Page 1

69

BULLETIN

INSTRUCTIONS 1494D

I

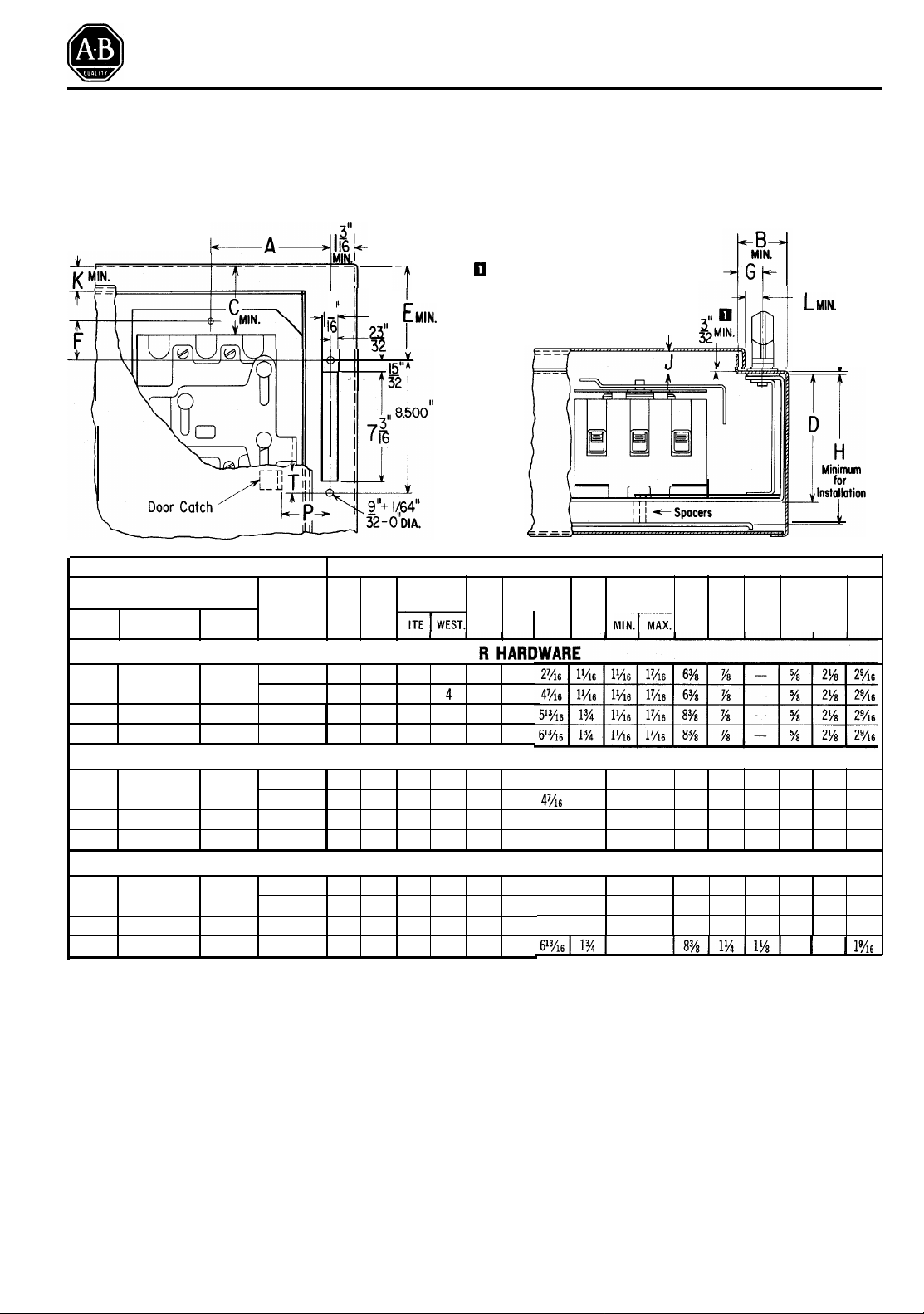

FLANGE MOUNTED CIRCUIT BREAKER OPERATORS

FOR 100, 225 AND 400 AMPERE FRAMES

ENCL

OSURE CONSTRUCTION

k---A--dL

I ’

Ii

7 ’

5I 23

:

0 3/32" minimum

T

I

37

the door to clear the flange

plate. A smaller dimension increases “G” and “B” by 3/1 6”

minimum and “L” by 3/8" min.

is required

for

-

LMIN.

