Page 1

Industrial 20" CRT Monitor

(Bullet in 61 57)

Installation and User Manual

Page 2

2 Table of Contents

7

7D

DEOH R

EOH RI

Industrial 20" CRT Monitor.............................................. 3

Description........................................................................... 3

Package Contents................................................................. 4

Installing the 6157 Industrial Monitor ................................... 5

Panel Mounting.................................................................... 6

Connecting the 6157 Industrial Monitor................................ 12

Operating the 6157 Industrial Monitor.................................. 16

Routine Maintenance............................................................ 20

Troubleshooting................................................................... 23

Appendix A: Touchscreen Serial Interface........................ 25

Description........................................................................... 25

Setting Up the Touchscreen Interface.................................... 25

Performing a Calibration...................................................... 27

Appendi x B : Video Ca bl es ................................................. 28

HD-15 Connectors ............................................................... 28

BNC Connectors.................................................................. 29

Specifications...................................................................... 31

I &RQWH

&RQWHQ

QWV

WV

Important U s er Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. "Safety Guidelines for the Application, Installation, and

Maintenance of Solid State Controls" (Publication SGI-1.1) describes some important

differences between solid state equipment and hard-wired electromechanical devices.

Because of this difference, and because of the wide variety of uses for solid state

equipment, all persons responsible for applying this equipment must satisfy themselves

that each intended application of this equipment is acceptable.

In no event will Rockwell Automation be responsible or liable for indirect or

consequential damages resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes.

Because of the many variables and requirements associated with any particular

installation, Rockwell Automation cannot assume responsibility or liability for actual

use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation with respect to use of the

informat ion, cir cuits, equipment, or s of twar e described in this manu al.

Reproduction of the contents of this manual, in whole or in part, without written

permission of Rockwell Automation is prohibite d.

Throughout this manual, we use notes to make you aware of safety considerations.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death,

property damage, or economic loss.

Important:

application and understanding of the product.

Identifies information that is espe cially imp ortant for succe ssful

Publication 6157-5.1

Page 3

,QGXVWULDO

,QGXVWULDO

&57 0RQLW

Industrial 20" CRT Monitor 3

&57 0RQLWR

RU

U

Description

The Bulletin 6157 20" Industrial CRT Monitor is a general purpose

monitor suitable for a wide range of industrial computing applications. It

offers the following features:

• Versatile multi-sync interface (640 x 480 to 1280 x 1024 resolution)

• High-contrast INVAR mask tube

• Reliable and rugged industrial design

• Durable NEMA 4/4X/12 front panel

• Full y- i nt egrat ed dig it a l des ig n

• Microprocessor communications port for remote control of all

monitor functi ons.

ATTENTION: The equipment described in this

document generates, uses, and emits radio frequency

energy. The equipment has been t ested and found to

comply with FCC Rules, Part 15, subpart J, for Class A

computing devices.

The use of non-shielded interface or power cords with

All e n-Bradley indust rial monitor s is prohibited.

ATTENTION: X-ray emissions from these monitors are

typically about 0.05 mR/hr maximum, well below the 0.5

mR/hr maximum rec ommend e d by the US. Departme nt of

Heal th and Human Resour ces an d specif ied i n "Federal

Perf orman ce Standar ds for Television R e ceiv ers", Section

10, Part 1020, Title 21, of the U. S. Code of Regulation

(PL90-620), Vol. 38, No. 198.

These m onitors are equip ped wit h X-ray protection

circuits which cause automatic shutdown of the

equipment i n cas e its X-r ay emissions begin to ap pr oach

Feder al limits .

Publication 6157-5.1

Page 4

4 Industrial 20" CRT Monitor

Availab l e O pt ions

The following options are available to the 6157 Industrial Monitor:

Video interface options (HD-15, 5 BNC)

•

Touchscreen options (r esist i v e, ca p acitive)

•

Touchscreen cable optio ns

•

Video ca ble options

•

Power cord options

•

Magnetic shield options

•

Package Contents

The monitor shipping carton contains the following items:

Monitor

•

Pa cka g e of mou nt i ng ha r dwa r e

•

AC power cord (optional)

•

Video cable (optional)

•

This user manual

•

A 6157 Industrial Monitor with a touchscreen option is shipped with

these additional items:

Supporting software and manuals

•

RS-232 serial extension cable (optional)

•

Un packing the Unit

Before unpacking a new monitor, inspect the shipping carton for

damage. If damage is visible, immediately contact the shipper and

request assistance. Otherwise, proceed with unpacking.

Publication 6157-5.1

Note:

Make s ure you keep t he ori ginal packagin g f or the monitor

in case you need to return the monitor for repair.

Page 5

Industrial 20" CRT Monitor 5

Installing the 6157 Industrial Monitor

This section describes how to install the monitor.

Tools Needed

In addition to the tools required to make the cutout, you will need the

following tools:

3/8” Deep Well Socket

•

1/4” Drive Extension - 12” or longer

•

1/4” Drive Ratchet or 1/4” Drive Torque Ratchet

•

Before Installation

When installing the unit, it is important to consider environmental

factors at the site that could affect performance as well as possible

effects from equipment operation on personnel and nearby equipment.

Following the guidelines will help ensure that the monitor will provide

safe and reliable service.

Ensure that sufficient power is available from a single phase AC

•

outlet at the site.

Ensure that sufficient space is available around air inlets and outlets

•

to provide the circulation necessary for cooling. Never allow air

passages to become obstructed. The monitor is equipped with a fan

to ensure proper cooling.

• Dust and smoke part icl es ca n ca us e pr obl ems , s ince they can collect

at ventilating holes in the enclosure and interfere with cooling.

Accordingly, wh ere dust and smoke are probl ems it is esp ecia lly

important to keep air vents clean. Refer to the Routine Maintenance

section (Page 20) for more information.

Ensure that the ambient air temperature will not exceed the

•

specified maximum temperature. A user supplied fan, heat exchanger

or air conditioner may be required to meet this condition in some

installations.

Leave the m onitor’s enclosure or cover in place at all times during

•

oper ation. The c over affords prote c tion agai nst hig h voltages inside

the monitor and inhibits radio-frequency emissions that might

interfere with other equipment.

The Federal Communications C ommission has prepa red a pamphlet

•

that addr esses the pr ob lem of radio frequency interference to radio

and televisio n receptio n, which should b e consu lted i n c ase of

problems with such interference. This publication, “How to Identify

and Resolve Radio/TV Interference Problems” (Stock #004-00000345-4) may be obtained from the US. Government Printing Office,

Washington, DC 20402.

Publication 6157-5.1

Page 6

6 Industrial 20" CRT Monitor

Determine the mini mum and maximum ambient humidity for the

•

monitor by consulting the specification sheets at the back of this

manual. Ensure that the humidity of the ambient air will not exceed

these limits. In very dry environments, static charges build up very

rea dily. Proper groundi ng of t he equ ipment through th e AC pow er

cord can help reduce the likelihood of static discharges, which may

cau se shoc ks and damage e lectronic c omponents.

