Page 1

Industrial 14” CRT Monitors

(Bulletin Number 6156)

Product Data and Installation Instructions

Page 2

Industrial Computer with Integrated Display and Keypad2

&%$'#"

!"&#"&

"&' '#" "&'%('#"&

#""'" #)%

# &

+$ $'#"

+#% *'"% &

#(&%" $'#"

#""'" '# #!$('%

#"'%# & " "'#%&

"'""

%#( &##'"

$'#"&

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. “Safety Guidelines for the Application, Installation and

Maintenance of Solid State Controls” (Publication SGI-1.1) describes some important

differences between solid state equipment and hard–wired electromechanical devices.

Because of this difference, and because of the wide variety of uses for solid state

equipment, all persons responsible for applying this equipment must satisfy themselves

that each intended application of this equipment is acceptable.

In no event will the Allen-Bradley Company be responsible or liable for indirect or

consequential damages resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes.

Because of the many variables and requirements associated with any particular

installation, the Allen-Bradley Company cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Allen-Bradley Company with respect to use of

information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written

permission of the Allen-Bradley Company is prohibited.

Throughout this manual we use notes to make you aware of safety considerations.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

!

damage, or economic loss.

Publication 6156-2.0

Important: Identifies information that is especially important for successful application

and understanding of the product.

Page 3

3

Industrial 14" CRT Monitors

Description

Bulletin 6156 Industrial 14 in. CRT Monitors are general purpose

monitors suitable for a wide range of industrial computing

applications.

Package Contents

The Bulletin 6156 Industrial Monitor is shipped with the following

items:

• 6156 Industrial 14 in. Color CRT Monitor with configurable

options for keypads, touchscreen, and video interface

Monitors without the touchscreen option have a polycarbonate

screen protector.

• panel mounting hardware (package of 20 10–32 lock nuts with

flat washers)

• 1.8 m (6 ft) AC power cord (optional)

• video cable (optional)

• keyboard cable (optional)

• Industrial 14” CRT Monitors Product Data & Installation

Instructions (Publication 6156-2.0).

An Industrial Monitor with a touchscreen option is shipped with

these additional items:

• supporting software and manuals

• RS-232 serial cable (optional)