L

Enclosure Flange

#10 Gauge Max.

Circuit Breaker

Frame Size

AmperesWestinghouse ITE

Maximum

Current A

Rating

(Amperes)

ITE WEST.

B

C

WITHOUT DOO

5

4

100 EB, EHB, FB E, EF, EH 70

225

JA, KA FJ

400 LB,LBB, HLB

-

150 4

225 3

400 3

/16 21/4 2 2 415/16 21/2

5

1

/

/16 2

/4 4

1

1

/8

2

/4 5 5 615/16 5

7

/8 21/4

-

6 6

SMALL & INTERMEDIATE ENCLOSURES WITH DOOR HARDWARE

100 EB,EHB,FB E,EF,EH

225

JA, KA FJ

400

LB,LBB,HLB

-

70

150

225

400

5

4

/16 29/16 2 2 415/16 21/2 21/16 11/16 13/8

5

4

/16 29/16 4 4 415/16 41/2 d7/16 11/16 13/8 63/8 7/8

7

3

9

3

/8

2

/16 5 5 615/165

7

/8 29/16

-

LARGE ENCLOSURES WITH DOOR HARDWARE

100

EB, EHB, FB E,EF, EH

225 JA, KA FJ 225

400 LB,LBB,HLB

- 400

70 4

150 4

5

/16 29/16 21/4 25/16 415/16 23/4

5

9

4 4

2

/16

/16

7

3

/8 29/16 5 5 613/165

7

3

/8 29/16

-

INSTRUCTIONS

NOTE: The circuit breakers are not supplied with these

kits and are shown only for convenience.

1. Select the table which applies to your enclosure.

2. Determine the enclosure flange width “B” and the

mounting depth “H” to ensure the cabinet is at least as

large as these minimum values.

3. Refer to N.E.C. for required wire bending space, Di-

mension “C”. The minimum value given for “C” is the

minimum wire bending space for the maximum wire

size that can be connected to each circuit breaker for

its current rating.

Dimensions in Inches

E G

D

F H J K L P T

15

4

/16 41/2

13

/16

15

/16

-

13

6 6

6 6

13

/16 5

15

/16

15

4

/16

15

/16

13

-

6

3

2

7

1

4

4

/2

13

13

/16

5

-

1

/16 13/4

/16 13/4

/4 11/16 13/8 63/8 11/4 11/8 5/8 21/4 19/16

/16 11/16

3

/16

1

/4

4. Provide slot and mounting holes on the right hand

flange as indicated.

5. Provide spacer brackets for the circuit breaker mount-

ing plate as shown. Typical spacer brackets are shown

on Page 2. Please note notch and clearance holes required for slide assembly.

6. Locate door catch using

enclosures using door hardware disregard the door

catch supplied with operating mechanism. Instead, use

door catch furnished with door hardware, and refer to

Page 4 for additional door catch instructions.

