ROCKINGER RO 560 User Manual

T

Series ROi560

Fully automatic trailer coupling

with homologation 94/20/EC

Fully automatic

trailer coupling

for drawbar eyes 50 DIN 74053,

EC 94/20 class D, ISO 1102,

drawbar eye RO

i

57005

IInnssttaallllaattiioonn aanndd

ooppeerraattiinngg iinnssttrruuccttiioonnss

1. Fitting

1.1 Before installation

Note: Please comply with the following when fitting coupling:

– applicable national regulations

– vehicle manufacturer’s specifications

– clearance for axial rotation of coupling head of at least e 25h

The coupling is supplied ready to operate.

1.2 Installation

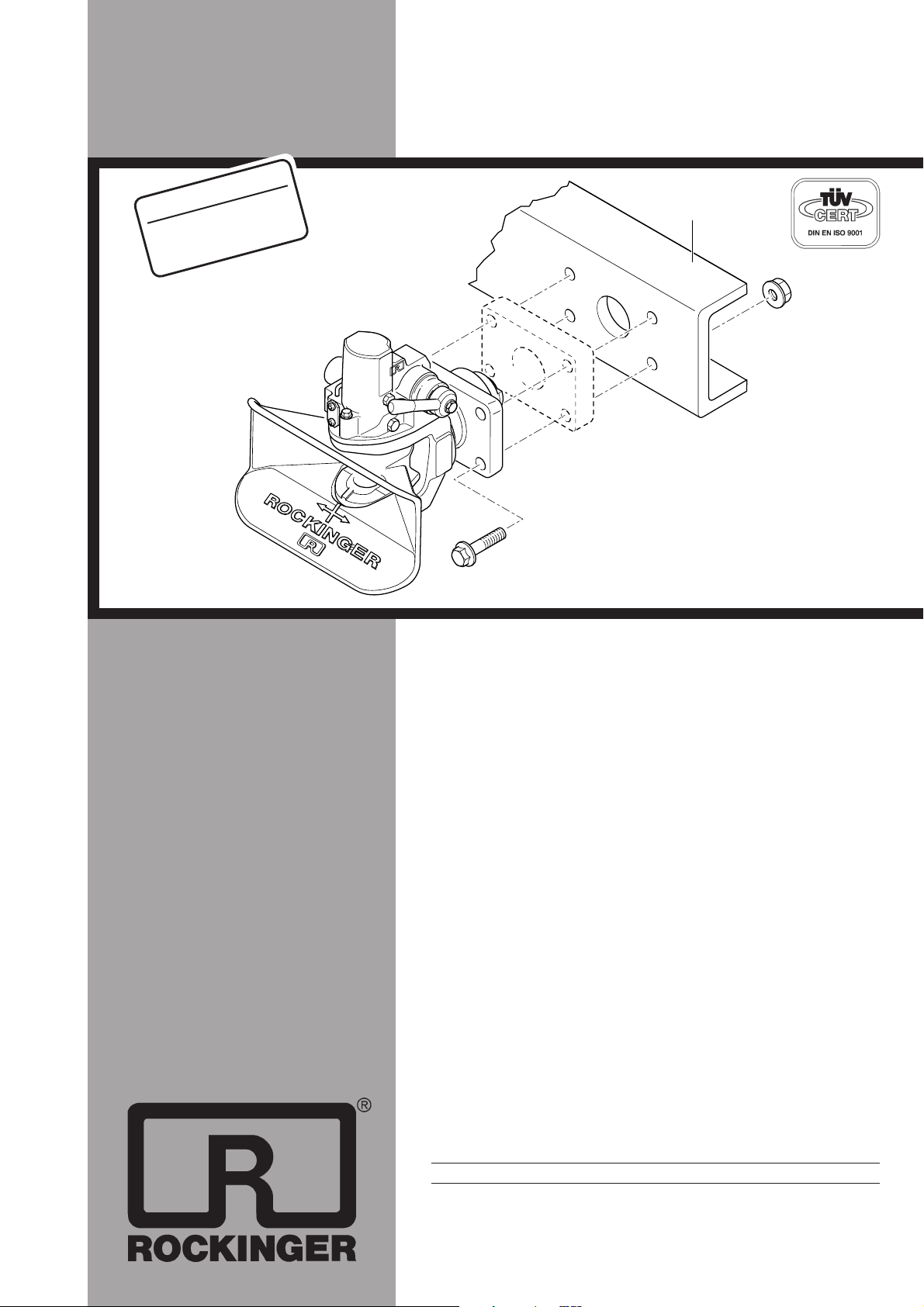

x Mounting plate must be mounted to the crossbar (T)

