Page 1

Guardmaster® 440G-LZ Guard Locking Switch

User Manual

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment.

Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication

SGI-IN001_-EN-P

http://www.rockwellautomation.com/literature/

equipment and hard-wired electromechanical devices. Because of this difference, and also because of the wide

variety of uses for solid-state equipment, all persons responsible for applying this equipment must satisfy

themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages

resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular installation, Rockwell Automation, Inc. cannot

assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits,

equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell

Automation, Inc., is prohibited.

available from your local Rockwell Automation sales office or online at

) describes some important differences between solid-state

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

It is recommended that you save this user manual for future use.

2 Rockwell Automation Publication 440G-UM001A-EN-P — November 2013

Page 3

Read this preface to become familiar with the rest of the manual.

It provides information concerning:

• who should use this manual

• the purpose of this manual

• related documentation

• conventions used in this manual

Preface

Who Should Use This Manual

Purpose of This Manual

Conventions Used in This

Manual

Use this manual if you are responsible for designing, installing,

programming, or troubleshooting systems that use the Guardmaster

440G-LZ guard locking switch.

You should have a basic understanding of electrical circuitry and

familiarity with safety-related systems. If you do not, obtain the proper

training before using this product.

This manual is a reference guide for the Guardmaster 440G-LZ guard

locking switch. It describes the procedures you use to install, wire, and

troubleshoot your switch. This manual:

• Explains how to install and wire your 440G-LZ

• Provides an overview of the Guardmaster 440G-LZ guard locking

switch

The following conventions are used throughout this manual:

• Bulleted lists such as this one provide information, not procedural

steps.

• Numbered lists provide sequential steps or hierarchical

information.

Additional Resources

The following document offers additional information about related

Rockwell Automation products:

Resource Description

Allen-Bradley Industrial Automation Glossary,

publication AG-7.1

Rockwell Automation Publication 440G-UM001A-EN-P — November 2013 3

Glossary of industrial automation terms and

abbreviations

Page 4

Preface

Terminology

You can view and download publications at http://

www.rockwellautomation.com/literature/ . To order paper copies of

technical documents, contact your local Rockwell Automation distributor

or sales representative.

OSSD Output Signal Switching Device. Typically designates a pair of solid state

signals pulled up to the DC source supply. The signals are usually tested for

short circuits to the DC power supply, short circuits to the DC common, and

short circuits between the two signals.

Standard coding Same as Low coding as defined in EN/ISO 14119:2013

Unique coding Same as High coding as defined in EN/ISO 14119:2013

4 Rockwell Automation Publication 440G-UM001A-EN-P — November 2013

Page 5

General Description

Safety Concept

Table of Contents

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Preface

Who Should Use This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Purpose of This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Conventions Used in This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Additional Resources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Chapter 1

Guardmaster 440G-LZ Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Assembly Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Packaging Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 2

Safety Standards Applied to Guardmaster 440G-LZ. . . . . . . . . . . . . 11

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Safety Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Installation and Wiring

Description of Operation

Chapter 3

General Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Pair Proximity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Orientation of Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Setting the Actuator Direction of Approach . . . . . . . . . . . . . . . . . . . . 15

Mounting the Assembled Actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Mounting the Switch Body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Setting Actuator to Switch Alignment . . . . . . . . . . . . . . . . . . . . . . . . . 17

Actuator RFID Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

LED Error Codes During the Learning Process . . . . . . . . . . . . . . . . . . 19

Proving Basic Lock Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Connection Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Chapter 4

Description of LEDs During Operation . . . . . . . . . . . . . . . . . . . . . . . . . 23

Status/Diagnostic LED During Troubleshooting . . . . . . . . . . . . . . . . 24

Auxiliary Out Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Guardmaster 440G-LZ Wiring with GSR Relay . . . . . . . . . . . . . . . . . . 25

Guardmaster 440G-LZ Wiring with Point I/O . . . . . . . . . . . . . . . . . . . 26

Guardmaster 440G-LZ Wiring with GLP Relay . . . . . . . . . . . . . . . . . . 26

Guardmaster 440G-LZ Troubleshooting Series Circuit . . . . . . . . . . 27

Unit Response Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

OSSD Output Test Pulses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Auxiliary/Manual Release. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Rockwell Automation Publication 440G-UM001A-EN-P — November 2013 5

Page 6

Table of Contents

Appendix A

Specifications

Typical Installations

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Safety Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Operating Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Environmental and General Protection. . . . . . . . . . . . . . . . . . . . . . . . . 31

Certifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Compliance to European Union Directives . . . . . . . . . . . . . . . . . . . . . 32

Overall Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Catalog Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Appendix B

Switch Mounted Parallel to Hinge Axis . . . . . . . . . . . . . . . . . . . . . . . . . 35

Switch Mounted Perpendicular to Hinge Axis . . . . . . . . . . . . . . . . . . 36

Switch Mounted to a Sliding Guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

EU Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6 Rockwell Automation Publication 440G-UM001A-EN-P — November 2013

Page 7

General Description

Chapter 1

Guardmaster 440G-LZ

Overview

This Guardmaster 440G-LZ guard locking switch functions by extending a

locking bolt from the switch through a hole in the actuator, thus

preventing the opening of a guard.

The locking bolt drive mechanism and logic ensure that the locking bolt

is allowed to extend only when the corresponding actuator is detected

within range.

The appropriate actuator is detected by RFID coding.

This version of the Guardmaster 440G-LC guard locking switch features

OSSD outputs that are enabled only when the locking bolt is sensed in its

extended position in the actuator, which happens only when the guard is

both closed and locked.

The locking bolt drive mechanism uses a bi-stable solenoid; as a result,

the switch consumes very little electrical power, with peak currents

occurring only briefly, upon start-up and after each movement of the

locking bolt.

Because of its bi-stable drive, not only does the device consume minimal

power, but it does not produce heat whether in its locked or unlocked

condition.

Despite the bi-stable design of the locking bolt drive, the device logic and

functionality are configured to replicate the functionality of a power-torelease or power-to-lock solenoid-operated switch (depending on type).