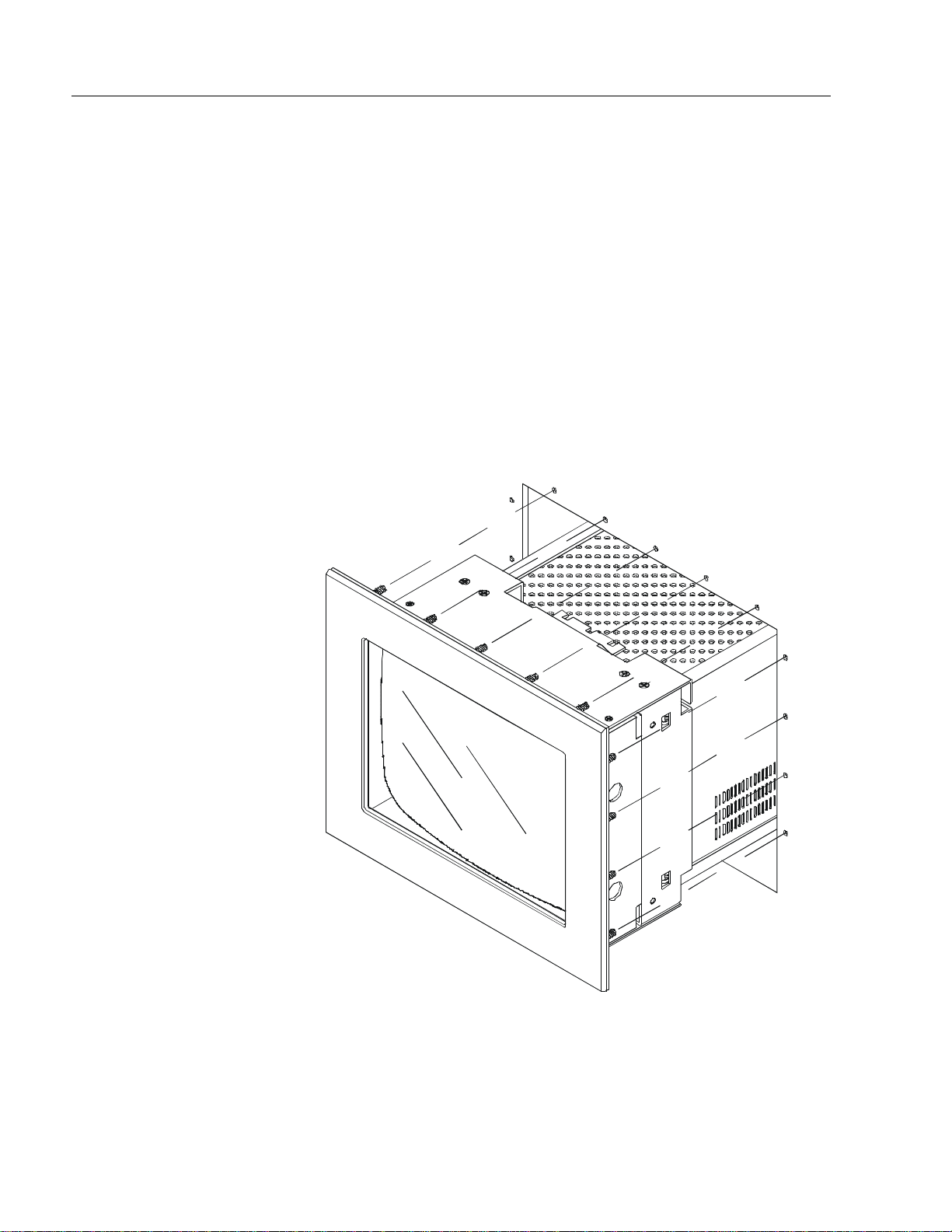

Panel Mounting

When properly installed, the 6157 Industrial Monitor is designed to

pr ovide prot ection agai nst wa ter a nd dust to NEMA 4, NEMA 4X

(plastic panel), and NEMA 12 standards.

No slides or shelves are required because the 6157 Industrial Monitor is

designed to be supported by the panels in which it is installed.

Figure 1

Generic Panel Mount Diagram

Publication 6157-5.1

Page 7

Industrial 20" CRT Monitor 7

Panel Mounting Guidelines

Observe the following precautions before installing the unit in a panel:

Confirm that there is ad eq uate spac e behind the p anel. Rememb er to

•

allow extra space (3 in. (76.2 mm) behind and 1 in. (25.4 mm) below

and on each side) for air circulation.

Confirm that the cabinet is deep enough to accommodate the

•

monitor's depth while providing rear clearance for airflow. A cabinet

with depth of 23.11 in. (587 mm) is sufficient.

Take precautio ns so tha t meta l c utti ngs do not enter any c ompone nts

•

that are already installed in the panel.

Supporting panels should be at least 14 gauge to ensure proper

•

sealing against water and dust and to provide proper support. The

mounting hardware supplied accommodates panels up to 0.25 in.

(6.35 mm) thick.

Note:

Supporting panels must be cut and drilled to

specifications prior to installation.

ATTENTION: Failure to follow these warnings may

result in personal injury or damage to the panel

components.

