Page 1

FLEX Ex

Thermocouple/

RTD/mV Input

Module

Cat. No. 1797-IRT8

User Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this

control equipment must satisfy themselves that all necessary steps

have been taken to assure that each application and use meets all

performance and safety requirements, including any applicable laws,

regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown

in this guide are intended solely for purposes of example. Since there

are many variables and requirements associated with any particular

installation, Allen-Bradley does not assume responsibility or liability

(to include intellectual property liability) for actual use based upon

the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some

important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole

or part, without written permission of Rockwell Automation, is

prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION

Identifies information about practices or

circumstances that can lead to personal injury or

death, property damage or economic loss

!

Attention statements help you to:

• identify a hazard

• avoid a hazard

• recognize the consequences

IMPORTANT

Allen-Bradley, FLEX Ex, FLEX I/O, and ControlNet Ex are trademarks of Rockwell Automation

ControlNet is a trademark of ControlNet International

Identifies information that is critical for successful

application and understanding of the product.

Page 3

Using This Manual

Preface

Why Read this Manual

Who Should Read this Manual

About the Vocabulary

What this Manual Contains

This manual shows you how to use your FLEX Ex thermocouple/

RTD/mV module with the ControlNet Ex

network. The manual helps you install, program, and troubleshoot

your module.

You must be able to program and operate a ControlNet Ex product

and ControlNet

In this manual, we refer to the:

1797-IRT8 as the “input module”. or “module.”

•

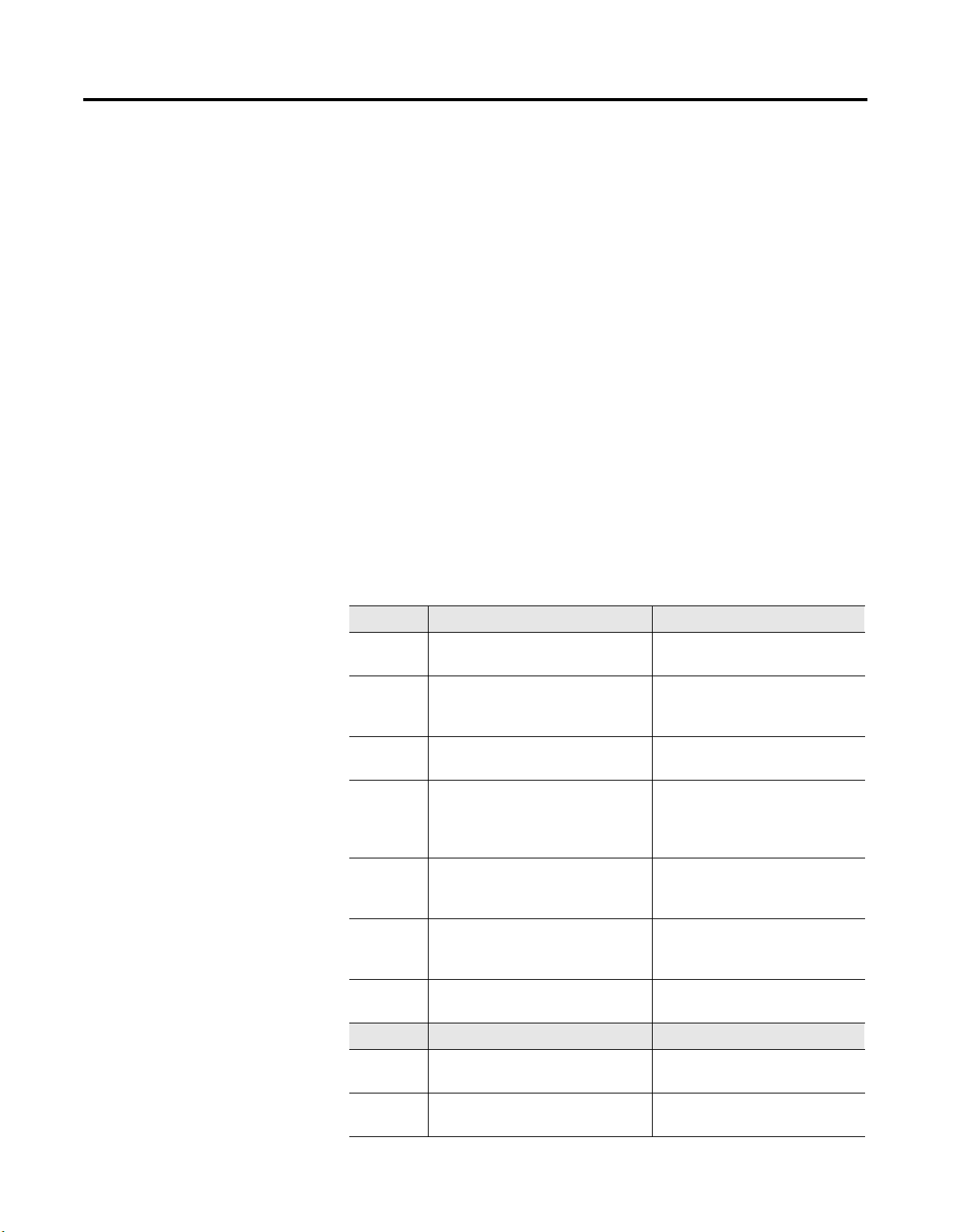

The following chart lists each chapter with its corresponding title and

a brief overview of the topics covered in that chapter.

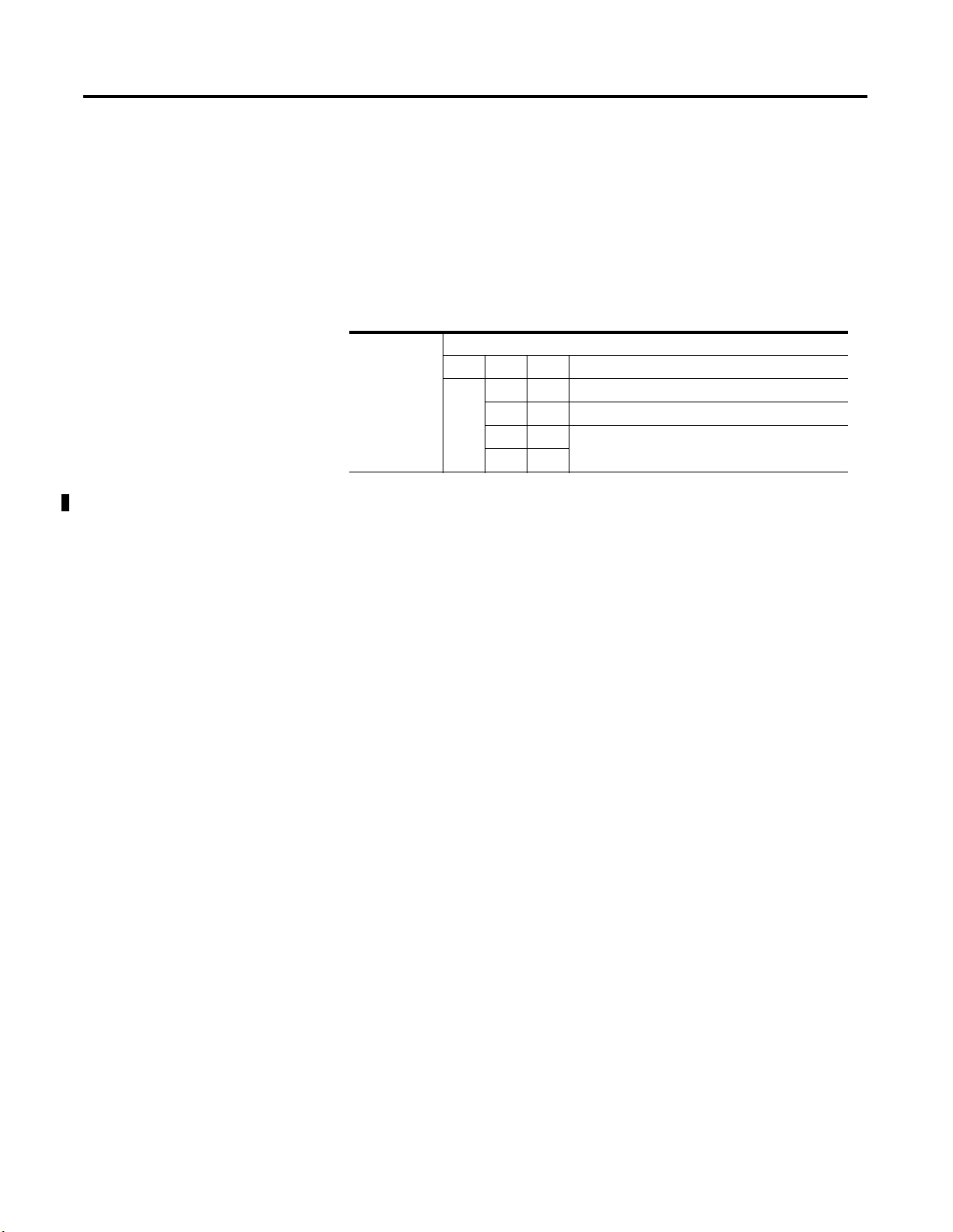

Chapter Title Contents

1 About the FLEX Ex Analog Modules Describes features, capabilities,

2 Understanding Configurable FLEX Ex

network to make efficient use of a FLEX Ex module.

thermocouple/RTD/mV Input Module

Features

products and ControlNet

and hardware components

Describes configurable features of

the input module

3 How to Install Your Thermocouple/

RTD/mV Module

4 Input, Output and Configuration Files

for the hermocouple/RTD/mV Module

on the ControlNet network

5 Calibrating Your Module Lists the tools needed, and the

6 Applying FLEX Ex Analog Modules Learn how to evaluate, define,

7 Troubleshooting Your Module How to use the indicators to

Appendix Title Contents

A Specifications Outlines module specifications and

B Programming the FLEX Ex Analog

Module using RIO

3 Publication 1797-6.5.2 - February 2001

How to install and wire the module

Describes communication over the

I/O backplane between the module

and the adapter, and how data is

mapped into the image table

methods used to calibrate the

module

select, match and optimize your

system.

troubleshoot your module

accuracy

Shows ladder diagramming for

programming.

Page 4

Using This Manual 4

For Additional Information

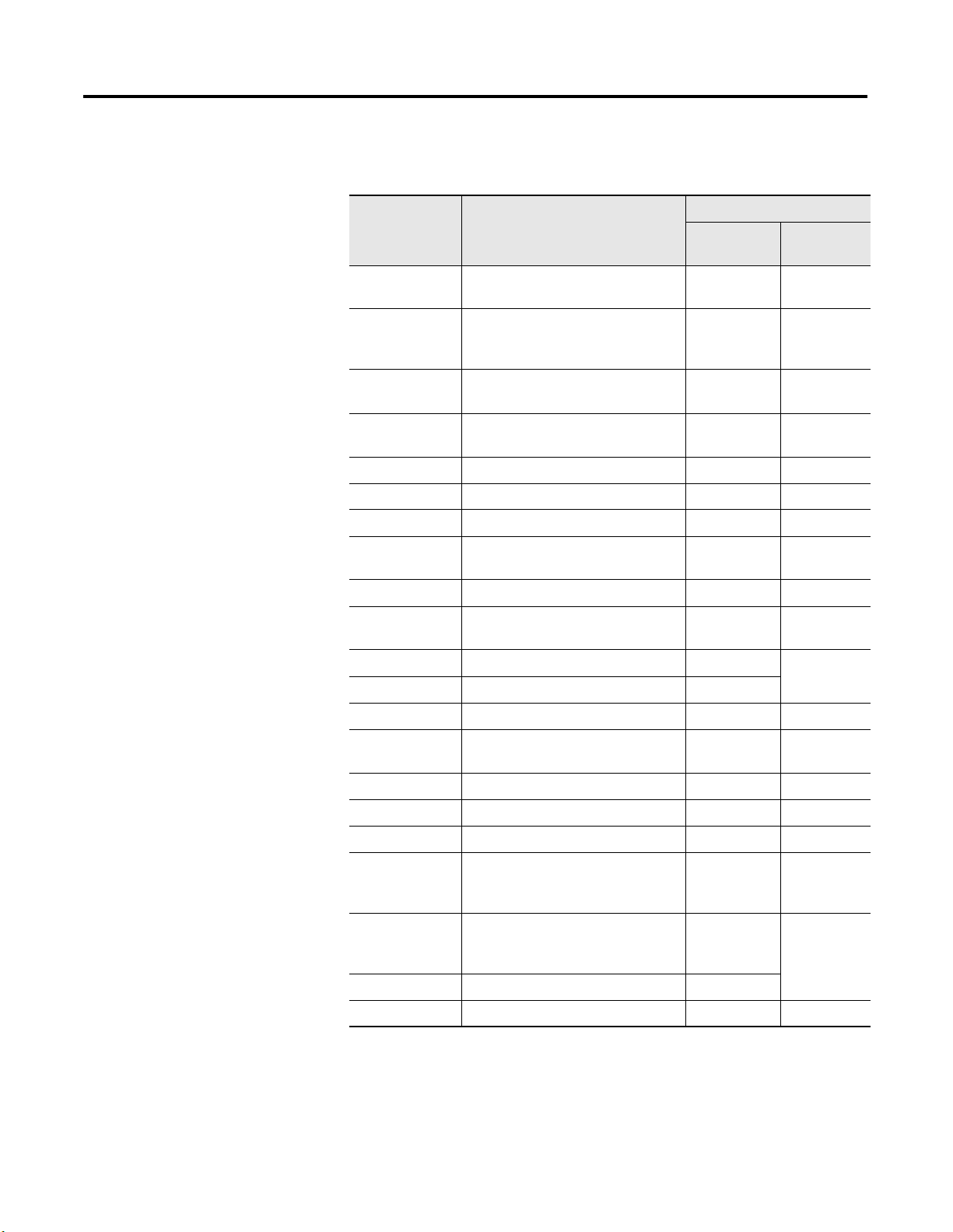

For additional information on FLEX Ex systems and modules, refer to

the following docum en ts ,

Catalog

Number

1797 Series FLEX Ex Product Data 1797-2.1

1797 Series FLEX Ex System Overview 1797-2.2

1797 Series ControlNet Ex System Cable Guide 1797-6.2.1

1797 Series FLEX Ex System Certification

Reference Manual

1797-TB3 FLEX Ex Terminal Base 1797-5.1

1797-TB3S FLEX Ex Spring Clamp Terminal Base 1797-5.2

1797-OE8 FLEX Ex 8 Output Analog Module 1797-5.3 1797-6.5.1

1797-IRT8 FLEX Ex RTD/Thermocouple/mV

Module

1797-IE8 FLEX Ex 8 Input Analog Module 1797-5.5 1797-6.5.1

Description

Publications

Installation

Instructions

(Product data)

