Page 1

User Manual

Non-display Industrial Computers

Catalog Numbers 6177R-MM, 6177R-RM, 6189V-DVIVGA, 6189V-HDDTRAY, 6189V-PCIBARMM, 6189V-PCIBARRM,

6189V-PSU600W, 6189V-RACKSLIDES, 6189V-4GDDR3, 6189V-8GDDR3, 6189V-16GDDR3, 6189V-35HDD500GB, 6189V-35SSD128GB

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, Rockwell Software, and Rockwell Automation are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

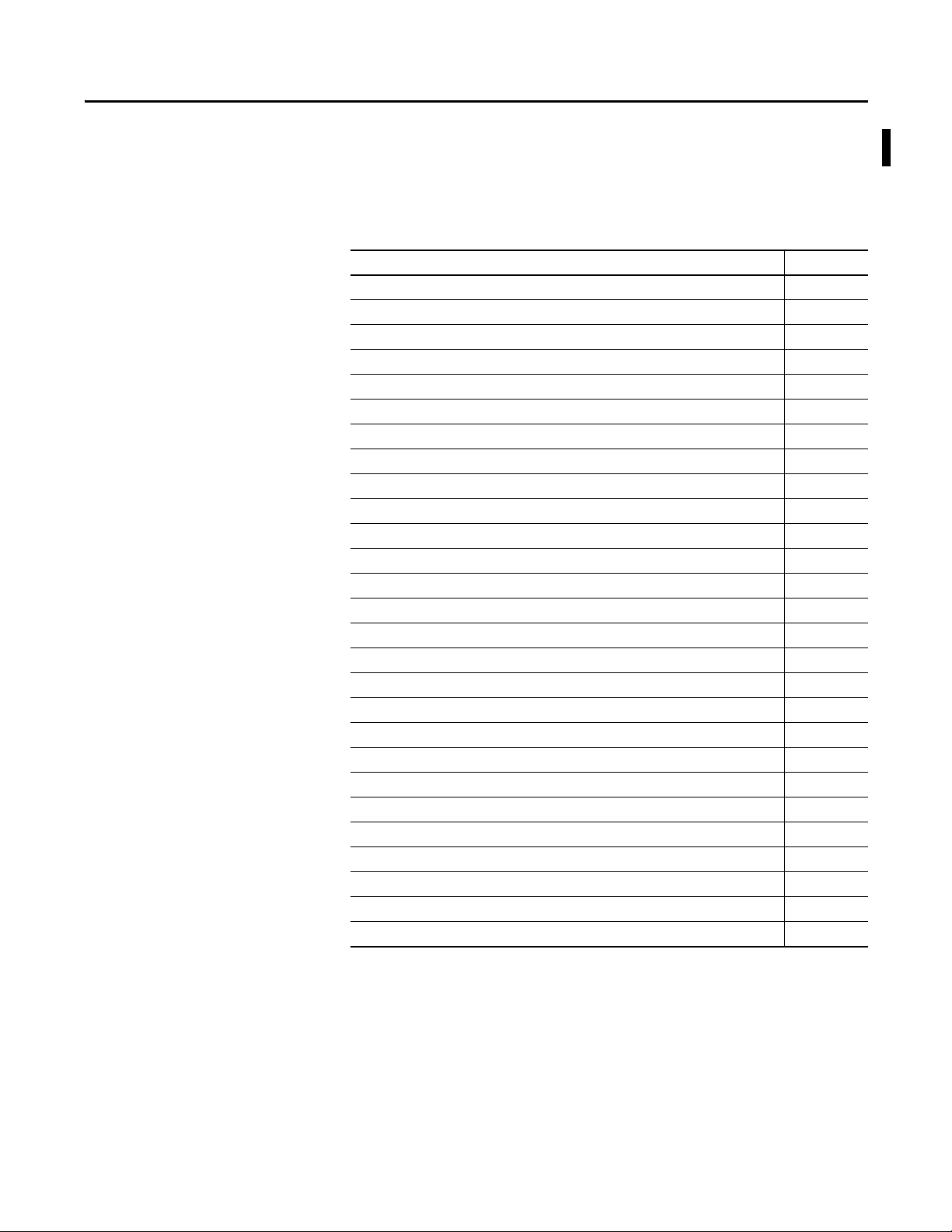

Summary of Changes

This manual contains new and updated information. Changes throughout this

revision are marked by change bars, as shown to the right of this paragraph.

New and Updated Information

This table contains the changes made to this revision.

Top ic Pag e

Expanded Abbreviations table 10

Revised and added available operating systems 11

Added Important table 11

Added catalog numbers to table in ‘Computer Options’ section 12

Updated information in ‘Parts List’ section 13

Revised footnote information in ‘Hardware Features’ section 14, 15

Updated CISPR number in ‘Environment and Enclosure Information’ section 20

Added catalog numbers to table in ‘Mounting Hardware’ section 22

Revised information in ‘Functional Ground Screw’ section 29

Changed callout description in Figure 10 42

Revised information in ‘Replace or Add a Memory Module’ section 43

Revised information in ‘Set-up Screen Overview’ section 52

Revised information in both ‘SATA Configuration’ subsections 60, 61

Revised information in ‘Super I/O Configuration’ subsection 65

Consolidated ‘System Temperature History’ subsection into ‘Hardware Monitor’ subsection 67

Revised and added information in ‘Boot’ subsection 70

Revised and added information in ‘Security’ subsection 71

Added information in ‘Diagnostics’ section 73, 74

Added Important tables in ‘AMI Backup’ section 75, 76, 77

Added Important table in ‘AMI Restore’ section 79

Added information in ‘Diagnostics’ section 87

Added Important table in ‘Load the System Defaults’ section 88

Added information in ‘Clear the UEFI’ section 89

Added ‘Dispose of the Computer’ section 90

Added new catalog numbers to Table 5, Hardware and Softwa re Specifications 91

Added new Table 6, Physical Specifications 92

Revised and added information in Table 9, Certifications 94

Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014 3

Page 4

Summary of Changes

Notes:

4 Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014

Page 5

Table of Contents

Preface

Features

Installation

Preface Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Purpose of This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

More Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Abbreviations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 1

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Computer Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operating Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Computer Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Hardware Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

750R Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1450R Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

System Boards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Chapter 2

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Installation Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Environment and Enclosure Information. . . . . . . . . . . . . . . . . . . . . . . 20

European Union Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Installation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Mounting Clearance Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Mounting Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Computer Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Install the Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Mount the 750R Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Mount the 1450R Computer in a Rack Cabinet . . . . . . . . . . . . . . . . 26

Connect Peripherals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Internal USB Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Connect Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Functional Ground Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Connect to a Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Operation

Chapter 3

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Operating Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Start the Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Restart the Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Restart the Computer with the Reset Button . . . . . . . . . . . . . . . . . . . 33

Shut Down the Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014 5

Page 6

Table of Contents

Chapter 4

Component Replacement

UEFI Set-up Utility

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Accessories and Replacement Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Voltage Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Electrostatic Discharge Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Pre-configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Post-configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Required Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Remove the Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Reinstall the Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Drive Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Replace a Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Replace or Add Memory Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Memory Configuration Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Replace or Add a Memory Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Replace the RTC Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Replace the Power Supply Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Chapter 5

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Set-up Utility Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Access the Set-up Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Set-up Screen Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Firmware Update. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Firmware Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Common Buttons at the Bottom of Screens. . . . . . . . . . . . . . . . . . . . . 54

Main . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Advanced . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Chipset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Save and Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

AMI Rescue. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

AMI Backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

AMI Restore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

6 Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014

Page 7

Chapter 6

Table of Contents

System Troubleshooting

Specifications

Accessories Installation

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Hardware Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Troubleshooting Checklists. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Issues during Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Issues after Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Issues Running New Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Issues with the Add-in Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Issues with an External Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Load the System Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Clear the UEFI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Ship or Transport the Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Dispose of the Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Appendix A

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Appendix B

Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Pre-installation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Install a Second HDD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Install I/O Card Retention Bracket. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Install an Add-in Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Install Rack Slides (1450R Computer) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Install More Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014 7

Page 8

Table of Contents

Notes:

8 Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014

Page 9

Preface

Preface Objectives

Purpose of This Manual

More Resources

This preface covers the following topics:

• Purpose of This Manual

• More Resources

• Abbreviations

This manual is a user guide for non-display industrial computers. It provides

procedures to the following:

• Install the computer.

• Make computer connections.

• Operate the computer.

• Troubleshoot the computer.

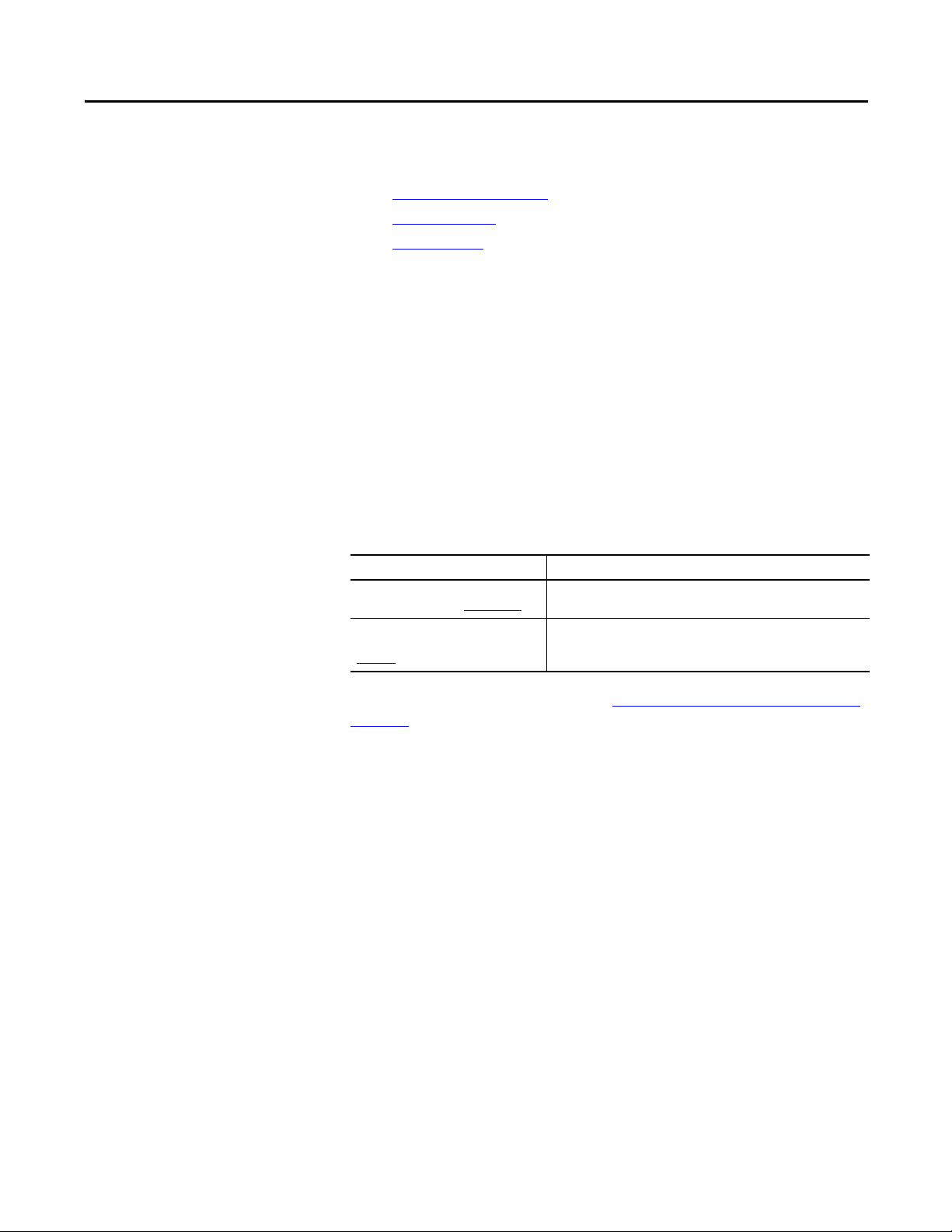

These documents contain more information to related products from Rockwell

Automation.

Resource Description

Industrial Non-display Computers Product

Information, publication 6177R-PC001

Industrial Automation Wiring and

Grounding Guidelines, publication

1770-4.1

Provides basic product information on the non-display industrial

computers.

Provides general guidelines for installing a Rockwell Automation

industrial system.

You can view or download publications at http://www.rockwellautomation.com/

literature.

To order paper copies of technical documentation, contact your local

Allen-Bradley distributor or Rockwell Automation sales representative.

Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014 9

Page 10

Preface

Abbreviations

This publication can use the following abbreviations.