Rockwell Automation Publication 440G-UM001A-EN-P — November 2013 7

Page 8

Chapter 1 General Description

Locking bolt

Act uato r

Switch body

Actu ator

mounting bracket

QR Code

Alignment guide

Guardmaster 440G-LZ

Assembly Overview

Packaging Contents

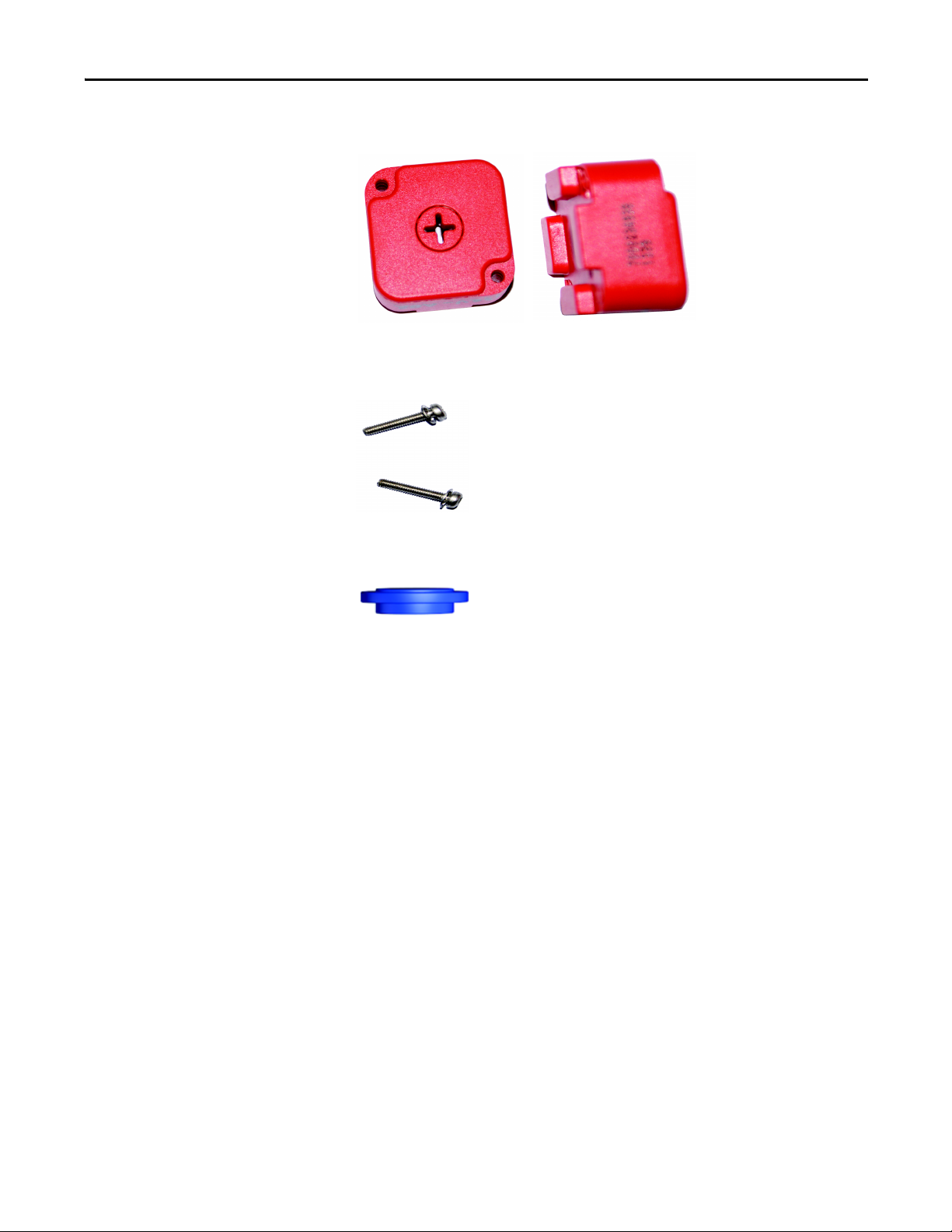

The box includes the following components:

Switch body including connection lead: 3 m or 10 m flying lead or

pigtail equipped with M12 QD connector

Actuator mounting bracket

8 Rockwell Automation Publication 440G-UM001A-EN-P — November 2013

Page 9

General Description Chapter 1

Actuator

Actuator-to-actuator mounting bracket mounting screws: 2 x T10

To r x

Alignment guide

Rockwell Automation Publication 440G-UM001A-EN-P — November 2013 9

Page 10

Chapter 1 General Description

Notes:

10 Rockwell Automation Publication 440G-UM001A-EN-P — November 2013

Page 11

Safety Concept

Chapter 2

Safety Standards Applied to

the Guardmaster 440G-LZ

Guard Locking Switch

Introduction

Safety Certification

The Guardmaster 440G-LZ satisfies applicable requirements in the

following standards related to functional and machinery assembly:

• IEC 60947-5-1: 2003+A1: 2009

• IEC 60947-5-3: 1999/A: 2005

• IEC 61508:2010 SIL 3

• IEC 62061:2005 SIL 3

• EN/ISO 13849-1:2008/AC: 2009 Performance Level e (PLe), Category

4

• EN/ISO 14119:2013

• UL 508 17

This section describes the safety performance level concept and explains

how the Guardmaster 440G-LZ meets the requirements for SIL 3, Cat. 4 or

Performance Level “e” (PLe) applications.

The Guardmaster 440G-LZ is certified for use in safety applications up to

and including SIL 3 according to IEC 61508 and IEC 62061 with a proof test

interval of 20 years, Performance Level PLe and Category 4 in compliance

with ISO 13849-1.

th

Edition dated 3/19/2013

Safety requirements are based on the standards applicable at the time of

certification.

The TÜV Rheinland group has approved the Guardmaster 440G-LZ for use

in safety-related applications where Performance Level “e” is required for

the door position and lock monitoring functions.

The 440G-LZ must be installed in accordance with the applicable

regulation and standards.

While the 440G-LZ can be used for SIL 3, PLe and Category 4 applications,

the installer must comply with guard requirements (e.g. EN/ISO13854

and EN/ISO 13857) and in some cases also minimum (safe) distance

requirements (e.g. EN/ISO 13855).

Rockwell Automation Publication 440G-UM001A-EN-P — November 2013 11

Page 12

Chapter 2

The installed system, including the safety control system and the means

by which the machine stops, must achieve the needed safety

performance. The 440G-LZ is one element in the safety system.