(System

overview)

(System guide)

1797-6.2.6

1797-5.4 1797-6.5.2

User

Manual

1797-IE8NF FLEX Ex 8 Input Analog Module w/

Noise Filter

1797-OB4D 4 Output Module 1797-5.6

1797-IBN16 FLEX Ex NAMUR Digital Input Module 1797-5.7

1797-IJ2 2 Frequency Input Module 1797-5.9 1797-6.5.4

1797-PS2N

1797-PS2E

1797-ACNR15 ControlNetEx Adapter 1797-5.14 1797-6.2.1

1797-RPA, -RPFM Fiber Hub 1797-5.15 1797-6.2.1

1797-BIC Bus Isolator 1797-5.13

1797-TPR,

- TPRS, -TPYR,

-TPYS

1797-CE1S,

-CE3S, -CEFTN,

-CEFTE

1797-EXMK Marker Kit 1797-5.23

1797 FLEX Ex System Certification 1797-6.5.6

FLEX Ex Power Supplies 1797-5.12

FLEX Ex Taps 1797-5.18 1797-6.2.1

Interconnect Cables 1797-5.20

1797-5.31 1797-6.5.1

In Summary

Publication 1797-6.5.2 - Febr uary 2001

This preface gave you information on how to use this manual

efficiently. The next chapter introduces you to the 1797-IRT8

Thermocouple/RTD / mV Inpu t module .

Page 5

Preface

Using This Manual

Table of Contents

About the FLEX Ex Thermocouple/

RTD/mV Input Module

Table of Contents

Important User Information. . . . . . . . . . . . . . . . . . . . . . . . . . 2

Why Read this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Who Should Read this Manual. . . . . . . . . . . . . . . . . . . . . . . . 3

About the Vocabulary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

What this Manual Contains . . . . . . . . . . . . . . . . . . . . . . . . . . 3

For Additional Information . . . . . . . . . . . . . . . . . . . . . . . . . . 4

In Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Chapter 1

What this Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . . 1-1

What the FLEX Ex Thermocouple/RTD/mV Modules Do. . . 1-1

How FLEX Ex Thermocouple/RTD/mV Modules

Communicate with Programmable Controllers . . . . . . . . . . 1-2

Events following Power-Up . . . . . . . . . . . . . . . . . . . . . 1-2

Features of Your Module. . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Using Alarms on the 1797-IRT8 Module . . . . . . . . . . . . . . . 1-3

Data Format Alarm Example. . . . . . . . . . . . . . . . . . . . . 1-4

Overrange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Underrange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Open Wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Cold Junction Compensation Alarm . . . . . . . . . . . . . . . . . . . . 1-4

Data Formats and Fault Modes . . . . . . . . . . . . . . . . . . . 1-5

Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Chapter 2

Understanding Configurable FLEX

Ex Thermocouple/RTD/mV Input

Module Features

i Publication 1797-6.5.2 - February 2001

What this Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Setting a FLEX Ex Thermocouple/RTD Module’s Operating

Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Input Type Select. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Sensor Type Select. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Input Filter Cutoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Data Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Sensor Mode Select . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Preset Temperature Select . . . . . . . . . . . . . . . . . . . . . . 2-5

RTD Loop Resistance Offset Select . . . . . . . . . . . . . . . . 2-6

Fault Mode Select . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Using Module Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Overrange Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Underrange Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Fault Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Page 6

Table of Contents ii

How to Install Your FLEX Ex

Thermocouple/RTD/mV Module

Chapter 3

What this Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Before You Install Your Analog Module. . . . . . . . . . . . . . . 3-1

Compliance to European Union Directives. . . . . . . . . . . . . 3-2

EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Ex Directive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Installation in Zone 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Electrostatic Charge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Removal and Insertion

Under Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Installing the Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Mounting on a DIN Rail . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Panel/Wall Mounting . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Mounting the 1797-IRT8 Module on the Terminal

Base Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Wiring the Terminal Base Units . . . . . . . . . . . . . . . . . . . . . 3-9

Connecting Wiring to the

FLEX Ex Thermocouple/RTD/mV Module . . . . . . . . . . . . . 3-10

Inputs/Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Wiring connections for the 1797-IRT8 Module. . . . . . . . 3-11

Grounding the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Input, Status, Output and

Configuration Files for the

Thermocouple/RTD/mV Module on

the ControlNet Network

Chapter 4

What this Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Using Programming Software in Your FLEX Ex Application. 4-2

About the ControlNet Ex Adapter. . . . . . . . . . . . . . . . . . . . 4-2

Communication Over the FLEX Ex Backplane . . . . . . . . . . 4-2

Scheduled Data-Transfer . . . . . . . . . . . . . . . . . . . . . . . 4-3

Unscheduled Data-Transfer . . . . . . . . . . . . . . . . . . . . . 4-3

Module I/O Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

I/O Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Adapter Status Word . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Fault State Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Device Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Communication Fault Behavior. . . . . . . . . . . . . . . . . . . 4-6

Idle State Behavior. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Input Data Behavior upon Module Removal . . . . . . . . . 4-7

Thermocouple/RTD/mV Input Module (1797-IRT8) Image

Table Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Bit/Word Description for the Thermocouple/RTD/mV Input

Module (1797-IRT8) . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Publication 1797-6.5.2 - Febr uary 2001

Page 7

Calibrating Your Module

Applying FLEX Ex Thermocouple/

RTD/mV Input Modules

Table of Contents iii

Chapter 5

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . 5-1

When and How to Calibrate Your FLEX Ex

Thermocouple/RTD/mV Input Module. . . . . . . . . . . . . . . . 5-1

Tools and Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Calibration Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Chapter 6

What this Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Evaluate the Application . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Define the Area Classification . . . . . . . . . . . . . . . . . . . . . . 6-2

Decide Classification Method . . . . . . . . . . . . . . . . . . . . 6-2

Determine Hazard . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Determine Temperature Rating. . . . . . . . . . . . . . . . . . . 6-2

Select Protection Method(s). . . . . . . . . . . . . . . . . . . . . . . . 6-3

Match Field Devices and I/O Modules . . . . . . . . . . . . . . . . 6-3

1797-IRT8 and Thermocouple and RTD Functional and IS

Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Using the Entity Method. . . . . . . . . . . . . . . . . . . . . . . . 6-5

Entity Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

General Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Interconnect Wiring 6-7

I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Optimize Power Distribution . . . . . . . . . . . . . . . . . . . . . . . 6-8

Assigning Power Supplies . . . . . . . . . . . . . . . . . . . . . . 6-8

Power Supply Considerations. . . . . . . . . . . . . . . . . . . . 6-9

Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Troubleshooting the FLEX Ex

Thermocouple/RTD/mV Input

Module

Specifications

Chapter 7

What this Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Repair. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Appendix A

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

CE/CENELEC I/O Entity Parameters . . . . . . . . . . . . . . . . . . A-2

UL, C-UL I/O Entity Parameters . . . . . . . . . . . . . . . . . . . . . A-3

Table 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Wiring Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Table 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

FM I/O Entity Parameters . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Wiring Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Table 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Table 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Publication 1797-6.5.2 - February 2001

Page 8

Table of Contents iv

Programming the FLEX Ex I/O

Modules

Using RIO

Index

Back Cover

Appendix B

What this Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . . B-1

Enter Block Transfer

Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Using the PLC-5C Processor. . . . . . . . . . . . . . . . . . . . . . . . B-2

Publication 1797-6.5.2 - Febr uary 2001

Page 9

Chapter

About the FLEX Ex Thermocouple/RTD/mV Input Module

1

What this Chapter Contains

What the FLEX Ex Thermocouple/RTD/mV Modules Do

Read this chapter to familiarize yourself with the 1797-IRT8 input

module.

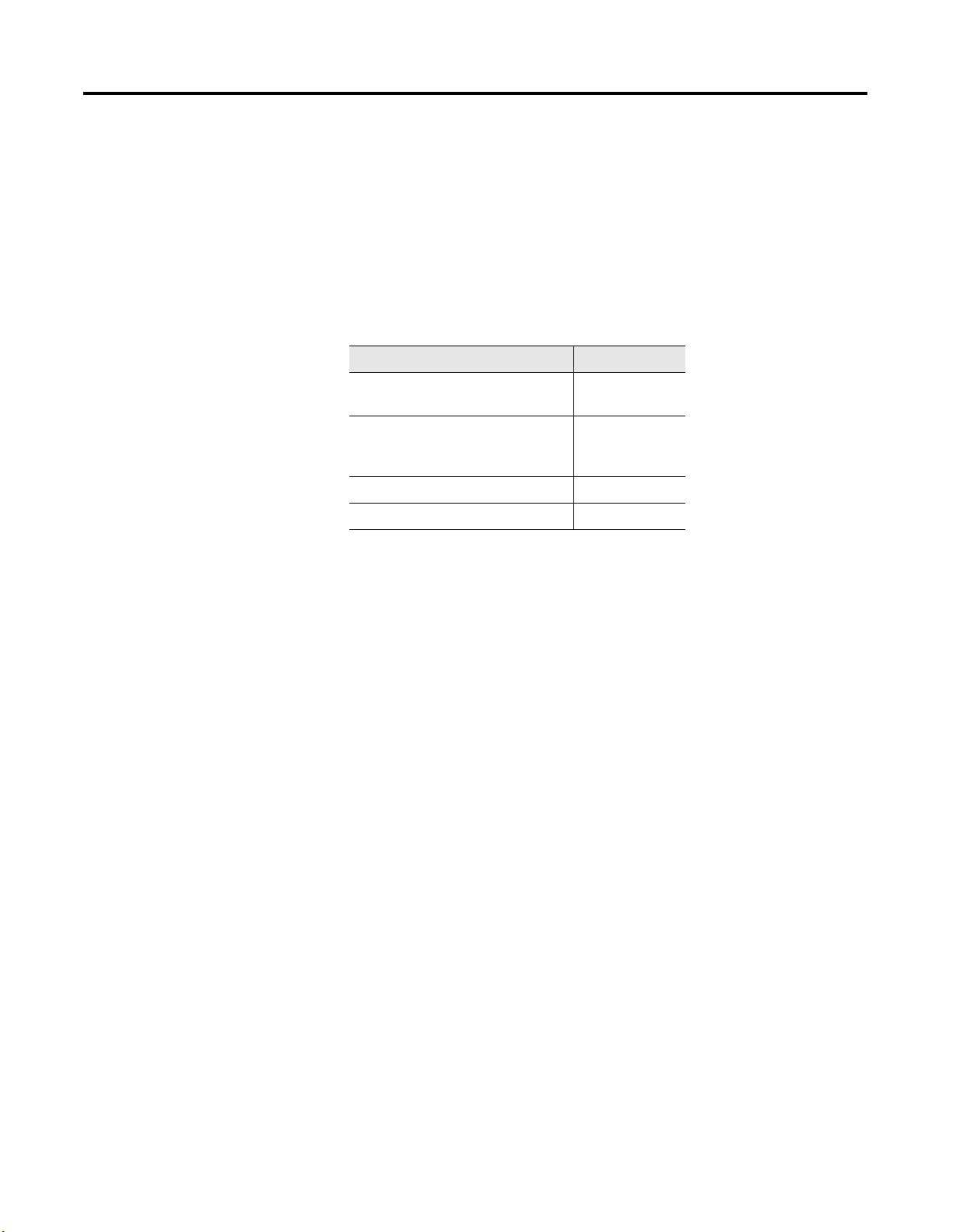

For information on: See page:

What the FLEX Ex Thermocouple/

RTD/mV Modules Do

How FLEX Ex Thermocouple/RTD/mV

Modules Communicate with

Programmable Controllers

Features of Your Module 1-2

Chapter Summary 1-5

The 1797-IRT8 module accepts up to 8 thermocouple, RTD or mV

inputs. The inputs are nonisolated and are selected with analog

multiplexers which have a common-mode input range of -0.5 to +3.6

volts. The inputs will accept a millivolt or resistive input. Default input

spans are –40.00mV to +100.00mV or 0.00 to 500.00 ohms. Fault

Indicators are located on the field side.

No switches or jumpers are us ed on t he th ermocouple/RTD/mV input

module. The Inputs have both fixed hardware filters and selectable

firmware digital filters.

1-1

1-2

This module offers:

• local microprocessor intelligence for advanced features

• full functionality without switches or jumpers

• multiple data ranges that can be independently programmed in

channel groups

• lead breakage detection

• overrange/underrange alarms

as well as a host of other module features.

1 Publication 1797-6.5.2 - February 2001

Page 10

1-2 About the FLEX Ex Thermocouple/RTD/mV Input Module

How FLEX Ex Thermocouple/RTD/mV Modules Communicate with Programmable Controllers

FLEX Ex thermocouple/RTD/mV modules provide best utility when

used with ControlNet Ex products on the Co ntrolNet network. Data

connections are established between the I/O module and an

Allen-Bradley programmable controller to transfer information

between the two at a scheduled rate.

Input module information is then automatically made available in the

PLC data table.

When the data connection is established, configuration information

for the module is automatically transferred to it via the network.

