Page 1

Installation Instructions

FLEX Ex NAMUR Input Module

Catalog Number 1797-IBN16

Contents

Top ic Page

Important User Information 2

Module Installation 3

Installation in Zone 1 5

Installation in Zone 22 5

Electrostatic Charge 5

Removal and Insertion Under Power 6

European Communities (EC) Directive Compliance 6

Inputs 7

Wire the Module 9

Input/Output Mapping 11

Set Input Filter Times 11

Specifications 14

Entity Parameters 17

Publication 1797-5.7 - March 2010

Page 2

2 FLEX Ex NAMUR Input Module

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical

equipment. Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls

(Publication SGI-1.1

http://literature.rockwellautomation.com

equipment and hard-wired electromechanical devices. Because of this difference, and also because of

the wide variety of uses for solid state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages

resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the

many variables and requirements associated with any particular installation, Rockwell Automation, Inc.

cannot assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits,

equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell

Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

available from your local Rockwell Automation sales office or online at

Identifies information about practices or circumstances that can cause an explosion

in a hazardous environment, which may lead to personal injury or death, property

damage, or economic loss.

Identifies information that is critical for successful application and understanding of

the product.

Identifies information about practices or circumstances that can lead to personal

injury or death, property damage, or economic loss. Attentions help you identify a

hazard, avoid a hazard and recognize the consequences.

) describes some important differences between solid state

Publication

Labels may be on or inside the equipment (for example, drive or motor) to alert

people that dangerous voltage may be present.

Labels may be on or inside the equipment (for example, drive or motor) to alert

people that surfaces may reach dangerous temperatures.

1797-5.7 - March 2010

Page 3

FLEX Ex NAMUR Input Module 3

1

2

3

4

5

6

7

Label Here or

Under Here

8

40231

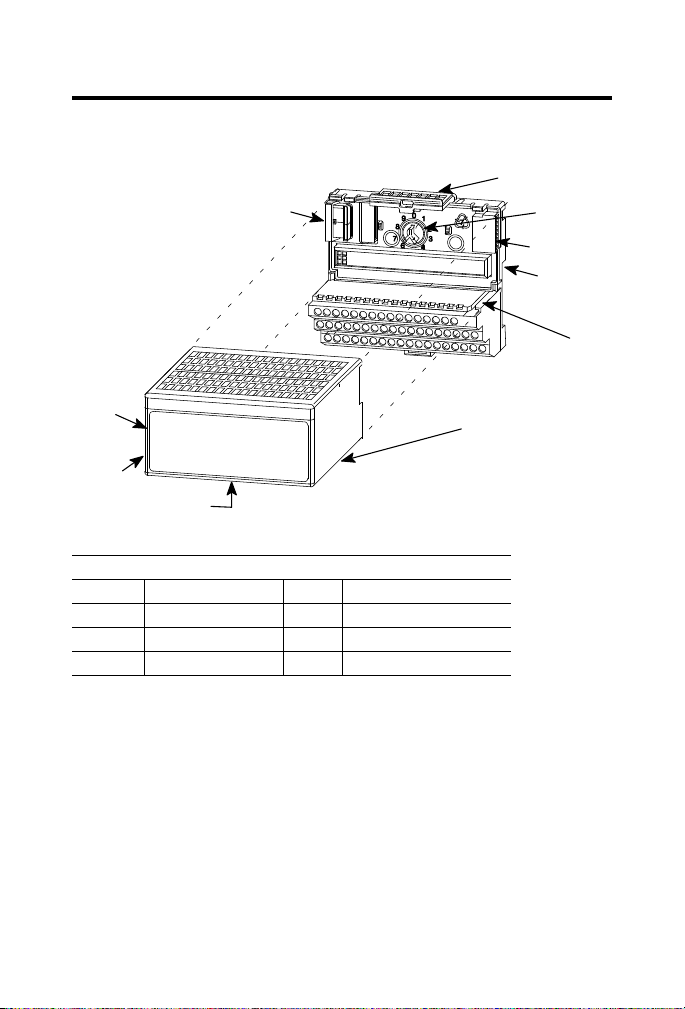

Module Installation

Component Identification

1 Keyswitch 5 Alignment Bar

2 Terminal Base Unit 6 Alignment Groove

3 Flexbus Connector 7 Latching Mechanism

4 Module 8 Cap Plug

This module must be used with a 1797-TB3 or -TB3S intrinsically safe

terminal base unit.

Publication

1797-5.7 - March 2010

Page 4

4 FLEX Ex NAMUR Input Module

ATTENTION

20128-M

This equipment is considered Group 1, Class A industrial equipment according

to IEC/CISPR Publication 11. Without appropriate precautions, there may be

potential difficulties ensuring electromagnetic compatibility in other

environments due to conducted as well as radiated disturbance.

This equipment is supplied as open-type equipment. It must be mounted within

an enclosure that is suitably designed for those specific environmental

conditions that will be present and appropriately designed to prevent personal

injury resulting from accessibility to live parts. The interior of the enclosure

must be accessible only by the use of a tool. Subsequent sections of this

publication may contain additional information regarding specific enclosure

type ratings that are required to comply with certain product safety

certifications.

1. Rotate keyswitch (1) on terminal base unit (2) clockwise to position 6

as required for this type of module.

Do not change the position of the keyswitch after wiring the

terminal base unit.

2. Make certain the flexbus connector (3) is pushed all the way to the left

to connect with the neighboring terminal base/adapter.

You cannot install the module unless the connector is fully extended.