Publication 6156-2.0

Page 4

Industrial 14” CRT Monitors4

Dimensions

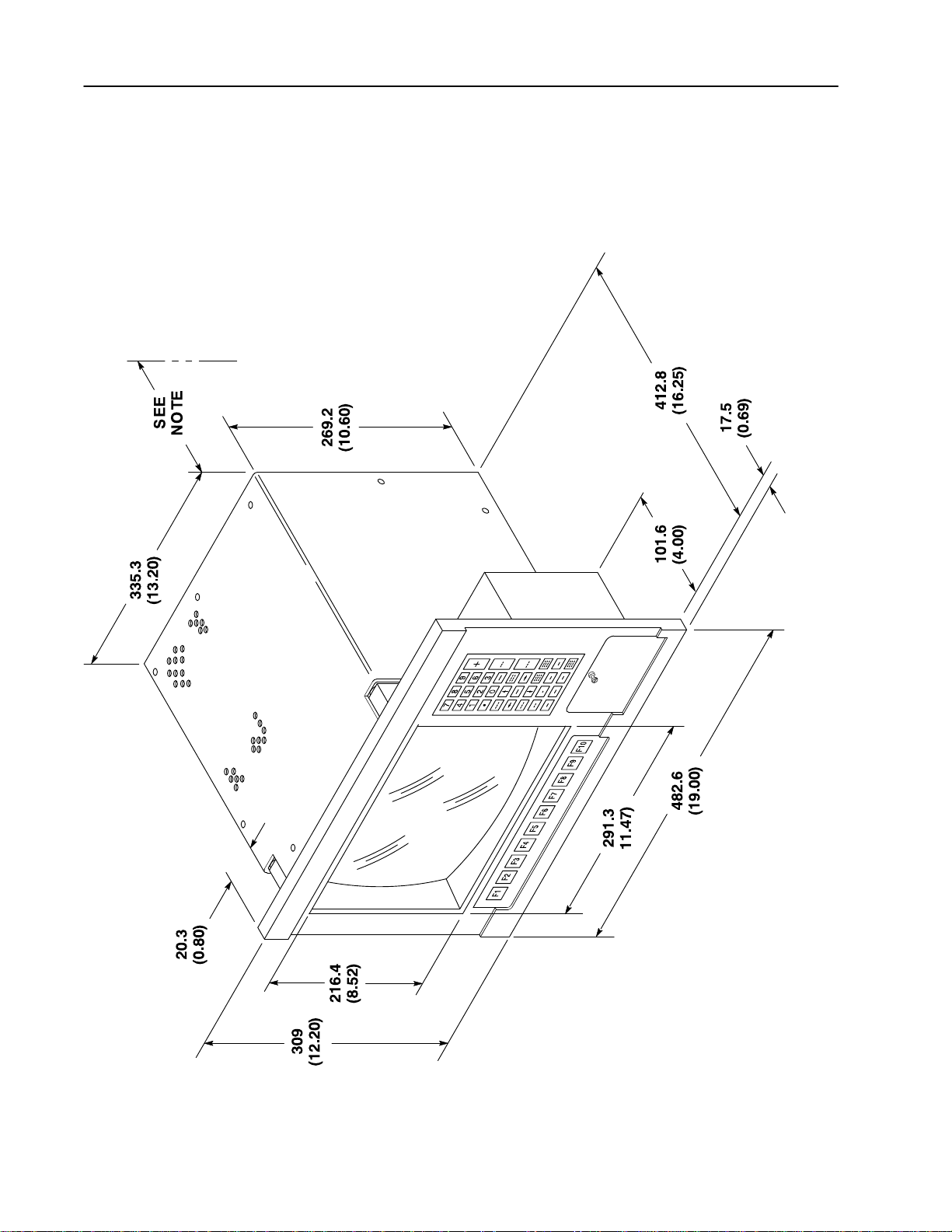

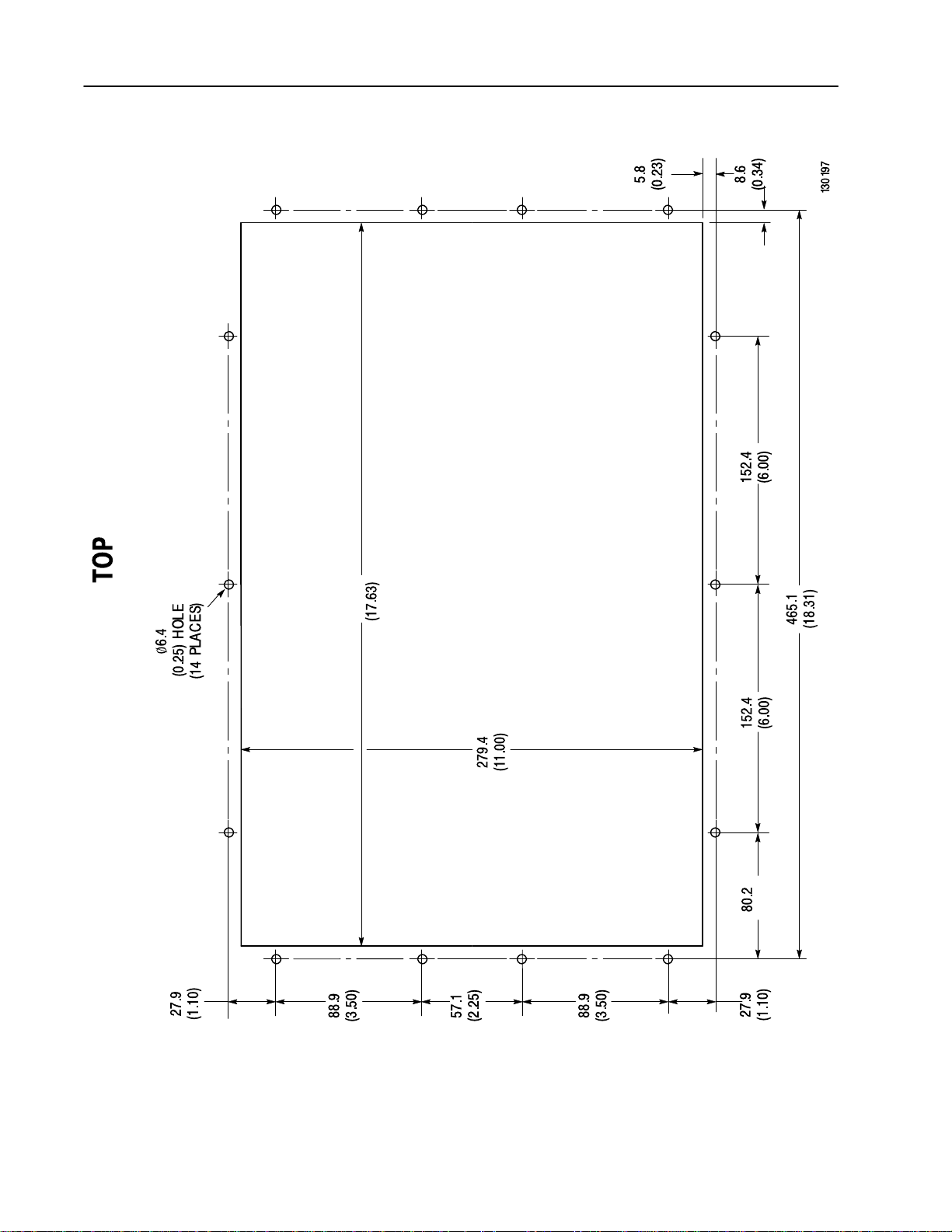

Figure 1

Bulletin 6156 Industrial Monitor (With Keypads)

Physical Dimensions

Publication 6156-2.0

Note: Be sure to allow at least 76.2 mm (3.0 in.) depth clearance for cable connections and air flow.

