Page 1

POINT I/O and ArmorPOINT I/O

DeviceLogix Modules

Catalog Numbers 1734-8CFGDLX, 1738-8CFGDLXM8,

1738-8CFGDLXM12, 1738-8CFGDLXM23

User Manual

Original Instructions

Page 2

POINT I/O and ArmorPOINT I/O DeviceLogix Modules User Manual

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize

themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to

be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may

lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or

economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may

be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach

dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to potential Arc

Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL Regulatory requirements

for safe work practices and for Personal Protective Equipment (PPE).

2 Rockwell Automation Publication 1734-UM015B-EN-E - May 2020

Page 3

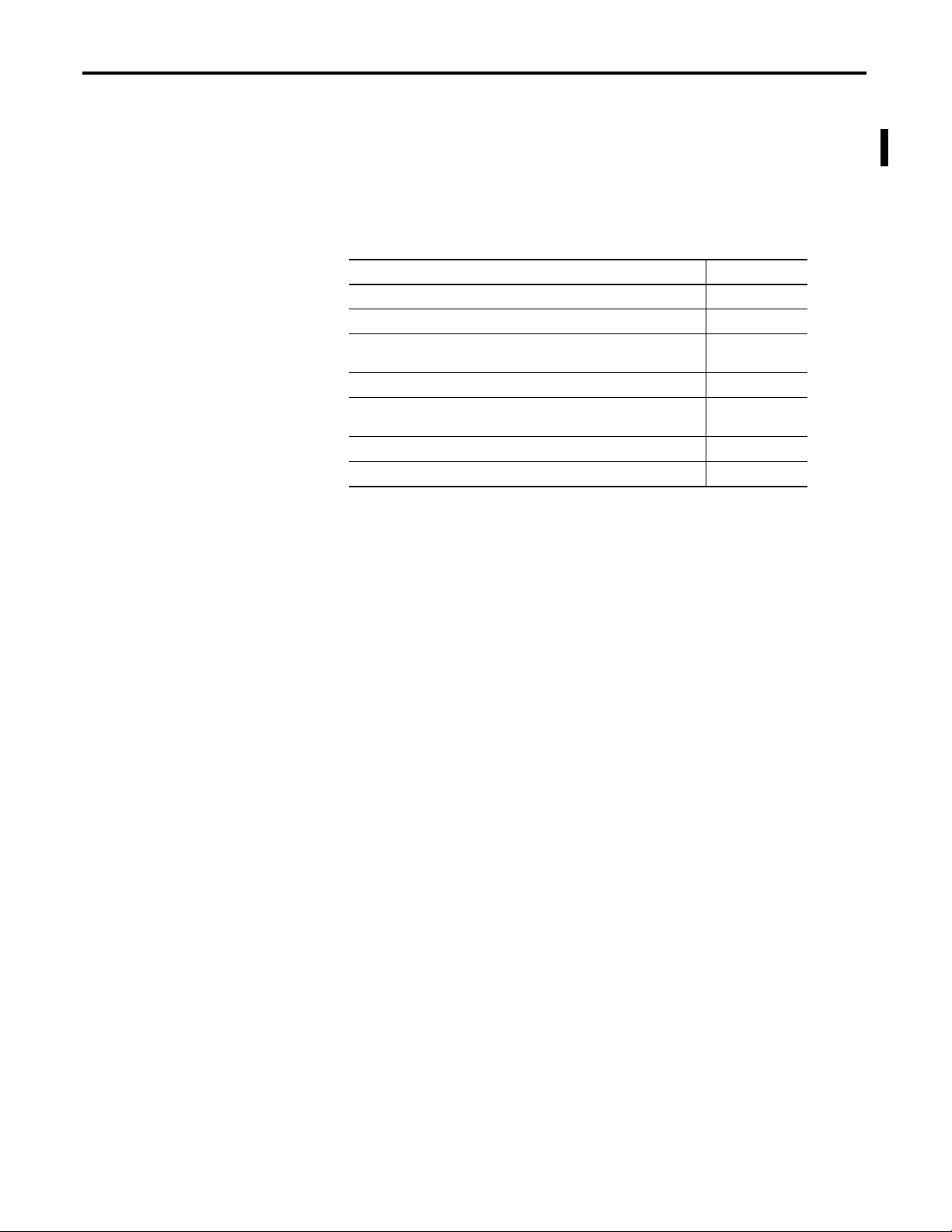

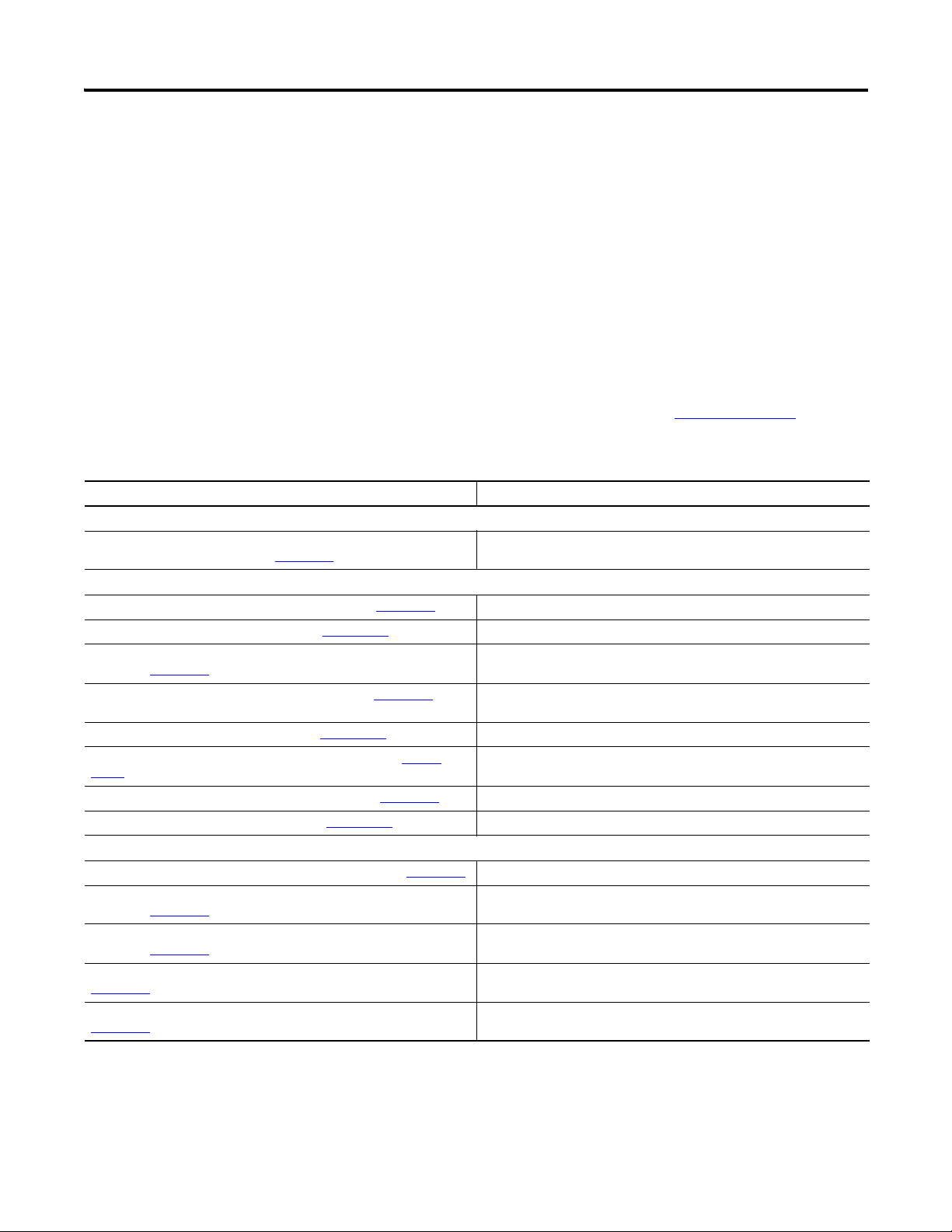

Table of Contents

Summary of Changes New and Updated Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Preface Purpose of This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Related Publications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 1

Introduction About This Chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

About the Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1734-8CFGDLX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1738-8CFGDLXM8, 1738-8CFGDLXM12, and 1738-

8CFGDLXM23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Modes of Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Standard POINT I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Stand Alone DeviceLogix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Peer Enabled POINT I/O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Quick Start - Prepare the Modules to work on DeviceNet . . . . . . . . 16

Quick Start - Prepare the Modules to work on EtherNet/IP and

ControlNet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Install POINT I/O DeviceLogix

Modules

Install ArmorPOINT I/O

DeviceLogix Modules

Chapter 2

About This Chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Install the Mounting Base Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Install an I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Install the Removable Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Remove a 1734-TB or 1734-TBS Base . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Remove a 1734-TOP or 1734-TOPS Base. . . . . . . . . . . . . . . . . . . . . . . 27

Wire the Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

1734-8CFGDLX I/O Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

1734-8CFGDLX Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . 28

System and Power Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Chapter 3

About This Chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Install the Mounting Base. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Install the Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Remove the Module from the Mounting Base. . . . . . . . . . . . . . . . 34

Wire the Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

1738-8CFGDLXM8 I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . . 34

1738-8CFGDLXM12 I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . 35

1738-8CFGDLXM23 I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . 36

DeviceLogix for POINT I/O and

ArmorPOINT I/O on DeviceNet

Chapter 4

About This Chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Offline Configuration using RSNetWorx for DeviceNet . . . . . . . . . 37

Example: Build the Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Rockwell Automation Publication 1734-UM015B-EN-E - May 2020 3

Page 4

Table of Contents

Online Configuration using RSNetWorx for DeviceNet . . . . . . . . . 40

I/O Data Assembly Maps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Chapter 5

DeviceLogix for POINT I/O and

ArmorPOINT I/O on Ethernet/

ControlNet

About This Chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Add a POINT I/O DeviceLogix Module to RSLogix 5000. . . . . . . . 47

I/O Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Launch RSNetWorx for DeviceNet to Configure the Module . . . . 51

Chapter 6

Configuring POINT I/O and

ArmorPOINT I/O DeviceLogix

modules using RSNetWorx for

DeviceNet

About This Chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Configure the Module using the Configuration tab . . . . . . . . . . . . . . 53

Parameters on the Parameters tab . . . . . . . . . . . . . . . . . . . . . . . . 57

Configure Peer Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Set Up Peer Communication Parameters . . . . . . . . . . . . . . . . . . . . 59

Produce Data Without Using a Master. . . . . . . . . . . . . . . . . . . . . . . . . . 62

Start the Function Block Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Chapter 7

DeviceLogix Capabilities About This Chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Function Block Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Process Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Filter Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Select Limit Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Statistical Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Timer/Counter Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Comparison Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Compute Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Move/Logical Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Logic Execution Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Digital Inputs to Function Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Analog Inputs to Function Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Digital Outputs from Function Blocks . . . . . . . . . . . . . . . . . . . . . . 78

Analog Outputs from Function Blocks . . . . . . . . . . . . . . . . . . . . . . 80

Enable Line feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Offline and Online Editing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Enable/Disable Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Logic Enable On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Logic Enable Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Dependent Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Chapter 8

Troubleshooting About This Chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

About Module Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

4 Rockwell Automation Publication 1734-UM015B-EN-E - May 2020

Page 5

Table of Contents

Status Indicators of POINT I/O Module . . . . . . . . . . . . . . . . . . . . . . . 88

1734-8CFGDLX Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Status Indicators of ArmorPOINT I/O Modules . . . . . . . . . . . . . . . . 90

1738-8CFGDLXM8, 1738-8CFGDLXM12, and 1738-

8CFGDLXM23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Troubleshooting Scenarios . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Peer connection is not working . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Configuration or DeviceLogix program cannot be downloaded to

the module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Module’s DeviceLogix program exits the Run mode unexpectedly

94

Appendix A

Peer Data Maps About This Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Peer I/O Sizes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Digital Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Analog and Specialty Input Modules . . . . . . . . . . . . . . . . . . . . . . . . 97

Peer Data Maps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

2-Point Digital Input Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

4-Point Digital Input Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

4-Point Digital Input with Diagnostics Modules . . . . . . . . . . . . 100

8-Point Digital Input Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

8-Point Configurable Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

16-Point Digital Input Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

8-Point Digital Input Modules with DeviceLogix . . . . . . . . . . . 102

2-Point Analog Input Modules and RTD (Resistant Temperature

Device) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

4-Point Analog Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

8-Point Analog Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

2-Point Thermocouple Input Modules . . . . . . . . . . . . . . . . . . . . . 107

Very High-Speed Counter Input Modules . . . . . . . . . . . . . . . . . . 108

Encoder/Counter Input Modules. . . . . . . . . . . . . . . . . . . . . . . . . . 110

Synchronous Serial Interface Modules . . . . . . . . . . . . . . . . . . . . . . 110

RS232 and RS485 Interface Module . . . . . . . . . . . . . . . . . . . . . . . 111

Set Write Enable Flag using

RSNetWorx for DeviceNet

Appendix B

About This Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Flag Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Affected Behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Disabled Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Risk Factors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Rockwell Automation Publication 1734-UM015B-EN-E - May 2020 5

Page 6

Table of Contents

Notes:

6 Rockwell Automation Publication 1734-UM015B-EN-E - May 2020

Page 7

Summary of Changes

This manual contains new and updated information. Changes throughout this

revision are marked by change bars, as shown to the right of this paragraph.

