Page 1

505 z 509

FULL VOLTAGE STARTERS z SIZE 8

SERIES B CONSTRUCTION

BULLETIN

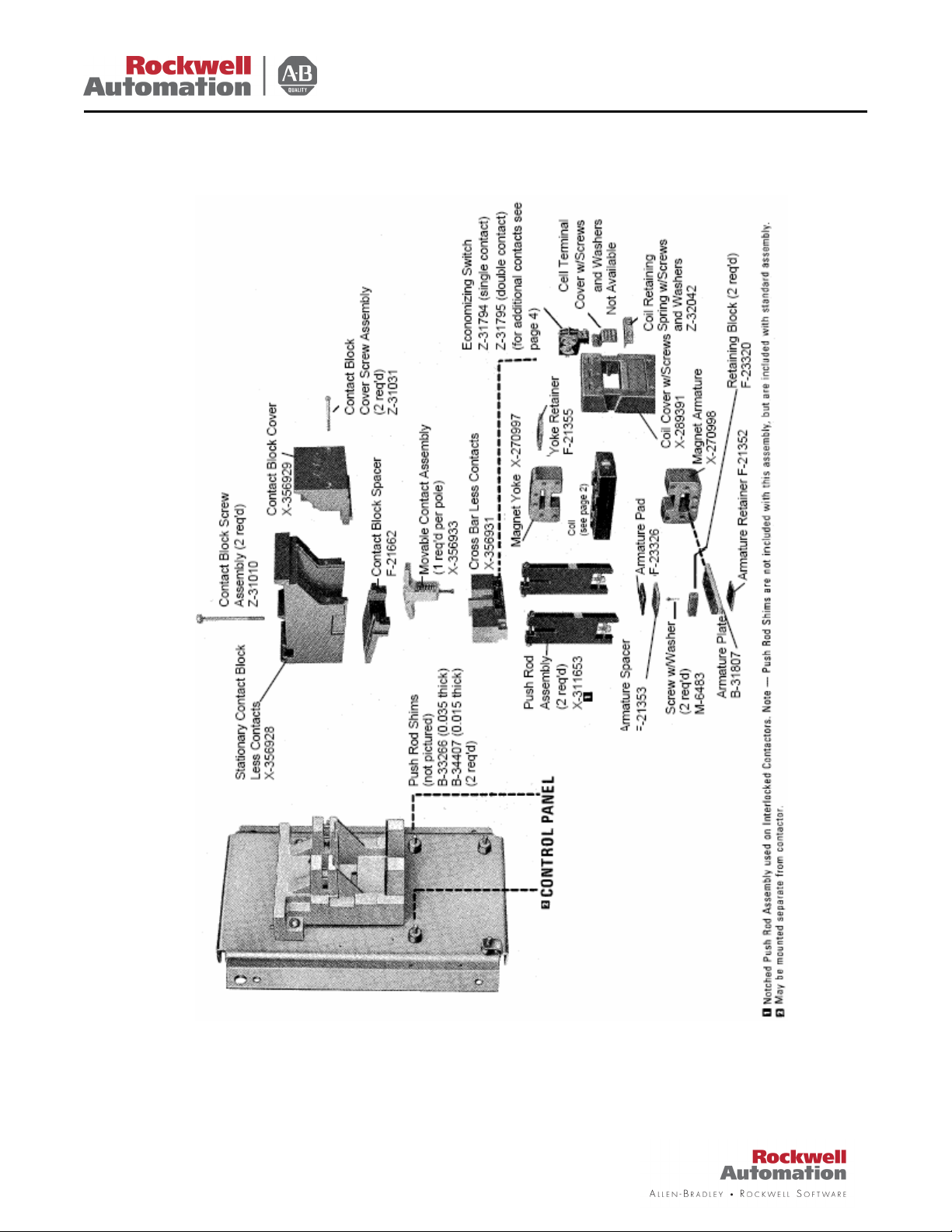

CONTACTS

contacts are of cadmium oxide silver. Square, solid

seating prevents twisting or sliding motion and

extends contact life.

These contacts should not be filed or dressed.

- The weld-resistant, double break

Removal of the contact block cover makes the

mounting screws for the front stationary contact

assembly accessible. The contacts are brazed on

heavy copper parts which are attached to the

stationary contact block by two screws. Remove

these screws and extract the front stationary contact

assembly by depressing the movable contact. To

take out the rear stationary contact assembly, simply

remove the coil cover and slide out the cross bar

assembly, which includes the following items: cross

bar, push rod assemblies, and the magnet armature

assembly. With the cross bar assembly out, the

mounting screws for the rear stationary contacts

accessible and they can be removed along with the

arc quenchers which are attached to the stationary

contact block.

