Page 1

Instructions

B

lock

b

N. O. Pole Conversion Kits

500LC–2PCK, 500LC–4PCK,

500LC–6PCK, 500LC–LS3 for

Bulletin 500LC Lighting Contactors

Use these instructions to change poles on Bulletin 500LC Lighting Contactors.

Contact

Kit No.

500LC–2PCK

500LC–4PCK

500LC–6PCK

500LC–LS3

Kit

num

of Poles

2 1top

4 1top

6 1top 1top 1top 2both

leaf spring 1 1 1

A new and different contact block is needed in the lighting contactor when

the number of poles is changed. A leaf spring must be used on 2–...6–pole

(without a bottom contact block). Two actuators are used on all

configurations. When changing poles, also change catalog number on

nameplate.

Number of Contactor Poles (Normally Ope n )

er

2 4 6 8 10 12

1

bottom

1

bottom

Recommended Tools Screwdriver and scriber (to change nameplate catalog number)

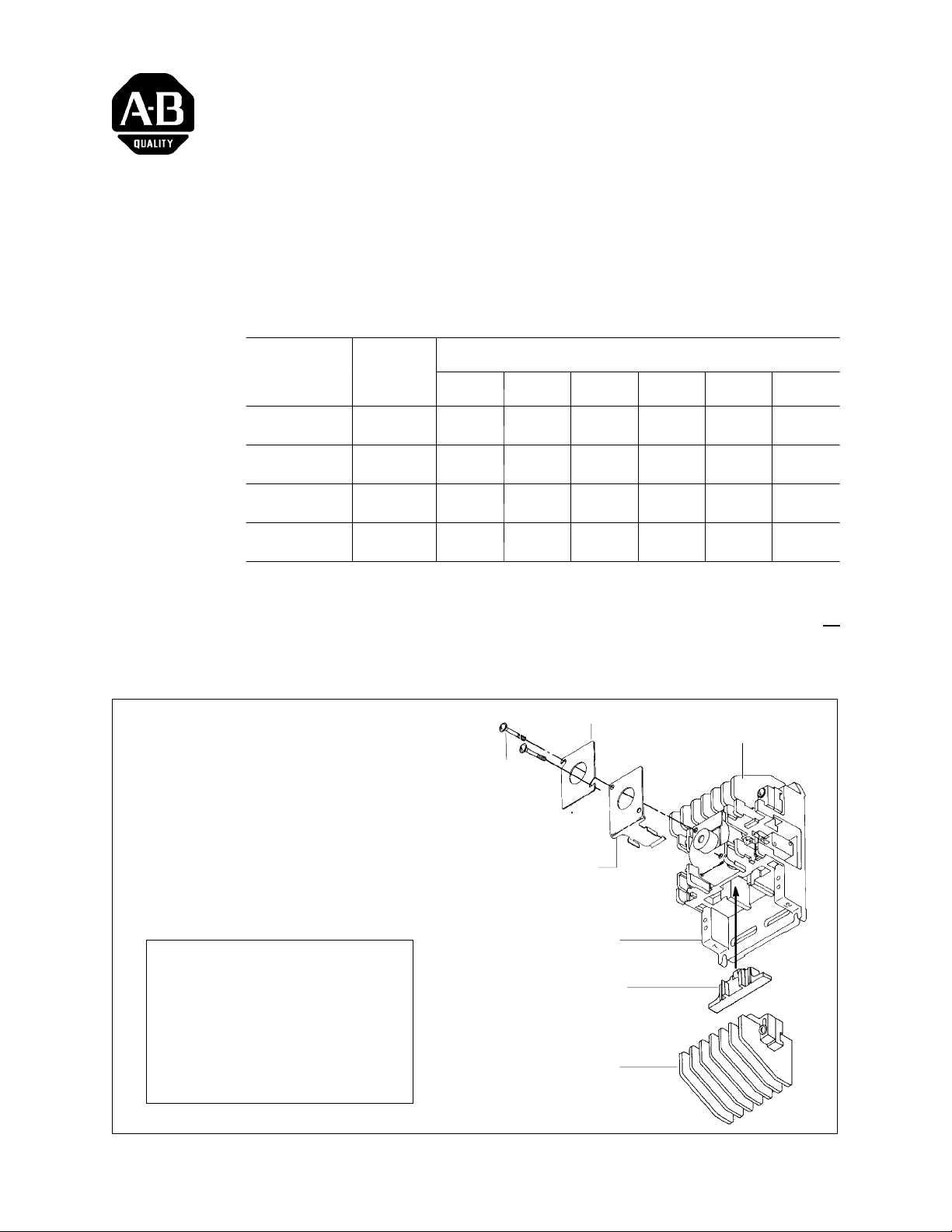

upper

contact block

Tighten nameplate screws

evenly to 10 in–lb.

Be sure to change the catalog

number on the nameplate.

nameplate

nameplate screw

CAM / CORE must be white.

This kit should not be applied

to Lighting Contactors with

black CAM / CORE.

*leafspringisnotused

on 8–...12–pole

When a lower contact block is

added remove the leafspring.

Two actuators are always

used (top and bottom).

leaf spring *

(2–...6–pole only)

base

actuator

(2 used; 1 top, 1 bottom)