3. Make sure the pins on the bottom of the module are straight so they

will align properly with the connector in the terminal base unit.

4. Position the module (4) with its alignment bar (5) aligned with the

groove (6) on the terminal base.

5. Press firmly and evenly to seat the module in the terminal base unit.

The module is seated when the latching mechanism (7) is locked into

the module.

6. Make certain that you only connect terminal base units to other

intrinsically safe system modules or adapters to maintain the integrity

of the intrinsically-safe backplane.

Publication

1797-5.7 - March 2010

Page 5

FLEX Ex NAMUR Input Module 5

ATTENTION

7. Remove cap plug (8) and attach another intrinsically safe terminal base

unit to the right of this terminal base unit if required.

Installation in Zone 1

This module must not be exposed to the environment. Provide a suitable

metal enclosure. This module has a protection factor of IP20.

This module cannot be used in an intrinsically safe environment after it has

been exposed to non-intrinsically safe signals.

Installation in Zone 22

When the module is installed in Zone 22, the following cabinets must be used:

IVK-ISRPI-V16LC; IVK-ISRPI-V8HYW; or IVK-ISRPI-V8LC. These

cabinets can be purchased from Pepperl+Fuchs GmbH, Lilienthalstrasse 200,

68307 Mannheim, Germany. Information available at

www.pepperl-fuchs.com.

The IS-RPI cabinets (type IVK2-ISRPI-V8LC, IVK2-ISRPI-V8HYW, or

IVK2-ISPRI-V16LC) ensures the basic protection for the intrinsically safe

apparatus of the FLEX Ex system for use in Zone 22. It corresponds with

category 3D according to RL 94/9 EG and with the type label marked with

the following information:

Pepperl+Fuchs GmbH

68307 Mannheim

IVK2-ISRPI-V8LC (or IVK2-ISRPI-V8HYW or

IVK2-ISRPI-V16LC)

II 3 D Ex tD A22 IP54 T70 °C X

CE

Serial (manufacturing) number

Model

Electrostatic Charge

Protect the system against electrostatic charge. Post a sign near this module:

WARNING Avoid electrostatic charging.

Publication

1797-5.7 - March 2010

Page 6

6 FLEX Ex NAMUR Input Module

WARNING

ADVERTÊNCIA! PREVENIR CONTRA O ACÚMULO DE CARGA

ELETROSTÁTICA.

For your convenience, a sign that can be cut out and posted is included in this

installation instruction.

Removal and Insertion Under Power

These modules are designed so you can remove and insert them under

power. However, take special care when removing or inserting modules in an

active process. I/O attached to any module being removed or inserted can

change states due to its input/output signal changing conditions.

If you insert or remove the module while backplane power is on, an electrical

arc can occur. This could cause an explosion in hazardous location

installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

European Communities (EC) Directive Compliance

If this product has the CE mark it is approved for installation within the

European Union and EEA regions. It has been designed and tested to meet

the following directives.

EMC Directive

These products are tested to meet the Council Directive 2004/108/EC by

applying the following standards:

• EN 61000-6-4:2007, Electromagnetic Compatibility (EMC) - Part 6-4:

Generic Standard for Industrial Environments (Class A)

• EN 61000-6-2:2005, Electromagnetic Compatibility (EMC) - Part 6-2:

Generic Standards - Immunity for Industrial Environments

• EN61326-1:2006 (Industrial), Electrical Equipment For

Measurement, Control, and Laboratory Use - Industrial EMC

Requirements

Publication

1797-5.7 - March 2010

Page 7

FLEX Ex NAMUR Input Module 7

+V

-V

-

+

NAMUR

Prox

Lead Break

Defeat

Bus

μC

Flexbus

Power

Supply

ATEX Directive

These products are tested in conjunction with associated I/O modules to

meet the Council Directive 94/9/EC (ATEX) Equipment and Protective

Systems Intended for Use in Potentially Explosive Atmospheres by applying

the following standards:

• EN60079-11:2007, Explosive atmospheres - Part 11 : equipment

protection by intrinsic safety "i"

• EN60079-0:2006, Electrical apparatus for explosive gas atmospheres Part 0 : general requirements

• EN 60079-26 : 2004, Electrical apparatus for explosive gas

atmospheres - Part 26 : construction, test and marking of Group II

Category 1 G electrical apparatus

• EN61241-0 : 2006, Electrical apparatus for use in the presence of

combustible dust - Part 0: General requirements

• EN61241-11:2006, Electrical apparatus for use in the presence of

combustible dust – Part 11: Protection by intrinsic safety 'iD'

