Page 1

Allen-Bradley

Ethernet

SLC 500t

Quick Start

Processors

(Catalog Numbers

1747-L551, -L552, and -L553)

for

Experienced

Users

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this

control equipment must satisfy themselves that all necessary steps

have been taken to assure that each application and use meets all

performance and safety requirements, including any applicable laws,

regulations, codes and standards.

The illustrations, charts, sample programs and layout examples

shown in this guide are intended solely for purposes of example.

Since there are many variables and requirements associated with any

particular installation, Allen-Bradley does not assume responsibility

or liability (to include intellectual property liability) for actual use

based upon the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation, and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some

important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in

whole or in part, without written permission of Allen-Bradley

Company, Inc., is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION: Identifies information about practices

or circumstances that can lead to personal injury or

!

Attention statements help you to:

death, property damage or economic loss.

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifies information that is critical for successful

application and understanding of the product.

SLC 5/05, SLC 500, and Data Highway Plus are trademarks of Rockwell Automation.

RSLogix 500 and RSLinx are trademarks of Rockwell Software., Inc.

Ethernet is a registered trademark of Digital Equipment Corporation, Intel, and Xerox Corporation.

Microsoft Windows is a registered trademark of Microsoft Corporation.

Page 3

Table of Contents

Preface

SLC 5/05 Ethernet Processor

Features

Who

Should Use this Manual

Purpose

Conventions

Allen-Bradley

of This Manual

Related

Local

Technical Product Assistance P–3. . . . . . . . . . . . . . . . . . . . . . . .

Your Questions or Comments on this Manual P–4. . . . . . . . . . . . .

Documentation

Used in this Manual

Support

Product Support

Chapter 1

SLC

5/05 Processors and Ethernet Communication

Passthru

SLC 5/05

Hardware

Processor

Keyswitch

Feature

Performance Considerations

Features

Status LED Operation

Operation

RUN

Position

PROG

Position

REM

Position

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . .

P–1. . . . . . . . . . . . . . . . . . . . . . . . . .

P–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P–2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

P–3. . . . . . . . . . . . . . . . . . . . . . .

P–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–1

1–2

1–2

1–2

1–3

1–4

1–4

1–4

1–4

Setting Up the SLC and PC

Hardware

Configuring the Ethernet

Channel for Local

Chapter 2

Required Tools and Equipment

Install

the Power Supply

Install the Processor

Apply Power to the Processor

Connect

Load Y

the SLC 5/05 and the PC to the Ethernet Network

Ethernet Network Topology

Ethernet

Cables

Channel 1 8-Pin 10Base-T Connector

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

our Programming Software

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

Chapter 3

Configuration Methods

Configuration

Define

Create Program and Configure Comms Drivers

Download

Switch

Using RSLogix500 Programming Software

SLC 5/05 Processor and I/O Modules

the Program

to the Ethernet Network and Go ONLINE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . .

. . . . . . . . . . .

. . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . .

2–1

2–1

2–3

2–4

2–4

2–4

2–5

2–5

2–5

3–1

3–2

3–2

3–5

3–6

3–7

Publication

1747-10.4

Page 4

ii

Communicating on the

Ethernet Network

Configuration Via BOOTP

Using DOS/Windows BOOTP

Install the DOS/Windows BOOTP server

Edit

the DOS/Windows BOOTP Configuration File

Run

the Boot Server Utility

Running the DOS-Based Utility

Running

the Windows-Based Utility

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4

Ethernet

MSG

Interpreting MSG Error Codes

Interpreting

Using Subnet Masks and Gateways

Connections

Instruction

Limitation

Control Block Layouts

MSG

Manually

Using

for Manipulating the Control Block Bits

Instruction Control Block

Ethernet Status Data

Configuring Channel 1 for Processors on Subnets

BOOTP to Configure Channel 1 for Processors on

Subnets

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

3–7

3–8

3–9

3–9

3–1

3–1

3–12

4–1

4–2

4–2

4–3

4–4

4–6

4–8

4–10

4–1

4–12

1. . . . . . . . . . . . . . . . . . . . . . . . . .

1. . . . . . . . . . . . . . . . . . . . .

1. .

Using RS232-to-Ethernet

Channel-to-Channel

Passthru

Specifications

(Optional) Return

Processor to Initial Factory

Conditions

Chapter 5

Passthru

Status

MSG

Passthru Examples

Feature

Address

File Bits

Error Code

Example

Example

Routing T

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

able

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1: DF1-to-Ethernet and Ethernet-to-DF1

2: DH485-to-Ethernet and Ethernet-to-DH485

. . . . . . . . .

5–1

5–1

5–2

5–2

5–3

5–3

5–1

1. . . . .

Appendix A

System Test General Specifications

Processor

General Specifications

A–1. . . . . . . . . . . . . . . . . . . . . .

A–2. . . . . . . . . . . . . . . . . . . . . . .

Appendix B

Publication

1747-10.4

Page 5

Preface

Read this preface to familiarize yourself with the rest of the manual.

This preface covers the following topics:

• who should use this manual

• how to use this manual

• related publications

• conventions used in this manual

• Allen-Bradley support

Who Should Use this Manual

Purpose of This Manual

Use this manual if you are responsible for designing, installing,

programming, or troubleshooting control systems that use

Allen-Bradley small logic controllers.

You should have a basic understanding of SLC 500t products. You

should understand programmable controllers and be able to interpret

the ladder logic instructions required to control your application. If

you do not, contact your local Allen-Bradley representative for

information on available training courses before using this product.

This manual is for users of the Ethernet SLC 5/05 processor. It:

• presents you with the basic information you need to get your

system up and running

• provides “memory jogger” information, such as specific bit and

switch settings for modules

• includes high-level procedures with cross-reference to other

manuals for more detail

Publication

1747-10.4

Page 6

PrefaceP–2

Related Documentation

The table below provides a listing of publications that contain

important information about Allen-Bradley Small Logic Controllers

and their installation and application. You may want to reference

them while you are installing the SLC 500 controller. (To obtain a

copy of one of these publications, contact your local Allen-Bradley

office or distributor.)

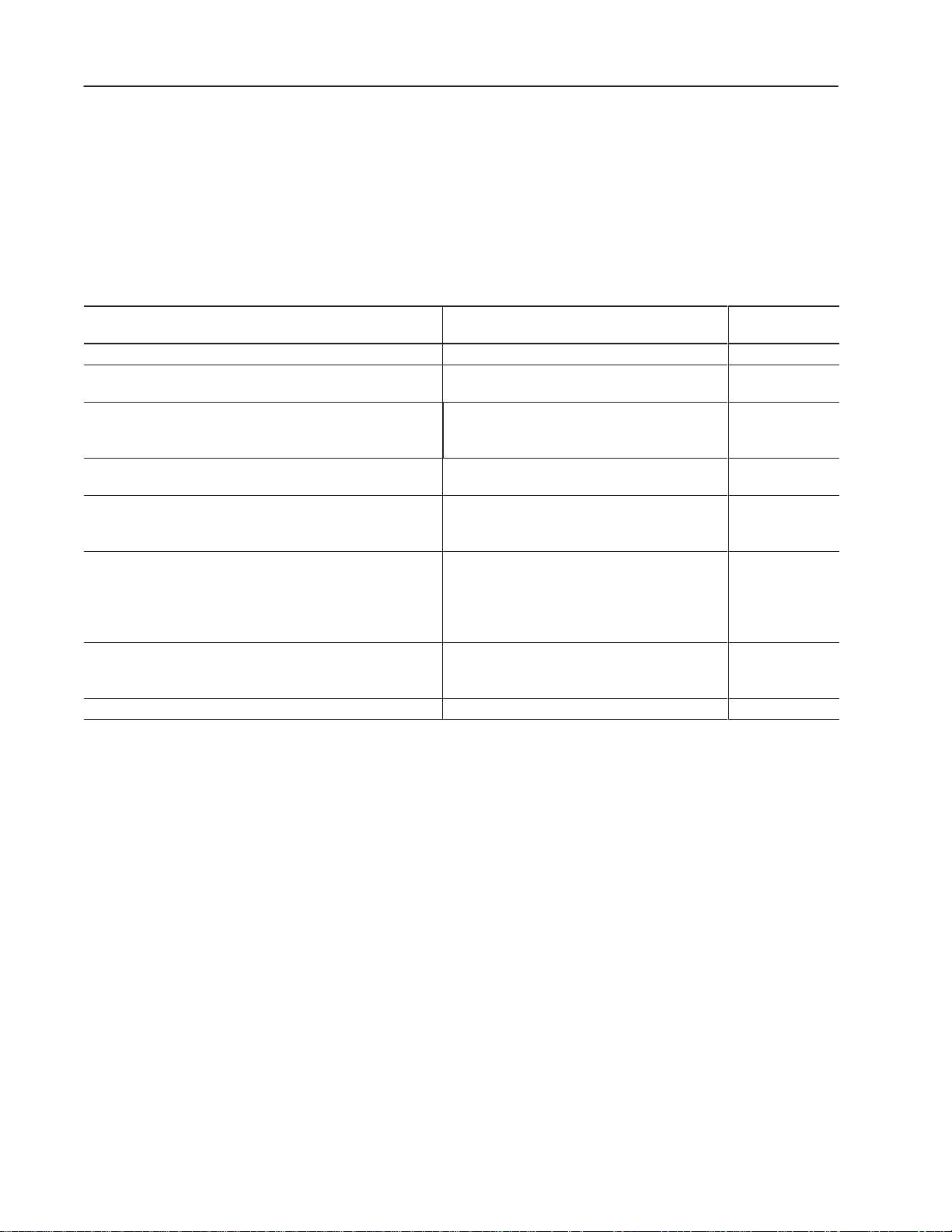

For Read This Document

An overview of the SLC 500 family of products SLC 500 System Overview 1747-2.30

A description on how to install and use your Modular SLC 500

programmable controller

A reference manual that contains status file data and instruction set

information for the SLC 500 processors and MicroLogix 1000

Controllers.

In-depth information on grounding and wiring Allen-Bradley

programmable controllers

A description of important differences between solid-state

programmable controller products and hard-wired

electromechanical devices

An article on wire sizes and types for grounding electrical

equipment

A complete listing of current Allen-Bradley documentation,

including ordering instructions. Also indicates whether the

documents are available on CD-ROM or in multiple languages.

A glossary of industrial automation terms and abbreviations Allen-Bradley Industrial Automation Glossary AG-7.1

Installation & Operation Manual for Modular

Hardware Style Programmable Controllers

SLC 500 and MicroLogix 1000 Instruction Set

Reference Manual

Allen-Bradley Programmable Controller Grounding

and Wiring Guidelines

Application Considerations for Solid-State Controls SGI-1.1

National Electrical Code

Allen-Bradley Publication Index SD499

Document

Number

1747-6.2

1747-6.15

1770-4.1

Published by the

National Fire

Protection

Association of

Boston, MA.

Publication

1747-10.4

Page 7

Preface P–3

Conventions Used in this Manual

Allen-Bradley Support

The following conventions are used throughout this manual:

• Bulleted lists such as this one provide information, not procedural

steps.

• Numbered lists provide sequential steps

• Italic type is used for emphasis.

• Text in this

font

indicates words or phrases you should type.

• Text enclosed “in quotation marks” indicates selections you

should make.

Allen-Bradley offers support services worldwide, with over 75

Sales/Support Offices, 512 authorized Distributors and 260

authorized Systems Integrators located throughout the United States

alone, plus Allen-Bradley representatives in every major country in

the world.

Local Product Support

Contact your local Allen-Bradley representative for:

• sales and order support

• product technical training

• warranty support

• support service agreements

Technical Product Assistance

If you need to contact Allen-Bradley for technical assistance, please

record information about the problem situation, including any error

codes and state of LED indicators. If possible, please also have the

following information ready: hardware series, operating system

used, firmware level, and software release. Then call your local

Allen-Bradley representative.