lower

contact block

Figure 1 Contact block and actuator

Publication 500LC–IN004A–EN–P May 2005

Page 2

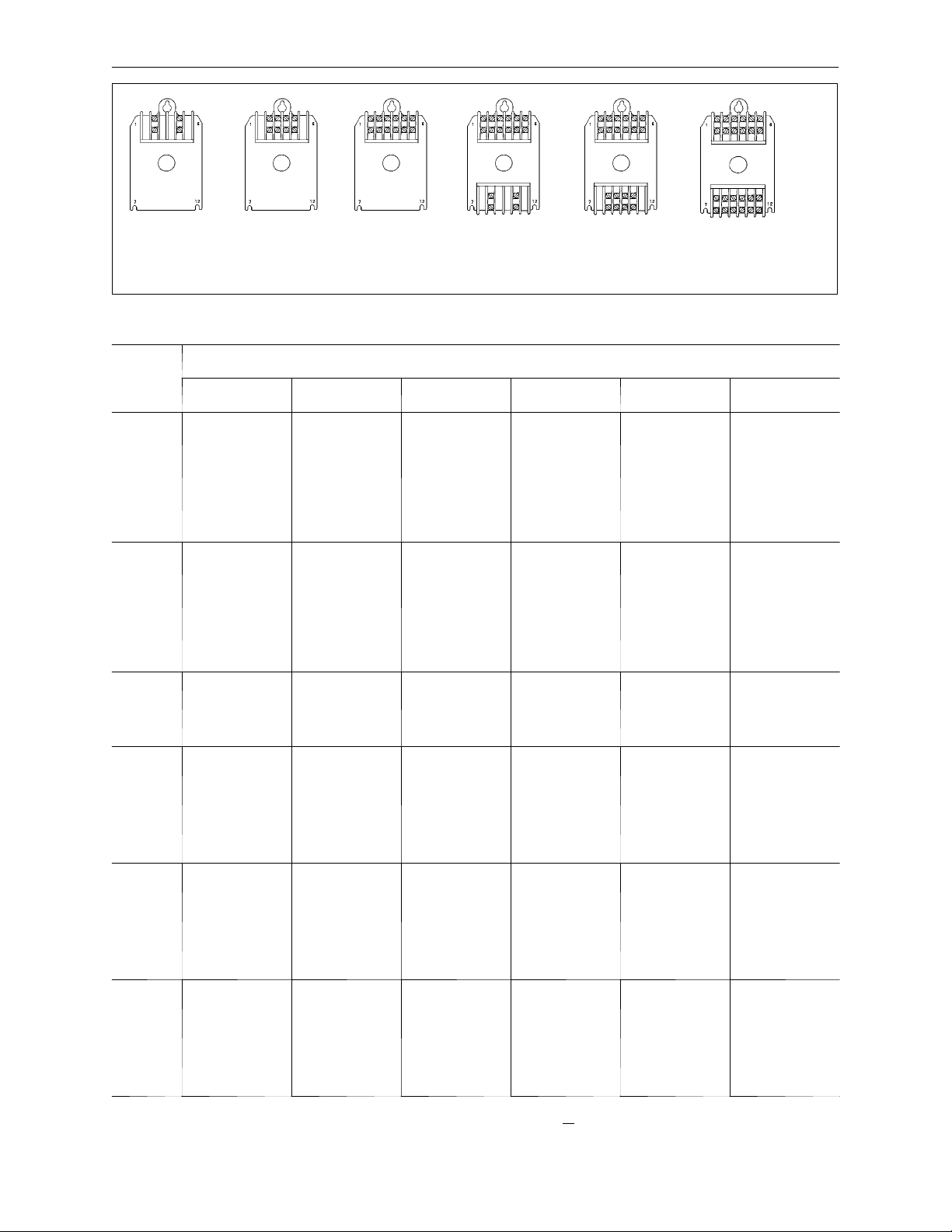

Installing Pole Conversion Kits 500LC–2PCK, 4PCK, 6PCK, LS3 to Bulletin 500LC Lighting Contactors

Pol

2

A

2Pole

B

4Pole

C

6Pole

D

8Pole

E

10 Pole

Figure 2 Location of contact block(s) in relation to number of poles

TableA–N.O.PoleConversionKits

top

bottom

F

12 Pole

To t al

es

Needed 2

2

see

Fig. 2A

4

see

Fig. 2B

6

see

Fig. 2C

8

see

Fig. 2D

10

see

Fig. 2E

12

see

Fig. 2F

Number of Poles on Exi st in g Bulletin 500LC Li ght i ng Contactor

4 6 8 10 12

Remove top block.

Remove bottom

block and

reinstall it on top.

Install a new

leaf spring

500LC–LS3

on bottom.

Remove top block.

Install new block

500LC–4PCK

on top. Remove

bottom block.

Install a new

leaf spring

500LC–LS3

on bottom.

Remove bottom

block. install a

new leaf spring

500LC–LS3.

Remove bottom

block. Install

new block

500LC–4PCK

on the bottom.

Remove bottom

block. Install

new block

500LC–6PCK

on the bottom.

Remove top

block. Install

new block

500LC–4PCK

on top.

Remove top

block. Install

new block

500LC–6PCK

on top.

Remove leaf

spring. Remove

top block and

reinstall it on

bottom. Install

new block

500LC–6PCK

on top.

Remove top block.

Install new block

500LC–6PCK

on top. Remove

leaf spring. Install

