Page 1

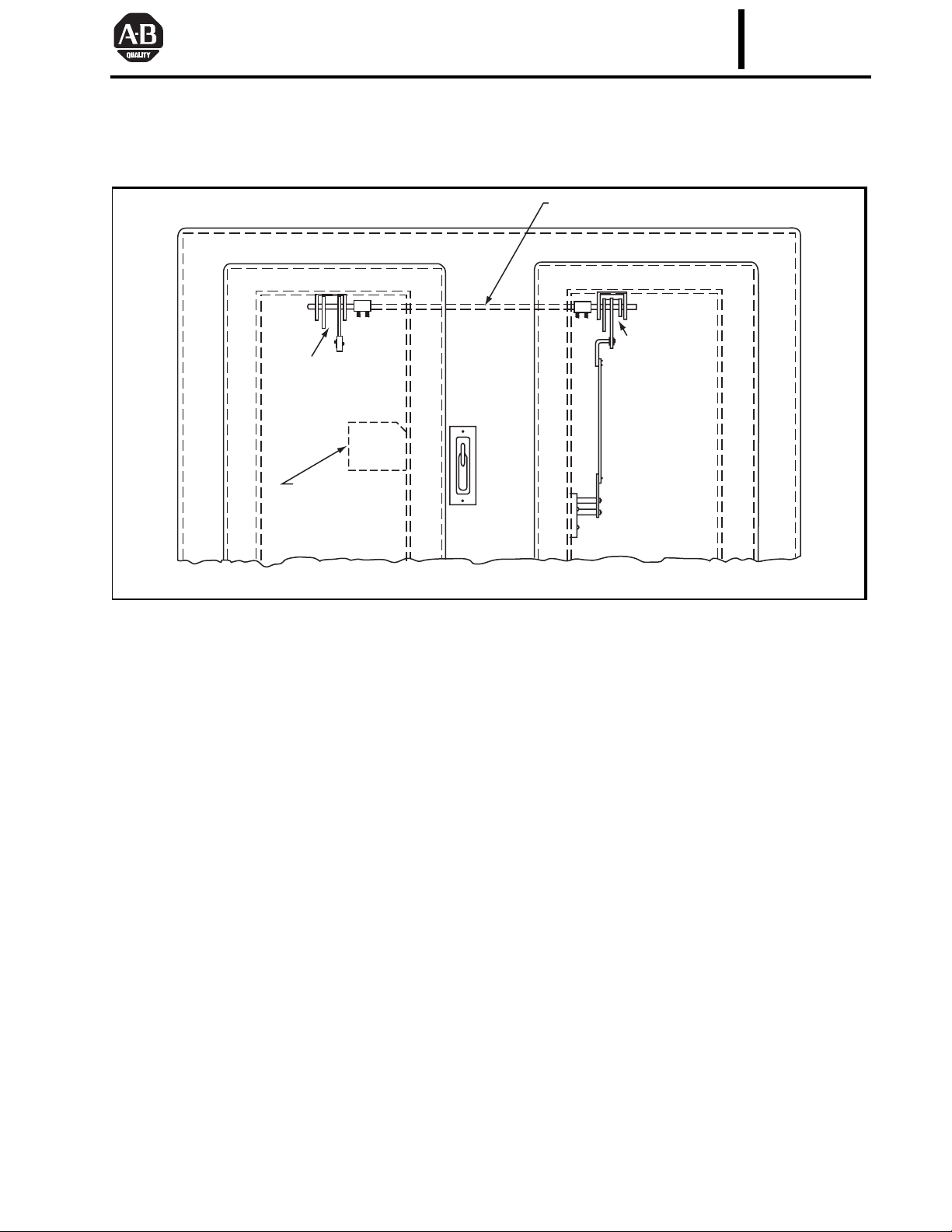

MULTIPLE DOOR INTERLOCK

METHOD OF ASSEMBLY

Connecting Rod

Master Door

Operating

Mechanism

BULLETIN

INSTRUCTIONS 1494F

Auxiliary Door

Operating

Mechanism

Disconnect Switch

or Circuit Breaker

The multiple door interlock hardware kits are to be

used with Catalog Numbers 1494F-L4, 1494F-LL4,

1494V-L3, and 1494V-LL3 door hardware kits to provide

interlocking of Auxiliary Doors with the Master Door for

NEMA Type 1 and Type 12 enclosures.