3

6

/8 7/8 11/16

3

7

7

/8

/8

/8

6

3

1

/8 67/8 7/8 11/16 5/8 21/8

3

1

/8 63/8 11/4 11/8

3

1

/8 83/8 11/4 11/8 5/8 2

3

1

/8

"P"

and “T”. NOTE: With

5

11

/8 25/32 21/8

/16 5/8 25/32 21/8

11

/16 5/8 25/32 21/8

5

/8 21/4

1

/4

5

/8 21/4

2

1

1

1

9

/16

9

/16

9

/16

1%6

Publication 1494D-5.0-December 1975

1494D-800Supersedes Instructions

41494D-80

Dated June, 1970

Page 2

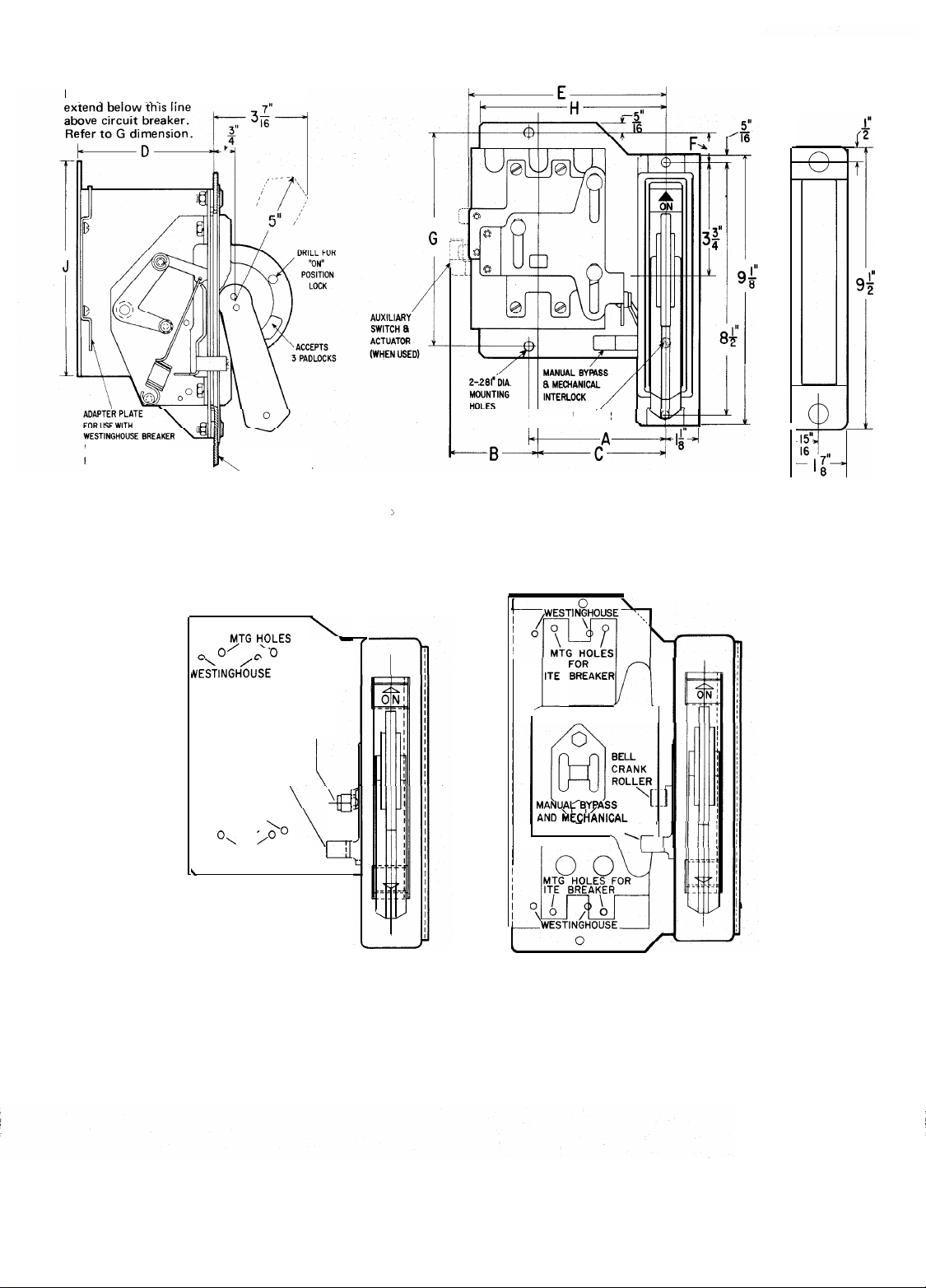

Metal Darts must not

extend below this line

;;pFs3;J

WITH AN EB, EHB OR FB

FRAME ONLY

ENCLOSURE FLANGE

10 GAUGE MAX

OPERATOR AND SLIDE MECHANISM

DEFEATER

I I

100A Frame Size Shown

FLANGE PLATE

0

ITE YTG

o”

NE&NGH<“SE

NESTINGHOUSE

0’

ITE MTG HOLES

\

H\OLES

o”

MTG

HOLES

MANUAL BYPASS

AND MECHANICAL

INTERLOCK

MTG

HOLES

O\ /O

\

‘0

0

BELL

CRANK

ROLLER

100A Frame Size

CIRCUIT BREAKER MOUNTING

.

JITE “‘AKEF~,/J

\

-El

INTERLOCK

I

225A and 400A Frame Size

\‘I-

-2-

Page 3

DIMENSIONS

Circuit Breaker

I

Frame Size

Amperes Westinghouse

100

225

400

EB,EHB,FB E,EF,EH 4

JA, KA

LB,LBB, HLB

B

ITE

FJ

A

ITE WEST ITE WEST

-

5

/16 35/16 31/4

7

-

/8

-

1 1

INSTALLATION INSTRUCTIONS

Operating Mechanism

NOTE: For ease of assembly it might be advisable to

install the circuit breaker operator and then the circuit

breaker.

1. Remove nuts and washers from flange plate.

2. Place the operating mechanism into the enclosure with

the operating handle in the ‘Off’ position. Tilt the

assembly under the flange and at the same time bring

the handle through the slot provided.

3. Place flange plate studs through the holes in the flange

and mechanism frame while holding the assembly

against the under side of flange. Secure assembly to

flange.

4. Attach operating mechanism mounting bracket firmly

