Page 1

OPERATION MANUAL

FOR

MODELS

R4Y Series A

Serial Numbers-R4YxxxxxxA

and

R6Y Series A

Serial Numbers-R6YxxxxxxA

robot coupe U.S.A., Inc.

P.O. Box 16625, Jackson, MS 39236-6625

280 South Perkins St., Ridgeland, MS 39157

email: robocoup@misnet.com

website: www.robotcoupeusa.com

1-800-824-1646

Page 2

R4Y and R6Y Series A

Operation Manual

I. INTRODUCTION

The Robot Coupe commercial food processor performs a host

of culinary feats. It is designed for high speed and quality

vegetable processing. The Robot Coupe will chop, grind,

puree, mix, or knead using the cutter bowl attachment.

This operators manual is broken down into sections giving

you detailed instructions for assembly and operation of the

continuous feed attachment and the cutter bowl attachment.

Close attention should be paid to all instructions in this manual

to ensure a long life utilization of your food processor.

This manual should be kept within easy access

to all users for reference, and should be read

completely by all first time users of the machine.

Maintaining the food processor in good working condition is

one of the most important measures to be taken. Inspect the

machine and all parts regularly to make sure they are in good

working condition.

I. INTRODUCTION

II. ASSEMBLY/DISASSEMBLY

INSTRUCTIONS

III. OPERATING INSTRUCTIONS

IV. PREVENTIVE MAINTENANCE

GUIDE

V. TROUBLE SHOOTING AIDS

VI. SERVICE AGENCY LISTING

DO NOT operate a machine that has malfunctioned in any way.

Discard any food processed at the time of a malfunction and have the machine inspected and repaired at

one of the Robot Coupe Authorized Service Agencies, a list is

provided in the back of this manual. Contact one of these

service agencies for all of your service, parts and accessory

requirements.

CAUTION: Your Robot Coupe comes with a

sharp cutting “S” blade. Always handle with

safety in mind. We suggest that a pair of cutresistant gloves be worn when handling the “S”

blade.

Machine Specifications:

The Models R4Y and R6Y are equipped with a high speed

motor generating 1 Hp which plugs into a standard 120 volt/

60 Hz, 15 amp power outlet. The full load amperage rating is

12 amps. The machines are supplied with a stainless steel

bowl. The R4Y has a 4 liter bowl and the R6Y has a 6 liter

bowl. The machines are supplied with S-blade and clear plastic cover. The machines are equipped with push type on/off

buttons.

Page 3

R4Y and R6Y Series A

Operation Manual

II. ASSEMBLY/DISASSEMBLY

INSTRUCTIONS

Your Robot Coupe should be placed on a sturdy work surface at a comfortable working height and have a standard 115 volt

power outlet available. Always keep the machine unplugged during assembly and disassembly.

