blocks . . . . . . . . . . . . . . . . . . . . . . 4-43

Configuring SLC 500 Processors

with 1747-KE Interface Modules

Publication AG-UM008C-EN-P - February 2005

Chapter 5

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Installing the Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Installing the 1747-KE

Interface Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Configuring the Processor . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Configuring the 1747-KE

Interface Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Prepare to Configure the Driver . . . . . . . . . . . . . . . . . . 5-4

Configure the DF1 Protocol Driver . . . . . . . . . . . . . . . . 5-7

Save the Configuration. . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Polled Report-by-Exception . . . . . . . . . . . . . . . . . . . . . 5-11

Processor-to-Processor . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Considerations When Configuring MSG Control Blocks . 5-12

Example MSG Control Blocks. . . . . . . . . . . . . . . . . . . . 5-13

Page 9

Configuring MicroLogix 1000

Controllers

Table of Contents 5

Chapter 6

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Installing the Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Isolated Connections . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Automatic Protocol Switching . . . . . . . . . . . . . . . . . . . . . . 6-4

Using Modems that Support DF1 Communication Protocols 6-5

Dial-up Phone Modems . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Leased-Line Modems . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Radio Modems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Line Drivers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Modem Control Line Operation . . . . . . . . . . . . . . . . . . . . . 6-7

DF1 Full-Duplex Operation . . . . . . . . . . . . . . . . . . . . . 6-7

DF1 Half-Duplex Slave Operation. . . . . . . . . . . . . . . . . 6-7

DF1 Slave on a Multi-drop Link . . . . . . . . . . . . . . . . . . 6-8

Ownership Timeout. . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Configuring a Slave Station . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Configuring RTS Send Delay and RTS Off Delay. . . . . . . . . 6-11

Configuring Poll Timeout . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Configuring a Point-to-Point Station . . . . . . . . . . . . . . . . . . 6-13

Messaging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Polled Report-by-Exception . . . . . . . . . . . . . . . . . . . . . 6-15

Processor-to-Processor . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Considerations When Configuring MSG Control Blocks . 6-16

Configuring MSG Block Message Timeout. . . . . . . . . . . 6-17

Example MSG Control Blocks. . . . . . . . . . . . . . . . . . . . 6-18

Configuring Logix Controllers

Chapter 7

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Installing the Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Using Modems that Support DF1 Communication Protocols 7-3

Dial-up Phone Modems . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Leased-Line Modems . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Radio Modems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Line Drivers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Configuring the Controller to Use the Serial Port . . . . . . . . 7-5

Modem Control Line Operation . . . . . . . . . . . . . . . . . . . . . 7-7

No Handshake Selected . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Full-Duplex Selected . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Half-Duplex Selected with Continuous Checked . . . . . . 7-7

Half-Duplex Selected with Continuous Carrier

Unchecked . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Configuration Considerations for RTS Send and Off Delays. 7-8

Publication AG-UM008C-EN-P - February 2005

Page 10

6 Table of Contents

Configuring a Standard-Mode DF1 Half-Duplex

Master Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Configuring a Master Station for Standard Polling Mode . . . 7-9

Minimum DF1 Half-Duplex Master ACK Timeout . . . . . 7-11

Determining Minimum Master Serial Port ACK Timeout . 7-12

DF1 Half-Duplex Master Diagnostic Counter . . . . . . . . . . . 7-13

Create Polling List(s) . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

Monitor Active Stations. . . . . . . . . . . . . . . . . . . . . . . . . 7-16

Configuring a Message-Based Mode DF1 Half-Duplex

Master Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

Configuring a Master Station for Message-based

Polling Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

Configuring the Controller as a Slave Station . . . . . . . . . . . 7-19

Configuring Slave Poll Timeout . . . . . . . . . . . . . . . . . . . . . 7-20

DF1 Half-Duplex Slave Diagnostic Counters. . . . . . . . . . . . 7-20

Configuring the Controller as a Station on a

Point-to-Point Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

DF1 Point-to-Point Diagnostic Counters . . . . . . . . . . . . . . . 7-24

Accessing DF1 Diagnostic Counters . . . . . . . . . . . . . . . . . . 7-25

Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-28

Master Station to Slave Station . . . . . . . . . . . . . . . . . . . 7-28

Polled Report-by-Exception . . . . . . . . . . . . . . . . . . . . . 7-28

Controller-to-Controller . . . . . . . . . . . . . . . . . . . . . . . . 7-29

Considerations When Configuring MSG Control Blocks . 7-30

Example MSG Control Blocks . . . . . . . . . . . . . . . . . . . . . . 7-31

Logix Controller Error Codes for PLC and SLC Messages . . . 7-38

Configuring Modems

Publication AG-UM008C-EN-P - February 2005

Chapter 8

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Installing a Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Configuration Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Telephone Modem Configurations . . . . . . . . . . . . . . . . . . . 8-2

Rockwell Automation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

DATA-LINC Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

DLM4300. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

LLM1000-2 and LLM1000-4 . . . . . . . . . . . . . . . . . . . . . . 8-6

DLM4000. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

DLM4100-SLC and DLM4100-PLC . . . . . . . . . . . . . . . . . 8-10

Miille Applied Research Company, Inc. (MARC) . . . . . . . . . 8-11

MARC Model 166-101. . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

MARC Model 137-001. . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

MARC Model 148-001. . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

MARC Model 166-100. . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

MARC Model 166-010. . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

Radio Modem Configurations. . . . . . . . . . . . . . . . . . . . . . . 8-21

Page 11

Configuring RSLinx Classic

Software for DF1

Half-Duplex Communications

Table of Contents 7

DATA-LINC Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-23

SRM6000/6100/6200E. . . . . . . . . . . . . . . . . . . . . . . . . . 8-23

SRM6000/6100/6200E-SLC . . . . . . . . . . . . . . . . . . . . . . 8-25

SRM6000/6100/6200E-PLC . . . . . . . . . . . . . . . . . . . . . . 8-27

Electronic Systems

Technology (ESTeem) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-29

Microwave Data Systems (MDS). . . . . . . . . . . . . . . . . . . . . 8-35

MDS Model 2100 and 4100 Master Stations . . . . . . . . . . 8-36

MDS Model 2310 and 4310 Remote Stations . . . . . . . . . 8-37

MDS Model 9810 Spread Spectrum . . . . . . . . . . . . . . . . 8-38

Power Line Modem

Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-39

DATA-LINC Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-39

LCM100 Line Carrier Modem . . . . . . . . . . . . . . . . . . . . 8-39

Chapter 9

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Configuring RSLinx Classic Version 2.x as a Master Station . 9-1

Configuring RSLinx Classic Version 2.x as a Slave Station . . 9-10

Using Dial-up Telephone

Communication

Remotely Program Allen-Bradley

Processors Over a Telemetry

Network

Chapter 10

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Setting up the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

Configure the Processor . . . . . . . . . . . . . . . . . . . . . . . . 10-3

Configure the Modems for the PLC-5, SLC, and Logix

Processors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

Configure the Modems for MicroLogix 1100/1200/1500

Controllers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

Communicating Over the Telephone Line . . . . . . . . . . . . . 10-4

Initiate Modem Dialing. . . . . . . . . . . . . . . . . . . . . . . . . 10-5

Verify Connection to the Remote Modem . . . . . . . . . . . 10-6

Transfer Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-7

Disconnect the Telephone Link . . . . . . . . . . . . . . . . . . 10-7

Peer-to-Peer Communication . . . . . . . . . . . . . . . . . . . . . . . 10-8

Report-by-Exception and/or

Master Station-Initiated Communication . . . . . . . . . . . . . . . 10-9

Chapter 11

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

Remote Programming via RSLinx® Gateway™ . . . . . . . . . . 11-2

Remote Programming via SLC 5/05 Ethernet to

DF1 Passthru . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-4

Remote Programming via Logix EtherNet/IP to DF1 Bridge. 11-7

Publication AG-UM008C-EN-P - February 2005

Page 12

8 Table of Contents

Modem Cable Reference

Basic DF1 Protocol

Troubleshooting

Appendix A

Appendix Objective . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Enhanced PLC-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

1747-KE Interface Module . . . . . . . . . . . . . . . . . . . . . . . . . A-3

ASCII Terminal to 1747-KE module . . . . . . . . . . . . . . . . . . A-4

SLC 5/03, 5/04, or 5/05, Logix, and MicroLogix 1500

Channel 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

1785-KE Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

MicroLogix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Appendix B

Appendix Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

General Tips. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Communication Troubleshooting . . . . . . . . . . . . . . . . . . . . B-1