Publication 6157-5.1

Page 8

8 Industrial 20" CRT Monitor

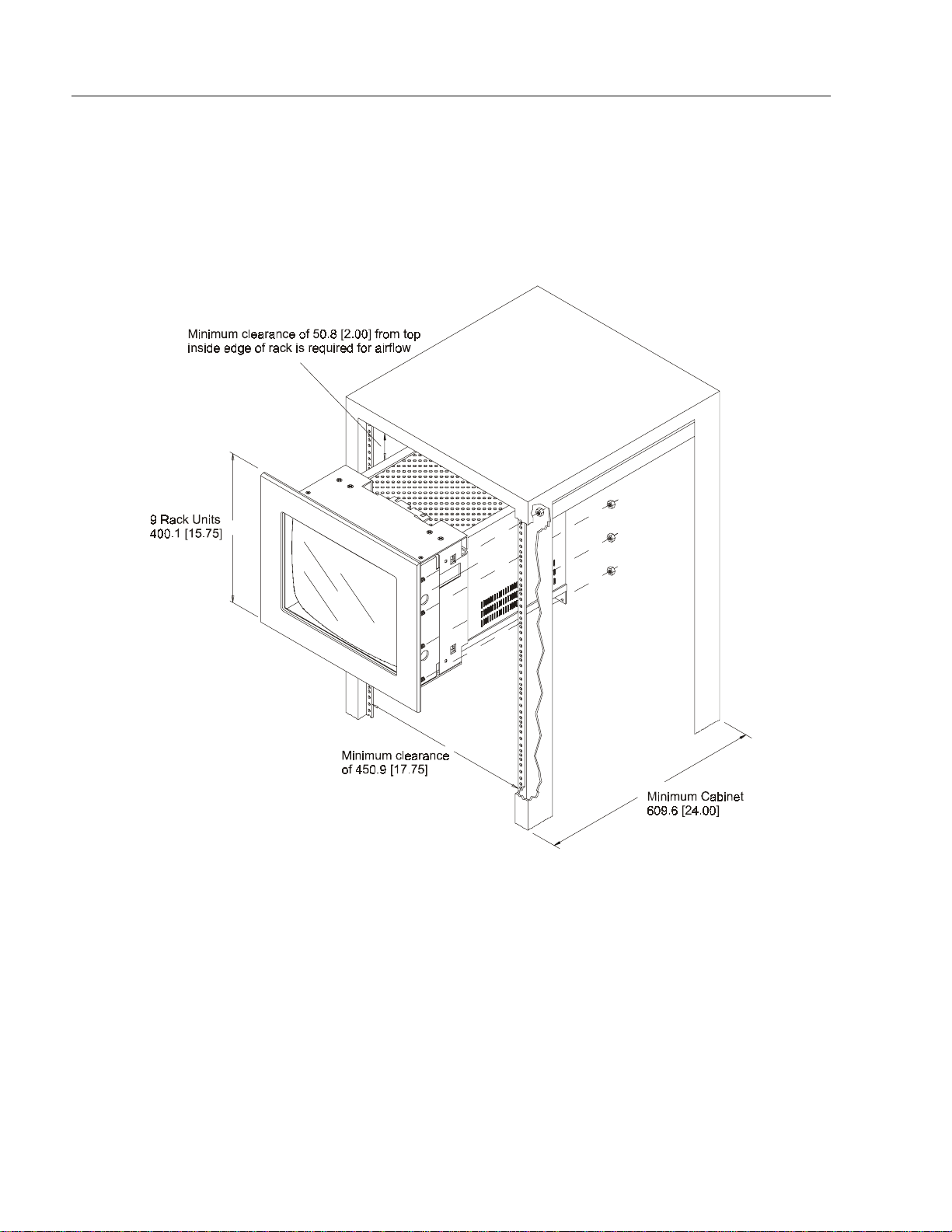

Mounting the 6157 Industrial Monitor in a Rack

Due to the front panel size and stud pattern, the 6157 Industrial Monitor

can be installed in an EIA 19” 9U panel standard rack. Refer to the

following figure:

Figure 2

Generic Rack Mounting Diagram

Publication 6157-5.1

Important:

If you install the 6157 Industrial Monitor in a rack, you

must ensure that the rack can support the weight of the

monitor.

You might need to install a support or shelf under the rear

of the monitor to support the weight.

Page 9

Industrial 20" CRT Monitor 9

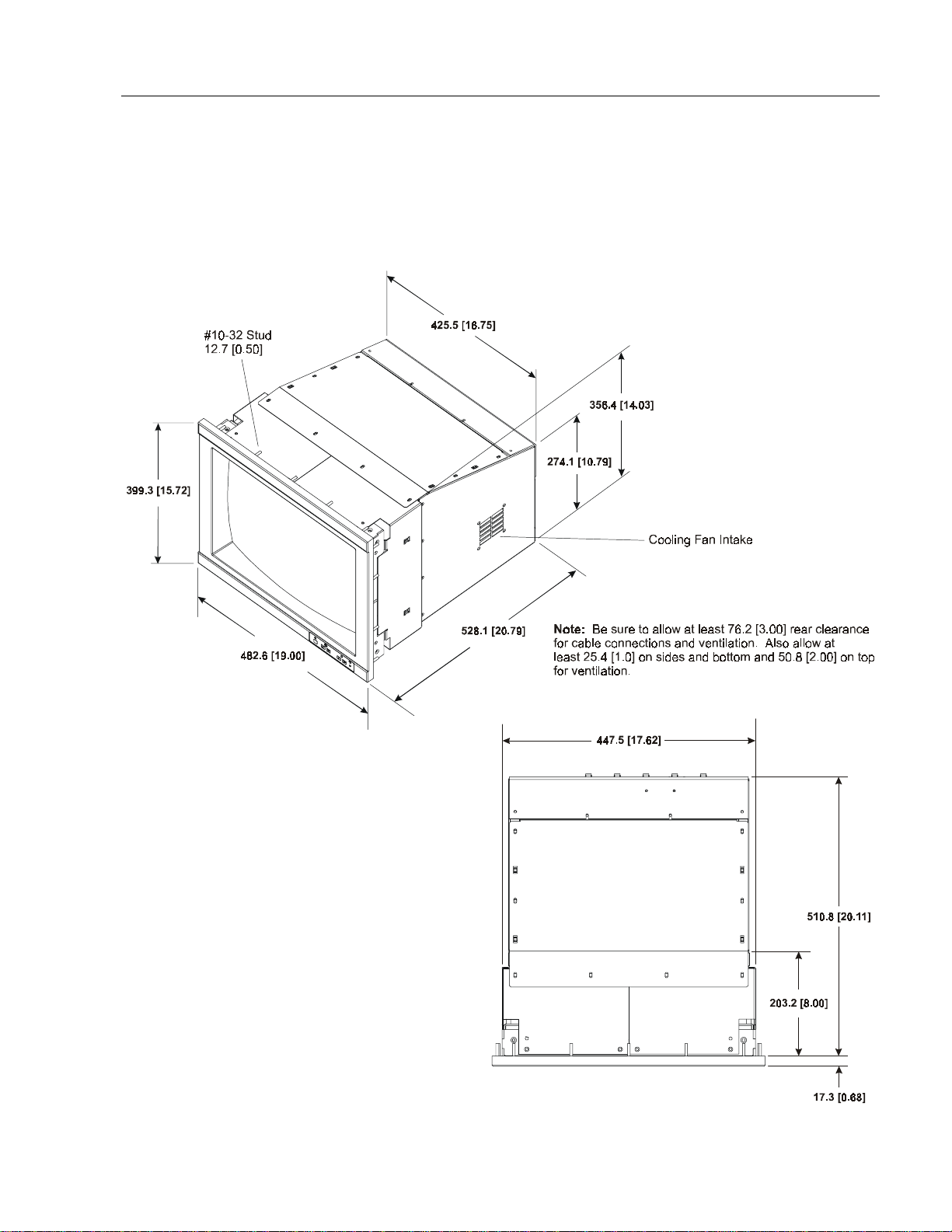

Dimensions

This section provides diagrams you need to follow to install the unit.