Publication

1747-10.4

Page 8

PrefaceP–4

Your Questions or Comments on this Manual

If you find a problem with this manual, please notify us using the

enclosed Publication Problem Report.

If you have any suggestions for how this manual could be made

more useful to you, please contact us at the address below:

Allen-Bradley Company, Inc.

Control and Information Group

Technical Communication, Dept. A602V, T122

P.O. Box 2086

Milwaukee, WI 53201-2086

Publication

1747-10.4

Page 9

Chapter 1

essors and

SLC 5/05 Ethernet Processor

Features

This chapter:

• describes SLC 5/05 processors and Ethernet communication

• describes SLC 5/05 performance considerations

• illustrates SLC 5/05 hardware features

• explains processor status LED operation

• explains keyswitch operation

SLC 5/05 Proc

Ethernet Communication

Ethernet is a local area network that provides communication

between various devices at 10 Mbps. The physical communication

media options for the SLC 5/05 are:

• built-in

– twisted pair (10Base-T)

• with media converters or hubs

– fiber optic

– broadband

– thick-wire coaxial cable (10Base-5)

– thin-wire coaxial cable (10Base-2)

See page 2–4 for more information on Ethernet physical media.

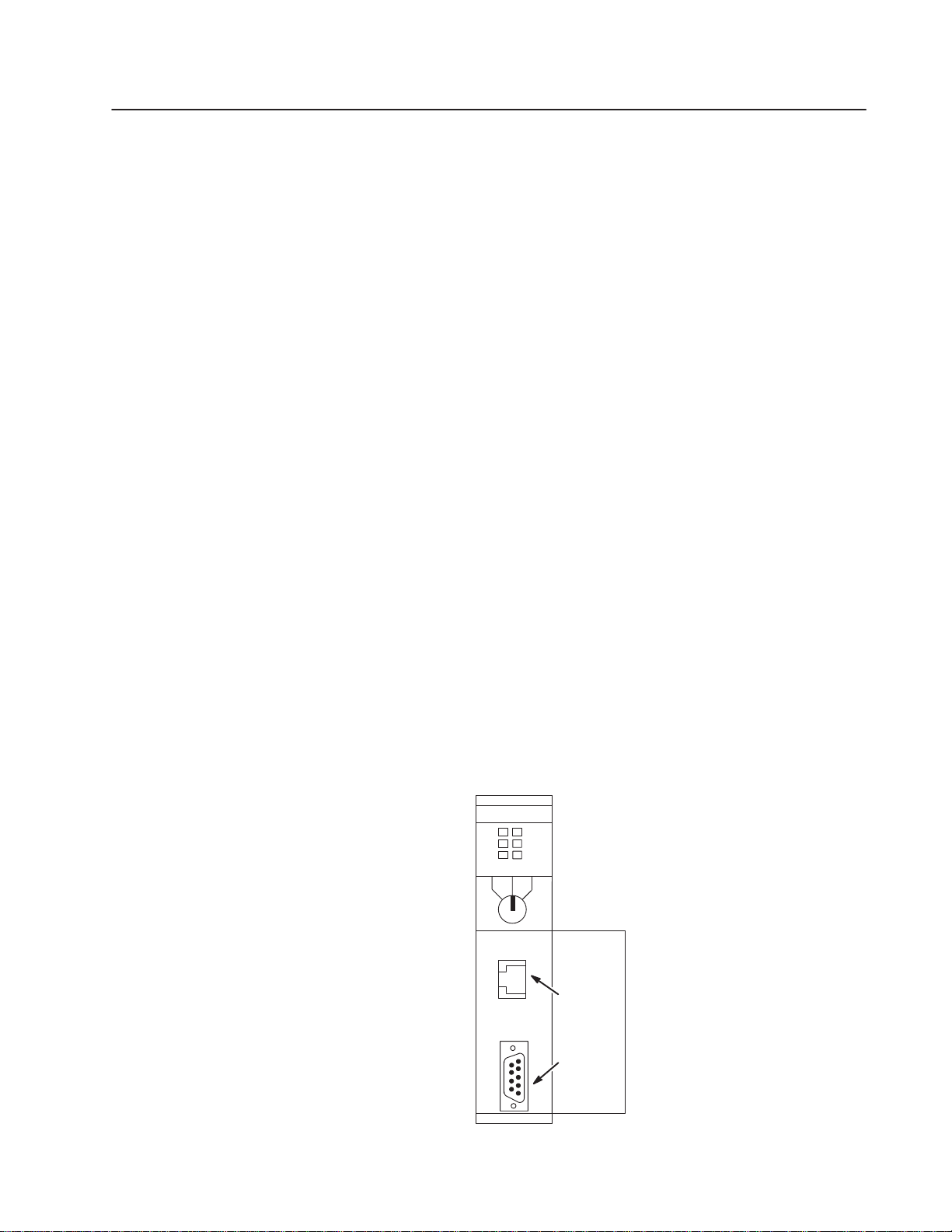

The SLC 5/05 supports Ethernet communication via the Ethernet

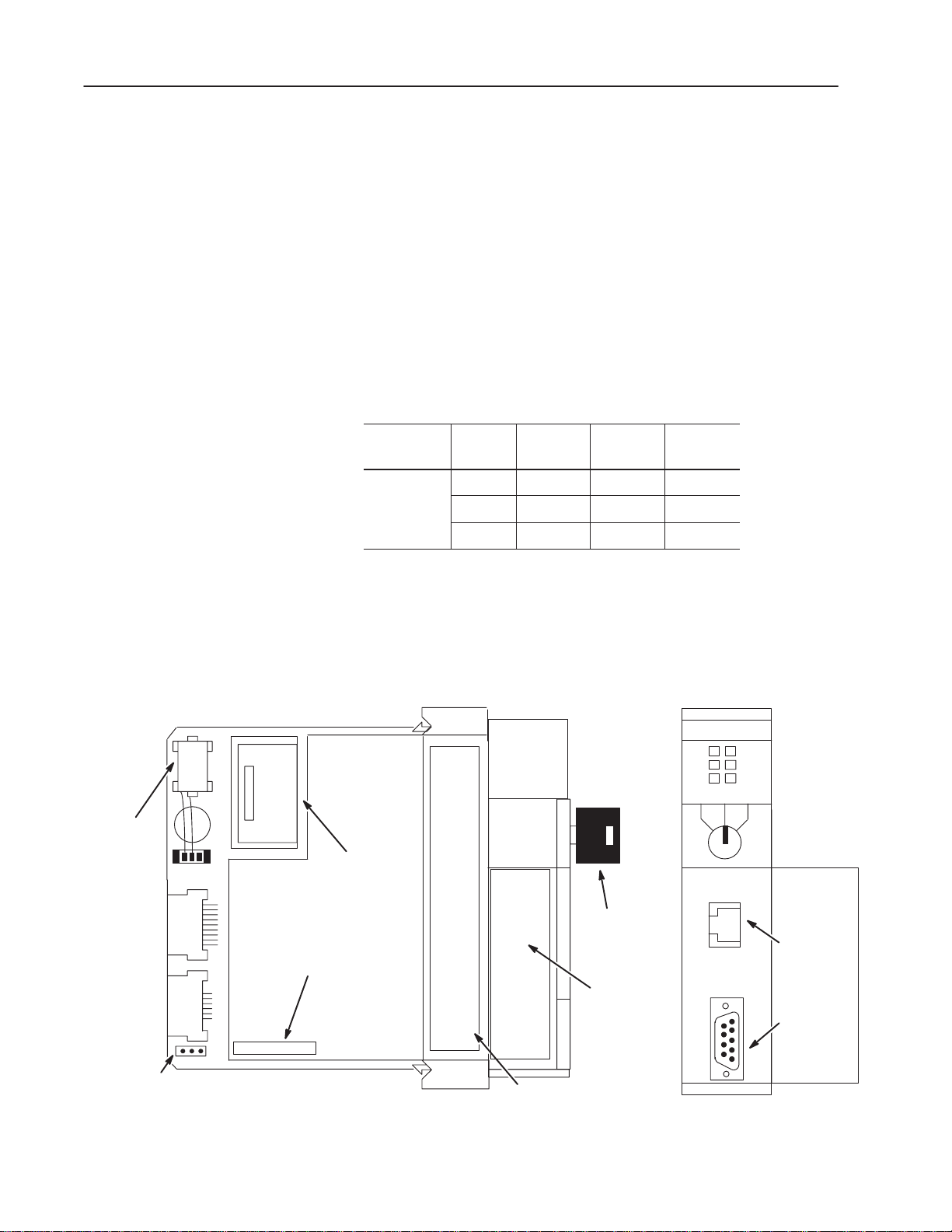

communication channel 1 shown in the drawing below.

SLC

5/05 CPU

FORCE

RUN

ENET

FLT

RS232BATT

RUN PROG

REM

Channel 1

Ethernet

(10Base-T)

Channel 0

RS232

(DH485,

DF1, or

ASCII)

Publication

1747-10.4

Page 10

1–2

SLC 5/05 Ethernet Processor Features

Passthru Feature

SLC 5/05 Performance Considerations

SLC 5/05 (1747-OS501, FRN 3) processors support

RS232-to-Ethernet channel-to-channel passthru. See Chapter 5 for

more information on using the new passthru feature.

Actual performance of an SLC 5/05 processor varies according to:

• size of Ethernet messages

• frequency of Ethernet messages

• network loading

• the implementation of and performance of your processor

application program

Optimal Performance: SLC 5/05 to SLC 5/05 Processor

(2-node Ethernet network)

Operation

Single

Typed reads

MSG per

Words

1 33 30.8 33

20 32 31.1 640

100 32 31.2 3200

second

ms per

MSG

Words per

second

Hardware Features

Battery

(Battery Provides

Back-up Power for

the CMOS RAM)

