Page 1

Installation Instructions

Bulletin 1494F Disconnect Switch and Accessory Kits for Bulletins 502, 502L,

506, 512, 522, 1232X and 1494G

WARNING: To prevent electrical shock, disconnect from power source before installing or servicing. Follow NFPA 70E requirements. Install in suitable enclosure. Keep free from

contaminants.

The following procedures are critical to the proper operation of the disconnect handle and switch. Failure to follow these steps can result in damage to the equipment and / or serious

injury or death to the operator.

Installation, adjustments, putting into service, use, assembly, disassembly, and maintenance shall be carried out by suitably trained personnel in accordance with applicable code of

practice. In case of malfunction or damage, no attempts at repair should be made. The product should be returned to the manufacturer for repair. Do not dismantle the product.

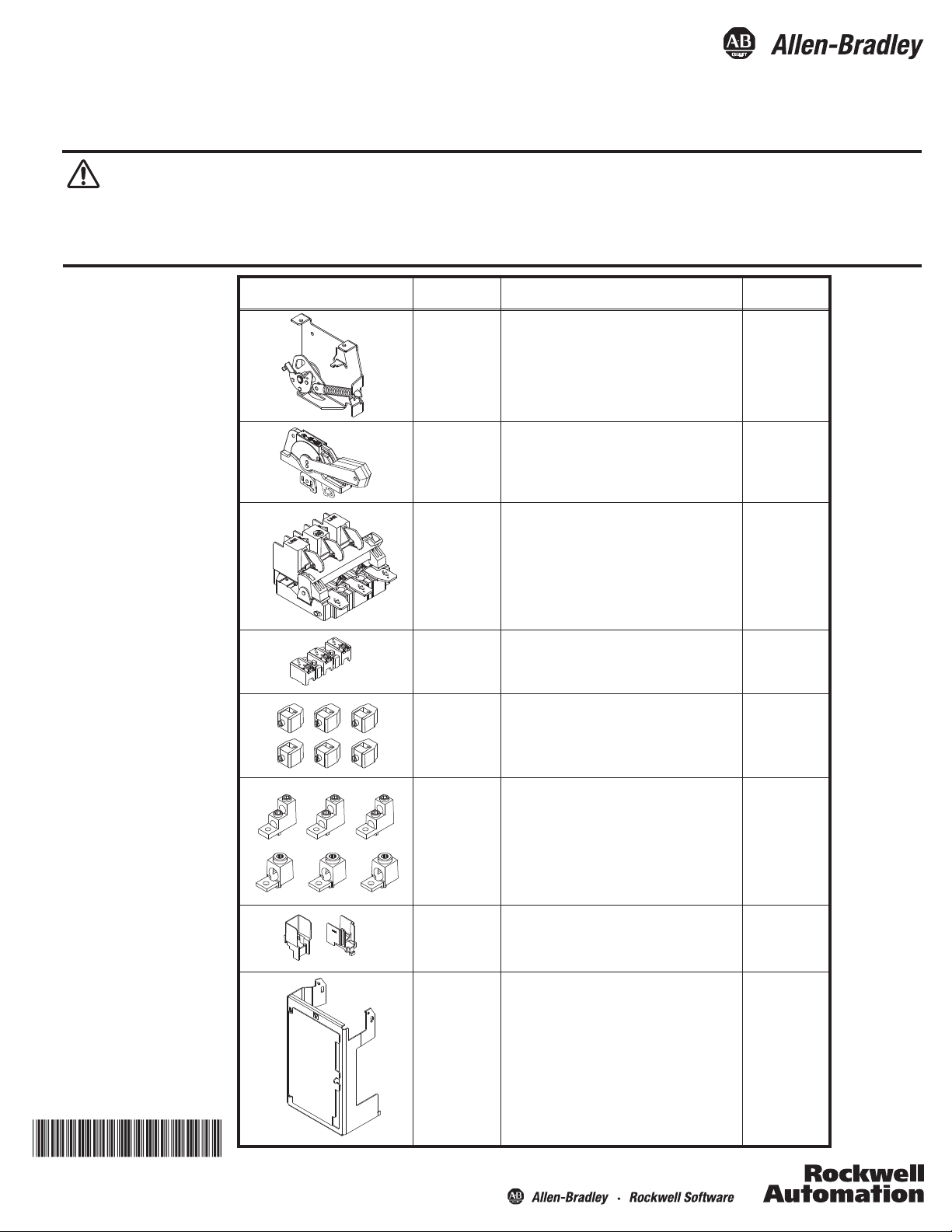

Disconnect Kit Cat No. Description

1494F-MS400 5400 Amp Mechanism

1494F-M2

1494F-S2

1494F-D400 5400 Amp Switch

1494F-FS400 5400 Amp Fuse Block

1401-N46

1401-N45

1401-N54

1401-N55

7-1/2" Painted Metal Handle

7-1/2" Stainless Steel Handle

Fuse Clip, Class H, J, 400A - 250V, 400A - 600V

Fuse Clip, Class H, J, 200A-250V, 200A-600V

Fuse Clip, Class R, 200A-250V, 200A-600V

Fuse Clip, Class R, 400A-250V, 400A-600V

NEMA Starter

Size(s)

5

5

5

5

5

5

42052-105-01

DIR 42052-105 (Version 03) Publication 1494F-IN014C-EN-E - January 2013

Copyright © 2013 Rockwell Automation, Inc. All Rights Reserved. Printed in USA.