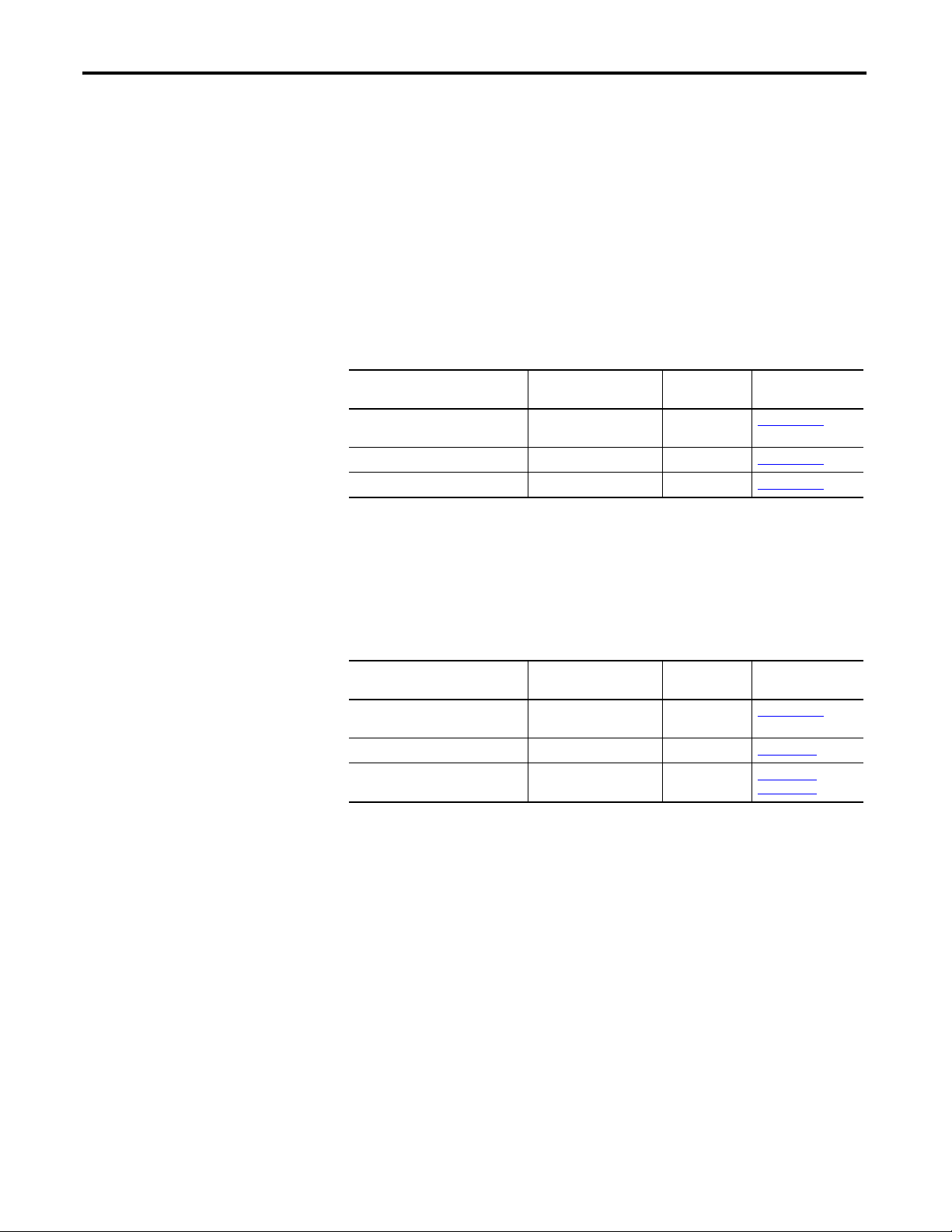

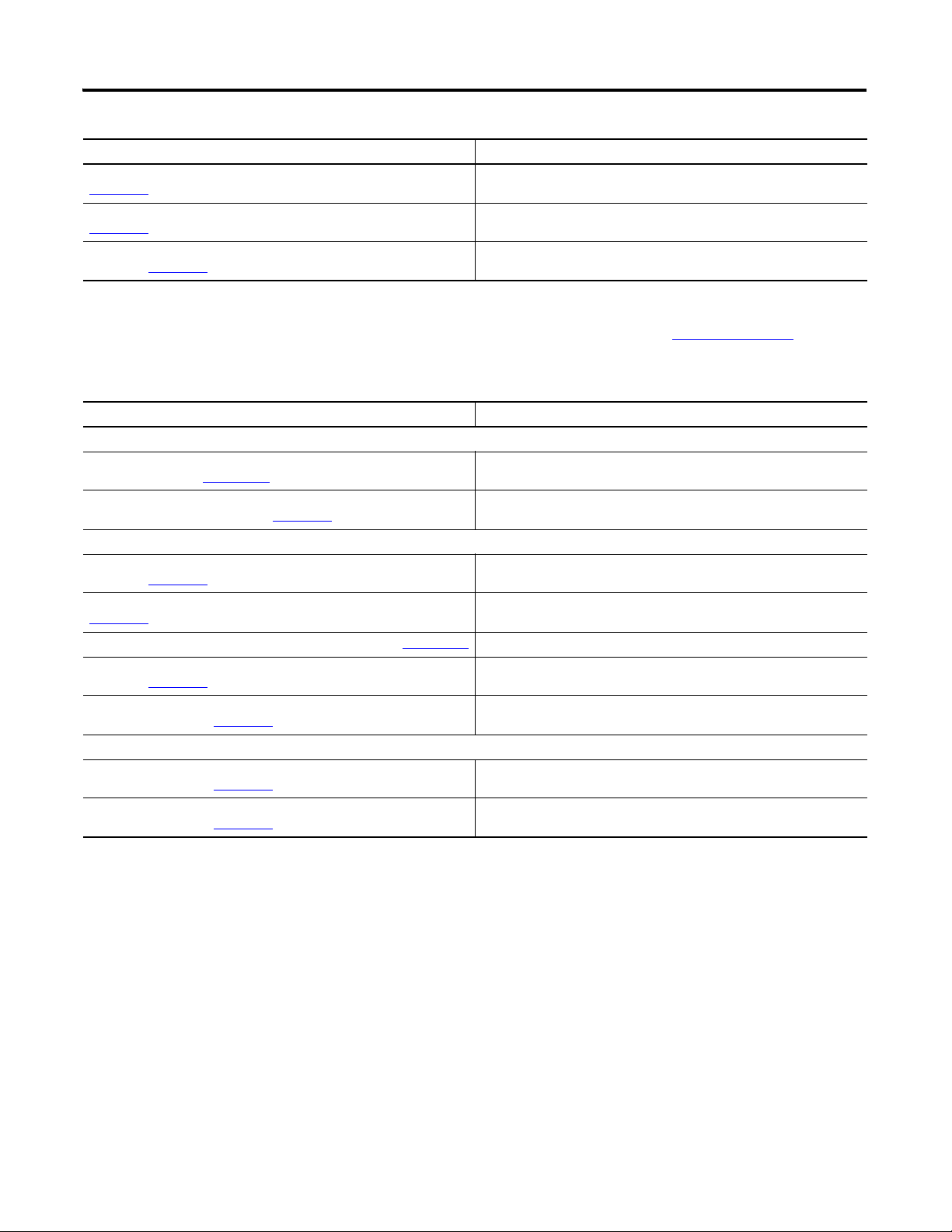

New and Updated Information

This table contains the additions made to this revision.

Topic Page

Updated version and revision information 13, 84

Changed Function Block category to Compute/Math 67

Added Down Counter type in Timer/Counter category instruction

types

Updated Timer/Counter Category information 70

Removed Square Root (SQR) and Power (XPY) in the Compute

Category

Updated Logic Execution Time table 74

New Appendix section for Write Enable Flag Feature 113

69

71

Rockwell Automation Publication 1734-UM015B-EN-E - May 2020 7

Page 8

Summary of Changes

Notes:

8 Rockwell Automation Publication 1734-UM015B-EN-E - May 2020

Page 9

Preface

Purpose of This Manual

This manual describes how to install, configure, and troubleshoot your

POINT I/O™ DeviceLogix™ and ArmorPOINT® I/O DeviceLogix

modules.

POINT I/O and ArmorPOINT I/O modules can be used in EtherNet/IP™,

DeviceNet®, and ControlNet® systems. As such, you may need to refer to

other publications in addition to this one.

When using POINT I/O DeviceLogix modules with a communication

adapter, use this manual in conjunction with the user manual for the adapter

you are using as shown in the table.

When Using POINT I/O

Modules on This Network

DeviceNet network DeviceNet adapter 1734-ADN

ControlNet network ControlNet adapter 1734-ACNR 1734-UM008

EtherNet/IP network EtherNet/IP adapter 1734-AENT 1734-UM011

Refer to Publication

for

Catalog No. Publication No.

1734-UM002

1734-ADNX

POINT I/O DeviceLogix modules are not compatible with the PROFIBUS

adapter.

When using ArmorPOINT I/O DeviceLogix modules with a communication

adapter, use this manual in conjunction with the user manual for the adapter

you are using as shown in the table.

When Using ArmorPOINT I/O

Modules on This Network

DeviceNet network DeviceNet adapter 1738-ADN

ControlNet network ControlNet adapter 1738-ACNR 1738-IN016

EtherNet/IP network EtherNet/IP adapter 1738-AENT

Refer to Publication

for

Catalog No. Publication No.

1738-ADNX

1738-AENTR

1738-UM001

1738-IN017

1738-IN028

ArmorPOINT I/O DeviceLogix modules are not compatible with the

PROFIBUS adapter.

The modules in this manual are DeviceNet-ready. Each module can exist on

the DeviceNet network as one of the following:

• An individual node

• With an adapter (catalog number 1734-ADN or 1734-ADNX) as a

single node

For applications using these modules in a network with a 1734-PDN

DeviceNet Communication Interface, or a 1734D-xx POINTBlock I/O

module, this user manual is the primary documentation.

Rockwell Automation Publication 1734-UM015B-EN-E - May 2020 9

Page 10

Preface

Who Should Use This Manual

This manual is intended for qualified personnel. You should know how to do

the following:

• Use RSNetWorx™ software or similar configuration software to se

and calib

•

Download and use electronic data sheet (EDS) files.

rate these module

s.

In addition, you should be familiar with RSLogix 5000® and CIP™ Network

terminology. If you do not, refer to your

software documentation or online

help before attempting to use these modules.

Related Publications

Refer to this table for a list of related POINT I/O products and

documentation. The publications are available at rok.auto/literature. For

specification and safety certification information, refer to the installation

instructions.

Resource Description

POINT I/O DeviceLogix Module

POINT I/O Module with 8 Configurable 24V DC Points and DeviceLogix

Installation Instructions, publication 1734-IN039

Communication Devices

ControlNet Adapter Installation Instructions, publication 1734-IN582 Provides installation information about 1734-ACNR adapters.

ControlNet Adapter User Manual, publication 1734-UM008

DeviceNet Communication Interface Module Installation Instructions,

publication 1734-IN057

DeviceNet Adapter Installation Instructions, publication 1734-IN026 Provides installation information about 1734-ADN and 1734-ADNX

DeviceNet Adapter User Manual, publication 1734-UM002

RSNetWorx for DeviceNet Getting Results Guide, publication DRNET-

GR001

EtherNet/IP Adapter Installation Instructions, publication 1734-IN590 Provides installation information about 1734-AENT adapters.

EtherNet/IP Adapter User Manual, publication 1734-UM011

Power Supplies, Wiring Base Assemblies, Miscellaneous

Field Potential Distributor Installation Instructions, publication 1734-IN059 Provides installation information about 1734-FPD distributors.

POINT I/O 24V DC Expansion Power Supply Installation Instructions,

publication 1734-IN058

POINT I/O 120/240V AC Expansion Power Supply Installation Instructions,

publication 1734-IN017

POINT I/O Common Terminal Module Installation Instructions, publication

1734-IN024

POINT I/O Voltage Terminal Module Installation Instructions, publication

1734-IN024

Provides installation information and wiring diagrams for 1734-8CFGDLX

modules.

Describes how to use 1734-ACNR adapters.

Provides installation information about 1734-PDN modules.

adapters.

Describes how to use 1734-ADN and 1734-ADNX adapters.

Describes how to install and navigate the RSNetWorx for DeviceNet

software.

Describes how to use 1734-AENT adapters.

Provides installation information about 1734-EP24DC power supplies.

Provides installation information about 1734-EPAC power supplies.

Provides installation information about 1734-CTM modules.

Provides installation information about 1734-VTM modules.

t up

10 Rockwell Automation Publication 1734-UM015B-EN-E - May 2020

Page 11

Resource Description

POINT I/O Wiring Base Assembly Installation Instructions, publication

1734-IN511

POINT I/O Wiring Base Assembly Installation Instructions, publication

1734-IN013

POINT I/O One-piece Wiring Base Assembly Installation Instructions,

publication 1734-IN028

Provides installation information about 1734-TB and 1734-TBS assemblies.

Provides installation information about 1734-TB3 and 1734-TB3S

assemblies.

Provides installation information about 1734-TOP, 1734-TOPS, 1734-TOP3,

and 1734-TOP3S assemblies.

Refer to this table for a list of related ArmorPOINT I/O products and

documentation. The publications are available at rok.auto/literature. For

specification and safety certification information, refer to the installation

instructions.

Resource Description

ArmorPOINT I/O DeviceLogix Module

ArmorPOINT I/O Modules with 8 Configurable 24V DC Points Wiring

Diagrams, publication 1738-WD009

ArmorPOINT Module with Configurable 24V DC Points and DeviceLogix

Installation Instructions, publication 1738-IN027

Communication Devices

ArmorPOINT ControlNet Adapter, Series A Installation Instructions,

publication 1738-IN016

ArmorPOINT I/O DeviceNet Adapter Installation Instructions, publication

1738-IN014

ArmorPOINT I/O DeviceNet Adapter User Manual, publication 1738-UM001 Describes how to use 1738-ADN and 1738-ADNX adapters.

ArmorPOINT EtherNet/IP Adapter, Series A Installation Instructions,

publication 1738-IN017

ArmorPOINT I/O 2-Port EtherNet/IP Adapter, Series A Installation

Instructions, publication 1738-IN028

Power Supplies, Wiring Base Assemblies, Miscellaneous

ArmorPOINT I/O Field Potential Distributor, Series A Installation

Instructions, publication 1738-IN019

ArmorPOINT I/O 24V DC Expansion Power Supply, Series A Installation

Instructions, publication 1738-IN020

Provides wiring diagrams for 1738-8CFGDLXM8, 1738-8CFGDLXM12, and

1738-8CFGDLXM23.

Provides installation information about 1738-8CFGDLXM8, 17388CFGDLXM12, and 1738-8CFGDLXM23.

Provides installation information about 1738-ACNR adapters.

Provides installation information about 1738-ADN and 1738-ADNX

adapters.

Provides installation information about 1738-AENT adapters.

Provides installation information about 1738-AENTR adapters.

Provides installation information about 1738-FPD distributors.

Provides installation information about 1738-EP24DC power supplies.

Preface

Rockwell Automation Publication 1734-UM015B-EN-E - May 2020 11

Page 12

Preface

Notes:

12 Rockwell Automation Publication 1734-UM015B-EN-E - May 2020

Page 13

Introduction

Chapter

1

About This Chapter

About the Modules

This chapter introduces POINT I/O and ArmorPOINT I/O configurable

modules with DeviceLogix capability.

•About the Modules

• Quick Start - Prepare the Modules to work on DeviceNet

• Quick Start - Prepare the Modules to work on EtherNet/IP and

ControlNet

The POINT I/O and ArmorPOINT I/O modules work with EtherNet/IP,

DeviceNet, and ControlNet network adapters. Each module has eight 24V DC

I/O points that self-configure to be inputs or outputs. Inputs are IEC Type 3

and outputs are self-protecting 0.5 A outputs.

The firmware in these modules uses Version 3 (1738-8CFGDLXM8,

1738-8CFGDLXM12, 1738-8CFGDLXM23) and Version 7

(1734-8CFGDLX) of the DeviceLogix master library. The modules can

execute 144 DeviceLogix function blocks in 3 ms. Smaller programs that

contain fewer than 40 function blocks can be executed in 1 ms.

Each module produces 20 bytes of data including I/O state (8 bits), eight

user-defined bits, and eight user-defined words of analog data to be consumed

by processors or other DeviceLogix modules. Each module consumes 20 bytes

of data to set the I/O state (8 bits), eight user-defined control bits, and eight

user-defined words of analog data. It is also possible to consume the data from

up to eight other peers.

