Rockwell Automation Allen-Bradley MicroLogix 1100, Allen-Bradley GuardShield Micro 400, Allen-Bradley MSR42 Quick Start Manual

Page 1

Bidirectional (4-sensor, T-type) Muting

With MSR42 Relay

Connected Components Building Block

Catalog Numbers MSR42, MicroLogix 1100, GuardShield Micro 400

Light Curtains

Quick Start

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment. Safety Guidelines

for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

Automation sales office or online at http://www.rockwellautomation.com/literature/

between solid state equipment and hard-wired electromechanical devices. Because of this difference, and also because of the

wide variety of uses for solid state equipment, all persons responsible for applying this equipment must satisfy themselves that

each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING

Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

available from your local Rockwell

) describes some important differences

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Allen-Bradley, Rockwell Automation, TechConnect, MicroLogix, PanelView, Rockwell Software, and GuardShield are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Identifies information that is critical for successful application and understanding of the product.

Identifies information about practices or circumstances that can lead to personal injury or death, property damage,

or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may

be present.

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach

dangerous temperatures.

Page 3

Connected Components Building Block Outline

Follow the path below to complete your connected components building block.

Connected Components

Building Blocks, publication

CC-QS001

Where to Start

Chapter 1 Product

Integration

Chapter 2 System

Validation and Application

Tips

ESC OK

3Publication CC-QS015A-EN-P - November 2009 3

Page 4

Where to Start

4 Publication CC-QS015A-EN-P - November 2009

Page 5

Product Integration

System Validation and Application

Tips

Table of Contents

Preface

About This Publication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Additional Resources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Understand the Safety Function . . . . . . . . . . . . . . . . . . . . . . 10

Set Up the Configuration and Diagnostic Software . . . . . . . . 12

Configure the MSR42 Safety Relay . . . . . . . . . . . . . . . . . . . . 13

Download the Configuration . . . . . . . . . . . . . . . . . . . . . . . . 19

Confirm the Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Chapter 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Validate Proper Operation of the Safety Systems. . . . . . . . . . 26