DF1 Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

DF1 Half-Duplex Protocol . . . . . . . . . . . . . . . . . . . . . . . . . B-4

DF1 Full-Duplex Protocol . . . . . . . . . . . . . . . . . . . . . . . . . B-6

DF1 Radio Modem Protocol. . . . . . . . . . . . . . . . . . . . . . . . B-7

Third-Party Supplier Contact

Information

Worksheets

Appendix C

Appendix Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Contact List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Appendix D

Appendix Objective . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

When You’re Finished. . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

How to Use the Worksheets . . . . . . . . . . . . . . . . . . . . . . . D-3

Worksheet 1.1 SCADA System Schematic . . . . . . . . . . . . . . D-4

Worksheet 2.1 Enhanced PLC-5 DF1 Half-Duplex Master

Station Configuration Using Standard Communication. . . . . D-5

Worksheet 2.2 Enhanced PLC-5 DF1 Half-Duplex Master

Station Configuration Using Message-based Communication D-6

Worksheet 2.3 Enhanced PLC-5 DF1 Half-Duplex Slave

Station Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-7

Worksheet 2.4 Enhanced PLC-5 DF1 Full-Duplex

Point-to-Point Configuration . . . . . . . . . . . . . . . . . . . . . . . D-8

Worksheet 3.1 MicroLogix 1100/1200/1500 DF1 Half-Duplex

Master Station Configuration Using Standard

Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-9

Worksheet 3.2 MicroLogix 1100/1200/1500 DF1 Half-Duplex

Master Station Configuration Using Message-based

Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-10

Worksheet 3.3 MicroLogix 1100/1200/1500 DF1 Half-Duplex

Slave Station Configuration . . . . . . . . . . . . . . . . . . . . . . . D-11

Publication AG-UM008C-EN-P - February 2005

Page 13

Table of Contents 9

Worksheet 3.4 MicroLogix 1100/1200/1500 DF1

Full-Duplex Point-to-Point Configuration . . . . . . . . . . . . . D-12

Worksheet 3.5 MicroLogix 1100/1200/1500 Radio Modem

Slave Station Configuration . . . . . . . . . . . . . . . . . . . . . . . D-13

Worksheet 4.1 SLC 5/03, 5/04, and 5/05 DF1 Half-Duplex

Master Station Configuration Using Standard

Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-14

Worksheet 4.2 SLC 5/03, 5/04, and 5/05 DF1 Half-Duplex

Master Station Configuration Using Message-based

Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-15

Worksheet 4.3 SLC 5/03, 5/04, and 5/05 DF1 Half-Duplex

Slave Station Configuration . . . . . . . . . . . . . . . . . . . . . . . D-16

Worksheet 4.4 SLC 5/03, 5/04, and 5/05 DF1 Full-Duplex

Point-to-Point Configuration . . . . . . . . . . . . . . . . . . . . . . D-17

Worksheet 4.5 SLC 5/03, 5/04, and 5/05 DF1 Radio

Modem Station Configuration . . . . . . . . . . . . . . . . . . . . . D-18

Worksheet 5.1 SLC 500 Processor with 1747-KE Module

DF1 Half-Duplex Slave Station Configuration . . . . . . . . . . D-19

Worksheet 5.2 SLC 500 Processor with 1747-KE Module

Point-to-Point Configuration . . . . . . . . . . . . . . . . . . . . . . D-20

Worksheet 6.1 MicroLogix 1000 DF1 Half-Duplex Slave

Station Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . D-21

Worksheet 7.1 Logix DF1 Half-Duplex Master Station

Configuration Using Standard Communication . . . . . . . . . D-22

Worksheet 7.2 Logix DF1 Half-Duplex Master Station

Configuration Using Message-based Communication . . . . D-23

Worksheet 7.3 Logix DF1 Half-Duplex Slave Station

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-24

Worksheet 7.4 Logix DF1 Full-Duplex Point-to-Point

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-25

Sample Ladder Logic

Appendix E

Appendix Objective . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

SLC DF1 Half-Duplex Master Standard Mode,

Master-initiated MSG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-2

SLC DF1 Half-Duplex Master Message-based Mode and DF1

Radio Modem initiated MSG . . . . . . . . . . . . . . . . . . . . . . . E-4

SLC DF1 Half-Duplex Slave and DF1 Radio Modem

Report-by-Exception MSG . . . . . . . . . . . . . . . . . . . . . . . . . E-6

PLC-5 and MicroLogix 1100/1200/1500 DF1 Half-Duplex

Master Standard Mode, Master-initiated MSG . . . . . . . . . . . E-8

PLC-5 and MicroLogix 1100/1200/1500 DF1 Half-Duplex

Master Message-based, Master-initiated MSG . . . . . . . . . . E-10

PLC-5 and MicroLogix 1100/1200/1500 DF1 Half-Duplex

Slave Report-by-Exception MSG. . . . . . . . . . . . . . . . . . . . E-12

Publication AG-UM008C-EN-P - February 2005

Page 14

10 Table of Contents

MicroLogix 1000 Analog DF1 Half-Duplex Slave

Report-by-Exception MSG . . . . . . . . . . . . . . . . . . . . . . . . E-14

Logix DF1 Half-Duplex Master Standard Mode,

Master-Initiated MSG . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-16

Logix DF1 Half-Duplex Master Message-based Mode,

Master-Initiated MSG . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-19

Logix DF1 Half-Duplex Slave Report-By-Exception MSG. . E-21

Glossary

Index

Publication AG-UM008C-EN-P - February 2005

Page 15

Preface

What SCADA Information Is Available?

Audience

Two principle SCADA documents are available:

• SCADA System Application Guide Publication AG-UM008 (this

manual)

– Describes how to configure Allen-Bradley® products and

third-party modems

– Describes how to send messages

– Provides application samples

• SCADA System Selection Guide (Publication AG-SG001)

– Presents Allen-Bradley capabilities for SCADA applications

– Guides you through choosing SCADA system components

We designed this document for individuals who are configuring a

SCADA system or are answering configuration questions. This

document assumes you know how to:

• handle, install, and operate the products referenced in this

document

• install, navigate through, and use the software products

referenced in this document

• prepare cables, if necessary

1 Publication AG-UM008C-EN-P - February 2005

Page 16

2 Preface

Contents of this Manual

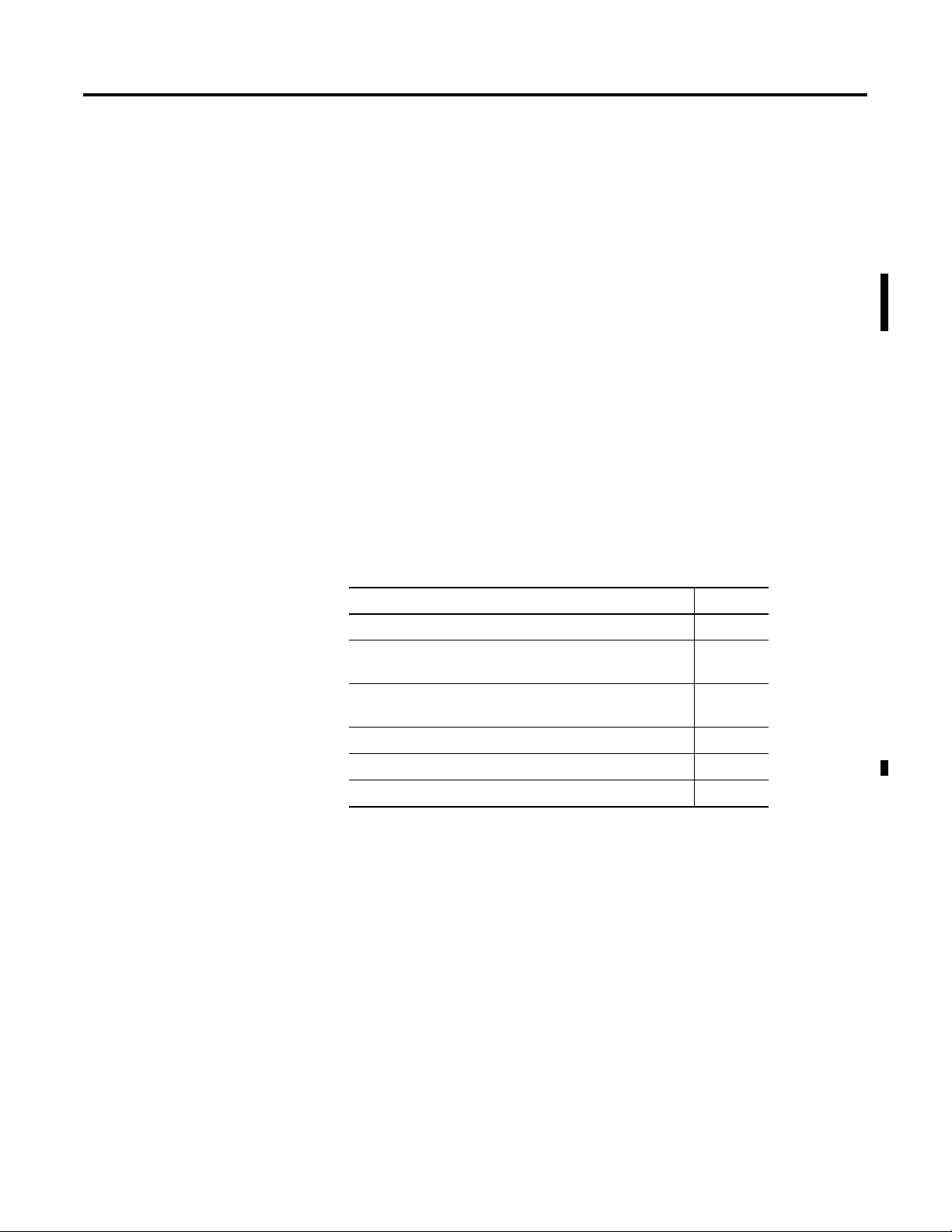

Refer to the following listing for the contents of this user manual.