another new block

500LC–6PCK

on the bottom.

Remove top

block. Install

new block

500LC–2PCK

on top.

Remove top

block. Install

new block

500LC–6PCK

on top.

Remove top

block. Install

new block

500LC–2PCK

on top.

Remove leaf

spring. Remove

top block and

reinstall it on

bottom. Install

new block

500LC–6PCK

on the top.

Remove top block.

Install new block

500LC–6PCK

on top. Remove

leaf spring. Install

another new block

500LC–6PCK

on the bottom.

Remove top

block. Install

new block

500LC–2PCK

on top.

Remove top

block. Install

new block

500LC–4PCK

on top.

Remove leaf

spring. Install

new block

500LC–2PCK

on the bottom.

Remove leaf

spring. Install

new block

500LC–4PCK

on the bottom.

Remove the leaf

spring. Install

new block

500LC–6PCK

on the bottom.

Remove top block.

Install new block

500LC–2PCK

on top. Remove

bottom block and

install a new

leaf spring

500LC–LS3

on bottom.

Remove top block.

Remove bottom

block and

reinstall it on top.

Install a new

leaf spring

500LC–LS3

on bottom.

Remove bottom

block. install a

new leaf spring

500LC–LS3.

Remove bottom

block. Install

new block

500LC–2PCK

on bottom.

Remove bottom

block. Install

new block

500LC–6PCK

on the bottom.

Remove top block.

Install new block

500LC–2PCK

on top. Remove

bottom block and

install a new

leaf spring

500LC–LS3

on bottom.

Remove top block.

