Page 1

Installation Instructions

FLEX Ex Bus Isolator and Flexbus Connector

Catalog Numbers 1797-BIC, 1797-CEC

Top ic Page

Important User Information 2

About the Isolator and Flexbus Connector 3

Product Features 4

Intermixed Systems 4

Module Installation 5

Installation in Zone 2 10

Installation in Zone 22 10

Electrostatic Charge 11

Removal and Insertion Under Power 11

European Communities (EC) Directive Compliance 12

Inputs and Outputs 15

Wire the Isolator Module 16

Indicators 17

About the Mounting Kit 17

Specifications 20

Publication 1797-5.13 - June 2010

Page 2

2 FLEX Ex Bus Isolator and Flexbus Connector

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical

equipment. Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls

(Publication SGI-1.1 available from your local Rockwell Automation sales office or online at

http://www.literature.rockwellautomation.com) describes some important differences between solid

state equipment and hard-wired electromechanical devices. Because of this difference, and also because

of the wide variety of uses for solid state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages

resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the

many variables and requirements associated with any particular installation, Rockwell Automation, Inc.

cannot assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits,

equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell

Automation, Inc., is prohibited.

Throughout this manual we use notes to make you aware of safety considerations.

Identifies information about practices or circumstances that can cause an explosion in a

hazardous environment, which may lead to personal injury or death, property damage, or

economic loss.

Identifies information that is critical for successful application and understanding of the

product.

Identifies information about practices or circumstances that can lead to personal injury or

death, property damage, or economic loss. Attentions help you identify a hazard, avoid a

hazard, and recognize the consequences.

Publication

Labels may be on or inside the equipment to alert people that dangerous voltage may be

present.

Labels may be on or inside the equipment to alert people that surfaces may reach

dangerous temperatures.

