Page 1

Arena®Packaging

USER’S GUIDE

PUBLICATION ARENPK-UM001F-EN-P–November 2007

Supersedes Publication ARENPK-UM001E-EN-P

Page 2

Contact Rockwell

Customer Support Telephone — 1.440.646.3434

Online Support — http://www.rockwellautomation.com/support/

Copyright Notice

Trademark Notices

Other Trademarks

Warran ty

© 2007 Rockwell Automation Technologies, Inc. All rights reserved. Printed in USA.

This document and any accompanying Rockwell Software products are copyrighted by Rockwell Automation

Technologies, Inc. Any reproduction and/or distribution without prior written consent from Rockwell Automation

Technologies, Inc. is strictly prohibited. Please refer to the license agreement for details.

Arena, Rockwell Automation, and SIMAN are registered trademarks of Rockwell Automation, Inc.

ActiveX, Microsoft, Microsoft Access, SQL Server, Visual Basic, Visual C++, Visual SourceSafe, Windows, Windows

ME, Windows NT, Windows 2000, Windows Server 2003, and Windows XP are either registered trademarks or

trademarks of Microsoft Corporation in the United States and/or other countries.

Adobe, Acrobat, and Reader are either registered trademarks or trademarks of Adobe Systems Incorporated in the

United States and/or other countries.

ControlNet is a registered trademark of ControlNet International.

DeviceNet is a trademark of the Open DeviceNet Vendor Association, Inc. (ODVA)

Ethernet is a registered trademark of Digital Equipment Corporation, Intel, and Xerox Corporation

OLE for Process Control (OPC) is a registered trademark of the OPC Foundation.

Oracle, SQL*Net, and SQL*Plus are registered trademarks of Oracle Corporation.

All other trademarks are the property of their respective holders and are hereby acknowledged.

This product is warranted in accordance with the product license. The product’s performance may be affected by system

configuration, the application being performed, operator control, maintenance and other related factors. Rockwell

Automation is not responsible for these intervening factors. The instructions in this document do not cover all the

details or variations in the equipment, procedure, or process described, nor do they provide directions for meeting every

possible contingency during installation, operation, or maintenance. This product’s implementation may vary among

users.

This document is current as of the time of release of the product; however, the accompanying software may have

changed since the release. Rockwell Automation, Inc. reserves the right to change any information contained in this

document or the software at anytime without prior notice. It is your responsibility to obtain the most current information

available from Rockwell when installing or using this product.

Version: 12.00.00 (CPR9)

Modified: October 8, 2007 10:39 am

ii

Page 3

Contents

1 • Welcome to the Arena Packaging Template 1

What is the Arena Packaging template?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Intended audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Where can I go for help? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Reference the user’s guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Explore our examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Get help. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Use the HSMARTs library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Access the Arena Symbol Factory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Get phone support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Get Web support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Get training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Get consulting services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Contact us . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 • General Concepts 5

Template overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Template framework and modeling methodology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

•

Step 1

Step 2

Step 3

Step 4

Step 5

Place and connect equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

•

Define equipment behavior. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

•

Run the model. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

•

View automatic statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

•

Experiment with complex strategies. . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3 • The Packaging Panel 21

Panel modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Actions module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Conveyor module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Conveyor Link (CLink) module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Label module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Machine module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Machine Link (MLink) module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Merge module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Operator module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Operator Group module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Operator Schedule module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

iii

Page 4

ARENA PACKAGING TEMPLATE USER’S GUIDE

• • • • •

Palletizer module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Product module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Production Plans module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Simulate module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Split module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Storage module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Switch module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Tank module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Valve module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Common module dialogs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Actions dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Animation dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Controls dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Costs dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Loss dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Operators dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Production and Changeovers dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Reliability dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Run Options dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Scheduled Stops dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Sensors dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4 • Statistics 47

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Selecting the statistics to report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Statistic descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Machine statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Conveyor statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Palletizer statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Storage statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Operator statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Operator Group statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5 • Variables 67

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Organization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Assigning and referencing Arena Packaging template variables . . . . . . . . . . . . . 67

Updating Arena Packaging template variables. . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Variables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Assigning and referencing variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Assigning values to variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

iv

Page 5

CONTENTS

Referencing variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

References in Arena and SIMAN template modules . . . . . . . . . . . . . . . . . . . . . . 71

References in Arena Packaging template modules. . . . . . . . . . . . . . . . . . . . . . . . 72

Updating variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Updating variables for animation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Updating variables at a specific time—The Update action . . . . . . . . . . . . . . . . . 73

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Conveyor variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Conveyor Link variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Machine variables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Palletizer variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Storage variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Switch variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Tank variables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Valve variable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

A • Equipment Reliability and Loss 85

Defining reliability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Using expected uptime . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Using reliability over a time span. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Using individual failure streams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Questions and answers about reliability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Defining loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Event-based loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Production-based loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Questions and answers about loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

• • • • •

B • Placing Animation 99

The Animation dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

State or Level Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Blocked/Starved symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Product picture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Variables or statistics table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Questions and answers about animation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Index 103

v

Page 6

ARENA PACKAGING TEMPLATE USER’S GUIDE

• • • • •

vi

Page 7

1

Welcome to the Arena Packaging Template

What is the Arena Packaging template?

Arena Packaging is a simulation system developed by Rockwell Automation for the

performance analysis of high-speed, high-volume manufacturing systems.

The initial design of the Packaging template was developed by Ouroumoff Diffusion (a

consulting firm headquartered in Lyon, France) during a consulting engagement with

Pechiney CRV to analyze canning lines. The core algorithms of the product involved vital

input from the engineering staff at Pechiney. The final design of the Packaging template

then involved significant input by staff at Rockwell Automation as well as Michigan State

University’s School of Packaging.

Intended audience

The Arena Packaging template is designed for manufacturing or business process consultants and analysts and industrial or systems engineers. It is typically deployed as an enterprise business analysis and productivity tool.

We assume that you are familiar with the basic concepts and terms used in these types of

systems. You are interested in improving business or manufacturing productivity and are

responsible for evaluating and predicting the impact of proposed strategic and tactical

changes to help improve performance. A familiarity with computers and the Microsoft

Windows

in simulation is also helpful.

®

operating system is assumed. A familiarity with the concepts and terms used

1 • Welcome

®

Where can I go for help?

Our commitment to your success starts with the suite of learning aids and assistance we

provide for Arena. Whether you’re new to simulation or a seasoned veteran putting a new

tool to use, you’ll quickly feel at home with Arena Packaging.

Reference the user’s guides

The documentation set includes this manual, Arena Packaging Template User’s Guide,

which cover the product basics as well as the Arena User’s Guide, which covers the

standard product modules and offers an easy, “click-by-click” tutorial, and the Variables

Guide, a separate reference booklet providing complete descriptions of Arena variables

found in the Arena product templates.

1

Page 8

ARENA PACKAGING TEMPLATE USER’S GUIDE

• • • • •

D

OCUMENT CONVENTIONS

Throughout the guides, a number of style conventions are used to help identify material.

New terms and concepts may be emphasized by use of italics or bold; file menu paths are

in bold with a (>) separating the entries (e.g., go to Help > Arena Help); text you are

asked to type is shown in Courier Bold (e.g., in this field, type Work Week), and dialog

box and window button names are shown in bold (e.g., click OK).

Explore our examples

Arena is accompanied by a number of sample models that illustrate many of the

commonly used approaches for capturing the essence of manufacturing processes.

Examples are provided for both job shop and flow shop environments. For a description

of and list of Arena’s examples, go to Help > Arena Help. On the Contents tab, choose

Model Building Basics, and then select Viewing Arena Example Models.

Get help

Online help is always at your fingertips! Arena incorporates the latest in help features,

including What’s This? help that displays a brief description of fields in dialog boxes,

context-sensitive help on menu and toolbar buttons, and a help button on each of Arena’s

modules. Just refer to the Arena help table of contents and index for a list of all help

topics.

Use the HSMARTs library

As you craft models of your own manufacturing processes, use our HSMARTs library to

explore how to best use Arena. HSMARTs are a collection of small, self-contained models

that illustrate different aspects of modeling in Arena Packaging. We recommend you go

through these small files to see how concepts are implemented in actual models. For a list

of categories and their related HSMARTS, go to Help > Arena Help. On the Contents

tab, choose Template Help > Packaging > Arena Packaging Template > Learning

Arena Packaging Template with the HSMART Files.

Access the Arena Symbol Factory

Arena animations can be enhanced using Arena Symbol Factory’s extensive library of

over 4,000 symbols. These symbols can be used for entity, resource, transporter or global

pictures; or as graphic symbols within a model window. You can copy these symbols

directly to the Arena model window, add them to your own libraries (.plb files), or add

them to any of the Arena picture library files.

2

Page 9

1 • WELCOME TO THE ARENA PACKAGING TEMPLATE

Get phone support

Rockwell Automation’s support team of outstanding professionals provides top-notch

technical support—monitoring and tracking your experience with our simulation products

to pave the road to your success in understanding and improving your performance.

Rockwell Automation provides full support for the entire Arena family of products.

Questions concerning installation, how modules work, the use of the model editor, and the

use of the software are handled by technical support.

A

RENA TECHNICAL SUPPORT INCLUDES

(for users on active maintenance) a technical support hotline and e-mail address

staffed by full-time, experienced professionals

help with installation problems or questions related to the software’s requirements

troubleshooting

limited support regarding the interaction of Arena with other programs

support of the Arena Object Model, which is used in Microsoft Visual Basic for

Applications.

If you call the support line (1.440.646.3434), you should be at your computer and be

prepared to give the following information:

:

• • • • •

1 • Welcome

the product serial number

the product version number

the operating system you are using

the exact wording of any messages that appeared on your screen

a description of what happened and what you were doing when the problem occurred

a description of how you tried to solve the problem.

Get Web support

In addition to phone support, the Rockwell Automation Customer Support Center offers

extensive online knowledgebases of tech notes and frequently asked questions for support

of non-urgent issues. These databases are updated daily by our support specialists.

To receive regular e-mail messages with links to the latest tech notes, software updates,

and firmware updates for the products that are of interest to you or to submit an online

support request, go to support.rockwellautomation.com/supportrequests

And be sure to check the Arena User Zone section of our Web site at www.ArenaSimulation.com. The User Zone links to a peer-to-peer forum on Arena topics and has a link to a

download page where you can check for possible software updates (patches). If you can’t

find the answer you need, contact your local representative or Arena technical support.

.

3

Page 10

ARENA PACKAGING TEMPLATE USER’S GUIDE

• • • • •

Get training

Do you need training? Rockwell Automation offers a standard training course comprised

of lecture and hands-on workshops designed to introduce you to the fundamental concepts

of modeling with Arena.

We also offer customized training courses designed to meet your specific needs. These

courses can be held in our offices or yours, and we can accommodate one person or

twenty. You design the course that’s right for you! Simply contact our consulting services

group to discuss how we can help you achieve success in your simulation efforts.

Get consulting services

Rockwell Automation provides expert consulting and turnkey implementation of the

entire Arena product suite. Please call our offices for more information or e-mail ArenaInfo@ra.rockwell.com.

Contact us

We strive to help all of our customers become successful in their manufacturing improvement efforts. Toward this objective, we invite you to contact your local representative or

Rockwell Automation at any time that we may be of service to you.

Support E-mail: Arena-Support@ra.rockwell.com

Corporate E-mail: Arena-Info@ra.rockwell.com

Support Phone: 1.440.646.3434

URL: www.ArenaSimulation.com

URL: www.rockwellautomation.com

4

Page 11

2

General Concepts

Template overview

Arena Packaging is one of a family of application solution templates (ASTs) built on the

Arena simulation system. It is designed specifically for performing accurate and efficient

simulations of high-speed, high-volume manufacturing systems, where the processing rates

take place at hundreds, even thousands, of entities per minute. The Packaging template

enables users to build and run simulation models of high-speed processing lines quickly

and easily, and to analyze the results that these models produce.

