Page 1

AADvance

The Next Step in Automation

AADvance Controller

Solutions Handbook

Issue: 09

DOCUMENT: 553631

(ICSTT-RM447J_EN_P)

Page 2

ii

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

Solutions Handbook (AADvance Controller)

This page intentionally left blank

Page 3

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

iii

Notice

In no event will Rockwell Automation be responsible or liable for indirect or

consequential damages resulting from the use or application of this equipment. The

examples given in this manual are included solely for illustrative purposes. Because of

the many variables and requirements associated with any particular installation,

Rockwell Automation does not assume responsibility or reliability for actual use based

on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, with respect to use of

information, circuits, equipment, or software described in this manual.

Reproduction of this manual in whole or in part, without written permission of

Rockwell Automation is prohibited.

All trademarks are acknowledged.

Disclaimer

It is not intended that the information in this publication covers every possible detail

about the construction, operation, or maintenance of a control system installation. You

should refer to your own (or supplied) system safety manual, installation instructions

and operator/maintenance manuals.

Revision and Updating Policy

This document is based on information available at the time of its publication; however,

the document contents are subject to change from time to time. You should contact

Rockwell Automation Technical Support by e-mail — icstsupport@ra.rockwell.com to

check if you have the latest version of this publication.

© Copyright Notice, Rockwell Automation 2012

This document contains proprietary information that is protected by copyright. All

rights are reserved.

Documentation Feedback

Your comments will help us to serve your documentation needs better. If you

discover any errors or have any suggestions on how to improve this publication send

your comments to our product support group: icstsupport@ra.rockwell.com

This manual is applicable to Release R1.3 of the AADvance controller.

Page 4

iv

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

Solutions Handbook (AADvance Controller)

Notes and Symbols used in this manual

This symbol calls attention to items which "must" be considered and implemented

when designing and building an AADvance controller for use in a Safety

Instrumented Function (SIF). It appears extensively in the AADvance Safety Manual.

WARNING

ELECTRICAL ARCS AND EXPLOSION RISK IN HAZARDOUS

AREAS

If you connect or disconnect wiring, modules or communications cabling while

power is applied, an electrical arc can occur. This could cause an explosion in

hazardous location installations. Do not remove wiring, fuses, modules or

communications cabling while circuit is energized unless area is known to be

non hazardous.

Failure to follow these instructions may result in personal injury.

WARNING

MAINTENANCE

Maintenance must be carried out only by qualified personnel.

Failure to follow these instructions may result in personal injury.

CAUTION

RADIO FREQUENCY INTERFERENCE

Most electronic equipment is influenced by Radio Frequency Interference.

Caution should be exercised with regard to the use of portable communications

equipment around such equipment. Signs should be posted in the vicinity of the

equipment cautioning against the use of portable communications equipment.

CAUTION

HEAT DISSIPATION AND ENCLOSURE POSITION

System and field power consumption by modules and termination assemblies is

dissipated as heat. You should consider this heat dissipation on the design and

positioning of your enclosure; e.g. enclosures exposed to continuous sunlight

will have a higher internal temperature that could affect the operating

temperature of the modules. Modules operating at the extremes of the

temperature band for a continuous period can have a reduced reliability.

Note: Notes are used extensively to provide important information about the

product.

Standard Warnings and Cautions

Page 5

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

v

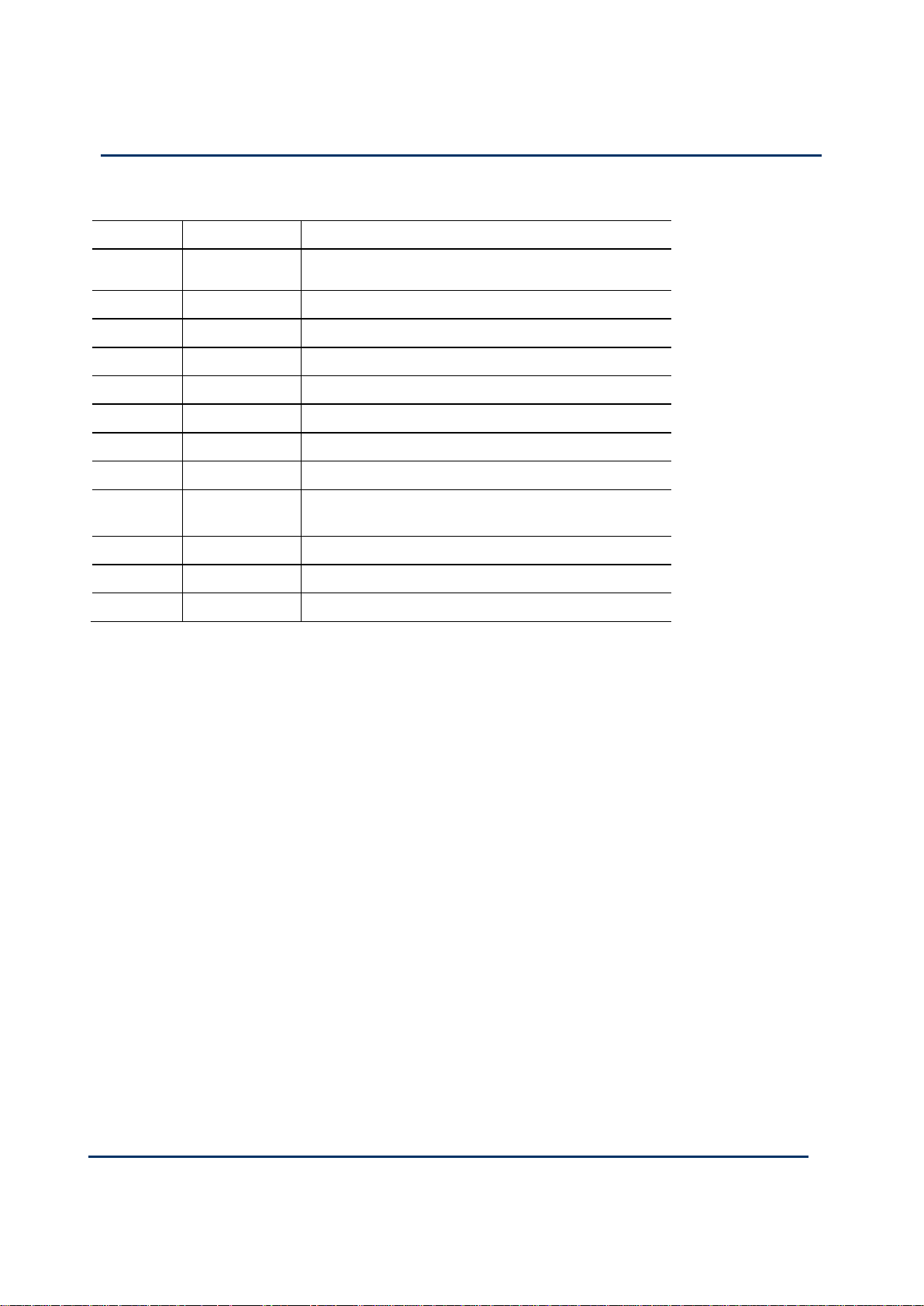

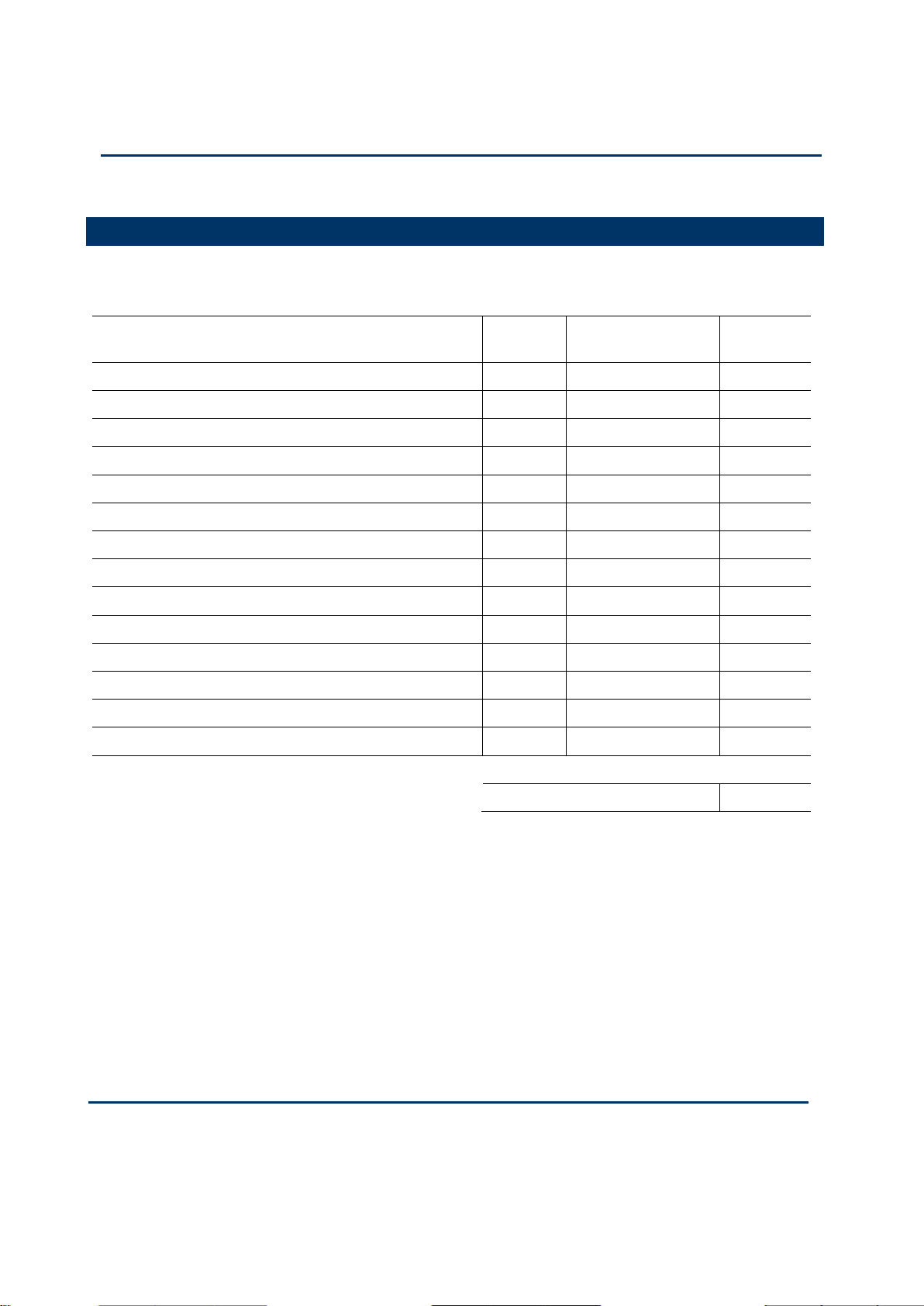

Issue Record

Issue

Date

Comments

01

Dec 2008

First Issue

02

Feb 2009

03

Feb 2010

04

Mar 2010

Updates after peer review

05

June 2010

updates for release 1.1.1

06

Oct 2010

updates to meet UL requirements

07

Nov 2010

updates for ATEX and UL Certification and release 1.2

08

July 2012

Release 1.3 version

09

Aug 2013

Changes to TUV certification topic, add On-line update

feature and module specification data.

Page 6

vi

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

Solutions Handbook (AADvance Controller)

Forward

This technical manual describes the features, performance and functionality of the

AADvance controller and systems. It sets out some guidelines on how to specify a

system to meet your application requirements.

Note: The AADvance controller is a logic solver. It uses processor modules and I/O

modules. An AADvance system is formed by one or more controllers, their power

sources, communications networks and workstations.

Who Should Use this Manual

This manual is intended primarily for system designers and technical sales people who

need to understand the capabilities of an AADvance controller. This manual will assist

you to design a suitable system.

The information contained in this manual is intended to be used in conjunction with

(and not as a substitute for) expertise and experience in safety-related systems. In

particular, it is expected that the reader has a thorough understanding of the intended

application and can understand the generic terms used within this manual and the

terminology specific to the integrator's or project's application area.

