Page 1

Industrial 19" CRT Monitor

(Bullet in 61 57 -C )

Installation and User Manual

Page 2

2

Table of Contents

7

7D

DEOH R

EOH RI

Industrial 19" CRT Monitor

Description........................................................................... 3

Package Contents................................................................. 6

Installation Guidelines.......................................................... 6

Panel Mounting (6157-CE/ 6157-CF)................................... 8

Rack Mounting (6157-CB)................................................... 14

Connecting the 6157- C Industrial Monitor........................... 21

Operating the 6157- C Industrial Monitor............................. 25

Routine Maintenance............................................................ 39

Troubleshooting................................................................... 40

Allen-Bradley Support ......................................................... 42

Appendix A: Touchscreen Serial Interface

Description........................................................................... 43

Setting Up the Touchscreen Interface.................................... 43

Performing a Calibration...................................................... 45

Appendi x B : Video Cabl es

HD-15 Connectors ............................................................... 46

BNC Connectors.................................................................. 47

Specifications

I &RQWH

&RQWHQ

...................................................................... 48

QWV

WV

.............................................. 3

........................ 43

................................................. 46

Importan t User Informat ion

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. "Safety Guidelines for the Application, Installation, and

Maintenance of Solid State Controls" (Publication SGI-1.1) describes some important

differences between solid state equipment and hard-wired electromechanical devices.

Because of this difference, and because of the wide variety of uses for solid state

equipment, all persons responsible for applying this equipment must satisfy themselves

that each intended application of this equipment is acceptable.

In no event will Rockwell Automation be responsible or liable for indirect or

consequential damages resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes.

Because of the many variables and requirements associated with any particular

installation, Rockwell Automation cannot assume responsibility or liability for actual

use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation with respect to use of the

information, circuits , equi pment, or sof tware des c ribe d i n this m anual .

Reproduction of the contents of this manual, in whole or in part, without written

permis si on of Rockwell Automation is prohibited.

Throughout this manual, we use notes to make you aware of safety considerations.

ATTENTION:

circumstances that can lead to personal injury or death,

property damage, or economic loss.

Important:

application and understanding of the product.

Identifies infor mation t hat is es peci al ly impor tant f or successfu l

Identifies information about practices or

Publication 6157-UM001A-EN-P

Page 3

Industrial 19" CRT Monitor

Descript ion

,QGXVWULDO

,QGXVWULDO

The 6157-C Industrial 19" CRT Monitor is a general-purpose monitor

suitable for a wide range of industrial computing applications. It offers

the following features:

Panel a nd ra c k mount enclosu res

•

Pure flat screen

•

Reliable and rugged industrial design

•

Bright, c risp display

•

Touchscreens

•

Sync- o n-green, separa te sync , and comp osite sync video su pport

•

On-scr een disp la y f or easy setup

•

Versatile multi-sync design (640x480 to 1600x1200 resolution)

•

&57 0RQLW

&57 0RQLWR

RU

U

3

Note:

This monitor can display resolutions up to 1600x1200

at 75 Hz. If you experience unexpected results

operating the monitor at this resolution, verify that the

monitor is operating a t 75 Hz or less.

ATTENTION:

document generates, uses, and emits radio frequency

energy. The equipment has b een tested and fou n d to

comply with FCC Rules, Part 15, subpart J, for Class A

computing devices.

The use of non-shielded interface or power cords with

All e n-Br adley indu str i al mo nitor s is p rohib ited.

ATTENTION:

typically about 0.05 mR/hr maximum, well below the

0.5 mR/hr maximum recommended by the US.

Depa rtment of Heal th a nd Human Resources and

specified in "Federal Performance Standards for

Television Receivers", Section 10, Part 1020, Title 21, of

the U. S. Code of Regulation (PL90-620), Vol. 38, No.

198.

These monitors ar e equippe d with X-r ay pro tecti on

circuits that cause automatic shutdown of the equipment

in ca se its X -ray emissions be gin t o app roach federal

limits.

The equipment described in this

X-ray emissions from these monitors are

Publication 6157-UM001A-EN-P

Page 4

4

Industrial 19" CRT Monitor

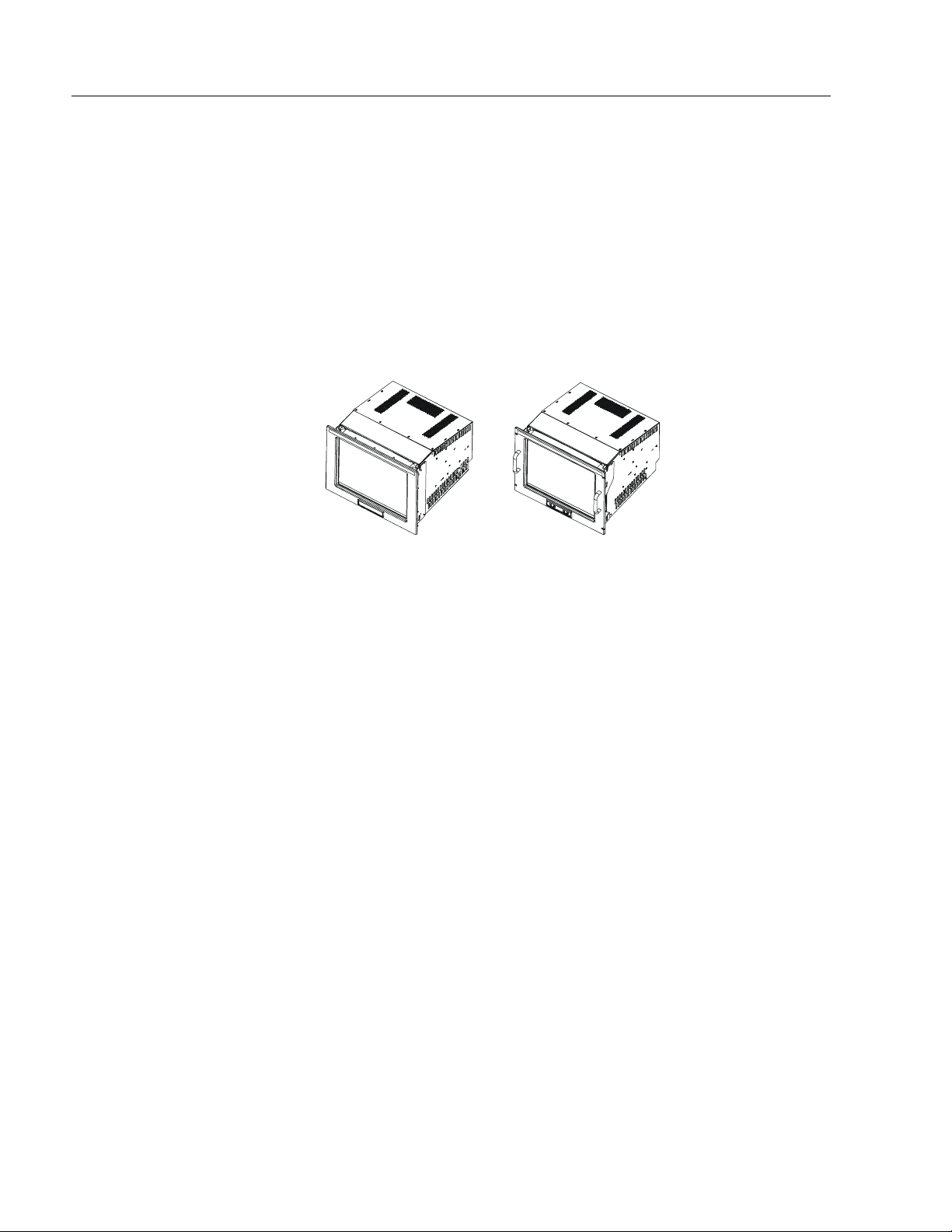

Models

The 6157- C Industrial Monitor is available in the following models:

Panel mount with front controls (6157-CE)

•

Panel mount with rear controls (6157-CF)

•

Rack mount (6157-CB)

•

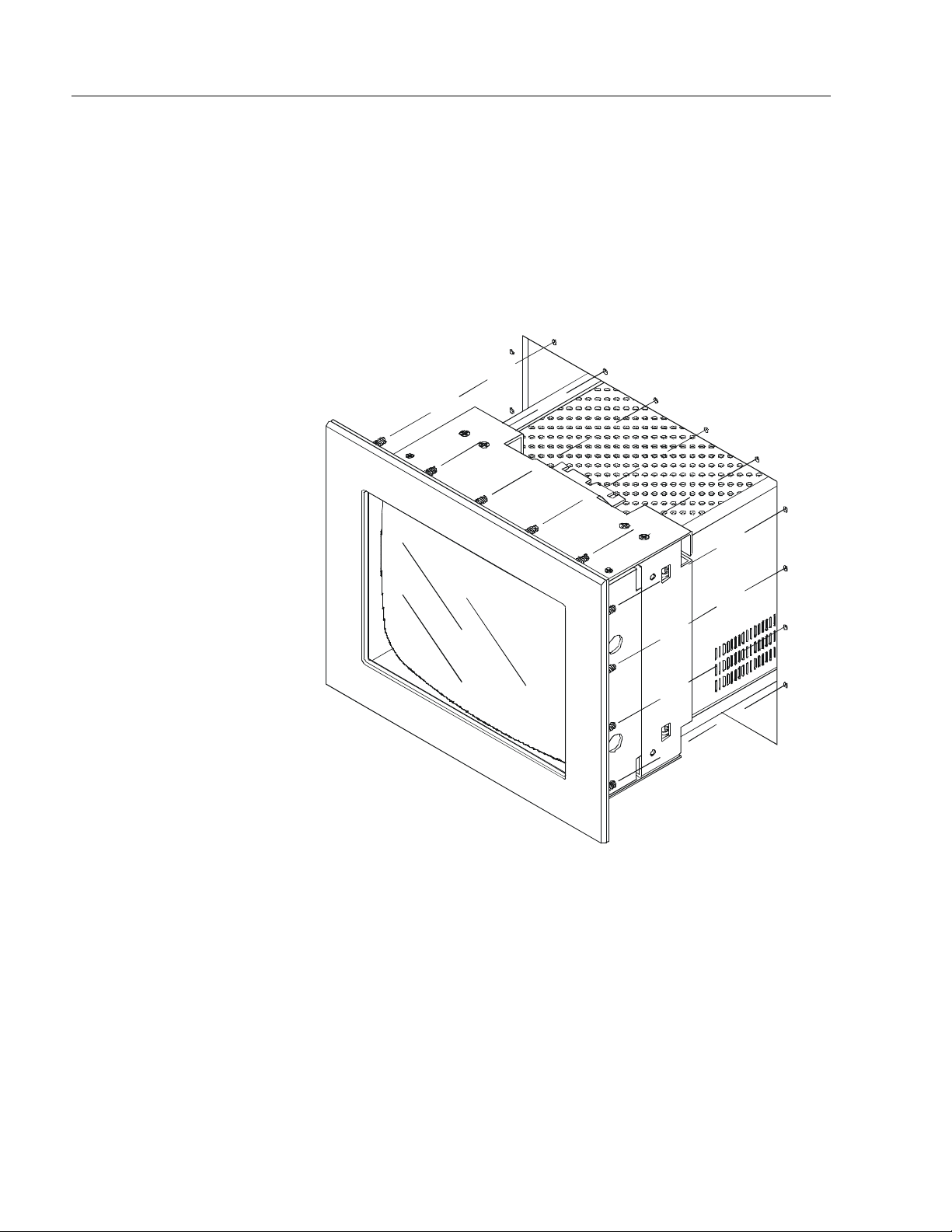

Figure 1

6157-C Monitor Models

Panel Mount Rack Mount

(6157-CE/6157-CF) (6157-CB)

Availabl e O pt io n s

The following options are available on each model of the 6157- C

Industrial Monitor:

Video interface options

•

(HD-15 and five BNCs through an adapter cable)

Resistiv e or ca p acitive touchscreen

•

Surface acoustic wave (SAW) touchscreen option (6157-CB only)

•

Touchscreen cable opti ons

•

Video cable opti ons

•

Power cord options

•

Publication 6157-UM001A-EN-P

Page 5

Industrial 19" CRT Monitor

Part Numbers

The part number for your particular unit consists of the model number

(6157) followed by a nine-digit code indicating the options on your unit.

Example:

5

6157 -

CE D A A Z A A Z Z

1 2345678910

Following are exp lana tio ns of t he pa rt nu mbers for t he various mode ls of

the 6157-C units.