Additional guidance on guards, guard locking and guard interlocking

may be found in:

• EN/ISO 12100

• EN/ISO 13854

• EN/ISO 13855

• EN/ISO 13857

• EN/ISO 14119

• EN/ISO TR 24119

• EN/ISO 14120

• Application specific C-Level standards

12 Rockwell Automation Publication 440G-UM001A-EN-P — November 2013

Page 13

Installation and Wiring

Chapter 3

General Considerations

The 440G-LZ guard locking switch is designed for use on guards that are

engineered to be rigid without sag. A separately mounted latch (e.g.

magnetic or mechanical) and mechanical stop are required.

It can be used on Full Body Access guards that do not require escape

release, emergency release or remote release guards, and in any situation

where the alignment tolerance falls within the stated specification.

Installation must be in accordance with the present manual and must be

carried out by qualified personnel exclusively. The 440G-LZ guard locking

switch is intended to be part of the safety-related control system of a

machine. Before installation, a thorough risk assessment must be

performed to determine whether the specifications of this device are

suitable for all foreseeable operational and environmental characteristics

of the application.

Refer to the Specifications section of this manual. Use appropriate screws,

bolts, or nuts fitted by tools to mount the switch and actuators to avoid

tampering.

Do not over-torque the mounting hardware.

Pair Proximity

ATTENTION: For the switch, actuator and actuator mounting bracket:

• Only use the designated mounting holes.

• Never drill or use to support other structures such as a conduit, cable

ways, or other hardware.

During installation, make sure you observe the following restriction: you

must maintain a minimum distance between each pair of switches you

mount. Make sure to maintain a minimum distance of 120 mm (4.72 in.)

between any two switches and actuators, as indicated in the following

illustrations.

Rockwell Automation Publication 440G-UM001A-EN-P — November 2013 13

Page 14

Chapter 3 Installation and Wiring

120 mm

120 mm

Orientation of Switches

If the recommended minimum proximity dimension is not observed, the

units will fault.

Can be used in all mounting orientations.

14 Rockwell Automation Publication 440G-UM001A-EN-P — November 2013

Page 15

Installation and Wiring Chapter 3

Align the white triangles.

0.4 Nm

2 x T10 Torx screws

Setting the Actuator

Direction of Approach

The actuator can approach the switch from all four directions.

Ensure the white arrow on the actuator aligns with the white arrow on

the switch body.

The actuator must be fitted to the actuator mounting bracket in such a

manner that the white alignment triangles marked on both the actuator

and switch body are in the installed position.

Rockwell Automation Publication 440G-UM001A-EN-P — November 2013 15

Ensure the locking bolt enters the actuator mounting bracket first.

Page 16

Chapter 3 Installation and Wiring

Mounting the Assembled

Actuator

Ensure two fasteners are used with at least one fastener fitted close to the

actuator bracket bend.

The following drawings show mounting possibilities when attaching to

extruded aluminum profile and flat surface guard doors.

Removal of the Actuator Plug

This plug may be broken out from the actuator if a through hole is

required to prevent a food trap when mounted on the hazard side of a

guard door.

The plug can be broken out by using a screwdriver and twisting until it

comes apart.

16 Rockwell Automation Publication 440G-UM001A-EN-P — November 2013

Page 17

Installation and Wiring Chapter 3

3 x M5

G

H

Mounting the Switch Body

Setting Actuator to Switch

Alignment

Three M5 fasteners (not provided) are required for proper mounting to a

rigid guard door frame.

There are three ways to achieve proper alignment.

1. By setting gap

2.5 mm (0.09 in.) [

2. By mounting hole alignment

6.5 mm (0.25 in.) [4…9 mm (0.15…0.35 in.)]

3. Using the alignment

provided

“G”

0…5 mm (0…0.19 in.)

”H”

guide

]

Rockwell Automation Publication 440G-UM001A-EN-P — November 2013 17

Page 18

Chapter 3 Installation and Wiring

ATTENTION: After installation, ensure

that there is no possibility of lifting the

actuator over the extended locki ng bolt.

ATTENTION: After installation, ensure

there is no possibility of collision when

the actuator approaches the switch body.

Actuator RFID Setting

Switches with standard coded actuators

These switches are ready for use and need no special RFID setting.

Switches with unique coded actuators

Before use, the switches must first “learn” a new RFID guard actuator. This

task is not performed at the factory, as there are two possible methods:

• “Multi-time” learning: the switch can learn up to eight actuators

consecutively.

• “One-time” learning: The switch learns one actuator only, for life,

irreversibly.

The “one-time” learning method may be invoked at any time, not just

during RFID setting. For example, the switch could “multi-time” learn four

different actuators consecutively, then complete a “one-time” learning

process that would prevent it from learning any additional actuators.

Learning the First “Multi-Time” Actuator

Connect the switch to 24V DC (see the wiring diagrams on page 21

ensure that the lock command is off.

), and

The Status/Diagnostic LED will blink a number of times corresponding to

the number of times a new actuator may be acquired (a total of eight

times when the switch is new), then repeat, indicating that the switch has

yet to learn a new actuator.

The switch automatically starts the learning process as soon as an

actuator is placed in the guard-closed position of the switch.

18 Rockwell Automation Publication 440G-UM001A-EN-P — November 2013

Page 19

Installation and Wiring Chapter 3

Learning Sequence as Indicated by the Status/Diagnostic LEDs

Actuator present Blinking green, 1 Hz rate

Verifying actuator Blinking green/red, 1 Hz rate (15 sec)

Programming switch (15 sec) Blinking green/red, 4 Hz rate (15 sec)

Program finalization Blinking green (remaining number of times

a new actuator may be acquired, 15 sec)

Ready state (learning process is complete) Solid green (Power-to-release)

Solid red (Power-to-lock)

Learning Additional “Multi-Time” Actuators

Mount the new actuator on the guard and repeat the above process.,

introducing the actuator to the switch as previously described. During

program finalization, the LED will blink green a number of times

corresponding to the number of remaining learnable actuators.

Note: Once a new actuator is learned by a unique coded switch, any

previous actuator is no longer usable by that switch.

“One-time” Learning Process

Proceed just as in the “multi-time” teaching process described above,

with the following exception: at the programming finalizing (last) stage,

withdraw the actuator from the switch, until the LED turns solid red, then

immediately reposition the actuator near the switch. This process must

be executed within 15 seconds.

The LED blinks, then turns solid to indicate that the learning process is

complete.