xx:xx:xx

Hardware

Address

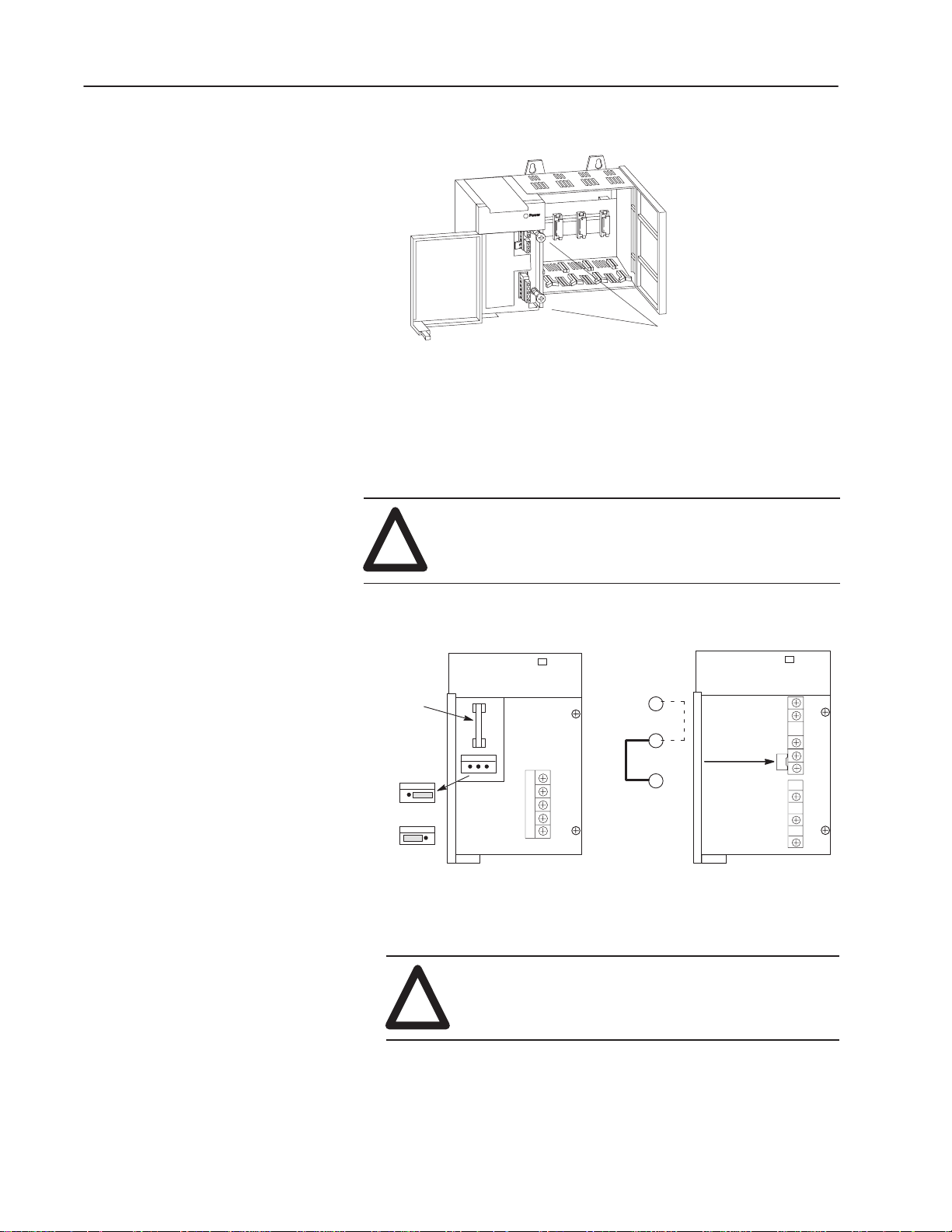

The figure below shows some of the hardware components of the

SLC 5/05 processors (1747-L551, 1747-L552, and 1747-L553).

SLC

5/05 CPU

Memory Module

_______ . _______ . _______ . _______

IP

ADDRESS

Keyswitch

Write-on

Area for

Address

IP

RUN

FLT

BATT

RUN PROG

FORCE

ENET

RS232

REM

Channel 1

Ethernet

(10Base-T)

Channel 0

RS232

(DH485,

DF1, or

ASCII)

Operating System

Memory Module

Download Protection

Jumper

Publication

1747-10.4

Location of Serial and

Left Side View Front View

Catalog Numbers

Page 11

SLC 5/05 Ethernet Processor Features

(Color: red)

(Color: red)

FORCE

FORCE

Channel 1

(Color: green)

(Color: green)

1–3

Processor Status LED Operation

Processor LED When It Is Indicates that

RUN

(Color: green)

FLT

BATT

(Color: amber)

The table below provides a general explanation of the processor

status LEDs.

On (steadily) The processor is in Run mode.

Flashing (during operation)

Off The processor is in a mode other than Run.

Flashing (at power up) The processor has not been configured.

Flashing (during operation)

On (steadily) A fatal error is present (no communications).

Off There are no errors.

On (steadily)

Off The battery is functional, or the battery jumper is present.

Flashing

On (steadily)

The processor is transferring a program from RAM to the

memory module.

The processor detects a major error either in the processor,

expansion chassis, or memory.

The battery voltage has fallen below a threshold level, or the

battery or the battery jumper is missing or not connected.

One or more input or output addresses have been forced to an

On or Off state, but the forces have not been enabled.

The forces have been enabled.

ENET

Channel 1

(Color:

green or red)

RS232

Channel 0

Off No forces are present or enabled.

Solid Green

Flashing Green

Flashing Red

Off No Ethernet connection or port not configured.

On (steadily)

DF1 Protocol

Off

DF1 Protocol

On (steadily)

ASCII Mode

Off

ASCII Mode

On (steadily)

DH485 Protocol

Flashing

DH485 Protocol

The Ethernet port is functioning properly and is connected to

an active Ethernet network.

The Ethernet port is functioning properly, is connected to an

active Ethernet network, and is transmitting packets.

A hardware or software fault has occurred and is being

reported via a code. Contact Allen-Bradley Global Technical

Services for assistance.

The SLC 5/05 processor is transmitting.

The SLC 5/05 processor is not transmitting.

The SLC 5/05 processor is transmitting.

The SLC 5/05 processor is not transmitting.

The Channel 0 Communications Active Bit (S:33/4) is set in

the System Status file, and the processor is actively

communicating on the network.

The processor is trying to establish communications, but there

are no other active nodes on the network.

Off

DH485 Protocol

A fatal error is present.

Publication

1747-10.4

Page 12

1–4

SLC 5/05 Ethernet Processor Features

Keyswitch Operation

The processors include a 3-position keyswitch on the front panel that

lets you choose from three modes of operation: Run, Program, and

Remote. You can remove the key in any of the three positions.

ATTENTION: Depending on the size of your user

program, the processor can take up to 2.5 seconds to

!

change modes when you change the position of the

keyswitch from RUN to PROG or to REM. Do not use

the keyswitch in place of a hardwired master control

relay or an emergency-stop switch.

RUN Position

This position places the processor in the Run mode. The processor

scans/executes the ladder program, monitors input devices, energizes

output devices, and acts on enabled I/O forces. You can only change

the processor mode by changing the key position. You cannot

perform online program editing.

To change the mode to Run, turn the key from PROG or REM to

RUN. When the key is in the RUN position, you cannot use a

programmer/operator interface device to change modes.

PROG Position

This position places the processor in the Program mode. The

processor does not scan/execute the ladder program, and the

controller outputs are de-energized. You can perform online

program editing. You can only change the mode by changing the

key position.

To change the processor mode to Program, turn the key from REM

or RUN to PROG. When the key is in the PROG position, you

cannot use a programmer/operator interface device to change

modes.

REM Position

This position places the processor in the Remote mode: either the

REMote Run, REMote Program, or REMote Test mode. You can

change the processor mode by changing the keyswitch position or by

changing the mode from a programmer/operator interface device.

You can perform online program editing in this position.

To change the mode to REM, turn the key from RUN or PROG to

REM. When the key is in the REM position, you can use a

programmer/operator interface device to change modes.

Publication

1747-10.4

Page 13

Chapter 2

nd

Setting Up the SLC and PC

Hardware

This chapter tells you:

• what tools and equipment you need

• how to install and wire your power supply

• how to install and apply power to your processor

• how to configure the SLC 5/05 processor to communicate on the

Ethernet network

Required Tools a

Equipment

Install the Power Supply

Have the following tools and equipment ready:

• a medium blade screwdriver

• programming equipment

• a 1747-CP3 programmer cable, a 10Base-T Ethernet PC card and

a 10Base-T Ethernet hub

Follow the steps below:

1. Align the circuit board of the power supply with the card guides

on the left side of the chassis, and slide the power supply in until

it is flush with the chassis.

Publication

1747-10.4

Page 14

2–2

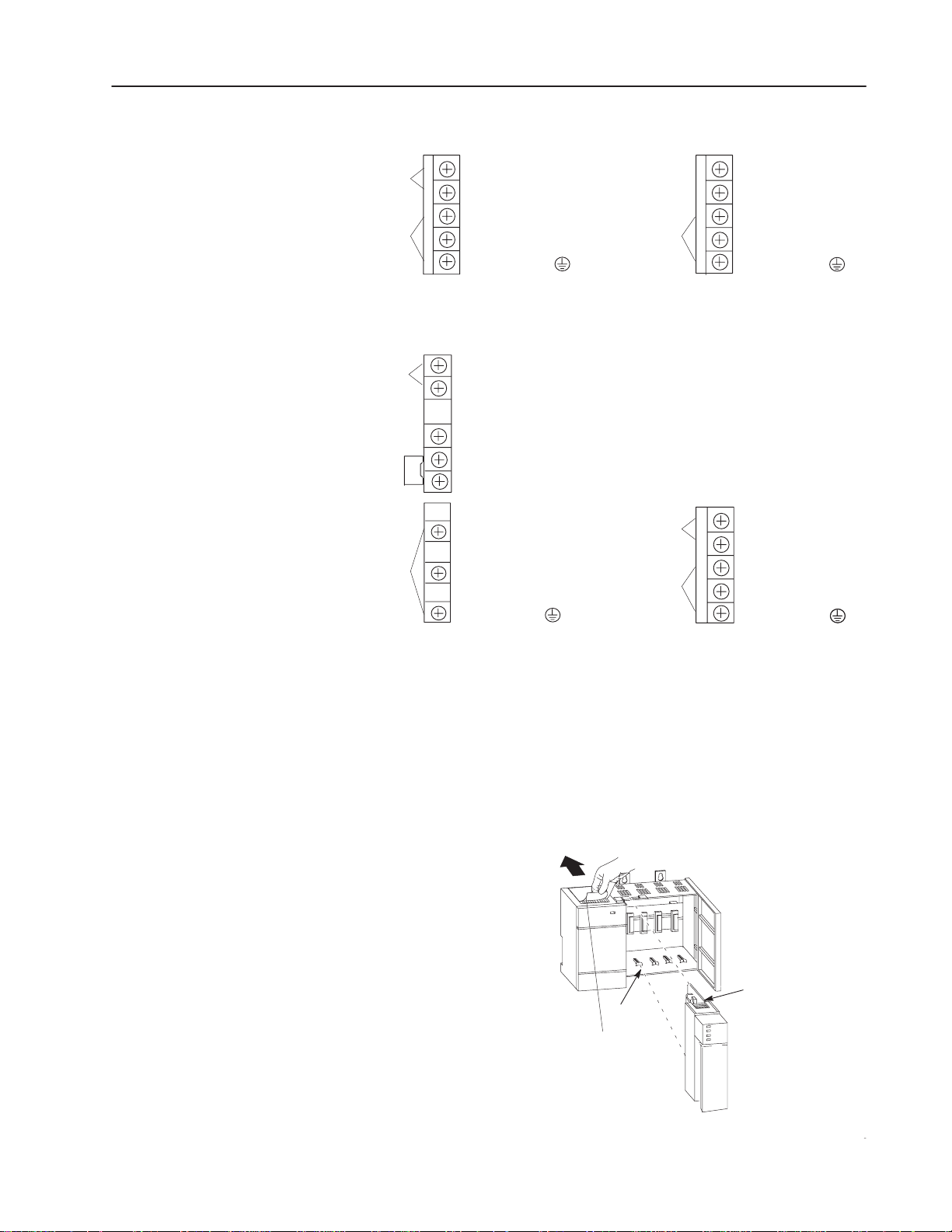

Setting Up the SLC and PC Hardware

2. Fasten the power supply to the chassis.

3. Make jumper selection for 120/240V ac on 1746-P1, 1746-P2,

and 1746-P4 Power Supplies.

Place the input voltage jumper to match the input voltage. This

does not apply to the 1746-P3 or 1746-P5, which do not have

jumpers.

!

Use these screws to fasten the

power supply to the chassis.

ATTENTION: Set the input jumper before applying

power. Hazardous voltage is present on exposed pins

when power is applied; contact with the pin may cause

injury to personnel.

Catalog Number

1746-P1 & P2

POWER

Fuse

Jumper Selection

100/120 Volts

200/240 V

olts

4. Wire power to power supply.

ATTENTION: Turn off incoming power before

connecting wires; failure to do so could cause injury

!

to personnel and/or equipment.