To use the Arena Packaging template, you attach the Packaging panel to the Arena

development environment. The Packaging panel contains a collection of objects or

modules. Each module defines the logic, data, animation, and/or statistics collection for a

particular element in a model (e.g., machines, conveyors, operators).

The Packaging panel contains the following modules:

A Machine module for modeling the physical components of a line where the actual

processing or conversion of units takes place.

A Conveyor module for modeling the accumulating conveyors between machines

where units are transferred and buffered.

Machine Link and Conveyor Link modules for linking machines and conveyors

directly together.

Merge, Split, and Switch modules for modeling transfer points between conveyors

where product flow is split or combined (i.e., flow controls).

2 • General Concepts

Operator, Operator Group, and Operator Schedule modules for modeling the

availability and organization of labor in the system.

Palletizer and Storage modules for modeling the physical components of a line where

units are stored on or removed from pallets.

Val ve and Tank modules for modeling fluid constraints of filling operations.

Product and Production Plans modules for defining multiple products processed in a

system and their requirements.

An Actions module for performing actions on a high-speed system (e.g., changing run

speeds of machines, adjusting valves, adding pallets to a storage) using discrete

entities and logic.

A Label module for labeling a particular portion of the model logic, whereby discrete

entities may be sent easily to the label from other locations in the model.

5

Page 12

ARENA PACKAGING TEMPLATE USER’S GUIDE

• • • • •

A Simulate module for advanced model options (e.g., units of measure, statistic

collection switches).

Template framework and modeling methodology

Simulation studies are initiated because a decision maker or group of decision makers face

a problem and need a solution. You should begin a simulation project by first collecting

enough information and data to provide an adequate understanding of both the problem

and the system to be studied. Once that step is complete, you are then ready to formulate

models.

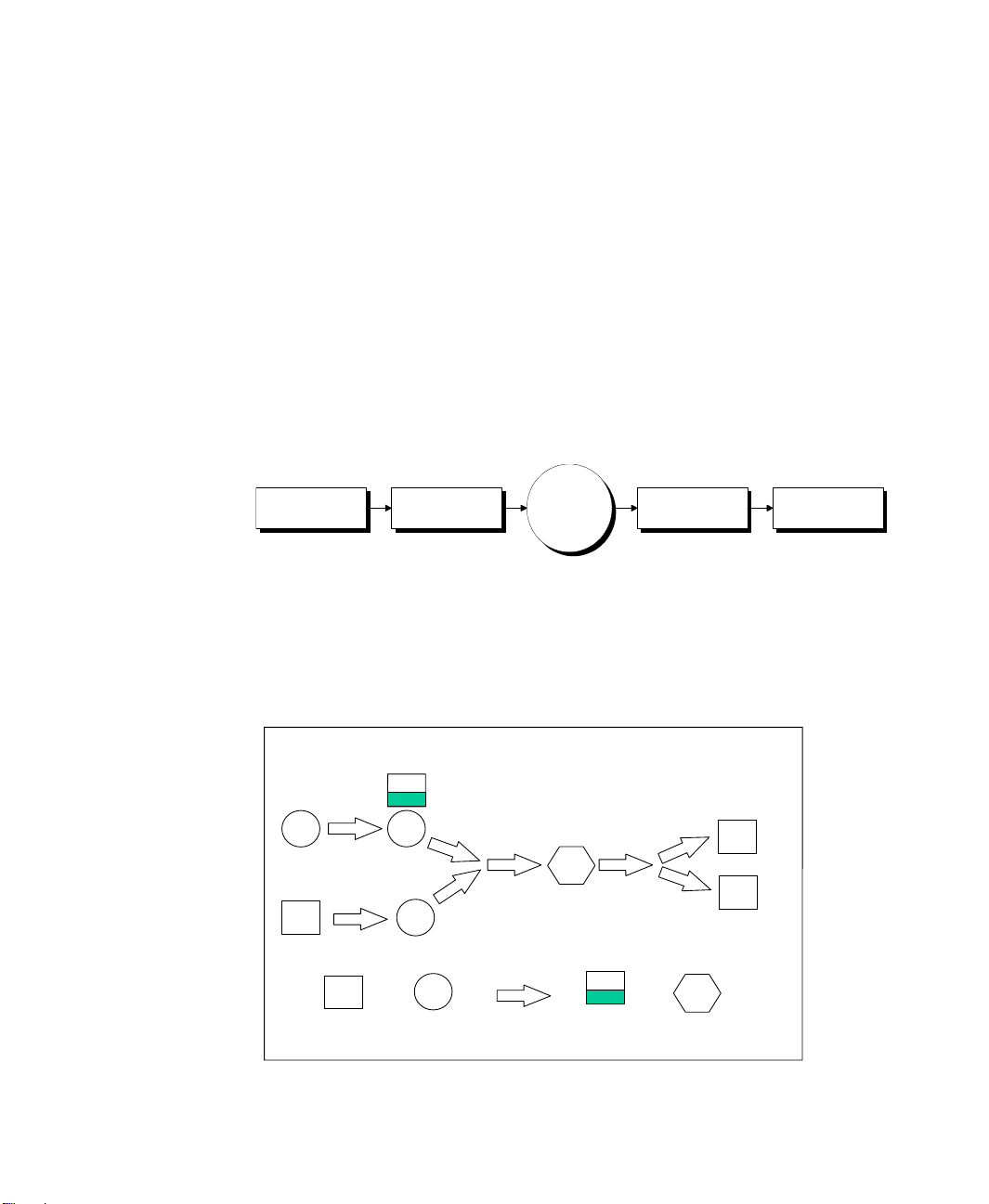

This section introduces a five-step modeling methodology for developing those simulation models in Arena Packaging. The steps of the methodology are illustrated in the

following diagram.

Place & Connect

Equipment

Define Equipment

Behavior

Run

the

Model

View Automatic

Statistics

Experiment with

Complex Strategies

Step 1 • Place and connect equipment

First, flowchart on paper the step-by-step sequence of your line as raw goods are converted

into finished product. For example, you might construct flowcharts of the machines,

conveyors, palletizers, merges, splits, etc., in your line similar to the flowchart below.

(De)Palletizer

Processing Step

Conveyor

Tank

Inspection

6

Page 13

2 • GENERAL CONCEPTS

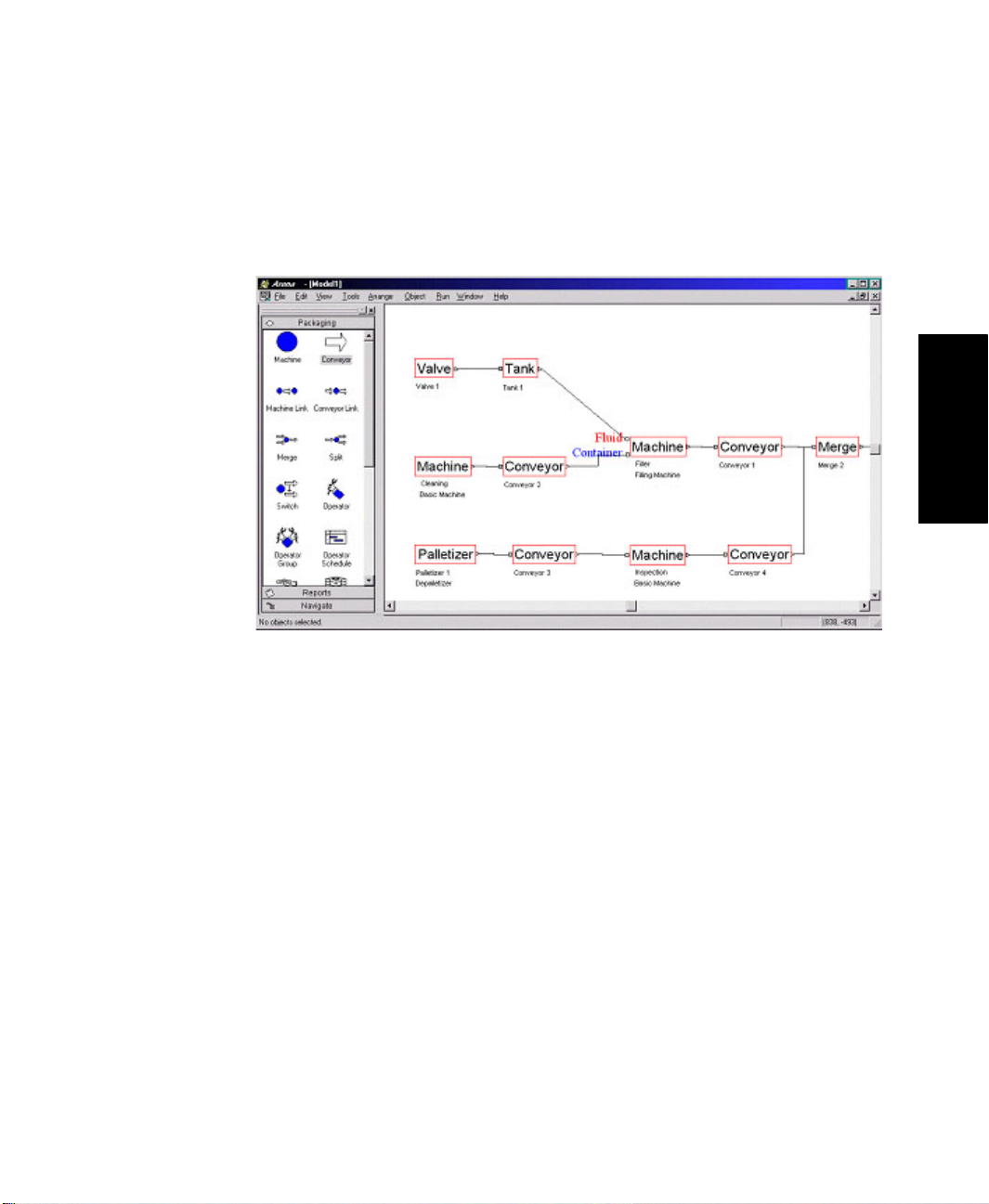

Once you have flowcharted your process, duplicate that flowchart in Arena by graphically

placing and connecting appropriate modules from the Packaging panel into an Arena

model window. To select a module, you simply drag and drop an icon in the panel onto the

workspace region where you want the module to be placed.

• • • • •

2 • General Concepts

HSMARTs are a collection of small models that illustrate modeling techniques. To learn

combinations of Packaging modules that are appropriate for specific situations, it is useful

to refer to the HSMART examples for Step 1.

Step 1 • Place and Connect Equipment

Processing

HSMART01: Basic Processing Operation

HSMART02: Basic Processing Operation Using a Non-accumulating

Conveyor

HSMART03: Assembly Operation

HSMART04: Packing Operation

HSMART05: Filling Operation

HSMART06: Inspection Operation

HSMART07: Linking Two Machines

HSMART08: Modeling a Supply Constraint for an Operation

HSMART09: Modeling a Machine as Two or More Separate Components

7

Page 14

ARENA PACKAGING TEMPLATE USER’S GUIDE

• • • • •

Conveyors and Flow Control

HSMART10: Accumulating Conveyors

HSMART11: Linking Two Accumulating Conveyors

HSMART12: Splitting Conveyor Flow by Count

HSMART13: Merging Conveyor Flow

HSMART14: Modeling a Surge Area or Table

HSMART15: Modeling a Secondary Line

HSMART16: Modeling Rework

Tanks and Valves

HSMART17: Simple Tank and Valve

HSMART18: Tank Farm

Fronts (Sources) and Ends (Sinks) of Lines

HSMART19: Using Palletizers to End a Line

HSMART20: Using Depalletizers to Begin a Line

HSMART21: Storage Example Using Palletizer/Depalletizer

Step 2 • Define equipment behavior

The next step is to specify the basic run parameters (e.g., run speeds), characteristics (e.g.,

reliability, loss), and dimensions (e.g., length, width, capacity) for each individual element

in the line. For example, you might have collected and organized data about the equipment in your line as follows.

