Page 1

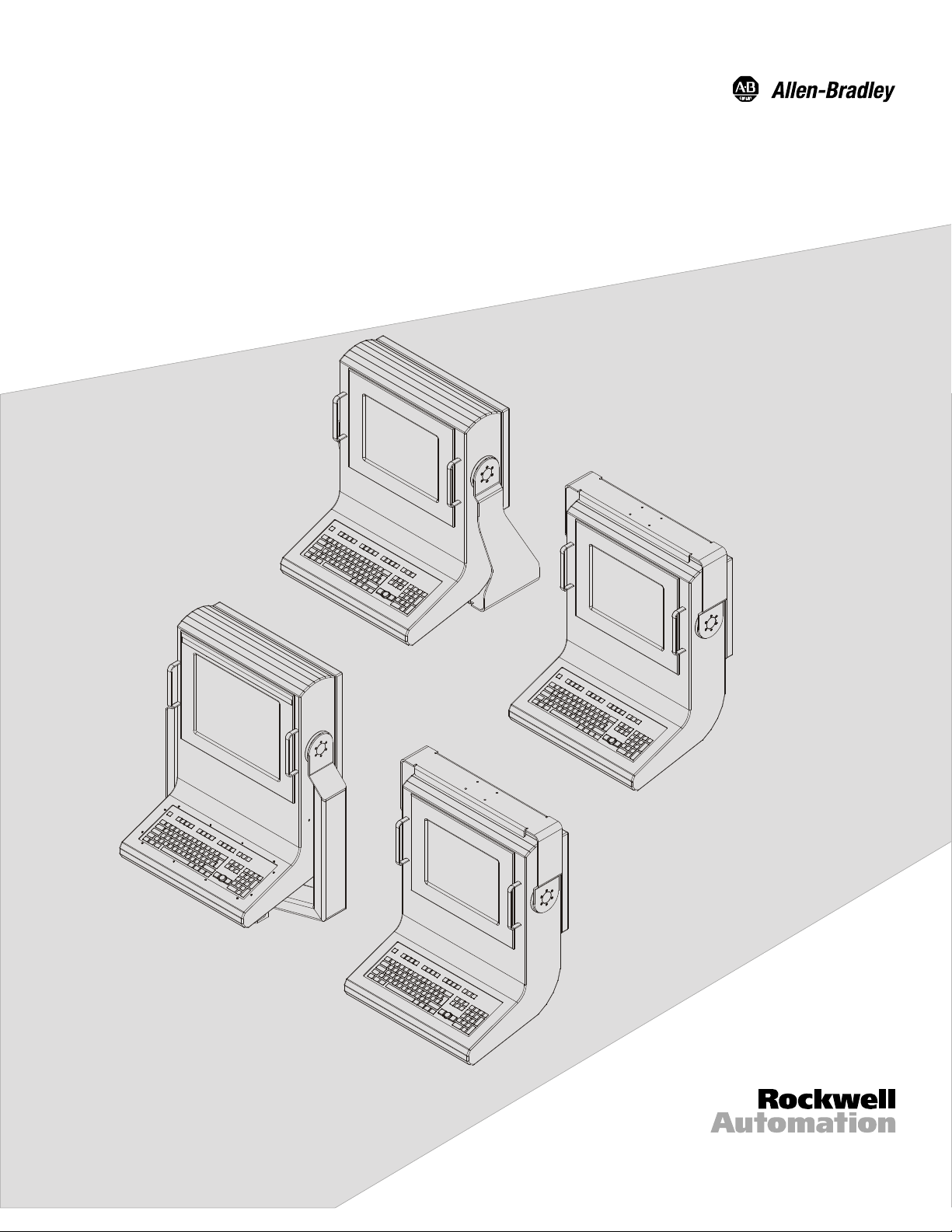

RAC6188 Operator Display Station

Installation and User Manual

Bulletin 6188-A, and 6188-B

Page 2

2

Important User Information

Table of Contents

Table of Contents

Table of ContentsTable of Contents

6188 Operator Display Station ............................................. 3

Operator Display Station Feature Overview ...................... 4

Part Numbers........................................................................... 6

Setting up Your Operator Display Station .......................... 9

Before you Begin .................................................................... 9

Unpacking the Operator Display Station ................................ 10

Mounting the Operator Display Station.................................. 10

Making Connections............................................................. 13

Connecting Power................................................................... 1 4

Connecting the Cat-5 Cable between the Operat or

Display Station and the Host Computer Signal Transmitter ... 15

Installing the Signal Extender................................................. 15

Connecting the Video Source.................................................. 17

Powering Up the System......................................................... 17

Configuring Vide o Setup......................................................... 17

Setting Up Touchscreen Functionality.................................... 20

Performing Routine Maintenance....................................... 21

Cleaning.................................................................................. 21

Replacing a Line Cord ............................................................ 21

Other Maintenance..................................................... ... ... .. ... .. 21

Troubleshooting and Support .............................................. 23

Troubleshooting Solutions...................................................... 23

Allen-Bradley Support............................................................ 28

Appendix A: Te chnical Specifications ................................. 29

Dimensions.............................................................................. 30

Wall Mount Arm and Overhead Mounting.............................. 31

Display Specifications............................................................. 32

Keyboard and Mouse Specifications....................................... 34

Signal Extender Specifications ............................................... 34

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. "Safety Guidelines for the Application, Installation, and Maintenance of Solid State Controls"

(Publication SGI-1.1) describes some important differences between solid state equipment and hard-wired electromechanical

devices. Because of this difference, and because of the wide variety of uses for solid state equipment, all persons responsible for

applying this equipment must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation be responsible or liable for indirect or consequential damages resulting from the use or

application of this equipment. The examples and diagrams in this manual are included solely for illustrative purposes. Because

of the many variables and requirements associated with any particular installation, Rockwell Automation cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation with respect to use of the information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation is

prohibited.

Throughout this manual, we use notes to make you aware of safety considerations.

Important: Identifies information that is especially important for successful application and understanding of the product.

ATTENTION: Identifies information about practices or circumstances that can

lead to personal injury or death, property damage, or economic loss.

Page 3

Operator Display Station Feature Overview 3

6188 Operator Display Station

6188 Operator Display Stat

6188 Operator Display Stat6188 Operator Display Stat

The 6188 Operator Display Station is a sealed ergonomic industrial

enclosure that gives your operators one si mple, but elegant interface to

applications.

You view an application on the display of the flat panel monitor and use

the keyboard, mouse, or integrated touchscreen to control and monitor

your system.

The slim, attractive, tightly integrated design of the RAC6188 would be

impossible to replicate with an off-the-shelf enclosure. The RAC6188 is

a complete solution, ready to go with no engineering required.

The 6188 incorporates industry-leading Allen-Bradley flat panel

monitors (RAC6185) to give you a bright and easy-to-read display.

Operators need a simple, efficient interface with their applicatio n . The

RAC6188 is an ideal solution for your distributed control system or

process control application.

This one-piece operator station connects to any standard PC computer,

and it includes:

ion

ionion

• Flat panel monitor the most widely-installed products from our

RAC6185 family of industrial flat panel monitors (6185-C 15.0 in. or

6185-D 18.1 in.)

• Integrated touchscreens for the most intuitive operator interface

• Sealed membrane 101-key keyboard and touch mouse

• Signal extender to allow remote operation up to 400 ft. (122 m) from

the host PC. The extender sends video, keyboard, mouse, and

touchscreen signals over a single, low-cost Cat - 5 cable.

This manual provides installation, operation, and maintenance

instructions for the Allen-Bradley 6188 Operator Display Station.

The shipping cartons contain the following items:

• 6188 Operator Display Station

• ScreenSet monitor setup utility

• This user manual

• An Operator Display Station with a touchscreen option ships wi th

supporting software and manuals on disk or CD

Publication 6188-UM001A-EN-P

Page 4

4 6188 Operator Display Station

Operator Display Station

Operator Display Station

Operator Display StationOperator Display Station Feature Overview

Feature Overview

Feature OverviewFeature Overview

Resolutions

The Operator Display Station auto-syncs to lower resolution video

signals, plus, has on-screen set up menus/controls for any manual

adjustments.

Table A

Resolutions

Flat Panel Display

Size

15.0” 640 x 480 to 1024 x 768 (Native) 17”

18.1” 640 x 480 to 1280 x 1024 (Native) 20”

Resolution CRT Equivalent

Size

15.0 and 18.1 Specific Features

Capabilities specific to the 15.0 display include the following:

• 1024x768 resolution

• 256K color (18-bit) display

• Bright (200 nits) Active Matrix-TFT 1024x768 display

• Auto-Adjustment function attempts to adjust the settings properly

based on the current signal.