Events following Power-Up

You must apply intrinsically safe +/-V power to your FLEX Ex I/O

modules. The following sequence of events occurs after power has

initially been applied to your module:

1. The module begins an interal diagnostic check. The channel 0 LED

indicator turns ON to indicate the check has begun. The indicator

turns OFF when th e che ck is finish ed.

Features of Your Module

2. After the diagnostic check, module configuration information,

selected by the user and downloaded over the network, is applied

by the module.

For more information on configuration options, see Chapter 2.

3. Following the module configuration download for the 1797-IRT8

module, the module begins producing runtime data for the PLC.

4. If any diagnostics or alarms are generated during normal module

operation, the data is returned to the PLC.

The module label identifies the keyswitch position, wiring and

module type. Use the removable label to note individual designations

per your application.

Publication 1797-6.5.2 - Febr uary 2001

Page 11

About the FLEX Ex Thermocouple/RTD/mV Input Module 1-3

Indicators

Indicators are provided to identify input or output fault conditions,

and to show when power is applied to the module.

1797-IRT8

Module Type

Using Alarms on the 1797-IRT8 Module

Removable Label

Keyswitch Position

Indicator (#2)

Power On Indicator

40070

Input Designato rs

1797-IRT8

Ex

PWR

The 1797-IRT8 FLEX Ex module is capable of generating four alarms:

Underrange

•

Overrange

•

Fault (open wire)

•

Cold junction compensation Fault

•

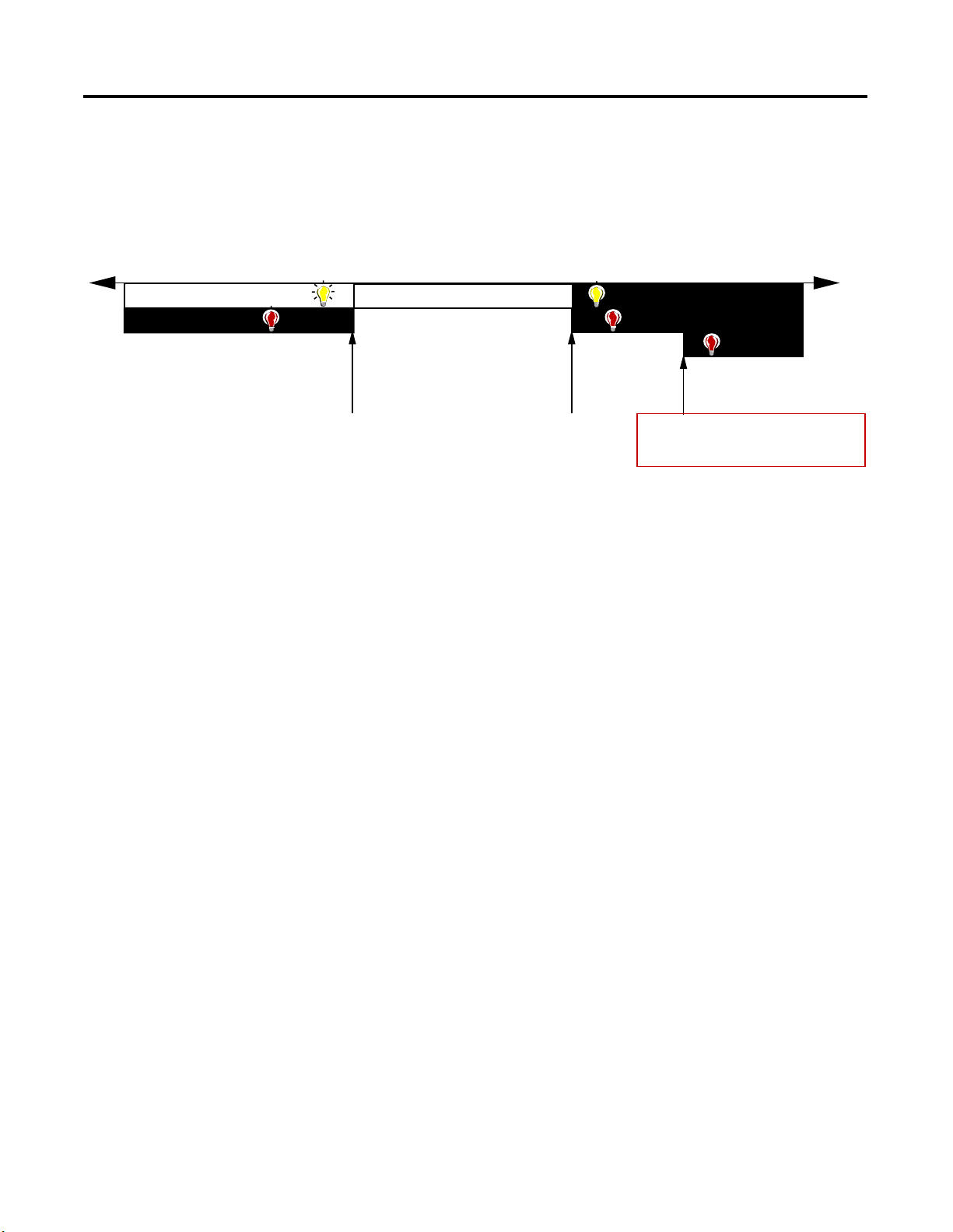

These alarm conditions are described in general terms and as they

relate to bits on the FLEX Ex I/O module on the following pages. The

graphic below shows at what values these alarms are generated for

Data Format 4.

Publication 1797-6.5.2 - February 2001

Page 12

1-4 About the FLEX Ex Thermocouple/RTD/mV Input Module

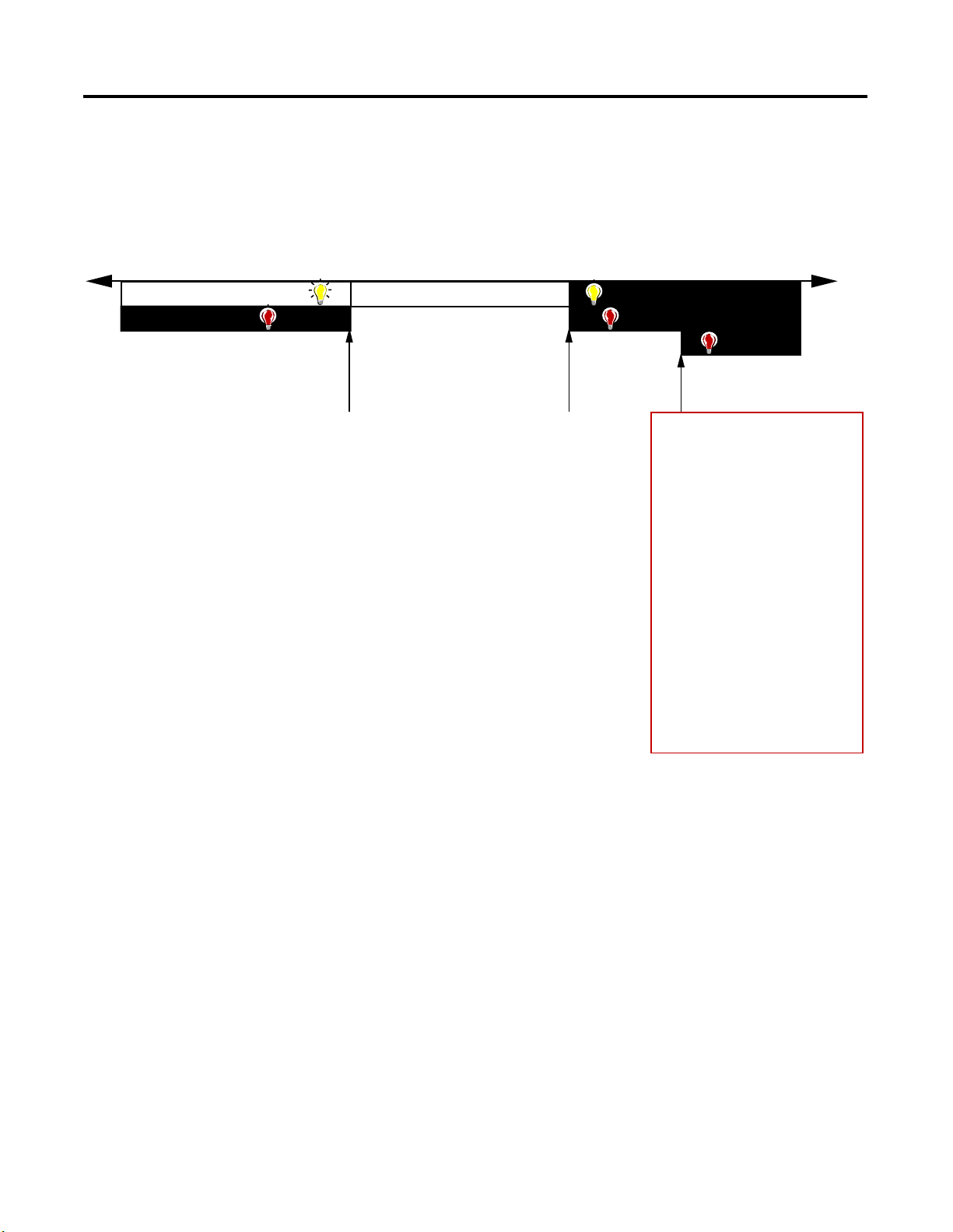

Data Format Alarm Example

In this example, the normal active data range is 4-20mA. The alarms

are generated in three overlapping bands.

PHYSICAL INPUT SIGNAL RANGE

CJC fault

underrange

overrange

CJC fault

Maximum

Measureable

Value

open w i re fault

Channel Data

Forced to

Maximum for Type

Minumum

Value for

Sensor

Type

normal signal range

Maximum

Value for

Sensor

Type

Overrange

If the input is greater than the maximum temperature of the

thermocouple or RTD range, millivolt (+100mV), or resistance (500W)

the overrange bit for that channel will be set.

Underrange

If the input is less than the minimum temperature of the thermocouple

or RTD range, millivolt (-40mV), or resistance (0W) the underrange bit

for that channel will be set.

Publication 1797-6.5.2 - Febr uary 2001

Open Wire

Individual channel fault alarm for broken wire. If a broken wire/

detached lead is detected, the data value is forced to maximum. In

RTD/W mode, input levels above 540W will set this bit; in

thermocouple/mV mode, input levels above 210mV will set this bit.

Cold Junction Compensation Alarm

Broken or detached lead or shorted lead detection is included for

CJCs. This detection is only available when the input type selected is

thermocouple and sensor mode is set to CJC compensation.

When either CJC fails its fault is reported. Both CJCs ae normally used

in compensation calculations. If one CJC fails, calculations use the

remaining good device. If both fail, calculations use the last good

value.

Page 13

About the FLEX Ex Thermocouple/RTD/mV Input Module 1-5

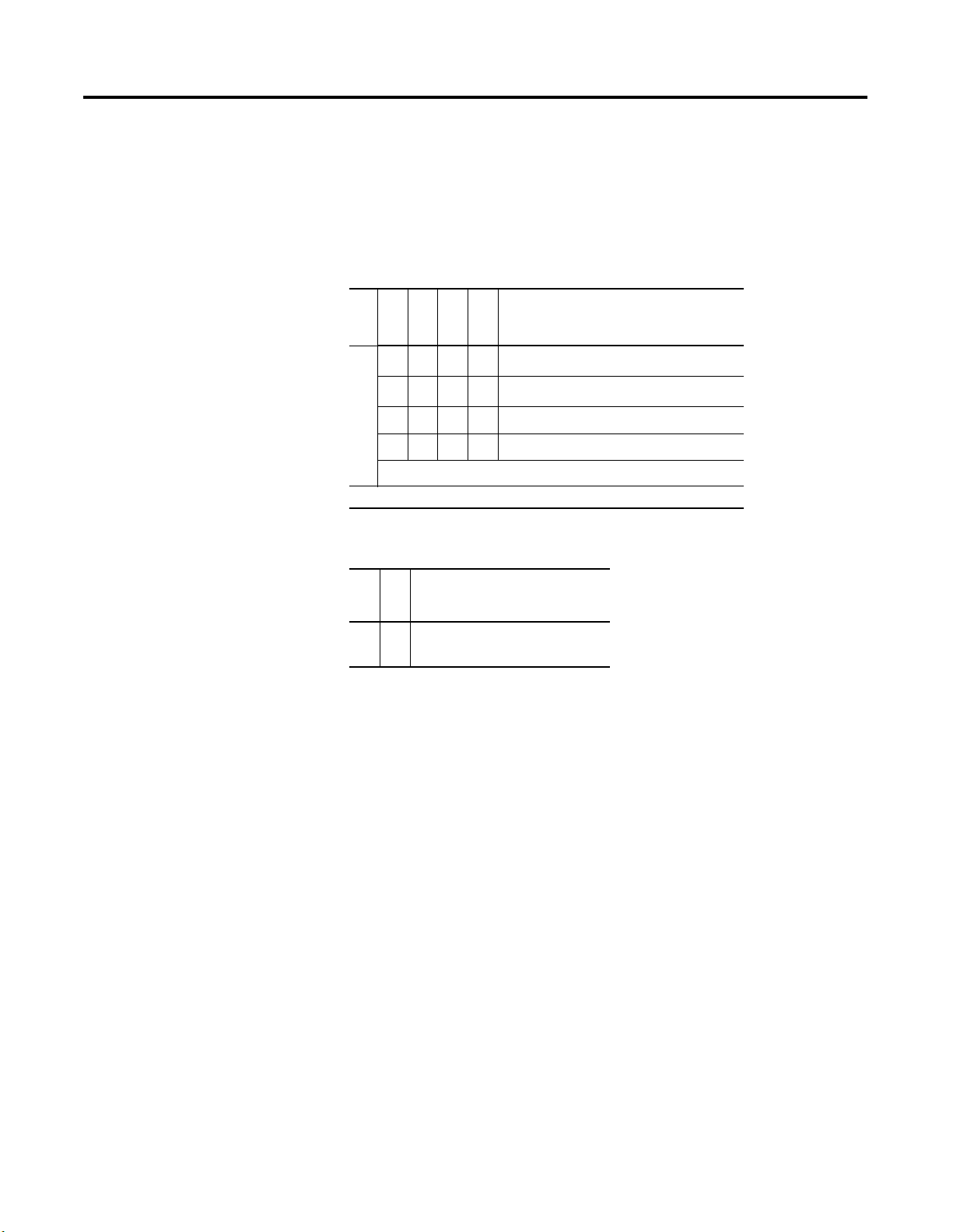

Data Formats and Fault Modes

The tables below shows the bit settings for the data formats and fault

modes for your FLEX Ex thermocouple/RTD/mV module.