130680

Page 5

309

(12.20)

216.4

(8.52)

20.3

(0.80)

Industrial 14” CRT Monitors 5

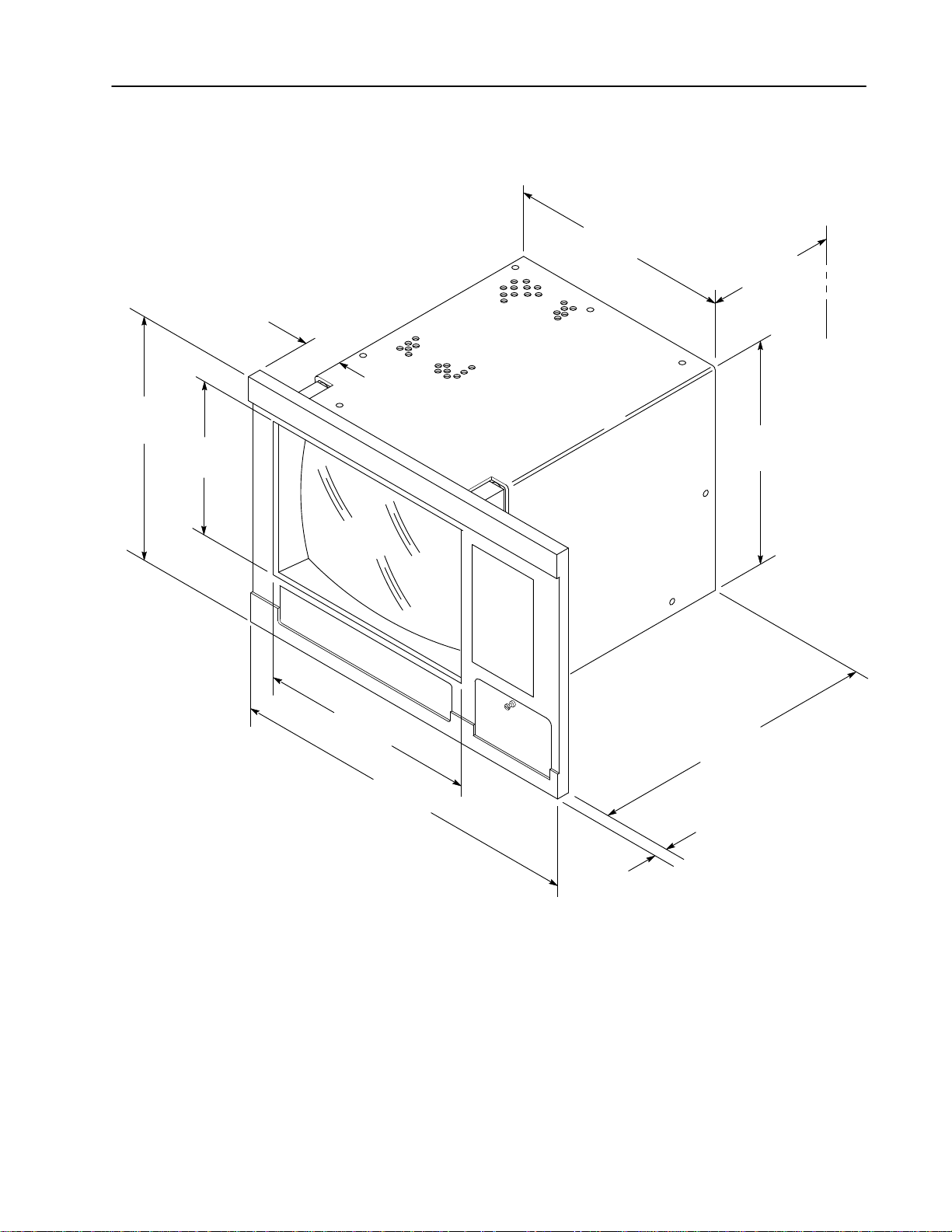

Figure 2

Bulletin 6156 Industrial Monitor (Without Keypads) Physical

Dimensions

335.3

(13.20)

SEE

NOTE

269.2

(10.60)

291.3

11.47)

482.6

(19.00)

Note: Be sure to allow at least 76.2 mm (3.0 in.) depth clearance for cable connections and air flow.

412.8

(16.25)

17.5

(0.69)

130681

Publication 6156-2.0

Page 6

Industrial 14” CRT Monitors6

Installation Instructions

Environmental Considerations

The 6156 Industrial Monitor requires a minimum free air space of

76.2 mm (3 in.) behind and 50.8 mm (2 in.) above and below for

proper cooling. Allen-Bradley Industrial Monitors have been

designed to function without cooling fans. Therefore, maintenance of

fan filters and access to them need not be a concern.

Strong magnetic fields near the front of the monitor outside the

enclosure could potentially distort the image over time. This type of

image distortion generally disappears after degaussing occurs.

Allen-Bradley Industrial Monitors automatically degauss each time

AC power is applied, or when the degauss button is pressed.

Note: The internal degauss will not prevent color impurities caused

by local magnetic fields. Make certain the Industrial Monitor’s

enclosure is free of residual magnetism.