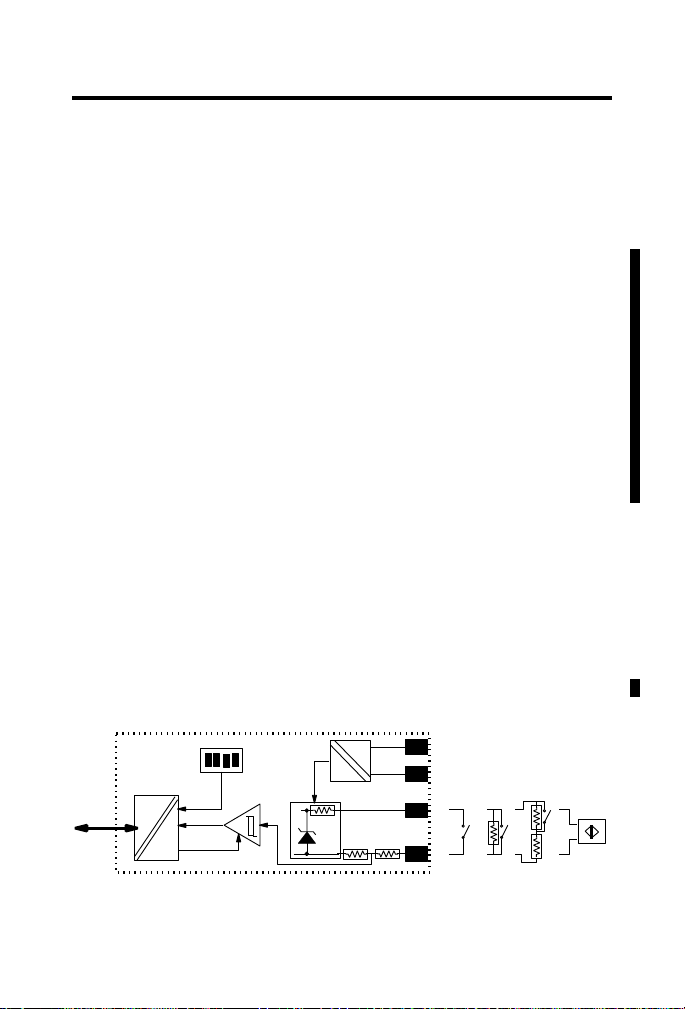

Inputs

Each input can be operated from a NAMUR sensor or a mechanical contact

(if mechanical inputs are used). Do not apply any nonintrinsically safe

signals to this module.

When using an intrinsically safe electrical apparatus according to EN50020,

the European Community directives and regulations must be followed.

The channels in this module are electrically connected to each other.

Publication

1797-5.7 - March 2010

Page 8

8 FLEX Ex NAMUR Input Module

WARNING

41504

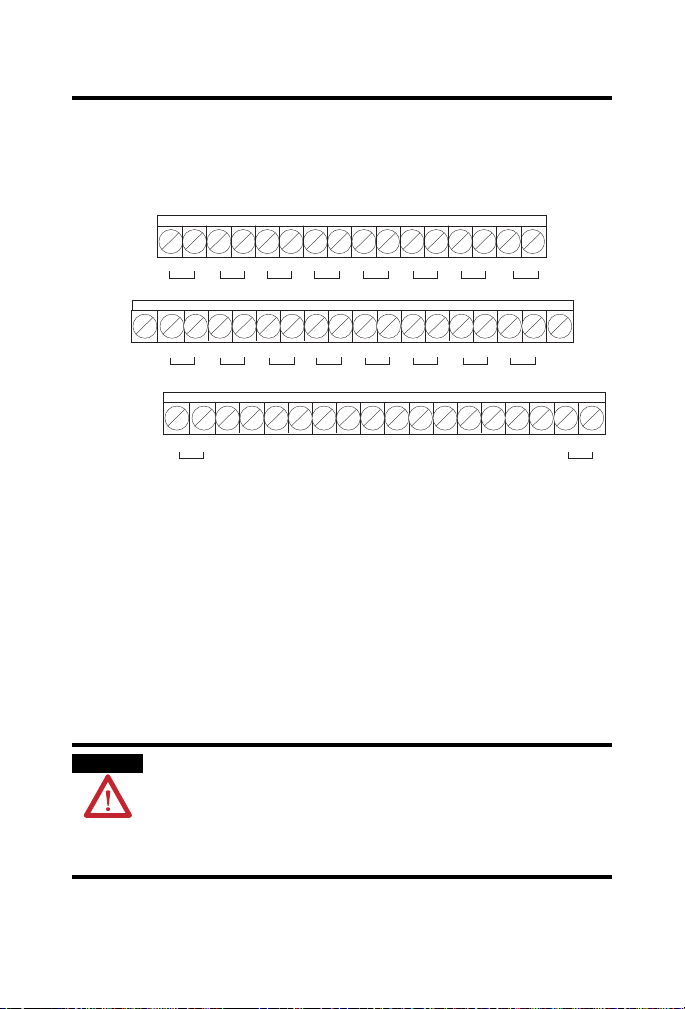

Row A

Row B

Row C

++ + +-- --

ch0 ch1 ch2 ch3

+V -V

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33

No connections allowed to terminals 36 or 49.