1797-5.13 - June 2010

Page 3

FLEX Ex Bus Isolator and Flexbus Connector 3

QUALITY

B-A

Allen-Bradley

1797 - CEC

FLEXBUS

CONNECTOR

12 4

3

+V -V +V -V

1797 - BIC

PWR

QUALITY

B-A

Allen-Bradley

FLEXBUS

ISOLATOR

42641

1

2

3

4

5

6

7

8

2

3

1797-CEC 1797-BIC

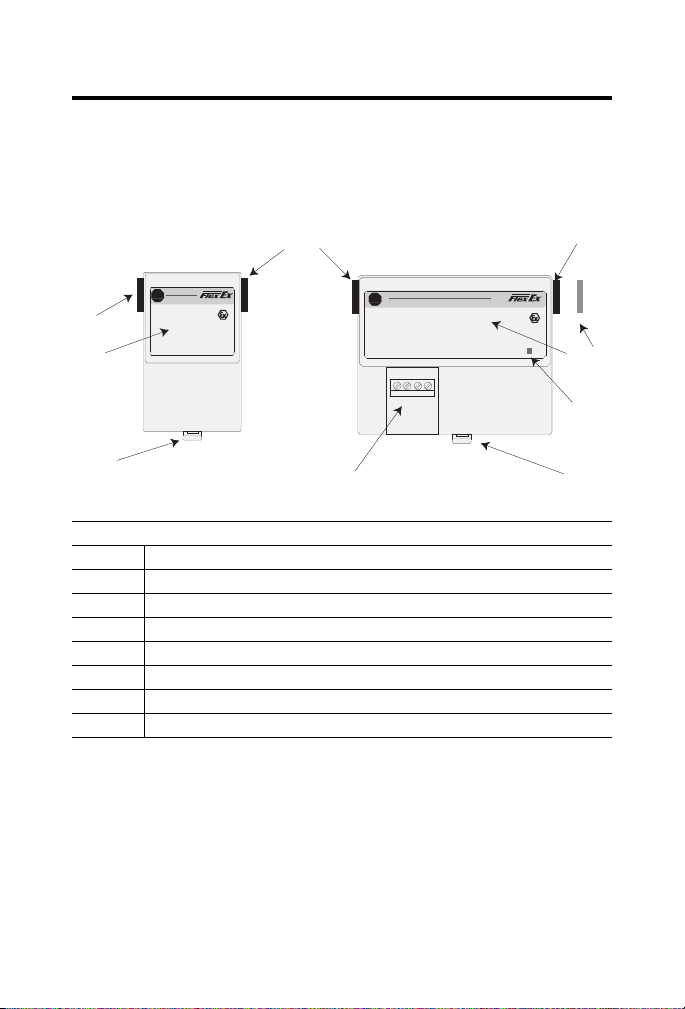

About the Isolator and Flexbus Connector

Use the FLEX Ex bus isolator to interconnect standard FLEX I/O modules

to intrinsically-safe FLEX Ex modules in the same I/O group

Component Identification

1 Power indicators

2 Label

3 Module locking tab

4 Removable power connector

5 FLEX Ex backplane connector

6 FLEX Ex backplane connector cover

7 Master backplane connector

8 FLEX I/O backplane connector

Publication

1797-5.13 - June 2010

Page 4

4 FLEX Ex Bus Isolator and Flexbus Connector

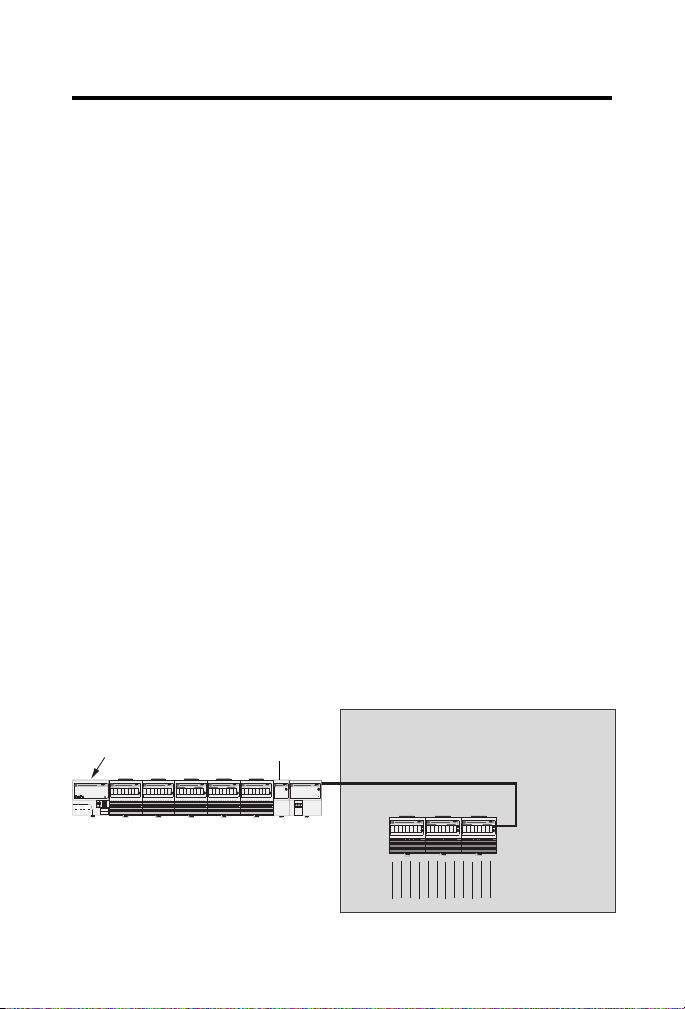

Mix Systems in the Safe Area

Any Communication

Adapter Supported by

FLEX I/O system

Bus Isolator

1797-CEC

1797-BIC

FLEX I/O system

Nonhazardous Area

or

Zone 2

Hazardous Area

Zone 1

1794-CE3

FLEX Ex system

Max of

1 m (3.28 ft)

Field Wiring to

Zone 0

40087

Product Features

Provides an IS-compatible mechanism to separate two sections of the

backplane allowing IS and non-IS field-device wiring to the same I/O

group.

Converts hazardous power to IS-safe power to run one side of the bus

receiver/transmitter circuitry and IS-safe FLEX Ex backplane power

to slave side modules.

Allows up to eight FLEX Ex modules may be attached to the slave

side.

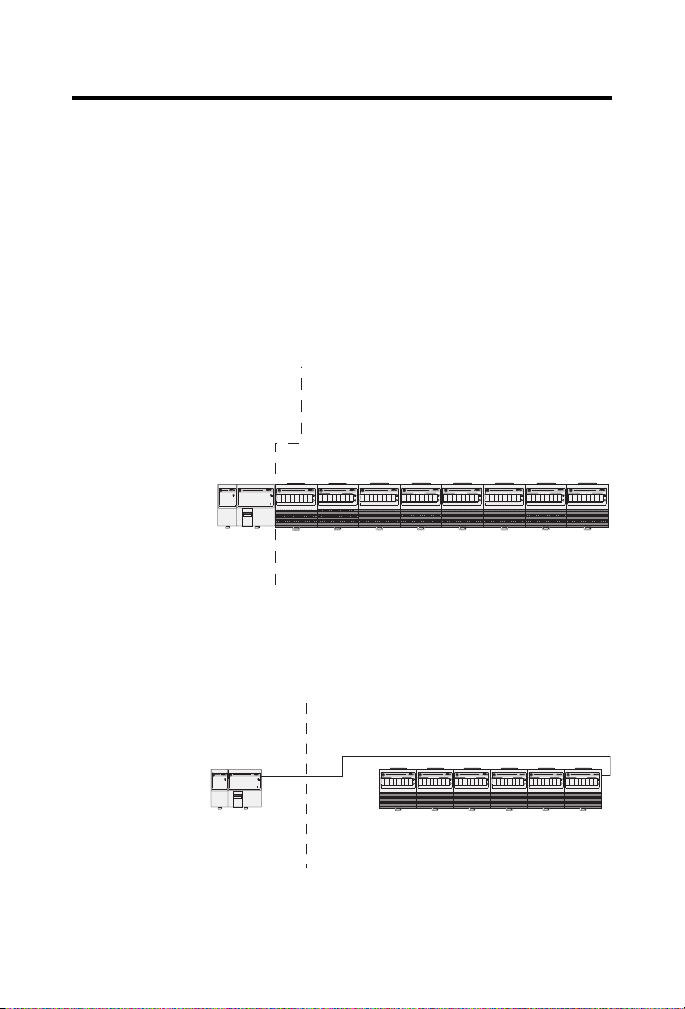

Intermixed Systems

The bus isolator modules, 1797-BIC and 1797-CEC, let you configure FLEX

Ex modules and FLEX I/O modules on the DIN rail when attached to the

same adapter and grouped together on appropriate sides of the bus isolator

module. This highly flexible, cost-effective solution combines intrinsically safe

and nonintrinsically safe systems.

Intermixed systems can be configured for use in the:

safe area much like traditional IS and I/O systems.

hazardous and safe control equipment where the distance of physical

separation is short.

FLEX Ex I/O with communication adapters that are not intrinsically

safe.

.

..

.

.

.

1

.

.

..

.

.

.

.

.

Publication

1797-5.13 - June 2010

.

.

..

..