Panel Mounting

The panel on which you will mount the Industrial Monitor should be

at least 14 gauge to insure a NEMA 4 seal and proper support for the

unit. The mounting studs attached to the rear of the monitor bezel

will accommodate this minimum thickness panel and panels up to

6.35 mm (0.25 in.) thick.

To install the Bulletin 6156 Industrial Monitor:

1. Confirm that the shipping carton contains a package of 20 10-32

lock nuts and 20 flat washers. You will need 14 nuts and washers

for installation.

2. Refer to the physical dimension drawings (Figures 1 and 2, pages

4 and 5) and confirm that there is adequate space behind the

panel where the unit is to be situated. Remember to allow extra

space for air circulation.

3. Refer to the panel cutout drawing (Figure 3 Page 8) for

dimensions of the panel cutout and mounting hole locations. Cut

and drill the panel.

4. Carefully remove the monitor from its packaging. Avoid

damaging the monitor gasket.

Tip: It will be easier to install the monitor if you support it with a

shelf or other support adjusted to the appropriate height.

Publication 6156-2.0

Page 7

Industrial 14” CRT Monitors 7

5. Insert the monitor in the panel cutout from the front of the panel.

Be careful not to damage the threaded mounting studs as you

position the monitor.

6. Secure the unit with the locknuts and washers provided. Tighten

evenly to 25 inch-pounds of torque.

Important: To assure a proper seal, be sure to install a washer

and nut on each of the 14 mounting studs.

ATTENTION: Mounting nuts must be tightened to a

torque of 25 inch-pounds to provide panel seal and

!

7. Remove the protective adhesive sheet from the screen of the

Industrial Monitor. The sheet is designed to prevent scratching of

the polycarbonate screen protector or the optional touchscreen

during shipping and installation. It should be removed before use.

avoid potential damage to the Bulletin 6156 Industrial

Monitor. Allen–Bradley assumes no responsibility for

water or chemical damage to the Bulletin 6156

Industrial Monitor or other equipment within the

enclosure due to improper installation.

Publication 6156-2.0

Page 8

Industrial 14” CRT Monitors8

Figure 3

Bulletin 6156 Panel Cutout Dimensions

447.7

(3.16)

Publication 6156-2.0

Page 9

Industrial 14” CRT Monitors 9

Connecting AC Power

The Bulletin 6156 Industrial Monitor requires a single phase power

supply providing 100 to 250V AC at 50 to 60 Hz. Power must be

available at a grounded three-pin outlet located nearby. Whenever

possible, connect the monitor to the same AC source that supplies

the computer.

To connect AC power to the monitor:

1. Turn off the main switch or breaker.

2. Use the GND point on the rear panel of the monitor to establish a

chassis to earth ground connection. Secure one end of a ground

strap to the GND point. Connect the other end of the ground strap

to a good earth ground.

The ground terminals are M5 screws.

ATTENTION: Chassis ground must be connected

for safe operation of the monitor. The AC receptacle

!

on the monitor is a 3-wire type with chassis ground

pin, and the mating AC cord supplied is a 3-wire

type, designed for connection to a grounded 3-pin

AC outlet. However a properly grounded AC outlet

is not always available, and grounding using a

3-wire cord can easily be defeated. If you fail to

ground the monitor properly, the setup may result in

personal injury from electrical shock or damage to

equipment.

Product Options

3. Connect the socket end of the AC power cord to the mating

connector on the rear panel of the monitor. Position the power

cord retaining clip attached to the rear panel connector over the

cord’s socket to secure it in place.

4. Connect the plug end of the AC power cord to the mains outlet.

5. Restore AC power to the outlet.

The Bulletin 6156 Industrial 14 in. CRT Monitor can be configured

with the following options.

• VGA or BNC video cables

• keypads

• external keyboard connectors

• touchscreen

Publication 6156-2.0

Page 10

Industrial 14” CRT Monitors10

Video Cables

The Bulletin 6156 Industrial Monitor can be configured with various

industrial grade video cables. The standard HD15 cable is equipped

with a conventional HD15 connector at each end.

Figure 4

Standard Video Cable

1234

678910

11 12

13

5

14 15

HD15

Table A

Standard Video Cable Construction

Monitor HD15

2 Green Video 2

7 Green Video Ground 7

1 Red Video 1

6 Red Video Ground 6

3 Blue Video 3

8 Blue Video Ground 8

5 Composite Sync 5 (Not Used)

11 (Floating) ID0 11

12 (Floating) ID1 12

4 (Gnd) ID2 4

9 Not Connected 9

14 Vertical Sync 14

10 Sync Ground 10

15 Control 15 (Not Used)

13 Horizontal Sync 13

Signal Description Computer HD15

View looking into the Pin End of the

Male connector

Publication 6156-2.0

In addition to the standard video cable, special low noise coaxial

video cables are available in various lengths. They are equipped with

a DB-13C3 connector at the monitor end and a standard HD15

connector at the computer end.