34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

+- +- +- +-

ch7ch6ch5ch4

+- +- +- +-

+

-

+-

+-

+-

ch8 ch9 ch10 ch11 ch15ch14ch13ch12

+V -V

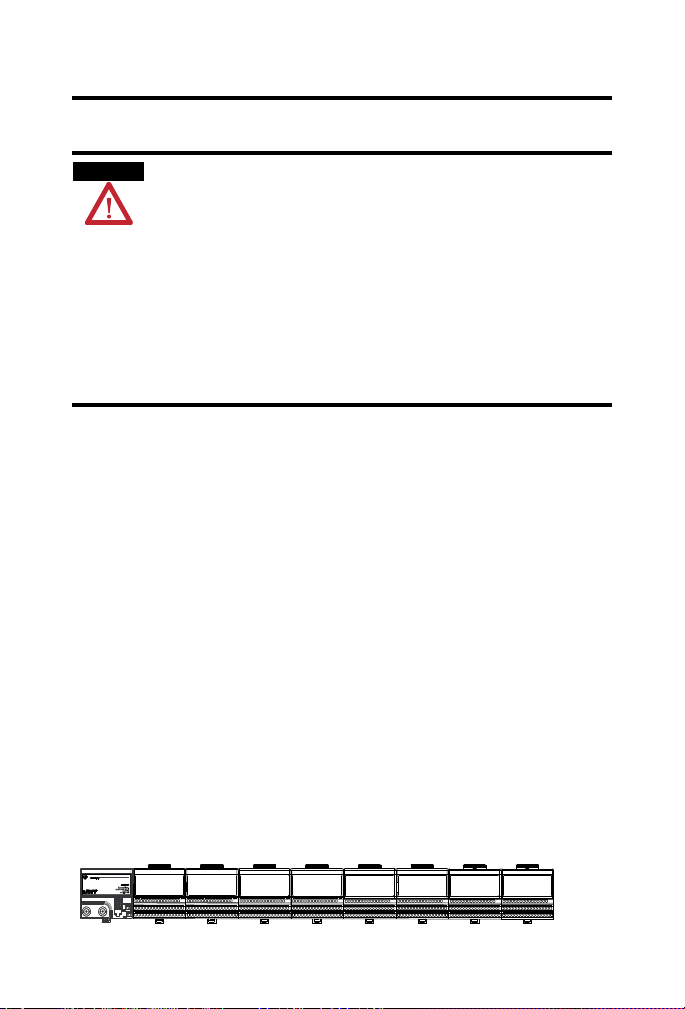

Wiring to a 1797-TB3 or -TB3S Terminal Base Unit

Connect wiring to the 1797-TB3 or 1797-TB3S terminal base unit as shown

below.

1. Connect the individual input wiring to (+) terminals (0, 2, 4, 6, 8, 10,

12, 14) on the 0 to 15 row (A) and on the 16 to 33 row (B) (terminals

17, 19, 21, 23, 25, 27, 29, 31)as indicated in the table below.

2. Connect the associated input to the corresponding (-) terminal (1, 3,

5, 7, 9, 11, 13, 15) on the 0 to 15 row (A), and on the 16 to 33 row (B)

(terminals 18, 20, 22, 24, 26, 28, 30, 32) for each input as indicated in

the table below.

3. Connect +V dc power to terminal 34 on the 34 to 51 row (C).

4. Connect -V to terminal 35 on the 34 to 51 row (C).

Publication

Make certain that you power this module with an intrinsically safe power

supply. Do not exceed the values listed in the specifications for this module.

If you connect or disconnect wiring while the field-side power is on, an

electrical arc can occur. This could cause an explosion in hazardous location

installations. Be sure that power is removed or the area is nonhazardous

before proceeding.

1797-5.7 - March 2010

Page 9

FLEX Ex NAMUR Input Module 9

ATTENTION

5. If continuing power to the next terminal base unit, connect a jumper

from terminal 50 (+V) on this base unit to terminal 34 on the next

base unit.

6. If continuing common to the next terminal base unit, connect a

jumper from terminal 51 (-V) on this base unit to terminal 35 on the

next base unit.

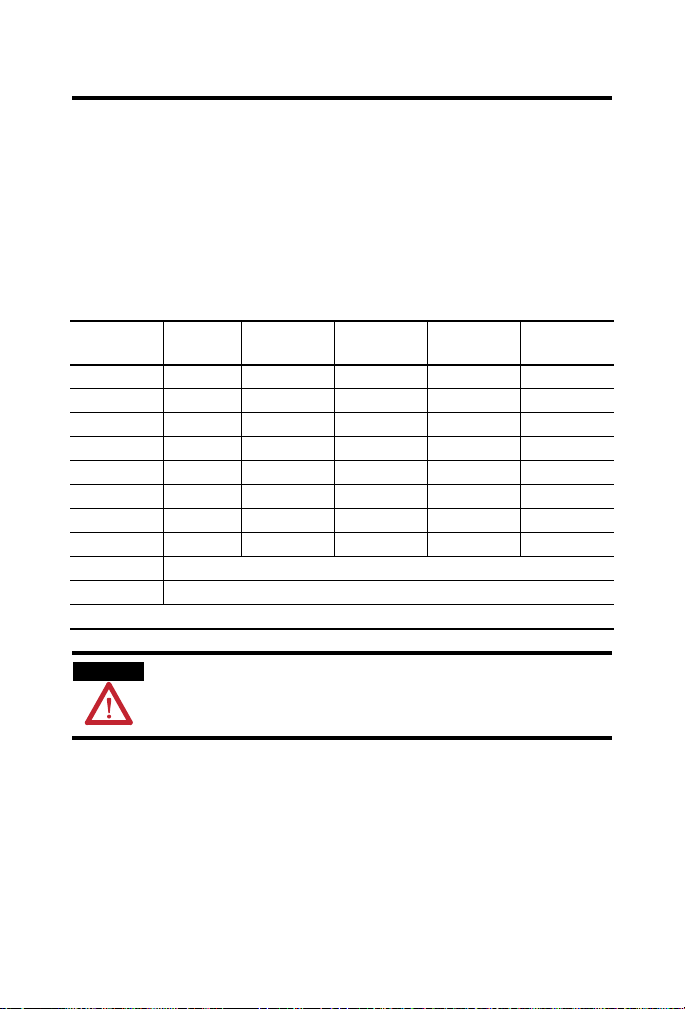

Wire the Module

Input Input

Source

Input 0 A-0 A-1 Input 8 B-17 B-18

Input 1 A-2 A-3 Input 9 B-19 B-20

Input 2 A-4 A-5 Input 10 B-21 B-22

Input 3 A-6 A-7 Input 11 B-23 B-24

Input 4 A-8 A-9 Input 12 B-25 B-26

Input 5 A-10 A-11 Input 13 B-27 B-28

Input 6 A-12 A-13 Input 14 B-29 B-30

Input 7 A-14 A-15 Input 15 B-31 B-32

+V Terminals 34 and 50

-V Terminals 35 and 51

Terminals 16, 33, 40, 41, 42, 43, 44, and 45 are connected to chassis ground.

