Page 1

Over 100 years cumulative experience

24 hour rush turnaround / technical support service

Established in 1993

The leading independent repairer of servo motors and drives in North America.

Visit us on the web:

www.servo-repair.com

www.servorepair.ca

www.ferrocontrol.com

www.sandvikrepair.com

www.accuelectric.com

Scroll down to view your document!

For 24/7 repair services :

USA: 1 (888) 932 - 9183

Canada: 1 (905) 829 -2505

Emergency After hours: 1 (416) 624 0386

Servicing USA and Canada

Page 2

1397 DC Drive

1.5 - 150HP @230VAC

7 - 265ADC @380/415VAC

3 - 600HP @460VAC

Firmware Rev. 2.xx

User Manual

Page 3

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. “Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls” (Publication SGI-1.1

available from your local Allen-Bradley Sales Office or online at

www.ab.com/manuals/gi

solid state equipment and hard-wired electromechanical devices. Because of

this difference, and also because of the wide variety of uses for solid state

equipment, all persons responsible for applying this equipment must satisfy

themselves that each intended application of this equipment is acceptable.

In no event will the Allen-Bradley Company be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for

illustrative purposes. Because of the many variables and requirements

associated with any particular installation, the Allen-Bradley Company

cannot assume responsibility or liability for actual use based on the

examples and diagrams.

No patent liability is assumed by Allen-Bradley Company with respect to

use of information, circuits, equipment, or software described in this

manual.

) describes some important differences between

http://

Reproduction of the contents of this manual, in whole or in part, without

written permission of the Allen-Bradley Company is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

!

damage, or economic loss.

Attentions help you:

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifies information that is especially important for successful

application and understanding of the product.

Shock Hazard labels may be located on or inside the drive to

alert people that dangerous voltage may be present.

Page 4

Summary of Changes

Summary of Changes

Description of New or Updated Information Page Type

FS2/FS3 Control Options 1-4 Updated

200% Overload Capacity 1-4 Updated

Publication 1397–5.0 – June, 2001

Page 5

Page 6

Table of Contents

Introduction

Installation

Chapter 1

Manual Objectives 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter Objective 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage Conditions 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drive Identification Nameplate 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Firmware Version 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Catalog Numbering Convention 1-3. . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Ratings and Supply Capacity (230/460VAC) 1-6. . . . . . . . . . . .

Power Ratings and Supply Capacity (380/415VAC) 1-6. . . . . . . . . . . .

Drive I/O Specifications Logic Inputs 1-7. . . . . . . . . . . . . . . . . . . . . . .

Logic Outputs 1-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog Inputs 1-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog Outputs 1-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drive Description 1-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options 1-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2

Chapter Objectives 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environment 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cooling Airflow 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Filters (CE Only) 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC Line Inductors (CE Only) 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Enclosure Mounting Minimum Clearances 2-3. . . . . . . . . . . . . . . . . . .

Enclosure Mounting Dimensions 2-4. . . . . . . . . . . . . . . . . . . . . . . . . .

Grounding Procedures 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Clearance 2-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disconnect 2-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24V Power Supply 2-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wire Size, Type & Class 2-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor Installation 2-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Wiring Procedure 2-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC Line Torque Recommendations 2-24. . . . . . . . . . . . . . . . . . . . . . . .

Recommended AC Line and DC Armature Fuses 2-25. . . . . . . . . . . . . .

Control Connections 2-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Wiring Procedure 2-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Publication 1397-5.0 —June, 2001

Page 7

Table of Contentsii

Programming Terminal

Start–Up and Adjustment

Chapter 3

General 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HIM Description 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HIM Operation 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HIM Programming Steps 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HIM Programming Modes 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program and Display Modes 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bit ENUMS 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Process Mode 3-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EEprom Mode 3-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Search Mode 3-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Status Mode 3-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4

Introduction 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Tools and Equipment 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended Tools and Equipment 4-2. . . . . . . . . . . . . . . . . . . . . .

General 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drive Hardware Adjustments 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor Ground Check 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pre–Power Checks 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pre–Power Checklist 4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Field Supply Configuration 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power–On Checks 4-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameter Set–Up 4-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameter Modification Sequence 4-17. . . . . . . . . . . . . . . . . . . . . . . . .

Jumper Settings 4-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Verify the Correct Operation of 24V I/O Inputs 4-26. . . . . . . . . . . . . . . .

Motor and Feedback Polarity Checks 4-29. . . . . . . . . . . . . . . . . . . . . .

Autotuning 4-35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Auto–Tune Set–Up 4-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Auto–Tune Execution 4-37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Application Set–Up 4-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming Parameters

Publication 1397-5.0 —June, 2001

Chapter 5

Introduction 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Record Keeping 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Precautions 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameter Groups 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Numeric Parameter Table 5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameter Descriptions (By Group) 5-14. . . . . . . . . . . . . . . . . . . . . . . .

Parameters (Alphabetical) 5-97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hidden Parameters 5-100. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 8

Table of Contents iii

Troubleshooting

Firmware Block Diagram

Chapter 6

Introduction 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Equipment 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HIM Fault Display 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clearing a Fault 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clearing an Alarm 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault Description Table 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarm Description Table 6-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A

Standard Inputs A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I/O Expansion Inputs A-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Speed/Trim Reference Select A-3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Speed Reference Ramp A-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Outer Control Loop A-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Speed Reference Mode Select A-6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Speed Loop A-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Current Minor Loop Reference A-8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Current Minor Loop A-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Field Control Loop A-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Outputs A-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Level Detectors A-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I/O Expansion Outputs A-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CE Conformity

Derating

Appendix B

EMC Compliance B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EMC Requirements B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Requirements B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting the Equipment B-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Grounding Requirements B-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring the Equipment B-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix C

High Ambient Temperature Conditions C-1. . . . . . . . . . . . . . . . . . . . . .

Derating for High Altitude C-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air Conditioning C-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Space Heaters C-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Publication 1397-5.0 —June, 2001

Page 9

iv

Table of Contents

Using SCANport

Capabilities

Lifting Instructions

Appendix D

Chapter Objectives D-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic Status Parameter D-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the SCANport Controls D-3. . . . . . . . . . . . . . . . . . . . . . . .

Setting the Loss of Communications Fault D-5. . . . . . . . . . . . . . . . . . .

Using the SCANport I/O Image D-5. . . . . . . . . . . . . . . . . . . . . . . . . . .

Supported SCANport Messages D-11. . . . . . . . . . . . . . . . . . . . . . . . . .

Logic Status Format D-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic Command Format D-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

User Parameter Value Table D-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix E

Introduction E-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lifting Component Ratings E-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drive Mounting E-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Publication 1397-5.0 —June, 2001

Page 10

Introduction

Chapter 1

Manual Objectives

The purpose of this manual is to provide you with the necessary

information to install, program, start up and maintain the 1397 DC

Drive. This manual should be read in its entirety before operating,

servicing or initializing the 1397 Drive. This manual must be

consulted first, as it will reference other 1397 manuals for option

initialization.

This manual is intended for qualified service personnel responsible

for setting up and servicing the 1397 DC Drive. You must have

previous experience with and a basic understanding of electrical

terminology, programming procedures, required equipment and

safety precautions, as typical applications will consist of a properly

rated DC motor, with or without feedback based on performance

requirements, and the 1397.

ATTENTION: Only qualified electrical personnel

!

familiar with the construction and operation of this

equipment and the hazards involved should install,

adjust, operate and/or service this equipment. Read and

understand this section in its entirety before

proceeding. Failure to observe this precaution could

result in bodily injury or loss of life.

ATTENTION: An incorrectly installed or applied

drive can result in component damage or a reduction in

product life. Wiring or application errors such as

undersizing the motor, incorrect or inadequate AC

supply or excessive ambient temperatures may result in

damage to the Drive or motor.

ATTENTION: This drive contains ESD (Electrostatic

Discharge) sensitive parts and assemblies. Static

control precautions are required when installing,

testing, servicing or repairing this assembly.

Component damage may result if ESD control

procedures are not followed. If you are not familiar

with static control procedures, reference Allen–Bradley

Publication 8000 – 4.5.2, Guarding against

Electrostatic Damage or any other applicable ESD

protection handbook.

Publication 1397-5.0 — June, 2001

Page 11

1–2 Introduction

Chapter Objective

Storage Conditions

Drive Identification

Nameplate

Chapter 1 in addition to detailing drive features and specifications,

also supplies the information needed to unpack, properly inspect and

if necessary, store the 1397 Drive. A complete explanation of the

catalog numbering system is also included in this chapter.

After receipt inspection, repack the Drive in its original shipping

container until ready for installation. To ensure satisfactory

operation at startup and to maintain warranty coverage, store the

Drive as follows:

• In its original shipping container in a clean, dry, safe place.

• In an ambient temperature that does not exceed 65_C (149_F) or

go below -30_C (-22_F).

• Within a relative humidity range of 5 to 95% without

condensation.

• At an altitude of less than 3,000 meters (10,000 ft.) above sea

level.

The 1397 DC Drive has a nameplate on the side of the chassis

(Fig. 1.1) that identifies the specific model number design,

applicable AC input power and DC output power data. All

communication concerning this product should refer to the

appropriate model number information.

Firmware Version

Figure 1.1

Bulletin 1397 Nameplate

BULLETIN 1397

M/N 1397-BO10R 5/10HP

INPUT 230/460VAC 19A 3PH 50/60HZ

OUTPUT 240/500VDC 20A

DC FIELD 150/300VDC 10A

SHORT CIRCUIT RATING 5000A

I/M 1397-5.0 W/D 30371–23

FOR 230V OPERATION, SEE I/M

SERIAL NO. 1397-B010R V 001 WY

The technical power information on the nameplate should be

referenced to verify proper power application.

The manual covers firmware versions through 2.xx.

MADE IN USA

Publication 1397-5.0 — June, 2001

Page 12

1–3Introduction

Catalog Numbering

Convention

1397– B005 – OPTIONS

1397 –

First Position

Bulletin Number

1397

Second Position

Voltage

Letter

A

U

B 460V AC

B

Voltage

230V AC

380/415V AC

Drive specific data, such as horsepower (or output current),

regenerative or non-regenerative type, line voltage etc. can be

determined by the Drive model number. The model number structure

is shown below.

Rating

001

002

003

005

007

010

015

020

025

030

040

050

060

075

100

125

150

ADC

7

29

55

110

265

003

005

007

010

015

020

025

030

040

050

060

075

100

125

150

200

250

300

400

500

600

005

Third Position

Rating

HP (kW)

1.5 (1.1)

2 (1.5)

3 (2.2)

5 (3.7)

7.5 (5.8)

10 (7.5)

15 (11)

20 (15)

25 (18)

30 (22)

40 (29)

50 (37)

60 (44)

75 (55)

100 (74)

125 (93)

150 (111)

380/415

2.4 (1.8)/2.8 (2.1)

12 (9)13.8 (10.3)

24 (17.9)/27.6 (20.8)

48 (35.8)/55.2 (41.2)

120 (89.5)/138 (102.9)

3 (2.2)

5 (3.7)

7.5 (5.6)

10 (7.5)

15 (11)

20 (15)

25 (18)

30 (22)

40 (29)

50 (37)

60 (44)

75 (55)

100 (74)

125 (93)

150 (111)

200. (149)

250 (186)

300 (224)

400 (298)

500 (373)

600 (448)

R

Fourth Position

Type

N = Non Regen

R = Regen

1

– OPTIONS

Fifth Position

–DS

–MB

–L10

–L11

–DB

–FS2

–FS3

–PE

–AC

–HAB

–HAP

–HA1

–HA2

1203–GD1

1203–GD2

1203–GK1

1203–GK2

1203–GK5

NOTE: Refer to page

1–4 for additional option

information.