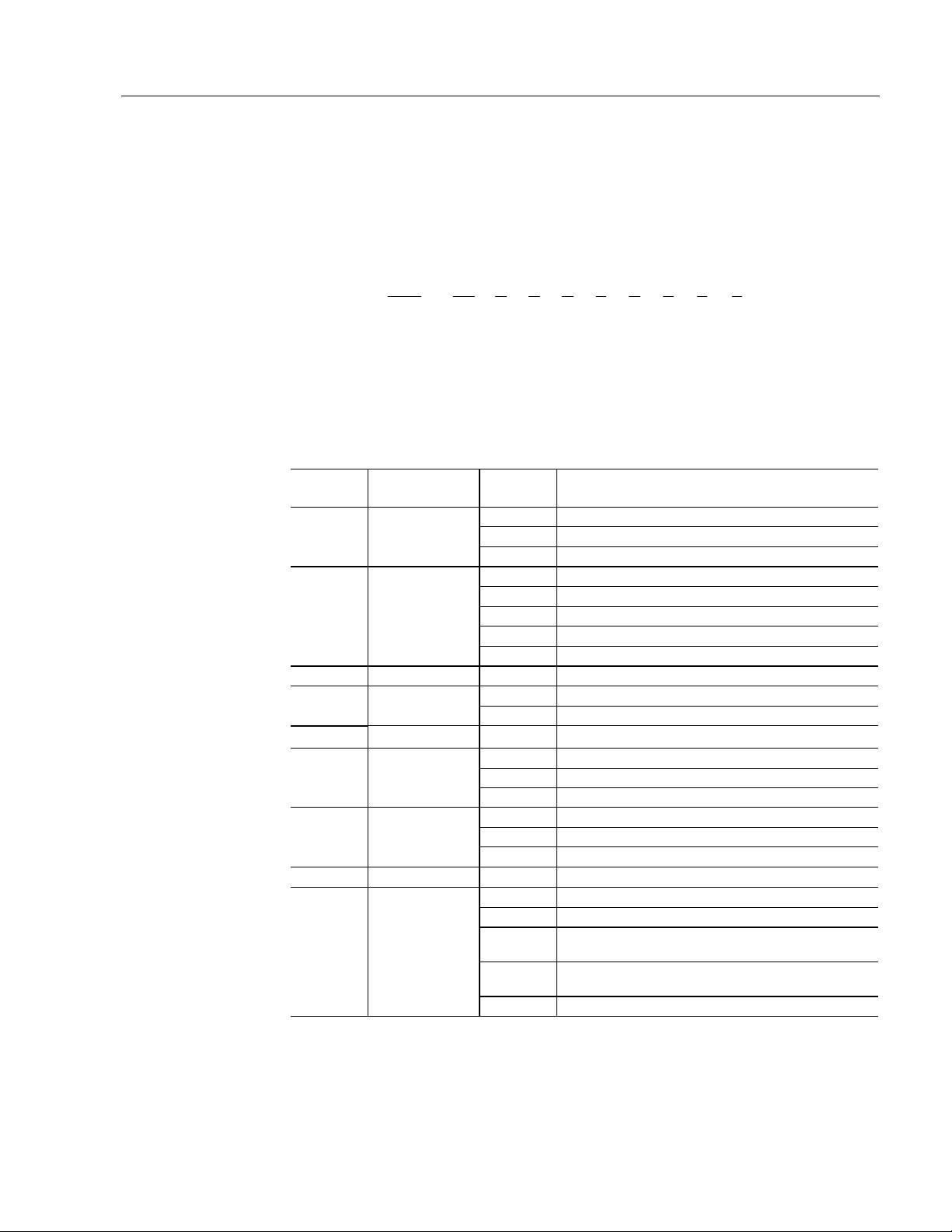

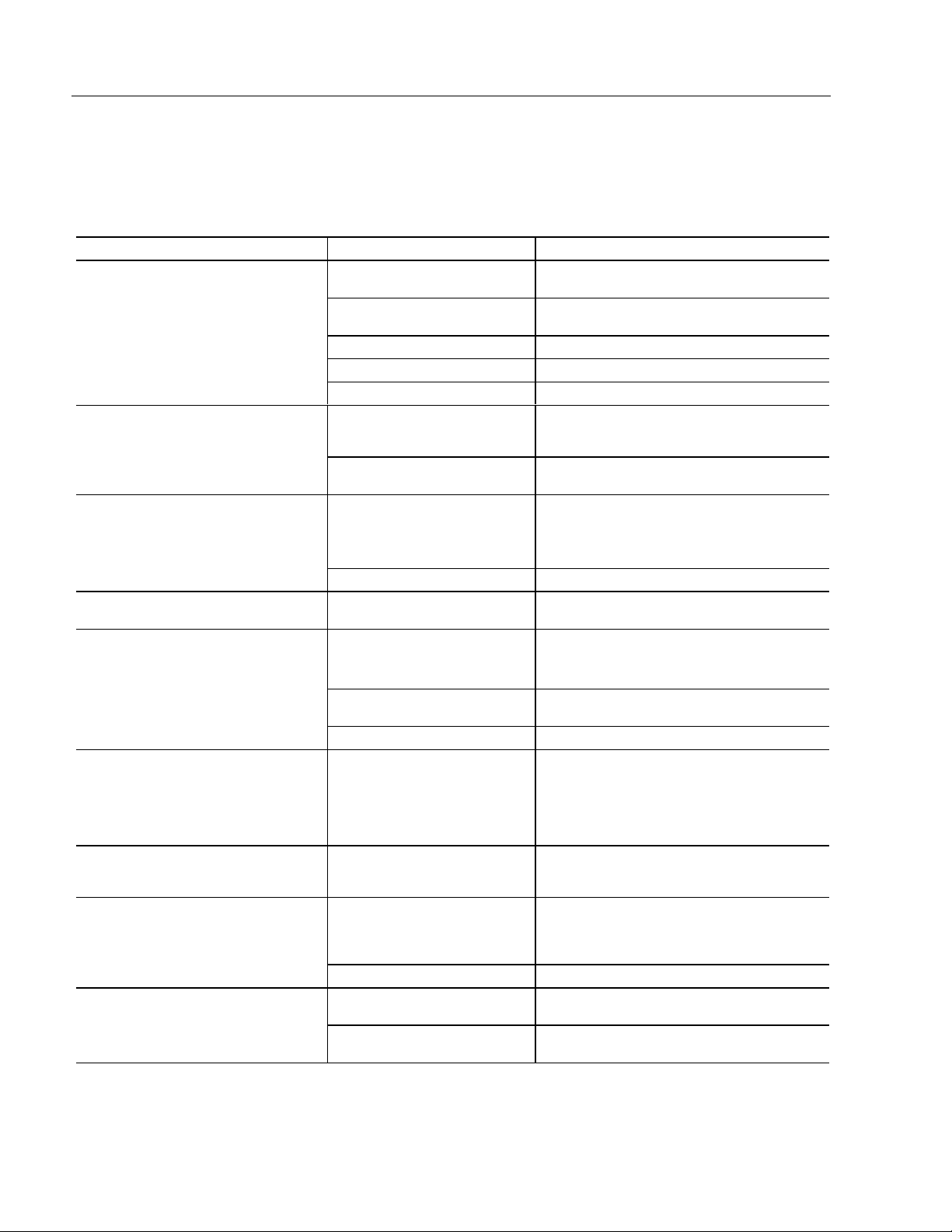

Table A

Catalog Number Explanation for 6157- C Industrial Monitors

Position Option Option

Letter

2

3 Touchscreen/

4 Vid eo In terfac e A HD- 15

5

6

7 External Video

8 Touchscreen

9 Future Options Z None

10 Enclosure

Display/

Enclosure

Display Shield

Power Inp ut/

Line Cord

Future Options Z None

Cable

Cable

Accessories

CB Rack Mount, NEMA 1, 9U, Front Controls

CE Panel Mount, NEMA 4/4X, 9U, Front Controls

CF Panel Mount, NEMA 4/4X, 9U, Rear Controls

B Resisti ve A nt ig lare Touc hs c reen

D Capacitive Antiglare Touchscreen

G SAW Polished Touchscreen (Rack Mount Only)

W Tempered Glass Anti -refle c tive Display Shield

Z None (No Display Shield)

A 120/240 VAC, USA Power Cord

B 120/240 VAC, No Power Cord

A 6 ft (1.8 m) HD-15 - HD-15 Cable

B 15 ft (4.6 m) HD-15 - HD- 15 Cable

K 1ft (0.3 m) 5-BNC - HD-15 Cable

A 6 ft (1.8 m) DE9 - DE9 Cable

B 15 ft (4.6 m) DE9 - DE9 Cable

ZNone

B 18" Rack Mount Slides (Pair)

C 24" Rack Mount Slides (Pair)

D 18" Rack Mount Slides (Pair), EIA 19" 1U Adapter

E 24" Rack Mount Slides (Pair), EIA 19" 1U Adapter

ZNone

Category Description

Panel

Panel

Note:

Not a ll op ti o ns are a vailab le with all models.

Publication 6157-UM001A-EN-P

Page 6

6

Package Contents

Installation Guidelines

Industrial 19" CRT Monitor

Before unpacking a new monitor, inspect the shipping carton for damage.

If damage is visibl e, immediat e ly conta c t the shipper a nd request

assistance. Otherwise, proc eed wit h u npa ck i n g.

Note:

The monitor shipping carton contains the following items:

Monitor

•

Pa cka g e of mou nt i ng ha r dwa r e

•

AC power cord (optional)

•

Video cable (optional)

•

Enclosure accessories (i.e. rack sides for rack mount only) (optional)

•

This user manual

•

An 6157- C Industrial Monitor with a touchscreen option is shipped with

these additional items:

Supporting software and manuals

•

RS-232 serial extension cable (optional)

•

When installing the unit, it is important to consider environmental

factors at the site that could affect performance as well as possible

effects from equipment operation on personnel and nearby equipment.

Make s ure you ke ep the orig inal packagi ng for the mo nitor

in case you need to return the monitor for repair.

Note:

Important:

Remember th at hea t ris es—many time s t he temper at ure at

the top of an enclosure is much higher than the rest of the

enclosure if the air is not circulating. Without active

cooling or an internal fan, the temperature at the top of an

enclosure can be 10° - 20°C hotter than at the middle or

bottom of the enclosu re.

This monito r is designed to operate a t a range of extr emes,

however it is not good design practice to continuously

op erate the monitor at th e highest end of the sp ecified

tem perature ra n ge.

While the product will operate at its highest specified

tempera ture, the ov erall life s p an of a ny elec tronic d e v i ce is

shorten e d whe n it operates at its highest rated te mperature.

Publication 6157-UM001A-EN-P

Page 7

Industrial 19" CRT Monitor

Following the guidelines below will help ensure that the monitor will

provide safe and relia ble serv ic e.

Ensure that sufficient

•

is available from a single phase AC

power

outlet at the site.

Ensure that sufficient

•

is available around air inlets and outlets

space

to provide the circulation necessary for cooling. Never allow air

passages to become obstructed. The monitor is equipped with a fan

to ensure proper cooling.

7

• Dust and smoke

part icl es ca n ca u s e pr obl ems, since they can collect

at ventilating holes in the enclosure and interfere with cooling.

Accordingly, where dust and smoke are problems it is especially

important to keep air vents clean. Refer to the Routine Maintenance

section (Page 39) for more information.

Ensure that the

•

ambient air temperature

will not exceed the

specified maximum temperature. A user supplied fan, heat exchanger,

or air conditioner may be required to meet this condition in some

installations.

Leav e the monitor’s

•

enclosure or cover

in place at all times during

oper ation. The cover aff ords p rotecti on against hi gh volt ages inside

the monitor and inhibits radio-frequency emissions that might

interfere with other equipment.

The Federal Communications Commission has prepared a pamphlet

•

that addresses the pr oblem of

radio frequency interference

to radio

and telev i si on recept ion, which shoul d be consu lted in ca se of

problems with such interference. This publication, “How to Identify

and Resolve Radio/TV Interference Problems” (Stock #004-00000345-4) may be obtained from the US. Government Printing Office,

Washington, DC 20402.

Determin e t he min imum a n d maxi mum a mbient

•

humidity

for the

monitor by consulting the specification sheets at the back of this

manual. Ensure that the humidity of the ambient air will not exceed

these limits. In very dry environments, static charges build up very

rea dily. Pr oper grou nding of the equipment through the AC po w er

cord can help reduce the likelihood of static discharges, which may

cau se shocks and damag e e lect ronic compo n ents.

Publication 6157-UM001A-EN-P

Page 8

8

Panel Mounting (6157-CE/

6157-CF)

Industrial 19" CRT Monitor

When properly installed, the panel mount version of the 6157- C

Industrial Monitor is designe d to p rovide prot ecti on aga inst water a nd

dust to NEMA 4 and 4X (IP 65 equivalent) and NEMA 12 (IP 52

equivalent) standards.

No slides or shelves are required because the 6157- C Industrial Monitor

is designed to be supported by the panels in which it is installed.

Figure 2

Generic Panel Mount Diagram

Publication 6157-UM001A-EN-P

Tools Needed

In addition to the tools required to make the cutout, you will need the

following tools to mount the monitor:

3/8 in. deep well socket

•

¼ in. drive extension – 12 in. or longer

•

¼ in. drive ratchet or ¼ in. drive torque ratchet

•

Page 9

Industrial 19" CRT Monitor

Panel Mounting Guidelines

Observe the following precautions before installing the unit in a panel:

Confirm that there i s adequa te space be hin d the pa nel. Remember to

•

allow extra space for air circulation and cabling. Allow 63.5 mm

(2.5 in) behind and 50.8 mm (2 in) above, below, and on each side for

air cir c u l atio n and cabling.

Confirm that the cabinet is deep enough to accommodate the

•

monitor's depth while providing rear clearance for airflow. A cabinet

with depth of 523.7 mm (20.62 in.) is sufficient.

Take precaut ions so that metal cuttings d o n ot enter a ny comp onents

•

that are already installed in the panel.

Supporting panels should be at least 14 gauge to ensure proper

•

sealing against water and dust and to provide proper support. The

mounting hardware supplied accommodates panels up to 6.4 mm

(0.25 in) thick.

9

Note:

Supporting panels must be cut and drilled to

specifications prior to installation.

ATTENTION:

Failure to follow these warnings may

result in personal injury or damage to the panel

components.

Publication 6157-UM001A-EN-P

Page 10

10

Industrial 19" CRT Monitor

Mounting the 6157-CE/6157-CF in a Rack

Due to the front panel size and stud pattern, the panel mount versions of

the 6157- C Industrial Monitor can be installed in an EIA 19 in. 9U panel

standard rack. Refer to the following figure:

Figure 3

Generic Rack Mounting Diagram

Publication 6157-UM001A-EN-P

Important:

If you install the panel mount versions of the 6157- C

Industrial Monitor in a rack, you must ensure that the rack

can support the weight of the monitor. You may need to

install a support or shelf under the rear of the monitor to

support the weight.

