Robot Coupe R502X Service Manual

OPERATION MANUAL

FOR

Models

R502 Series E

Serial Numbers: 537xxxxx03

and

R602 Series E

Serial Numbers: 540xxxxx03

Also includes submodels R502Y,

R602Y, R502X and R602X

I. INTRODUCTION

II. ASSEMBL Y/DISASSEMBL Y INSTRUCTIONS

III. OPERA TING INSTRUCTIONS

IV . PREVENTIVE MAINTENANCE GUIDE

V . TROUBLE SHOOTING AIDS

VI. SERVICE AGENCY LISTING

PARTS DRA WINGS & P ART LISTS

ELECTRICAL SCHEMA TICS

SERVICE AGENCY LIST

robot coupe U.S.A., Inc.

P.O. Box 16625, Jackson, MS 39236-6625 264

South Perkins St., Ridgeland, MS 39157

email: info@robotcoupeusa.com

website: www.robotcoupeusa.com

1-800-824-1646

August 2009

IMPORTANT NOTICE

3-PHASE MOTORS

DRIVE SHAFT ROTATION

R502 and R602 Operation Manual

Series E versions

Three phase motors may rotate either direction.

The required motor rotation is counterclockwise.

Check the rotation before attaching the cutter blades.

Changing the motor rotation requires a qualified electrician.

Also, see the note attached to the end of the power cord.

2

R502 and R602 Operation Manual

Series E versions

CAUTION:

Always connect the Robot Coupe to a grounded

outlet with Ground fault circuit interrupter

(GFCI) protection device.

Disconnect the machine from the power outlet

when not in use and when cleaning or servicing the unit.

Machine must be operated and stored in a location not subject to water drips or spray or

explosive vapors.

The machine must not be modified in any way

from its original configuration.

Should the machine malfunction or should any

part be damaged, it must not be operated until

it is repaired by a qualified technician using only

genuine Robot Coupe® repair parts.

Operating times of 5 minutes or longer can

cause processed food to increase to temperatures above 125 F.

Failure to follow operating instructions or attempts to operate the machine outside its design limits may create a hazardous condition

that could damage the machine and /or injure

users.

I. INTRODUCTION

The Robot Coupe commercial food processor performs a host

of culinary feats. It is specifically designed for high speed and

quality vegetable processing. The Robot Coupe also provides

a wealth of safety and operating features to make volume food

preparation a pleasure rather than a chore.

This operators manual is broken down into sections giving

you detailed instructions for assembly and operation of the

continuous feed attachment and the cutter bowl attachment.

Close attention should be paid to all instructions in this manual

to ensure a long life and safe utilization of your food proces-

sor.

This manual should be kept within easy access

to all users for reference, and should be read

completely by all first time users of the machine.

CAUTION: Y our Robot Coupe comes with sharp

cutting blades and or, cutting “Discs”. Always

handle with safety in mind. Always wear a pair

of cut-resistant gloves when handling any cutting discs or blades.

Never put nonfood items in the machine.

NOTICE: If the machine fails to operate as described in this manual, or if the machine malfunctions in any way , remove the machine from

use and have it serviced. Additionally, discard

all food processed at the time of the malfunc-

tion.

The machine must be operated on a clean sturdy

counter or table. Keep the area around and

under the machine clear to allow air circulation.

Otherwise, the motor can overheat.

Machine Specifications:

Models R502 and R602 are equipped with 2 speed motors that

plug into a standard 208/240 volt 60 Hz 3 phase power outlet.

The full load amperage rating is 2.6 amps on low speed and 2.8

amps on high speed. The machines are supplied with stainless steel bowls: the R502 with a five quart and the R602 having a 7 quart bowl. Both machines are supplied with s-blade

and clear polycarbonate cover. The machines are supplied

with a continuous feed attachment and 2 cutting discs as

standard equipment. Additional cutting discs are available as

optional equipment.

