Page 1

Allen-Bradley

PanelV iew

1000e, 1200e, and

1400e Operator

Terminals

(Cat. No. 2711E-T10C6, 2711E-K10C6,

271 1E-T10C7, 2711E-K10C7,

271 1E-T10C15, 2711E-K10C15,

271 1E-K12C6, 2711E-K12C6L2,

271 1E-T12C6, 2711E-T12C4,

271 1E-T14C6, 2711E-K14C6,

271 1E-T14C7, 2711E-K14C7,

271 1E-T14C15, 2711E-K14C15)

User

Manual

product icon

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this

control equipment must satisfy themselves that all necessary steps

have been taken to assure that each application and use meets all

performance and safety requirements, including any applicable laws,

regulations, codes and standards.

The illustrations, charts, sample programs and layout examples

shown in this guide are intended solely for purposes of example.

Since there are many variables and requirements associated with any

particular installation, Allen-Bradley does not assume responsibility

or liability (to include intellectual property liability) for actual use

based upon the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation, and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some

important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in

whole or in part, without written permission of Allen-Bradley

Company, Inc., is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION: Identifies information about practices

or circumstances that can lead to personal injury or

!

death, property damage or economic loss.

Attention statements help you to:

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifies information that is critical for successful

application and understanding of the product.

PanelBuilder, PanelView, Data Highway Plus, DH+, Modbus, SLC and SLC 500 are trademarks, and PLC, PLC-2, and PLC-3

are registered trademarks of Allen-Bradley, Inc.

Intel is a trademark of Intel Corporation.

IBM, PC, AT, XT, PS/2 and PC DOS are registered trademarks of International Business Corporation.

Epson is a registered trademark of Seiko Epson Corporation.

Microsoft Windows is a trademark, and Microsoft, MS, and MS-DOS are registered trademarks of Microsoft Corporation.

All other brand and product names are trademarks or registered trademarks of their respective companies and are hereby

acknowledged.

Page 3

Preface

About This Manual P–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intended Audience P–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Publications P–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Support Services P–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introducing the PanelView

Terminals

Chapter 1

Welcome to the PanelView Family 1–1. . . . . . . . . . . . . . . . . . . . . . . .

Keypad and Touch Screen Terminals and Software 1–5. . . . . . . . . . . . .

Keypad Terminals 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Function Keys 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Numeric Keypad 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Keys 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Touch Screen Terminals 1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PanelBuilder 1400e Configuration Software 1–1 1. . . . . . . . . . . . . . . .

Features of the PanelView Terminals 1–11. . . . . . . . . . . . . . . . . . . . . . .

New Features of the PanelView Terminals 1–13. . . . . . . . . . . . . . . . . . .

Applicable Programmable Controllers and Connections 1–14. . . . . . . . .

Remote I/O Communications 1–14. . . . . . . . . . . . . . . . . . . . . . . . . .

PLC-5/1 1, 5/15, 5/20, 5/25, 5/30, 5/40, 5/60, 5/80 and

5/250 Processors 1–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLC-5/10 Processor 1–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLC-3 and PLC-3/10 Processors 1–14. . . . . . . . . . . . . . . . . . . . .

PLC-2 Family Processors via 1771-SN or 1772-SD2 1–15. . . . . . . .

SLC-5/02, 5/03, or 5/04 via 1747-SN Series A or B 1–15. . . . . . . . .

1771-SN I/O Subscanner Module 1–15. . . . . . . . . . . . . . . . . . . . .

6008-SI IBM PC I/O Scanner 1–15. . . . . . . . . . . . . . . . . . . . . . . .

6008-SV VME I/O Scanner 1–15. . . . . . . . . . . . . . . . . . . . . . . . . .

6008-SQ DEC Q-BUS I/O Scanner 1–16. . . . . . . . . . . . . . . . . . . .

DH+ Communications 1–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLC-5/10, 5/11, 5/15, 5/20, 5/25, 5/30, 5/40, 5/60, 5/80, 5/40L,

5/60L, 5/80L 1–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SLC-5/04 1–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLC2/PLC3 1–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ControlNet Communications 1–16. . . . . . . . . . . . . . . . . . . . . . . . . . .

PLC-5/20C, 5/40C, 5/60C, 5/80C 1–18. . . . . . . . . . . . . . . . . . . . .

Publication 2711E-821 – January 1998

Page 4

Table of Contentstoc–ii

Installing PanelView 1000e Terminals

Chapter 2

Overview 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PanelView 1000e Terminal Dimensions 2–2. . . . . . . . . . . . . . . . . . . . .

Tools for Installing Your PanelV iew 1000e Terminal 2–4. . . . . . . . . . . . .

Mounting Options for PanelView 1000e Terminals 2–4. . . . . . . . . . . . .

Mounting a Clip-Mount Touch Screen Terminal in a Panel or

Wall Cutout 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting a Clip-Mount Keypad Terminal in a Panel or

Wall Cutout 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting a Touch Screen Terminal in a 19-inch Rack 2–9. . . . . . . . .

Mounting a Keypad Terminal in a 19-inch Rack 2–9. . . . . . . . . . . . .

Setting Up the PanelView 1000e Terminal 2–9. . . . . . . . . . . . . . . . . . .

Switching Modes 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Backlight Intensity 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting Power to the Terminal 2–10. . . . . . . . . . . . . . . . . . . . . . .

Connecting the Upload/Download Cable 2–1 1. . . . . . . . . . . . . . . . . .

Connecting the Serial Printer 2–1 1. . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting an External Alarm Relay 2–12. . . . . . . . . . . . . . . . . . . . .

Connecting a Terminal to Your PLC System 2–13. . . . . . . . . . . . . . . .

Using the PCMCIA Card Slots 2–15. . . . . . . . . . . . . . . . . . . . . . . . .

Installing PanelView 1200e Terminals

Chapter 3

Overview 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PanelView 1200e Terminal Dimensions 3–3. . . . . . . . . . . . . . . . . . . . .

Tools for Installing Your PanelV iew 1200e Terminal 3–5. . . . . . . . . . . . .

Mounting Options for PanelView 1200e Terminals 3–5. . . . . . . . . . . . .

Mounting a Stud-Mount Keypad or Touch Screen Terminal in a

Panel or Wall Cutout 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting a Clip-Mount Touch Terminal in a Panel or Wall Cutout 3–8.

Mounting a Stud-Mount Keypad Terminal in a 19-inch Rack 3–10. . . . .

Mounting a Touch Screen Terminal in a 19-inch Rack 3–10. . . . . . . . .

Setting Up the PanelView 1200e Terminal 3–10. . . . . . . . . . . . . . . . . . .

Adjusting Contrast and Brightness 3–10. . . . . . . . . . . . . . . . . . . . . . .

Switching Modes 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting Power to the Terminal 3–11. . . . . . . . . . . . . . . . . . . . . . .

Connecting the Upload/Download Cable 3–12. . . . . . . . . . . . . . . . . .

Connecting the Serial Printer 3–13. . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting an External Alarm Relay 3–14. . . . . . . . . . . . . . . . . . . . .

Connecting a Terminal to Your PLC System 3–15. . . . . . . . . . . . . . . .

Using the PCMCIA Card Slot 3–16. . . . . . . . . . . . . . . . . . . . . . . . . .

Publication 2711E-821 – January 1998

Page 5

Table of Contents toc–iii

Installing PanelView 1400e Terminals

Configuring PanelView Operator Terminals

Chapter 4

Overview 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PanelView 1400e Terminal Dimensions 4–2. . . . . . . . . . . . . . . . . . . . .

Tools for Installing Your PanelV iew 1400e Terminal 4–4. . . . . . . . . . . . .

Mounting Options for PanelView 1400e Terminals 4–4. . . . . . . . . . . . .

Mounting a Stud-Mount Keypad or Touch Screen Terminal in a

Panel or Wall Cutout 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting Your PanelView 1400e Terminal in a 19-inch Rack 4–6. . . .

Mounting Your Keypad Terminal in a T30 Cutout 4–7. . . . . . . . . . . . .

Setting Up the PanelView 1400e Terminal 4–7. . . . . . . . . . . . . . . . . . .

Adjusting Contrast and Brightness 4–7. . . . . . . . . . . . . . . . . . . . . . .

Adjusting Horizontal and Vertical Position 4–7. . . . . . . . . . . . . . . . .