Page 11

Industrial 19" CRT Monitor

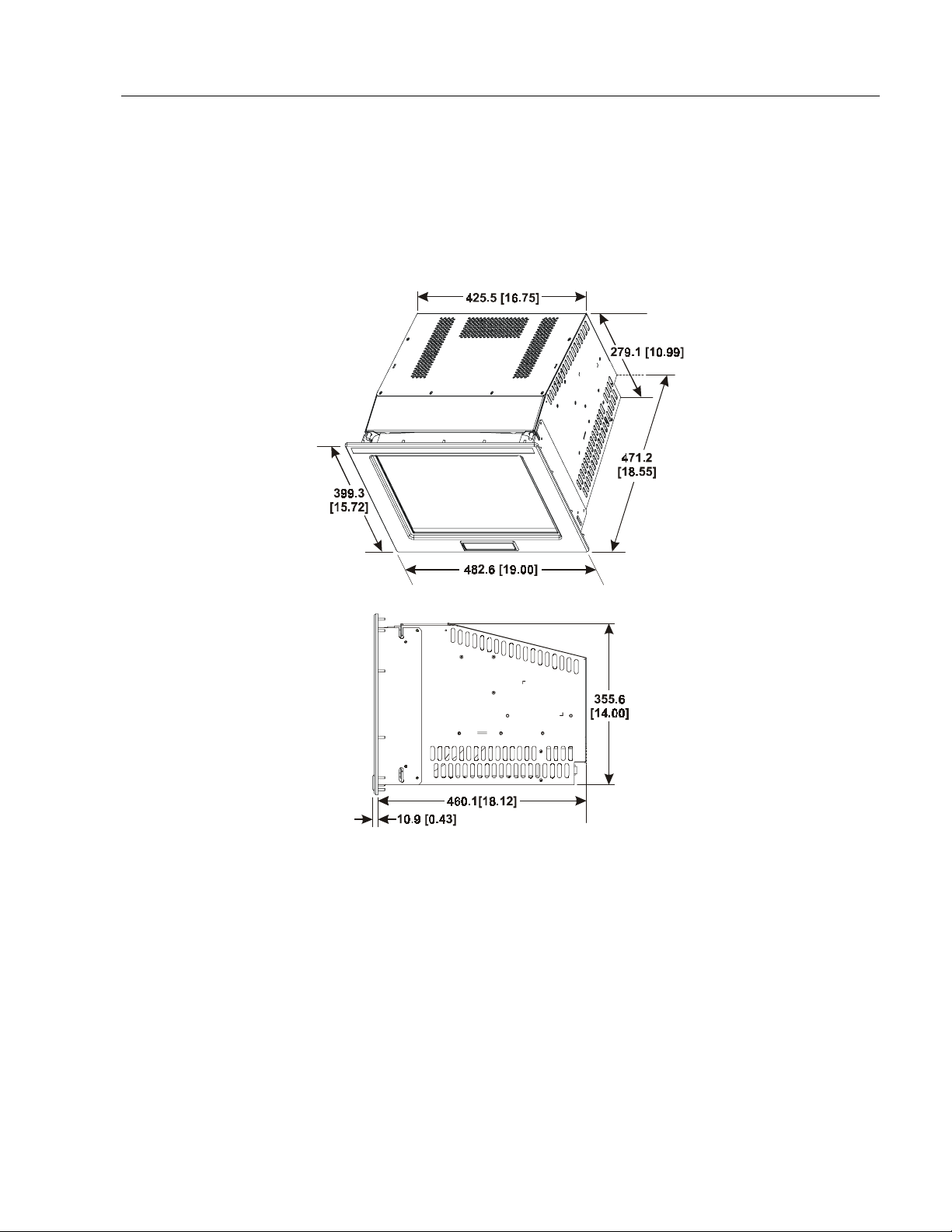

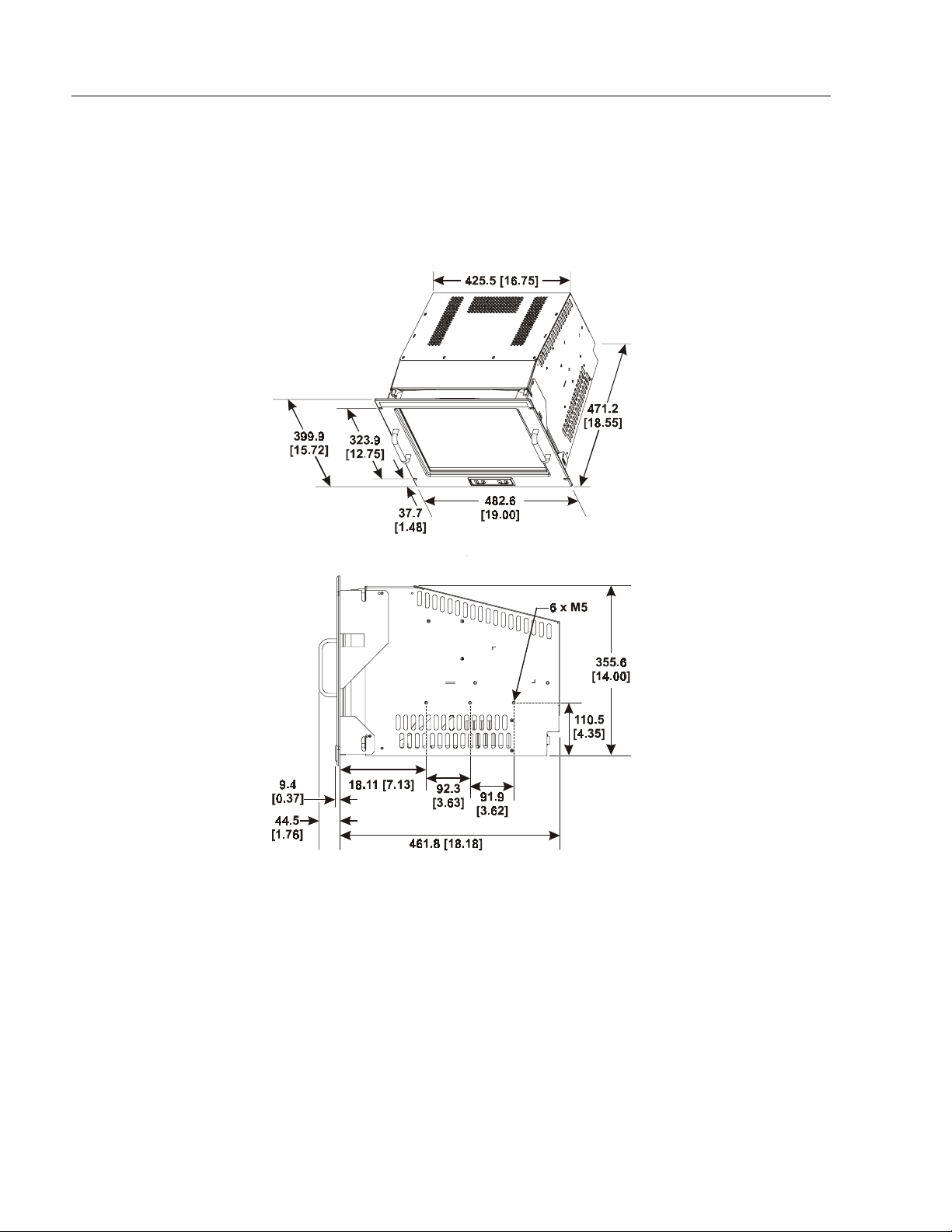

Panel Mount Dimensions (6157-CE/6157-CF)

This section provides diagrams you need to follow to install the unit.

Dimensions are supplied in mm [in.]

Figure 4

6157-CE/6157-CF Industrial Monitor Dimensions

11

Publication 6157-UM001A-EN-P

Page 12

12

Industrial 19" CRT Monitor

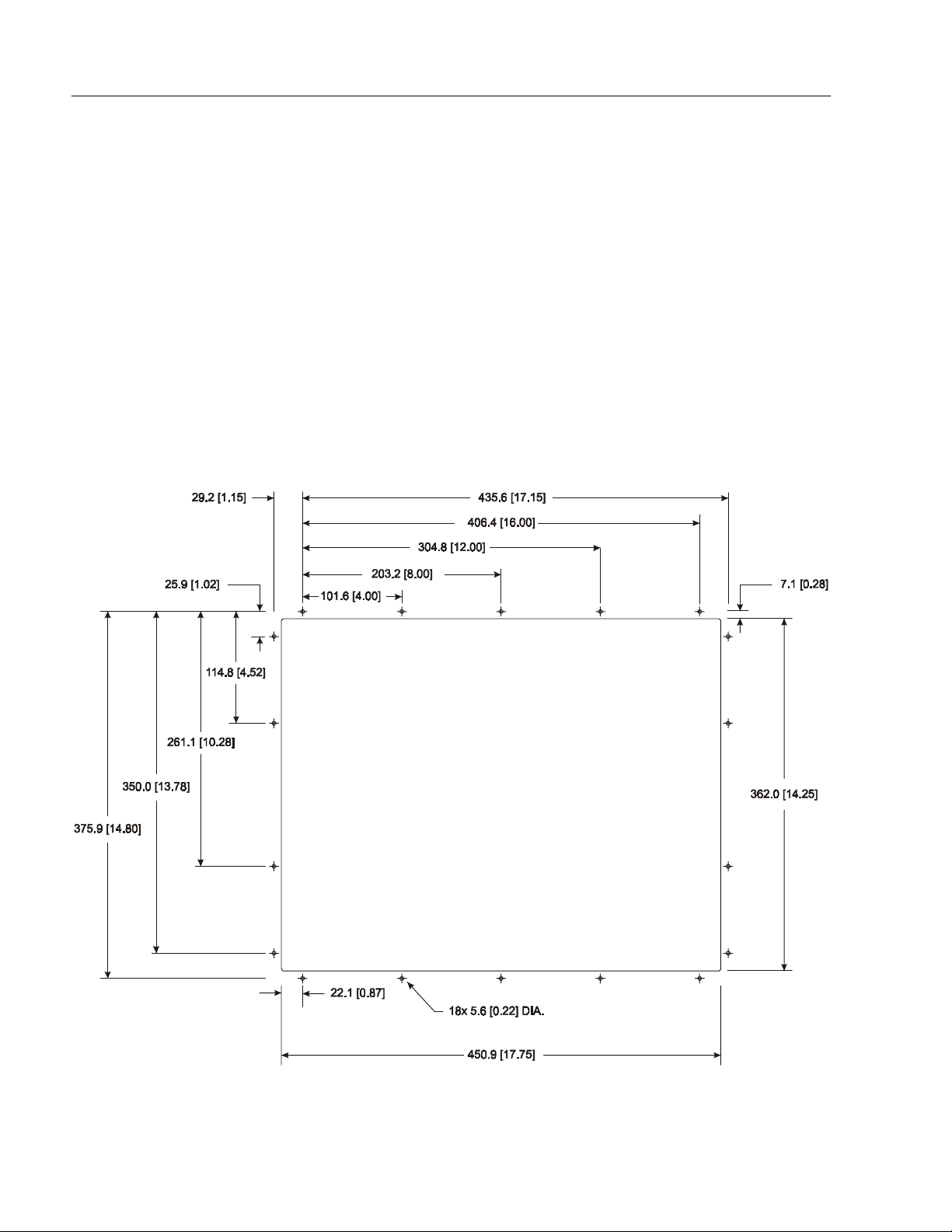

Panel Mounting Procedure

1. Confirm that the shipping carton contains a package of 10-32 lock

nuts and fl at wash ers. You will n e e d 18 nuts and washers f or

installati on. E xtra lock nu ts and washers are pr ovided.

2. Refer to t he ph ysical di me nsion drawi ng ( Figu re 4) and conf irm that

th ere is adequat e space be hin d th e pa nel. R emem ber to allow extra

space for cir c ulatio n and cabling.

3. Refer to the panel cutout drawing below for dimensions of the panel

cutout and mounting hole locations. Cut and drill the panel.

Note:

Figure 5

Panel Mounting Cutout

Use #10-32 or M5 self-locking nuts for mounting.

Publication 6157-UM001A-EN-P

Page 13

Industrial 19" CRT Monitor

4. Carefully remove the monitor from its packaging. Avoid damaging

the monitor gasket.

It will be easier to install the monitor if you support it with a shelf

Tip:

or other support adjusted to the appropriate height.

5. Insert the monitor in the panel cutout from the front. Do not damage

the threaded mounting studs as you position the monitor.

6. Secure the unit with the lock nuts and washers provided. Tighten

evenly to 24 inch-pounds of torque.

13

Important:

To ensure a proper seal, be sure to install a washer and

nut on each of the 18 mounting studs.

ATTENTION:

Mounting nuts must be tightened to a

torque of 24 inch-pounds to provide panel seal and

avoid potential damage. R ockw e ll Automa ti on

assumes no responsibility for water or chemical

damage to the monitor or other equipment within the

enclosure due to improper installation.

7. Remove the protective adhesive sheet from the screen of the

Industrial Monitor. The sheet is designed to prevent scratching of

the polycarbonate screen protector or the optional touchscreen

during shipping and installation. It should be removed before use.

Publication 6157-UM001A-EN-P

Page 14

14

Rack Mounting (6157-CB)

Industrial 19" CRT Monitor

When properly installed, the 6157-CB industrial monitor is designed to

provid e p rotection to NEMA 1 (IP 10 equ ivalent) standards.

The rack mounting versions of the 6157- C Industrial Monitor are

designe d for insta llation in a rack enc losure that co nfor ms to EIA

standards for equipment with 19" (483 mm) wide rails.

Note:

Retainer screws prevent the unit from being pulled out on

its slides accidentally; they are not intended to support the

weight of the unit.