Processing Elements:

Element Name

Nom. Run Speed

(units/min) Unit Loss

Reliability

for a Week

Cleaner 500 .01% .97

Filler 650 .01% .99

Inspector 500 1.0% .98

Depalletizer 600 .01% .99

8

Page 15

2 • GENERAL CONCEPTS

Conveyor Elements:

Conveyor

Name

Nom.

Ve lo ci t y

(ft/min)

Length

(ft)

Width

(ft)

Unit

Density

(units/ft

Unit

2

)

Loss

Reliability

for a

Week

Conveyor 1 100 200 3 10 .01% .995

Conveyor 2 90 100 2 10 .01% .995

Conveyor 3 90 100 2 10 .01% .995

Conveyor 4 100 150 2 10 .01% .995

Conveyor 5 95 50 3 10 .01% .995

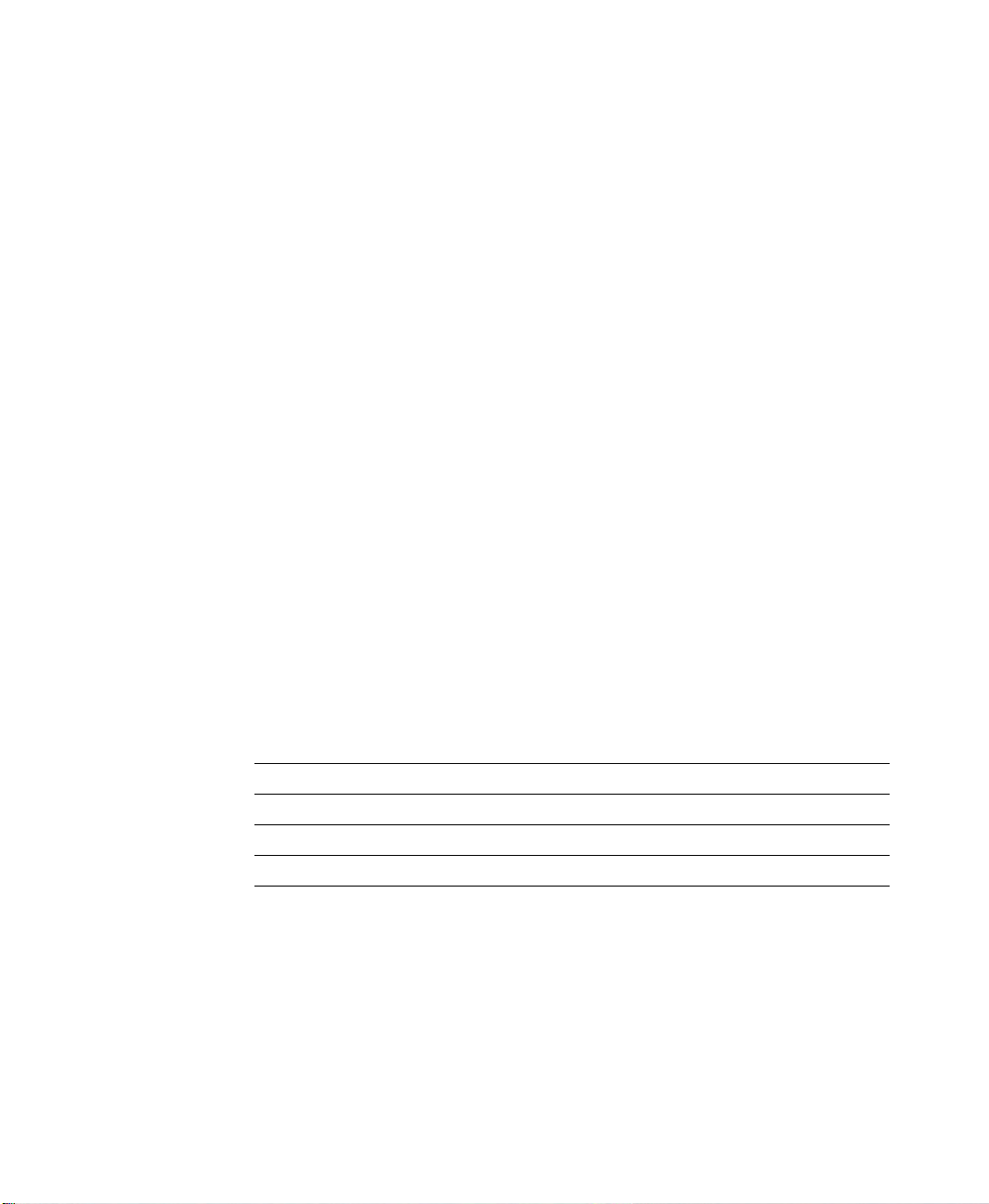

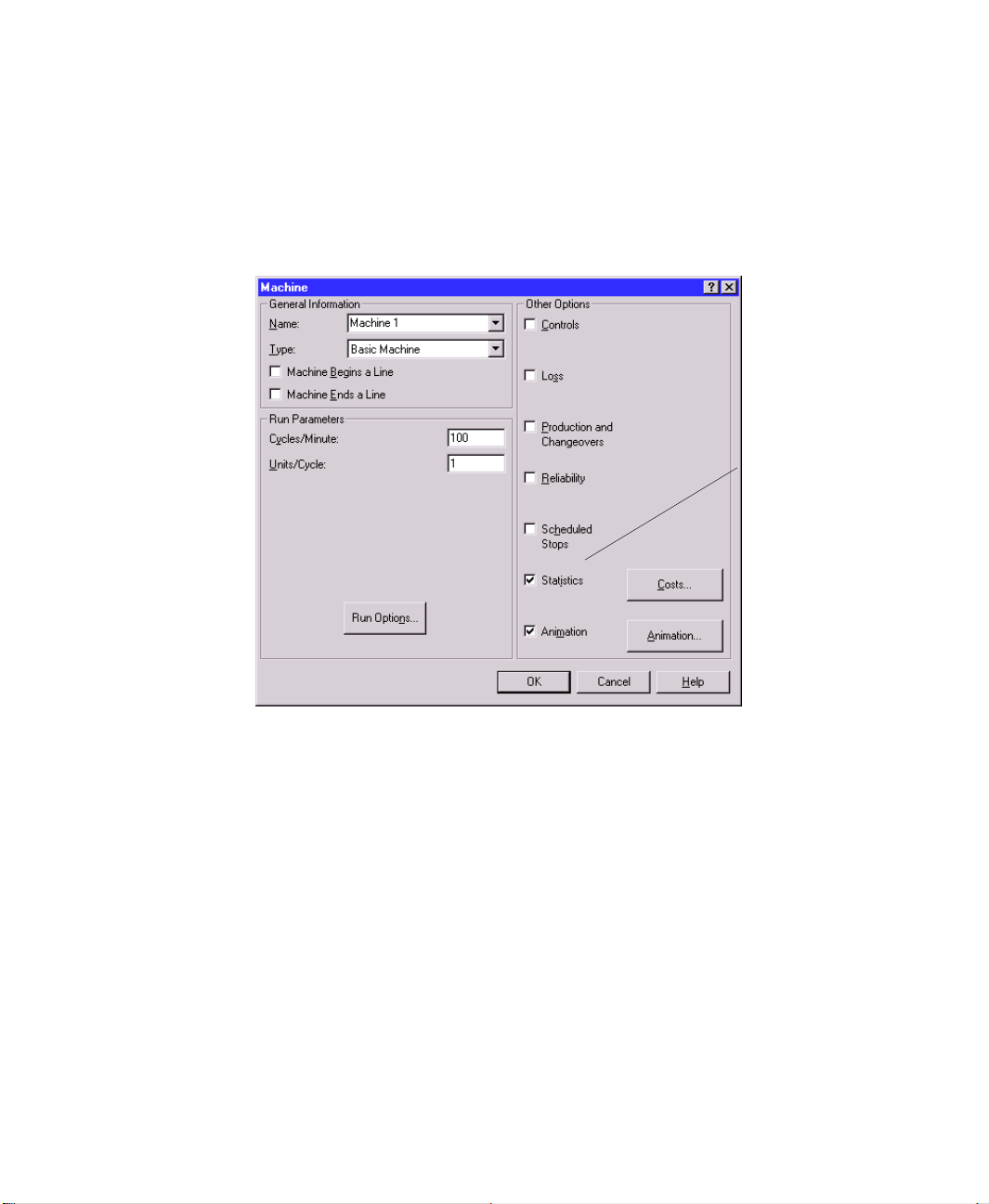

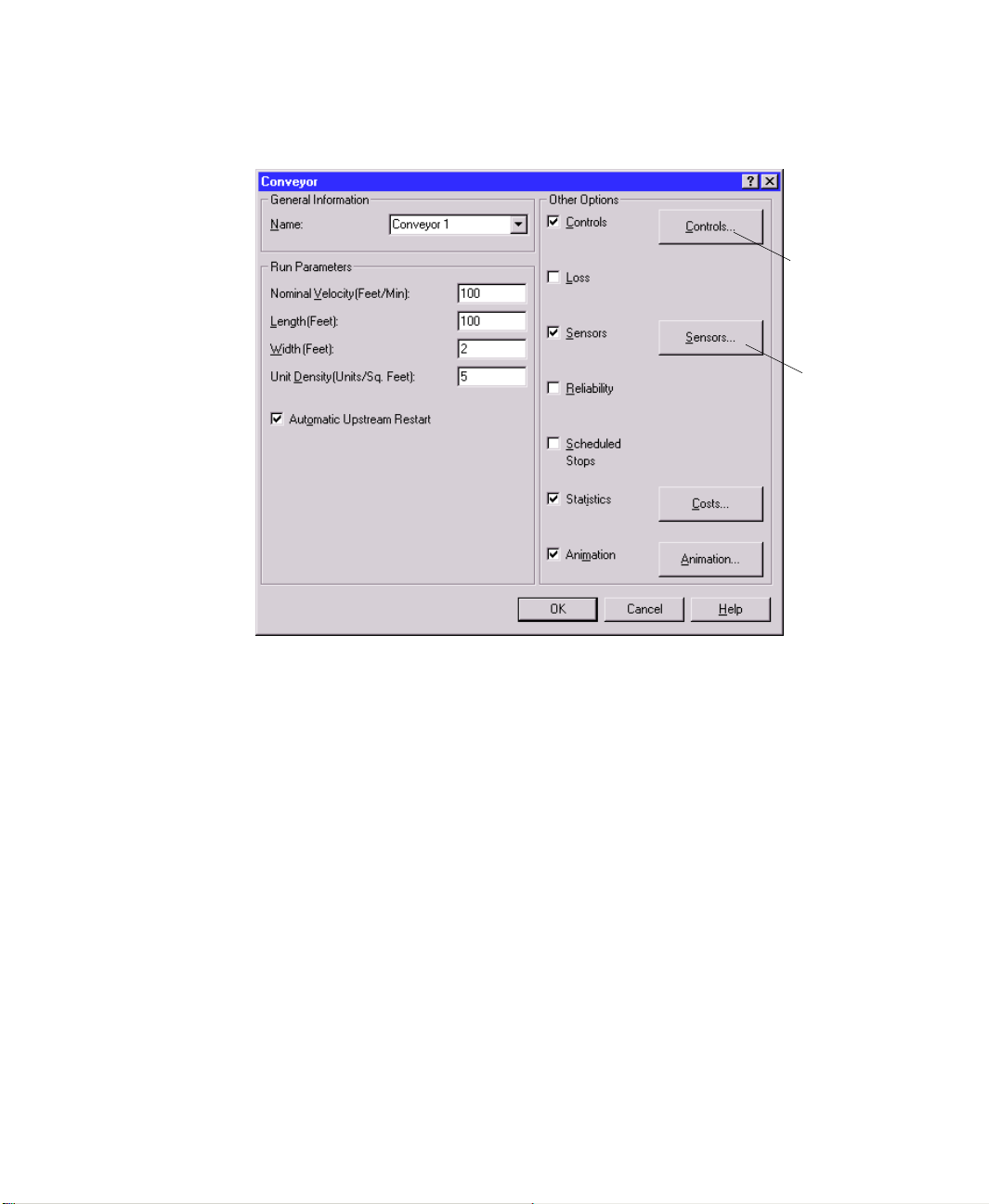

In Arena Packaging, you define equipment parameters such as those listed above by

double-clicking on modules and filling in the descriptive information in the module

dialogs. For example, the main dialog box of the Conveyor module is shown below.