3

R502 and R602 Operation Manual

Series E versions

II. ASSEMBLY / DISASSEMBLY

INSTRUCTIONS

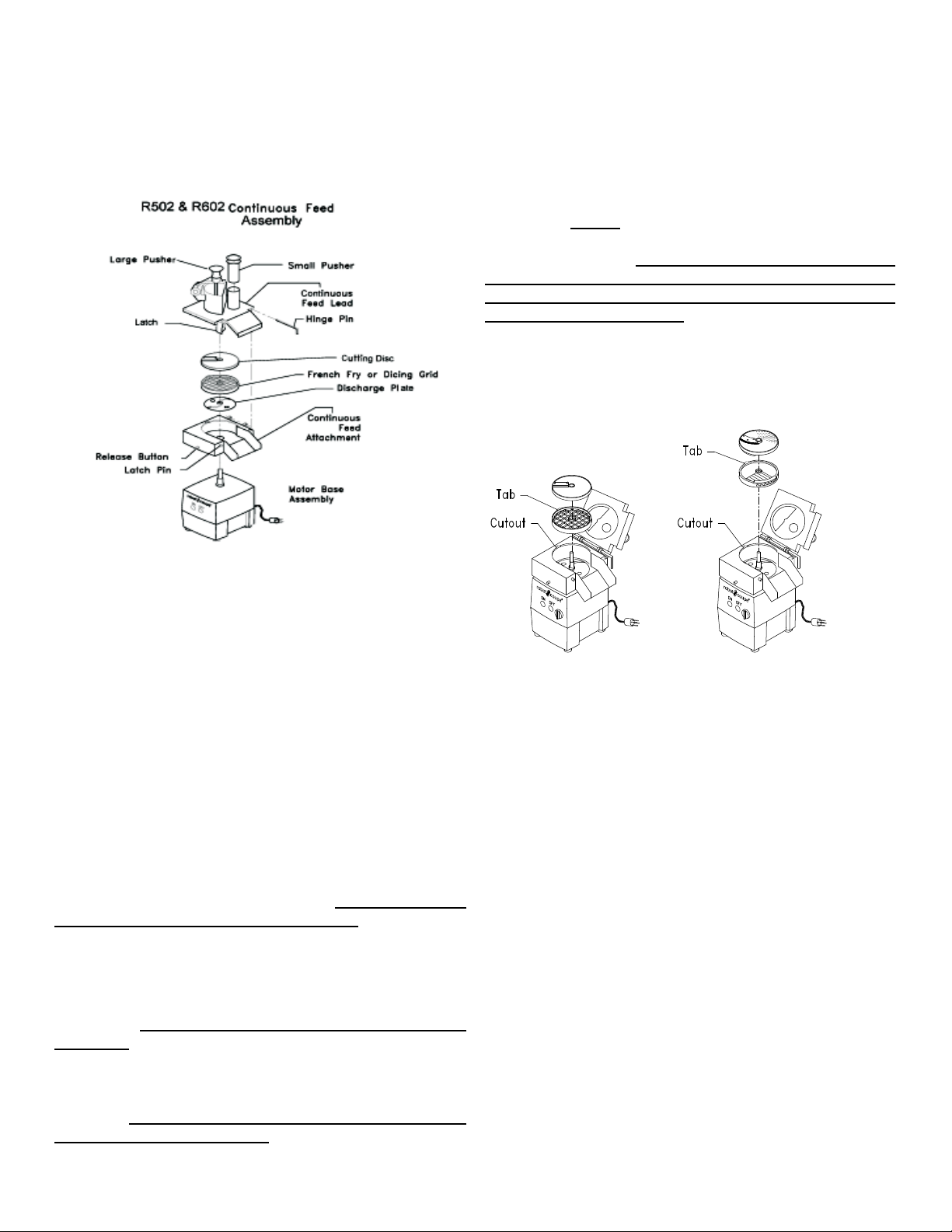

A. Assembling the Continuous Feed

Attachment

and clean so the grid can be firmly seated. The discharge

plate must be in the machine or the product will not exit.