Capabilities specific to the 18.1 display include the following:

• 1280x1024 resolution

• 16m (24-bit) True Color display

• Bright (200 nits) Active Matrix-TFT 1280x1024

Publication 6188-UM001A-EN-P

Mounting Options

The RAC6188 has four mounting options: Each option gives you the

flexibility to adjust the enclosure for ideal positioning.

• Table Top and Floor Pedestal

For applications where you need the operator station in a fixed

position, Rockwell Automation offers the RAC6188 with a table top

Page 5

Operator Display Station Feature Overview 5

or floor pedestal mounting option. Both of these mounti ng opt ions

provide side-to-side swivel (180°) and tilt (30°) for optimum viewing.

• Wall Mount Arm and Overhead

For applications where floor or tabletop space is limited, consider the

overhead or wall mount arm options.

The overhead mount option allows you to mount the Operator

Display Station above the operator in a fixed position. This option

gives you 30° tilt adjustment.

Each wall mount arm provides 360° swivel, 30° tilt, and full side-toside positioning. Vertical positioning options depend on the

enclosure material.

Enclosure Options

The RAC6188 can withstand the rigors of your harsh environment. In

addition to its ergonomic design, the RAC6188 is rugged. You can chose

from:

Environmental Rating NEMA 4/12 NEMA 4X

Construction Material Painted aluminum,

powder coat finish

Type 316L

Stainless Steel

Remote Operation with Signal Extender

You can install the Operator Display Station up to 400 ft (122 m) away

from any standard PC computer.

You can install the 6188 on the factory floor where the environment is

harsh and space is at a premium, and then connect the Op erat or Display

Station to the signal transmitter located on the other side of the plant.

Simply connect the signal transmitter to the host PC.

You can connect to the host computer using your own low-cost, twistedpair Cat-5 cable. The video, keyboard, mouse, and touchscr een host

signals are multiplexed across the Cat-5 cable by the transmitter, located

at the computer and the transmitter in the Operator Display Station.

You can even connect an additional monitor, keyboard, and mouse to the

transmitter for backup, troubleshooting, setup and local control. All

power for the signal extender transmitter is supplied by the Operator

Display Station.

Publication 6188-UM001A-EN-P

Page 6

6 6188 Operator Display Station

Heat Sink Option

For warmer environments, the RAC6188 has an optional heat sink with

internal fans that raises the operating temperature spec to 45°C.

Connections

The 6188 supports standard PS/2 mouse and keyboard connections as

well as AT keyboard and serial mouse connectors and accommodates

standard Windows operating systems

Part Numbers

The part number for your particular unit consists of the Bulletin number

(6188) followed by a ten-digit code indicating the enclosure type,

equipment configuration, and options on your unit.

Following are explanations of the part numbers for the various models of

monitors.

Example:

6188

1 2 3 4 5 6 7 8 9

AB CF A A A Z F Z

Publication 6188-UM001A-EN-P

Page 7

Operator Display Station Feature Overview 7

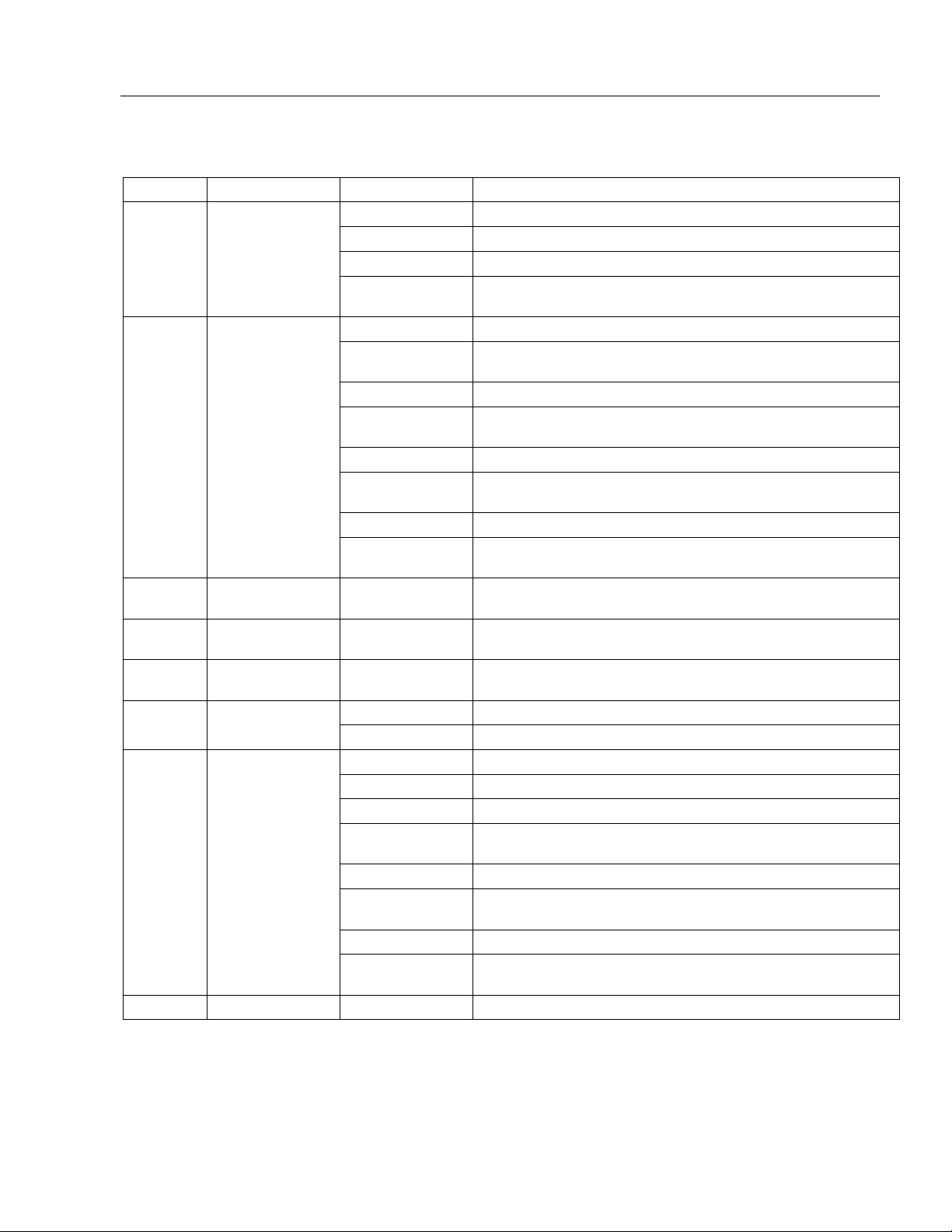

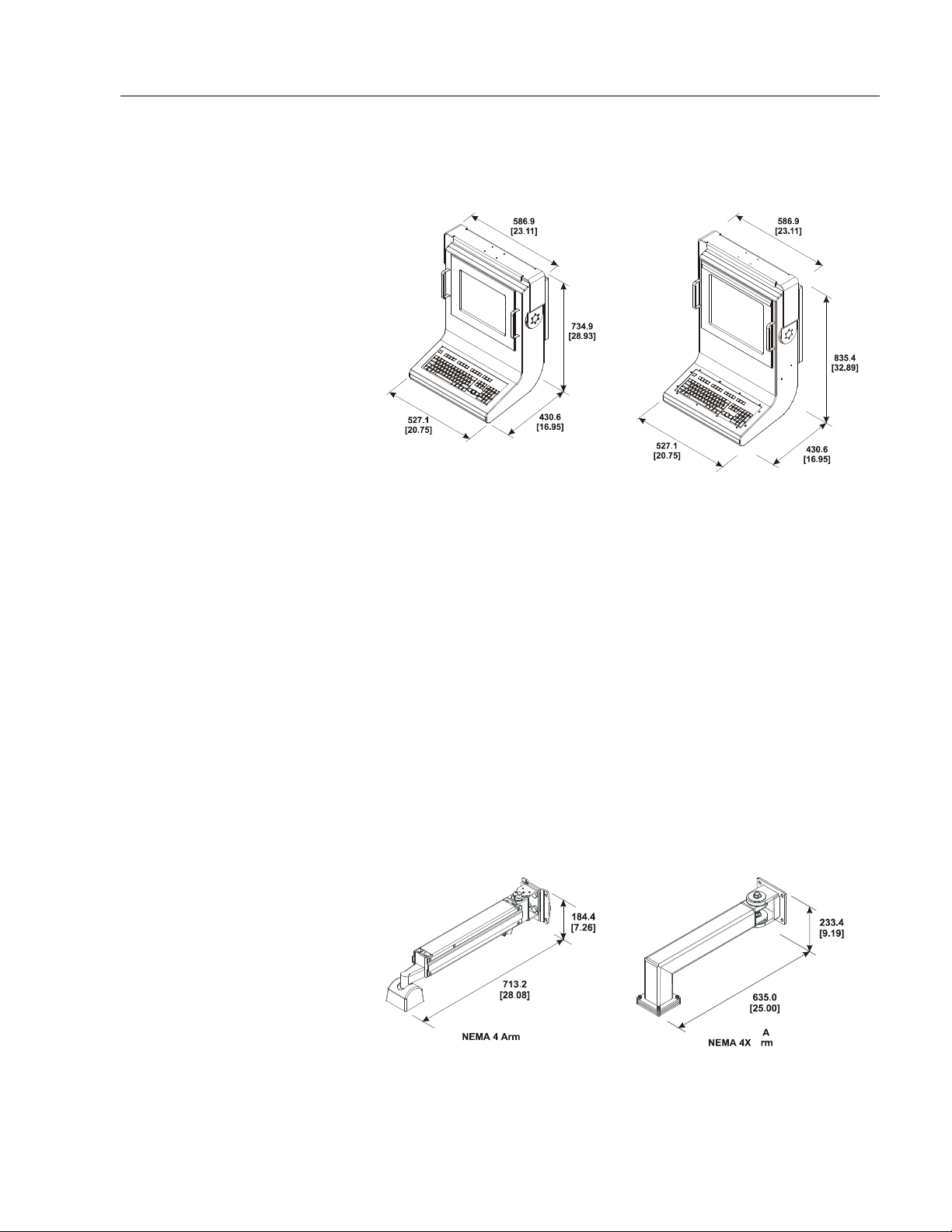

Table B

Catalog Number Explanation for 6185 Economy Line Monitors

Position Option Option Letter Category Description

2 Enclosure Type

3 Equipment

Configuration

4 Power Input/

Connections

5 Input Device A Sealed NEMA 4/4X 101 Membrane Keyb oard, Sealed Touch

6 Communications A Cat-5 Extender (Video, Keyboard, Mouse, Touchscreen) 400 ft.

8 Enclosure

Accessories

9 Future Use Z None

AA L-Series Enclosure for 15 in. display, NEMA 4 (Aluminum)

AB L-Series Enclosure for 15 in. display, NEMA 4X (Stainless Steel)

BA L-Series Enclosure for 18.1 in. display, NEMA 4 (Aluminum)

BB L-Series Enclosure for 18.1 in. display, NEMA 4X (Stainless

Steel)

CA 15 in. Monitor, 1024x768), No Touchscreen

CB 15 in. Monitor, 1024x768), NEMA 4X Stainless Steel, No

Touchscreen

CE 15 in. Monitor, 1024x768), Resistive Antiglare Touchscreen

CF 15 in. Monitor, 1024x768), NEMA 4X Stainless St eel, Res istive

Antiglare Touchscreen

DA 18.1 in. Monitor, 1280x1024), No Touchscreen

DB 18.1 in. Monitor, 1280x1024), NEMA 4X Stainless Steel, No

Touchscreen

DE 18.1 in. Monitor, 1280x1024), Resistive Antiglare Touchscreen

DF 18.1 in. Monitor, 1280x1024), NEMA 4X Stainless Steel, Resistive

Antiglare Touchscreen

A 100 to 132 V AC, Conduit Connection Pa nel

Mouse

max, No Cable

A Heat Sink with Internal Fans (Mounted on Rear Door) 7 Cooling Option

Z None

A Table Top Mounting, NEMA 4 (Tilt and swivel)

B Floor Pedestal Mounting, NEMA 4 (Tilt and swivel)

C Overhead Mounting (Tilt)

D Wall Mount Arm Mounting (Tilt and swivel, up and down, side to

side)

E Table Top Mounting, NEMA 4X Stainless Steel (Tilt and swivel)

F Floor Ped e s tal Mounting, NEMA 4X Stainless Steel (Tilt and

swivel)

G Overhead Mounting, NEMA 4X Stainless Steel (Tilt)

H Wall Mou nt Arm Mounting, NEMA 4X Stainless St eel (Tilt and

swivel, side to side)

Publication 6188-UM001A-EN-P

Page 8

Page 9

Setting up Your Operator Display Station 9

Before you Begin

Setting up Your Operator Display

Setting up Your

Setting up Your Setting up Your

Station

Station

StationStation

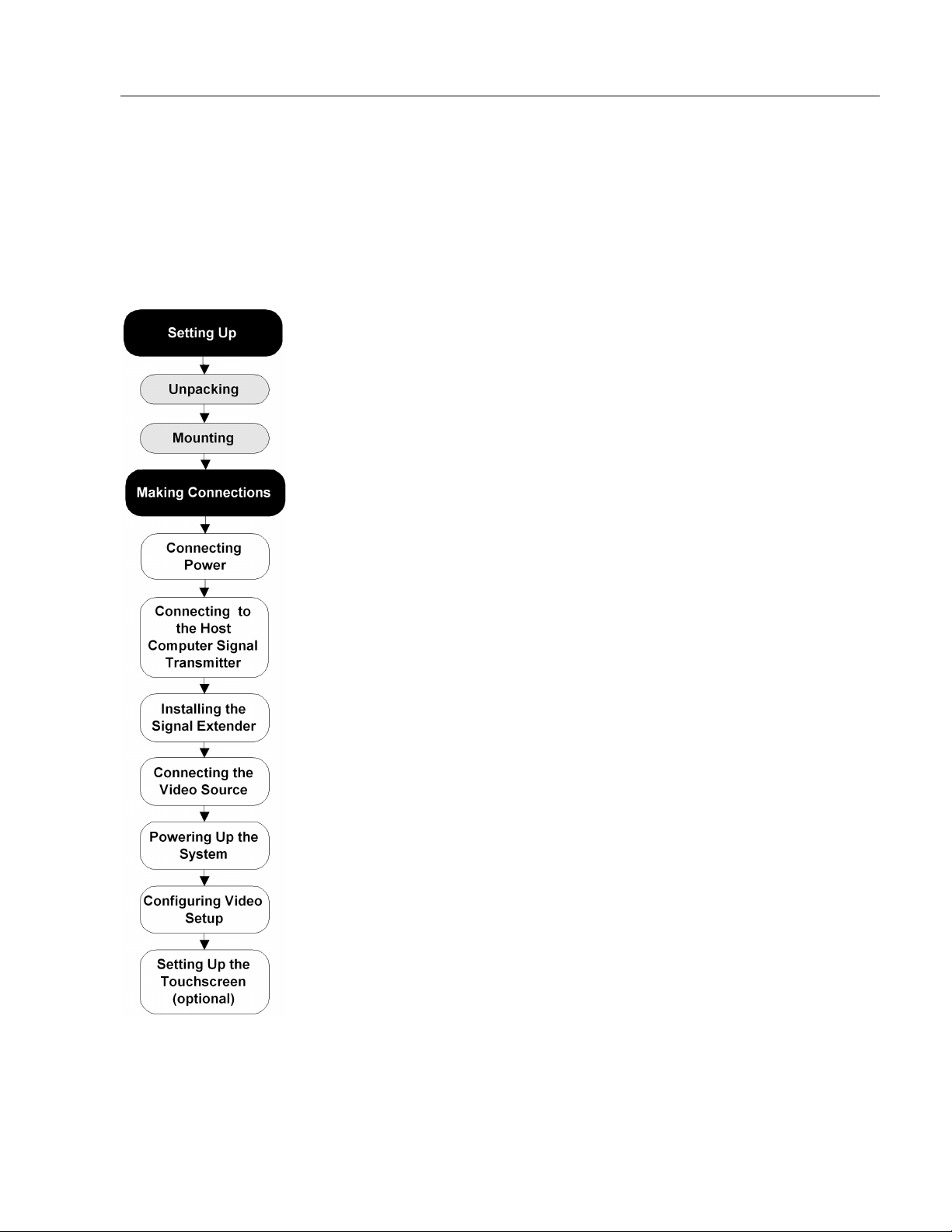

This section describes how to setting up 6188.

When installing the Operator Display Station, it is important to consider

environmental factors that could affect performance as well as possible

effects from equipment operation on personnel and nearby equipment.

The figure on the left displays the general process to install, connect, and

adjust your monitor.

Operator Display

Operator Display Operator Display

Installation Guidelines

Following these guidelines will help ensure that the monitor provides

safe and reliable service.

• Ensure that sufficient power is available from a single phase AC

outlet at the site.

• Ensure that sufficient space is available for air circulation necessary

for cooling.

• Ensure that the ambient air temperature will not exceed the

specified maximum temperature.

Important:

This Operator Display Station is designed to operate at a

range of extremes, however it is not good design practice to

continuously operate it at the highest end of the specified

temperature range.