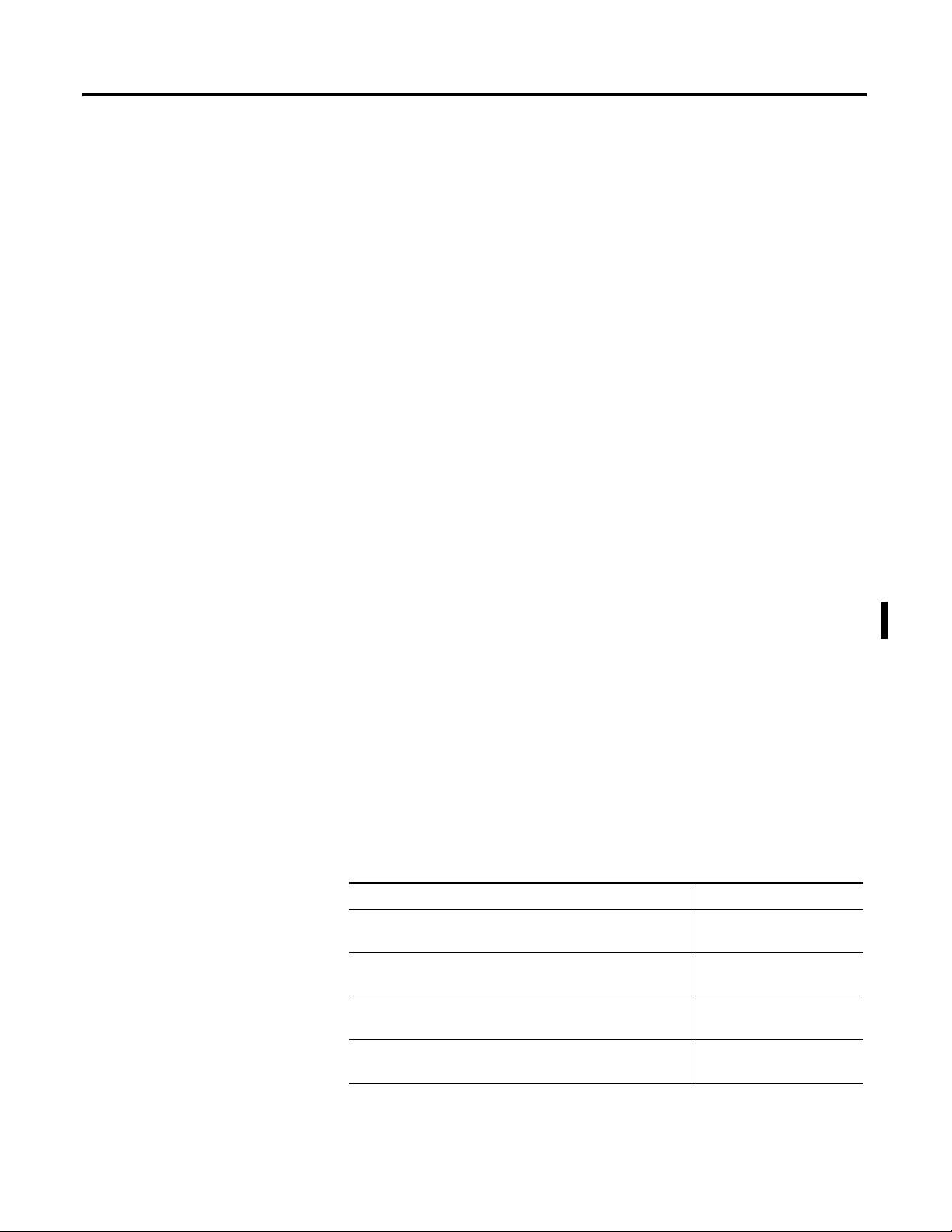

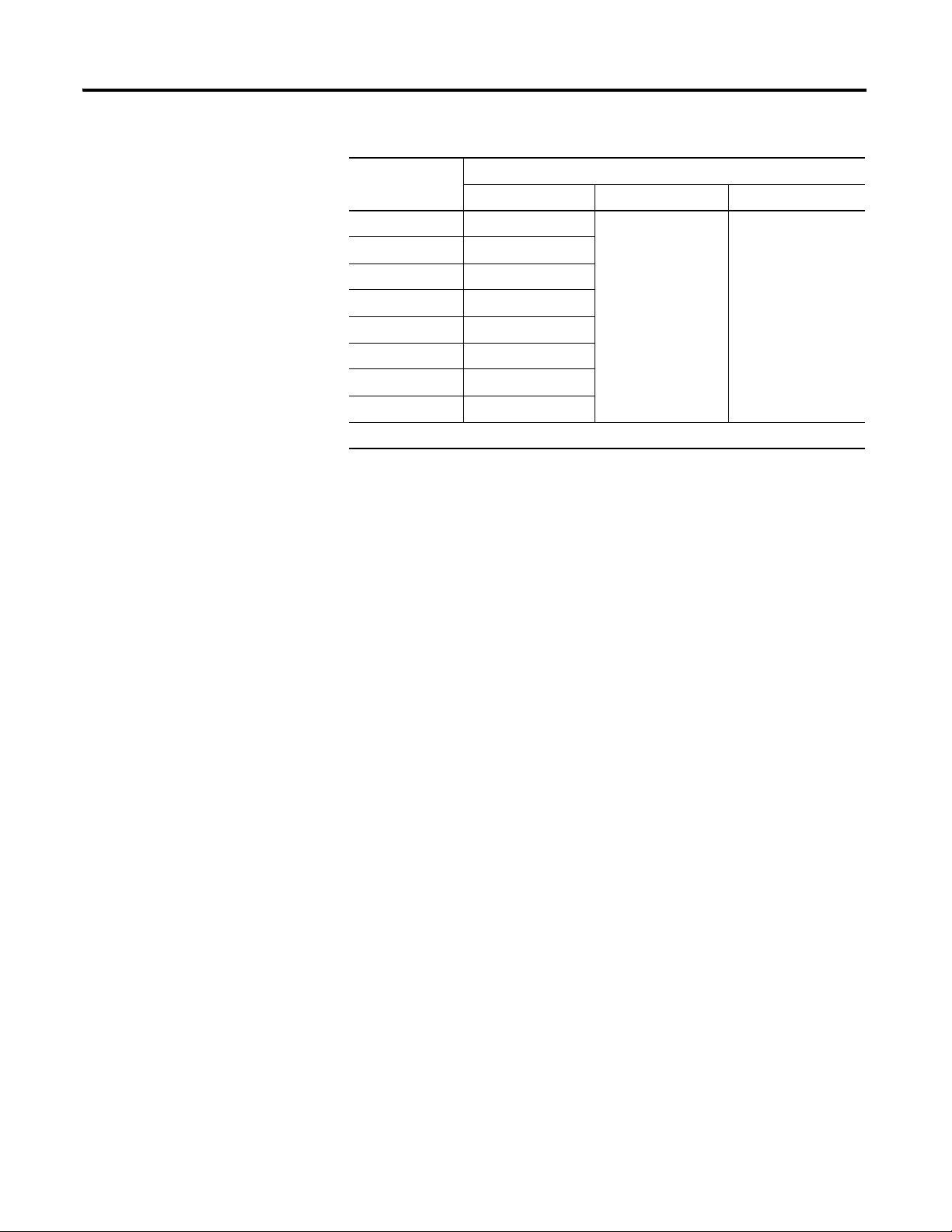

This table lists 1734 and 1738 configurable I/O modules with DeviceLogix.

Module Description Cat. No.

POINT I/O module with 8 configurable 24V DC I/O points

and DeviceLogix capabilities

ArmorPOINT I/O module with 8 configurable 24V DC M8

connectors and DeviceLogix

ArmorPOINT I/O module with 8 configurable 24V DC M12

connectors and DeviceLogix

ArmorPOINT I/O module with 1 configurable 24V DC M23

connector and DeviceLogix

Rockwell Automation Publication 1734-UM015B-EN-E - May 2020 13

1734-8CFGDLX

1738-8CFGDLXM8

1738-8CFGDLXM12

1738-8CFGDLXM23

Page 14

Introduction

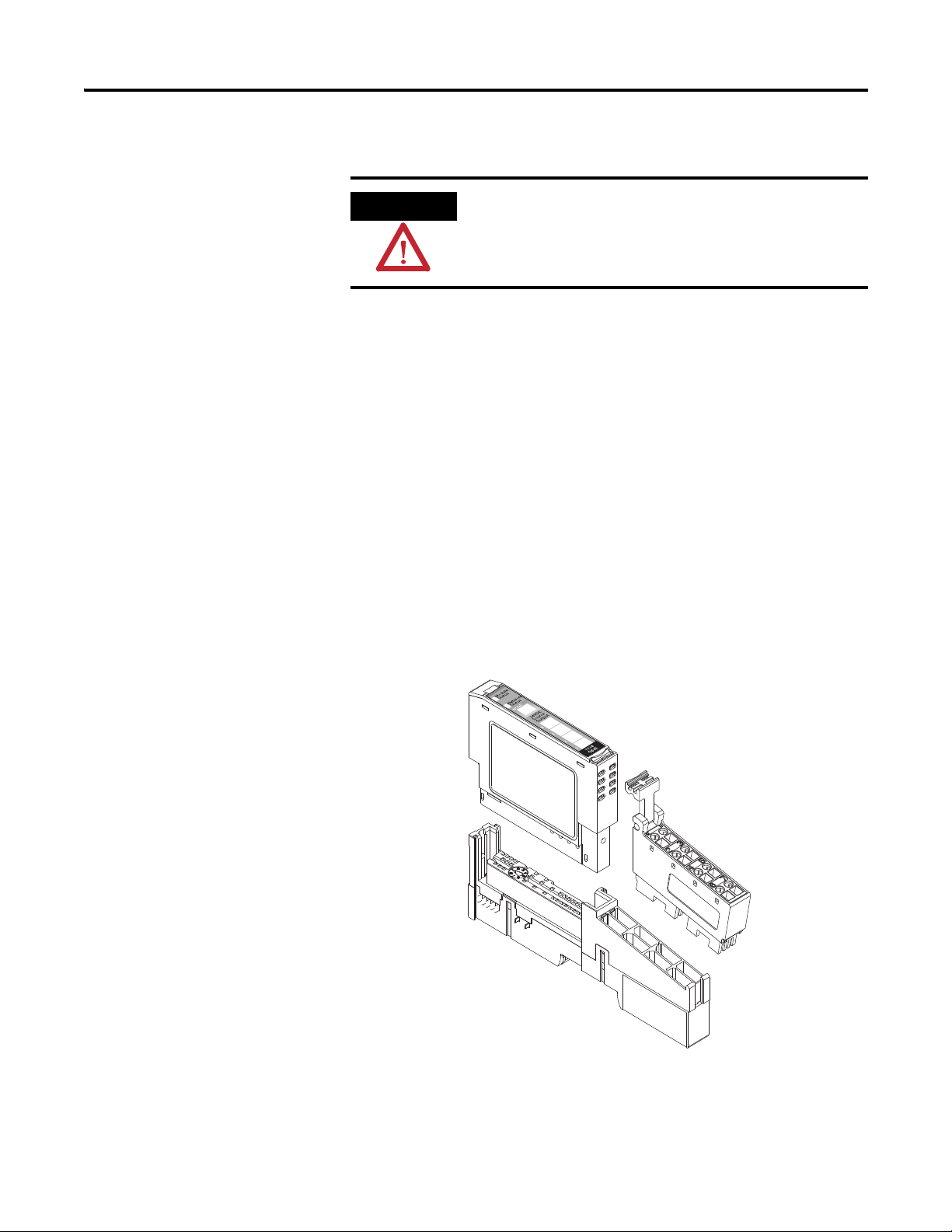

1734-8CFGDLX

This module is an 8-point 24V DC I/O module with eight self-configuring

points and DeviceLogix capabilities. Each of the I/O points can be either a

DC input or output. The module supports removal and insertion under power,

auto-address, and auto-baud in compliance with the POINTBus™ backplane.

1738-8CFGDLXM8, 1738-8CFGDLXM12, and 1738-8CFGDLXM23

The ArmorPOINT I/O family consists of modular I/O modules. The sealed

IP67 housing of these modules requires no enclosure. Environmental

requirements other than IP67 may require an additional appropriate housing.

I/O connectors are sealed M8 (Pico™), M12 (micro) or M23 styles. The

mounting base ships with the module.

Modes of Usage

The module can be used in one of the following modes:

• as a standard POINT I/O module,

• in a standalone DeviceLogix program where it controls its own I/O, and

• in network applications with or without the peer exchange of data.

Standard POINT I/O Module

The module can simply be used as an 8-point configurable POINT I/O

module. It uses ODVA pre-defined Produce and Consume assemblies. Default

settings help to facilitate quick setup right out-of-the-box. It is CIP network

independent and it can run on DeviceNet, EtherNet/IP or ControlNet when

used in conjunction with an adapter.

14 Rockwell Automation Publication 1734-UM015B-EN-E - May 2020

Page 15

Introduction

Stand Alone DeviceLogix

If DeviceLogix is enabled (programmed), then the module becomes the owner

of its outputs. The DeviceLogix program reads inputs and controls the

onboard outputs.

• The produced assembly may be shared with a controller if a connection

exists.

• As the owner of its local outputs, the module may run without an

external controller.

An external controller, which is the owner of the connection to the module,

can influence the module’s logic via a consume assembly – both digital and

analog data. Configuration of the module is performed via RSNetWorx for

DeviceNet. When used on ControlNet or EtherNet/IP, the tool bridges

through the adapter to directly communicate with the DeviceLogix module on

the POINT I/O backplane.

Peer Enabled POINT I/O

The POINT I/O DeviceLogix module can “listen in” on data connections to

other POINT I/O modules on the backplane. This data can be used in the

DeviceLogix program to control the outputs. It can consume data from eight

different peers. The data from each peer can be up to 24 bytes long. The data

can be digital, analog (16-bit), or a mixture. The module supports the “Auto

Produce” parameter to produce I/O data automatically without the need for a

master. It will also produce and consume network data. Configuration of peer

data is performed via RSNetWorx.

See Chapter 6, Configuring POINT I/O and ArmorPOINT I/O DeviceLogix

modules using RSNetWorx for DeviceNet.