Chapter Title Contents

1 Designing

Communication

2 Configuring Enhanced

3 Configuring MicroLogix™

4 Configuring SLC™ 5/03,

5 Configuring SLC™ 500

6 Configuring MicroLogix

7 Configuring Logix

8 Configuring Modems Provides information on connecting

®

Processors

PLC-5

1100/1200/1500

Controllers

5/04, and 5/05

Processors

Processors with 1747-KE

Interface Modules

1000 Controllers

Controllers

Design and configuration choices for

getting information to and from slave

stations.

Set up an enhanced PLC-5 processor as a

master station, slave station, or a station on

a point-to-point link.

Set up a MicroLogix 1100/1200/1500

controller as a master station, slave station,

or a station on a point-to-point link.

Set up an SLC 5/03, 5/04, and 5/05

processor as a master station, slave station,

or a station on a point-to-point link.

Set up an SLC 500 fixed or modular

processor (SLC 5/01 or 5/02) with a 1747-KE

as a remote station, or a station on a

point-to-point link.

Set up a MicroLogix controller as a slave

station, or a station on a point-to-point link.

Set up Logix controllers as a master station,

slave station, or a station on a

point-to-point link.

modems to Allen-Bradley devices.

9

10 Using Dial-up Telephone

11 Remotely Programming

A Modem Cable Reference Provides cable information.

B Basic DF1 Protocol

C Third-Party Supplier

D Worksheets Provides worksheets to document your

E Sample Ladder Logic Provides information for developing your

Glossary

Configuring RSLinx®

Classic Software for DF1

Half-Duplex

Communications

Communication

Allen-Bradley Processors

Over a Telemetry

Network

Troubleshooting

Contact Information

Provides reference information needed

while configuring RSLinx Classic

communication server software as a DF1

half-duplex polling master station or as a

DF1 half-duplex slave station.

Provides information on how to set up and

initiate dial-up communication.

Provides information on how to set up and

configure RSLogix programming terminals

on Ethernet to program remote processors.

Provides information on how to

troubleshoot communication errors.

Provides 3rd party vendor contact

information.

serial channel configurations.

messaging logic.

Publication AG-UM008C-EN-P - February 2005

Page 17

Preface 3

Terms

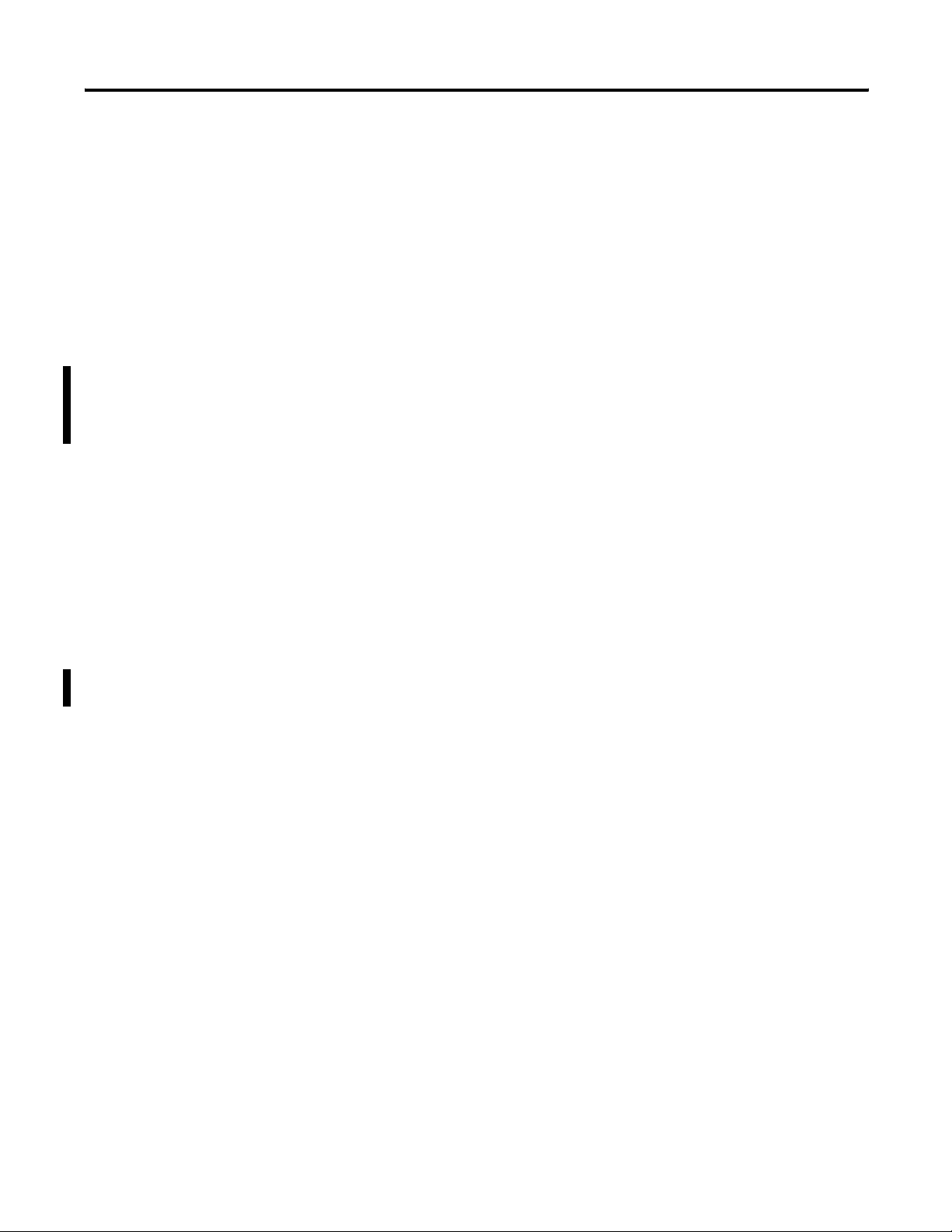

We use these terms frequently in this book:

Te rm Definition

Logix processor A collective name used to refer to ControlLogix™,

FlexLogix™, and CompactLogix™ processors.

Enhanced PLC-5 processor A collective name used to refer to PLC-5/11, -5/20,

-5/30, -5/40, -5/60, and PLC-5/80 processors.

Ethernet PLC-5 processor A collective name used to refer to PLC-5/20E,

-5/40E, and -5/80E processors.

master station A device (programmable controller with I/O modules

or a workstation) that sends data to and collects

data from devices connected on a

point-to-multipoint, half-duplex network.

slave station A device (programmable controller with I/O modules)

that is located in a remote site away from the master

station and that controls I/O points at the remote

site. A slave station accepts commands from and

can send data (if capable) to a master station via a

telemetry network.

See the Glossary for other definitions.

Address Conventions

Addresses

These values Are represented as

octal X

decimal X

8

10

Publication AG-UM008C-EN-P - February 2005

Page 18

4 Preface

Related Publications

The following documents contain additional information concerning

Allen-Bradley programmable controller products. To obtain a copy,

contact your local Allen-Bradley office or distributor:

Title Publication Number

Enhanced and Ethernet PLC-5 Programmable Controllers

User Manual

PLC-5 Instruction Set Reference Manual 1785-RM001

SLC 500 Instruction Set Reference Manual 1747-RM001

SLC 500 Modular Hardware Style Manual 1747-UM0011

DH-485/RS232C Interface Module User Manual 1747-UM005

MicroLogix 1000 Programmable Controllers Users Manual 1761-UM003

ControlLogix System User Manual 1756-UM001

Logix5000™ Controllers Common Procedures Programming

Manual

Logix Controllers General Instruction Set Reference

Manual

MicroLogix 1200 and 1500 Instruction Set Reference

Manual

MicroLogix 1200 User Manual 1762-UM001

1785-UM012

1756-PM001

1756-RM003

1762-RM001

MicroLogix 1500 User Manual 1764-UM001

CompactLogix System User Manual 1769-UM011

FlexLogix System User Manual 1794-UM001

DF1 Protocol and Command Set Reference Manual 1770-RM516

2004-2005 Americas Edition/Encompass Program Product

Directory

6873-SG003

If you would like a manual, you can:

• download a free electronic version from the internet at

www.rockwellautomation.com/literature.