Jumper Selection

85–132 V

AC

170–265 V

AC

Catalog Number

1746-P4

POWER

Publication

1747-10.4

Page 15

Setting Up the SLC and PC Hardware

5. Connect incoming power, as shown in the following diagrams.

2–3

User

Power

Incoming

Power

User

Power

Incoming

Power

PWR OUT +24V dc

PWR OUT COM

120/240V

ac

V ac NEUT

CHASSIS GROUND

1746-P1 and -P2

PWR OUT +24V dc

PWR OUT COMMON

85–132V ac

JUMPER

170–265V ac

L185–132/170–265

L2

NEUTRAL

CHASSIS GROUND

Incoming

Power

User

Power

Incoming

Power

NOT USED

NOT USED

+ 24V dc

dc NEUT

CHASSIS GROUND

1746-P3

PWR OUT +24V dc

PWR OUT COM

+125V dc

dc NEUT

CHASSIS GROUNDCHASSIS GROUND

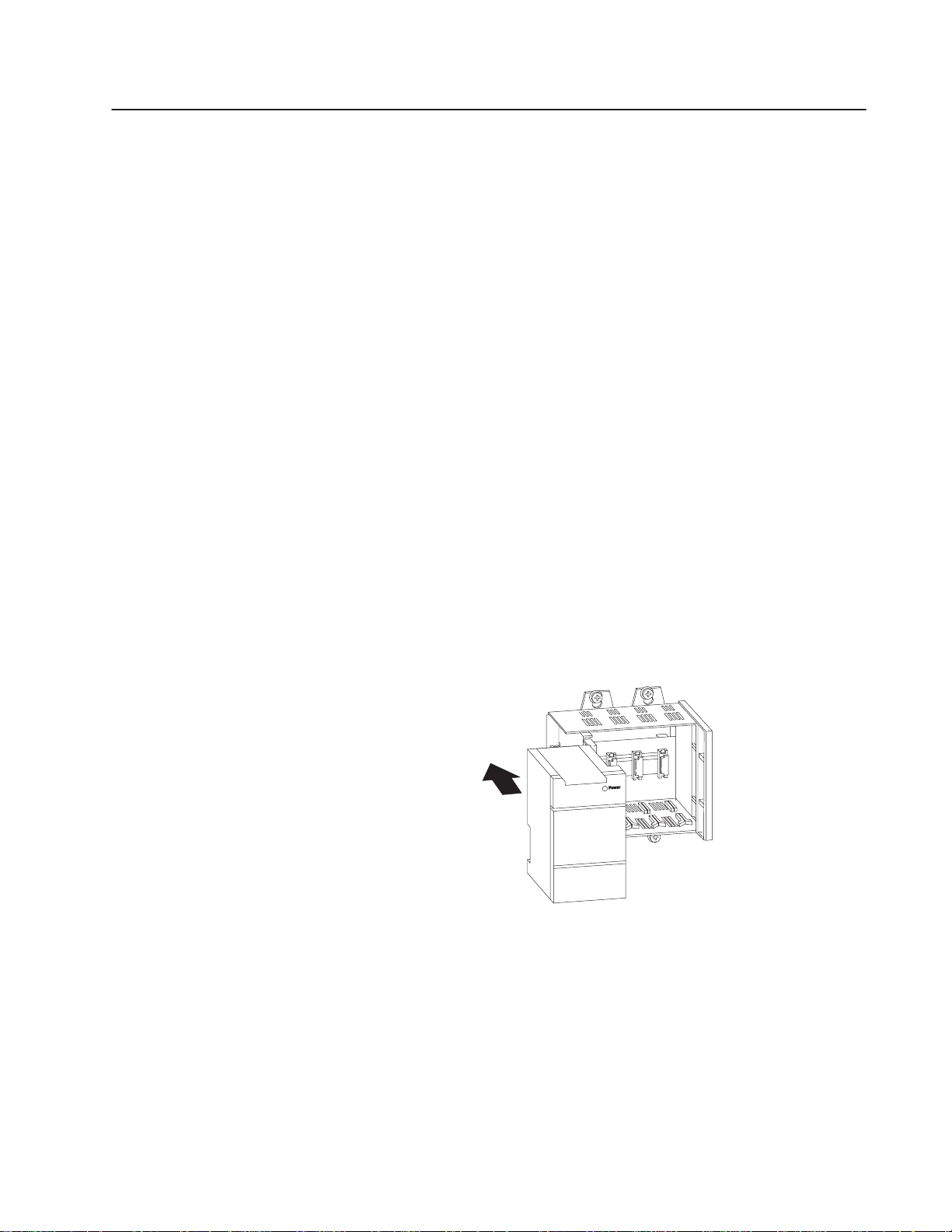

Install the Processor

1746-P4 1746-P5

Make sure system power is off; then insert the processor into the

1746 chassis.

Important: SLC 500 Modular Processors must be inserted into the

left slot (slot 0), as shown below. Remove the

protective label after installing the processor.

Module Release

Card Guide

Protective Label

Publication

1747-10.4

Page 16

2–4

Setting Up the SLC and PC Hardware

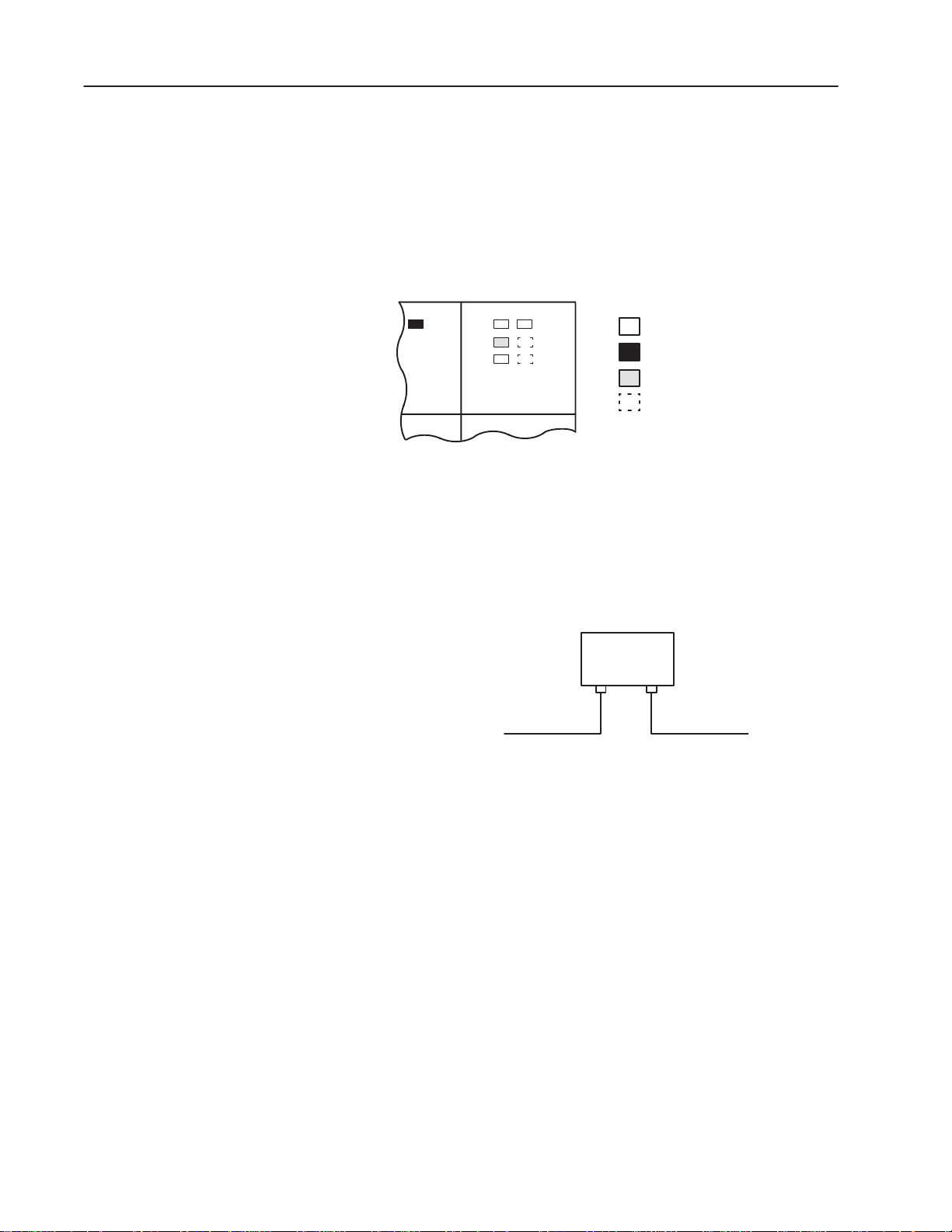

Apply Power to the Processor

Connect the SLC 5/05 and the PC to the Ethernet Network

Follow the steps below:

1. Energize the chassis power supply.

2. Check the chassis power supply and processor LEDs. The power

LED on the power supply should be on and the fault LED on the

processor should be flashing.

Power supply and LED Indicators

POWER

RUN

FLT

BATT

FORCE

ENET

RS232

Indicates the LED is OFF.

Indicates the LED is ON.

Indicates the LED is FLASHING.

Status of LED does not matter.

The SLC 5/05 Ethernet connector conforms to ISO/IEC 8802-3 STD

802.3 and utilizes 10Base-T media. Connections are made directly

from the SLC 5/05 to an Ethernet hub. Typical network topology is

pictured below.

Ethernet Network Topology

RJ45

Ethernet

Hub

to PC Ethernet Card

Important: The SLC 5/05 processor contains a 10Base-T, RJ45

Ethernet connector which connects to standard Ethernet

hubs via 8-wire phone jack cable. To access other

Ethernet mediums, use Ethernet hubs that can be

connected together via fiber, thin-wire, or thick-wire

coaxial cables, or any other physical media

commercially available with Ethernet hubs. In addition,

media converters are commercially available to convert

10Base-T to other Ethernet media.

connectors

on both ends of cable

(10Base-T)

to SLC 5/05

Channel 1

Publication

1747-10.4

Page 17

Setting Up the SLC and PC Hardware

2–5

Ethernet Channel 1 8-Pin 10Base-T Connector

The Ethernet connector is an RJ45, 10Base-T connector. The pin-out

for the connector is shown below:

Pin Pin Name

1 TD+

2 TD–

3 RD+

4 not used by 10BASE-T

5 not used by 10BASE-T

6 RD–

7 not used by 10BASE-T

8 not used by 10BASE-T

When to use straight-through and cross-over pin-out:

• SLC 5/05 Ethernet port to 10Base-T Ethernet hub cables utilize a

straight-through pin-out (1-1, 2-2, 3-3, 6-6).

• Direct point-to-point 10Base-T cables, with cross-over pin-out

(1-3, 2-6, 3-1, 6-2), connect the SLC 5/05 Ethernet port directly

to another SLC 5/05 Ethernet port (or a computer 10Base-T port).

Load Your Programming Software

Cables

Shielded and non-shielded twisted-pair 10Base-T cables with RJ45

connectors are supported. The maximum cable length between an

SLC 5/05 Ethernet port and a 10Base-T port on an Ethernet hub

(without repeaters or fiber) is 100 meters (328 feet). However, in an

industrial application, the cable length should be kept to a minimum.

Install RSLogix500 programming software and RSLinx

communication software. Refer to your software package’s

documentation for installation instructions. Be sure to use the

version of the software listed below. Earlier versions of the software

do not support the SLC 5/05 processor.

• RSLogix500 – Rev. 2.10.12 or later (OS500)

– Rev. 2.51.0 or later (OS501)

• RSLinx – Rev. 1.70.62 or later

Contact Rockwell Software for information on upgrading your

software.

Publication

1747-10.4

Page 18

2–6

Setting Up the SLC and PC Hardware

Publication

1747-10.4

Page 19

Chapter 3

Configuring the Ethernet

Channel for Local

Communication

This chapter:

• describes the configuration methods and configuration parameters

• explains how to configure the Ethernet channel using RSLogix

Programming Software

• explains how to configure the Ethernet channel via BOOTP

Configuration Methods

There are two ways to configure the SLC 5/05 Ethernet channel 1.

The configuration can be done via a BOOTP request at processor

powerup, or by manually setting the configuration parameters using

RSLogix 500 Programming Software. The configuration parameters

are shown below and the configuration procedures follow.