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

Page 5

FLEX Ex Bus Isolator and Flexbus Connector 5

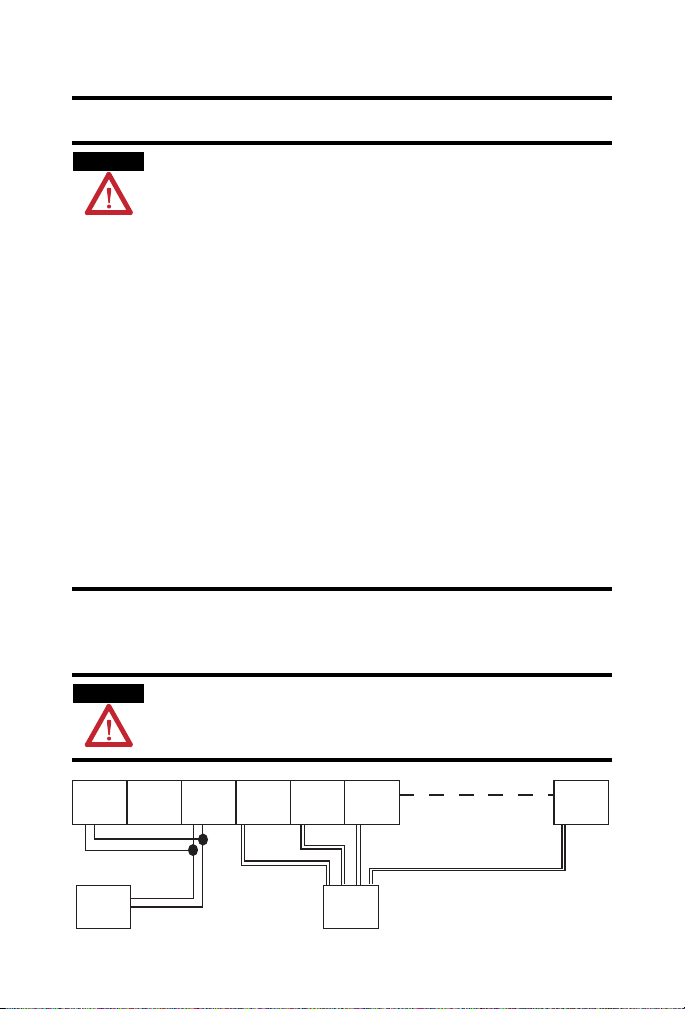

ATTENTION

ATTENTION

1794

Adapter

1797

CEC

1797

BIC

1797 I/O

& Base

1797 I/O

& Base

1797 I/O

& Base

1797 I/O

& Base

1797

Power

Supply

24V dc

Power

Supply

42754

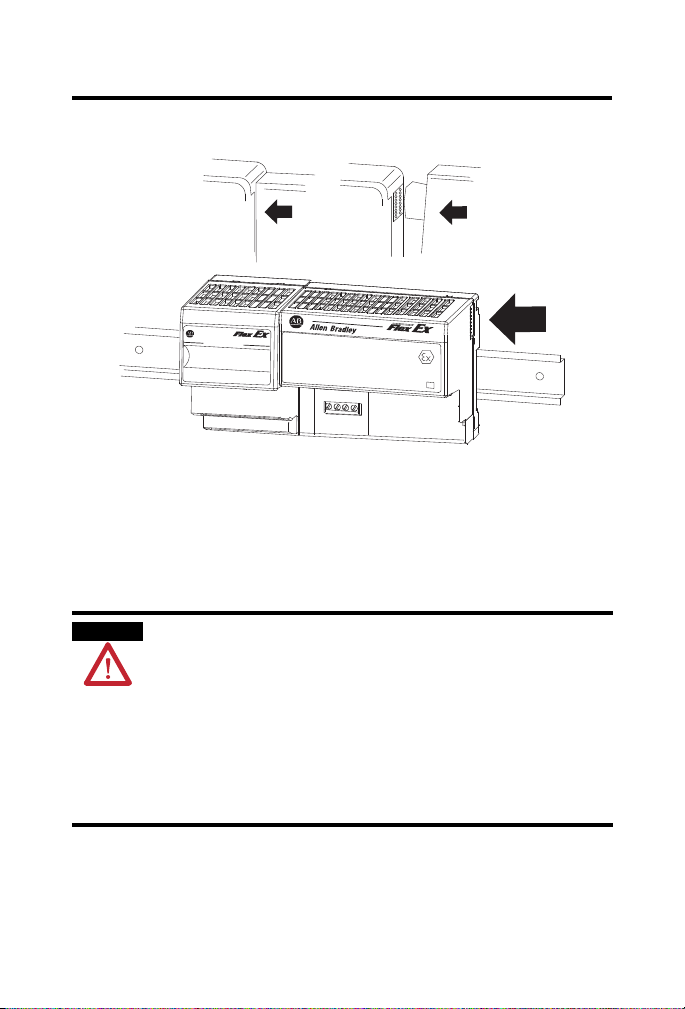

Module Installation

This equipment is considered Group 1, Class A industrial equipment

according to IEC/CISPR Publication 11. Without appropriate

precautions, there may be potential difficulties ensuring

electromagnetic compatibility in other environments due to

conducted as well as radiated disturbance.

This equipment is supplied as open-type equipment. It must be

mounted within an enclosure that is suitably designed for those

specific environmental conditions that will be present and

appropriately designed to prevent personal injury resulting from

accessibility to live parts. The interior of the enclosure must be

accessible only by the use of a tool. Subsequent sections of this

publication may contain additional information regarding specific

enclosure type ratings that are required to comply with certain

product safety certifications.

These products are grounded through the DIN rail to the dedicated

intrinsic safety ground. Use zinc plated yellow-chromate steel DIN

rail to assure proper grounding. The use of other DIN rail materials

(such as aluminum or plastic) that can corrode, oxidize, or are poor

conductors, can result in improper or intermittent grounding.

Make certain that you only connect the FLEX Ex backplane connector to

other intrinsically-safe system modules to maintain the integrity of the

intrinsically-safe backplane.

For proper operation, cycle power to the 1797-BIC module at the

same time power is cycled to the associated adapter.