Knowledgebase Technotes ID # Q18318, can be found at http://support.rockwellautomation.com/

The movable contacts are carried in stainless steel

cages which in turn are mounted in cavities in the

molded portion of the cross bar. This cage assembly

is held in place by a screw which can be loosened

from the underside. Therefore, to replace movable

contacts, it is only necessary to replace the

assembly with a new assembly.

STATIONARY CONTACT BLOCK molded contact block has a high degree of

mechanical strength and dimensional accuracy.

Material resists arc tracking and arc blast damage.

Separate arc chambers contain efficient metal arc

quenchers.

To detach the stationary contact block, remove the

contact block cover which is held in place by two

captive screws. Then take out the two contact block

screws which hold the stationary contact block to the

base assembly. The contact block can now be

detached.

CROSS BAR ASSEMBLY

cross bar carrying the movable contacts is molded,

but the movable contacts are carried in stainless

steel cages which in turn are mounted in cavities in

the molded portion. The push rod assemblies are

attached to the cross bar molding with screws which

clamp together two sides of a dovetail joint to make

a very rigid connection. The push rod assemblies

are molded with insert studs at the lower end which

are used to fasten the lower cross member which is

a steel plate going through the armature iron. Make

certain that upon replacement the push rod

assemblies lie against the shoulder of the cross

bar.

The cross bar is available less the movable

contacts. However, if the movable contacts are

needed, they can be purchased as a completed

assembly. The push rod assemblies are obtainable

as separate items. The magnet armature assembly

can be disassembled and its parts procured

separately. Part numbers for each item can be found

on Page 3 and 4.

To remove the cross bar assembly: first, detach

contact block cover whish is held in place by two

captive screws; second, loosen the screws on the

- The portion of the

The hot-

Page 1 of 10

Page 2

505 z 509

BULLETIN

coil retaining spring; third, loosen the four captive

screws holding down the coil cover; and fourth, slide

off the coil cover. The cross bar assembly, as one

unit, is then lifted out. Disassembly of all parts of the

cross bar assembly is easily accomp-lished by

loosening all the nuts and screws on the push rod

assemblies.

MAGNET ARMATURE ASSEMBLY – The magnet

armature is laminated and is mounted on the

armature plate with a rubber pad to absorb shock

and prolong life. To remove the magnet armature

assembly, loosen the lock nut at the lower end of the

push rods. Note – Removal of the magnet

armature assembly will probably cause the push

rod shims to fall free. Be sure that upon

replacing the magnet armature assembly, the

push rod shims are placed in the same position,

so that consistent overtravel may be maintained.

Take out the retaining blocks located on each side of

the magnet armature. Force the armature plate

through the armature, thereby isolating the magnet

armature. Note - The armature pad, spacer, and

retainer must be replaced in the same order. For

correct replacement, refer to the exploded view

on Page 3.

MAGNET YOKE

and mounted on an aluminum base casting. The

pressure molded coil is mounted with the yoke

projecting into the openings of the coil so that the

coil slides out with the magnet yoke.

OPERATING COIL

in a coil protected against mechanical damage and

the corrosive effects of atmospheric conditions and

protects the coil against swelling when subjected to

over-voltage. Very little trouble can be expected

from the operating coils.

Removing the coil is a simple operation that is

easily performed from the front. First, remove the

coil terminal cover; second, detach the coil leads;

third, loosen the two

screws located on the coil retaining spring; and

fourth, slacken the four captive screws holding down

the coil cover. The coil cover is then lifted out from

the font. Now remove the operating coil and magnet

yoke and detach the yoke from the coil.

To replace the operating coil, first insert the

magnet yoke into the operating coil. After this has

been accomplished, insert both the operating coil

and the magnet yoke, as a unit, into the switch unit

– The magnet yoke is laminated

– Unique high-pressure results

securely. Now replace the coil cover into the switch

unit, but do not tighten the screws on the coil

retaining spring. Be sure to place the auxiliary

contact operating lever into the auxiliary contact

actuator fastened to the cross bar.

on page 3.)

and the four captive screws on the coil cover.

Restore the coil leads and put back the coil terminal

cover.

NOTE

into the control transformers with 120 volt, 60 Hz

secondary.