1494R-N14

1494R-N15

1494F-PH5 400 Amp Phase Barrier 5

1495-N68

Lug Connector: Wire Size (2) #1/0 - 250 MCM

Lug Connector: Wire Size #4 ... 500 MCM

5

5

5Fuse Cover with Door

Page 2

2

Bulletin 1494F Disconnect Switch and Accessory Kits

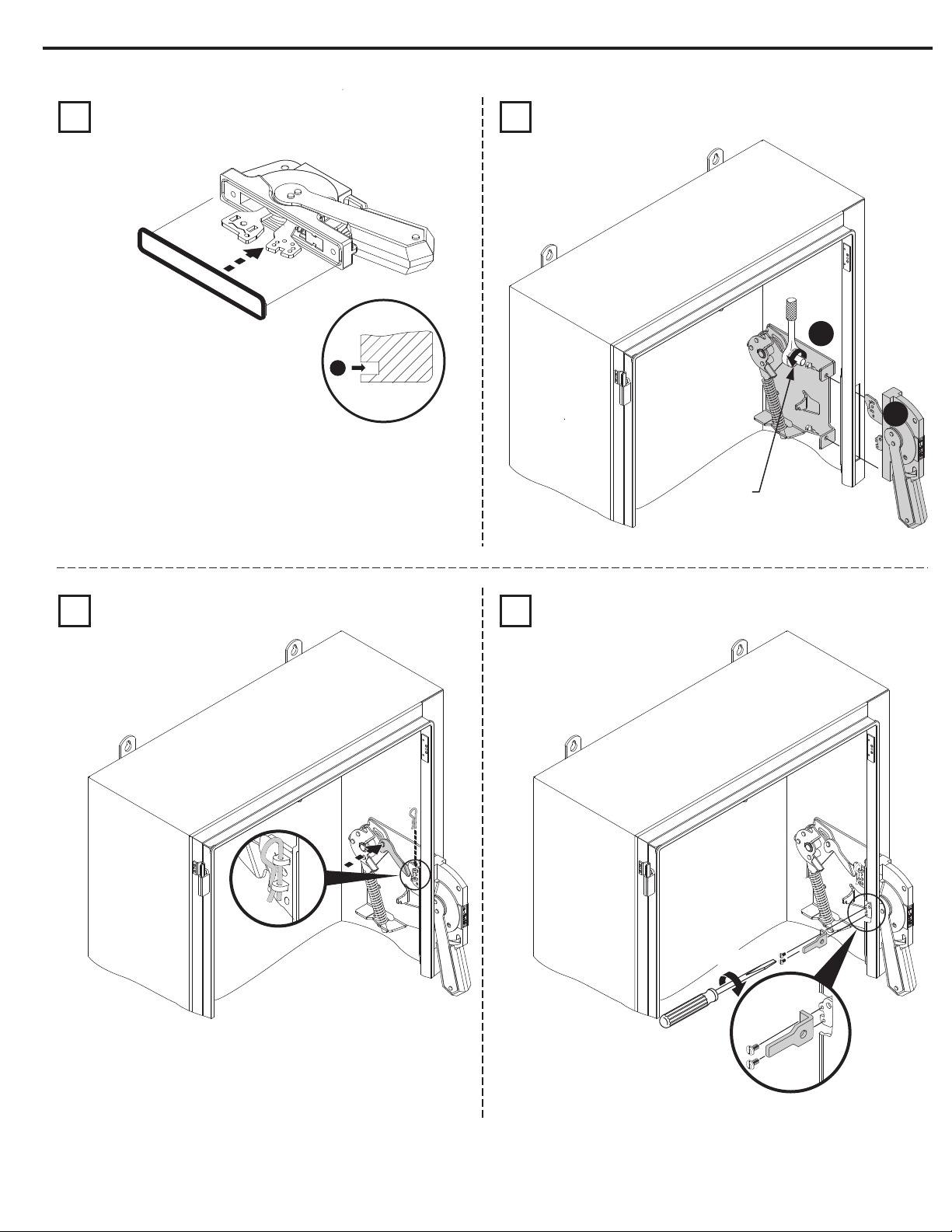

Operating Mechanism and Handle Installation

1 2

IMPORTANT: Apply grease to O-Ring

seal to retain into handle groove.

3 4

2

1

60 - 80 lb-in

8 lb-in

Publication 1494F-IN014C-EN-E - January 2013 42052-105-01 DIR 42052-105 (Version 03)

Page 3

Operating Mechanism and Handle Installation (Cont’d)

5

1

2

3Bulletin 1494F Disconnect Switch and Accessory Kits

Disconnect Switch Installation

1 2

90 - 130 lb-in

IMPORTANT: Move operating handle to “ON” position

after assembly to ensure the proper engagement of the

disconnect switch cross bar to the handle operating

mechanism.

LINE TERMINAL GUARD

Publication 1494F-IN014C-EN-E - January 2013 42052-105-01 DIR 42052-105 (Version 03)

Page 4

4

Bulletin 1494F Disconnect Switch and Accessory Kits

Trailer Fuse Block Installation

Note: Not required for non-fusible disconnect switch applications.

1. Refer to the gures and chart below to determine the position on the mounting plate and the orientation of

the trailer fuse block.

400 Amp Disconnect Switch

and Trailer Fuse Block on a

NEMA Size 5 Combination Starter

Position 1

Position 2

Position 3

Position 4

Position 5

Position 6

Position

3

5

1

4

6

2

Amps

200

200

200

400

400

400

Voltage

250

600

600

250

600

600

Fuse Class

H/R

H/R

J

H/R

H/R

J

90 - 130 lb-in

Publication 1494F-IN014C-EN-E - January 2013 42052-105-01 DIR 42052-105 (Version 03)