Tools Needed

You will need the following tools and hardware:

EIA panel mounting hardware

•

Chassis slides or shelf

•

Screwdriver

•

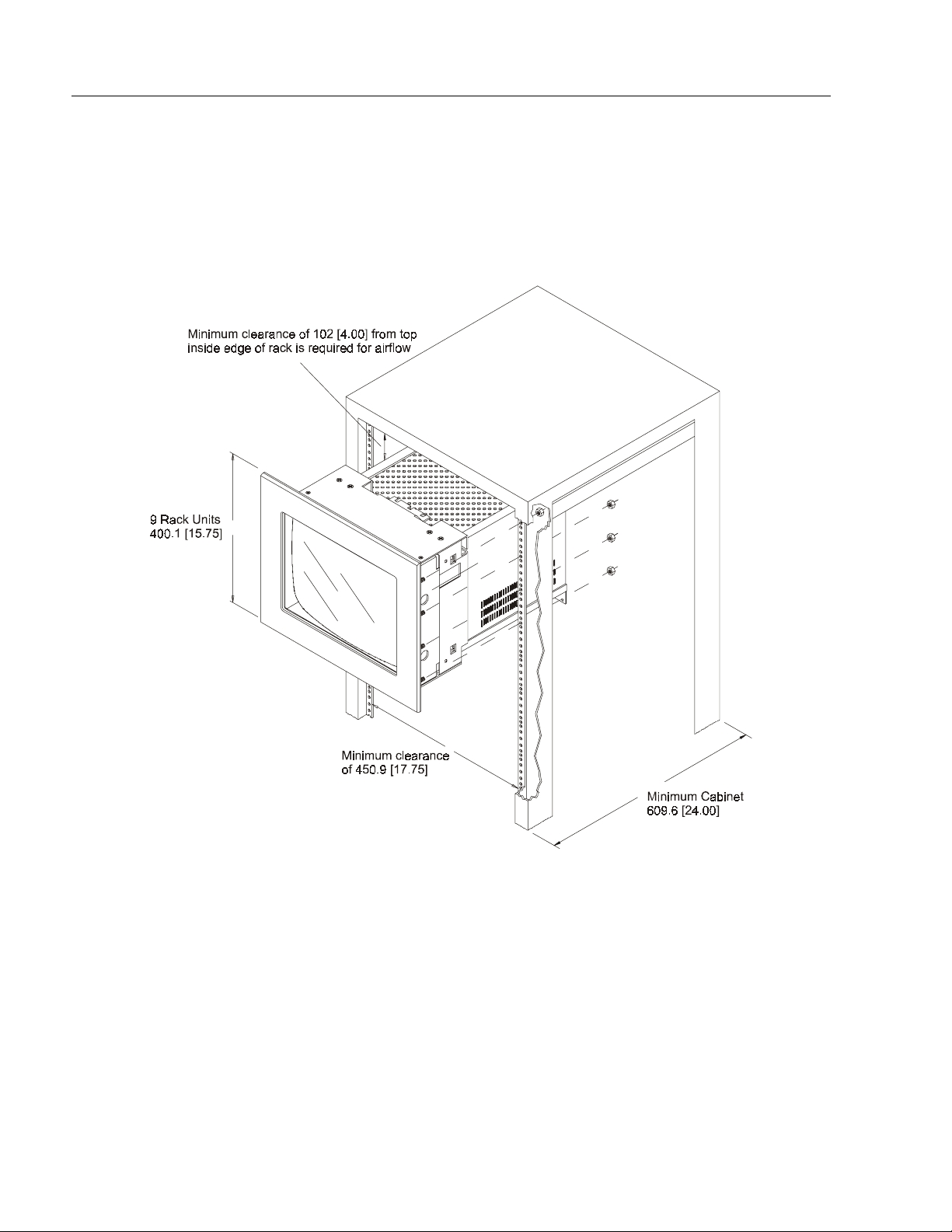

Rack Mounting Guidelines

Observe the following precautions when installing this unit in a rack:

The cabinet must be tall enough to accommodate the monitor's panel

•

height of 9 rack units, 15.75 in. (400 mm), and deep enough to

accommodate the monitor's depth while providing rear clearance for

cabling and air flow. A cabinet with depth of 24 in. (610 mm) is

sufficient. A minimum clearance of 4 in. (102 mm) from the top

inside edge of the rack is required for airflow.

Publication 6157-UM001A-EN-P

The monitor is designed to be supported in the cabinet by telescoping

•

slides. Slide mounting points are provided on the lower sides of the

monitor chassis. These mounting points are designed to accommodate

General Devices Co. Chassis-Trak

slides. Slides of this kind are available from Rockwell Automation in

18 in. and 24 in. lengths, with or without 6 in. extenders.

®

Model C-300-S or equivalent

Page 15

Industrial 19" CRT Monitor

15

Note:

The mounting rails that run vertically along the inside

edges of the fr ont a nd rear openings of EIA rac k

cabinets can be of two types:

“Wide” rails have holes spaced 0.5 in. (12.7mm)

•

and 1.25 in. (31.8mm) on centers, in a repeating

patter n . Th ese rails are prevalent in E urope.

“Universal” rails have holes spaced 0.5 in.

•

(12.7mm), 0.625 in. (15.9mm), and 0.625 in.

(15.9mm) on centers, in a repeating pattern. Thus,

the “universal” rails have a hole pattern that

contains the “wide” pattern but provides an

additional hole at the midpoint of the pattern.

“Universal” rails are most prevalent in the US.

ATTENTION:

Failure to follow these warnings may

result in personal injury or damage to the panel

components.

Publication 6157-UM001A-EN-P

Page 16

16

Industrial 19" CRT Monitor

Rack Mounting Dimensions (6157-CB)

This section provides diagrams you need to follow to install the unit.

Figure 6

6157-CB Industrial Monitor Dimensions

Publication 6157-UM001A-EN-P

Page 17

Industrial 19" CRT Monitor

17

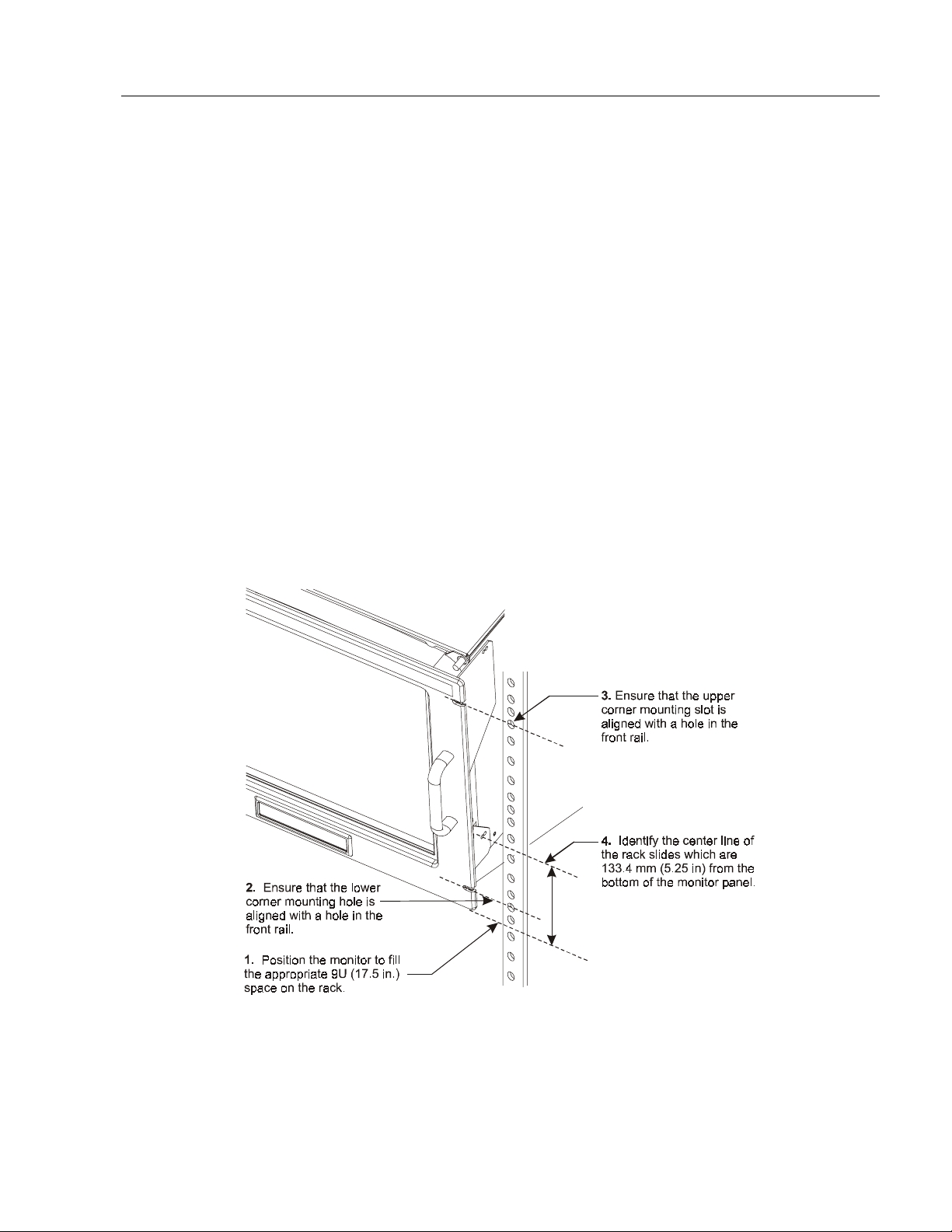

Rack Mounting Procedure

Step 1 - Locate the mounting areas:

You must allocate the required space in your enclosure for the monitor.

The monitor’s panel height is 9 rack units (15.75 in. or 400 mm) and you

must determine if panel spacers are required above or below the monitor.

Locate the following areas to mount the slides:

Locate the points at which the bottom edge of the monitor front panel

•

will intersect the cabinet front mounting rails. The four slots in the

monitor front panel should be aligned with holes in the front

mounting rails.

Locate points on the front rails 5.25 in. (133 mm) above the points of

•

where the bot tom edge of th e monitor pane l intersect s t he r ail . Th ese

points indicate the center line of each slide.

Locate points on the rear rails equal in height to the slide center line

•

points on the front rails.

Figure 7

Mounting Areas on a Rack

Publication 6157-UM001A-EN-P

Page 18

18

Industrial 19" CRT Monitor

Note:

Clearance between the insi de e dges of the fron t

mounting rails is nominally 17.75 in. (451 mm) for

standard cabinets.

This c learance can vary s omewha t and might or might

not be adjustable. Ensure that the clearance is at least

17.65 in. (448 mm) for standard monitors and at least

17.73 in. (450 mm) for monitors with magnetic shields

option installed.

Note:

Magnetic shields are secured with nylon rivets inserted

through their sides. The rivet heads require clearance

greater than 17.73 in. (450 mm). If this additional

clearance is not available, the rivets must be removed

before the monitor is installed in the cabinet.

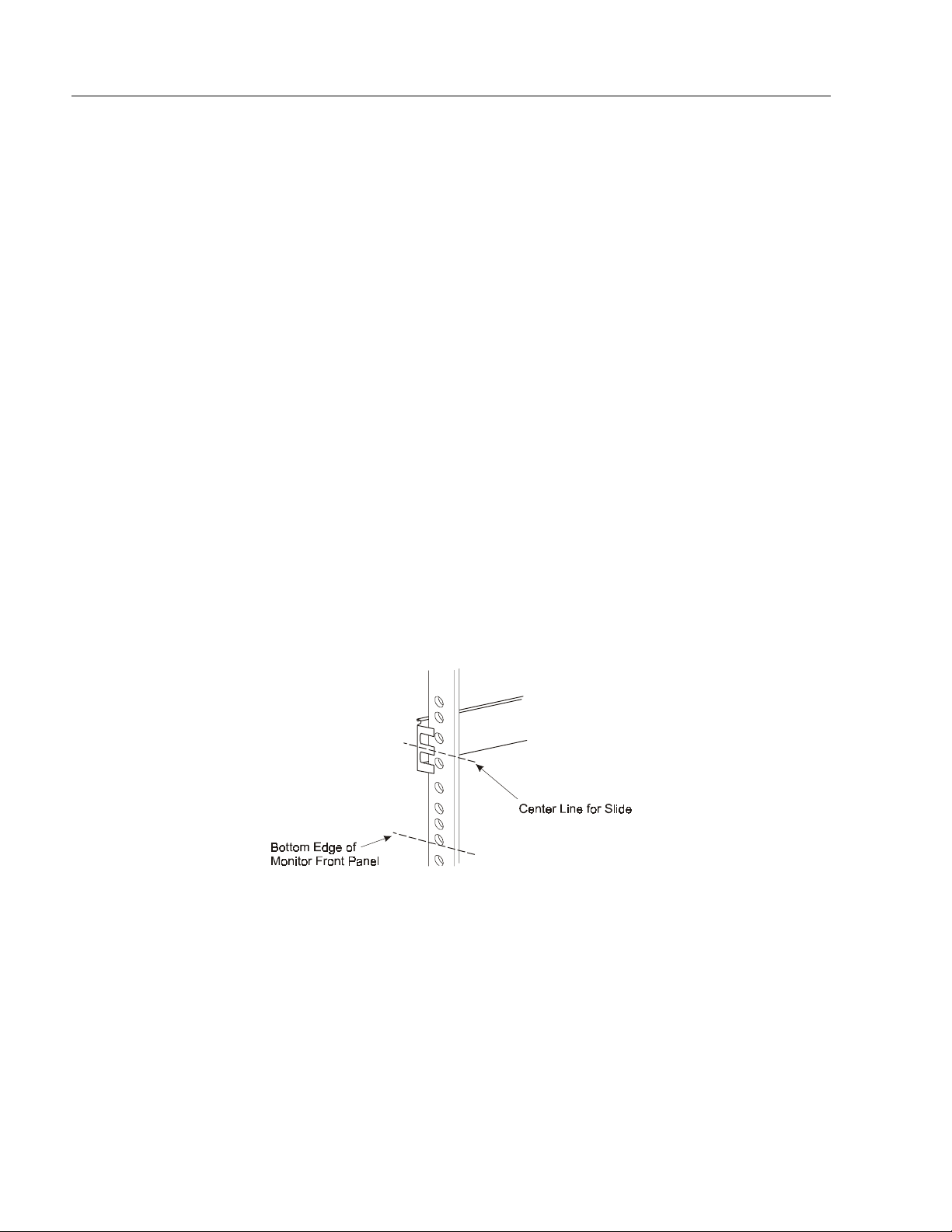

Step 2 - Install the slides in the cabinet:

1. Disassemble each slide by pressing out the spring-loaded stop that

holds the intermediate section of the slide to the stationary section.

Pull the intermediate section all the way out of the stationary section.

2. Mount the stationary section of one slide to the front and rear

mounting rails using the hardware supplied with the slides. Ensure

that the slide is aligned on the center line you located previously.

