Page 1

Installation Instructions

6189V-HPMOUSEP Panelmount Industrial

Pointing Device

Catalog Number 6189V-HPMOUSEP

Topic Page

Important User Information 2

Overview 3

Cutout Dimensions 4

Panel Mounting with Mounting Studs 5

Specifications 7

Additional Resources 7

Page 2

2

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment.

Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls (Publication

SGI-1.1 available from your local Rockwell Automation sales office or online at

http://literature.rockwellautomation.com

equipment and hard-wired electromechanical devices. Because of this difference, and also because of the

wide variety of uses for solid state equipment, all persons responsible for applying this equipment must

satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages

resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular installation, Rockwell Automation, Inc. cannot

assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits,

equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell

Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

) describes some important differences between solid state

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information about practices or circumstances that can cause an explosion in

a hazardous environment, which may lead to personal injury or death, property

damage, or economic loss.

Identifies information that is critical for successful application and understanding of

the product.

Identifies information about practices or circumstances that can lead to personal injury

or death, property damage, or economic loss. Attentions help you identify a hazard,

avoid a hazard and recognize the consequences.

Labels may be on or inside the equipment (for example, drive or motor) to alert people

that dangerous voltage may be present.

Labels may be on or inside the equipment (for example, drive or motor) to alert people

that surfaces may reach dangerous temperatures.

Publication 6189-IN001C-EN-P - October 2007

Page 3

Overview

This document describes installation of the 6189V-HPMOUSEP Panelmount

Industrial Pointing Device including how to install the 6189V-HPMOUSEP in a

panel using mounting studs.

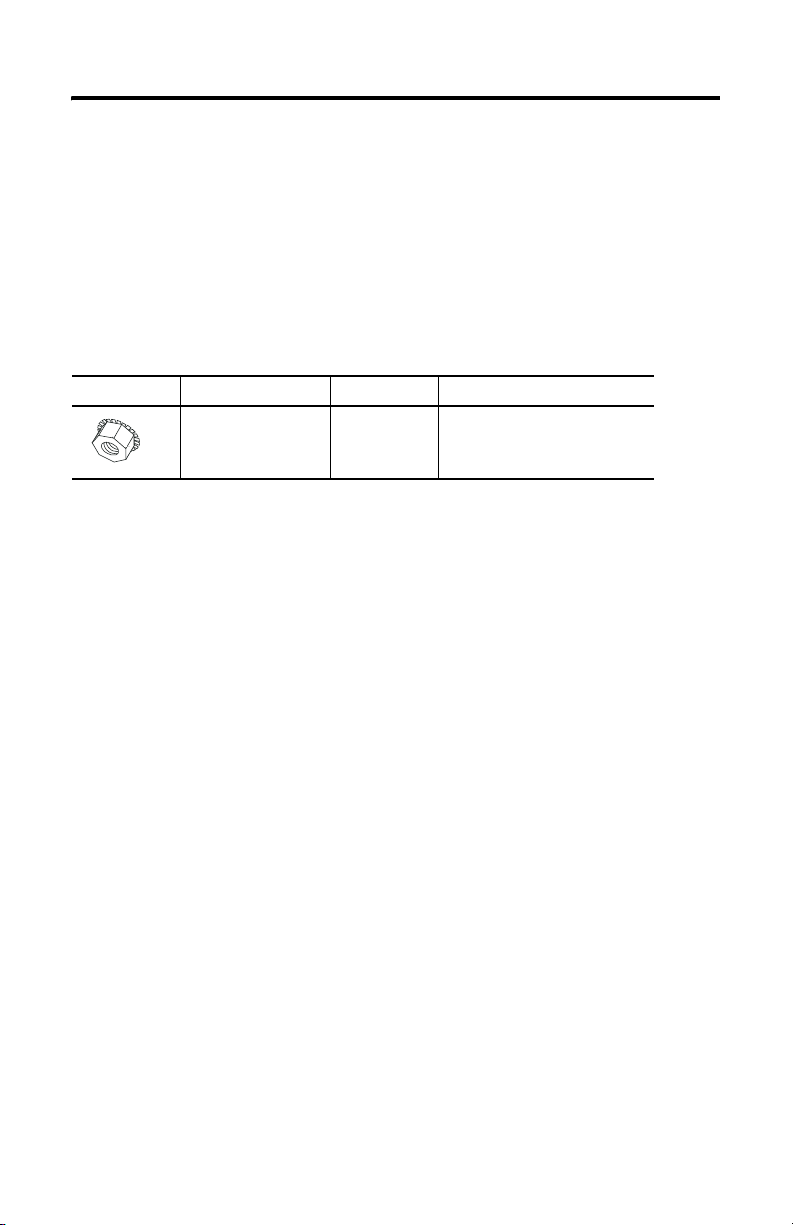

Mounting Hardware

The 6189V-HPMOUSEP is shipped with the following mounting hardware:

Item Description Quantity Use For

Self-locking nuts 8 Panel or enclosure mounting

Tools Required

In addition to the tools required to make the cutout, you will need the following

tools:

• 3/8 inch socket

• 6 inch (15 cm) extension rod (minimum)

• Socket driver (in/lb. torque wrench recommended)

• Ruler

3

Publication 6189-IN001C-EN-P - October 2007

Page 4

4

Cutout Dimensions

The following figure provides the dimensions for making the panel or enclosure

cutout for the 6189V-HPMOUSEP.

4.76 mm (3/16 in.)