Power-to-release Solid green

Power-to-lock Solid red

Note: For power-to-release switches, you will need to execute a manual

release in order to withdraw the actuator away from the switch as

described above.

Rockwell Automation Publication 440G-UM001A-EN-P — November 2013 19

Page 20

Chapter 3 Installation and Wiring

Status/Diagnostic LED Error

Codes During the Learning

Process

Proving Basic Lock Function

The following code sequences persist until a Power On/Off cycle is

completed.

Status/Diagnostic LED Flashes (4 Hz) Error Code

Green OSSD inputs not valid

Red-red-red-green Cannot learn a standard actuator

Red-red-red-green-green Actuator already learned

Red-red-red-green-green-green Bad RFID; actuator moved out of range

Red-red-red-green-green-green-green Exceeded learning eight actuators

Red-red-red-green-green-green-green-

Unit locked: cannot learn another actuator

green

To prove basic lock function and to verify correct actuator alignment, it

may be necessary to extend the locking bolt. The locking bolt cannot be

extended by mechanical means; you must proceed electrically. The

following basic connections are required:

• Pin 2 (brown wire) must be connected to 24V DC

• Pin 7 (blue wire) must be connected to 0V (GND)

In the case of a power-to-release switch, the locking bolt will extend

when the guard is shut and the actuator is aligned. Connect Pin 3 (green

wire) to 24V DC to unlock the switch and withdraw the locking bolt.

If power is removed from a power-to-release switch in the locked

position, the locking bolt will remain in its extended position (switch

locked). Use the manual auxiliary release to unlock the switch.

In the case of a power-to-lock switch, connect Pin 3 (green wire) to 24V

DC to lock the switch (i.e. extend the locking bolt). Disconnecting Pin 3

will unlock the switch.

If power is removed from a power-to-lock switch in the locked position,

the switch unlocks.

In either type of lock, the locking bolt never extends in the absence of the

actuator.

20 Rockwell Automation Publication 440G-UM001A-EN-P — November 2013

Page 21

Wiring

2

1

7

6

3

8

4

5

8-Pin Micro (M12)

8-Pin Cordset

889D-F8AB-* or

cable version

Installation and Wiring Chapter 3

3 Lock Command

8 Safety A+

4 Safety B+

5 Safety A

Color Function Pin

White Aux 1

Brown 24V DC+ 2

Green Lock 3

Yellow Safety B+ 4

Grey Safety A 5

Pink Safety B 6

Blue Gnd/0V 7

Red Safety A+ 8

2 24V DC+

Keyway

1 Aux

7 0V

6 Safety B

Connections Systems

The following connection system components facilitate connection:

Safety-wired Splitter/T-Port Cat. No 898D-438Y-D8

Rockwell Automation Publication 440G-UM001A-EN-P — November 2013 21

Page 22

Chapter 3 Installation and Wiring

PWR

OSSD 1+

OSSD 2+

NA

Pin 1

Pin 2

Pin 3

Pin 4

NA

Pin 5

Safety-wired Shorting Plug Cat. No 898D-418U-DM

2

5

3

1

4

8-pin Device Patchcords Cat. No.

1 meter, 8-pin 889D-F8ABDM-1

2 meters, 8-pin 889D-F8ABDM-2

5 meters, 8-pin 889D-F8ABDM-5

10 meters, 8-pin 889D-F8ABDM-10

Note: Add the letter “S” to above cat. nos. for stainless steel connectors;

e.g. 889DS-F8ABDM-1

5-pin Patchcords Cat. No.

1 meter, 5-pin 889D-F5ACDM-1

2 meters, 5-pin 889D-F5ACDM-2

5 meters, 5-pin 889D-F5ACDM-5

10 meters, 5-pin 889D-F5ACDM-10

Note: Add the letter “S” to above cat. nos. for stainless steel connectors;

e.g. 889DS-F5ACDM-1

5-pin Cordsets

Cat. No.

2 meters, 5-pin 889D-F5AC-2

5 meters, 5-pin 889D-F5AC-5

10 meters, 5-pin 889D-F5AC-10

Note: Add the letter “S” to above cat. nos. for stainless steel connectors;

e.g. 889DS-F5AC-1

More detailed information may be found online at ab.com/product

catalogues/ (search for “Connection Systems”).

22 Rockwell Automation Publication 440G-UM001A-EN-P — November 2013

Page 23

Description of Operation

Chapter 4

Status/Diagnostic LEDs

During Operation

During operation, the LEDs indicate the status of the Guardmaster

440G-LZ guard locking switch as follows:

Power -to-Lock

Versions

Power on and lock

CMD off

Lock CMD on, door

open

Lock CMD on, door

closed

Lock CMD on, door

closed

Power -toRelease Versions

Power on with

door open

Power on with

door closed

Guard

Status

Open or

closed

Open On Off or onUnlocked Fast flash green Off

Closed On Off Locked Slow flash green Off

Closed On On Locked Solid green On

Guard

Status

Open Off Off or onUnlocked Blinks 6x green,

Closed Off Off Locked Blinks 6x green,

Lock

OSSD

CMD

Input

Off Off or onUnlocked Blinks 6x green

Lock

OSSD

CMD

Input

Lock

Status

Lock

Status

LED

Status

then solid red

LED

Status

then blinks 1x

red, followed by

fast flash green

then blinks 1x

red, followed by

slow flash green

OSSD

Status

Off

OSSD

Status

Off

Off

Power on with

door open, and

OSSD input active

Unlock CMD on,

and door closed or

open

Rockwell Automation Publication 440G-UM001A-EN-P — November 2013 23

Closed Off On Locked Blinks 6x green,

then blinks 1x

red, followed by

solid green

Open or

closed

On Off or onUnlocked Solid red Off

On

Page 24

Chapter 4 Description of Operation

Status/Diagnostic LEDs

During Troubleshooting

This section explains the meaning of the various LEDs during

troubleshooting.

LED Status Switch Status

Off Not powered

Solid green Door shut, locked, and OSSDs are ON.

Fast flash, green (4 Hz) Waiting to lock, actuator is not within range

Slow flash, green (1 Hz) Door shut, locked. OSSDs are OFF because there’s no safety

input signal.

Solid red (PTL versions) Door open or shut, not locked. No lock signal.

Solid red (PTR versions) Door open or shut, not locked. Unlock signal is ON.