• purchase a printed manual by contacting your local

Allen-Bradley distributor or Rockwell Automation sales office.

Publication AG-UM008C-EN-P - February 2005

Page 19

Designing Communication

Chapter

1

Chapter Objectives

Use this chapter along with the configuration chapters of the devices

in your SCADA system to help you make design and configuration

choices for getting information to and from slave stations.

While designing your communication scheme, consider these

application requirements:

• responsiveness

• determinism

• cost

• efficiency

The factors that affect communication are a result of the protocol you

are use, either half-duplex or full-duplex.

For information about See page

choosing a polling mode for the DF1 Half-Duplex protocol 1-2

designing a communication scheme using

standard-communication mode

designing a communication scheme using message-based

communication mode

1-8

1-15

designing communication for DF1 Full-Duplex protocol 1-16

designing communication for DF1 Radio Modem protocol 1-17

what to do next 1-19

1 Publication AG-UM008C-EN-P - February 2005

Page 20

1-2 Designing Communication

Choosing a Polling Mode for DF1 Half-Duplex Master

A master station can be configured to communicate with slave stations

in either Message-based polling mode or Standard polling mode. The

pros and cons of each polling mode are described below.

Message-Based Polling Mode

Message-based polling mode is best used in networks when

communication with the slave stations is not time critical and where

the user needs to be able to limit when and how often the master

station communicates with each slave station. It is NOT recommended

for systems that require time continuous communication between the

master and all the slave stations have MSG instructions in their

programs.

With Message-Based polling mode, the only time a master station

communicates with a slave station is when a message (MSG)

instruction in ladder logic is triggered to that particular slave station’s

address. This polling mode gives the user complete control (through

ladder logic) over when and how often to communicate with each

slave station.

If multiple MSG instructions are triggered simultaneously, they will be

executed in order, one at a time, to completion (i.e., the first MSG

queued up will be transmitted and completed to done or error before

the next queued up MSG is transmitted. Refer to appendix E for

sample application programs). Any time a message is triggered to a

slave station that can’t respond (for instance, if its modem fails), the

message will go through retries and timeouts that will slow down the

execution of all the other queued up messages. The minimum time to

message to every responding slave station increases linearly with the

number of slave stations that can’t respond.

If the Message-based selection is ‘don’t allow slaves to initiate

messages,’ then even if a slave station triggers and queues up a MSG

instruction in its ladder logic, the master station will not process it.

This mode is similar to how a master/slave network based on Modbus

protocol would work, since Modbus slave stations cannot ever initiate

a message.

If the Message-based selection is ‘allow slaves to initiate messages,’

when a slave station initiates a message to the master station (polled

report by exception messaging) or to another slave station

(slave-to-slave messaging), the MSG command packet will remain in

that slave station’s transmit queue until the master station triggers its

own MSG command packet to it (which could be seconds, minutes or

hours later, depending on the master’s ladder logic).

Publication AG-UM008C-EN-P - February 2005

Page 21

Designing Communication 1-3

Standard Polling Mode

Standard polling mode is strongly recommended for larger systems

that require time critical communication between the master and all

the slave stations, or for any system where slave station-initiated

messages are going to be used (this includes slave programming over

the network, since this uses the same mechanism that slave-to-slave

messaging uses). The Active Node Table automatically keeps track of

which slaves are (and are not) communicating. Standard polling mode

should NOT be used in cases where the user needs to be able to limit

when and how often the master station communicates with each slave

station.

Standard polling mode causes the master station to continuously send

one or more 4-byte poll packets to each slave station address

configured by the user in the poll list(s) in round robin fashion. As

soon as the end of the polling list is reached, the master station

immediately goes back and starts polling slave stations from the top of

the polling list over again. This is independent and asynchronous to

any MSG instructions that might be triggered in the master station

ladder logic. In fact, this polling continues even while the master

station is in program mode. Refer to chapter 3 of the DF1 Protocol and

Command Set Reference Manual, publication 1770-RM516, for

additional information.

When a MSG instruction is triggered while the master station is in run

mode, the master station will transmit the message packet just after it

finishes polling the current slave station in the poll list and before it

starts polling the next slave station in the poll list (no matter where in

the poll list it is currently at). If multiple MSG instructions have been

triggered simultaneously, at least four message packets may be sent

out between two slave station polls. Each of these messages will have

an opportunity to complete when the master polls the slave station that

was addressed in the message packet as it comes to it in the poll list.

If each of the transmitted message packets is addressed to a different

slave station, the order of completion will be based upon which slave

station address comes up next in the poll list, not the order that the

MSG instructions were executed and transmitted in.

When a slave station receives a poll packet from the master station, if

it has one or more message packets queued up to transmit (either

replies to a command received earlier or MSG commands triggered

locally in ladder logic), the slave station will transmit the first message

packet in the transmit queue.

If the standard mode selection is ‘single message per poll scan,’ then

the master station will then go to the next station in the poll list. If the

standard mode selection is ‘multiple messages per poll scan,’ the

Publication AG-UM008C-EN-P - February 2005

Page 22

1-4 Designing Communication

master station will continue to poll this slave station until its transmit

queue is empty.

The master station knows the slave station has no message packets

queued up to transmit when the slave station responds to the master

poll packet with a 2-byte poll response.

Every time a slave station responds or doesn’t respond to its poll

packet, the master station automatically updates its active node list

(again, even if it’s in program mode). In this list, one bit is assigned to

each possible slave station address (0 to 254). If a slave station doesn’t

respond when it is polled, its active node list bit is cleared. If it does

respond when it is polled, its active node bit is set. Besides being an

excellent online troubleshooting tool, two common uses of the active

node list are to report good/bad communication status for all slave

stations to an operator interface connected to the master station for

monitoring, alarming and logging purposes, and to precondition MSG

instructions to each particular slave.

This second use is based on the supposition that if a slave station

didn’t respond the last time it was polled (which was just a few

seconds ago, if that long), then chances are it won’t be able to receive

and respond to a MSG instruction now, and so it would most likely

just end up going through the maximum number of retries and

timeouts before completing in error (which slows down both the poll

scan and any other messaging going on). Using this technique, the

minimum time to message to every responding slave station actually

decreases as the number of slave stations that can’t respond increases.

IMPORTANT

In order to remotely monitor and program the slave

stations over the half-duplex network while the

master station is configured for Standard polling

mode, the programming computer DF1 slave driver

(Rockwell Software RSLinx) station address must be

included in the master station poll list.

About Polled Report-by-Exception

Publication AG-UM008C-EN-P - February 2005

Polled report-by-exception lets a slave station initiate data transfer to

its master station, freeing the master station from having to constantly

read blocks of data from each slave station to determine if any slave

input or data changes have occurred. Instead, through user

programming, the slave station monitors its own inputs for a change

of state or data, which triggers a block of data to be written to the

master station when the master station polls the slave.

Page 23

Designing Communication 1-5

If your SCADA application is time-critical and any two or more of the

following apply, then you can benefit from polled report-by-exception

messaging:

• communication channel is slow (2400 bps or less)

• average number of words of data to monitor in each slave

station is greater than five

• number of slave stations is greater than ten

About Slave-to-Slave Messaging

Most SCADA half-duplex protocols do not allow one slave station to

talk to another slave station, except through special

application-specific code, which requires processing overhead in the

master station. However, Allen-Bradley’s DF1 half-duplex protocol

implements slave-to-slave communications as a feature of the protocol

within the master station, without any additional application code or

extra processing overhead. Refer to chapter 3 of the DF1 Protocol and

Command Set Reference Manual, publication 1770-RM516, for

additional information.

If one slave station has a message to send to another, it simply

includes the destination slave station’s address in the message

instruction’s destination field in place of the master station’s address

when responding to a poll. The master station checks the destination

station address in every packet header it receives from any slave

station. If the address does not match its own station address, the

entire message is forwarded back onto the telemetry network to the

appropriate slave station, without any further processing.

IMPORTANT

Slave stations using 1747-KE interfaces can respond

to slave-to-slave messages but cannot initiate

slave-to-slave messages.