Switching Modes 4–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting Power to the Terminal 4–8. . . . . . . . . . . . . . . . . . . . . . .

Connecting the Upload/Download Cable 4–10. . . . . . . . . . . . . . . . . .

Connecting the Serial Printer 4–10. . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting an External Alarm Relay 4–11. . . . . . . . . . . . . . . . . . . . .

Connecting a Terminal to Your PLC System 4–12. . . . . . . . . . . . . . . .

Chapter 5

Power-Up Functions 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power On Self-Test (POST) 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Firmware Integrity Check 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Failure Test 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Watchdog Test 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting Up the Terminal in Configuration Mode 5–2. . . . . . . . . . . . . . .

The Configuration Mode Menu 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Transferring Application Files 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Application File Transfers 5–5. . . . . . . . . . . . . . . . . . . . . . . .

Summary of Steps 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Memory Card Transfers 5–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Formatting the PCMCIA Card or the Onboard Flash

Memory (F5) 5–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Erasing a Destination Partition (F4) 5–12. . . . . . . . . . . . . . . . . . . . . .

Pass-Through Application File Transfers 5–13. . . . . . . . . . . . . . . . . .

PLC Controllers Required for Pass-Through 5–15. . . . . . . . . . . . . . . .

DH+ Direct/ControlNet Direct 5–16. . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting an Application 5–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Terminal Network Setup for Remote I/O Applications 5–20. . . . . . . . . . .

Terminal Network Setup for DH+ Applications 5–22. . . . . . . . . . . . . . . .

Terminal Network Setup for ControlNet Applications 5–23. . . . . . . . . . . .

Application Startup 5–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Application Security 5–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Screen Security 5–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mode Switch 5–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Publication 2711E-821 – January 1998

Page 6

toc–iv

Table of Contents

Setting Time and Date 5–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Terminal Response 5–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Button Audio, Alarm Audio, Audio Volume 5–32. . . . . . . . . . . . . . . . .

Alarm Settings 5–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stuck Cell Timeout 5–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Screen Saver Display Intensity (1000e only) 5–36. . . . . . . . . . . . . . .

Screen Saver Timeout 5–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Terminal Display Intensity (1000e only) 5–38. . . . . . . . . . . . . . . . . . .

Aligning the 1200e Screen 5–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Aligning on a Keypad Terminal 5–39. . . . . . . . . . . . . . . . . . . . . . . . .

Aligning on a Touch Screen Terminal 5–39. . . . . . . . . . . . . . . . . . . . .

Printing 5–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Print Priorities 5–41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printing Screens from the Terminal 5–41. . . . . . . . . . . . . . . . . . . . . .

Formatting Reports 5–41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printer Errors 5–42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Terminal Diagnostics 5–42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performing Terminal Diagnostics 5–42. . . . . . . . . . . . . . . . . . . . . . . .

Hours Logged 5–45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Restoring Defaults 5–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Upgrading Firmware 5–48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Terminal Information 5–49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault Conditions 5–50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Major Faults 5–50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Minor Faults 5–51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mistakes 5–51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Errors 5–52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Terminal Messages 5–52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Verifying PanelView Terminal Operation

Publication 2711E-821 – January 1998

Chapter 6

Testing the PanelView Terminal 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Downloading the Application File 6–2. . . . . . . . . . . . . . . . . . . . . . . . . .

Matching Communications Settings 6–2. . . . . . . . . . . . . . . . . . . . . .

Download Procedure 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Running the Application File 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting the PLC Controller 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing Retentive Objects 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing the Whole System 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 7

Table of Contents

toc–v

Maintaining PanelView Terminals

Troubleshooting PanelView Terminals

Chapter 7

Maintaining Your PanelView Operator Terminal 7–1. . . . . . . . . . . . . . .

Cleaning 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Touch Screen 7–1. . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Keypad 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Enclosure 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

CRT Intensity (1200e and 1400e) 7–1. . . . . . . . . . . . . . . . . . . . .

Changing the Fan Filter (1200e and 1400e) 7–2. . . . . . . . . . . . . . . .

Degaussing the CRT (1200e and 1400e) 7–2. . . . . . . . . . . . . . . . . .

Avoiding Strong Magnetic Fields (1200e and 1400e) 7–2. . . . . . . . . .

Backlight Replacement (1000e) 7–3. . . . . . . . . . . . . . . . . . . . . . . .

Chapter 8

Verifying Configuration Settings 8–1. . . . . . . . . . . . . . . . . . . . . . . . . .

PanelView Major Fault Messages 8–1. . . . . . . . . . . . . . . . . . . . . . . . .

PanelView Minor Fault Messages 8–3. . . . . . . . . . . . . . . . . . . . . . . . .

PanelView Mistake Messages 8–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

PanelView Firmware Messages 8–6. . . . . . . . . . . . . . . . . . . . . . . . . .

PLC Communication Problems: Remote I/O 8–7. . . . . . . . . . . . . . . . . .

PLC Communication Problems: Data Highway Plus 8–8. . . . . . . . . . . .

PLC Communication Problems: ControlNet 8–9. . . . . . . . . . . . . . . . . .

Specifications: 1000e Operator Terminal

Appendix A

Product List A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Approvals and Compliances A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Standards Approvals A–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

EMC Standards Complied with A–1. . . . . . . . . . . . . . . . . . . . . . . . .

Environmental Standards A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

European Union Directive Compliance A–2. . . . . . . . . . . . . . . . . . . . . .

EMC Directive A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Low Voltage Directive A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intended Use of Product A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Recommendations A–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Terminal Weights A–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel Design A–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keypad Terminals A–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Touch Screen Terminals A–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Touch Cell Format A–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flat Panel Display A–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Backlight Life A–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Color Unit Display Attributes A–4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Highway Plus Communications A–5. . . . . . . . . . . . . . . . . . . . . . .

ControlNet Communications A–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLC Remote I/O Communications A–5. . . . . . . . . . . . . . . . . . . . . . . . .

Publication 2711E-821 – January 1998

Page 8

toc–vi

Table of Contents

Serial Communications Port A–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCMCIA Memory Card Support A–6. . . . . . . . . . . . . . . . . . . . . . . . . .

AC Power A–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuses A–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Character Set A–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

User Memory A–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarm Relay A–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Batteries A–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Time and Date Clock A–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Temperature, Humidity, and High Altitude A–9. . . . . . . . . . . . . . . . . . . .

Ambient Operating Temperature Limits A–9. . . . . . . . . . . . . . . . . . .

Storage Temperature Limits A–9. . . . . . . . . . . . . . . . . . . . . . . . . . .

Humidity A–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Altitude A–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Heat Generation A–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shock and Vibration A–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shock Amplitudes A–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vibration Amplitudes for Operating Units A–9. . . . . . . . . . . . . . . . . .

Specifications: 1200e Operator Terminal

Appendix B

Product List B–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Approvals and Compliances B–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Standards Approvals B–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

EMC Standards Complied with B–1. . . . . . . . . . . . . . . . . . . . . . . . .

Environmental Standards B–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keypad Terminals B–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Touch Screen Terminals B–1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Terminal Weights B–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel Design B–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keypad Terminals B–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stainless Steel Keypad Terminals B–2. . . . . . . . . . . . . . . . . . . . . . .

Touch Screen Terminals B–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Touch Cell Format B–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CRT Display B–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Color Unit Display Attributes B–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Degauss B–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Highway Plus Communications B–4. . . . . . . . . . . . . . . . . . . . . . .

PLC Remote I/O Communications B–4. . . . . . . . . . . . . . . . . . . . . . . . .

Serial Communications Port B–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCMCIA Memory Card Support B–5. . . . . . . . . . . . . . . . . . . . . . . . . .

AC Power B–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuses B–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Character Set B–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

User Memory B–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarm Relay B–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Publication 2711E-821 – January 1998

Page 9

Table of Contents

Batteries B–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Time and Date Clock B–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Temperature, Humidity, and High Altitude B–8. . . . . . . . . . . . . . . . . . . .

Ambient Operating Temperature Limits B–8. . . . . . . . . . . . . . . . . . .

Storage Temperature Limits B–8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Humidity B–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Altitude B–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Heat Generation B–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Color Terminals B–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shock and Vibration B–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shock Amplitudes B–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vibration Amplitudes for Operating Units B–9. . . . . . . . . . . . . . . . . .