Page 5

Phase Barrier and Fuse Clip Installation

5Bulletin 1494F Disconnect Switch and Accessory Kits

Amp

Rating

400

400 Amp Rating

Phase Barrier

Catalog Number

1494F-PH5

1

21

1

2

2

Click

200A Clips

16 - 22 lb-in

400A Clips

22 - 37 lb-in

43

2

1

200A Clips

22 - 37 lb-in

400A Clips

40 - 50 lb-in

Publication 1494F-IN014C-EN-E - January 2013 42052-105-01 DIR 42052-105 (Version 03)

Page 6

Fuse Cover Installation

Cat 1495-N68

Non-Fused

200 A, 250 V, Class H, R Fuses

200 A, 600 V, Class H, J, R Fuses

400 A, 250 V, Class H, R Fuses

400 A, 600 V, Class H, J, R Fuses

1

2

2

1

Testing of Disconnect Switch

1. Verify that both the disconnect switch and the disconnect handle are in the OFF position. (the disconnect switch can be moved into the

OFF position by moving the crossbar downward (counter-clockwise) so that the blades are exposed).

2. To test that the disconnect switch and the mechanism are properly aligned. Verify that the disconnect switch can be turned on by

moving the defeater lever downward and moving the disconnect handle to the ON position (the blades should enter the disconnect

switch arc hood).

3. Verify that the disconnect switch can be turned o by moving the disconnect handle to the OFF position (the blades should exit the

disconnect switch arc hood).

Click

Allen-Bradley, Rockwell Software, and Rockwell Automation are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication 1494F-IN014C-EN-E - January 2013

Copyright © 2013 Rockwell Automation, Inc. All Rights Reserved. Printed in USA.

DIR 42052-105 (Version 03)

42052-105-01

Loading...

Loading...