Validate Proper Operation of the PanelView Screens . . . . . . 31

5Publication CC-QS015A-EN-P - November 2009 5

Page 6

Table of Contents

6 Publication CC-QS015A-EN-P - November 2009

Page 7

Preface

About This Publication

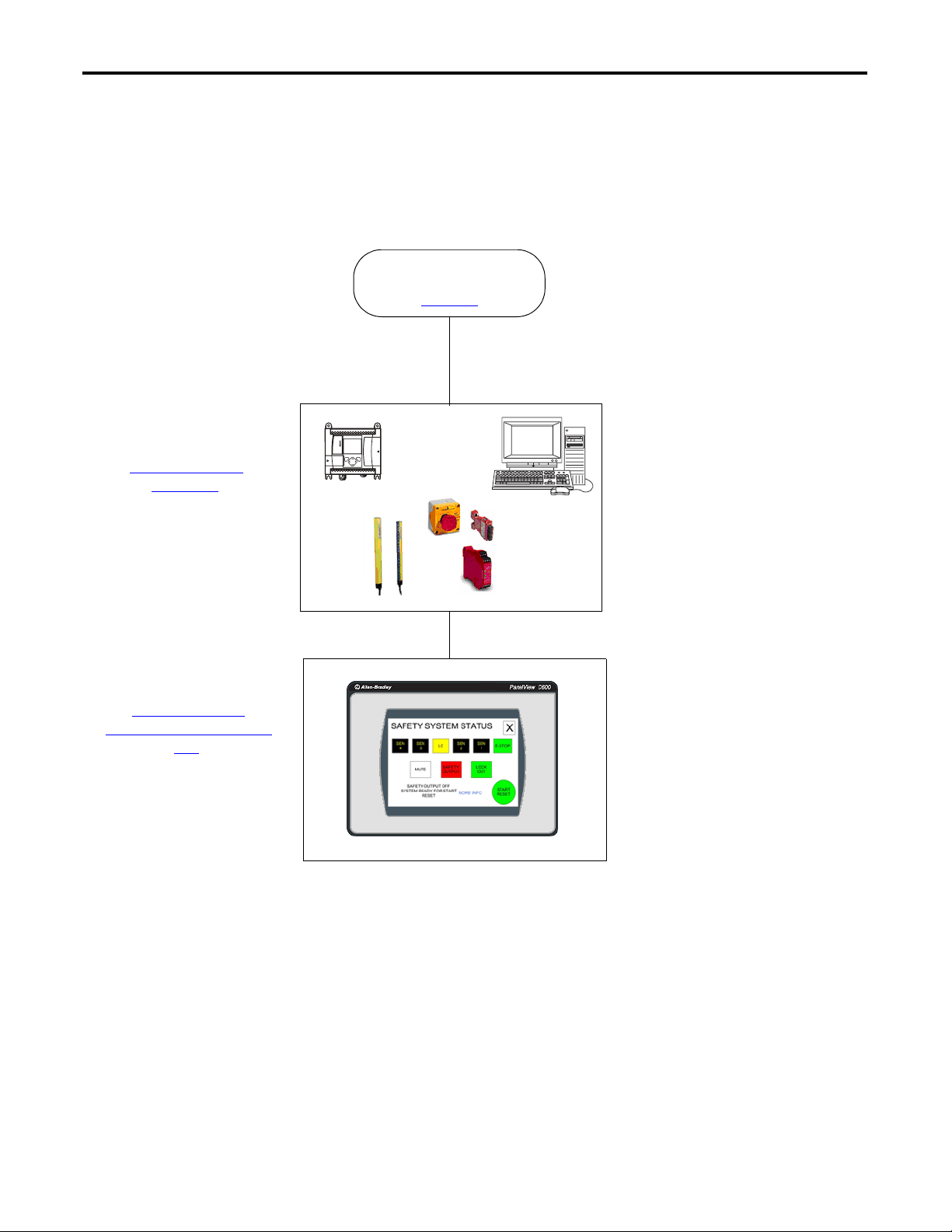

This quick start illustrates one way of combining a set of Micro 400 Light Curtains, an MSR42

safety relay, an MSR45E expansion module, an MSR127 safety relay, an E-stop, and two

contactors into an integrated safety system providing both a bidirectional, four-sensor, T-type

muting function and an E-stop function.

A MicroLogix 1100 controller and a PanelView HMI are included to provide a convenient and

graphical way to monitor the operation of the safety systems and provide basic diagnostic

information and corrective action suggestions when appropriate. The MicroLogix controller and

PanelView terminal only monitor the safety systems. They are not safety components and they

have no safety control or function. The safety systems operate independently from the

MicroLogix controller and PanelView terminal.

IMPORTANT

To assist in the design and installation of your system, application files and other information are

provided on the Connected Components Building Blocks Overview CD, publication CC-QR001.

The CD provides bills of materials (BOM), CAD drawings for panel layout and wiring, control

programs, Human Machine Interface (HMI) screens, and more. With these tools and the built-in

best-practices design, the system designer is free to focus on the design of their machine control

and not on design overhead tasks.

Read these sections carefully before beginning work in each chapter. The beginning of each

chapter contains the following information:

• Before You Begin - This section lists the steps that must be completed and decisions that

must be made before starting that chapter.

• What You Need - This section lists the tools that are required to complete the steps in the

current chapter. This includes, but is not limited to, hardware and software.

• Follow These Steps - This illustrates the steps in the current chapter and identifies which

steps are required to complete the examples.

Use this Simple Machine Safety Connected Components Building Block Quick Start in conjunction

with the Connected Components Building Blocks Quick Start, publication CC-QS001.

Refer to Additional Resources on page 8 for a listing of quick starts.

7Publication CC-QS015A-EN-P - November 2009 7

Page 8

Preface

Conventions

Convention Meaning Example

Check or uncheck To activate or deactivate a checkbox. Check Disable Keying.

Click

Double-click

Expand Click the + to the left of a given item /folder to show its contents. Expand 1768 Bus under I/O Configuration.

Right-click

Select Using the mouse to highlight a specific option. Select the New Module folder.

Press Pressing a specific key on the keyboard or button on a touchscreen. Press Enter.

> Use this symbol to indicate the sub-menu name. Choose File

‘Project’ Refers to the application on both the controller side and the PanelView component side.

Click the left mouse button once while the cursor is positioned on

object or selection to initiate an action.

Click the left mouse button twice in quick succession while the cursor

is positioned on object or selection to initiate an action.

Click the right mouse button once while the cursor is positioned on

object or selection.

Click Browse.

Double-click the application icon.

Right-click the 1768 Bus icon.

>Menu>Options.

Additional Resources

Resource Description

Connected Components Building Blocks Quick Start,

publication CC-QS001

Connected Components Building Blocks Overview CD,

publication CC-QR001

Position Control Connected Components Building

Block Quick Start, publication CC-QS003

MicroLogix 1100 Controller User Manual, publication

176

3-UM001

MSR42 Safety Base Module Operating Manual,

publication 440R-IN017

MSR45E Safety Expander Module, Operation Manual,

publication 440R-IN018

GuardShield Micro 400 Safety Light Curtain Operation

Manual, publication 445L-IN001

Configuration Tool for MSR42, GuardShield Micro 400

and Safe 2/4 Light Curtains Software Description

http://www.ab.com

http://www.rockwellautomation.com/knowledgebase

http://www.rockwellautomation.com/components/

connected/blocks.html

Provides information on how to select products and gain access to panel and

wiring information

Provides files for the Connected Components Building Blocks

Provides information installing and setting up the PowerFlex 40P drive

parameters with the pre-configured RSLogix 500 program that controls you base

system including application tips, as well as implementing the drive parameter

backup and restore functionality

Provides information on using the MicroLogix 1100 Programmable Controller

Provides information wiring and operating the MSR42 safety controller

Provides information on using the MSR45E expander module

Provides information on mounting, wiring, and using safety light curtains

Provides information on configuring and programming an MSR42 safety controller

with Configuration Tool software

Provides access to the Allen-Bradley website

Provides access to self-service support

Provides access to the Connected Components website

8 Publication CC-QS015A-EN-P - November 2009

Page 9

Chapter

1

Product Integration

Introduction

A bidirectional, four-sensor, T-type muting system lets valid loads or objects pass through its light

curtains in either direction without shutting down the machine or process, but will stop the

machine or process if anything or anyone attempts to move past the light curtain in any other

manner. This type of system is often used to guard the access point at a hazardous portion of a

machine or process where material must pass either into or out of the guarded area, such as an

automatic palletizing system or automatic assembly machine. This Connected Components

Building Block is intended to ease the installation, configuration, and implementation of such a

system.