Vibration Amplitudes for Non-Operating Units B–9. . . . . . . . . . . . . . .

toc–vii

Specifications: 1400e Operator Terminal

Appendix C

Product List C–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Approvals and Compliances C–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Standards Approvals C–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

EMC Standards Complied With C–1. . . . . . . . . . . . . . . . . . . . . . . . .

Environmental Standards C–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

European Union Directive Compliance C–2. . . . . . . . . . . . . . . . . . . . . .

EMC Directive C–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Low Voltage Directive C–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intended Use of Product C–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Recommendations C–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Terminal Weights C–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel Design C–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keypad Terminals C–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Touch Screen Terminals C–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Touch Cell Format C–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CRT Display C–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Color Unit Display Attributes C–4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Degauss C–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Highway Plus Communications C–5. . . . . . . . . . . . . . . . . . . . . . .

ControlNet Communications C–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLC Remote I/O Communications C–5. . . . . . . . . . . . . . . . . . . . . . . . .

Serial Communications Port C–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCMCIA Memory Card Support C–6. . . . . . . . . . . . . . . . . . . . . . . . . .

AC Power C–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuses C–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Character Set C–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

User Memory C–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarm Relay C–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Batteries C–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Time and Date Clock C–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Publication 2711E-821 – January 1998

Page 10

toc–viii

Table of Contents

Temperature, Humidity, and High Altitude C–9. . . . . . . . . . . . . . . . . . . .

Ambient Operating Temperature Limits C–9. . . . . . . . . . . . . . . . . . .

Storage Temperature Limits C–9. . . . . . . . . . . . . . . . . . . . . . . . . . .

Humidity C–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Altitude C–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Heat Generation C–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Color Terminals C–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shock and Vibration C–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shock Amplitudes C–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vibration Amplitudes for Operating Units C–10. . . . . . . . . . . . . . . . . .

Vibration Amplitudes for Non-Operating Units C–10. . . . . . . . . . . . . . .

Installing the PanelView Serial Firmware Upgrade Utility

Appendix D

Installing SFU32 from CD-ROM on Windows NT or Windows 95 D–1. . .

Installing SFU from CD-ROM on Windows 95 or Windows 3.x D–2. . . . .

Installing SFU32 from Floppy Disks on Windows NT or

Windows 95 D–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing SFU from Floppy Disks on Windows 95 or Windows 3.x D–5. .

Installing Additional Communication Drivers D–6. . . . . . . . . . . . . . . . . .

Starting the PanelView Serial Firmware Upgrade Utility D–7. . . . . . . . . .

Performing a Serial Firmware Upgrade D–7. . . . . . . . . . . . . . . . . . . . .

Exiting from the PanelView Serial Firmware Upgrade Utility D–8. . . . . . .

Index

Publication 2711E-821 – January 1998

Page 11

About This Manual

"

This manual describes the PanelView 1000e, 1200e, and 1400e

operator terminals and includes information about the following:

• installing your PanelView terminal

• configuring your PanelView terminal

• verifying or testing your PanelView terminal

• maintaining your PanelView terminal

• troubleshooting your PanelView terminal

Note: This manual also applies to the enhanced PanelView 1200

Series F and higher terminals running PanelView 1400e firmware.

Chapter 1, Introducing PanelView Terminals, provides an overview

of the PanelView 1000e, 1200e, and 1400e terminal family,

summarizes new features, and lists applicable PLC controllers and

connections.

Chapters 2, 3, and 4, Installing PanelView 1000e/1200e/1400e

Terminals, provide installation instructions, equipment dimensions,

and mounting options for each model.

Chapter 5, Configuring PanelView Terminals, describes the power-up

tests and how to configure your terminal.

Chapter 6, Verifying PanelView Terminal Operation, describes how

to verify the terminal is communicating correctly, explains the

download procedure for the demo package, and describes testing

retentive objects and the overall system.

Chapter 7, Maintaining PanelView Terminals, provides maintenance

instructions to ensure the longevity and top performance of your

terminal.

Chapter 8, Troubleshooting PanelView Terminals, lists the fault and

error messages that could occur in Configure or Run mode and

provides information to solve problems quickly.

Appendix A contains the Specifications for the PanelView 1000e

terminal.

Appendix B contains the Specifications for the PanelView 1200e

terminal.

Appendix C contains the Specifications for the PanelView 1400e

terminal.

Publication 2711E-821 – January 1998

Page 12

PrefaceP–2

Appendix D, Installing the PanelView Serial Firmware Upgrade

Utility, describes how to install SFU or SFU32.

Intended Audience

Related Publications

This manual is to be used by:

• System Integrators

• Mechanical Installers

• Field Service Personnel

• End Users

The following related publications provide information on

programmable controllers and I/O scanners. To identify the manuals

that refer to these programmable controllers, consult the

Allen-Bradley Publication Index, Publication SD499.

I/O Scanner Publications Pub. No.

1772-SD/SD2 Remote I/O Scanner/Distribution Panel

1775-S4A I/O Scanner-Programmer Interface Module User’s Manual 1775-6.5.1

1775-S5, 1775-SR5 I/O Scanner-Communication Adapter Module User’s

Manual

5150-RS PI Start-up and Integration Manual 5000-6.5.1

6008-SI IBM PC I/O Scanner User’s Manual

6008-SV VME I/O Scanner User’s Manual 6008-6.5.2

6008-SQ Q-Bus I/O Scanner Utility Software User’s Manual 6008-6.4.1

1771-SN Sub I/O Scanner Module Data Sheet 1771-2.91

1747-SN RIO Scanner User’s Manual 1747-NM005

1772-2.18

1775-6.5.5

6008-6.5.3

Publication 2711E-821 – January 1998

Programmable Controller Publications Pub. No.

1772-LP2 PLC-2/20 Controller Programming and Operations Manual

1772-LP3 PLC-2/30 Controller Programming and Operations Manual 1772-6.8.3

PLC-3 Family Controller Programming Reference Manual 1775-6.4.1

PLC-5 Family Programmable Controllers Hardware Installation Manual 1785-6.6.1

PLC-5 Programming Software 6200-6.4.7

ControlNet PLC-5 Programmable Controllers 1785-6.5.14

5250-LP1, LP2 PLC-5/250 Programming Manual 5000-6.4.8

SLC 500 Family of Programmable Controllers Advanced Programming

Software User’s Manual

1772-6.8.1

1747-NM002

Page 13

Preface P–3

Technical Support Services

If you have questions about PanelView terminals, consult the user

documentation first. If you can’t find the answer, take advantage of our

Technical Support Fax Back system, available 24 hours a day, 7 days a

week at 1-440-646-5436. Or, you can browse through our technical

support document library on the World Wide Web at

http://www.ab.com/mem/ prodserv/services/technotes/

techmain.html.

Alternatively, contact:

Allen-Bradley

Technical Support

1 Allen Bradley Drive

Mayfield Heights, Ohio 44124-6118

or call 1-440-646-6800 or fax 1-440-646-6890 for technical support

between the hours of 8

AM and 5 PM (EST), Monday to Friday.

The catalog number, series, revision letter, and firmware revision are

on the label on the back of the terminal. Have this information ready

when you call for technical support.

Publication 2711E-821 – January 1998

Page 14

Introducing the PanelView

Terminals

This chapter provides an overview of the PanelView 1000e, 1200e,

and 1400e operator terminals. It describes:

• types and features of the PanelView terminals

• new features of the PanelView terminals

• options and accessories

• the supported Allen-Bradley PLC and SLC and Remote I/O

scanners for Remote I/O, Data Highway Plus (DH+),

ControlNet communications

and

Welcome to the PanelView Family

"

PanelView 1000e, 1200e, and 1400e terminals are the latest

generation of PanelView terminals. Like the PanelView 1200

terminals, PanelView 1000e, 1200e, and 1400e terminals provide a

fast, easy, flexible, and low-cost operator interface for a PLC system.

They are ideal replacements for traditional control panels.

PanelView 1000e, 1200e, and 1400e terminals are pre-assembled and

ready to install in a control panel cutout or 19-inch rack with the

adapter kit. They connect directly to any Allen-Bradley Remote I/O,

Data Highway Plus (DH+), or optionally, ControlNet link.

An Allen-Bradley, IBM, or compatible computer (the development

computer) is used to create terminal screens and functions. Refer to

the PanelBuilder 1400e Configuration Software for Windows User

Manual for complete information.