1 Regen (R) required for reversing applications

Publication 1397-5.0 — June, 2001

Page 13

1–4 Introduction

1397 – OPTIONS

CONTROL OPTIONS

–DS AC Line Disconnect

–MB Blower Motor Starter

–L10 Control Interface – 115VAC

–L11 I/O Expansion Cord

–DB Dynamic Braking

–FS3 Enhanced Field Supply

–FS2 Field Current Regulator

–PE Pulse Encoder Kit

–AC AC Tachometer Kit

–IFB (400 – 600 HP only)

Specifications

COMMUNICATION OPTIONS (Loose Kits)

–1203–GD1 Single Point Remote I/O (RIO) – 115V AC

–1203–GD2 RS–232/422/485, DF1 and DH485 Protocol – 115VAC

–1203–GK1 Single Point Remote I/O (RIO) – 24 VDC

–1203–GK2 RS–232 Interface Brd

–1203–GK5 DeviceNet – 24 VDC

HUMAN INTERFACE OPTIONS

–HAB Blank – No Functionality

–HAP Programmer Only

–HA1 Programmer / Controller with Analog Pot

–HA2 Programmer / Controller with Digital Pot

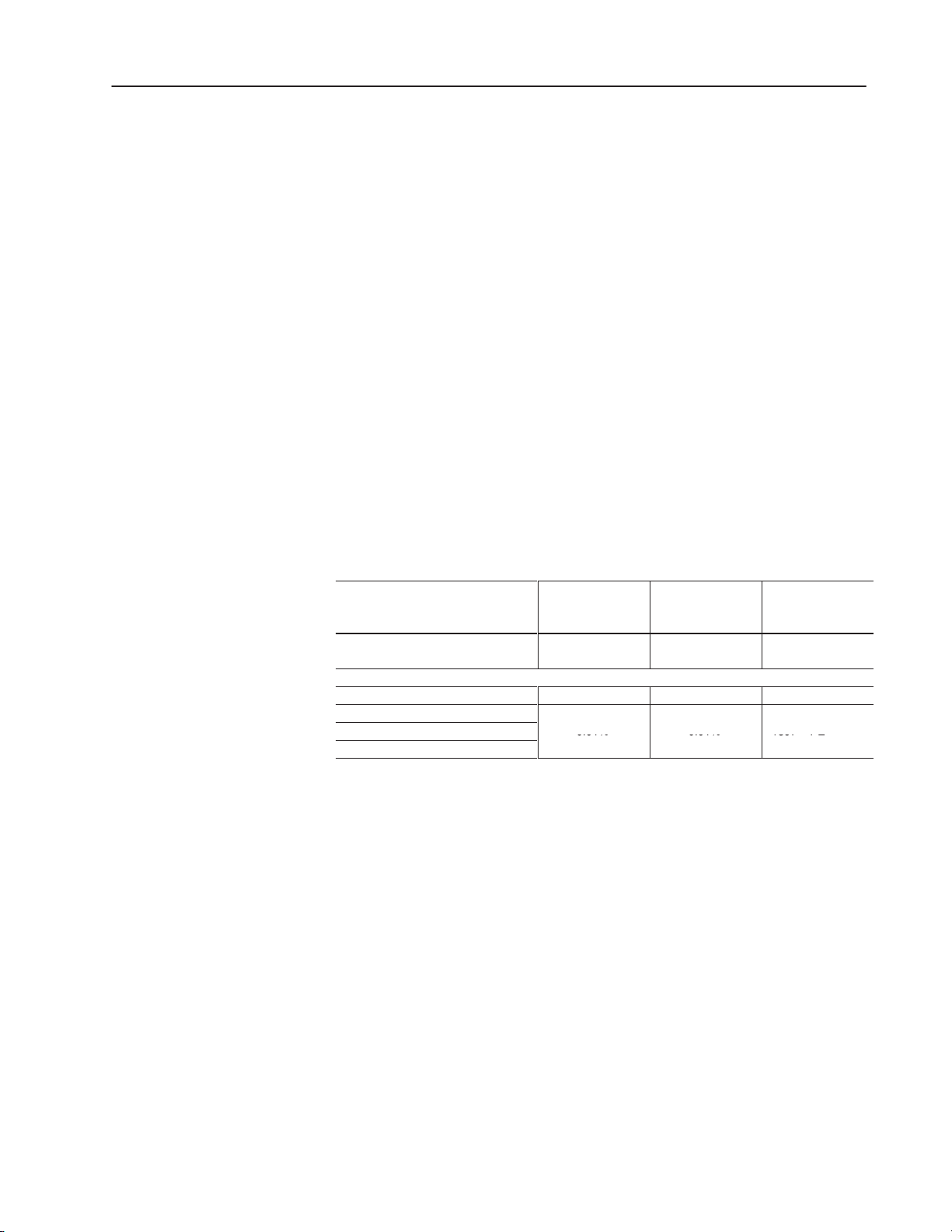

OPTION CROSS REFERENCE

380/415VAC 460VAC

7A 3 HP

29A 15 HP

55A 30 HP

110A 60 HP

265A 150 HP

Input Voltage and Frequency Ratings

Nominal Voltage 207 to 253 VAC or 414 to 506 VAC

(Horsepower-rated drives)

342 to 437 VAC or 374 VAC to 477 V AC

(Current-rated drives)

Nominal Line Frequency 50 or 60 cycles per second

Frequency Variation +

2 cycles of nominal

AC Line Fault Capacity

Allowable AC Line Symmetrical (See Power Ratings and Supply Capacity)

AC Line kVA

AC Line Distribution Capacity Maximum 3 drives per transformer

Minimum Source kVA (See Power Ratings and Supply Capacity)

DC Voltage Ratings

230 VAC Line

Armature Voltage 240 VDC

Field Voltage (w/basic fld supply) 150 VDC

380/415 VAC Line

Armature Voltage 400/460 V DC

Field Voltage (w/basic fld supply) 250/270 VDC

460 VAC Line

Armature Voltage 500 V DC

Field Voltage (w/basic fld supply) 300 VDC

Service Factor Ratings

Service Factor 1.0 Continuous

Overload Capacity (drive only) 150% of full load rating for one minute

200% of full load rating for 13 seconds

Minimum Load 5% of rated load

Publication 1397-5.0 — June, 2001

Page 14

1–5Introduction

0.01%

0.01%

1397

PE

Service Conditions

Ambient Temperature

Chassis 55_C (131_F) maximum

Cabinet 40_C (104_F) maximum

Altitude

Chassis and Cabinet 3300 feet above sea level

Above 3300 feet Derate 3% for every 1000 ft above

3300 ft up to 10000 ft.

Humidity

Chassis and Cabinet 5 to 95% non-condensing

Environment The drive should be located in an area

that is free of dust, dirt, acidic or

caustic vapors, vibration and shock,

temperature extremes, and electrical or

electromagnetic noise interference.

Regulation

Tachometer Speed Regulation

Speed Change

with 95% Load

Regulation Arrangement

Armature voltage regulation w/IR

Compensation

( DC Tach Feedback) 1% 2% Standard

(Pulse Encoder Feedback )

( RD–120 Pulse Encoder FDBK)

1

Optional pulse encoder feedback kit required.

1

1

Change

2-3 % 15% Standard

Closed Loop

0.01% 0.01% 1397 – PE

Speed Change

from All other

Variables

Kit Model Number

Speed Change

Operator’s Speed Adjustment 0 to rated speed

Specification Speed Range 100:1 based on top speed and

tachometer

Drive Efficiency

Drive Only 98.6% (rated load and speed)

Drive and Motor 85% typical

Note: Typical percent shown depends on motor operating speed and frame size.

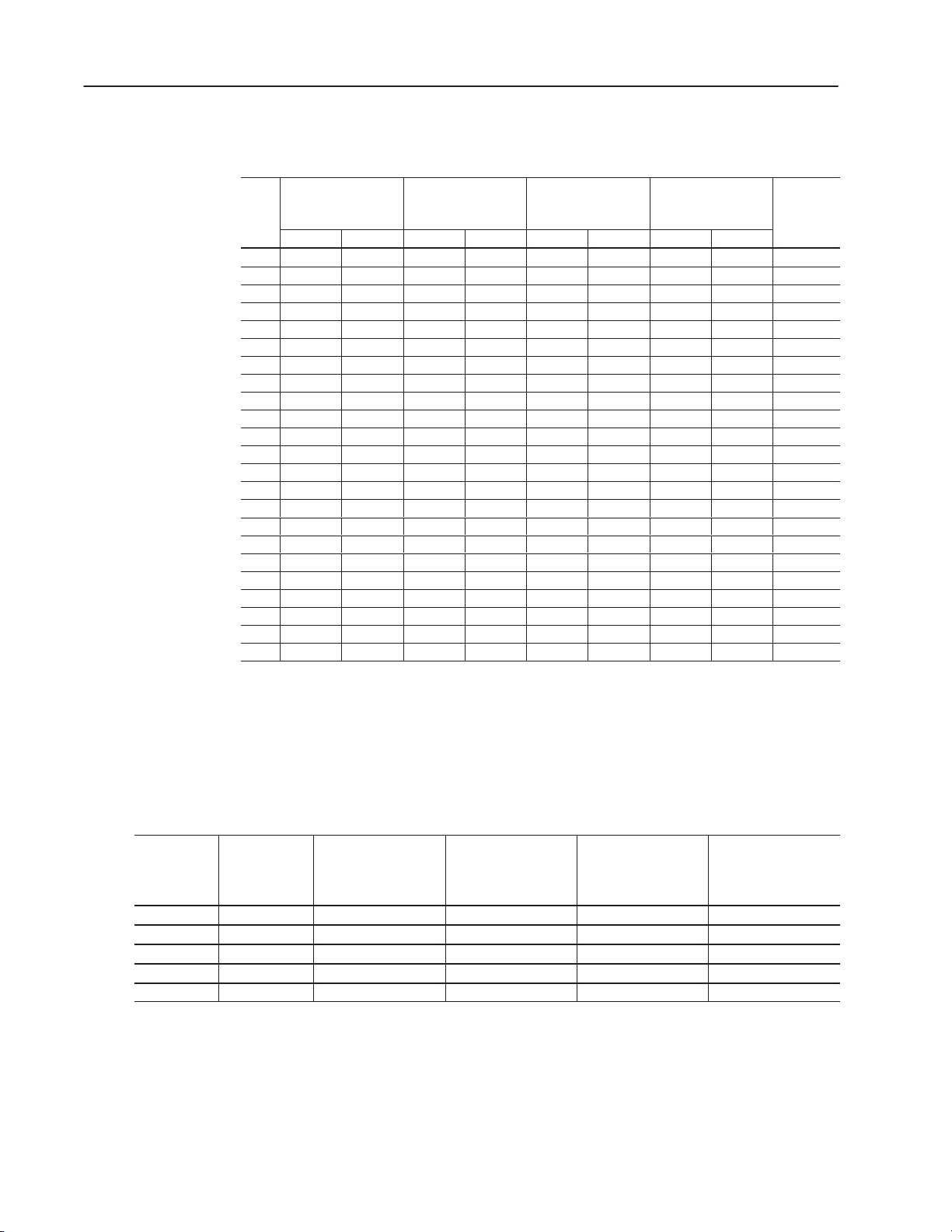

Power Ratings

Displacement Power Factor 88% typical (rated load and speed)

Note: Typical percent shown depends on motor operating speed and frame size.

Publication 1397-5.0 — June, 2001

Page 15

1–6 Introduction

Source

Power Ratings and Supply

Capacity (230/460VAC)

Full Load Rated

RMS AC Line

Current (Amperes)

230 V AC

HP

1.5 10 - 7 - 10 - 5000 - 4

2 11 - 9 - 10 - 5000 - 5

3 13 10 12 6 10 10 5000 5000 6

5 19 12 20 10 10 10 5000 5000 7.5

7.5 26 15 29 14 10 10 5000 5000 11

10 33 18 38 19 10 10 5000 5000 15

15 48 24 55 27 10 10 5000 5000 20

20 63 31 73 35 15 10 10000 5000 27

25 80 39 93 45 15 10 10000 5000 34

30 94 45 110 52 15 10 10000 5000 40

40 125 63 146 73 15 15 25000 10000 51

50 154 74 180 86 15 15 25000 10000 63

60 186 86 218 100 15 15 25000 10000 75

75 226 110 265 129 15 15 25000 25000 93

100 307 143 360 167 15 25000 118

125 370 177 434 207 15 25000 145

150 443 213 521 250 15 25000 175

200 281 330 15 30000 220

250 351 412 15 30000 275

300 421 495 15 30000 330

400 567 667 15 75000 440

500 680 800 15 75000 550

600 816 960 15 75000 660

ATTENTION: When applying 1397 Drives to a power distribution system with KVA capacity in excess of five times the smallest

drive rating the use of an isolation transformer or line reactors of similar impedance is required. Also, the Drives are designed

for a maximum of three units per transformer.

1 Maximum permissible available symmetrical RMS fault current.

460 V AC 240 VDC 500 V DC 150 VDC 300 V DC 230 VAC 460 V AC

Full Load Rated

DC Armature

Current (Amperes)

Rated Field Current

(Amperes)

Power Source

Capacity

(Amperes)

1

Minimum

Source

kVA

Power Ratings and Supply

Capacity (380/415VAC)

380 VAC

KW/HP

1.8/2.4 2.1/2.8 10 7 10 5,000

9/12 10.3/13.6 26 29 10 5,000

17.9/24 20.6/27.6 48 55 10 5,700

35.8/48 41.2/55.2 94 11 0 15 11,500

89.5/120 102.9/138 226 265 15 25,000

Publication 1397-5.0 — June, 2001

415 VAC

KW/HP

380/415

Full Load Rated

RMS AC Line

Current Amperes

380/415

Full Load Rated

DC Armature

Current Amperes

Rated

Field

Current

Power

Source

Capacity

(Amperes)

Page 16

1–7Introduction

Drive I/O Specifications

Logic Inputs

The following sections describe drive inputs and outputs. Refer to

Chapter 3 for terminal strip connections and wiring diagrams.

Logic Inputs

ATTENTION: Connecting an external power source

!

The logic input circuits can be powered either from the internal +24

VDC power supply or from an external +24 V DC power source. The

internal +24 VDC power supply is available at the regulator board

terminal strip (see Fig. 2.15). If an external power source is used,

only its common must be connected to 24VCOM on the regulator

board (terminal 15).

to any of the +24 volt connections (terminals 1, 7, 11,

and 14) on the regulator board terminal strip will

damage the drive. Do not connect the external power

source to the +24 volt connections on the regulator

board terminal strip. Failure to observe this precaution

could result in damage to, or destruction of, the

equipment.

Logic Outputs

Electrical Specifications

Input Voltage +24 VDC

Turn On Voltage +8 VDC

Turn Off Current 0.5 mA

Common All input circuits have the same

common.