Before You Begin

Review the Connected Components Building Blocks Quick Start, publication CC-QS001, verifying

that you have completed the hardware design and installation as well as software installation.

IMPORTANT

A safety risk assessment must be completed to make sure that all tasks and hazards are

considered and to confirm that the example circuit provides adequate risk reduction for your

specific application.

What You Need

• Personal computer

• Connected Components Building Blocks Overview CD, publication CC-QR001

• MicroLogix 1100 controller, catalog number 1763-L16BBB

• PanelView Component C600 terminal, catalog number 2711C-T6C

• Stratix 2000 Ethernet switch, catalog number 1783-US05T (or equivalent) to connect the

MicroLogix controller to the PanelView terminal

• Ethernet cables, catalog number 1585J-M8TBJM-2 or equivalent

• MSR127 safety relay, catalog number 440R-N231132

• MSR42 safety relay, catalog number 440R-P226AGS-NNR

• MSR45E expander module, catalog number 440R-P4NANS

• Optical Interface Tool, catalog number 445L-AF6150, which includes the Optical Interface

Tool-MSR42 Configuration and Diagnostic Software

9Publication CC-QS015A-EN-P - November 2009 9

Page 10

Chapter 1 Product Integration

• Optical Interface Tool Fastener, to attach the Optical Interface securely to the MSR42 relay

• 24V DC power supply, catalog number 1606-XL120D

• Safety components such as E-stops, GuardShield Micro 400 light curtains, as listed in the bill