Publication AG-UM008C-EN-P - February 2005

Page 24

1-6 Designing Communication

Addressing Tips

Each station on the network including the master station must have a

unique address. The address range is 0 to 254

have a maximum of 254

address 255

(3778) is the broadcast address, which you cannot select

10

stations on a single telemetry network. Station

as a station’s individual address.

A remote programming terminal station address should be reserved,

even if remote programming is not considered a requirement initially.

This address will need to be periodically polled, even though it will

remain on the inactive poll list unless a remote programming terminal

is online.

SLC 500 and MicroLogix 1000 Processor Addressing Considerations

When an SLC 5/02 or MicroLogix 1000 slave station issues a

®

PLC

-2-type message to a PLC-5 master station, the message’s

destination in the PLC-5 processor’s data table is an integer file with

the file number equal to the SLC 500 or MicroLogix 1000 processor

station address.

(3768), so you can

10

An address lower than 9 may interfere with a PLC-5 processor master

station since files 0-8 are usually left in their default configuration; file

9 is often used by programmers for the I/O list. Station address 255

is the broadcast address. So, assign addresses between 10

TIP

For all other master station types, the SLC 5/02

or MicroLogix 1000 slave station can initiate a 500

-25410.

10

10

CPU-type message.

When using an SLC 5/03, 5/04, or 5/05 processor, or a MicroLogix

1100, 1200 or 1500 controller, as a master station, the poll list

configuration consists of a contiguous block of addresses. Therefore,

assign slave station addresses in a contiguous block in order to avoid

polling for nonexistent slave stations.

Publication AG-UM008C-EN-P - February 2005

Page 25

Designing Communication 1-7

SLC 500 Processors with a 1747-KE Module Addressing Considerations

Since you can have up to 254 devices on a half-duplex network and

32 devices on a DH-485 network, to allow 255 DH-485 nodes requires

using a group number. This parameter defines the address group of

the SLC 500 half-duplex address. Each address group can consist of 32

addresses.

The slave address of the SLC 500 processor is determined with the

following formula: (32*G)+ Α, where G is the group number (0 to 7)

and A is the DH-485 node address of the SLC 500 processor.

One station address within each group of size 32 must be reserved for

any 1747-KE modules configured with that group number. A second

address within each group should also be reserved for local DH-485

programming terminals. These 16 addresses (two per group) should

never have to be polled by the master station.

ATTENTION

Do not use slave addresses contained within a KE

group. When nodes are added to respective DH-485

networks, there is a possibility of duplicate nodes.

Publication AG-UM008C-EN-P - February 2005

Page 26

1-8 Designing Communication

Communication Scheme Design Using Standard-Mode

Polling List

Stn 1

Stn 2

Stn 3

1. Master station polls a slave station for data.

2. If the slave station has data to send, then it sends a

data packet. If there is no data to send then it sends

an end of transmission packet (DLE EOT).

Standard-communication mode for an Allen-Bradley master station

uses centralized polling to gather data from slave stations. A master

station using this communication technique asks (polls) individual

slave stations if they have any information to send. All stations on the

link ‘hear’ the master station’s requests, but only the slave station to

which a request is addressed replies. PLC-5, Logix and RSLinx master

stations poll slave stations based on an ordered list (polling list)

configured by the system designer. SLC 500 and MicroLogix master

stations poll slave stations sequentially in a range of addresses

configured by the system designer.