• • • • •

2 • General Concepts

1. Double-click on a

module.

2. Fill in the basic

run parameters.

3. Define loss and

reliability, if

possible.

4. Define basic

animation and/or

desired statistics

for module.

9

Page 16

ARENA PACKAGING TEMPLATE USER’S GUIDE

• • • • •

All module dialogs are self-contained and designed with terminology for high-volume

applications. The graphical “point-and-click” interface allows you to develop models of

sophisticated systems without writing any code. You just answer the questions in the

dialog boxes.

It is also easy to define basic animation and statistics for a module. Arena Packaging

allows you to generate animation and statistics (e.g., production summary, costing, or

state statistics) for modules automatically by clicking on the Animation and Statistics

check boxes. Animation is placed upon exiting the dialog box. It can then be enhanced by

using symbols from Arena’s picture libraries, Arena Symbol Factory, or from other

graphics files such as Clip Art or AutoCAD

To learn more about defining basic behavior for the Arena Packaging template’s modules,

refer to the module descriptions in Chapter 3 or the HSMART examples listed below.

Step 2 • Define Equipment Behavior

HSMART22: Defining Event-Based Loss

HSMART23: Defining Production-Based Loss

HSMART24: Modeling Reliability Using Expected Uptime

HSMART25: Modeling Reliability Using Reliability

HSMART26: Modeling Reliability Using Multiple Failure Streams

Step 3 • Run the model

At this stage, while you’re probably not ready to reach significant conclusions yet with

your model, you do have a complete tool that you can now build on as your project

progresses. It is a good idea to run this first model to verify that your basic logic is

working correctly. Animation is a great tool for verifying model logic. You can also gain

valuable insight on further detail to add and future strategies with which to experiment.

®

.

10

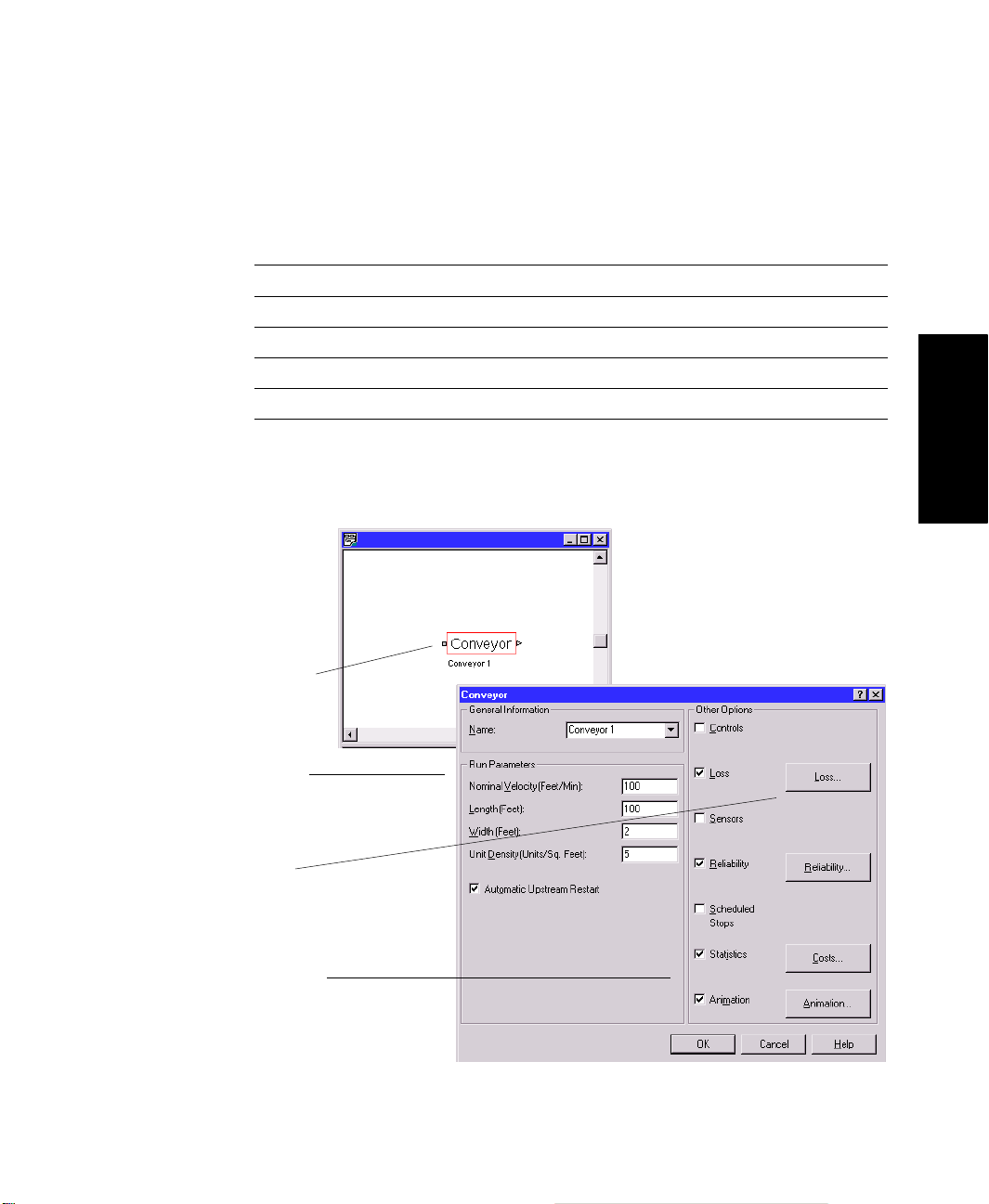

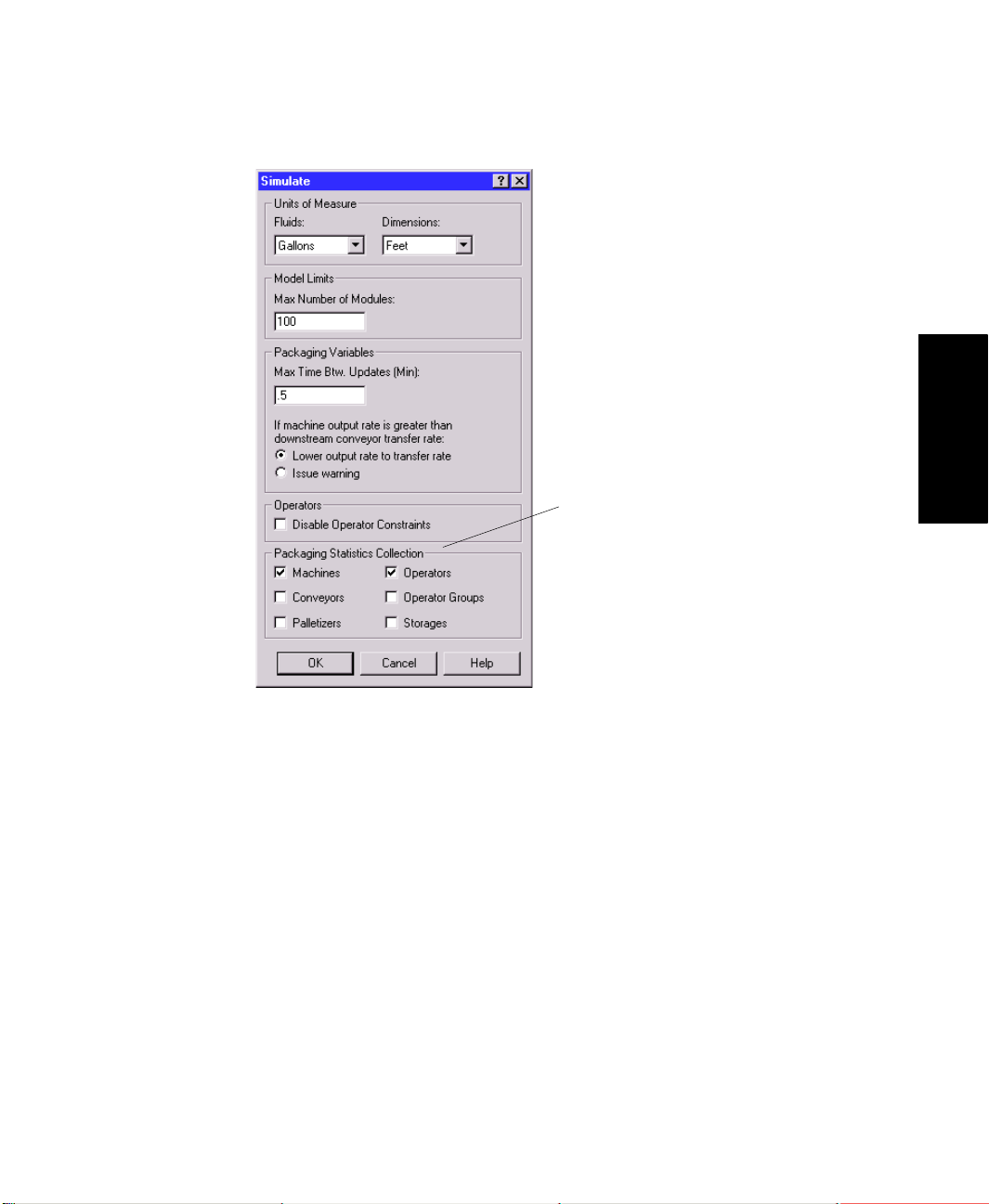

In Arena Packaging, to run a model, you must first place a Simulate module. This module

defines which categories of Packaging module statistics will be collected as well as additional information such as units of measure. Before starting a simulation run, you will want

to specify the simulation project parameters, such as the number of replications, the run

length, and base time units. This is done by choosing the

File

Arena’s

parameters. Then use the

menu. This opens the Run Setup dialog box. Enter the replication and project

Go

command (

Run

menu) to start the simulation run.

Run > Setup

menu option from

Page 17

3. Watch Arena Packaging

track variables such as

input and output rates,

throughputs, states,

conveyor accumulations,

etc.

4. Place additional

animation constructs

(e.g., plots) to animate

system variables.

2. Click the Go button on

the Run toolbar to start

the simulation.

1. Place the Simulate

module and specify

advanced options. Enter

replication parameters in

Arena’s Run > Setup

menu.

• • • • •

2 • GENERAL CONCEPTS

2 • General Concepts

When a simulation run begins, Arena Packaging first processes the data and logic of the

system as defined by the modules in the model. Special-purpose variables called Arena

Packaging variables are automatically created for each module. These variables are

dynamic quantities that describe the state of the system. Examples of Arena Packaging

template variables include equipment states, run speeds, input and output rates, throughputs, conveyor accumulation levels, tank levels, etc. A more detailed discussion and list of

the Arena Packaging template variables can be found in Chapter 5 of this user’s guide.

The model of the system is then input into a simulation engine specifically designed for

simulating high-speed, high-volume flow. This engine utilizes two distinct technologies:

SIMAN and an algorithmic kernel. The SIMAN portion of the engine manages discrete

system events such as equipment failures, changeovers, and stops, as well as system

resources such as operators. SIMAN is the core language of the Arena development

environment and has been designed, developed, and successfully used since 1982 to

conduct discrete-event simulations.

11

Page 18

ARENA PACKAGING TEMPLATE USER’S GUIDE

• • • • •

Packaging Edition

Model

Animation

SIMAN Engine

Algorithmic Engine

Statistics

The algorithmic portion of the Arena Packaging

template

’s engine manages the complex

logic and statistics associated with high-speed, high-volume flow. Specifically designed for

simulating high-speed processes, it allows Arena Packaging to simulate the performance of

a high-volume system accurately and efficiently without using entities to represent individual units or batches of units.

As the simulation begins, unit flow starts at the front of lines and moves downstream. The

simulation then automatically tracks, updates, and collects statistics on the Arena

Packaging variables for the length of the simulation run. Numeric values, plots, and levels

of Arena Packaging template variables can be viewed during the simulation using Arena’s

animation constructs.