of material on the Connected Components Building Blocks Overview CD, publication

CC-QR001

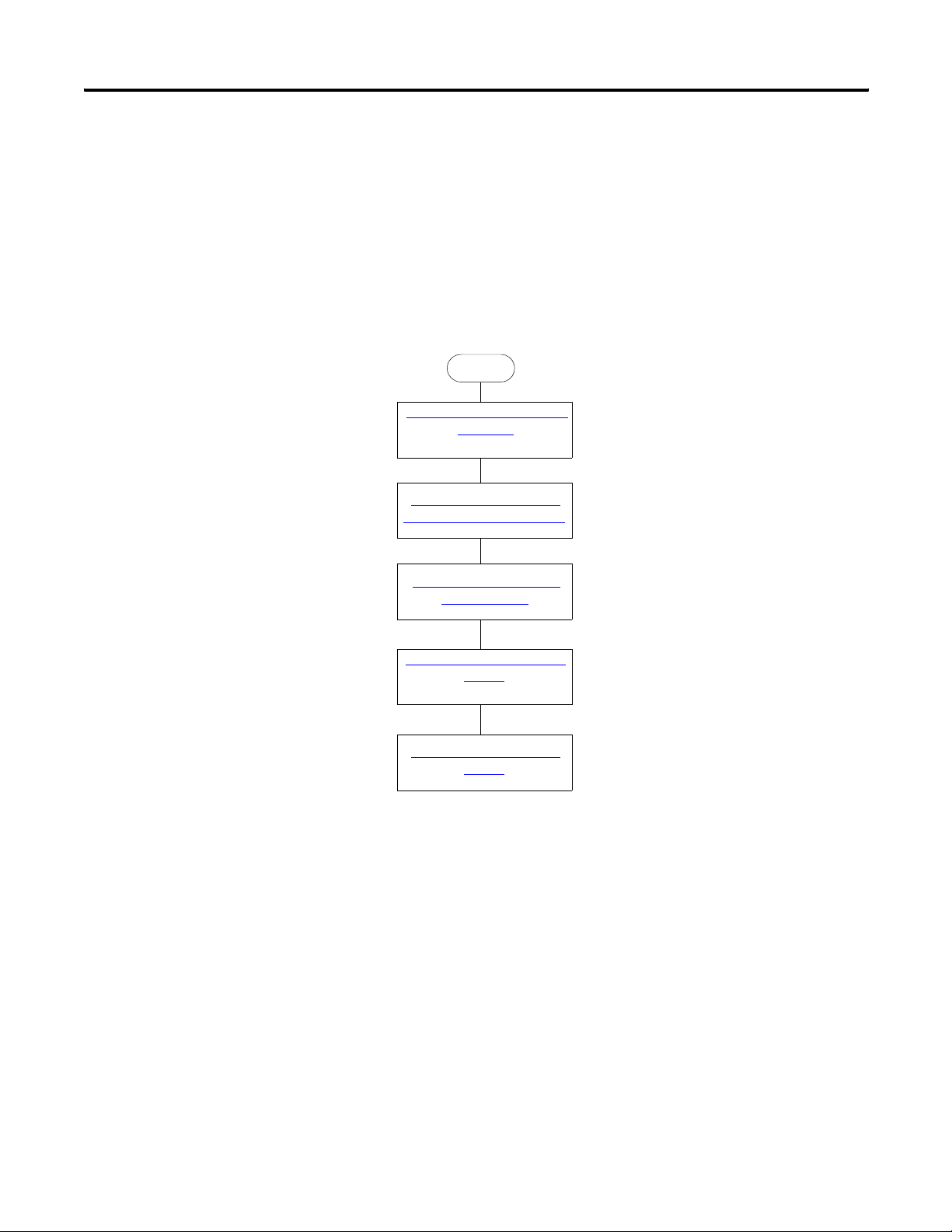

Follow These Steps

Start

Understand the Safety Function

on page 10

Set Up the Configuration and

Diagnostic Software on page 12

Configure the MSR42 Safety

Relay on page 13

Download the Configuration on

page 19

Confirm the Configuration on

page 22

Understand the Safety Function

Two separate safety functions are provided.

1. The GuardShield Micro 400 light curtains and MSR42 safety relay provide a bidirectional,

four-sensor, T-type muting function.

2. The E-stop and MSR127 safety relay provide an E-stop function.

These two safety functions are independent of one another. When set up properly, either safety

system is capable of stopping dangerous motion.

10 Publication CC-QS015A-EN-P - November 2009

Page 11

Product Integration Chapter 1

The MicroLogix 1100 controller monitors the safety systems and, via the PanelView terminal,

provides a simple, graphical representation of the operation and status of the safety systems and

recommends corrective actions in response to system faults. The controller and the terminal

perform no safety or control functions.

If the PanelView terminal is mounted so that it provides the operator a clear and complete view

of the hazard area, and local safety regulations permit, the PanelView START RESET button may

be used to start or reset the safety systems, just like the Start – Reset push button.

IMPORTANT

If the operator stationed at the PanelView terminal’s location cannot see the guarded area well

enough to be certain that no one is in the guarded area, you must not use the START RESET

button.

The START RESET button can be disabled by removing three wires from the MicroLogix controller

I/O.

• Wire 6041

• Wire 10231

• Wire 10071

Safety Systems Diagram

800F

Start

Reset

MicroLogix 1100

Stratix

2000

PanelView

Component

Term in al

Personal

Computer

MSR45E

Expansion

Controller

MSR127

Safety

Relay

100S-C

100S-C

M

RightSight

Sensors

RightSight

Sensors

GuardShield Micro 400

Light Curtains

MSR42

Multi-

function

Safety

Relay

800FP

STOP

Publication CC-QS015A-EN-P - November 2009 11

Page 12

Chapter 1 Product Integration

Set Up the Configuration and Diagnostic Software

Follow these steps to install and set up the Configuration and Diagnostic software.

1. If you do not have the Configuration and Diagnostic software, go to

http://www.ab.com/safety/logic/relays/msr4x/ to download the Configuration Tool for

MSR42 relay, GuardShield Micro 400 and Safe2/4 Light Curtains.

a. Go to Related Links on the right side of the page and choose ‘Safety Software [ZIP]’.

b. Save the zip file to your personal computer.

c. Unzip the file.

d. Run the SetupDiagnosticAndConfiguration_Vxxx.exe file to install the software.

2. Start the Configuration and Diagnostic software.

3. Click MSR42 and then OK.

4. If this is the first time you have used

the Configuration and Diagnostic

software, register the software.

a. From the Options menu, choose

User Registration.

b. Type in your information and

click OK.

TIP

It is not necessary to change the password for this building block. The default password is

ABGM.

12 Publication CC-QS015A-EN-P - November 2009

Page 13

Configure the MSR42 Safety Relay

1. On the Configuration

dialog box, select ‘Micro

400 Light Curtain’ from the

Micro 400 Inputs

pull-down menu.

Product Integration Chapter 1

2. Edit the settings as shown.

a. Choose Manual.

b. Leave Stop Delay set to No.

c. Choose Resolution 30 mm.

d. From the Protective height

pull-down menu, choose 1200

mm.

The software automatically

displays 48 as the ‘Total beam

number of system (n):’.

e. Leave Double Scan set to Yes.

3. Click OK.

Publication CC-QS015A-EN-P - November 2009 13

Page 14

Chapter 1 Product Integration

Notice that Micro 400 Light

Curtains have been added

to the Design Output

diagram.

4. On the Configuration

dialog box, select Start

from the IN1 Inputs

pull-down menu.

In addition to the

Micro 400 Light Curtains, a

NO momentary push

button, connected to IN1,

appears on the Design

Output diagram. The red

error message disappears,

replaced by ‘Design OK’.

14 Publication CC-QS015A-EN-P - November 2009

Page 15

5. From the IN2 pull-down

menu, choose Start

Release.

Notice that Start Release is

shown connected to IN2.

Start Release is a feedback

circuit that confirms, at

Start – Reset, that neither of

the two final switching

devices (FSD)

normally-open (NO)

outputs are shorted, that is,

closed.

In this application, the Start

Release circuit goes from

+24V through one auxiliary

normally-closed (NC)

contact of each 100S

contactor to the MSR42

relay. Similar to EDM, if

either or both of these NC

contacts are open, the

MSR42 relay cannot be

started or reset.