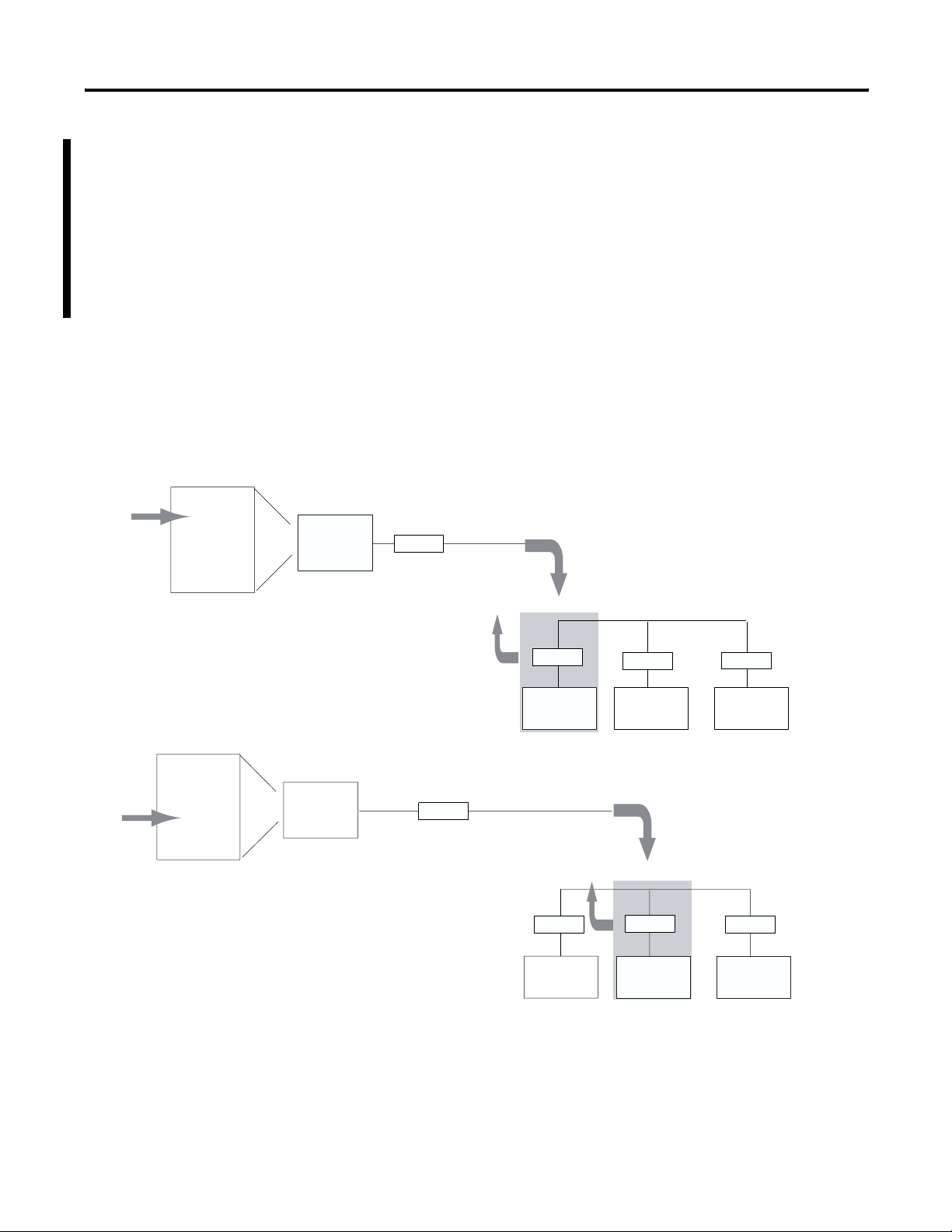

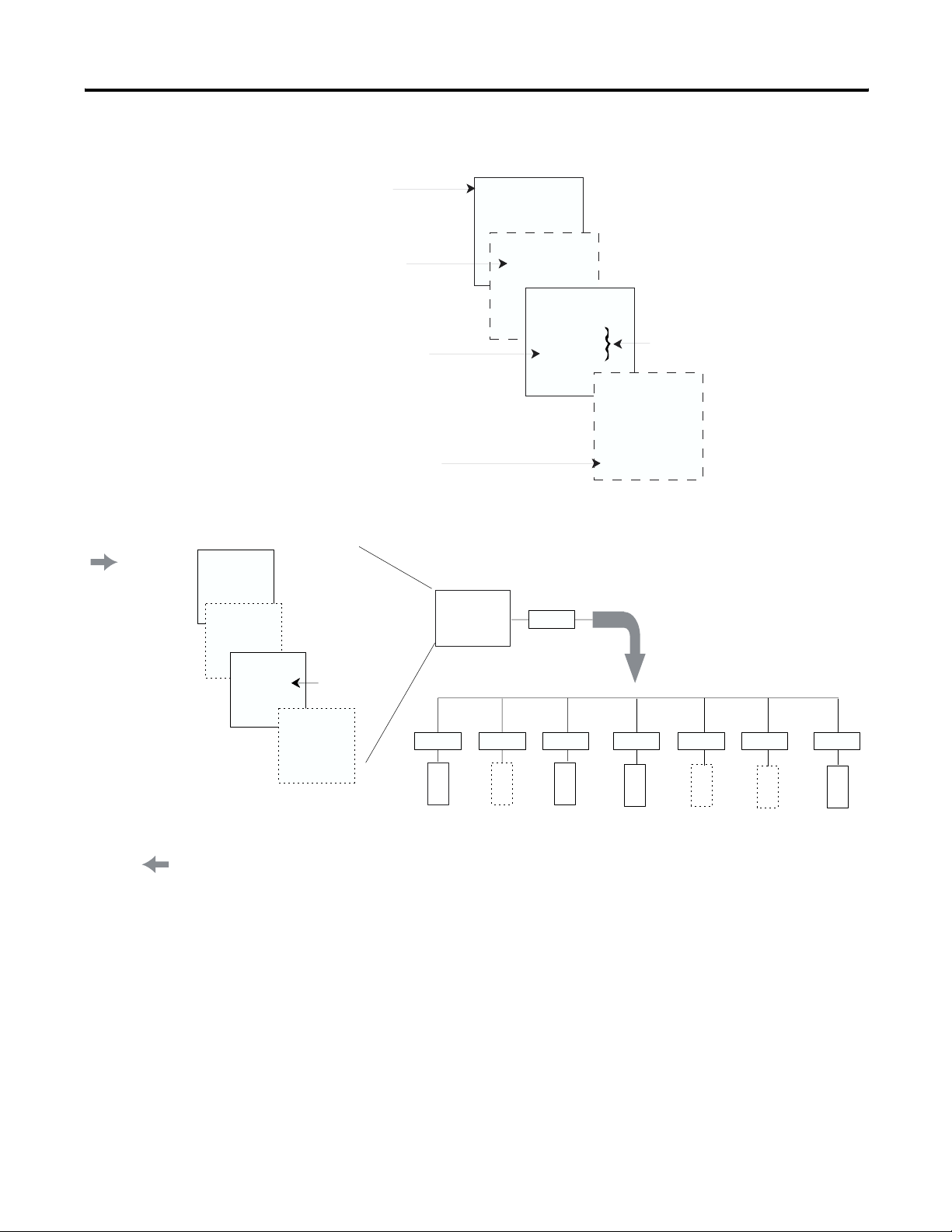

Figure 1.1 shows how a slave

station gets polled and how it responds.

A master station polls the slave stations in the order the slave stations

appear on the list. Slave stations send either a data packet or a packet

indicating that the station has no data to send.

Figure 1.1 Slave Station Polling and Response

Master

Station

Modem

Return Data

Packet or DLE

EOT to Master

Modem

slave

station 1

Poll to slave

Modem

slave

station 2

Modem

slave

station 3

Polling List

Stn 1

Stn 2

Master

Station

Stn 3

1. Master station polls the next slave station for data.

2. If the slave station has data to send, then it sends a

data packet. If there is no data to send then it sends

an end of transmission packet (DLE EOT).

3. Master station continues to poll each slave station

in the polling list. When the end of the list is

reached, the master station then moves back to the

beginning of the list and starts the polling sequence

over again.

Publication AG-UM008C-EN-P - February 2005

Modem

Return Data

Packet or DLE

EOT to Master

Modem

slave

station 1

Modem

slave

station 2

Poll to slave

Modem

slave

station 3

41180

Page 27

Designing Communication 1-9

When the master station is configured for standard-communication

mode, you do not need to program any master-station message

instructions to communicate with slave stations. Communication with

slave stations occurs by the master station sending polling packets to

slave stations. You only need message instructions when you want the

master station to write data to or read data from a location within a

slave station’s data table.

To help you understand See

standard-communication mode Figure 1.2

how a master station requests data Figure 1.3

Figure 1.2 Standard Communication Mode

• Check for and send

outgoing MSG

• Select next station

to poll

timeout received and

station active and tries

< or = ‘DF1 message

retries’

MSG received and

multiple mode

forward data to or

return data from

data table

timeout received and

station inactive

• Send poll

• Start ACK timeout

• Wait for EOT or

MSG (or timeout)

timeout received and

station active and

tries > ‘DF1 message

retries’ make

station inactive

EOT received indicating no MSG to

send make station active

(if inactive)

MSG received and single

poll mode forward data

to or return data from

data table

41181

Publication AG-UM008C-EN-P - February 2005

Page 28

1-10 Designing Communication

Master data table

reply packet

received return

data

Figure 1.3 How a Master Station Requests Data

• Ladder logic

triggers MSG

• Master driver

formats command

packet

ACK timeout received and

tries > ‘DF1 message

retries’ return error

indication

• Send command

packet

• Start ACK timer

• Wait for ACK (or

timeout)

ACK timeout received

and station active and

tries < or = ‘DF1 message

retries’

reply timeout received

return error

indication

• Start reply timer

• Resume polling

• Wait for reply (or

timeout)

ACK received

To design a communication scheme using standard-communication

mode, you must do the following:

• design a polling scheme

• plan for timing issues

41182

Publication AG-UM008C-EN-P - February 2005

Page 29

Designing Communication 1-11

Designing a Polling Scheme

Each master station in a SCADA application must have a polling

scheme configured. To design a polling scheme, do the following:

• choose the type of scheme best suited for your application

• optimize your polling scheme to obtain the best efficiency

The master station you are using determines the type of polling

choices you have; however, Allen-Bradley master stations offer similar

choices, such as:

• normal and priority polling lists

• ability to poll a slave station:

– once per occurrence in the poll list (single)

– until it has no more messages to send (multiple)

Choosing Normal or Priority Polling Lists

Slave stations listed in a priority poll list are polled more frequently

than those listed in the normal poll list. Place the slave stations that

you need information from more frequently in a priority poll list.

Within each poll list, slave stations are assigned a status, which is

either active or inactive. A slave station becomes inactive when it does

not respond to a master station’s poll packet after the configured

number of retries.

If your master station is a Logix controller or PLC-5, you can use

application logic to reorder the polling lists and priority while the

application logic is executing.

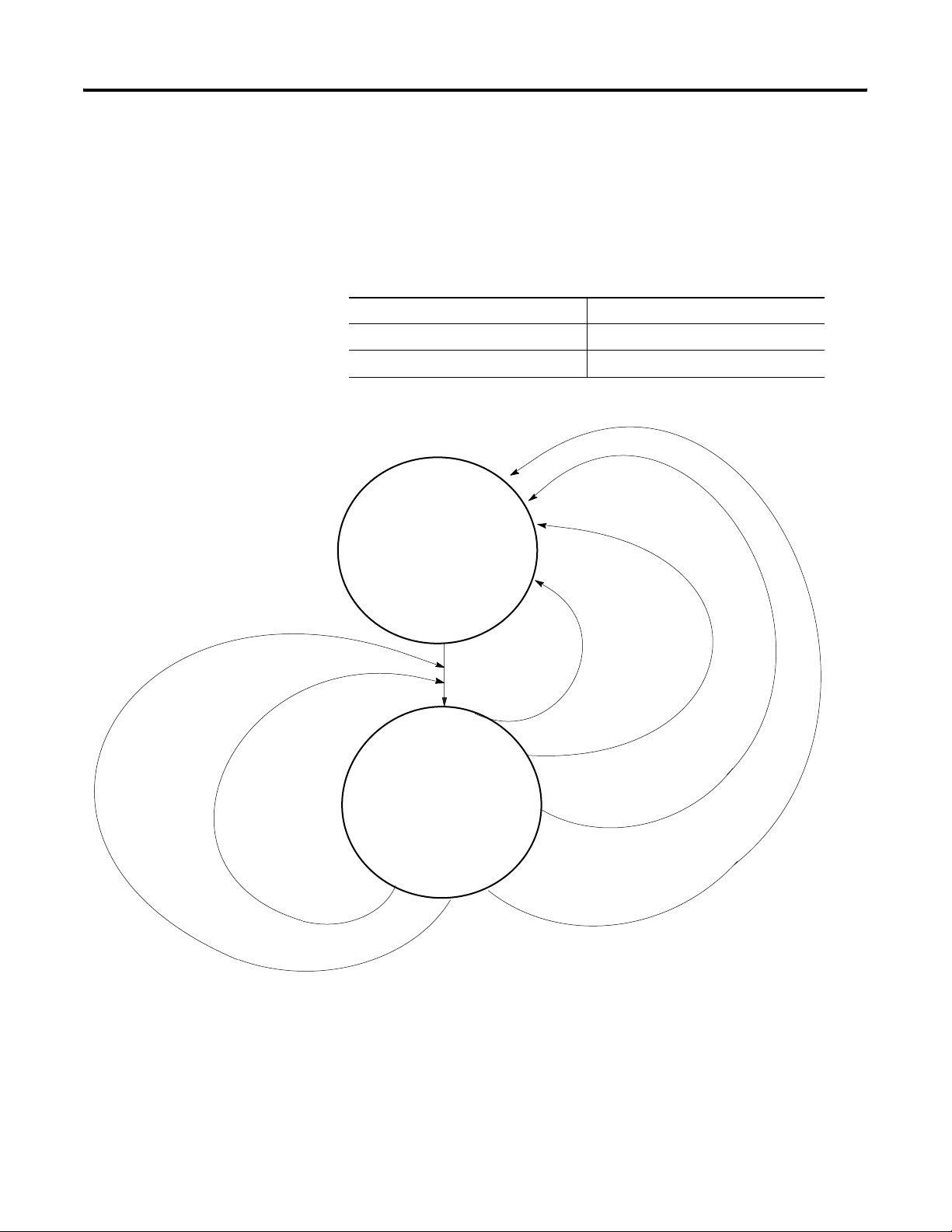

Figure 1.4 and Figure 1.5 show how normal and priority lists relate to

one another.