Page 7

Page 8

viii

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

Solutions Handbook (AADvance Controller)

Contents

Chapter 1 The AADvance System ........................................................................... 1-1

The AADvance Controller .............................................................................................................................. 1-1

Performance and Electrical Specifications .............................................................................................. 1-3

Scan Times ..................................................................................................................................................... 1-4

Environmental Specifications ..................................................................................................................... 1-5

Controller TUV Certification ................................................................................................................... 1-7

Certification for use in Hazardous Environments ................................................................................ 1-7

File No: E341697 .......................................................................................................................................... 1-7

File No: E251761 .......................................................................................................................................... 1-8

KCC-EMC Registration ........................................................................................................................... 1-12

Main Components ........................................................................................................................................... 1-13

Hardware Components............................................................................................................................ 1-13

AADvance Workstation Software and Application Development Environment ....................... 1-14

Controller Functionality ................................................................................................................................. 1-16

SNTP ............................................................................................................................................................. 1-16

CIP over EtherNet/IP ................................................................................................................................ 1-16

HART ............................................................................................................................................................ 1-17

SNCP Safety Networks ............................................................................................................................ 1-18

Peer-to-Peer ................................................................................................................................................ 1-20

Serial Communication Interface ............................................................................................................. 1-22

Time Synchronization (SNTP) ................................................................................................................ 1-22

Modbus Master ........................................................................................................................................... 1-23

The OPC Portal Server ............................................................................................................................ 1-24

Controller IP Address Setting ................................................................................................................. 1-25

Recovery Mode .......................................................................................................................................... 1-25

DiffServ Configuration .............................................................................................................................. 1-25

Ethernet Forwarding ................................................................................................................................. 1-26

Transparent Communication Interface (TCI) ..................................................................................... 1-27

Compiler Verification Tool ..................................................................................................................... 1-27

Technical Features ........................................................................................................................................... 1-28

TUV Approved Operating System ......................................................................................................... 1-28

Internal Diagnostics ................................................................................................................................... 1-28

Controller Internal Bus Structure ......................................................................................................... 1-28

System Modification and On-line Updates ........................................................................................... 1-29

ControlFLASH Firmware Upgrades ...................................................................................................... 1-31

Physical Features .............................................................................................................................................. 1-32

Product Dimensions .................................................................................................................................. 1-32

Compact Module Design.......................................................................................................................... 1-33

Module Polarization Keying ..................................................................................................................... 1-34

Module Locking Mechanism .................................................................................................................... 1-35

Termination Assemblies ........................................................................................................................... 1-35

Ethernet, Serial Data and Power Connections ................................................................................... 1-37

Page 9

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

ix

Serial Communications ............................................................................................................................. 1-37

Field Wiring Connections ........................................................................................................................ 1-38

Corrective Maintenance and Module Replacement .......................................................................... 1-38

Chapter 2 AADvance System Architectures .......................................................... 2-1

SIL2 Architectures ............................................................................................................................................. 2-1

SIL2 Fail-safe Architecture ......................................................................................................................... 2-2

SIL2 Fault Tolerant Input Architectures ................................................................................................. 2-3

SIL2 Output Architecture .......................................................................................................................... 2-4

SIL2 Fault Tolerant Input High Demand Architecture ........................................................................ 2-5

SIL3 Architectures ............................................................................................................................................. 2-6

SIL3 Fail-safe I/O, Fault Tolerant Processor .......................................................................................... 2-7

SIL3 Fault Tolerant I/O Architectures .................................................................................................... 2-8

SIL3 TMR Input and Processor, Fault Tolerant Output ................................................................... 2-10

Planned Certified Configurations ................................................................................................................. 2-11

Chapter 3 Building Architectures with TUV Approved Modules ......................... 3-1

Fundamental Architectures ............................................................................................................................. 3-1

Simplex I/O Architecture ................................................................................................................................. 3-1

Dual Architecture for Fault Tolerant Applications .................................................................................... 3-5

Triple Modular Redundant Architecture ..................................................................................................... 3-7

Chapter 4 Mixed Architectures ................................................................................ 4-1

Example Controllers ......................................................................................................................................... 4-1

Mixed I/O Architectures .................................................................................................................................. 4-3

Mixed Safety Integrity Levels ........................................................................................................................... 4-4

Distributed Architectures ................................................................................................................................ 4-5

Typical Network Applications ........................................................................................................................ 4-6

Specifying a Safety Network ...................................................................................................................... 4-6

Controller Network Connectors ............................................................................................................ 4-7

Chapter 5 AADvance Scalability .............................................................................. 5-1

I/O Channel Capacity ........................................................................................................................................ 5-1

Simplex I/O Channel Capacity .................................................................................................................. 5-2

Dual I/O Channel Capacity ........................................................................................................................ 5-3

Triple Modular Redundant Channel Capacity ....................................................................................... 5-4

Adding I/O Channel Capacity ......................................................................................................................... 5-5

Bus Connectors and Expansion Cable .......................................................................................................... 5-5

Redundancy and Fault Tolerance ................................................................................................................... 5-6

Expansion using Distributed Controllers ..................................................................................................... 5-6

Chapter 6 Specifying a New Controller .................................................................. 6-1

Information to Specify a New Controller .................................................................................................... 6-1

Define a New System ....................................................................................................................................... 6-2

Choosing Termination Assemblies ................................................................................................................ 6-5

Specify I/O Base Units....................................................................................................................................... 6-5

Estimate AADvance Controller Weight ...................................................................................................... 6-6

Page 10

x

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

Solutions Handbook (AADvance Controller)

Estimate Module Supply Power Dissipation and Field Loop Power Dissipation ................................ 6-7

Chapter 7 Module Overview and Specifications ..................................................... 7-1

T9110 Processor Module ................................................................................................................................ 7-2

Processor Module Specification ............................................................................................................... 7-4

T9100 Processor Base Unit............................................................................................................................. 7-5

T9100 Base Unit Specification .................................................................................................................. 7-7

T9300 I/O Base Unit (3 way) .......................................................................................................................... 7-8

T9300 Base Unit Specification .................................................................................................................. 7-9

T9310 Expansion Cable Assembly ............................................................................................................... 7-10

T9310 Extension Cable Specification .................................................................................................... 7-11

T9401/2 Digital Input Module, 24V dc, 8/16 channel .............................................................................. 7-12

T9401/2 Digital Input Module Specification ......................................................................................... 7-13

T9801/2/3 Termination Assemblies for Digital Inputs ............................................................................ 7-14

T9801/2/3 Digital Input Termination Assembly Specification ......................................................... 7-15

T9431/2 Analogue Input Module, 8/16 Channel....................................................................................... 7-16

T9431/2 Analogue Input Module Specification ................................................................................... 7-17

T9831/2/3 Termination Assemblies for Analogue Inputs ....................................................................... 7-18

T9831/2/3 Analogue Input Termination Assembly Specification .................................................... 7-19

T9451 Digital Output Module, 24V dc, 8 channel ................................................................................... 7-20

T9451 Digital Output Module Specification ........................................................................................ 7-21

T9851/2 Termination Assemblies for Digital Outputs ........................................................................... 7-22

T9851/2 Digital Output Termination Assembly Specifications ....................................................... 7-23

T9481/2 Analogue Output Module ............................................................................................................. 7-24

T9481/2 Analogue Output Module Specification ............................................................................... 7-25

T9881/2 Termination Assembly for Analogue Output Module............................................................ 7-26

T9881/2 Analogue Output Termination Assembly Specification ................................................... 7-27

Chapter 8 Application (Resource) Development ................................................... 8-1

Programming Language Support ..................................................................................................................... 8-1

Program Management Facilities ...................................................................................................................... 8-1

Support for Variable Types ............................................................................................................................. 8-2

I/O Connection (Addressing of Physical I/O) ............................................................................................. 8-2

Off-line Simulation and Testing ...................................................................................................................... 8-2

Application (Resource) Program Security ................................................................................................... 8-2

Aids to Software Development ...................................................................................................................... 8-3

AADvance Workbench Licensing Options ................................................................................................. 8-3

DIN Rails Fitting ................................................................................................................................................. 8-4

Chapter 9 System Build ............................................................................................ 9-1

Free Space Around the Controller ............................................................................................................... 9-1

Base Units, DIN Rail installations and Expansion Cables ......................................................................... 9-3

Assemblies of Base Units ................................................................................................................................. 9-3

Page 11

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

xi

Power Supply Requirements ........................................................................................................................... 9-4

Adding Cable Management .............................................................................................................................. 9-4

Chapter 10 Parts List ................................................................................................ 10-1

Chapter 11 Glossary of Terms ................................................................................. 11-1

Chapter 12 Additional Resources ............................................................................ 12-1

Page 12

Page 13

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

1-1

An AADvance system consists of an AADvance controller, an external operator's

In This Chapter

The AADvance Controller ............................................................................... 1-1

Main Components ............................................................................................ 1-13

Controller Functionality .................................................................................. 1-16

Technical Features ............................................................................................ 1-28

Physical Features ............................................................................................... 1-32

Chapter 1

The AADvance System

workstation, field connections, power sources and external network connections. The

flexibility of the design allows a system to be built to suit your own requirements from

a standard range of modules and assemblies.

This chapter describes the main components that can be used to build an AADvance

controller.

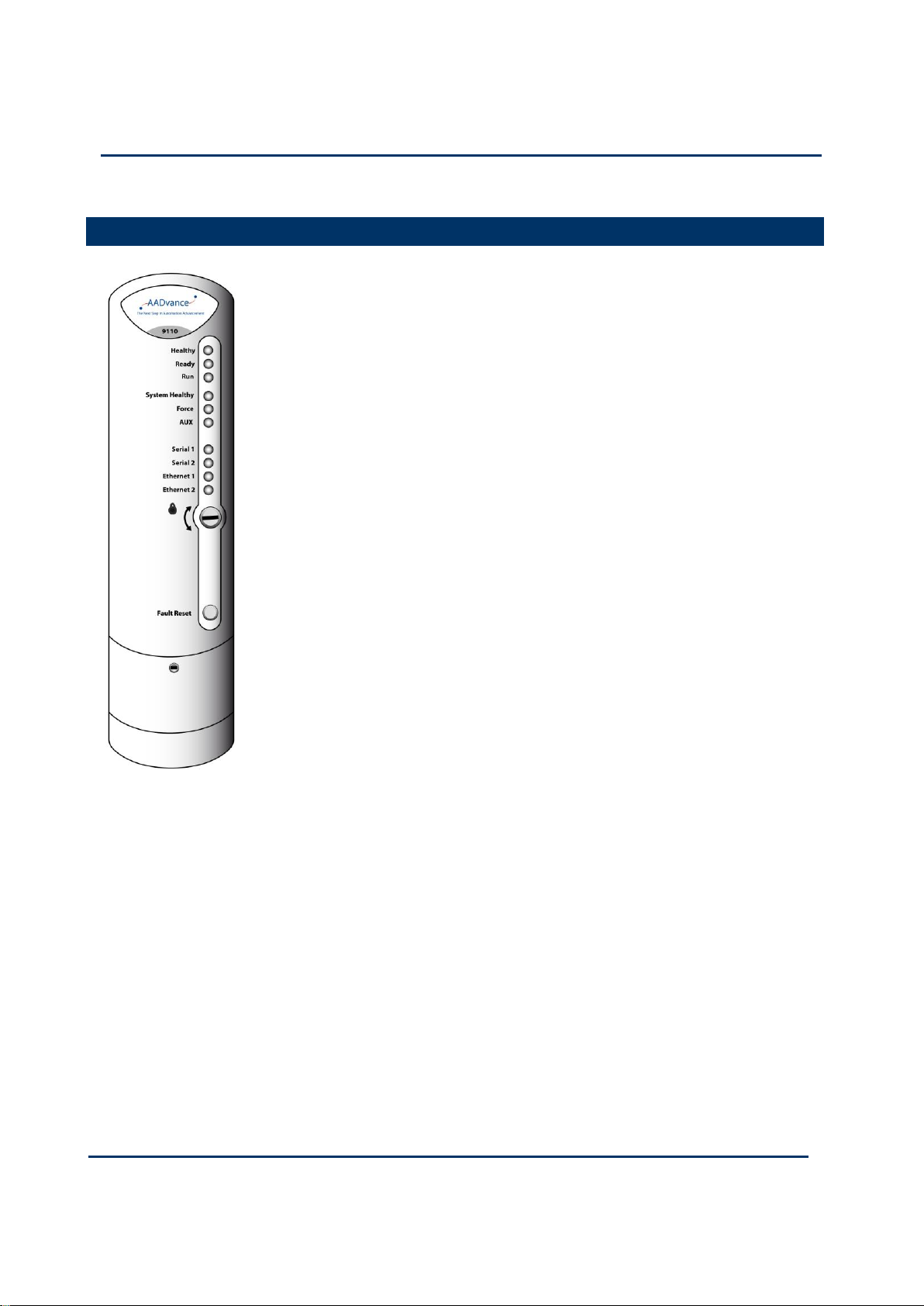

The AADvance Controller

The AADvance controller is specifically designed for functional safety and critical

control applications; it provides a flexible solution for your smaller scale requirements.

The system can be used for safety implement functions as well as applications that are

non-safety but still critical to a business process. This controller offers you the ability

to create a cost-effective system to suit any of the following applications:

Critical process control

Fire and gas protection systems

Rotating machinery control systems

Burner management

Boiler and furnace control

Distributed process monitoring and control

The AADvance controller is a logic solver and I/O processing device that consists of

processor modules, I/O modules and field termination assemblies that can easily be

assembled and configured. A system is built up from one or more controllers, a

combination of I/O modules, power sources, communications networks and user

workstations. How you configure the system determines the type of application it can

be used for.

An AADvance controller is particularly well suited to emergency shut down and fire

and gas detection protection applications by providing a system solution with

integrated and distributed fault tolerance. It is designed and validated to international

standards and is certified by TÜV for functional safety control installations.

A Frequency Input Module (not yet released) will provide the functionality to meet the

requirements of turbomachinary governor control and overspeed protection.

Page 14

1-2

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

Solutions Handbook (AADvance Controller)

The significant benefits of the AADvance controller are its performance and flexibility.