Note: This note applies only if you are using versions earlier than

Version 4 of the PanelView 1200/1400e Transfer Utility. To use an

application file created by PanelBuilder Development Software for

DOS or PanelBuilder 1200 Configuration Software for Windows

(Version 5.0), you must upload the file to your development

computer using the original package or PanelView 1200/1400e

Transfer Utility, and then open it using PanelBuilder 1400e

Configuration Software for Windows. It must then be saved as a .pvd

file format that can be downloaded to a PanelView terminal. Refer to

the PanelBuilder 1400e Configuration Software for Windows User

Manual and the PanelView 1200/1400e Transfer Utility User Manual

for details. Alternatively, the PanelView 1200/1400e Transfer Utility

will enable you to download the application to the PanelView

terminal without having PanelBuilder installed.

Publication 2711E-821 – January 1998

Page 15

1–2 Introducing the PanelView Terminals

Table 1.A lists the PanelView 1000e, 1200e, and 1400e terminal line

and the accompanying software. Note that Series F and above

PanelView 1200 terminals can be enhanced to PanelView 1200e

functionality. Unless otherwise indicated, replacement kits and

accessories can be used for PanelView 1000e, 1200, 1200e, and

1400e terminals.

Table 1.A PanelV iew Terminal Products and Catalog Numbers

Catalog Number Product Description

2711E-T10C6

2711E-K10C6 1000e Keypad Terminal Color display, clip mount, NEMA 4X

2711E-T10C7 1000e Touch Screen

2711E-K10C7 1000e Keypad Terminal ControlNet-enhanced release 1.25 2711E-K10C6 terminal

2711E-T10C15 1000e Touch Screen

2711E-K10C15 1000e Keypad Terminal ControlNet-enhanced release 1.5 2711E-K10C6 terminal

2711E-T12C6 1200e Touch Screen

2711E-T12C4 1200e Touch Screen

2711E-K12C6 1200e Keypad Terminal Color display, stud mount, NEMA 4X (Indoor use only)

2711E-K12C6L2 1200e Keypad Stainless

2711E-T14C6 1400e Touch Screen

2711E-K14C6 1400e Keypad Terminal Color display, stud mount, NEMA 4X (Indoor use only)

2711E-T14C7 1400e Touch Screen

2711E-K14C7 1400e Keypad Terminal ControlNet-enhanced release 1.25 2711E-K14C6 terminal

2711E-T14C15 1400e Touch Screen

2711E-K14C15 1400e Keypad Terminal ControlNet-enhanced release 1.5 2711E-K14C6 terminal

2711E-ND1 PanelBuilder 1400e

2711E-ND1DE PanelBuilder 1400e

2711E-ND1FR PanelBuilder 1400e

1000e Touch Screen

Terminal

Terminal

Terminal

Terminal

Terminal

Steel Terminal

Terminal

Terminal

Terminal

Configuration Software for

Windows

Configuration Software for

Windows – German Version

Configuration Software for

Windows – French Version

Color display, clip mount, NEMA 4X

ControlNet-enhanced release 1.25 2711E-T10C6 terminal

ControlNet-enhanced release 1.5 2711E-T10C6 terminal

Color display, clip mount, NEMA 12

Color display, stud mount, NEMA 4X (Indoor use only)

Color display, stud mount, stainless steel bezel, NEMA 4X (Indoor use only)

Color display, stud mount, NEMA 4X (Indoor use only)

ControlNet-enhanced release 1.25 2711E-T14C6 terminal

ControlNet-enhanced release 1.5 2711E-T14C6 terminal

Includes PanelBuilder 1400e software, manuals

Includes PanelBuilder 1400e software, manuals

Includes PanelBuilder 1400e software, manuals

Publication 2711E-821 – January 1998

Page 16

Catalog Number DescriptionProduct

2711E-ND1ES

PanelBuilder 1400e

Includes PanelBuilder 1400e software, manuals

Configuration Software for

Windows – Spanish Version

2711E-ND7 File Transfer Utility for

Windows – English Version

Standalone File Transfer Utility for all PanelView enhanced terminals and PanelView 1200

terminals, which require less hard disk space than the PanelBuilder 1400e Configuration

Software kits.

Note: This File Transfer Utility is included in all PanelBuilder 1400e Configuration Software

kits.

Table 1.B PanelView Terminals Accessories

Catalog Number Product Description

2711-NC1

Upload/Download Cable For 1200e/1400e terminals only. Includes a 9-pin or 25-pin RS-232 serial cable

(Upload/Download cable) to transfer files between terminal and development computer. The

cable is 10 ft (3.1 m) long.

2711-NC13 Upload/Download Cable For 1000/1000e terminals only. Includes a 9-pin RS-232 serial cable (Upload/Download

cable) to transfer files between terminal and development computer. The cable is 16.4 ft (5 m)

long.

2711-NC14 Upload/Download Cable For 1000/1000e terminals only. Includes a 9-pin RS-232 serial cable (Upload/Download

cable) to transfer files between terminal and development computer. The cable is 32.7 ft

(10 m) long.

2706-NC13 Upload/Download Cable For 1000/1000e terminals only. Includes a 9-pin RS-232 serial cable (Upload/Download

cable) to transfer files between terminal and development computer. The cable is 10 ft (3 m)

long.

2711-NC2 Remote Keyswitch and

RS-232 Port Assembly

2711E-NC1 Remote RS-232 Serial Port

Assembly

2711-NM11 256K PCMCIA Installation

Kit

2711-NM12 1-MB PCMCIA Memory

Card for Application

For 1200/1200e/1400e terminals only. Includes RS-232 port assembly and remote

keyswitch. Allows remote mode selection and serial port access.

For 1000e terminals only. Includes a 9-pin RS-232 port assembly to allow serial port

access.

Includes blank 256K PCMCIA memory card for application file storage, and instruction

sheet.

Includes blank 1-MB PCMCIA memory card for application file storage, and instruction

sheet.

Expansion

2711-NM13 2-MB PCMCIA Memory

Includes blank 2-MB PCMCIA card for application file storage, and instruction sheet.

Card for Application

Expansion

2711-NM14 4-MB PCMCIA Memory

Includes blank 4-MB PCMCIA card for application file storage, and instruction sheet.

Card for Application

Expansion

2711-NM15 8-MB PCMCIA Memory

Includes blank 8-MB PCMCIA card for application file storage, and instruction sheet.

Card for Application

Expansion

2711-NV1 Anti-Glare Overlay for

Includes 5 anti-glare protective overlays for your 1200 and 1200e terminal screens.

terminals

2711-NR5T Adapter for PanelView

1000/1000e Touch Screen

Includes an adapter for PanelView 1000/1000e Touch Screen terminals to mount in

PanelView 1200 Touch Screen terminal panel cutouts.

Terminals

1–3Introducing the PanelView Terminals

Publication 2711E-821 – January 1998

Page 17

1–4 Introducing the PanelView Terminals

Catalog Number DescriptionProduct

2711-NR5K

Adapter for PanelView

1000/1000e Keypad

Includes an adapter for PanelView 1000/1000e Keypad terminals to mount in PanelView

1200 Keypad terminal panel cutouts.

Terminals

2711-NR6T 19-in. Rack Mount Kit for

PanelView 1000/1000e

Includes a 19-inch rack adapter and mounting hardware for 1000/1000e clip-mount touch

screen terminals.

Touch Screen Terminals

2711-NR6K 19-in. Rack Mount Kit for

PanelView 1000/1000e

Includes a 19-inch rack adapter and mounting hardware for 1000/1000e clip-mount keypad

terminals.

Keypad Terminals

2711-NR1 19-in. Rack Mount Kit for

PanelView 1200 and 1200e

Includes a rack adapter and mounting hardware for stud-mount and clip-mount touch

screen terminals.

Touch Screen Terminals

(not for 2711 or 2711E

Keypad Terminals)

2711-NR4 19-in. Rack Mount Kit for

PanelView 1400e Touch

Includes a rack adapter and mounting hardware for stud-mount and clip-mount touch

screen terminals.

Screen Terminals (not for

2711E Keypad Terminals)

2711-NV6T Anti-Glare Overlay for

Includes an anti-glare overlay for PanelView 1000/1000e Touch Screen terminals.

1000/1000e touch screen

terminals

2711-NV6K Anti-Glare Overlay for

Includes an anti-glare overlay for PanelView 1000/1000e Keypad terminals.