Install new block

500LC–4PCK

on top. Remove

bottom block and

install a new

leaf spring

500LC–LS3

on bottom.

Remove bottom

block. install a

new leaf spring

500LC–LS3.

Remove bottom

block. Install

new block

500LC–2PCK

on bottom.

Remove bottom

block. Install

new block

500LC–4PCK

on the bottom.

NOTE: T op and bottom actuators are required for all configurations;

top actuator with a contact block, bottom actuator with a contact block or a leaf spring.

Publication 500LC–IN004A–EN–P May 2005

Page 3

Installing Pole Conversion Kits 500LC–2PCK, 4PCK, 6PCK, LS3 to Bulletin 500LC Lighting Contactors

How to Install a Contact Block

3

1. Open circuit breakers, then use a voltmeter to verify no voltage is present at

2. Label, disconnect, and tape all wires (control, line, load) from the lighting

3. Loosen the mounting screws and remove the Bulletin 500LC Lighting

Disassembly

The contact blocks are mounted on the top and bottom of the lighting contactor.

A bottom contact block is used only for lighting contactors with more than six

poles. See Figure 2 and Table A.

1. Remove the contact block(s). Skip this step if it is not necessary to move or

2. Remove leaf spring if converting a 2–...6–pole lighting contactor to an

Reassembly

Be sure the contact blocks and actuator are correct for the number of poles

required. Lighting contactors with more than six poles use two contact blocks.

When two are used, always mount the six pole contact block on the top of the

lighting contactor. See Figure 2 and Table A.

1. Slide the actuator into the cavity (roller facingin, with the guides facingaway

2. With actuator(s) already installed, install the new contact block(s) onto the

3. Converted lighting contactors must be assembled as shown with contact blocks as

4. Use a scriber to change the nameplate catalog number (number of poles).

5. Install the manual operat ing screw. Insert the #8–32 screw (fromthe kit) into

6. Manually operate the lighting contactor. Use the plastic screw to close and

CAUTION

To avoid personal injury or property

damage, de–energize both line and control

power connected to the Bulletin 500LC

Lighting Contactor before proceeding.

both control and line terminal screws.

contactor.

Contactor from the enclosure.

remove a contact block. Loosen the two screws in each contact block. Then

pull the contact block straight out.

Do not remove the captive screws from the conta ct block. The lower actuator

may drop out when the bottom contact block is removed.

8–...12–pole lighting contactor. For leaf spring removal see Figure 1.

Note: When converting an 8–...12–pole N.O. lighting contactor to a

2–...6–pole lighting contactor a leaf spring and new actuator must be installed.

SeeFigure1.

from the base of the lighting contactor) before installing the contact block.

base. Tighten the two screws in each contact block to 10 in–lb. See Figure 1.

shown in Figure 2. If any contact blocks are removed to accomplish the

conversion, a leaf spring must be installed.

the center of the coil and carefully turn it clockwise until the threads engage

thecam/core.SeeFigure3.Tightenhandtight.SeeFigure3.

open the lighting contactor by pushing it inward and pulling it outward.

Observe the buttons in the contact blocks(s); the contacts are open when the

buttons are out. The action should be smooth, without any binding. If not,

recheck alignment of contact block(s) and actuator.

Publication 500LC–IN004A–EN–P May 2005

Page 4

Installing Pole Conversion Kits 500LC–2PCK, 4PCK, 6PCK, LS3 to Bulletin 500LC Lighting Contactors

4

Re mo ve the plastic operat in g screw !

7. Remove the plastic operating screw from the lighting contactor.

8. Reinstall the lighting contactor into the enclosure and tighten the mounting

screws.

9. Reconnect all wires previously removed. Tighten control connections to

10 in–lb. Tighten the line and load connectio ns to 18 in–lb.

10. Close circuitbreakers and check electrical operation of the lighting contactor

with the new control voltage.

manual

operating

screw

push — pull

Do not manually operate

until all power and control

circuits are disconnected.

Figure 3 Manual operating screw

Publication 500LC–IN004A–EN–P May 2005

2005 Rockwell Automation. All rights reserved. Printed in USA.

381339–266

Loading...

Loading...