Input Signal Input Input Source Input Signal

Do not use the unused terminals on this terminal base unit. Using these

terminals as supporting terminals can result in damage to the module

and/or unintended operation of your system.

Publication

1797-5.7 - March 2010

Page 10

10 FLEX Ex NAMUR Input Module

30820-M

Ex

1797-IBN16

PWR

6

A

B

C

40064A

Grounding

All I/O wiring must use shielded wire. Shields must be terminated external to

the module, such as bus bars and shield-terminating feed throughs.

Indicators

A = Status Indicators

yellow - individual input present;

flashing red - channel fault;

solid red - module did not pass powerup check (channel 0 is solid red

while Powerup check is running)

B = Insertable labels for writing individual input designations

C = Power Indicator - green indicates power applied to module

Publication

1797-5.7 - March 2010

Page 11

FLEX Ex NAMUR Input Module 11

40154

FT = 12 to 15

(14 to 17)

Dec.

(Octal)

O:010

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

10 0 10 0

FT = 00 to 11

(00 to 13)

=44 Octal

or 36 Decimal

Input/Output Mapping

Dec. Bit

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Oct. Bit

17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

Read 0I15I14I13I12I11I10I9 I8 I7I6I5I4I3I2I1I0

Read 1 F15F14F13F12F11F10F9 F8 F7F6F5F4F3F2F1F0

Read 1 Input 15 Counter

Write 0 CF CR FC Input Filter - Ch

Where:I = Input

F = Fault Alarm for an individual chann el

CF = Counter Fast - Filter time constant or bypass, depending on setting (when input 15 is in counter mode) -

CR = Counter Reset- Resets the counter value in read word 1 when input 15 is in counter mode.

FC = Fault mode or Counter mode - determines content of read word 1 (counter value of input 15, or

0 = normal, 1 = fast

0 = normal, 1 = reset

fault data of individual channel) . 0 = counter, 1 = fault data - wire off or short

circuit detect

12…15

Input/Alarm

Filter - Ch

0…11

Set Input Filter Times

You can select the input filter time constant for each group of channels

(channels 00 to 11 or channels 12 to 15).

For example, to set a filter time constant of 5 ms for a dc input module, set

bits 05, 04, 03, 02, 01, and 00 as shown below.

Publication

1797-5.7 - March 2010

Page 12

12 FLEX Ex NAMUR Input Module

OFF

1234

OFF

1234

Input Filter Times

Bits Description Maximum

02 01 00 Filter Times 00…11 (00…13)

05 04 03 Filter Times 12…15 (14…17)

0 0 0 Filter Time 0 (default) 1 ms

0 0 1 Filter Time 1 1 ms

0 1 0 Filter Time 2 2 ms

0 1 1 Filter Time 3 3 ms

1 0 0 Filter Time 4 5 ms

1 0 1 Filter Time 5 9 ms

1 1 0 Filter Time 6 17 ms

1 1 1 Filter Time 7 33 ms

Bits 00…02 also control the filter times of all 16 fault alarm bits of read word 1 when

module is in fault mode

.

Filter Time

Set the Fault Detect Switch

A switch, located on the backside of the module, lets you select the action of

the module when a fault (wire off or short circuit) is detected. Switch position

1 determines the action for channels 0 to 3, position 2 for channels 4 to 7,

position 3 for channels 8 to 11, and position 4 for channels 12 to 15.

Set the switch:

• OFF to disable fault detection for the selected channels.

• ON to enable fault detection for the selected channels.

Publication

1797-5.7 - March 2010

Page 13

FLEX Ex NAMUR Input Module 13

Repair

This module is not field-repairable. Any attempt to open this module will void

the warranty and IS certification. If repair is necessary, return this module to

the factory.

Publication

1797-5.7 - March 2010

Page 14

14 FLEX Ex NAMUR Input Module

Specifications

1797-IBN16 16 NAMUR Input Module

Attribute Value

Number of inputs 16 (1 group of 16), nonisolated, sinking

IS input type Ex ia IIB/IIC T4,

AEx ia IIC T4,

Class I, II, III Division 1 Group A-G T4

IS module type Ex ib IIB/IIC T4,

AEx ib IIC T4,

Class I, Division 1 Group A-D T4

Input type NAMUR compatible

ON-state current 2.1 mA

OFF-state current 1.2 mA

Hysteresis 0.2 mA

Input frequency 1000 Hz max

Input pulse width >500 µs on or off

Max load voltage U/V = 7.5V DC

Short circuit current I = 7.5 mA

Short circuit threshold I > 6 mA

Lead breakage threshold I < 0.35 mA

Input delay times

OFF to ON

ON to OFF

Indicators (field side

indication, customer device

driven)

1 ms, 2 ms, 3 ms, 5 ms, 9 ms, 17 ms, 33 ms

1 ms, 2 ms, 3 ms, 5 ms, 9 ms, 17 ms, 33 ms

1 ms default - selectable thru output image table (see

Setting Input Filter Times)