While the product will operate at its highest specified

temperature, the overall life span of any electronic device is

shortened when it operates at its highest rat ed temperature.

• Leave the Operator Display Station’s rear door closed at all times

during operation. The sealed enclosure affords protection against

dust, dirt, and liquids in the environment.

• The Federal Communications Commission has prepared a pamphlet

that addresses the problem of radio frequency interference to radio

and television reception, which should be consulted in case of

problems with such interference. This publication, “How to Identify

and Resolve Radio/TV Interference Problems” (Stock #004-00000345-4) may be obtained from the US Government Printing Office,

Washington, DC 20402.

Publication 6188-UM001A-EN-P

Page 10

10 6188 Operator Display Station

Unpacking the Operator

Display Station

Mounting the Operator Display Station

1. Open the top cap from the

shipping box.

2. Make sure the unit is free from defects, scratches, or other blemishes

in appearance. All Allen-Bradley products are shipped in specially

designed boxes with foam inserts, to minimize the possibility of

damage. However, if a problem has occurred in shipping, please

make note on the bill of lading, contact the shipping carrier

immediately and notify Allen-Bradley of the circumstances. In

addition, save all packing materials and take p i ctures of the damage

noted.

3. Make sure that the unit(s) and all accessories l i sted on the packing

slip are included.

4. With the assistance of 2-3 people, carefully lift unit out of the box by

reaching under the unit, on the sides.

5. Place the unit on a flat, level surface for further inspection.

6. Select on of the basic mounting configurations.

Mounting on a Table-Top

1. No assembly is required. Simply place the unit onto the table or

bench top.

2. You may want to adjust (tilt) the workstation forward or backward to

the best ergonomic position.

3. Tighten down the palm grip handles to lock it in place.

Mounting on a Pedestal

1. Bolt the mounting pedestal to the floor.

2. Then bolt the workstation to the mounting pedestal using hardware

supplied.

The (4) hole pattern in the 9”x9” top mounting plate matches the

hole pattern in the bottom of the yoke assembly.

3. Tilt the workstation forward or backward to the best ergonomic

position and tighten down the palm grip handles to lock it in place.

Publication 6188-UM001A-EN-P

Page 11

Setting up Your Operator Display Station 11

Mounting Using a Flex Arm

1. Bolt the flex arm mounting plate to the mounting surface (wall or tall

pedestal) using the hardware supplied.

2. Then remove the yoke from the Operator Display Station enclosure

and mount it to the swivel part of the flex arm using the hardware

provided.

3. Re-assemble the yoke to the Operator Display Station enclosure

using the two side-mount palm grip handles. This may require 1 or 2

people to hold the enclosure while installing the palm grip handle

studs through the yoke index plates and into the workstation yoke

mounts.

4. Tilt the workstation forward or backward to the best ergonomic

position and tighten down the palm grip handles to lock it in place.

WARNING: Once installed into the yoke, do not loosen

the palm grip handles more that 1 or 2 turns while

adjusting the workstation’s tilt position. Unscrewing the

palm grip handles to far can cause the workstation to

detach from the yoke and drop.

Mounting Overhead

1. Remove the yoke from the Operator Display Station.

2. Bolt the yoke to an overhead surface.

3. Re-assemble the yoke to the Operator Display Station enclosure

using the two side-mount palm grip handles. This may require 1 or 2

people to hold the enclosure while installing the palm grip handle

studs through the yoke index plates and into the workstation yoke

mounts.

4. Tilt the workstation forward or backward to the best ergonomic

position and tighten down the palm grip handles to lock it in place.

Publication 6188-UM001A-EN-P

Page 12

Page 13

Making Connections 13

Making Connections

Making Connections

Making ConnectionsMaking Connections

The RAC6188 gives you great flexibility— you can install the Operator

Display Station up to 400 ft (122 m) away from any standard PC

computer. After installing the RAC6188 on the factory floor, you then

connect the RAC6188 to the signal transmitter located on the other side

of the plant, and connect the signal transmitter to the host PC.

The RAC6188 connects to the host computer using your own low-cost

CAT-5 cable. The RAC6188 sends video, keyboard, mouse, and

touchscreen signals across the CAT-5 cable to the transmitter.

You can even connect an additional monitor, keyboard, and mouse to the

transmitter for easy troubleshooting, setup and local control. The

Operator Display Station internal cables for video, keyboard,

touchmouse and optional touchscreens are factory-installed to the signal

extender.

All power for the signal extender and transmitter is supplied by the

Operator Display Station.

In the figure on the left, the gray shaded areas represent where you are

now in the general process to install, conn ect , and adjust your Operator

Display Station.

Publication 6188-UM001A-EN-P

Page 14

14 6188 Operator Display Station

Connecting Power

Make sure you follow local codes and company procedures to

ensure compliance with all governing rules and regulations.

WARNING: Prior to bringing any electrical power to the

Workstation, read the following section.

Install all conduits and wire in accordance with the National Electric

Code for the area that the Operator Display Station is installed, in

addition to any relevant local codes.

The power source must originate from a dedicated 15 Amp circuit

breaker or fused disconnect. This source should provide uninterrupted

power to the Operator Display Station.

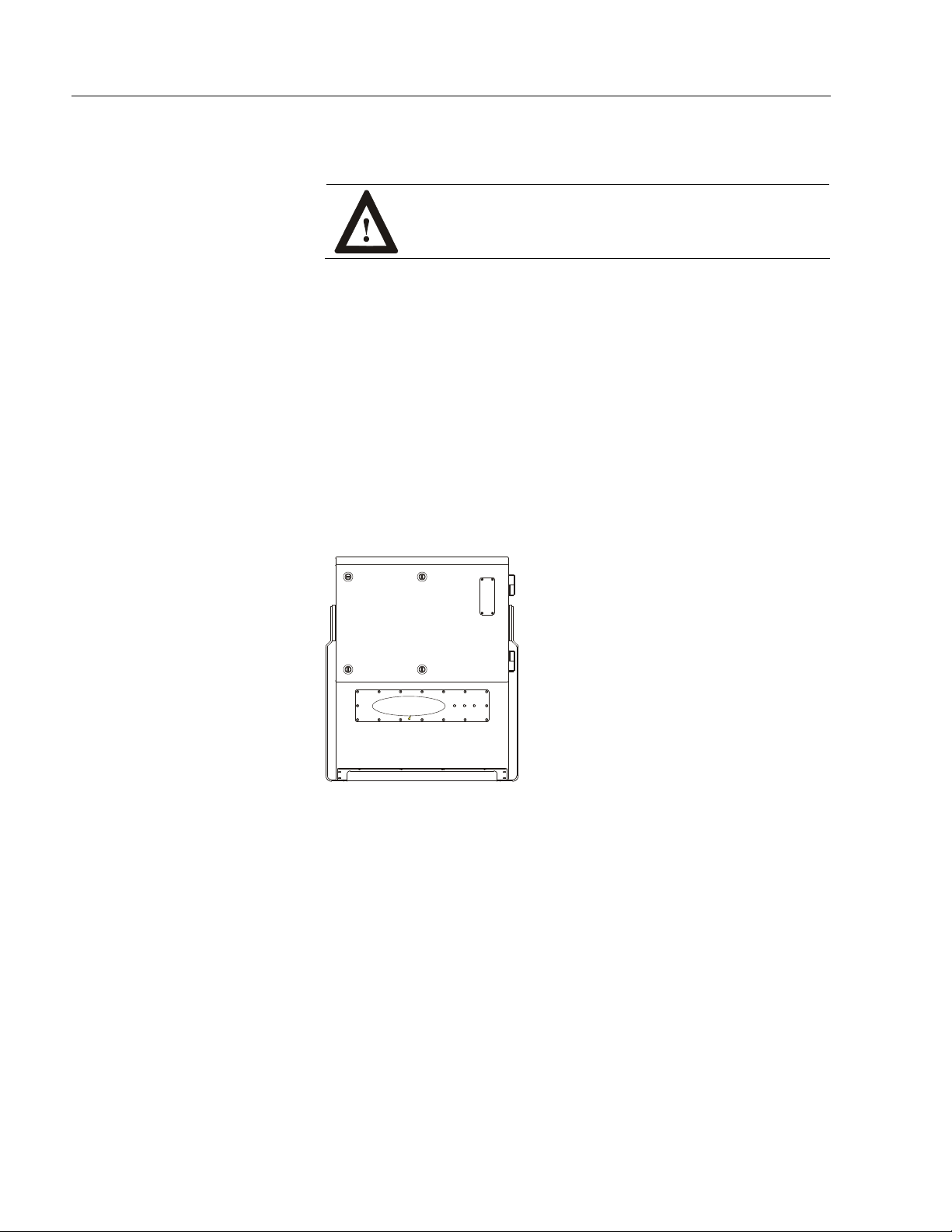

You need to supply Power wiring to the Operator Display Station via

conduit through the lower-rear access panel.