1000/1000e keypad

terminals

2711E-U1B12C PanelView 1200

Enhancement Kit with

Includes 2-MB SIMM and 4-MB PCMCIA memory card preloaded with new version of

firmware. Also includes 3 product identification labels (terminal types).

preloaded 4-MB PCMCIA

memory card and 2-MB

SIMM

2711E-UMOD Firmware Enhancement Kit

for Modbus connectivity on

terminals

Includes firmware upgrade for Modbus support on PanelView 1000e/1400e terminals.

Note: For Modbus communications, you need a Modbus ISA/EISA Interface Card and a

2711E-NA1 or 2711-NA2 Adapter Kit.

2711E-NA1 ISA Card Adapter Kit Includes an ISA card adapter to install a communication card in a PanelView 1400e

Terminal.

2711E-NA2 ISA Card Adapter Kit Includes an ISA card adapter to install communication cards in a PanelView 1000e

Terminal.

Publication 2711E-821 – January 1998

Table 1.C PanelView Replacement Kits

Catalog Number Product

2711-NP2

Mounting Clips for PanelView 600/900/1000/1000e Terminals

2711E-NF1 Function Key Legend Strips for PanelView 1000e Keypad

Terminals

6189-NL2 Backlight Replacement Kit for PanelView 1000e and 6189

Industrial Computers

2711E-NK2 Keypad Replacement Kit for PanelView 1200e Terminals

2711E-NK3 Stainless Steel Keypad Replacement Kit for PanelView 1200

(Series D and above) and 1200e Keypad Terminals

Page 18

1–5Introducing the PanelView Terminals

Catalog Number Product

2711E-NK5

2711-NT1 Touch Screen Replacement Kit for PanelView 1200 (Series D,

2711E-NT2 Analog Touch Screen Replacement Kit for PanelView 1400e

46715-414-01 Spare Mode Select Keys

46715-416-01 PanelView 1200 and 1200e Touch Screen Mounting hardware

46715-418-01 Replacement Keyswitch Assembly for PanelView

46715-419-01 Blank keypad legend inserts for PanelView 1200 and

22112-046-03 Remote I/O connector for PanelView 1000e, 1200, 1200e, and

Keypad Replacement Kit for PanelView 1400e Terminals

E, F, and G) and 1200e Terminals

for clip mounting

1200/1200e/1400e Terminals

PanelView 1200e Keypad Terminals (note: not for

2711E-K12C6L2)

1400e Terminals

Keypad and Touch Screen Terminals and Software

Keypad and touch screen terminals are configured the same with

these exceptions:

• different button setups

• certain screen objects are specific to keypad terminals and others

to touch screen terminals. For information about objects, refer to

the PanelBuilder 1400e Configuration Software for Windows

User Manual or the PanelBuilder 1400e Configuration Software

for Windows Screen Objects Reference Manual.

The PanelView 1000e and 1400e touch screen terminals use

analog-resistive touch screens. This allows input objects to be any

size (minimum 40 by 40 pixels) and to be placed anywhere on the

screen. The analog-resistive touch screen provides greater flexibility

in screen design compared to PanelView 1200 and 1200e terminals.

PanelView 1200 and 1200e terminals use a touch matrix which

requires that all input objects align with a touch grid.

ATTENTION: In the unlikely event that two or more

touches occur simultaneously in the same horizontal or

!

vertical line, an input object located half-way between

the two touches could be activated. This is inherent in

the analog-resistive touch screen technology that is

used in PanelView 1000e and 1400e terminals.

Publication 2711E-821 – January 1998

Page 19

1–6 Introducing the PanelView Terminals

Keypad Terminals

The keypad terminal has:

• 21 user-definable function keys

• a keypad for entering numeric values

• up, down, left, and right arrow keys

• Home, Enter, Select, Cancel, Raise, Lower, and Backspace keys

The user-definable function keys on keypad terminals are pre-labeled

at the factory, but you can create key labels (legends) to suit your

application. The replacement key legends slide in from the rear of

the faceplate. The Legend Kit, included with your shipment,

provides blank card material that accepts most types of markers or

paste-on labels.

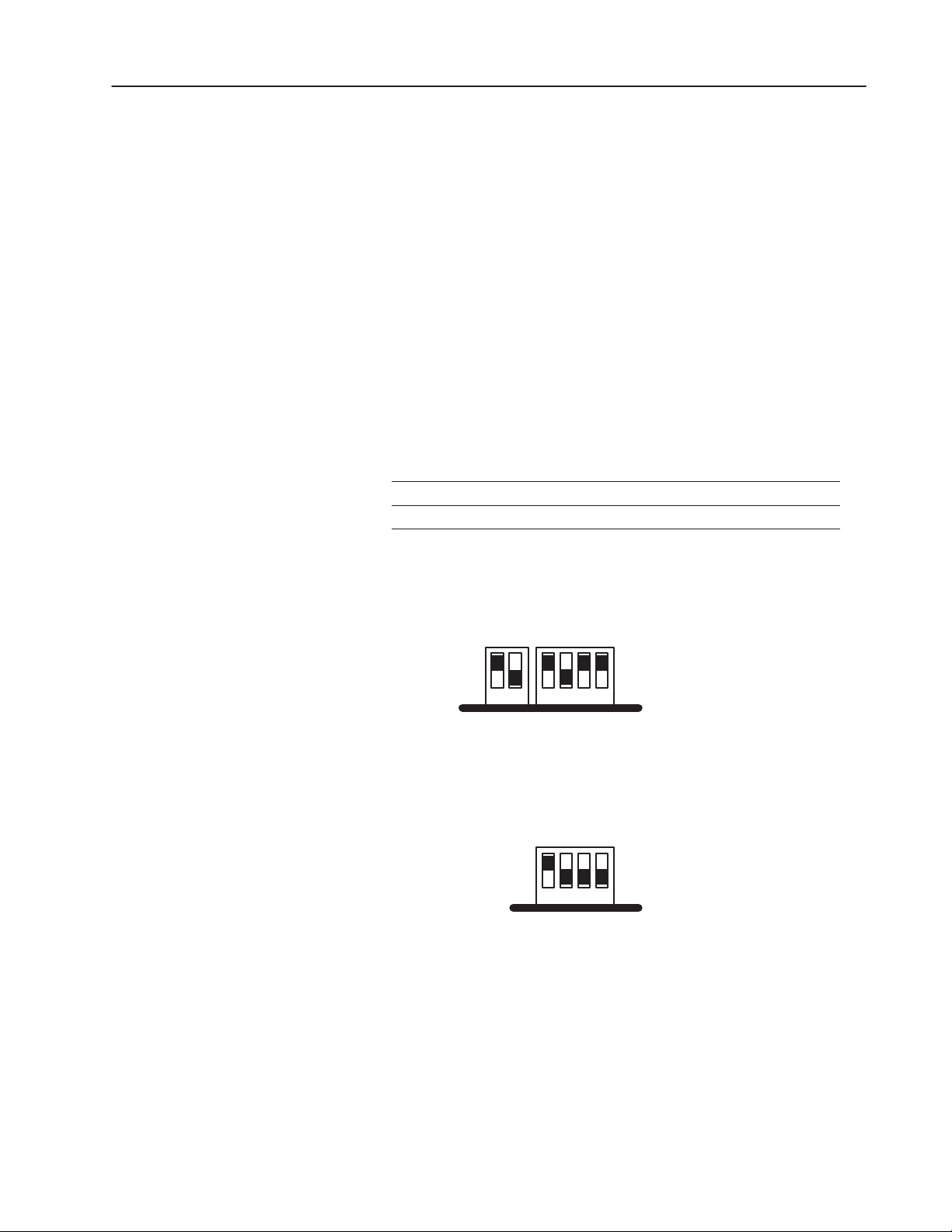

Figure 1.1 1000e, 1200e, and 1400e Keypad Terminals (Front

View)

Publication 2711E-821 – January 1998

Page 20

1–7Introducing the PanelView Terminals

Publication 2711E-821 – January 1998

Page 21

1–8 Introducing the PanelView Terminals

Function Keys

When creating screens, you can assign any of the 21 function keys to

objects so they do several tasks, such as turning on PLC input bits or

changing screens. Keys can have different task assignments for each

screen created.