With the tab on the plastic grid aligned with the cutout in the

Continuous Feed Attachment, place the plastic grid onto the

recessed rim of the Continuous Feed Attachment. Put the

appropriate slicing plate on top of the dicing grid with the stem

of the plate DOWN. NOTE: Only those slicing plates designed with a locking “L” shape slot can be used in conjunction with a dicing grid. Never attempt to use a “regular” slicing

disc (1mm, 2mm, 3mm) in conjunction with a dicing grid as it

may cause damage to the continuous feed lead and/or the

pusher (see chart on page 7). Rotate the disc until the cutout

in the stem drops into place on the motor shaft pin. Continue

rotating the disc a full turn. If rubbing occurs,

DO NOT PROCEED-call your service agency .

French Fry Combination

Dicing Combination

Assembly

Assembly

ALWAYS UNPLUG THE CORD DURING

ASSEMBL Y AND DISASSEMBL Y

STEP #1 Place the motor base assembly at a comfortable

height on a sturdy work surface. Remove the plastic discharge

plate from inside the continuous feed attachment. Place the

continuous feed attachment on the motor base with the release button at front center of the motor base assembly . Rotate the attachment counterclockwise until it locks into place

with a snap action. When the attachment is in the proper

position, it should be level with the top surface of the motor

base assembly. NOTE: The machine will not operate correctly unless the continuous feed attachment is fully seated

and secured in place.

STEP #2 Place the discharge plate on the motor shaft with

the appropriate side up. Use the side with the small straight

fins for all julienne cuts or other delicate cuts. The large finned

side may be used for dicing or shredding. The product will not

exit the machine without the discharge plate.

Warning Wear cut-resistant gloves when

handling the cutting plates or the blade.

STEP #3 IF YOU ARE PREPARING TO SLICE OR

JULIENNE: Place the plate of your choice on the motor shaft

and turn clockwise until it drops into place and is fully seated.

The top of the plate should be just above the surface of the

continuous feed attachment.

STEP #4 IF YOU ARE PREPARING TO DICE OR USE A

FRENCH FRY COMBINATION: NOTE: The recessed rim

on the continuous feed attachment must be free from product

STEP #5 Place the continuous feed lead on the continuous

feed attachment and secure in place with the holding pin. The

lead should fit flush on the continuous feed attachment.

B. Disassembly of the continuous feed

attachment

STEP #1 Turn the unit off and unplug the power cord from

the wall outlet.

STEP #2 Pull out the hinge pin from continuous feed lead

and lift the latch at upper right front of machine and remove

the continuous feed lead.

STEP #3 Remove the cutting disc. Wear cut-resistant gloves.

Rotate the disc slightly counterclockwise, then lift up and off of

the motor shaft. Remove the dicing or French fry grid (if any)

then, lift out the plastic discharge plate.

STEP #4 Press the release button on the continuous feed

attachment and at the same time turn the continuous feed

clockwise . The continuous feed releases and can be lifted

off over the motor shaft.