Being designed to IEC 61508 it meets both SIL2 and SIL3 application requirements

from the basic range of modules and mixed SIL rated applications can be covered by

this range of modules.

All of the configurations are readily achieved by combining modules and assemblies

without using special cables or interface units. System architectures are user

configurable and can be changed without major system modifications. Processor and

I/O redundancy is configurable so you can choose between fail safe and fault tolerant

solutions. This scalability is user configurable, therefore, there is no change to the

complexity of operations or programming if you choose to add redundant capacity to

create a fault tolerant solution.

A controller is built from a range of compact plug-in modules that are straightforward

to assemble into a system. They can be mounted onto DIN rails in a cabinet (see

photograph) or directly mounted onto a wall in a control room. They do not require

forced air cooling or special environmental control equipment. However, certain

consideration to the cabinet type must be applied when used in hazardous

environments.

A secure network communications protocol, developed by Rockwell Automation for

the AADvance system, permits distributed control using new or existing network

infrastructure while ensuring the security and integrity of the data. Individual sensors

and actuators can connect to a local controller, minimizing the lengths of dedicated

field cabling. There is no need for a large central equipment room; rather, the

complete distributed system can be administered from one or more PC workstations

placed at convenient locations.

Page 15

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

1-3

Single input modules are designed to meet SIL3 and in the most basic simplex

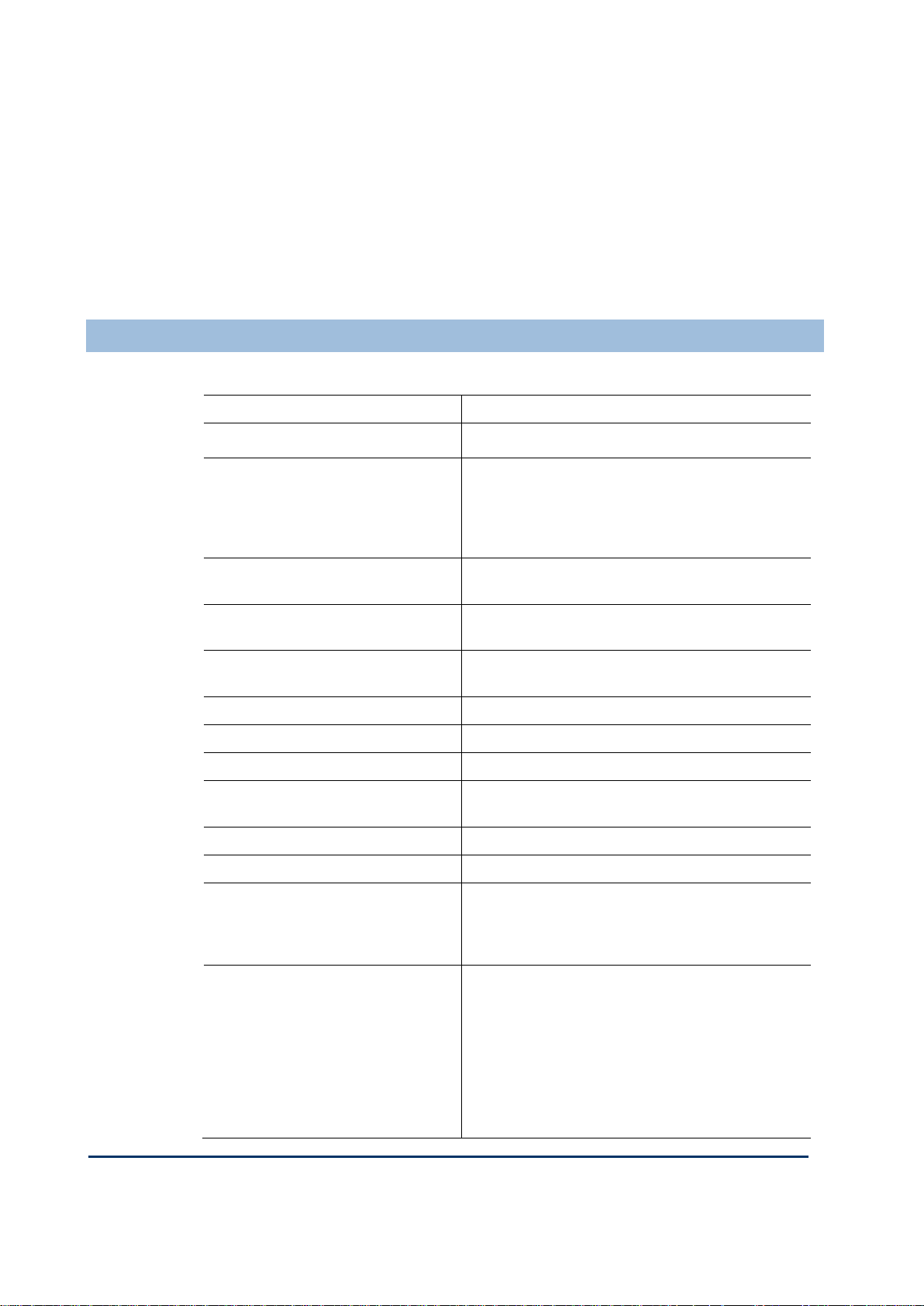

Attribute

Value

Functional Characteristics

Number of processor modules

1 (non-safety applications, SIL1 and SIL2 safety

applications)

2 (SIL3 applications)

3 (SIL3 fault tolerant and TMR applications)

Maximum number of I/O modules

48 modules (16 base units) - Two I/O busses each

holds 24 modules (8 I/O base units)

External interfaces

Network (10/100BASE-TX Ethernet)

Serial data communications (RS-485)

Inter-controller links

High integrity communications using Safety Network

Control Protocol (SNCP)

Application software support

All IEC 61131 languages

Displays

Status LEDs on each module

User controls

Fault Reset button on each processor module

Security

Plug-in "Program Enable" key for access to application

project and system configuration tools.

Mounting

DIN rail or flat panel

Performance Characteristics

Safety integrity level

IEC 61508 SIL2

IEC 61508 SIL3

(depending on processor and I/O module

configuration)

Sequence of Event

Processor Module (for internal

variables)

Event Resolution

Time Stamp Accuracy

Digital Input Module

Event Resolution

1ms

Application Scan

1ms

configuration they offer a fail-safe solution. The AADvance system has comprehensive

built-in diagnostics, while maintenance activities are straight forward operations which

maximize system availability.

The AADvance controller is developed and built for IEC 61131 compliance and

includes support for all five programming languages. Program access is secured by a

removable "Program Enable" key. Simulation software lets you prove a new application

before reprogramming and downloading, again maximizing system uptime.

Performance and Electrical Specifications

Table 1: Performance and Electrical Specifications

Page 16

1-4

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

Solutions Handbook (AADvance Controller)

Time Stamp Accuracy

10ms

Safety accuracy limit

200µA for Analogue Inputs and 1.0V dc for Digital

Inputs.

Electrical Characteristics

Supply voltage

Redundant 24V dc nominal, 18V dc to 32V dc range

Channel isolation (channel to channel

and channel to chassis)

Maximum withstanding

± 1.5kV dc withstand for one minute.

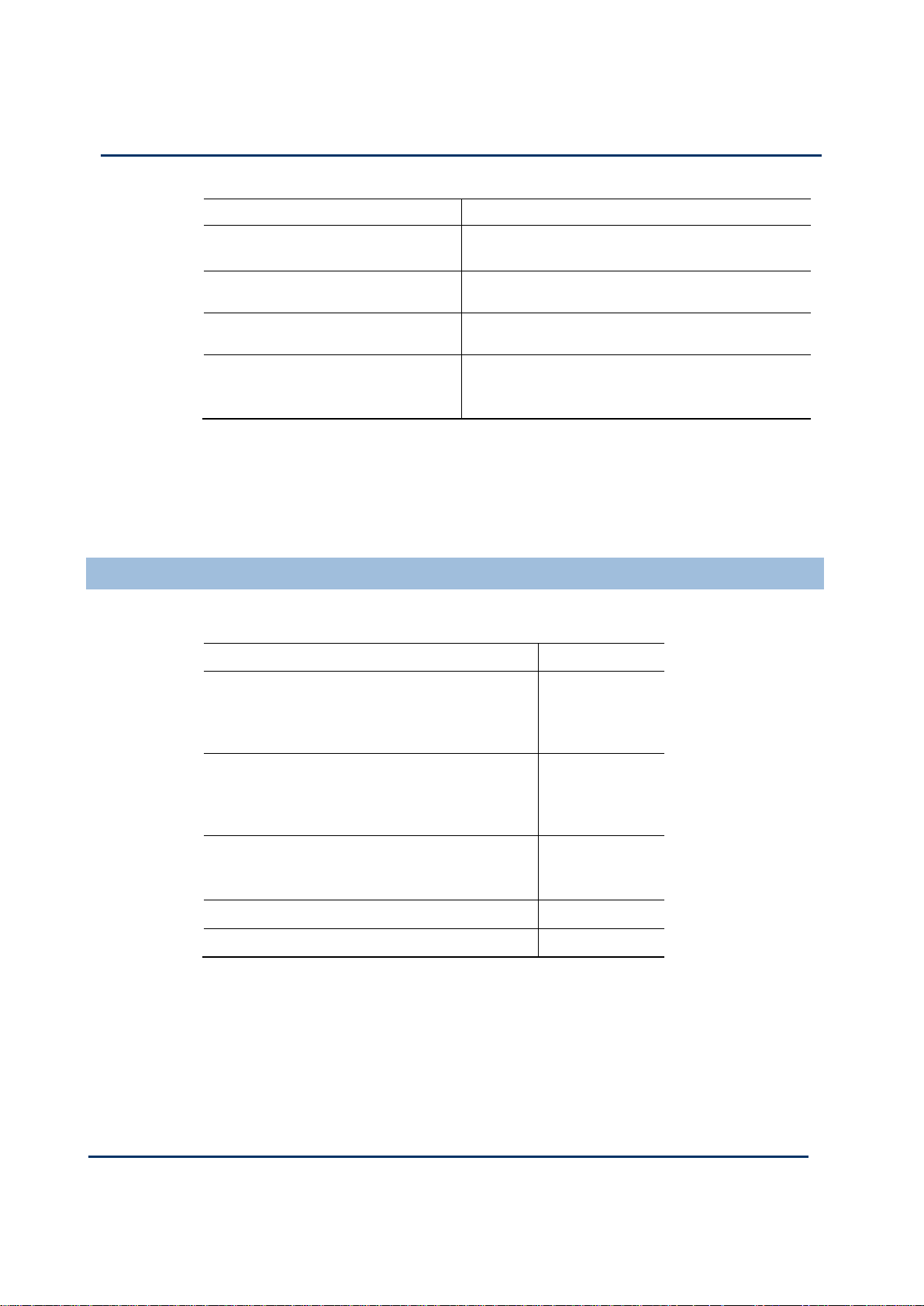

Module

Scan Time

T9401 Digital input module, 24V dc, 8 channel

Single

Dual

Triple

1.23ms

1.73ms

2.08ms

T9431 Analogue input module 24V dc, 8 channel

Single

Dual

Triple

1.26ms

1.91ms

2.33ms

T9451 Digital output module, 24V dc, 8 channel

Single

Dual

1.43ms

2.44ms

AADvance Workbench Sleep Period

57.2ms

Scan overhead per module

0.09ms

Scan Times

Power consumption, heat dissipation and weight depend on the arrangement of the

controller. You can estimate these values when you specify the controller using the

tables provided in this manual.

A typical module surface temperature measured against a processor module is 43°C ±

2°C.

The following scan times were taken from a test system consisting of production

modules.

The tests did not measure the effect of logic complexity and communications loading.

The scan time is:

(Number of module groups x scan time shown above) + Sleep Period + (Total

modules x scan overhead)

The scan time will vary by up to +/- 5ms (not including the effect of logic and

communications).

