Page 1

Installation Instructions

Differential Air-pressure Transmitter

Catalog Numbers

1414-IPZ10FODAA, 1414-IPZ10FNDAA, 1414-IPD10FNRAA,

1414-CPZ10FODAA, 1414-CPZ10FNDAA, 1414-CPD10PNRAA

Top ic Pa ge

Before Installation 1

Important User Information 2

About the Differential Air-pressure Transmitter 3

Differential Air-pressure Transmitter Installation 4

Power-up Instruction 7

Specifications 9

Dimensions 10

Before Installation

Read these installation instructions carefully before commissioning the pressure transmitter.

ATTENTION:

• Failure to follow these instructions may result in product damage. This device must be

installed by a qualified technician.

• Use electrostatic discharge precautions during installation and do not exceed the device

ratings.

WARNING: Do not use in an explosive or hazardous environment, with

combustible or flammable gasses, as safety or emergency stop devices or in any

other application where failure of the product could result in personal injury.

Page 2

2 Differential Air-pressure Transmitter

Important User Information

Solid-state equipment has operational characteristics differing from those of electromechanical equipment.

Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls (Publication SGI-1.1

available from your local Rockwell Automation sales office or online at

http://www.rockwellautomation.com/literature/

equipment and hard-wired electromechanical devices. Because of this difference, and also because of the wide

variety of uses for solid-state equipment, all persons responsible for applying this equipment must satisfy

themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages

resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular installation, Rockwell Automation, Inc. cannot

assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits,

equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell

Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an

explosion in a hazardous environment, which may lead to personal injury or death, property

damage, or economic loss.

) describes some important differences between solid-state

ATTENTION: Identifies information about practices or circumstances that can lead to personal

injury or death, property damage, or economic loss. Attentions help you identify a hazard, avoid

a hazard and recognize the consequences.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, drive or motor, to

alert people that dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, drive or motor, to

alert people that surfaces may reach dangerous temperatures.

IMPORTANT Identifies information that is critical for successful application and understanding of the

product.

Publication 1414-IN011B-EN-P - July 2010

Page 3

Differential Air-pressure Transmitter 3

About the Differential Air-pressure Transmitter

The transmitter can be used to measure positive, negative, or differential pressure in the range of

1.0…20.0 in. wc (water column). The piezoresistive sensor is ideal for monitoring the pressure for

air or other clean inert gas and is limited only to those media that will not attack polyetherimide,

silicon, fluorosilicone, silicone, EPDM, and neoprene seals.

The module features field-selectable pressure ranges and output signal types for the most flexible

application. Typical HVAC applications include monitoring of filter differential pressure or

clean room pressure. The output signal is factory calibrated and temperature compensated for

highest start-up accuracy and trouble-free operation.

The low-pressure room differential transmitter is designed to measure the pressure difference

from one room to another. This is done by mounting the main transmitter unit that is housed in

the ABS enclosure in one room and mounting the AE enclosure in the other. The ABS enclosure

has two ports, one on the side and one on the back. The side port is used to measure the pressure

in the room that it is mounted in while the back port is connected via a supplied tube to the port

that is on the back of the AE enclosure.

There is a second fitting on the back of the ABS enclosure that can be used as a wire entrance. An

electrical box can be used to mount the two enclosures to the wall or a hole can be made in the

wall to accommodate the fittings. Attach the supplied tube to the fittings on the back of the AE

and ABS enclosures.

TIP

The following is the factory setup for the tubing inside the ABS enclosure.

• The LOW side of the sensor is connected to the AE to monitor the remote

room.

• The HIGH side of the sensor is connected to the port on the side of the ABS

enclosure.

The tubes on the sensor can be reversed if required

Publication 1414-IN011B-EN-P - July 2010

Page 4

4 Differential Air-pressure Transmitter

Differential Air-pressure Transmitter Installation

The transmitter mounts on any surface using the two holes provided on the base of the unit.

Make sure there is enough space around the unit to connect the pressure tubing without kinking

and avoid locations where severe vibrations or excessive moisture are present. Mount the

enclosure with two user-supplied screws but do not over-tighten.

The unit may be mounted in any position but is typically installed on a vertical surface with the

pressure ports on the right and the cable entrance on the left. The enclosure has a standard ½ in.

conduit opening and may be installed with either conduit and a conduit coupler or a cable gland

type fitting.

Room Pressure Monitor - Mount the ABS box in the room where the pressure display is desired.