4

R502 and R602 Operation Manual

Series E versions

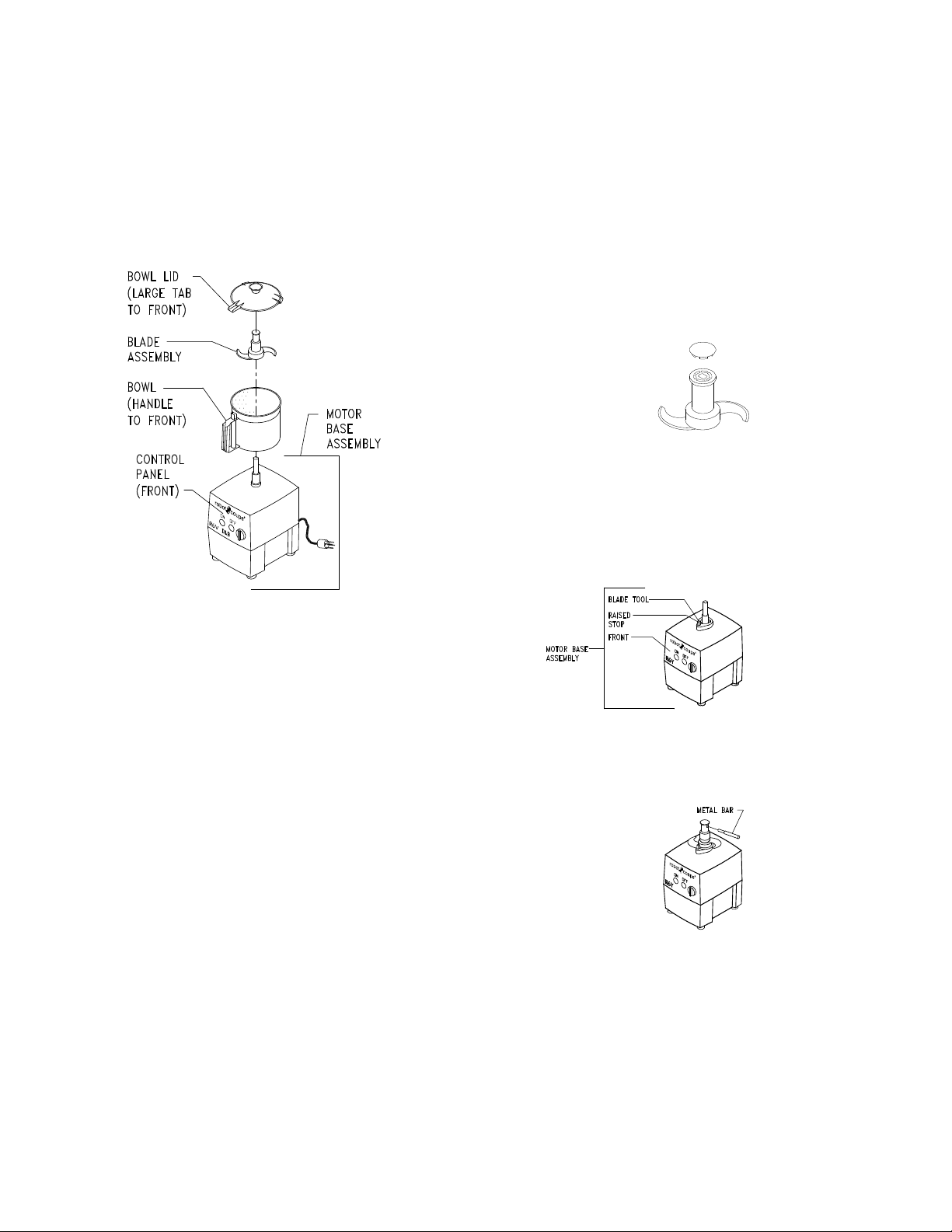

C. Assembling the Cutter Bowl Attachment

1. The cord should always be unplugged during assembly

and disassembly .

2. With the handle turned to the front, put the bowl down on

the motor base. Turn the bowl handle to the lef t of center

and the bowl should drop into place level with the top of the

motor base.

E. Blade Assembly / Disassembly

The blade should be disassembled and cleaned at least

once a day and after each day’s use.

R502 Blade:

1. Unplug the cord and wear cut-resistant gloves!

2. There is a removable cap in the top of the Blade. The cap

should be removed before cleaning. T o remove the cap, push

a long blunt object such as a screwdriver, through the bottom

of the blade, and knock out the top cap.

R602 Blade:

1. Unplug the cord and wear cut-resistant gloves!

2. Locate the blade tool shipped with your machine and put

it down over the motor shaft with the raised stop facing the

front of the machine.

3. Turn the handle back to the right until it comes to a stop

and is centered with the front of the motor base.

4. Put the blade on the motor shaft and turn until it drops

into place. The bottom blade should be parallel to and

almost touching the bottom of the bowl.

5. With the long tab on the bowl lid turned to the left of

center, put the lid on the bowl and turn counterclockwise

until it stops. The long tab should be centered over the

bowl handle.