Page 11

Table B

Coaxial Cable Construction

Industrial 14” CRT Monitors 11

Monitor DB-13C3

A1 Center Pin Green Video 2

A1 Outer Green Video Ground 7

A2 Center Pin Red Video 1

A2 Outer Red Video Ground 6

A3 Center Pin Blue Video 3

A3 Outer Blue Video Ground 8

1, 2, 3, 6, 7, 8 Not Connected 4, 9, 11, 12, 15

4 Vertical Sync 14

5 Horizontal Sync Ground 10

9 Vertical Sync Ground 5

10 Horizontal Sync 13

Signal Description Computer HD15

Another low noise video interface is the Differential BNC Input

connectors option which accepts red, green and blue video signals

(RS-343 analog signaling) and a separate composite sync signal from

the video source. BNC to BNC cable options are available.

The Keypad Option

The keypad option provides a 10-key function keypad and a 33-key

pad with numeric keys, cursor keys, and modifier keys. The keypad

keys function just like the equivalent keys on standard IBM AT

keyboards.

Figure 5

The Function Key Pad

Table C

Keypad Scan Code Values

Keypad Legend

F1 3B

F2 3C

F3 3D

F4 3E

F5 3F

F6 40

F7 41

F8 42

F9 43

F10 44

Scan Code (Hex)

Publication 6156-2.0

Page 12

Industrial 14” CRT Monitors12

Figure 6

Numeric Keypad

Table D

Numeric Keypad Functions and Scan Codes

Keypad

Legend

Corresponding AT Key

Scan Code

(Hex)

Keypad

Legend

Corresponding AT Key

Scan Code

(Hex)

7 Number Pad 7 / Home 47 TAB Main Pad Tab 0F

8 Number Pad 8 / Up Arrow 48 ENTER Main Pad Enter 1C

9 Number Pad 9 / Pg Up 49 SPACE Main Pad Space Bar 20

– Number Pad – 4A SHIFT Main Pad Left Shift 2A

4 Number Pad 4 / Left Arrow 4B CTRL Main Pad Left Control 1D

5 Number Pad 5 4C ALT Main Pad Left Alt 38

6 Number Pad 6 / Right Arrow 4D HOME Home E0, 47

+ Number Pad + 4E

↑

Up Arrow E0, 48

1 Number Pad 1 / End 4F PAGE UP Page Up E0, 49

2 Number Pad 2 / Dn Arrow 50

3 Number Pad 3 / Pg Dn 51

←

→

Left Arrow E0, 4B

Right Arrow E0, 4D

0 Number Pad 0 / Ins 52 END End E0, 4F

. Number Pad . / Del 53

↓

Down Arrow E0, 50

* Number Pad * 37 PAGE DOWN Page Down E0, 51

ESC Main Pad Escape 01 INS Insert E0, 52

BACK SPACE Main Pad Back Space 0E DEL Delete E0, 53

PRINT

SCREEN

Print Screen E0, 2A, E0, 37

Publication 6156-2.0

Page 13

Industrial 14” CRT Monitors 13

Keyboard Extender Cables

For units configured with the keypad option, a keyboard extender

cable is available in various lengths.

2

4

1

13

Table E

Standard Keyboard Cable Construction

The Touchscreen Option

The Touchscreen option provides a high resolution resistive or

capacitive touchscreen system. Software drivers provided with the

touchscreen option allow you to use the touchscreen as a pointing

device with many popular DOS and Windows-based industrial

applications. Refer to the touchscreen documentation for information

on installing and using the touchscreen.

5

Female

5

DIN-5

Connector

331

Female DIN–5

1 Keyboard Clock 1

2 Keyboard Data 2

3 Not Used 3

4 0 Volts 4

5 +5V 5

Signal Description Male DIN–5

4

Male

DIN-5

Connector

13

(Computer End)

2

Touchscreen Serial Cables

For units configured with the touchscreen option, a touchscreen

serial cable is available in various lengths and with either a 9-pin or

25-pin communications port D-shell.

Table F

Allen–Bradley Touchscreen Serial (RS-232) Cable Construction

9-pin D Signal Description 9-pin D

1 Not Connected 1

2 Transmit Data 2

3 Receive Data 3

4 Data Terminal Ready (DTR) 4

5 Common Signal Return 5

6 Not Connected 6

7 Request To Send (RTS) 7

8 Clear To Send (CTS) 8

9 Not Connected 9

Cable shield is grounded through the connector shells

Publication 6156-2.0

Page 14

Industrial 14” CRT Monitors14

Connecting to a Computer

(female)

(male)

Connect the Industrial Monitor to a computer with a video cable. A

keyboard extender cable is required for monitors equipped with the

keypad option. A touchscreen serial cable is required for monitors

equipped with the touchscreen option. To connect your monitor to a

computer:

1. Plan the route for the cables through the enclosure and confirm

that the cables you have ordered are long enough for the routing

you have chosen.

Figure 7

Rear Panel of Monitor

Sync Selector

RGBCS

Publication 6156-2.0

AC Cable Restraint

Page 15

Industrial 14” CRT Monitors 15

2. If you are using a standard HD15 video cable with the Industrial

Monitor, connect either end of the cable to the 15-pin video input

connector. See the rear panel drawing (Figure 7) to locate the

connector. Tighten the captive screws on the cable connector to

secure it.