Figure 8

Chassis Slide Aligned on Center Line

3. Tighten the mounting screws enough to hold the slides in place.

Publication 6157-UM001A-EN-P

Page 19

Industrial 19" CRT Monitor

4. Repeat these steps to mount the stationary section of the other slide

to the front and rear mounting rails on the opposite side.

5. Measur e the space betw een the inside ed ges o f the sta tiona ry slides

to determine the clearance. Adjust the spacing to 16.8 in. (427 mm

6. Fully tighten the mounting screws holding the stationary sections to

the front and rear mounting rails of the cabinet.

7. Locate the holes in the front mounting rails corresponding to the

monitor’s front panel mounting holes. Install clip nuts behind the

ho les in the ra ils i f the holes are not threaded.

Step 3 - Mount the slides on the monitor:

1. Take up the sections of the slides previously removed from the

stationary s e c tio ns. Pull the int erior sectio ns out of the intermediat e

sections far enough to gain access to the mounting holes in the

interior sections.

2. Align the interior section’s mounting holes with corresponding holes

on the brace of the monitor chassis. Attach the interior section of the

slide to the side of the chassis with hardware supplied. Tighten

screws securely.

19

3. Repeat these steps to attach the interior section of the other slide to

the opposite side of the chassis.

Step 4 - Install the monitor in the cabinet:

1. Position the monitor chassis, with slide extensions installed, in front

of t he prepared cab inet.

2. Lift the monitor chassis to the height required to align the

intermediate sections of the slides (attached to the chassis) with the

corresponding stationary sections (attached to the cabinet rails).

ATTENTION:

To avoid danger of personal injury or

accidenta l damage to equipmen t , it is recommended

the monitor be lifted by two persons, both wearing

back braces.

3. Push the intermediate sections of the slides into the stationary

sections until the retaining locks are engaged.

4. If the monitor will be accessible from the rear after installation,

cabling may be installed from the rear at a later time. Otherwise,

power and vide o c abling should be installed at this time, while the

monitor is supported by the slides in extended position.

Publication 6157-UM001A-EN-P

Page 20

20

Industrial 19" CRT Monitor

5. Slide the chassis into the cabinet. Secure the monitor chassis to the

cabinet by installing screws through the four holes in the monitor

front panel in such a way that they engage the threaded holes on the

clip nuts installed previously behind corresponding holes in the rails.

Note:

Retainer screws prevent the unit from being pulled out

on its slides accidentally; they are not intended to

support the weight of the unit.

6. Remove the protective adhesive sheet from the screen of the

Industrial Monitor. The sheet is designed to prevent scratching of

the polycarbonate screen protector or the optional touchscreen

during shipping and installation. It should be removed before use.

Publication 6157-UM001A-EN-P

Page 21

Industrial 19" CRT Monitor

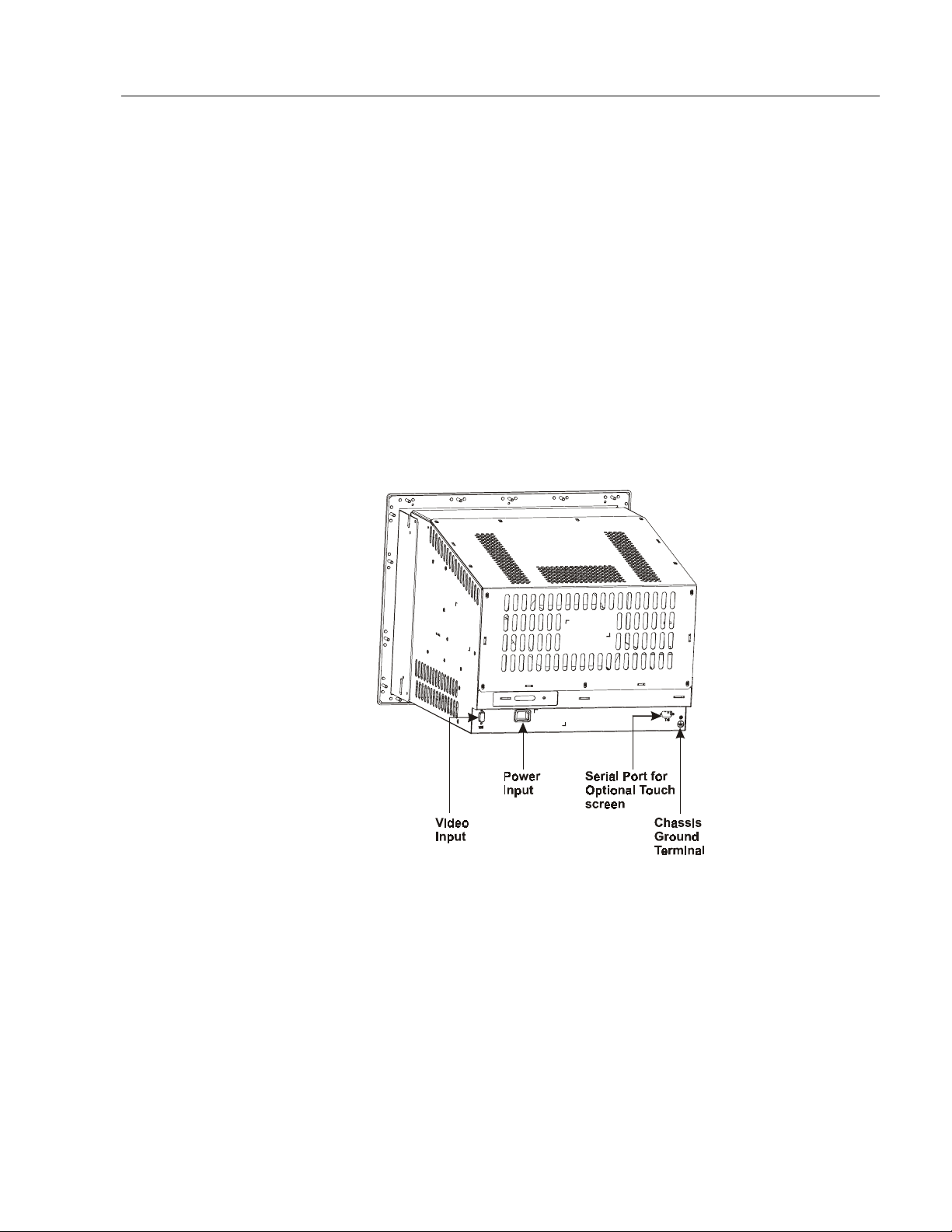

Connecting the 6157- C Industrial Monitor

The rear panel of the 6157- C Industrial Monitor has connectors for

attaching cables to accomplish the following:

Connecting to a host video source

•

(HD-15 VGA or optional HD-15 to BNC adapter)

Connecting to a host t ouc hscreen control port (DE-9 connector)

•

(optional)

Connecting to AC power

•

21

Note:

Some connectors on your monitor may differ from the

following figure.

The following figure illustrates the standard configuration for the 6157C Indu strial Monitor.

Figure 9

Rear Panel

Publication 6157-UM001A-EN-P

Page 22

22

Industrial 19" CRT Monitor

Connecting the Video Source

The video connection to the host is made through a HD-15 (female)

connector or to BNC connectors using a 5-BNC to HD-15 adapter cable.

For more information on using an HD-15 video cable to connect to the

host computer, refer to Appendix B (Page 46).

To establish a signal using the HD-15 connector:

1. Obtain a shielded, properly terminated video cable of length as short

as possible. Longer cables (up to approximately 50 feet in some

cas es) ma y be used, provide d they ar e p roperl y c onst ruc ted. Your

package may include a 6- or 15-foot video cable, if specified.

2. Connect one end of the cable to the female HD-15 video input

connector on the rear panel of the monitor.

3. Conn e ct t h e other end to t he outp ut of any I BM-c ompa tibl e VGA

ada pter or other video generator.

Note:

It may be possible to connect the monitor to video

generator s that do n ot conform to VGA standar ds. The

main requirement is that the generator provide analog

RGB video signals (0.714V or 1V above reference

black into 75 ohms) and separate horizontal and vertical

sync signals. Please contact your Rockwell Automation

representative for more information,

To establish a signal using the BNC to HD-15 BNC adapter cable:

1. Obtain 75-ohm coaxial cables fitted with BNC connectors. Make

su re the c ab les are of equal lengt h .

Note:

A BNC to HD-15 adapter cable is available from

Rockwell Automation for connecting the monitor to a

BNC terminated RGB video source.

2. Connect one end of the cable to the appropriate BNC input

connectors (R, G, B, HS/CS, VS) on the video source.

Note:

The BNC ca bles ar e color coordinated for the red,

green, and blue connectors. The horizontal and vertical

sync connectors are typically gray and black. The

letters H (horizontal sy nc) a nd V ( verti c al s ync) a re

embossed on the plastic covering of the appropriate

connectors.

Publication 6157-UM001A-EN-P

3. Connect the other end to the corresponding connector of the BNC to

HD-15 adapter cable.

Page 23

Industrial 19" CRT Monitor

4. Connect the adapter to the HD-15 video connector on the rear panel

of the monitor.

Connecting the Touchscreen Interface

The serial touc hscreen int erface connection to the host is made throug h

an RS-232 DE-9 (female) connector located on the rear panel.

The optional touchscreen provides a high-resolution touch input system.

Driver software included with the package allows the touchscreen to

function with many popular DOS and Windows

applications as a pointing device (mouse).

®

-based industrial

23

Note:

Refer to the manual included with the touchscreen option

and Appendix A of this manual (page 43) for additional

details on the installation and operation of the touchscreen.

To connect the touchscreen:

1. For units with the touchscreen option, make sure you have one of the

opti onal serial cables .

2. Connect one end of the touchscreen serial cable to the T/S port

connector on the rear of the monitor.

3. Conn e c t th e other end to any serial communica tions port on th e host

computer.

4. Tighten the captive screws on the cable connector to secure it.

Publication 6157-UM001A-EN-P

Page 24

24

Industrial 19" CRT Monitor

Connecting AC Power

The 6157- C Industrial Monitor requires a single-phase power supply

providing 100-130 or 198-264 VAC at 50-60 Hz. Power must be

available at a grounded three-pin outlet located nearby. Whenever

possible, connect the monitor to the same AC source that supplies the

computer.

To connect AC power to the monitor:

1. Turn off the ma in switch or break er.

2. Use the ground terminal of the monitor to establish a chassis-to-earth

ground c onnec tion. Sec ure one e nd of a ground st rap to the ground

terminal. Connec t th e other end of the grou nd st rap to a good earth

ground.

The ground terminal is an M5 screw.

A TTENTION:

Chassis ground must be connected for

safe operation of the monitor. The AC receptacle on th e

monitor is a 3-wire type with chassis ground pin, and the

mating AC cord supplied is a 3-wire type, designed for

connection to a grounded 3-pin AC outlet. However, a

properl y ground AC ou tlet is not always availabl e, and

grounding using a 3-wire cord can easily be defeated. If

you fail to ground the monitor properly, the setup may

resu lt in pers onal i njur y f rom e lectrical shock or damage

to the equipment.

3. Connect the socket end of the AC power cord to the mating

connector on the rear panel of the monitor.

4. Connect the plug end of the AC power cord to the main outlet.

5. Res tore AC p ower t o the outlet.

Publication 6157-UM001A-EN-P

Page 25

Operating the 61 57- C

Industrial Monitor

Industrial 19" CRT Monitor

The 6157- C Industrial Monitor is furnished with operation keys that

allow digita l on-screen adjust ments. On-screen a d justments are

performed from th e on-s cree n display ( OSD) . Using the opera tion keys

on the front panel or rear chassis (depending on the enclosure option),

you can maneuver to the appropriate selection or setting in the menu.

Figure 10

Operation Keys

Select Adjust

Table B

Operation Keys Description Table

25

<

+

-

Control Description

and

>

Arrow keys have several functions:

•

Displays the main menu.

•

If the main menu is displayed, pressing these keys moves the cursor to desired

variable that needs adjusting. Arrow keys to move to the left (<) and to the right (>).

•

Toggles between the control box and any of its secondary control boxes

This operation key:

•

Increases the setting in the control box displayed

•

Closes the main men u w hen the exi t box is hi ghlighted. This acti on memori zes any

settings and completes the adjust ments.

•

Answers “Yes” to questions.

This operation key:

•

Decreases the setting in the control box displayed

•

Closes the main men u w hen the exi t box is hi ghlighted. This acti on memori zes any

settings and completes the adjust ments.

•

Answers “No” to questions.

Publication 6157-UM001A-EN-P

Page 26

26

Industrial 19" CRT Monitor

Status LEDs

The 6157- C Industrial Monitor has two status LED indicators on the

keypad. The following table lists the functions assigned to the LEDs:

Table C

6157- C Industrial Monitor Status LED Indicators

LED Description

Power LE D ( Green ) Indicates that power is applied t o the monitor.

Status LED (Amber) Indicates that the monitor is not receivi ng a video

signal.

Note:

For information on troubleshooting the 6157- C Industrial

Monitor, refer to Page 40.

Auto Degaus s

Degauss is au tomatic ally activated when the dis pla y has b e e n powere d

off for at least 20 minutes and power is applied.

Auto Registr at ion

If adjustments have been made, the new settings are saved after ten

seconds of inactivity when the display automatically closes the windows.

Publication 6157-UM001A-EN-P

Page 27

Industrial 19" CRT Monitor

Self-Test Display

When there is no signal input (no connection), the OSD shows the

following:

Figure 11

Self-Test Display

27

9300K 6500K 5500K

When the synchronization signal is out of specification, the OSD will

sho w c urrent horiz onta l and v erti c al frequency on red image, then

disappear. For example:

106Khz/85.0Hz

Publication 6157-UM001A-EN-P

Page 28

28

Industrial 19" CRT Monitor

Adjusting the On-Screen Display (OSD)

This section explains the on-screen display and explains how to make

oper atio n adjustmen ts.

To display the main menu:

Press

> or <

to display the menu. The on-screen display appears on the

screen.