Abbr Description Abbr Description

ACPI Advanced configuration (and) power

interface

AHCI Advanced host controller interface PCAP

AMI American Megatrends, Inc. PCB Printed circuit board

AMT Active management technology PCDC Product Compatibility and Download Center

BIOS Basic input/output system PCH Platform control hub

CF CompactFlash PCI Peripheral component interconnect

CPU Central processing unit PCIe Peripheral component interconnect express

CMOS Complementary metal oxide semiconductor PEG PCI express graphics

COM Communication (serial port interface) PELV Protective extra-low voltage

CRC Cyclic redundancy check PERR PCI parity error

DDR Double data rate (RAM) POST Power on self-test

DIMM Dual in-line memory module PSU Power supply unit

DP DisplayPort (digital display interface) PXE Pre-boot execution environment

DVI Digital video interface RAID Redundant array (of) independent disks

DVMT Dynamic video memory technology RAM Random access memory

ECC Error correcting code RIUP Remove or insert under power

eDP Embedded DisplayPort RMS Root-mean-square

EEA European Environment Agency RTC Real-time clock

EMC Electromagnetic compatibility SAS Serial attached SCSI

EOS Embedded operating system SATA Serial advanced technology attachment

ESD Electrostatic discharge SCSI Small computer system interface

EWF Enhanced write filter SELV Safety extra-low voltage

FAT File allocation table SERR PCI signal error

HDD Hard disk drive SPD Serial presence detect

HORM Hibernate once, resume many SSD Solid-state drive

IDE Integrated device electronics TFT Thin film transistor

IEC International Engineering Consortium UEFI Universal extensible firmware interface

IGD Intel graphics driver USB Universal serial bus

KVM Keyboard video mouse UPS Uninterruptible power source

LAN Local area network VBAT Voltage (battery)

NEMA

National Electrical Manufacturers Association

ODD

Optical disk drive

OSK

On-screen keyboard

Protective capacitive (touch screen)

VDDR Voltage (DDR RAM)

VGA Video graphics array

10 Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014

Page 11

Features

IMPORTANT

Chapter 1

Chapter Objectives

Computer Overview

Operating Systems

This chapter provides information on the following topics:

• Computer Overview

• Operating Systems

• Computer Options

• Before You Begin

• Parts List

• Hardware Features

Non-display industrial computers run operations from small visual interface and

maintenance applications to large control and information applications.

Combine an industrial display with the 750R (catalog number 6177R-MM) or

1450R (catalog number 6177R-RM) computer to complete your system.

These computers are available with performance, advanced, and server features.

They come standard with a selection of I/O ports for peripheral connections and

expansion slots.

The following Microsoft-licensed operating systems are available:

• Windows Embedded 8.1 Industry Pro (64-bit)

• Windows 7 Professional, Service Pack 1 (64-bit)

• Windows XP Professional, Service Pack 3

• Windows Server 2012 R2 Standard (64-bit)

• Windows Server 2008 R2 Standard, Service Pack 1(64-bit)

No operating system updates have been applied to the factory image beyond the

service packs.

Computers with HDDs include a recovery partition with the original factory

image. You can use AMI Rescue that is embedded in the BIOS/UEFI set-up

utility to restore the operating system from the recovery partition, and create a

recovery image. See AMI Rescue

Computers with the Windows Embedded 8.1 Industry Pro operating system do

not contain a backup of the factory image in the recovery partition.

Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014 11

on page 75 for instructions.

Page 12

Chapter 1 Feat ures

To obtain a copy of a factory system image, contact your local technical support

center or access the Rockwell Automation Product Compatibility and Download

Center (PCDC) at http://www.rockwellautomation.com/support/pcdc.page

.

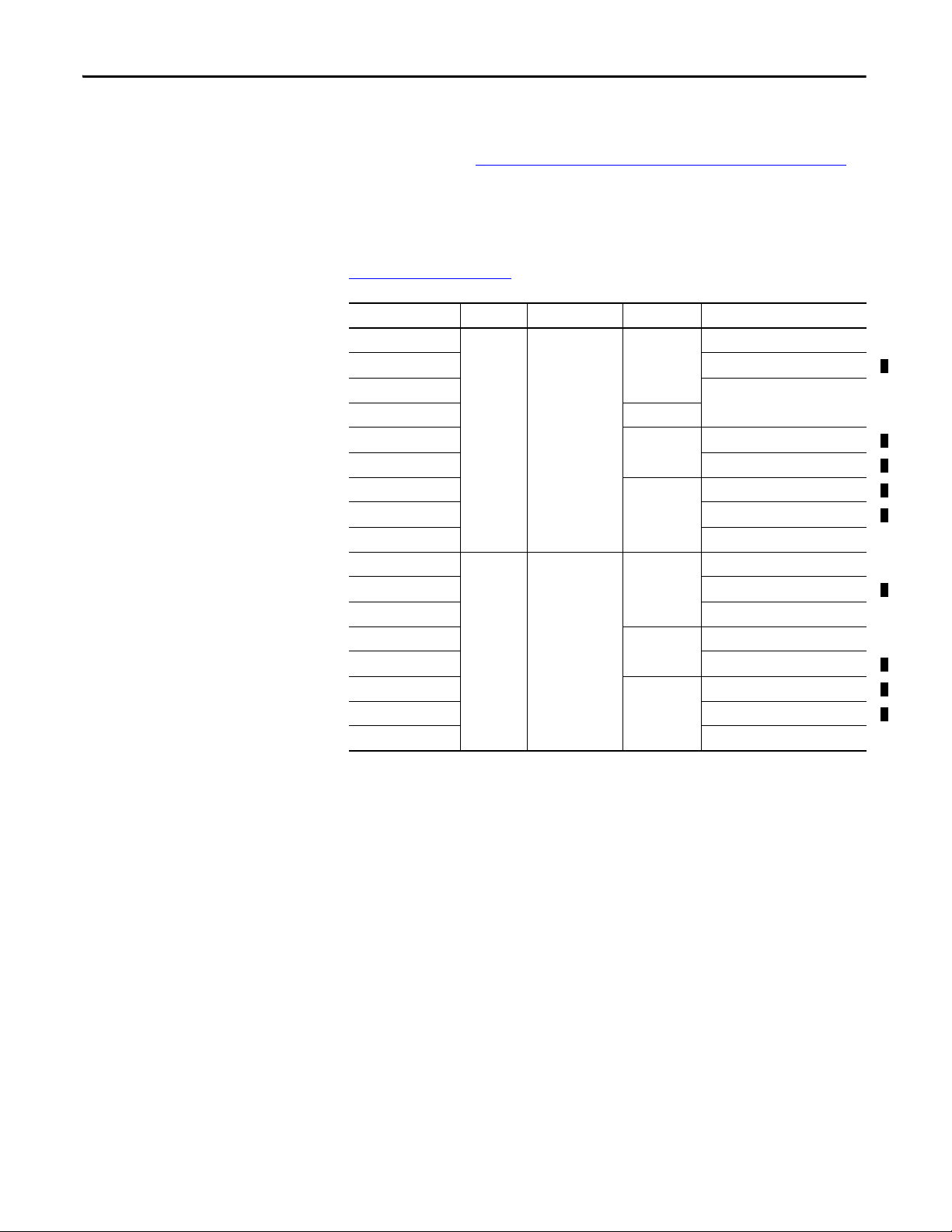

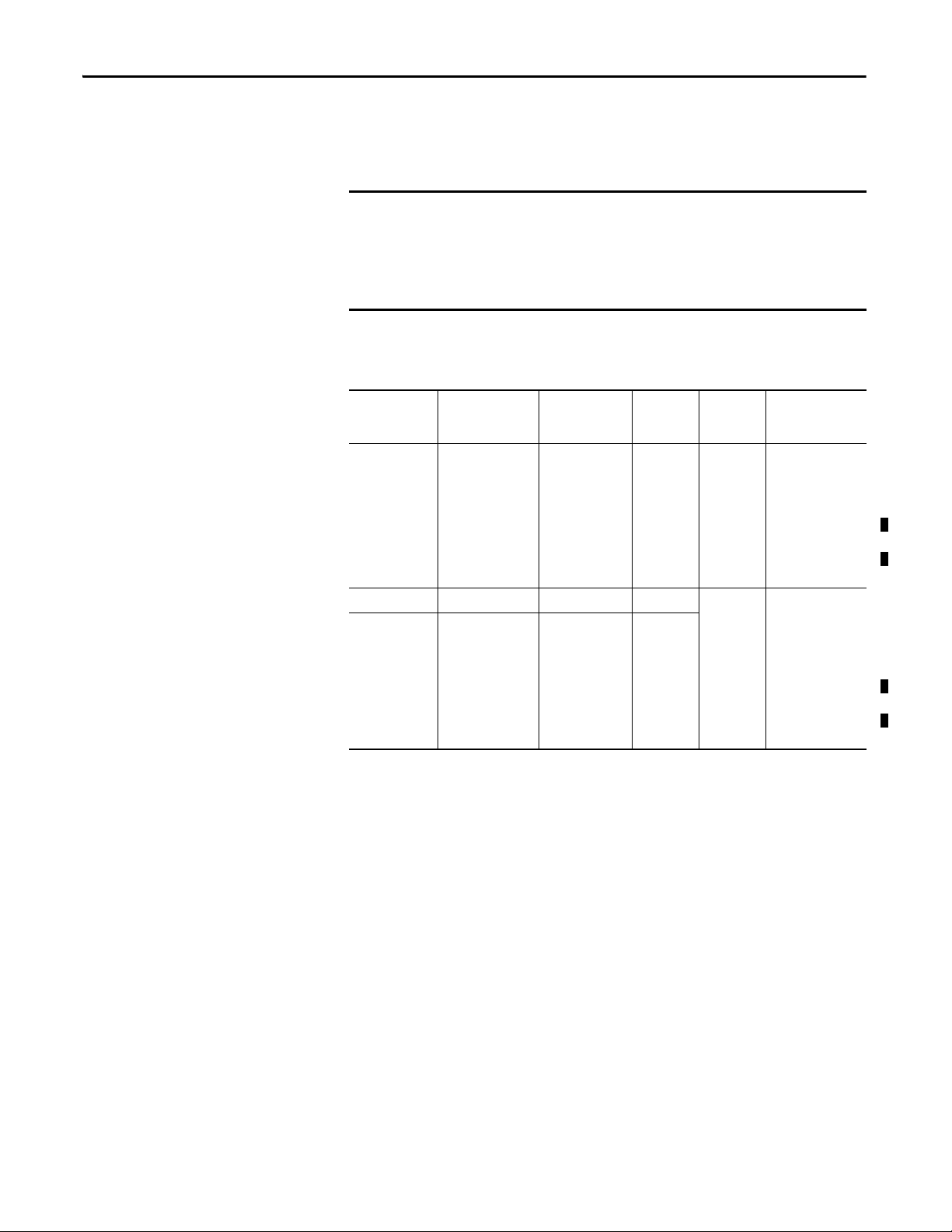

Computer Options

This table summarizes the options that are available for non-display industrial

computers. A comparative summary of features for the computers is in Appendix A,

Specifications

Cat. No. M odel Form Fa ctor Package Wind ows OS

6177R-RMPXP 1450R 4U rack mount Performance XP Professional SP3

6177R-RMPW7 7 Professional SP1

6177R-RMPNO None

6177R-RMRNO Redundant

6177R-RMAW7 Advanced 7 Professional SP1

6177R-RMAW8 Embedded 8.1 Industry Pro

6177R-RMSS8 Server Server 2008 R2 Standard SP1

6177R-RMS12 Server 2012 R2 Standard

6177R-RMSNO None

6177R-MMPXP 750R Machine mount Performance XP Professional SP3

6177R-MMPW7 7 Professional SP1

6177R-MMPNO None

6177R-MMAW7 Advanced XP Professional SP3

6177R-MMAW8 Embedded 8.1 Industry Pro

6177R-MMSS8 Server Server 2008 R2 Standard SP1

6177R-MMS12 Server 2012 R2 Standard

6177R-MMSNO None

on page 91.

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1) 64-bit operating system.

Before You Begin

Before you unpack the computer, inspect the shipping carton for damage. If

damage is visible, immediately contact the shipper and request assistance.

Otherwise, continue to unpack.

Keep the original packing material in case you must return the computer for

repair or transport it to another location. Use both inner and outer packing

cartons to provide adequate protection for a computer that is returned for service.