to the enclosure mounting plate surface. See line

drawing Page 1 (Bolts and spacers are furnished by

user).

NOTE: It is recognized that holes in the enclosure

mounting plate surface used to secure the circuit breaker

operating mechanism can be located previous to installation. Refer to line drawings on Page 2.

Circuit Breaker Operator Mechanism

1. Place the circuit breaker Operating Mechanism handle

in the “ON” position by first pushing the defeater

by-pass lever upward and then moving the operator

handle from “OFF” to “ON”.

2. Place circuit breaker toggle lever in the “ON”

position.

3. Place circuit breaker Slide Mechanism on top of

breaker so that the slide bushings seat in the breaker

mounting holes, the toggle lever is through the slide

slot and the slot for receiving the bellcrank roller is

oriented

circuit breaker terminals, as illustrated on Page 2.

and Slide Mechanism

90” clockwise from the line side of the

- -

-

Dimensions in Inches

C

1

4

/4 41/8 415/16

7

-3

(

3

/8 43/835413435/85/1615/16 145/8

D F G H J

ITE

NOTE: Loosen adjustment plate screws on slide

mechanism, when provided.

4.

Insert the long mounting screws into the circuit

breaker mounting holes.

WESTINGHOUSE BREAKER WITH EB, EHB, or

5.

FB FRAME ONLY. Secure adapter plate provided

with Slide Mechanism Kit, onto the mounting

bracket, as illustrated on Page 2.

6.

Position circuit breaker assembly obtained in steps 3

and 4 so that the breaker line terminals are toward

the “ON” direction of the Operating Mechanism

handle and the bellcrank roller (operating mechanism) is in the bellcrank slot (slide mechanism).

Align the four circuit breaker mounting screws with

7.

the proper tapped holes in the Operating Mechanism

frame mounting surface. See illustrations on Page 2

for ITE and Westinghouse mounting.