Flashing 3x green, then red - repeats Attempting to lock/unlock, actuator not aligned.

Flashing 3x green, then red repeating, then finally fast flash red

Slow flash, red (1 Hz) OSSD fault, check outputs are not shorted to GND, 24V DC,

Fast flash, red (4 Hz) General fault. Cycle power to reset.

Failure to lock/unlock. Align actuator, then cycle power.

or each other. Cycle power to reset.

Auxiliary Out Function

The Auxiliary Out only changes state when the door is shut and locked,

regardless of OSSD status.

Power-to-Lock Versions Lock CMD Lock Status Auxiliary Out

Door open On or off Unlocked On

Lock CMD on, door closed On Locked Off

Power-to-Release Versions Lock CMD Lock Status Auxiliary Out

Door open On or off Unlocked On

Lock CMD off, door closed On Locked Off

24 Rockwell Automation Publication 440G-UM001A-EN-P — November 2013

Page 25

Guardmaster 440G-LZ Wiring

889D-F8AX-X

Pigtail

Red

Brn

Wht

Grn

Pnk Gry

Ye l

Blu

Power

In1

In2

Out

Logic

A2

A1

+-

S11

S21

S12

S22

S32

S42

L12

L11

Y32

S34

13

14

23

24

24VDC

IN1

DI

IN2

0

1

2

3

4

56

7

8

LOGIC

Test Out

A2A1

+-

B2 37B1 47 4838

L12 L11 X32 17

27

2818

24VDC

EMD

171827

28

373847

48

N/C

E-Stop

K1

K2

M

K1

K2

Reset

440G-LZS

24V DC Supply

24V DC COM

with GSR Relay

Description of Operation Chapter 4

Rockwell Automation Publication 440G-UM001A-EN-P — November 2013 25

Page 26

Chapter 4 Description of Operation

1734-IB8S

I0 I4 I5I1

I2 I6 I7I3

COM COM COMCOM

T0 T2 T3MT1

1734-OB8S

O0 O4 O5O1

O2 O6 O7O3

COM COM COMCOM

889D-F8AX-X

Pigtail

COM COM COM COM

M

K1

K2

Safety

Reset

Faul t

Reset

N/C

Red

Brn

Wht

Grn

Pnk

Gry

Yel

Blu

24V DC Supply

24V DC COM

K1

K2

Unlock

Request

Unlock

Signal

E-Stop

800FM-MT44

800F-MX02S

Reset

GLP

440R-GL2S2P

A2S12 S22

L11

L12

L61

51

P12 P22

A1X14 X24 S54

S44

AP

Y32

Reset &

Gate Lock

Request

Gate

Unlock

Request

Y32

DI

440R-D22R2

S32

A1 13

S21S11 S22S12 S34

S42

L12

14

872C-D8NP18-E5 (2)

24V DC, Class 2 Supply

24V DC COM

0

1

4

5

6

7

8

9

SL2

2

3

0

1

3

4

5

6

7

8

9

SL1

2

LOGIC

0

1

2

3

4

5

6

7

9

8

E-Stop

800FM-MT44

800F-MX02S

0

1

2

3

4

56

7

8

LOGIC

Brn

Brn

Blk

Blk

Blu

Blu

23

24

Safety

Status

to PLC

L11 A2

Brn Red Yel

Grn

Wht Blu Gr y Pnk

Reset

440G‐LZS21SPRA

SLS

Request

to PLC

+24V DC

COM

Status

Safety Input 1

Safety C ommon

Safety Input 2

K 300

Safe Torque-o (STO)

Connector With

Wiring Header

Drive Status

to PLC

Stop/Start/SLS

from PLC

Gate Open

- Unlocked

Guardmaster 440G-LZ Wiring

with Point I/O

Point to Point I/O with Unlock request.

Guardmaster 440G-LZ Wiring

with GLP Relay

26 Rockwell Automation Publication 440G-UM001A-EN-P — November 2013

E-Stops with Speed Monitoring, Guard Locking and Servo Drive

Page 27

Troubleshooting Series

Actuator 1

Actuator 2

Actuator 3

Switch 1

Switch 2

Switch 3

RTN

24V DC

Power

Supply

+24

1606-

XL120D

Green

Pink

Grey

Brown

Red

Yel

White

A2

440R-N23132

Initial Conditions:

All switches are

locked

Switch 1 receives

Unlock command

(guard can then

be opened).

Lock/unlock

command

Switch 2 drops the 24 volts

(red and yellow) from

switch 1 OSSD outputs.

Green LED ashes.

Switch 3 drops the 24 volts

(red and yellow ) from

switch 3 OSSD outputs.

Green LED ashes.

Pink

Grey

Red

Yel

White

Green

Blue

Pink

Grey

Red

Yel

White

S11 41332313S12S52

S21 S22 42342414A1S34

200 ms150 ms100 ms0 ms

650 ms625 ms600 ms0 ms

Switch 1 guard is

closed

Switch 1 OSSD

outputs are

energized.

Switch 2 OSSD inputs (red

and yellow) transition to

24V DC from switch 1 OSSD

outputs. Switch 2 OSSD

outputs are energized.

Switch 3 OSSD inputs (red

and yellow) transition to

24V DC from switch 2

OSSD outputs. Switch 3

OSSD outputs are energized.

Green

Brown

Blue

Brown

Blue

Switch 1

Switch 2

Switch 3

Circuit

+24

24V DC

Power

Supply

1606-

XL120D

RTN

Switch 1 Switch 2 Switch 3 Switch 4 Switch 5

Description of Operation Chapter 4

Green

Yellow

White

Red

Lock/Unlock Lock/UnlockLock/UnlockLock/UnlockLock/Unlock

Recoverable

Actuator 1 is in sensing range

and guard is locked.

Fault

Guard 1 functions properly.

OSSDs are energized to 24V.

Green LED is ON.

Unit Response Times When

Connected in Series

Blue

Brown

Grey

Pink

Green

White

+24V +24V

+24V +24V

Actuator 2 is in sensing range

and guard is locked.

Guard 2 functions properly.

OSSDs are energized to 24V.

Green LED is ON.

Brown

Yellow

Grey

Red

Blue

Pink

Green

Actuator 3 is in sensing

range and guard is locked.

Guard 3 has a fault.

See Diagnostic table.

Red LED is ashing.

