Page 1

INSTALLATION INSTRUCTIONS

800HL-EMP SELECTOR SWITCHES

FOR NEMA TYPE 7 [3/8" (9.5) TO 2-1/2" (50.8)

PANELS] AND TYPE 9 [7/32" (7.2) TO 2-1/2" (50.8) PANELS]

(Dimensions shown in parentheses are in millimeters)

�

WARNING

STANDARD

KNOB

LEGEND PLATE

To a vo id d am ag e to e qu ip me nt or in ju ry t o pe rs onne l, e le ct ri cal

power must be off before and during installation and maintenance.

Ma in t ain ½ " (1 2 .7) m in i mu m cl e a ra nc e t hro ug h a ir be tw e en

current-carrying parts and enclosure.

PANEL � �

MOUNTING

�

�

BUSHING

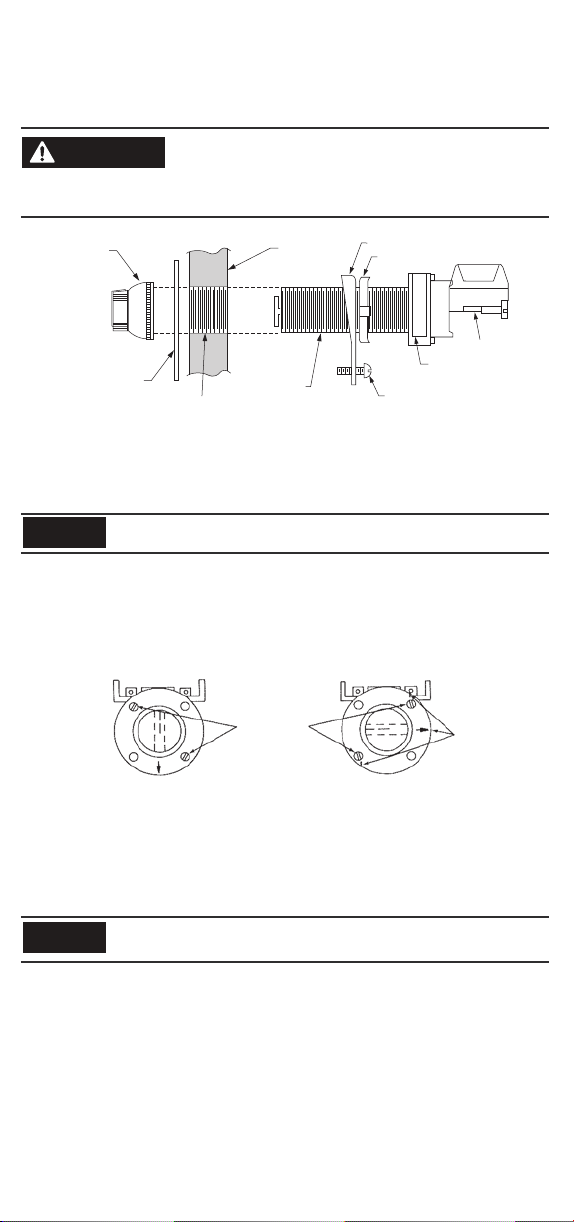

Figure 1

SECURING RING

ADJUSTING NUT

LOCKING SCREW

CONTACT BLOCK

NAMEPLATE

Installation: See Figure 1 for illustrated assembly

1. Pla ce sec urin g ring a nd/o r adju stin g nut as s uppl ied on u nit as s hown a bove a nd thr ead un it int o

panel until bushing ex tends approximatel y 9/32" (7.1) [3 to 4 threads ] past front of panel. 7/3 2" (5.6)

[2 to 3 threads] if a legend plate is not to be used.

NOTICE

2. To secur e unit, ro tate to ass ure elec trical cl earance a nd tight en adjust ing nut an d/or lock ing screw

sec urel y. Where t wo un its a re mou nted adj ace nt to e ach ot her, arr ang e secu ring rin gs to a voi d

interference.

3. Place legend plate, if used, over mounting bushing.

The specified extension of the bushing is necessary to provide engagement of the operating knob.

FLAT HEAD

SCREWS

REFERENCE MARKS

Device For Vertical Mounting

Front View

Device For Horizontal Mounting

Front View

Figure 2

NOTE: Remove knob, lever or key before modification.

1. Wi th a fel t pen o r cray on , mak e refe ren ce mar ks on t he mou nti ng bus hi ng to i dent ify t he sid e

adjacent to the nameplate and the holes in which the flat-head screws are assembled.

2. Remove the two flat-head screws and lift the mounting bushing straight off of the base. Do not twist.

Do not rotate any parts within either t he base assembly or the mounting bushi ng while these two

NOTICE

3. 2 an d 3 pos iti on se lec tor swit ches: Wh ile sepa rat ed from th e base, tu rn the mou nti ng bushi ng

counterclockwise 90° and reassemble the unit.

4 position se lector swi tches: Whil e separated f rom the base, t urn the mount ing bushin g clockwise

90° and reassemble the unit.

NOTE: In the proper position originally - used mounting screw holes will be aligned with tapped h oles in

the base.

4. Reassemble and torque the two flat-head screws to 8

5. Check the switch for proper operation and correct contact action.

To assemble th e operating kn ob, align the co lored insert w ith the rivet of t he shaft plate (s ee Figure 3).

Tig hte n the k nob as sembly o nto t he mo unt ing b ush ing . Kno b asse mbly sho uld c lam p leg end p lat e

tightly when properly assembled.

subassem blies are separate d from each ot her, as this c an cause incorrect sw itch operation aft er

reassembly.

±

1 lb.-in.

Page 2

SHAFT PLATE

RIVET

Figure 3

Knobs have repl aceable color i nserts. To remo ve place sharp in strument unde r insert at the mou nting ring

and pry u p. Gra sp ins ert and r emov e from op erat or. To i nstal l new in sert, p lace i nto sl ot in ope rato r and

apply light pressure to assure seating place (see Figure 4).

MOUNTING

RING

KNOB

ASSEMBLY

KNOB

Enclosur e must comp ly with U.L. s tandards 6 98 and 1203 an d CSA stand ard C22.2 No . 30 for Class I

Gro ups B, C a nd D ha zar dou s loca tions or C 22.2 N o. 25 for Cl ass II G roups E, F a nd G haz ardous

locations. For Class I locations, a suitable seal fitting is required within 18 inches.

Figure 4

PRY UP HERE

INSERT

Hole size to be .958 (24.30) to .970 diameter (24.60) ¾-14NPSM tap.

Apply grease from caps ule (supplied) to thre ads of ¾-14NPSM hole befo re assembling units in to panel

and to the threads of the lens assembly.

Maximum p anel thic kness is 2- 1/2" (63. 5). For pan els above 2 " (50.8) bu t not excee ding 2-1 /2" (63.5 )

remove and discard securing ring and tighten device with adjusting nut only.

For Class I Group B application, 5/8" (15.9) minimum panel thickness is required.

PN-25582

DIR 10000008895 (Version 01)

Printed in U.S.A.

0359 II 2 G EEx d IIB + Hydrogen ITS07ATEX15664U

SYRACUSE, NY 13221 USA

Loading...

Loading...