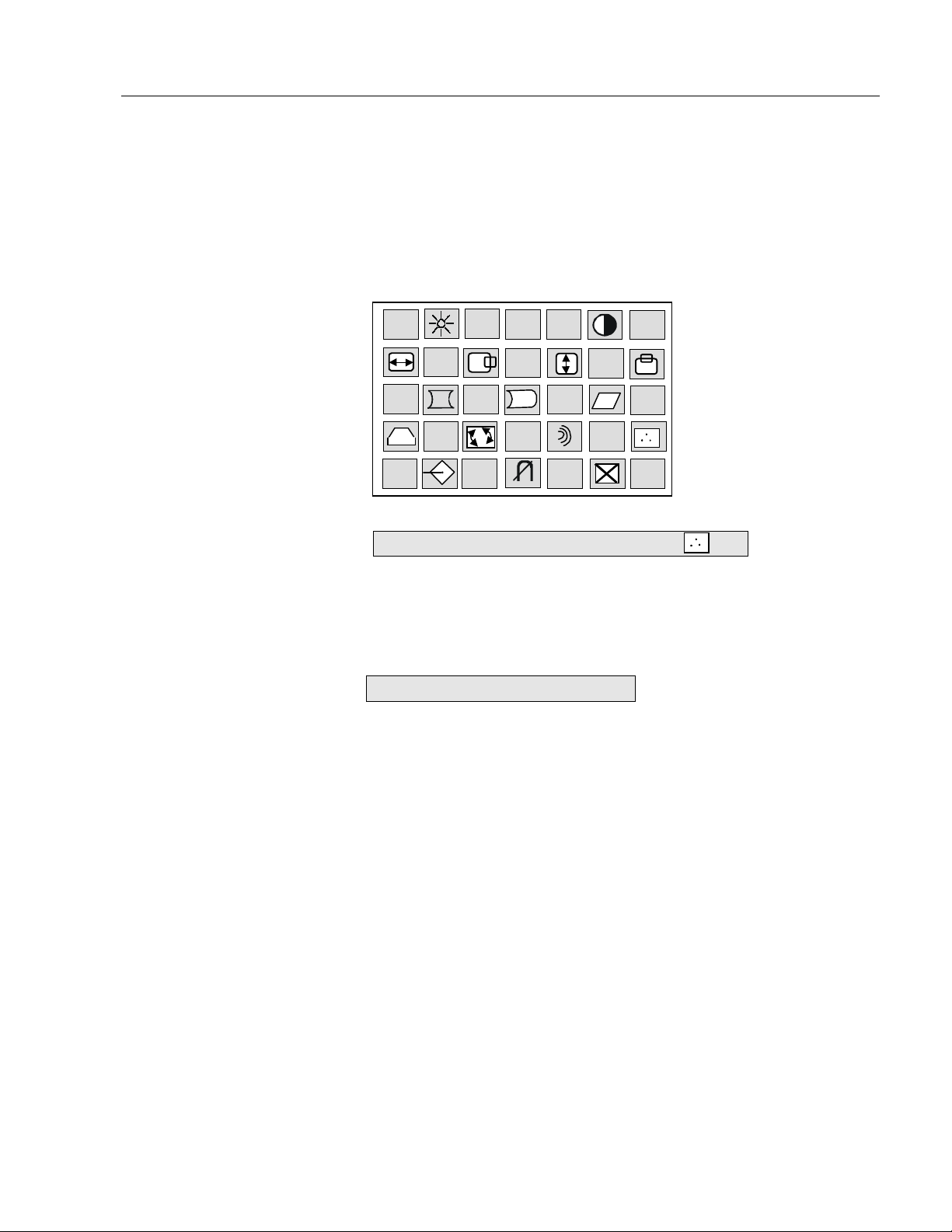

Figure 12

On-Screen Display

You can make all the necessary adjustments by making selections in the

on-sc ree n display using one or all of the operation keys . The f ollow ing

table describes the controls on the on-screen display.

Table D

On-Screen Display Definitions

Publication 6157-UM001A-EN-P

Symbol Control Action

Brightness I ncreases or decreases the intensity

(il luminat ion) of t he im age.

Contrast Increases or decreases the strength

(lightness or di mness) of the i mage.

Horizontal

Sizing

Horizontal

Position

Vertical Sizing Increases or decreases the size of the image

Vertical

Position

Pincushion Adjusts the side pincushion (or barreling)

Pinbalance Adjusts the curvature of the left and right

Increases or decreases the size of the image

horizontally.

Moves images horizontally on screen left (-)

or right (+).

vertically.

Moves images horizontally on screen up (+)

or down (-).

si des of the screen i mag e.

Page 29

Industrial 19" CRT Monitor

Symbol Control Action

Par all el Cor rects the i mag e shap e to a recta ngle.

Trapezoid Corrects the image shape to a rectangle.

29

Rotation

Color Adjusts the color temperature or white

Recall Resets the display settings to their original

Degauss Demagnetizes the CRTs metal frame for

Exit

Cor rects the scr een ti l t . For exam ple, adjusts

the screen image to be horizontally level.

Reduces the opti cal ef fect of wavy lines on

the display image.

balance of the image.

factory val ues.

improved image clarity.

Select Ex it t o close the o n-sc reen d isplay

main window.

Before a dvancing to these a djustments, you need to underst and t he basic

functions of the operation keys. To aid in this understanding, a sample

procedure is provided below:

Sample Procedure

>

1. Display the on-screen display (OSD) window by pressing

>

2. Press

<

to highlight the variable you want to adjust. Refer to

or

or

<.

Table B.

+

3. Press

or – to adjust the variable.

4. Repeat steps 2-3 for any variables you need to adjust.

>

<

5. Press

6. Press

Note:

+

to select the exit icon from the OSD.

or

or – to exit the OSD.

If you do nothing for ten seconds, the display will

automatically close the window, memorize the settings and

complete the adjustments.

Publication 6157-UM001A-EN-P

Page 30

30

Industrial 19" CRT Monitor

Brightness Control

Use the brightness control to adjust the overall intensity of the display.

After allowing the CRT to warm up for at least a minute, adjust for the

least amount of brightness needed to make the display clearly viewable.

Adjust the brightness to match the brightness level in the room so that

the level will be easy to see.

1. Display the OSD.

2. Use the arro w keys (

3. Adjust the brightness value to its lowest setting. (For example, black

background with no text).

4. Adjust the brightness until black changes to dark gray.

5. Adjust the brightness down until the bar changes back to black. This

is the optimal brightness setting given the current lighting

conditions.

Note:

6. Proceed to make oth er adjustment s as necessary.

Note:

Pressing the arrow keys simultaneously while the

brightne ss a dju st me nt box is display e d sets the s tandard

level.

If you wait ten seconds, the display will automatically close

the window, memorize the settings and complete the

adjustments.

> or <

) to select the brightness adjustment box.

Publication 6157-UM001A-EN-P

Page 31

Industrial 19" CRT Monitor

Contrast Control

Use the co n tr as t co ntrol to adju st the differe n ce between the m onitor’s

light and dar k elements. With a suitabl e imag e displayed on the screen,

adj ust t he c ont rast cont rol to achi eve the bes t b alance be tween image

brightness and fine detail rendition.

1. Display the OSD.

31

2. Use the arro w keys (

Note:

3. Press

conditions.

4. Proceed to make oth er adjustment s as necessary.

Note:

Pressing the arrow keys simultaneously while the

contrast adju st me nt box is displa yed s et s the s tandard

level.

+

or – to adjust t he contrast value given the cu rr ent lig hting

If you wait ten seconds, the display will automatically close

the window, memorize the settings and complete the

adjustments.

> or <

) to select the contrast adjustment box.

Horizontal Position

Use the horizontal position controls to center the image horizontally on

the screen.

1. Display the OSD.

2. Use the arro w keys (

+

– t

3. Press

on your screen.

Note:

4. Proceed to make oth er adjustment s as necessary.

Note:

or

You can use the arrow keys (

the horizontal size and horizontal position control

boxes.

If you wait ten seconds, the display will automatically close

the window, memorize the settings and complete the

adjustments.

> or <

o move the image to the left or right until it is centered

) to select the horizontal position box.

> or <

Publication 6157-UM001A-EN-P

) to toggle between

Page 32

32

Industrial 19" CRT Monitor

Horizontal Size

Use the horizontal size controls to makes the image wider or narrower.

Note:

1. Display the OSD.

2. Use the arro w keys (

3. Press

4. Proceed to make oth er adjustment s as necessary.

Note:

Before adjusting the horizontal size, you must first center

the image in the screen using the horizontal position

controls.

Pressing

horizontal position control boxes.

+

or – narrow or widen the image on your screen.

> toggles between the horizontal size and

> or <

If you wait ten seconds, the display will automatically close

the window, memorize the settings and complete the

adjustments.

) to select the horizontal size box.

Vertical Position

Use the vertical position controls to center the image vertically on the

screen.

Publication 6157-UM001A-EN-P

Note:

1. Display the OSD.

2. Use the arro w keys (

3. Press

screen.

4. Proceed to make oth er adjustment s as necessary.

Note:

Pressing

position control boxes.

+

or – to move the image up or down until it is centered on the

> toggles between the vertical size and vertical

> or <

If you wait ten seconds, the display will automatically close

the window, memorize the settings and complete the

adjustments.

) to select the vertical position box.

Page 33

Industrial 19" CRT Monitor

Vertical Si ze

Use the vertical size controls to make the image taller or shorter.

33

Note:

1. Display the OSD.

2. Use the arro w keys (

3. Press

4. Proceed to make oth er adjustment s as necessary.

Note:

Before adjusting the vertical size, first center the image in

the screen.

> or <

+

or – key heighten or shorte n the image on th e screen.

If you wait ten seconds, the display will automatically close

the window, memorize the settings and complete the

adjustments.

) to select the vertical size box.

Vertical Pincushion

Use the vertical pincushion controls to correct the image for barrel or

pincushion distortion.

1. Display the OSD.

2. Use the arro w keys (

+

3. Press the

4. Proceed to make oth er adjustment s as necessary.

Note:

or – key to straighten the sides of the screen image.

If you wait ten seconds, the display will automatically close

the window, memorize the settings and complete the

adjustments.

> or <

) to select the vertical pincushion box.

Publication 6157-UM001A-EN-P

Page 34

34

Industrial 19" CRT Monitor

Trapezoid

Use the trapezoid controls to correct trapezoidal distortion of the image.

1. Display the OSD.

2. Use the arro w keys (

+

– t

3. Press

screen.

4. Proceed to make oth er adjustment s as necessary.

Note:

or

If you wait ten seconds, the display will automatically close

the window, memorize the settings and complete the

adjustments.

> or <

o make the image w ider or narr ower at t he t op of the

) to select the trapezoid box.

Pinbalance

Use the pinbalance controls to adjust the curvature of the left and right

sides of the screen image.

1. Display the OSD.

2. Use the arro w keys (

+

3. Press

the image until the sides of the image are straight.

or – key to adjust the curvature at the left and right sides of

> or <

) to select the pinbalance box.

Publication 6157-UM001A-EN-P

4. Proceed to make oth er adjustment s as necessary.

Note:

If you wait ten seconds, the display will automatically close

the window, memorize the settings and complete the

adjustments.

Page 35

Industrial 19" CRT Monitor

Parallelogram

Use the parallelogram controls to correct parallelogram distortion of the

image on the screen.

1. Display the OSD.

35

2. Use the arro w keys (

+

3. Press the

4. Proceed to make oth er adjustment s as necessary.

Note:

or – key to skew the image to the left or right.

If you wait ten seconds, the display will automatically close

the window, memorize the settings and complete the

adjustments.

> or <

) to select the parallelogram box.

Rotation

Use the rotation controls to adjust for tilt of the image on the screen.

1. Display the OSD.

2. Use the arro w keys (

3. Press the

4. Proceed to make oth er adjustment s as necessary.

+

or – key to adjust the tilt of the image on the screen.

> or <

) to select the rotation box.

Note:

If you wait ten seconds, the display will automatically close

the window, memorize the settings and complete the

adjustments.

Publication 6157-UM001A-EN-P

Page 36

36

Industrial 19" CRT Monitor

Color Temperature

Use the color temperature controls to adjust the color white in an image

(in Ke l vin ). The higher t he temperature, the red der, or war m er, t h e image

color sc hem e. The lower t he temperature, t h e bluer, o r co ld er, t he image

color scheme.

1. Display the OSD. Press

2. Press

>

<

to move to the color control icon.

or

+

or – to select the color icon. The following appears:

9300K 6500K 5500K

Note:

3. Press

4. Press

screen color adjustment window will appear.

5. Press

+ or –

three color variables.

Before making any ad justments , record t he init ial color

setting because memory recall will not reset this value.

>

or <

+

or – to enter your choice. If you select the color icon, the

> or <

to adjust the selected value. Repeat this step to adjust all

to choose 9300K, 6500K, 5500K, or the color icon.

to select R (red), G (green), or B (blue) and then press

Publication 6157-UM001A-EN-P

6. Press the

return to the OSD main window. The window closes automatically

after ten seconds.

> or <

keys to select the exit icon, then press + or – to

Page 37

Industrial 19" CRT Monitor

Recall

Use this option to reset the display settings to their original factory

values.

1. Display the OSD.

2. Use the arro w keys (> or <) to select the recall box.

+

3. Press the

factory settings.

or – key to reset the display values to their original

Degauss

The display screen is degaussed automatically each time the monitor is

powered on. This degaussing eliminates color impurities and other

distort ions of the display b y neutralizin g the e ffect s of ma gnet i c fie lds i n

the surrounding environment.

37

When the unit is left on for a long period, or is repositioned following

power-up, the screen may pick up additional magnetic flux, causing

colors to appear "blotchy" or otherwise distorted. For full effectiveness,

allow at least 20 minutes between manual degaussings. Shorter intervals

may r es ult i n an incomplet e removal of flux and residual color

impurities.

Note:

Note:

The degauss ing operates f or a pprox imatel y f ive seco nds a fter selecti on.

In this durat ion, t he front panel keys are not oper ati onal.