12 Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014

Page 13

Featu res Chapter 1

Parts List

Hardware Features

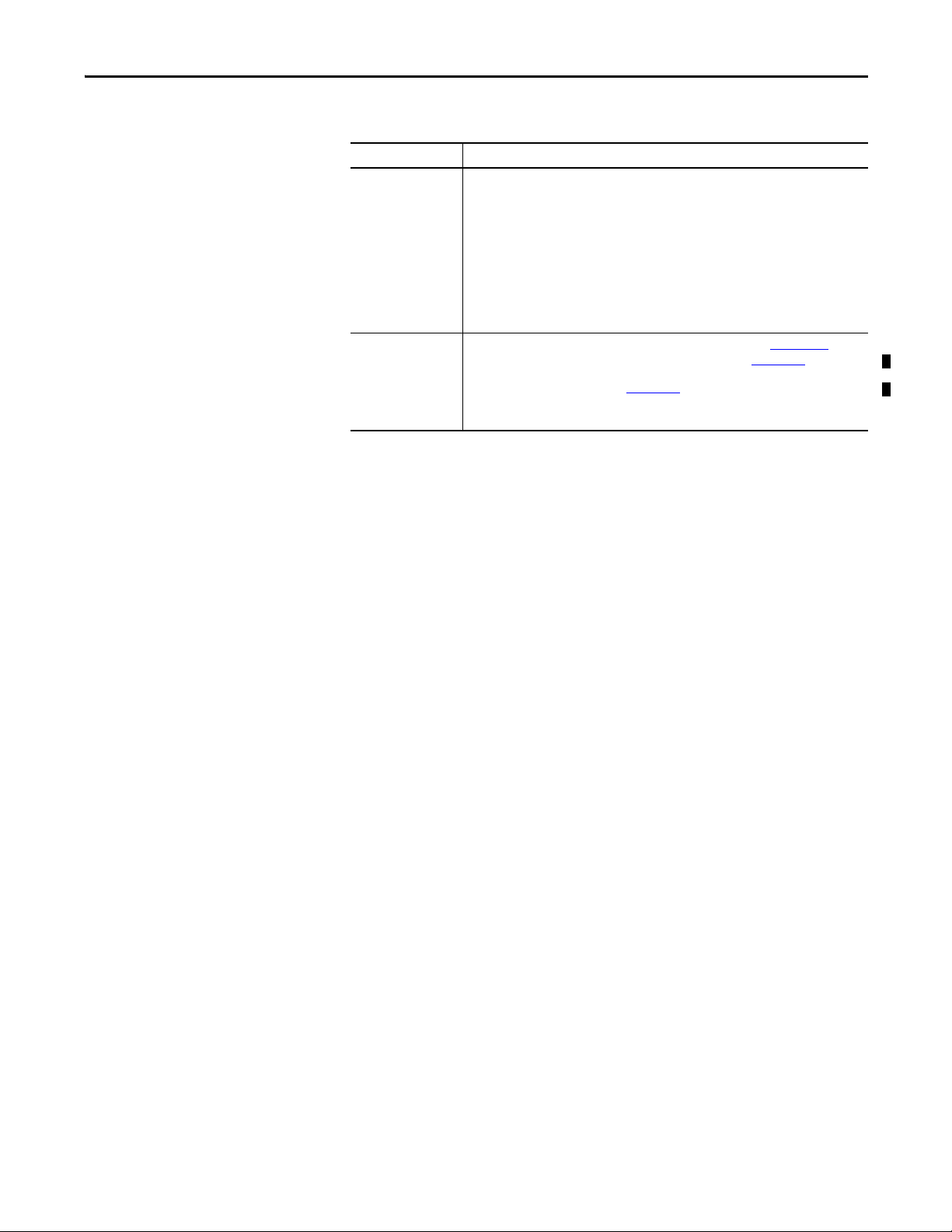

The computers ship with the following items.

Item Description

Hardware • Power cord for AC power models

• Mounting hardware

– Rack handles for 1450R computers

– Mounting brackets for 750R computers

– Mounting fasteners

– Cable ties for internal USB device

• Keys for door lock for 1450R computers

• Assembly screw bag

• DVI-to-VGA adapter

• CD with CD/DVD creation software

Documents • Non-display Industrial Computers Product Information, publication 6177R-PC001

• Shipped Compact Discs (CDs) Update Release Note, publication 6000-RN009

• Industrial Computers with the Windows Embedded 8.1 Industry Professional Operating

System Release Note, publication 6000-RN011

• China RoHS hazardous material table insert

• Production test report

(1) Shipped only with computers with the Windows XP Professional operating system.

(2) Shipped only with computers with the Windows Embedded 8.1 Industry Pro operating system.

(1)

(1)

(2)

The illustrations in this section show the hardware features of each computer:

• Exterior views

– Front panel

– Rear panel

• Status indicators

• System boards

– Motherboard

– Front panel board

– HDD adapter boards

– PCI expansion board

Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014 13

Page 14

Chapter 1 Feat ures

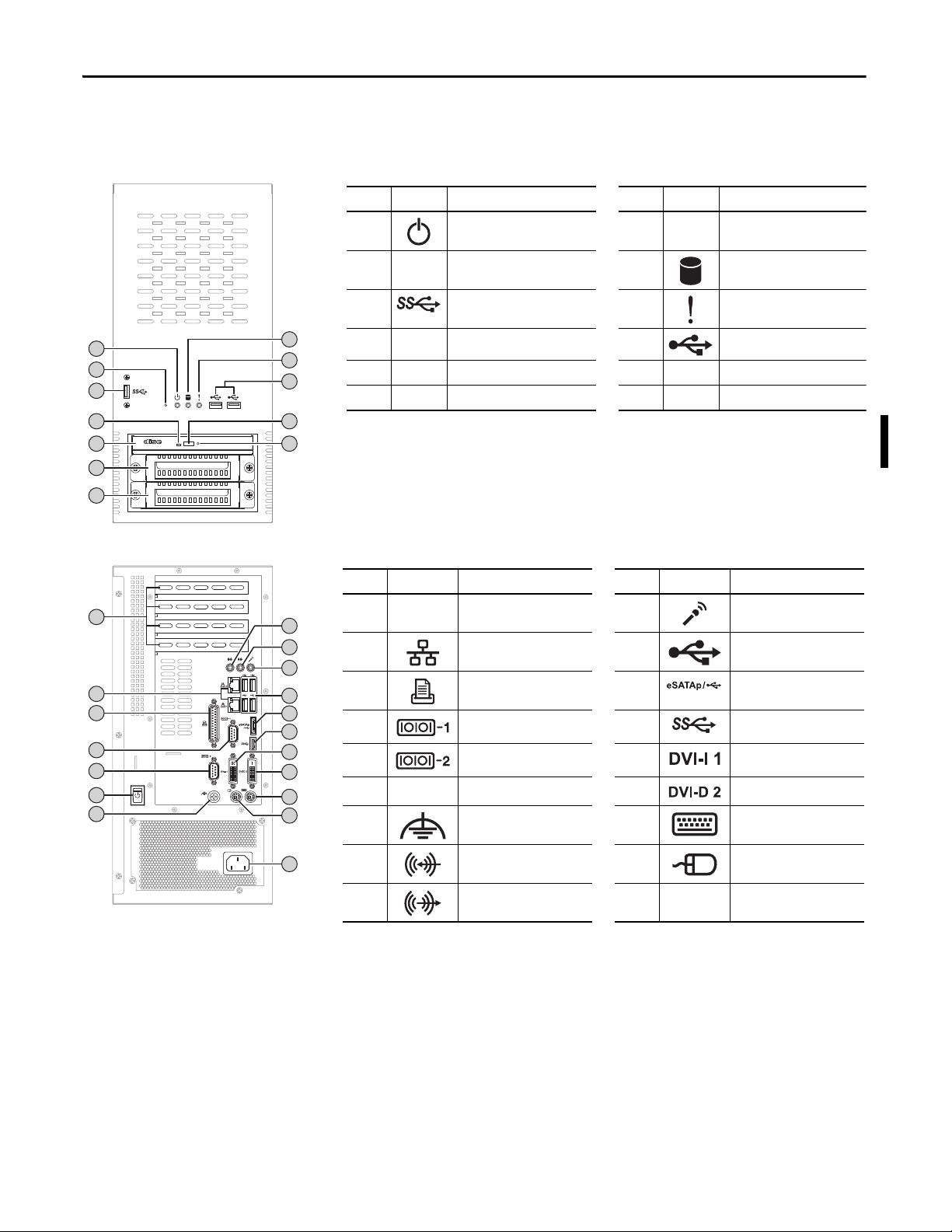

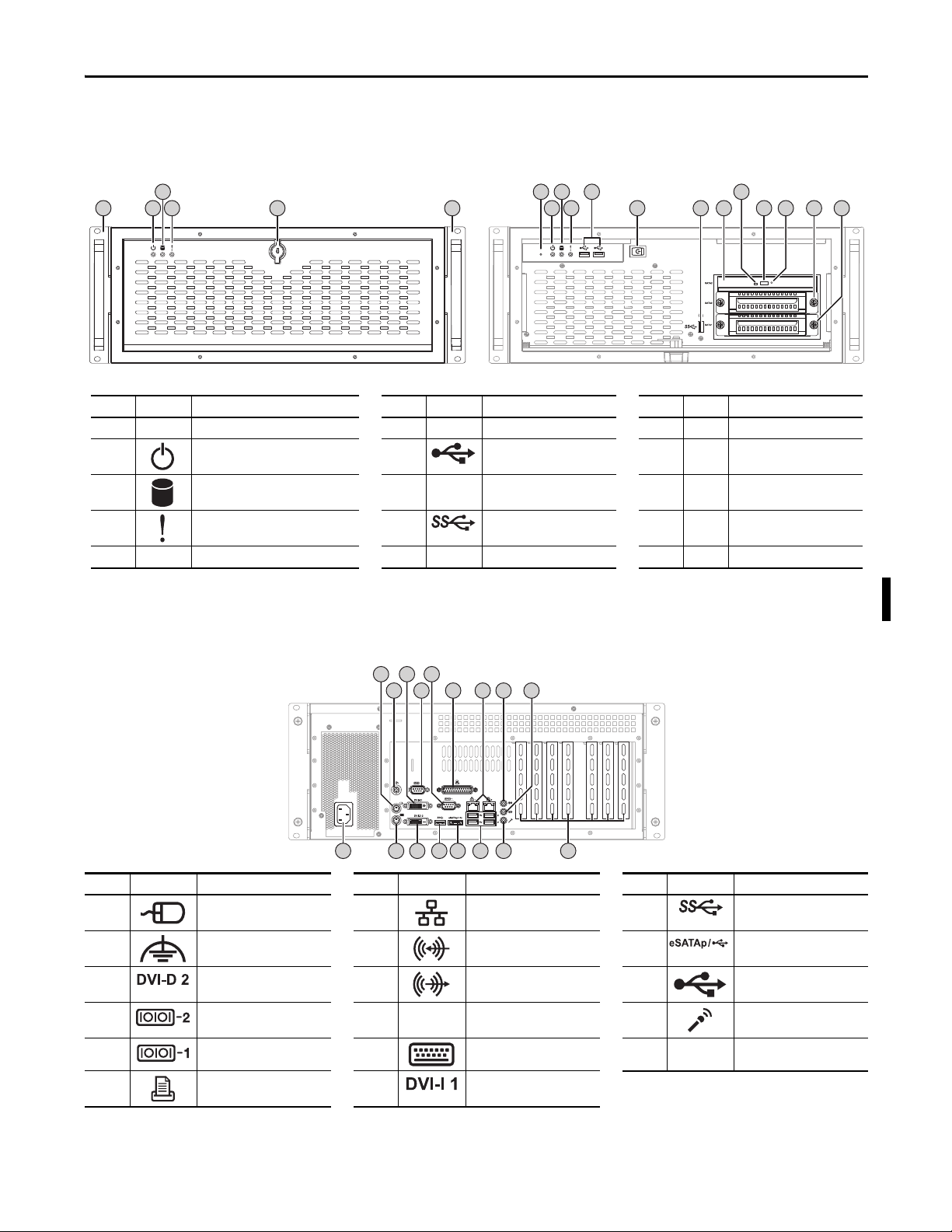

Item Icon Component Item Icon Component

1 Power status indicator 7 HDD SATA 1

(2)

(2) A second HDD is optional for computers with non-server operating systems.

2 Reset button 8 Disk drive access status

indicator

3 USB 3.0 por t 9 System health status indicator

4 ODD access indicator 10 USB 2.0 ports, 2

5 ODD SATA 2 11 ODD eject button

6HDD SATA 0

(1)

(1)

Computers with Windows Server operating systems ship with two HDDs that are configured for RAID 1 operation. Computers that ship

with two HDDs but no operating system are not configured for RAID 1 operation.

12 ODD mechanical eject hole

1

2

3

4

5

6

7

8

9

10

11

12

Item Icon Component Item Icon Component

1 PCI expansion slot covers, 4 10 Microphone-in jack

2 Gigabit LAN ports, 2 11 USB 2.0 por ts, 4

3 Parallel port 12 eSATAp port

4 Serial COM1 port (RS-232) 13 USB 3.0 port

5 Serial COM2 port (RS-232) 14 DVI-I1 port

6 Power switch 15 DVI-D2 port

7 Functional ground screw 16 PS/2 keyboard port

8 Line-in jack 17 PS/2 mouse por t

9 Line-out jack 18 Power input, AC

1

2

3

4

5

6

7

8

11

9

10

12

13

14

15

16

17

18

750R Computer

Figure 1 - Front Panel

Figure 2 - Rear Panel

14 Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014

Page 15

Featu res Chapter 1

421214

3

5

736

10981312 14 15

11

With Door Closed With Door Open

42

1

1411 13

35

7

12

698

10 1615 17

1450R Computer

Figure 3 - Front Panel

Item Icon Component Item Icon Component Item Icon Component

1Rack handle 6Reset button 11ODD access indicator

2 Power status indicator 7 USB 2.0 ports, 2 12 ODD eject button

3 Disk drive access status indicator 8 Power switch 13 ODD mechanical eject hole

4 System health status indicator 9 USB 3.0 port 14 HDD SATA 0

5 Door lock 10 ODD SATA 2 15 HDD SATA 1

(1)

Computers with Windows Server operating systems ship with two HDDs that are configured for RAID 1 operation

1 operation.

(2) A second HDD is optional for computers with non-server operating systems.