Numeric Keypad

The keypad terminal has a numeric input keypad that includes

number keys, Enter, Backspace, – (negative), and . (decimal) keys.

To make a numeric entry, you call up a pop-up Numeric Entry

Scratchpad that displays the numbers as you type. You can send the

data to the PLC controller.

Special Keys

The keypad terminal includes special keys:

• the arrow keys and Home are used to navigate through Set Bit

Cursor and Numeric Input Cursor Points, or the ASCII input

object

• Select is used with the Set Bit Cursor and Numeric Input Cursor

Points to pop up the numeric entry scratchpad

• Cancel can be used with all numeric keypads, Set Bit Cursor and

Numeric Input Cursor Points to remove the numeric entry

scratchpad

• Raise and Lower are used with Numeric Input Cursor Point only,

to change the numeric value sent to the PLC

The three blank keys on the bottom right of the 1200e terminals are

reserved for future development and cannot be configured.

Refer to the PanelBuilder 1400e Configuration Software for

Windows User Manual for details.

Publication 2711E-821 – January 1998

Page 22

1–9Introducing the PanelView Terminals

Touch Screen Terminals

To operate a touch screen terminal, you press buttons directly on the

screen.

Figure 1.2 1000e, 1200e, and 1400e Touch Screen Terminals (Front

View)

Publication 2711E-821 – January 1998

Page 23

1–10 Introducing the PanelView Terminals

The 1200e touch screen contains 120 touch cells, laid out in a 10-cell

by 12-cell grid. Each touch cell is 64 pixels wide by 40 pixels high.

For the 1000e and 1400e analog touch screen, the minimum touch

object size is 40 by 40 pixels. There is no touch matrix for the 1000e

and 1400e touch screens so the objects can be placed at any location.

In PanelBuilder, a grid can be made visible to allow you to align

screen objects.

Touch cells are grouped to create different types and sizes of buttons.

You can activate input functions by touching the appropriate object

on the terminal and can configure the terminal to beep when a touch

cell is pressed.

The PanelView 1000e and 1400e Touch Screen terminals use

analog-resistive touch screens. This allows input objects to be any

size (minimum 40 by 40 pixels) and to be placed anywhere on the

screen. The analog-resistive touch screen provides greater flexibility

in screen design compared to PanelView 1200 and 1200e terminals.

PanelView 1200 and 1200e terminals use a touch matrix which

requires that all input objects align with a touch grid.

Publication 2711E-821 – January 1998

Page 24

1–11Introducing the PanelView Terminals

ATTENTION: In the unlikely event that two or more

touches occur simultaneously in the same horizontal or

!

vertical line, an input object located half-way between

the two touches could be activated. This is inherent in

the analog-resistive touch screen technology that is

used in PanelView 1000e and 1400e terminals.

PanelBuilder 1400e Configuration Software

PanelBuilder 1400e Configuration Software for Windows is an

easy-to-learn tool for developing complex applications quickly and

efficiently. You run PanelBuilder 1400e Configuration Software on a

personal computer to develop operator interface applications for

PanelView 1000e, 1200e, or 1400e operator terminals.

The Windows platform offers many advantages. In addition to a

superior graphical interface, you can work within several

applications at once and transfer information between them easily.

Features of the PanelView Terminals

Figures 1.1 and 1.2 show the front view of the PanelView 1000e,

1200e, and 1400e terminals. The back of each terminal is shown in

the installation chapter for each terminal type.

The PanelView 1000e, 1200e, and 1400e terminals differ from the

PanelView 1200 terminal as follows:

• Remote I/O, DH+, and ControlNet connectivity are now available

(used one at a time).

• The PanelView 1000e terminal is available in four models:

– color touch screen clip mount (2711E-T10C6)

– color keypad clip mount (2711E-K10C6)

– color touch screen clip mount with ControlNet support

(2711E-T10C7, 2711E-T10C15)

– color keypad clip mount with ControlNet support

(2711E-K10C7, 2711E-K10C15)

• The PanelView 1200e terminal is available in four models:

– color touch screen clip mount (2711E-T12C6)

– color touch screen stud mount (2711E-T12C4)

– color keypad stud mount (2711E-K12C6)

– color keypad stainless steel stud mount (2711E-K12C6L2)

Publication 2711E-821 – January 1998

Page 25

1–12 Introducing the PanelView Terminals

• The 1400e terminal is available in four models:

– color touch screen stud mount (2711E-T14C6)

– color keypad stud mount (2711E-K14C6)

– color touch screen stud mount with ControlNet support

– color keypad stud mount with ControlNet support

• The front panels of the PanelView 1000e, 1200e, and 1400e

terminals have new graphics.

• The PanelView 1000e and 1400e terminals have analog touch

screens.

• The PanelView 1400e terminal has an analog touch screen with

built-in, anti-glare glass.

• The PanelView 1000e terminals run firmware versions 3 and

above only. The PanelView 1200e and 1400e terminals run

firmware versions 1 and above. The application you run on

PanelView 1000e, 1200e, and 1400e terminals is displayed in a

pixel graphics format, rather than a character-based format.

• The logic board has a communication slot for communication

options, such as ControlNet.

(2711E-T14C7, 2711E-T14C15)

(2711E-K14C7, 2711E-K14C15)

ATTENTION: The Keyboard port is not currently

supported by the PanelView Firmware. Connecting a

!

Table 1.D outlines the main changes that have been made to the

memory configuration on the terminal’s logic board.

keyboard could produce unpredictable results, and

could reset the terminal.

Publication 2711E-821 – January 1998

Page 26

Table 1.D Memory Configuration on PanelView 1200 (Series

F and above) and PanelView 1000e, 1200e, and 1400e

Operator Terminals

1–13Introducing the PanelView Terminals

Memory Type PanelView 1000e

Terminal

User RAM (SRAM)

(Battery-backed)

Flash 1.75 MB for

E/EPROM N/A Optional 64K/128K

PCMCIA memory

card support

128K of

battery-backed

static RAM (stores

the terminal

configuration

parameters, alarm

status and history,

retentive data; no

application file

storage)

firmware; 2.25 MB

for application file

storage

Provides

application file

storage up to

15.75 MB

PanelView 1200

Terminal (Series F

and Above)

128K (stores the

terminal

configuration

parameters, alarm

history, and

application file)

256K (stores

firmware and

BIOS); no flash for

application file

storage

E/EPROM (provide

backup application

file storage)

1.75 MB for

firmware;

application file

storage up to

2.25 MB for

enhanced F and

above terminals

PanelView 1200e

and 1400e

Terminals

128K of

battery-backed

static RAM (stores

the terminal

configuration

parameters, alarm

status and history,

retentive data; no

application file

storage)

1.75 MB for

firmware; 256K for

application file

storage

N/A

Provides

application file

storage up to

15.75 MB

New Features of the PanelView Terminals

Version 3 Firmware Features

PanelView Version 3 firmware supports the following PanelBuilder

features:

• Goto Configure Mode button

• PanelView 1000e applications

• Retain Cursor On Cancel feature

• Modbus Communications (with the Modbus Communications

Kit, A-B Catalog Number 2711E-UMOD)

Version 4 Firmware Features

PanelView Version 4 firmware supports a maximum of 1500 alarm

history records.

Publication 2711E-821 – January 1998

Page 27

1–14 Introducing the PanelView Terminals

Applicable Programmable Controllers and Connections

PanelView terminals can be connected to any Allen-Bradley 1771

Remote I/O, Data Highway Plus, or ControlNet link. Applicable host

controllers include almost all Allen-Bradley Programmable Logic

Controllers, as well as certain IBM computers, interface cards, VME

Controllers, and the DEC Q-Bus interface.

Newly-released Allen-Bradley programmable controllers not yet

listed will support PanelView terminals as long as they support 1771

Remote I/O, DH+, or ControlNet networks.

Remote I/O Communications

The terminal can occupy up to 64 I/O racks in a PLC. It has

the same configurability—and more—as a standard I/O rack. Refer

to your applicable Allen-Bradley Programmable Controller and

Remote I/O Scanner user’s manuals for connection and Remote I/O

configuration limitations.

The following host controllers can be connected to the terminals over

a Remote I/O link.

PLC-5/11, 5/15, 5/20, 5/25, 5/30, 5/40, 5/60, 5/80 and 5/250

Processors

You can connect one or more terminals directly to a PLC-5 Remote

I/O Port (in Scanner Mode) with other I/O racks. If the PLC-5

Remote I/O Port is used in the adapter mode, one or more terminals

can be connected to that PLC-5 along with other I/O racks via a

1771-SN I/O Subscanner Module.