Data Formats

Bit 11 10 09 08 Data type for channels 0 thru 7

0000

0001

0010

0 0 1 1 -32767 to +32767

0 1 0 0 0 to 65535

0101 thru 1111 not used

Note: Module defaults to -4000 to 10,000 in millivolt mode, and 0 to 5000 in ohms mode

o

C (see note)

o

F (see note)

o

K (see note)

Chapter Summary

Fault Mode

Bit 06 Fault enable for channels 0-3

07 Fault enable for channels 4-7

0 = disabled

1 = enable wire-off detection

In this chapter, we told you about the FLEX Ex system and the

thermocouple/RTD/mV module, and how it communicates with

programmable controllers.

Publication 1797-6.5.2 - February 2001

Page 14

1-6 About the FLEX Ex Thermocouple/RTD/mV Input Module

Publication 1797-6.5.2 - Febr uary 2001

Page 15

Understanding Configurable FLEX Ex

Thermocouple/RTD/mV Input

Module Features

Chapter

2

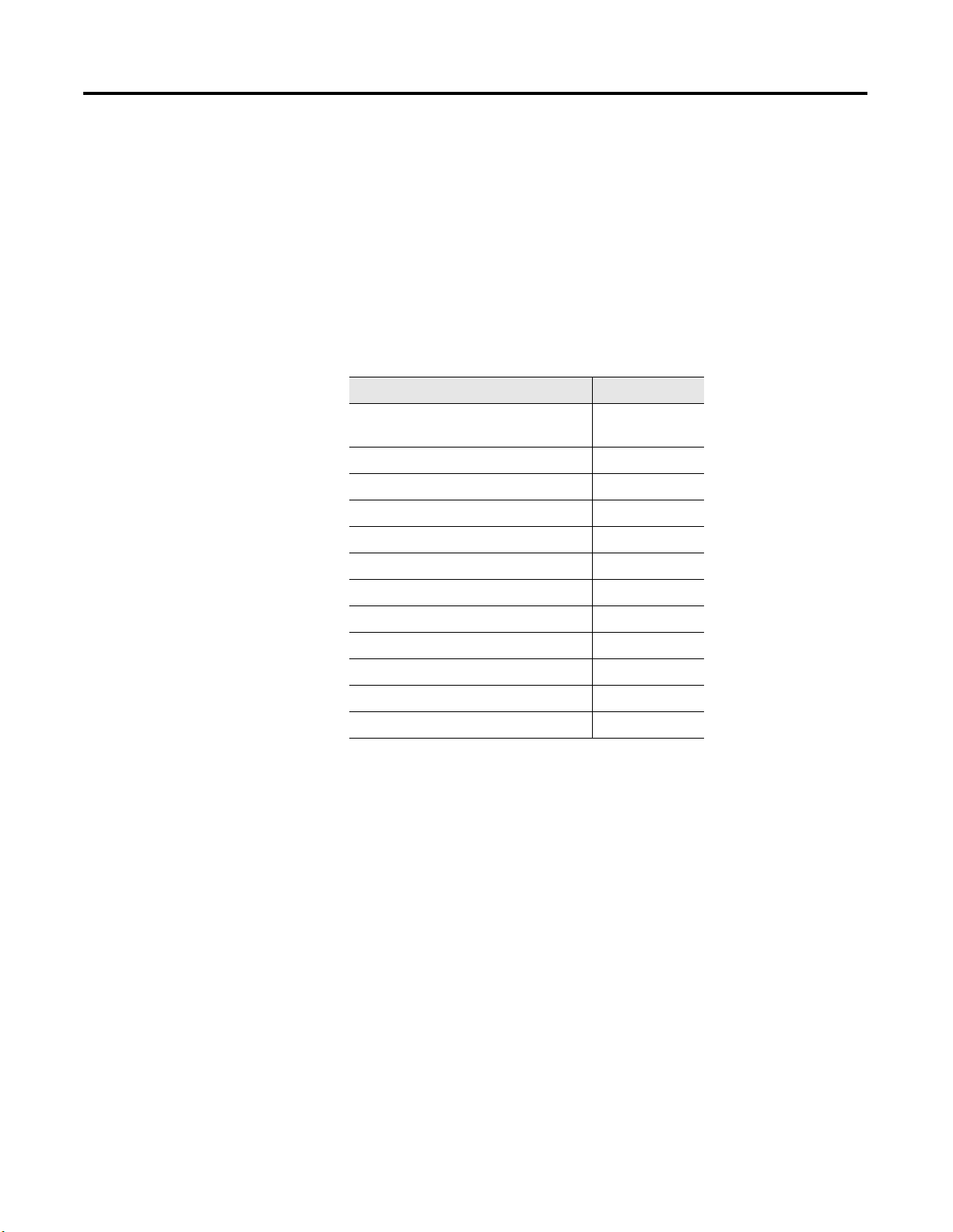

What this Chapter Contains

Read this chapter to familiarize yourself with configurable features on

the 1797-IRT8 module.

For information on: See page:

Setting a FLEX Ex Thermocouple/RTD

Module’s Operating Status

Input Type Select 2-2

Sensor Type Select 2-2

Data Format 2-4

Preset Temperature Select 2-5

RTD Loop Resistance Offset Select 2-6

Fault Mode Select 2-7

Using Module Alarms 2-7

Overrange Alarm 2-7

Underrange Alarm 2-8

Fault Alarm 2-9

Chapter Summary 2-9

This chapter describes the following features:

2-2

Input type

•

Sensor type

•

• Data formats

• Preset temperature selection

• RTD loop resistance offset selections

• F a ult mode

• Overrange Alarms

• Und errange alarms

• Fault alarms

Important:You must use your programming software to configure

these features. A brief description of each module feature

is provided in this chapter, but you must use the online

help included with your programming software to perform

specific configuration.

1 Publication 1797-6.5.2 - February 2001

Page 16

2-2 Understanding Configurable FLEX Ex Thermocou ple/RTD/mV Input Module Features

Setting a FLEX Ex

Thermocouple/RTD

Module’s Operating

Status

Input Type Select

Select the thermocouple or RTD mode for input channel groups 0-3

and 4-7. If 2 is selected, the module defaults to thermocouple. If 3 is

selected, the module defaults to RTD.

Range: 0 = thermocouple, 1 = RTD, 2 and 3 not used

Bits 06-07 Input Type Select

Bit 07 06 Input type sel ect ion for channels 0-3

0 0 Thermocouple

01RTD

10

11

Input type select for channels 4 through 7 use bits in word 1.

Not used

Sensor Type Select

Select the type of sensor for input channel groups 0-3 and 4-7.

Thermocouple mode 0 = mV, 1 = B, 2 = E, 3 = J, 4 = K, 5 = TXK/

XK(L), 6 = N, 7 = R, 8 = S, 9 = T, 10-15 not used.

RTD mode: 0 = W , 1 = Pt100 IEC 751 Amen dment 2, 2 = Pt200 IEC 751

Amendment 2, 3 = Pt1 00 JIS C1604-1989, 4 = Pt200 JIS C1604- 1989, 5 =

Ni100 DIN 43760-1987, 6 = Ni200 DIN 4376 0-1987, 7 = Ni120 Min co, 8

= Cu10 Minco, 9-15 not used.

If unused settings are chosen, diagnostic status “2 = configuration

failure” will be set, and the last valid configuration will be used. The

default = 0.

Publication 1797-6.5.2 - Febr uary 2001

Page 17

Understanding Configurable FLEX Ex Thermocouple/RTD/mV Input Module Features 2-3

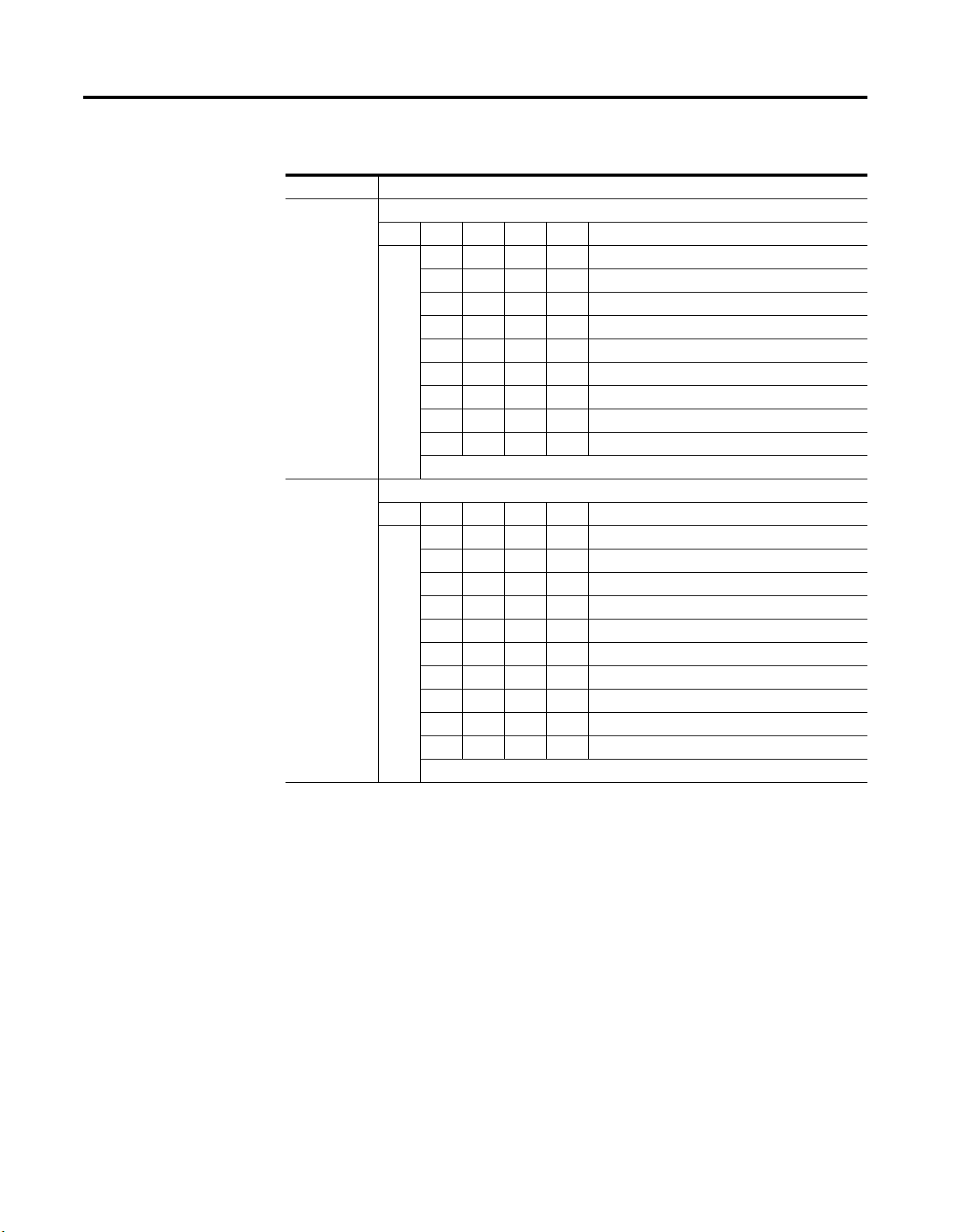

Bits 00-03 Sensor Type (Thermocouple or RTD)

RTD Type

Bit03020100Sensor type for channels 0 through 3

0000Resistance (default)

0001100 ohm Pt α = 0.00385 Euro (–200 to +870°C)

0010200 ohm Pt α = 0.00385 Euro (–200 to +400°C)

0011100 ohm Pt α = 0.003916 U.S. (–200 to +630°C)

0100200 ohm Pt α = 0.003916 U.S. (–200 to +400°C)

0101100 ohm Nickel (–60 to +250°C)

0110200 ohm Nickel (–60 to +200°C)

0111120 ohm Nickel (–80 to +320°C)

100010 ohm Copper (–200 to +260°C)

1001 through 1111 not used

Bits 00-03 Thermocouple Type

Bit03020100Sensor type for channels 0 through 3

0000mV (default)

0001B 300 to 1800°C (572 to 3272°F)

0010E –250 to 1000°C (–418 to 1832°F)

0011J –210 to 1200°C (–346 to 2192°F)

0100K –250 to 1372°C (–418 to 2502°F)

0101L –200 to 800°C (–328 to 1472°F)

0110N –250 to 1300°C (–418 to 2372°F)

0111R –0 to 1768°C (32 to 3214°F)

1000S –0 to 1768°C (32 to 3214°F)

1001T –250 to 400°C (–418 to 752°F)

1010 through 1111 not used

Input Filter Cutoff

A series of eight available input filters – filters are hardware and

software – allow you to choose the best rolloff frequency for input

channels on your I/O module. When choosing a filter, remember that

time frequency rolloff may affect your input signal’s accuracy.

For example, in configuration word 0, if you choose the fastest time

frequency of 600Hz (hardware filter only), little noise is added, but the

slowest frequency of 0.2Hz will provide the most accurate process

noise filtering. See below to decide which input filter to use in your

application:

Publication 1797-6.5.2 - February 2001

Page 18

2-4 Understanding Configurable FLEX Ex Thermocou ple/RTD/mV Input Module Features

Input Filter Cutoff bits

Bit020100Definition

0 0 0 Hardware filtering only (default filtering) 600Hz (1.7ms)

0 0 1 40Hz (25ms)

0 1 0 10Hz (100ms)

0 1 1 4Hz (250ms)

1 0 0 2Hz (500ms)

1011Hz(1s)

1100.5Hz(2s)

1110.2Hz(5s)

Choose the best input filter cutoff in your programming software.