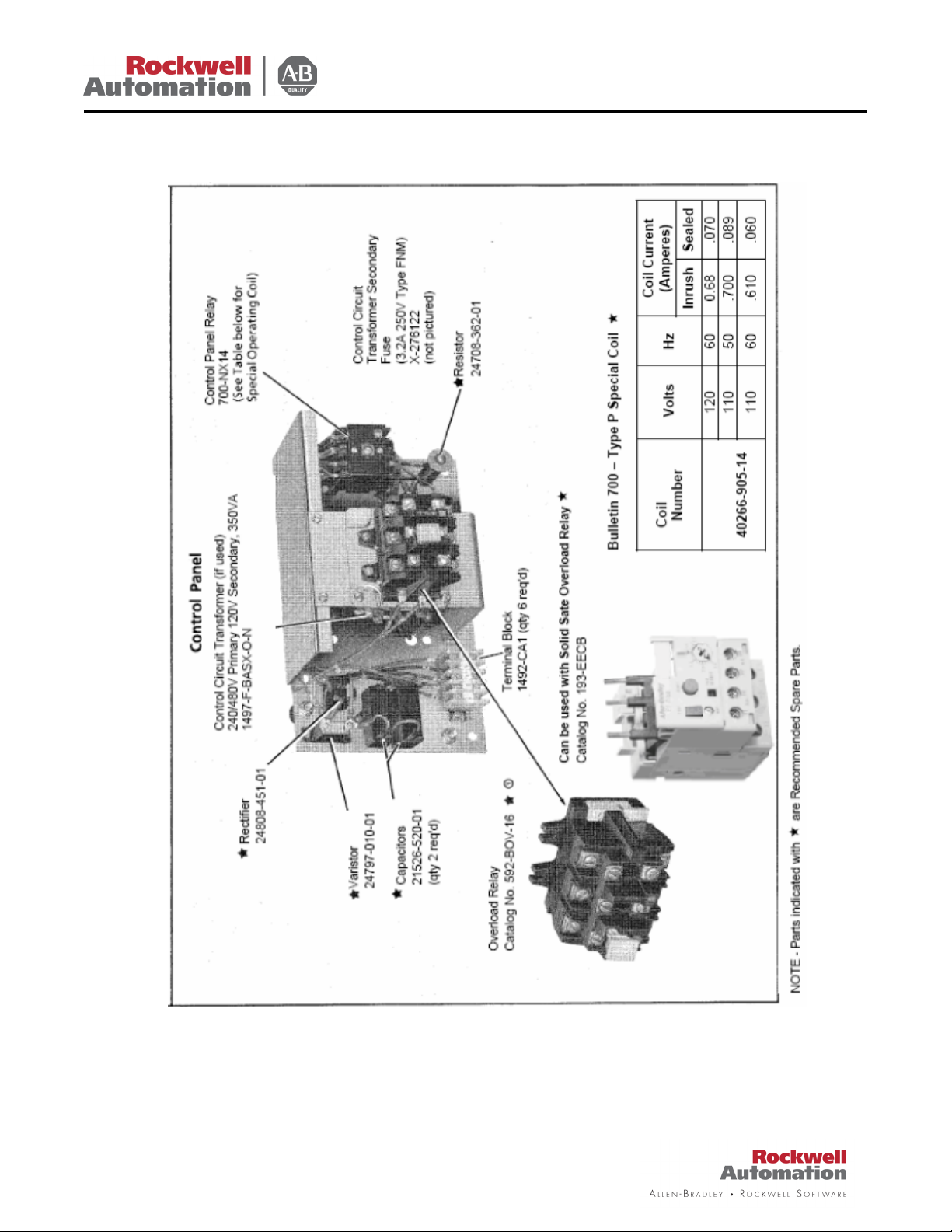

CONTROL PANEL

capacitor, rectifier, resistors, contact protector,

terminal blocks and control transformer (when used)

– is mounted in a metal cabinet. The cabinet is

normally mounted below the starter, but may be

mounted separate from the starter. The cabinet

(when below starter) is mounted on rubber

grommets to absorb heavy shock during opening

and closing of starter. The control panel has a

hinged cover which can be swung out for inspection

or to check wiring of auxiliary equipment.

BULLETIN 1495 AUXILIARY CONTACTS –

Provisions are made for two auxiliary contacts in

addition to the one which is required for the

economizing action. Each auxiliary contact provides

two independent circuits, either of which can be set

as normally open and normally closed, depending

on the circuit requirements. (

Tighten the coil retaining spring screws

Operating Coil

Coil

Number

107D206

(90V DC)

volts

120 17.6 .392

208 10.2 .226

240 8.8 .196

480 4.4 .093

600 3.5 .078

Coil Current

(Amperes)

Inrush sealed

– Given values are input current (amperes)

- All auxiliary equipment –

See Instructions - Page 6.)

(See instructions

Page 2 of 10

Page 3

505 z 509

BULLETIN

Page 3 of 10

Page 4

505 z 509

BULLETIN

Page 4 of 10

Page 5

505 z 509

BULLETIN

Page 5 of 10

Page 6

505 z 509

BULLETIN

Bulletin 592 Manual Reset Overload Relay

Optional: Bulletin 193 E1 Plus Solid State Overload

Relay

(See Page 5)

ORDERING INFORMATION – Your order cannot be

entered unless the following information is given:

Part number, description of part and series letter of

starter. This renewal parts list applies also to these

starters when used on control apparatus listed under

other Bulletin numbers.