The terminals can communicate at 57.6, 115.2, and 230.4 kilobauds

with any PLC-5 that can support those baud rates.

If you are using a PLC-5/15 with partial rack addressing and block

transfers, you must use PLC-5/15 Series B, revision J or later.

PLC-5/10 Processor

One or more terminals can be connected to this processor with other

I/O racks by a 1771-SN I/O Subscanner Module.

PLC-3 and PLC-3/10 Processors

One or more terminals can be connected directly to a PLC-3 or

PLC-3/10 remote I/O Scanner along with other I/O racks.

If you are using a 1775-S4A Remote Scanner/Distribution panel, you

must use Series B or higher.

Publication 2711E-821 – January 1998

Page 28

1–15Introducing the PanelView Terminals

PLC-2 Family Processors via 1771-SN or 1772-SD2

The PLC-2 family includes the PLC-2/05, 2/15, 2/20, and 2/30. One

or more terminals can be connected to these processors with other

I/O racks by the 1771-SN I/O Subscanner Module.

If you are using a 1772-SD2 Scanner/Distribution panel, you must

use Revision 3 or later.

SLC-5/02, 5/03, or 5/04 via 1747-SN Series A or B

One or more terminals can be connected to the 1747-SN I/O

Subscanner Modules (SLC-RIO connection) for the SLC processors.

Each module provides an additional remote I/O link for the host

programmable controller. The rack range of the 1747-SN Series A or

B is 0 to 3.

Important: The 1747-SN Series A supports only discrete data

whereas Series B also provides block transfer support.

Series B also supports Pass-Through communication

capability when used with the 5/04.

1771-SN I/O Subscanner Module

One or more 1771-SN I/O Subscanner Modules can be installed in

any standard Allen-Bradley 1771 I/O rack. Each module provides an

additional Remote I/O link for the host programmable controller.

One or more terminals can be connected to any of the previously

mentioned processors along with other I/O racks via a 1771-SN I/O

Subscanner Module. Refer to the 1771-SN Sub I/O Scanner Module

Data Sheet for specific details.

6008-SI IBM PC I/O Scanner

This module can be installed in an IBM PC or compatible

computer to provide the computer with an Allen-Bradley 1771

Remote I/O Link. You can then connect Allen-Bradley Remote I/O

racks and devices such as the PanelView 1000e/1200e/1400e

terminal to this computer.

6008-SV VME I/O Scanner

This module can be installed in a VME backplane, providing the

VME controller with an Allen-Bradley 1771 Remote I/O Link.

Allen-Bradley Remote I/O racks and devices such as the PanelView

1000e/1200e/1400e terminal can then be connected to this VME

controller.

Publication 2711E-821 – January 1998

Page 29

1–16 Introducing the PanelView Terminals

6008-SQ DEC Q-BUS I/O Scanner

This module can be installed into a DEC Q-Bus controller to provide

it with an Allen-Bradley 1771 Remote I/O Link. Allen-Bradley

Remote I/O racks and devices such as the PanelView

1000e/1200e/1400e terminal can then be connected to this controller.

DH+ Communications

The terminal can be directly connected to a DH+ network so it can

communicate with several controllers simultaneously. It can be

connected to the SLC-5/04 and the following PLC-5 host controllers

over DH+.

PLC-5/10, 5/11, 5/15, 5/20, 5/25, 5/30, 5/40, 5/60, 5/80, 5/40L,

5/60L, 5/80L

One or more terminals can be connected directly to one of the PLC-5

family of programmable controllers over DH+ so it can

communicate with several controllers simultaneously.

SLC-5/04

One or more terminals can be connected directly to one of the

SLC-5/04 family of programmable controllers over DH+ so it can

communicate with several controllers simultaneously.

PLC2/PLC3

The terminal supports communications to one or more PLC2s or

PLC3s via offlink addressing: the PLC2 also communicates by a

1785-KA module (DH+ to DH bridge), while PLC3 communication

is by a 1775-KA module.

ControlNet Communications

To communicate on ControlNet, install the ControlNet

Communication Interface Card (A-B Catalog Number 1784-KTCX,

Series B or later) in your PanelView terminal. This card enables the

terminal to communicate with devices on the ControlNet network

and also acts as an interface between the terminal and ControlNet for

ControlNet-Direct application file transfers. The 1784-KTCX card is

pre-installed in PanelView 1000e and 1400e operator terminals (A-B

Catalog Numbers 2711E-K10C7, 2711E-T10C7, 2711E-K14C7, and

2711E-T14C7).

Publication 2711E-821 – January 1998

Page 30

1–17Introducing the PanelView Terminals

The ControlNet network is scheduled to be upgraded to Version 1.5.

To use Version 1.5 of ControlNet, you will have to upgrade all

ControlNet devices, including the firmware on the KTCX card.

Follow all upgrade procedures included in the ControlNet upgrade.

For Version 1.5 availability, contact your Allen-Bradley Sales

Representative.

For information about installing communication cards in the

PanelView terminal see PanelView ISA Card Adapter Installation

Data Sheet, A-B publication 2711E-5.6.

Important: The DIP switch settings on the KTCX card must be

configured to work with PanelView. If the settings have

been changed and you want to use the card in the

PanelView terminal, you must use the DIP switches on

the KTCX card to select the following addresses:

Address Setting

Base Memory

Base I/O 220

D400:0000

Figure 1.3 KTCX Switch Settings – Base Memory Address

Base Memory Address D400:0000

up (1)

12 1234

down (0)

Figure 1.4 KTCX Switch Settings – Base I/O Address

Base I/O Address 220

up (1)

1234

down (0)

For more information, see the documentation that comes with the

KTCX card.

For more information about communication devices for ControlNet,

see the PanelBuilder 1400e Configuration Software for Windows

User Manual, A-B publication 2711E-819.

Publication 2711E-821 – January 1998

Page 31

1–18 Introducing the PanelView Terminals

You may notice a delay of 5 to 10 seconds when you switch from

Configure to Run mode to execute ControlNet applications. During

this time, the message “Initializing Communications” appears on the

screen. The delay occurs because the KTCX card has a separate

processor that takes 5 to 10 seconds to synchronize with ControlNet.

When you switch to Run mode the application screen will appear

after approximately 5 seconds. Then the message “Communication

Lost” will appear for approximately 5 seconds, while the connection

is established.

PLC-5/20C, 5/40C, 5/60C, 5/80C

The PanelView terminal can be connected to the PLC-5C enhanced

family of programmable controllers over ControlNet.

Publication 2711E-821 – January 1998

Page 32

Installing PanelView 1000e

Terminals

Overview

This chapter explains how to install a PanelView 1000e terminal in

your plant. Specifically, it provides:

• terminal dimensions

• a list of tools for installing the terminal

• cutout dimensions for panel mounting

• information about mounting options

This chapter also provides information about the correct use of the

following hardware features, specifically:

• how to switch modes

• how to connect power to the terminal

• how to connect a serial printer

• how to connect an external alarm relay

• how to connect a terminal to your PLC system

• information about the Upload/Download cables and PCMCIA

cards

Figure 2.1 shows the rear and bottom panel of the PanelView 1000e

terminal. Note the location of the power connector, alarm relay

connector, RS-232 port, and Remote I/O and DH+ connector.

Power Connector

Figure 2.1 Rear and Bottom View of PanelView 1000e

Terminal

Run/Configuration Switch

Alarm Relay Connector

RS-232 Port

Remote I/O DH+ Connector

2

ISA Card Slots

1

PCMCIA Memory

2

Card Slots (Slot 1

1

is active; slot 2 is

inactive and has a

protective label

cover.)

24771

Publication 2711E-821 – January 1998

Page 33

2–2 Installing PanelView 1000e Terminals

PanelView 1000e Terminal Dimensions

Clip Slot

0.15”

(3.81 mm)

0.69”

(18 mm)

10.03”

(255 mm)

1.2”

(30.4 mm)

0.53”

(13 mm)

8.43”

(224 mm)

Figure 2.2 shows the dimensions of the keypad terminals.