6. DO NOT OPERA TE THE MACHINE UNLESS IT IS

PROPERLY ASSEMBLED AND THE LID IS FULLY

SEA TED AND CENTERED OVER THE BOWL!

D. Disassembly of the cutter bowl attachment.

STEP #1 Turn the machine OFF and UNPLUG it.

STEP #2 Rotate bowl lid clockwise and lift off.

STEP #3 Remove the blade assembly.

STEP #4 Locate the release trigger on the lower back portion

of the bowl handle. Pull the trigger and, at the same time,

turn the bowl clockwise and lift free.

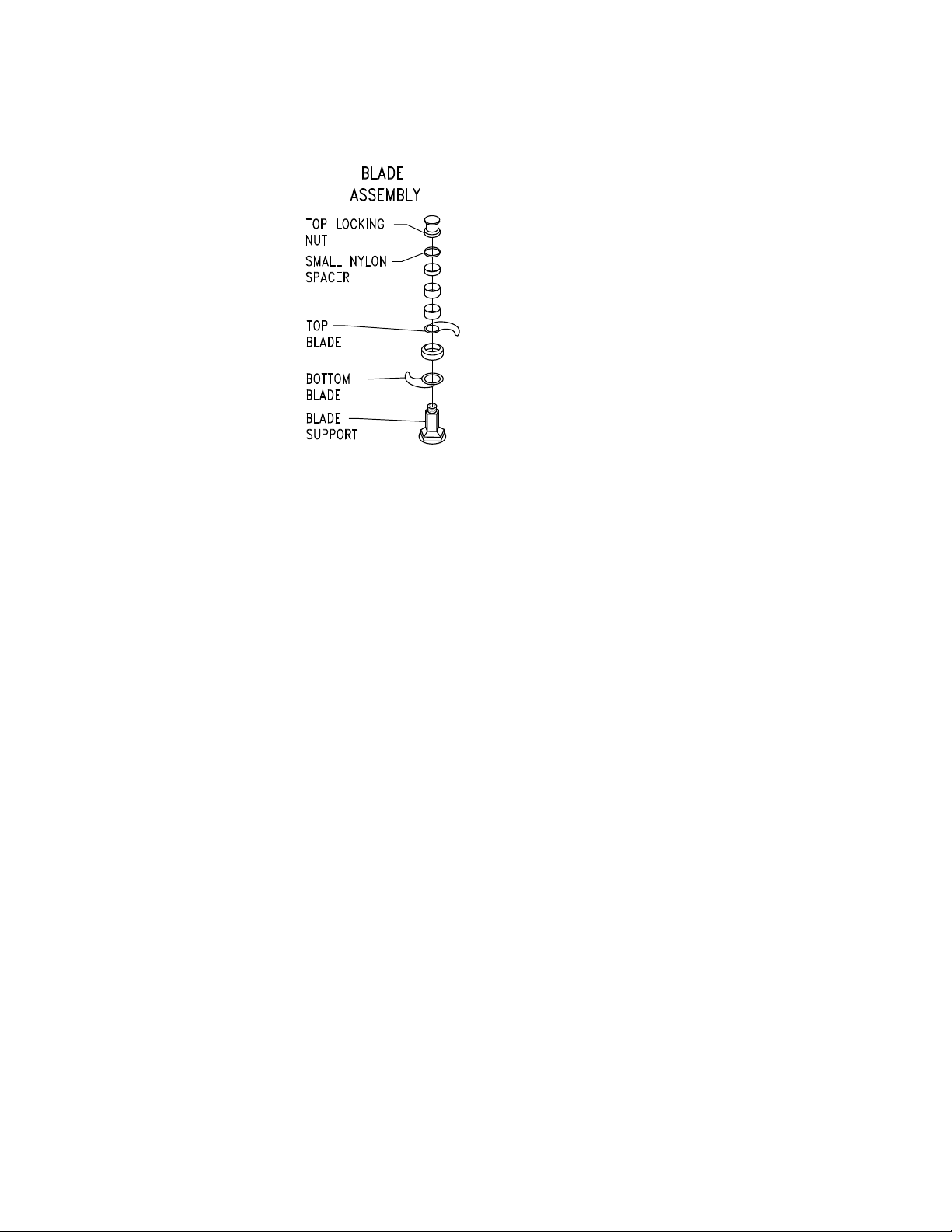

3. Put the blade on the motor shaft so that the center of the

blade assembly rests flat on the blade tool. Insert the metal

bar into one of the holes in the blade cap.