Page 17

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

1-5

Throughput time is the time from input change to output action. Due to the discrete

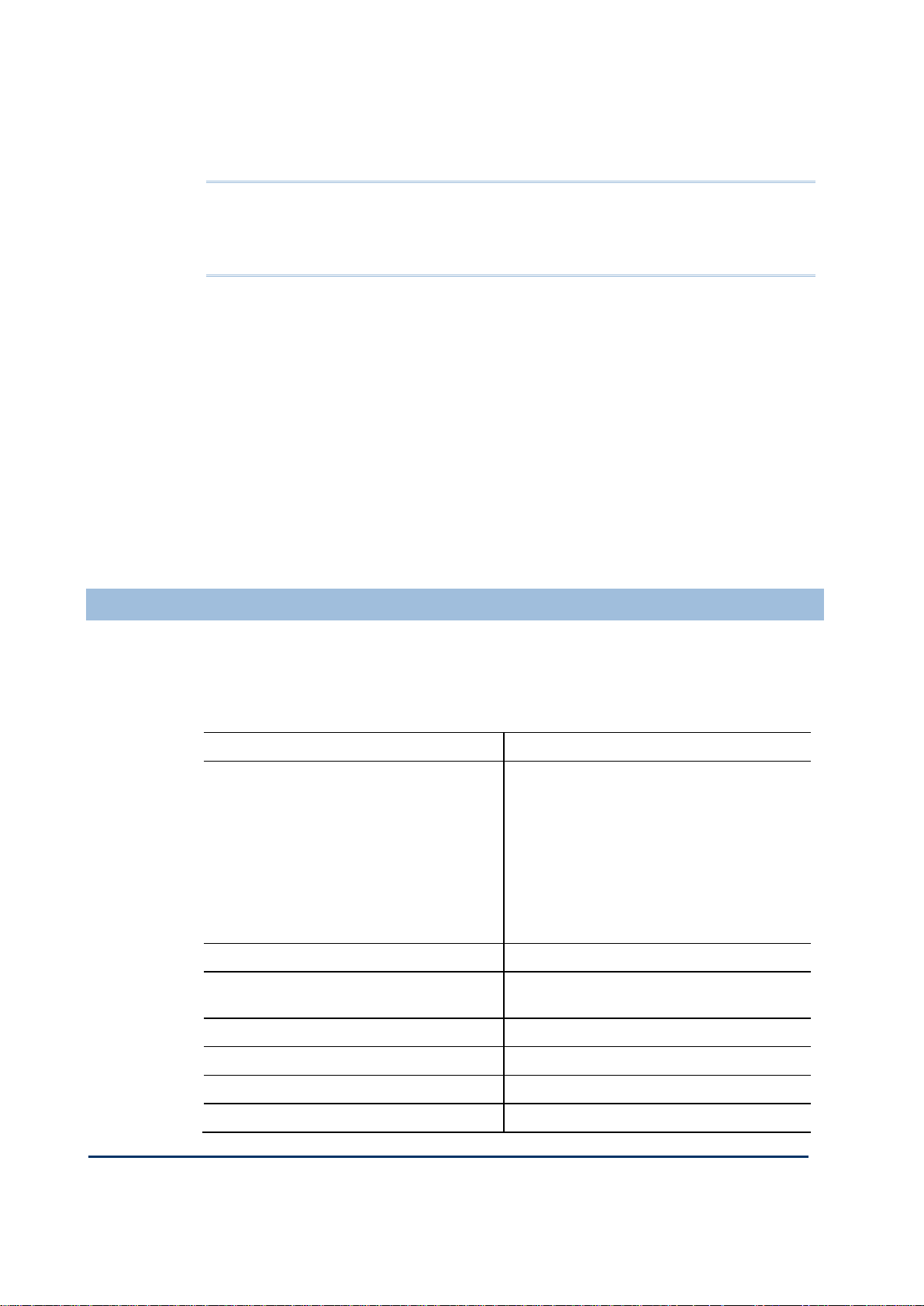

Attribute

Value

Operating Temperature Range:

For use in Hazardous Environments (UL

Certification):

Processor Modules

I/O Modules and Assemblies

For use in Non-Hazardous Environments

(TUV Certification)

All Modules and Assemblies

–25 °C to 60 °C (–13 °F to 140 °F)

–25 °C to 70 °C (–13 °F to 158 °F)

–25 °C to 70 °C (–13 °F to 158 °F)

Storage and Transport Temperature

–40 °C to 70 °C (–40 °F to 158 °F)

Module Surface Temperature (during normal

operation)

43° C (109 °F) ± 2 °C

Humidity

Operating

10% to 95% RH, non-condensing

Storage and Transport

10% to 95% RH, non-condensing

Vibration

nature of the scan, the throughput time will vary between one and two scans.

Note: The AADvance application scan time is limited to a minimum of 64ms to allow

all processes to run. Small applications will report a scan time of approximately 57 61ms. Large applications may have longer scan times but each scan time will be

consistent to within approximately 5ms.

An example configuration scan time:

T9431 Analogue input simplex modules x 30

T9451 Digital output simplex modules x 18

Total I/O modules = 48

Estimated scan time = (30 x 1.23ms) + (18 x 1.43ms) + 57.2ms + (48 x 0.09ms)

= 125.1ms

Throughput time:

min = 125.1ms

Avg = 187.6ms

Max = 250.1ms

Environmental Specifications

The following environmental specification defines the minimum recommended

environmental conditions for an AADvance controller installation. Additional

conditions apply to installations in a Hazardous environment.

Table 2: Environmental Specification

Page 18

1-6

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

Solutions Handbook (AADvance Controller)

Functional Stress

5Hz to 9Hz

Continuous

1.7mm amplitude

Occasional

3.5mm amplitude

Withstand

10Hz to 150Hz

Acceleration

0.1g in 3 axes

Endurance

10Hz to 150Hz

Acceleration

0.5g in 3 axes

Shock

15g peak, 11ms duration, ½ sine

Altitude

Operating

0 to 2000m (0 to 6,600 ft.)

Storage and Transport

0 to 3000m (0 to 10,000 ft.)

This equipment must not be transported in

unpressurized aircraft flown above 10,000 ft.

Electromagnetic Interference

Tested to the following standards: EN 613261:2006, Class A; EN 61326-3-1:2008, EN 54-4:

1997, A1; EN 61131-2:2007; EN 62061:2005.

Hazardous Location Capability

Suitable for Class I Div 2 and Zone 2

Note:

Casing: Standard AADvance modules also have a plastic casing and are rated IP20:

Protected against solid objects over 12mm (1/2in.) for example "fingers". There is no

specific protection against liquids.

Page 19

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

1-7

IEC 61508, Part 1-7:1998-2000

EN 50178:1997

IEC 61511-1:2004

EN 50156-1:2004

EN 61131-2:2007

EN 54-2:1997, A1:2006 (†)

EN 61326-3-1:2008

NFPA 72:2007

EN 61000-6-2:2005

NFPA 85:2007

EN 61000-6-4:2007

NFPA 86:2007

Controller TUV Certification

TÜV Certification

TÜV is the safety certifying authority for an AADvance controller. The AADvance

system is certified to the following standard:

(†) The analogue output modules are not certified to EN 54-2.

You can download a copy of the TUV certificate from www.tuvasi.com.

The Euro Controller version of the AADvance product is also tested to Q1 Extended

Design levels of ISO 13628-6: 2006 Sub Sea Production Control System.

Certification for use in Hazardous Environments

The AADvance controller has been investigated and approved by UL (UL508) for use

as Industrial Control Equipment in a general industrial environment and for use in

hazardous locations, Class I, Division 2, Groups A, B, C and D. The UL file numbers

are: E341697 and E251761.

File No: E341697

The AADvance controller investigation and approval is contained in the following files:

NRAQ.E341697: Programmable Controllers investigated to ANSI/UL 508.

The products have been investigated using requirements contained in the following

standards:

UL508, Industrial Control Equipment, Seventeenth edition, with revisions through

and including April 15, 2010.

NRAQ7.E341697: Programmable Controllers Certified for Canada

The products have been investigated using requirements contained in the following

standards:

CSA C22.2 No 142-M1987, Process Control equipment, Edition 1 - Revision date

1990-09-01

Page 20

1-8

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

Solutions Handbook (AADvance Controller)

Products Covered

The products investigated and approved:

Programmable Logic Controllers Models: 9110 Processor Module; 9401/2 Digital

Output Module; 9431/2 Analogue Input module; 9451 Digital output module; 9482

Analogue Output Module.

Listed Accessories for use with PLCs: 9100 Processor Backplane, 9300 I/O Backplane,

9801 Digital Input Termination Assembly, Simplex; 9802 Digital Input Termination

Assembly, Dual; 9803 Digital Input Termination Assembly, TMR; 9831 Analogue input

Termination Assembly, Simplex; 9832, Analogue Input Termination Assembly, Dual;

9833 Analogue Input Termination Assembly, TMR 9851 Digital Output Termination

Assembly, Simplex and 9852 Digital Output Termination Assembly, Dual; 9881

Analogue Output Termination Assembly, Simplex; 9882 Analogue Output Termination

Assembly, Dual.

File No: E251761

The AADvance controller investigation and approval is contained in the following file

certifications:

NRAG.E251761: Programmable Controllers for Use in Hazardous Locations Class I,

Division 2, Groups A, B, C and D.

The products have been investigated using requirements contained in the following

standards:

ANSI/ISA 12.12.01-20007, Nonincendive Electrical Equipment for use in Class I and

UL508, Industrial Control Equipment, Seventeenth edition, with revisions through

II, Division 2 and Class III, Division 1 and 2 Hazardous Locations.

and including April 15, 2010.

NRAG7.E251761: Programmable Controllers for Use in Hazardous Locations

Certified for Canada; Class I, Division 2, Groups A, B, C and D

The products have been investigated using requirements contained in the following

standards:

CSA C22.2 No 213-M1987, Nonincendive Control Equipment for Use in Class I,

CSA C22.2 No 142-M1987, Process Control equipment, Edition 1 - Revision date

Products Covered

The products investigated and approved:

Programmable Logic Controllers Models: 9110 Processor Module; 9401/2 Digital

Output Module; 9431/2 Analogue Input module; 9451 Digital output module; 9482

Analogue Output Module.

Division 2, Hazardous Locations.

1990-09-01

Page 21

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

1-9

Listed Accessories for use with PLCs: 9100 Processor Backplane, 9300 I/O Backplane,

9801 Digital Input Termination Assembly, Simplex; 9802 Digital Input Termination

Assembly, Dual; 9803 Digital Input Termination Assembly, TMR; 9831 Analogue input

Termination Assembly, Simplex; 9832, Analogue Input Termination Assembly, Dual;

9833 Analogue Input Termination Assembly, TMR 9851 Digital Output Termination

Assembly, Simplex and 9852 Digital Output Termination Assembly, Dual; 9881

Analogue Output Termination Assembly, Simplex; 9882 Analogue Output Termination

Assembly, Dual.

Page 22

1-10

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

Solutions Handbook (AADvance Controller)

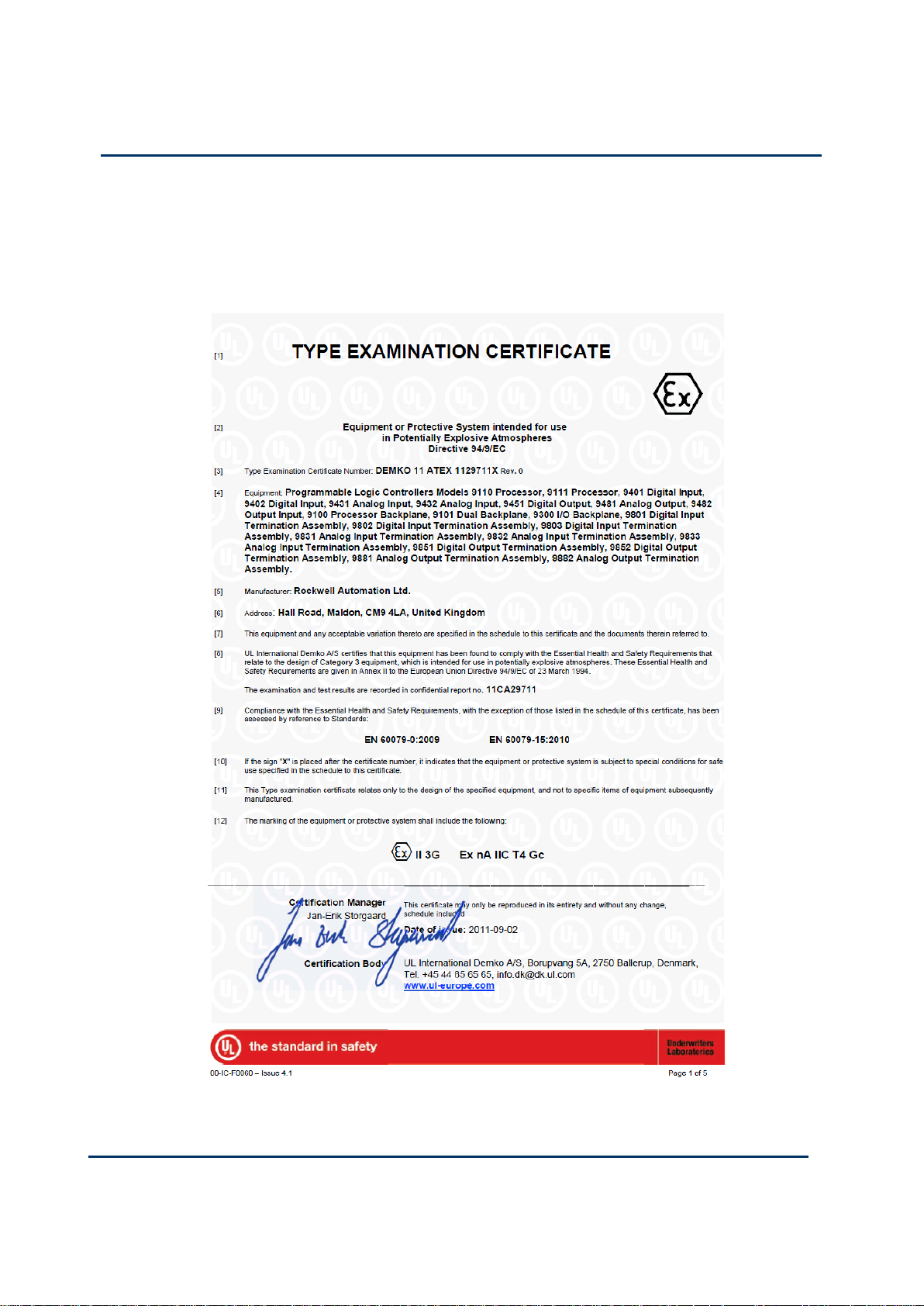

Certificate

The AADvance controller modules have been evaluated to the requirements of EN

60079-0: 2009 and EN 60079-15: 2010 under Certificate Number: DEMKO 11 ATEX

1129711X .