For more information, refer to the HSMART examples for Step 3.

Step 3 • Run the Model

HSMART28: Updating Arena Packaging Template Variables Automatically

HSMART29: Animating Arena Packaging Template Variables

HSMART31: Custom Pictures for Conveyor Animation

12

Page 19

2 • GENERAL CONCEPTS

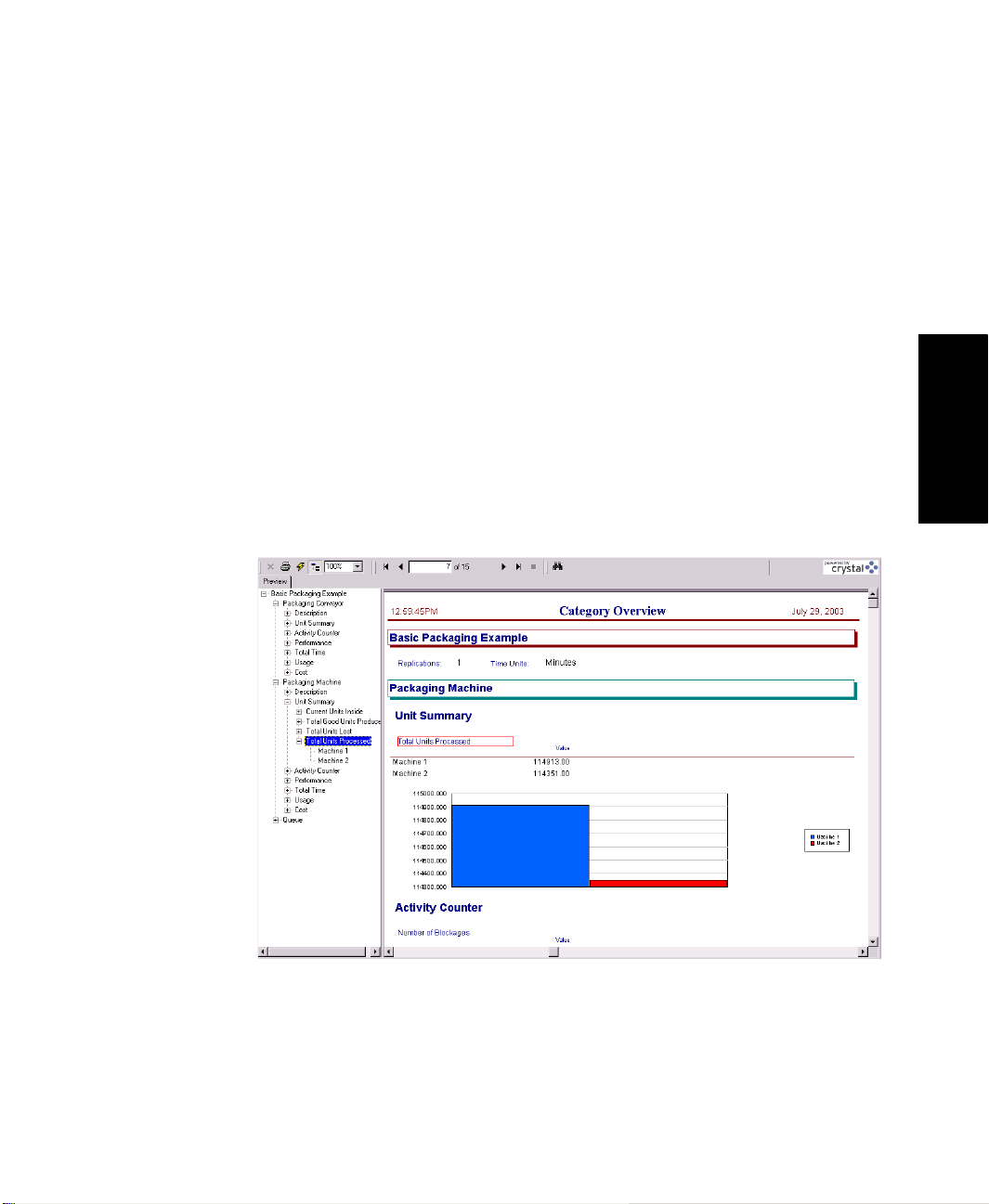

Step 4 • View automatic statistics

A primary objective of most simulation studies is to generate statistics about a system’s

performance so that you can make the “right” decisions.

When an Arena Packaging template model (i.e., .doe file) is run, the simulation results are

stored in a Microsoft Access database (.mdb) file by the same name (e.g., the simulation

results for CandyLine.doe are stored in CandyLine.mdb).

®

Arena Packaging then utilizes Crystal Reports

database. The Category Overview report displays information for system resources

defined using the Packaging template modules, such as machines, palletizers, conveyors,

storages, etc. It also displays information for system resources defined using the Arena

template modules.

Each major section of the report pertains to a type of system resource (e.g., machines,

conveyors, palletizers, storages). Within these sections, statistics are listed by module and

grouped into categories. The categories are Description, Unit Summary, Activity Counter,

Total Time, Cost, Performance, Usage, and Other.

to display the statistics stored in the report

• • • • •

2 • General Concepts

13

Page 20

ARENA PACKAGING TEMPLATE USER’S GUIDE

• • • • •

Module statistics are not generated by default. Instead, Arena Packaging allows you to

choose which statistics you want to collect, write to the report database, and see in Crystal

Reports. You specify that a module’s statistics are included in the reports by selecting the

Statistics option in the module dialog box.

Check Statistics to

report statistics for a

module.

14

It is also easy to turn off statistics for all modules of a particular type (e.g., turn off

statistics for all conveyors, or all machines). Within the Simulate module, there are check

boxes for collecting statistics on Machines, Conveyors, Palletizers, Operators, Operator

Groups, and Storages. When one of those prompts is checked, statistics will be reported

for all modules of that type that have their individual module-level statistics check box

selected. When one of those prompts is not checked, no modules of that type will have

statistics reported, regardless of whether the individual module-level statistics are

selected.

Page 21

2 • GENERAL CONCEPTS

Turn on/off statistics for all modules of

a particular type in the Simulate

module.

• • • • •

2 • General Concepts

Refer to the HSMART examples for Step 4 for more information.

Step 4 • View Automatic Statistics

HSMART30: Generating Cost Statistics

Step 5 • Experiment with complex strategies

In the first four steps of the methodology, you built a base model of your system’s process;

defined basic equipment behavior such as run speeds, loss, and reliability; and performed

an initial simulation run.

Once that base model and study are completed, you can utilize additional features in

Arena Packaging to experiment with more complex strategies and issues in your line. For

discussion purposes, these strategies and feature sets have been divided into five main

topics.

15

Page 22

ARENA PACKAGING TEMPLATE USER’S GUIDE

• • • • •

The five topics are introduced briefly below.

Products, production plans, and changeovers

By default, the Arena Packaging template’s algorithms simulate the flow of a

“generic” or single product type through the system. Optionally, you can model the

flow of multiple product types and thus incorporate product-related issues such as

changeovers, set-up times, product-dependent run speeds, etc.

The Product and Production Plans modules are available for defining multiple products

processed in a system and their requirements. The Production and Changeovers option

in Machine and Palletizer modules is where you assign changeover times or production

plan data to those elements.

The Switch module can be used to split unit flow based on product type.

16

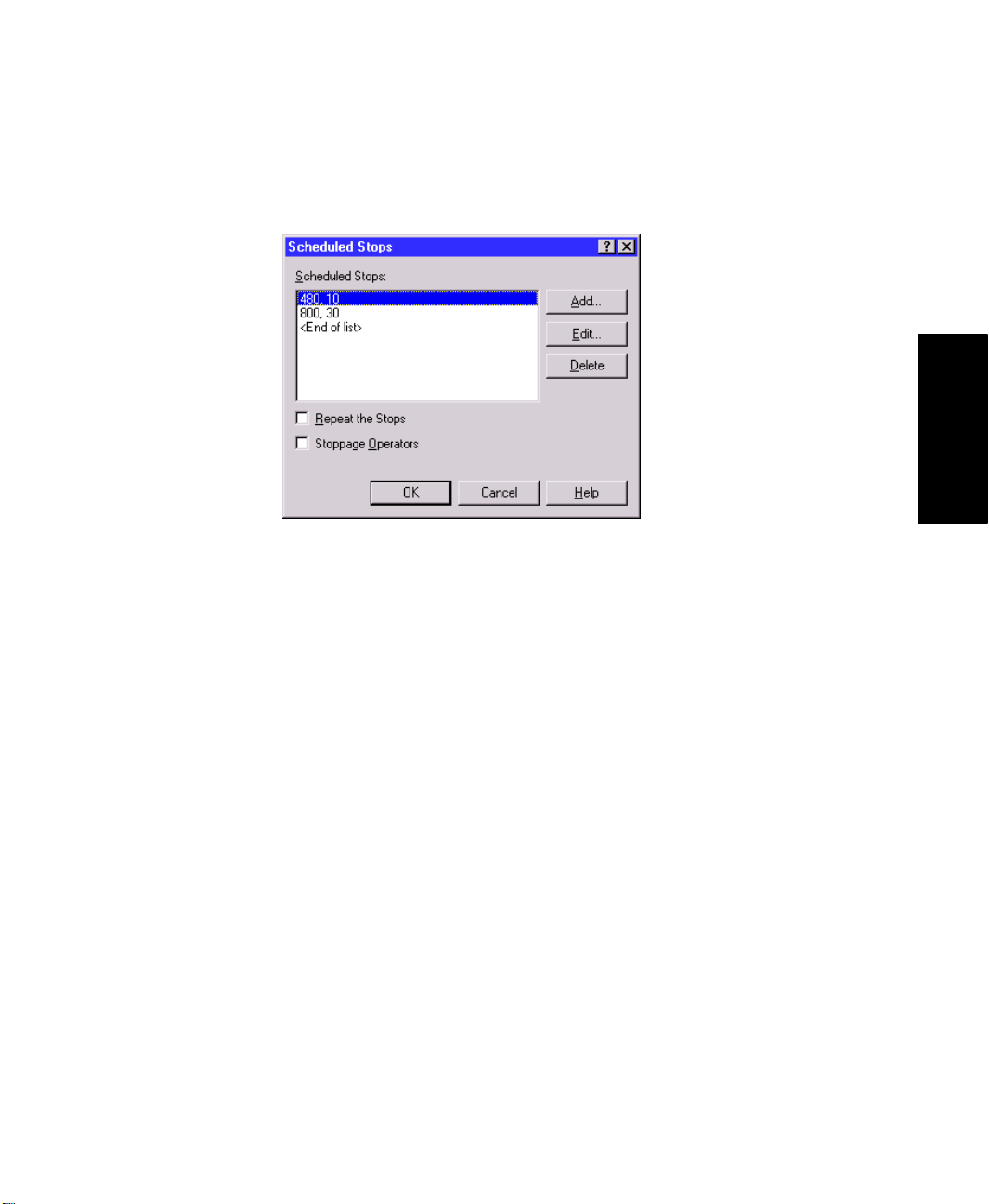

Scheduled stops

Arena Packaging has options for defining scheduled downtimes or maintenance for

machines, conveyors, and palletizers in the system. Scheduled stops are considered to

be planned downtimes and thus are reported and tracked separately from the failures

that occur due to equipment reliability. Unlike failures, scheduled stops are also not

factored into utilization.

Page 23

2 • GENERAL CONCEPTS

The Scheduled Stops option in Machine, Palletizer, and Conveyor modules is where

you define scheduled downtimes for those elements.

Dynamic line control

• • • • •

2 • General Concepts

Dynamic line control is often necessary for regulating or directing particular situations

and events in a system. It can be a critical factor of a line’s design, impacting system

utilization and performance.

The Arena Packaging template has options for placing controls and sensors on equipment such that the details of your functional control system can be incorporated into

the model logic. A control is a function that monitors system status for one or more

conditions. When a condition is true, one or more actions can be taken (e.g., change

the speed factor of a machine). Sensors are devices that can be placed anywhere along

the lengths of conveyors and tanks to monitor accumulation levels of units or fluids.