16 yellow status indicators

16 red fault indicators

1 green module power indicator

Publication

1797-5.7 - March 2010

Page 15

FLEX Ex NAMUR Input Module 15

1797-IBN16 16 NAMUR Input Module

Attribute Value

Output (intrinsically safe)

(16 pin male and female

flexbus connector)

Isolation path

Input to power supply

Input to flexbus

Input to input

Power supply to flexbus

Power supply

(+V, -V intrinsically safe)

Module field-side power

consumption

Power dissipation 2.8 W

Thermal dissipation Max 9.6 BTU/hr

Module location Cat. No. 1797-TB3 or 1797-TB3S Terminal Base Unit

Conductor wire size

Dimensions 46 mm x 94 mm x 75 mm

Weight 200 g (approximate)

Keyswitch Position 6

U

< 5.8V DC

i

I

< 400 mA

i

= Negligible

L

i

C

= Negligible

i

Isolation Type

Galvanic to DIN EN 60079-11

Galvanic to DIN EN 60079-11

None

Galvanic to DIN EN 60079-11

U

< 9.5V DC

i

< 1 A

I

i

= Negligible

L

i

= Negligible

C

i

2.8 W

2

(12 gauge) stranded max

4 mm

1.2 mm (3/64 in.) insulation max

(1.8 in. x 3.7 in. x 2.95 in.)

Publication

1797-5.7 - March 2010

Page 16

16 FLEX Ex NAMUR Input Module

Environmental

Attribute Value

Temperature, operating -20…70 °C (-4…+158 °F)

Temperature,

nonoperating

Relative humidity 5…95% noncondensing

Vibration Tested 2 g @ 10…500 Hz per IEC68-2-6

Shock, operating Tested to 15 g peak acceleration, 11(+1) ms pulse width

Shock, nonoperating Tested to 15 g peak acceleration, 11(+1) ms pulse width

-40…85 °C (-40…185 °F)

Agency Certification

Attribute Value

CENELEC II (1) 2G Ex ib[ia] IIC T4

II (1) D [Ex iaD]

U, C-UL Class I, Groups A, B, C and D; Class II, Groups E, F and G;

FM Intrinsically safe Class I, Div 1, Groups A, B, C, D, T4.

IECEx [Zone 0] Ex ib[ia] IIC T4

INMETRO BR-Ex ia/ib IIB/IIC T4

Class III hazardous Locations.

Class I, Zone 1, AEx ib[ia] IIC T4.

Associated Apparatus with intrinsically safe

Connections Class I, II, III, Div 1, Groups A--G

Intrinsically safe Class I, Zone 1, AEx ib[ia] IIC T4.

[Ex iaD]

Certificate of Conformity

Attribute Value

CENELEC DMT 98 ATEX E013 X

U, C-UL UL, C-UL File Number E197983

Publication

1797-5.7 - March 2010

Page 17

FLEX Ex NAMUR Input Module 17

Certificate of Conformity

Attribute Value

FM FM Certificate Number 3009806

INMETRO 05/UL-BRAE-0012X

IECEx IECEx BVS 09.0027X

Entity Parameters

CE/CENELEC I/O Entity Parameters (Each Channel)

Protection Group Allowed

Capacitance

Uo < 14.5V

Io < 15 mA

Po < 40 mW

Characteristic:

linear

Ex ia IIB 1 μF 10 mH 2.6 mH/Ω

Ex ia IIC 300 nF 2 mH 0.65 mH/Ω

UL, C-UL I/O Entity Parameters

If this product has the UL/C-UL mark, it has been designed, evaluated,

tested, and certified to meet the following standards:

• UL 913, 1988, Intrinsically Safe Apparatus and Associated Apparatus

for Use in Class I, II, and III Division 1, Hazardous (Classified)

Locations

• UL 1203, Explosion-Proof and Dust-Ignition-Proof Electrical

Equipment for Use in Hazardous (Classified) Locations

• UL 2279, Electrical Equipment for Use in Class I, Zone 0, 1, and 2

Hazardous (Classified) Locations

• UL 61010, UL Standard for Safety Electrical Equipment For

Measurement, Control, and Laboratory Use; Part 1: General

Requirements

• CSA C22.2 No. 157-92, Intrinsically Safe and Non-Incendive

Equipment for Use in Hazardous Locations

Allowed

Inductance

Publication

Lo/Ro Ratio

1797-5.7 - March 2010

Page 18

18 FLEX Ex NAMUR Input Module

• CSA C22.2 No. 30-M1986, Explosion-Proof Enclosures for Use in

Class I Hazardous Locations

• CSA-E79-0-95, Electrical Apparatus for Explosive Gas Atmospheres,

Part 0: General Requirements

• CSA-E79-11-95, Electrical Apparatus for Explosive Gas

Atmospheres, Part 11: Intrinsic Safety “i”

• CSA C22.2 No. 14-95, Industrial Control Equipment

Table 1

Wiring

Channel Terminals Voc

Method

1 and 2 Any one

channel (for

example,

ch0)

0(+), 1(-) 14.5 15 - - A, B 0.3 80.0

Isc

Vt

It

(V)

(mA)

(V)

Groups Ca (μF) La (mH)

(mA)

C, E 0.9 320.0

D, F, G 2.4 640.0

Wiring Methods

• Wiring method 1 - Each channel is wired separately.

• Wiring method 2 - Multiple channels in one cable, providing each

channel is separated in accordance with the National Electric Code

(NEC) or Canadian Electric Code (CEC).