Mount the AE enclosure in the second room and connect the two using the supplied hose or

equivalent. Note that the unit is factory set with the LOW port in the ABS enclosure and the

HIGH port in the AE enclosure. To change this, reverse the hose connections on the board in

the ABS enclosure.

Differential Air-pressure Transmitter Wiring and Connection

The transmitter has standard screw-block connectors and easy wire access to facilitate wiring. We

recommend that shielded twisted-pair wiring at least 22 AWG be used for all connections and

that the device wires not be run in the same conduit with wiring used to supply inductive loads

such as motors.

ATTENTION: Disconnect the power supply before making any connections to

prevent electrical shock or equipment damage.

Make all connections in accordance with national and local electrical codes.

The device power (12…28V AC or 15…35V DC measured at the transmitter) is connected to

the terminal marked PWR. This terminal is used for the positive DC voltage or the hot side of

the AC voltage. The device is reverse voltage protected and as such will not operate if connected

backwards.

For voltage output signal types (three-wire) or for AC power supply operation (three-wire), the

common of the power supply is connected to the terminal marked COM. Note that this device

has a half-wave type power supply which means the power supply common is the same as the

output signal common. Therefore, several devices may be connected to one power supply and the

output signals all share the same signal common. Use caution when grounding the secondary of

an AC transformer or when wiring multiple devices to ensure that the circuit ground point is the

same on all devices and the controller. This terminal is not used for loop-powered 4…20 mA

output type (2-wire).

Publication 1414-IN011B-EN-P - July 2010

Page 5

Differential Air-pressure Transmitter 5

The analog output signal is available on the OUT terminal. This signal is jumper selectable for

either a voltage output or a standard loop-powered 4…20 mA output signal type. When voltage

mode is selected, either 0…5V DC or 0…10V DC can also be selected. These options are

indicated on the device circuit board. The analog output signal is typically connected directly to

the Building Automation System (B.A.S.) and used as a control parameter or for logging

purposes.

For voltage type output signal the device has a minimum load that it is able to drive, similarly for

current type output signal the device has a maximum load that it is able to drive with a particular

power supply voltage. Observe and follow these ratings in the Specification section or inaccurate

reading may result.

The 4…20 mA output signal can easily be converted to a 1…5V DC signal for controllers

accepting this type of input. Simply insert a 250 Ω (0.1% is best) resistor between the ‘+’ and ‘-’

inputs of the controller. This will convert the 4…20 mA signal to the desired 1…5V DC.

Pneumatic Connections

The two pressure ports on the end of the enclosure are labeled High and Low. The output signal

reads a positive value when the port pressure is higher on the High port than the Low port so

ensure these ports are connected correctly.

Use 0.170 in. I.D. flexible tubing for the High and Low pressure connections. Arrange the tubing

to minimize stress on the connections and ensure there are no kinks in the tubing. For most

accurate measurements, do not leave the Low port open to the atmosphere, run a return line

from the Low port to the vicinity of the point being measured.

Ensure the tubing to be used is clean and do not allow material to fall into the pressure ports as

contamination could damage the sensor.

When removing tubing use care to avoid breaking the ports. In some cases it is better to cut the

tubing off rather than pulling it off but be careful not to cut the fitting or an air leak may occur.

Differential Air-pressure Transmitter Configuration

The transmitter is configured with push-on type jumpers on the circuit board as shown on the

Power Supply

pressure range.

The module is factory configured to operate in the 4…20 mA output mode. You can change the

voltage mode by moving the three jumpers from the positions marked Current to the positions

marked Voltage. Before moving these jumpers, study the current jumper position and then move

the jumpers to the new position. If these jumpers are rotated 90 degrees and installed incorrectly

the product will not work and device damage may occur.

Once the output mode is changed to voltage, the output scale may be changed to either

0…5V DC or 0…10V DC. This is done by moving the single jumper to the 0…5V or 0…10V

position.

drawing. These jumpers are used to select the output signal type and the input

Publication 1414-IN011B-EN-P - July 2010

Page 6

6 Differential Air-pressure Transmitter

The input pressure range is set by moving two jumpers to the appropriate range. The available

ranges are marked 1…8 on the circuit board. The two jumpers must be set to the same range or