8.

CAUTION: Position circuit breaker so that mounting

screws are perpendicular to mounting surface and

secure the breaker to Operating Mechanism frame by

tightening the mounting screws.

NOTE: The circuit breaker can be secured onto the

Operator Mechanism mounting frame either before or

after the Operator Mechanism has been secured to the

enclosure flange.

ITE BREAKER WITH FJ FRAME AND WESTING-

9.

HOUSE BREAKER WITH JA FRAME ONLY. Ad-

just the drive plate on the slide, per instructions

provided on Slide Mechanism.

10.

Move Operator Mechanism handle from “ON” to

“OFF” and then from “OFF” to “ON” to ensure

proper mechanical and electrical operation.

CAUTION: Place Operator Mechanism handle in

11.

“OFF” position before installation of wiring, for

maximum safety.

E

WEST.

9

6

/16 63/8 11/16 73/16

7

1 1 1 1 1

3

1

/4

10

1

6

/4

7

/8 6 11

I

13

7

/16

1

/2

1

-3-

Page 4

B-jp

DOOR AND HARDWARE CONSTRUCTION

il

//j

‘I

I

Small and intermediate

1

Enclosures

I

Lat.

Nos.1494F-L1

i:

A!-

Large Enclosures

(Cat. No. 1494F-L4

Hardware Kit)

M

il

-++B

~-------_-_-____

-------------

Frame Size

Amperes

225

W ‘estlnghouse 1 ITE

I

I

225

0:

I

JA, KA

Use with Hardware Kits 1494F-L1 (to

for 1494F-L2);

iij

‘1

I

%

Circuit Breaker

Maximum

I

Current

Rating

[ (Amperes)

LARGE ENCLOSURES

225 4

p

side

d

I

150 4

400 4

latching); 1494F-L2 (top and bottom latching); and 1494F-L3 (side latching accessory

Min.

Clearance

for 2 - #1/4-20

Holes

Dimensions in Inches

A B C D

E

ITE WEST.

Q

11

1

3

2 3 /16 3/8

1

/2 311/16 31/8 163/16 163/16 5/8 5/16 21/4 19/16

1

/2 311/16 31/8

1

3

-

13

14

1

7

17

/8 131/

/8

14

Hardware Dimensions

Kits in Inches

Catalog No. K M

1494F-L1

1494F-L2

1494F-L4

F G

5

/8 5/16

8

13

/16 5/8 5/16 21/4 19/16

3

/16

5

/8 5/16 21/4 19/16

q Use with Hardware Kit 1494F-L4 (top, side and bottom latching).

3

-

-

Min.

1

/4

-

5

6

P T

25/32

1

2

/4 19/16

2%

I

GUIDELINES

Small Enclosures: 30” high or less with 2 or 3 point latch-

ing. Intermediate Enclosures: 30” thru 48” high with 3

point latching. Large Enclosures: Above 48” high with 3

point latching.

INSTRUCTIONS

1.

Check all minimum enclosure and door dimensions

required for installation. Refer to Page 1 and above.

2. Select the dimensions from above which apply to the

roller latching arrangement to be installed.

NOTE: Door catch supplied with operating mechanism

is not to be used with these door hardware kits.

3. Locate holes in door to secure handle assembly.

4. Determine Dimensions “B” and “C” to locate locking

bar guide bracket(s).

5. Locate door catch using “P” and “T” dimensions. Location varies with each hardware kit. On 1494F-L4

hardware kits, attach the adjustable catch after the

support bracket is located. NOTE: Door catch and

guide bracket(s) are made with projections for welding

to the enclosure door. However, if a specific installation permits, holes can be drilled in the door catch and

guide bracket(s) using the projections as centers. Then,

after proper location and using them as templates,

corresponding holes can be drilled in the enclosure

door. Door catch and guide bracket(s) are then fastened to the enclosure door with hardware furnished

by user.