There are two possible methods by which the Master

and Auxiliary Interlock Kit can be installed. Certain conditions dictate which method to use.

Use Assembly Method Number 1: On all normal

installations.

Use Assembly Method Number 2: Only when the connecting rod between the Master Kit and Auxiliary Kit(s)

passes over the disconnect switch or circuit breaker, as

shown in the figure above, and one of the following conditions exists:

• Dimension “E” on Page 1 of the Circuit Breaker

Operator Installation Instructions (Publication 1494D-5.0) is less than 4-3/8 in. (111) for

devices rated at 15…70 Amperes;

• Dimension “S” on Page 1 of the Flange Mounted

Disconnect Switch Installation Instructions (Publi-

Figure 1

cations 1494F-5.0, 1494M-800, and 1494M-801)

is less than 4-3/8 in. (111) for 30 and 60 Ampere

devices and less than 6 in. (152) for 100 Ampere

Devices;

• Dimension “C” on Page 1 of the Circuit Breaker

Operator Installation Instructions (Publication 1494V-5.05) is less than 5-1/2 in. (140) for

devices rated at 15…70 Amperes; or

• Dimension “C” on Page 1 of the Disconnect

Switch Installation Instructions (Publication 1494V-5.0) is less than 5-1/2 in. (140) for

30 and 60 Ampere devices.

NOTE: The purpose of Assembly Method Number 2 is to

move the connecting rod to a higher position which will

provide greater electrical clearance between it and the disconnect switch or circuit breaker.

When the method of assembly has been determined,

it is required that both the Master Kit and the Auxiliary

Kit(s) employ the same method.

NOTE: Dimensions shown in parentheses are in millimeters.