Brown

Yellow

White

Red

Grey

Pink

Blue

Green

White

0V

Actuator 4 is in sensing range

and guard is locked. Guard

4 functions properly. Series

inputs are 0V. OSSDs are

de-energized to 0V. Green

LED is ashing to indicate

series inputs are not 24V.

Yellow

Red

Blue

Brown

Grey

Pink

Green

0V0V

0V

Actuator 5 is in sensing range

and guard is locked. Guard 5

functions properly.

Series inputs are 0V. OSSDs

are de-energized to 0V. Green

LED is ashing to indicate

series inputs are not 24V.

Brown

Yellow

White

Red

Grey

Pink

Blue

0V

0V

OSSDs

are OFF

Rockwell Automation Publication 440G-UM001A-EN-P — November 2013 27

Page 28

Chapter 4 Description of Operation

Safety A

Safety B

Occurs every 25 ms

Occurs every 25 ms

Occurs every 11 sec

300 μs

300 μs

˂ 600 μs

˂ 600 μs

Occurs every 11 sec

OSSD Output Test Pulses

Auxiliary/Manual Release

The Guardmaster 440G-LZ guard locking switch uses test pulses to check

for OSSD output faults. This process is illustrated graphically as follows:

The manual release is provided to allow you to

unlock the guard door in the event of

unforeseen and uncommon circumstances.

< 2.5 (0.098) dia.

If power is supplied to the switch and the latter

is in its locked state, invoking the auxiliary

release will cause the switch to enter a fault

condition (blinking red LED).

To reset the switch, simply cycle the power.

28 Rockwell Automation Publication 440G-UM001A-EN-P — November 2013

Page 29

Specifications

Appendix A

Introduction

Safety Ratings

This appendix provides the specifications for the Guardmaster 440G-LZ

guard locking switch.

Note: The holding force Fzh is in accordance to EN/ISO 14119:2013,

clause 5.7.4. Additional validation was performed in accordance with IEC

60947-5-1:2009, clause C.1.2.2.

Standards IEC 60947-5-3, IEC 60947-5-1, IEC 61508, EN/

ISO 13849-1, IEC 62061, EN/ISO14119, UL 508

Safety Classification: Guard door sensing and

lock monitoring

Functional Safety Data: Guard door sensing and

lock monitoring

PLe Category 4 per ISO 13849-1, SIL 3 per IEC

61508 and IEC 62061

PFHD: 9.1 x 10

Dual channel interlock may be suitable for use

in applications up to PLe (in accordance with

ISO 13849-1) and for use up to SIL 3 systems (in

accordance with IEC 62061), depending on

application characteristics.

Mission time/PTI: 20 years

-10

Operating Characteristics

440G-LZS21*PR* Power-to-release

440G-LZS21*PL* Power-to-lock

Switch function OSSDs enable when guard closed and locked

Torque for M5 mounting of switch and actuator

mounting bracket

Locking bolt insertion for assured locking and

holding force

Approach speed Minimum of 2 mm/s

Locking bolt alignment tolerance X, Y, Z Maximum of +/- 2.5 mm

Holding force Fmax (EN/ISO 14119) 1,690 N

Holding force Fzh (EN/ISO 14119) 1,300 N

Maximum output current (each output) 200 mA

Quiescent power consumption, Locked or

Unlocked

Rockwell Automation Publication 440G-UM001A-EN-P — November 2013 29

2 Nm max.

Minimum of 5 mm (0.19 in.), maximum of 10

mm (0.39 in.)

2.5 W

Page 30

Appendix A Specifications

Peak current, during turn-on or after Lock/

Unlock operation

Duration of peak current, at turn-on or after

Lock/Unlock operation

Maximum number of switches connectable in

series

Operating voltage Ue 24V DC + 10% / -15% Class 2 SELV

Maximum frequency of operating cycles 0.2 Hz

Dwell time between subsequent locking/

unlocking

Response time (Off) 100 ms first switch, +50 ms for each additional

Risk time (according to IEC 60947-5-3) 100 ms

Start-up time (availability) 5 s

Usage category (IEC 60947-5-2) DC-13 24V 200 mA

Insulation voltage Ui (IEC 60947-5-1) 75 V

Impulse withstand voltage Uimp (IEC 60947-5-1)1 kV

Pollution degree (IEC 60947-5-1) 3

400 mA

100 ms

Unlimited, See Chapter 4, Unit Response Times

2.5 s

switch

Outputs (Guard Closed

and Locked)

Manual (auxiliary) release Built-in

Emergency release No

Escape release No

Protection class (IEC 61140) Class II

* See nomenclature section below, and cat. nos. section on page 34.

Nomenclature for Complete Switches

440G-LZS21

abc

S Standard Coding R Power-to-Release A 3 m Cable

U Unique Coding L Power-to-Lock B 10 Cable

Outputs Description/Status

Safety 2 x PNP, 0.2 A max. / ON (+24V DC)

P

abc

H M12 8-pin

Auxiliary 2 x PNP, 0.2 A max. / OFF (+0V DC)

30 Rockwell Automation Publication 440G-UM001A-EN-P — November 2013

Page 31

Specifications Appendix A

Environmental

General

Operating temperature [C (F)] 0…55º (+14…131º)

Storage temperature [(C (F)] -25…75º (+13…167º)

Operating humidity 5…95%, relative

Enclosure ingress rating NEMA 3, 4x, 12, 13, IP66, IP67, IP69K

Shock and vibration IEC 68-2-27 30 g, 11 ms/IEC 68-2-6 10…55 Hz

Hygienic ISO 14159:2004 and EN 1672-2005 (for part of

the machine defined as “food splash area”)

Washdown Suitable for sodium hydroxide-based

washdown fluids

Radio frequency / EMC IEC-60947-5-3, FCC-1 (Parts 18 & 15), R&TTE

Materials ABS, locking bolt and mounting bracket 304

stainless steel

Weight switch/actuator Switch 400 g, actuator 22 g,

actuator mounting bracket 60 g

Connection Flying lead or pigtail with M12 8-pin QD

connector (stainless steel)

Protection

Certifications

Short-circuit protection Incorporated

Current limitation Incorporated

Overload protection Incorporated

Reverse polarity protection Incorporated

Overvoltage protection Incorporated (up to 60V max.)

Thermal shutdown/restart Incorporated

See the Product Certification link at http://

www.rockwellautomation.com/rockwellautomation/certification/ for

Declaration of Conformity, Certificates, and other certification details.