. Computers that ship with two HDDs but no operating system are not configured for RAID

(1)

(1)(2)

Figure 4 - Rear Panel

Item Icon Component Item Icon Component Item Icon Component

1 PS/2 mouse port 7 Gigabit LAN ports, 2 13 USB 3.0 port

2 Functional ground screw 8 Line-in jack 14 eSATAp port

3 DVI-D2 port 9 Line-out jack 15 USB 2.0 ports, 4

4 Serial COM2 port (RS-232)

5 Serial COM1 port (RS-232) 11 PS/2 keyboard port 17 PCI expansion slot covers, 7

10 Power input, AC 16 Microphone-in jack

6 Parallel port 12 DVI-I1 port

Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014 15

Page 16

Chapter 1 Feat ures

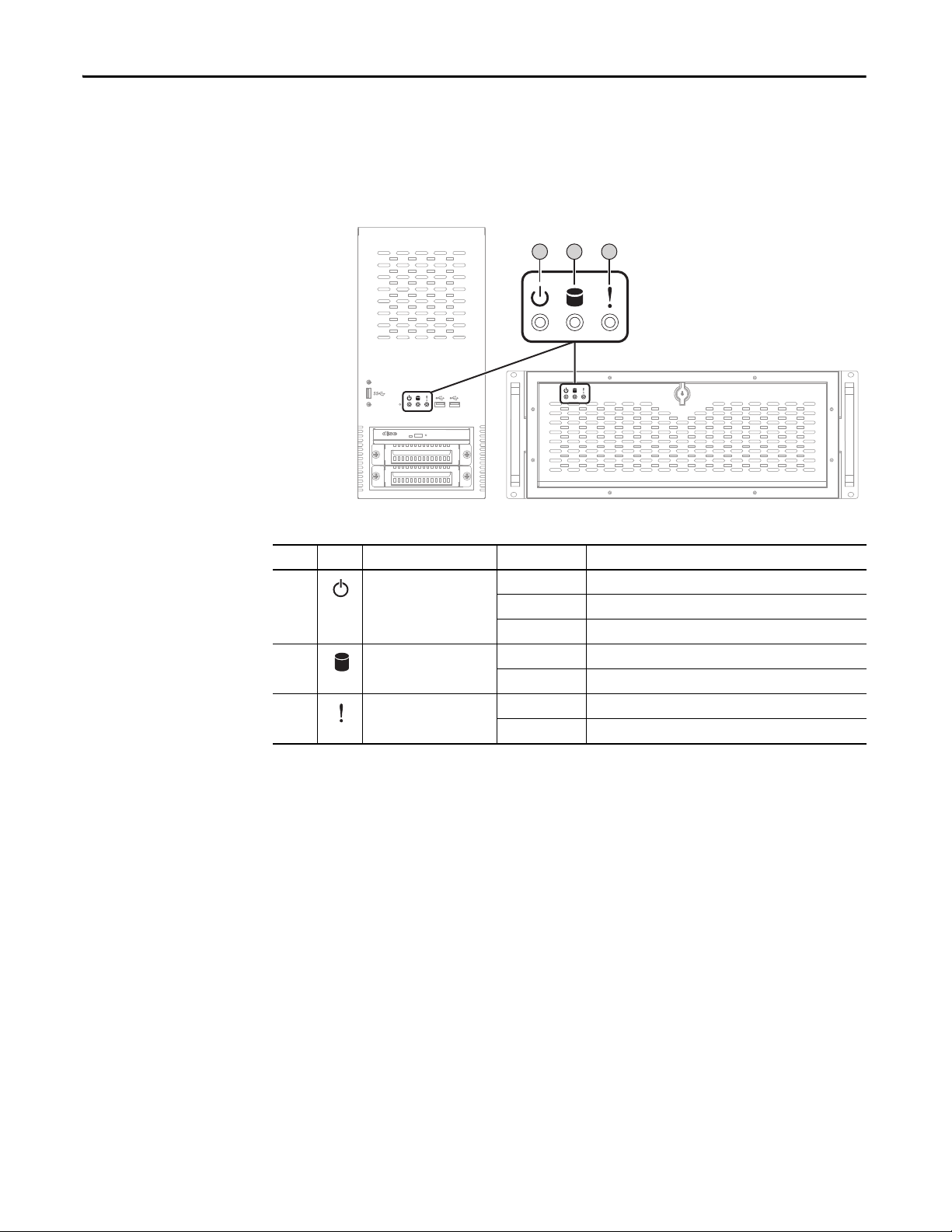

750R-Front Panel

1450R-Front Panel

321

Status Indicators

There are three status indicators on the front panel of the 750R and 1450R

computers. These indicators aid in issue diagnosis by providing status

information of different system components.

Item Icon Indicator Status Description

1 Power status Green The computer is operating.

Flashing orange The computer is in standby mode.

Off The computer is off.

2 Disk drive access status Flashing red HDD or ODD activity.

Off No HDD or ODD activity.

3 System health status Red The computer temperature threshold has been exceeded.

Off System health is normal.

16 Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014

Page 17

Featu res Chapter 1

4

2

1

12

16

11

3

5

7

17

69

810

18

13

19

14

15

202122232425

26

27

28

29

30

32

31

33

34

35

36

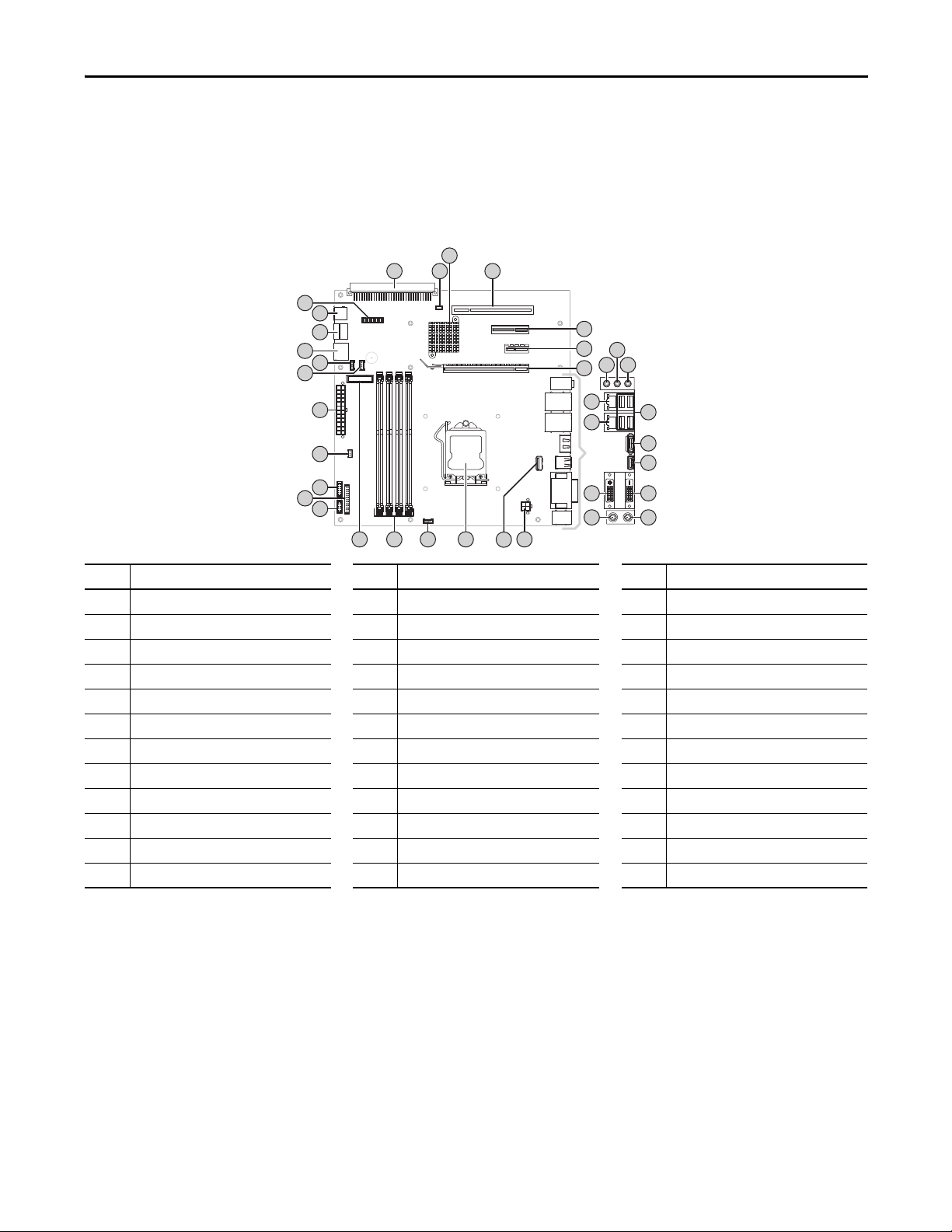

System Boards

The illustrations in this section show the system board layouts for the computers.

The 750R and 1450R computers share system boards except for the PCI

expansion board, which is available only on 1450R computers.

Figure 5 - Motherboard

Item Component Item Component Item Component

1 PCI expansion board connector 13 Rear USB 3.0 port 25 Battery socket

2 Clear UEFI (CMOS1) jumper 14 DVI-D2 connector 26 Serial port (COM1)

3 Platform control hub 15 PS/2 keyboard port 27 Internal parallel connector

4 PCI expansion slot 16 Gigabit LAN/2 port 28 Serial port (COM2)

5 PCIe x4 expansion slot 17 Gigabit LAN/1 port 29 Power switch cable connector

6 PCIe x1 expansion slot 18 DVI-I1 connector 30 ATX 24-pin power connector

7 PCIe x16 expansion slot 19 PS/2 mouse port 31 System fan 2 connector

8 Line-in jack 20 +12V 4-pin power connector 32 System fan 1 connector

9 Line-out jack 21 Internal USB 3.0 connector 33 SATA 3.0 cable connector

10 Microphone-in jack 22 LGA1155 processor socket 34 SATA 2.0 cable connector

11 Rear USB 2.0 ports, 4 23 Processor fan connector 35 Internal USB 2.0 connector

12 eSATAp port 24 DDR3 DIMM slots, 4 36 Front panel board cable connector

Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014 17

Page 18

Chapter 1 Feat ures

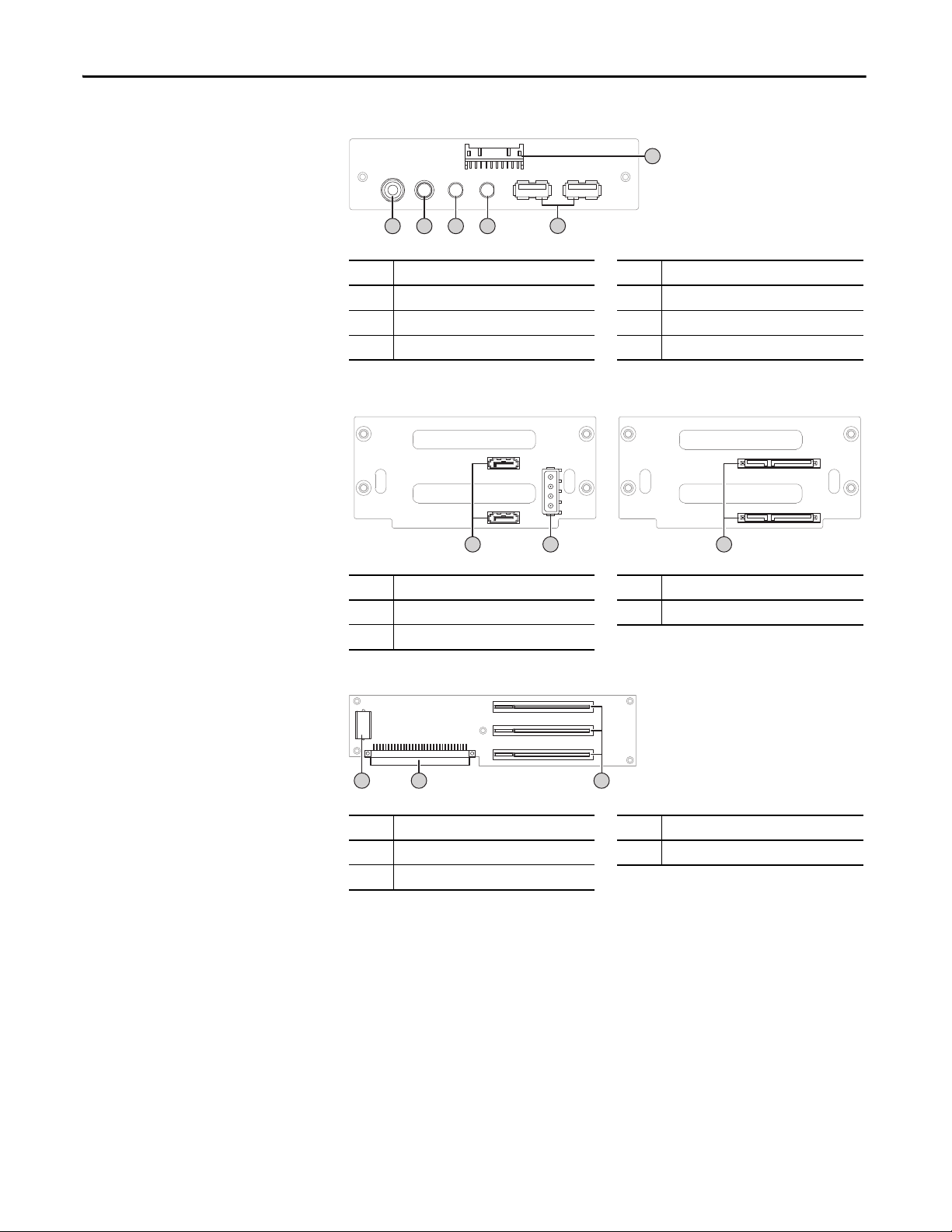

52143

6

321

Motherboard Interface

HDD Tray Interface

321

Figure 6 - Front Panel Board

Item Component Item Component

1 Reset button 4 System health indicator

2 Power status indicator 5 USB 2.0 por ts

3 Disk drive access indicator 6 Front panel board cable connector

Figure 7 - HDD Adapter Boards

Item Component Item Component

1 SATA cable connectors 3 SATA drive connectors

2 Power connector

Figure 8 - PCI Expansion Board (1450R computers)

Item Component Item Component

1 PCI expansion board power connector 3 PCI expansion slots

2 Motherboard connector

18 Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014

Page 19

Installation

Chapter 2

Chapter Objectives

This chapter provides information on the following topics:

• Installation Precautions

• Installation Guidelines

• Mounting Clearance Requirements

• Mounting Hardware

• Computer Dimensions

• Required Tools

• Install the Computer

• Connect Peripherals

• Connect Power

• Functional Ground Screw

• Connect to a Network

Review each mounting type and computer dimensions before you install the

computer.

Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014 19

Page 20

Chapter 2 Installation

Installation Precautions

Read and follow these precautions before you install the computer.

Environment and Enclosure Information

ATTENTION:

environment, in overvoltage Category II applications (as defined in IEC 60664-1),

at altitudes up to 2000 m (6561 ft) without derating.

This equipment is considered Group 1, Class A industrial equipment according to

IEC/CISPR 22. Without appropriate precautions, there can be potential difficulties

with electromagnetic compatibility in other environments due to conducted and

radiated disturbance.

This equipment is supplied as open type equipment. The interior of the enclosure

must be accessible only by the use of a tool. UL Listed equipment need not be

mounted inside another enclosure. Subsequent sections of this publication can

contain extra information about specific enclosure type ratings that are required to

comply with certain product safety certifications.

In addition to this publication, see the following:

• Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1

for additional installation requirements

• NEMA 250 and IEC 60529, as applicable, for explanations of the degrees of

protection that are provided by different types of enclosure

This equipment is intended for use in a Pollution Degree 2 industrial

,

European Union Directive

This computer meets the European Union Directive requirements when installed

within the European Union or EEA regions and have the CE mark. A copy of the

declaration of the conformity is available at http://www.rockwellautomation.com/

certification

.

ATT EN TI ON : This computer is intended to operate in an industrial or control

room environment, which uses some form of power isolation from the public

low–voltage mains. Some computer configurations cannot comply with the

EN 61000-3-2 Harmonic Emissions standard as specified by the EMC Directive of

the European Union. Obtain permission from the local power authority before

you connect any computer configuration that draws more than 75 W of AC

power directly from the public mains.

To comply with EN 55024, the Ethernet port LAN cable must be only used indoors.

All other I/O cables must be less than 3 m (9.84 ft) and only used indoors.

20 Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014

Page 21

Installation Chapter 2

TIP

IMPORTANT

Installation Guidelines

Follow these guidelines to make sure that your computer provides service with

excellent reliability:

• The installation site must have sufficient power.

ATTENTION: To maintain an electrically safe installation, AC powered

computers must be plugged into a grounded outlet.

• In dry environments, static charges can build up easily. A properly

grounded computer helps to reduce static discharges, which can cause

shock and damage electronic components.

• The enclosure must allow sufficient space around air inlets and outlets to

provide the circulation necessary for cooling. See Mounting Clearance

Requirements on page 22 for further information. Never allow air passages

to become obstructed.

• The ambient air temperature must not exceed the maximum operating

temperature that is specified in

supplied

in the enclosure.

fan, heat exchanger, or air conditioner for heat from other devices

Hot air rises. The temperature at the top of the enclosure is often

higher than the temperature in other parts of the enclosure, especially

when air does not circulate.

Tab le 8 o n p ag e 9 3

. Consider a user-

The computer can operate at a range of extremes. However, the life

span of the computer is shortened if you continuously operate it at its

highest rated temperature.

• The humidity of the ambient air must not exceed limits that are specified

in Ta bl e 8 on pag e 93

•

The enclosure or cover must always remain in place during operation. The

cover provides protection against high voltages inside the computer and

inhibits radio-frequency emissions that can interfere with other equipment.

and must avoid condensation.

Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014 21

Page 22

Chapter 2 Installation

IMPORTANT

Mounting Clearance Requirements

Mounting Hardware

When selecting an installation site for the computers, allow a minimum of

76 mm (3 in.) clearance at the front and rear of the computer for adequate

ventilation and cable connections.

Computers generate heat. Therefore, do not operate the computer in an

enclosure with the minimum clearances unless adequate ventilation or other

methods are used to lower the temperature within the enclosure.

Allow enough clearance to install or remove peripheral

components, such as

storage drives.

The table lists the hardware that is required for each type of installation.

Supplied

Description Cat. No. Application

Mounting

brackets (2)

Rack handles (2) N/A Rack Yes 1450R 6177R-RMPXP

Rack slides (2) 6189V-RACKSLIDES Rack No

N/A Machine or wall Yes 750R 6177R-MMPXP

with

computer? Applies to Cat. No.

6177R-MMPW7

6177R-MMPNO

6177R-MMSS8

6177R-MMS12

6177R-MMAW7

6177R-MMAW8

6177R-MMSNO

6177R-RMPW7

6177R-RMPNO

6177R-RMRNO

6177R-RMSS8

6177R-RMS12

6177R-RMAW7

6177R-RMAW8

6177R-RMSNO

22 Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014

Page 23

Installation Chapter 2

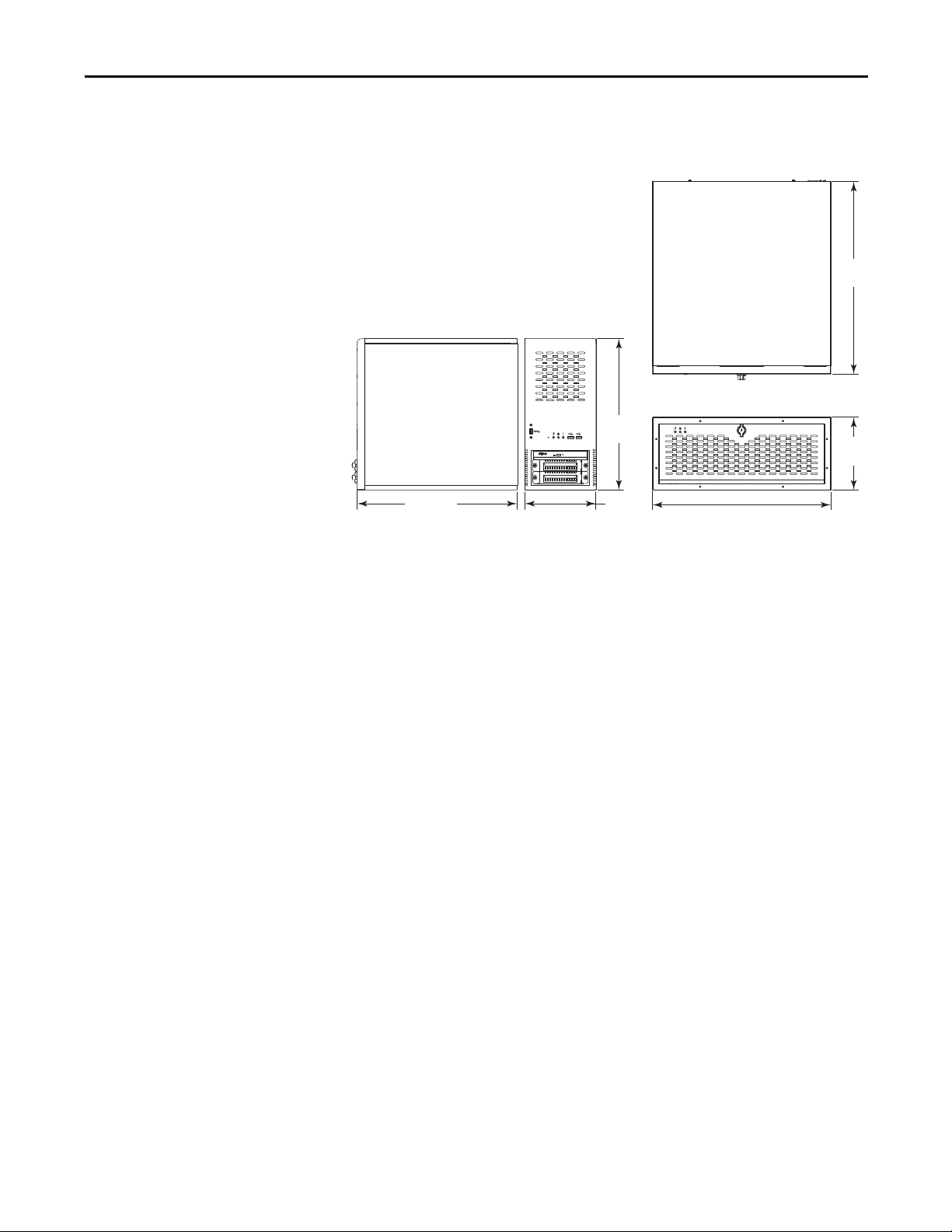

360

(14.2)

170

(6.7)

381 (15)

750R Computers 1450R Computers

Front View

Front View

Side View

Top Vie w

465

(18.3)

176

(6.9)

Computer Dimensions

Review computer dimensions to estimate the clearance necessary for computer

installation. Dimensions are given in mm (in.).

Required Tools

These tools are required for computer installation:

• #2 cross-head screwdriver

• Slot-head screwdriver

• Drill motor and drill bit

• Antistatic wriststrap

Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014 23

Page 24

Chapter 2 Installation

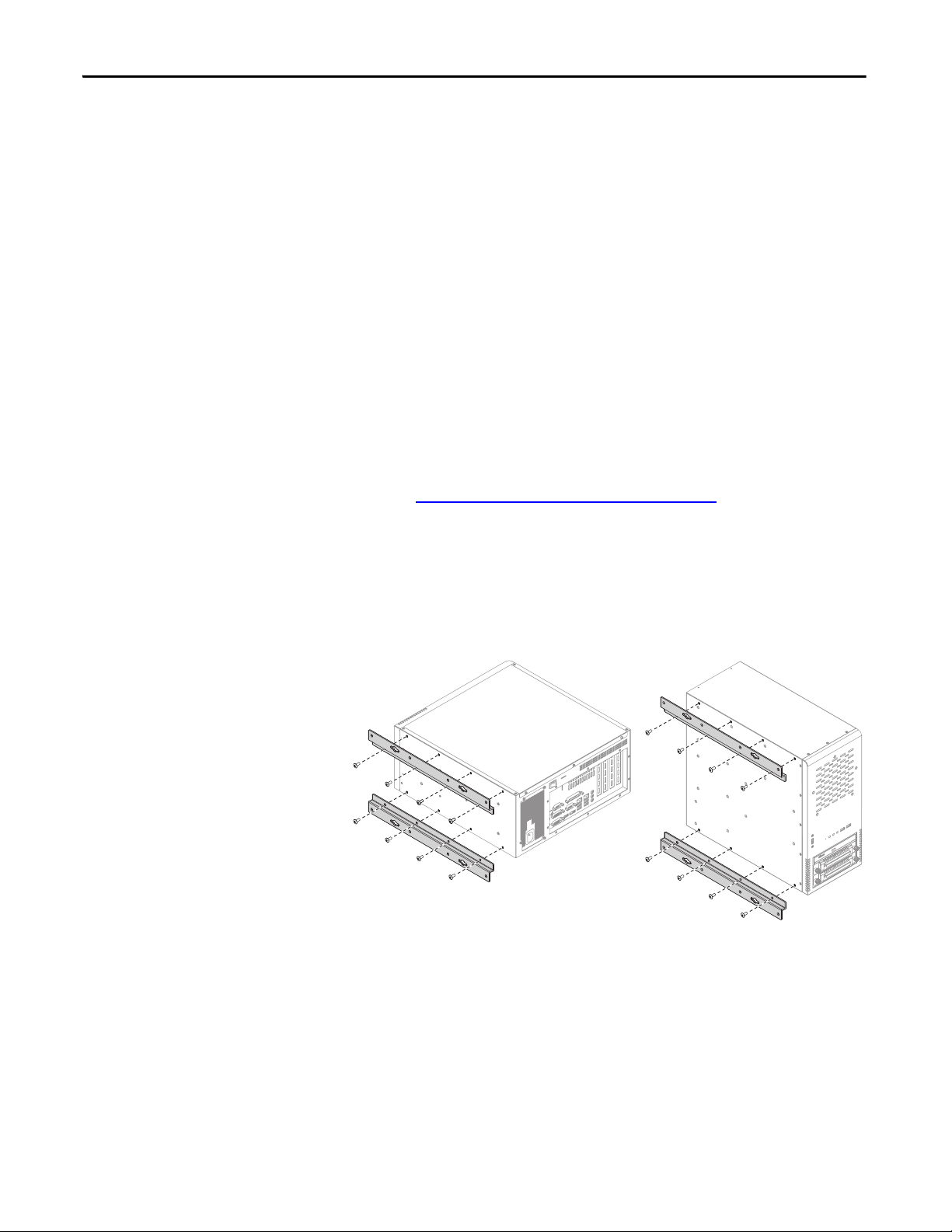

TIP

Bottom Mounting Brackets Side Mounting Brackets

Install the Computer

The computers support the following mounting options:

• Machine or wall mount (for 750R models)

• Rack mount (for 1450R models)

Mount the 750R Computer

You can mount the 750R computer on any flat surface, such as a shelf inside a

machine or against a wall, by using mounting brackets. Holes are provided on

both sides of the 750R computer for side mounting installation.