Figure 3

6157 Industrial Monitor Dimensions

Publication 6157-5.1

Page 10

10 Industrial 20" CRT Monitor

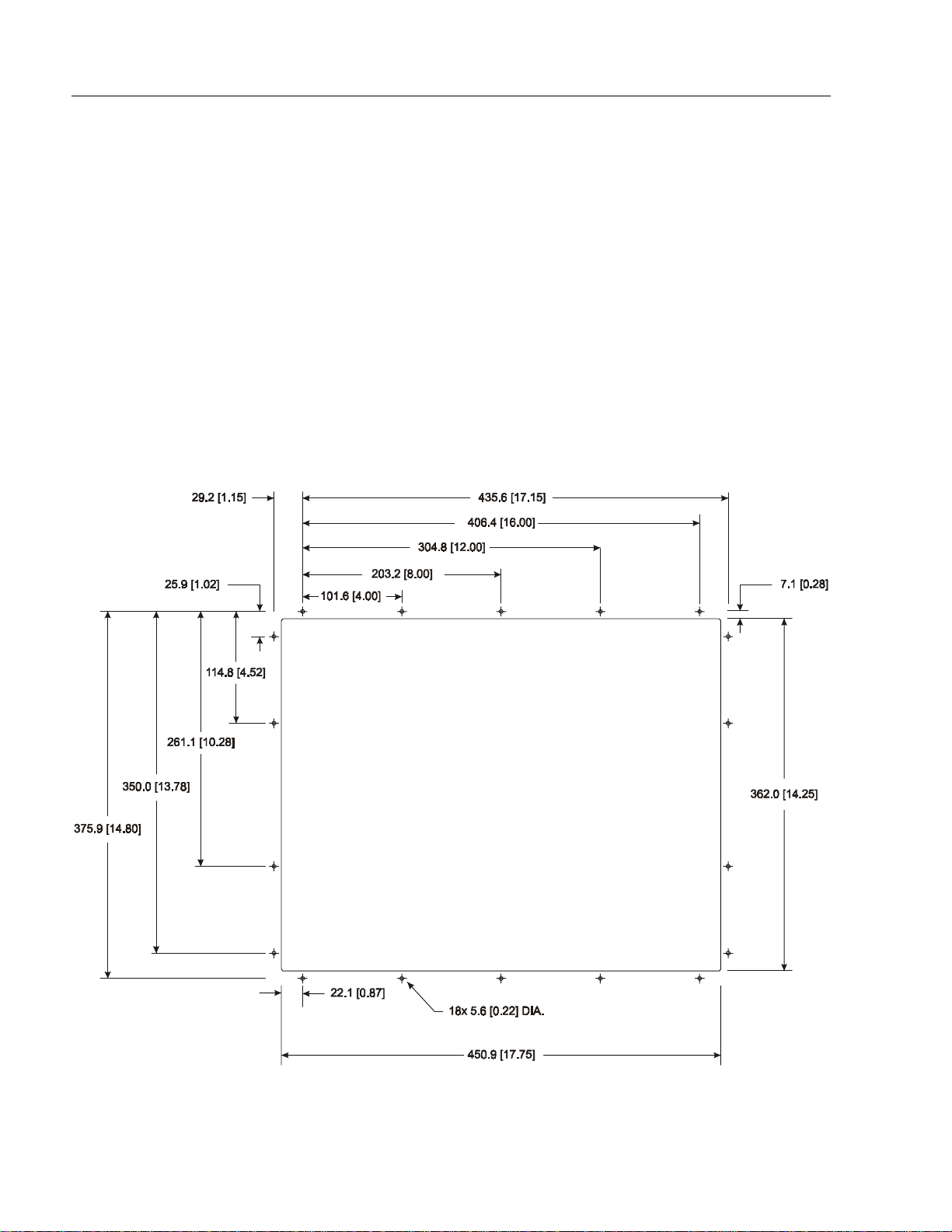

Panel Mounting Procedure

1. Confirm that the shipping carton contains a package of 20 10-32 lock

nuts and 20 flat washers. You will ne e d 18 nut s and washers for

installation.

2. Refer to th e physic al dimension drawing ( Figure 3) and confir m t hat

th ere is adequate spa ce be h ind the pane l. R emember to a l low extra

space for c i rculation and cabli ng.

3. Refer to the panel cutout drawing below for dimensions of the panel

cutout and mounting hole locations. Cut and drill the panel.

Note:

Figure 4

Panel Mounting Cutout

Use #10-32 or M5 self-locking nuts for mounting.

Publication 6157-5.1

Page 11

Industrial 20" CRT Monitor 11

4. Carefully remove the monitor from its packaging. Avoid damaging

the monitor gasket.

Tip: It will be easier to install the monitor if you support it with a shelf

or other support adjusted to the appropriate height.

5. Insert the monitor in the panel cutout from the front. Do not damage

the threaded mounting studs as you position the monitor.

6. Secure the unit with the lock nuts and washers provided. Tighten

evenly to 24 inch-pounds of torque.

Important:

To ensure a proper seal, be sure to install a washer and

nut on each of the 18 mounting studs.

ATTENTION: Mounting nuts must be tightened to a

torque of 24 inch-pounds to provide panel seal and

avoid potential damage. Rockwell Automation

assumes no responsibility for water or chemical

damage to the monitor or other equipment within the

enclosure due to improper installation.

7. Remove the protective adhesive sheet from the screen of the

Industrial Monitor. The sheet is designed to prevent scratching of

the polycarbonate screen protector or the optional touchscreen

during shipping and installation. It should be removed before use.

Publication 6157-5.1

Page 12

12 Industrial 20" CRT Monitor

Connecting the 6157 Industrial Monitor

The rear panel of the 6157 Industrial Monitor has connectors for

attaching cables to accomplish the following:

Connecting to a host video source (HD-15 VGA or BNC connectors)

•

Connecting to a host t ouchscreen control port (DB-9 connector)

•

(optional)

Connecting to AC power

•

Note:

Some connectors on your monitor may differ from the

following figure.

The following figure illustrates the standard configuration for the 6157

Industrial Monitor.

Figure 5

Rear Panel

Publication 6157-5.1

Page 13

Industrial 20" CRT Monitor 13

Connecting the Video Source

The video connection to the host is made through a HD-15 (female)

connector or through BNC input connectors.

To establish a signal using the HD-15 connector:

Note:

For more information on using an HD-15 video cable to

connect to the host computer, refer to Appendix B

(Page 28).

1. Obtain a shielded, properly terminated video cable of length as short

as possible. Longer cables (up to approximately 50 feet in some

cases) may be used, provided they are properly constructed. Your

package may include a six-foot video cable, if specified.

2. Connect one end of the cable to the female HD-15 video input

connector on the rear panel of the monitor.

3. Conn e c t the other en d to th e ou tput of any IBM-co mp atible VGA

ada pter or other vide o generator.

Note:

You may connect the monitor to video generators that

do not conform to VGA standards. The main

requirement is that the generator provide analog RGB

video signals (0.714V above reference black into 75

ohms) and separate horizontal and vertical sync signals.

To establish a signal using the BNC connectors:

Note:

For more information on using BNC connectors, refer to

Appendix B (Page 29).

1. Obtain 75 ohm coaxial cables fitted with BNC connectors. Make

su re the ca bles are of eq ual length.

Note:

An HD-15 to BNC video cable is available from

Rockwell Automation for connecting the monitor to a

VGA video source.

2. Connect one end of the cable to the appropriate BNC input

connectors (R, G, B, HS/CS, VS) on the rear panel of the monitor.

3. Connect the other end to the corresponding output of any video

source. For example, connect the red output cable from the host to

the red input connector on the monitor.

Publication 6157-5.1

Page 14

14 Industrial 20" CRT Monitor

Connecting the Configuration Port

The 6157 Industrial Monitor is equipped for remote control by the host

computer. You can use the serial configuration port to provide bidirectional communication between the monitor and the host computer.

The host computer can send commands to the monitor requesting

information about the monitor’s status or to adjust monitor operating

conditions.