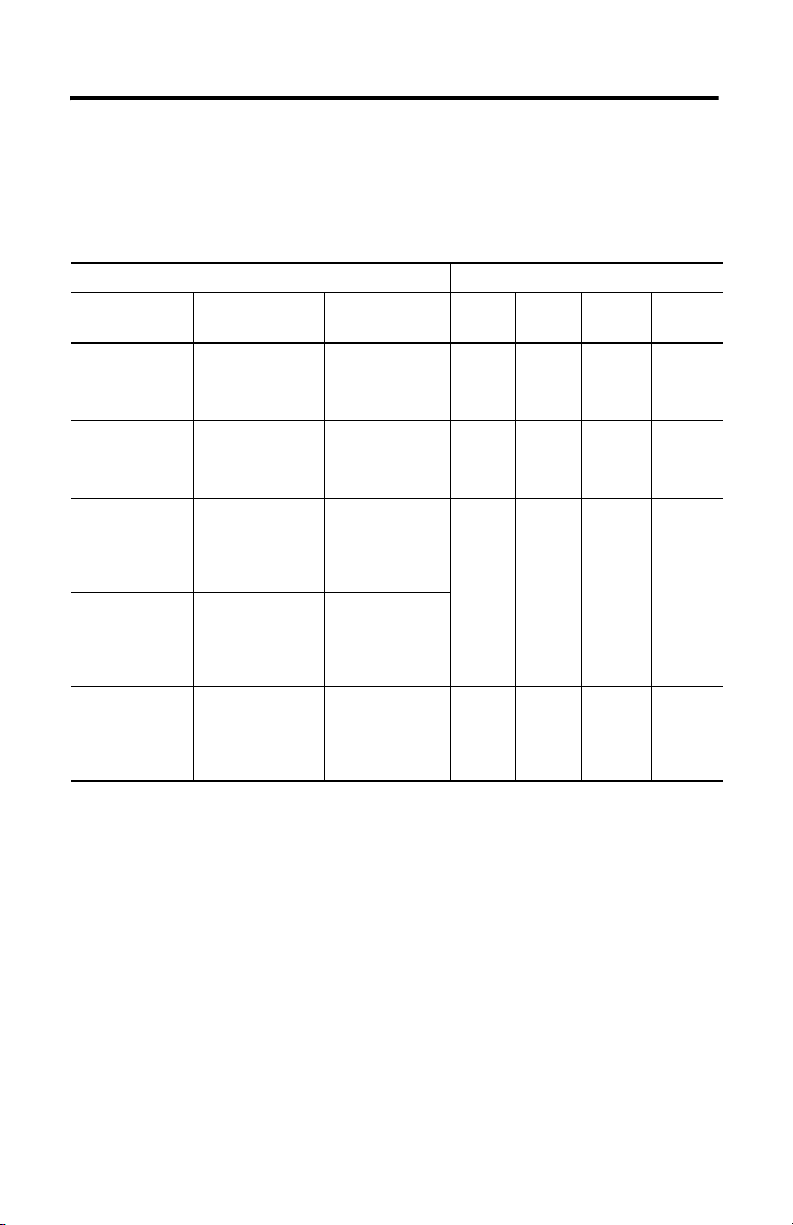

incorrect readings result. The pressure ranges are shown in the following chart:

Available Differential Air-pressure Transmitters

Low Pressure Transducer Jumper selectable pressure range

Description Commercial Industrial,

cc-pcb

Room differential

w/4-20mA±2.5”,

±5.0”,0-5”,0-10”

WC

Room differential

w/4-20mA±5.0”,

±10.0”,0-10”,0-20

” WC

Room differential

w/4-20mA &

LCD±2.0”,

±4.0”,0-4”,0-8”

WC

Static differential

w/4-20mA & duct

probe±2.0”,

±4.0”,0-4”,0-8”

WC

Static differential

w/4-20mA & duct

probe±3.0”,

±6.0”,0-6”,0-12”

WC

1414-CPZ10FVRAA ±2.5 in. ±5.0 in. 0…5 in. 0…10 in.

1414-CPZ10FRRAA ±5.0 in. ±10.0 in. 0…10 in. 0…20 in.

1414-CPD10PNRAA 1414-IPD10FNRAA ±2.0 in. ±4.0 in. 0…4 in. 0…8 in.

1414-CPZ10FNDAA 1414-IPZ10FNDAA

1414-CPZ10FODAA 1414-IPZ10FODAA ±3.0 in. ±6.0 in. 0…6 in. 0…12 in.