Page 23

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

1-11

Module label

The AADvance controller has also been evaluated under certificate IECEx UL

12.0032X to the standards IEC 60079-0; (5th Edition) and IEC 60079-15 (4th Edition).

[ certificate to be supplied]

For a system that is located in a Zone 2 Hazardous environment where ATEX

certification is required, all modules should be installed in an ATEX and IECEx

Certified, tool accessible IP54 enclosure. The enclosure is to be marked with the

following: "Warning - Do not open when energized". After installation of the modules

into the enclosure, access to termination compartments shall be dimensioned so that

conductors can be readily connected. The modules and assemblies are for use in an

area of not more than pollution degree 2 in accordance with IEC 60664-1

Page 24

1-12

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

Solutions Handbook (AADvance Controller)

KCC-EMC Registration

KCC- EMC Registration

Page 25

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

1-13

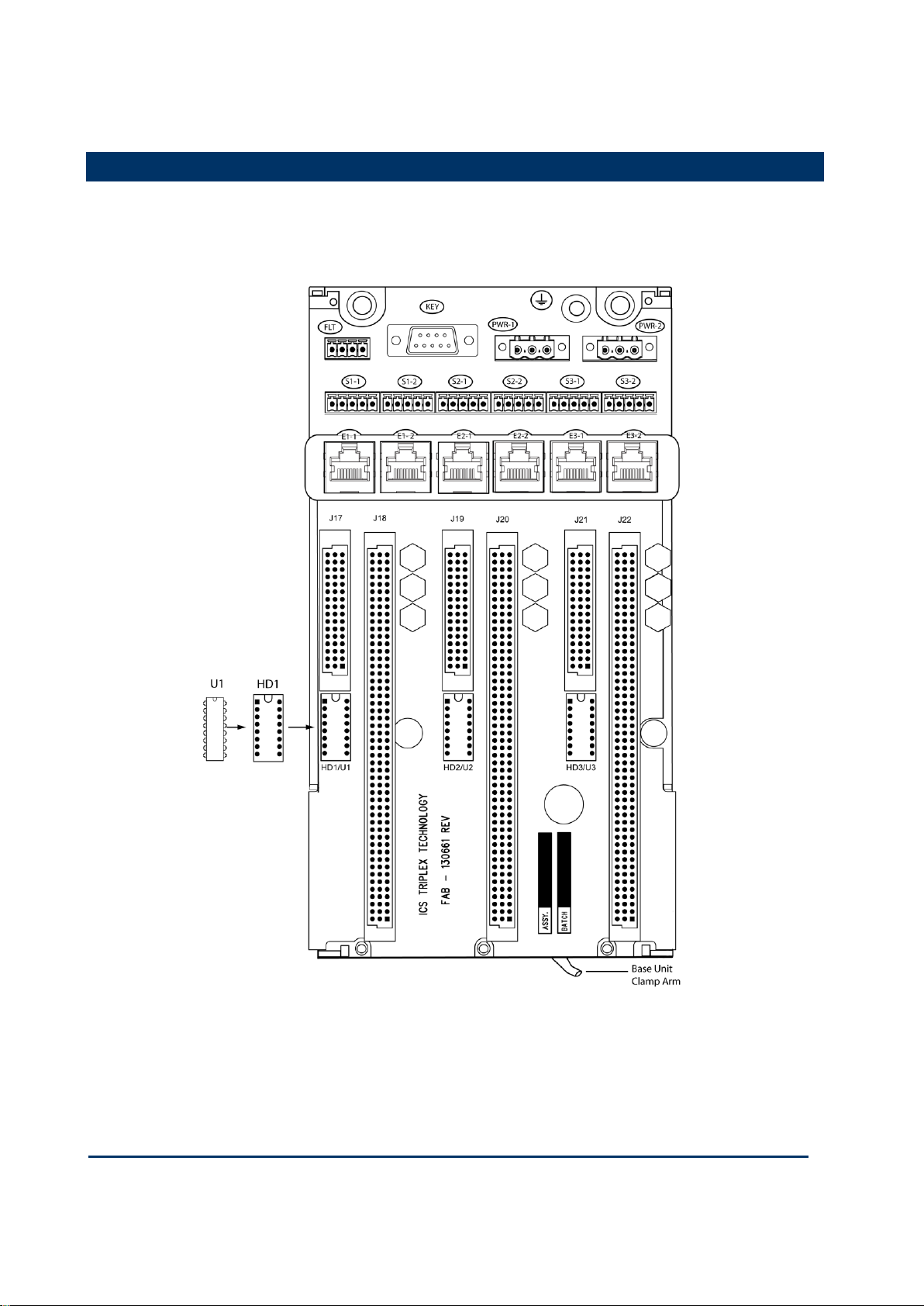

Main Components

Hardware Components

Each controller is built from a standard range of modules and assemblies; it consists of

processor modules, a processor base unit, digital and analogue I/O modules, I/O base

units and termination assemblies all of which are assembled as follows:

A processor module is installed into a processor base unit that can hold up to 3

processor modules.

3-way I/O base units are connected to the processor base unit and to each other.

Each I/O base unit holds up to three I/O modules and termination assemblies. A

controller can have up to 8 I/O base units on each of two I/O busses, giving a total

capacity for up to 48 I/O modules.

I/O modules are connected to field devices through external connectors on the

termination assemblies.

The processor module and base units are designed for use as either single, dual or

triple redundant processor module arrangements. The base processor base unit

provides external connections for Serial and Ethernet networks and the dual

redundant system power inputs.

The I/O base unit plugs directly into the processor base unit and carries the redundant

system power for the modules, the processor commands across a command bus and

I/O data across individual data response busses.

I/O base units also directly plug into each other and are secured and held in place by a

clamping arm and retaining clips; hence, a controller becomes a complete mechanically

and electrically interconnected assembly without the need for additional wiring or

cabling. The I/O modules are also designed for use in single or dual or triple redundant

configurations.

Termination assemblies are matched to a specific type of I/O module and have terminal

blocks that provide 8 or 16 connections for the wiring to the field elements. The

termination assemblies for dual and triple arrangements have channel to channel

isolation. Termination assemblies for simplex input modules and termination

assemblies for simplex and dual output modules are single ended (non-isolated) with a

common return.

An expansion cable can be used to connect the processor base unit or an I/O base unit

to another I/O base unit. This is useful for to breaking long runs of interconnected

base units and provides some flexibility in the physical layout of a controller

installation, particularly if the controller is installed in a cabinet.

Page 26

1-14

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

Solutions Handbook (AADvance Controller)

AADvance Workstation Software and Application Development Environment

Workstation Software

The AADvance workstation uses software that enables you to design the complete

control strategy as one, then to target parts of the strategy at each controller.

Interaction between the resources is automatic, significantly reducing the complexity of

configuration in a multi-resource solution.

The workstation software, known as the Workbench is compliant with IEC61131

industrial standard and has the following powerful features:

the regulation of the flow of control decisions for an interacting distributed control

system

providing for the consistency of data

providing a means for synchronous operation between devices

eliminating the need to have separate synchronous schemes

easing the development and maintenance of robust systems

The Workbench lets you create local and distributed control applications using the

five languages of IEC 61131-3. Engineers can choose one language or a combination of

languages that best suits their knowledge and programming style and the nature of the

application.

It is also a secure development environment that requires a hardware (USB Dongle) or

software license to run on a PC. There is also a Program Enable key (not applicable

to a Euro Controller) that must be plugged into the processor base unit to allow the

user to modify and download the application resource or access the

AADvanceDiscover utility to check the status of the controller IP address. The

Program Enable key when it is removed protects the application from unauthorized

access.

The development environment includes:

tools for program development

program documentation

function block library management

application archiving

database configuration

import/export utilities

on-line monitoring

off-line simulation and controlled on-line changes.

Page 27

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

1-15

Programs can be simulated and tested and tested on the computer before downloading

CAUTION

WORKBENCH FOR USE IN SAFETY APPLICATIONS

If the Workbench is used for safety related applications then you must follow

the guidelines given in the AAdavnce Safety Manual (Doc No: 553630).

CAUTION

WORKBENCH OPERATING SYSTEM

Do not use XP Professional x64 edition.

to the controller hardware. Also provided is a set of configuration tools that enables

you to define the hardware architecture in the software; set up the processor

functionality; and connect application variables to the Workbench application

resource program that will monitor processor and I/O module status information and

report I/O channel data values to the Workbench. Resource Control applications can

be distributed across several hardware platforms, communicating with each other

through secure networks.

Operating System

The 9110 Processor Module must have an operating system with the following

specification:

Windows XP with Service Pack 3

Windows Vista, Windows 7 & Server 2003 in both 32-bit and 64-bit versions

Note: Work Bench Licensing –Windows 64-bit version will only work with the

USB Licensing option (dongle option).

Network port (10/100 Base T Ethernet)

Access to a CD-ROM drive, for software installation

Note: If the application adopts the USB (dongle) licensing option for the

Workbench software, the processor module will also require one free USB port.

AADvanceDiscover Utility

The AADvanceDiscover utility is installed when you install the

<DevelopmentSoftwareTools>, and appears on the Start menu of the computer. it

displays a list of the <ProductName> controllers on the broadcast network, and

reports a status for each one.

Importing and Exporting Data

The AADvance Workbench can import and export existing data in standard file

formats such as Microsoft Excel.

Page 28

1-16

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

Solutions Handbook (AADvance Controller)

Controller Functionality

SNTP

The AADvance controller supports the Simple Network Time Protocol (SNTP)

service that can circulate an accurate time around the network. As an SNTP client the

controller will accept the current time from external Network Time Protocol

(NTP) and SNTP network time servers.

SNTP clients settings tell the controller the IP address of the external server; the

version of SNTP offered by the server; and the operating mode for the time

synchronization signal that the processors will use for their real time clock.

An AADvance controller can also fulfill the role of one or more SNTP servers (one for

each processor) to provide a network time signal throughout the network. To enable

server time on an interface it is necessary to specify the direct broadcast address for

that interface. This works for broadcast or unicast modes. This method of configuring

is derived from the NTP configuration command language.

CIP over EtherNet/IP

The Common Industrial Protocol (CIP) over EtherNet/IP protocol enables

AADvance controllers to exchange data with ControlLogix controllers programmed

by RSLogix 5000. The exchange of data uses the produce/consume tag method

currently used for sharing data between Logix-based controllers; this mechanism is

similar to the variable bindings mechanism used by the AADvance controller.

The AADvance controller supports produce and consume communications to

redundancy systems. The support for produce/consume variables is non-interfering; a

failure of the EtherNet/IP stack will not interfere with the safe operation of the

controller.

To use CIP over EtherNet/IP you have to first define a CIP network. Then you

configure the exchange of data by defining a produce variable (or structure) for

AADvance controller and a corresponding consume variable (or structure) for the

ControlLogix controller. At runtime, the controller with the consume variable pulls

data from the controller with the produce variable.

Note: The AADvance Controller will support the following number of connections

and variables:

Connections: Maximum 255

A maximum of 128 producer and 128 consumer variables can be defined.

Page 29

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

1-17

Note: The CIP Protocol is intended to allow AADvance users to exchange data

between AADvance controllers and the Allen Bradley Logix family controllers, using

produce/consume messaging. Produce/Consume messaging does not support

downloading to or for monitoring AADvance controllers. It is not recommended to

use the CIP network to exchange data between AADvance controllers unless this is

exclusively for non-safety data. The SNCP network should be used for Safety related

data exchange between AADvance Controllers (see SNCP and variable Bindings in this

publication).

HART

The AADvance controller supports utilizing dedicated HART modems on each

analogue input and output channel allowing HART field device status, diagnostics and

process data to be integrated into the application logic, thus increasing the level of SIF

diagnostics significantly.

The AADvance analogue input/output modules use HART commands #03 to collect

data from the field device as defined by Revision 5 of the HART specification. The

application can be configured to use HART information to monitor and respond to

device conditions. It may also be used to provide diagnostic information such as

comparison and error reporting.