– Lead the cone into the middle of the hole from the crossbar

– or

– use the interim plate (see Fig. 1, Ref. no. 71053)

– Agriculture- and forestry in connection with a suitable

– ROCKINGER-coupling holder, mounting dimension 330mm:

– Mount the fastening bearing of the coupling on the coupling holder –

– 70904 (with vertical load 2000 kg interim plate not permissible)

– see page 4 too.

x Attach with:

– 4 hexagon head cap screws to DIN 931, grade 10.9

– 4 self-locking nuts to DIN 6925, grade 10

Please see table for details of nut and screw size.

Note: Please comply with vehicle manufacturer’s specifications

regarding nut and screw grade if these differ from above!

Caution: Bolt heads should be on coupling head side

(outer side of crossbar) to avoid impairing movability of coupling

(see Fig. 1)

Tightening torques when attaching screws to mounting plate:

coupling screw tightening width across

size size torque (Nm) flats S (mm)

6 M 20 725 30

Crossbars with holes through the entire surface

Grip corresponding to the crossbar design of the vehicle manufacturer, with

S=2000 kg: min. grip 60 mm, load 430 N/mm

2

Note: Before painting, it is essential to close coupling and grease or

cover coupling pin.

Im

p

o

rta

n

td

o

c

u

m

e

n

t!

m

ust be handed to the

custom

er before the coupling

is m

ounted!

Fig. 1

Type 560 U 6 e1 00-0404

class C 50-X

KE 0700 II 1249-GB As at 0700

Subject to technical changes without prior notice

2. Operation

2.1 Hitching

The regulations of the relevant employer’s liability insurance

association must be observed when hitching and unhitching.

x Push hand lever upwards until it engages when hitching.

x Check whether funnel is locked.