Rockwell Automation Publication 1734-UM015B-EN-E - May 2020 15

Page 16

Introduction

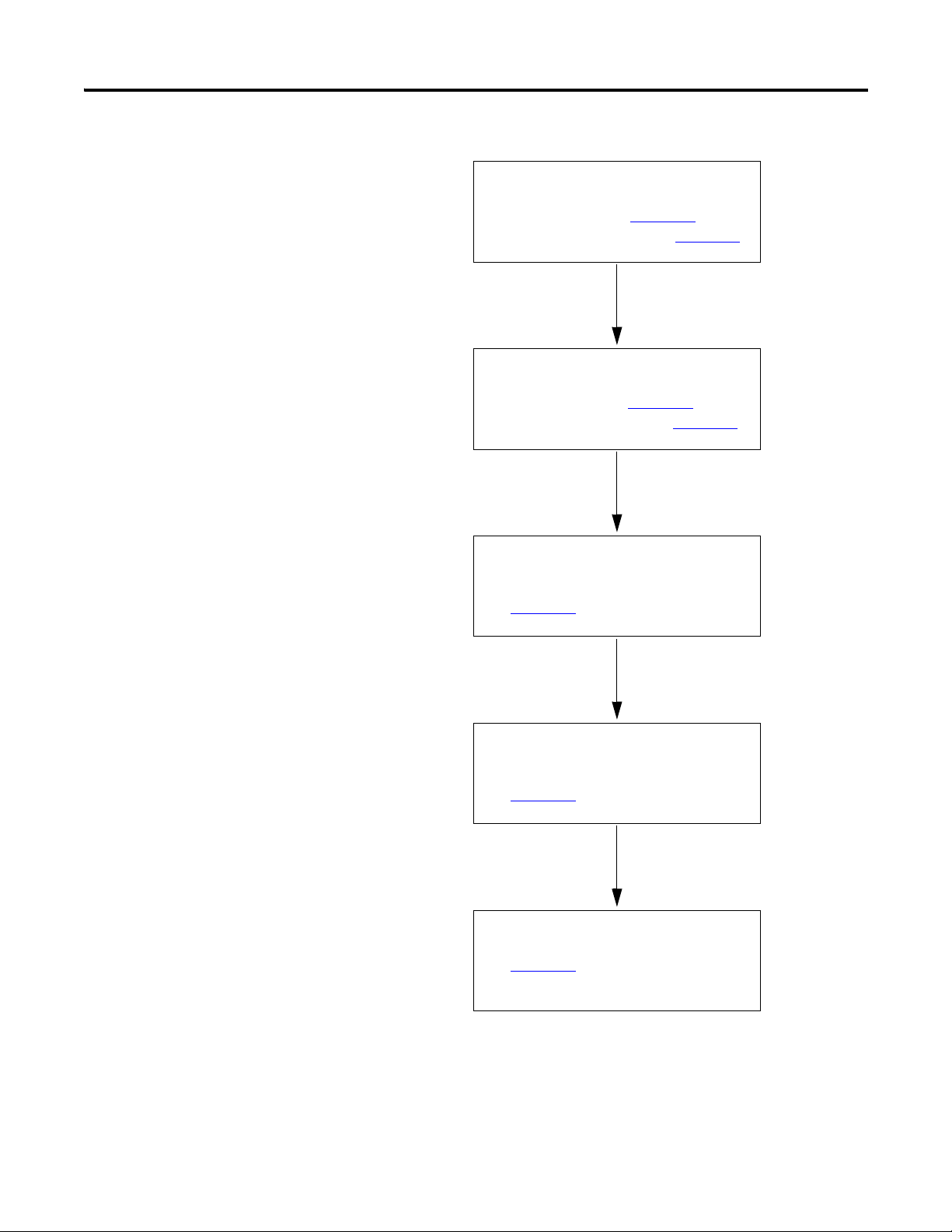

Mount the Module

For POINT I/O, see Chapter 2

.

For ArmorPOINT I/O, see Chapter 3

.

Wire the Module

For POINT I/O, see Chapter 2

.

For ArmorPOINT I/O, see Chapter 3

.

Configure DeviceNet Network and

Scanner

See Chapter 4

.

Configure the Module using

RSNetWorx for DeviceNet

See Chapter 6

.

Write the DeviceLogix Program

See Chapter 7

.

Quick Start - Prepare the Modules to work on DeviceNet

16 Rockwell Automation Publication 1734-UM015B-EN-E - May 2020

Page 17

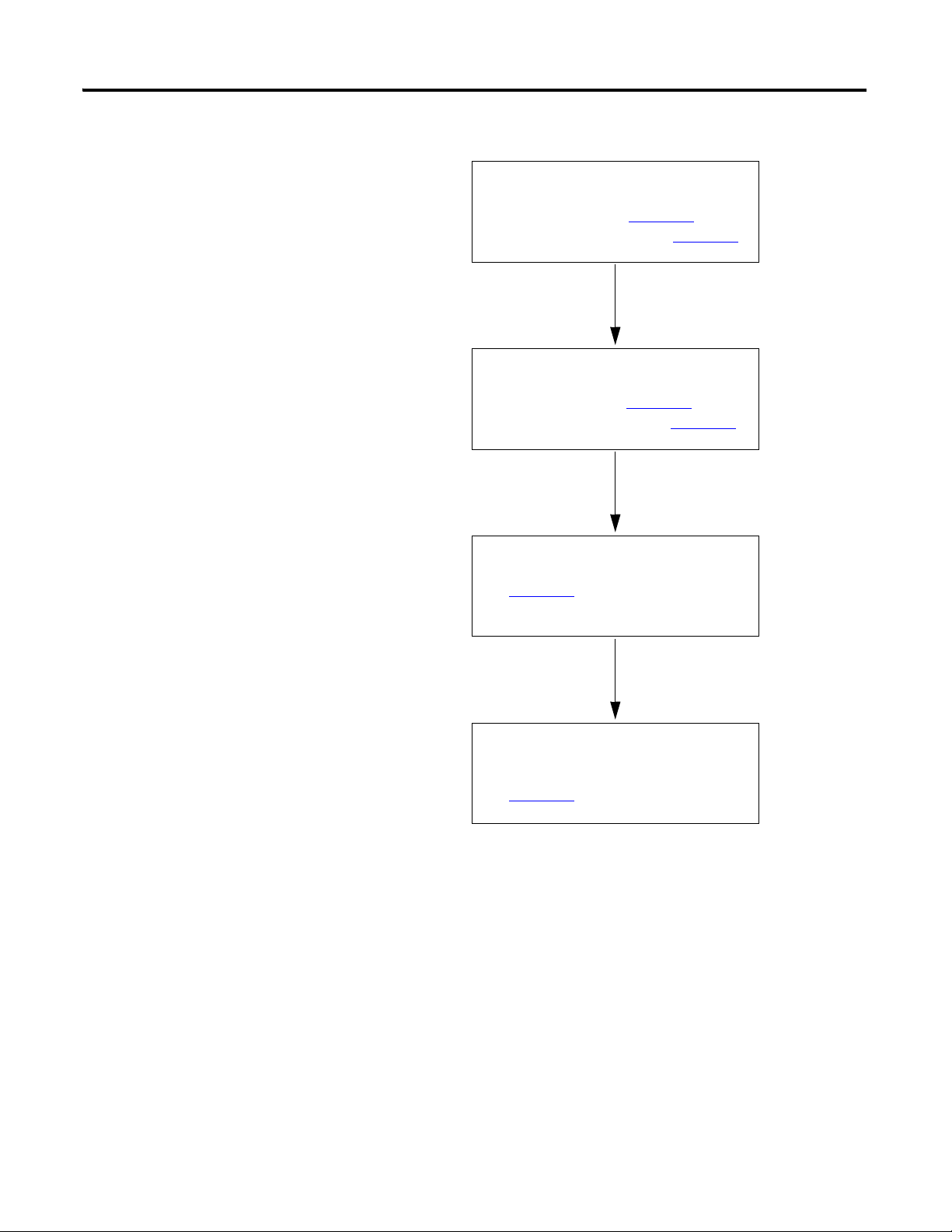

Quick Start - Prepare the

Mount the Module

For POINT I/O, see Chapter 2

.

For ArmorPOINT I/O, see Chapter 3

.

Wire the Module

For POINT I/O, see Chapter 2

.

For ArmorPOINT I/O, see Chapter 3

.

Add Module to RSLogix 5000

See Chapter 5

.

Write the DeviceLogix Program in

RSNetWorx for DeviceNet

See Chapter 7

.

Modules to work on

EtherNet/IP and ControlNet

Introduction

Rockwell Automation Publication 1734-UM015B-EN-E - May 2020 17

Page 18

Introduction

Notes:

18 Rockwell Automation Publication 1734-UM015B-EN-E - May 2020

Page 19

Chapter

ATTENTION

2

Install POINT I/O DeviceLogix Modules

If you are using ArmorPOINT I/O modules

(1738-8CFGDLXM8/M12/M23), go to Chapter 3, Install ArmorPOINT I/O

DeviceLogix Modules.

About This Chapter

Read this chapter for installation and wiring information including how to

complete the following:

• Install the Mounting Base Assembly

• Install an I/O Module

• Install the Removable Terminal Block

• Remove a 1734-TB or 1734-TBS Base

• Wire the Modules

Environment and Enclosure

This equipment is intended for use in a Pollution Degree 2

industrial environment, in overvoltage Category II applications

(as defined in IEC publication 60664-1), at altitudes up to 2000 m

(6561 ft) without derating.

This equipment is considered Group 1, Class A industrial

equipment according to IEC/CISPR 11. Without appropriate

precautions, there may be potential difficulties ensuring

electromagnetic compatibility in other environments due to

conducted as well as radiated disturbance.

This equipment is supplied as open-type equipment. It must be

mounted within an enclosure that is suitably designed for those

specific environmental conditions that will be present and

appropriately designed to prevent personal injury resulting from

accessibility to live parts. The interior of the enclosure must be

accessible only by the use of a tool. Subsequent sections of this

publication may contain additional information regarding specific

enclosure type ratings that are required to comply with certain

product safety certifications.

See NEMA Standards 250 and IEC 60529, as applicable, for

explanations of the degrees of protection provided by different

types of enclosure. Also, see the appropriate sections in this

publication, as well as the Allen-Bradley publication 1770-4.1

(Industrial Automation Wiring and Grounding Guidelines), for

additional installation requirements pertaining to this equipment.

Rockwell Automation Publication 1734-UM015B-EN-E - May 2020 19

Page 20

Install POINT I/O DeviceLogix Modules

ATTENTION

WARNING

ATTENTION

POINT I/O is grounded through the DIN rail to chassis ground.

Use zinc-plated, yellow-chromated steel DIN rail to assure proper

grounding. The use of DIN rail materials (for example, aluminum

or plastic) that can corrode, oxidize, or are poor conductors, can

result in improper or intermittent grounding.

Secure DIN rail to mounting surface approximately every 200 mm

(7.8 in.).

EXPLOSION HAZARD

• Do not disconnect equipment unless power has been

removed or the area is known to be nonhazardous.

• Do not disconnect connections to this equipment

unless power has been removed or the area is known to

be nonhazardous. Secure any external connections that

mate to this equipment by using screws, sliding latches,

threaded connectors, or other means provided with this

product.

• Substitution of components may impair suitability for

Class I, Division 2.

• If this product contains batteries, they must only be

changed in an area known to be nonhazardous.

Prevent Electrostatic Discharge

This equipment is sensitive to electrostatic discharge, which can

cause internal damage and affect normal operation. Follow these

guidelines when you handle this equipment:

• Touch a grounded object to discharge potential static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component boards.

• Do not touch circuit components inside the equipment.

• Use a static-safe workstation, if available.

• Store the equipment in appropriate static-safe packaging

when not in use.

20 Rockwell Automation Publication 1734-UM015B-EN-E - May 2020

Page 21

Install POINT I/O DeviceLogix Modules

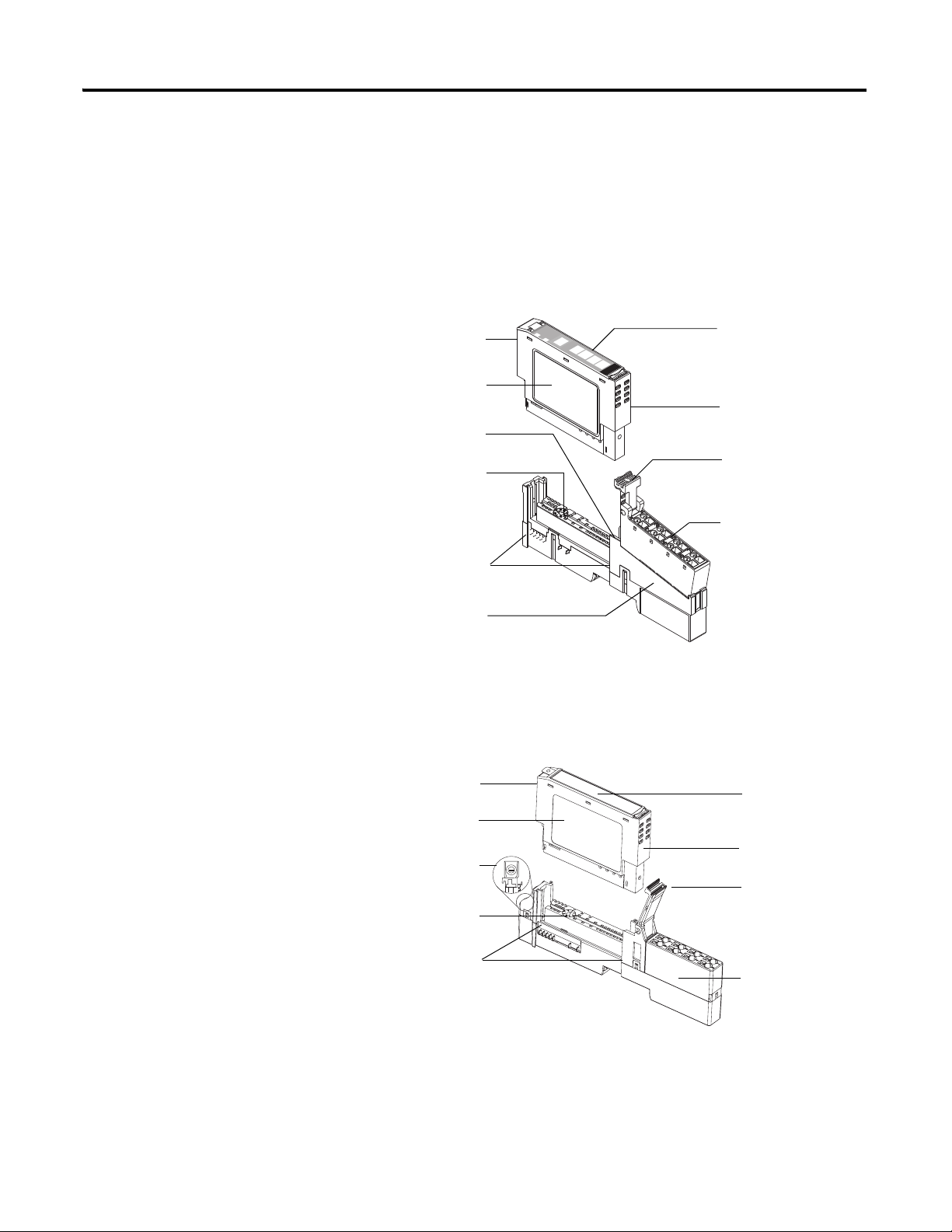

Module

Status

Network

Status

NODE:

0

1

2

3

4

5

6

7

Mechanical

Keying (orange)

Module Wiring

Diagram

Module Locking

Mechanism

Insertable I/O

Module

Mounting Base

Removable Terminal

Block (RTB)

DIN Rail Locking

Screw (orange)

Slide-in Writable

Label

Interlocking Side

Pieces

44713

RTB Removal

Handle

44714

1734-TOP or

1734-TOPS

One-piece

Terminal Base

with Screw or

Spring Clamp

Insertable

I/O Module

Slide-in

Writable Label

Handle

Module Locking

Mechanism

Interlocking

Side Pieces

DIN Rail Locking

Screw (orange)