Publication 1494F-5.2 — November 2002

Supersedes Instructions 1494F-5.1 — March 1977

Page 2

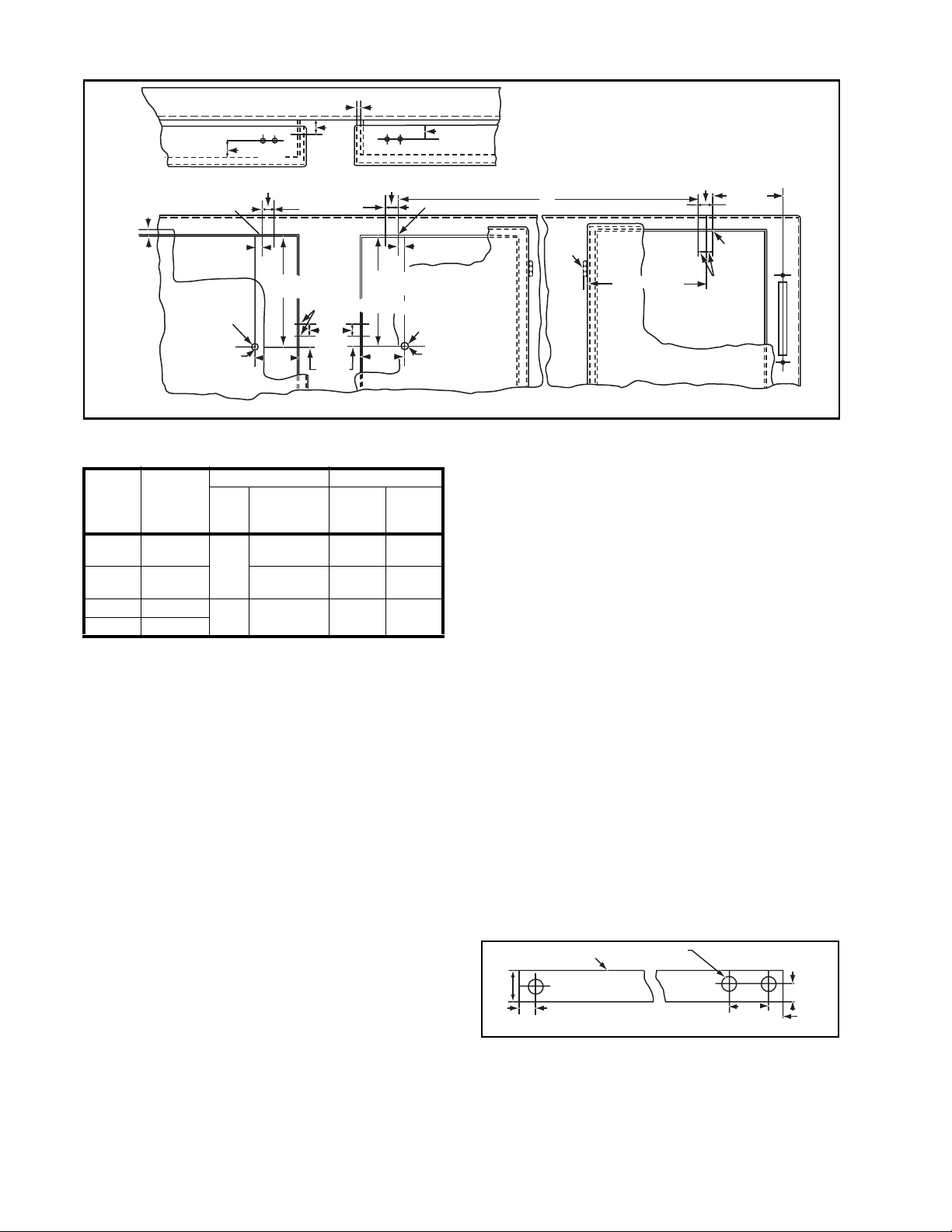

ENCLOSURE CONSTRUCTION

3/16" (4.8) MIN.

7/16"

(11)

C = 3-7/8"

(98.5) MIN.

D = 11"

(279) MIN.

2 Holes 9/32" (7.1) Dia.

1-3/8"

(35)

Dia.

15/16"

(24)

1-3/8" (35)

D = 11"

(279) MIN.

2-5/8"

(66.5)

2 Holes 9/32" (7.1) Dia.

5/16" (7.9)

Door Handle

Mounting Hole

.750" (19) Dia.

2 Holes 9/32" (7.1) Dia.

3/16"

(4.8)

MIN.

5/16" (7.9)

Door Handle

Mounting Hole

.750" (19) Dia.

3/8"(9.5)

MIN.

1-3/8" (35)

2-5/8"

(66.5)

Dimension “A” Minimum

Dimension A

Disconnect

Switches

30A 8-3/4 (222)

60A 8-3/4 (222)

100A 9-1/4 (244)

200A 12-1/2 (318)n

n Applies to Bulletin 1494F only.

Bulletin

1494F

and 1494V

NOTE: The above figure depicts a right-hand Master

Installation. The left-hand Master Installation is a mirror

image of the right-hand installation.

A typical Master Auxiliary Installation is shown in the

figure above with one Master Kit and two Auxiliary Kits. A

maximum of 10 Auxiliary Kits can be employed with one

Master. The dimensions would simply continue. Further,

the location or position of these Kits could be arranged in

any order, so that the Master Kit could be between Auxiliary Kits or to the left of Auxiliary Kits; or the Auxiliary Kits

could be all right-hand, left-hand, or any combination of

both types.

Circuit Breaker Dimension A

Ty pe

Westing-

house

Aux.