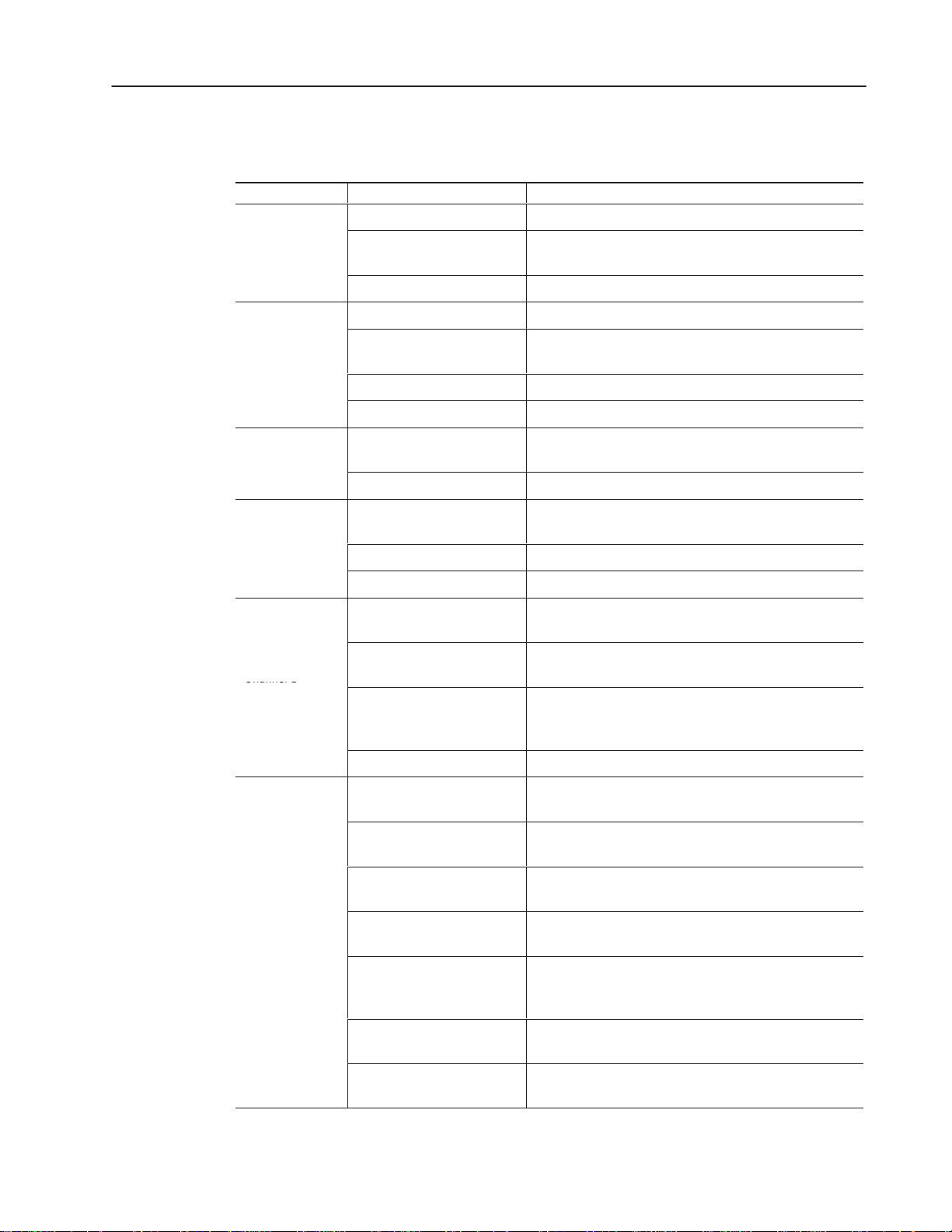

Parameter Description Default Status

Diagnostic File

Number

MSG

Connection

Timeout

MSG Reply

Timeout

Inactivity

Timeout

IP Address

Subnet Mask

Broadcast

Address

Gateway

Address

BOOTP Enable

Hardware

Address

The file number, which states the channel status diagnostic counters for this channel. A

Diagnostic File Number value of zero means that no diagnostics file was configured for this

channel. The Diagnostic File Number must be an integer within the limits of 7, 9–255.

The amount of time (in ms) allowed for a MSG instruction to establish a connection with the

destination node. The MSG Connection Timeout has 250 ms resolution and a range from 250 to

65,500.

The amount of time (in ms) that the SLC 5/05 waits for a reply to a command it initiated via a

MSG instruction. The MSG Reply Timeout has 250 ms resolution and a range from 250 to

65,500.

The amount of time (in minutes) that a MSG connection may remain inactive before it is

terminated. The Inactivity Timeout has a 1 minute resolution and a range from 1 to 65,500

minutes.

The SLC 5/05 internet address (in network byte order). The internet address must be specified

to connect to the TCP/IP network.

The SLC 5/05 subnet mask (in network byte order). The Subnet Mask is used to interpret IP

addresses when the internet is divided into subnets. A Subnet Mask of all zeros indicates that

no subnet mask has been configured.

NOT

SUPPORTED AT THIS TIME. The SLC 5/05 broadcast address (in network byte order). The

Broadcast Address is used in sending multicast messages. A Broadcast Address of all zeros

indicates that no broadcast address was configured. In this case, the network code chooses a

valid broadcast address when needed for that current subnet.

The address of a gateway (in network byte order) that provides connection to another IP

network. A Gateway Address of all zeros indicates that no gateway was configured.

The BOOTP enable switch. When BOOTP is enabled, the SLC 5/05 attempts to learn its

network related parameters at powerup via a BOOTP request. There must be a BOOTP server

on the network capable of responding to this BOOTP request. When BOOTP is disabled, the

SLC 5/05 uses the locally configured network related parameters (IP Address, Subnet Mask,

Broadcast Address, etc.).

The SLC 5/05 Ethernet hardware address.

0 read/write

15,000 ms read/write

3,000 ms read/write

30 minutes read/write

0 (undefined) read/write

0 read/write

0

0 read/write

1 (enabled) read/write

Ethernet

hardware

address

read only

Publication

1747-10.4

Page 20

3–2

Configuring the Ethernet Channel for Local Communication

Configuration Using RSLogix500 Programming Software

The following step-by-step procedure shows how to set up the

SLC 5/05 and establish local communication on an Ethernet

network. You need to assign a unique IP address for your processor.

This procedure also shows how to create a ladder program for an

SLC 5/05 processor and download it via the RS232 COM port on

your computer to channel 0 (RS232) on the SLC 5/05. You can use

the 1747-CP3 Programmer Cable to make the physical connection.

Important: For this configuration method, you must first download

a program to the SLC 5/05 (via RS232) before you can

establish Ethernet communications.

Finally, this procedure assumes that you have previous experience

with SLC 500 processors and RSLogix500 programming software.

If you do not, the following publications will help with the SLC 500

hardware and the instruction set. For the software (RSLogix500 and

RSLinx), use the online HELP screens to guide you through

developing a program and configuring channel 0 communication

parameters.

• SLC 500 and MicroLogix 1000 Instruction Set Reference Manual,

publication 1747-6.15.

• SLC 500 Modular Hardware Style Installation and Operation

Manual, publication 1747-6.2.

Define SLC 5/05 Processor and I/O Modules

1. Start RSLinx software.

2. When the RSLinx window appears, click on the

“Communications” pull-down menu and select “Configure

Drivers”.

3. In this step, you will configure RS232 driver.

In the “Configure Drivers” window, select “RS232 DF1 Devices”

and click on the “Add New” box. The “Configure Allen-Bradley

DF1 Communications Device” window appears.

Select the communications port you wish to use. This is the PC

serial port COM1 through COM9.

Under Device Type, select “SLC–CH0” and “CRC error

checking”.

If you have an RS232 cable connected between the selected COM

port on your PC and channel 0 on your SLC 5/05, you can click

on “Auto-configure” to define your interface parameters.

Publication

1747-10.4

Page 21

Configuring the Ethernet Channel for Local Communication

3–3

If you do not use “Auto-Configure”, you must enter the channel 0

default parameters as follows:

• Device Type: SLC-CH0

• Baud Rate: 19200

• Parity: None

• Error Checking: CRC

• Stop Bits: 1

• Protocol: Full Duplex

When finished, click “OK”. “AB_DF1-1 DH485 Sta:0 COMn:

RUNNING” is added to the list of configured drivers (where n =

the number of the COM port you selected).

Minimize the RSLinx window.

4. Start RSLogix500 programming software and create a new file.

5. In the “Select Processor Type” window, choose the SLC 5/05

processor type:

• 1747-L551, 16K memory

• 1747-L552, 32K memory

• 1747-L553, 64K memory

Assign a name to the processor and click “OK”. A ladder

programming screen appears showing only an END rung.

6. Using the list on the left side of the screen, double-click on

“Controller Properties” under the “Controller” category (folder).

7. In the “Controller Properties” window, click on the “Controller

Communications” tab. In this window, select “AB_DF–1” as the

driver. Click “OK”.

8. Using the list on the left side of the screen, double-click on “I/O

Configuration” under the “Controller” category.

9. In the “I/O Configuration” window, you can identify your SLC

hardware (chassis and I/O modules) either manually or

automatically.

Note: For automatic configuration, you need to have

your SLC hardware installed and the

programming cable (1747-CP3 or equivalent)

connected between the SLC 5/05 channel 0 and

the PC COM port.

Manually –

In the “I/O Configuration” window, select the chassis and I/O

modules that you have. Close this screen (click the close button

[x] in the upper right corner of the window).

Publication

1747-10.4

Page 22

3–4

Configuring the Ethernet Channel for Local Communication

Automatically –

In the “I/O Configuration” window, click on “Read I/O Config”.

The “Read I/O Configuration from Online Processor” pop-up

appears. Select “AB_DF1–1” as the driver and click on the

“Read I/O Config” button. Your chassis and I/O configuration

updates automatically. Close this window.

10.Using the list on the left side of the screen, double-click on

“Channel Configuration” under the “Controller” category.

11. In the Channel 1 section of the General tab, enter an unused file

number, such as 9, in the “Diagnostic File” field. This allows the

programming software to display Channel 1 status, which are the

Ethernet communications diagnostic counters.

12.In the “Channel Configuration” window, click on the “Chan. 1 –

System” tab. Deselect the “BOOTP Enable” option by clicking

on the checked box. Enter your unique IP address in the space

provided.

A subnet mask is used to interpret IP addresses when the internet

is divided into subnets. If your network is not divided into

subnets, then leave the “Subnet Mask” at the default. If you

change the default and need to reset it, type 0.0.0.0.

Note: The “Hardware Address” is filled in by the

processor when you download this program to

the SLC 5/05 processor.

After you have entered your IP address and disabled the BOOTP

option, click “Apply” and then “OK”.

Publication

1747-10.4

Page 23

Configuring the Ethernet Channel for Local Communication

Create Program and Configure Comms Drivers

1. You are now ready to create your ladder logic. An example is

shown below. In this example, there are two SLC 5/05

processors. The MSG instruction from the first processor reads

the seconds value of the Real Time Clock (S:42) from the second

processor and constantly places the value in the first processor’s

file at N7:60. Add the MSG rung to the ladder.

Note: The control block length for Ethernet MSGs is

51 words (when not using Logical ASCII

addressing).

3–5

2. In the “Message Setup” window, enter the MSG parameters and

click “OK”. Then click on the “verify file” button at the top of

the screen. Then save your program file.

3. With RSLogix500 still up and running, click on the RSLinx

program previously minimized at the bottom of the screen.

4. When the RSLinx window appears, click on the

“Communications” pull-down menu and select “Configure

Drivers”.

5. In this step, you will configure the Ethernet driver.

Note: If you have not configured the RS232 DF1

Device, refer to the procedure “Define SLC 5/05

Processor and I/O Modules” on page 3–2

before configuring the Ethernet driver.