For ease of installation, use two or more people to install the computer.

Follow these steps to mount the 750R computer.

1. Verify that the mounting location provides adequate space for cables and

airflow.

See Mounting Clearance Requirements

allowances.

2. Decide where to locate the mounting brackets (the bottom side for an

upright installation or the side for a wall installation).

on page 22 for recommended

3. Attach each mounting bracket to the computer with four screws.

Torque the screws to 1.3 N•m (12.1 lb•in).

24 Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014

Page 25

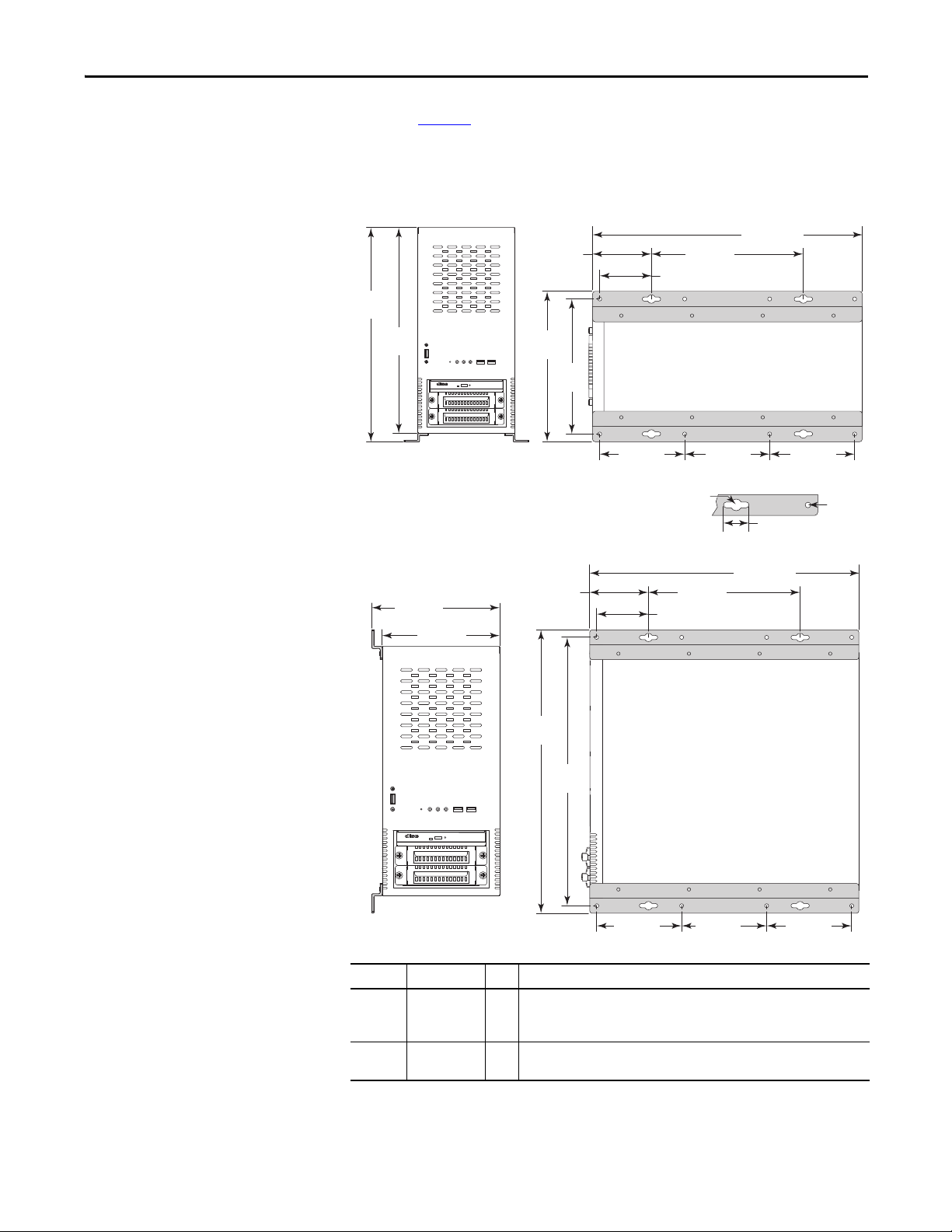

Bottom Mounting Bracket Hole Locations

Dimensions are in mm (in.).

IMPORTANT: Bottom view is enlarged

for detail and not in scale to front view.

120 (4.73) 120 (4.73)120 (4.73)

24 (0.95) x 4

382.1 (15.04)

60 (2.36)

240 (9.45)

210

(8.27)

194

(7.64)

70.5 (2.78)

375

(14.76)

360

(14.17)

A

B

Side Mounting Bracket Hole Locations

120 (4.73)

120 (4.73)120 (4.73)

382.1 (15.04)

60 (2.36)

240 (9.45)

401.6

(15.81)

385.6

(15.18)

70.5 (2.78)

185 (7.28)

175 (6.89)

Mounting Hole Details (all brackets)

Installation Chapter 2

4. See Figure 9 to decide which mounting holes to use on the bracket.

5. Drill holes in the wall or shelf to accommodate screws sized M6…M8.

Figure 9 - Mounting Hole Locations on 750R Computers

Callout Dim, mm (in.) Qty Description

A Ø 10 (0.39) 4 Use these mounting holes for the following.

B Ø 6.5 (0.25) 8 Use these mounting holes when shock and vibration are environmental

• You are replacing a legacy computer.

• Shock and vibration are not environmental elements.

elements.

6. Fasten the computer to the wall or shelf with M6…M8 mounting screws.

Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014 25

Page 26

Chapter 2 Installation

IMPORTANT

TIP

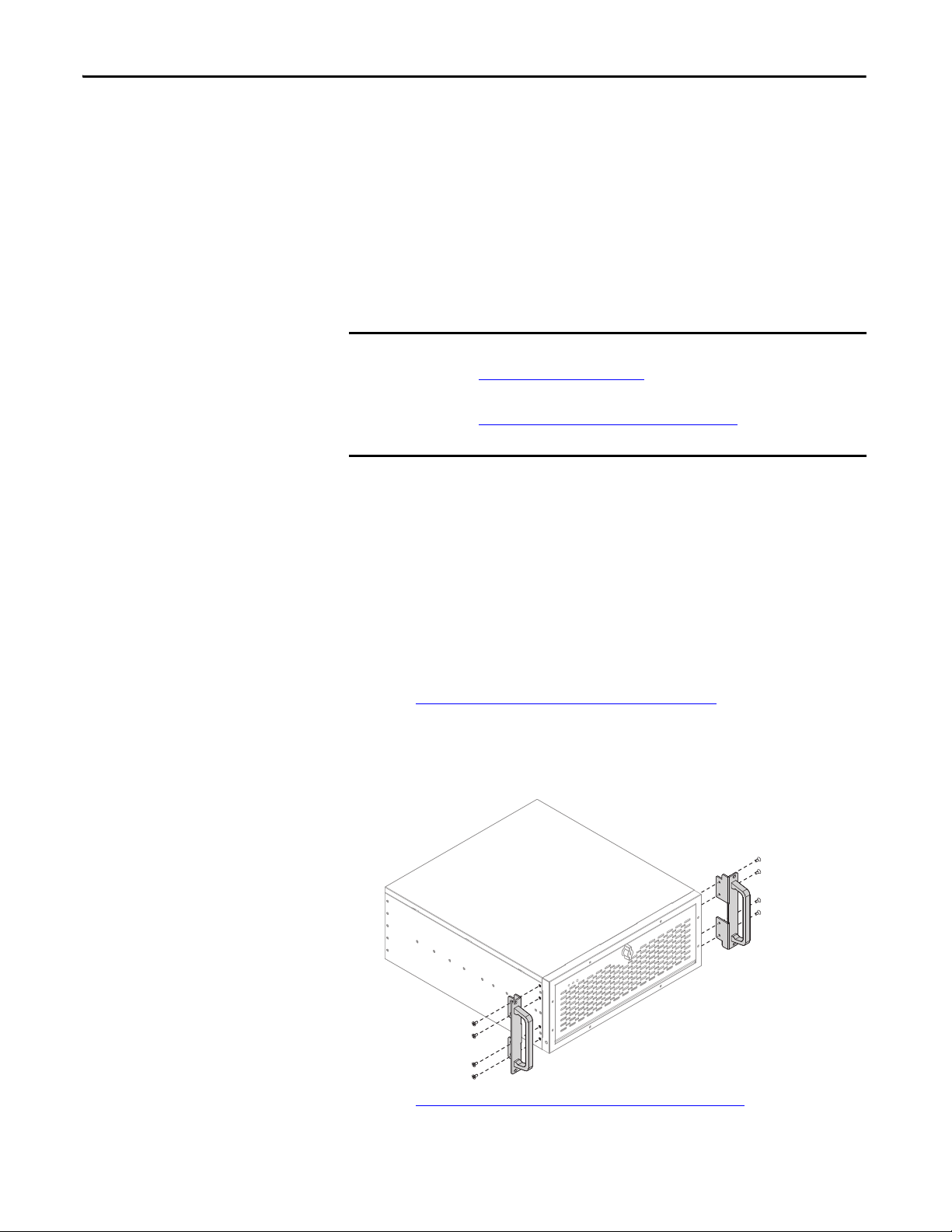

Mount the 1450R Computer in a Rack Cabinet

You can install the 1450R computer in a rack cabinet that does the following:

• Conforms to EIA standards for equipment with 483 mm (19 in.) wide

panels

• Accommodates the 4U height and depth of the computer

• Provides rear clearance for cables and airflow

A rack cabinet with a depth of 610 mm (24 in.) is sufficient.

Rack slides are not supplied with the computer and must be ordered separately.

See Mounting Hardware on page 22 for the catalog number necessary for

ordering.

See Install Rack Slides (1450R Computer)

the rack slides.

Support the computer with rack slides or by fastening it to a shelf. The four

flanges of the computer secure the computer horizontally only to the front

mounting rails of the rack cabinet.

on page 102 if you have purchased

For ease of installation, use two or more people to install the computer.

Follow these steps to mount the 1450R computer.

1. Verify that the mounting location provides adequate space for cables and

airflow.

See Mounting Clearance Requirements

on page 22 for recommended

allowances.

2. Attach the supplied rack handles to the computer.

Torque the screws to 1.3 N•m (12.1 lb•in).

3. See Install Rack Slides (1450R Computer)

rack slides to the rack cabinet and the 1450R computer.

26 Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014

on page 102 on how to install

Page 27

Installation Chapter 2

TIP

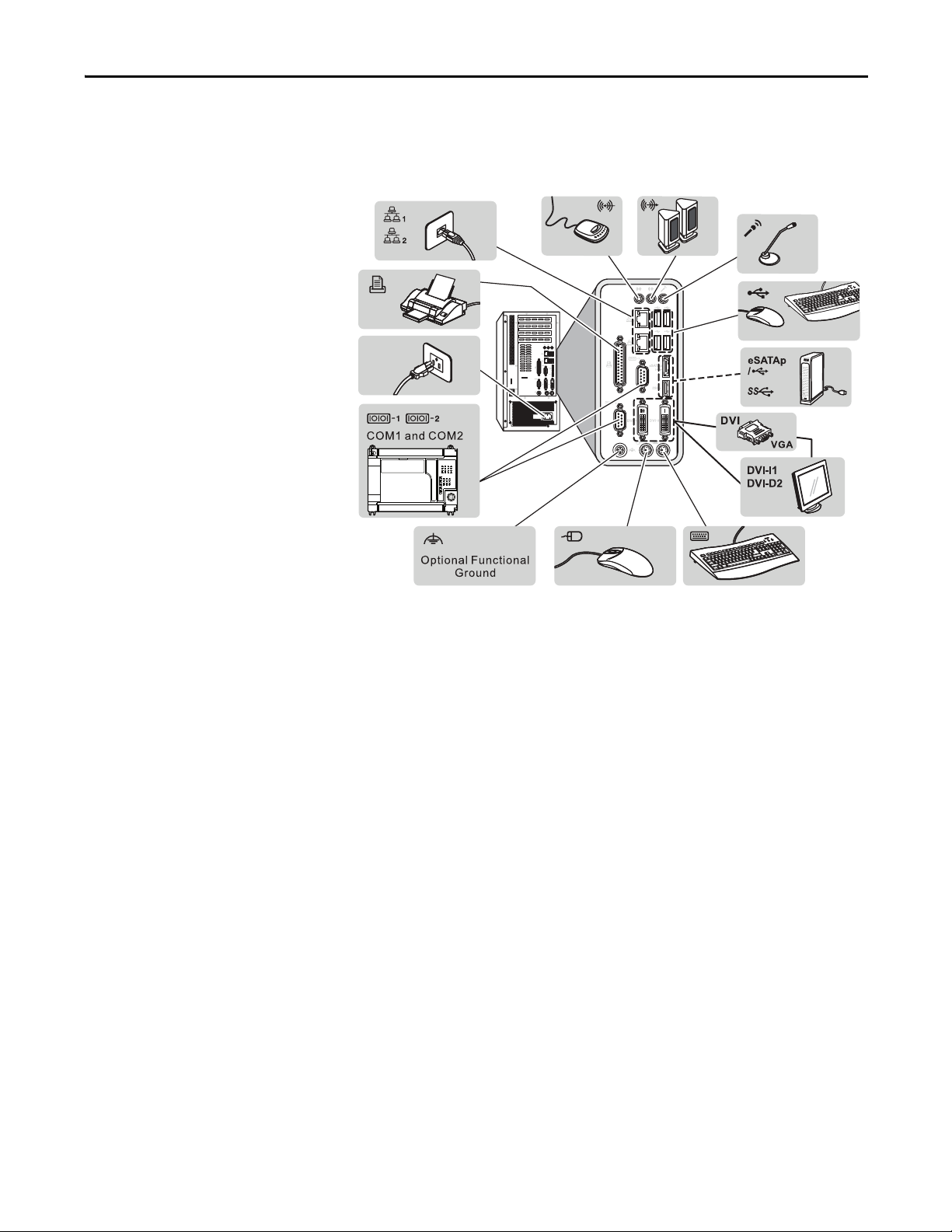

Connect Peripherals

The following illustration shows the I/O port panel of the computers. Peripheral

components compatible to each port are inside the callout figures.