Data Format

You must choose a module data format in your user program. Select

the format by setting bits as shown below. Note that this parameter

affects channel accuracy.

Data format – module defaults to –4000 to 10000 in millivolt mode, and 0 to 5000 in ohms mode

Bit 11 10 09 08 Data type for channels 0-7

0000°C

0001°F

0010×K

0 0 1 1 –32767 to +32767

0 1 0 0 0 to 65535

0101 through 1111 not used

o

C, oF and oK will have formats appropriate to the selected

thermocouple or RTD range (e.g. -xxxx to +xxxx with 1 decimal place

implied - 3500 = 350.0). For Cu10 RTD, 2 decimal points are implied.

If using mV, data format defaults to -4000 to +10000 (2 decimal points

implied (e.g. -40 to 100.00). If using W mode selection, data format

defaults to 0 to 5000 (1 decimal point implied, e.g. 0.- to 500.0).

In the thermocouple and RTD modes, if unused data formats are

o

chosen, the module will default to

C.

Publication 1797-6.5.2 - Febr uary 2001

Page 19

Understanding Configurable FLEX Ex Thermocouple/RTD/mV Input Module Features 2-5

Sensor Mode Select

Selects the sensor mode for input channels 0-3 and 4-7.

If using cold junction compensation, both CJCs must be installed. The

difference between the CJCs will be linearly apportioned to each

thermocouple channel based on its position across the base. If one

CJC is broken or missing, the remaining CJC is used t o compensate all

channels. The appropriate CJC alarm will be set in this case. If the

second CJC fails, the last valid reading is frozen for compensation use.

The second CJC alarm will also be set.

When using only channels 0-3 for thermocouples, connect the CJCs to

terminals 5 and 12. If only using channels 4-7, connect the CJCs to

terminals 22 and 29. If all channels are configured for thermocouples,

connect the CJCs to terminals 5 and 29.

When CJC thermistor temperature compensation is sele cted for one

channel group, all channels configured for thermocouple inputs will

use the CJC compensation.

05 04 Sensor mode for channels 0 thru 3

Bit

13 12 Sensor mode for channels 4 thru 7

Thermocoupl e Mode

00

0 1 Internal compensation - Uses the value selected for reference junction

10

1 1 Differential measurement between 2 channels

0 0 2-wire RTD - no compensation

0 1 2-wire RTD with user compensation

1 0 3-wire RTD

1 1 4-wire RTD

External compensation - uses cold junction sensors

o

No compensation (Data is referenced to 0

RTD Mode

C)

Preset Temperature Select

This parameter is used if Input Type Select is set to thermocouple and

Sensor Mode Select is set to fixed compensation. This parameter then

sets a fixed reference temperature used to compensate all

thermocouple channels.

The default = 0.

Publication 1797-6.5.2 - February 2001

Page 20

2-6 Understanding Configurable FLEX Ex Thermocou ple/RTD/mV Input Module Features

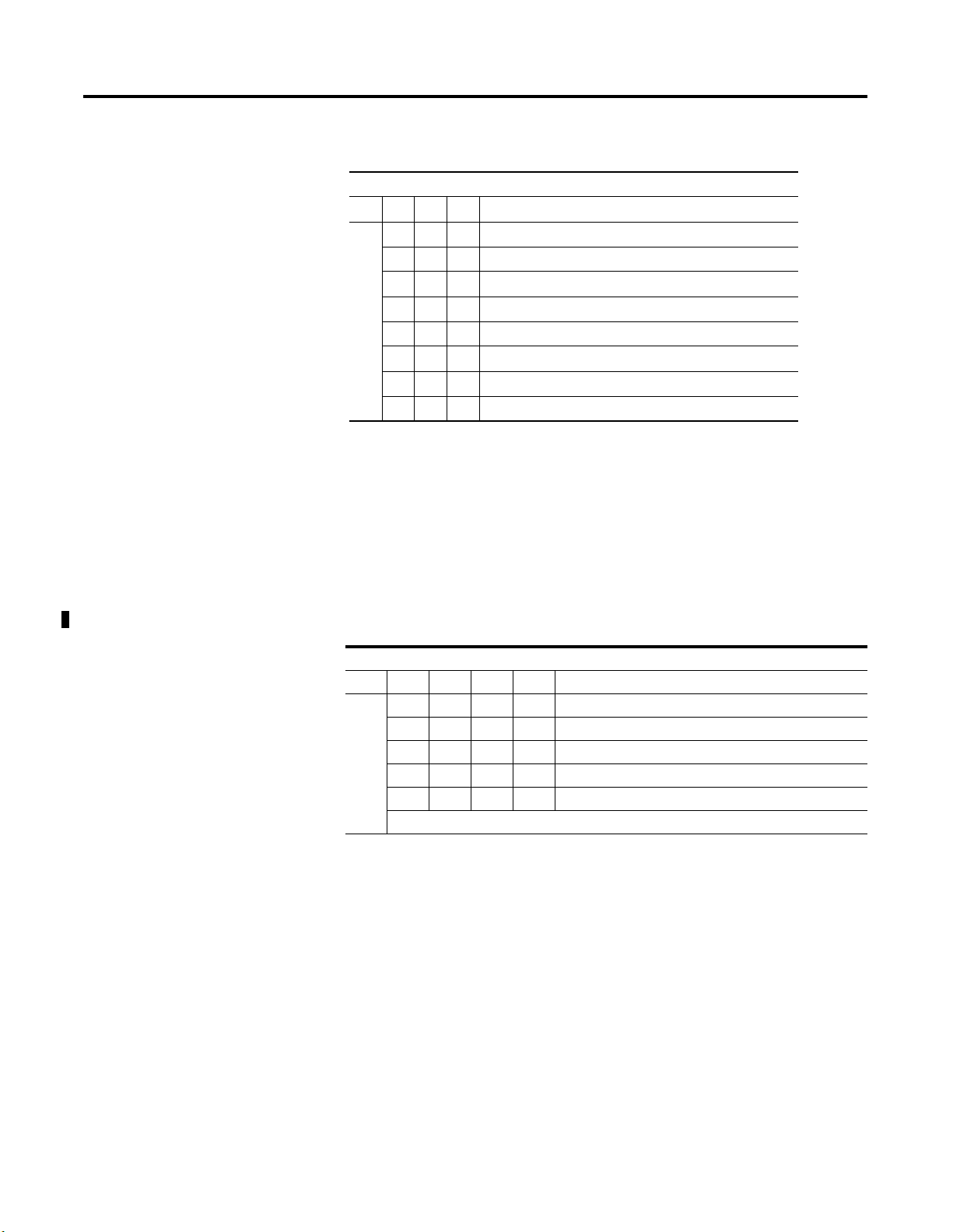

Bits 03-05 Reference Junction – used when input type is set to thermocouple and sensor

mode is set to fixed compensation. Sets a fixed reference junction to compensate

all thermocouple channels.

Bit050403Reference Junction

0000°C

00120°C

01025°C

01130°C

10040°C

10150°C

11060°C

11170°C

RTD Loop Resistance Offset Select

This parameter is used if Input Type Select is set to RTD and Sensor

Mode Select is set to 2-wire with loop resistance compensation. This

parameter then sets total RTD loop resistance compensation for each

RTD channel. Either the value stored for each channel during

calibration is used to compensate the module RTD channels, or one of

3 fixed values is used to compensate module RTD channels.

This parameter is disabled for Cu10 RTDs.

00-15 (00-17) RTD loop resistance offset select bits – used input type is set to RTD and sensor

mode select is set to 2-wire with loop resistance compensation. Allows you to set

the type of RTD loop resistance compensation used for all RTDs or one of three fixed

values for all channels. NOTE: Not applicable to 10W copper RTD, which defaults to

0W.

Bit 01 00 RTD channel 0

Bit 03 02 RTD channel 1

Bit 05 04 RTD channel 2

Bit 07 06 RTD channel 3

Bit 09 08 RTD channel 4

Bit 11 10 RTD channel 5

Bit 13 12 RTD channel 6

Bit 15 14 RTD channel 7

0 0 Use channel loop compensation value stored during

calibration procedure for 2-wire RTD (default = 0W)

015W

1 0 10W

1 1 15W

Range: 0 = use channel loop compensation value determined and

stored during calibration procedure for 2-wire RTD, 1 = 5Ω, 2 = 10Ω,

3= 15Ω. Default = 0.

Publication 1797-6.5.2 - Febr uary 2001

Page 21

Understanding Configurable FLEX Ex Thermocouple/RTD/mV Input Module Features 2-7

Fault Mode Select

Select whether the channel fault detection is enabled or disabled for

channels 0-3 and 4-7.

Range: 0 = disable, 1 = fault detection enabled (wire off, mV

overvoltage, RTD open). Default = 0.

Using Module Alarms

Bits 06-07 Fault Mode bits – when a bit is set (1), fault mode is enabled for that channel.

Bit 06 corresponds to channels 0-3; bi t 07 corresponds to channels 4-7.

0 = disabled

1 = enable wire-off detection

FLEX Ex I/O modules are capable of generating four alarms:

Overrange

•

Underrange

•

Fault

•

Cold Junction Compensation (CJC) Fault

•

These alarm conditions are described in general terms and as they

relate to bits on the FL EX Ex I/O module on the following pages.

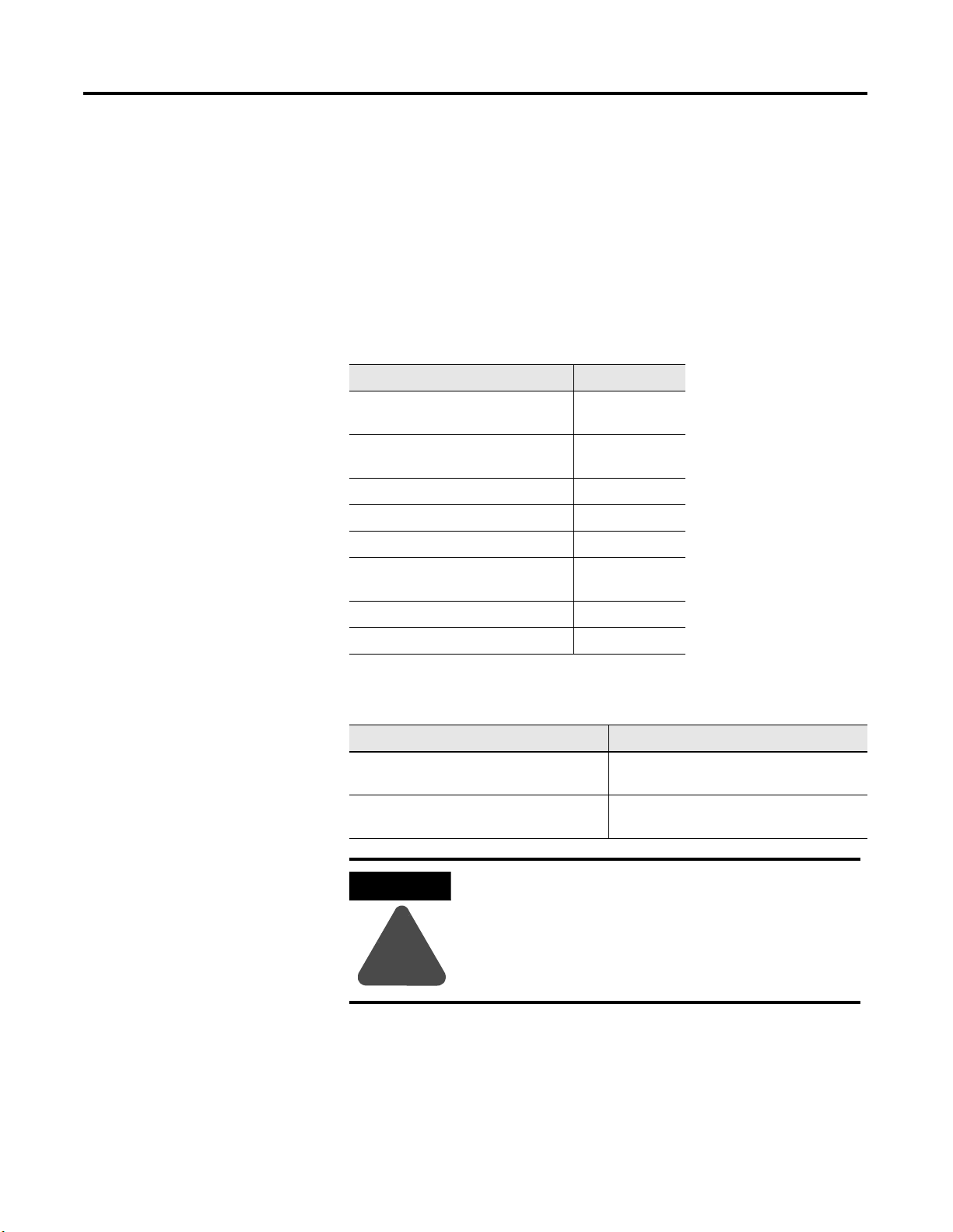

Overrange Alarm

The channel overrange alarm is set if the input is greater than the

maximum temperature (thermocouple or RTD range dependent),

millivolt (+100mV) or resistance (500Ω) range value.

Range: 0 = normal, 1 = input overrange. Default = 0.

This alarm stays active at any value above 100% of range and is

always enabled by the module. Refer to the figure below for the

sensor dependent signal which causes this alarm to be generated.