Master

Frame

Size

EHD, FD, FDB,

FDC, HFD, HMCP

JD, JDB, JDC,

HJD, HMCP

KD, KDB, KDC,

HKD, HMCP

Bulletin

1494D

7-1/4 (184) 8-5/8 (219)

7-1/2 (191) 9 (229)

8-1/2 (216) 10- 3/8 (264)

Bulletin

1494V

Enclosure Instructions

CAUTION: The Door Hardware Kits installed on all the

auxiliary enclosure doors require a slightly different drilling

pattern from that used for Catalog Numbers 1494F-L4,

1494F-LL4, 1494V-L3, and 1494V-LL3. The 0.406 (10.3)

diameter hole located 2-3/8 in. (60.5) up from the 0.750

(19) diameter door handle mounting hole should be omitted. In addition, it is unnecessary to add the two tapped

holes to the top locking bar since the defeater actuator

lever need not be attached where no disconnect switch or

circuit breaker is installed. It is also unnecessary to install

the door catch. The door catch and defeater actuator lever

and the screws that attach these parts may be discarded.

ENCLOSURE THICKNESS

7/16" (11)

12 (2.7) Gauge Minimum

10 (3.4) Gauge Maximum

B

1-3/8" (35)

Hinge

6" (152) MIN.

2 Holes

11/16"

(17.5)

A MIN.

9/32"

(7.1)

Dia.

MasterLeft-Hand AuxiliaryRight-Hand Auxiliary

Figure 2

1. Provide mounting holes on the enclosure’s upper

flange lip for the Master Interlock Kit as indicated in

Figure 2.

NOTE: The Master Kit is always fastened to the

door opening having the disconnect switch or circuit

breaker.

2. Provide mounting holes on the enclosure’s upper

flange lip and side flange lip for the Auxiliary Kit(s) as

indicated in the Figure 2.

Connecting Rod Instructions

1. Establish the length(s) of the connecting rod(s) from

Master Kit to Auxiliary Kit(s) by measuring Dimension

“B” and subtracting 1-11/16 in. (43). Cut to size.

NOTE: The 3/8 in. (9.5) square rod(s) is not supplied with these kits.

2. Establish the length(s) of the connecting rod(s) from

Master Kit to Auxiliary Kit(s) by measuring Dimension

“C” and subtracting 1-11/16 in. (43). Cut to size.

NOTE: The 3/8 in. (9.5) square rod(s) is not supplied with these kits.

Lifting Rod Instructions

1. Determine the length(s) of the Lifting Rod(s) from the

upper auxiliary mechanism(s) to the lower auxiliary

mechanism(s) by determining Dimension “D” and:

A. Subtracting 8-7/8 in. (225) when using Assembly

Method Number 1.

B. Subtracting 7-3/4 in. (197) when using Assembly

Method Number 2.

2. Cut rod to size.

Bar Thickness

1/2"

(12.7)

1/8" (3.2)

.250"

(6.4)

3. Locate and provide holes as indicated in the figure

above.

NOTE: The standard mill rectangular Lifting Rod is

not supplied with these assemblies.

3 - 13/64" (5.2)

Mtg. Holes

STEEL

Figure 3

.625"

(15.9)

1/4"

(6.4)

.250"

(6.4)

NOTE: Dimensions shown in parentheses are in millimeters.

Page 3

Enclosure Upper

k

Flange Lip

Connecting

Rod

Coupling

Figure 4

Gasket

ASSEMBLY METHOD NUMBER 1

Mounting Plate

Master

Interloc

1. Remove nuts and washers from mounting plate.

2. Place the mounting plate studs through the holes in

the enclosure’s upper flange lip and the master interlock, as shown in the figure to the left, and secure

assembly to flange.

3. Attach the coupling to the master interlock as indi-

cated.

NOTE: The Master Interlock Assembly should be exactly

at a right angle with the enclosure side flange lip. Otherwise binding could result.