Module Wiring

Diagram

Mechanical

Keying (orange)

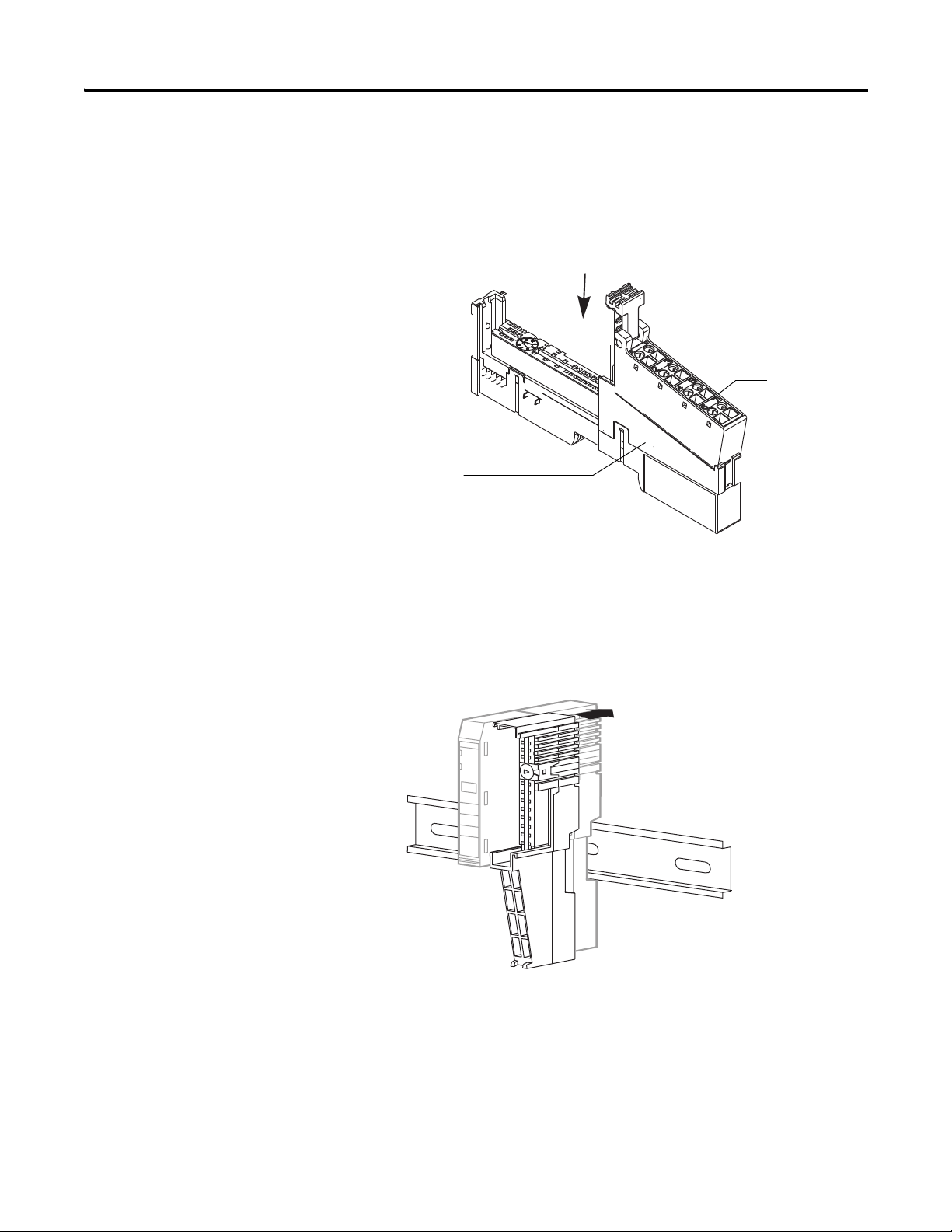

Install the Mounting Base Assembly

The 1734-8CFGDLX is compatible with 1734-TB, 1734-TBS, 1734-TOP, and

1734-TOPS wiring bases.

The 1734-TB or 1734-TBS wiring base assembly consists of a 1734-MB

mounting base and a 1734-RTB or 1734-RTBS removable terminal

block (RTB).

1734-TB or 1734-TBS wiring base

The 1734-TOP and 1734-TOPS are one-piece terminal bases.

1734-TOP or 1734-TOPS wiring base

Rockwell Automation Publication 1734-UM015B-EN-E - May 2020 21

Page 22

Install POINT I/O DeviceLogix Modules

44858

Removable Terminal

Block (RTB)

Mounting Base

31586

To install the mounting base assembly on the DIN rail, proceed as follows.

1. If you are using the 1734-TB or 1734-TBS mounting base, attach the

RTB to the mounting base.

Otherwise, skip to step 2.

2. Position the mounting base (wiring base assembly) vertically above the

installed units, for example, adapter, power supply, or existing module.

3. Slide the mounting base down, allowing the interlocking side pieces to

engage the adjacent module, power supply, or adapter.

4. Press firmly to seat the mounting base on the DIN rail until the base

snaps into place.

22 Rockwell Automation Publication 1734-UM015B-EN-E - May 2020

5. Use a small-bladed screwdriver to rotate the DIN-rail locking screw to

the horizontal position.

This locks the assembly to the DIN rail.

Page 23

Install POINT I/O DeviceLogix Modules

WARNING

Notch

Position 1 is shown.

44710

44966

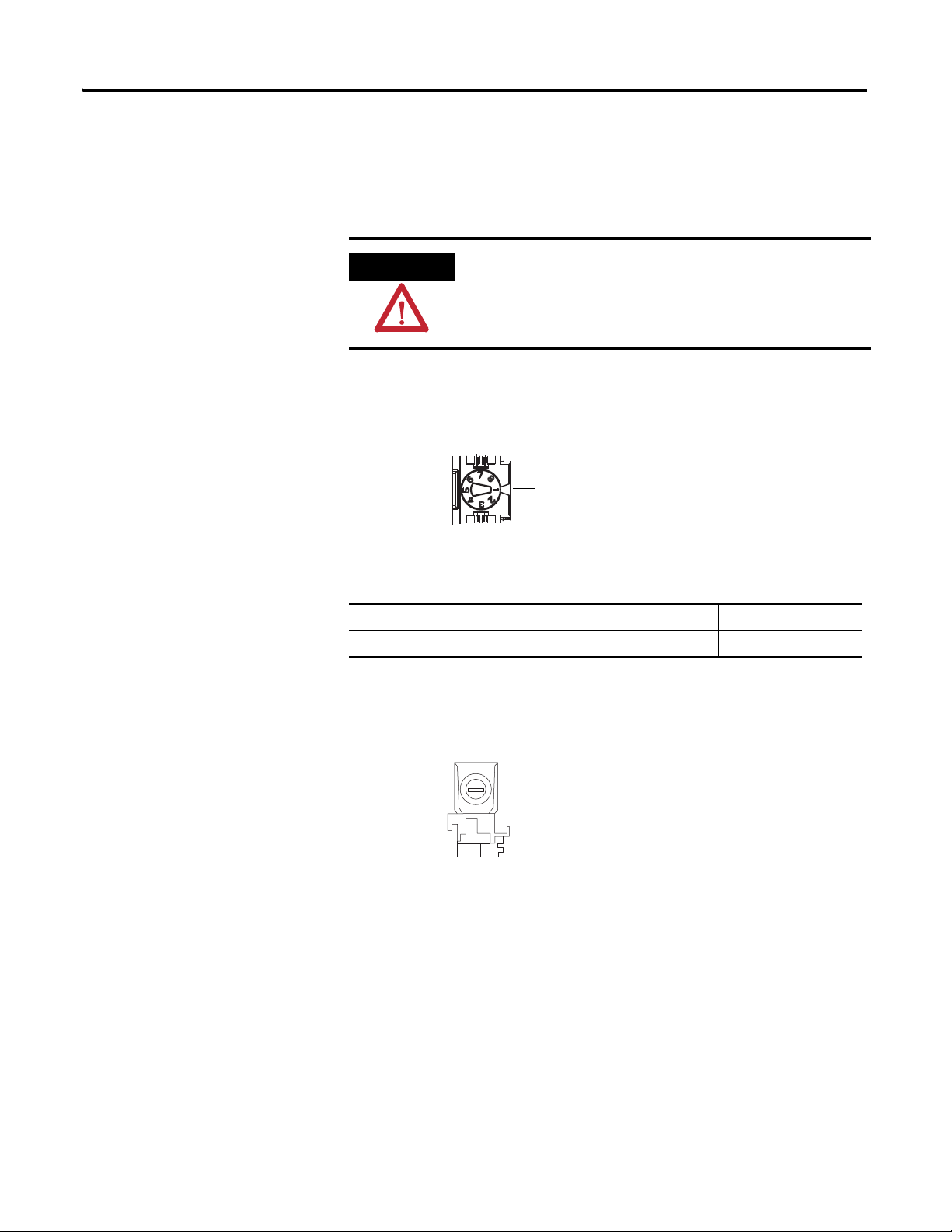

Install an I/O Module

Install the module before or after base installation. Make sure that the

mounting base is correctly keyed before installing the module into the

mounting base. In addition, make sure the mounting base locking screw is

positioned horizontally referenced to the base.

When you insert or remove the module while backplane power is

on, an electrical arc can occur. This could cause an explosion in

hazardous location installations. Be sure that power is removed

or the area is nonhazardous before proceeding.

1. Use a bladed screwdriver to rotate the keyswitch on the mounting base

clockwise until the number required for the type of module aligns with

the notch in the base.

Module Keyswitch Position

1734-8CFGDLX 1

2. Make certain the DIN-rail locking screw is in the horizontal position,

noting that you cannot insert the module if the locking mechanism is

unlocked.

Rockwell Automation Publication 1734-UM015B-EN-E - May 2020 23

Page 24

Install POINT I/O DeviceLogix Modules

2

4V

D

C

Source

Ou

tput

Module

S

t

atus

N

etw

ork

St

a

t

us

17

3

4

O

B

4

E

0

1

2

3

N

ODE:

44967

44859

Handle

Module

3. Insert the module straight down into the mounting base and press to

secure.

4. Secure the module with the RTB removal handle (for 1734-TB or

1734-TBS bases) or handle (for 1734-TOP or 1734-TOPS bases).

24 Rockwell Automation Publication 1734-UM015B-EN-E - May 2020

Page 25

Install POINT I/O DeviceLogix Modules

WARNING

44968

Install the Removable Terminal Block

A removable terminal block (RTB) is supplied with your mounting base

assembly.

To remove, pull up on the RTB handle. This lets you remove and replace the

base when necessary without removing any of the wiring.

To reinsert the RTB, proceed as follows.

When you connect or disconnect the RTB with field-side power

applied, an electrical arc can occur. This could cause an

explosion in hazardous location installations. Be sure to remove

power or that the area is nonhazardous before proceeding.

1. Insert the RTB end opposite the handle into the base unit.

This end has a curved section that engages with the mounting base.

2. Rotate the terminal block into the mounting base until it locks itself in

place.

3. If an I/O module is installed, snap the RTB handle into place on the

module.

Rockwell Automation Publication 1734-UM015B-EN-E - May 2020 25

Page 26

Install POINT I/O DeviceLogix Modules

WARNING

44969

Remove a 1734-TB or 1734-TBS Base

To remove a 1734-TB or 1734-TBS mounting base, do the following.

When you insert or remove the module while backplane power

is on, an electrical arc can occur. This could cause an explosion

in hazardous location installations. Be sure to remove power or

that the area is nonhazardous before proceeding.

1. Unlatch the RTB handle on the I/O module.

2. Pull on the RTB handle to remove the RTB.

3. Press the module lock on the top of the I/O module and pull the I/O

module out of the base.

4. Remove the I/O module to the right of the base you are removing,

noting that the interlocking portion of the base sits under the adjacent

module.

5. Use a small-bladed screwdriver to rotate the orange DIN-rail locking

screw on the mounting base to a vertical position.

6. This unlocks the mounting base from the DIN rail.

7. Lift the mounting base straight up to remove.

26 Rockwell Automation Publication 1734-UM015B-EN-E - May 2020

Page 27

Install POINT I/O DeviceLogix Modules

WARNING

Remove a 1734-TOP or 1734-TOPS Base

To remove a wiring base from the DIN rail, you must remove the module

installed to the right of the base.

If you connect or disconnect wiring while the field-side power

is on, an electrical arc can occur. This could cause an explosion

in hazardous location installations.

Be sure that power is removed or the area is nonhazardous

before proceeding.

1. Squeeze the module locking mechanism of the module to the right of

the base, pulling up to remove the module.

2. Use a small-bladed screwdriver to rotate the orange DIN-rail locking

screw on the mounting base to a vertical position.

This unlocks the mounting base from the DIN rail.

3. Slide the base up to release it from its mating units.

Rockwell Automation Publication 1734-UM015B-EN-E - May 2020 27

Page 28

Install POINT I/O DeviceLogix Modules

7

1

3

0

2

Module

Status

Network

Status

Device

Logix

Status

1734

8CFGDLX

1

3

0

2

5

7

4

6

NODE:

44758

Module Status

Network Status

I/O 0 I/O 1

I/O 2 I/O 3

I/O 4 I/O 5

I/O 6 I/O 7

Status of I/O 0

Status of I/O 1

Status of I/O 2

Status of I/O 3

Note that voltage and current to the module is applied through the adapter,

the 1734-FPD module, or the 1734-EP24DC module. V = 10…28.8 V DC.

Status of I/O 4

Status of I/O 5

Status of I/O 6

Status of I/O 7

DeviceLogix Status

Prox

I/O 0

Load

Prox

Prox

Prox

Load

Load

Load

I/O 2

I/O 4

I/O 6

I/O 1

I/O 3

I/O 5

I/O 7

V C C

If a connection to Common or the Supply Voltage is required for two- or

three-wire devices, then a 1734-CTM or 1734-VTM can be used.

Each I/O point is either Input or Output.

44687

Wire the Modules

This section provides wiring instructions for the modules.

1734-8CFGDLX I/O Module

28 Rockwell Automation Publication 1734-UM015B-EN-E - May 2020

1734-8CFGDLX Wiring Diagram

Prox

Prox

Prox

Prox

I/O 0

I/O 2

I/O 4

I/O 6

I/O 1

I/O 3

I/O 5

I/O 7

Load

Load

Load

Load

Page 29

Install POINT I/O DeviceLogix Modules

Channel Terminal Number

I/O Common Voltage

00

External

(1)

11

22

33

44

55

66

77

10/28.8 V DC is supplied through the internal power bus.

(1)

Common connections require an external connection, such as a 1734-CTM module.

(2)

Supply Voltage Connections require an external connection such as a 1734-VTM module.