Publication

1797-5.13 - June 2010

Page 6

6 FLEX Ex Bus Isolator and Flexbus Connector

42642

A

A

41377

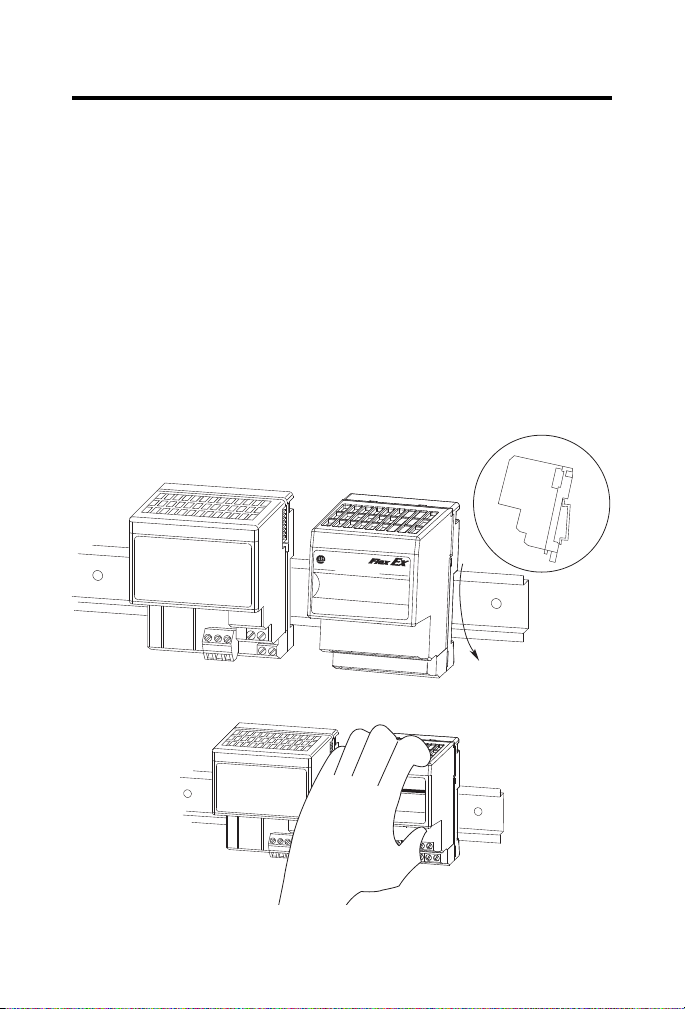

1797-CEC Module Installation

The 1797-CEC module mounts on a DIN rail. It connects to an adapter or

another FLEX I/O module. If using this module with FLEX I/O modules,

do not mount between FLEX I/O modules. Mount the 1797-CEC module to

the right of FLEX I/O modules. Follow these steps to mount this module.

1. Remove the cover plug (if used) in the male connector of the unit to

which you are connecting this module.

2. Position the module on the 35 x 7.5 mm DIN rail A (A-B pt. no.

199-DR1).

3. Rotate the module onto the DIN rail with the top of the rail hooked

under the lip on the rear of the module.

1797-CEC

4. Press down to lock the module on the DIN rail.

Publication

1797-5.13 - June 2010

Page 7

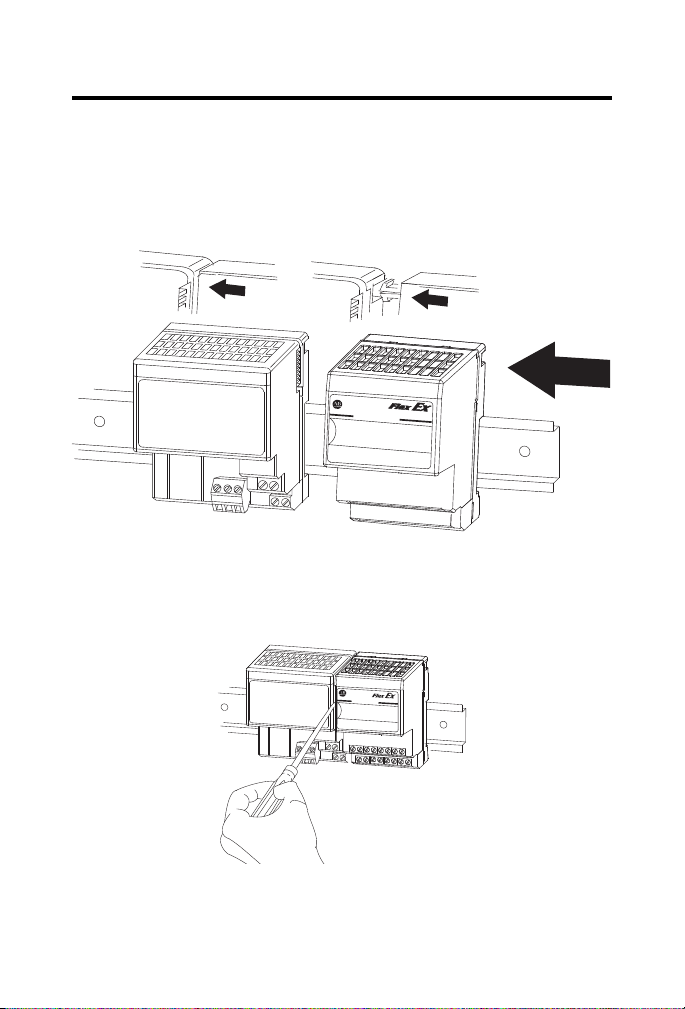

FLEX Ex Bus Isolator and Flexbus Connector 7

42643

1797-CEC

42644

If the module does not lock in place, use a screwdriver or similar

device to move the locking tab down, press the module flush with the

DIN rail and release the locking tab to lock the module in place.

5. Firmly push the module into the adjacent module or terminal base

until the units lock together.

1797-CEC

6. To remove the 1797-CEC module, you must work from the right side

and remove one module at a time. To disengage a module from its

neighbor, place a common, flat-bladed screwdriver between the two

modules and turn 1/4 turn to separate the modules.

7. Then slide the module away from its left neighbor, and release the

locking lever to remove the module from the DIN rail.