Note:

Please contact Technical Support for more information on

using the configuration port.

To connect the configuration port:

1. Obtain a “straight” wired serial cable (RS-232) with a 9-pin D-shell

connector.

2. Connect one end of the serial cable to the CONFIG port connector

on the rear of the monitor.

3. Conn e c t the other en d to any serial communications port on th e host

computer.

4. Tighten the captive screws on the cable connector to secure it.

Connecting the Touchscreen Interface

The serial touc hscreen interfa ce connection to th e host is made through

an RS-232 DB-9 (female) connector located on the rear panel.

The optional touchscreen provides a high-resolution touch input system.

Driver software included with the package allows the touchscreen to

function with many popular DOS and Windows

applications as a pointing device (mouse).

®

-based industrial

Publication 6157-5.1

Note:

Refer to the manual included with the touchscreen option

and Appendix A of this manual (page 25) for additional

details on the installation and operation of the touchscreen.

Page 15

Industrial 20" CRT Monitor 15

To connect the touchscreen:

1. For units with the touchscreen option, make sure you have one of the

opti onal serial c ables.

2. Connect one end of the touchscreen serial cable to the T/S port

connector on the rear of the monitor.

3. Conn e c t the other en d to any serial communications port on th e host

computer.

4. Tighten the captive screws on the cable connector to secure it.

Connecting AC Power

The 6157 Industrial Monitor requires a single phase power supply

providing 90 to 264V AC at 47 to 70 Hz. Power must be available at a

grounded three-pi n outlet locate d nearby. Whenever possible, connect

the monitor to the same AC source that supplies the computer.

To connect AC power to the monitor:

1. Turn off the mai n switch or breaker.

2. Use the ground terminal of the monitor to establish a chassis-to-earth

ground connection. Secur e one en d of a grou nd strap t o the ground

termina l. Conne ct th e other end of t he ground strap to a good earth

ground.

The ground terminal is an M5 screw.

A TTENTION: Chassis ground must be connected for

safe operation of the monitor. The AC receptacle on the

monitor is a 3-wire type with chassis ground pin, and the

mating AC cord supplied is a 3-wire type, designed for

connection to a grounded 3-pin AC outlet. However, a

properly ground AC ou tlet is not always avai lable, and

grounding using a 3-wire cord can easily be defeated. If

you fail to ground the monitor properly, the setup may

resu lt in p ersona l injury fro m e lectric al shock or damage

to the equipment.

3. Connec t the socket end of t he AC power cord to the mat ing

connector on the rear panel of the monitor.

4. Connect the plug end of the AC power cord to the main outlet.

5. Restore AC power to the outlet.

Publication 6157-5.1

Page 16

16 Industrial 20" CRT Monitor

Operat i n g th e 6157 Industrial Monitor

This section describes how to operate the 6157 Industrial Monitor.

Controls

The f o llowi n g is a summary of the controls and indicators on the

membrane keypad on the 6157 Industrial Monitor:

Figure 6

Monitor-Re sident Control s

Note:

The number of controls supported by the monitor may vary

depending on the monitor type or customer-specified

options.

Status LED Indicators

The keypa d includes seven green L ED in dicators and one amber LED

indicator. These provide information about the current status of the

monitor.

When the monitor is operating in normal mode, one of the green LEDs

will be lit. The monitor indicates an error condition if more than one

gre e n L E D is lit, or if only the amb er SCF LED is lit.

Note:

Saving Changes

When you finish adjusting the monitor’s settings, the monitor

automatically saves your changes. Approximately 20 seconds after you

stop pressing controls, the amber SCF LED blinks twice to indicate that

your changes were saved.

For information on troubleshooting the 6157 Industrial

Monitor, refer to Page 23.

Publication 6157-5.1

Page 17

Industrial 20" CRT Monitor 17

Manual Degauss

The monitor is equipped with an automatic degaussing system to remove

residual magnetism from the CRT’s shadow mask at power-up.

Degaussing helps keep the screen free of any color impurities which

might otherwise result from magnetism picked up by the shadow mask

from the earth’s magnetic field when the monitor is moved.

In addition, a degauss push button is provided on the control panel. This

manual control can be us e d if col or impurities appear on the screen wh ile

the monitor is in operation.

Note:

Tip: For best results, perform a manual degauss only after allowing at

least 15 minutes to pass following power-up or a previous manual

degauss.

The internal degauss will not prevent color impurities

caused by local ma g netic fields. Metal encl osu res can

easily become magnetized by welding and machinery

operations.

Use a hand held degaussing coil to remove residual

magnetism from the enclosure.

Brightness and Contrast

The 6157 Industrial Monitor is equipped with adjustable brightness and

contrast c o ntrols. Th ese controls are located on the front panel of the

unit.

To obtain the best display, first set the brightness control to the

appropriate setting under the lighting conditions in which the monitor

will be used. Then adjust the contrast control to increase or decrease the

intensity of the video imag e as required.

To set the brightness and contrast controls:

1. Press the Select Mode button until the status LED indicator below

the Brightness icon is lit.

Note:

2. Use the left arrow button to adjust the brightness value to its lowest

setting.

3. Use the right arrow button to adjust the brightness until the black

colors in the screen image change from black to dark gray.

For best results, display a screen image with a large

black area before setting these controls.

Publication 6157-5.1

Page 18

18 Industrial 20" CRT Monitor

4. Use the left arrow button to lower the brightness until the dark gray

colors change back to black. This is the optimal brightness setting

given the current lighting conditions

5. Press the Select Mode button until the status LED indicator below

the Contrast icon is lit.

6. Use the left and right arrow buttons to change the value for the

contras t contr ol to achieve t he appropr iate level of i ntensity in t h e

image.

Horizontal and Vertical Size and Position

The mo nitor is fa c tory preset and normally requires no manual

adjustment for vertical or horizontal alignment. However, four

adjustable size and position contr ols are provide d to permit adjustment if

it should become necessary.

To change size or position:

1. Press the Select Mode button until the status LED indicator below

the a p propriate icon is lit .

2. Use the left and right arrow buttons to change the value for the

selected control.

Raster Rot ation

A ra ster rotation contro l allows for c orrectio ns to any disp lay

misalignment which might be present as a result of interaction between

the monitor and an external, low-level uniform magnetic field, such as

th e ea r t h ’s ma g netic fi e l d.

All C RT displays are affe c ted by the earth’s magn etic fi e ld and by

simi lar low level uniform fields. Ge nerall y, th e eff e c ts of su ch a field on

the display vary with the display’s spatial orientation relative to the field

lines. For example, wh en th e unit’s screen is faci n g west, t h e effects of

the earth’s field are minimal. When the screen is rotated toward the north

or south, the disp lay ca n exhibit a small amount of rota tion, so that its

top and bottom edges are no longer parallel to the edges of the panel.

Note:

This effect is differ ent from the effect of magn etis m on th e

shadow mask, which takes the form of color impurity and is

corrected b y th e d egau s s ing system.

Publication 6157-5.1

Before making any adjustments, display a f ull scre e n image a n d chec k

for rotation (top or bottom edge of the image out of parallel with the

corresponding edge of the panel).