BULLETIN 1495 AUXILIARY CONTACT KITS

Catalog Number 1495-J6 (Single Contact)

Catalog Number 1495-K6 (Double Contact)

Overload Relay

CHANGING BULLETIN 1495 AUXILIARY CONTACT

FROM NORMALLY OPEN TO NORMALLY CLOSED

AND VICE VERSA

Auxiliary Contact from Normally Open to Normally

Closed and vice versa, first loosen the screw which

holds the drive plate and adjusting plate together.

Then lift the drive plate as shown in the illustration.

Now rotate the adjusting plate to the opposite hole

and snap the drive plate into place. Then tighten the

screw. Double contact auxiliary switches have

isolated circuits; therefore, each side must be

adjusted independently.

TYPICAL WIRING DIAGRAM – (See applicable

codes and laws - Schematic is shown on page 7)

– To change the Bulletin 1495

MOUNTING INSTRUCTION – To mount the Bulletin

1495 Auxiliary Contact place the auxiliary contact

operating lever into the auxiliary contact actuator

fastened to the cross bar. Tighten the two mounting

screws on the auxiliary contact to the coil cover. The

cross bar will now engage the operating lever of the

auxiliary contact.

Page 6 of 10

Page 7

505 z 509

BULLETIN

Page 7 of 10

Page 8

505 z 509

BULLETIN

Spare part List for Bulletin 505, Size 8

Part Number Part Description QTY Part Number Part Description QTY

X-356928 Stationary Contact Block Less Contacts 1 M-922 Support Screw 1

Z-31010 Contact Block Screw Assembly 2 B-32105 Locking Plate 1

X-356929 Contact Block Cover 1 199-LG1 Lug 3

Z-31031 Contact Block Cover Screw Assembly 2 G-13422 Front Terminal Extension 1

F-21662 Contact Block Spacer 1 B-35910 Locking Plate 1

X-356933 Movable Contact Assembly 1 X-319610 Front Terminal Assembly 1

X-356931 Cross Bar Less Contacts 1 X-298507

B-33266 Push Rod Shims (0.035 thick) 2 M-7693 Screw 1

B-34407 Push Rod Shims (0.015 thick) 2 M-103 Lock Washer 1

Z-31794 Single Contact 1 M-248 Lock Washer 1

Z-31795 Double Contact 1 M-471 Screw 1

X-270997 Magnet Yoke 1 M-180 Lock Washer 1

F-21355 Yoke Retainer 1 M-5683 Washer 1

X-2311653 Push Rod Assembly 2 M-22 Iron Nut 1

F-21353 Armature Spacer 1 M-165 Screw 1

F-23326 Armature Pad 1 M-756 Screw 1

M-6483 Screw w/Washer 2 M-7692 Screw 1

B-31807 Armature Plate 1 M-1100 Lock Washer 1

F-21352 Armature Retainer 1 M-12 Lock Washer 1

F-23320 Retaining Block 2 M-144 Screw 1

X-270998 Magnet Armature 1 M-1552 Terminal Screw 1

X-289391 Coil Cover w/Screws 1 24808-451-01 Rectifier 1

Z-32042

B-35910 Locking Plate 1 21526-520-01 Capacitors 2

B-32105 Locking Plate 1 1492-CA1 Terminal Block 6

199-LC1 Lug 3 24708-362-01 Resistor 1

G-13411 Rear Terminal Extension 1 X-276122

B-33300 Control Terminal 1 700-NX14 Control Panel Relay 1

X-319611 Rear Terminal Assembly 1 193-EECB E1 Plus Solid Sate Overload Relay 1

X-298508

B-34853 Transformer Clamp 1 193-ERA E1 Plus Reset Adapter 1

M-2185 Clamp Screw 1 193-BC8 E1 Plus Shield 1

M-6 Clamp Washer 1 A40266-601-01 700P Control relay 1

M-7 Clamp Nut 1 A40185-450-02 Over current Relay 1

X-316050

B-34612 Transformer Support 1 700-P220A1 Industrial relay 1

M-6 Support Washer 1

Coil Retaining Spring w/Screws and

Washers

Rear Contact Assembly w/Screws &

Washers

Current Transformer (1200 to 5 amp

ratio)

1 24797-010-01 Varsitor 1

1 193-EPB E1 Plus Adapter 1

1 A40460-002-01 Insulation, Resistor 1

Front Contact Assembly w/Screws &

Washers

Transformer Sec. fuse (3.2A 250V Type

FNM)

1

1

Page 8 of 10

Page 9

505 z 509

BULLETIN

Page 9 of 10

Page 10

505 z 509

BULLETIN

Publication 505-QS001A-EN-P – November 2006 Copyright © 2006 Rockwell Automation, Inc. All rights reserved. Printed in the USA.

Loading...

Loading...