Product Integration Chapter 1

6. From the Outputs Info1

pull-down menu, choose

Micro 400 Light Curtain.

Status Micro 400 Light

Curtain is shown

connected to Info1. This

output switches High or

Low, depending on

whether the light curtain

beam is broken or

complete. This is

independent of the safety

output and can be

considered an auxiliary

output.

Publication CC-QS015A-EN-P - November 2009 15

Page 16

Chapter 1 Product Integration

7. From the Inputs GPIO pull-down menu, choose Muting Micro 400.

8. Click OK on the safety notice dialog box.

9. On the Muting dialog box, click 4 sensor T-type.

This dialog box helps you configure your muting system properly.

The Muting dialog box shows that a load on the conveyor travels left-to-right, passing in

sequence through the first two muting sensors and the LC (light curtain). After passing the

light curtain, the load passes, in sequence, the last two sensors. An object passing the

sensors in the proper sequence and within the configured time constraints is permitted to

pass though the light curtains without triggering a safe stop. The light curtains are ignored

by the safety system until the object passes completely through, clearing the light curtain

sensing field and passing the third sensor, ending the muting period.

As soon as the third sensor is cleared, the safety system will again trigger a safe stop if

anything breaks the sensing field without first passing S1 and S2 in the proper order and

within the configured time constraints.

10. Click Help in the lower right corner of the Muting dialog box.

16 Publication CC-QS015A-EN-P - November 2009

Page 17

The Muting Help dialog box shows

the proper timing sequence for 4

sensor, T-type muting. An object

must not only pass the sensors and

the light curtain in the proper

sequence. To initiate muting, an

object moving right to left in the

diagram must be in front of both

S1 and S2 for an instant. When

moving left to right, an object must

be in front of both S3 and S4, for

an instant. Take this timing and the

size of the load into consideration

when mounting the sensors. The

minimum load must be long

enough to be in front of both S1

and S2 or S3 and S4 sensors

simultaneously.

Product Integration Chapter 1

The Muting Help dialog box also provides definitions for the t(sens), t(espe), t(mute),

t(mdo), and t(msdel) times, which you can configure on the 4 sensor T-type dialog box. A

load that exceeds any of these configured times as it moves across the conveyor causes a

muting error, which results in the light curtain not being muted. A load entering the light

curtain sensing field during a muting error triggers a safe stop.

11. Click Close to return to the Muting dialog box.

12. Type the timing values or use the slider to edit the default values.

Publication CC-QS015A-EN-P - November 2009 17

Page 18

Chapter 1 Product Integration

Time settings are intended to help make sure that only valid objects of the right size, moving

at the right speed, can initiate and maintain a muting sequence.

You may want to add a few seconds to some of your calculations to allow for variations.

Time Setting Description

t(sens) Since both S1 and S2 or both S3 and S4 sensors must be broken simultaneously to initiate a muting sequence,

these sensors should be spaced no further apart than the length of the smallest typical load. Calculate how

long a load takes from the time it first reaches S1 until it reaches S2 (or S3 until it reaches S4), based on the

speed of the conveyor. This is the t(sens) time for your system.

t(espe) The t(espe) field is disabled until you check the Light curtain interruption monitored checkbox under Additional

Settings. The t(espe) of your system is the time from the moment a load reaches the second sensor (S2 from

the right or S3 from the left) until it enters the light curtain sensing field. Once the light curtain is muted, the

load must interrupt the light curtain within 3 seconds. Therefore, the second sensor must be placed within 3

seconds travel time from the light curtain. t(espe) should be no longer than 3 seconds except in extraordinary

circumstances supported by the risk assessment.

t(mute) This setting establishes the maximum length of time the light curtain remains muted. Calculate the length of

time it takes the load to travel from the point where it first reaches the second sensor until the trailing edge of

the load leaves the light curtain based on the speed of the conveyor. This is the minimum t(mute) for your

system, which is entered in minutes.

t(mdo) This setting establishes the maximum length of a Mute Dependent Override. Occasionally, a load may stop

within the light curtain sensing field. It may be difficult to move the load past the light curtain sensing field

with a safe stop in effect. Mute Dependent Override is a function that lets a safety stop be paused and muting

to be re-initiated for the duration of the t(mdo) setting, which lets the load move beyond the light curtain

sensing field. As soon as the load moves past the light curtain sensing field, muting ceases. If the hazardous

area is in clear view of the operator and no personnel or objects are in the hazard area, Mute Dependent

Override can be initiated, in this case, by pressing and releasing the Start/Reset button. Calculate the time it

takes the load to travel from the point where it first reaches the second sensor (S2 from the right, or S3 from

the left) until the trailing edge of the load leaves the light curtain sensing field, based on the speed of the

conveyor.

t(msdel) In some instances, loads may have gaps that the first two sensors might sense through as the load passes.

This could lead to a muting error. One method to avoid such errors is to delay the sensors’ response to allow

for seeing through gaps. The t(msdel) configures that delay time. Unless the gap is very long or the load is

moving very slowly, the gap is present for only a short time. In most instances, the default 0.050 is suitable.

Leave this value set at 0.050.