Publication AG-UM008C-EN-P - February 2005

Page 30

1-12 Designing Communication

Figure 1.4 The master station scans slave stations in a set sequence.

1. Scans all stations in the active priority

2. Scans one station in the inactive priority

3. Scans stations in the active normal poll file

4. Scans one station in the inactive normal poll file

Active Priority

Inactive Priority

Active Normal

poll file.

poll file.

based on the normal poll group size, which you

specify during configuration. For example, if

the group size were 3, then three stations

would be polled in the normal file before the

master continues to the next step in the

sequence.

after all stations in the active normal list have

been polled.

Figure 1.5 Here is how the polling sequence applies to an application.

Poll List

STN1

STN7

Poll List

STN2

STN6

Poll List

STN3

STN4

Group size = 1

Active Priority

Poll List

Master

Station

Inactive Priority

Poll List

Active Normal

Poll List

aa

bb

cc

dd

Modem

Inactive Normal

Poll List

41183

Polling Sequence:

STN1

STN7

STN2

STN3

STN1

STN7

STN6

STN4

STN5

Inactive Normal

Beginning of new scan

Poll List

STN5

Modem

1

Modem

2

Modem

3

Modem

4

Modem

5

Modem

6

Modem

7

41184

Publication AG-UM008C-EN-P - February 2005

Page 31

Designing Communication 1-13

Choosing Single or Multiple Message Transfer

Depending on your application’s requirement, you can choose the

number of messages you want to receive from a slave station during

its turn.

If you want to receive Choose

only one message from a slave station per poll

per a station’s turn.

Choose this method only if it is critical to keep the

poll list scan time to a minimum.

single transfer

as many messages from the slave station as it has

in its queue.

multiple transfer

Planning for Timing Issues

Two types of timing categories exist.

• Protocol timers, which specify how long a master station will

wait to ‘hear’ from a slave station.

• Request to send (RTS) timers, which you can use to make sure

the modem is ready to accept data or has passed on the data

(does not apply when control line is configured for No

Handshaking).

Set and adjust these timing values as necessary for your application.

Set your RTS times based on the communication media and modem

you are using.

Design Considerations

• Define a polling list type to use (normal or priority).

• Define a station list.

• Use Figure 1.6 to help understand how the MSGs are handled

using standard communication.

Publication AG-UM008C-EN-P - February 2005

Page 32

1-14 Designing Communication

1. Polled station 1; ready to poll station 2.

2. MSG sent to station 3 (MSG was waiting in queue).

Polling List

Stn 1

Stn 2

Stn 3

Figure 1.6 Effect of MSGs on Logix, PLC-5, SLC 500, and MicroLogix Polling

Master

Station

Modem

MSG to slave

3. Master station continues polling where it left off in the polling

sequence, e.g., station 2.

Polling List

Stn 1

Stn 2

Master

Station

Stn 3

4. Master station polls station 3.

5. Station 3 replies with data.

Polling List

Stn 1

Stn 2

Master

Station

Modem

Stn 3

Modem

Modem

slave

station 1

Return Data Packet

or DLE EOT to

Master

Modem

slave

station 1

Modem

slave

station 2

Poll to slave

Modem

slave

station 2

Return Data Packet

to Master

Modem

slave

station 3

Modem

slave

station

Poll to slave

6. Master station returns to beginning of the poll list.

Publication AG-UM008C-EN-P - February 2005

Modem

slave

station 1

Modem

slave

station 2

Modem

slave

41185

station 3

Page 33

Designing Communication 1-15

Communication Scheme Design Using Message-Based Mode

Master

Station

3. Master station waits a user-defined time ‘Reply

Modem

Message Wait’ parameter before polling the

station for a reply.

In message-based communication mode, the master station sends

solicited messages (messages programmed via ladder logic) to a

specific slave station when the master requires information. In this

mode, the communication link is inactive until the master station has a

message to send to a slave station.

Figure 1.7 explains the

communication sequence that occurs.

Figure 1.7

Message-Based Communication

1. Message (via MSG instruction) sent

to a specific slave station

(eg., slave station 1).

2. Slave station receives message and

sends an acknowledgment back (ACK).

Modem

Slave

Station 1

4. Slave station forms a reply message to the

master station’s enquiry.

Modem

Slave

Station 2

5. Master station polls slave station for its reply.

6. Slave station sends its reply message.

7. Master station receives reply and sends an

acknowledgement back (ACK).

41186

Publication AG-UM008C-EN-P - February 2005

Page 34

1-16 Designing Communication

Designing Communication for DF1 Full-Duplex Protocol

Data table

reply packet received

return data

When designing communication using DF1 full-duplex protocol, you

must configure timeout values and retry counts that control the

communication between a transmitting station and a receiving station.

Consider the type of link media you are using to help you determine

the best values for the timer and counters. For example, you can

expect a message being sent over a satellite link to take longer than

one being sent over a telephone leased-line link.

Figure 1.8 shows the

communication sequence for DF1 full-duplex protocol.

Figure 1.8 Read or Write Requests via DF1 Full-Duplex

• Ladder logic

triggers MSG

• DF1 driver

formats

command

packet

NAK received and retries

NAK received and retries >

‘NAK retries’

or

ACK timeout received and

tries > ‘ENQ retries’ return

error indication

• Send command

packet

• Start ACK timer

• Wait for ACK

(or timeout)

< or = ‘NAK retries’

or

ACK timeout received and

tries < or = ‘ENQ retries’

send enquiry

reply timeout received

return error indication

Publication AG-UM008C-EN-P - February 2005

• Start reply

timer

• Wait for

reply (or

timeout)

ACK received

41187

Page 35

Designing Communication 1-17

Designing Communication for DF1 Radio Modem Protocol

When designing communication using DF1 Radio Modem protocol,

you must consider the capabilities of both the controllers and radio

modems. The DF1 Radio Modem protocol can only be used with

contollers that support and are configured for this protocol.

Determining When to Use DF1 Radio Modem Protocol

If your radio modem can handle full-duplex data port buffering and

radio transmission collision avoidance, you can use peer-to-peer

message initiation capability in every node (i.e., the ladder logic in

any node can trigger a MSG instruction to any other node at any

time). For messaging between nodes that are outside of radio

transmission/reception range of each other, you may use either the

Store and Forward capability of the protocol or the repeater capability

of the radios.

If your radio modem cannot handle full-duplex data port buffering

and radio transmission collision avoidance, you can still use DF1

Radio Modem protocol in a Master/Slave configuration, with message

initiation limited to a single master node. If you still require slave

node message initiation, then you must use the DF1 Half-Duplex

protocol.