The logic output circuits are normally open (when de-energized)

relay contacts. When energized (contacts closed), the three circuits

indicate the following drive conditions. Terminals are on the

terminal strip on the regulator board.

Running Terminal 27 to 28

Alarm Terminal 29 to 30

No Fault Terminal 31 to 32

Electrical Specifications

Operating Voltage 250 VAC maximum

30 VDC maximum

Switching Current 2 Amps maximum resistive

1 Amp maximum inductive

Publication 1397-5.0 — June, 2001

Page 17

1–8 Introduction

Analog Inputs

The three customer analog inputs are Analog Reference 1, Analog

Reference 2 and Analog Tachometer Feedback. These inputs are

converted within the Drive to 12 bits plus sign at their full range.

The electrical specifications for each of these are listed below.

Analog Reference 1 (Terminals 19,20)

(see page 4.25 for J10 & J12 jumper settings)

Voltage Reference +

Milliamp Reference 4-20 mA or 10-50 mA

Analog Reference 2 (Terminals 16, 17, 18)

(see page 4.24 for J19 jumper settings)

Potentiometer 5kΩ minimum

External Voltage Source +

Analog Tachometer Feedback

(see page 4.20 for J11 and J14 jumper settings)

Tach Voltage at Top speed 10 to 250 VDC

10 VDC

10 VDC

0 to 10 Volts DC

Analog Outputs

The two metering analog outputs are available at regulator board

terminals 24, 25 and 26. Terminal 25 is the common connection for

both output signals. The selected signals for both meter outputs are

averaged (filtered) over 100 ms to reduce meter fluctuations.

NOTE: Refer to the Start-Up chapter for information on

programming Analog Outputs.

Electrical Specifications

Output Voltage ±10 V DC, 4 mA

Publication 1397-5.0 — June, 2001

Page 18

1–9Introduction

Drive Description

I/O Expansion

Board

Regulator Board

Terminal Strip

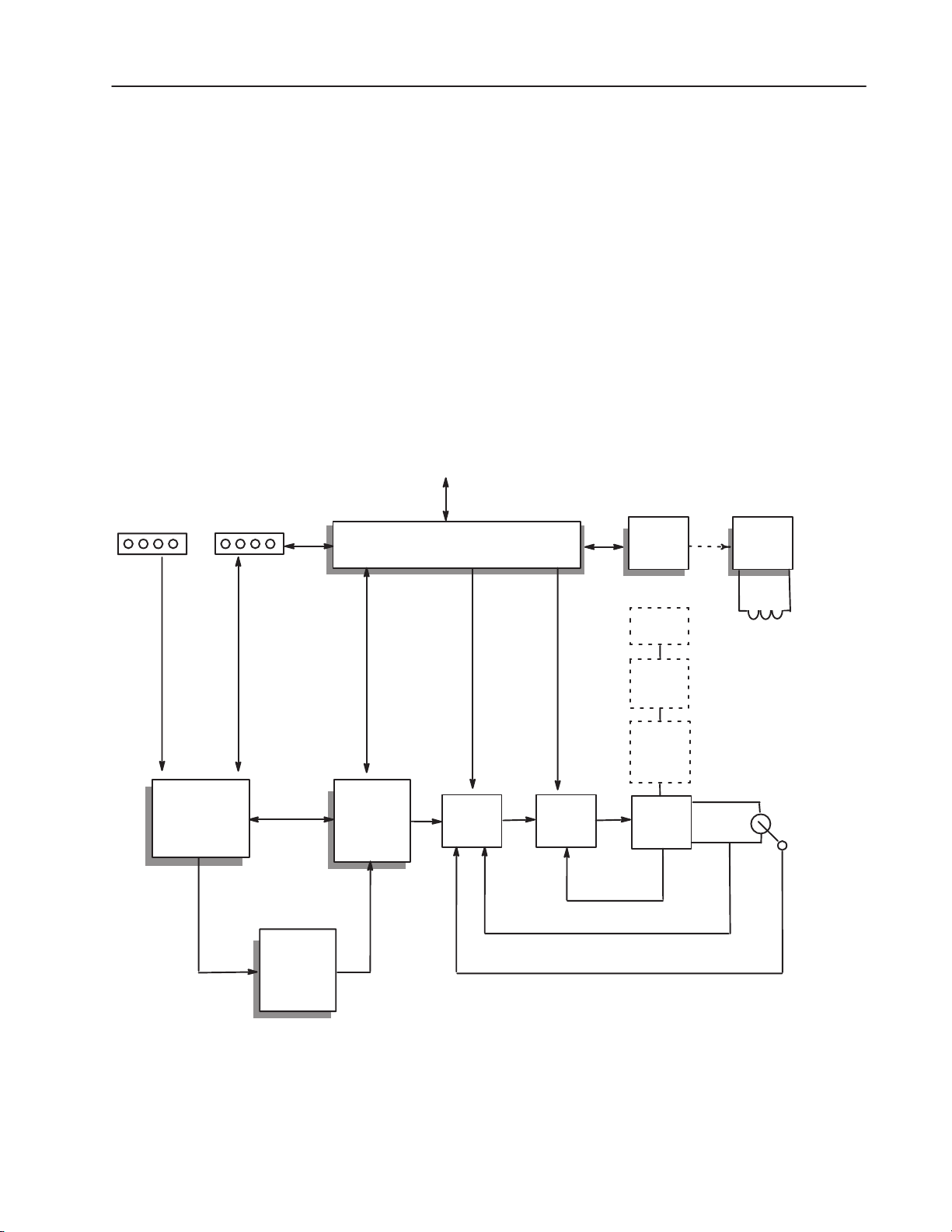

The Drive is a 3 phase full-wave power converter without flyback

rectifier, complete with a digital current regulator and a digital speed

regulator for armature voltage or speed regulation by tachometer

feedback. Shown in Figure 1.2 is a block diagram of the 1397 Drive.

The Drive employs wireless regulator construction and uses a keypad

for Drive setup, including parameter adjustments and unit selection,

monitoring, and diagnostics. Reference, feedback, and metering

signals can be interfaced to the Drive. The Drive can be controlled

locally by the control device (HIM, GPT, DriveTools etc.) keypad or

remotely by using the terminals at the regulator board terminal strip.

Figure 1.2

1397 Block Diagram

SCANPORT

DRIVE CONTROL SIGNALS

AND SEQUENCING

FIELD

CONTROL

FIELD

POWER

SUPPLY

DIGITAL

ANALOG &

FREQUENCY

INPUTS/OUTPUTS

OUTER

CONTROL

LOOP

(OCL)

SPEED

REFERENCE

SELECTION

AND

SCALING

SPEED

LOOP

CE Line

Inductor

CE Line

Filter

(Option)

Optional

Arm R–Gen

6 SCR

Power Unit

CURRENT

LOOP

6 SCR

POWER

UNIT

Armature

Current

Feedback

Armature Voltage Feedback

Speed Feedback

MOTOR FIELD

MOTOR

ARMATURE

ANALOG

TACH

OR

PULSE

ENCODER

Publication 1397-5.0 — June, 2001

Page 19

1–10 Introduction

БББББББББББББББ

Á

БББББББББББББББ

Á

Á

Á

БББББББББББББББ

Á

Á

БББББББББББББББ

Á

Á

Á

Á

Á

Á

Á

Á

Á

БББББББББББББББ

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

БББББББББББББББ

Á

Á

Á

Á

Á

Á

БББББББББББББББ

Á

Á

Á

Á

Á

Á

Á

Á

Á

БББББББББББББББ

Á

БББББББББББББББ

Á

Á

Á

БББББББББББББББ

БББББББББББББББ

Á

БББББББББББББББ

Á

Á

Á

Á

Á

БББББББББББББББ

Á

Á

Á

Á

Á

Á

БББББББББББББББ

Á

БББББББББББББББ

Á

Á

Á

БББББББББББББББ

Á

БББББББББББББББ

Á

Á

Á

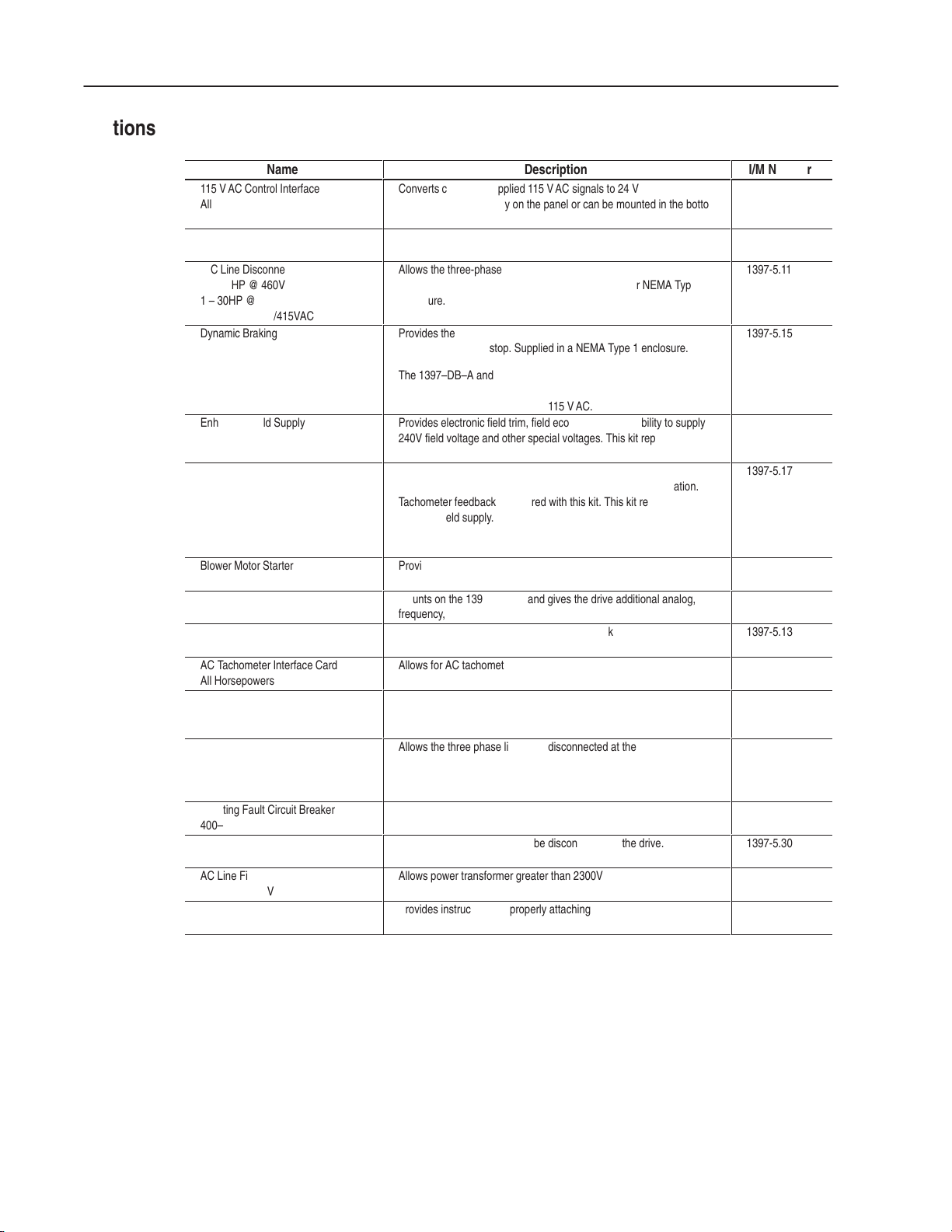

Options

Name

115 VAC Control Interface

All Horsepowers

ББББББББ

230 V AC Conversion

A-C Line Disconnect

ББББББББ

3 – 60 HP @ 460V

1 – 30HP @ 230V

ББББББББ

7 – 100A @ 380/415VAC

Dynamic Braking

ББББББББ

ББББББББ

ББББББББ

Enhanced Field Supply

ББББББББ

Regulated Field Supply

Supplied as standard on:

ББББББББ

400 – 600HP @ 460V

150HP @ 460V

ББББББББ

75 HP @ 230V and up

ББББББББ

265 & 521 ADC @ 380/415 VAC

Blower Motor Starter

Expansion I/O Module

ББББББББ

Pulse Encoder Interface Card

All Horsepowers

AC Tachometer Interface Card

All Horsepowers

AC Line Disconnect

ББББББББ

75 – 150 HP @ 460V

40 – 75 HP @ 230V

AC Line Disconnect

ББББББББ

200 – 300 HP @ 460V

100 – 150 HP @ 230V

ББББББББ

521 ADC @ 380/415 VAC

Inverting Fault Circuit Breaker

400–600 HP

AC Line Disconnect

ББББББББ

400 – 600 HP @ 460V

AC Line Filter Kit

600 HP @ 460V

Dynamic Braking Resistor Assembly

Lifting Instructions 250–600HP

ББББББББ

Description

Converts customer-supplied 115 V AC signals to 24 VDC for operating a

1397. Mounts separately on the panel or can be mounted in the bottom

БББББББББББББ

of a NEMA Type 1 enclosed drive.

Allows conversion of the 460 V AC 1397 to a 230 V AC 1397 at one-half

the 460 V AC horsepower rating.