Notice that the Connecting diagram shows a lamp, as well as muting sensors connected to

GPIO1 and GPIO2, and that IN1 is labeled Start/Mute override. In this application a Muting

Lamp is required for safety purposes to warn personnel in the area when the light curtain is

muted.

13. Review the Additional Settings.

a. Make sure that the Muting Lamp monitored box is checked.

Muting lamp monitoring means that should the muting lamp fail, short, or open, the

MSR42 controller will sense it and not initiate or maintain muting. In applications where a

muting lamp is required, generally the muting lamp is required to be monitored.

b. Because you entered a t(mdo) time earlier, leave the Mute dependent override box

checked.

c. In the Muted light curtain section, note that GuardShield Micro 400 is selected and

disabled and make sure that the Light curtain interruption monitored box is checked.

18 Publication CC-QS015A-EN-P - November 2009

Page 19

14. Click OK to complete the

configuration.

15. Choose File>Save and

save the configuration as

‘4sensor T-type muting’.

16. Do not exit the MSR42

configuration and

diagnostic software.

Product Integration Chapter 1

Download the Configuration

1. Write down the device number from the label on the side of the MSR42 relay.

2. Apply power to the MSR42 relay.

3. Attach the suction-cup connector to the interface window on the side of the MSR42 relay.

Publication CC-QS015A-EN-P - November 2009 19

Page 20

Chapter 1 Product Integration

4. In Microsoft Windows,

open the Control Panel.

5. Double-click on System.

6. On the System Properties

dialog box, click

Hardware.

7. Click Device Manager.

8. Expand Ports (COM &

LPT).

9. Plug the USB connector of

the Optical Interface into

an available USB port on

your personal computer.

10. Note the new COM port

that appears in the list.

This is the port assigned to

the Optical Interface, which you will need to select in the Configuration and Diagnostic

software as part of the download procedure.

11. Close the Control Panel.

12. In the Configuration and Diagnostic software, choose

Options>USB/Comport settings.

TIP

If USB/Comport settings is not available, check

Support Mode active and choose

Options>USB/Comport settings.

20 Publication CC-QS015A-EN-P - November 2009

Page 21

13. On the OptiLink Communication dialog box,

select Compatibility mode.

14. Choose the Comport assigned by Windows

Device Manager.

15. Click OK.

16. From the File menu, choose PC->MSR42 (Download).

Product Integration Chapter 1

17. When prompted, type the password ‘ABGM’.

18. On the Controller Description dialog box, type

the six-digit Device number and click OK.

19. Cycle power to the MSR42 relay to allow the

download to proceed.

Once the download is complete, the Configuration control document dialog box appears.

Publication CC-QS015A-EN-P - November 2009 21

Page 22

Chapter 1 Product Integration

Confirm the Configuration

1. On the Configuration control document

dialog box, review the configuration

and check the confirmation box.

2. Click Continue.

3. When prompted to print the document,

click No.

The software saves a copy that can be

printed later from the File menu.

4. On the Attach Safety Configurator Label dialog

box, click OK.

The MSR42 is now fully configured and ready for

operation.

5. Click the Diagnosis tab.

22 Publication CC-QS015A-EN-P - November 2009

Page 23

Product Integration Chapter 1

This screen lets you monitor the status of the light curtain when a computer is attached to

the MSR42 relay via the Optical Interface. It has other helpful diagnostic features that are

described in the MSR42 Safety Base Module Operation Manual, publication 440R-IN017, and

the Configuration Tool for MSR42, GS Micro 400 and Safe 2/4 Light Curtains Software

Description document, available on the CD that ships with the Optical Interface tool.

Otherwise, a personal computer is neither required, nor recommended, for normal system

operation.

6. Disconnect the Optical Interface tool.

Publication CC-QS015A-EN-P - November 2009 23

Page 24

Chapter 1 Product Integration

Notes:

24 Publication CC-QS015A-EN-P - November 2009

Page 25

Chapter

2

System Validation and Application Tips

Introduction

In this chapter, you validate the operation of the two safety functions as well as the operation of

the MicroLogix 1100 controller and PanelView Component 600 terminal.

Before You Begin

• Review the Connected Components Building Blocks Quick Start, publication CC-QS001,

verifying that you have completed all of the steps in Chapter 3 of that publication.

• Verify that you have completed all of the steps in Chapter 1 of this document.

• Verify that all components of the system are assembled and wired per the Bill of Materials

Assembly Diagrams and Wiring Diagrams provided for this Connected Components Building

Block, and as required for your application.

• Verify that the MicroLogix controller and the PanelView Component terminal have power

applied to them.

What You Need

• Personal computer

• Connected Components Building Blocks Overview CD, publication CC-QR001

• MicroLogix 1100 controller, catalog number 1763-L16BBB

• PanelView Component C600 terminal, catalog number 2711C-T6C

• Stratix 2000 Ethernet switch, catalog number 1783-US05T (or equivalent) to connect the

MicroLogix controller to the PanelView terminal

• Ethernet cables, catalog number 1585J-M8TBJM-2 or equivalent

25Publication CC-QS015A-EN-P - November 2009 25

Page 26

Chapter 2 System Validation and Application Tips

Follow These Steps

Start

Validate Proper Operation of the

Safety Systems on page 26

Validate Proper Operation of the

PanelView Screens on page 31

Validate Proper Operation of the Safety Systems

To confirm that the system is operating properly, you need to perform a series of tests.