4. Turn the blade cap clockwise to tighten or counterclockwise to loosen. The bottom blade should hit the stop on the

blade tool which prevents the assembly from turning. Do

not overtighten.

Continued next page

5

R502 and R602 Operation Manual

Series E versions

5. Assemble the blades as shown, with the small nylon

spacer directly under the top locking nut. The blades

should be installed beveled side up. The correctly assembled

blade looks like the letter “S”.

THE BLADE ASSEMBLY

SHOULD BE TAKEN

AP ART AND CLEANED

AT LEAST ONCE A DAY.

APPLY SOME FOODGRADE GREASE OR OIL

TO THE R6N ASSEMBLY

TO EASE DISASSEMBLY.

III. OPERATING INSTRUCTIONS

A. Operation of the Continuous Feed Attachment

THE UNIT SHOULD BE IN THE OFF POSITION EXCEPT

WHEN PROCESSING IS UNDERWAY. It is recommended

that the machine be operated on a 50% duty cycle. This is

easily accomplished since the preparation time (cleaning, coring, peeling, and loading) takes longer than the processing

time.

If necessary , cut products to fit the chosen opening. Use the

small round opening for (carrots, cucumbers, etc.).

Always use the food pushers to force the product through the openings.

DO NOT attempt to run frozen products through

the cutting plates.

(1) Slicing Operation:

The vegetables must be prepared so that they will fit into the

chosen entry port. Produce such as carrots, cucumbers, etc.,

should be “squared” at both ends. This will provide a consistent slice throughout the whole product. Remove the core

from cabbage and lettuce and cut into halves or thirds to fit in

the large entry port.

(2) Grating Operation:

Veget ables must be prepared so that they will fit into the chosen entry port.

Use cold cheese and apply a fine coating of cornstarch before

grating to keep the finished product from sticking together.

The cornstarch will not be visible and is tasteless. Grating

cheese can cause overheating of the motor if not grated in the

recommended manner. It is recommended that a slight pulsating pressure be applied with the pusher, alternating slight

pressure then no pressure. Prepare the cheese in volumes

that will permit motor cool down time during long production

runs.

(3) Dicing Operation: The dicing operation requires that product be sliced both horizontally and vertically . The smaller the

dice required, the more difficult the cut is to achieve. Soft or

juicy produce will tend to mush if the dice is too small or the

produce is too soft.

Do not attempt to dice meats or cheeses.

Damage could occur to the blades and/or the motor that will

not be covered under warranty .

Constant pressure with the pusher will yield a consistent output. More pressure will increase the thickness of the product,

while light pressure will result in a thin product. If no pressure

is applied, the result is sometimes inconsistent. When the

pusher comes to a stop, push the off button and reload the

entry port.

Note: Application of too much pressure will

increase the motor load without increasing the

amount of product being cut.

DO NOT remove the continuous feed lead when

the motor is running. Wait until the motor has

come to a full stop.

DO NOT put anything other than food products

inside the entry or exit port.

During the dicing operation, attention should be given to the

finished product. A visible change in the product will occur

when the dicing grid requires cleaning eg., more liquid. The

best way to clean the grid is to remove it from the machine

and force any produce on the grid through with a stiff bristle

brush.

(4) Julienne Operation: Insertion of the product to be cut must

be horizontal if a long “stick” is to be achieved, e.g. julienne

zucchini for sauté. Vertical insertion will result in finely chopped

products, e.g. celery. A finely chopped onion product may

also be obtained with this operation by quartering the food

and letting it gravity feed.

Do not attempt to julienne meats or cheeses.

6

Loading...

Loading...