1. Open the lower rear access panel using a phillips-head screwdriver.

Publication 6188-UM001A-EN-P

2. Bring single phase, 120 VAC (240 VAC Optional) electrical power

into the workstation via the lower rear access panel. The rear panel

can be tapped to accept conduit entry.

3. Route the wires to the main terminal block, located on the back of

the access panel. Using the following:

• Hot to Black

• Neutral to White

• Ground to Green.

Note:

Integrated components requiring power, such as the Flat

Panel Display, Signal Extender, etc., are plugged into the

Surge Suppressor when assembled at the factory.

Page 15

Making Connections 15

Connecting the Cat-5 Cable between the Operator Display Station and the Host Computer Signal Transmitter

Installing the Signal Extender

Install your computer in a Local (Safe) Location some distance from the

Operator Display Station to protect it from the harsh environment. This

area should be compatible with your computer’s environmental needs.

1. Bring the Cat-5 (UTP)

communications cable into the

Operator Display Station via the

lower rear access panel.

2. Route this cables into the Operator Display Station separately from

the power cable.

3. Route Cat-5 (UTP) communications cable to the signal extender

receiver mounted on the rear door of the enclosure.

The Signal Extender is simple-to-install, and no software or expensive

networking is required. There are no switch setting changes required to

adapt to the connected peripherals.

The advanced circuitry provides automatic compensation for different

cable lengths, video resolutions and COM serial port data rates.

Signal Extender Receiver

The Signal Extender Receiver unit is factory installed in the 6188 with

the video, PS/2 keyboard, PS/2 touchmouse and optional serial

touchscreen cables pre-wired.

The extender power supply is included, mounted, and pre-wired to the

Receiver unit inside the Operator Display Station enclosure.

Signal Extender Transmitter

The Signal Extender Transmitter module comes as a boxed accessory

with your system. This must be installed at the host computer.This

includes the following:

• Transmitter box

• Custom prefabricated cable bundle that has Video, Keyboard and

Touchmouse cables all terminating into one 25 pin D-sub connector

marked “CUFC-GC”.

• Serial cable for computer connection of the touchscreen will also be

included if you purchased the touchscreen option.

The Signal Extender Transmitter module also supports a local monitor,

keyboard and mouse for redundant control, troubleshooting, backup and

hardware and software maintenance.

Publication 6188-UM001A-EN-P

Page 16

16 6188 Operator Display Station

Signal Extenders Power

There are no power On/Off switches on either unit so they will be

functional once power is applied.

Connecting the Signal Extender

Your Signal Extender Transmitter module comes with a KVM-extension

cable used to connect to your IBM PC compatible computer.

Connect the Transmitter Signal Extender Extension Module

1. Power down the computer.

2. Identify the KVM-extension custom bundled cable (CUFC-GC).

WARNING: Do not install a power supply on the

Transmitter unit since required power is transmitted from

the Receiver side over the Cat-5 extender cable.

These cables have one 25 pin D-sub connector

• The keyboard cable has PS/2 and AT style connectors on the end

for support of either type system.

• The mouse cable has a PS/2 and 9-pin serial connectors on the

end for support of either a PS/2 or serial mouse.

• The video cable (the larger one) has a HD-15 connector on the

end.

3. Plug the 25-pin connector into the matching 25-pin female connector

on the front panel of the Transmitter module.

4. Take the KVM connectors at the other end and plug them into the

applicable computer ports, being careful not to switch the

keyboard/mouse cables.

5. Plug the touchscreen (Optional) serial cable from the serial port on

the Transmitter to a serial port on your computer.

Note:

Do not forget that you must load the touchscreen driver

onto your computer and calibrate it for the touchscreen

to function.

Publication 6188-UM001A-EN-P

Page 17

Making Connections 17

Connecting the Video Source

Powering Up the System

The video connection to the host is made through a HD-15 (female)

connector.

You can connect the Operator Display Station either:

• Directly to your computer

• To your computer via the Signal Extender

To establish a signal using the HD-15 connector:

1. Obtain a shielded, properly terminated video cable of length as short

as possible

2. Connect one end of the cable to the female HD-15 video input

connector on the Operator Display Station.

3. Connect the other end to the output to one of the following:

• Signal Extender

• IBM-compatible VGA adapter

To power up the other devices attached to the Extender units, take these

steps:

Configuring Video Setup

1. Power up the CPU and your computer’s display, if necessary.

Your CPU should boot normally - sensing the video, optional

touchscreen, keyboard and touchmouse signals.

This completes the installation of your Signal Ex t enders; they are now

ready for continuous operation.

This section describes how to setup and configure your Operator

Display Station.

Important:

Since the 6188 incorporates industry-leading Allen-Bradley

flat panel monitors (RAC6185), we have included the

appropriate RAC6185 manual.

Use the procedure in this manual to configure your video

setup. The information in this section provides a summary

of the overall process.

Publication 6188-UM001A-EN-P

Page 18

18 6188 Operator Display Station

The Operator Display Station is configured at the factory, but typically

requires initial adjustments to match the video card in your computer.

Rockwell Automation provides the Flat Panel Monitor Adjustment

Utility to assist you in adjusting the monitor settings.

Workstation Setup

You need to verify that your workstation is using the appropriate

settings.

There are three important aspects of your workstation setup that affect

the screen image of the Operator Display Station:

• Monitor type

• Video resolution

• Video refresh rate

After setting up your workstation, you are ready to begin to adjust the

monitor itself.

Publication 6188-UM001A-EN-P

Page 19

Making Connections 19

Push Buttons

The Operator Display Station provides push buttons on the rear of the

monitor to adjust the following settings:

• Brightness

• Contrast

• Position Information

By using the Flat Panel Monitor Adjustment Utility and push buttons on

the rear of the monitor you can adjust these settings. The push buttons

control the monitor’s On-screen display (OSD).

The following table provides a summary to using the pushbuttons:

Table C

Pushbutton Summary

The Select Pushbutton… The Up and Down Pushbuttons…

Starts the OSD. Highlight the option you want.

Selects a highlighted option. Adjust the selected option higher or

lower.

Saves the value and returns to the

previous menu.

Publication 6188-UM001A-EN-P

Page 20

20 6188 Operator Display Station

Setting Up Touchscreen Functionality

Touchscreen provides an additional method of operator interface.

1. You must install a software

driver on your computer to handle communications with the

touchscreen controller.

Install the software on the host computer using the installation disks

or CD included with the system accessories.

All touchscreen controllers are configured by default to provide

serial communications at 9600 baud, 8 data bits, 1 stop bit, no parity.

2. Perform a calibration on the touchscreen display by doing the

following:

a. Select the Start button and select Settings to access Control

Panel.

b. In Control Panel, select Elo Touchscreen/Monitor Mouse.

c. Select the General tab and click on the Calibrate button.

d. Touch the three reference targets that appear.

e. Follow the directions that are presented

Because the touchscreen emul a t es a mouse, there may be compati bility

issues involving how the touchscreen emulates mouse buttons, especially

multiple buttons.

For more information, refer to the touchscreen documentation included

with the touchscreen software.

Publication 6188-UM001A-EN-P

Page 21

Performing Routine Maintenance 21

Performing Routine Maintenance

Performing Routine Maintenance

Performing Routine MaintenancePerforming Routine Maintenance

Cleaning

Replacing a Line Cord

Occasionally clean the Operator Display Station with a soft cloth

dampened (not soaked) with a mild (non-abrasive) glass cleaner. Keep

turning a fresh side of the cloth toward the screen su rface to avoid

scratching it with accumulated grit.

Note:

Special care should be taken when cleaning a touchscreen or

polycarbonate shield that is installed over the screen. Abrasive and

certain chemical cleaners can easily damage th e surface.

To avoid shock and fire hazards, the Operator Display Station’s power

cord should be replaced if the insulation becomes broken or if it develops

a loose internal connection.

The solvent should be applied only to the cloth, and not

directly on the monitor screen.

Do not use paper products as they may scratch the surface.

To minimize the risk of abrasion, allow the screen to

stand dry.

ATTENTION: You can use alcoholic or ammoniacal

cleaners to clean the polycarbonate shield or a

touchscreen. However, use only one or the other at all

times. A re sidue mixture can cause a chemical reaction .

Other Maintenance

Qualified service personnel should perfor m all maintenance, except for

the power cord replacement described above.