123 4

Publication 1414-IN011B-EN-P - July 2010

Page 7

Power Supply

Differential Air-pressure Transmitter 7

0…5V DC Output with 24V AC Power Supply

120V AC

CONTROLLER

CONTROLLER

24V AC

COM

IN

4…20 mA Output with 24V DC External Power Supply

POWER SUPPLY

24V DC

PWR COM OUT

PWR COM OUT

( - ) ( + )

COM

IN

4…20 mA (two-wire)

LCD

LCD

HIGH

HIGH

RANGE

RANGE

ZERO

ZERO

LOW

OUTPUT SIGNAL

CURRENT

VOLTAGE

LOW

OUTPUT SIGNAL

VOLTAGE

CURRENT

10V

5V

10V

5V

Power-up Instruction

Follow these steps before using the transmitter.

1. Before turning on the power, verify all wiring to ensure that it complies with the wiring

diagrams and verify that the output signal type is correctly selected on the jumpers.

2. Review the specifications to ensure the power supply is correct and that the pressure is

within the correct range.

3. Inspect the internal pressure tubing that connects the sensor to the external ports to

ensure that the tubing did not get kinked during shipping or installation.

Publication 1414-IN011B-EN-P - July 2010

Page 8

8 Differential Air-pressure Transmitter

4. Allow the transmitter to warm-up for several minutes before attempting to verify the

device accuracy or adjust the null offset.

The module uses a sophisticated temperature compensation circuit to ensure maximum

accuracy of the device. It is best to allow the transmitter to operate for one hour before

any adjustment or calibration is performed.

5. Verify proper operation by measuring the output signal.

• For voltage output configuration, measure the voltage between the OUT and COM

terminals. The voltmeter should read between 0…5V DC or 0…10V DC depending

on the output range selected.

• For current output configuration, insert a mA meter in series with the OUT

terminal. The mA meter should read between 4…20 mA.

Operation

If the module is set to a unipolar range such as 0…2 in. wc, then the pressure applied to the High

port must be higher than the pressure applied to the Low port. In this case, if the Low port is left

open to ambient pressure and the High port is used to measure a positive pressure, then the

output pressure can be calculated as follows:

• 4…20 mA Pressure = [(Output current – 4 mA) / 16 mA] x Range

• 0…5V DC Pressure = (Output voltage / 5 V) x Range

• 0…10V DC Pressure = (Output voltage / 10 V) x Range

In the case of 0… 2 in. wc, 4 mA or 0 V = 0 in. wc, and 20 mA or 5 V or 10 V = 2 in. wc. Since the

transmitter is linear, 1 in. wc would be 12 mA or 2.5 V or 5 V.

If the positive pressure connection is reversed then the transmitter will always output

4 mA or 0 V.

If the module is set to a bipolar range such as ±2 in. wc, then the pressure applied to the High

port should be higher than the pressure applied to the Low port for a positive output response. In

this case, differential pressure can be measured using both ports. If the High port has a positive

pressure with respect to the Low port, then the output indicates a positive pressure. Negative

pressure is indicated if the High pressure is less than the Low pressure. For bipolar ranges, the

output pressure can be calculated as follows:

• 4…20 mA Pressure = [(Output current – 4 mA) / 16 mA] x 2 x Range – Offset

• 0…5V DC Pressure = (Output voltage / 5 V) x 2 x Range – Offset

• 0…10V DC Pressure = (Output voltage / 10 V) x 2 x Range – Offset

In the case of ±2 in. wc, 4 mA or 0 V = -2 in. wc and 20 mA or 5 V or 10 V = +2 in. wc. Since the

transmitter is linear, 0 in. wc would be 12 mA or 2.5 V or 5 V.

Publication 1414-IN011B-EN-P - July 2010

Page 9

Differential Air-pressure Transmitter 9

Calibration

All pressure ranges are factory calibrated and no calibration is necessary. You may adjust the zero

point if desired when changing ranges for example.

1. Allow the product to warm-up for 10 minutes (one hour is best) before you make a zero

adjustment.

2. With both ports open to the ambient pressure, press and hold the auto-zero button for at

least three seconds.

3. Release the auto-zero button after at least three seconds and the device will calculate and

store the new zero point.

TIP

Generally, we do not recommended that the span calibration be performed in

the field unless a high quality calibrator with low differential pressure ranges is

available and the temperature of the sensor can be maintained. Contact the

factory for information on this type of calibration.