• UL Listed Industrial Control Equipment, Certified for US and Canada

• CE Marked for all applicable directives

• C-Tick Marked

• TÜV Certified for Functional Safety up to SIL 3 Category 4 for use in

safety applications up to and including SIL 3, in accordance with IEC

61508 and EN 62061, Performance Level “e” and Category 4 in

accordance with ISO 13849-1, both for guard positioning and for

lock monitoring according to EN/ISO 14119:2013.

Rockwell Automation Publication 440G-UM001A-EN-P — November 2013 31

Page 32

Appendix A Specifications

25

(0.98)

50

(1.97)

22.5

(0.89)

45 (1.77)

8

(0.31)

10

(0.39)

22.9

(0.90)

140 (5.51)

10

(0.39)

9.5

(0.37)

9.525

(0.37) dia.

22.5

(0.88)

134.5 (5.29)

33

(1.29)

2 x 5.5

(0.22) dia.

Compliance to European

Union Directives

Overall Dimensions

This product bears the CE Mark and is approved for installations within

the European Union and EEA regions. It has been designed and tested to

meet the following directives (Machine Safety and EMC).

For a complete list of standards used (including Machine Safety Directive

and EMC Directive), see EU Declaration of Conformity on page 37

of this

manual.

Switch Body

Actuator and Actuator Mounting Bracket

(1.57)

65

(2.56)

25.4

(1.0)

7

(0.28)

25 (0.98)

6 x 6.35

(0.25) dia.

12.5

(0.5)

40

47

(1.85)

51.5 (2.03)

40 (1.57)

3

(0.12)

32 Rockwell Automation Publication 440G-UM001A-EN-P — November 2013

Page 33

Switch Mounting Bracket 440G-LZAM2

40 (1.57)

Specifications Appendix A

+1

R6

-3

2x 6.35

(2x 0.25)

100 (3.93)

22.75 (0.89)

18.5

(0.73)

2x 15.5 (2x 0.61)

145.5

(5.72)

3x 5.5

(3x 0.22)

3 x 5.5

(3x 0.22)

2x 15

(2x 0.59)

54

(2.12)

2x 33

(2x 1.3)

2x 31.5

(2x 1.24)

6.35

(0.25)

4x R6

± 1 mm

6x M5

x 0.8-6H

Rockwell Automation Publication 440G-UM001A-EN-P — November 2013 33

Page 34

Appendix A Specifications

Cat. Nos.

Complete switches, including switch body, actuator and actuator

mounting bracket

Cat. No.

Connection

6 in. pigtail with

M12 8-pin Quick

Type Actuator Coding

Standard

3 m lead 10 m lead

440G-LZS21SPRA 440G-LZS21SPRB 440G-LZS21SPRH

Disconnect

(Low level to EN/

ISO 14119:2013)

Unique

440G-LZS21UPRA 440G-LZS21UPRB 440G-LZS21UPRH

(High level to EN/

Power-t o-

ISO 14119:2013)

Release

Standard

440G-LZS21SPLA 440G-LZS21SPLB 440G-LZS21SPLH

(Low level to EN/

ISO 14119-2013)

Unique

440G-LZS21UPLA 440G-LZS21UPLB 440G-LZS21UPLH

(High level to EN/

Power-to -Lock

ISO 14119:2013)

Spare actuators and actuator mounting bracket

Type Coding Cat. No.

Standard

440G-LZASPR

(Low level EN/ISO 14119:2013)

Power-to -Relea se

Unique

(High level EN/ISO 14119:2013)

Standard

440G-LZAUPR

440G-LZASPL

(Low level EN/ISO 14119:2013)

Unique

440G-LZAUPL

(High level EN/ISO 14119:2013)

Power-to -Lock

Actuator mounting bracket 440G-LZAM1

Accessories

Description Cat. No.

Switch body mounting bracket 440G-LZAM2

34 Rockwell Automation Publication 440G-UM001A-EN-P — November 2013

Page 35

Typical Installations

Mounting

bracket

440G-LZAM2

X

Z

Y

Y

X

Actuator

Hole

14mm

Locking bolt

9mm

Appendix B

Switch Mounted Parallel to

Hinge Axis

The X and Y positions can be

adjusted using the slotted holes of

the mounting bracket and

appropriate selection of the three

pairs of actuator bracket holes,

once the bracket is centered.

The tolerance to misalignment is

±2.5 mm.

The Z (height) position is adjusted

by sliding the actuator bracket up/

down on the profile. If the setting

gap is centered between the

minimum of 0 mm and the

maximum of 5 mm, a tolerance to

misalignment of ±2.5 mm is

achieved.

The Z position should be carefully selected to offset the anticipated door

sag or door drop. At the same time, ensure that the alignment is such that

it is not possible to lift the door up and off the locking bolt. Also make

sure that there is no possibility that the actuator would collide with the

switch when the guard door is being closed. It is essential to check the

alignment periodically throughout the use of the guard locking switch.

Rockwell Automation Publication 440G-UM001A-EN-P — November 2013 35

Page 36

Appendix B Typical Installations

2 mm

(at min. radius)

Minimum radius when

guard hinge axis is

perpendicular to the

switch body axis

Min R 300 mm

Mounting

bracket

440G-LZAM2

X

Z

Y

Switch Mounted

Perpendicularly to

Hinge Axis

The Z (height) position is adjusted

by sliding the actuator bracket up/

down on the profile. If the setting

gap is centered between the

minimum of 0 mm and the

maximum of 5 mm, a tolerance to

misalignment of ±2.5 mm is

achieved.

The X and Y positions can be

adjusted using spacers

underneath the switch and

appropriate selection of the three

pairs of actuator bracket holes,

once the bracket is centered.

The tolerance to misalignment is

±2.5 mm.

The Z position should be carefully

selected to offset the anticipated

door sag or door drop. At the same

time, ensure that the alignment is

such that it prevents lifting the

door up and off the locking bolt.

Also check to ensure there is no

possibility that the actuator would

collide with the switch when

closing the guard door. It is

essential to check the alignment

periodically throughout the use of

the guard locking switch.

Z

Y

X

Switch Mounted to a Sliding

Guard Door

36 Rockwell Automation Publication 440G-UM001A-EN-P — November 2013

The Z (height) position is adjusted

by sliding the actuator bracket up/

down on the profile. If the setting

gap is centered between the

minimum of 0 mm and the

maximum of 5 mm, a tolerance to

misalignment of ±2.5 mm is

achieved.