Allows the three-phase line to be disconnected at the drive. Molded

БББББББББББББ

case switch that mounts on the chassis of the drive or NEMA Type 1

enclosure.

БББББББББББББ

Provides the hardware, including braking grids, needed to provide

dynamic braking on stop. Supplied in a NEMA Type 1 enclosure.

БББББББББББББ

The 1397–DB–A and 1397–DB–B series allow the kit to be panel

БББББББББББББ

mounted. These kits include the resistor grid assembly and contactor.

БББББББББББББ

The customer must supply fused 115 VAC.

Provides electronic field trim, field economy, and the ability to supply

240V field voltage and other special voltages. This kit replaces the

БББББББББББББ

standard field supply.

Provides field economy, as well as pre-weakening of the field using a

fixed reference or field weakening for above base speed operation.

БББББББББББББ

Tachometer feedback is required with this kit. This kit replaces the

standard field supply.

БББББББББББББ

БББББББББББББ

Provides a fused A-C starter with adjustable overload and interlocking

for control of three phase blower motor used to cool the DC motor.

Mounts on the 1397 chassis and gives the drive additional analog,

frequency, and digital I/O capability.

БББББББББББББ

Allows for digital pulse encoder speed feedback

Allows for AC tachometer speed feedback

Allows the three phase line to be disconnected at the drive.

БББББББББББББ

Allows the three phase line to be disconnected at the drive.

БББББББББББББ

БББББББББББББ

Allows high inertia loads on regenerative 1397 drives.

Allows the three phase line to be disconnected at the drive.

БББББББББББББ

Allows power transformer greater than 2300V RMS to be applied to the

drive.

Provides instructions for properly attaching and lifting Dynamic Braking

Kits.

БББББББББББББ

I/M Number

1397-5.18

ÁÁÁ

1397-5.16

1397-5.11

ÁÁÁ

ÁÁÁ

1397-5.15

ÁÁÁ

ÁÁÁ

ÁÁÁ

1397-5.24

ÁÁÁ

1397-5.17

ÁÁÁ

ÁÁÁ

ÁÁÁ

1397-5.20

1397-5.19

ÁÁÁ

1397-5.13

1397-5.22

1397-5.21

ÁÁÁ

1397-5.27

ÁÁÁ

ÁÁÁ

1397-5.29

1397-5.30

ÁÁÁ

1397-5.31

1397-5.32

ÁÁÁ

Publication 1397-5.0 — June, 2001

Page 20

Installation

Chapter 2

Chapter Objectives

Environment

The following data will guide you in planning the installation of the

1397 Drive. Since most start-up difficulties are the result of

incorrect wiring, every precaution must be taken to assure that the

wiring is done as instructed.

IMPORTANT: You are responsible for completing the installation,

wiring and grounding of the 1397 Drive and for complying with all

National and Local Electrical Codes.

ATTENTION: The following information is merely a

!

The Drive must be mounted in a clean, dry location. Contaminants

such as oils, corrosive vapors and abrasive debris must be kept out of

the enclosure. Temperatures around the Drive must be kept between

0° and 55°C (32°F and 131°F). Humidity must remain between 5%

to 95% non-condensing. The Drive can be applied at elevation of

3300 feet (1,000 meters) without derating. The Drive current rating

must be derated by 3% for each additional 1,000 feet (300 meters).

Above 10,000 feet (3,000 meters), consult the local Allen-Bradley

Sales Office.

guide for proper installation. The National Electrical

Code and any other governing regional or local code

will overrule this information. The Allen-Bradley

Company cannot assume responsibility for the

compliance or noncompliance to any code, national,

local or otherwise for the proper installation of this

Drive or associated equipment. A hazard of personal

injury and/or equipment damage exists if codes are

ignored during installation.

Mounting

The 1397 Drive is of the open chassis type construction and is

designed to allow you to install it in a suitable enclosure. The

selection of enclosure type is the responsibility of the user.

Dimensions and clearances for the 1397 are detailed in the figures on

the following pages.

ATTENTION: Plan Drive installation so that all

!

cutting, drilling, tapping and welding can be done with

the Drive removed from the enclosure. The Drive is of

the open type construction and any metal debris must

be kept from falling into the Drive. Metal debris or

other foreign matter may become lodged in the

circuitry resulting in component damage.

Publication 1397-5.0 — June, 2001

Page 21

2–2 Installation

)

Cooling Airflow

Line Filters (CE Only)

AC Line Inductors (CE Only

In order to maintain proper cooling, the Drive must be mounted in a

vertical position. Refer to Figure 2.1 for the recommended minimum

clearance of each Drive.

The Drive design produces up to a 10°C or 18°F air temperature rise

when the Drive is operated at full capacity. Precautions should be

taken not to exceed the maximum inlet ambient air temperature of

55°C (131°F). If the Drive is in an enclosed cabinet, air circulation

fans or a closed circuit heat exchanger may be required.

For information on installing, wiring and grounding Line Filters used

in CE compliant applications, refer to Appendix B.

For installation information on AC Line Inductors used in CE

compliant applications, refer to Appendix B.

Publication 1397-5.0 — June, 2001

Page 22

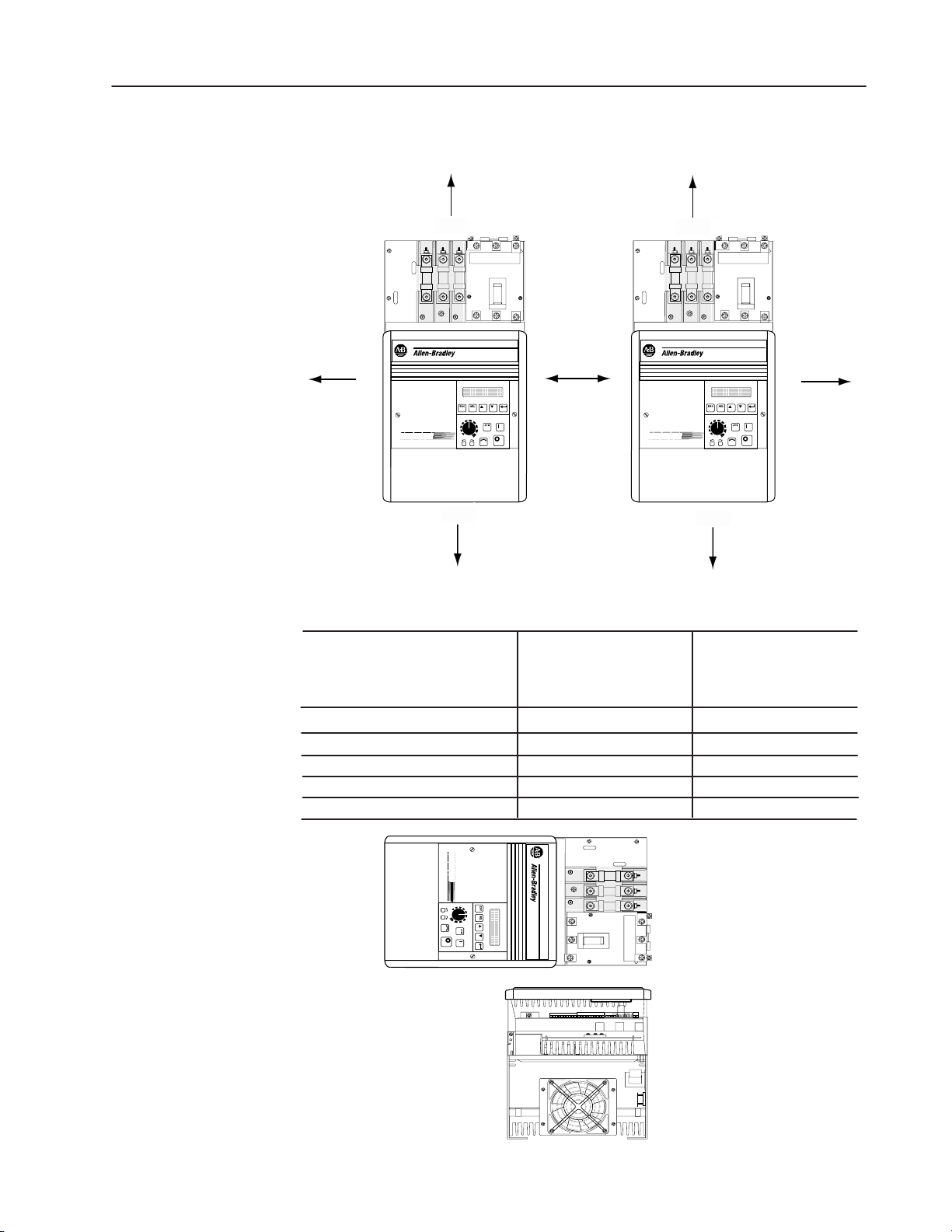

Figure 2.1

Enclosure Mounting Minimum Clearances

2–3Installation

E

A

D

Approved Mounting Methods

All Dimensions Millimeters and (Inches)

Enclosure Mounting Clearances

A Leftside Clearance

B Rightside Clearance

C Drive to Drive Side Clearance

D Bottom Clearance

E Top Clearance

C

1.5 – 30 HP @ 230VAC

3 – 60 HP @ 460VAC

7 – 110A @ 380 / 415 VAC

76 mm (3 in.)

51 mm (2 in.)

101 mm (4 in.)

127 mm (5 in.)

127 mm (5 in.)

E

B

D

40 – 150 HP @ 230VAC

75 – 600 HP @ 460VAC

265A @ 380 / 415 VAC

76 mm (3 in.)

51 mm (2 in.)

101 mm (4 in.)

305 mm (12 in.)

305 mm (12 in.)

NOT APPROVED

Note: Do Not Mount

Drive Horizontally

on Side or Back.

Publication 1397-5.0 — June, 2001

Page 23

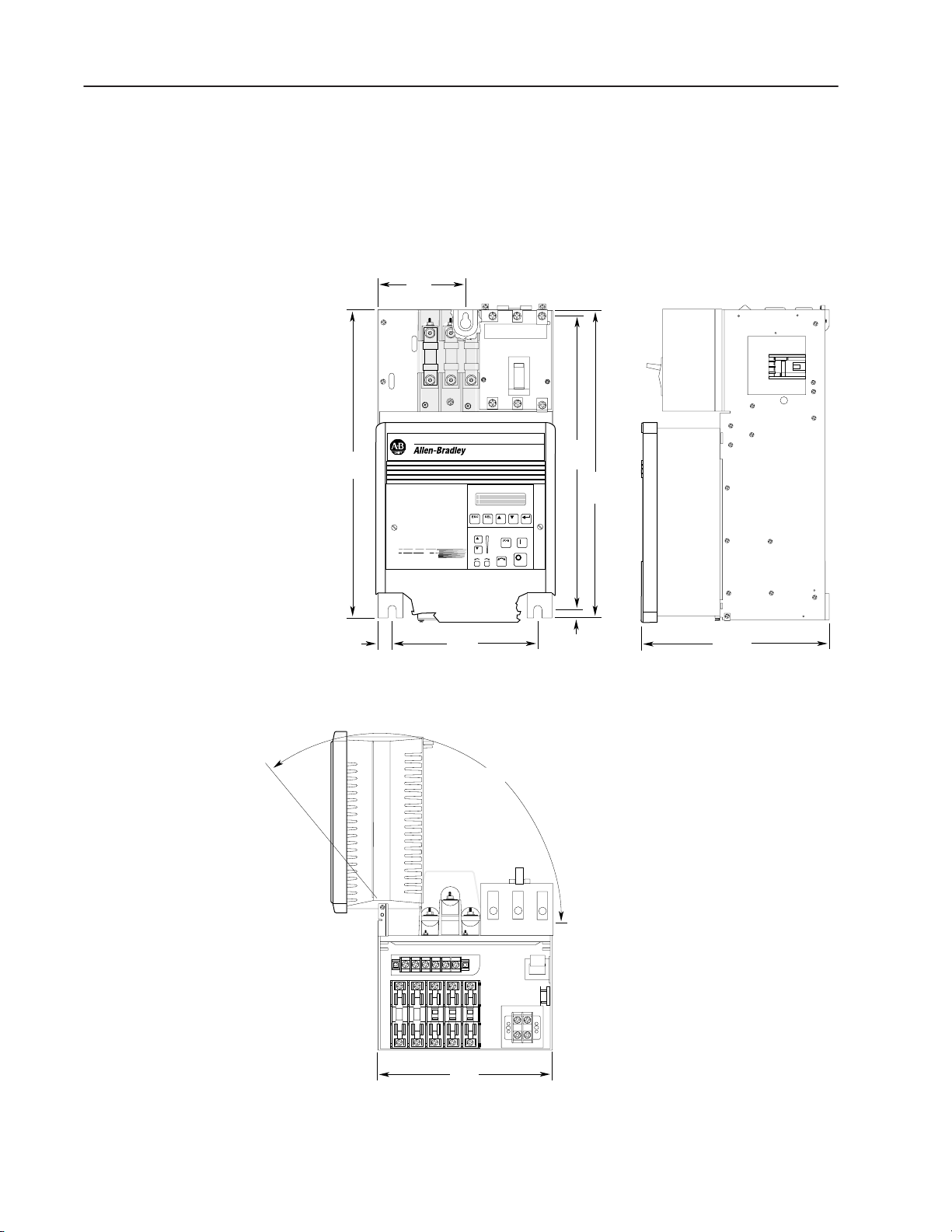

2–4 Installation

Enclosure Mounting

Dimensions

Figure 2.2

Drive Mounting Dimensions –

1.5 to 30 HP at 230 VAC

7 to 110A @ 380/415 VAC

3 to 60 HP at 460 VAC

136.0

(5.35)

477.5

(18.80)

22.5

(0.89)

225.0

(8.86)

FRONT

135˚

463.0

(18.23)

7.0

(0.28)

497.5

(19.59)

300.0

(11.81)

SIDE

Publication 1397-5.0 — June, 2001

270.5

(10.65)

TOP

Rec Hardware

3 x M6 or 1/4”

All Dimensions Millimeters and (Inches)

Approximate Shipping Weight 30.8 kg (68 lbs.)