Publication 1797-6.5.2 - February 2001

Page 22

2-8 Understanding Configurable FLEX Ex Thermocou ple/RTD/mV Input Module Features

IRT8 Specific alarming performance

PHYSICA L I NPUT SIGNAL RANGE

underran ge

CJC fault

Sensor Type

IEC PT100

IEC PT200

JIS PT100

JIS PT200

DIN Ni100

DIN Ni200

Minco Ni120

Minco Cu10

0-500 Resistance

millivolt ~ 210mV

B

E

J

K

N

R

S

T

Cold Junction Compensation

normal signal range

-200C + 870C

-200C +400C

-200C +630C

-200C +400C

-60C +250C

-60C +200C

-80C +320C

-200C +260C

0ohm 500ohm

-40mV +100mV

300C +1800C

-250C +1000C

-210C +1200C

-250C

-200C + 800CTXK/XK(L)

-250C +1300C

0C

0C

-250C + 400C

-20C 100C

+1372C

+1768C

+1768C

overrange

CJC faul t

open w i re f ault

~ 520ohm equivalent

~ 520ohm equivalent

~ 520ohm equivalent

~ 520ohm equivalent

~ 520ohm equivalent

~ 520ohm equivalent

~ 520ohm equivalent

~ 520ohm equivalent

~ 520ohm

~ 210mV equivalent

~ 210mV equivalent

~ 210mV equivalent

~ 210mV equivalent

~ 210mV equivalent

~ 210mV equivalent

~ 210mV equivalent

~ 210mV equivalent

~ 210mV equivalent

Channel

Data

Forced

to

Maximum

for Type

Publication 1797-6.5.2 - Febr uary 2001

Underrange A l arm

The channel underrange alarm is set if the input is less than the

minimum temperature (thermocouple or RTD range dependent),

millivolt (-40mV) or resistance (0Ω) range value.

Range: 0 = normal, 1 = input overrange. Default = 0.

This alarm stays active at any value below 0% of range and is always

enabled by the module.

Range: 0 = normal, 1 = input overrange. Default = 0.

Page 23

Understanding Configurable FLEX Ex Thermocouple/RTD/mV Input Module Features 2-9

Fault Alarm

The module has individual channel fault alarms for a broken or

detached wire. In any mode, if a broken/detached lead is detected,

the data value is forced to maximum. Once the alarm is issued, it

remains active as long as the input signal is faulted.

In mV mode, for input levels above 210mV, this bit is set.

In RTD mode, an open input will set this bit.

Range: 0 = normal,1 = wire off, excessive input fault detected.

Default = 0.

Chapter Summary

In this chapter , we told you about the F LEX Ex sys tem and the analog

I/O modules, and how they communicate with programmable

controllers.

Publication 1797-6.5.2 - February 2001

Page 24

2-10 Understanding Configurable FLEX Ex Thermocouple/RTD/mV Input Module Features

Publication 1797-6.5.2 - Febr uary 2001

Page 25

Chapter

How to Install Your FLEX Ex Thermocouple/ RTD/mV Module

3

What this Chapter Contains

Before You Install Your Analog Module

Read this chapter to install the 1797-IRT8 thermocouple/RTD/mV

module.

For information on: See page:

Before You Install Your Analog

Module

Compliance to European Union

Directives

Installation in Zone 1 3-2

Removal and Insertion Under Power 3-3

Installing the Module 3-3

Connecting Wiring to the FLEX Ex

Thermocouple/RTD/mV Module

Grounding the Module 3-13

Chapter Summary 3-13

Before installing your FLEX Ex analog module:

You need to: As described under:

Verify that the module will be installed in a

suitable metal enclosure

3-1

3-2

3-10

Installation in Zone 1, page 3-2

Position the keyswitch on the

terminal base

ATTENTION

These modules do not receive primary operational

power from the backplane. +/-V dc power must be

applied to your module before installation. If power

is not applied, the module position will appear to the

adapter as an empty slot in your chassis.

Installing the Module, page 3-8

!

1 Publication 1797-6.5.2 - February 2001

Page 26

3-2 How to Install Your FLEX Ex Thermocouple/RTD/mV Module

Compliance to European Union Directives

If this product has the CE mark, it is approved for installation within

the European and EEA regions. It has been designed and tested to

meet the following directives.

EMC Directive

This product is tested to meet the Council Directive 89/336/EC

Electromagnetic Compatibility (EMC) by applying the following

standards, in whole or in part, documented in a technical construction

file:

EN 50081-2 EMC - Generic Emission Standard, Part 2 - Industrial

•

Environment

EN 50082-2 EMC - Generic Immunity Standard, Part 2 - Industrial

•

Environment

This product is intended for use in an industrial environment.

Ex Directive

Installation in Zone 1

This product is tested to meet the Council Directive 94/9/EC (ATEX

100a) Equipment and Protective Systems Intended for Use in

Potentially Explosive Atmospheres by applying the following

standards:

EN50014:1992, Electrical Apparatus for Potentially Explosive

•

Atmospheres

EN50020:1994, Electrical Apparatus for Potentially Explosive

•

Atmospheres - Intrinsic Safety “i”

prEN50284:1997, Special requirements for construction, test and

•

marking of electrical apparatus of equipment group II, category

1G

This module must not be exposed to the environment. Provide a

suitable metal enclosure.

ATTENTION

This module cannot be used in an

intrinsically safe environment after it has

been exposed to non-intrinsically safe

signals.

Publication 1797-6.5.2 - Febr uary 2001

!

Page 27

How to Install Your FLEX Ex Thermocouple/RTD/mV Module 3-3

Electrostatic Charge

Removal and Insertion Under Power

Installing the Module

Protect the system against electrostatic charge. Post a sign near this

module: Attention! Avoid electrostatic charge. For your

convenience, a sign which can be cut out and posted is included in

this user manual before the back cover.

ATTENTION

!

Installation of this module consists of:

mounting the terminal base unit

•

installing the analog I/O module into the terminal base unit

•

installing the connecting wiring to the terminal base unit

•

This module is designed so you can remove and

insert it under power. However, take special care

when removing or inserting this module in an

active process. I/O attached to any module being

removed or inserted can change states due to its

input/output signal changing conditions.

If you are installing your module into a terminal base unit that is

already installed, proceed to “Mounting the 1797-IRT8 Module on the

Terminal Base” on page 8.

ATTENTION

!

Moun ting on a DIN Rail

ATTENTION

Make certain that you power this terminal base module

combination with an instrinsically safe power supply.

Do not exceed the values listed in the specifications for

the terminal base or module.

Do not use the unused terminals on the terminal

base unit. Using the terminals as supporting

terminals can result in damage to modules and/or

unintended operation of your system.

Do not remove or replace a terminal base unit when

power is applied. Interruption of the flexbus can

result in unintended operation or machine motion.

!

Publication 1797-6.5.2 - February 2001

Page 28

3-4 How to Install Your FLEX Ex Thermocouple/RTD/mV Module

1. Remove the cover plug in the male connector of the unit to

which you are connecting this terminal base unit.

2. Check to make sure that the 16 pins in the male connector on

the adjacent device are straight and in line so that the mating

female connector on this terminal base unit will mate correctly.

3. Make certain that the female flexbus connector is fully

retracted into the base unit.

4. Position the terminal base over the 35 x 7.5mm DIN rail A

(A-B pt. no. 199-DR1).

A

A

Position terminal base at a slight angle and

hooked over the top of the DIN rail A.

Slide the terminal base over tight against the adapter (or proceeding terminal

base). Make sure the hook on the terminal base slides under the edge of the

adapter (or proceeding terminal base) and the flexbus connector is fully retracted.

ATTENTION

Do not force the terminal base into the adjacent

modules. Forcing the units together can bend or

break the hook and allow the units to separate

and break communication over the backplane.

41106

41107

Publication 1797-6.5.2 - Febr uary 2001

!

Page 29

How to Install Your FLEX Ex Thermocouple/RTD/mV Module 3-5

5. Rotate the terminal base onto the DIN rail with the top of the rail

hooked under the lip on the rear of the terminal base. Use

caution to make sure that the female flexbus connector

does not strike any of the pins in the mating m a le

connector.

41108

Press down on the terminal base unit to lock the terminal base on the DIN rail. If

the terminal base does not lock into place, use a screwdriver or similar device t o

open the locking tab, press down on the terminal base until flush with the DIN rail

and release the locking tab to lock the base i n pl ace.

Gently push the flexbus connector into the side of the adapte r (or pr oceeding

terminal base) to complete the backplane connection.

41109

6. For specific wiring information, refer to the installation

instructions for the module you are installing in this terminal

base unit. Terminal assignments are also given later in this

chapter, see page 3-10.

7. Repeat the above steps to install the next terminal base.

8. Install the flexbus connector cover on the last terminal base is in

place.

Publication 1797-6.5.2 - February 2001

Page 30

3-6 How to Install Your FLEX Ex Thermocouple/RTD/mV Module

Panel/Wall Mounting

Installation on a wall or panel consists of:

laying out the drilling points on the wall or panel

•

drilling the pilot holes for the mounting screws

•

mounting the adapter mounting plate

•

installing the terminal base un its and securing them to the wall

•

or panel

If you are installing your module into a terminal base unit that is

already installed, proceed to Mounting the 1797-IRT8 Module on the

Terminal Base Unit on page 3-8.

Use the mounting kit Cat. No. 1794-NM1 for panel/wall mounting.

1 - Mounting Plate for Adapter

2 - 18 #6 self -tapping screws

(2 for the adapter, and 2

each for up to 8 modules)

Adapter Module

(not included)

1.4

(35.5)

1

2

41547

Terminal Base Unit

(not included)

To install the mounting plate on a wall or panel:

Publication 1797-6.5.2 - Febr uary 2001

Page 31

How to Install Your FLEX Ex Thermocouple/RTD/mV Module 3-7

1. Lay out the required points on the wall/panel as shown in the

drilling dimension drawing.

Drilling Dimensions for Panel/Wall Mounting of FLEX Ex I/O

.83 (21)

2.0

(50)

Inches

(Millimeters)

!

1.4

(35.5)

2.3

(58.5)

1.4

(35.5)

ATTENTION: Be careful of metal chips when

drilling cable mounting hol es. Do not drill holes

above a system that has any modules installed.

2. Drill the necessary holes for the #6 self-tapping mounting

screws.

2.3

(58.5)

Cable length

approximately 11.5

(292.1) or 35.5

(901.0) from upper

connector [length

depends upon

cable -1ft (0.3m) or

3ft (0.091m)]

1.4

(35.5)

1.6

(40.5)

(15.6)

+V

1

.61

-V

2

.3

(8)

+V

-V

3

4

40871

3. Mount the mounting plate (1 ) fo r the ad apter modu le us ing two

#6 self-tapping screws (18 included for mounting up to 8

modules and the adapter).

Make certain that the mounting plate is properly grounded to the

panel. Refer to “Industrial Automation Wiring and Grounding

Guidelines,” publication 1770-4.1.

4. Hold the adapter (2) at a slight angle and engage the top of the

mounting plate in the indention on the rear of the adapter

module.

5. Press the adapter down flush with the panel until the lockin g

lever locks.

6. Position the terminal base unit up against the adapt er and push

the female bus connector into the adapter.

7. Secure to the wall with two #6 self-tapping screws.

8. Repeat for each remaining terminal base unit.

Publication 1797-6.5.2 - February 2001

Page 32

3-8 How to Install Your FLEX Ex Thermocouple/RTD/mV Module

Mounting the 1797-IRT8 Module on the Terminal Base Unit

The 1797-IRT8 module mounts on a 1797-TB3 or TB3S intrinsically

safe terminal base unit.

1. Rotate keyswitch (1) on terminal base unit (2) clockwise to

position 2 as required for this type of module. Do not change

the position of the keyswitch after wiring the terminal

base unit.

7

4

Label under here

or under here

3

5

1

8

2

6

40231

2. Make certain the flexbus connector (3) is pushed all the way to

the left to connect with the neighboring ter minal ba se/ adapte r.

You cannot install the module unless the connector is fully

extended.

Publication 1797-6.5.2 - Febr uary 2001

3. Make sure the pins on the bottom of the module are straight so

they will align properly with the connector in the terminal base

unit.

4. Position the module (4) with its alignment bar (5) aligned with

the groove (6) on the termin a l base .

5. Press firmly and evenly to seat the mo dule in the terminal base

unit. The module is seated when the latching mechanism (7) is

locked into the module.

Page 33

How to Install Your FLEX Ex Thermocouple/RTD/mV Module 3-9

6. Make certain that you only connect terminal base units to other

intrinsically safe system modules or adapters to maintain the

integrity of the intrinsically-safe backplane.

7. Remove cap plug (8) and attach another intrinsically safe

terminal base unit to the right of this terminal base unit if

required. Make sure the last terminal base has the cap plug (8)

in place.

41307

The adapter is capable of addressing eight modules. Do not exceed

a maximum of eight terminal base units in your system.

Wiring the Terminal Base Units

Wiring the FLEX Ex I/O modules is done through the 1797-TB3 and

1797-TB3S terminal base units.

ATTENTION

!

The FLEX Ex I/O modules do not receive primary

operational power from the backplane. +/- V dc

power must be applied to your module before

operation. If power is not applied, the module

position will appear to the adapter as an empty

slot in your chassis. If the adapter does not

recognize your module after installation is

completed, cycle power to the adapter.

Make certain that you power these modules w ith an

intrinsically safe power supply. Do not exceed the

values listed in the specifications for the modules.

Publication 1797-6.5.2 - February 2001

Page 34

3-10 How to Install Your FLEX Ex Thermocouple/RTD/mV Module

Connecting Wiring to the FLEX Ex Thermocouple/ RTD/mV Module

Inputs/Outputs

Each input can be operated from a thermocouple (TC), resistance

temperature detector (RTD), or millivolt. Do not apply any

non-intrinsically safe signals to this module.

When using an intrinsically safe electrical apparatus according to

EN50020, the European directives and regulations must be follow ed.

The channels in this module are electrically connected to each other

and have a common plus-line.

When interconnecting several lines, you must consider the total

accumulated power and check for intrinsic safety.