Page 19

Industrial 20" CRT Monitor 19

To change raster rotation:

1. Press the Select Mode button until the status LED indicator below

the raster rotation icon is lit.

2. Use the left and right arrow buttons to adjust the rotation.

Important:

The raster rotation control cannot correct for the effects of

external AC fields such as those produced by large motors,

generators a nd trans formers. Such eff ects often take the

for m of display jitter. Protectio n agai nst this kind of

magn etic interf erence requires sp ecial sh ieldin g.

Secondary Control Function Mode (SCF) for Vertical

Pincushion

The 6157 Industrial Monitor allows you to adjust the vertical pincushion

to straighten the sides of the screen. You adjust the vertical pincushion

by switching the monitor to sec ondary control function mode.

To change the vertical pincushion:

1. Press the arrow buttons simultaneously to enter secondary control

function mode.

The SCF status LED indicator and the brightness LED indicator are

lit to indicate secondary control function mode.

2. Use the left and right arrow buttons to adjust the value.

Note:

3. Press the arrow buttons simultaneously to exit secondary control

function mode.

To best observe the effects of the vertical pincushion

adjus tment, disp lay an approp riat e full-sc reen i mage on

the monitor.

Publication 6157-5.1

Page 20

20 Industrial 20" CRT Monitor

Routine Maintenance

Cleaning

Occasionally clean the display panel and cabinet with a soft cloth

dampened (not soaked) with a mild (non-abrasive) glass cleaner. Keep

turning a fresh s ide of the cloth t owar d the screen surface to a void

scratching it with accumulated grit.

Note:

Special ca re shou ld be taken when cl eanin g a resistive touc hscr e e n or

polycarbonate shield that is installed over the screen. Abrasive and

certain chemical cleaners can easily damage the surface. Never use

alcoholic or ammoniac cleaners.

The solvent should be applied only to the cloth, and not

directly on the monitor screen.

Do not use paper products as they may scr atch the surfac e.

To minimize the risk of abrasion, allow the screen to

sta nd dr y.

Publication 6157-5.1

Page 21

Industrial 20" CRT Monitor 21

Fuse Replacement

The Bulletin 6157 Industrial Monitor is equipped with two AC line fuses

housed in the IEC connector (2.5A 250V). To access the fuses, you must

remove the rear cover of the unit.

A TTENTION: Fuse replacement requires work in

areas that can present dangerous voltages. Always

disconnect the AC power cord and wait one minute

before attempting fuse replacement. Replace the rear

cover before restoring power to the monitor.

To replace the fuses:

1. Disconnect the power cord and remove all other cables attached to

the monitor.

2. Remove the four screws that secure the rear panel of the monitor

using a Philips screwdriver. Refer to the following figure.

Figure 7

Fuse Replacement

3. Remove the rear panel to expose the rear section of the AC input

connector. Pull off the plastic ca p , situated at the rear of t he AC

connector, to expose the fus es.

Publication 6157-5.1

Page 22

22 Industrial 20" CRT Monitor

4. Remove each fuse by inserting the tip of a small flat-bladed

screwdriv er bet w een t h e fuse clip and the metal end cap of the fuse

and gently prying the fu se out of its c lip.

5. Replace each fuse as required with a 5ST Slo-Blo type fuse rated at

2.5A, 250VAC.

6. After replacing each fuse in its clip holder, reinstall the plastic cover

over the fuses, reinstall the rear panel of the mon itor, and recon nect

the AC power cord.

Note:

If a fuse continues to blow, consult a qualified service

technician.

ATTENTION: To avoid danger of fire, always

replace the fuse with one of the same type and rating.

Replacing a Line Cord

To avoid s hock and fire haza rds, the moni tor’s power cord should be

replaced if the insulation becomes broken or if it develops a loose

internal conne c tion.

Other Maintenance

Qualified service personnel should perform all maintenance, except for

the fuse and power cord replacement described above.

Publication 6157-5.1

Page 23

Industrial 20" CRT Monitor 23

Troubleshooting

You can refer to this table to help identify the cause and offer a solution

to a problem. This table lists typical problems you may encounter.

Table A

Troubleshooting Table

Symptom Possible Proble m Action

None of the sta tus LEDs are lit. Power cord not connected.

No power available at AC outlet. Test AC outlet by plugging in a lamp or other

Blown fuse. Replace fuse. Refer to Page 21.

Power cord faulty. Replace power cord. Refer to Page 22.

Monitor f aulty. Have moni tor servic ed.

One green status LED is lit, but no screen

image when power switch is closed.

More than one green status LED is lit, but

no screen image.

The amber SCF status LED is lit and one

green status LED is lit.

Only the amber SCF status LED is lit, and

no screen image.

No raster vis i ble even when br ig ht ness

and contrast controls are set full ON.

Raster di m l y vis ib l e wit h br ig htness and

contrast controls set full ON, but no

displ ay present

Display is pr esent, but gar bl ed or r olling Monitor n ot s ynched to video

Display is present and stable, but appears

“wrapp ed” at on e si d e or oth er wise not

properly centered or sized.

Screen saver activated.

Brightness and contrast controls

not proper l y ad jus ted.

Monitor ou t of ad jus t ment. Turn monit or OF F an d t h en tur n bac k ON .

Monitor is in secondary control

functi on m od e.

Monitor n ot s ynched to video

sourc e.

Monitor f aulty. Have moni tor servic ed.

Monitor ou t of ad jus t ment or

faulty.

Video cable problem.

Fault in vid eo s our ce. Test vid eo s our ce by connect in g to an other

Fault in monitor. Have monitor serviced.

sourc e.

Size and pos it ion controls n ot

proper l y adj us t ed.

Open power switch. Reconnect power cord at

monitor an d at AC out l et . Close power sw itc h.

known good devic e.

Disable screen saver by activating an input to the

host system.

Adjust brightness and contrast controls.

Press both arrow buttons simultaneous l y to exit

secondary control function mode. Refer to

Page 19.

Check for proper video cable installation. Replace

suspected faulty cable.

Check to ens ure that video s ource is oper ating

within th e m oni t or ’s r ang e.

Have moni tor servic ed.

Check f or pr oper install ation of video c abl e( s ).

Refer to installation instructions.

Replace suspected faulty cable (s).

monitor that is known to b e operational.

Refer to installation instructions.

Check for proper video cable installation. Replace

suspected faulty cable.

Check to ens ure that video s ource is oper ating

within th e m oni t or ’s r ang e.

Adjust c ontrols for pr op er siz e an d p osit ion of

displ ay. R ef er t o op erator instr uc ti ons

Publication 6157-5.1

Page 24

24 Industrial 20" CRT Monitor

Symptom Possible Proble m Action

Display is present and stable, but missing

some co lor(s)

Display is present and stable, but colors

are not pur e

Display is pr esent, but “jit ters” or is

severely distorted

Do not confuse the flicker

NOTE:

associated with an in t erlaced vid eo m od e

with jitter.

Display is present, but “bars” appear

across it.

Connected monitor to computer. When

powered, the PC locked up (For units

using th e HD-15 only)

Video cable problem. Check for proper video cable installation.