Page 24

491.8

(19.36)

464.6

(18.29)

37.5

(1.48)

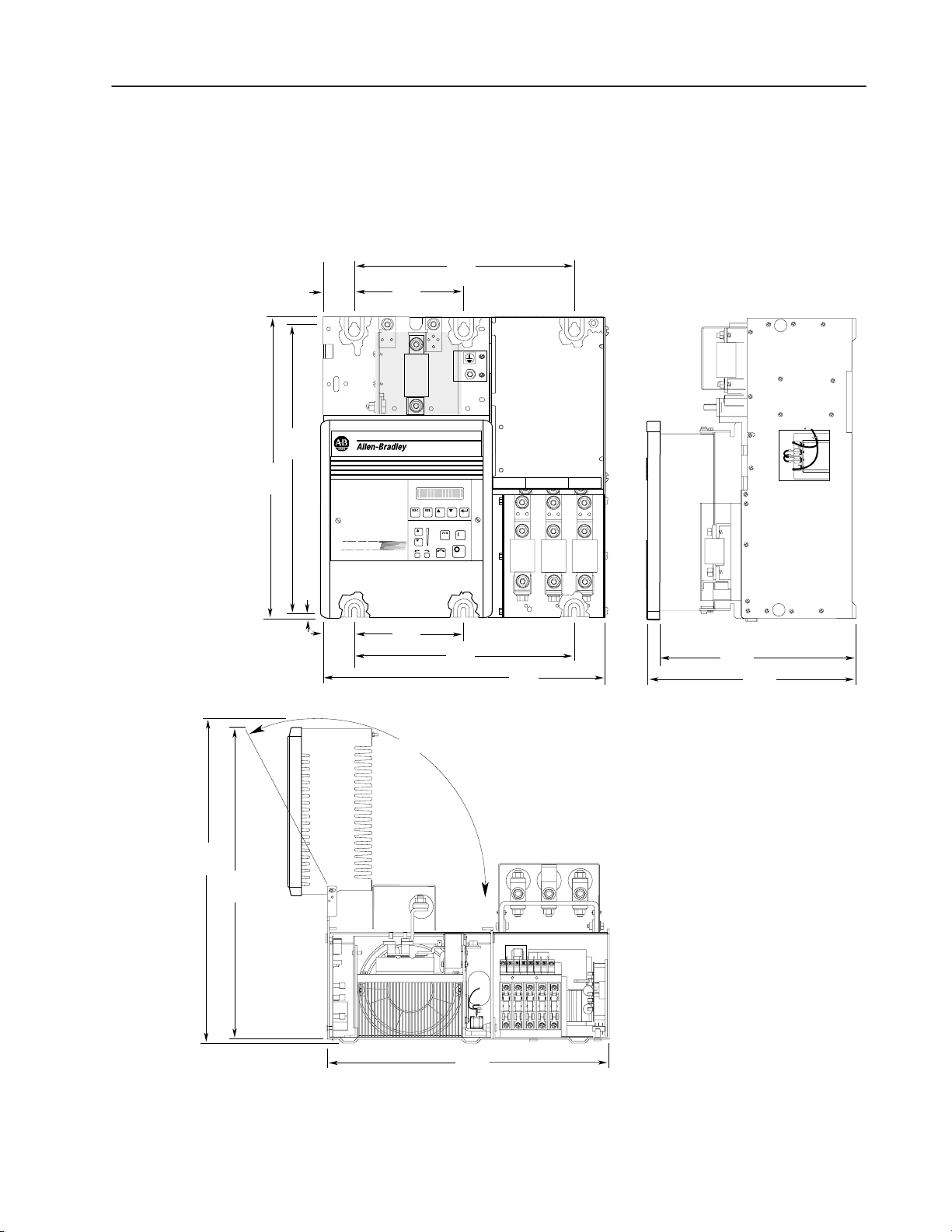

Figure 2.3

Drive Mounting Dimensions –

40 to 75 HP at 230 VAC

265A @ 380/415 VAC

75 to 150 HP at 460 VAC

375.0

(14.76)

200.0

(7.87)

45

A1

GRD

181 182

2–5Installation

P4

P4

S4

P4

S4

S4

183

531.7

(20.93)

509.5

(20.06)

16.8

(0.66)

37.5

(1.48)

200.0

(7.87)

135˚

375.0

(14.76)

FRONT

461.6

(18.17)

TOP

461.6

(18.17)

300.0

(11.81)

334.3

(13.16)

SIDE

Rec Hardware

6 x M8 or 5/16”

All Dimensions Millimeters and (Inches)

Approximate Shipping Weight 55.0 kg (122 lbs.)

Publication 1397-5.0 — June, 2001

Page 25

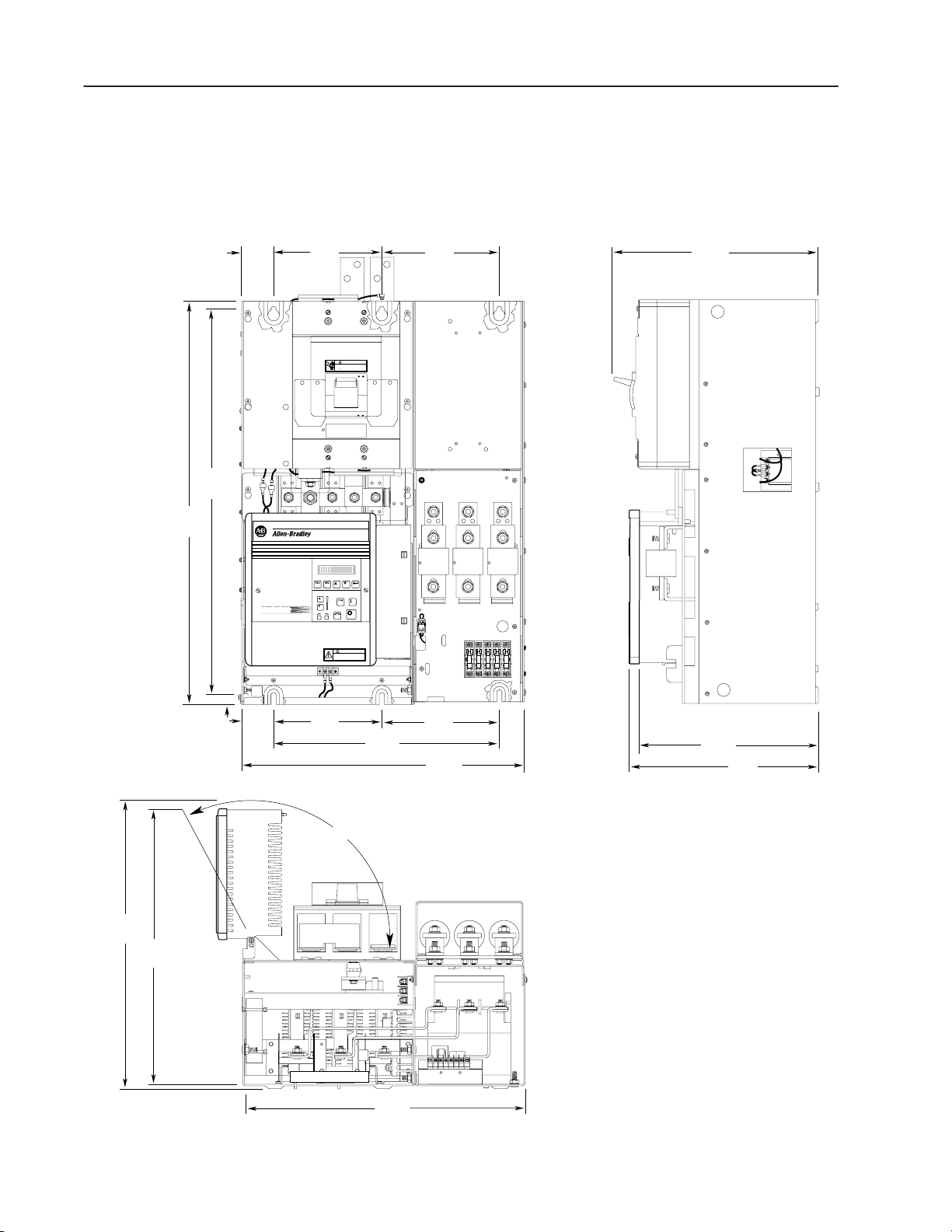

2–6 Installation

(2.66)

822.8

(32.39)

850.0

(33.46)

67.5

230.0

(9.06)

Figure 2.4

Drive Mounting Dimensions – 150 HP at 230 VAC;

200 – 300 HP at 460 VAC

599.0

(23.58)

240.0

(9.45)

DANGER

CIRCUIT BREAKER DOES NOT DISCONNECT INCOMING A0

LINE POWER IT ONLY PROVIDES DC FAULT PROTECTION.

LE DISCONECTEUR NE COUPTE PAS L'AUTOMENTATION DU SPOTEUR IL NES

810903-2424

SERT QUE A ASSURER UNE PROTECTION CONTRE LES DESFAULTS DC.

424.7

(16.72)

598.4

(23.56)

578.9

(22.79)

12.7

(0.50)

GND

TORQUE

14-10GA 35 LB.-IN

0 GA 48 LB.-IN.

SPEC

67.5

(2.66)

!

DANGER

RISK OF ELECTRICAL SHOCK. DISCONNECT INPUT

POWER BEFORE SERVICING EQUIPMENT.

P/N 33145

.

230.0

(9.06)

470.0

(18.50)

FRONT

240.0

(9.45)

599.0

(23.58)

371.1

(14.61)

406.0

(15.99)

SIDE

135˚

599.0

(23.58)

TOP

Approximate Shipping Weight 100 kg (220.5 lbs.)

Mounting Hardware

6 x M10 or 3/8”

All Dimensions Millimeters and (Inches)

Publication 1397-5.0 — June, 2001

Page 26

Figure 2.5

Drive Mounting Dimensions –

400 to 600 HP at 460 VAC

2–7Installation

45.25"

(1149.2mm)

(1104.0mm)

43.47"

2.12"

(53.8mm)

42.37"

(1076.3mm)

2.12"

(53.8mm)

10.20"

(259.1mm)

10.20"

(259.1mm)

26.68"

(677.7mm)

(261.6mm)

(261.6mm)

10.30"

81 82 83

1FU 2FU 3FU

281 282 283

BLOWER MOTOR

STARTER KITS

10.30"

18.82"

(478.1mm)

ON

OFF

5FU4FU

288 289

18.30"

(464.7mm)

25.61"

(650.5mm)

Publication 1397-5.0 — June, 2001

Page 27

2–8 Installation

Grounding Procedures

The purpose of grounding is to:

• Limit dangerous voltages to ground potential on exposed parts in

the event of an electrical fault.

• To facilitate proper operation of overcurrent device when ground

fault conditions are incurred.

• To provide suppression of electrical interference.