Or

If you are using the optional DB-13C3 video interface, connect

the large end of the video cable to the large video input connector.

Tighten the captive screws on the cable connector to secure it.

Or

If you are using the optional 4 BNC video interface, connect the

ends of the BNC video cable to the red, green, blue and

composite sync input connectors.

Note: The 6156 Industrial Monitor has one HD15 video

connector and can be optionally equipped with two different

video connectors. The conventional HD15 connector and the

larger DB-13C3 connector are wired in parallel and constitute a

single interface, or the HD15 and the Differential BNC inputs are

wired in parallel and constitute a single interface.

Note: The DB-13C3 type connector supports special low noise

cables. These video cables are recommended especially for high

noise environments and for longer cable runs. The computer end

of all standard HD15 and optional DB-13C3 cables include a

standard HD15 connector. The BNC cables available are 4 BNC

to 4 BNC connections.

3. For monitors configured with the keypad option and keypad

extender cable, use the 5-pin DIN keyboard cable. Connect the

female end to the monitor’s keypad/auxiliary keyboard output

connector.

Note: When this cable is connected to the computer keyboard

connector, an IBM AT keyboard may be connected to the front

panel 5–pin DIN connector or to the rear panel Auxiliary

Keyboard input connector. Only one auxiliary keyboard input

port can be used at any time.

4. You may use a standard RS-232 cable to support a mouse or other

device connected via the monitor’s RS-232 connector (located

behind the front panel door). Connect one end of the RS-232

cable to the connector labeled ”COM” on the rear panel of the

monitor. A cable with captive screws should be used and they

should be tightened to secure it.

Publication 6156-2.0

Page 16

Industrial 14” CRT Monitors16

5. For monitors configured with the touchscreen option, connect one

end of the serial touchscreen cable to the connector labeled

”AUX1” on the rear panel of the monitor. Tighten the captive

screws to secure it.

6. Route and secure the cables. In cases where the cable crosses a

door hinge, be sure to leave enough excess cable for a loose fit in

all door positions. Bulletin 6156 Industrial Monitor cables are

designed to be flexible, so routing across a hinge should not result

in application failure. The minimum recommended bend radius

for a video cable is 38 mm (1.5 in.).

7. Connect the standard 15-pin connector end of the video cable to

the computer’s video output connector. Tighten the captive

screws on the cable connector to secure it.

8. Connect the keyboard cable to the keyboard input connector on

the computer.

9. Connect the touchscreen cable free end to an appropriate RS-232

communications port on the computer. Tighten the captive screws

on the cable connector to secure it.

10. If you are installing an RS-232 serial communications cable,

connect the free end to an appropriate RS-232 port on the

computer.

11. Coil and secure any extra cable length in a convenient location.

Publication 6156-2.0

Page 17

Industrial 14” CRT Monitors 17

Controls & Indicators

Power Indicator

Size and Position

The following is a summary of the controls and indicators on the

Bulletin 6156 Industrial Monitor.

Figure 8

Controls and Indicators

Brightness and Contrast

Manual Degauss

Raster Rotation

Power Indicator

The presence of AC power at the Bulletin 6156 Industrial Monitor is

indicated by a green LED on the rear panel.

Contrast, Brightness, Size and Position Controls

The Bulletin 6156 Industrial Monitor is equipped with adjustable

contrast and brightness controls. These controls are located on the

rear panel of the unit.

To obtain the best display, first set the contrast control for

comfortable viewing under lighting conditions that match those in

which the monitor will be used. Adjust the brightness control to

increase or decrease the video image’s intensity as required.

Publication 6156-2.0

Page 18

Industrial 14” CRT Monitors18

The monitor is factory preset and normally requires no manual

adjustment for vertical or horizontal alignment. However, four

screwdriver adjustable size and position controls are provided to

permit adjustment if it should ever become necessary. Adjust

controls using a non–metallic insulated 1/8” (3mm) flat screwdriver

passed through the hole(s) of the rear cover. With a suitable full

screen image on display, adjust the Vertical Size for a height of 7.5”

and the Horizontal Size for a width of 10.0”. Adjust Vertical and

Horizontal Position controls as necessary to center the image on the

screen.

Degauss

The monitor is equipped with an automatic degaussing system to

remove residual magnetism from the CRT’s shadow mask at

power-up. Degaussing helps keep the screen free of any color

impurities which might otherwise result from magnetism picked up

by the shadow mask from the earth’s magnetic field when the

monitor is moved.

In addition, a degauss push button is provided on the rear panel. This

manual control can be used if color impurities appear on the screen

while the monitor is in operation.

Note: The internal degauss will not prevent color impurities caused

by local magnetic fields. Make certain the monitor’s enclosure is free

of residual magnetism.

Tip: For best results, perform a manual degauss only after allowing

at least 15 minutes to pass following power-up or a previous manual

degauss.

Raster Rotation

A raster rotation allows for corrections to any display misalignment

which might be present as a result of interaction between the monitor

and an external, low level uniform magnetic field, such as the earth’s

magnetic field.