Connections for the 1797-IRT8 Module

+V

Power

Supply

-V

FLEX Bus

Bus

+

H

Thermocouple

uC

L

-

+

CJC

-

CJC

2W RTD

+

mV

-

3W RTD

4W RTD

Row A

Row B

Row C

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Ch 1

H

-

+

L

-

+

L

Ch 2

Ch 6

-

LH

+

-

LH

Ch 3

-

LH

+

-

LH

Ch 7

CJC

1+

1-

Chassis

GND

for shield

+

LH

H

+

-

Ch 0

16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33

+

-

+

LH

Ch 4 Ch 5

34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

+V -V +V -V

0+

CJC

Chassis

GND

for shield

0-

No connection allowed to terminals 36 and 49

41505

Publication 1797-6.5.2 - Febr uary 2001

Page 35

How to Install Your FLEX Ex Thermocouple/RTD/mV Module 3-11

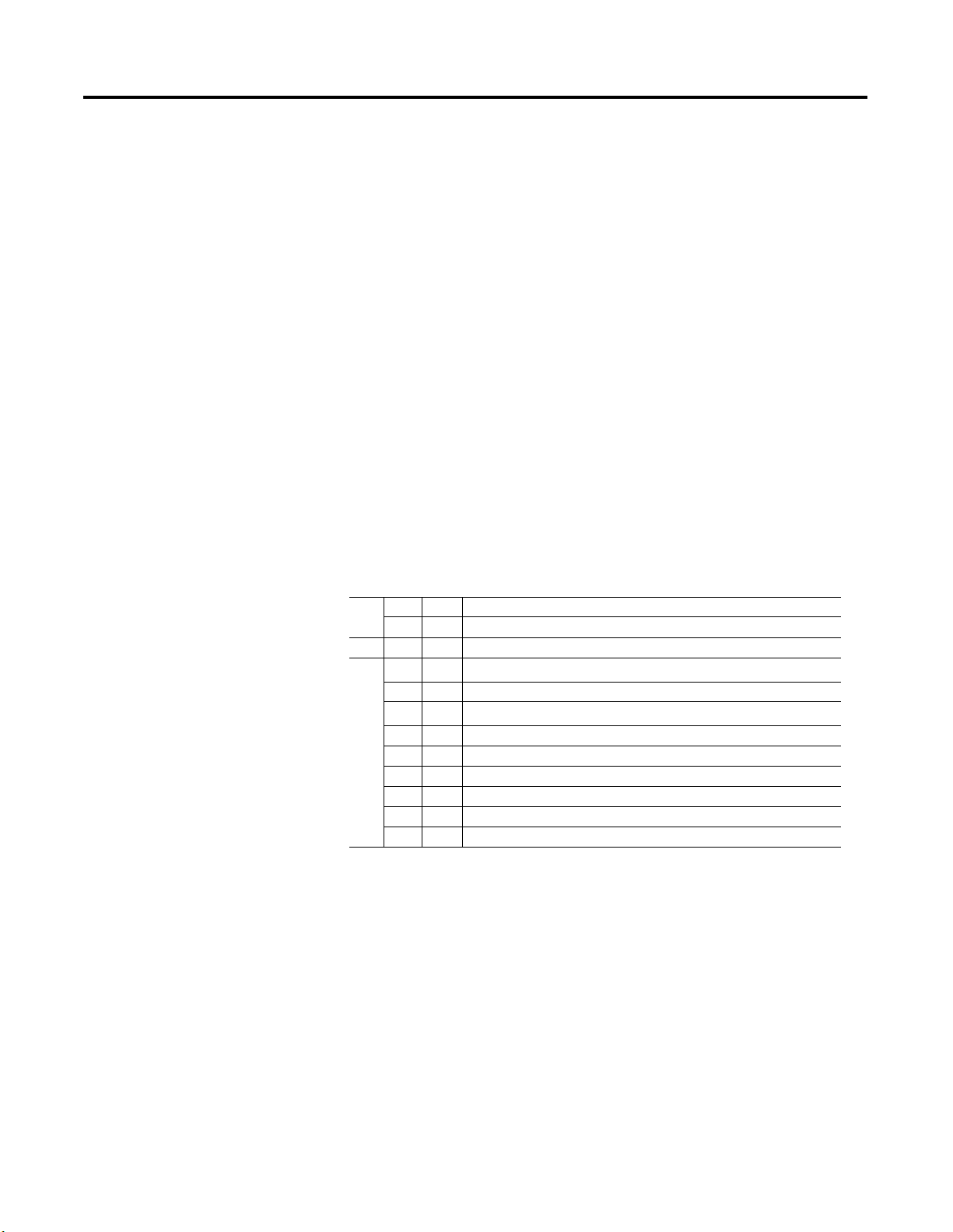

Wiring connections for the 1797-IRT8 Module

1. For RTD inputs:

a. connect the individual source current input wiring to (+)

terminals for each individual channel (0, 4, 8 and 12) on the 0-15

row (A) and terminals 17, 21, 25, and 29 on the 16-33 row (B) as

indicated in the table below.

b. connect the associated signal return (-) to the corresponding (- )

terminals (3, 7, 11, and 15) on the 0-15 row (A), and terminals 20,

24, 28 and 32 on the 16-33 row (B).

2. For thermocouple inputs:

a. connect the individual high signal input wiring to (L) terminals

for each individual channel (2, 6, 10, and 14) on the 0-15 row (A)

and terminals 19, 23, 27 and 31 on the 16-33 row (B) as indicated

in the table below.

b. connect the associated low signal (-) to the corresponding (-)

terminals (3, 7, 11 and 15) on the 0-15 row (A), and terminals 20,

24, 28, and 32 on the 16-33 row (B).

c. connect cold junction compensation wiring to terminals 37, 38

and 39, and terminals 46, 47 and 48.

d. Connect the tail of the CJC as follows:

• when using inputs 0-3 (row A) only for thermocouple inputs:

connect the tail of CJC1 to terminal 5 and CJC2 to terminal 12 on

row A.

• when using inputs 4-7 (row B) only for thermocouple inputs:

connect the tail of CJC1 to terminal 22 and CJC2 to term inal 29

on row B.

• when using thermocouple inputs 0-7: connect the tail of CJC1 to

terminal 5 on row A, and CJC2 to terminal 29 on row B.

Importan t : Whenever you use thermocouple inputs, you must use

both cold junction compensators.

3. Connect +V to terminal 34 on the 34-51 row (C).

4. Connect -V to terminal 35 on the 34-51 row (C).

ATTENTION

ATTENTION:Make certain that you power this

module with an int rinsically safe power supply . Do

not exceed the values listed in the specifications

for this module.

!

5. If continuing power to the next terminal base unit, connect a

jumper from terminal 50 (+V) on this base unit to terminal 34 on

the next base unit.

6. If continuing common to the next terminal base unit, connect a

jumper from terminal 51 (-V) on this base unit to termin al 35 on

the next base unit.

Publication 1797-6.5.2 - February 2001

Page 36

3-12 How to Install Your FLEX Ex Thermocouple/RTD/mV Module

1

2

3

1a

2a

1

2

1

2

1

2

1

2

2-wire RTD

3-wire RTD

4-wire RTD

Thermocouple

Millivolt

Type of Input

Connect the following:

+HL-

RTD - 2-wire 1 2

RTD - 3-wire 1 3 2

RTD - 4-wire 1 1a 2a 2

Thermocouple 1 2

Millivolt 1 2

1Terminals 16, 33, 40 thru 45 are chassis ground.

RTD or

Thermocouple

Channel

00123

RTD Source

Current

(+)

High Signal

Terminal (H)

Low Signal

Terminal (L)

14567

2891011

312131415

417181920

521222324

625262728

729303132

+V Terminals 34 and 50

-V Terminals 35 and 51

1 Terminals 37, 38 and 39 and 46, 47 and 48 are for cold junction

compensation (with 38 and 47 chassis ground). Connect CJC1 to

terminal 5 or 21, CJC2 to terminal 12 or 29

2 Terminals 16, 33, and 40 thru 45 are chassis ground.

Shield

Signal

Return

(-)

1

Publication 1797-6.5.2 - Febr uary 2001

Page 37

How to Install Your FLEX Ex Thermocouple/RTD/mV Module 3-13

Grounding the Module

All I/O wiring must use shielded wire. Shields must be terminated

external to the module, such as bus bars and shield-terminating feed

throughs.

30820-M

Chapter Summary

In this chapter, we told you how to install your thermocouple/RTD/

mV module in an existing programmable controller system and how

to wire to the terminal base units.

Move to chapter 3 to learn about input, output and configuration files

for the thermocouple/RTD/mV module on ControlNet.

Publication 1797-6.5.2 - February 2001

Page 38

3-14 How to Install Your FLEX Ex Thermocouple/RTD/mV Module

Publication 1797-6.5.2 - Febr uary 2001

Page 39

Chapter

4

Input, Status, Output and Configuration Files

for the Thermocouple/RTD/mV Module on

the ControlNet Network

What this Chapter Contains

Read this chapter to familiarize yourself with input, output and

configuration files for the thermocouple/RTD/mV module on

ControlNet.

For information on: See p age:

Using Programming Software in Y ou r

FLEX Ex Application

Using Programming Software in Y ou r

FLEX Ex Application

Communication Over the FLEX Ex

Backplane

I/O Structure 4-4

Fault State Data 4-6

Device Actions 4-6

Chapter Summary 4-14

In this chapter, you will learn about:

using software to configure the FLEX Ex I/O modules

•

ControlNet Ex Adapter

•

I/O structure

•

• fault state data

• communication fault data

• idle state behavior

• input data behavior upon module removal

This chapter provides a brief description of the steps you must

take in your programming software to configure FLEX Ex I/O

modules and an overview of what occurs during configur ation .

4-2

4-2

4-2

For a full explanation of how to use your programming

software to perform module configuration, use the

software online help.

Publication 1797-6.5.2 - February 2001

Page 40

4-2 Input, Status, Output and Configuration Files for the Thermocouple /R TD/mV Module on the ControlNet Net w or k

Using Programming Software in Your FLEX Ex Application

When using FLEX Ex thermocouple/RTD/mV modules, you must

perform I/O mapping and configure the ControlNet network before

generating configuration data for your I/O modules.

For example, you may use RSNetWorx™ to connect FLEX Ex I/O

modules to a ControlNet processor or scanner through a FLEX Ex

ControlNet Ex adapter (cat. no. 1797-ACNR15). The I/O configuration

portion of another programming software, for example RSLogix5™

could be used to generate the configuration data for each I/O module

in the control system.

Configuration data is then transferred to the controller during the

program download and subsequently transferred to the appropriate I/

O modules.

Follow these general guidelines when configuring I/O modules:

1. Perform I/O mapping.

2. Instruct the FLEX Ex I/O modules to use I/O mapping file from

step 1.

3. Configure all I/O modules.

About the ControlNet Ex Adapter

Communication Over the FLEX Ex Backplane

Networ

ControlNet Ex

Adapter

Write

The FLEX Ex ControlNet Ex ada pter (cat. no. 1 797-ACNR15) i nterfaces

up to 8 FLEX Ex modules to a ControlNet processor or scanner. The

adapter can support ControlNet real-time data connec tion s to

individual modules or module groups. Each connection is

independent of the others and can be from different processors or

scanners.

One 1797-ACNR15 ControlNet Ex adapter can interface up to eight

terminal base units with installed FLEX Ex modules, forming a FLEX

Ex system of up to eight slots. The adapter communicates to other

network system components (typically one or more controlle rs or

scanners, and/or programming terminals) over the ControlNet

network. The adapter communicates with its I/O modules over the

FLEX Ex back plane.

Read

I/O Module I/O ModuleI/O Module

Inputs Inputs Inputs

Status

Outputs

Configuration Configuration Configuration

Slot 0 Slot 1 Slot 7

0

Read

Words

Write

Words

X

StatusStatus

OutputsOutputs

41626

Publication 1797-6.5.2 - Febr uary 2001

Page 41

Input, Status, Output and Confi gur at ion Files for the Thermocouple/RTD / mV Module on the ControlNet Network 4-3

Scheduled Data-T ransfer

Scheduled data transfer:

is continuous.

•

is asynchronous to the controller program scan.

•

occurs at the actual rate displayed in the Actual Packet Interval

•

field on the programming software ControlNet I/O mapping

(monitor) screen

Unscheduled Data-Transfer

Unscheduled operations include:

unscheduled non-discrete I/ O data transfers–throu gh ControlNet

•

I/O Transfer (CIO) instructions

peer-to-peer messaging–through message (MSG) instructions

•

messaging from programming devices

•

Unscheduled messaging on a ControlNet network is

non-deterministic. Your application and your configuration–number of

nodes, application program, NUT, amount of scheduled bandwidth

used, etc.–determine how much time there is for unscheduled

messaging.

Module I/O Mapping

The I/O map for a module is divided into read words and write

words. Read words consist of input and status words, and write

words consist of output and configuration words. The number of

read words or write words can be 0 or more. The length of each I/O

module’s read words and write words vary in size depending on

module complexity. Each I/O module will support at least 1 input

word or 1 output word. Status and configuration are optional,

depending on the module.

Publication 1797-6.5.2 - February 2001

Page 42

4-4 Input, Status, Output and Configuration Files for the Thermocouple /R TD/mV Module on the ControlNet Net w or k

For example, a 16 point discrete input module will have up to 2 read

words and 1 write word.

ControlNet Image

Input Size

1 Word

Status Size

1 Word

Configuration

Module Image

Input

Faults

I/O Structure

Network READ

1 Word

Check the I/O map for the module for the exact mapping.

Output data is received by the adapter in the order of the installed I/O

modules. The output data for slot 0 is received first, followed by the

output data for slot 1, and so on up to slot 7.

The first word of input data sent by the adapter is the Adapter status

word. This is followed by the input data from each slot, in the order

of the installed I/O modules. The input data from slot 0 is first after

the status word, followed by input data from slot 1, and so on up to

slot 7.