AUXILIARY KIT INSTALLATION

Master Interlock Installation

Mounting Plate

Gasket

Connecting

Rod

Coupling

Upper

Operator

Adjusting

Nuts

Lower

Operator

Lifting

Rod

Link

Enclosure Upper

Flange Lip

Connecting

Rod

Coupling

Eye Bolt

Enclosure Side

Flange Lip

Gasket

Mounting

Plate

Enclosure Upper

Flange Lip

Connecting

Rod

Mounting

Plate

Coupling

Upper

Operator

Adjusting

Nuts

Link

Enclosure Side

Flange Lip

Gasket

Mounting Plate

Gasket

Connecting

Rod

Coupling

Eye Bolt

Lifting

Rod

Lower Operator

Right-Hand Auxiliary

Figure 5

Upper Operator Assembly

1. Remove nuts and washers from upper operator

mounting plate.

2. Place the mounting plate studs through the holes in

the enclosure upper flange lip and the upper operator,

as shown in Figure 5 or 6, and secure assembly to

flange with nuts tightened to 40…50 lb-in. torque.

NOTE: The Upper Operator Assembly should be exactly

at a right angle with the enclosure side flange lip. Otherwise, binding could result.

3. Fasten the Connecting Rod(s) between Master and

Auxiliary Kit(s) as indicated in the figures above and

on page 3. Tighten coupling screws to 24…32

lb-in. torque.

Left-Hand Auxiliary Figure 6

Lower Operator Assembly

1. Remove nuts and washers from side mounting plate.

2. LEFT-HAND AUXILIARY KIT ONLY: Disassemble

lower operator and reassemble as shown in Figure 6.

Tighten the screws to 24…32 lb-in. torque.

3. Place the mounting plate studs through the holes in

the enclosure’s side flange lip and auxiliary kit lower

operator mechanism, as shown, and secure to flange

with nuts tightened to 40…50 lb-in. torque.

4. Attach the Lifting Rod to the upper and lower auxiliary

kit operator(s) as indicated, using a torque of

24…32 lb-in. for the shoulder screw and the screws

used to connect to the link.

Page 4

Lifting Rod Adjustment

Shoulder in line

with center

of screw

Sliding

Portion

Stationary

Portion

Figure 7

With the Master Door closed and the Door Hardware

Kit installed in the Auxiliary Door, proceed as follows:

1. Align the center of the screw head on the stationary

portion of the lower operator with the shoulder of the

sliding portion of the lower operator (see Figure 7) by

ASSEMBLY METHOD NUMBER 2

moving and adjusting nuts on the upper operator eye

bolt (see Figure 5 or 6). Tighten nuts to 22…30 lb-in.

torque.

2. Close Auxiliary Door.

NOTE: Auxiliary Door should not open when the

Master Door is closed.

3. Open Master Door and attempt to open Auxiliary

Door. If Auxiliary Door opens, assembly is operating

properly.

NOTE: If trouble is encountered opening the Auxiliary Door(s), a minor turn of the adjusting nuts on the

upper operator eye bolt is required. Loosen nuts and

retighten to 22…30 lb-in. torque.

4. Close Master Door and repeat steps 2 and 3 until

proper action is obtained.

5. Tighten nuts when adjustment is completed to

22…30 lb-in. torque.

Figure 8

Master Interlock Installation

1. Disassemble Master Interlock and reassemble as

shown in the figure above. Tighten the No. 10 screws

to 22…32 lb-in. torque.

2. Follow Master Interlock Installation Instructions as

given on page 3.

ALLEN-BRADLEY

A ROCKWELL INTERNATIONAL COMPANY

Figure 9

Auxiliary Kit Installation

Upper Operator Assembly

1. Disassemble upper operator assembly and reassemble as shown in the figure above. Tighten the No. 10

screws to 22…32 lb-in. torque.

2. Follow Upper Operator Assembly Instructions as

given on page 3.

Lower Operator Assembly

1. Follow Lower Operator Assembly Instructions given

on page 3.

Lifting Rod Adjustment

1. Follow Lifting Rod Adjustment Instructions above.

Loading...

Loading...