Figure 10 - 750R and 1450R Computer Peripherals

• There are three USB ports on the front panel. Use these ports to connect

various USB devices to the computer, such as an external drive.

• You can use a DVI-to-VGA adapter to connect an external VGA display to

the DVI-I1 port of the computer.

Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014 27

Page 28

Chapter 2 Installation

TIP

Internal USB port secured with factory installed cable tie.

An activation dongle that is connected to internal USB port and secured with the supplied cable ties.

Internal USB Port

There is an internal USB port for activation dongles or other USB storage

devices. You must first remove the computer cover to access the port.

See Chapter 4

for how to remove and reinstall the computer cover.

28 Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014

To connect an external device, cut the factory installed cable tie that secures

the internal USB port.

We recommend that you fasten any device that is connected to the internal

USB port with the supplied cable ties.

Page 29

Installation Chapter 2

Connect Power

A grounded, 3-prong IEC60320-C13 power cord provides power to the

computer. The power supply input accepts 100…240V AC and is autoranging.

ATT EN TI ON : When you connect power to the computer for the first time, the

following actions occur:

• The default UEFI setting automatically starts the computer after it is plugged

into a power source.

• You must read and accept an End User Setup procedure for computers with a

Windows operating system (requires an external display).

Do not disconnect power from the system until after the Windows Setup

procedure is completed. If power is disconnected during this procedure, it can

result in a corrupted system image.

Operate the computer in an industrial or control room environment, which uses

some form of power isolation from the public low-voltage mains.

ATT EN TI ON : Supply the computer circuit with its own disconnect. Use an

uninterruptible power source (UPS) to help protect against unexpected power

failure or power surges.

Always shut down the Windows operating system before you disconnect power to

the computer to minimize performance degradation and operating system failures.

Functional Ground Screw

Follow these steps to connect the computer to an AC power source.

1. Connect the power cord to the AC power input. See Hardware Features

starting on page 13

model.

2. Connect the AC power cord to a power source.

3. Apply 100…240V AC power to the computer.

The pre-installed functional ground screw is not required for safety or regulatory

compliance. If a supplemental ground is desired, use the functional ground screw

on the rear panel of the 750R and 1450R computers. See pages 14

where the functional ground screw is on each computer model.

If you use the functional ground screw, connect the computer to earth ground by

using a 1.5 mm

insulation color that is approved by the local inspection authority.

2

(16 AWG) or larger external wire. Use a ground wire with an

for where the power inputs are on each computer

SHOCK HAZARD:

earth ground. Failure to follow this warning can result in electrical shock.

Connect the AC power cord to a power source with an

and 15 for

Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014 29

Page 30

Chapter 2 Installation

IMPORTANT

Connect to a Network

The computers have two 1 GB LAN ports that connect to an Ethernet network

by using CAT5 or CAT5E twisted-pair Ethernet cable with RJ45 connectors. See

Hardware Features

computer model.

starting on page 13 for where the LAN ports are on each

To help prevent performance degradation of Ethernet communication, do not

subject the computer or cables to extreme radiation or conducted

high-frequency noise.

In industrial environments, proper cable routing and power conditioning are

required for Ethernet communication. We recommend that you route all

Ethernet cabling through dedicated metal conduits. For improved performance

reliability, install ferrite bead filters at the cable ends.

30 Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014

Page 31

Operation

Chapter 3

Chapter Objectives

Operating Guidelines

This chapter provides information on the following topics:

• Operating Guidelines

• Start the Computer

• Restart the Computer

• Shut Down the Computer

Follow these operating guidelines for your computer:

• If you use an external display, turn on the display first.

SHOCK HAZARD: Do not operate the computer with the covers

removed. An electrical shock hazard exists. All covers are required to

maintain EMI shield.

• Always use the proper power down procedures as required by your

operating system, such as the Shut Down command in the Microsoft

Windows operating system.

• After you shut down the computer, do not apply power again until

shutdown is complete.

For computers with an HDD, the HDD must come to a complete stop,

which can take up to 30 seconds after shutdown is initiated.

Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014 31

Page 32

Chapter 3 Operation

IMPORTANT

Start the Computer

Follow these steps to start the computer.

The following steps apply to when you must manually start the computer. See

Connect Power

first time.

1.

Make sure any connected components with separate power supplies (such

as an external display) are turned on first.

2.

Make sure all necessary peripheral devices are connected to the corresponding

I/O ports on the computer.

3. If you have a1450R computer and the front

door is locked, complete the following steps:

a. Unlock the front door with the provided

key.

b. Open the door to access the power

switch.

4. Plug the AC power cable into the power

input on the computer and into a power

source or wall outlet.

on page 29 for when power is applied to the computer for the

SHOCK HAZARD:

earth ground. Failure to follow this warning can result in electrical shock.

5. Press the power switch.

See Hardware Features

The computer performs certain actions when it is started or reset. See Restart the

Computer on page 33.

If your computer does not start or you notice other anomalies, refer to the

Troubleshooting

on page 84.

Connect the AC power cord to a power source with an

on page 13 for the power switch location.

32 Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014

Page 33

Operation Chapter 3

IMPORTANT

Resetting the 1450R ComputerResetting the 750R Computer

Restart the Computer

Use any of the following methods to restart your computer:

• From the Start menu, choose Restart.

• Press Ctrl+Alt+Delete on an attached keyboard and click Restart.

• Press the reset button.

During a restart, the computer does the following:

• Clears the RAM.

• Starts the POST.

• Initializes peripheral devices such as drives and printers.

• Loads the operating system.

Use an external display to view the progress of the POST, the initialization of

accessory devices, and the start-up dialogs for the operating system that is installed.

Restart the Computer with the Reset Button

Press the reset button only if the system locks up or some other anomaly

occurs.

1. If you have a1450R computer and the front

door is locked, complete the following steps:

a. Unlock the front door with the provided

key.

b. Open the door to access the reset button.

2. Lightly press the tip of a stylus or any other

pointed device to the reset button.

Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014 33

Page 34

Chapter 3 Operation

Shut Down the Computer

Use either of the following methods to shut down the computer.

Method Actions

Windows O S With an attach ed mouse, keyboard, and display, do one of the following.

• Press Ctrl+Alt+Delete and click Shut Down.

• From the Start menu, click or choose Shut Down from the pull-down menu.

Power switch Mo mentarily press the power switch to shut down the comp uter. See Hard ware

Featu res on page 13 for the power switch location.

After you shut down the computer, do not apply power again until shutdown is

complete. For computers with an HDD, the HDD must come to a complete

stop, which can take up to 30 seconds after shutdown is initiated.

34 Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014

Page 35

Component Replacement

IMPORTANT

Chapter 4

Chapter Objectives

Accessories and Replacement Parts

This chapter provides information on the following topics:

• Accessories and Replacement Parts

• Vol ta ge Pre caut ion s

• Electrostatic Discharge Precautions

• Pre-configuration

• Post-configuration

• Required Tools

• Remove the Cover

• Reinstall the Cover

• Drive Precautions

• Replace a Drive

• Replace or Add Memory Modules

• Replace the RTC Battery

• Replace the Power Supply Unit

You can view a list of accessories and replacement parts at

http://ab.rockwellautomation.com/Computers

.

Voltage Precautions

Review the specifications of a new component before you install it to make sure it

is compatible with the computer. Record the model, serial number, and any other

pertinent information of new components for future reference.

We recommend that you use only Allen-Bradley approved accessories and

replacement parts.

The computers contain line voltages. Disconnect all power to the computer

before you install or remove components.

SHOCK HAZARD: Disconnect all power to the computer before you remove

components.

Failure to disconnect power can result in severe electrical shock to an individual or

electrostatic discharge (ESD) damage to the computer and components.

Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014 35

Page 36

Chapter 4 Component Replacement

IMPORTANT

Electrostatic Discharge Precautions

ATT EN TI ON : Electrostatic discharge (ESD) can damage static-sensitive devices

or microcircuitry.

• Disconnect all power before you work on the computer as detailed in Volt age

Precautions on page 35.

• Observe proper packaging and grounding techniques to help prevent damage.

Follow these ESD precautions:

• Transport the computer and replacement parts in static-safe containers,

such as conductive tubes, bags, or boxes.

• Keep electrostatic-sensitive parts in their containers until they arrive at the

designated static-free work area.

• Cover the designated work area with approved static-dissipating material:

– Use an antistatic wriststrap that is connected to the work surface.

– Use properly grounded tools and equipment.

• Keep the designated work area free of nonconductive materials, such as

plastic assembly aids and foam packing.

• Avoid contact with pins, leads, or circuitry.

• Always hold components with a printed circuit board (PCB) by its edges

and place it with the assembly side down.

Pre-configuration

Before you install hardware or perform maintenance procedures that require

access to internal components, we recommend that you first back up all

computer data to avoid loss.

ATTENTION: Make sure to read and understand all installation and removal

procedures before you configure the computer hardware.

Follow these steps before you remove the cover or you replace a hardware component.

1. Shut down the computer and all peripherals that are connected to it.

2. Disconnect all cables from power outlets to avoid exposure to high energy

levels.

If necessary, label each cable to expedite reassembly.

3. Disconnect telecommunication cables to avoid exposure to a shock hazard

from ring voltages.

36 Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014

Page 37

Component Replacement Chapter 4

Post-configuration

Required Tools

Follow these steps after you install or you remove a hardware component.

1. Verify that all components are installed according to instructions.

2. Make sure that no tools or loose parts are left inside the computer.

3. Reinstall any expansion boards, peripherals, chassis cross members, and

system cables that were previously removed.

4. Reinstall the cover according to the instructions on page 39

5. Reconnect all external cables and power to the computer.

6. Press the power switch to start the computer.

The following tools are required for component replacement:

• #2 cross-head screwdriver

• Antistatic wriststrap

• Side cutters (to cut cable ties, if necessary)

.

Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014 37

Page 38

Chapter 4 Component Replacement

750R Computer

1450R Computer

A

A

A

C

B

C

B

A

B

C

B

C

A

Remove the Cover

To install, replace, or upgrade internal computer components, you must first

remove the cover.

Follow these steps to remove the side cover for a 750R computer or the top cover

for a 1450R computer.

1. Follow the steps for Pre-configuration

on page 36.

2. Unfasten the cover from the computer chassis:

• 750R computers: Remove the three screws on the rear edge of the side

cover (A).

• 1450R computers: Remove the two screws on the rear edge of the top

cover (A).

3. Slide the cover back about 1.5 cm (0.5 in.) to release the hinge tabs (B).

4. Tilt the cover up slightly to disengage the hinge tabs from their lock slots.

5. Pull the cover away from the chassis (C).

6. After you install, replace, or upgrade internal computer components,

38 Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014

reinstall the cover as detailed in Reinstall the Cover

on page 39.

Page 39

Component Replacement Chapter 4

750R Computer

1450R Computer

C

C

C

A

B

A

B

C

B

A

B

A

C

Reinstall the Cover

Follow these steps to reinstall the side cover for the 750R computer or the top

cover for the 1450R computer.

1. Verify that the computer is in the upright position.

2. Follow step 1

through step 3 of the Post-configuration on page 37.

3. Position the cover so its hinge tabs align and engage the lock slots on the

chassis (A).

Tilt the cover slightly to make sure that all hinge tabs are engaged and

locked properly.

4. Slide the cover forward to lock the hinge tabs into place (B).

5. Secure the cover to the computer chassis.

• 750R computers: Reinstall the three screws on the rear edge of the side

cover (C).

• 1450R computers: Reinstall the two screws on the rear edge of the top

cover (C).

6. Torque the screws to 0.6 N•m (5.2 lb•in).

Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014 39

Page 40

Chapter 4 Component Replacement

IMPORTANT

IMPORTANT

IMPORTANT

Drive Precautions

Follow these precautions when you work with a drive.

Back up or clone your computer before you replace a drive.

• Do not touch internal components.

• Always handle the drive by its frame.

• Never remove or install a drive with the power on.

• Store the drive in an antistatic bag when it is not installed.

SHOCK HAZARD: Electrostatic discharge (ESD) can damage the computer and

components. Read and follow Electrostatic Discharge Precautions

before you remove a drive.