Figure 2.2 PanelView 1000e Keypad Terminal Dimensions

11.12”

(282 mm)

3.64”

(92 mm)

F2

F1

F3 F4 F5 F6 F7

F10

F9 F11 F12 F13 F14 F15 F16

F9 F11 F12 F13 F14 F15 F16F10

5.43”

(138 mm)

F17

F18

F19

F20

F21

F8

1.06”

(27 mm)

6.15”

(156 mm)

0.94”

(24 mm)

0.69”

(18 mm)

4.48”

(114 mm)

4.48”

(114 mm)

1.37”

(35 mm)

Allen–Bradley

3.2”

(81 mm)

1.46”

(37 mm)

PanelView 1000e

7

89

456

123

.

0

Home

Raise SELECT

Lower

CANCEL

(113 mm)

–

0.69”

(18 mm)

4.45”

6.8”

(173 mm)

0.95”

(24 mm)

11.11”

(282 mm)

0.9”

(23 mm)

0.55”

(14 mm)

6.15”

(156 mm)

(17 mm)

0.65”

16.64”

(423 mm)

24751

Publication 2711E-821 – January 1998

Page 34

0.7”

(18 mm)

10.03”

(255 mm)

1.2”

(30 mm)

8.43”

(224 mm)

Clip Slot

0.15”

(3.81 mm)

Figure 2.3 shows the dimensions of the touch screen terminals.

Figure 2.3 PanelView 1000e Touch Screen Terminal

Dimensions

0.69”

(18 mm)

4.45”

(113 mm)

(24 mm)

11.11”

(282 mm)

1.06”

(27 mm)

(13 mm)

0.5”

0.94”

(24 mm)

0.69”

(18 mm)

4.48”

(114 mm)

1.37”

(35 mm)

Allen–Bradley

3.64”

(92 mm)

11.12”

(282 mm)

(106 mm)

4.17”

0.85”

(22 mm)

PanelView 1000e

2–3Installing PanelView 1000e Terminals

1.2”

(30 mm)

6.83”

(174 mm)

0.96”

0.55”

(14 mm)

0.9”

(23 mm)

6.18”

(157 mm)

0.65”

(17 mm)

4.48”

(114 mm)

14.58”

(370 mm)

3.75”

(95mm)

Allow 3.75” at this side

internally so that unit can

be opened for replacing

backlight module.

24752

Publication 2711E-821 – January 1998

Page 35

2–4 Installing PanelView 1000e Terminals

Tools for Installing Your PanelView 1000e Terminal

"

You need the following tools to make a wall or panel cutout and

install a PanelView 1000e terminal in it. The terminal shipment

includes a terminal cutout template for your use.

Note: Converted metric values have been rounded off. This applies

to the dimensions specified in the drawings in this chapter.

To make a rectangular wall or panel cutout, you need these tools:

• center punch

• scriber

• hammer

• power jig saw

• set of drill bits (1/8 to 3/8 inch)

• metal ruler for drawing lines on the panel

• power drill

• torque wrench

• metal file

To install the terminal, you need this tool:

• slot screwdriver or Phillips screwdriver

Mounting Options for PanelView 1000e Terminals

"

You can install your PanelView 1000e terminal in a rectangular

cutout in a panel or wall or in a 19-inch rack with the adapter kit.

The terminals are mounted with mounting clips.

Note: When choosing a location in which to install the PanelView

terminal, we recommend you provide at least 3.75 inches (9.5 cm)

clearance around the terminal from the panel or rack in which it is

installed, for proper ventilation.

Mounting a Clip-Mount Touch Screen Terminal in a Panel or Wall

Cutout

T o prepare the location:

1. Make the appropriate cutout in the wall or panel location. Figure 2.4

shows the cutout dimensions for the clip-mount terminal.

2. Insert the terminal into the panel or wall cutout.

Publication 2711E-821 – January 1998

Page 36

Figure 2.4 Clip-Mount Touch Screen Terminal Panel

Cutout

2–5Installing PanelView 1000e Terminals

Bezel Border Line

C

L

C

L

10.11”

(257 mm)

11.11”

(282 mm)

CUTOUT

13.29”

(338 mm)

14.58”

(370 mm)

Eight assembled mounting clips are provided with the clip-mount

touch screen terminals; only six clips are used for the mount.

T o install the clips:

1. Make sure the gasket is installed. If not, NEMA 4X will not be

met.

2. Install the six mounting clips (2 on top, 2 on bottom, 1 on each

side). The ends of the clips slide into the slots on the terminal.

24756

3. Tighten the mounting clip screws by hand until the gasket seal

contacts the mounting surface uniformly. See Figures 2.5 and 2.6

for details.

Publication 2711E-821 – January 1998

Page 37

2–6 Installing PanelView 1000e Terminals

Figure 2.5 Touch Screen Clip Mount (Side View)

Screw Driver Slot

Mounting

Mounting Slot

Upper Right Side

Touch Screen

Terminal Front Bezel

Figure 2.6 Touch Screen Clip Mount (Back View)

Clip

Gasket

Rack Mount Adapter

or User Panel

Front Bezel

24772

Mounting Slot

Foot Pad

Panel Mount Screw

Mounting Clip

Screw Driver Slot

24780

4. Tighten the mounting clip screws to a torque of 10 inch-pounds. Do

not over-tighten.

ATTENTION: Tighten mounting clips to a torque of

10 inch-pounds to provide a proper seal and to prevent

!

potential damage to the terminal. Allen-Bradley

assumes no responsibility for water or chemical

damage to the terminal or other equipment within the

enclosure because of improper installation.

Publication 2711E-821 – January 1998

Page 38

2–7Installing PanelView 1000e Terminals

5. Remove the protective installation label covering the top vents of

the terminal.

ATTENTION: Remove the protective installation

label covering the top vents to prevent overheating and

!

damage to the terminal.

Mounting a Clip-Mount Keypad Terminal in a Panel or Wall

Cutout

T o prepare the location:

1. Make the appropriate cutout in the wall or panel location. Figure 2.7

shows the cutout dimensions for the clip-mount terminal.

2. Insert the terminal into the panel or wall cutout.

Figure 2.7 Clip-Mount Keypad Terminal Panel Cutout

Bezel Border Line

C

L

C

L

10.11”

(257 mm)

11.11”

(282 mm)

CUTOUT

15.35”

(390 mm)

16.64”

(423 mm)

Eight assembled mounting clips are provided with the clip-mount

keypad terminals; only six clips are used for the mount.

3. Make sure the gasket is installed. If not, NEMA 4X will not be

met.

T o install the clips:

1. Install the six mounting clips (2 on top, 2 on bottom, 1 on each

side). The ends of the clips slide into the slots on the terminal.

24755

2. Tighten the mounting clip screws by hand until the gasket seal

contacts the mounting surface uniformly. See Figures 2.8 and 2.9

for details.

Publication 2711E-821 – January 1998

Page 39

2–8 Installing PanelView 1000e Terminals

Figure 2.8 Keypad Terminal Clip Mount (Side View)

Screw Driver Slot

Mounting Slot

Upper Right Side

Touch Screen

Terminal Front Bezel

Gasket

Rack Mount Adapter

or User Panel

Mounting

Clip

Figure 2.9 Keypad Terminal Clip Mount (Back View)

Mounting Slot

Foot Pad

Panel Mount Screw

Mounting Clip

Screw Driver Slot

Front Bezel

24780

24772

3. Tighten the mounting clip screws to a torque of 10 inch-pounds.

Do not over-tighten.

Publication 2711E-821 – January 1998

ATTENTION: Tighten mounting clips to a torque of

10 inch-pounds to provide a proper seal and to prevent

!

potential damage to the terminal. Allen-Bradley

assumes no responsibility for water or chemical

damage to the terminal or other equipment within the

enclosure because of improper installation.

Page 40

2–9Installing PanelView 1000e Terminals

4. Remove the protective installation label covering the top vents of

the terminal.

ATTENTION: Remove the protective installation

label covering the top vents to prevent overheating and

!

damage to the terminal.

Mounting a Touch Screen Terminal in a 19-inch Rack

To mount the PanelView 1000e Clip-Mount Touch Screen terminals

in a standard 19-inch EIA rack, you need a Rack Mount Kit (A-B

Catalog Number 2711-NR6T). This kit consists of a rack adapter and

mounting hardware.

Mounting a Keypad Terminal in a 19-inch Rack

To mount the PanelView 1000e Clip-Mount Keypad terminals in a

standard 19-inch EIA rack, you need a Rack Mount Kit (A-B