DIA THRU HOLE

53.97 [2.125]

63.3 [2.49]

76.2 [3.00]

38.1 [1.50]

CUTOUT

107.95 mm x 107.95 mm

(4.25 in x 4.25 in)

152.4 [6.00]

EDGE OF BEZEL

107.95 [4.25]

107.95 [4.25]

ORIGIN: 0,0

152.4 [6.00]

38.1 [1.50]

53.97 [2.125]

63.3 [2.49]

76.2 [3.00]

Publication 6189-IN001C-EN-P - October 2007

Page 5

5

Panel Mounting with Mounting Studs

Follow these steps to install the 6189V-HPMOUSEP in a panel using eight mounting

studs.

ATTENTION

Disconnect all electrical power from the panel before making cutout.

Make sure the area around the panel cutout is clear.

Take precautions so that metal cuttings do not enter any components that are already

installed in the panel.

Failure to follow these warnings may result in personal injury or damage to the panel

components.

1. Cut an opening in the panel using the appropriate panel cutout dimensions

provided on page

4.

2. Carefully drill eight 4.76 mm (3/16 in.) holes for the mounting studs as

indicated.

3. Make sure the sealing gasket is properly positioned on the pointing device.

This gasket forms a compression type seal (NEMA Type 4). Do not use

sealing compounds.

4. Place the 6189V-HPMOUSEP in the panel cutout aligning the studs with the

mounting holes.

5. Install the eight self-locking nuts hand tight.

Publication 6189-IN001C-EN-P - October 2007

Page 6

6

6. Alternately tighten the self-locking nuts (use 3/8 inch socket) until the

6189V-HPMOUSEP is held firmly against the panel. See recommended

tightening sequence below. The amount of torque required increases

significantly as the gasket reaches the proper compression. Tighten nuts to a

torque of 2.3 N-m (20 in-lbs).

ATTENTION

6

3

8

2

Tighten mounting nuts to a torque of 2.3 N-m (20 in-lbs) to provide a proper seal and

prevent damage to the 6189V-HPMOUSEP. Rockwell Automation assumes no

responsibility for water or chemical damage to the pointing device or other equipment

within the enclosure because of improper installation.

1

7

4

5

Connecting the 6189V-HPMOUSEP

The 6189V-HPMOUSEP plugs into the mouse port of your industrial computer.

Consult you industrial computer user manual for specific details.

Publication 6189-IN001C-EN-P - October 2007

Page 7

Specifications

Attribute Value

Keyboard/Mouse Type

6189V-HPMOUSE

6189V-HPMOUSEP

Hardware Interfaces PS/2 mouse port

Cursor Directional Control Continuous 360° control

Cursor Speed Control Proportional to applied pressure

Compatibility

Power Consumption Less than 10MA @ 5V dc

Mechanical All materials are UL 94 HB (minimum) flammability rated

Dimensions (HxWxD), approx.

6189V-HPMOUSE

6189V-HPMOUSEP

Weight, approx.

6189V-HPMOUSE

6189V-HPMOUSEP

Enclosure and Keypad

Appearance

Temperature, operating 0…55 °C (32 …131 °F)

Temperature, storage -40…90 °C (-40 …194 °F)

Relative Humidity 5…95% non-condensing

Operating Altitude 4,572 m (15,000 ft)

Storage Altitude 15,240 m (50,000 ft)

Key Contacts Conductive Carbon Pills

Keyswitch Travel 1.5 mm (0.06 in.)

Operating Force 130 grams

Feel Tactile with mechanical snap

Lifetime Greater than 10 million cycles

3 Button HulaPoint Desktop

3 Button HulaPoint Panel Mount

Fully compatible with industry standard, PS/2, Serial, Microsoft and

Logitech Mouse (HulaPoint ™ driver available)

114.3 x114.3x 25.4 mm (4.5 x4.5x1 in.)

152.4 x 19.1 mm (6 x 6 x 0.75 in.)

635 g (1.4 pounds) unpackaged

544 g (1.2 pounds) unpackaged

Full rotation travel, positive directional positioning, third programmable

button, stainless steel case with industrial silicone rubber

7

Additional Resources

You can view or download publications at

http://literature.rockwellautomation.com

documentation, contact your local Rockwell Automation distributor or sales

representative.

. To order paper copies of technical

Publication 6189-IN001C-EN-P - October 2007

Page 8

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in

using its products. At http://support.rockwellautomation.com

technical manuals, a knowledge base of FAQs, technical and application notes,

sample code and links to software service packs, and a MySupport feature that you

can customize to make the best use of these tools.

For an additional level of technical phone support for installation, configuration and

troubleshooting, we offer TechConnect support programs. For more information,

contact your local distributor or Rockwell Automation representative, or visit

http://support.rockwellautomation.com

.

Installation Assistance

If you experience a problem within the first 24 hours of installation, please review

the information that's contained in this manual. You can also contact a special

Customer Support number for initial help in getting your product up and running.

, you can find

United States 1.440.646.3434

Outside United

States

Monday – Friday, 8 a.m. – 5 p.m. EST

Please contact your local Rockwell Automation representative for any

technical support issues.

New Product Satisfaction Return

Rockwell Automation tests all of its products to ensure that they are fully

operational when shipped from the manufacturing facility. However, if your

product is not functioning and needs to be returned, follow these procedures.

United States Contact your distributor. You must provide a Customer Support case number

Outside United

States

Allen-Bradley, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

(see phone number above to obtain one) to your distributor in order to

complete the return process.

Please contact your local Rockwell Automation representative for the return

procedure.

Publication 6189-IN001C-EN-P - October 2007 PN 16495

Supersedes Publication 6189-IN001B-MU-P - January 2004 Copyright © 2007 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

Loading...

Loading...