When a sensor is either covered or uncovered, it is triggered and one or more actions

can be taken.

The Controls option in Machine, Palletizer, and Conveyor modules is where you

define controls for those elements. The Sensors option in Conveyor and Tank modules

is where you define sensors for those elements.

The Actions module is also available for performing actions on the system using

discrete entities and logic rather than controls or sensors.

17

Page 24

ARENA PACKAGING TEMPLATE USER’S GUIDE

• • • • •

Define

controls for

equipment in

the Controls

dialog box.

Place

sensors on

conveyors or

tanks in the

Sensors

dialog box.

18

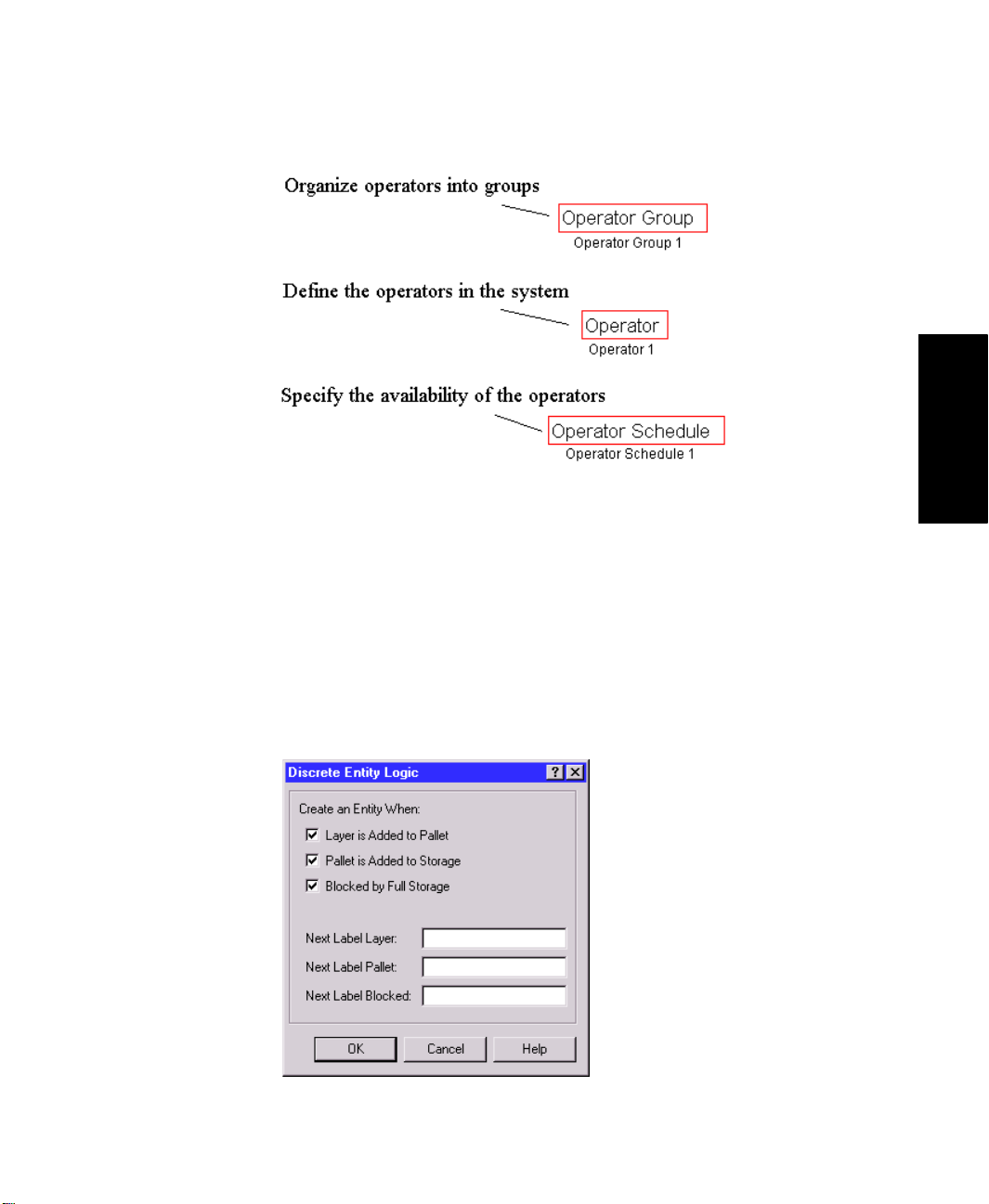

Labor

The availability and training of personnel connected to a high-speed line can be

critical to the line’s success. It can have a direct effect on issues such as utilization,

machine maintenance, and output.

Arena Packaging provides the Operator, Operator Group, and Operator Schedule

modules for modeling the availability and organization of labor in the system. You can

assign operators to failure repairs, scheduled stops, and/or changeover activities in the

equipment modules.

Page 25

2 • GENERAL CONCEPTS

Discrete entity creation and logic

The Arena Packaging template supports the modeling of discrete or “low-speed” logic

in your system. There are several options for creating entities at discrete times during

high-speed simulations, such as when a sensor or control is activated, or when a

palletizer completes a pallet.

• • • • •

2 • General Concepts

The Actions module can also be used to perform actions on the high-speed system (e.g.,

changing run speeds of machines, opening or closing valves, adding pallets to a storage,

etc.) using discrete entities and logic. Therefore, this module facilitates the integration

of discrete logic built with constructs from the general-purpose Arena template.

19

Page 26

ARENA PACKAGING TEMPLATE USER’S GUIDE

• • • • •

Refer to the HSMART examples for Step 5 for illustrations.

Step 5 • Experiment with Complex Strategies

Operators

HSMART32: Modeling Operators and Operator Groups

HSMART33: Modeling Operator Schedules

Control Logic

HSMART34: Adjusting Equipment Speeds Using Controls

HSMART35: Adjusting Equipment Speeds Using Conveyor Sensors

HSMART36: Adjusting Equipment Speeds Using the Actions Module

HSMART37: Writing Detailed Data to Files Using Controls

HSMART38: Writing Detailed Data to Files Using Sensors

HSMART39: Opening and Closing Valves Using Tank Sensors

Products and Changeovers

HSMART40: Using Products and Production Plans (Plan-based Equipment

Changeover)

HSMART41: Modeling Equipment Changeovers (Product-based Equipment

Changeover)

HSMART42: Defining Loss for Changeovers

HSMART43: Product Flow Controls Using the Switch Module

HSMART44: Adjusting Equipment Speeds Based on Product Type

HSMART45: Adjusting Container Volumes at a Filler Based on Product Type

20

Scheduled Stops

HSMART46: Modeling Scheduled Stops

HSMART47: Defining Loss for Scheduled Stops

Integrating with the Arena Template

HSMART48: Creating Discrete Entities

HSMART49: Referencing Arena Packaging Template Variables in Arena

Modules

HSMART50: Modeling the Delivery of Raw Material to an Arena Packaging

Template Line

HSMART51: Modeling Discrete Deliveries of Fluid to a Tank

Page 27

3

The Packaging Panel

Panel modules

This chapter contains a detailed description of each of the Packaging panel modules,

including prompt descriptions and remarks on module usage.

Actions module

D

ESCRIPTION

The Actions module is useful for modeling discrete entity logic that alters the status of the

system, but which is not directly dependent upon equipment sensors or controls. When an

entity enters this module, it performs the set of actions defined in the Actions repeat

group. The Actions module is similar to the Actions dialog box found in the Controls and

Sensors dialog boxes of Machines, Conveyors, and Palletizers. There is no time delay

associated with this module.

R

EMARKS

The Actions dialog boxes found in the Controls and Sensors dialog boxes of Machines,

Conveyors, and Palletizers allow you to alter system status when controls and/or sensors

are activated. The Actions module provides similar functionality as those Actions dialog

boxes in the equipment modules. It provides additional system control by allowing you to

initiate actions using discrete entities.

The Arena Packaging

Packaging modules. These special-purpose variables are automatically defined and

assigned values over the course of a simulation by the Arena Packaging engine. They

reference both dynamic and static information of a modeled system (e.g., equipment run

speeds, input and output rates, conveyor accumulation levels, throughput quantities,

storage and tank levels, etc.).

Use the Update HiSpeedSim Variables action to make sure that all packaging-related

variables reflect the current state before using them. This is especially useful if you will be

making decisions based on variable values, writing them, or using them in calculations.

Note that the action is named “Update HiSpeedSim Variables” rather than “Update

Packaging Variables” to maintain compatibility with models built in earlier versions of the

software.

template

provides a set of Packaging variables for several of the

3 • Packaging Panel

21

Page 28

ARENA PACKAGING TEMPLATE USER’S GUIDE

• • • • •

Conveyor module

D

ESCRIPTION

This module defines the accumulating conveyor elements that move product through the

system. Accumulating conveyors allow products to move on the conveyor even if products

at the end of the conveyor are stopped. They are typically used as buffers to level out line

fluctuations caused by machine stoppages, failures, differences in run speeds, etc. The

following figure shows some basic terminology and attributes for accumulating conveyors.

Upstream

Module

Accumulating Conveyor

Velocity (F eet or Meters/ Min

Input Rate

(Units/Min)

Traveling Units

Capacity (Units) = (Length) * (Width) * (Unit Density)

Nominal Run Speed (Units/Min) = (Velocity) * (Width) * (Unit Density)

Length (Feet or Meters)

Width (Feet or Meters)

Output Rate

(Units/Min)

Accumulated Units

of Specified Density

Downstream

Module

Products enter the conveyor from the upstream module and travel along the conveyor’s

length. If the Output Rate off of the conveyor is less than the Input Rate onto the

conveyor, then products accumulate in front of the downstream module.

You can also specify optional characteristics for conveyors such as sensors, controls, loss,

reliability, and scheduled stops.

R

EMARKS

Refer to the Sensors, Controls, Loss, Reliability, Scheduled Stops, Costs, and Animation

dialog boxes for more information on these options.

Accumulating conveyors are always initially active with a speed factor of 1 at the beginning of a simulation run.

22

A conveyor’s run parameters may be specified in either metric or English units of

measure, depending on what is selected for Units of Measure in the Simulate module. See

the “Simulate module” on page 36 for further information.

Conveyor modules may not be linked directly to other Conveyor modules. The Conveyor

Link module must be used to model adjoining conveyors.

Page 29

3 • THE PACKAGING PANEL

To model non-accumulating conveyors, use a Machine module of type Conveyor Machine.

The Split and Merge modules may be used to model splitting product flow across multiple

conveyors or merging the product flow of multiple conveyors onto a single conveyor.

The Switch module may be used to direct flow off a single inbound conveyor onto one of

two possible outbound conveyors (i.e., flow goes “left” or “right”).

Conveyor Link (CLink) module

D

ESCRIPTION

The Conveyor Link module is used to connect two Conveyor modules directly.

R

EMARKS

You may open or close a conveyor link using the Actions dialog box to permit or prohibit

material from passing between conveyors.

• • • • •

Label module

D

ESCRIPTION

The Label module may be used to identify a particular portion of the model logic,

whereby discrete entities may be sent easily to the label from other locations in the model.

The name of a label module can be referenced in a “Send to Label” field (e.g., in a Sensor

dialog box) to send discrete entities to this module. Upon arriving to the Label module,

each entity will immediately proceed to the next module that is graphically connected to

the Label module’s exit point.

Machine module

D

ESCRIPTION

The Machine module defines the processing elements of the system. Four general types of

machines are available for modeling purposes. These types are Basic Machines, Assembly

Machines, Filling Machines, and Conveyor Machines (standard or single-file). Each is

detailed below.