Publication

1747-10.4

Page 24

3–6

Configuring the Ethernet Channel for Local Communication

Ethernet –

In the “Configure Drivers” window, select “Ethernet to

PLC-5 or 5820-EI” and click on the “Add New” box. The

“Configure Ethernet-to-AB Communications” window appears.

Enter the IP address for your SLC 5/05 processor beginning with

node 1 under “Current Mappings”. Use the “IP Address or

hostname” box to enter the address and click “Accept”. After

entering the IP address, click “OK”. “AB_ETH-1 A-B Ethernet

RUNNING” is added to the list of Configured Drivers.

Close the “Configure Drivers” window and minimize RSLinx as

before.

Download the Program

1. In RSLogix, click on the “Comms” pull-down menu and select

“System Comms”.

2. Be sure that you have connected your PC COM1 port to

SLC 5/05 channel 0 (RS232 Programmer Cable 1747-CP3). In

the RSLogix “System Options” window, verify that “AB_DF1-1”

driver is selected and click on “Download”.

Enter a version number when asked, click “OK”, and answer

“yes” to any further pop-up windows that appear. Your program

will be downloaded to the processor. When asked if you wish to

go online, click “yes”.

3. Using the list on the left side of the screen, double-click on

“Channel Configuration” under the “Controller” category. Select

the “Chan.1 – System” tab to view the IP address you entered and

the hardware Ethernet address assigned by the SLC 5/05

processor. Verify that this information is correct. Click on

“Cancel”.

4. Go “OFFLINE”.

Publication

1747-10.4

Page 25

Configuring the Ethernet Channel for Local Communication

3–7

Switch to the Ethernet Network and Go ONLINE

1. Connect your computer and your SLC 5/05 processor to any

standard Ethernet hub. You need an Ethernet communication

card to connect your PC to the Ethernet hub.

2. In RSLogix, click on the “Comms” pull-down menu and select

“System Comms”. In the “System Options” window, change the

“Driver” to “AB_ETH-1” and “Apply”. Click on “Who Active”.

3. The “Who Active” window appears, showing your Ethernet node.

Your computer will be “STA 63 AB_ETH-1” with its assigned

name. Your SLC 5/05 will be “STA 1” with its assigned name.

Double-click on the “STA 1” icon. Then go on-line with your

SLC 5/05 via Ethernet.

4. If you have a second SLC 5/05 processor, set it up following the

same procedure as for the first SLC 5/05, but using its own

unique IP address. Also assign this address to the next available

STA address in RSLinx.

Configuration Via BOOTP

5. If you have two SLC 5/05 processors, and you have entered the

one-rung MSG into both of them, you may put them both in the

“RUN” mode and monitor N7:60 in either processor. The value

of N7:60 should increment with each tick of the Real Time Clock

in the other SLC 5/05 processor.

If you only have one SLC 5/05, you cannot send MSGs, but you

are on-line with your processor via 10 Mbps Ethernet.

BOOTP is a standard protocol that TCP/IP nodes use to obtain

start-up information. By default, the SLC 5/05 broadcasts BOOTP

requests at powerup. The BOOTP valid parameter remains clear

until a BOOTP reply has been received. BOOTP lets you

dynamically assign IP Addresses to processors on the Ethernet link.

To use BOOTP, a BOOTP server must exist on the local Ethernet

subnet. The server is a computer that has BOOTP server software

installed and reads a text file containing network information for

individual nodes on the network.

The BOOTP request can be disabled by clearing the BOOTP Enable

parameter in the channel Configuration File. When BOOTP Enable

is cleared (disabled), the SLC 5/05 uses the existing channel

configuration data.

Important: If BOOTP is disabled, or no BOOTP server exists on

the network, you must use SLC 500 programming

software to enter/change the IP address for

each processor. See page 3–2 for that configuration

procedure.

Publication

1747-10.4

Page 26

3–8

Configuring the Ethernet Channel for Local Communication

The host system’s BOOTP configuration file must be updated to

service requests from SLC 5/05 processors. The following

parameters must be configurable:

Parameter Description

IP Address A unique IP Address for the SLC 5/05 processor.

Subnet Mask

Gateway

Specifies the net and local subnet mask as per the standard on

subnetting RFC 950, Internet Standard Subnetting Procedure.

Specifies the IP address of a gateway on the same subnet as the

SLC 5/05 that provides connections to another IP network.

Note: If you do not have BOOTP server capabilities on your

network, and you want to dynamically configure

Channel 1, you can download the utility from

http://supportbbs.ra.rockwell.com or via modem at

440-646-5441.

When BOOTP is enabled, the following events occur at power-up:

• The processor broadcasts a BOOTP request message containing

its hardware address over the local network or subnet.

• The BOOTP server compares the hardware address with the

addresses in its look-up table in the BOOTPTAB file.

• The BOOTP server sends a message back to the processor with

the IP address and other network information that corresponds

to the hardware address it received.

With all hardware and IP addresses in one location, you can easily

change IP addresses in the BOOTP configuration file if your

network needs change.

Using DOS/Windows BOOTP

Both the DOS-based and Windows-based BOOTP server utilities

provide BOOTP services for SLC 5/05 processors. Regardless of the

platform you are using, you must:

• install the boot-server utility

• edit the boot-server configuration file

• run the boot-server utility

Important: Do not use the BOOTP utility if you already have

INTERCHANGE software installed. Instead, use the

boot-server capabilities that came with your

INTERCHANGE software.

Publication

1747-10.4

Page 27

Configuring the Ethernet Channel for Local Communication

3–9

Install the DOS/Windows BOOTP server

To install the DOS BOOTP server:

1. Change the directory to the drive containing the BOOTP utility.

2. Type

3. The software is installed in

install, and press [Enter].

the path statement of your

C:\ABIC\BIN. Put this directory in

AUTOEXEC.BAT file.

Edit the DOS/Windows BOOTP Configuration File

The boot-server configuration file,

BOOTPTAB, is located in the

C:\ABIC\BIN directory. This file contains the information needed to

boot SLC 5/05 processors.

You must edit the

BOOTPTAB file, which is an ASCII text file, to

include the name, IP address, and hardware address for each

SLC 5/05 processor you want the server to boot. To edit this file:

1. Open the

BOOTPTAB file using a text editor.

The file contains lines that look like this:

#Default

defaults5E: ht=1:vm=rfc1048

string for each type of Ethernet client

These are the default parameters for SLC 5/05 processors and

must always precede the client lines in the

BOOTPTAB file.

The file also contains a line that looks like this:

plc5name:

tc=defaults5E:ip=aa.bb.cc.dd:ha=0000BC1Cxxyy

Important: Use this line as the configuration template for

SLC 5/05 processors.

2. Make one copy of the SLC 5/05 processor template for every

SLC 5/05 processor in your system.

3. Edit each copy of the template as follows:

A. Replace plc5name with the name of the SLC 5/05 processor.

Use only letters and numbers; do not use underscores.

B. Replace

aa.bb.cc.dd with the IP address to be assigned to

the processor.

Publication

1747-10.4

Page 28

3–10

Configuring the Ethernet Channel for Local Communication

C. Replace xxyy with the last four digits of the hardware

address. Use only valid hexadecimal digits (0-9, A-F); do

not use the hyphens that separate the numbers. (You will

find the hardware address on a label affixed to the printed

circuit board of the SLC 5/05 processor. Note: See page

1–2 for an illustration showing the location of the hardware

address.)

4. Save, close, and make a backup copy of this file.

Example

In this example, there are three SLC 5/05 processors and an HP 9000

programming terminal. The names and hardware addresses are

device specific:

HP 9000

(HP-UNIX)

computer)

BOOTP

server

Device Name IP

SLC 5/05

SLC 5/05

SLC 5/05

802.3/Ethernet (TCP/IP)

SLC-5/05

processor

sigma1

sigma1 12.34.56.1 00–00–BC–1D–12–34

sigma2 12.34.56.2 00–00–BC–1D–56–78

sigma3 12.34.56.3 00–00–BC–1D–90–12

Address Hardware Address

SLC-5/05

processor

sigma2

SLC-5/05

processor

sigma3

Based on this configuration, the BOOTPTAB file looks like:

# Legend: gw –– gateways

#ha

#ht

#ip

#sm

#vm

#tc

#Default string for each type of Ethernet client

defaults5E: ht=1:vm=rfc1048

#Entries for SLC 5/05 processors:

sigma1: tc=defaults5E:ip=12.34.56.1:ha=0000BC1D1234

sigma2: tc=defaults5E:ip=12.34.56.2:ha=0000BC1D5678

sigma3: tc=defaults5E:ip=12.34.56.3:ha=0000BC1D9012

––

hardware address

––

hardware type

––

host IP address

––

subnet mask

––

BOOTP vendor extensions format

––

template host

➀

➁

Publication

1747-10.4

➀

1 = 10MB Ethernet

➁

Use rfc1048

Page 29

Run the Boot Server Utility

You can run either the DOS-based utility or the Windows-based

BOOTP utility, but not both.

3–1

1Configuring the Ethernet Channel for Local Communication

If you have BOOTP enabled and the message

BOOTP response

not received appears, check the cabling connections and the

BOOTP server system.

If you’re using

this platform

DOS-based

Windows DTLBOOTW.EXE Windows Program

then invoke this

executable from the See page

DTLBOOTD.EXE DOS command line

(specify optional

parameters if necessary)

Manager

3–11

3–12

Both utilities are located in the C:\ABIC\BIN directory and use the

information contained in the

Be sure to place the

BOOTPTAB file in the directory from which you

BOOTPTAB file.

are running the BOOTP utility. If this file is not found in that

directory, the utility will try to find the file in the directory specified

by the environment variable ABIC_CONFIG.

Running the DOS-Based Utility

To run the boot-server utility,

DTLBOOTD.EXE, follow these steps:

1. At the DOS prompt, type:

DTLBOOTD [–D

[

–F

<numfiles>

Parameter Description

–D

–T <timeout> exit after <timeout> seconds of inactivity.

–B <numboots> exit after answering <numboots> number of boot requests.

–F <numfiles> exit after answering <numfiles> number of file requests.

configfile name of the boot server configuration file to use. The default

logfile name of the log file to use. The default log file is

] [

–T

<timeout>

] [

configfile

provide additional information for debug purposes.

configuration file is

%ABIC_CONFIG%\DTLBOOTD.LOG.

] [

–B

<numboots>

] [

logfile

%ABIC_CONFIG%\BOOTPTAB.

]

]

Once you invoke the utility, it runs until the specified exit

parameter is satisfied. Exit any time by pressing

[Esc].

Publication

1747-10.4

Page 30

3–12

Configuring the Ethernet Channel for Local Communication

2. Apply power to all chassis containing SLC 5/05 processors.

At power-up, each SLC 5/05 processor broadcasts a

BOOTP

request if BOOTP was enabled at the channel 1 configuration

screen. The Ethernet boot server compares the hardware address

with those listed in

BOOTPTAB and responds by sending the

corresponding IP address and other configuration data to the

client via a

BOOTP reply.

Running the Windows-Based Utility

To run the boot-server utility,

DTLBOOTW.EXE, follow these steps:

1. Start Microsoft Windows, if it is not already running.

2. Open the Program Manager window, if it is not already open.

3. Choose File on the menu bar and select Run from the menu.

4. In the dialog box, type

“OK” or press

[Enter].

C:\ABIC\BIN\DTLBOOTW; then choose

Once you invoke the utility, it will run until you terminate it by

closing the

DTLBOOTW.EXE

window and exiting from Windows.

5. Apply power to all chassis containing and SLC 5/05 processors.

At power-up, each SLC 5/05 processor broadcasts a BOOTP

request. The Ethernet boot server compares the hardware address

with those listed in

the

BOOTPTAB

file and responds by sending

the corresponding IP address and other configuration data to the

client via a BOOTP reply.