Publication 6188-UM001A-EN-P

Page 22

Page 23

Publication

Troubleshooting and Support

Troubleshooting and Support

Troubleshooting and SupportTroubleshooting and Support

Troubleshooting Solutions

This section covers some typical problems you may encounter. The

following identifies symptoms, possible problems and solutions for

workstation components including the Flat Panel Display, Touchscreen,

Keyboard w/Touchmouse, Signal Extender and Fiber Signal Extender.

The Troubleshooting Tables are arranged as follows:

• Flat Panel Displays

• LED Interpretation – Flat Panel Displays

• Touchscreens

• Keyboard with Touchmouse

• Signal Extender

Refer to this table to help identify the cause and offer a solution to a

problem. This table lists typical problems you may encounter.

Table D:

Troubleshooting Table

Symptom Possible Problem Action

Status LED does not come on.

Screen is blank.

Image is too bright or white Contrast contr ol not pr operly

No image visible even when

brightness control is set full UP

Display or video source off. Turn on display, power source or

Power cord not connected. Reconnect power cord.

Power cord faulty. Replace power cord.

Monitor faulty. Have monitor serviced.

Screensaver or energy saver

activated by workstation.

Contrast control not properly

adjusted.

Video cable problem Check for proper inst a llation of video

adjusted.

Monitor is out of adjustment or faulty. Have monitor serviced.

Video cable problem Check for proper inst a llation of video

video source.

Disable screen saver by activating

input device.

Turn the contrast control UP using

on-screen menu or luminance control

on the 18"

cable. Replace suspected faulty

cable.

Turn the contrast control DOWN

using on-screen menu.

cable. Replace suspected faulty

cable.

Page 24

24 6188 Operator Display Station

Fault in video source Test video source by connecting to

known good monitor.

Fault in monitor Have monitor serviced.

Symptom Possible Problem Action

Image is not centered. Position c ontrols are not properly

adjusted.

Image will not adjust. Video timing outside of range. Use on-screen menu to adjust the

Image position changes are not

saved.

Image is not stable Monitor is not synched to video

Image not properly centered or sized. Size an d position controls incorrectly

Vertical shaded bars on screen

image.

Colors are missing.

Screen jitter or noisy video

Slight distortion in text or graphics. Not operating monitor in native

Screen image does not fill the display Not operating monitor in native

Image has blurry streaks or

“ghosting” to the right of objects on

the screen. Screen lacks one or two

colors.

NOTE: The On-Screen Menu can be activated and navigated using the SELECT, UP & DOWN buttons on the rear

panel of the flat panel display.

Position mode no exited correctly. Reposition the image using on-

source.

adjusted.

Horizontal size not properly adjusted. Adjust horizontal size set ting using

Video cable problem Check for proper video cable

Fault in monitor Have monitor serviced.

Monitor clock phase not proper ly

adjusted.

Video cable problem Check for proper video cable

Electrical noise interference from

nearby equipment

resolution

resolution

Contrast is set too high or overdriven

video if full range dimming option is

installed.

Video cable problem. Check for proper video cable

Reset horizontal and vertical

positioning using display on-screen

menu. Check to see if video source

is operating within monitor’s range.

phase control. Make sure timing is

set within guidelines.

screen menu and select EXIT to save

the changes/exit.

Check for proper video cable

installation. Replace suspected faulty

cable. Check to ensure that video

source is operating within monitor ’s

range. Adjust Phase control using

on-screen menu.

Adjust controls for proper size/

position using onscreen menu.

on-screen menu.

installation. Replace suspected faulty

cable.

Adjust monitor clock phase setti ng

using on-screen menu.

installation. Replace suspected faulty

cable.

Check for proper video cable

installation. Re-route cables or

replace suspected faulty cables.

Check host and monitor ground.

Change the Expand/Center settings

using the on-screen menu or change

the video source to native resolution.

Change the Expand/Center settings

using the on-screen menu or change

the video source to native resolution.

Adjust brightness and contrast

settings using on-screen menu.

Calibrate video gain using on- s creen

menu.

installation. Replace suspected faulty

cable.

Publication 6188-UM001A-EN-P

Page 25

Symptom Possible Problem Action

Touchpoint different from area

touched.

Touchscreen does not work.

Touchmouse movement or

activation not acceptable.

Troubleshooting and Support 25

Table E

LED Interpretation

Heading Heading

GREEN (SOLID) Normal Operation

AMBER (SOLID) Power ON, loss of video sync or disconnected video

cable.

Table F

Touchscreens

Calibration Recalibrate touchscreen

Touchscreen cable problem Check for proper touchscreen

cable installation. Replace

suspected faulty cable.

Software driver not loaded. Install software driver using disk

provided.

Software driver load did not fully

install.

Uninstall and re-install software

driver.

Software settings need adjusted On computer go to START,

Settings & Control Panel. Select

Elo Touchscreen Monitor Mouse

Icon and make modifications to

settings.

Publication 6188-UM001A-EN-P

Page 26

26 6188 Operator Display Station

Table G

Installing the Touchscreen Driver Software

1. Open the file.

2. If more than one COM port is available, you will select the port your touchscreen cable is connected to.

3. The calibration displays automatically. Calibrate the monitor by touching in the following corner s o f the

display:

• Upper left

• Lower right

• Upper right

From an unzipped downloaded f il e:

If you are using 95/98 If you are using Windows NT

• Double-click setup.exe in the

elowin95 folder.

• Follow the installation

directions

From a shipped diskette:

• Double-click setup.exe on the diskette

• Follow the installation directions

Table H

Uninstalling the Touchscreen Driver Software

• Start NT Explorer

• Right-click on the Start

button

• Click Explore

• Double-click the setup.exe

file in the EloNT directory

and follow the installation

directions.

If you are using 95/98 If you are using Windows NT

Click on the Start button. Click on the Start button.

Select Control Panel. Select Control Panel.

Double-click Add/Remove

Programs.

Double-click Monitor Mouse

for Windows 95.

Click OK. Click Yes.

Using Explorer, delete the

elowin95 folder.

Reboot.

Double-click Add/Remove Prog ra ms.

Double-click MonitorMouse for Windows NT.

Using Explorer, delete the ElowinNT and

EloNt folders.

Using Explorer, delete the following files:

Files Locations

monmouse.cpl winnt/system32

monmouse.sys winnt/system32/d

rivers

elocal32.exe winnt/system32

mmstub.sys winnt/system32/d

rivers

Reboot.

Publication 6188-UM001A-EN-P

Page 27

Troubleshooting and Support 27

Table I

Keyboard with Touchmouse Troubleshooting

Symptom Possible Problem Action

Keyboard or Touchmouse not working Computer off Turn on computer or power source.

Keyboard not functioning

Touchmouse not functioning

Keyboard cable

problem

Keyboard faulty Install in known good computer to confirm fault.

Computer faulty Substitute known good keyboar d on c o mputer to

Touchmouse cable

problem

Touchmouse faulty Install touchmouse in known good c omputer to confirm

Computer faulty Substitute known good touch m ou s e on computer to

Table J

Signal Extender

Check for proper keyboard cable installation. Replace

suspected faulty cable.

Replace or service keyboard.

confirm fault.

Check for touchmouse cable instal lation. Replace

suspected faulty cable.

fault. Have unit replaced or serviced.

confirm fault.

Symptom Possible Problem Action

POWER indicator (s) not lit

No video or poor video quality

No keyboard/mouse operation

No touchscreen operation

Power supply Verify that power supply is connect ed to Receiver

unit. Verify 120VAC power source and 24VDC

supply output.

Cat-5 extension cable Check Cat-5 extension cable is connect ed a t both

ends.

Computer off Turn on computer

Transmitter/Receiver

video cable

Display problem Ensure display is working correctly by connecting

Cat-5 extension cable

length

Transmitter/Receiver

Keyboard/Mouse cables

Keyboard/mouse cables Ensure keyboard/mouse cab les are plugged into

Cat-5 extension cable

connection

Keyboard/mouse

problem

Transmitter/Receiver

touchscreen cables

Cat-5 extension cable Check Cat-5 extension cable is connect ed a t both

Touchscreen problem Ensure touchscreen is working correctly by

Check for proper video cable installation. Replace

suspected faulty cable.

it directly to computer.

Verify length of Cat-5 extension cable is within

tolerable limits for resolution & refresh rate.

Check for proper keyboard /mouse cable

installation. Replace suspected faulty cable.

the correct jacks, then reboot.

Check Cat-5 extension cable is connected at both

ends.

Ensure keyboard/mouse is working correctly by

plugging it directly to the computer.

Check for proper touchscreen cable installation.

Replace suspected faulty cabl e.

ends.

connecting it directly to compu ter.

Publication 6188-UM001A-EN-P

Page 28

28 6188 Operator Display Station

Allen-Bradley Support

Rockwell Automation offers support services worldwide, with over 75

Sales/Support Offices, 512 authorized Distributors and 260 authorized

Systems Integrators located throughout the United States alone, plus

Allen-Bradley representatives in every major country in the world.