3 • Packaging Panel

23

Page 30

ARENA PACKAGING TEMPLATE USER’S GUIDE

• • • • •

Basic Machines for standard processing. Examples include labeling, inspecting, and

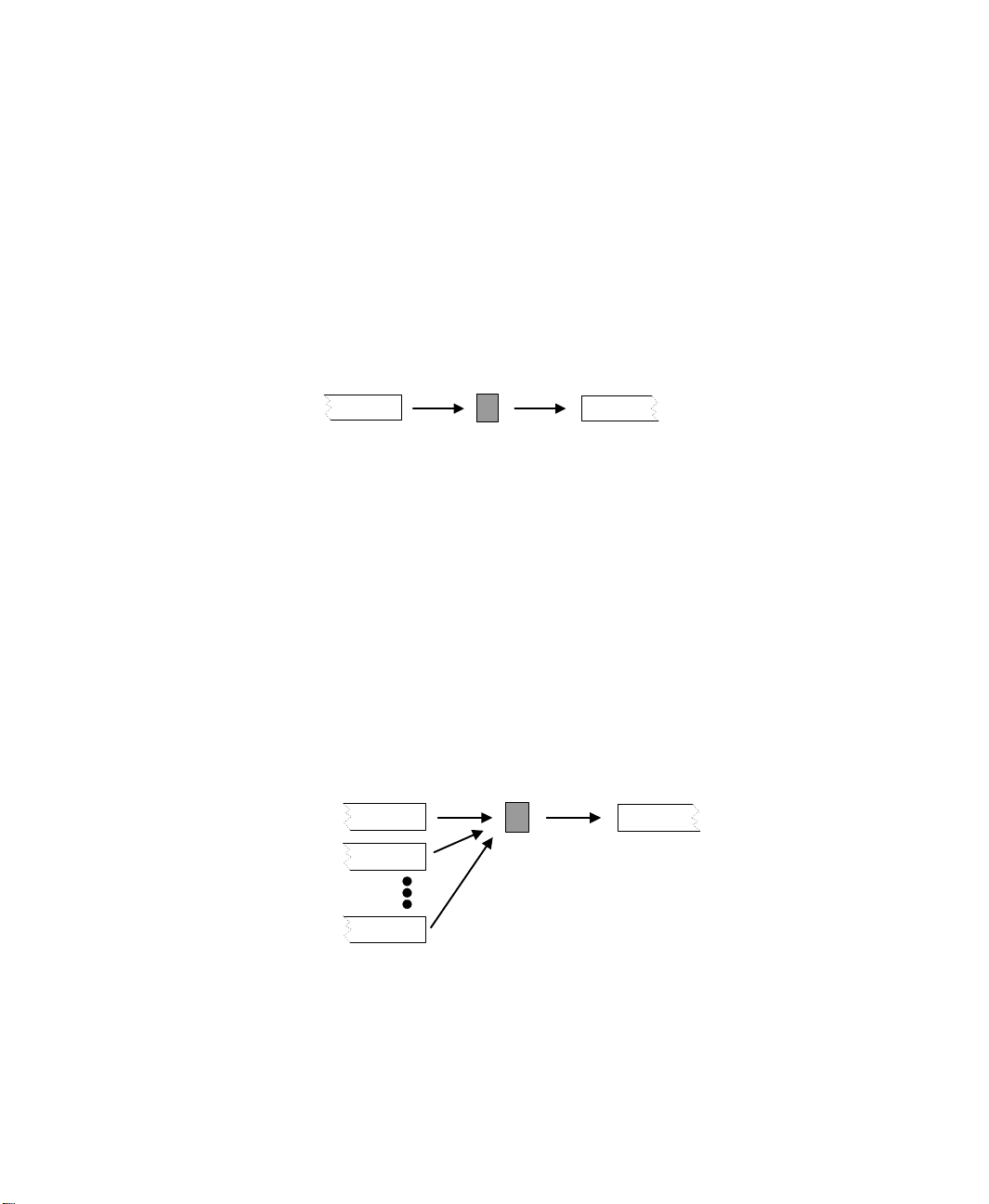

packaging operations that do not involve multiple inbound lines. The nominal run

speed of the machine is defined in terms of cycles/min and units/cycle. Basic

machines do not have capacity; the process is instantaneous and capacity is 0.

Inbound Line Outbound Line

Assembly Machines for merging input from two or more inbound lines (non-fluid).

Examples include capping and packaging operations. The nominal run speed of the

machine is defined in terms of cycles/min and assemblies/cycle. In addition to the run

speed of the assembly operation, output rates from the inbound lines are dependent on

the units/assembly required from each line.

A single inbound line can also be defined for an assembly machine to model a batching operation (e.g., shrink-wrapping inbound units). Assembly machines do not have

capacity; the process is instantaneous and capacity is 0.

Basic Machine

Nominal Run Speed

Cycles/Minute

Units/Cycle

24

Assembly Machine

Nominal Run Speed

Cycles/Minute

Inbound Line Outbound Line

Units/Assembly

Assemblies/Cycle

Page 31

3 • THE PACKAGING PANEL

Filling Machines for specifically merging an inbound fluid line (i.e., a tank module)

with an inbound container line. The nominal run speed of the machine is defined in

terms of cycles/minute and containers/cycle. To model product movement during the

filling operation, a Machine Capacity may be specified. The volumes of the containers

can be constant (Fixed) or vary by product type (Variable).

Filling Machine

Nominal Run Speed

Inbound Line

Fluid

Containers

Cycles/Minute

Containers/Cycle

Outbound Line

Capacity

Fixed or Variable

Container Volumes

• • • • •

3 • Packaging Panel

Conveyor Machines are useful for modeling processes that involve significant

product movement on a non-accumulating conveyor. Examples include washing and

drying operations. You may specify the run parameters of the conveyor in two ways. If

the units on the conveyor always travel in single file, then you may specify the

machine Type as “Conveyor Machine (Single File)” and directly specify the nominal

run speed of the machine and its capacity (i.e., max length of the single file). Or,

specify the machine Type as simply “Conveyor Machine” and enter the nominal

velocity, length, width, and unit density parameters for the conveyor.

25

Page 32

ARENA PACKAGING TEMPLATE USER’S GUIDE

• • • • •

See the diagrams below for further illustration of the Conveyor Machine run

parameters.

Conveyor Machine

(Non-Accumulating Conveyor)

Nominal Velocity (Units/Min)

Inbound Line

Traveling Units at

Inbound Line

Unit Density

Units/Minute

Length (Feet or Meters)

or (Single File)

Nominal Velocity (Units/Min)

Units/Minute

Capacity (max # units on

the conveyor in single file

Outbound Line

Width (Feet or

Meters

Outbound Line

For all the machine types in this module, optional characteristics such as loss, scheduled

stops, changeovers, reliability, and controls may be defined.

R

EMARKS

All of the machine types have the same dialog boxes for Run Options, Controls, Loss,

Production and Changeovers, Reliability, Scheduled Stops, Costs, and Animation. Refer

to these dialog boxes for more information.

The nominal run speed is usually thought of as the maximum speed at which the machine

can maintain a consistent production of quality units.

26

The module connected to the input line(s) of a Basic, Assembly, or Conveyor Machine

must be a Conveyor or Machine Link module. See the “Filling Machines” notes below

regarding connecting modules to the inputs of a Filling Machine.

The module connected to the output line of any Machine module must be a Conveyor or

Machine Link module.

Page 33

3 • THE PACKAGING PANEL

Machine modules may not be directly linked to other machine modules. Use a Machine

Link module to connect two machines directly together (i.e., there is a negligible accumulator between the machines).

• • • • •

Assembly Machines.

A maximum of 10 entry lines may be specified for the Assembly

Machine type. Note that the first entry line always defines the outbound product name.

For example, if units from the first entry line have the product name “bottles,” and units

from the second entry line have the product name “caps,” the product name for the

assembled units is “bottles.”

Filling Machines.

For Filling Machines, the container input line always defines the

outbound product name.

The module connected to the fluid input line of a Filling Machine must be a Tank module

from either the Packaging or Flow Process panel. The Flow Process Tank module is

recommended when modeling advanced tank-related logic such as semi-continuous batch

processes feeding a high-speed packaging line.

The module connected to the container input line of a Filling Machine must be a

Conveyor or Machine Link module.

If using a filling machine, note that all volumetric data in the model, such as tank capacities, valve maximum rates, and container volumes, must be specified in the same units of

measure (e.g., gallons, liters, fluid ounces, etc.).

Conveyor Machines.

A Conveyor Machine is a non-accumulating conveyor. You may

specify the run parameters of the conveyor in two ways. If the units on the conveyor

always travel in single file, then you may specify the machine Type as “Conveyor

Machine (Single File)” and directly specify the nominal run speed of the machine and its

capacity. Or, specify the machine Type as simply “Conveyor Machine” and enter the

velocity, length, width, and unit density parameters for the conveyor.

3 • Packaging Panel

Machine Link (MLink) module

D

ESCRIPTION

The Machine Link (ML) module may be used to connect two Machine modules directly.

Use this module if there is no buffer between the machines. If accumulation can occur

between the machines, then use the Conveyor module to model the accumulator.

A Machine Link module may only be connected to Machine modules. If your logic requires

that two non-Machine modules be connected without a buffer in between, then use a

Conveyor module. Define the Nominal Velocity to a high rate (e.g., 100,000 feet/min) and

the Length, Width, and Unit Density so the conveyor capacity is 1 unit. This approach

models a negligible buffer.

27

Page 34

ARENA PACKAGING TEMPLATE USER’S GUIDE

• • • • •

Merge module

D

ESCRIPTION

The Merge module merges two or more incoming streams from accumulating conveyors

into a single outgoing stream. A product name may be assigned to the outgoing stream.

R

EMARKS

Only Conveyor modules can be connected to a Merge module. There is no limit on the

number of incoming conveyors that may be connected to the input of the merge.

If the downstream conveyor cannot accept all of the flow from the upstream conveyors,

each will be adjusted proportionally. Proportions are recalculated any time any flow rate

of any of the conveyors change.

For example, if three conveyors (A, B, and C) each capable of producing 100 units/minute

were merged onto a single conveyor with a flow rate of 150 units/minute, then A, B, and C

would each have a flow rate of (100 * (150/(100+100+100)) = 50 units/minute. If at a later

time, the flow of conveyor A were to stop (perhaps it is starved), then B and C will each be

adjusted to a flow rate of (100 * (150/(100+100)) = 75 units/minute.

Operator module

28

D

ESCRIPTION

The Operator module defines an operator that may be allocated to activities in the system.

Activities include device changeovers (specified in Production and Changeovers dialogs),

device repairs (specified in Reliability dialogs), and scheduled stops of devices (specified

in Scheduled Stops dialogs).

R

EMARKS

If a schedule name is specified for an operator, that schedule should be defined using the

Operator Schedule module.

The Operators module may be used in conjunction with the Operator Group module to

define a set of operators that may be referenced with a common name. For example, the

operators Bill, Mary, and Joe may be grouped into a set of operators named Mechanics.

There are three automatic operator states for operators: On-Duty Idle, Working (or UserDefined), and Off-Duty. An operator is in the state On-Duty Idle whenever the operator is

not busy, but it is on-shift. Upon being allocated to an activity, an operator is automatically assigned the state Wo rk in g. The Wo rk in g state may be replaced with a user-defined

state for any activity through a Machine, Conveyor, or Palletizer Operator dialog box (for

the specific activity).

Page 35

3 • THE PACKAGING PANEL

The state Off-Duty is automatically assigned to an operator when the operator follows an

Operator Schedule and that schedule has the operator unavailable. This includes any

Break and Lunch periods specified by the schedule.

If cost statistics are used, operators accrue cost whenever they are available, busy, or in a

lunch or break.

If an operator follows an Operator Schedule and is scheduled for either Off-Duty, Lunch,

or Break at a specific time, the task will be suspended immediately. The task will wait

until the specific operator (or another operator from the group if a group was specified)

becomes available. At that point, the task will resume with the remaining time adjusted by

the appropriate labor skill factors.

Statistics may be obtained and displayed for operator states by checking the Statistics

toggle. Refer to the Statistic dialog box for more information.

The following table summarizes how the states relate to each other, when they are entered,

and the costing considerations.

• • • • •

Operator State When Assigned Cost Applied?