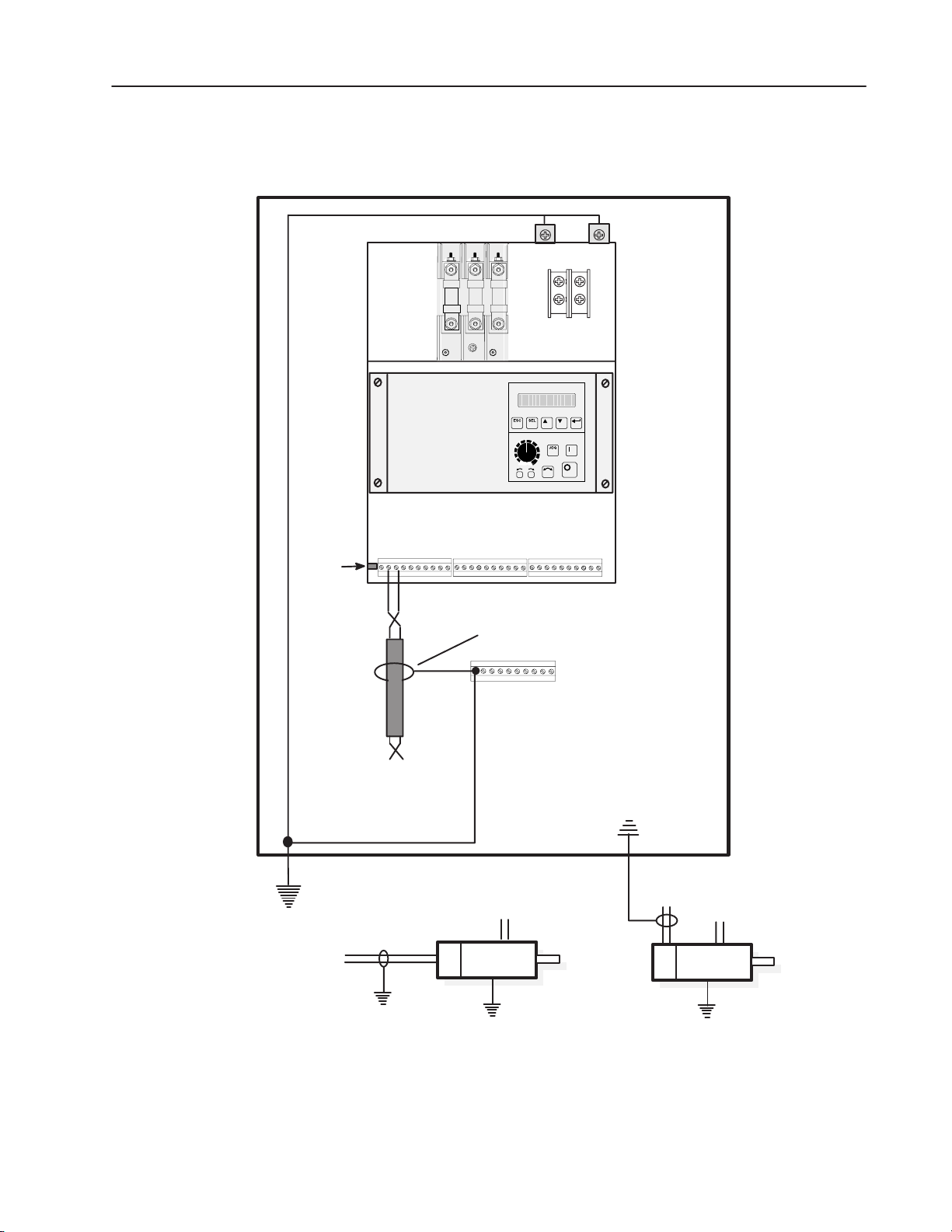

The general grounding concept for the 1397 is shown in Figure 2.6

and explained below. Specific Drive ground point locations are

detailed in Figures 2.7, 2.8 and 2.9.

Safety Ground – Is the safety ground required by code. The

ground bus can be connected to adjacent building steel (girder, joist)

or a floor ground grid, provided grounding points comply with NEC

regulations. Multiple connections are permitted, but Do Not ground

at the same point as a Signal Ground. The minimum distance

between Signal and Safety Ground is 10 feet (3 meters). The ground

bus is limited to a maximum of 1 ohm resistance to ground.

Power Feeder – Each power feeder from the substation transformer

to the Drive must be provided with properly sized ground cables.

Simply utilizing the conduit or cable armor as a ground is not

adequate. The conduit or cable armor and ground wires should be

bonded to substation ground at both ends. Each transformer

enclosure and/or frame must be bonded to ground at a minimum of

two locations.

Motor Connection – Each DC motor frame must be bonded to

grounded building steel within 20 feet (6 meters) of its location and

tied to the drives Safety Ground via ground wires within the power

cables and/or conduit. Bond the conduit or cable armor to ground at

both ends. The ground wire size and installation must be per NEC

Article 250.

Encoder Connections – If used, must be routed in grounded steel

conduit. The conduit must be grounded at both ends. Ground the

cable shield at the motor only (See Figure 2.6).

Tachometer Connections – If used, must be routed in grounded

steel conduit. The conduit must be grounded at both ends. Ground

the cable shield at the Drive end Only (See Figure 2.6).

(CE) Line Filter Connections – For grounding reqirements in CE

compliant applications, refer to page B.8 in this manual.

(CE) AC Line Inductor Connections – For grounding reqirements

in CE compliant applications, refer to page B.8 in this manual.

Publication 1397-5.0 — June, 2001

Page 28

Figure 2.6

1397 Grounding Practices

A1 45

Safety

Ground

Studs

2–9Installation

Control

Ground

Stud

(Located

behind

swing out

panel)

GROUND STUD

(BUS)

A

B

+ –

Twisted

Pair

DC Encoder

Regulator Board

Terminal Strip

Ground shield to terminal strip

Customer supplied terminal strip

mounted in close proximity to Drive

to keep shield length to a minimum.

+ –

Motor

DC Tach

Tach cable in steel conduit

(Grounded – wiring Class 8)

+ –

+ –

Motor

IMPORTANT: For CE requirements refer to Appendix B

Publication 1397-5.0 — June, 2001

Page 29

2–10 Installation

CONTROL GROUND

POINTS (on bottom

left side of drive)

M5 with Lug

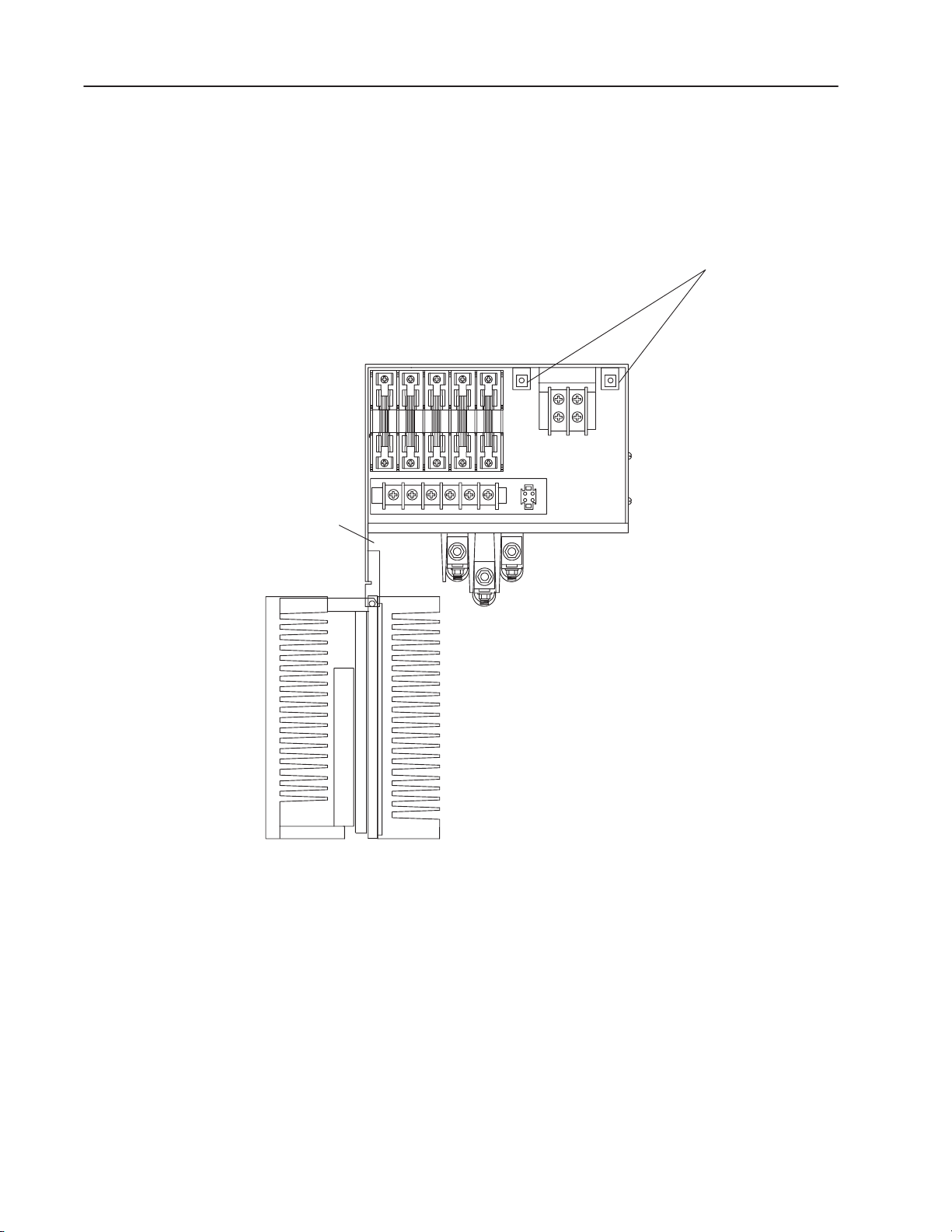

Figure 2.7

Drive Ground Point Locations – 1.5-30 HP at 230 VAC

7–100 A @ 380/415 VAC

3-60 HP at 460 VAC

POWER

GROUND

TOP VIEW

M6 with Lug

POINTS

Publication 1397-5.0 — June, 2001

Page 30

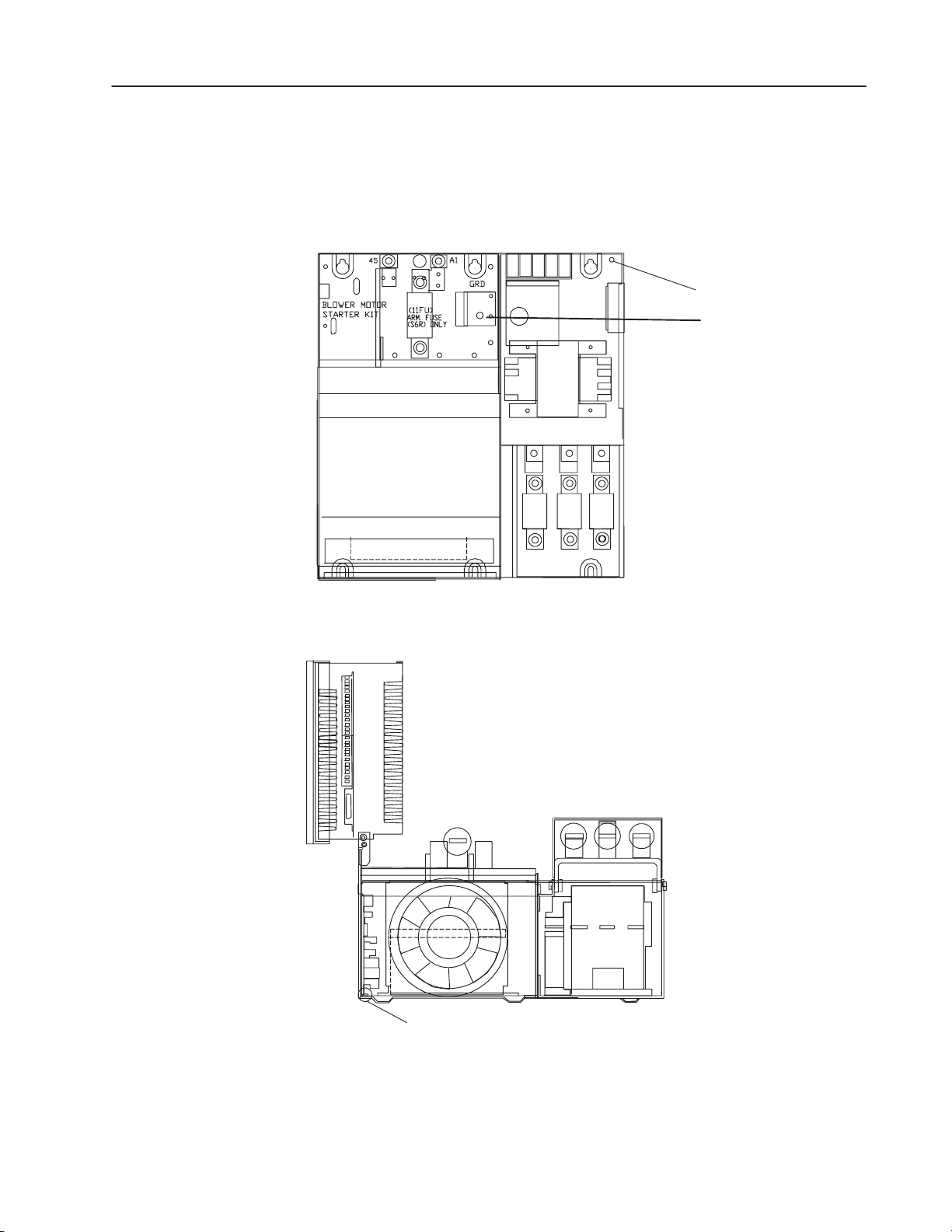

Figure 2.8

Drive Ground Point Locations – 40-75 HP at 230 VAC

265A @ 380/415 VAC

75-150 HP at 460 VAC, 265 Amp Rated Output

POWER

GROUND POINT

M8

2–11Installation

FRONT VIEW OF DRIVE

WITHOUT DISCONNECT

BOTTOM VIEW

CONTROL GROUND POINT

M6 With Lug

Publication 1397-5.0 — June, 2001

Page 31

2–12 Installation

Figure 2.9

Drive Ground Point Locations – 150 HP at 230 VAC;

300 HP at 460 VAC

10mm DIA

GROUND STUD

Located at back of chassis

6mm DIA

CONTROL

GROUND

14-10GA 35 LB.-IN

0 GA 48 LB.-IN.

GND

TORQUE

.

SPEC

STUD

45

DANGER

CIRCUIT BREAKER DOES NOT DISCONNECT INCOMING A0

LINE POWER IT ONLY PROVIDES DC FAULT PROTECTION.

LE DISCONECTEUR NE COUPTE PAS L'AUTOMENTATION DU SPOTEUR IL NES

SERT QUE A ASSURER UNE PROTECTION CONTRE LES DESFAULTS DC.