Note:

When contacting Technical Support, always provide the

serial number of the unit in question.

Local Product Support

Contact your local Allen-Bradley representative for:

• Sales and order support

• Product technical training

• Warranty support

• Support service agreements

Refer to the Rockwell Automation/Allen-Bradley Internet site at

http://www.ab.com for local contact information.

Technical Product Assistance

If you need to contact Allen-Bradley for technical assistance, please

review the information in the Troubleshooting section first. Then call

your local Allen-Bradley representative or contact Allen-Bradley

technical support at (440) 646-5800.

For additional product information and a description of the technical

services available, visit the Rockwell Automation/Allen-Bradley Internet

site listed above.

Publication 6188-UM001A-EN-P

Page 29

Appendix A: Technical Specifications 29

: Technical

Appendix A

Appendix

Appendix Appendix

Specifications

Specifications

Specifications Specifications

A: Technical

: Technical : Technical

AA

Materials

Enclosure

• Painted Aluminum (NEMA 4) or

• Stainless Steel 316L (NEMA 4X)

Pedestal

• Painted Steel (NEMA 4) or Stainless Steel (NEMA 4X)

Paint (NEMA 4)

• Crowe Industries Powder Coat (or equivalent) or

• Sherwin-Williams Polane T-Plus (or equivalent)

Weight (Approximate)

Table K

Weight Specifications

Enclosure Display Size Weight

NEMA 4 15.1” Display 50 Lbs.

18.1” Display 59 Lbs.

NEMA 4X 15.1” Display 74 Lbs.

18.1” Display 83 Lbs.

Note:

Additional options will add to the total weight.

Electrical Requirements:

Power

• 15 Amps. Maximum – 120 VAC, 60 Hz

Weight estimate includes yoke.

• (Optional 220-240 VAC, 50Hz)

Outlets

• 8-Outlet Surge Suppressor

Publication 6188-UM001A-EN-P

Page 30

30 6188 Operator Display Station

Dimensions

This section shows the dimensions. Use this information to ensure you

have adequate space to install the unit and route cables. Units are in mm

[inches].

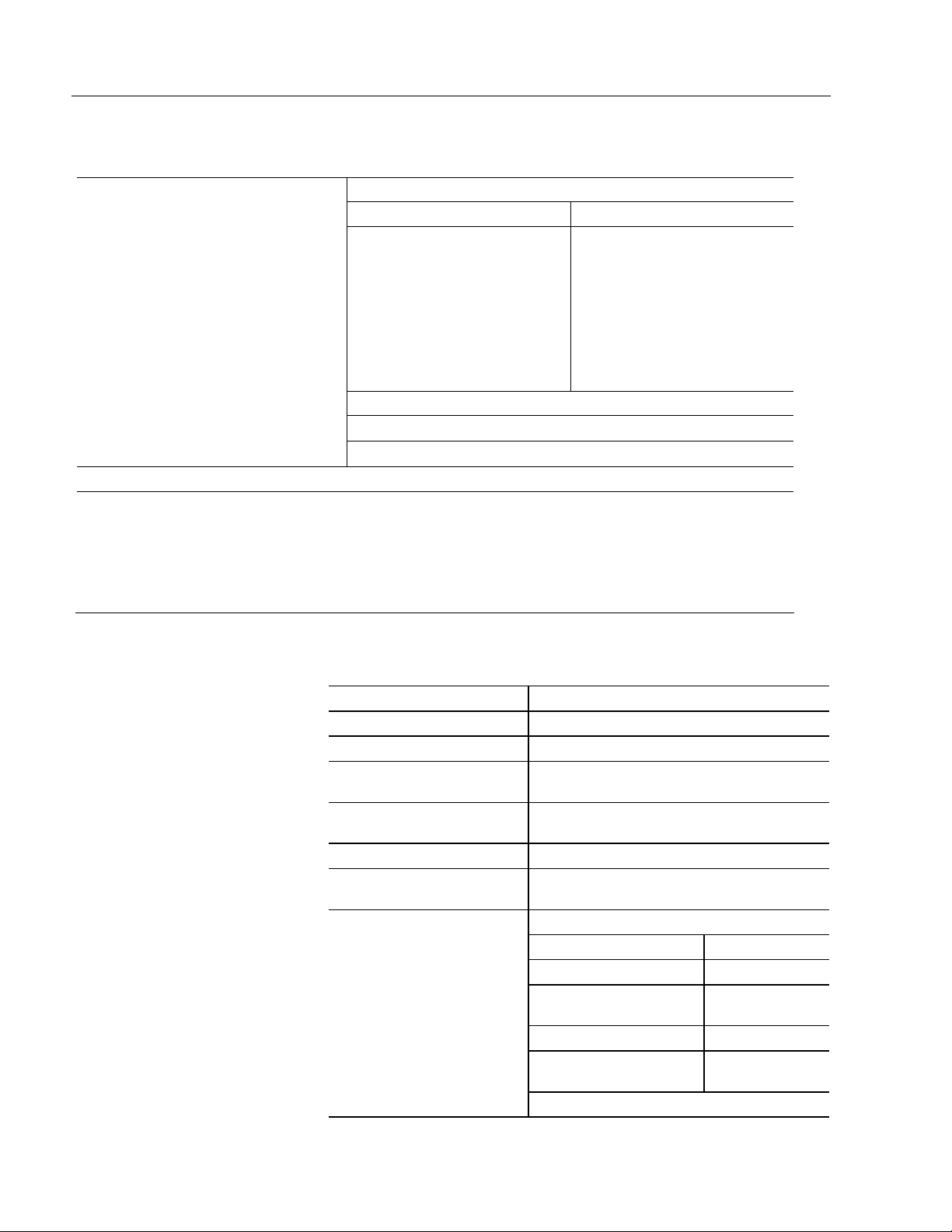

Table Top and Floor Pedestal Mounting

For applications where you need the operator station in a fixed position,

Rockwell Automation offers the RAC6188 with a table top or floor

pedestal mounting option. Both of these mounting options provide sideto-side swivel (180°) and tilt (30°) for optimum viewing.

15.1 Display 18.1 Display

Pedestal Specifications

RAC6188 pedestals are available in NEMA 4 and NEMA 4X stainless

steel. The height of the pedestal varies according to the size of the flat

panel display selected

• 15.1 Display 749.3 [29.50]

• 18.1 Display 952.5 [37.50]