Specifications

Technical Specifications - Differential Air-pressure Transmitter

Attribute 1414-IPZ10FODAA, 1414-IPZ10FNDAA, 1414-IPD10FNRAA,

Pressure ranges ±0.5 in., ±1 in., ±2 in., 0…1 in., 0…2 in., 0…4 in. wc

Calibration accuracy ± 1% F.S.O.

Measurement type Differential (two port)

Response time 1 mS maximum

Stability < ± 1% F.S.O. per year

Thermal effects < ± 3% over compensated range

Compensated range 10…50 °C (50…122 °F)

Over pressure 20 psi or 2 x range (whichever is greater)

Operating conditions 0…60 °C (32…140 °F), 10…90% RH non-condensing

Media compatibility Limited only to those that will not attack polyetherimide, silicon,

Power supply (at transmitter) 12…28V AC, 15…35V DC (non-isolated half-wave rectified)

Supply current < 4 mA

Input voltage effect Negligible over specified operating range

1414-CPZ10FODAA, 1414-CPZ10FNDAA, 1414-CPD10PNRAA

±1.5 in., ±3 in., ±6 in., 0…3 in., 0…6 in., 0…12 in. wc

fluorosilicone, silicone, EPDM, and neoprene seals. Typically dry air or

inert gas but liquid is allowed.

Publication 1414-IN011B-EN-P - July 2010

Page 10

10 Differential Air-pressure Transmitter

Technical Specifications - Differential Air-pressure Transmitter

Attribute 1414-IPZ10FODAA, 1414-IPZ10FNDAA, 1414-IPD10FNRAA,

1414-CPZ10FODAA, 1414-CPZ10FNDAA, 1414-CPD10PNRAA

Protection circuitry Reverse voltage protected and output limited

Output signal 4…20 mA (2-wire), 0…5V DC or 0…10V DC (3-wire) Pin jumper

Current output drive capability 400 Ω maximum @ 24V DC

Voltage output drive capability 2 KΩ minimum for 0…5V DC signal 10 KΩ minimum for 0…10V DC

Zero adjustment Pushbutton auto-zero

Wiring connections Screw terminal block (14…22 AWG)

Pressure Connections Barbed ports for 4.32 mm (0.170 in.) ID flexible tubing

Conduit Connection Access hole for ½ in. NPT conduit or cable gland

Enclosure High Impact Black ABS, plenum rated with optional gasket

Weight 159 grams (5.6 oz)

Optional Display 3½ digit, 10.16 mm (0.4 in.) digit height

selectable

signal

127 mm x 84 mm x 53 mm (5.00 in. W x 3.3 in. H x 2.1 in. D)

Dimensions

84.3mm

(3.32 in.)

53.6mm

(2.11 in.)

115.8mm

(4.56 in.)

Publication 1414-IN011B-EN-P - July 2010

yticoleV wolfriA tcuDgnirotinoM retliF

Filter

Airflow

Page 11

Notes:

Differential Air-pressure Transmitter 11

Publication 1414-IN011B-EN-P - July 2010

Page 12

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in using its products. At

http://www.rockwellautomation.com/support/

technical and application notes, sample code and links to software service packs, and a MySupport feature that

you can customize to make the best use of these tools.

For an additional level of technical phone support for installation, configuration and troubleshooting, we offer

TechConnect support programs. For more information, contact your local distributor or Rockwell Automation

representative, or visit http://www.rockwellautomation.com/support/

Installation Assistance

If you experience a problem within the first 24 hours of installation, please review the information that's

contained in this manual. You can also contact a special Customer Support number for initial help in getting your

product up and running.

United States or Canada 1.440.646.3434

Outside United States

or Canada

Use the Worldwide Locator

http://www.rockwellautomation.com/support/americas/phone_en.html

your local Rockwell Automation representative.

New Product Satisfaction Return

Rockwell Automation tests all of its products to ensure that they are fully operational when shipped from the

manufacturing facility. However, if your product is not functioning and needs to be returned, follow these

procedures.

, you can find technical manuals, a knowledge base of FAQs,

.

at

, or contact

United States

Outside United States

Contact your distributor. You must provide a Customer Support case number (call the

phone number above to obtain one) to your distributor to complete the return process.

Please contact your local Rockwell Automation representative for the return

procedure.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to

improve this document, complete this form, publication RA-DU002

http://www.rockwellautomation.com/literature/

Allen-Bradley, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

.

Publication 1414-IN011B-EN-P - July 2010 PN-79836

Supersedes Publication 1414-IN011A-EN-P - October 2005 Copyright © 2010 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

, available at

Loading...

Loading...