Table 2

Ter mi na ls Vt (V) It (mA) Groups Ca (μF) La (μH)

Male Bus

Connector

5.8 400 A-G 3.0 3.0

The entity concept allows interconnection of intrinsically safe apparatus

with associated apparatus not specifically examined in combination as a

system when the approved values of Vt and It of the associated apparatus are

less than or equal to V

apparatus and the approved values of C

are greater than C

apparatus.

Publication

1797-5.7 - March 2010

+ C

i

and Isc or V

oc

and Li + L

cable

and I

max

cable

of the intrinsically safe

max

and La of the associated apparatus

a

respectively for the intrinsically safe

Page 19

FLEX Ex NAMUR Input Module 19

WARNING

AVERTISSEMENT

IMPORTANT

Simple apparatus is defined as a device which neither generates nor stores

more than 1.2V, 0.1 A, 20 mJ, or 25 mW.

Wiring methods must be in accordance with the National Electric Code,

ANSI/NFPA 70, Article 504 and 505 or the Canadian Electric Code CSA

C22.1, Part 1, Appendix F. For additional information refer to ANSI/ISA

RP12.6.

This module, 1797-IBN16, must be used with terminal base 1797-TB3

or 1797-TB3S.

Terminals 36 to 39, and 46 to 49 shall not be connected.

Substitution of components may impair intrinsic safety.

La substitution de composant peut compromettre la securite

intrinseque.

For detailed certification information, refer to the FLEX Ex System

Certification Reference Manual, publication 1797-6.5.6.

Publication

1797-5.7 - March 2010

Page 20

20 FLEX Ex NAMUR Input Module

ATTENTION

1797- IBN16

Allen-Bradley

B-A

7PWR6543210 98 1110 1312 1514

6

16 Point NAMUR Input Module

6

FLEX Ex NAMUR Input

I/O Module

Indicators

Female Bus

Connection

Field Wiring

Terminals

Terminal Base

Terminal Base

Key

Male Bus

Connection

Key Position for

Termina l Base

Insertion

A terminal base may or may not have an I/O module installed.

Publication

1797-5.7 - March 2010

Page 21

FLEX Ex NAMUR Input Module 21

Hazardous (Classified) Location

Class I, Zones 0, 1, & 2 Groups IIC, IIB, IIA

Class I, Div. 1 & 2 Groups A, B, C, D

Class II, Div. 1 & 2 Groups E, F, G

Class III, Div. 1 & 2

Hazardous (Classified) Location

Class I, Zones 1 & 2 Groups IIC, IIB,

IIA

Class I, Div. 1 & 2 Groups A, B, C, D

Any Simple Apparatus or I.S. device

with Entity Concept parameters (V

max

, I

max

,

C

i

, Li) appropriate for connection to

associated apparatus with Entity Concept

To any intrinsically safe

device or associated

apparatus with Entity

Concept parameters of V

oc

< 5.8V; Isc < 400 mA.

To any intrinsically safe

device or associated

apparatus with Entity

Concept parameters of

V

oc

< 9.5V; Isc < 1 A.

To any IS device with Entity

Concept parameters of

(V

max

, I

max

, Ci, Li) appropriate for

connection to associated

apparatus with Entity

Concept parameters listed in

Table 2.

ch0

ch1

ch2

ch3

ch4

ch5

ch6

ch7

29(+)

30(-)

1797-IBN16

16

Shield Connection Only

50

51

35

34

Female Bus Connector

V

max

=5.8V

I

max

=400mA

C

i

=1350nF

L

i

=negligible

V

max

=9.5V

I

max

=1A

C

i

=negligible

L

i

=negligible

Male Bus

Connector

33

40

41

42

43

44

45

31(+)

32(-)

25(+)

26(-)

27(+)

28(-)

21(+)

22(-)

23(+)

24(-)

17(+)

18(-)

19(+)

20(-)

12(+)

13(-)

14(+)

15(-)

8(+)

9(-)

10(+)

11(-)

4(+)

5(-)

6(+)

7(-)

0(+)

1(-)

2(+)

3(-)

ch8

ch9

ch10

ch11

ch12

ch13

ch14

ch15

Publication

1797-5.7 - March 2010

Page 22

22 FLEX Ex NAMUR Input Module

FM I/O Entity Parameters (Each Channel)

If this product has the FM mark, it has been designed, evaluated, tested and

certified to meet the following standards:

• FM C1. No 3600:1998, Electrical Equipment for Use in Hazardous

(Classified) Locations General Requirements

• FM C1. No 3610:1999, Intrinsically Safe Apparatus and Associated

Apparatus for Use in Class I, II, III Division 1 Hazardous (Classified)

Locations

• FM C1. No 3615:1989, Explosionproof Electrical Equipment General

Requirements

• FM C1. No 3810:1989, 1995, Electrical and Electronic Test,

Measuring and Process Control Equipment

• ANSI/NEMA 250, 1991, Enclosures for Electrical Equipment

Wiring Methods

• Wiring method 1 - Each channel is wired separately.

• Wiring method 2 - Multiple channels in one cable, providing each

channel is separated in accordance with the National Electric Code

(NEC).