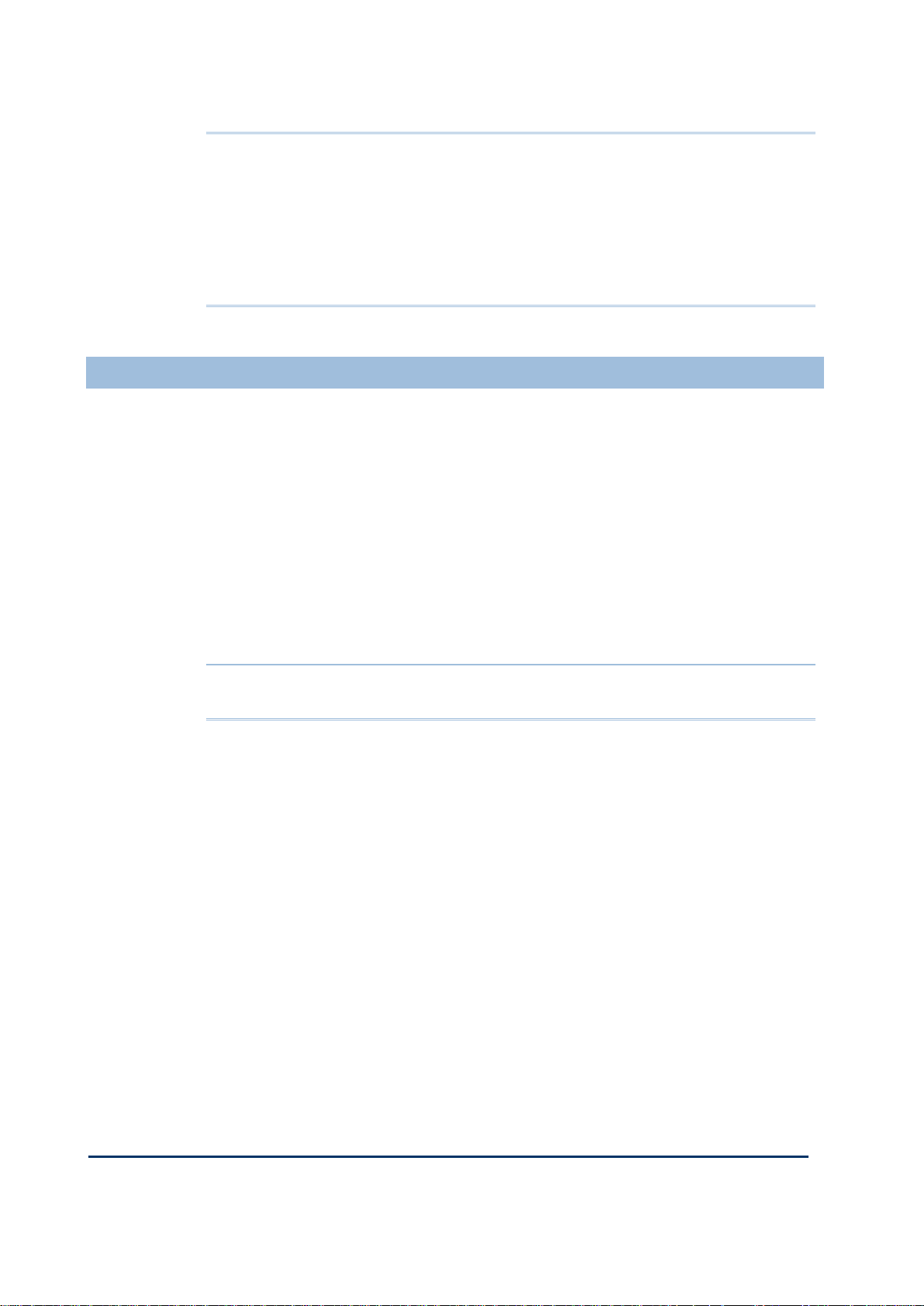

An additional feature of the AADvance controller is that it also combines with the

AADvance DTM to enable asset management software (ASM) to communicate with

HART devices.

Note: The AADvance system does not alter the messages passed between the asset

management software and the field device and acts as a transport mechanism only.

AADvance HART Features

Provides passthru support for HART Standards 5, 6 and 7.

Variables can be configured for each Analogue input and output channel to

monitor HART device information.

HART support is available on each Analogue Input or Output channel.

AADvance uses a single dedicated Ethernet port for HART passthru

communication.

Supports the AADvance DTM provided by Rockwell Automation.

A typical HART set up is shown below:

Page 30

1-18

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

Solutions Handbook (AADvance Controller)

Figure 1: Example HART Pass-through System

SNCP Safety Networks

SNCP (Safety Network Control Protocol) is the Safety Protocol that allows

elements of an AADvance System to exchange data. AADvance SNCP is a SIL 3

certified protocol which provides a safety layer for the Ethernet network making it a

"Black Channel". Data is exchanged by creating a relationship between variables in

different AADvance controllers; this is called "Binding Variables". Once variables are

bound between controllers the SNCP protocol provides a transparent SIL 3 Certified

layer allowing safety related data to be passed between AADvance controllers.

The bindings are based on a producer/consumer model. The controller consuming the

data establishes a binding link with the Controller producing the data, and manages the

entire exchange of data, including scheduling the data exchange, providing the

diagnostics, managing the safety response in the event of faults and managing the

communications redundancy.

SNCP Networks can be configured as Simplex (Fail Safe) or Redundant (Fault tolerant),

the choice of network configuration is dependent on the applications safety and

availability requirements. The data exchange is independent of the physical; network

configuration as the connection between the controllers is treated as a logical

network.

Page 31

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

1-19

The physical network is considered a "Black Channel" so the design of the Ethernet

network and the equipment used does not impact the SIL rating of the

communications interface, but the design of the network does affect the reliability of

the network and does impact the spurious trip rate. SNCP Network data can be

combined on a common network resulting in safety and non-safety data sharing in a

common physical network; this does not compromise the SIL rating of the network

but again does introduce failure modes and possibly security risks which can increase

the spurious trip rate, careful consideration should be given to the network topology

during the applications specification and design phase.

Page 32

1-20

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

Solutions Handbook (AADvance Controller)

Peer-to-Peer

AADvance provides the capability for a SIL 3 certified Peer-to-Peer data connections,

allowing safety data to be transferred between AADvance and Trusted Controllers.

The Trusted Peer-to-Peer network protocol enables you to share safety data between

AADvance systems or AADvance and Trusted

TM

systems across an Ethernet network.

Data can be transferred between individual systems or from one to several systems at

the same time using multicast network connections. Peer-to-Peer communication is

configured by defining a peer network controller and I/O devices within the application

program.

Note: AADvance currently supports multicast network connections on the left most

port only.

For safety related applications it is recommended that the Peer-to-Peer

communications use redundant networks (for availability) and separate networks (from

general purpose, for security and integrity). Any of the AADvance or Trusted ports

can be used for Peer-to-Peer data connections see Example shown.

The Trusted Peer-to-Peer protocol is a master/slave interaction. For each peer

communications subnet one system acts as a master while the others act as slaves.

During the Peer-to-Peer communication cycle the master sends a command to the

first slave to transmit its data. When the slave completes this task it acknowledges this

back to the master. The master repeats this with the next and all slaves in turn. Finally

the master transmits its own data then repeats the cycle with the slaves.

Page 33

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

1-21

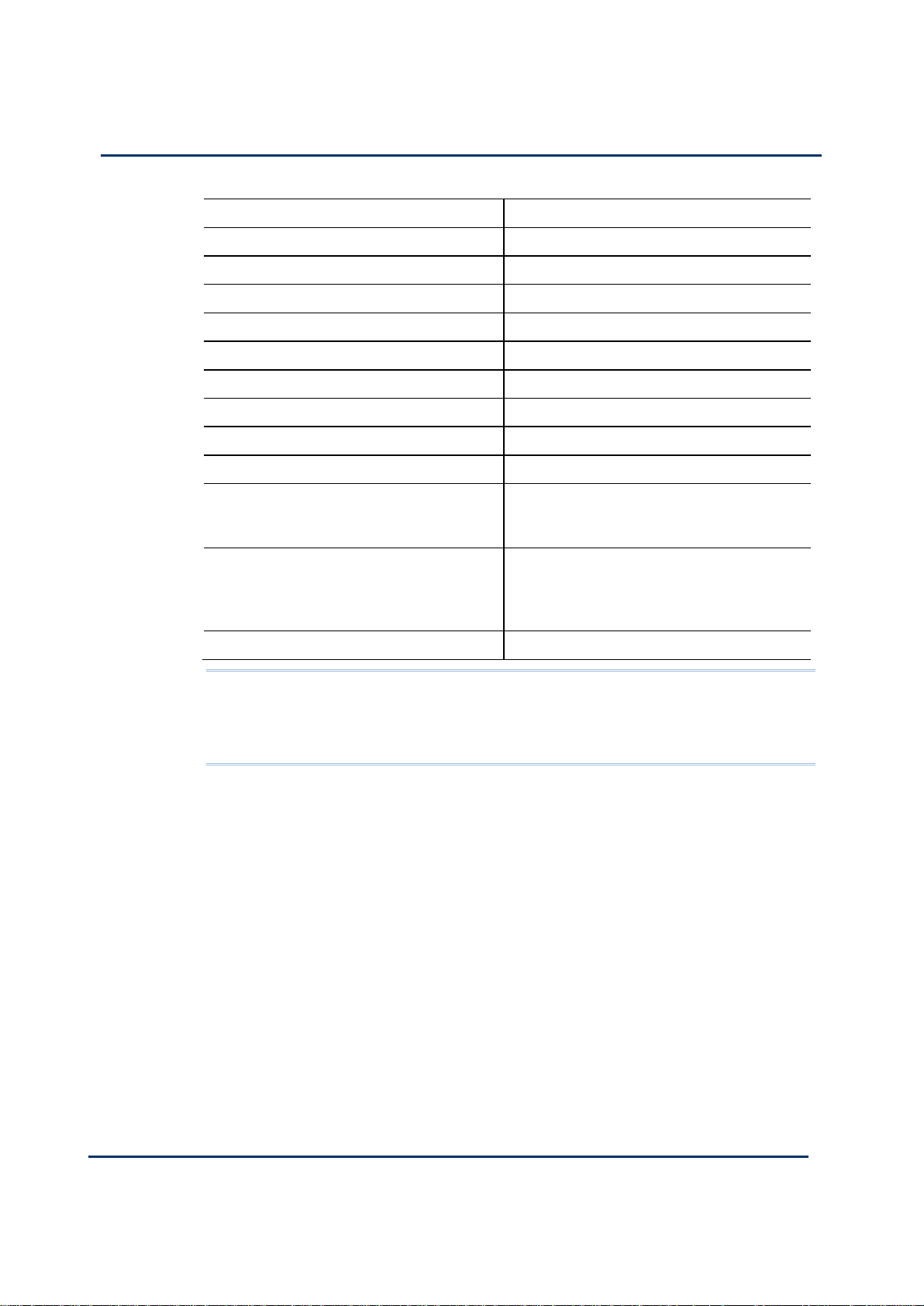

Peer-to-Peer

Settings

TÜV Certified

Configuration

Conditions

Software Board

Definitions:

Dxpdi16

Dxpdo16

Dxpao16

Dxpdi128

Dxpdi128 & dxpnc40

Certified for use over

a single

communication

network or multiple

networks

Certified as safety-related and can be used for safety

critical communications in SIL 3 applications.

Safety Related Peer-to-Peer Configurations

The following Peer-to-Peer configurations are approved for use in a safety Related

Function:

Table 3:

Page 34

1-22

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

Solutions Handbook (AADvance Controller)

Peer-to-Peer

Settings

TÜV Certified

Configuration

Conditions

Software Board

Definitions:

Dxpai128

Dxpao128

Certified for use over

a single

communication

network or multiple

networks

Certified as safety-related and can be used for safety

critical communications in SIL 3 applications

provided to separate Dxpai128 & Dxpao128 board

definitions are used for safety values, the safety

values from the tw oDxpai128 boards (or digital trip

points from the values) shall have a 1oo2 vote

within the receiving application.

Serial Communication Interface

Two serial ports on each processor module support the following signal modes

depending upon use:

RS485fd: A four-wire full duplex connection that features separate busses for

transmit and receive. This selection should also be used when the controller is

acting as a Modbus master using the optional four-wire definition described in

Section 3.3.3 of the Modbus-over-serial standard.

RS485fdmux: A four-wire full-duplex connection with tri-state outputs on the

transmit connections. This should be used when the controller is acting as a

Modbus slave on a four-wire bus.

RS485hdmux: A two-wire half duplex connection appropriate for or master slave

or slave use. This is shown in the Modbus-over-serial standard.

Time Synchronization (SNTP)

The AADvance controller supports the Simple Network Time Protocol (SNTP)

service that can circulate an accurate time around the network. It can be configured to

operate as a SNTP client or server.

As an SNTP client the controller will accept the current time from external Network

Time Protocol (NTP) and SNTP network time servers. The SNTP clients settings

tell the controller the IP address of the external server; the version of SNTP offered

by the server; and the operating mode for the time synchronization signal that the

processors will use for their real time clock. As a client the processor module can be

configured as a unicast or broadcast client.

The AADvance controller can also fulfill the role of one or more SNTP servers (one

for each processor module) to provide a network time signal throughout the network.

To enable server time on an interface it is necessary to specify the direct broadcast

address for that interface. This works for broadcast or unicast modes and when

configured as a broadcast server it can respond to Unicast requests from clients.