External

(2)

System and Power Considerations

There are no power terminals on the POINT I/O DeviceLogix module. The

module gets its power from the Field Power Bus of the back plane. Depending

on your system and network topology, power can be applied through one of

the following:

• 1734-PDN (DeviceNet adapter)

• 1734-ADN or 1734-ADNX (DeviceNet adapter)

• 1734-ACNR (ControlNet adapter)

• 1734-AENT or 1734-AENTR (EtherNet/IP adapter)

• 1734-EP24DC (Expansion power supply)

• 1734-FPD (Field power distribution)

Rockwell Automation Publication 1734-UM015B-EN-E - May 2020 29

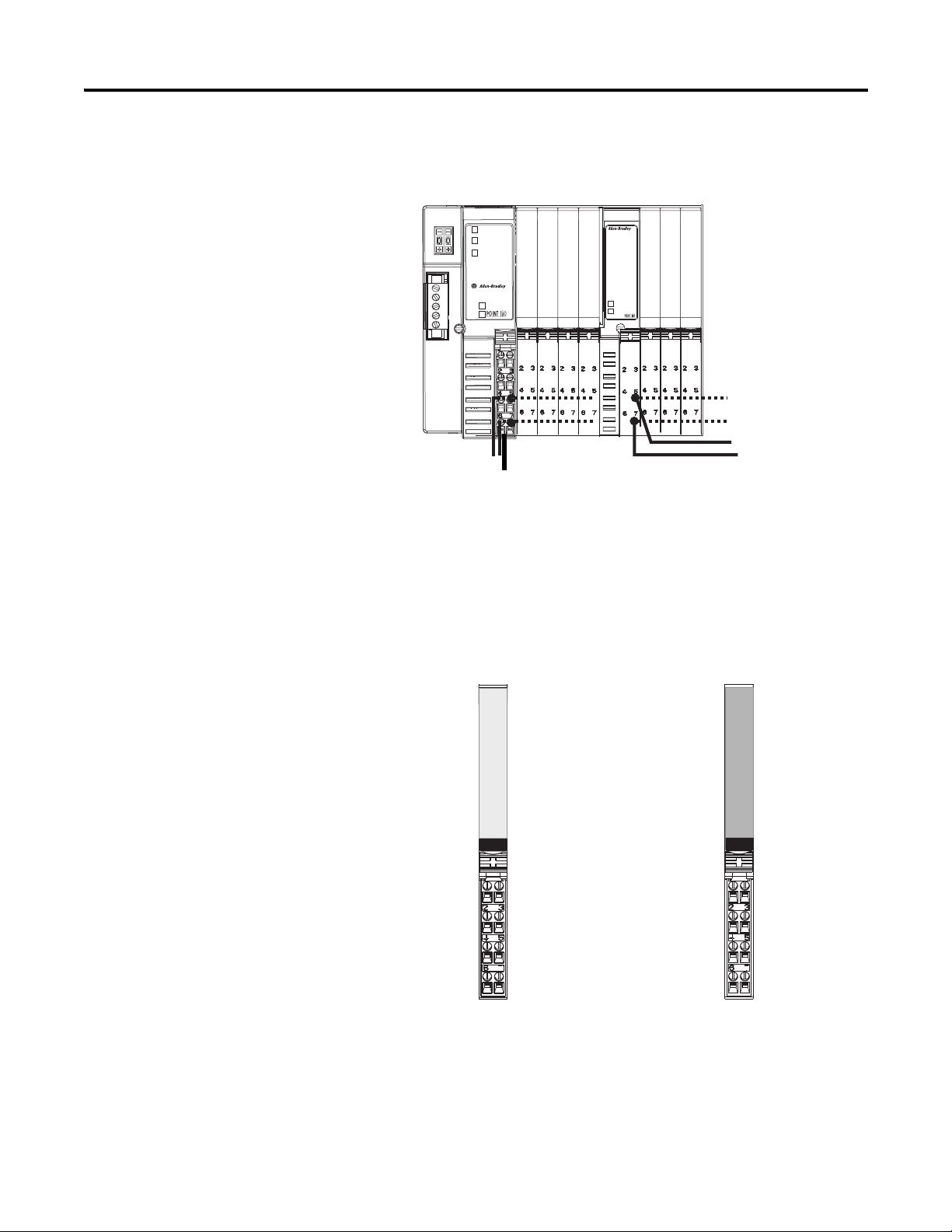

Page 30

Install POINT I/O DeviceLogix Modules

1734adn4

Adapter

Status

DeviceNet

Status

POINTBus

Status

I

E

2

C

O

E

2

C

I

B

2

O

B

2

E

ADN

I

B

2

O

B

2

E

O

B

4

E

EP24DC

0 1 0 1

0 1

0 1

0 1

24V DC supply

1734-EP24DC

1734-ADN

12V DC

Status

Power

Power

DeviceNet

System

DeviceNet

Power

Power

0 1 0 1 0 1

1734

VTM

1734-VTM

1734-CTM

Voltage Out

Voltage Out

Voltage Out

Voltage Out

Voltage Out

Voltage Out

Voltage Out

Voltage Out

Common

Common

Common

Common

Common

Common

Common

Common

43929

Voltage Out = 0…7

Common = 0…7

Example of Logical Partitioning

Similarly, field power and common (return) can be terminated in the POINT

I/O system by using the following modules:

• 1734-VTM (Voltage termination module)

• 1734-CTM (Common termination module)

1734

CTM

30 Rockwell Automation Publication 1734-UM015B-EN-E - May 2020

Page 31

Chapter

ATTENTION

IMPORTANT

ATTENTION

ATTENTION

3

Install ArmorPOINT I/O DeviceLogix Modules

If you are using POINT I/O modules (1734-8CFGDLX), go to Chapter 2,

Install POINT I/O DeviceLogix Modules.

About This Chapter

Install the Mounting Base

Read this chapter for information about how to install ArmorPOINT I/O

modules to include the following:

• Install the Mounting Base

• Install the Module

• Wire the Modules

• Remove the Modules

This equipment is considered Group 1, Class A industrial

equipment according to IEC/CISPR Publication 11. Without

appropriate precautions, there may be potential difficulties

ensuring electromagnetic compatibility in other environments

due to conducted as well as radiated disturbance.

Mount the I/O base on a wall or panel, using the screw holes provided in the

base.

The ArmorPOINT I/O module must be mounted on a grounded

metal mounting plate or other conductive surface.

Make sure all connectors and caps are securely tightened to

properly seal the connections against leaks and maintain IP

enclosure type requirements.

To comply with the CE Low Voltage Directive (LVD), all

connected I/O must be powered from a source compliant with

the following:

Safety Extra Low Voltage (SELV) or Protected Extra Low Voltage

(PELV).

Rockwell Automation Publication 1734-UM015B-EN-E - May 2020 31

Page 32

Install ArmorPOINT I/O DeviceLogix Modules

Adapter

102 mm

4.02 in

46 mm

1.81 in

47.2 mm

1.9 in

50 mm

2.0 in

22 mm

0.87 in

22 mm

0.87 in

50 mm

2.0 in

50 mm

2.0 in

Adapter

46 mm

1.81 in

47.2 mm

1.9 in

50 mm

2.0 in

22 mm

0.87 in

22 mm

0.87 in

50 mm

2.0 in

50 mm

2.0 in

43769

Ground lug connection

Latching mechanism

43675

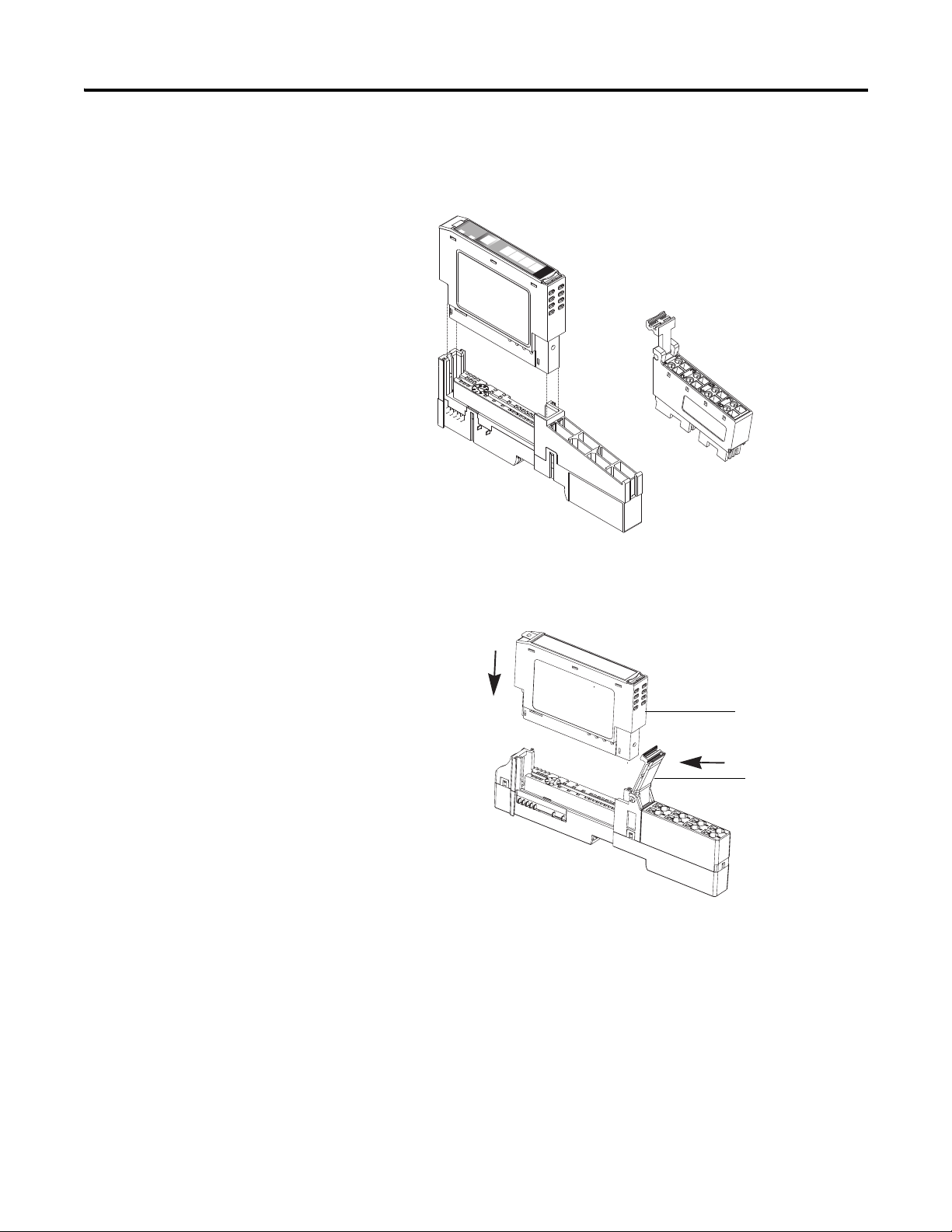

Mounting illustration for the ArmorPOINT adapter with I/O bases

Install the mounting as follows:

1. Lay out the required points as shown above in the drilling dimension

drawing.

2. Drill the necessary holes for M4 (#8) machine or self-tapping screws.

3. Mount the base using M4 (#8) screws.

4. Ground the system using the ground lug connection.

The ground lug connection is also a mounting hole.

32 Rockwell Automation Publication 1734-UM015B-EN-E - May 2020

Page 33

Install ArmorPOINT I/O DeviceLogix Modules

Keyswitch

43675

Set to position 1, for the

1738 24V DC modules

Module bridges two bases

43771

1738-8CFGDLXM12

shown

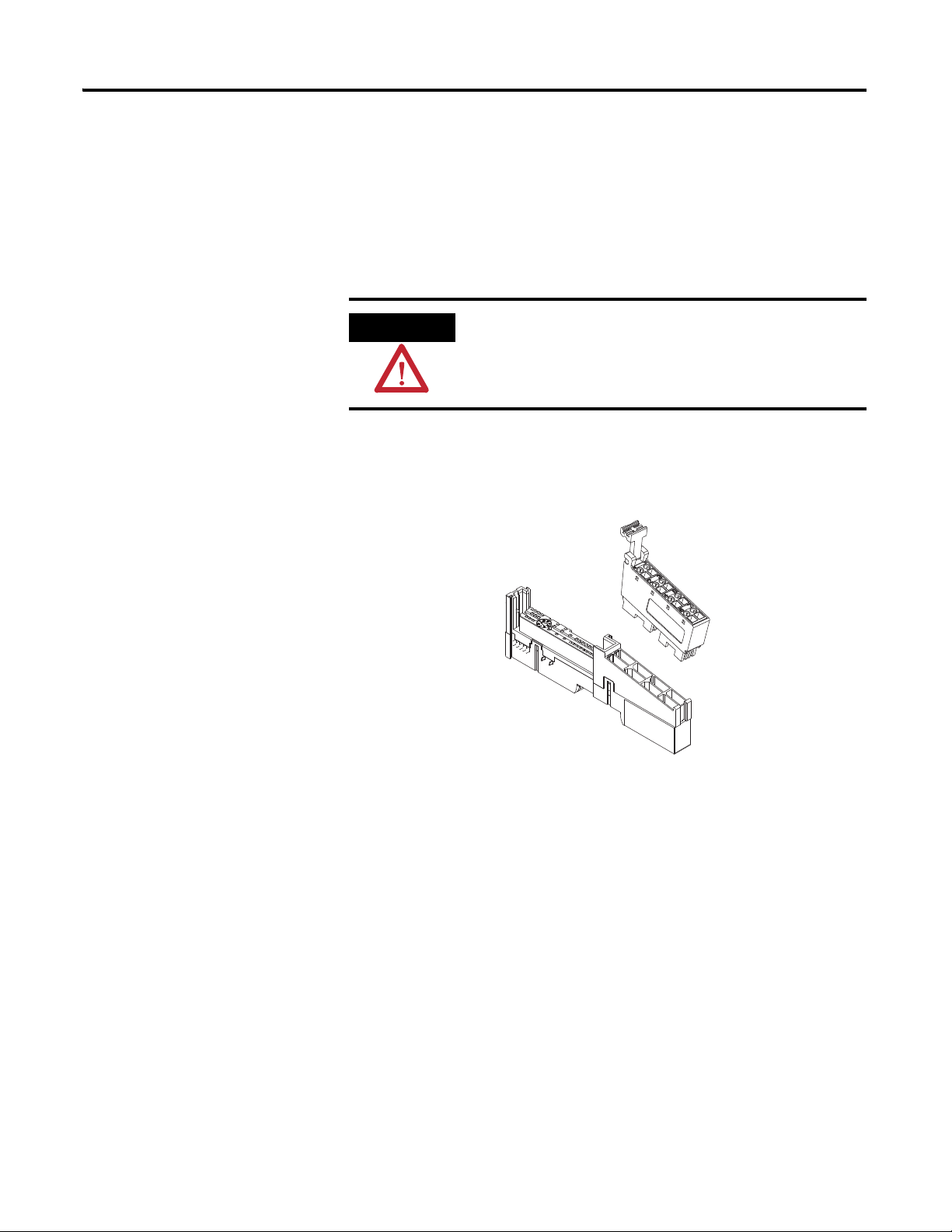

Install the Module

Follow the instructions to install the module.

1. Using a bladed screwdriver, rotate the keyswitch on the mounting base

clockwise until the number 1 aligns with the notch in the base.

2. Position the module vertically above the mounting base.

The module bridges two bases.