Start Up

1. Apply power to the system.

2. Check the following:

• The 100S contactors do not energize.

• Guarded motion does not start.

• The red stacklight is on.

3. Press and release the Start-Reset button.

4. Check the following:

• The 100S contactors energize.

• Guarded motions starts.

• The green stacklight is on.

E-stop Function

1. Press the E-stop.

2. Check the following:

• The two 100S contactors de-energize.

• Guarded motion stops.

• The red stacklight is on.

26 Publication CC-QS015A-EN-P - November 2009

Page 27

System Validation and Application Tips Chapter 2

3. Press and release the Start-Reset button.

4. Confirm that the two 100S contactors do not energize and guarded motion does not start.

5. Twist and release the E-stop button.

6. Press and release the Start-Reset button.

7. Check the following:

• The 100S contactors energize.

• Guarded motion starts.

• The green stacklight is on.

Light Curtain Function

1. Break the light curtain beam and keep it broken, taking care not to block any sensors.

2. Check the following:

• The two 100S contactors de-energize.

• Guarded motion stops.

• The red stacklight is on.

3. While the light curtain beam remains broken, press the Start-Reset button.

4. Confirm that the two 100S contactors do not energize and guarded motion does not start.

5. Restore the light curtain beam.

6. Press and release the Start-Reset button.

7. Check the following:

• The 100S contactors energize.

• Guarded motion starts.

• The green stacklight is on.

Publication CC-QS015A-EN-P - November 2009 27

Page 28

Chapter 2 System Validation and Application Tips

Muting Function

1. Send a load from the right through the muting system.

2. Check the following:

• S1 switches as the load passes.

• S2 switches as the load passes.

• The muting lamp turns on.

• The load passes through the light curtain without the system shutting off.

• The muting lamp turns off as the load passes S3.

3. Send a load from the left through the muting system.

4. Check the following:

• S4 switches as the load passes.

• S3 switches as the load passes.

• The muting lamp turns on.

• The load passes through the light curtain without the system shutting off.

• The muting lamp turns off as the load passes S2.

Muting Error (from Right)

1. From the right, let a load pass S1 and S2, but stop it short of the light curtain sensing field.

2. Confirm that the muting lamp turns on.

3. Wait the configured t(espe) delay for the muting lamp to start blinking.

4. Move the load forward to break the light curtain beam.

5. Check the following:

• The safety output turns off.

• The two 100S contactors de-energize.

• Guarded motion stops.

• The red stacklight turns on.

28 Publication CC-QS015A-EN-P - November 2009

Page 29

System Validation and Application Tips Chapter 2

Mute Dependent Override (from Right)

1. While the load is still disrupting the light curtain beam from the previous mute error test,

press and release the Start-Reset button.

2. Check the following:

• The safety output turns on.

• The two 100S contactors energize.

• Guarded motion starts.

• The muting lamp is on and is not blinking.

• The green stacklight turns on.

3. As soon as the load clears the light curtain, break the light curtain beam, taking care not to

block any sensors.

4. Check the following:

• The safety output turns off.

• The two 100S contactors de-energize.

• Guarded motion stops.

• The red stacklight turns on.

5. Press and release the Start-Stop button to start the system.

Muting Error (from Left)

1. From the left, let a load pass S4 and S3, but stop it short of the light curtain sensing field.

2. Confirm that the muting lamp turns on.

3. Wait the configured t(espe) delay for the muting lamp to start blinking.

4. Move the load forward to break the light curtain beam.

5. Check the following:

• The safety output turns off.

• The two 100S contactors de-energize.

• Guarded motion stops.

• The red stacklight turns on.

Publication CC-QS015A-EN-P - November 2009 29

Page 30

Chapter 2 System Validation and Application Tips

Mute Dependent Override (from Left)

1. While the load is still disrupting the light curtain beam from the previous mute error test,

press and release the Start-Reset button.

2. Check the following:

• The safety output turns on.

• The two 100S contactors energize.

• Guarded motion starts.

• The muting lamp is on and is not blinking.

• The green stacklight turns on.

3. As soon as the load clears the light curtain, break the light curtain beam, taking care not to

block any sensors.

4. Check the following:

• The safety output turns off.

• The two 100S contactors de-energize.

• Guarded motion stops.

• The red stacklight turns on.

5. Press and release the Start-Stop button to start the system.

Lockout

1. Carefully disconnect and reconnect one of the light curtain RJ45 connectors at the MSR42

relay.

2. Make sure the safety output triggers the instant the light curtain is disconnected.

This completes the validation of the safety systems.

30 Publication CC-QS015A-EN-P - November 2009

Page 31

System Validation and Application Tips Chapter 2

Validate Proper Operation of the PanelView Screens

Most of the buttons are real-time signals from the MSR42 or MSR127 relays, driven via the

MicroLogix 1100 controller to the PanelView terminal. The buttons change their appearance as

the signals driving them change.

This button Indicates

SEN

1

SEN

1

LC

LC

E-STOP

There is no load in front of the sensor.

A load is in front of the sensor.

The light curtain sensing field is not interrupted.