!

DANGER

RISK OF ELECTRICAL SHOCK. DISCONNECT INPUT

POWER BEFORE SERVICING EQUIPMENT.

FRONT

10mm DIA

GROUND STUDS

A1

Located at back of chassis

810903-2424

P/N 33145

SIDE

Publication 1397-5.0 — June, 2001

10mm DIA

GROUND STUD

TOP

10mm DIA

GROUND STUD

10mm DIA

GROUND STUD

(With Lug)

Page 32

Figure 2.10

34 PIN

60 PIN

Drive Ground Point Locations –

400-600 HP at 460 VAC

2–13Installation

M10 GROUND STUD

1FU

BLOWER MOTOR

STARTER KITS

182181 183

2FU 3FU

282281

283

4FU

288

M10 GROUND STUD

TOP VIEW

5FU

289

M6 CONTROL GROUND STUD

M6 CONTROL GROUND STUD

BOTTOM VIEW

Publication 1397-5.0 — June, 2001

Page 33

2–14 Installation

Table 2.A

Chassis Ground Connections

Hardware Size Tightening

M5 18 lb/in (2Nm)

M6 33 lb/in (3.7 Nm)

M8 100 lb/in (11.3 Nm)

M10 200 lb/in (23 Nm)

Lug with 14–10 AWG 35 lb/in (4 Nm)

Lug with 8 AWG 40 lb/in (4.5 Nm)

Lug with 6–4 AWG 45 lb/in (5.1 Nm)

Wiring Clearance

Disconnect

Although the minimum clearance should be maintained for proper

cooling, this space may not always provide proper wiring clearance.

The minimum allowable wire bending radius may necessitate that

extra space be provided to accommodate power wiring. Consult the

governing code for the proper wiring method.

NOTE: You are responsible for completing the installation of the

Drive system and to comply with all National and Local Electrical

Codes. The following information is to be used as a reference only.

ATTENTION: Hazard of electric shock or equipment

!

damage exist if the Drive is not installed correctly. The

National Electrical Code (NEC) and local codes outline

provisions for safely installing electrical equipment.

Installation must comply with specifications regarding

wire types, conductor sizes, branch circuit protection

and disconnect devices. Failure to do so may result in

personal injury and/or equipment damage.

You must provide a main disconnect and lockout device with cabinet

interlocks. This device must be wired in the isolation transformer or

reactor primary circuit. The device must be sized to handle 115% of

the full load primary current plus any additional loads that are

connected to the control system. Proper branch circuit protection for

the Drive and additional devices must be provided according to NEC

and local codes.

24V Power Supply

Publication 1397-5.0 — June, 2001

NOTE: Refer to Table on Page 1-6 for Drive current ratings to aid

in properly sizing wire.

The 1397 is equipped with a 250mA 24V power supply to power

additional peripheral devices. For example, up to two of the following

24V DC Scanport modules can be used:

1203-GK1 Single Point Remote I/O

1203-GK2 DFI (RS–232 / 422 / 485) or DH–485

Page 34

2–15Installation

If more than two SCANport modules are used with the 1397 Drive,

an additional 24V DC power supply must be installed, or 115V

SCANport modules must be used. Refer to the SCANport user

manual for information on installing additional SCANport modules.

The 24V DC power supply can be accessed at terminals #14 (24V

DC) and #15 (24VDC common) of the regulator board terminal strip.

Wire Size, Type & Class

14

15

+24V

24V COM

24V DC Power Supply

Wire sizes must be selected individually, observing all applicable

safety and NEC regulations. The minimum permissible wire size

does not necessarily result in the best operating economy. Due to the

Drive overload capacity, the conductors for the transformer primary

and secondary must be sized (at a minimum) for 125% of the full

load Drive line current. The motor armature conductors must also be

rated for 125% (at a minimum) of the full load motor current.

Shielded type wire is recommended in control circuits for protection

against interference. A shielded wire is required for all signal wires.

The recommended conductor size must be a minimum of 24 AWG.

The best interference suppression is obtained with a wire having an

individual shield for every pair. Table 2.B provides a listing and

description of cable types and wiring recommendations. Figure 2.9

shows recommended cable shielding. Note that wiring classes are

for reference only, and are not associated with any code or standard.

Terminal;

Symbol

Figure 2.11

Cable Shielding Recommendations

Shield

Shield

Shield

Shield Connection

2 Conductor

Shielded Cable

2 Conductor Shielded Cable

Multi-Conductor Shielded

Cable with Individual

Shielded Pairs

Publication 1397-5.0 — June, 2001

Page 35

2–16 Installation

Table 2.B

Cable and Wiring Recommendations

Category

Power

Control

Signal

(Process)

Signal

(Comm)

Wiring

Class

1

2

3

4

5

6

7

8

9

11

Signal Definition

AC Power (600V or greater)

AC Power (less than 600V)

DC Power

DC Power

115V AC/DC Logic

115V AC Power

24V AC/DC Logic

Analog Signals,

DC Supplies

Digital (low speed)

Digital

(high speed)

Serial

Communication

Serial Communication

(greater than 20k baud)

Signal Examples

2.3kV 3/Ph AC Lines

460V 3/Ph AC Lines

DC Motor Armature

DC Motor Field

Relay Logic/PLC I/O

Motor Thermostat

Power Supplies,

Instruments

PLC I/O

Reference/Feedback

Signal, 5 to 24V DC

TTL

I/O, Encoder, Count

Pulse Tach

RS-232, 422 to

Terminals/Printers

PLC Remote I/O,

PLC Data Highway

Cable Type

per NEC & Local Codes

per NEC & Local Codes

per NEC & Local Codes

per NEC & Local Codes

per NEC & Local Codes

per NEC & Local Codes

Shielded Cable – Belden

8735, 8737, 8404

Shielded Cable – Belden

9728, 9730

Shielded Cable – Belden

RS-232 – 8735, 8737

RS-422 – 9729, 9730

Twinaxial Cable – Belden

9463, A-B 1770-CD

Minimum Spacing in Inches between Classes –

1

0

3/9

3/9

3/

18

2/3/4

3/9

0

3/6

3/

12

Steel Conduit/Tray

7/8

3/18

3/12

3/9

0

9/10/11

Note6

Note 6

Note 6

1/3

5/6

3/9

3/6

0

3/9

Spacing

Notes

1/2/5

1/2/5

1/2/5

2/3/4/5

Note 6 1/3 0

Example: Spacing relationship between 480V AC incoming power leads and 24V DC logic leads.

– 480V AC leads are Class 2 ; 24V DC leads are Class 6

– For separate steel conduits, the conduits must be 3 inches (76 mm) apart

– In a cable tray, the two groups of leads are to be 6 inches (152 mm) apart

Spacing Notes:

1. Both outgoing and return current carrying conductors are to be pulled

in same conduit or laid adjacent in tray.

2.

Cables of the following classes can be grouped together.

A. Class 1; Equal to or above 601 volts

B. Classes 2,3, and 4 may have their respective circuits pulled in the

same conduit or layered in the same tray.

C. Classes 5 and 6 may have their respective circuits pulled in the

same conduit or layered in the same tray.

Note: Bundle may not exceed conditions of NEC 310

D. Classes7 and 8 may have their respective circuits pulled in the

same conduit or layered in the same tray.

Note: Encoder cables run in a bundle may experience some

amount of EMI coupling. The circuit application may dictate

separate spacing.

E. Classes 9, 10 and 11 may have their respective circuits pulled in

the same conduit or layered in the same tray.

Communication cables run in a bundle may experience some

amount of EMI coupling and corresponding communication faults.

The application may dictate separate spacing.

3. All wires of class 7 thru 11 MUST be shielded per the

recommendations

4. In cable trays, steel separators are advisable between the class

groupings.

5. If conduit is used, it must be continuous and composed of magnetic

steel.

6. Spacing of communication cables classes 2 thru 6 is:

CONDUIT SPACING THRU AIR

115 Volts – 1 inch 115 Volts – 2 inches

230 Volts – 1.5 inches 230 Volts – 4 inches

380/575 Volts – 3 inches 380/575 Volts – 8 inches

575 volts – proportional to 6” 575 volts proportional to 12”

per 1000 volts. per 1000 volts

General Notes

1. Steel conduit is recommended for all wiring classes. (Classes 7-11).

2. Spacing shown between classes is the minimum required for parallel

runs less than 400 feet. Greater spacing should be used where

possible.

3. Shields for shielded cables must be connected at one end only. The

other end should be cut back and insulated. Shields for cables from a

cabinet to an external device must be connected at cabinet end.

Shields for cables from one cabinet to another must be connected at

the source end cabinet. Splicing of shielded cables, if absolutely

necessary, should be done so that shields remain continuous and

insulated from ground.

4. Power wire is selected by load. 16AWG is the minimum

recommended size for control wiring.

LEGEND

2/3/4

3/9

Class Spacing

Steel Conduit/Tray

Publication 1397-5.0 — June, 2001

Page 36

2–17Installation

Motor Installation

The following procedure provides the steps needed to properly

install a DC motor for use with a 1397 Drive.

1. Verify that the motor you intend to install is the appropriate

rating for use with your model 1397 Drive.

2. Install the DC motor in accordance with the motor

manufacturer’s installation instructions.

3. Ensure that coupled applications have proper shaft alignment

with the driven machine or that belted applications have proper

sheave/belt alignment to minimize unnecessary motor loading.

4. If the motor is accessible while it is running, make certain all

guards necessary to satisfy local and national codes are

installed.

5. Size the motor armature circuit conductors for the specific

Drive rating and according to applicable codes.

6. Locate and connect the DC motor armature leads and the shunt

field supply leads on the Drive (Figures 2.13 through 2.16).

ATTENTION: 400 to 600 HP @ 460VAC

!

Regenerative Drives require an externally mounted

Inverting Fault Protection device connected in the

armature circuit. Refer to the instruction manual

provided with the Inverting Fault Protection device you

have selected for your drive for connection information.

Failure to provide Inverting Fault Protection could

result in severe bodily injury or loss of life.

Power Wiring Procedure

The following procedure provides the steps needed to properly

perform the power wiring connections to the 1397 Drive.

Using Table 2.C, verify that the motor field is compatible with the

DC field voltage output of the Drive.

Table 2.C

Standard Field Voltage Output

AC Incoming

Voltage to Drive

230V AC

380V AC

415V AC

460V AC

DC Supply Output

Voltage to Field

150V DC

250V DC

270V DC

300V DC

Publication 1397-5.0 — June, 2001

Page 37

2–18 Installation

1. Connect the motor armature and field leads to produce proper

direction of motor rotation. Figure 2.12 shows the connections

required to produce counterclockwise rotation of the motor

when viewed from the commutator end with a positive speed

reference input to the Drive.

Figure 2.12

Typical DC Motor Connections (CCW) Rotation

1.5 to 150HP @ 230VAC, 3 to 300HP @ 460VAC

Bulletin 1397

A2/S1–S2

Link

Removed

Bulletin 1397

F1 ( + )

A1

( – ) 45

F2 ( – )

F1 ( + )

( 2 )

A1

A2

( 2 )

S1

S2

F2 ( – )

Motor

Basic Stabilized Shunt Machine,

CCW Rotation, Facing Commutator End

F1 ( + )

DBR

A2/S1

A1

S1

*

F2 ( – )

F1 ( + )

A1

A2

S1

S2

F2 ( – )

Motor

(1)

400 to 600HP @ 460VAC

( 2 )

( 2 )

(1)

Bulletin 1397

Straight Shunt Machine,

CCW Rotation, Facing Commutator End

A2/S1–S2

Link

Installed

A2/S1

Bulletin 1397

F1 ( + )

( – ) 45

F2 ( – )

F1 ( + )

S1

DBR

F2 ( – )

A1

A1

F1 ( + )

( 2 )

A1

A2

( 2 )

A2

F2 ( – )

(1)

Motor

F1 ( + )

( 2 )

A1

A2

F2 ( – )

Motor

( 2 )

(1)

*

( 3 )

Basic Stabilized Shunt Machine,

CCW Rotation, Facing Commutator End

*If Used

Straight Shunt Machine,

CCW Rotation, Facing Commutator End

(1) In cases where full regenerative torque capability is required for braking or slow down operation or where the drive

will be applied for bi–directional operation, you should specify straight shunt DC motors (wound without a series field winding)

to assure symmetrical motor operation in both forward and reverse directions, full torque capability, and motor stability under

any mode of operation.

(2) If this connection of the motor armature leads results in motor rotation opposite of what is required, reverse the A1 and A2

lead connections at the motor.

(3) Connect Drive Terminal A2/S1 or S2 to motor terminal A2.

2. The 1397 is supplied with semi conductor fuses for line

protection. An isolation transformer can also be used. In

general, the 1397 is suitable for direct connection to a correct

voltage AC line that has minimum impedance of 3%. If the

Publication 1397-5.0 — June, 2001

Page 38

2–19Installation

line is lower impedance, a line reactor or isolation transformer

must be added upline from the Drive to increase line

impedance. If the line impedance is too low, transient voltage

spikes or interruptions can create excessive current spikes that

will cause nuisance input fuse blowing, and may cause damage

to the Drive power structure. Refer to Figures 2.13 through

2.16 for AC input wiring at the main fuses and the

following ATTENTION note when determining if a line reactor

or isolation transformer is required for your installation.