Working or User-Defined Upon allocation to any activity Yes

On-Duty Idle When the operator is scheduled, but not

busy

Off-Duty (including Lunch

and Break)

When operator is unavailable due to the

Operator Schedule

Ye s

Yes–Lunch and Break

No–Otherwise

Activities that may require operators include changeovers (specified in Production and

Changeovers dialog boxes), failure repairs (specified in Reliability dialog boxes), and

scheduled stops (specified in Scheduled Stops dialog boxes). Refer to these dialog boxes

and the Operators dialog box for information on specifying operator requirements.

Operator Group module

D

ESCRIPTION

The Operator Group module may be used in conjunction with the Operator module to

define a group of operators that may be referenced with a common name. For example,

the operators Bill, Tom, and Joe may be grouped into a set of operators named Mechanics.

Statistics for the operator group may be collected and reported by checking the Statistics

option.

3 • Packaging Panel

29

Page 36

ARENA PACKAGING TEMPLATE USER’S GUIDE

• • • • •

R

EMARKS

If an operator is selected for an activity from an operator set, the skill factor of that operator as defined in the Operator Group module will be used for that operator for that activity.

A common use of Operator Groups is to form a group of people who can perform certain

tasks. For example, you might have an Electricians group and a Mechanics group. Some

tasks might require just an Electrician, some tasks might require just a Mechanic, and

some tasks might require multiple Electricians and Mechanics.

Another common use is to create groups of primary and alternate people. For example,

you might form a group called Repairmen that consists of Journeyman, Apprentice, and

Supervisor (in that order). Then when you specify that an activity needs someone from the

Repairmen group, you can specify Preferred Order for the selection rule. This will select

Journeyman (if available); otherwise, Apprentice (if available); otherwise, Supervisor. If

none are available, it will wait for the first of the three that becomes available.

Operator Schedule module

D

ESCRIPTION

The Operator Schedule module defines schedules to which operators (individual or

groups) can be assigned. The schedule is based on the planning horizon structure, with an

operator availability state associated with each timeslot. A timeslot is the smallest time

period that can be scheduled (e.g., 15 min., 30 min., or 1 hour).

30

The defined availability states include On-Duty, Lunch, and Break. If a shift does not

define one of these states for any period of time, the operator is presumed to be Off-Duty.

R

EMARKS

By default, all timeslots are initialized to an Off-Duty availability state. Therefore,

operator shifts need only be defined for those time intervals that are not Off-Duty.

The starting and ending times for shifts must coincide with the starting and ending times

of timeslots within the planning horizon.

Overlapping operator shift intervals are not allowed. For example, a shift from 8:00

PM and a shift from 2:00 PM to 5:00 PM on the same day is invalid.

3:00

AM to

Shifts are defined for each calendar day. Therefore, a shift that spans two days must be

defined in two separate segments (e.g., Monday: 8:00

AM).

6:00

PM – midnight; Tuesday: midnight –

An entry must be made in the Daily Schedule for each day of the week, although no shifts

need to be defined for any day. For example, if everyone is Off-Duty on the weekends, no

Page 37

3 • THE PACKAGING PANEL

shifts need to be defined for Saturday and Sunday, although Saturday and Sunday must

appear in the Daily Schedule list.

The beginning of the simulation (time 0.0) is midnight before the first day. If days are

specified, the first day simulated will be Monday.

If costing is being applied to operators, costs are assigned only to Working (UserDefined), Lunch, On-Duty Idle, and Break times.

Palletizer module

D

ESCRIPTION

Palletizers model the physical ends of a line where units are stored onto or removed from

pallets. Each module defines either a palletizing or depalletizing piece of equipment.

Palletizers are one of the possible interfaces to the discrete world. A palletizer turns

individual units from a high-speed process into discrete pallets. A depalletizer turns

discrete pallets into units for high-speed processing.

A depalletizer is located at the front of a high-speed line. It removes pallets from storage

and then sweeps units off the pallets onto the downstream conveyor. A palletizer is

located at the end of a high-speed line. It sweeps units off the upstream conveyor onto

pallets, and then places the pallets into storage.

• • • • •

3 • Packaging Panel

It is important to note that Machine modules may also be used to model basic sources or

sinks of a processing line. Machine modules are more efficient than Palletizer modules

with regard to model execution speed. Therefore, if an end element can be modeled as a

simple “rate-in” or “rate-out” process with reliability, scheduled stop, or changeover

constraints, the Machine module is recommended.

Palletizer modules are most useful when:

Discrete batching of units onto or off of the line is a key issue in your problem solving.

The Palletizer module easily allows you to discretize high-speed, high-volume flow

into layers and pallets. Discrete entities representing these layers or pallets can be

received from or sent to “low-speed” portions of your modeled system.

You have supply or storage constraints in your model. In conjunction with the Storage

module, the Palletizer module allows you to model the starvation of depalletizing

equipment at the front of a high-speed line due to inadequate supplies of raw material.

Similarly, you can model the blockages of palletizing equipment at the end of a highspeed line due to inadequate storage space for finished product.

31

Page 38

ARENA PACKAGING TEMPLATE USER’S GUIDE

• • • • •

R

EMARKS

Palletizers and depalletizers are always connected to Conveyor modules.

If the Palletizer Type is Palletizer, then units accumulate in front of the Palletizer and are

removed at a maximum rate of approximately (Units/Layer)*(Nom. Run Speed) units/min

(assuming speed factor of 1) off the conveyor and stored in the storage area (a pallet at a

time) until the maximum capacity of the storage area is reached.

Run parameters include the number of units per layer and the number of layers per pallet.

The Time Between Layers is the setup time before the next layer can be filled, and the

Time Between Pallets is the setup time before the first layer of a pallet can be filled. The

palletizer cannot remove units from the upstream conveyor during these delays. Note that

filling, time between layers, and time between pallet operations are halted if the speed

factor of the palletizer is set to zero (e.g., due to a failure, scheduled stop, or changeover).

There is no module exit label if the Palletizer Type is Palletizer unless one or more

discrete entity options are enabled.

A Palletizer may be initially active or inactive, depending on what is specified in the Run

Options dialog box.

Storage capacity is assumed to be infinite unless a Storage module specifies a limit.

If the Palletizer Type is Depalletizer, then units are introduced from the Palletizer into the

accumulation conveyor (or Machine Link) at the rate of approximately (Units/Layer) *

(Nom. Run Speed) units/min (assuming speed factor of 1), unless the Palletizer is shut

down or there is no inventory in the storage area. The run parameters of the Depalletizer

are similar to the Palletizer, with the difference being that units are getting introduced

back into the system from storage rather than being removed.

32

There is no module entry label if the Palletizer Type is Depalletizer.

A Depalletizer initially may be active or inactive, depending on what is specified in the

Run Options dialog box.

The inventory in Storage Name may also be incremented or decremented (by pallets)

independent of the palletizer’s operation via the Actions dialog box or Actions module.

Refer to the Actions dialog box description for more information.

Refer to the Controls, Loss, Reliability, Run Options, and Scheduled Stops dialog boxes

for more information on these options.

Both types of palletizers interface between discrete operations and non-discrete, highspeed unit flow. Because each discrete operation causes system updates, use of a palletizer

with many discrete operations can slow the execution speed of the entire model. Often the

internal workings of a palletizer are not important to the system being modeled. If this is

the case, model execution speed can be improved dramatically by reducing the discrete

Page 39

3 • THE PACKAGING PANEL

interactions to the minimum level. One way of doing this is to assume (for modeling

purposes) that there is only one layer per pallet. Then set Units/Layer to the total number

of units on a pallet, Time Between Layers to 0.0, and Layers/Pallet to 1.0. Of course, if the

internal workings of the palletizer are important, then you should use all the available

options to model it accurately.

P

ALLETIZER LOGIC

The following diagram and discussion illustrate the detailed internal workings of a

palletizer.

Palletizer Logic

Fi ll Layer at

Run S peed (Layers/M in)

Conveyor

Pallet Storage

Layers/

Pallet

Capaci ty

• • • • •

Yes

Storag e Not Ful l

Time Betw.

Pallets

Add Pallet;

Create En tity

Time Betw.

Pallets

Fil l

Layer

Add Layer;

Create En tity

Time Betw.

Layers

Time Betw.

Layers

Pallet

Ful l?

No

Yes No

Storage

Full?

Create En tity

Blocked

First, the palletizer takes units off the upstream conveyor at its run speed and fills a layer.

The run speed of the palletizer is calculated as follows:

Run Speed (layers/min) = Nom. Run Speed (layers/min) * Sf

or

Run Speed (units/min) = Nom. Run Speed (layers/min) * Sf * Units/Layer.

S

is the speed factor of the palletizer. The speed factor can be dynamically assigned

f

values using the Change Speed Factor of Palletizer action. Nom. Run Speed and

Units/Layer are defined in the Run Parameters section of the Palletizer main dialog box.

3 • Packaging Panel

33

Page 40

ARENA PACKAGING TEMPLATE USER’S GUIDE

• • • • •

As an example, suppose a palletizer has a Nom. Run Speed of 3 layers per minute and the

Units/Layer is 150. Assume the speed factor of the palletizer is 1. When filling a layer, the

palletizer takes units off the conveyor at a rate of 450 units per minute (i.e., 3 layers/min *

150 units/layer). Therefore, if enough units are available on the conveyor, it takes 20

seconds to fill a layer.

After a layer is filled, the palletizer can delay for a specified amount of time (i.e., the Time

Between Layers). Normally, this period represents the time required to sweep the layer of

units onto the pallet. It can also represent any other type of time required before the next

layer is filled.

The Time Between Layers is defined in the Run Parameters section of the Palletizer main

dialog box. It can be a constant or sampled from a random distribution. Note that the input

rate of the palletizer is zero during the Time Between Layers. A palletizer only accepts

units from the upstream conveyor when it is filling a layer.

After Time Between Layers, the palletizer checks whether the pallet is full. The Layers/

Pallet parameter defines the pallet size. If the number of layers on the pallet is fewer than

Layers/Pallet, then the palletizer starts filling another layer. If the number of layers on the

pallet is equal to Layers/Pallet (i.e., the pallet is full), then the palletizer tries to place the

completed pallet into storage.

The Storage Name operand in General Information specifies the location where pallets are

stored. This operand may or may not reference the name of a Storage module. If Storage

Name does not reference a Storage module, the palletizer assumes an infinite pallet

capacity for the storage. In this case, the pallet is automatically added to the storage. The

palletizer can also create a discrete entity when a pallet is added.

34

If Storage Name does reference a Storage module, then the palletizer must check whether

the storage is full before adding the pallet. Storage modules have a pallet capacity. If the

storage is full, then the palletizer cannot add the pallet and it is blocked. It remains

blocked until space is available in the storage. Note that in Discrete Entity Logic you can

create a discrete entity when a palletizer is blocked.

After a pallet is stored, the palletizer can delay for a specified amount of time (i.e., the

Time Between Pallets). Normally, this period represents the time required to store the pallet

and then setup the next one. It can also represent any other type of time required before the

first layer of the next pallet is filled.

The Time Between Pallets is defined in the Run Parameters section of the Palletizer main

dialog box. It can be a constant or sampled from a random distribution. Note that the input

rate of the palletizer is still zero during the Time Between Pallets. A palletizer only

accepts units from the upstream conveyor when it is filling a layer.

Page 41

3 • THE PACKAGING PANEL

D

EPALLETIZER LOGIC

The figure below illustrates the basic operating behavior and characteristics of a

depalletizer:

Depalletizer Logic

• • • • •

Capacity

Storage

Empty?

Yes

Create Entity

Starved

Storage

Time B etw.

Pallets

No

Remove Pallet;

Create Entity

Storag e Not Empty

Layers/

Pallet

Ti m e B etw.

Pallets

Pallet

Time Betw.

Layers

Empty

Layer

Empty Layer at

Run S peed (Layers/M in)

Remove Layer;

Create Entity

Conveyor

Ti m e B etw.

Layers

Pallet

Empty?

No

Yes

The operation is parallel to the operation discussed previously for palletizers.

Product module

D

ESCRIPTION

The Product module defines the name of a product being produced in the system. Product

names may be referenced for changeovers, switches, production plans, and may be assigned

to product names in a model. Example names include “candy bars,” “demo boxes,”