Publication

1797-5.13 - June 2010

Page 8

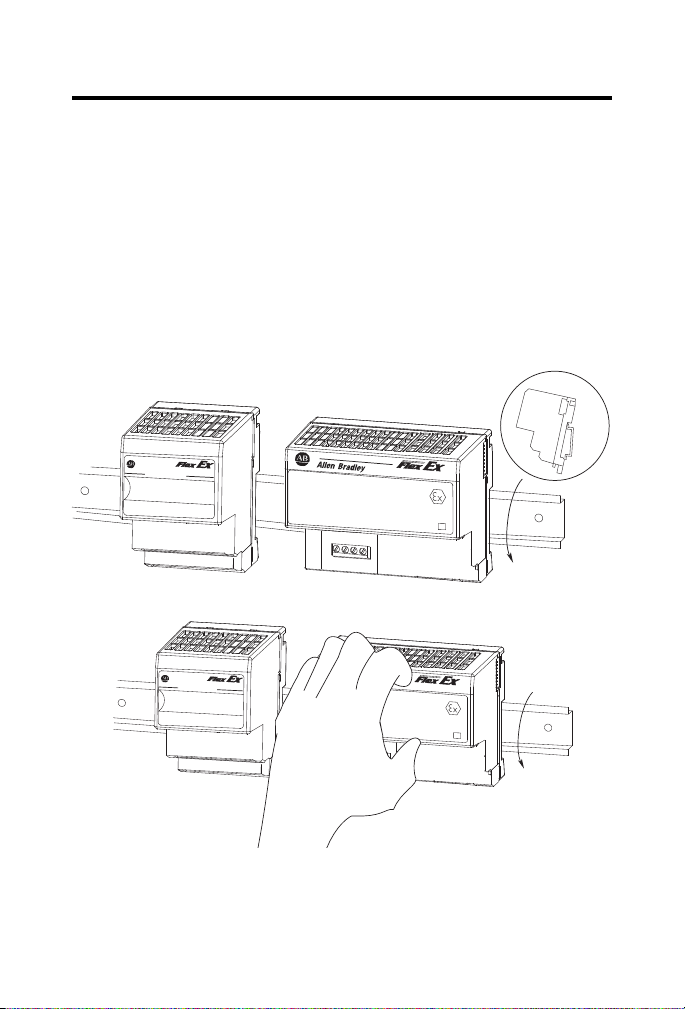

8 FLEX Ex Bus Isolator and Flexbus Connector

42645

A

A

1797-CEC

1

3

2

4

+V

+V

-V

-V

PWR

FLEXBUS

ISOLATOR

1797-BIC

42646

Install the 1797-BIC Module

The 1797-BIC module mounts on a DIN rail. It connects to a 1797-CEC

module.

1. Remove the cover plug (if used) in the male connector of the unit to

which you are connecting this module.

2. Position the module on the 35 x 7.5 mm DIN rail A (A-B pt. no.

199-DR1).

3. Rotate the module onto the DIN rail with the top of the rail hooked

under the lip on the rear of the module.

1797-CEC

+V

-V

+V

1

2

3

4

1797-BIC

FLEXBUS

ISOLATOR

PWR

-V

4. Press down to lock the module on the DIN rail.

If the module does not lock in place, use a screwdriver or similar

device to move the locking tab down, press the module flush with the

DIN rail, and release the locking tab to lock the module in place.

Publication

1797-5.13 - June 2010

Page 9

FLEX Ex Bus Isolator and Flexbus Connector 9

WARNING

1797-CEC

1

3

2

4

+V

+V

-V

-V

PWR

FLEXBUS

ISOLATOR

1797-BIC

42647

5. Firmly push the module into the adjacent module/terminal base until

the units interconnect.

6. Install DIN rail locks (supplied with the 1797-BIC module) to meet

shock and vibration specifications as listed on page 20.

7. To remove the 1797-BIC module, remove the DIN-rail locks and then

slide the module away from its left neighbor, and release the locking

lever to remove the module from the DIN rail.

Do not remove the 1797-CEC or 1797-BIC modules under power.

Removing these modules under power will break the electrical

backplane (flexbus) connections. This can cause personal injury or

property damage by:

sending an erroneous signal to your system’s field devices

causing unintended machine motion.

causing an explosion in a hazardous environment.

breaking communication to modules beyond this module.

Publication

1797-5.13 - June 2010

Page 10

10 FLEX Ex Bus Isolator and Flexbus Connector

WARNING

Installation in Zone 2

The 1797-CEC and 1797-BIC modules must not be exposed to the

environment. These modules have a protection factor of IP20. Provide a

suitable metal enclosure.

The 1797-BIC module cannot be used as an associated apparatus

after its FLEX Ex backplane connector has been exposed to

nonintrinsically safe signals.

Installation in Zone 22

When the modules are installed in Zone 22, the following cabinets must be

used: IVK-ISRPI-V16LC; IVK-ISRPI-V8HYW; or IVK-ISRPI-V8LC. These

cabinets can be purchased from:

Pepperl+Fuchs GmbH

Lilienthalstrasse 200

68307 Mannheim, Germany

Attn: PA Sales Dept.

Kirsten Becker

Telephone +49 776 1298

www.pepperl-fuchs.com

The IS-RPI cabinets (type IVK2-ISRPI-V8LC, IVK2-ISRPI-V8HYW, or

IVK2-ISPRI-V16LC) ensures the basic protection for the intrinsically safe

apparatus of the FLEX Ex system for use in Zone 22. It corresponds with

category 3D according to RL 94/9 EG and with the type label marked with

the following information:

Pepperl+Fuchs GmbH

68307 Mannheim

IVK2-ISRPI-V8LC (or IVK2-ISRPI-V8HYW or

IVK2-ISRPI-V16LC)

II 3 D Ex tD A22 IP54 T70 °C X

CE

Serial (manufacturing) number

Model

Publication

1797-5.13 - June 2010

Page 11

FLEX Ex Bus Isolator and Flexbus Connector 11

WARNING

Electrostatic Charge

Protect the system against electrostatic charge. Post a sign near this module:

WARNING Avoid electrostatic charging.

ADVERTÊNCIA! PREVENIR CONTRA O ACÚMULO DE CARGA

ELETROSTÁTICA.