ControlNet Adapter

Read Data

Adapter Status

Slot 0 Input Data

Slot 1 Input Data

Not used

Delay

Time

Delay

Time

41627

Network WRITE

Publication 1797-6.5.2 - Febr uary 2001

Slot 7 Input Data

Slot 0 Output Data

Slot 1 Output Data

Slot 7 Input Data

Read

Write

I/O

Module

Slot 0

I/O

Module

Slot 1

I/O

Module

Slot 7

41628

Page 43

Input, Status, Output and Confi gur at ion Files for the Thermocouple/RTD / mV Module on the ControlNet Network 4-5

Adapter Status Word

The status word consists of:

I/O module fault bits – 1 status bit for each slot

•

Additionally, in the case of a PLC-5 controller, it adds:

node address changed – 1 bit (created by PLC-5 controller)

•

I/O status – 1 bit (created by PLC-5 controller)

•

Resulting in the following FLEX Ex adapter status word for a

PLC-5 controller.

I/O Module Fault Bits

Bit: 15 910 through 15 8 7 6 5 4 3 2 1 0

Table 4.A

Created by PLC-5 controller

Bit Description: Bit: Explanation:

I/O Module Fault

Node Address Changed

(Created by PLC-5

controller.)

I/O Status Bit

Node Address Changed Bit

41629

As an example, in a PLC-5 system, the adapter status word bit

descriptions are shown in the following table.

0 This bit is set (1) when an error is detected in slot position 0.

1 This bit is set (1) when an error is detected in slot position 1.

2 This bit is set (1) when an error is detected in slot position 2.

3 This bit is set (1) when an error is detected in slot position 3.

4 This bit is set (1) when an error is detected in slot position 4.

5 This bit is set (1) when an error is detected in slot position 5.

6 This bit is set (1) when an error is detected in slot position 6.

7 This bit is set (1) when an error is detected in slot position 7.

8 This bit is set (1) when the node address switch setting has

been changed since power-up.

I/O State (Created by

PLC-5 controller.)

9 Bit = 0 -idle

bit = 1 - run

10 though 15 Not used – set to 0

Publication 1797-6.5.2 - February 2001

Page 44

4-6 Input, Status, Output and Configuration Files for the Thermocouple /R TD/mV Module on the ControlNet Net w or k

Possible causes for an I/O Module Fault are:

transmission errors on the FLEX Ex backplane

•

a failed module

•

a module removed from its terminal base

•

incorrect module inserted in a slot position

•

the slot is empty

•

the slot contains a non-discrete module

•

Fault State Data

Device Actions

The ControlNet Ex adapter provides storage for alternate module

output data during communication faults or processor idle state. This

“fault state data” assures that a known output will be applied to the

output devices during the previously mentioned modes. The

processor or scanner software must include the means to specify this

fault state data for each module. If applicable, this data is sent in the

configuration block, see Image Table Mapping on pages 4-8.

Device actions include:

communication fault behavior

•

idle state behavior

•

input data behavior upon module removal

•

Communication Fault Behavior

You can configure the adapter response to a communication fault for

each I/O module in its system. Upon detection of a communication

fault,

the adapter ca n:

Publication 1797-6.5.2 - Febr uary 2001

• leave the module output data in its last state (hold last state)

• reset the module output data to zero (reset)

• apply fault state data to the modu le output

Page 45

Input, Status, Output and Confi gur at ion Files for the Thermocouple/RTD / mV Module on the ControlNet Network 4-7

Idle State Behavior

The ControlNet Ex adapter can detect the state of the controlling

processor or scanner. Only 2 states can be detected:

– run mode,

– or program mode (idle).

When run mode is detected, the adapter copies the output data

received from the processor to the corresponding module output.

When program mode is detected, the adapter can be configured to:

leave the module output data in its last state (hold last state)

•

reset the module output data to zero (reset)

•

apply fault state data to the module output

•

Input Data Behavior upon Module Removal

I/O module input data sent by the adapter upon module removal is

configurable. The adapter can:

reset the module input data sent by the adapter to zero (reset)

•

leave the module input data sent by the adapter in the last state

•

before module removal (hold last state)

Publication 1797-6.5.2 - February 2001

Page 46

4-8 Input, Status, Output and Configuration Files for the Thermocouple /R TD/mV Module on the ControlNet Net w or k

Thermocouple/RTD/mV Input Module (1797-IRT8) Image Table

Mapping

Module Image

Input Data Channel 0

I/O Image

Input Size

1 to 11 Words

Overrange

Output Size

Input Data Channel 1

Input Data Channel 2

Input Data Channel 3

Input Data Channel 4

Input Data Channel 5

Input Data Channel 6

Input Data Channel 7

Underrange

Module command and responseRFlg

DiagnosticsCJCAlarms

0 to 4 Words

Bit/Word Description for the Thermocouple/RTD/mV Input

Module (1797-IRT8)

Input Word

Input Word 0 00-15 (00-17) Channel 0 Input data

Input Word 1 00-15 (00-17) Channel 1 Input data

Input Word 2 00-15 (00-17) Channel 2 Input data

Input Word 3 00-15 (00-17) Channel 3 Input data

Input Word 4 00-15 (00-17) Channel 4 Input data

Input Word 5 00-15 (00-17) Channel 5 Input data

Input Word 6 00-15 (00-17) Channel 6 Input data

Input Word 7 00-15 (00-17) Channel 7 Input data

Dec. Bits

(Octal Bits)

Data Format

RTD Offsets for each channel

Module command and dataCFlg

FM

TC/RTDTC/RTD

Description

Filter CutReference Jct

Sensor TypeSensor TypeMode Mode

5-04

Publication 1797-6.5.2 - Febr uary 2001

Page 47

Input, Status, Output and Confi gur at ion Files for the Thermocouple/RTD / mV Module on the ControlNet Network 4-9

Input Word

Input Word 8 00-07 Underr ange bits – these bits are set if the input signal is below the input channel’s minimum range.

Input Word 9 00-03 Diagnostic bits – represent module configuration and/or hardware errors.

Input Word 10 00-07 Module command response data bits – These bits echo th e m o du le co mm an d dat a writ t en to th e

Dec. Bits

(Octal Bits)

Bit 00 corresponds to channel 0, bit 01 corresponds to channel 1, etc.

08-15 (10-17) Overrange bits – these bits are set if 1), the input signal is above the input channel’s maximum

range, or 2), an open detector is detected. Bit 08 (10) corresponds to channel 0, bit 09 (11)

corresponds to channel 1, etc.

Bit03020100

0000Reserved for factory use

0010Improper module configuration

0001 and 0011 thru 1111 Reserved for factory use

04 Not used.

05-06 Cold junction compensation alarm bits – These bits are set (1) when the corresponding cold

junction compensator lead is broken, unattached or shorted. Bit 05 corresponds to CJC1, and bit 06

to CJC2.

07 Not used

08-15 (10-17) Fault alarm bits – An alarm bit is set (1) when an individual input lead opens (broken,

disconnected). If the alarm is enabled, the channel reads maximum value. Bit 08 (10) corresponds to

input channel 0, bit 09 (11) to channel 1, etc.

module during calibration.

08-14 (10-16) Module command response bits – These bits echo the module command written to the module

during calibration.

15 (17) Reserved for factory use

Description

Publication 1797-6.5.2 - February 2001

Page 48

4-10 Input, Status, Output and Configu ra tion Files for the Thermocouple /RTD /mV Module on the ControlNet Ne t wo r k

Configuration

Word

Configuration

Word 0

Dec. Bits

(Octal Bits)

Bits 00-02 Input Filter Cutoff bits

Bit 02 01 00 Definition

0 0 0 Hardware filtering only (default filtering)

0 0 1 40Hz (25ms)

0 1 0 10Hz (100ms)

0 1 1 4Hz (250ms)

1 0 0 2Hz (500ms)

1011Hz(1s)

1 1 0 0.5Hz (2s)

1 1 1 0.2Hz (5s)

Bits 03-05 Reference Junction – used when input type is set to thermocouple and sensor mode is set to Fixed

Temperature Compensation. Sets a fixed reference junction to compensate all thermocouple channels.

Bit 05 04 03 Reference Junction

0 0 0 0°C

0 0 1 20°C

0 1 0 25°C

0 1 1 30°C

1 0 0 40°C

1 0 1 50°C

1 1 0 60°C

1 1 1 70°C

Bits 06-07 Fault Mode bits – when a bit is set (1), fault mode is enabled for that channel. Bit 06 corresponds to

Bits 08-11

(10-13)

Bits 12-15

(14-17)

channels 0-3; bit 07 corresponds to channels 4-7.

0 = disabled

1 = enable wire-off detection

Data format – module defaults to –4000 to 10000 in millivolt mode, and 0 to 5000 in ohms mode

Bit 11 10 09 08 Data type for channels 0-7

0000°C

0001°F

0010°K

0 0 1 1 –32767 to +32767

0 1 0 0 0 to 65535

0101 through 1111 not used

Not used

Description

Publication 1797-6.5.2 - Febr uary 2001

Page 49

Input, Status, Out put and Configuration Files fo r th e Thermocouple/RTD/mV Module on the ControlNet Network 4-11

Configuration

Word

Configuration

Word 1

Dec. Bits

(Octal Bits)

Bits 00-03 Sensor Type (Thermocouple or RTD)

RTD Type

Bit 03 02 01 00 Sensor type for channels 0 through 3

0 0 0 0 Resistance (default)

0 0 0 1 100 ohm Pt α = 0.00385 Euro (–200 to +870°C)

0 0 1 0 200 ohm Pt α = 0.00385 Euro (–200 to +400°C)

0 0 1 1 100 ohm Pt α = 0.003916 U.S. (–200 to +630°C)

0 1 0 0 200 ohm Pt α = 0.003916 U.S. (–200 to +400°C)

0 1 0 1 100 ohm Nickel (–60 to +250°C)

0 1 1 0 200 ohm Nickel (–60 to +200°C)

0 1 1 1 120 ohm Nickel (–80 to +320°C)

1 0 0 0 10 ohm Copper (–200 to +260°C)

1001 through 1111 not used

Bits 00-03 Thermocouple Type

Bit 03 02 01 00 Sensor type for channels 0 through 3

0 0 0 0 mV (default)

0 0 0 1 B 300 to 1800°C (572 to 3272°F)

0 0 1 0 E –270 to 1000°C (–454 to 1832°F)

0 0 1 1 J –210 to 1200°C (–346 to 2192°F)

0 1 0 0 K –270 to 1372°C (–454 to 2502°F)

0 1 0 1 L –200 to 800°C (–328 to 1472°F)

0 1 1 0 N –270 to 1300°C (–450 to 2372°F)

0 1 1 1 R –50 to 1768°C (–58 to 3214°F)

1 0 0 0 S –50 to 1768°C (–58 to 3214°F)

1 0 0 1 T –270 to 400°C (–454 to 752°F)

1010 through 1111 not used

Description

Publication 1797-6.5.2 - February 2001

Page 50

4-12 Input, Status, Output and Configu ra tion Files for the Thermocouple /RTD /mV Module on the ControlNet Ne t wo r k

Configuration

Word

Configuration

word 1 cont.

Dec. Bits

(Octal Bits)

Bits 04-05 Sensor Mode Select bits

Bit 05 04 Sensor mode select for channels 0-3

Thermocouple

00CJC compensation – uses cold junction sensor

0 1 Fixed Temperature compensation – uses the value selected for reference junction

1 0 No compensation (Data is referenced to 0°C.)

1 1 Differential measurement between 2 channels

RTD

0 0 2-wire RTD no compensation

0 1 2-wire RTD with loop resistance compensation

1 0 3-wire RTD

1 1 4-wire RTD

Bits 06-07 Input Type Select

Bit 07 06 Input type selection for channels 0-3

0 0 Thermocouple

01RTD

10

11

Description

Not used

Publication 1797-6.5.2 - Febr uary 2001

Page 51

Input, Status, Out put and Configuration Files fo r th e Thermocouple/RTD/mV Module on the ControlNet Network 4-13

Configuration

Word

Configuration

Word 1 cont.

Dec. Bits

(Octal Bits)

Bits 08-11

(10-13)

Bits 12-13

(14-16)

Description

Sensor Type (Thermocouple or RTD)

RTD Type

Bit 11 10 09 08 Sensor type for channels 4 through 7

0 0 0 0 Resistance (default)

0 0 0 1 100 ohm Pt α = 0.00385 Euro (–200 to +870°C)

0 0 1 0 200 ohm Pt α = 0.00385 Euro (–200 to +400°C)

0 0 1 1 100 ohm Pt α = 0.003916 U.S. (–200 to +630°C)

0 1 0 0 200 ohm Pt α = 0.003916 U.S. (–200 to +400°C)

0 1 0 1 100 ohm Nickel (–60 to +250°C)

0 1 1 0 200 ohm Nickel (–60 to +200°C)

0 1 1 1 120 ohm Nickel (–80 to +320°C)

1 0 0 0 10 ohm Copper (–200 to +260°C)

1001 through 1111 not used

Thermocouple Type

Bit 11 10 09 08 Sensor type for channels 4 through 7

0 0 0 0 mV (default)

0 0 0 1 B 300 to 1800°C (572 to 3272°F)

0 0 1 0 E –250 to 1000°C (–418 to 1832°F)

0 0 1 1 J –210 to 1200°C (–346 to 2192°F)

0 1 0 0 K –250 to 1372°C (–418 to 2502°F)

0 1 0 1 L –200 to 800°C (–328 to 1472°F)

0 1 1 0 N –250 to 1300°C (–418 to 2372°F)

0 1 1 1 R 0 to 1768°C (32 to 3214°F)

1 0 0 0 S 0 to 1768°C (32 to 3214°F)

1 0 0 1 T –250 to 400°C (–418 to 752°F)

1010 through 1111 not used

Sensor Mode Select bits

Bit 13 12 Sensor mode select for channels 4-7