The X and Y positions can be

adjusted using the slotted holes of

the mounting bracket and

appropriate selection of the three

pairs of actuator bracket holes,

once the bracket is centered.

The tolerance to misalignment is

+/- 2.5 mm.

Page 37

Typical Installations Appendix B

EU Declaration of Conformity

Identification of the product:

Guard Locking Safety Switch

Name and address of the manufacturer:

Rockwell Automation, Inc.

2 Executive Drive

Chelmsford, MA 01824

USA

Name and address of the authorised representative:

Rockwell Automation B.V.

Rivium Promenade 160

2909 LM Capelle aan den Ijssel

The Netherlands

This declaration of conformity is issued under the sole responsibility of the manufacturer.

Object of the declaration:

Allen Bradley / Guardmaster 440G-LZ21 Series

(reference the attached list of catalogue numbers)

The object of the declaration described above is in conformity with the relevant EU harmonisation legislation:

2004/108/EC

EMC Directive

(EMC)

2006/42/EC

Machinery Directive

(MD)

References to the relevant harmonised standards used or references to the specifications in relation to which

conformity is declared:

EN 60947-1:2007

Low-voltage switchgear and controlgear – Part 1: General rules

EN 60947-5-3:1999 + A1:2005

Low- voltage switchgear and controlgear – Part 5-3: Control circuit devices

and switching elements – Requirements for proximity devices with defined

behaviour under fault conditions (PDF)

EN 60204-1:2006 + A1:2009

Safety of Machinery – Electrical equipment of machines – General

requirements

IEC 61508: Part 1-7:2010

Functional Safety of electrical /programmable electronic safety related

systems

EN ISO 13849-1:2008

Safety related parts of control systems – Part 1: General principles of design

EN 62061:2005

Safety of Machinery – Functional safety of safety related electrical, electronic

and programmable electronic control systems

EN ISO 14119:2013

Safety of Machinery – Interlocking devices associated with guards –

Principles for design and selection

Notified Body:

TUV Rheinland IndustrieService GmbH

51105 Koln Germany

performed:

EU Type Examination

and issued the certificate:

968/EZ 616.00/13

Additional information:

Person authorised to compile the

technical file (MD):

Authorised representative (see details above).

Product Safety Function (MD):

Interlocking devices suitable for use in safety related applications up to PLe

(EN ISO 13849-1) and SIL/SIL CL (EN 61508/EN 62061)

Signed for and on behalf of the above named manufacturer:

Place and date of issue:

Milwaukee, WI USA

11-Nov-2013

Name, function:

Daniel L. Nachtigall, Technical Leader – Product Certification Engineering

Signature:

Rockwell Automation Publication 440G-UM001A-EN-P — November 2013 37

Page 38

Appendix B Typical Installations

Catalogue number

Series 1

Description

Directive 2

EMC

MD

440G-LZ21****

Guard locking RFID non-contact safety switches

Yes

Yes

Accessories

889D-F8AB-*

Cordset for use with sensors with Micro (M12) connector

N/R

N/R

889D-F8ABDM-*

Patchcord for use with sensors with Micro (M12) connector

N/R

N/R

1) If no series number is given, then all series are covered

2) Yes = Product is certified to this directive.

N/R = This directive is not required for this product

NOMENCLATURE:

440G-LZS21

U P R

H

1 2 3 4 5

1

Designates Product Type

440G-LZS21 – Guard locking RFID non-contact safety switch w/2 safety outputs and 1 auxiliary output

2

Designates Actuator Coding Type

U – Unique

S – Standard code

3

Designates Sensor Type

P – Plastic Switch

4

Designates Lock Mode

R – Power to release

L – Power to lock

5

Designates Connection Type

H – 8 pin micro (M12) connector pigtail

A – 3 meter cable

B – 10 meter cable

38 Rockwell Automation Publication 440G-UM001A-EN-P — November 2013

Page 39

Page 40

Power, Control and Information Solutions Headquarters

Americas: Rockwell Automation, 1201 South Second Street, Milwaukee, WI 53204-2496 USA, Tel : (1) 414.382.2000, Fa x: (1) 414.382.4444

Europe/Middle East/Africa: Rockwell Automation NV, Pegasus Park, De Kleetlaan 12a, 1831 Diegem, Belgium, Tel: (32) 2 663 0600, Fax: (32) 2 663 0640

Asia Pacic: Rockwell Automation, Level 14, Core F, Cyberport 3, 100 Cyberport Road, Hong Kong, Tel : (852) 2887 4788, Fax: (852) 2508 1846

www.rockwel lautomation.com

Rockwell Automation Support

Rockwell Automation provides technical information on the web to assist you in using its products.

At http://www.rockwellautomation.com/support

notes, sample code and links to software service packs, and a MySupport feature that you can customize to

make the best use of these tools. You can also visit our Knowledgebase at

http://www.rockwellautomation.com/knowledgebase

forums, software updates, and to sign up for product notification updates.

, you can find technical manuals, technical and application

for FAQs, technical information, support chat and

For an additional level of technical phone support for installation, configuration, and troubleshooting, we offer

SM

Tec hCon ne ct

Rockwell Automation representative, or visit http://www.rockwellautomation.com/support/

support programs. For more information, contact your local Allen-Bradley distributor or

.

Installation Assistance

If you experience a problem within the first 24 hours of installation, review the information that is contained in

this manual. You can contact Customer Support for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or

Canada

Use the Worldwide Locator at http://www.rockwellautomation.com/support/americas/

phone_en.html, or contact your local Rockwell Automation representative.

New Product Satisfaction Return

Rockwell Automation tests all of its products to ensure they are fully operational when shipped from the

manufacturing facility. However, if your product is not functioning and needs to be returned, follow these

procedures.

United States Contact your distributor. You must provide a Customer Support case number (call the phone number above to

obtain one) to your distributor to complete the return process.

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

Rockwell Automation, Allen-Bradley, and POINT I/O are trademarks of Rockwell Automation, Inc. Guardmaster is a registered trademark of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are the property of their respective companies.

Publication 440G-UM001A-EN-P– November 2013 Copyright © 2013 Rockwell Automation, Inc. All rights reserved.

Loading...

Loading...