Publication

1747-10.4

Page 31

Chapter 4

Ethernet Conne

ons

Communicating on the

Ethernet Network

This chapter:

• describes how Ethernet connections are established

• provides information on MSG instruction parameters, interpreting

MSG error codes, and interpreting Ethernet status data

• explains how to use advanced Ethernet functions

cti

TCP/IP is the mechanism used to transport Ethernet messages. On

top of TCP, the Client/Server Protocol is required to establish

connections and to send the MSG commands. Connections can be

initiated by either a client program (INTERCHANGE or RSLinx

application) or a processor.

The client program or processor must first establish a connection to

the SLC 5/05 to enable the SLC 5/05 to receive messages from a

client program or another processor. In order to send an outgoing

message, the SLC 5/05 must first establish a connection with the

destination node at a specified IP address on the Ethernet network.

A connection is established when a MSG instruction executes and no

previous connection to that particular Ethernet device exists.

When a MSG instruction executes, the SLC 5/05 checks to see

whether a connection was established with the destination IP

address. If a connection was not established, the SLC 5/05 attempts

to establish a connection.

In order to receive messages from another device on Ethernet, an

“incoming” connection must be established. This incoming

connection is made by the sending processor and uses one incoming

connection in the receiving processor.

The SLC 5/05 supports a maximum of 16 connections, allowing

simultaneous communication with up to 16 other devices or

applications. The connections are dedicated as follows:

Number of Connections Dedicated to:

4 outgoing messages

4 incoming messages

8 either incoming or outgoing messages

Important: For outgoing connections, no more that one connection

per destination IP address is established. If multiple

MSG instructions use the same destination IP address,

they share the same connection.

Publication

1747-10.4

Page 32

4–2

M

Ins

on

Communicating on the Ethernet Network

SG

tructi

The SLC 5/05 processors use the MSG instruction to communicate

over the Ethernet network. The table below describes MSG

instruction parameters for Ethernet.

Parameter Value

Supported MSG Commands

Message Sizes (Channel 1)

Modifying Connections

Limitation for Manipulating the Control Block Bits

485 CIF Read

485 CIF Write

PLC5 Typed Read

PLC5 Typed Write

SLC 500 CPU Read

SLC 500 CPU Write

256 elements maximum, with two exceptions:

•PLC5 Type MSG, Timer File – 201 elements maximum

•All MSG Types, String File – 23 elements maximum

The user may change a MSG instruction destination while the processor is in

the RUN mode. If a MSG instruction’s destination IP address changes, the

next time the MSG instruction executes, a new connection is established with

the new destination node. The old connection remains open as long as either

another MSG instruction was sharing it, or the connection inactive timer has

not expired.

Do not manipulate the MSG instruction control block values except

as noted below. For example, do not clear the first word of the

control block, do not unlatch the time-out control bit, and so on.

The only MSG instruction control bits that may be manipulated by

the ladder program without adversely affecting the operation of the

instruction are the CO, EN, and TO bits. The enable bit

(EN = bit 15) may be unlatched, but only when the done bit

(DN = bit 13) or error bit (ER = bit 12) has been set, indicating the

successful or unsuccessful completion of the previous message.

In addition, when a MSG is in progress and the ladder program

wishes to terminate it for any reason, this may be done by enabling

the time-out bit (TO = bit 8). The next time the processor scans the

MSG instruction with the TO bit set, it will error the MSG (ER = 1).

The MSG instruction may then be re-enabled with a false-to-true

transition on the next program scan.

Publication

1747-10.4

Page 33

Communicating on the Ethernet Network

4–3

Control Block Layouts

The SLC 5/05 MSG control block length varies with the type of

communication and with the addressing you use. Control block

layouts are shown for:

• SLC 5/05 Channel 1 (Ethernet port)

MSG Control Block without Logical ASCII Addressing

• SLC 5/05 Channel 1 (Ethernet port)

MSG Control Block with Logical ASCII Addressing

valid for PLC-5 typed read or write only

The AO bit (word 12, bit 15) is used for PLC-5 type reads and

writes. If AO bit is reset to 0, then logical binary addressing is used

for PLC-5 type reads and writes. If AO is set to 1, then logical

ASCII addressing is selected; in this case the processor expects the

ASCII address string information to be stored in words 14 to 55 of

the MSG control block (see control block layout on page 4–5).

The AO bit has no meaning for 485CIF and 500CPU types of reads

and writes.

Publication

1747-10.4

Page 34

4–4

Communicating on the Ethernet Network

MSG Instruction Control Block

The following are MSG control blocks, without and with logical

ASCII addressing. The length of the control block without logical

ASCII addressing is 51 words. With logical ASCII addressing, the

length of the control block is 93 words.

MSG Control Block without Logical ASCII Addressing

WORD 15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

0 EN ST DN ER CO EW NR TO Error Code

1 Reserved (Target Node Not Used)

2 Number of Elements

3 Not Used

4 File Type (based on local source or destination address)

5 Not Used

6 Not Used

7 Reserved (Internal Messaging Bits) WQ

8 Message Timer Preset

9 Message Timer Scaled Zero

10 Message Timer Accumulator

11 Data Length in Bytes

12 AO=0 Reserved (Internal Messaging Bits) Reserved

13 Reserved

14

First Byte of IP Address String

15 Third Byte of IP Address String …

… …

… …

34 Forty-First Byte of IP Address String NULL Byte of Longest IP Address String

35 Reserved Reserved (Ethernet Message Type); must be 0

36–50 Reserved for Future Use

➀

The

IP Address string format is up to 42 ASCII characters including a terminating NULL character

left-most character in the string as written. For example: If the IP Address is 423.156.78.012, the first byte is the ASCII character “4”. If

the MSG destination is an INTERCHANGE client on a host computer, the destination is specified as “client” and stored as a NULL

terminated string.

➀

SLC 5/05 Channel 1 (Ethernet port)

Second Byte of IP Address String

. The first byte in the array is the

Publication

1747-10.4

Page 35

Communicating on the Ethernet Network

4–5

SLC 5/05 Channel 1 (Ethernet port)

MSG Control Block with Logical ASCII Addressing

valid for PLC-5 typed r

ead or write only

WORD 15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

0 EN ST DN ER CO EW NR TO Error Code

1 Reserved (Target Node Not Used)

2 Number of Elements

3 Not Used

4 File Type (based on local source or destination address)

5 Not Used

6 Not Used

7 Reserved (Internal Messaging Bits) WQ

8 Message Timer Preset

9 Message Timer Scaled Zero

10 Message Timer Accumulator

11 Data Length in Bytes

12 AO=1 Reserved (Internal Messaging Bits) Reserved

13 Reserved

14 Logical ASCII Address String Length including NULL Termination Character (bytes)

15 First Byte of ASCII Address String Second Byte of ASCII Address String

16 Third Byte of ASCII Address String …

… …

… …

55 Eighty-First Byte of ASCII Address String NULL Byte of Longest ASCII Address String

56

First Byte of IP Address String

➀

Second Byte of IP Address String

57 Third Byte of IP Address String …

… …

… …

76 Forty-First Byte of IP Address String NULL Byte of Longest IP Address String

77 Reserved Reserved (Ethernet Message Type); must be 0

78–92 Reserved for Future Use

➀

The

IP Address string format is up to 42 ASCII characters including a terminating NULL character

left-most character in the string as written. For example: If the IP Address is 423.156.78.012, the first byte is the ASCII character “4”. If

the MSG destination is an INTERCHANGE client on a host computer, the destination is specified as “client” and stored as a NULL

terminated string.

. The first byte in the array is the

Publication

1747-10.4

Page 36

4–6

Communicating on the Ethernet Network

Interpreting MSG Error Codes

Error Code Description of Error Condition

02H

03H Target node cannot respond because message is too large.

04H

05H Local processor is offline (possible duplicate node situation).

06H Target node cannot respond because requested function is not available.

07H Target node does not respond.

08H Target node cannot respond.

09H Local modem connection was lost.

0AH Buffer unavailable to receive SRD reply.

OBH Target node does not accept this type of MSG instruction.

0CH Received a master link reset (one possible source is from the DF1 master).

10H Target node cannot respond because of incorrect command parameters or unsupported command.

11H Local file has constant file protection.

12H Local channel configuration protocol error exists.

13H Local MSG configuration error in the Remote MSG parameters.

15H Local channel configuration parameter error exists.

16H Target or Local Bridge address is higher than the maximum node address.

17H Local service is not supported.

18H Broadcast (Node Address 255) is not supported.

19H Improperly formatted Logical ASCII Address string. String not properly terminated with a NULL character, or the string

20H PCCC Description: Host has a problem and will not communicate.

30H PCCC Description: Remote station host is not there, disconnected, or shutdown.

37H Message timed out in local processor.

38H Message disabled pending link response.

40H PCCC Description: Host could not complete function due to hardware fault.

50H Target node is out of memory.

60H Target node cannot respond because file is protected.

70H PCCC Description: Processor is in Program Mode.

80H PCCC Description: Compatibility mode file missing or communication zone problem.

90H PCCC Description: Remote station cannot buffer command.

B0H PCCC Description: Remote station problem due to download.

C0H PCCC Description: Cannot execute command due to active IPBs.

D0H No IP address configured for the network, –or–

D1H Maximum connections used – no connections available.

D2H Invalid internet address or host name.

D3H No such host / cannot communicate with the name server.

Target node is busy. The MSG instruction automatically reloads. If other messages are waiting, the message is

placed at the bottom of the stack.

Target node cannot respond because it does not understand the command parameters OR the control block was

inadvertently modified.

length does not match the value in the length parameter.

Bad command – unsolicited message error, –or–

Bad address – unsolicited message error, –or–

No privilege – unsolicited message error

When the processor detects an error during the transfer of message

data, the processor sets the .ER bit and enters an error code that you

can monitor from your programming software.

Publication

1747-10.4

Page 37

Communicating on the Ethernet Network

Error Code Description of Error Condition

D4H Connection not completed before user-specified timeout

D5H Connection timed out by the network

D7H Connection refused by destination host

D8H Connection was broken

D9H Reply not received before user-specified timeout

DAH No network buffer space available

E1H PCCC Description: Illegal Address format, a field has an illegal value.

E2H PCCC Description: Illegal Address format, not enough fields specified.

E3H PCCC Description: Illegal Address format, too many fields specified.

E4H PCCC Description: Illegal Address, symbol not found.

E5H PCCC Description: Illegal Address format, symbol is 0 or greater than the maximum number of characters supported

by this device.

E6H PCCC Description: Illegal Address, address does not exist, or does not point to something usable by this command.

E7H Target node cannot respond because length requested is too large.

E8H PCCC Description: Cannot complete request, situation changed (file size, for example) during multi-packet operation.

E9H PCCC Description: Data or file is too large. Memory unavailable.

EAH PCCC Description: Request is too large; transaction size plus word address is too large.

EBH Target node cannot respond because target node denies access.

ECH Target node cannot respond because requested function is currently unavailable.

EDH PCCC Description: Resource is already available; condition already exists.

EEH PCCC Description: Command cannot be executed.

EFH PCCC Description: Overflow; histogram overflow.

F0H PCCC Description: No access

F1H Local processor detects illegal target file type.

F2H PCCC Description: Invalid parameter; invalid data in search or command block.

F3H PCCC Description: Address reference exists to deleted area.

F4H PCCC Description: Command execution failure for unknown reason; PLC-3 histogram overflow.

F5H PCCC Description: Data conversion error.

F6H PCCC Description: The scanner is not able to communicate with a 1771 rack adapter. This could be due to the

scanner not scanning, the selected adapter not being scanned, the adapter not responding, or an invalid request of a

“DCM BT (block transfer)”.

F7H PCCC Description: The adapter is not able to communicate with a module.

F8H PCCC Description: The 1771 module response was not valid – size, checksum, etc.

F9H PCCC Description: Duplicated Label.