For your convenience, a sign that can be cut out is included in this installation

instruction.

Removal and Insertion Under Power

Do not remove the 1797-CEC or 1797-BIC modules under power.

Removing these modules under power will break the electrical

backplane (flexbus) connections. This can cause personal injury or

property damage by:

sending an erroneous signal to your system’s field devices

causing unintended machine motion.

causing an explosion in a hazardous environment.

breaking communication to modules beyond this module.

Publication

1797-5.13 - June 2010

Page 12

12 FLEX Ex Bus Isolator and Flexbus Connector

European Communities (EC) Directive Compliance

If this product has the CE mark it is approved for installation within the

European Union and EEA regions. It has been designed and tested to meet

the following directives.

EMC Directive

These products are tested to meet the Council Directive 2004/108/EC by

applying the following standards:

EN 61000-6-4:2007, Electromagnetic Compatibility (EMC) - Part 6-4:

Generic Standard for Industrial Environments (Class A)

EN 61000-6-2:2005, Electromagnetic Compatibility (EMC) - Part 6-2:

Generic Standards - Immunity for Industrial Environments

EN61326-1:2006 (Industrial), Electrical Equipment For

Measurement, Control, and Laboratory Use - Industrial EMC

Requirements

ATEX Directive

The 1797-BIC module is tested to meet the Council Directive 94/9/EC

(ATEX) Equipment and Protective Systems Intended for Use in Potentially

Explosive Atmospheres by applying the following standards:

EN60079-11:2007, Explosive atmospheres - Part 11 : equipment

protection by intrinsic safety "i"

EN60079-0:2006, Electrical apparatus for explosive gas atmospheres -

Part 0 : general requirements

EN 60079-26 : 2004, Electrical apparatus for explosive gas

atmospheres - Part 26 : construction, test and marking of Group II

Category 1 G electrical apparatus

EN61241-0 : 2006, Electrical apparatus for use in the presence of

combustible dust - Part 0: General requirements

EN61241-11:2006, Electrical apparatus for use in the presence of

combustible dust – Part 11: Protection by intrinsic safety 'iD'

Publication

1797-5.13 - June 2010

Page 13

FLEX Ex Bus Isolator and Flexbus Connector 13

The 1797-CEC module is tested to meet the Council Directive 94/9 EC

(ATEX) Equipment and Protective Systems Intended for Use in Potentially

Explosive Atmospheres by applying the following standards:

EN 60079-15:2005, Electrical Apparatus for Potentially Explosive

Atmospheres - Type of Protection “n”

FM Compliance

If this product has the FM mark, it has been designed, evaluated, tested, and

certified to meet the following standards:

FM C1. No.3600:1998, Electrical Equipment for Use in Hazardous

(Classified) Locations General Requirements

FM C1. No.3610:1999, Intrinsically Safe Apparatus and Associated

Apparatus for Use in Class I, II, III Division 1 Hazardous (Classified)

Locations

FM C1. No.3615:1989, Explosionproof Electrical Equipment General

Requirements

FM C1. No.3810:1989, 1995, Electrical and Electronic Test,

Measuring and Process Control Equipment

ANSI/NEMA 250, 1991, Enclosures for Electrical Equipment

USL Compliance

If this product has the UL mark, it has been designed, evaluated, tested, and

certified to meet the following standards:

UL 913, 5th Edition, Intrinsically Safe Apparatus and Associated

Apparatus for Use in Class I, II, III, Division 1, Hazardous

(Classified) Locations

UL 1604, 3rd Edition, Electrical Equipment for Use in Class I and II,

Division 2, and Class III Hazardous (Classified) Locations

UL 1203, 2nd Edition, Explosion-Proof and Dust-Ignition-Proof

Electrical

Equipment for Use inHazardous (Classified) Locations

UL 2279, 1st Edition, Electrical Equipment for Use Class I, Zone 0, 1,

and 2 Hazardous (Classified) Locations

Publication

1797-5.13 - June 2010

Page 14

14 FLEX Ex Bus Isolator and Flexbus Connector

UL 508, 17th Edition, Standard for Industrial Control Equipment

Switches

Publication

1797-5.13 - June 2010

Page 15

FLEX Ex Bus Isolator and Flexbus Connector 15

1797-CEC 1797-BIC

Flexbus FlexbusFlexbus

PWR

Limit

Bus

Bus

+V

-V

Standard

Power

Source

41693

FLEX Ex

Bus

IS Flexbus

IS Flexbus

CNL Compliance

If this product has the cUL mark, it has been designed, evaluated, tested, and

certified to meet the following standards:

CAN/CSA C22.2 No. 157-92, Intrinsically Safe and Non-Incendive

Equipment for Use in Hazardous Locations

CAN/CSA C22.2 No. 30-M1986, Explosion-Proof Enclosures for

Use in Class I Hazardous Locations

CAN/CSA E79-0-95, Electrical apparatus for explosive gas

atmospheres - Part 0: General requirements

CAN/CSA E79-11-95, Electrical apparatus for explosive gas

atmospheres - Part 11: Intrinsic safety "i"

CAN/CSA C22.2 No. 14-95, Industrial Control Equipment

CAN/CSA E79-15-95, Electrical apparatus for explosive gas

atmospheres - Part 15: Electrical Apparatus with Type of

Protection "n"

Inputs and Outputs

Do not apply any noninstrinsically safe signals to the FLEX Ex backplane

connector.

When using as an intrinsically safe electrical apparatus according to EN

60079-11, the European directives and regulations must be followed.

Publication

1797-5.13 - June 2010

Page 16

16 FLEX Ex Bus Isolator and Flexbus Connector

ATTENTION

WARNING

42648

41297

Wire the Isolator Module

When connecting wiring, torque terminal screws to 0.8…1.0 Nm

(7…9 lb-in).

B-A

Allen-Bradley

QUALITY

3

12 4

+V -V +V -V

Make certain that you power this device with normal 24V dc. Do not

use an intrinsically-safe power supply, such as the 1797-PS2E or

1797-PS2N, to power this module.