The primary advantage of using DF1 Radio Modem protocol for radio

modem networks is in the transmission efficiency. Each read/write

transaction (command and reply) requires only one transmission by

the initiator (to send the command) and one transmission by the

responder (to return the reply) as illustrated in

of transmissions is minimized, radio power is minimized, and

throughput is maximized. In contrast, DF1 Half-Duplex protocol

requires five transmissions for the DF1 Master to complete a

read/write transaction with a DF1 Slave as illustrated in

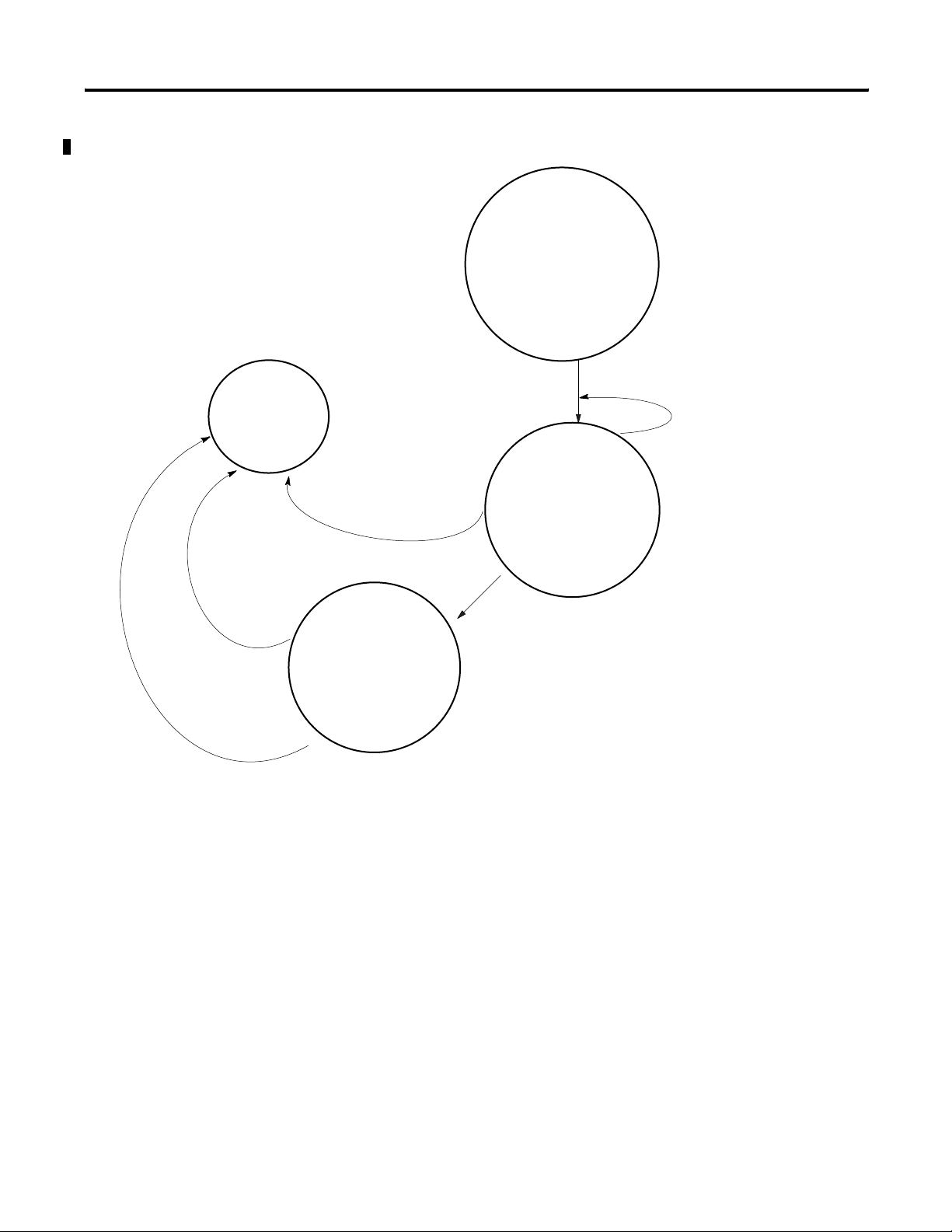

Figure 1.10 illustrates the DF1 Radio Modem protocol.

An efficiency trade-off exists in that the DF1 Radio Modem protocol

does not provide immediate feedback (ACK) to the initiator to indicate

that the responder successfully received the communications packet

without error.

The Store and Forward capability of the DF1 Radio Modem protocol

allows messages between nodes that are outside of radio

transmission/reception range of each other to be routed through

intermediary nodes that are within range. Each of the intermediary

nodes needs a Store and Forward table. The configuration needs to

indicate, based on the source and destination addresses in the

message packet, which packets to receive (store) and then

re-broadcast (forward).

capability.

Figure 1.11 illustrates the Store and Forward

Figure 1.9. The number

Figure 1.7.

Publication AG-UM008C-EN-P - February 2005

Page 36

1-18 Designing Communication

Station 2

Figure 1.9

DF1 Radio Communication

1. Message (via MSG instruction) sent to a specific

station (eg., station 1).

Modem

2. Station 1 sends its reply message.

Figure 1.10

Read or Write Requests via DF1 Radio Modem

Modem

Station 1

• Ladder logic

triggers MSG

• DF1 driver

formats

command

packet

Data table

reply packet received return data

reply timeout received

return error indication

• Send command

packet

• Start reply

timer

• Wait for reply

(or timeout)

Publication AG-UM008C-EN-P - February 2005

Page 37

Designing Communication 1-19

Figure 1.11

Applying Store and Forward in DF1 Radio Modem Protocol

What to Do Next?

Node 1

No Bits

(DST=4, SRC=1)

Make sure you:

• choose the communication method best suited for your

• make initial configuration choices for the communication

• use this chapter as a reference as you configure the devices in

(2nd rebroadcast)

REPLY 1

CMD 1

Node 2

1, 3, 4

CMD 1

(1st rebroadcast)

application.

method you have chosen.

your SCADA system.

(1st rebroadcast)

REPLY 1

Node 3

1, 2, 4

CMD 1

(2nd rebroadcast)

REPLY 1

(DST=1, SRC=4)

Node 4

No Bits

Publication AG-UM008C-EN-P - February 2005

Page 38

1-20 Designing Communication

Publication AG-UM008C-EN-P - February 2005

Page 39

Chapter

Configuring Enhanced PLC-5 Processors

2

Chapter Objectives

Overview

This chapter helps you set up an Enhanced PLC-5 processor as a

master station, as a slave station, or as a station on a point-to-point

link.

For information about See page

an overview of the tasks required to configure a PLC-5 processor 2-1

installing the processor 2-2

configuring the processor as a DF1 half-duplex master station using

standard-communication mode

configuring the processor as a DF1 half-duplex master station using

message-based communication mode

configuring the processor as a slave station 2-15

configuring the processor as a station on a point-to-point link 2-20

the types of messages you can send from a PLC-5 processor to

another processor, how to configure the MSG instruction, and some

configuration characteristics

To configure an Enhanced PLC-5 processor, perform these tasks:

2-3

2-11

2-23

1. Install the processor; connect the serial cable to channel 0.

2. Define the processor’s communication characteristics using your

PLC-5 programming software.

3. Install and configure the modem for communication with the

processor. Connect the modem to the processor’s serial channel.

1 Publication AG-UM008C-EN-P - February 2005

Page 40

2-2 Configuring Enhanced PLC-5 Processors

Figure 2.1 Configuring and Enhanced PLC-5

Modem

PLC-5

programming

software

41188

Installing the Processor

Before installing the processor, set the processor switch assemblies.

Define By setting switch assembly

DH+ and DF1 point-to-point station address S1

RS-232 as the electrical interface for the serial

S2

port

For details about installing the processor, see the Enhanced PLC-5

Programmable Controllers Quick Start, publication 1785-QS012.

For cable pinouts, see Figure 2.2 or Appendix A-2.

Figure 2.2 Enhanced PLC-5 Serial Port Pin Assignments and S2 Settings.

25-pin male 25-pin 9-pin

C. GND 1 1 NC

TXD.OUT 2 2 3

RXD.IN 3 3 2

RTS.OUT 4 4 7

CTS.IN 5 5 8

DSR.IN 6 6 6

SIG.GND 7 7 5

DCD.IN 8 8 1

DTR.OUT 20 20 4

Publication AG-UM008C-EN-P - February 2005

Page 41

Configuring Enhanced PLC-5 Processors 2-3

T

Configuring a DF1 Half-Duplex Standard Mode Master Station

Toggle pushed

toward TOP

OFF

Toggle pushed

toward BOTTOM

ON

o Specify:

RS-232C

Set Switches:

12345678910

ON ON ON OFF OFF ON ON OFF ON OFF

The DF1 Point-to-Point Station Address of the processor is the same as

the DH+ address defined by S1.

Choose standard-communication mode if you want to query slave

stations for information based upon user-configured polling lists. This

mode is used most often in point-to-multipoint configurations because

it allows polled report-by-exception (

page 1-4), slave-to-slave

messaging (page 1-5) and slave programming over the telemetry

network to be implemented. In addition, in this mode the master

station maintains an active node table which allows an HMI or

programming terminal to immediately identify which slave nodes can

currently communicate and which nodes cannot.

ATTENTION

Connect only the pins shown in figure 2.2. Do not

use a ribbon cable or one that connects to every

25-pin.

Publication AG-UM008C-EN-P - February 2005

Page 42

2-4 Configuring Enhanced PLC-5 Processors

1. Double-click on the Channel

Configuration file to bring up

the Edit Channel Properties

interface.

2. On the Channel 0 tab, choose

System (Master) for your

Communication Mode.

To configure the processor for a master station using standard

communication, place the processor into program mode and follow

the steps below using your RSLogix

™ 5 software:

3. Configure the Serial Port,

Options, and Polling

parameters according to

Table 2.1.

4.Configure Options parameters

according to Table 2.1.

5. Configure the Polling

parameters according to

Table 2.1.