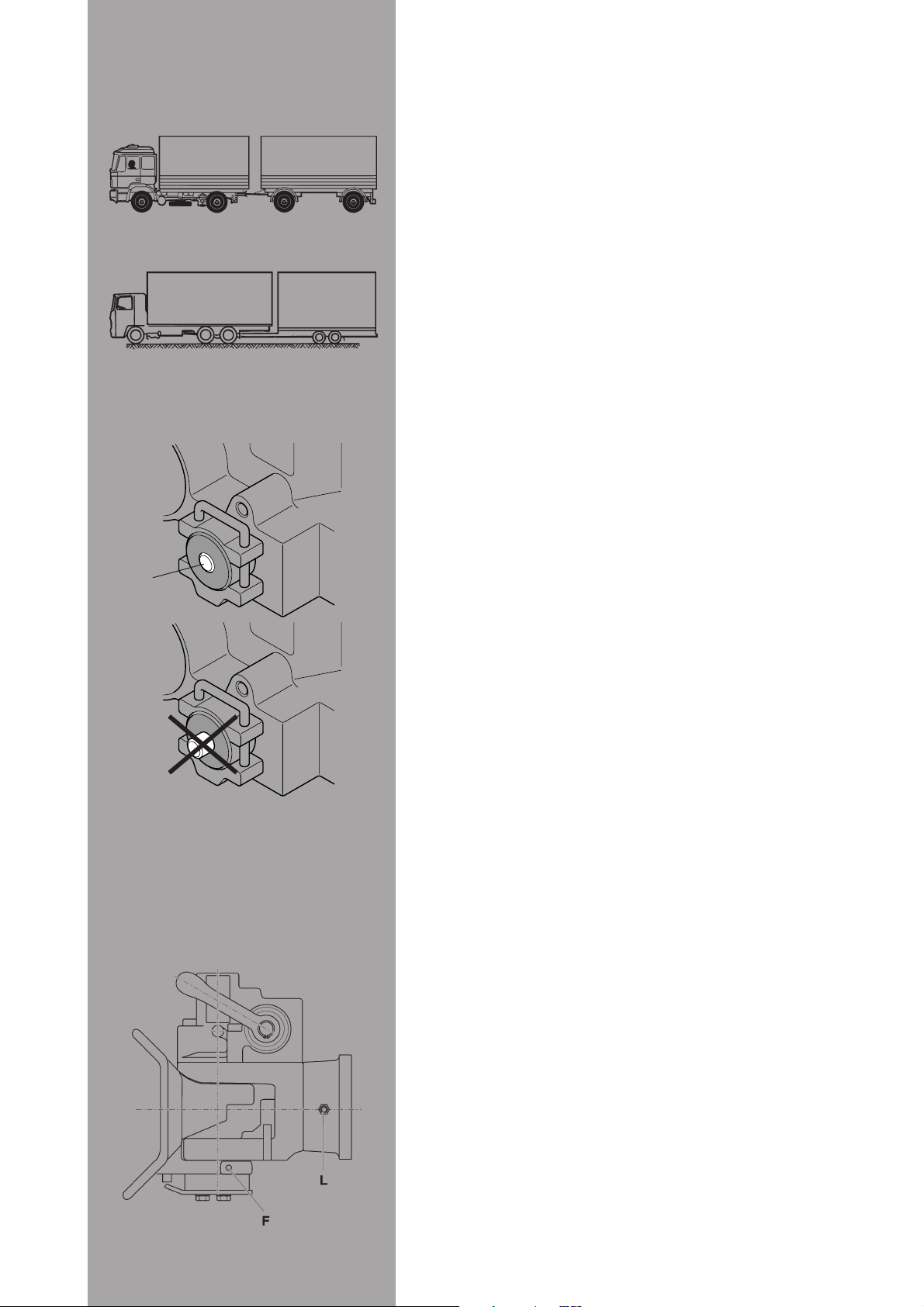

x Release brake on front axle of full trailer (Fig. 2).

x Set drawbar eye to height of coupling point (centre of

funnel).

x Slowly reverse tractor unit.

When hitching a central-axle trailer (Fig. 2) please note the

following:

x Drawbar eye must mate with centre of funnel. If not, this can

result in damage to funnel, drawbar eye, automatic unit and

support unit.

Check

Caution: After every hitching operation it is essential to check that

the coupling is engaged as required by regulations.

The check pin must be flush with its guide bush after hitching

(see Fig. 3).

If the check pin protrudes from its guide bush (this can also

be established by touch if dark), this indicates that hitching has

not been carried out correctly, and that you are at risk

of an accident.

The truck may not be driven with the trailer in this condition!

Remedy:

– Advance tractor unit approx. 1 m and then reverse again.

– Check again.

In-cab status indicator upgrade kit available for retrofitting.

2.2 Closing coupling manually

(e.g. for tow-rope)

x Raise coupling pin with suitable tool

or

x Strike hand lever knob briefly in opening direction with heel of

hand.

3. Maintenance

3.1 Care

x Lubricate coupling pin, support ring and drawbar eye with

heavy-duty grease (EP3) which is waterproof if possible before

first use and after extended period in use.

x Low-maintenance automatic unit has a grease reservoir

(regular greasing unnecessary, please see below for repair

information).

x Lubricate lower funnel bearing (F) and bearing (L) with EP3

(intervals: 6 months or 50.000 km), see Fig. 4

x Close coupling before cleaning with high-pressure washers

(see para. 2.2).

x After cleaning, relubricate coupling pin and support ring

with EP3.

Please note the following when carrying out repairs on coupling

(e.g. changing coupling pin):

x Remove as much of old grease as possible.

x Relubricate with multi-purpose grease NLGI 2.

OOppeerraattiioonn

MMaaiinntteennaannccee

Fig 3

Tractor unit with drawbar trailer

Tractor unit with central-axle trailer

Fig. 4

Fig. 2

o.k.

Loading...

Loading...