Failure to follow proper safety precautions can result in severe electrical shock to

an individual or ESD damage to the computer and its components.

ATT EN TI ON : Mechanical shock can damage a drive. Do not drop or bump the

drive.

on page 36

Replace a Drive

You can replace the HDD. All 6177R computers have two drive bays, but only

server models have two drives that are pre-installed.

This section is to replace an HDD in the first drive bay (SATA 0), which is the top

drive bay in either computer model. See pages

If you want to install or replace an HDD in the second (bottom) drive bay (SATA

1), see Install a Second HDD

Follow these steps to replace an HDD.

1. Follow the steps for Pre-configuration

page 36.

2. If you have a1450R computer and the front

door is locked, complete the following

steps:

a. Unlock the front door with the

provided key.

b. Open the door to access the drive bays.

c. Go ahead to step 3

.

on page 95 for further information.

on

14

and 15 for bay location.

Use an antistatic wriststrap that is connected to the work surface, and properly

grounded tools and equipment.

40 Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014

Page 41

Component Replacement Chapter 4

A

B

A

A

B

A

750R Computer 1450R Computer

Drive Tray

Mounting Screws (4)

C

C

C

C

D

F

F

F

F

E

Existing

HDD Module

New

HDD Module

3. Remove the HDD assembly from its bay.

a. Loosen the two captive thumbscrews of the HDD assembly (A).

b. Pull the HDD assembly from its bay (B).

4. Remove the HDD module from its tray.

a. Remove the four mounting screws from the bottom of the tray (C).

b. Detach the tray from the HDD module to be replaced (D).

5. Install the new HDD module to the tray.

ATT EN TI ON : Mechanical shock can damage a drive. Do not drop or bump the

drive.

a. Install the new HDD module with the PCB-side down.

Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014 41

b. Fasten the drive tray over the HDD module (E).

c. Secure the drive tray to the module with the four mounting screws (F).

Torque the screws to 0.59 N•m (5.2 lb•in).

Page 42

Chapter 4 Component Replacement

H

G

H

H

G

H

750R Computer 1450R Computer

IMPORTANT

4

Lock Lever

Keyed Surface

of DIMM Slot

123

6. Return the HDD assembly into its bay (G).

7. Tighten the two captive thumbscrews of the drive assembly to secure it to

the computer (H).

Replace or Add Memory Modules

8. Follow the steps for Post-configuration

on page 37.

The motherboard of the 750R and 1450R computers has four DIMM slots that

support up to 32 GB maximum system memory.

Figure 11 - Memory Module Slots and Module Alignment

When you install memory in pairs, install modules in slots 1 and 3 or slots 2

42 Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014

and 4 for optimal performance.

Page 43

Component Replacement Chapter 4

IMPORTANT

IMPORTANT

TIP

IMPORTANT

TIP

Memory Configuration Guidelines

Follow these guidelines when you replace or add memory to the computers:

• Use only standard unbuffered memory modules that conform to

non-ECC 240-pin DDR3 SDRAM (PC3-10600) standards.

• Use only DDR3 type memory modules.

• Use only memory modules with gold-plated contacts.

• Always handle a memory module by its edges.

We recommend that you use only Allen-Bradley approved memory

modules. See http://ab.rockwellautomation.com/Computers

qualified replacement parts and accessories.

for

Replace or Add a Memory Module

Follow these steps to replace or add a memory module.

Use an antistatic wriststrap that is connected to the work surface, and properly

grounded tools and equipment.

1. Follow the steps for Pre-configuration

2. Remove the computer cover as detailed in Remove the Cover

To install more memory, go ahead to step 5 of this section.

3. Locate the memory module that you want to replace.

See System Boards

4. Remove the selected memory module.

a. Use your thumbs or two fingers to push open the lock levers, which

release the memory module from its slot for easy removal.

See Figure 11 on page 42

b. Gently pull out the memory module to remove it from its slot.

c. Place the memory module on a static-dissipating work surface or inside

an antistatic bag.

5. Install the new memory module.

a. Hold the memory module by its edges as you remove it from its

antistatic bag.

b. Orient the module so the notch on its bottom edge aligns with the

keyed surface of the DIMM slot.

See Figure 11 on page 42

on page 17 for memory location on the motherboards.

.

When you install memory in pairs, install modules in slots 1 and 3 or

slots 2 and 4 for optimal performance.

.

The keyed surface is off center to assist the correct alignment.

on page 36.

on page 38.

c. Press the module fully into the slot to engage the lock levers.

See Figure 11 on page 42

Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014 43

.

Page 44

Chapter 4 Component Replacement

6. Reinstall the computer cover as detailed in Reinstall the Cover on page 39.

Replace the RTC Battery

7. Follow the steps for Post-configuration

on page 37.

The computers use nonvolatile memory that

requires an RTC battery to retain system

information when power is disconnected. The

3V, 600 mAh, CR2450 cell lithium battery is

on the motherboard.

The battery must be replaced during the life

of the computer. Battery life depends on the

amount of time the computer is on, or

on-time.

Table 1 - Battery Estimated Life Span

On-time (hrs/wk) Estimated Battery Life Span (yrs)

04

40 5.5

80 7

If the computer does not retain the correct time and date, replace the battery.

ATTENTION: A risk of fire and chemical burn exists if the battery is not handled

properly.

• Do not disassemble, crush, puncture, or short external contacts.

• Do not expose the battery to temperatures higher than the rated temperature

ranges in Table 8 on page 93

.

• Do not dispose of a used battery in water or fire.

For safety information on how to handle lithium batteries, see Guidelines for

Handling Lithium Batteries, publication AG-5.4

.

Follow these steps to replace the RTC battery.

1. Follow the steps for Pre-configuration

2. Remove the computer cover as detailed in Remove the Cover

on page 36.

on page 38.

3. For 750R computers, lay the computer on its side (components showing).

44 Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014

Page 45

4. If necessary, remove any accessory

TIP

IMPORTANT

Remove old battery.

Install new battery.

Battery Cover

RTC Battery

Battery Socket

Socket

Retaining

Latches

boards or cables that prevent access to

the RTC battery socket.

5. Remove the old battery.

a. Pull the battery cover straight out

of the battery socket.

b. Pull the old battery from its socket.

6. Install the new battery.

a. Insert the new battery with the

positive polarity (+ side) towards

the SO-DIMM memory slots.

Verify that the battery is seated

completely.

The socket retaining latches allow only one way for the battery to be

installed.

b. Reinstall the battery cover.

Component Replacement Chapter 4

7. Follow the steps for Post-configuration

8.

During POST, press F2 on an attached keyboard to access the UEFI

and reconfigur

e settings.

on page 37.

See Chapter 5 for more information on UEFI settings.

If you replace the battery, then all UEFI settings return to their default

settings. UEFI settings other than default must be reconfigured after

you replace a battery.

This computer contains a sealed lithium battery that could need

replacement during the life of the computer.

At the end of its life, collect the battery that is contained in this computer

separately from any unsorted municipal waste.

setup

Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014 45

Page 46

Chapter 4 Component Replacement

IMPORTANT

Replace the Power Supply Unit

Follow these steps to replace the power supply unit (PSU).

Use an antistatic wriststrap that is connected to the work surface, and properly

grounded tools and equipment when you handle internal computer components.

1. Follow the steps for Pre-configuration

2. Remove the computer cover as detailed in Remove the Cover

3. For 750R computers, lay the computer on its side (components showing).

4. Remove the factory-installed chassis cross member or optional I/O card

retention bracket as detailed in Install I/O Card Retention Bracket

page 98.

5. Cut the cable ties with side cutters in the following locations.

ATTENTION: The photo shows a 1450R computer, which has six cable

ties to cut. The circle with blue line is the cable tie to the PCI expansion

board, which does not apply to 750R computers.

on page 36.

on page 38.

on

46 Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014

Page 47

Component Replacement Chapter 4

6. For 1450R computers, disconnect the 4-pin power connector from the

PCI expansion board.

7. Disconnect the ATX 24-pin power connector from the motherboard.

Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014 47

Page 48

Chapter 4 Component Replacement

8. Disconnect the 4-pin power connector from the HDD assembly.

9. Disconnect the 4-pin power connector from the ODD assembly.

48 Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014

Page 49

Component Replacement Chapter 4

10. Disconnect the +12V 4-pin power connector from the motherboard.

11. Remove the five screws that secure the PSU to the chassis and chassis

bracket.

Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014 49

Page 50

Chapter 4 Component Replacement

IMPORTANT

12. Disconnect the two SATA cables from the HDD assembly.

Mark each SATA cable so that you can reconnect them to the correct

port after you install the new PSU.

13. Remove the PSU.

14. Install the new PSU in the reverse order of the removal steps.

a. Step 11: Torque the five screws to 1.4 N•m (12 lb•in) to secure the

new PSU.

b. Step 4: Reinstall the chassis cross member or I/O card retention

bracket as detailed in Install I/O Card Retention Bracket

c. Verify that all cables are properly connected before you reinstall the

cover.

d. Remove and replace any cut cable ties.

15. Follow the steps for Post-configuration

on page 37.

on page 98.

50 Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014

Page 51

UEFI Set-up Utility

Chapter 5

Chapter Objectives

Set-up Utility Overview

This chapter provides information about the set-up utility. It includes an

overview of set-up utility settings that you can change and how to upgrade to a

new universal extensible firmware interface (UEFI). In this chapter, UEFI

replaces Basic Input/Output System (BIOS) to describe the system firmware

except where BIOS is used, such as on a graphical interface.

The chapter covers the following topics:

• Set-up Utility Overview

• Access the Set-up Utility

• Set-up Screen Overview

• Firmware Update

• Firmware Configuration

• Diagnostics

• AMI Rescue

• Exit

The set-up utility is a hardware configuration program that is built into the

UEFI. The UEFI is already configured and optimized so there is no need to run

this utility. However, you can run the set-up utility to do the following:

• Change the system configuration.

• Change the UEFI setup when the system detects a configuration error.

• Redefine communication ports to prevent any conflicts.

• Read the current amount of system memory.

• Change the boot drive.

• Set or change the password or make other changes to the security settings.

• Upgrade the system firmware.

• Run the diagnostic utility to determine the cause of system malfunction.

• Restore or back up the operating system.

Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014 51

Page 52

Chapter 5 UEFI Set-up Utility

Access the Set-up Utility

Set-up Screen Overview

Follow these steps to access the set-up utility in your computer.

1. Start your computer.

2. During POST, you have two selections to access the set-up utility.

Press Result

F2 Accesses a graphical interface of set-up environment.

IMPORTANT: Screen shots in this chapter are from the UEFI graphical interface.

DEL (delete) Accesses a text mode set-up environment.

The set-up screen is the main screen for the UEFI graphical interface. On the left

are five menu options that are stacked vertically. Each menu button provides

access to information, commands, or configurable options for the following

topics:

• Firmware Update

• Firmware Configuration

• Diagnostics

• AMI Rescue

• Exit

52 Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014

Page 53

UEFI Set-up Utility Chapter 5

IMPORTANT

Firmware Update

You can update your system firmware from the Firmware Update menu.

Parameter Description

Browse Click to navigate to the fir mware file saved onto a media.

Firmware file location Select or type the file name for the firmware file.

Update Click to initialize the update process.

Exit Click to exit the set-up utility.

Follow these steps to update the system firmware.

1. Click the Firmware Update menu.

The Firmware Update screen appears.

2. Click Browse to locate the firmware file.

The USB mass storage device that contains the firmware file must be

FAT, FAT16, or FAT32 formatted to be recognized.

See http://www.rockwellautomation.com/support/pcdc.page

revisions and to download firmware files.

3. Click Update.

for

Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014 53

Page 54

Chapter 5 UEFI Set-up Utility

Firmware Configuration

You can view and modify the various system parameters from the Firmware

Configuration menu. On the left are six menu options that are stacked vertically.

Menu Description

Main Use this menu to view general computer information and for basic system configuration.

Advanced Use this menu to configure information for the PXE, PCI, ACPI, processor, SATA, USB,

power, video graphics, super I/O, hardware display, and AMT.

Chipset Use this menu to configure system chipset information.

Boot Use this menu to configure boot device priority.

Security Use this menu to set or change user and administrator passwords.

Save and Exit Allows you to save changes and reset, discard changes and reset, or restore defaults.

Common Buttons at the Bottom of Screens

Most screens have these common buttons.

Button Description

Help Click for general help on how to use the set-up utility.

Default Click to load the default values for all set-up options.

Restore Click to restore all set-up options to previously saved values.

Save Click to save configuration changes.

Previous (not shown) Click to navigate to the previous page.

Exit Click to close the set-up utility.

54 Rockwell Automation Publication 6177R-UM002D-EN-P - October 2014

Page 55

Main

UEFI Set-up Utility Chapter 5

Parameter

BIOS Vendor BIOS manufacturer

BIOS Version BIOS version information

Compliancy Unified Extensible Firmware Interface (UEFI) version information

Build Date and Time Date and time BIOS was created.

Total Memory Total system memory and memory type (in parentheses)

System Date Set the system date.

System Time Set the system time.

Runtime Hours Records the total hours of computer runtime.

Manufacturer System manufacturer

Catalog Number Allen-Bradley catalog number with series letter

WIN Number Warranty information number

Version-SYS System revision, manufacture date

Version-Board System board version information

Serial Number Unique system serial number

(1) See page 54 for an explanation of common buttons near the bottom of screen.

(1)