FAH Target node cannot respond because another node is file owner (has sole file access).

FBH Target node cannot respond because another node is program owner (has sole access to all files).

FCH PCCC Description: Disk file is write-protected or otherwise inaccessible (off-line only).

FDH PCCC Description: Disk file is being used by another application; update not performed (off-line only).

FFH Local communication channel is shut down.

4–7

Note: For 1770–6.5.16 DF1 Protocol and Command Set Reference Manual Users:

The MSG error code reflects the STS field of the reply to your MSG instruction.

Codes E0–EF represent EXT STS codes 0–F.

Codes F0–FD represent EXT STS codes 10–1D.

Publication

1747-10.4

Page 38

4–8

Communicating on the Ethernet Network

Interpreting Ethernet Status Data

Monitor the status of SLC 5/05 processors by accessing the Ethernet

channel 1 status screen of your programming software.

Publication

1747-10.4

Page 39

Communicating on the Ethernet Network

The diagnostic counter data displayed is stored in the diagnostic file

defined on the Ethernet channel 1 configuration screen.

Status field: Bytes: Displays the number of:

Commands

Replies sent 8-11 Replies sent by the channel.

Ethernet In Octets 28-31 Octets received on the channel.

sent 0-3 Commands sent by the channel.

received 4-7 Commands received by the channel.

received 12-15 Replies received by the channel.

sent with error 16-19 Replies containing errors sent by the channel.

received with error 20-23 Replies containing errors received by the channel.

timed out 24-27 Replies not received within the specified timeout period.

Out Octets 32-35 Octets sent on the channel.

In Packets 36-39 Packets received on the channel, including broadcast packets.

Out Packets 40-43 Packets sent on the channel, including broadcast packets.

alignment errors 44-47 Frames received on the channel that are not an integral number of octets in length.

FCS errors 48-51 Frames received on the channel that do not pass the FCS check.

carrier sense errors 52-55 Times that the carrier sense condition was lost or never asserted while trying to transmit a

frame.

excessive collisions 56-59 Frames for which a transmission fails due to excessive collisions.

excessive deferrals 60-63 Frames for which transmission is deferred for an excessive period of time.

MAC receive errors 64-67 Frames for which reception on an interface fails due to internal MAC sublayer receive error.

MAC transmit errors 68-71 Frames for which reception on an interface fails due to internal MAC sublayer transmit error.

single collisions 72-75 Successfully transmitted frames for which transmission was delayed because of collision.

multiple collisions 76-79 Successfully transmitted frames for which transmission was delayed more than once

because of collision.

deferred transmission 80-83 Frames for which the first transmission attempt is delayed because the medium is busy.

late collisions 84-87 Times that a collision is detected later than 512 bit-times into the transmission of a packet.

4–9

Publication

1747-10.4

Page 40

4–10

Communicating on the Ethernet Network

Using Subnet Masks and Gateways

Configure subnet masks and gateways using the Ethernet channel 1

configuration screen:

Important: If BOOTP is enabled, you can’t change any of the

advanced Ethernet communications characteristics.

If your network is divided into subnetworks that use gateways or

routers, you must indicate the following information when

configuring channel 1:

• subnet mask

• gateway address

A subnet mask is a filter that a node applies to IP addresses to

determine if an address is on the local subnet or on another subnet.

If an address is located on another subnetwork, messages are routed

through a local gateway to be transferred to the destination

subnetwork.

If your network is not divided into subnets, then leave the subnet

mask field at the default.

If you are Then See page

manually configuring channel 1

and have a network with subnets

• be sure the BOOTP enable field is disabled

• use your programming software to enter the

subnet mask and gateway address.

4–11

using BOOTP to configure

channel 1 and have a network

with subnets

• be sure BOOTP is enabled

• configure the BOOTPTAB file to include the

subnet mask(s) and gateway address(es)

4–12

Publication

1747-10.4

Page 41

4–1

Manually Configuring Channel 1 for Processors on Subnets

If you are manually configuring channel 1 for a processor located on

a subnet, deselect the “BOOTP Enable” option by clicking on the

checked box.

1Communicating on the Ethernet Network

See the table below to configure the subnet mask and gateway

address fields for each processor via your programming software.

Ethernet Channel 1 Configuration Screen Advanced Functions

This field: Specifies: Configure by doing the following:

Subnet Mask

Gateway Address The IP address of the gateway that

The processor’s subnet mask.

The subnet mask is used to interpret IP

addresses when the internet is divided

into subnets.

provides a connection to another

IP network.

This field is required when you

communicate with other devices not on a

local subnet.

Enter an address of the following form:

a.b.c.d Where: a, b, c, d are numbers between 0-255 (decimal)

If your network is not divided into subnets, then leave the subnet mask field

at the default. If you change the default and need to reset it, type 0.0.0.0.

Enter an address of the following form:

a.b.c.d Where: a, b, c, d are numbers between 0-255 (decimal)

The default address is No Gateway.

Publication

1747-10.4

Page 42

4–12

Communicating on the Ethernet Network

Using BOOTP to Configure Channel 1 for Processors on Subnets

Configure the BOOTPTAB file according to the subnet mask and

gateway address for each SLC 5/05 processor on the link. See the

example below and the corresponding

next page.

Important: Because BOOTP requests are seen only on the local

BOOTPTAB file on the

subnet, each subnet needs its own BOOTP server and

BOOTPTAB file.

personal computer WINDOWS

or HP 9000 or VAX computer

BOOTP

server

Ethernet TCP/IP network

Ethernet gateway

or “router”

BOOTP

server

130.151.132.1 130.151.138.1

130.151.132.xxx

SLC 5/05

processor

Subnet A

130.151.194.xxx

Hostname: Iota1

IP address: 130.151.194.19

Subnet Mask: 255.255.255.0

Gateway Address: 130.151.194.1

130.151.194.1

BOOTP

server

130.151.138.xxx

Publication

Subnet B Subnet C

Hostname: Iota2

IP address: 130.151.132.110

Subnet Mask: 255.255.255.0

Gateway

Address: 130.151.132.1

1747-10.4

SLC 5/05

processor

SLC 5/05

processor

Hostname: Iota3

IP address: 130.151.138.123

Subnet Mask: 255.255.255.0

Gateway

Address: 130.151.138.1

Page 43

Communicating on the Ethernet Network

The BOOTPTAB files that correspond to this example look like:

# Legend: gw –– gateways

––

#ha

#ht

#ip

#sm

#vm

#tc

#Default string for each type of Ethernet client

defaults5E: ht=1:vm=rfc1048:sm=255.255.255.0

#Entries for SLC 5/05 processors:

iota1:\

tc=defaults5E:\

gw=130.151.194.1:\

ha=0000BC1D1234:/

ip=130.151.194.19

# Legend: gw –– gateways

#ha

#ht

#ip

#sm

#vm

#tc

#Default string for each type of Ethernet client

defaults5E: ht=1:vm=rfc1048:sm=255.255.255.0

#Entries for SLC 5/05 processors:

iota2:\

tc=defaults5E:\

gw=130.151.132.1:\

ha=0000BC1D5678:/

ip=130.151.132.110

hardware address

––

hardware type

––

host IP address

––

subnet mask

––

BOOTP vendor extensions format

––

template host

––

hardware address

––

hardware type

––

host IP address

––

subnet mask

––

BOOTP vendor extensions format

––

template host

4–13

# Legend: gw –– gateways

––

#ha

#ht

#ip

#sm

#vm

#tc

#Default string for each type of Ethernet client

defaults5E: ht=1:vm=rfc1048:sm=255.255.255.0

#Entries for SLC 5/05 processors:

iota3:\

tc=defaults5E:\

gw=130.151.138.1:\

ha=0000BC1D9012:/

ip=130.151.138.123

hardware address

––

hardware type

––

host IP address

––

subnet mask

––

BOOTP vendor extensions format

––

template host

Publication

1747-10.4

Page 44

4–14

Communicating on the Ethernet Network

Publication

1747-10.4

Page 45

Chapter 5

Passthru Feature

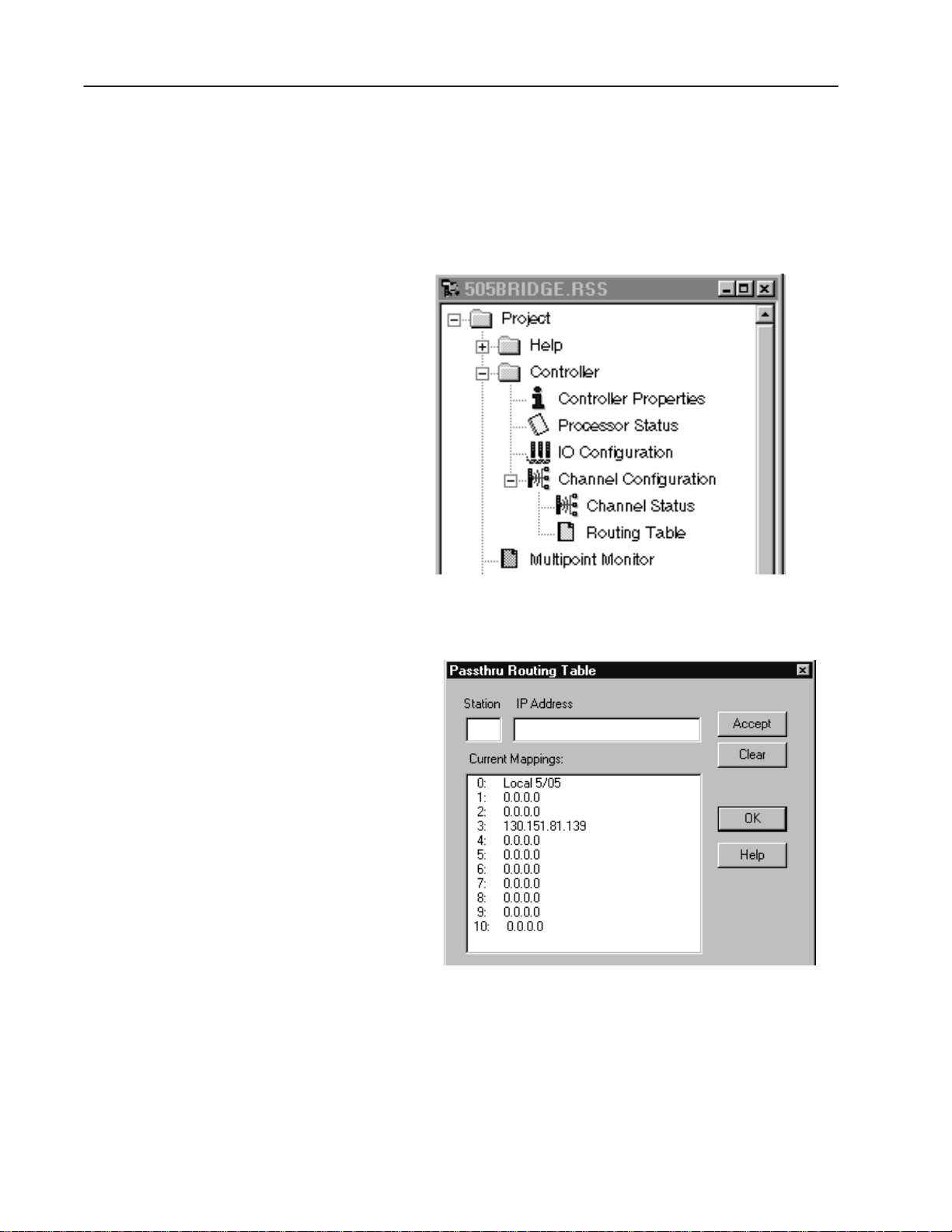

Using RS232toEthernet

ChanneltoChannel Passthru

This chapter contains information about the new passthru feature on

SLC 5/05 (1747-OS501, FRN 3) processors, including:

• Updated status file information