Table 1

Wiring

Method

1 and 2 Any one

Channel Terminals Voc

(V)

0(+), 1(-) 14.5 15 - - A, B 0.3 80.0

channel

(for

example,

ch0)

Isc

(mA)

Vt

(V)

It

Groups Ca

(mA)

C, E 0.9 320.0

D, F, G 2.4 640.0

(μF)

La

(mH)

Publication

1797-5.7 - March 2010

Page 23

FLEX Ex NAMUR Input Module 23

WARNING

AVERTISSEMENT

Table 2

Ter mi na ls Vt (V) It (mA) Groups Ca (μF) La (μH)

Male Bus

Connector

5.8 400 A-G 3.0 3.0

The entity concept allows interconnection of intrinsically safe apparatus

with associated apparatus not specifically examined in combination as a

system when the approved values of Voc and Isc or Vt and It of the associated

apparatus are less than or equal to V

apparatus and the approved values of C

+ C

are greater than C

i

and Li + L

cable

and I

max

cable

of the intrinsically safe

max

and La of the associated apparatus

a

respectively for the intrinsically safe

apparatus. The internal capacitances Ci of the terminal base must be taken

into account to verify the intrinsic safety.

Simple apparatus is defined as a device which neither generates nor

stores more than 1.2V, 0.1 A, 20 μJ, or 25 mW.

Wiring methods must be in accordance with the National Electric Code,

ANSI/NFPA 70, Article 504 and 505. For additional information refer to

ANSI/ISA RP12.6.

This module, 1797-IBN16, must be used with terminal base 1797-TB3

or 1797-TB3S.

Terminals 36 to 39, and 46 to 49 shall not be connected.

Substitution of components may impair intrinsic safety.

La substitution de composant peut compromettre la securite

intrinseque.

Publication

1797-5.7 - March 2010

Page 24

24 FLEX Ex NAMUR Input Module

ATTENTION

1797- IBN16

Allen-Bradley

B-A

7PWR6543210 98 1110 1312 1514

6

16 Point NAMUR Input Module

6

FLEX Ex NAMUR Input

I/O Module

Indicators

Female Bus

Connection

Field Wiring

Terminals

Terminal Base

Unit

Terminal Base

Key

Male Bus

Connection

Key Position for

Terminal Base

Insertion

42060

A terminal base may or may not have an I/O module installed.

Publication

1797-5.7 - March 2010

Page 25

FLEX Ex NAMUR Input Module 25

ch0

ch1

ch2

ch3

ch4

ch5

ch6

ch7

29(+)

30(-)

1797-IBN16

16

Shield Connection Only

50

51

35

34

Female Bus Connector

V

max

=5.8V

I

max

=400mA

C

i

=1350nF

L

i

=negligible

V

max

=9.5V

I

max

=1A

C

i

=negligible

L

i

=negligible

Male Bus

Connector

33

40

41

42

43

44

45

31(+)

32(-)

25(+)

26(-)

27(+)

28(-)

21(+)

22(-)

23(+)

24(-)

17(+)

18(-)

19(+)

20(-)

12(+)

13(-)

14(+)

15(-)

8(+)

9(-)

10(+)

11(-)

4(+)

5(-)

6(+)

7(-)

0(+)

1(-)

2(+)

3(-)

ch8

ch9

ch10

ch11

ch12

ch13

ch14

ch15

Any Simple Apparatus or FM approved device

with Entity Concept parameters (V

max

, I

max

, Ci, Li)

appropriate for connection to associated apparatus

For connection to other

modules, refer to the

General FM Certification

Information in publication

1797-6.5.6.

From FM approved devices,

1797-PS2N.

For connection to other

modules, refer to the

General FM Certification

Information in publication

1797-6.5.6.

Hazardous (Classified) Location

Class I, Zone 1 Group IIC

Class I, Div. 1 Groups A, B, C, D

Hazardous (Classified) Location

Class I, Zone 0 Group IIC

Class I, Div. 1 Groups A, B, C, D

Class II, Div. 1 Groups E, F, G

Class III, Div. 1

Publication

1797-5.7 - March 2010

Page 26

26 FLEX Ex NAMUR Input Module

WARNING Avoid electrostatic charging.

ADVERTÊNCIA! PREVENIR CONTRA O ACÚMULO

DE CARGA ELETROSTÁTICA.

Publication

1797-5.7 - March 2010

Page 27

Notes:

FLEX Ex NAMUR Input Module 27

Publication

1797-5.7 - March 2010

Page 28

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in using

its products. At http://support.rockwellautomation.com

manuals, a knowledge base of FAQs, technical and application notes, sample code and

links to software service packs, and a MySupport feature that you can customize to

make the best use of these tools.

For an additional level of technical phone support for installation, configuration, and

troubleshooting, we offer TechConnect Support programs. For more information,

contact your local distributor or Rockwell Automation representative, or visit

http://support.rockwellautomation.com

.

Installation Assistance

If you experience a problem with a hardware module within the first 24 hours of

installation, please review the information that's contained in this manual. You can also

contact a special Customer Support number for initial help in getting your module up

and running.

United States 1.440.646.3434 Monday – Friday, 8am – 5pm EST

Outside United States Please contact your local Rockwell Automation representative for

any technical support issues.

New Product Satisfaction Return

Rockwell tests all of its products to ensure that they are fully operational when shipped

from the manufacturing facility. However, if your product is not functioning, it may

need to be returned.

United States Contact your distributor. You must provide a Customer Support case

number (see phone number above to obtain one) to your distributor

in order to complete the return process.

Outside United States Please contact your local Rockwell Automation representative for

return procedure.

Allen-Bradley, Rockwell Automation, ControlLogix, RSLinx, TechConnect, and FLEX I/O are trademarks of

Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

, you can find technical

Publication 1797-5.7 - March 2010 PN-64735

Supersedes Publication 1797-5.7 - August 2008 Copyright © 2010 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

Loading...

Loading...