Fault in monitor. Have monitor serviced.

Monitor requires degaussing.

Enclos ure requires d egaussin g. M anu al ly degauss the enclosur e. R ef er t o

Interf eri ng external AC or DC

magnetic shield

“Noise” generated by other

equipment in the environment is

present at t h e vi d eo inputs

Graphics card driver is not

compatible with monitor

If using BNC inputs, test monitor as follows.

Disconnect sig nal cable(s) corresponding to the

missing color(s). Disconnect signal cable

corresp onding to a disp l ay ed c ol or an d c onn ect it

to the input( s) corresponding to the missing

color(s). If a missing color reappears, the signal

cable corresponding to that color is faulty;

otherwise, the monitor is faulty.

Replace suspected faulty cable.

Manually degauss the monitor. Refer to

Page 17.

Page 17.

If possible, reposition the moni tor beyond the

prox imity of large transformers, motors, bus bars,

etc.

Ask Roc k well A ut om ation abou t various shi el ding

options avai l ab le to protect th e mon it or .

Consult t h e app lication note which disc us ses

method’s of eliminating noise.

Update t h e graphics card dri ver s to th e latest

version.

Publication 6157-5.1

Page 25

$

$SSHQGL[ $

SSHQGL[ $

,QWHUIDFH

,QWHUIDFH

Industrial 20" CRT Monitor 25

7

7RX

RXF

FKVF

KVFU

UHHQ 6

HHQ 6H

HULDO

ULDO

Description

Setting Up the Touchscreen Interface

All touch controllers are configured by default to provide serial

communications at 9600 baud, 8 data bits, 1 stop bit, no parity.

For Allen-Bradley monitors equipped with touchscreens, a serial

communications cable is requ ir ed. A suit able cable can be obta i n ed fr o m

Rockwell Automation or you can create one.

The cable provides a communications channel between the touchscreen

controller, which is mounted inside the monitor, and an RS-232-C serial

port on the host computer. Because the touch controller obtains power

from the monitor's power supply, no external touch power connections

are necessary.

Software supplied with the touchscreen must be loaded on the host

computer to handle communications with the touch controller over the

channel.

Because t he touchscreen emu l ates a mouse, there may be c ompa tibili ty

issues involving how the touchscreen emulates mouse buttons, especially

multiple buttons. For a complete discussion of these issues and how to

troubleshoot them, refer to the touchscreen documentation.

This section describes how to set up the touchscreen system using the

6157 Industrial Monitor. Setup involves the following:

• Enabling the touchscreen interface

• Installing the software on the host computer that will handle

communications with the touchscreen controller

• Performing a calibrati o n

Enabl ing th e To uchscreen Interf a c e

The 6157 Industrial Monitor provides a female DB-9 connector on the

rear panel. This connector provides the serial interface for the touch

controller.

Publication 6157-5.1

Page 26

26 Industrial 20" CRT Monitor

Interconnecting wiring to the host serial port connection is shown in the

following table.

Table B

Touchscreen Interface

Monitor

(DCE Device) Host (DTE Device)

DB-9 (Female) Signal Description DB-9 (Male) DB-25 (Male)

1 Not Connected (DCD) 1 8

2 Transmit Data (TXD) 2 3

3 Receive Data (RXD) 3 2

4 Data Terminal Ready (DTR) 4 20

5 Common Signal Return (SG) 5 7

6 Not Conn ected (DSR) 6 6

7 Request To Send (RTS) 7 4

8 Clear To Send (CTS) 8 5

9 Not Conn ected 9 22

Installing the Touchscreen Driver Software

To install the touchscreen driver software correctly, obtain the following

information about the host hardware:

The COM port in use for the touchscreen. Ensure that the RS-232

•

cable is properly installed between the monitor port and the host’s

COM port.

The baud rate at wh ich the controller is oper ating. You will need to

•

match the baud rate at the COM port. The controller baud rate is

factory set at 9600.

Note:

Once you have obtained this information, install the software using the

installation disks found in the touchscreen accessory package.

If you are using older touchscreen software, you may be

prompted for the type of touchscreen controller being used.

The 6157 uses the following controllers:

Resistive: Elo TouchSystems model E271-2210.

•

Ca paciti ve: MicroTouch model SMT-3.

•

Publication 6157-5.1

Page 27

Industrial 20" CRT Monitor 27

Performing a Calibration

Note:

After installing the driver software, follow the instructions in the

touchscreen documentation.

Following installation of the touchscreen software and calibration, the

touchscreen is ready to use.

Before installation, you may want to check the touchscreen

manufacturer’s site on the World Wide Web for the latest

sof twa re drivers. Enter these ad d resses in y o ur I n ternet

browser:

www.elotouch.com for resistive touchscreens

•

www.micr otouch.c om for capaciti ve touchscr eens.

•

Publication 6157-5.1

Page 28

28 Industrial 20" CRT Monitor

$

$SSHQGL[ %

SSHQGL[ %

You can use two types of video cable connectors to connect the 6157

Industrial Monitor to the host computer:

• HD-15 connectors

• BNC connectors.

9

9LGHR &

LGHR &D

DEOHV

EOHV

HD-15 Connecto r s

The HD-15 video cable you use with this monitor is equipped with a

conventional HD-15 connector at each end.

Note:

Figure 8

HD-15 Video Connector

The following table provides the pin numbers and corresponding pin

assignments for the HD-15 video connect or with the DDC2B ca pability:

The following figure is the view looking into the pin end of

the male connector or solder term end of the female

connector.

Publication 6157-5.1

Page 29

Table C

Standard HD-15 Video Cable

Industrial 20" CRT Monitor 29

Monitor HD-15

(Female)

1Red Video 1

2 Gr een Video 2

3Blue Video 3

4Return 4

5Not Used 5

6 Red Video Ground 6

7 Green Video Ground 7

8 Blue Video Ground 8

9 +5V (Optional) 9

10 Sync Ground 10

11 Return 11

12 Bi-Directional Data 12

13 Horizontal Sync 13

14 Vertical Sync (VCLK) 14

15 Data Clock (SCL) 15

Signal Description

HD-15 (Male)

Host

BNC Connectors

The BNC cables you use with this monitor use a combination of three or

more BN C connect ors. The rear panel of the mon i tor c ontains fi v e BNC

connectors :

• R,B, and G: Red, Green, and Blue input connectors to establish

color. These are used for RS-343 analog signals.

• HS/CS: Separate horizonta l/composite sync s ignal f rom the video

source.

• VS: Separate vertical sync signal from the video source.

Publication 6157-5.1

Page 30

30 Industrial 20" CRT Monitor

The following table describes the signal types you can use with these

BNC connectors:

Table D

BNC Signal Types

BNC Signal Type Description R G B HS/CSVS

Sync-on-Green Use the three video connectors. Horizontal

and vertical syncs are supplied on the green

video line.

Separate

Composite Sync

Separate

Horizontal and

Vertical Sync

Use the three video connectors plus the

horizontal sync/composite sync input.

Use the three video connectors plus the

horizontal sync/composite sync and vertical

sync input.