The internal degauss will not prevent color impurities

caused by local magnetic fields. Metal enclosures can

easily become magnetized by welding and machinery

operations.

Use a hand held degaussing coil to remove residual

magnetism from the enclosure.

If the unit is located near electric transformers, motors,

loudspeakers or other strong magnetic sources, degaussing

alone may not be sufficient to eliminate interference. Try

reorienting the unit relative to the magnetic source or

moving the monitor further away.

If this still does not solve the problem, contact Rockwell

Automation about magnetic shielding.

Publication 6157-UM001A-EN-P

Page 38

38

Industrial 19" CRT Monitor

Exit

Use the ex i t icon on the scree n to close the OSD main window.

1. Display the OSD.

2. Use the arro w keys (

+

3. Press the

Note:

or – key to exit the OSD.

If you wait ten seconds, the display will automatically close

the window, memorize the settings and complete the

adjustments.

> or <

) to select the exit box.

Publication 6157-UM001A-EN-P

Page 39

Industrial 19" CRT Monitor

Routine Maintenance

Cleaning

Occasionally clean the display panel and cabinet with a soft cloth

dampened (not soaked) with a mild (non-abrasive) glass cleaner. Keep

turning a fr es h sid e of the cloth toward the screen s urf ace to avo i d

scratching it with accumulated grit.

39

Note:

Special care should be t aken when cleanin g a tou c hscreen or

polycarbonate shield that is installed over the screen. Abrasive and

certain chemical cleaners can easily damage the surface.

Note:

The solvent should be applied only to the cloth, and not

directly on the monitor screen. Do not use paper products

as they may scratch the surface. To minimize the risk of

abrasion, allow the screen to stand dry.

For best results cleaning a monitor with the optional

antireflective tempered glass display shield, a solution of

denatured alcohol is recommended to thoroughly clean the

display.

Replacing a Line Cord

To avoid shock and fi re hazards, the monitor’s po w er cor d should b e

replaced if the insulation becomes broken or if it develops a loose

internal co nnection.

Fuse Replacement

The 6157- C Industrial Monitor is equipped with one fuse, which can be

replaced by a qualified technician.

A TTENTION:

areas that can present dangerous voltages. Always

disconnect the AC power cord and wait one minute

before attempting fuse replacement. Replace the rear

cover before restoring power to the monitor.

The fuse is located inside the monitor chassis, mounted on the main

board in front of the IEC320 power connector. To access the fuse, you

must remove the rear cover of the unit. Replace the fuse as required with

a 5X20mm , T4AH 250V fuse.

Fuse replacement requires work in

Other Maintenance

Qualified service personnel should perform all maintenance, except for

the power cord replacement described above.

Publication 6157-UM001A-EN-P

Page 40

40

Troubleshooting

Industrial 19" CRT Monitor

You can refer to this table to help identify the cause and offer a solution

to a problem. This table lists typical problems you may encounter.

Table E

Troubleshooting Table

Sympto m Possib le Pr ob l e m Action

No screen image and the green power

LED is not lit.

The green power LED is lit, but no screen

image when power switch is closed.

The amber status LED is lit, and no

screen im ag e.

No raster vis i bl e ev en when brightn ess

and contrast are set full ON.

Raster di m l y vis ib l e wit h br ig ht ness and

contrast controls set full ON, but no

displ ay pr esent

Display is pr esent, but garbled or r olli ng Monitor not s ync h ed to video

Display is present and stable, but appears

“wrapp ed” at on e si d e or oth erw ise not

properly centered or sized.

Display is present and stable, but missing

some color(s)

Display is present and stable, but colors

are not pur e

Power cord not connected.

No power av ail able at AC ou tl et. Test AC outl et b y plu gg ing in a lamp or oth er

Power cord faulty. Replace power cord. Refer to Page 39.

Blown fuse. Have moni tor serviced.

Monitor f aulty. Have moni tor serviced.

Screen saver or power

manag em en t feature act ivated.

Brightness and contrast controls

not proper l y ad jus t ed.

Monitor n ot s ync h ed t o video

sourc e.

Monitor f aulty. Have moni tor serviced.

Monitor ou t of ad jus t m ent or

faulty.

Video cab l e pr ob l em. Check f or pr oper instal l at i on of vi deo cable( s ).

Fault in vid eo s our ce. Test vid eo s our ce by conn ect in g to anoth er

Fault in mon itor. Have moni tor serviced.

sourc e.

Size and pos it i on controls n ot

properly adjusted.

Video cab l e pr ob lem. Check for prop er vi d eo c ab le instal l ation.

Fault in mon itor. Have moni tor serviced.

Monitor requires degaussing. Manually degauss the monitor. Refer to

Enclos ur e r equ ires degaus s ing.

Open power switch. Reconnect power cord at

monitor an d at A C outlet. Cl ose power sw itc h.

known good device.

Disable screen saver by activating an input to the

host sys t em. Pr ess a ke y or m ove the mous e t o

cance l power save mode.

Adjust brightness and contrast controls.

Check f or pr oper video c ab le instal l ati on. Replace

suspected faulty cable.

Check to ens ure that vid eo s ou r ce is operati ng

within th e m oni t or ’s rang e.

Have moni tor serviced.

Refer to installation instructions.

Replace suspected faulty cable(s).

monitor th at is kn own t o b e op erat i on al .

Refer to installation instructions.

Check f or pr oper video c ab le instal l ati on. Replace

suspected faulty cable.

Check to ens ure that vid eo s ou r ce is operati ng

within th e m oni t or ’s rang e.

Adjust c ontrols f or pr op er siz e an d positi on of

displ ay. R ef er to op erator instructi ons

Replace suspected fau lty cable.

Check vid eo s our ce.

Page 37.

Manual l y deg aus s th e enc losure. R ef er t o Pag e

37.

Publication 6157-UM001A-EN-P

Page 41

Sympto m Possib le Pr ob l e m Action

Display is pr esent, but “ jit ters” or is

severely distorted

Do not confuse the flicker

NOTE:

associated with an interl ac ed video m od e

with jitter.

Display is present, but “bars” appear

across it.

Connected monitor to computer. When

powered, the PC locked up

Interf eri ng e xternal AC or DC

magnetic shield

“Noise” generated by other

equipment in the environment is

present at t h e vi d eo inputs

Graphics card driver is not

compatible with monitor

Industrial 19" CRT Monitor

If possible, reposition the monitor beyond the

proximity of large transformers, motors, bus bars,

etc.

Ask Rock w ell A ut om ation ab ou t various shi el di ng

options avai l able to prot ect the mon it or .

Consult the application note that discusses

methods of eli m in ating noise.

Update t h e grap hic s card drivers t o th e lat est

version.

41

Publication 6157-UM001A-EN-P

Page 42

42

Allen-Bradley Support

Industrial 19" CRT Monitor

Allen-Bradley offers support services worldwide, with over 75

Sales/Support Offices, 512 authorized Distributors and 260 authorized

Systems I ntegrators located throughou t th e United States alone, plus

Allen-Bradley representatives in every major country in the world.

Local Product Support

Contact your local Allen-Bradley representative for:

Sales and order support

•

Product technical training

•

Warranty support

•

Support service agreemen ts

•

Refer to the Rockwell Automation/Allen-Bradley Internet site at

http://www.a b. com for local contact information.

Technical Product Assistance

If you need to contact Allen-Bradley for technical assistance, please

review the information in the Troubleshooting section first. Then call

your local Allen-Bradley representative or contact Allen-Bradley

technical support at (440) 646-5800.

For additional product information and a description of the technical

services available, visit the Rockwell Automation/Allen-Bradley Internet

site listed above.

Publication 6157-UM001A-EN-P

Page 43

Industrial 19" CRT Monitor

Description

Setting Up the

$

$SSHQGL[ $

SSHQGL[ $

,QWHUIDFH

,QWHUIDFH

All touch controllers are configured by default to provide serial

communications at 9600 baud, 8 data bits, 1 stop bit, no parity.

For Allen-Bradley monitors equipped with touchscreens, a serial

communications cable is r equ ired. A suitable cable can b e obta i n ed fr o m

Roc kwell Automa ti on or you can c reate one.

The cable provides a communications channel between the touchscreen

controller, which is mounted inside the monitor, and an RS-232-C serial

port on the host computer. Because the touch controller obtains power

from the monitor's power supply, no external touch power connections

are necessary.

7

7RX

RXF

FKVF

KVFU

UHHQ 6

HHQ 6H

HULDO

ULDO

43

Touchscreen Interface

Software supplied with the touchscreen must be loaded on the host

computer to handle communications with the touch controller over the

channel.

Becau se the tou chsc reen e m ulates a mouse, there may be c ompat i bility

issues involving how the touchscreen emulates mouse buttons, especially

multiple buttons. For a complete discussion of these issues and how to

troubleshoot them, refer to the touchscreen documentation.

This section describes how to set up the touchscreen system using the

6157- C Industrial Monitor. Setup involves the following:

Enabling the touchscreen interface

•

Installing the software on the host computer that will handle

•

communications with the touchscreen controller

Performing a calibration

•

Publication 6157-UM001A-EN-P

Page 44

44

Industrial 19" CRT Monitor

Enablin g th e T ouchscr e en Int er f a c e

The 6157- C Industrial Monitor provides a female DE-9 connector on the

rear panel. This connector provides the serial interface for the touch

controller.

Interconnecting wiring to the host serial port connection is shown in the

following table.

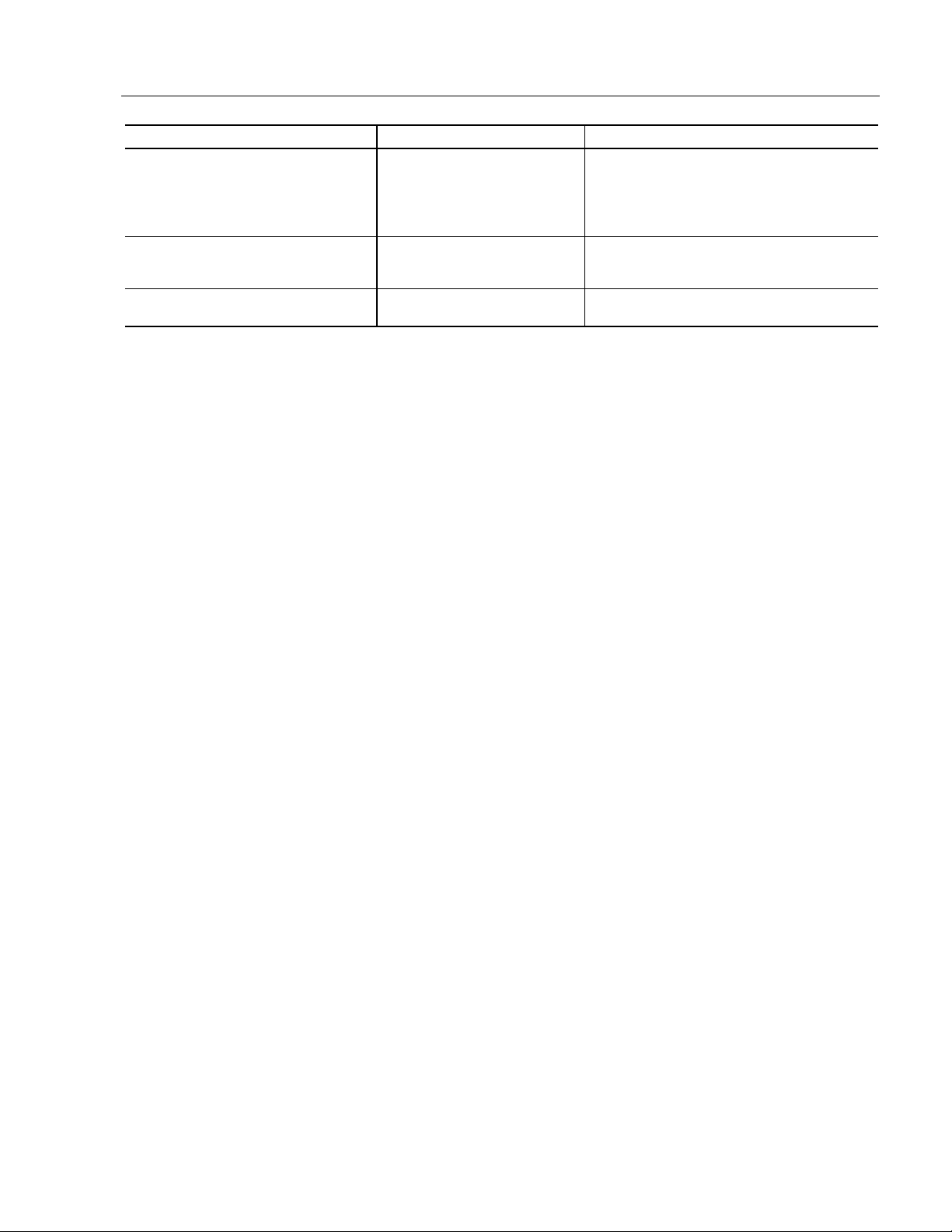

Table F

Touchscreen Interface

Monitor

(DCE Device) Host (DTE Device)

DE-9 (Female) Signal Description DE-9 (Male) DB-25 (Male)

1 Not Connected (DCD) 1 8

2 Transmit Data (TXD) 2 3

3 Receive Data (R XD) 3 2

4 Data Terminal Ready (DTR) 4 20

5 Common Signal Return (SG) 5 7

6 Not Connected ( DSR) 6 6

7 Request To Send (RTS) 7 4

8 Clear To Send (CTS) 8 5

9 Not Connected 9 22

Installing the Touchscreen Driver Software

To install the touchscreen driver software correctly, obtain the following

information about the host hardware:

The COM port in use for the touchscreen. Ensure that the RS-232

•

cable is properly installed between the monitor port and the host’s

COM port.

The baud rat e a t whic h the c o ntroller is operating. You will need to

•

match the baud rate at the COM port. The controller baud rate is

factory set at 9600.

Note:

If you are using older touchscreen software, you may be

prompted for the type of touchscreen controller being used.