AC Line Connection – Connect incoming three-phase AC line

power to the AC Line Terminals as shown in Figures 2.13 through

2.16. Note that the incoming AC power is wired to separate

terminals on the 1.5-30HP/3-60HP, 7–110A Drives, but is wired

directly to AC line fuses on 40-75HP/75-150HP,

100-150/200-300HP, 265A and higher and 400 to 600 HP Drives.

The fuses supplied are designed to provide protection against short

circuits for the Drive semiconductors and associated output wiring.

They are not to be considered a substitute for the user supplied motor

branch circuit protective devices that are required by the National

Electrical Code. Refer to Table 2.E for proper sizing of the AC

power and branch fuses.

ATTENTION: If the AC input power system does not

!

have a neutral or one phase referenced to ground, an

isolation transformer with the neutral of the secondary

grounded is highly recommended. If the line-to-line

voltages on any phase can exceed 125% of the nominal

line-to-line voltage, an isolation transformer with the

neutral of the secondary grounded, is always required.

Failure to observe these precautions could result in

bodily injury or damage to equipment.

Publication 1397-5.0 — June, 2001

Page 39

2–20 Installation

Figure 2.13

AC Line Connection Location

1.5-30 HP at 230 VAC; 3-60 HP at 460 VAC

7-110A @ 380/415 VAC

AC Line

Connection

FRONT

181

(L1)

AC Line

Connection

182

(L2)

183

(L3)

FRONT

81

(L1)

82

(L2)

83

(L3)

Without AC Line Disconnect

Publication 1397-5.0 — June, 2001

With AC Line Disconnect

Page 40

Figure 2.14

AC Line Connection Location

40-75 HP at 230 VAC; 75-150 HP at 460 VAC

265A @ 380/415 VAC

2–21Installation

AC Line

Connection

FRONT VIEW OF DRIVE WITHOUT DISCONNECT

Publication 1397-5.0 — June, 2001

Page 41

2–22 Installation

Figure 2.15

A-C Line Connection Locations

100-150 HP at 230 VAC; 200-300 HP at 460 V AC

14-10GA 35 LB.-IN

0 GA 48 LB.-IN.

DANGER

CIRCUIT BREAKER DOES NOT DISCONNECT INCOMING A0

LINE POWER IT ONLY PROVIDES DC FAULT PROTECTION.

LE DISCONECTEUR NE COUPTE PAS L'AUTOMENTATION DU SPOTEUR IL NES

810903-2424

SERT QUE A ASSURER UNE PROTECTION CONTRE LES DESFAULTS DC.

!

DANGER

RISK OF ELECTRICAL SHOCK. DISCONNECT INPUT

POWER BEFORE SERVICING EQUIPMENT.

P/N 33145

GND

TORQUE

.

SPEC

AC Line

Connection

SHOWN WITHOUT

AC LINE

DISCONNECT

Publication 1397-5.0 — June, 2001

Page 42

Figure 2.16

A-C Line Connection Locations

400-600 HP at 460 VAC

AC LINE

CONNECTION

AC LINE

CONNECTION

2–23Installation

81 82 83

ON

BLOWER MOTOR

STARTER KITS

Without AC

Line Disconnect

1FU

281

182181 183

2FU 3FU

282

283

4FU

288

OFF

1FU 2FU 3FU

282

281

5FU

289

BLOWER MOTOR

STARTER KITS

283

5FU4FU

288 289

With AC

Line Disconnect

Publication 1397-5.0 — June, 2001

Page 43

2–24 Installation

HP

1.5

2

3

5

7.5

10

15

20

25

30

40

50

60

75

100

125

150

200

250

300

400

500

600

Table 2.D

AC Line Connectors

Recommended Tightening Torque

230 V AC 380 VAC 415 VAC 460 V AC

6.2 Nm (55 lb-in)

6.2 Nm (55 lb-in)

6.2 Nm (55 lb-in)

6.2 Nm (55 lb-in)

6.2 Nm (55 lb-in)

6.2 Nm (55 lb-in)

13.6 Nm (120 lb-in)

13.6 Nm (120 lb-in)

13.6 Nm (120 lb-in)

13.6 Nm (120 lb-in)

22 Nm (200 lb-in)

22 Nm (200 lb-in)

22 Nm (200 lb-in)

22 Nm (200 lb-in)

22 Nm (200 lb-in)

40 Nm (350 lb-in)

40 Nm (350 lb-in)

—

—

—

—

—

6.2 Nm (55 lb-in)

6.2 Nm (55 lb-in)

6.2 Nm (55 lb-in)

6.2 Nm (55 lb-in)

6.2 Nm (55 lb-in)

6.2 Nm (55 lb-in)

6.2 Nm (55 lb-in)

6.2 Nm (55 lb-in)

13.6 Nm (120 lb-in)

13.6 Nm (120 lb-in)

13.6 Nm (120 lb-in)

13.6 Nm (120 lb-in)

22 Nm (200 lb-in)

22 Nm (200 lb-in)

22 Nm (200 lb-in)

22 Nm (200 lb-in)

22 Nm (200 lb-in)

6.2 Nm (55 lb-in)

6.2 Nm (55 lb-in)

6.2 Nm (55 lb-in)

6.2 Nm (55 lb-in)

6.2 Nm (55 lb-in)

6.2 Nm (55 lb-in)

6.2 Nm (55 lb-in)

6.2 Nm (55 lb-in)

13.6 Nm (120 lb-in)

13.6 Nm (120 lb-in)

13.6 Nm (120 lb-in)

13.6 Nm (120 lb-in)

22 Nm (200 lb-in)

22 Nm (200 lb-in)

22 Nm (200 lb-in)

22 Nm (200 lb-in)

22 Nm (200 lb-in)

—

—

6.2 Nm (55 lb-in)

6.2 Nm (55 lb-in)

6.2 Nm (55 lb-in)

6.2 Nm (55 lb-in)

6.2 Nm (55 lb-in)

6.2 Nm (55 lb-in)

6.2 Nm (55 lb-in)

13.6 Nm (120 lb-in)

13.6 Nm (120 lb-in)

13.6 Nm (120 lb-in)

13.6 Nm (120 lb-in)

22 Nm (200 lb-in)

22 Nm (200 lb-in)

22 Nm (200 lb-in)

22 Nm (200 lb-in)

22 Nm (200 lb-in)

34 Nm (300 lb-in)

34 Nm (300 lb-in)

34 Nm (300 lb-in)

34 Nm (300 lb-in)

34 Nm (300 lb-in)

Note: The tightening torque in the table applies to the wiring device (stud or terminal board)

provided. When an input or an output device (breaker or lug kit) is added, refer to the kit

instructions for tightening specifications.

Publication 1397-5.0 — June, 2001

Page 44

Recommended AC Line an

d

DC Armature Fuses

AC Line Fuse (1FU, 2FU, 3FU)

HP at 230 V AC HP at 380 V AC HP at 415 V AC HP at 460 V AC

1.5-5

7.5-10

15

20-30

40-60

75

100

125-150

2.4

12

24

48

120

2.8

13.8

27.6

55.2

138

The following tables list the recommended AC line and DC armature

fuses for the Drive. The armature fuse is required only for

regenerative Drives.

Standard models are shipped with the appropriate fuses.

You must select the correct replacement fuse type from Tables 2.E

and 2.F.

Table 2.E

AC Line Fuses

3-10

15-20

30

40-60

75-125

150

200

250-300

400-600

Fuse Rating (500 V) Fuse Class Manufacturer

40A

80A

90A

150A

300A

350A

600A

800A

600A (700V)

2 in parallel

XL50F

XL50F

XL50F

XL50F

XL50F

XL50F

XL50F

XL50F

A70QS600–4K

Bussman

Bussman

Bussman

Bussman

Bussman

Bussman

Bussman

Bussman

Gould

2–25Installation

Table 2.F

DC Armature Fuses (Regenerative Drives Only)

DC Line Fuse (11FU)

HP at 230 V AC A @ 380/415 V AC HP at 460 V AC

1.5

2

3

5

7.5

10

15

20-25

30

40

50

60

75

7

7

7

7

29

29

55

55

110

110

110

110

205

3

4

6

10

15

20

30

40-50

60

75

100

125

150

Fuse Rating (700 V) Fuse Class Manufacturer

15A

20A

25A

35A

40A

50A

70A

125A

150A

200A

250A

300A

350A

XL70F

XL70F

XL70F

XL70F

XL70F

XL70F

XL70F

XL70F

XL70F

XL70F

XL70F

XL70F

XL70F

Bussman

Bussman

Bussman

Bussman

Bussman

Bussman

Bussman

Bussman

Bussman

Bussman

Bussman

Bussman

Bussman

Publication 1397-5.0 — June, 2001

Page 45

2–26 Installation

DB Connections

2

1

Figure 2.17

DC Drive Motor Field and Armature Connection Locations

1.5-30 HP at 230 VAC

7-110A @ 380/415 VAC

3-60 HP at 460 VAC

DC Motor

Armature

Connection

45

A1

DC Motor

Field

Connection

F2

F1

4

3

TOP

Publication 1397-5.0 — June, 2001

Page 46

Figure 2.18

DC Motor Field and Armature Connection Locations

40-75 HP at 230 VAC

265A @ 380/415 VAC

75-150 HP at 460 VAC

GROUND POINT

2–27Installation

FRONT VIEW OF DRIVE

WITHOUT DISCONNECT

Publication 1397-5.0 — June, 2001

Page 47

2–28 Installation

Figure 2.19

DC Motor Field and Armature Connection Locations

100-150 HP at 230 VAC,

200-300 HP at 460 VAC

A1

45

DC MOTOR

ARMATURE

CONNECTION

DANGER

CIRCUIT BREAKER DOES NOT DISCONNECT INCOMING A0

LINE POWER IT ONLY PROVIDES DC FAULT PROTECTION.

LE DISCONECTEUR NE COUPTE PAS L'AUTOMENTATION DU SPOTEUR IL NES

810903-2424

SERT QUE A ASSURER UNE PROTECTION CONTRE LES DESFAULTS DC.

14-10GA 35 LB.-IN

0 GA 48 LB.-IN.

!

DANGER

RISK OF ELECTRICAL SHOCK. DISCONNECT INPUT

POWER BEFORE SERVICING EQUIPMENT.

P/N 33145

GND

TORQUE

.

SPEC

FRONT

SIDE

1 2 3 4 F1 F2

DB

Connections

For

Option

Kits

DC

Motor

Field

Connections

TOP

Publication 1397-5.0 — June, 2001

Page 48

Figure 2.20

DC Motor Field and Armature Connection Locations

400-600 HP at 460 VAC

2–29Installation

Publication 1397-5.0 — June, 2001

Page 49

2–30 Installation

Control Connections

The Bulletin 1397 is supplied with the following standard I/O

compliment:

• 10 Digital Inputs

24V DC internally or externally supplied

8V DC turn–on voltage

0.5 mA turn–off current

• 3 Contact Outputs

250V AC maximum

30V DC maximum

2A maximum resistive load

1A maximum inductive load

• 2 Speed Reference Inputs

Analog Reference 1

±10V DC

4 – 20 mA

10 – 50 mA

Converted within Drive to 12 bit plus sign

Analog Reference 2

External potentiometer (5kΩ min.)

±10V DC

Converted within Drive to 12 bit plus sign

• DC Tachometer Input

10 – 250V DC

Converted within Drive to 12 bit plus sign

• 2 Analog Outputs

±10V DC

4A maximum load

In order to maintain simplicity, the functions of the analog and

digital inputs are fixed. The analog and digital outputs, however,

may be reconfigured. See Chapter 5 for information on parameters

that must be manipulated to reconfigure the outputs.

ATTENTION: The 1397 Drive control circuitry

!

includes solid–state components. If hazards due to

accidental contact with moving machinery or

unintentional flow of liquid, gas or solids exist, an

additional hardwired stop circuit may be required to

remove AC line power to the Drive. When AC input

power is removed, there will be a loss of inherent

regenerative braking effect and the motor will coast to a

stop. An auxiliary braking method may be required.

Publication 1397-5.0 — June, 2001

Page 50

2–31Installation

Control Wiring Procedure

Most control connections on the 1397 Drive are made at the

Regulator Board Terminal Strip which is located at the bottom of the

Drive as shown in Figure 2.21.

Figure 2.21

Regulator Board Terminal Strip Location

J28

Terminal Strip

Regulator Board Input Signal Definitions

The 1397 Drive will recognize a change in the state of a digital input

(e.g. 0-24VDC) if it is applied longer than 20 ms. Power (24VDC)

signals are available on regulator terminal block pins TB-01, TB-07,

TB-11 and TB-14. The associated common connection is present on

TB-15. The Digital inputs shown Figure 2.18 are defined as follows:

TB–01 POWER – A 24VDC supply is available at this pin.

TB–02 RUN – Edge sensitive signal that initiates a Run

command (0 ✒ 1 = Run). If the Drive is Run, voltage

may be applied to the armature causing the motor to

reach the desired speed. The Run input is latched and

therefore does not have to be maintained to keep the

drive Running. This input can be masked through the

[Run Mask] (P. 201) or [Logic Mask] (P.207)

parameters.

Publication 1397-5.0 — June, 2001

Page 51

2–32 Installation