Note: To set up SNTP you need to connect your controller to a suitable network

using one of the Ethernet ports. The network must be connected to an external NTP

server or have NTP loaded on to it.

Page 35

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

1-23

Modbus Master

The AADvance controller can be used as a Modbus master to one or more Modbus

slave devices. Slave devices can include programmable logic controllers, remote devices

(typically with little or no processing capability) and, more rarely, other functional

safety controllers (Trusted or AADvance).

The controller supports the Modbus RTU and Modbus TCP protocols, and a subset

of Modbus commands. You can use Modbus RTU with point-to-point and multi-drop

serial links, and Modbus TCP with Ethernet.

Note: The AADvance controller does not support the Modbus ASCII protocol.

You can set up an individual list of messages (commands) for each slave device.

Modbus read commands cause data to read from the slave device to the Modbus

master, while Modbus write commands cause data to be copied from the Modbus

master to the slave device. You can also define a sequence of broadcast write

commands, which a Modbus master can send to multiple Modbus RTU slaves without

requiring an acknowledgement. The AADvance controller can control and monitor

individual Modbus master objects and their slave links.

The Modbus master functionality has a safety integrity level of zero (SIL0) and should

only be used for non-safety applications.

Page 36

1-24

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

Solutions Handbook (AADvance Controller)

Modbus Master Hardware and Physical Connections

The Modbus master functionality is built into the T9110 Processor Module; the

physical communication ports are located on the T9100 Processor Base Unit. You do

not need to add any extra hardware to the AADvance controller except to make the

physical connections to the processor base unit. The illustration shows some possible

arrangements of Modbus master connections.

The Modbus RTU slave devices are connected to one or more of the serial ports on

the controller; a typical arrangement will use a multi-drop (RS-485) arrangement. The

engineering workstation and the Modbus TCP devices are shown connected to the

Ethernet ports on separate networks; alternatively these can be combined onto one

network.

The OPC Portal Server

The OPC Portal Server is a windows-based application that allows OPC compatible

clients, such as HMIs and SCADA systems, to connect to one or more AADvance

controllers to access process data.

Page 37

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

1-25

Controller IP Address Setting

The AADvanceDiscover Utilility uses a discovery and configuration protocol

(proprietary to Rockwell Automation) to set the controller IP address within the

AADvance Workbench and to scan the broadcast domain for other AADvance

controllers. The utility locates each controller by its unique MAC Address. Having

located a particular controller to be configured, the utility lets you configure the

resource number and IP Address to be stored in the controller; after you have done

this, the AADvance Workbench can communicate with the other controller.

Recovery Mode

Recovery Mode is a shutdown mode and uses a base level firmware. It is entered

automatically when a critical firmware failure occurs or it can be entered manually by

pressing the processor Fault Reset button immediately after the module has booted

up. The Recovery Mode is also used when you want to download a new firmware

upgrade.

As an alternative firmware version it allows the following maintenance activities:

Update the firmware using the ControlFLASH utility

Program the processor IP Address with the AADvance Discover utility

Extract diagnostic information

Note: When in Recovery Mode the I/O communications are disabled and the

Application code is not running. The inputs and outputs will revert to their fail-safe

settings.

DiffServ Configuration

This option allows you to specify the priority of IP traffic and is particularly useful for

ensuring that high priority services are either not affected or less affected during

periods of network congestion.

When you set up this option you apply a priority value to a service and therefore

differentiate it from less important services. You can do this by setting a suitable

configuration of routers, or switches able to inspect IP headers and prioritize by the

Type of Service (ToS) header option. Network devices will then apply their rules to

prioritize IP traffic; AADvance simply maintains the priority when responding to

incoming messages and sets a priority according to the configuration for messages it

initiates.

Page 38

1-26

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

Solutions Handbook (AADvance Controller)

Ethernet Forwarding

When enabled, the "Ethernet Forwarding" feature will forward all Ethernet packets

destined for a host (3rd Party Device) connected to one of the AADvance’s Ethernet

ports along with any broadcast and multicast Ethernet traffic. Incoming messages on

the other port will be forwarded directly to the second. The forwarded messages will

be unaltered by the AADvance controller.

This feature can be enabled using the AADvance Discover utility. Packets intended for

the AADvance itself (i.e. the destination MAC address of the packet matches the

processor’s receiving port MAC address) as well as broadcasts and multicasts are still

sent to the AADvance application as normal.

Note: The Ethernet network carrying Safety Data on a Safety application is considered

to be a black channel, therefore, it is unaffected by this function. However, by

implementing Ethernet Forwarding you may be forwarding non-safety data onto a

safety network and could effectively bridge a safety and non-safety segregated network

through the AADvance.

Page 39

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

1-27

Transparent Communication Interface (TCI)

The AADvance controller processor module provides a Transparent Communications

Interface (TCI) function. This functionality will establish a pass-through

communications link between an Ethernet link to a Serial port allowing devices

attached to a serial port to be communicated with and for them to reply. The

controller does not tamper with or inspect the data passed over the channel.

TCI uses a TCP port number to represent a serial port. All six serial ports are

represented by each controller, so any serial port can be reached from any controller.

Traffic is routed through TCP to the relevant serial port and in reverse. However, TCI

communication from the serial ports is only available when the controller is not

executing an application.

Users can enable and disable the function and set the Inactivity Timeout and Idle Time

values.

Important Note: To use the TCI function you must stop the resource. This will

have a serious effect on a Safety Related application.

Compiler Verification Tool

The Compiler Verification Tool (CVT) is a software utility that validates the output of

the application compilation process. It is automatically enabled for resources when a

project is created and when you add a resource to an existing project. This process in

conjunction with the validated execution code produced by the AADvance

Workbench confirms that there are no errors introduced by the Compiler during the

development of the application.

To achieve this CVT decompiles the application project file and then compares each

individual application project (POU) source files with its decomposed version. The

CVT analysis is displayed in the Workbench window.

Page 40

1-28

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

Solutions Handbook (AADvance Controller)

Technical Features

TUV Approved Operating System

The AADvance system runs an IEC 61508 approved operating system and the overall

system is certified to IEC 61508, Part 1-7: 19T98 - 2000 SIL3.

Internal Diagnostics

The AADvance controller contains comprehensive internal diagnostic systems to

identify faults that develop during operation and raise appropriate alarm and status

indications. The diagnostic systems run automatically and check for system faults

associated with the controller, and field faults associated with field I/O circuits.

Serious problems are reported immediately, but faults on non-essential items are

filtered to avoid spurious alarms. The diagnostic systems monitor such non-essential

items only periodically, and need a number of occurrences of a potential fault before

reporting it as a problem.

The diagnostic systems use simple LED status indications to report a problem. The

LED indications identify the module and can also identify the channel where the fault

has occurred. There is also a summary system healthy indication for the whole

controller.

The application software uses its variable structures to report a problem; these

variables proved status reports and are configured using the AADvance Workbench.

A Fault Reset button on each processor module serves to clear a fault indication.

However, the diagnostic systems will report a serious problem again so quickly there

will be no visible change in the status indications. Pressing the Fault Reset button when

no fault is indicated has no effect.

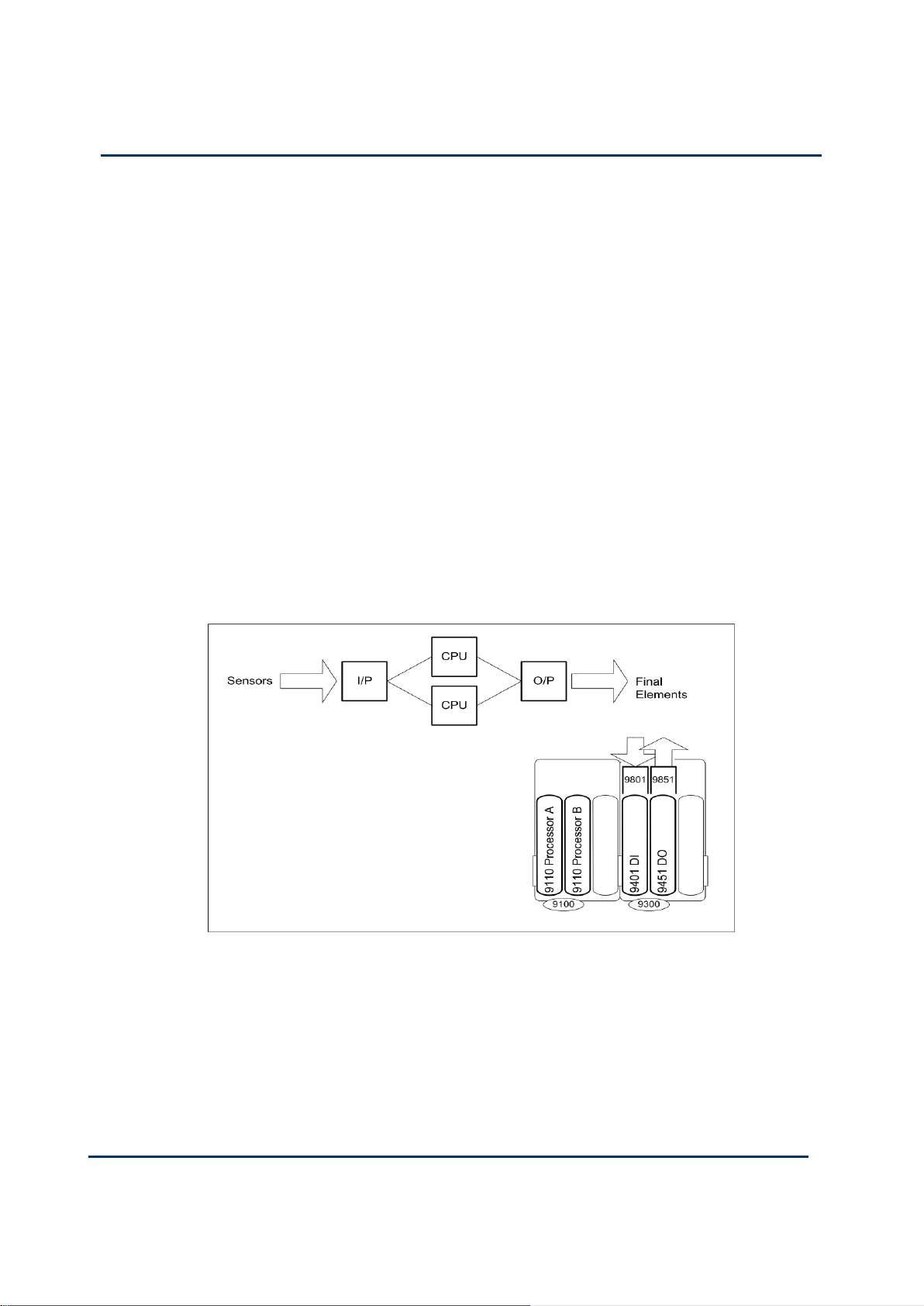

Controller Internal Bus Structure

Internal communication between the processor modules and I/O modules is supported

by command and response busses that are routed through the processor and I/O base

units.

The processor modules acts like a communications master, sending commands to its

I/O modules and processing their returned responses. The two command busses IO

Bus 1 and IO Bus 2 carry the commands from the processor to the I/O modules on a

multi-drop basis. An inter-processor link (IPL) provides the communication links

between dual or triple processor modules.

Each I/O module has a dedicated response line back to the processor. The unique

response line for each I/O module provides an unambiguous identification of the

source of the I/O data and assists with fault containment.