If you connect or disconnect wiring while the field-side power is on,

an electrical arc can occur. This could cause an explosion in

hazardous location installations. Be sure that power is removed or

the area is nonhazardous before proceeding.

1. Apply +V and -V power (24V dc) to the adapter through a removable

terminal block.

1797 - BIC

FLEXBUS

ISOLATOR

POWER

+V -V +V -V

Screw terminals and spring terminals are provided.

Publication

1797-5.13 - June 2010

+V -V +V -V

Page 17

FLEX Ex Bus Isolator and Flexbus Connector 17

ATTENTION

1794-NM1

Mounting Kit with

18 screws (2 screws for the

adapter and 2 screws for

each module).

30238

2. Strip the +V and -V wires to a length so no bare conductor shows

after inserting the wires into position (+V, -V).

3. If you are using the spring terminals of the plug, insert a screwdriver

into the slot and carefully pry until the spring clamp opens to accept

the wire.

4. Connect either a 1797-TB3 terminal base, a 1794-CE1 cable, or a

1794-CE3 cable onto the FLEX Ex backplane connector of the

1797-BIC module.

The FLEX Ex backplane connector cover must remain in place until a

FLEX Ex terminal base or cable is connected to the 1797-BIC module.

Indicators

The 1797-BIC isolator module provides a power indicator to show power has

been applied to the module.

About the Mounting Kit

Use the optional 1794-NM1 mounting kit to mount your system on a panel or

wall without a DIN rail.

Publication

1797-5.13 - June 2010

Page 18

18 FLEX Ex Bus Isolator and Flexbus Connector

ATTENTION

42649

mm (in.)

75

(2.95)

87

(3.4)

94

(3.7)

Dimensions for Mounting the 1797-BIC Isolator Module

1797-BIC

FLEXBUS

ISOLATOR

+V

-V

+V

1

2

3

PWR

-V

4

The DIN rail or mounting bracket must be appropriately connected to

the dedicated intrinsic safety ground.

Repair

The 1797-BIC isolator module is not field-repairable. Any attempt to open

the module will void its warranty and the IS certification. If repair is necessary,

return the module to the manufacturer.

Publication

1797-5.13 - June 2010

Page 19

FLEX Ex Bus Isolator and Flexbus Connector 19

ATTENTION

42650

mm (in.)

69

(2.72)

80

(3.15)

55

(2.17)

Dimensions for Mounting the 1797-CEC Flexbus Connector

1797-CEC

The DIN rail or mounting bracket must be appropriately connected to

the dedicated intrinsic safety ground.

Repair

The 1797-CEC Flexbus Connector module is not field-repairable. Any

attempt to open the module will void its warranty. If repair is necessary, return

the module to the manufacturer

Publication

1797-5.13 - June 2010

Page 20

20 FLEX Ex Bus Isolator and Flexbus Connector

Specifications

Table 1 1797-BIC Flex Ex Bus Isolator

Attribute Valu e

I/O module capacity

Indicators Power - green when power is applied

Isolation path

Flexbus to Flexbus

Flexbus slave side

to power supply

Power consumption 18…32V dc @ 0.15 A

Power source failure

Max input

Power dissipation 2.1 W

Thermal dissipation 7.2 BTU/hr

IS module type [Ex ib] IIC

Conductor wire size

Weight Approx. 200 g

Environmental conditions

Operational temperature

Storage temperature -40…85 °C (-40…185 °F)

Relative humidity 5…95% noncondensing

Shock operating Tested 30 g peak acceleration, 11 (±1) ms pulse width

nonoperating Tested 30 g peak acceleration, 11 (±1) ms pulse width

Vibration Tested 5 g @ 10…500 Hz per IEC 68-2-6

Output (intrinsically safe)

(16 pin male flexbus

connector)

CENELEC

Output (intrinsically safe)

(16 pin male flexbus

connector)

FM and cULus

8 FLEX Ex modules

Galvanic to DIN EN 60079-11

Galvanic to DIN EN 60079-11

Um = 253V ac

4 mm2 (12 gauge) stranded max

1.2 mm (3/64 in.) insulation max

-20…70 °C (-4…158° F)

Uo< 5.75V dc

Io< 400 mA

Po< 2.05 W

Lo< 100 H

Co< 39 F

Vt< 5.75V dc

It< 398.25 mA

Ca< 39.67 F

La< 210 H

(1)

Publication

1797-5.13 - June 2010

Page 21

FLEX Ex Bus Isolator and Flexbus Connector 21

Attribute Valu e

Agency certification Marking and classification

FM Nonincendive, use for Class I, Division 2 Groups A, B, C

and D. Provides Intrinsically safe outputs to Class I,

Division 1, Groups A, B, C and D when installed in

accordance with Control Drawing No. 1797-6.5.6

UL, C-UL Associated Apparatus, Class I, Division 2, Groups A, B,

C, and D Hazardous Locations; Class I, Zone 2,

AEx nA[ia] IIC, Ex nA[ia] IIC T4 (Ta = 70 °C) when

installed in accordance with Control Drawing No.

1797-6.5.6

INMETRO [BR-Ex ib] IIC

Approval marks and certification number

EXAM (ATEX)

DMT 00 ATEX E056

UL, C-UL

File No.: E197983

FM

INMETRO

IECEx

05/UL-BRAE-0010

IECEx BVS 09.0025

Declaration of conformity Marking

Directive 89/336/EEC (EMC)

Directive 94/9 EC (ATEX) II (2) G [Ex ib] IIC

II (2) D [Ex ibD]

II 3G Ex nA IIC T4 X

IECEx [Ex ib] IIC

IEC temp code T4

1 A total of eight I/O modules can be attached to a 1794 FLEX I/O adapter. The 1797-CEC and 1797-BIC

modules are not included in this number. In intermixed systems, the number of 1797 FLEX Ex I/O

modules (attached onto the 1797-BIC module) plus the number of 1794 FLEX I/O modules (connected

between the adapter and the 1797-CEC module) cannot exceed eight.