All CRT displays are affected by the earth’s magnetic field and by

similar low level uniform fields. Generally, the effects of such a field

on the display vary with the display’s spatial orientation relative to

the field lines. For, example, when the Bulletin 6156 Industrial

Monitor’s screen is facing West, the effects of the earth’s field are

minimal, but when the screen is rotated toward the North or South

the display itself can exhibit a small amount of rotation, so that its

top and bottom edges are no longer parallel to the edges of the panel.

Publication 6156-2.0

Page 19

Industrial 14” CRT Monitors 19

Note: This effect is different from the effect of magnetism on the

shadow mask, which takes the form of color impurity and is

corrected by the degaussing system described previously.

Before making any adjustment, display a full screen image and check

for rotation (top or bottom edge of the image out of parallel with the

corresponding edge of the panel).

If adjustment is necessary,

1. Loosen the lock nut on the control shaft.

2. While observing the display (in a mirror if necessary) use a flat

blade screwdriver to adjust the alignment.

Note: Don’t forget to re-tighten the lock nut after the adjustment is

made.

Important: The raster rotation control cannot correct for the effects

of external AC fields such as those produced by large motors,

generators and transformers. Such effects often take the form of

display jitter. Protection against this kind of magnetic interference

requires special shielding.

Maintenance

ATTENTION: Do not attempt to change any

adjustments located on the monitor chassis’ left side

!

(as viewed from the front of the monitor). These

adjustments are for factory trained personnel using

special test and alignment equipment and should not be

required to obtain a good display in the field.

Preparation for Shipment

If it is ever necessary to ship the monitor, first remove it from the

panel in which it has been installed, then securely pack it. To remove

the monitor from the panel, reverse the installation procedure that

begins on page 6. Whenever possible, ship the monitor in its

original container.

ATTENTION: Never try to ship the monitor while it

is mounted in a panel. Doing so could result in damage

!

to the panel or monitor.

Publication 6156-2.0

Page 20

Industrial 14” CRT Monitors20

Fuse replacement

Bulletin 6156 Industrial Monitors are equipped with an AC line fuse,

which is accessible from the rear panel. To replace the fuse:

1. Remove AC power by disconnecting the AC line cord.

2. Use a flat blade screwdriver to unscrew the cap on the fuse

holder.

3. Remove the cap and fuse.

4. Replace the fuse with a 5ST Slo-Blo type rated at 2.5A, 250VAC.

5. Secure the fuse holder cap with the screwdriver.

6. Restore AC power.

Cleaning instructions

To clean the monitor screen protector, use a 50% solution of alcohol

(ethanol or isopropyl) in water on a cotton gauze pad or soft cotton

cloth. Paper products may scratch the surface, and should be

avoided.

Note: The solvent should be applied only to the cloth, and not

directly to the surface to be cleaned.

Publication 6156-2.0

Page 21

Industrial 14” CRT Monitors 21

or

y( )

Color appears wrong

Troubleshooting

The following table can help you identify the potential cause of

problems you may encounter while using the 6156 Industrial

Monitor.

ATTENTION: When attempting to correct a problem,

do not change any adjustments located on the monitor

!

chassis’ left side (as viewed from the front of the

monitor). These adjustments are for factory trained

personnel using special test and alignment equipment.

Symptom Possible Cause Procedure

No Video No power Check to see if rear panel LED is illuminated; if not, check power wiring;

check for presence of proper voltage; check AC line fuse

Video cable problem Check for proper video cable installation; replace suspected faulty cable

Brightness/Contrast controls

misadjusted

Images distorted or off-center

or

Video not synced (screen rolls)

Color appears wrong

No keypad communications Keypad cable problem Check for proper cable installation; replace suspected faulty cable

No touchscreen

communications

Other touchscreen failures Various Refer to additional documentation provided with unit from touchscreen

Video adapter not compatible

or misconfigured

Monitor misadjusted

Video cable problem Check for proper video cable installation; replace suspected faulty cable

Sync select switch set

improperly (BNC Version only)

Video cable problem Check for proper video cable installation; replace suspected faulty cable

Build-up of residual

magnetism

Touchscreen cable problem Check for proper cable installation; replace suspected faulty cable

Adjust brightness/contrast controls

Check to insure that the graphics adapter is a VGA type and is configured to

provide a display compatible with the monitor

Adjust width, horizontal position, and vertical position controls

Set sync select switch to correct source

Manually degauss unit

manufacture

Publication 6156-2.0

Page 22

Industrial 14” CRT Monitors22

Specifications

Display

Type CRT, Color

CRT Size 14” Diagonal

Nominal Display Area 10.0” Horizontal x 7.5” Vertical (254mm x 191mm)

Resolution 640 x 480 to 1024 x 768, autosync

Dot Pitch 0.28mm

2

Luminance 40 ft–Lamberts (137 cd/m

with full screen white flood)

Horizontal Scan Rate 30 kHz to 56 kHz

Vertical Scan Rate 40 Hz to 90 Hz

Video Bandwidth 75 MHz

Video Inputs RGB Analog, RS-343A (0.7V peak into 75 Ohms =

100% modulation)

Sync Type Separate Horizontal and Vertical Sync Control. TTL

signal levels.