The light curtain sensing field is interrupted.

The E-stop has been pressed.

The following pages illustrate a typical sequence of PanelView screens. Confirm that the system

and PanelView screens operate as expected by following this sequence.

When you apply power to the system, the Safety System Status screen appears.

Publication CC-QS015A-EN-P - November 2009 31

Page 32

Chapter 2 System Validation and Application Tips

1. Press MORE INFO for two seconds.

Whenever an action may be

appropriate for an operator to perform,

MORE INFO is displayed on the screen.

Pressing MORE INFO calls the related

message screen.

2. Press RETURN for about five seconds to

return to the previous screen.

3. Press START RESET for three seconds

and release.

The system should start running. Note that the START RESET button is green only when the

system is ready for a Start Reset. It is no longer green once the system is running.

As the load enters the system from the

left and moves in front of S4 and S3,

muting is initiated. The load has not yet

interrupted the light curtain sensing

field.

As the load enters the light curtain

sensing field, the LC (light curtain)

button turns red to indicate that the

light curtain has been interrupted. The

Safety Output button remains on.

32 Publication CC-QS015A-EN-P - November 2009

Page 33

As the load leaves S2, muting ends.

4. Press the E-stop.

The screen updates in response.

System Validation and Application Tips Chapter 2

5. Press MORE INFO.

6. Press RETURN.

7. Twist and release the E-stop.

8. Press START RESET for three seconds

and release.

The system starts to run and guarded

motion begins.

Publication CC-QS015A-EN-P - November 2009 33

Page 34

Chapter 2 System Validation and Application Tips

9. While avoiding the sensors, interrupt

the light curtain and keep it interrupted.

10. Press MORE INFO.

11. Press RETURN.

12. Remove the object interrupting the light

curtain.

Once the light curtain is no longer

interrupted, the display returns to the

Ready for START RESET screen.

13. Press START RESET for three seconds

and release.

14. Move a load in front of S1 and S2, but

do not interrupt the light curtain.

15. Leave the load where it is.

34 Publication CC-QS015A-EN-P - November 2009

Page 35

After the configured t(espe), the time it

should take a load to travel between S2

and the light curtain, the muting lamp

begins to blink. The screen reflects the

muting error.

16. Press MORE INFO.

17. Press RETURN.

18. Move the load until it interrupts the

light curtain.

System Validation and Application Tips Chapter 2

19. Leave the load in the light curtain

sensing field.

Publication CC-QS015A-EN-P - November 2009 35

Page 36

Chapter 2 System Validation and Application Tips

20. Press MORE INFO.

21. Press RETURN.

22. Press START RESET for three seconds

and release.

The load is still interrupting the light

curtain. Pressing and releasing START

RESET initiated a Mute Dependent

Override, t(mdo). The system switches

to muted operation. Muting ends as

soon as the load clears the light curtain

or when the configured t(mdo) expires.

TIP

When the START RESET button is green, it may be used in place of the Start Reset push button. If

requirements dictate that remote reset must not be used, do not use it. If the operator stationed at

the PanelView terminal’s location cannot see the guarded area well enough to be certain that no

one is in the guarded area, you must not use the START RESET button.

The START RESET button can be disabled by removing three wires from the MicroLogix controller

I/O.

• Wire 6041

• Wire 10231

• Wire 10071

23. Carefully disconnect then reconnect

one of the light curtain cables from the

MSR42 relay at its RJ45 socket.

36 Publication CC-QS015A-EN-P - November 2009

Page 37

24. Press MORE INFO.

25. Press RETURN.

26. Press and hold START RESET for 10

seconds.

System Validation and Application Tips Chapter 2

Publication CC-QS015A-EN-P - November 2009 37

Page 38

Chapter 2 System Validation and Application Tips

Notes:

38 Publication CC-QS015A-EN-P - November 2009

Page 39

Page 40

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in using its products. At

http://www.rockwellautomation.com/support/

application notes, sample code and links to software service packs, and a MySupport feature that you can customize to make the

best use of these tools.

For an additional level of technical phone support for installation, configuration, and troubleshooting, we offer TechConnect

support programs. For more information, contact your local distributor or Rockwell Automation representative, or visit

http://www.rockwellautomation.com/support/

Installation Assistance

If you experience an anomoly within the first 24 hours of installation, review the inform ation that's contained in this manual.

You can contact Customer Support for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or

Canada

Use the Worldwide Locator

or contact your local Rockwell Automation representative.

, you can find technical manuals, a knowledge base of FAQs, technical and

.

at http://www.rockwellautomation.com/support/americas/phone_en.html,

New Product Satisfaction Return

Rockwell Automation tests all of its products to ensure that they are fully operational when shipped from the manufacturing

facility. However, if your product is not functioning and needs to be returned, follow these procedures.

United States Contact your distributor. You must provide a Customer Support case number (call the phone number

above to obtain one) to your distributor to complete the return process.

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this

document, complete this form, publication RA-DU002

, available at http://www.rockwellautomation.com/literature/.

Publication CC-QS015A-EN-P - November 2009 40

Copyright © 2009 Rockwell Automation, In c. All rights reserved. Printed in the U.S.A.

Loading...

Loading...