6. Establish the length of the top locking bar by meas-

uring Dimensions “E” and subtracting 3/4" for Kits L1

and L2; subtract 1-1/8" for Kit L4. Determine the

l

ength of the bottom locking bar by measuring Dimen-

sion “K” and subtracting 3/4" for Kit L2; subtract

l-l/8" for Kit L4. Dimension “H” is determined by

measuring Dimension “D” and adding 3-3/4" for Kits

L1 and L2; add 3-5/8" for Kit L4. Locate, drill, and

tap holes where necessary. NOTE: These standard mill

rectangular locking bars are not supplied with these

kits.

7. The door locking hardware assembly can now be attached to the door.

Page 5

INSTALLATION OF DOOR HARDWARE KITS

Enclosure

Size

Small

and

Intermediate

Large

Hardware

Kits

Catalog No.

1494F-L1

1494F-L2

1494F-L3

1494F-L4

INSTRUCTIONS

Locking Bar(s) and Handle Assembly

Using the roller latching arrangement to be installed and

the locking bar(s) prepared as specified on Page 4 proceed

as follows:

1.

Insert cam bearing(s) into the cam plate hole(s), insert

locking bar(s) in the cam bearing slot(s) and secure b

using the pin(s) provided. See above. NOTE: An alternate method requires using the screw(s) and nut(s) also

provided.

2. Remove door handle and cover plate from the handle

assembly.

removed from assembly

3. Slide locking bar(s) attached to the cam assembly

through the slot in the guide bracket(s) located on the

enclosure door.

NOTE: Rubber sealing gasket should not be

.

Dimensions

A

1

1%

Degrees

in Inches

B C

4

6

65

75

y

4. Insert cover plate studs through holes in door and

secure to cam assembly

5. Replace handle.

NOTE: An alternate method of assembly requires that the

.

handle assembly beinstalled first and then attach locking

bar(s) to the cam plate.

Roller Assembly and Defeater Actuator Lever

Attach top roller assembly and bottom roller assembly

(when used) to the locking bar(s). A slotted hole on

roller assembly provides adjustment to insure proper

gasket sealing when enclosure dimensional variation

are encountered.

Fasten side roller assembly (when used) to the cam

plate using various shims supplied. Nominal enclosure

dimensions will require one (1) 1/8" shim

Attach the defeater actuator lever to the upper locking

bar. Refer to inset for assembled view as seen from

inside of enclosure. The two screws should be located

near the center of the adjustment slot. Refer to Dimension “A”. Further adjustment may be required after

disconnect switch is installed

.

.

Door Hardware Adjustments

With the operating handle mechanism secured to the

flange in the “Off” position and the door hardware attached to the door proceed as follows:

1.

Close enclosure door and slowly turn the handle to the

right (counterclockwise) until the first notch on the

cam plate is engaged. At this point positive gasket seal

should be obtained with proper roller adjustment.

When seal is obtained further adjustment to the defeater actuator lever may be required if the operator

mechanism handle can be moved to the “On” position.

Rotate door handle further to the right. Relocate

2.

defeater actuator lever if necessary, so that the operating handle mechanism “On” position occurs well

before the fully latched (vertical) door handle position.

3.

With the operating handle in the “Off” position, turn

recessed door defeater screw, hold and simultaneously

turn handle to the left and pull. Door should open.

Close door, turn door handle to fully latched position

.

4

and place disconnect switch in “On” position. Turn

recessed door defeater screw, hold and at the same

time turn door handle to the left and pull. Door should

open only partially. Maintain force on handle and turn

recessed defeater

should now open.

Close door and rotate door handle to the fully closed

5.

position. Pull out handle padlocking bar. Insertion of a

3/16" minimum to 3/8" maximum lock hasp should

prevent against movement of the door handle.

screw

in cabinet flange. The door

s

ALLEN-BRADLEY

Milwaukee, Wisconsin 53204

w

0

Loading...

Loading...