Sync Polarity Horizontal – Negative or positive

Vertical – Negative or positive

Controls and Indicators Rear panel power–on LED (green), Brightness,

Contrast, Manual Degauss, Horizontal Size, Horizontal

Position, Vertical Size, Vertical Position, Raster Rotation

Electrical

Power Requirement 100–250VAC , 50–60 Hz, single phase

Power Consumption 120W maximum

Connectors

Video Input (rear panel) Female HD15, Female DB-13C3, or 4 BNC

Touchscreen port output (rear

Male 9-pin D

panel AUX1)

RS-232 port (rear panel COM

Female 9-pin D

for units with keypad option

only)

Keypad / Aux keyboard output

Male DIN 5-pin

(rear panel)

Aux keyboard input (rear

Female DIN 5–pin

panel for units with keypad

option only)

Aux keyboard input (behind

Female DIN 5-pin

front panel door, for units with

keypad option only)

RS-232 port (behind front

Male 9-pin D

panel door, for units with

keypad option only)

Publication 6156-2.0

Page 23

Industrial 14” CRT Monitors 23

Specifications (Continued)

Environmental

Operating Temperature

Storage Temperature

Relative Humidity 5% to 95% (non–condensing)

Operating Shock 15g (1/2 sine, 11 msec duration)

Non–operating Shock 30g (1/2 sine, 11 msec duration)

Operating Vibration 0.01 in. p-p 5-17 Hz sine, 1.5g peak, 17-640 Hz sine

Non–operating Vibration 0.2 in. p-p 5-16 Hz sine, 2.5g peak, 16-640 Hz sine

Physical

Faceplate Overall Height 12.2” (310mm)

Faceplate Overall Width 19.0” (483mm)

Overall Depth (from rear

surface of front panel to back)

Net Weight approx. 50lbs (23kg)

Standards Compliance

RF Emissions FCC Class A Certified

Safety (Electrical Shock, Fire) EN60950, UL / C-UL 1950 recognized component

CE Compliance Directives 89/336/EEC, 73/23/EEC

Enclosure UL / C-UL 508 Listed

X–ray Emissions DHHS CFR 21.1020 compliant

0°C to +50°C

–30°C to +70°C

16.3” (414mm)

NEMA 4, 12, 13 (when properly installed in panel)

Publication 6156-2.0

Page 24

IBM is a registered trademark of International Business Machines Corporation

VGA is a trademark of International Business Machines Corporation.

PC AT is a trademark of International Business Machines Corporation

Microsoft is a registered trademark of Microsoft.

Microsoft Windows is a trademark of Microsoft.

Rockwell Automation helps its customers receive a superior return on their investment by bringing

together leading brands in industrial automation, creating a broad spectrum of easy-to-integrate

products. These are supported by local technical resources available worldwide, a global network

of system solutions providers, and the advanced technology resources of Rockwell.

Worldwide representation.

Argentina • Australia • Austria • Bahrain • Belgium • Bolivia • Brazil • Bulgaria • Canada • Chile • China, People’s Republic of • Colombia • Costa Rica • Croatia • Cyprus

Czech Republic

Hungary

The Netherlands

Arabia

United Kingdom

Rockwell Automation Headquarters, 1201 South Second Street, Milwaukee, WI 53204-2496 USA, Tel: (1) 414 382-2000 Fax: (1) 414 382-4444

Rockwell Automation European Headquarters, Avenue Hermann Debroux, 46, 1160 Brussels, Belgium, Tel: (32) 2 663 06 00, Fax: (32) 2 663 06 40

Rockwell Automation Asia Pacific Headquarters, 27/F Citicorp Centre, 18 Whitfield Road, Causeway Bay, Hong Kong, Tel: (852) 2887 4788, Fax: (852) 2508 1846

World Wide Web: http://www.ab.com

Publication 6156-2.0 – March 1997 40061-392-01(A)

•

Denmark • Dominican Republic • Ecuador • Egypt • El Salvador • Finland • France • Germany • Ghana • Greece • Guatemala • Honduras • Hong Kong

•

Iceland • India • Indonesia • Iran • Ireland •Israel • Italy • Jamaica • Japan • Jordan • Korea • Kuwait • Lebanon • Macau • Malaysia • Malta • Mexico •Morocco

•

•

Singapore • Slovakia • Slovenia • South Africa, Republic of • Spain • Sweden •Switzerland • T aiwan • Thailand • Trinidad • Tunisia • Turkey • United Arab Emirates

New Zealand • Nigeria • Norway • Oman • Pakistan • Panama • Peru • Philippines • Poland • Portugal • Puerto Rico • Qatar • Romania • Russia • Saudi

•

United States • Uruguay • Venezuela

Publication 6156-2.0 – March 1997

Copyright 1997 Allen-Bradley Company, Inc. Printed in USA

Loading...

Loading...