ROCKINGER RO 810 D User Manual

Member of JOST-World

Montage- und Betriebsanleitung

Installation and operating instructions

Instructions de montage et d’utilisation

D

GB

F

Für Modellreihen

for Series

pour les séries

RR

RR

OO

OO

ii

ii

888811110000DD

DD

Manuelle Anhängekupplung mit Fahrstuhllager

Non-automatic trailer coupling with lift bearing

Attelage de remorque verrouillage avec palier

à hauteur variable

ROCKINGER

Member of JOST-World

13

TTaabbllee ooff ccoonntteennttss RROOii881100 DD

GB

Note:

When fitting the trailer coupling the Council Directive 89/173 EEC

and the relevant national regulations must be observed. The coupling

must be fitted in accordance with these assembly and operating

instructions.

If the installation of the trailer coupling should alter the load values of

the vehicle (e.g. permissible axle load, total weight, permissible vertical

load) the vehicle documents must be altered accordingly.

We reserve the right to make technical alterations.

Series ROi810 B

Non-automatic trailer coupling with flange

– Type 810

Version A with socket pin above

Version B with socket pin below

– Hand lever l 30,2 mm

Safety instructions 14

1. Fitting 15

2. Operating 16

2.1 Hitching 16

2.2 Unhitching 16

3. Maintenance 17 – 18

3.1 Inspection 17 – 18

4. Technical data 19 – 21

Drawbar eyes 22

Single hand pins 22

!

The coupling may only be fitted by qualified

personnel!

Read these instructions carefully before

starting work!

The assembly and operating instructions must be kept in the vehicle!

ROCKINGER

Member of JOST-World

4

ROCKINGER

Member of JOST-World

14

SSaaffeettyy iinnssttrruuccttiioonnss RROOii881100 DD

The safety instructions are summarised in a single chapter.

In any situation where the user of the trailer coupling is at

risk, the safety instructions are repeated in the individual

sections and marked with the warning symbol shown here.

When handling trailer couplings, tractor vehicles and trailers, the relevant

safety regulations in the respective country must be observed. Any safety

instructions in the operating manual of the tractor vehicle and the trailer

remain valid and must be observed.

For operation, maintenance and assembly, the safety instructions listed

below must be observed. Further safety instructions are then given in the

individual case which relate directly to the respective activity.

Safety instructions for operation

x The trailer coupling may only be operated by authorised persons.

x The installation and operatinginstructionsoftherespective trailer coupling

retain their validity and must be observed.

x Only use the trailer coupling and the towing eye of the trailer if they are in

perfect technical condition.

x Only carry out hitching / unhitching operations on firm, level ground.

x During hitching, nobody may stand between the tractor vehicle and the

trailer.

x After every hitching operation, the correct locked status of the trailer

coupling must be checked by means of the control pin or the remote

indicator. Only drive the rig in the correctly locked status

x Never reach into the opened coupling.

Safety instructions for maintenance

x For maintenance work, only use the specified lubricants.

x Maintenance work may only be carried out by qualified personnel.

Safety instructions for installation

x Installation may only be carried out by authorised workshops.

x Installation must be carriedoutincompliancewiththe relevant accident pre-

vention regulations and the technical regulations for mechanical equipment.

x Only original ROCKINGER components may be used. .

x Instructions and installation guidelines of the vehicle manufacturer must

be observed, e.g. type of fastening, clearances etc.

x All screwed connections must be tightened with the prescribed tightening

torque.

x Work may only be carried out on the trailer coupling when it is closed.

Risk of injury!

x The trailer coupling must be installed in accordance with these installation

and operation instructions and may only be carried out on agricultural or

forestry tractor machines in accordance with Directive 74/150/EEC.

x Type plates and warnings must be clearly visible before the coupling or

drawbar eye are used and must not be rendered illegible in any way. Paint

residues or protective foils must be removed.

Trailer couplings are vehicle connection parts which require

model approval and are subject to the highest safety re-

quirements.

Alterations of any kind shall cause the warranty to lapse and invalidate

the model approval, which in turn invalidates the vehicle operation

permit.

!

!