XXX

XXXX

XXXXX

Publication 6157-5.1

Page 31

Specifications

Industrial 20" CRT Monitor 31

Display

CRT Type 20” diagonal, 0.28mm dot pitch

SP phosphor, 51.5% glass, AGRAS coatin g, low

thermal exapansion shadow mask, DAF electron

guns, tension-band implosion protected

Degauss in g Manual and au t om at ic

Nominal Display Area

(4:3 aspect) Horizontal

(4:3 aspect) Vertical

(5:4 aspect) Horizontal

(5:4 aspect) Vertical

Non Linearity (CHP Method)

Horizontal

Vertical

Pincus hi on

Horizontal

Vertical

Keystone

Horizontal

Vertical

Regul ati on 2m m m a x p eak d eviation

Misconvergence 0.3mm max inside ce ntered cir c le 280mm dia.,

Lumin ance (typic al) 30 fL, sm all wh it e square

Lumin ance Uniformi ty Corners at leas t 70% of cent er

CIE coordinates

White x:=0.281, y:=0.311 (9300K)

14.7in. (374mm)

11.0in. (280mm)

13.8in. (350mm)

11.0in. (280mm)

5% max

4% max

3mm max

3mm max

1% max

1% max

0.4 max outside

Video

Resolut i on 640 x 480 to 1280 x 10 24, aut osync

Supported Standards IBM VGA (640x480 at 60Hz )

VESA (640x480 at 60/72Hz, 800 x600 at 56/6 0/72H z,

1024x7 68 at 60/ 70Hz)

DEC (1024x864 at 60Hz, 1280x1024 at 66/72Hz)

SUN (1152x900 at 67/76Hz)

SG/I BM RISC (1280x1024 at 60Hz); IBM RISC

(1280x1 0 24 at 77 Hz)

HP700 (1280x1024 at 72Hz)

Horizontal Scan Rate Variable: 30k Hz to 82kHz

Vertical Scan Rate Variable: 50Hz to 80Hz

Retra ce Times

Horizontal

Vertical

Video B and w id th 140MHz

Black Level Stability Within 1%

Video Input Signal RGB analog (white level = 0.714V above ref. black,

2.7 usec m ax

0.475 msec max

into 75 Oh ms , sin gle ended)

Publication 6157-5.1

Page 32

32 Industrial 20" CRT Monitor

Video (cont.)

Sync Input Signals Separate Horizontal and Vertical Sync Control, TTL

Input Connection 5 BNC (R,G,B,HS/CS,VS), Female HD-15

signal l evel s

Sync on green ( 0. 28 6V b el ow ref . bl ac k) or

Composite separate (into 75 Ohms, single ended)

Controls and Indicators

Operator Input

Environmental

Pane l Rating NEMA 4/4x/12, designed to IP65 standards

Operating Temperature 0C to 50C

Storag e T emperatur e - 30C to 65C

Relati ve Hu midity 10% to 90% n on-condensing

Operating Altitude Sea level to 10,000 ft (3048m)

Non-Operating Altitude Sea level to 40,000 ft (12000m)

Operating Electrostatic

Discharge

Non-Operating Electrostatic

Discharge

Opera ting Shock 20g (1/2 sine, 11msec)

Non-Operating Shock 30g (1/2 sine, 11msec)

Operating Vibration 0.006in. p-p, 10-70Hz,

Non-Operating Vibration 0.015in. p-p, 10-51Hz,

Front Panel: Degauss, Brightness, Contrast, Raster

Rotation, H Size, H Pos, V Size, V Pos (sealed digital)

Touchscreen Option - Resistive touch screen, with

interface controller and RS-232 interf ace

8.0K VDC (IE C 801-2, level 3)

20.0K VDC

1.0g peak, 70-640Hz sine

2.0g peak 51-64 0Hz sine

Publication 6157-5.1

Electrical

Line Volt age 90 to 264VAC

Line Frequency 47- 70Hz

Ground Leakage 1.0 uA max at 1.5KVDC

Power Consumption 130W max, 190 VA max

Physical

Panel Bezel Dimensions

(W x H x D)

Overall Dimensions (from rear

surface of front panel to back)

Net Weight 84lb (38.2kg)

Certifications

19.0in. x 15 . 7 in. x .7 in. (4 82 m m x 39 9mm x 17mm)

17.6in. x 14 . 0 in. x 20. 1 in . (44 7mm x 356mm x

511mm)

UL 1950 Recognized Component,

C-UL 950 R ec og ni z ed C om p onent,

CE97 (89/336/EEC and 73/23/EEC),

FCC Class A

Page 33

IBM is a registe red trademark of Inte rn ational Business Machines Corporation.

VGA is a trademar k of International Business Machines Corporation.

PC AT is a trademark of International Business Machines Corporation.

Microsoft is a registered trademark of Microsoft Corporation.

Microsoft Windows is a trademark of Microsoft Corporation .

Rockwell A utomation h el ps i ts custom ers receive a superior return on their investment by bringing

together leading brands in industri al aut omation, creating a broad spect rum of easy-t o-i ntegrate

products. T hese are supported by local technical resources availabl e worldwide, a gl obal network of

system s olutions provid ers, and the advanced technology resources of Rockwell.

Worldwide representation.

Argentina • Australia • Austria • Bahrain • Belgium • Bolivia • Brazil • Bulgaria • Canada • Chile • China, People’s Republic of • Colombia • Costa Rica • Croatia • Cyprus • Czech

Republic • Denmark • Dominican Republic • Ecuador • Egypt • El Salvador • Finland • France • Germany • Ghana • Greece • Guatemala • Honduras • Hong Kong • Hungary

Iceland • India • Indonesia • Iran • Ireland • Israel • Italy • Jamaica • Japan • Jordan • Korea • Kuwait • Lebanon • Macau • Malaysia • Malta • Mexico • Morocco • The Netherlands

New Zealand • Nigeria • Norway • Oman • Pakistan • Panama • Peru • Philippines • Poland • Portugal • Puerto Rico • Qatar • Romania • Russia • Saudi Arabia • Singapore

Slovakia • Slovenia • South Africa, Republic of • Spain • Sweden • Switzerland • Taiwan • Thailand • Trinidad • Tunisia • Turkey • United Arab Emirates • United Kingdom • United

States • Uruguay • Venezuela

Rockwell Automation Headquarters, 1201 South Second Street, Milwaukee, WI 53204-2496 USA, Tel: (1) 414 382-2000, Fax: (1) 414 382-4444

Rockwell Automation European Headquarters, Avenue Hermann Debroux, 46 1160 Brussels, Belgium, Tel: (32) 2 663 06 00, Fax: (32) 2 663 06 40

Rockwell Automation Asia Pacific Headquarters, 27/F Citicorp Centre, 18 Whitfield Road, Causeway Bay, Hong Kong, Tel: (852) 2887 4788, Fax: (852) 2508 1846

World Wide Web: http://www.ab.com

998051-010

Publication 6157-5.1

Copyright 1999 Rockwell Automation Corporation. All rights reserved. Printed in USA.

•

•

•

Loading...

Loading...