NEMA 4 NEMA 4X

Publication 6188-UM001A-EN-P

Page 31

Appendix A: Technical Specifications 31

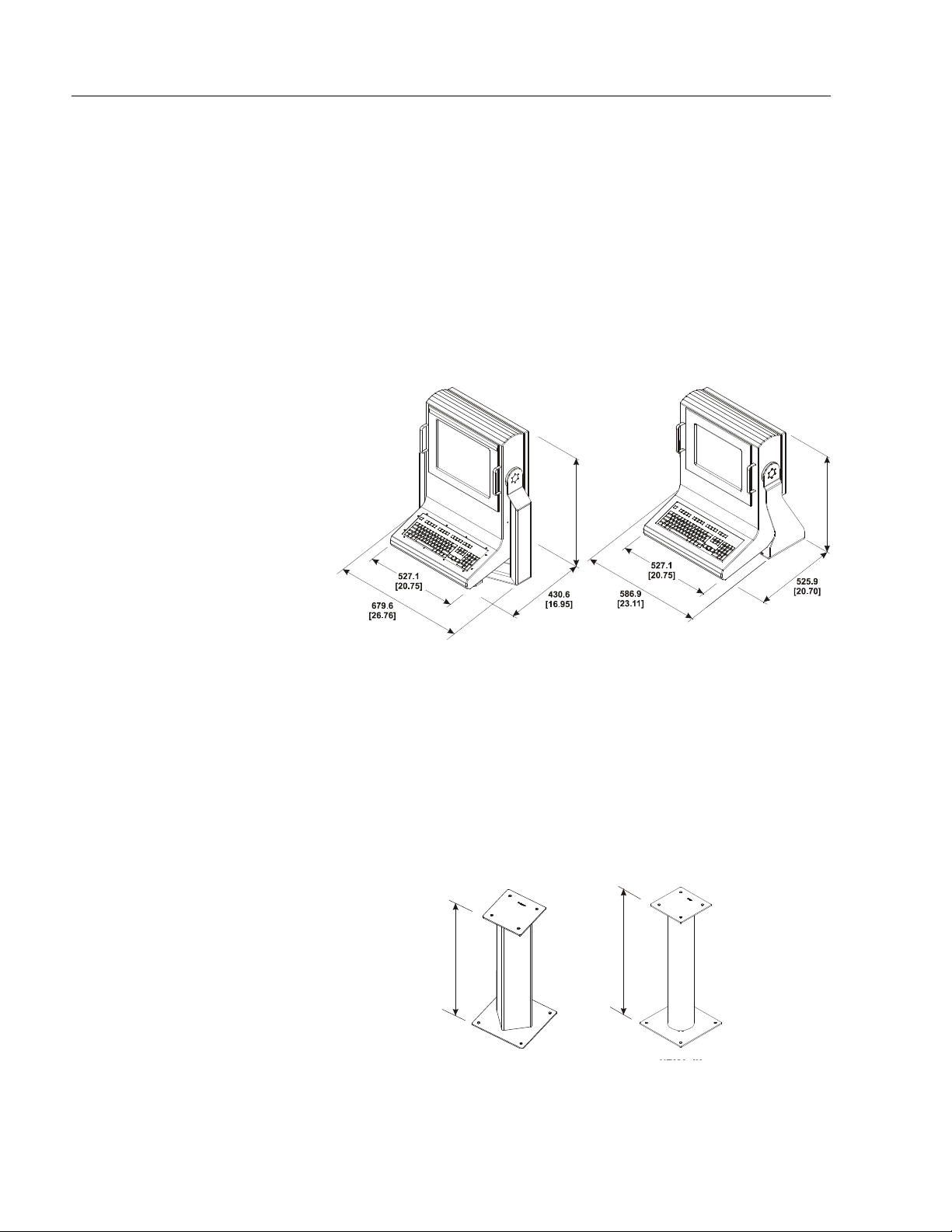

Wall Mount Arm and Overhead Mounting

For applications where floor space is limited, consider the overhead or

wall mount arm options of the RAC6188.

15.1 Display 18.1 Display

Overhead Specifications

The overhead mount option allows you to mount the RAC6188 above

the operator in a fixed position. This option gives you 30°tilt

adjustment.

Wall Mount Arm Specifications

Each wall mount arm for the RAC6188 provides 360° swivel, 30° tilt,

and full side-to-side positioning. Vertical positioning options depend on

the enclosure material:

• The NEMA 4X stainless steel arm has a fixed vertical position.

• The NEMA 4 aluminum construction provides 12 in. vertical height

adjustment.

NEMA 4 NEMA 4X

Publication 6188-UM001A-EN-P

Page 32

32 6188 Operator Display Station

Display Specifications

Table L

Display Specifications

Display 15.0” Flat Panel 18.1” Flat Panel

Type Active Matrix Color Thin Film Transistor (TFT) LCD

Backlight

Type

Life Expectancy

Field Replacement

Nominal Display Area

Diagonal

Horizontal

Vertical

Resolution 1024 x 768 pixels, 256K colors 1280 x 1024 pixe ls, full color

Viewing Angle

Horizontal(Typical)

Vertical (Typical)

Luminance (Typical) 200 nit, 58fL (screen overlay option reduces luminance)

Contrast Ratio(Typical) 250 : 1 100 : 1

Response Time 35 msec (Typical) 45 msec (Typical)

Cold Cathode Tube (CCT)

50,000 Hours (Typical)

Yes

15.1 In. (383 mm)

12.0 In. (304 mm)

9.0 In. (228 mm)

+/- 60 Deg.

+ 55/- 45 Deg.

Cold Cathode Tube (CCT)

50,000 Hours (Typical)

No

18.1 In. (460 mm)

14.1 In. (359 mm)

11.3 In. (287 mm)

+/- 85 Deg.

+/- 85 Deg.

Table M

Video Specifications

Video 15.1” Flat Panel 18.1” Flat Panel

Supported Standards 640 x 480 @ 60Hz and 75Hz

800 x 600 @ 60Hz and 75Hz

1024 x 768 @ 60Hz (Native)

and 75Hz

Video Input Signal RGB analog (white level = 0.714V above

ref. Black, into 75 Ohms

Sync Input Signals H & V separate (TTL levels, positive or

negative)

Input Connection HD- 15 HD-15

720 x 400 @ 70Hz (VGA text)

640 x 480 @ 60Hz and 75Hz

800 x 600 @ 60Hz and 75Hz

1024 x 768 @ 60Hz and 75Hz

1280 x 1024 @ 60Hz and 75Hz

(Native)

RGB analog (white level = 0.714V above

ref. Black, into 75 Ohms

H & V separate (TTL levels, positiv e or

negative)

Publication 6188-UM001A-EN-P

Page 33

Appendix A: Technical Specifications 33

Table N

Controls & Indicators Specifications

Controls & Indicators

Front Panel Luminance with Status LEDs (18” Display Only)

Back Panel Access on-screen display (Top Button)

Adjust controls through on-screen display (Second and third butt on )

On-Screen Display and

Auto Adjust

Touchscreen Touchscreen Option – Resistive Antiglare , with Serial Controller using DOS and

Horizontal Size, Vertical Position, Horizontal Position, Contrast, Brightness, Clock

Phase, Expand/ Center, Languag e

Table O

Operator Input Specifications

Controls & Indicators

Windows drivers

Table P

Environmental and Power Specifications

Environmental and Power Specifications

Environmental Rating NEMA 4/12 (IP65) Painted Aluminum Enclosure

NEMA 4X (IP65) Stainless Steel Enclosure

Temperature:

Operating

Non-Operating

Electrical Line Voltage 100 to 132 VAC

Line Frequency 50-60Hz

Electrical Power

Consumption

0C to 40C (45C with optional heat sink )

-20C to 65C

6185-C – 61W max, 75 VA max

6185-D – 86W max, 100 VA max

Publication 6188-UM001A-EN-P

Page 34

34 6188 Operator Display Station

Keyboard and Mouse

Table Q

Keyboard – Uses Mouse (Integrated) Specifications

Specifications

Physical

Rating NEMA 4 / 4X

Keys Embossed for enhanced feel

Overlay Characteristic Wear and chemical resistant

Language English Standard

Mechanical

Keys Sealed Mechanical

Cutout for Integrated Mouse

Key Operation 0.4 mm

Key Life Expectation > 20 million switch cycles

Key Operating Force 150 gms (nominal)

Table R

Mouse (Integrated) Specifications

Mouse (Integrated)

Material Industrial Silicone Rubber

Compatibility Microsoft, PS/2, Ligitech

Features Full rotation travel and positive directional positioning;

Proprietary Fujitsu position sensors

Rating NEMA 4 and NEMA 4X

Signal Extender Specifications

Publication 6188-UM001A-EN-P

Table S

Signal Extender Specifications

Mechanical – Transmitter

Weight: 1 Lb. (0.45 kg)

Height: 1.9 In. (48 cm)

Width: 8.1 In. (206 cm)

Depth: 4.8 In. (122 cm)

Environmental / Power

Power Supply: 24 VDC @ 500 mA supplied from RAC6188 through

Cat-5 cable.

Operating

Temperature:

Storage Temperature: -20 Deg. C to +50 Deg. C

0 Deg. C to +40 Deg. C

Page 35

Appendix A: Technical Specifications 35

Supported Hardware

Computers: Computers using 100% IBM PS/2 compatible

peripherals.

Video Modes Non-interlaced VGA, SVGA, XGA, SXGA

640 x 480 up to 1280x1024

Peripherals PS/2 or Serial Mouse, PS/2 Keyboard (150 mA

max.)

VGA, HD-15 high density “D” connector

Serial Port (Or Serial

Mouse)

To Speakers 3.5 mm stereo jack for powered speakers, 3 Vpp

From Microphone 3.5 mm stereo/mono jack, 5.6K ohm pullup for 2

FCC class A, UL, CUL, CE, VCCI Class A

EIA-232 async up to 19.2 Kbps, 9-pin “ D ” connector

(female to PC, male to peripheral) TD, RD, RTS,

CTS, DTR, DSR, Ground

Audio

max., 200 ohms output impediance, < 0.01% THD at

1 KHz

powered electret microphones in a s i ngle stereo

jack, dynamic microphone support ed with reduced

volume and quality

Agency Approvals

Publication 6188-UM001A-EN-P

Page 36

0101

IBM is a registered trademark of International Business Machines Corporation.

VGA is a trademark of International Business Machines Corporation.

PC AT is a trademark of International Business Machines Corporation.

Microsoft is a registered trademark of Microsoft Corporation.

Microsoft Windows is a trademark of Microsoft Corporation.

AccuTouch is a trademark of Elo TouchSystems.

ClearTek is a trademark of Microtouch.

Publication 6188-UM001A-EN-P

Copyright 2001 Rockwell Automation Corporation. All rights reserved. Printed in USA.

41061-213-01(A) 998087-

Loading...

Loading...