A

H

DLX

B

C

D

1738-8CFGDLXM12

24V DC Out

MOD

NET

G

F

E

0

1

2

3

4

5

6

7

3. Push the module down until it engages the latching mechanism.

You will hear a clicking sound when the module is properly engaged.

The locking mechanism locks the module to the base.

Rockwell Automation Publication 1734-UM015B-EN-E - May 2020 33

Page 34

Install ArmorPOINT I/O DeviceLogix Modules

ATTENTION

M

OD

NET

1738-8CFG

DLXM8

24V DC

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

DLX

Connector M8-A

LED indicators

Connector M8-B

Connector M8-G

Connector M8-H

43683

Connector M8-C

Connector M8-E

Connector M8-F

Connector M8-D

Remove the Module from the Mounting Base

Follow the instructions to remove the module from the mounting base.

1. Put a flat blade screwdriver into the slot of the orange latching

mechanism.

2. Push the screwdriver toward the I/O module to disengage the latch.

The module lifts up off the base.

3. Pull the module off the base.

Wire the Modules

This section provides wiring instructions for the modules.

Make sure all connectors and caps are securely tightened to

properly seal the connections against leaks and maintain IP

enclosure type requirements.

1738-8CFGDLXM8 I/O Module

34 Rockwell Automation Publication 1734-UM015B-EN-E - May 2020

Page 35

1738-8CFGDLXM8 Wiring Diagram

43583

(view into connector)

Pin 1 - 24V DC

Pin 3 - Common

Pin 4 - I/O 0 (M8-A)

I/O 1 (M8-B)

I/O 2 (M8-C)

I/O 3 (M8-D)

I/O 4 (M8-E)

I/O 5 (M8-F)

I/O 6 (M8-G)

I/O 7 (M8-H)

44355

LED indicators

Connectors M12-A...D

Connectors M12-E...H

43664

(view into connector)

Pin 1 - 24V DC

Pin 2 - Not used

Pin 3 - Common

Pin 4 - I/O 0 (M12-A)

I/O 1 (M12-B)

I/O 2 (M12-C)

I/O 3 (M12-D)

I/O 4 (M12-E)

I/O 5 (M12-F)

I/O 6 (M12-G)

I/O 7 (M12-H)

Pin 5 - Not used

1738-8CFGDLXM12 I/O Module

A

Install ArmorPOINT I/O DeviceLogix Modules

H

1738-8CFGDLXM12 Wiring Diagram

X

L

D

B

C

D

1738-8CFGDLXM12

24V DC Out

G

F

E

MOD

NET

0

1

2

3

4

5

6

7

Rockwell Automation Publication 1734-UM015B-EN-E - May 2020 35

Page 36

Install ArmorPOINT I/O DeviceLogix Modules

44353

LED indicators

M23 connector

43681

(view into connector)

Pin 1 - I/O 0

Pin 2 - I/O 1

Pin 3 - I/O 2

Pin 4 - I/O 3

Pin 5 - I/O 4

Pin 6 - I/O 5

Pin 7 - I/O 6

Pin 8 - I/O 7

Pin 9 - Return (Com)

Pin 10 - Return (Com)

Pin 11 - 24V DC

Pin 12 - Chassis

1738-8CFGDLXM23 I/O Module

1738-8CFGDLXM23

24V D

1738-8CFGDLXM23 Wiring Diagram

In

C

MOD

NET

DLX

0

1

2

3

4

5

6

7

1

2

3

4

8

9

10

7

12

6

11

5

The ArmorPOINT I/O DeviceLogix module gets its power from the Field

Power Bus of the backplane. Depending on your system and network

topology, power can be applied through one of the following:

• 1738-ADN12 or 1738-ADN18, 1738-ADN18P, 1738-ADNX

(DeviceNet adapter)

• 1738-ACNR (ControlNet adapter)

• 1738-AENT or 1738-AENTR (EtherNet/IP adapter)

• 1738-EP24DC (Expansion power supply)

• 1738-FPD (Field power distribution)

36 Rockwell Automation Publication 1734-UM015B-EN-E - May 2020

Page 37

Chapter

4

DeviceLogix for POINT I/O and ArmorPOINT

I/O on DeviceNet

About This Chapter

Offline Configuration using RSNetWorx for DeviceNet

This chapter provides information on the following:

• Offline Configuration using RSNetWorx for DeviceNet

• Online Configuration using RSNetWorx for DeviceNet

• I/O Data Assembly Maps

This section is not a substitute for RSNetWorx or DeviceNet scanner and

adapter publications. It is suggested that you have those publications available

while performing the procedures in this section See Related Publications

list of related publications.

This section describes the setup of a DeviceNet network using RSNetWorx for

DeviceNet when the module is not connected to the network.

When configuring the module in the Offline mode, you must place all nodes

on the network in The view window manually. Use the Hardware tree to find

each module and place it into the view window. This can be done by

double-clicking the module or dragging it to the view window.

If using a POINT I/O or ArmorPOINT I/O DeviceNet adapter, make sure

you select Adapter for the main DeviceNet network, and Scanner for the

POINTBus backplane.

for a

Rockwell Automation Publication 1734-UM015B-EN-E - May 2020 37

Page 38

DeviceLogix for POINT I/O and ArmorPOINT I/O on DeviceNet

Example: Build the Backplane

This example shows you how to build the backplane. The following screen

shows the 1734-ADN POINT I/O Scanner added.

Next, locate the I/O modules. In this example, the following modules will be

added:

• 1734-8CFGDLX POINT I/O DeviceLogix module

• 1734-IB8 POINT I/O DC Input module

• 1734-IE4C POINT I/O 4...20 mA Analog Input module

38 Rockwell Automation Publication 1734-UM015B-EN-E - May 2020

Page 39

DeviceLogix for POINT I/O and ArmorPOINT I/O on DeviceNet

The digital modules can be found under the category, “General Purpose

Discrete I/O”, and the analog modules can be found under the “Rockwell

Automation miscellaneous” category.

The configuration of each module can now be edited from the Properties

dialog box of each module. For instructions on editing the configuration of the

DeviceLogix module, see Chapter 6

.

Include all the I/O modules in the backplane to the Scanner’s scan list.

After configuration is complete, save your work in the DNT file. “DNT” is the

three-letter file name extension. One file contains all the configuration data for

all the modules on the network or backplane.

Remember that you need to go to the Online mode with RSNetWorx for

DeviceNet to download all the configuration data to the I/O modules and

scanners.

Rockwell Automation Publication 1734-UM015B-EN-E - May 2020 39

Page 40

DeviceLogix for POINT I/O and ArmorPOINT I/O on DeviceNet

Online Configuration using RSNetWorx for DeviceNet

To set up a DeviceNet network using RSNetWorx for DeviceNet when

connected to the network, do the following:

1. If you have a DNT file that has been configured, open the file in

RSNetWorx for DeviceNet. To do this, go to the Online mode by

pressing <F10>. You can also click Network > Online, or click the

Online button .

RSLinx® application will start. If the Online path is not set in Network

> Properties, the Browse for network dialog box will appear.

2. Navigate to the DeviceNet network or DeviceNet subnet if configuring

the backplane.

The OK button will become available when you select a valid network.

RSNetWorx will automatically browse the network to discover all the

participants.

3. If there are any module identity issues, correct them before continuing.

4. Ensure that the configuration in the DNT file matches the configuration

in each node.

In this section, it is assumed that all the work was done in the Offline

mode and that the DNT file contains all the correct information.

40 Rockwell Automation Publication 1734-UM015B-EN-E - May 2020

Page 41

DeviceLogix for POINT I/O and ArmorPOINT I/O on DeviceNet

To update all the modules in the most efficient way, click Network >

Download to Network on the menu bar.

5. Review the Message window for any errors.

The stored configuration (DNT file) and the configuration of all the

modules now match.

6. If any changes are made, be sure to download them to the module and

save them in the DNT file.

7. When in the Online mode, you can change the configuration of a

module by double-clicking its icon. You can also right-click the icon and

select Properties.

Rockwell Automation Publication 1734-UM015B-EN-E - May 2020 41

Page 42

DeviceLogix for POINT I/O and ArmorPOINT I/O on DeviceNet

Familiarize yourself with all the tabs in the Properties window before

proceeding to Chapter 6

DeviceLogix module.

where you will learn how to configure the

42 Rockwell Automation Publication 1734-UM015B-EN-E - May 2020

Page 43

DeviceLogix for POINT I/O and ArmorPOINT I/O on DeviceNet

I/O Data Assembly Maps

Read this section for information about how to communicate with your

module.

I/O messages are sent to (consumed) and received from (produced) the I/O

modules. These messages are mapped into the processor’s or scanner’s

memory. Each module produces 1 byte, 8 or 20 bytes of input data based on

which produced assembly is selected. The default setup is 20 bytes.

It consumes 1 byte, 8 or 20 bytes of I/O data (scanner Tx).

Default Data Map - Produced Assembly Instance 101

Message Size: 20 Bytes

Bit 76543210

Data [0] Pt 07 Pt 06 Pt 05 Pt 04 Pt 03 Pt 02 Pt 01 Pt 00

Data [1] PNB 07 PNB 06 PNB 05 PNB 04 PNB 03 PNB 02 PNB 01 PNB 00

Data [2] Reserved Owned LogicEn

Data [3] PM7 PM6 PM5 PM4 PM3 PM2 PM1 PM0

Data [4] Produced Network Analog Word 0

Data [5]

Data [6] Produced Network Analog Word 1

Data [7]

Data [8] Produced Network Analog Word 2

Data [9]

Data [10] Produced Network Analog Word 3

Data [11]

Data [12] Produced Network Analog Word 4

Data [13]

Data [14] Produced Network Analog Word 5

Data [15]

Data [16] Produced Network Analog Word 6

Data [17]

Data [18] Produced Network Analog Word 7

Data [19]

Where:

Pt = value of the I/O point,

PNB = Produced Network Bit,

PM = Peer Missing (a 1 indicates the absence of a configured peer)

Owned = Owned by a master.

When set to 0, the module is producing data without a master.

When set to 1, the module is producing while being owned by a master.

LogicEn = Logic Enabled (0 = logic disabled, 1 = logic enabled)

Rockwell Automation Publication 1734-UM015B-EN-E - May 2020 43

Page 44

DeviceLogix for POINT I/O and ArmorPOINT I/O on DeviceNet

You can select other produced assemblies:

• Produced assembly instance 4 is the first byte of produced assembly

• Produced assembly instance 111 is the first eight bytes of produced

Default Data Map - Consumed Assembly Instance 102

Message Size: 20 Bytes

Bit 76543210

Data [0] Pt 07 Pt 06 Pt 05 Pt 04 Pt 03 Pt 02 Pt 01 Pt 00

Data [1] CNB 07 CNB 06 CNB 05 CNB 04 CNB 03 CNB 02 CNB 01 CNB 00

Data [2] Reserved

Data [3]

Data [4] Consumed Network Analog Word 0

Data [5]

Data [6] Consumed Network Analog Word 1

instance 101 (Data [0]).

assembly instance 101 (Data [0]…[7]).

Data [7]

Data [8] Consumed Network Analog Word 2

Data [9]

Data [10] Consumed Network Analog Word 3

Data [11]

Data [12] Consumed Network Analog Word 4

Data [13]

Data [14] Consumed Network Analog Word 5

Data [15]

Data [16] Consumed Network Analog Word 6

Data [17]

Data [18] Consumed Network Analog Word 7

Data [19]

Where: Pt = value to be applied to the output point, CNB = Consumed Network Bit

You can select other consumed assemblies:

• Consumed assembly instance 34 is the first byte of consumed assembly

instance 102 (Data [0]).

• Consumed assembly instance 112 is the first eight bytes of consumed

assembly instance 102 (Data [0]…[7]).

44 Rockwell Automation Publication 1734-UM015B-EN-E - May 2020

Page 45

DeviceLogix for POINT I/O and ArmorPOINT I/O on DeviceNet

Data Map - Configuration Assembly Instance 123

Message Size: 48 Bytes

Bit 76543210

Data [0] Group Off2On Input filter

Data [1]

Data [2] Group On2Off Input filter

Data [3]

Data [4] FltM 7 FltM 6 FltM 5 FltM 4 FltM 3 FltM 2 FltM 1 FltM 0

Data [5] FltV 7 FltV 6 FltV 5 FltV 4 FltV 3 FltV 2 FltV 1 FltV 0

Data [6] IdlM 7 IdlM 6 IdlM 5 IdlM 4 IdlM 3 IdlM 2 IdlM 1 IdlM 0

Data [7] IdlV 7 IdlV 6 IdlV 5 IdlV 4 IdlV 3 IdlV 2 IdlV 1 IdlV 0

Data [8] Reserved RACK CFO DM MP

Data [9] Reserved

Data [10] Masterless Produce Assembly Instance (0, 4, 101, 111)

Data [11]

Data [12] Masterless Produce EPR (ms)

Data [13]

Data [14] Masterless Produce PIT (ms)

Data [15]

Data [16] Peer 0 - Slot/MacID

Data [17] Peer 0 - Consume Message Length (bytes)

Data [18] Peer 0 - EPR (ms)

Data [19]

Data [20] Peer 1 - Slot/MacID

Data [21] Peer 1 - Consume Message Length (bytes)

Data [22] Peer 1 - EPR (ms)

Data [23]

Data [24] Peer 2 - Slot/MacID

Data [25] Peer 2 - Consume Message Length (bytes)

Data [26] Peer 2 - EPR (ms)

Data [27]

Data [28] Peer 3 = Slot/MacID

Data [29] Peer 3 - Consume Message Length (bytes)

Data [30] Peer 3 - EPR (ms)

Data [31]

Data [32] Peer 4 - Slot/MacID

Data [33] Peer 4 - Consume Message Length (bytes)

Rockwell Automation Publication 1734-UM015B-EN-E - May 2020 45

Page 46

DeviceLogix for POINT I/O and ArmorPOINT I/O on DeviceNet

Data Map - Configuration Assembly Instance 123 (Continued)

Message Size: 48 Bytes

Data [34] Peer 4 - EPS (ms)

Data [35]

Data [36] Peer 5 - Slot/MacID

Data [37] Peer 5 - Consume Message Length (bytes)

Data [38] Peer 5 - EPR (ms)

Data [39]

Data [40] Peer 6 - Slot/MacID

Data [41] Peer 6 - Consume Message Length (bytes)

Data [42] Peer 6 - EPR (ms)

Data [43]

Data [44] Peer 7 - Slot/MacID

Data [45] Peer 7 - Consume Message Length (bytes)

Data [46] Peer 7 - EPR (ms)

Data [47]

Where:

Filter = 0 to 65535 s (1000 = default)

FltM = Fault Mode (0 = Use Fault Value (default), 1 = Hold Last State)

FltV = Fault Value (0 = OFF (default), 1 = ON)

IdlM = Idle Mode (0 = Use Idle Value (default), 1 = Hold Last State)

IdlV = Idle Value (0 = OFF (default), 1 = ON)

RACK = Produce with Rack Assembly 4 and Consume Rack Assembly 34

(0 = Disabled (default), 1 = Enabled)

CFO = DeviceLogix Communication Fault Override of Outputs

1 = Enabled. When enabled, the DeviceLogix program will continue to control the

outputs even in the event of a communication fault.