Page 41

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

1-29

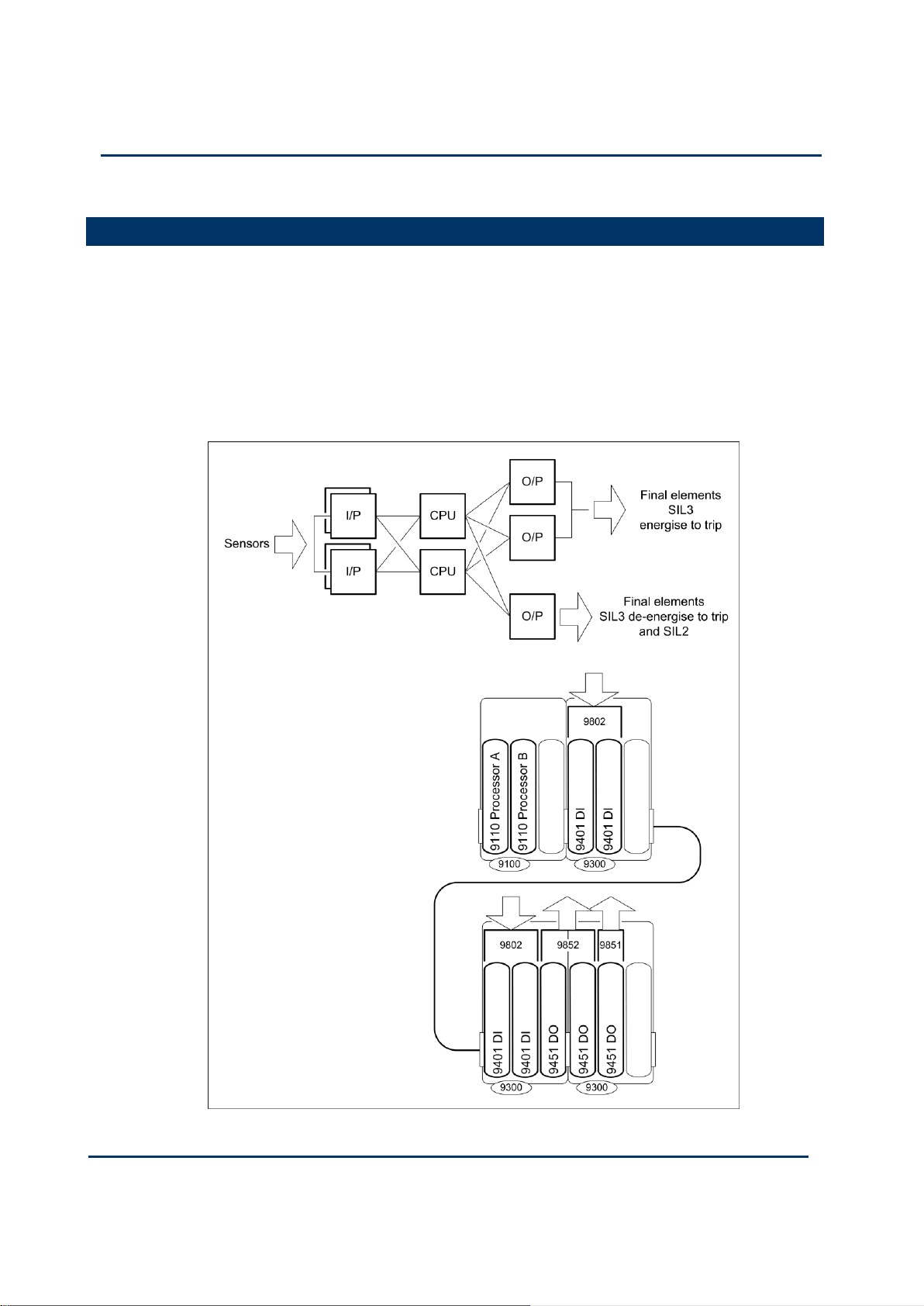

System Modification and On-line Updates

The AADvance controller has a modular design which allows you to change the I/O

hardware configuration. An on-line update feature also allows you to make the

required changes to the workbench I/O configuration.

The following changes can be made by an on-line update:

Add new I/O base units, termination assemblies and extra I/O modules.

Delete modules from the system

Change the size of a termination assembly to change the configuration to

either increase the size or reduce the size of the module configuration.

Move a module to a different slot.

Change the variables for an I/O configuration change.

Making on-line changes after the system has been commissioned is the responsibility of

users and can have safety integrity implications the safety guidelines in the Safety

Manual need to be consulted before doing an on-line update.

On-line modifications must follow the end users' MOC process as required by the

applicable industry safety standards. On-line modifications must include any specific

checks recommended by Rockwell Automation for the product.

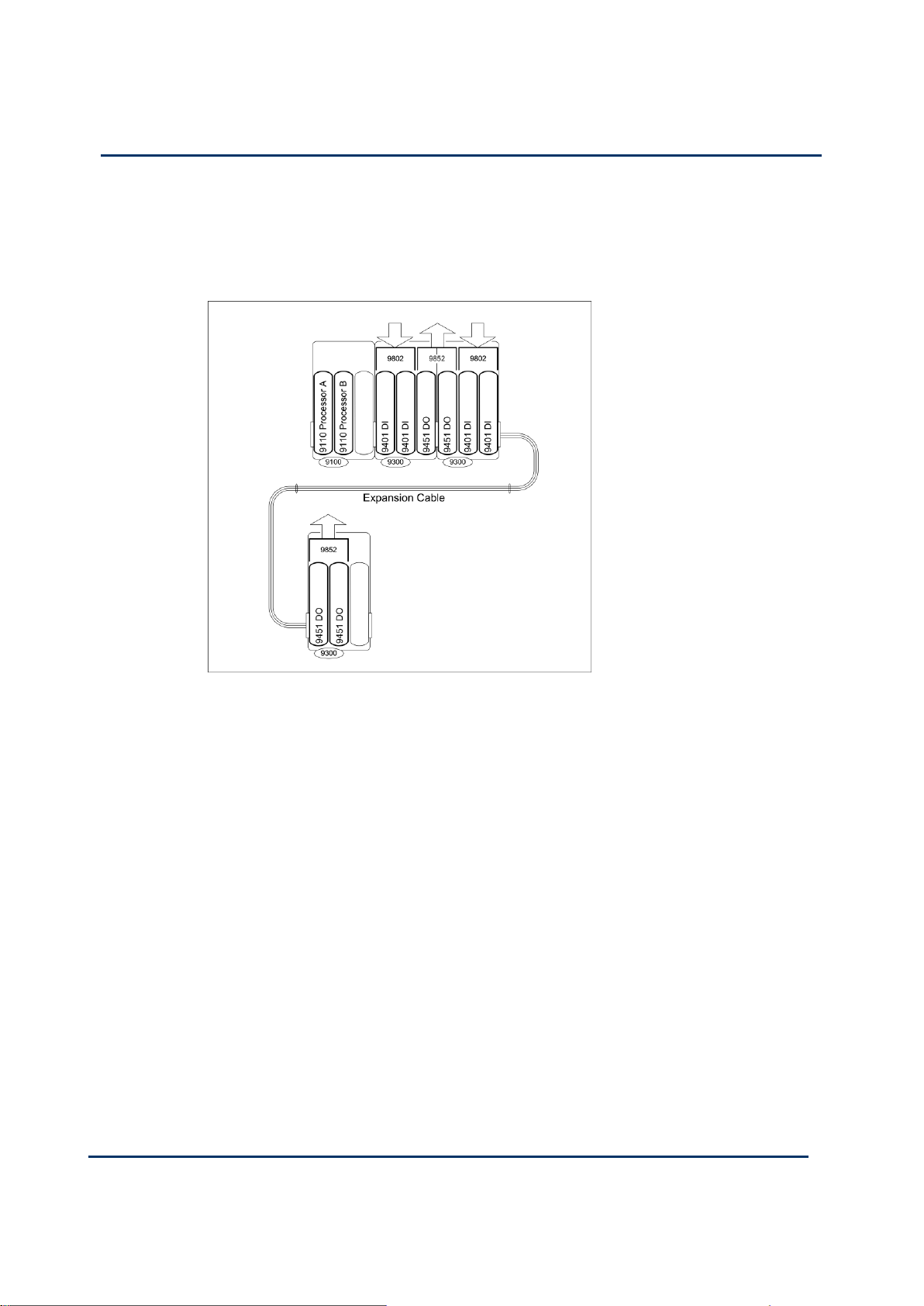

Expansion Cable

NOTE: If you are still using an earlier product release the I/O module configuration

cannot be changed with an on-line update.

Page 42

1-30

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

Solutions Handbook (AADvance Controller)

When new I/O modules need to be added and there is not enough space in the

existing row of modules, you can use an Expansion Cable to install a new row of

modules. A typical arrangement using an expansion cable is shown below.

Page 43

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

1-31

ControlFLASH Firmware Upgrades

WARNING

FIRMWARE UPGRADE DANGER TO A RUNNING SYSTEM

Do not attempt to upgrade firmware on a running system. Control

FLASH will not warn you that a system is running and you will lose

control of the application when the system reboots.

The AADvance controller supports upgrades of processor module firmware by using

the ControlFLASH utility. You need the ControlFLASH firmware upgrade kit that

includes and RSLinx Classic Lite software or better. To install and configure the

ControlFLASH utility refer to the Rockwell Automation ControlFLASH Firmware

Upgrade Kit documentation, Publication No: 1756-UM105C-EN-E March 2012

available from the Rockwell Automation Literature Library. This document defines

what you will need to carry out the procedures.

Note: I/O module upgrades using ControlFLASH are not currently supported in this

release.

Upgrading the processors is a two stage process:

Stage 1: Run the 350720_102_ControlFLASH.msi program to install the

ControlFLASH firmware upgrade kit for the Recovery Mode on your PC. Then

run the ControlFLASH utility to upgrade your processor module and install the

Recovery Mode. If your module is delivered with the Recovery Mode installed then

this stage is not necessary.

Stage 2: Reboot the processor and enter the Recovery Mode. The run

354400_0199_ControlFLASH.msi program to install the ControlFLASH to

upgrade your processor's OS, FPGA, LSP and BUSP.

Page 44

1-32

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

Solutions Handbook (AADvance Controller)

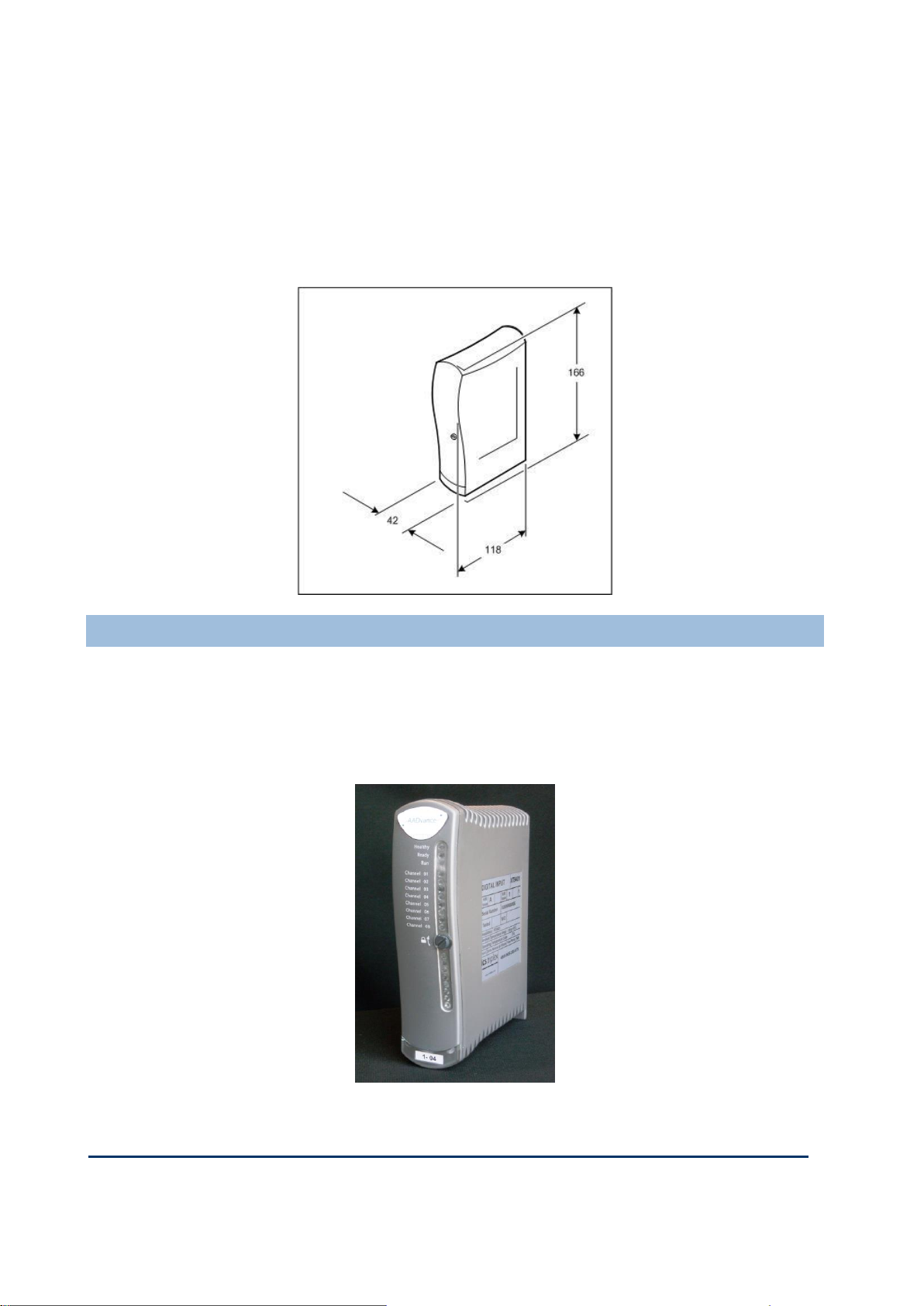

Attribute

Value

Base unit dimensions (H × W × D), approx.

233 × 126 × 18mm (see text)

(9-¼ in × 5 × ¾ in)

Module dimensions (H × W × D), approx.

166 × 42 × 118mm

(6-½ in × 1-⅝ in × 4-⅝ in)

Physical Features

An innovative feature of the AADvance controller is the design of the hardware.

Everything fits together easily without any need for inter-module wiring.

Product Dimensions

Overall Dimensions of Modules with Base Units

Table 4: Summary of Dimensions

Page 45

Document: 553631

(ICSTT-RM447J_EN_P) Issue: 09:

1-33

The depth of the base unit (18mm) excludes the parts of the backplane connectors

that mate inside the module connectors. Adding the depth of module (118mm) to the

depth of the base unit gives the overall depth of the controller assembly, which is

136mm.

Module Dimensions

All modules have the same dimensions.