Publication

1797-5.13 - June 2010

Page 22

22 FLEX Ex Bus Isolator and Flexbus Connector

Table 2 Flexbus Connector - 1797-CEC

Attribute Value

Indicators Not applicable

Weight Approx. 100 g

Environmental conditions

Operational temperature

Storage temperature

Relative humidity 5…95% noncondensing

Shock operating Tested 30 g peak acceleration, 11 (±1) ms pulse width

nonoperating Tested 30 g peak acceleration, 11 (±1) ms pulse width

Vibration Tested 5 g @ 10…500 Hz per IEC 68-2-6

Agency certification Marking and classification

UL, C-UL Class I, Division 2, Groups A, B, C, and D Hazardous

UL, C-UL

-20…70 oC (-4…158 oF)

-40…85 oC (-40…185 oF)

FM Nonincendive, use for Class I, Division 2 Groups A , B,

C, and D Hazardous Locations;. A temp rating of T4

applies with Ta = 70 °C.

Locations; Class I, Zone 2, AEx nA IIC, Ex nA IIC T4

(Ta = 70 °C)

Approval mark and certificate number

File No.: E197983

FM

Declaration of conformity Marking

Directive 89/336/EEC (EMC)

Directive 94/9 EC (ATEX) II 3G Ex nA IIC T4 X

Publication

1797-5.13 - June 2010

Page 23

FLEX Ex Bus Isolator and Flexbus Connector 23

Nonhazardous or Hazardous

(Classified) Location

Class I, Zone 2, Group IIC or

Class I, Division 2, Groups A to D

Nonhazardous or Hazardous

(Classified) Location

Class I, Zone 1, Group IIC or

Class I, Division 1, Groups A to D

42876

.

.

Nonhazardous or Hazardous

(Classified) Location

Class I, Zone 2, Group IIC or

Class I, Division 2, Groups A to D

Nonhazardous or Hazardous

(Classified) Location

Class I, Zone 1, Group IIC or

Class I, Division 1, Groups A to D

42877

CENELEC Information

The isolator type 1797-BIC/* module is an associated apparatus according to

EN 60079-11. If the isolator is connected to intrinsically-safe circuits the

applicable national local construction, installation and operating regulations

must be heeded (in Germany DIN EN 60079-11, DIN VDE 0165).

UL Information

Diagram 1

Diagram 2

.

Publication

..

1797-5.13 - June 2010

Page 24

24 FLEX Ex Bus Isolator and Flexbus Connector

IMPORTANT

Isolator Restriction

1797-BIC and -CEC Max of 8 I/O modules

I/O module capacitance value is cumulative. Ci (total) = Ci (I/O module

1) + Ci (I/O module 2) + ...Ci (I/O module 8). Ci (total) must be less than

F. The limitation of eight I/O modules per isolator is a functional

65

limitation. Refer to table 2 of the appropriate I/O Modules sections in this

document (1797-6.5.6).

Application

The isolator type 1797-BIC/* module functions as a galvanic isolation barrier

for signals between a nonintrinsic backplane bus and an intrinsic safe

backplane bus. The isolator must be installed in a safe or Zone 2 area.

Cover Plug for IS Backplane Bus

The 16-pole male connector for the FLEX Ex IS backplane bus is provided

with a cover plug. The cover plug can only be removed when a 1797-TB3

terminal base, a 1794-CE1 cable or a 1794-CE3 cable is connected. The

connection must not be connected to any signals that exceed the instrinsically

safe values of the IS backplane.

Power Supply

The isolator is powered via a removable terminal connector with a dc-voltage

between 18V and 32V. Due to a failure in the power supply a maximum

voltage U

of 253V ac is permitted.

m

Publication

For detailed certification information, refer to the FLEX Ex

System Certification Reference Manual, publication

1797-6.5.6.

1797-5.13 - June 2010

Page 25

FLEX Ex Bus Isolator and Flexbus Connector 25

WARNING Avoid electrostatic charging.

ADVERTÊNCIA! PREVENIR CONTRA O ACÚMULO

DE CARGA ELETROSTÁTICA.

Publication

1797-5.13 - June 2010

Page 26

26 FLEX Ex Bus Isolator and Flexbus Connector

Notes:

Publication

1797-5.13 - June 2010

Page 27

Notes:

FLEX Ex Bus Isolator and Flexbus Connector 27

Publication

1797-5.13 - June 2010

Page 28

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in using

its products. At http://support.rockwellautomation.com

manuals, a knowledge base of FAQs, technical and application notes, sample code and

links to software service packs, and a MySupport feature that you can customize to

make the best use of these tools.

For an additional level of technical phone support for installation, configuration, and

troubleshooting, we offer TechConnect Support programs. For more information,

contact your local distributor or Rockwell Automation representative, or visit

http://support.rockwellautomation.com

.

Installation Assistance

If you experience a problem with a hardware module within the first 24 hours of

installation, please review the information that's contained in this manual. You can also

contact a special Customer Support number for initial help in getting your module up

and running.

United States 1.440.646.3434 Monday – Friday, 8am – 5pm EST

Outside United States Please contact your local Rockwell Automation representative for

any technical support issues.

New Product Satisfaction Return

Rockwell tests all of its products to ensure that they are fully operational when shipped

from the manufacturing facility. However, if your product is not functioning, it may

need to be returned.

United States Contact your distributor. You must provide a Customer Support case

number (see phone number above to obtain one) to your distributor

in order to complete the return process.

Outside United States Please contact your local Rockwell Automation representative for

return procedure.

Allen-Bradley, Rockwell Automation, ControlLogix, RSLinx, TechConnect, and FLEX I/O are trademarks of

Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

, you can find technical

Publication 1797-5.13 - June 2010 PN-79498

Supersedes Publication 1797-5.13 - February 2007 Copyright © 2010 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

Loading...

Loading...