0 = Disabled (default). When disabled, the outputs will follow the Fault and Idle

settings in the event of a communication fault.

DM = Dependent Mode

1 = Enabled. When enabled, the DeviceLogix program execution will follow the

Run/Idle state of the owning processor.

MP = Masterless Produce

0 = Disabled (default), 1 = Enabled. When enabled, the module will begin producing

data at power-up and after a connection with a controller is terminated.

EPR = Expected Packet Rate

PIT = Production Inhibit Time

Slot/MacID = Address of peer

Configuration of the modules must be done through RSNetWorx for

DeviceNet. See Chapter 6

46 Rockwell Automation Publication 1734-UM015B-EN-E - May 2020

for details.

Page 47

Chapter

5

DeviceLogix for POINT I/O and ArmorPOINT

I/O on Ethernet/ControlNet

About This Chapter

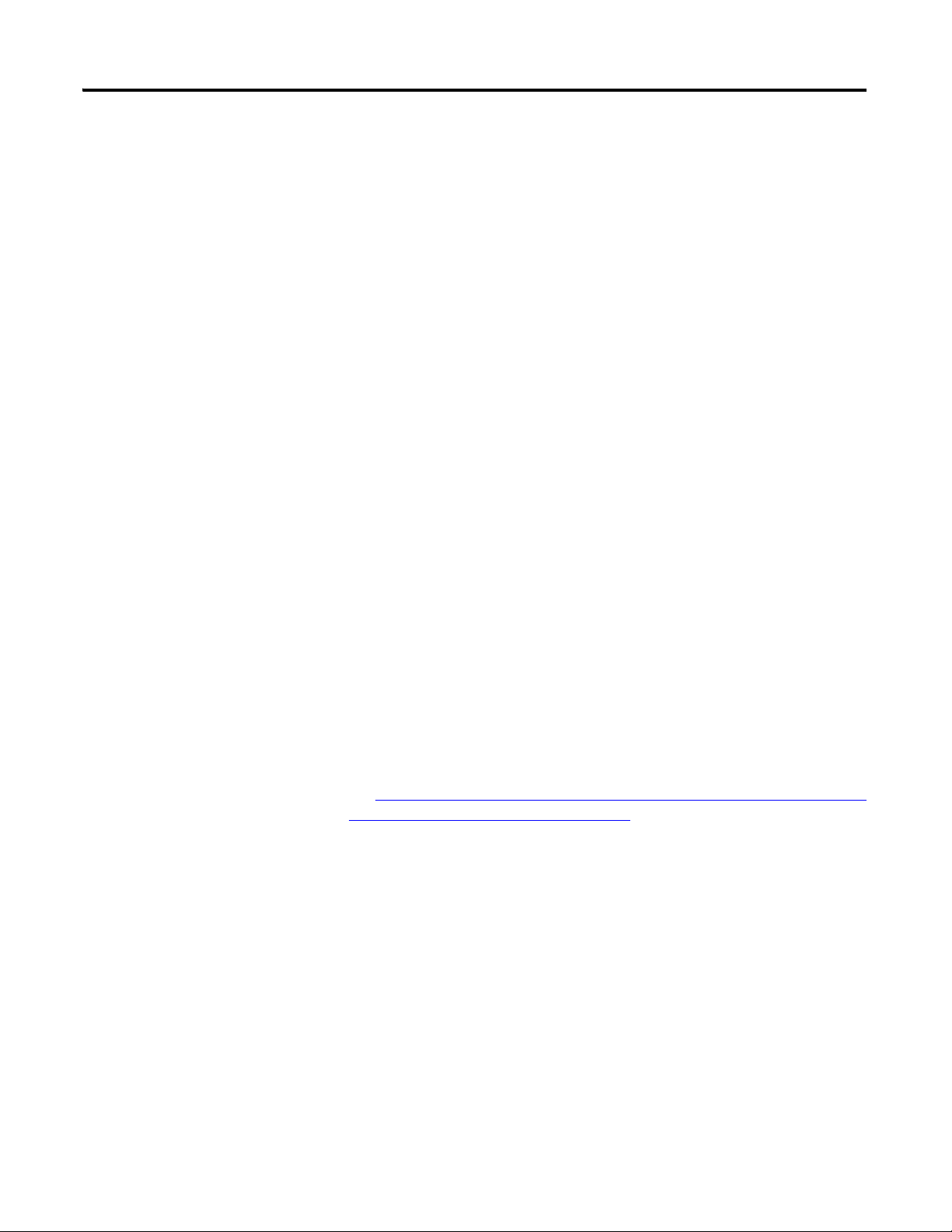

Add a POINT I/O DeviceLogix Module to RSLogix 5000

In this chapter, you will learn how to perform the following tasks:

• Create a POINT I/O DeviceLogix module in RSLogix 5000 when using

EtherNet/IP or ControlNet adapters

• Identify the tags created in your program for your use

• Use RSNetWorx for DeviceNet to configure the POINT I/O

DeviceLogix module

To add a POINT I/O DeviceLogix module to RSLogix 5000, do the

following.

1. In the I/O Configuration tree, find the adapter.

In this example, we will be using the 1734-AENT with the

1734-8CFGDLX. The same procedure applies if you are using an

ArmorPOINT I/O DeviceLogix module, or if the network is

ControlNet.

2. Right-click the POINT I/O Chassis and select New Module.

47 Rockwell Automation Publication 1734-UM015B-EN-E - May 2020 47

Page 48

DeviceLogix for POINT I/O and ArmorPOINT I/O on Ethernet/ControlNet

IMPORTANT

3. Under Digital, double-click the POINT I/O DeviceLogix module.

If you cannot find the module in the Select Module dialog box,

you will need to install the Add-On Profile (AOP) for the module.

You can download the AOP at rok.auto/pcdc

The following dialog box appears.

.

48 Rockwell Automation Publication 1734-UM015B-EN-E - May 2020

Page 49

DeviceLogix for POINT I/O and ArmorPOINT I/O on Ethernet/ControlNet

4. Enter the slot number in the Slot box.

It is not possible to make a Rack connection to the POINT I/O

DeviceLogix module. The connection must be a direct one.

On the Connection tab, you can change the Requested Packet Interval

(RPI), the default is 20 ms.

The Module Info tab will display the status and identity information of

the module when the module is online.

There is no tab for configuration. Configuration of the POINT I/O

DeviceLogix modules is done only using RSNetWorx for DeviceNet.

See Chapter 6

for more details.

RSLogix 5000 will create the following input tags:

• AdapterName:SlotNumber:I.Data

• AdapterName:SlotNumber:I.LogicDefinedData

• AdapterName:SlotNumber:I.Status.LogicEnabled

• AdapterName:SlotNumber:I.Status.Owned

• AdapterName:SlotNumber:I.PeerMissing

• AdapterName:SlotNumber:I.LogicDefinedIntData[0...7]

RSLogix 5000 will create the following output tags:

• AdapterName:SlotNumber:O.Data

• AdapterName:SlotNumber:O.LogicDefinedData

• AdapterName:SlotNumber:O.LogicDefinedIntData[0...7]

Rockwell Automation Publication 1734-UM015B-EN-E - May 2020 49

Page 50

DeviceLogix for POINT I/O and ArmorPOINT I/O on Ethernet/ControlNet

I/O Tags

The following table lists the input tags and their descriptions.

Input tags and their descriptions

Tag Description

Data This will contain the state of eight I/O points. See Chapter 6

LogicDefinedData These 8 bits are assigned using the Network Output Bit tags in

LogicEnabled When set, the DeviceLogix program is running.

Owned When set, the module is owned by a master.

PeerMissing Each bit represents one of the eight possible peers. If a bit is

LogicDefinedData[] These eight values are assigned using the Network Output

for

details.

the DeviceLogix program.

set, the data from that peer is missing or invalid.

Word tags in the DeviceLogix program.

The following table lists the output tags and their descriptions.

Output tags and their descriptions

Tag Description

Data This value is sent by the master to set the output state of the

eight output points. This can be overwritten if the DeviceLogix

program is controlling the outputs (Logic Enable On).

See Chapter 6

LogicDefinedData These 8 bits can be used in the DeviceLogix program with the

Network Input Bit tags.

LogicDefinedIntData[] These eight values can be used in the DeviceLogix program

with the Network Input Word tags.

for details.

50 Rockwell Automation Publication 1734-UM015B-EN-E - May 2020

Page 51

DeviceLogix for POINT I/O and ArmorPOINT I/O on Ethernet/ControlNet

Launch RSNetWorx for DeviceNet to Configure the Module

The POINT I/O DeviceLogix module can only be configured using

RSNetWorx for DeviceNet.

The following example assumes that the module is configured while it is

online. If the module is configured offline, then apply the same procedure

when you download the contents of the DNT file to the I/O module.

To configure the module:

1. Start RSNetWorx for DeviceNet.

2. Go online by doing one of the following:

• Click the Online button.

• On the Network menu, click Online.

• Press <F10>.

The RSLinx Browse window appears.

3. Navigate the tree down to the EtherNet/IP or ControlNet POINT I/O

or ArmorPOINT I/O adapter.

4. Expand the tree branch for the adapter.

You should see two additional ports. The first is the backplane, and the

second is a DeviceNet port. Physically they are the same port, which is

the backplane.

RSNetWorx needs a DeviceNet port.

Rockwell Automation Publication 1734-UM015B-EN-E - May 2020 51

Page 52

DeviceLogix for POINT I/O and ArmorPOINT I/O on Ethernet/ControlNet

IMPORTANT

5. Select POINTBus Port, DeviceNet, and click OK.

RSNetWorx automatically browses the network to discover all the

participating modules.

Note the online path in the Messages window at the bottom

half of the screen. This path will be saved in the DNT file. To

open the file, select Properties on the Network menu.

6. If you are configuring the module offline, you must download the

configuration to the module after you go online. To do this, right-click

the module’s icon and select Download to Device.

7. To change the configuration of a module, double-click that module’s

icon. Alternatively, you can right-click the icon and select Properties.

Details on configuring the module can be found in Chapter 6

.

52 Rockwell Automation Publication 1734-UM015B-EN-E - May 2020

Page 53

Chapter

6

Configuring POINT I/O and ArmorPOINT I/O

DeviceLogix modules using RSNetWorx for

DeviceNet

About This Chapter

Configure the Module using the Configuration tab

In this chapter, you will learn how to do the following:

The following diagram shows the Configuration tab of a POINT I/O

DeviceLogix module in RSNetWorx for DeviceNet. The Configuration tab of

an ArmorPOINT I/O DeviceLogix module looks similar.

• Configure the module using the Configuration tab

• Use the data on the Parameters tab

• Configure peer communication

• Produce data without using a master

• Start the DeviceLogix Function Block Editor on the DeviceLogix tab

Rockwell Automation Publication 1734-UM015B-EN-E - May 2020 53

Page 54

Configuring POINT I/O and ArmorPOINT I/O DeviceLogix modules using RSNetWorx for DeviceNet

Parameters on the Configuration tab

Parameter Description

Off-to-On Delay This is the OFF to ON filter constant for all inputs on the module. A

high signal must be present for this amount of time before the module

will report an ON.

The value must be entered in microseconds (s). The default value is

1000 s. The minimum value is 0 and the maximum is 65535 s.

The actual resolution of this value is milliseconds. The user selected

value will be truncated at milliseconds. For example, 65535 s

represents a 65 ms filter value.

On-to-Off Delay This is the ON to OFF filter constant for all inputs on the module. A

low signal must be present for this amount of time before the module

will report an OFF.

The value must be entered in microseconds (s). the default value is

1000 s. The minimum value is 0 and the maximum is 65535 s.

The actual resolution of this value is millisecond. User selected value

will be truncated at milliseconds. For example, 65535 s represents a

65 ms filter value.

Output Fault

State

This parameter controls the action of each output during a

communication fault.

0 = Go to Output Fault Value (default)

1 = Hold Last State

This parameter is ignored if DLX Fault Override is enabled.

Output Fault

Value

The state of each output if a communication fault occurs. This

parameter is ignored if the Output Fault State is set to Hold Last State

or if DLX Fault Override is enabled.

0 = OFF (default)

1 = ON

Output Idle State This parameter controls the action of each output when in Idle state

or Program mode.

0 = Go to Output Idle Value (default)

1 = Hold Last State

This parameter is ignored if DLX Fault Override is enabled.

Output Idle Value The state of each output when in Idle state or Program mode. This

parameter is ignored if the Output Idle State is set to Hold Last State

or if DLX Fault Override is enabled.

0 = OFF (default)

1 = ON

Auto Produce Enabling this parameter will allow the module to produce data

without a master. This parameter is disabled by default.

If enabled, the module will begin to produce data on the backplane or

network after power up and network address verification (Dup MAC

check). The Owned bit in the produced assembly will be cleared (0).

A master may still make a connection to the module and then the

Owned bit will be set (1). If a master connection fails, the module will

continue to produce data, but the Owned bit will be cleared (0).

The produced assembly, EPR, and PIT are described later in this table.

Auto Production may be important to support data to listening peers.

54 Rockwell Automation Publication 1734-UM015B-EN-E - May 2020

Page 55

Configuring POINT I/O and ArmorPOINT I/O DeviceLogix modules using RSNetWorx for DeviceNet

Parameters on the Configuration tab (Continued)

Parameter Description

DLX Dependent

Mode

This parameter allows the logic in the module to be enabled or

disabled according to the I/O connection status or the state of the

owning processor. The default is disabled.

If Dependent Mode is enabled, the DeviceLogix program will be

disabled when the owning processor is in program mode. When the

processor transitions to RUN, the logic will automatically be enabled.

DLX Fault

Override

When an output is being locally controlled, its state is either

controlled by the DeviceLogix program or by the Fault/Idle states.

Enabling this parameter allows the local logic to override the

Fault/Idle states in the event of a communication fault or transition to

Idle (Program) state. When this parameter is disabled (default) and a

communication fault occurs or when in Idle (Program) state, all

outputs, including those that are locally controlled, will go to the

Fault/Idle states. Enabling this parameter and using the "Network

Fault" status bit (Bus-off or Dup Mac Error) or COS/Cyclic Cnxn

Idle/Fault bits in the DeviceLogix program, a controlled stop or

maintenance of a machine state can be achieved when

communication is lost with a master.

Auto Produce

Assembly

When the Auto produce parameter is enabled, this parameter selects

which assembly to produce:

000: 20-byte assembly (default)

004: 1-byte assembly

101: 20-byte assembly

111: 8-byte assembly

For details on the contents of the assembly, see I/O Data Assembly

Maps in Chapter 4.

For the list of I/O tags, see I/O Tags

in Chapter 5.

The 20-byte assembly contains all the data. The 8-byte assembly can

be produced in one packet (non-fragmented).

Auto Produce EPR When the Auto Produce parameter is enabled, this parameter sets the

Expected Packet Rate. The units are milliseconds (ms). The default is

1000 ms. The maximum is 65535 ms and the minimum is 0 ms.