The 6157-C uses the following controllers:

Resistive: Elo TouchSystems Model E271-2210

•

Capaciti v e: MicroTouch Model SMT-3

•

SAW: Elo TouchSystems Model 2310 Serial

•

Publication 6157-UM001A-EN-P

Page 45

Industrial 19" CRT Monitor

Performing a Calibr at ion

Once you have obtained this information, install the software using the

installation disks found in the touchscreen accessory package.

45

Note:

Before installation, you may want to check the touchscreen

manufacturer’s site on the World Wide Web for the latest

sof tware dr ivers . E nter thes e ad d res ses in your Internet

browser:

www.elotouch.com for resistive and SAW touchscreens

•

www.microtou ch.co m for capacitive touchscr eens.

•

After installing the driver software, follow the instructions in the

touchscreen documenta t i o n.

Following installation of the touchscreen software and calibration, the

touchscreen is ready to us e.

Publication 6157-UM001A-EN-P

Page 46

46

HD-15 Con ne ct or s

Industrial 19" CRT Monitor

$

$SSHQGL[ %

SSHQGL[ %

You can connect the 6157- C Industrial Monitor to the host computer

with an HD-15 connector or with a BNC to HD-15 adapter cable.

An HD-15 video cable equipped with a conventional HD-15 connector at

each end connects the 6157- C Industrial Monitor to the host computer.

9

9LGHR &

LGHR &D

DEOHV

EOHV

Note:

Figure 13

HD-15 Video Connector

The following table provides the pin numbers and corresponding pin

assignme nts for t he H D - 15 video connector with the DDC2B ca p ability:

Table G

Standard HD-15 Video Cable

Monitor (Fema le) Signa l Description Host (Male)

This figure is the view looking into the pin end of the male

connector or solder term end of the female connector.

1Red Video 1

2 Gr een Vi deo 2

3Blue Video 3

4 Ground 4

5 Ground 5

6 Red Video Ground 6

7 Green Video Ground 7

8 Blue Video Ground 8

9Not Used 9

10 Sync G round 10

11 Ground 11

12 Bi-Direct ional Data (SDA) 12

13 Horizontal Sync 13

14 Vertical Sync (VCLK) 14

15 Data Clock (SCL) 15

Publication 6157-UM001A-EN-P

Page 47

Industrial 19" CRT Monitor

BNC Connectors

The BNC cables you use with this monitor uses a conventional HD-15

connector at the monitor end to connect the 6157- C Industrial Monitor

to the host computer with five BNC connectors:

47

• R, B

, and G: Red, Green, and Blue input connectors to establish

color. T h ese are used for RS-343 analog si gnals .

• HS/CS

: Separate horizontal/composite sync signal from the video

source.

: Separate vertical sync signal from the video source.

• VS

Figure 14

BNC Video Connector

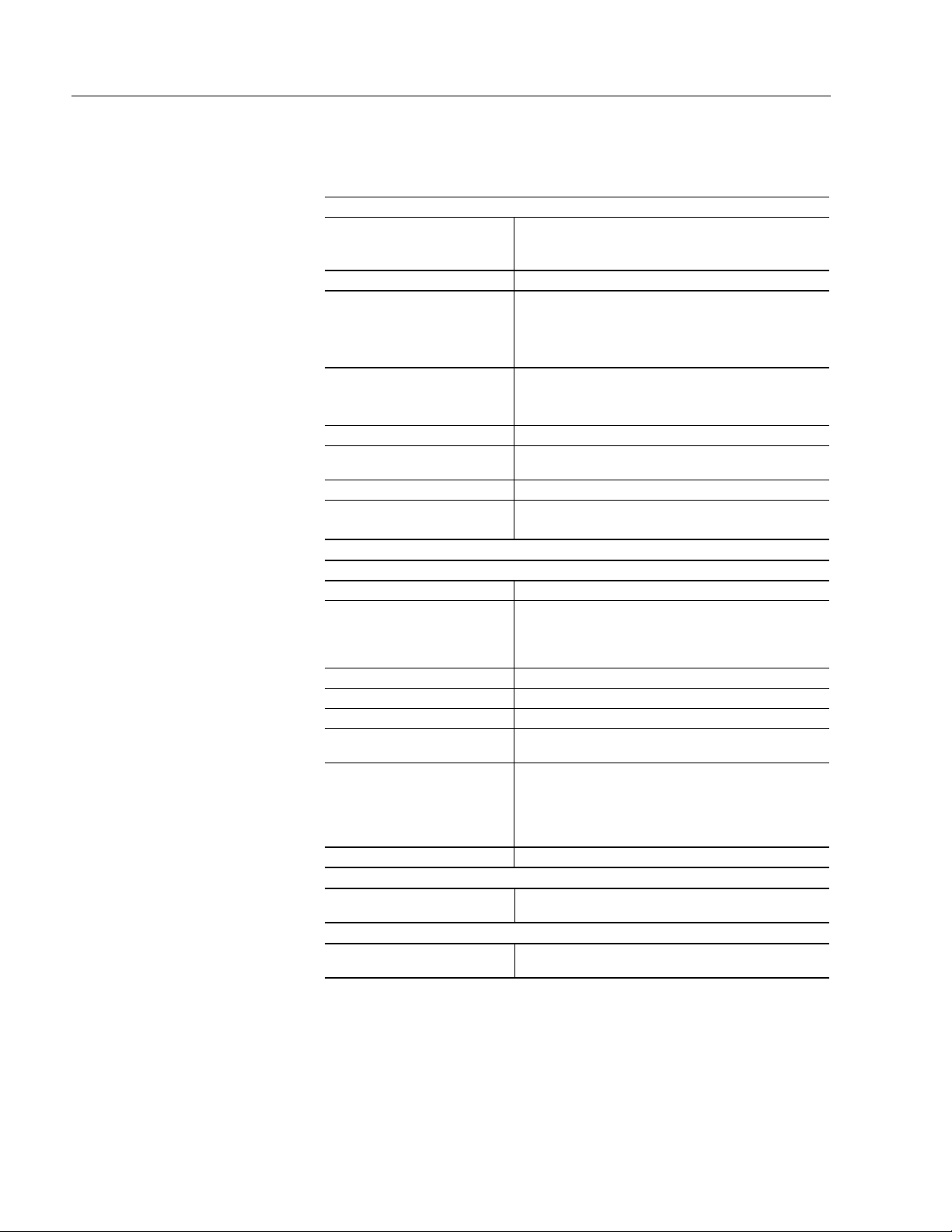

The following table describes the signal types you can use with these

BNC connectors:

Table H

BNC Signal Types

BNC Signal Type Description R G B HS/CSVS

Sync-on-Green Use the three video connectors. Horizontal

and vertical syncs are supplied on the green

video line.

Separate

Composite Sync

Separate

Horizontal and

Vertical Sync

Use the three video connectors plus the

horizontal sync/composite sync input.

Use the three video connectors plus the

horizontal sync/composite sync and vertical

sync input.

XXX

XXXX

XXXXX

Publication 6157-UM001A-EN-P

Page 48

48

Specific ations

Industrial 19" CRT Monitor

Display

CRT Type 19 in. diagonal pure flat, 0.25mm dot pitch

Degauss in g Manual and au t om at ic

Nominal Displa y Area

(4:3 aspect) Horizontal

(4:3 aspect) Vertical

Diagonal

Non Linearity (CHP Method)

Horizontal

Vertical

Regul ati on 2mm m ax peak de vi ati o n

Misconvergence 0.3mm max inside (centered circle 225mm diameter)

Lumin ance (typical) 35 fL, small wh it e squ are

CIE coordinates

White x:=0.283, y:=0.298 (9300K +8MPCD)

RGB short persistence, Anti-glare treated, Anti-static,

INVAR shadow mask

14.17 in. (360mm)

10.63 in. (270mm)

17.72 in. (450mm)

7% max

6% max

0.4mm m ax ou t s id e

Video

Resolut i on 1600x1200 m ax at 7 5H z ma x

Supported Standards IBM VGA (640x480 at 60Hz, 720x400 @ 70 Hz )

VESA (640x480 at 60/75/85H z, 800x6 00 at

60/75/85 Hz, 1024x768 at 60/75/85 Hz, 1280x1024 at

60/75/85 Hz, 1600x1200 at 75 Hz)

Horizontal Scan Rate Variable: 30-98kHz

Vertical Scan Rate Variable: 50H-160Hz

Video D ot R ate 210MHz

Video Input Signal RGB analog (white level = 0.714V above ref. black,

Sync Input Signals

Input Connection HD-15, Plug and Play DDC1/2B

Controls and Indi cat or s

Operator Input

into 75 Oh ms , sin gl e ended)

Separate horizontal and vertical sync control,

•

TTL signal levels

Sync on green

•

Composite sync

•

Front Panel: On-Screen Display, Power, Sync

detection

Touchscreen Option: Resistive, capacitive, or SAW

touchscreen, with serial controller and driver software

Publication 6157-UM001A-EN-P

Page 49

Industrial 19" CRT Monitor

Environmental

Panel Rating

Panel Mount

Rack Mount

Operati ng Temperat ure 0ºC to 40ºC

Storage Temperature -20ºC to 60ºC

Relati ve Hu midit y 10 % to 90% non-condens i ng

Operati ng Al tit ude S ea lev el to 10,000 ft (3, 04 8 m)

Non-Operating Altitude Sea level to 40,000 ft (12,192m)

Operating Electrostatic

Discharge

Non-Operating Electrostatic

Discharge

Opera ting Shock 10g (1/2 sine, 11msec)

Non-Operating Shock 20g (1/2 sine, 11msec)

Operating Vibration 0.003in. p-p, 5-57Hz,

Non-Operating Vibration 0.006in. p-p, 5-57Hz,

Electrical

Line Volt age 10 0- 1 30 /198-26 4 VA C, au t os witching

Line Frequ ency 50-60H z

Ground Leakage 1.0 uA max at 1.5K VDC

Power Consumption 135W max

NEMA 4/4X/12, (IP65/IP52) (6157-CE/6157-CF)

NEMA 1 (IP10) (6157-CB)

8.0K VDC (IE C 801-2, l evel 3)

20.0K VDC

0.5g peak, 57-640Hz sine

1.0g peak 51-640Hz sine

49

Physical

Panel Mount

Panel Bezel Dimensions

(W x H x D)

Overall Dimensions (from

rear surface of front panel

to back)

Net Weight 64lb (29.0kg)

Rack Mount

Panel Bezel Dimensions

(W x H x D)

Overall Dimensions (from

rear surface of front panel to

back)

Net Weight 64lb (29.0kg)

Certifications - Agency Approvals

LVD (73/2 3/ EEC ) EN 609 50 (per UL 195 0 3rd ed. w ithout D3 d ev. )

EMC (8 9/336/EEC)

Emissions

Immunity

19.0 in. x 15.7 in. x 0.43 in. (483m m x 39 9m m x

11mm)

16.75 in. x 14.0 in. x 18.1 in. (426mm x 356mm x

460mm)

19.0 in. x 15.7 in. x 0.4 in. (482mm x 399mm x 10m m)

16.75 in. x 14.0 in. x 18.2 in. (426mm x 356mm x

462mm)

UL 1950 Recognized Component,

C-UL 950 R ec og ni z ed C om p on ent

EN 50081-2

EN 50082-2

Australia n C-Tick

DHHS

DHHS 21 CFR 1020.10 Compliant

FCC Class A

Publication 6157-UM001A-EN-P

Page 50

IBM is a registered trademar k of In ternational Business Machines Cor poration.

VGA is a trademar k of International Business Mach ines Corporation.

PC AT is a tradem ark of International Business Machines Corporat ion.

Microsoft is a registered trademark of Microsoft Corporation.

Microsoft Windows is a tr ademark of Microsoft Corpor ati on.

Chassis-Trak is a registered trademar k of the General Devices Company.

Rockwell Automati on helps its customers receive a sup erior retu rn on their in vestment b y bri nging

together leading br an ds in i ndustrial autom ation, creatin g a broad spect rum of easy-to-int egrate

products. T hese are supported by l ocal technical resources availabl e worldwide, a global n etwork of

system s olutions provi ders, and the advanced technology resources of Rockwell.

Worldwide representation.

Argentina • Australia • Austria • Bahrain • Belgium • Bolivia • Brazil • Bulgaria • Canada • Chile • China, People’s Republic of • Colombia • Costa Rica • Croatia • Cyprus • Czech

Republic • Denmark • Dominican Republic • Ecuador • Egypt • El Salvador • Finland • France • Germany • Ghana • Greece • Guatemala • Honduras • Hong Kong • Hungary

Iceland • India • Indonesia • Iran • Ireland • Israel • Italy • Jamaica • Japan • Jordan • Korea • Kuwait • Lebanon • Macau • Malaysia • Malta • Mexico • Morocco • The Netherlands

New Zealand • Nigeria • Norway • Oman • Pakistan • Panama • Peru • Philippines • Poland • Portugal • Puerto Rico • Qatar • Romania • Russia • Saudi Arabia • Singapore

Slovakia • Slovenia • South Africa, Republic of • Spain • Sweden • Switzerland • Taiwan • Thailand • Trinidad • Tunisia • Turkey • United Arab Emirates • United Kingdom • United

States • Uruguay • Venezuela

Rockwell Automation Headquarters, 1201 South Second Street, Milwaukee, WI 53204-2496 USA, Tel: (1) 414 382-2000, Fax: (1) 414 382-4444

Rockwell Automation European Headquarters, Avenue Hermann Debroux, 46 1160 Brussels, Belgium, Tel: (32) 2 663 06 00, Fax: (32) 2 663 06 40

Rockwell Automation Asia Pacific Headquarters, 27/F Citicorp Centre, 18 Whitfield Road, Causeway Bay, Hong Kong, Tel: (852) 2887 4788, Fax: (852) 2508 1846

World Wide Web: http://www.ab.com

998078-010

Publication 6157-UM001A-EN-P

Copyright 2000 Rockwell Automation Corporation. All rights reserved. Printed in USA.

•

•

•

Loading...

Loading...