GB

ROCKINGER

Member of JOST-World

15

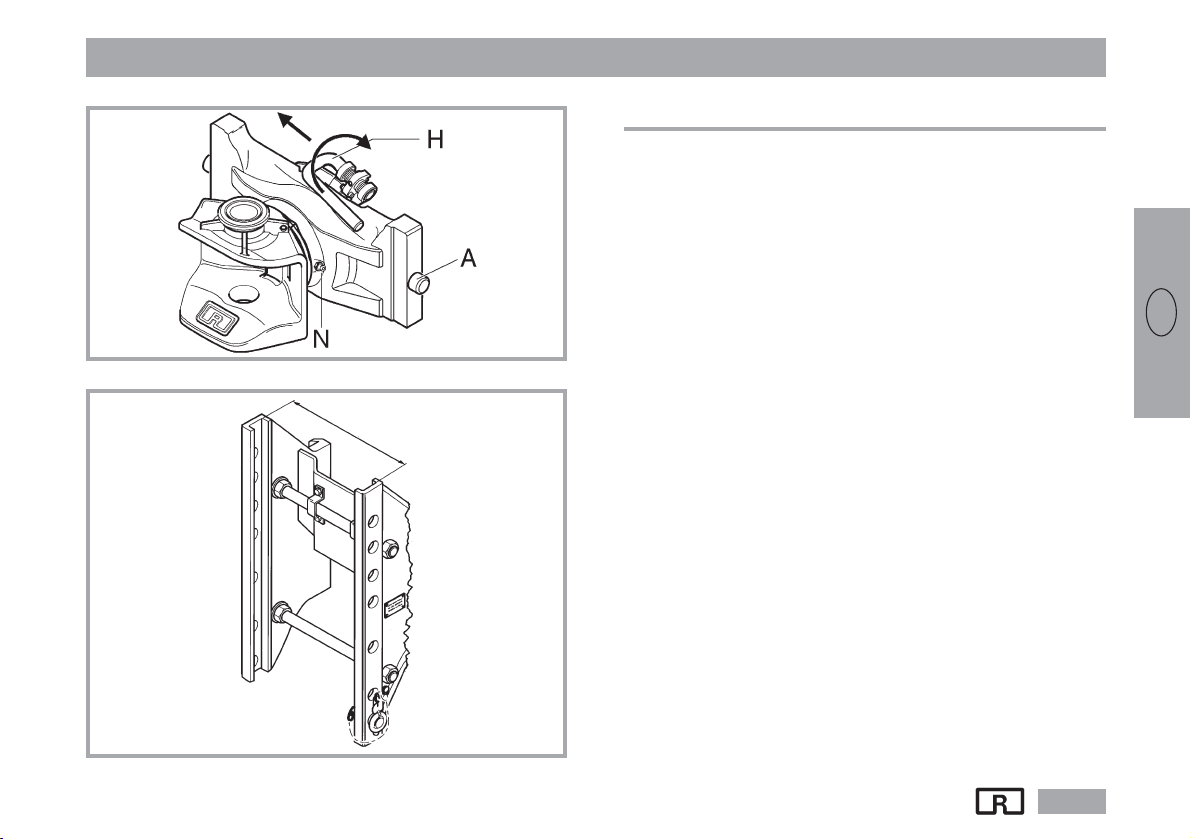

11.. FFiittttiinngg RROOii881100 DD

1. Fitting

The coupling is supplied in a ready-to-use condition.

The relevant regulations must be observed for installation

(UVV (German accident protection regulations) 3.2 for agricultural

and forestry vehicles)

x Inspection of the anti-slip device in the trailer block (D) (s.Abb. 2)

x Insert the coupling from above into the guide rails

x Attention: Keep a good grip on the coupling!

x Turn hand grip (H) of the cam plate upwards and press to the left:

the arresting bolts (A) move inwards (see Fig. 1)

x Place the coupling at the desired height in the trailer block

x Hold the coupling inplace and at thesame time turnthehand grip (H)

back to the right to allow it to engage

x Release the hand grip in the resting position (see Fig. 1)

Inspection: In the secured position it should only be possible to move

the hand grip (H) about 4 mm to the left

Attention: Do not use any aids to operate the height adjustment and

avoid impact on the cam plate: Risk of damage!

Attention: Only use ROCKINGER single hand pins and Fendt pins

according to the general operation permit!

In the case of non-observance, the model permit lapses.

1

S

w

2

GB

Loading...

Loading...