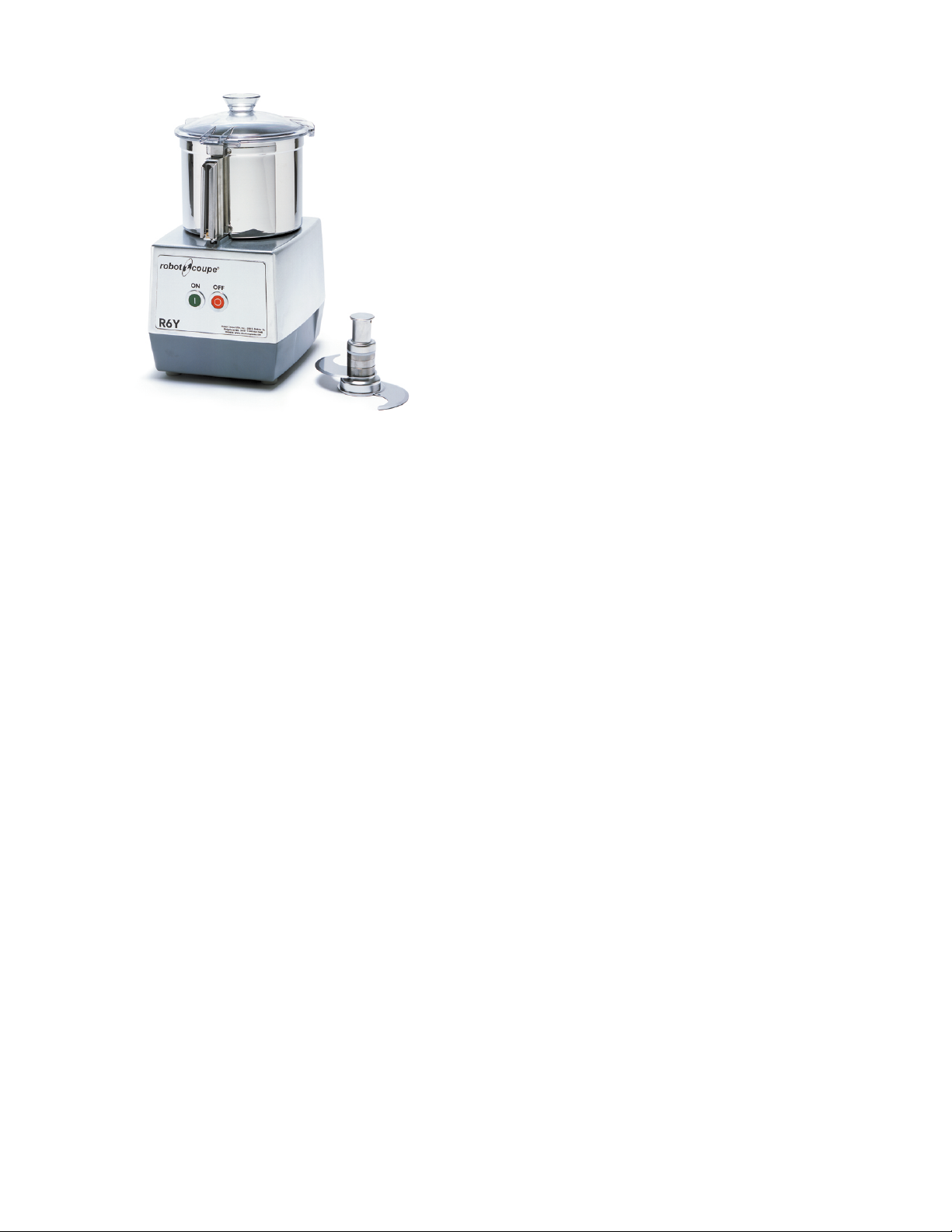

A. CUTTER BOWL ATTACHMENT

ASSEMBLY INSTRUCTIONS

Illustration #1

Become familiar with the part names as you

assemble the unit.

Always use caution and wear cut-resistant

gloves when handling the blade.

Always unplug the machine during

assembly and disassembly.

Illustration #2

1. Unplug the machine.

2. Place the bowl on the motor base assembly with the

handle located just off center, and to the left, as you are

facing the front of the unit.

Bowl Lid

(large tab to

front)

Blade

Assembly

Bowl

Control Panel

(front)

Illustration

#1

Motor Base

Assembly

Illustration

2

3

#2

3. Then, turn the bowl back counterclockwise, locking it

in place.

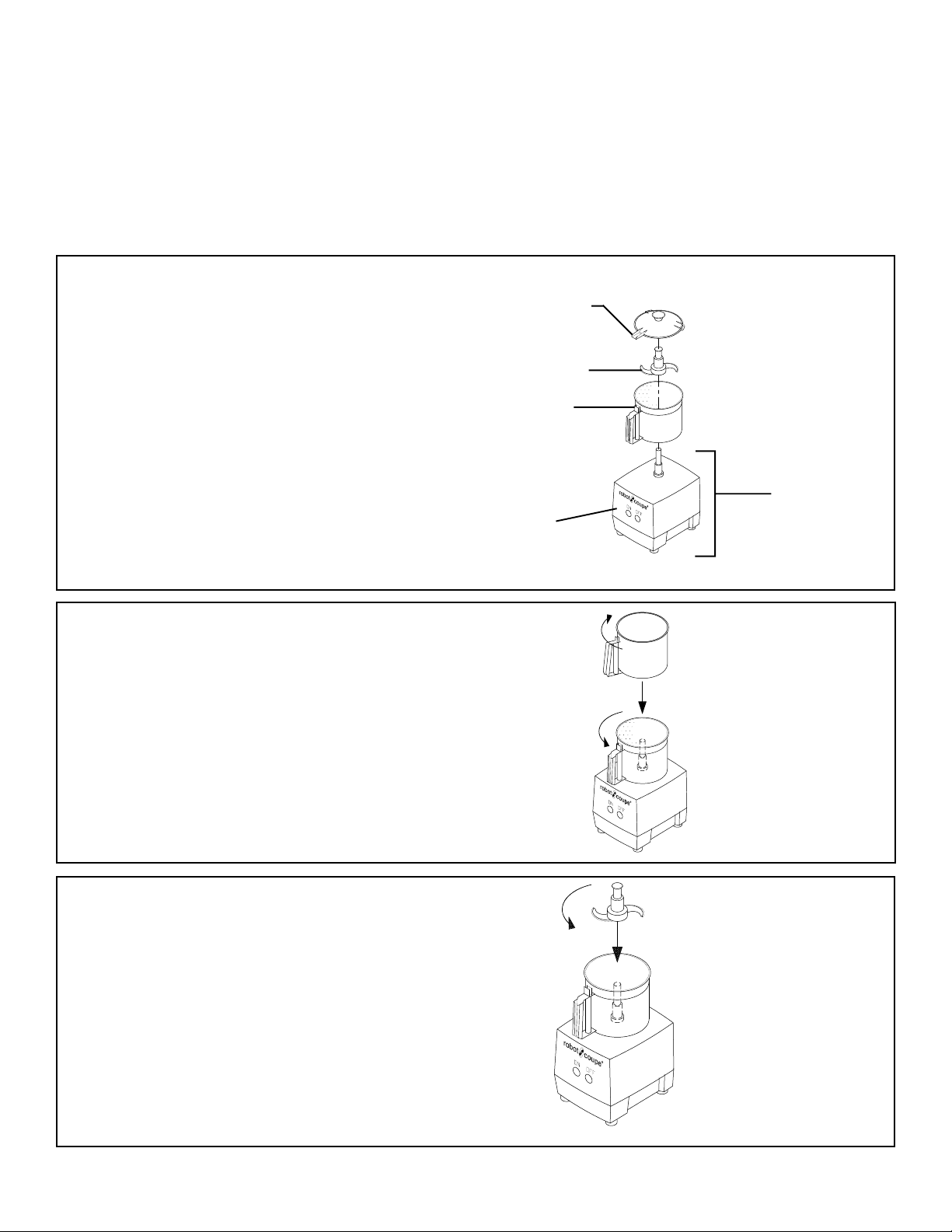

Illustration #3

4. Place the blade on the motor shaft. Rotate the blade

until it falls into place on the motor shaft. The bottom

blade should be just off of and parallel with the bottom of

the bowl.

4

Illustration

#3

Page 4

R4Y and R6Y Series A

Operation Manual

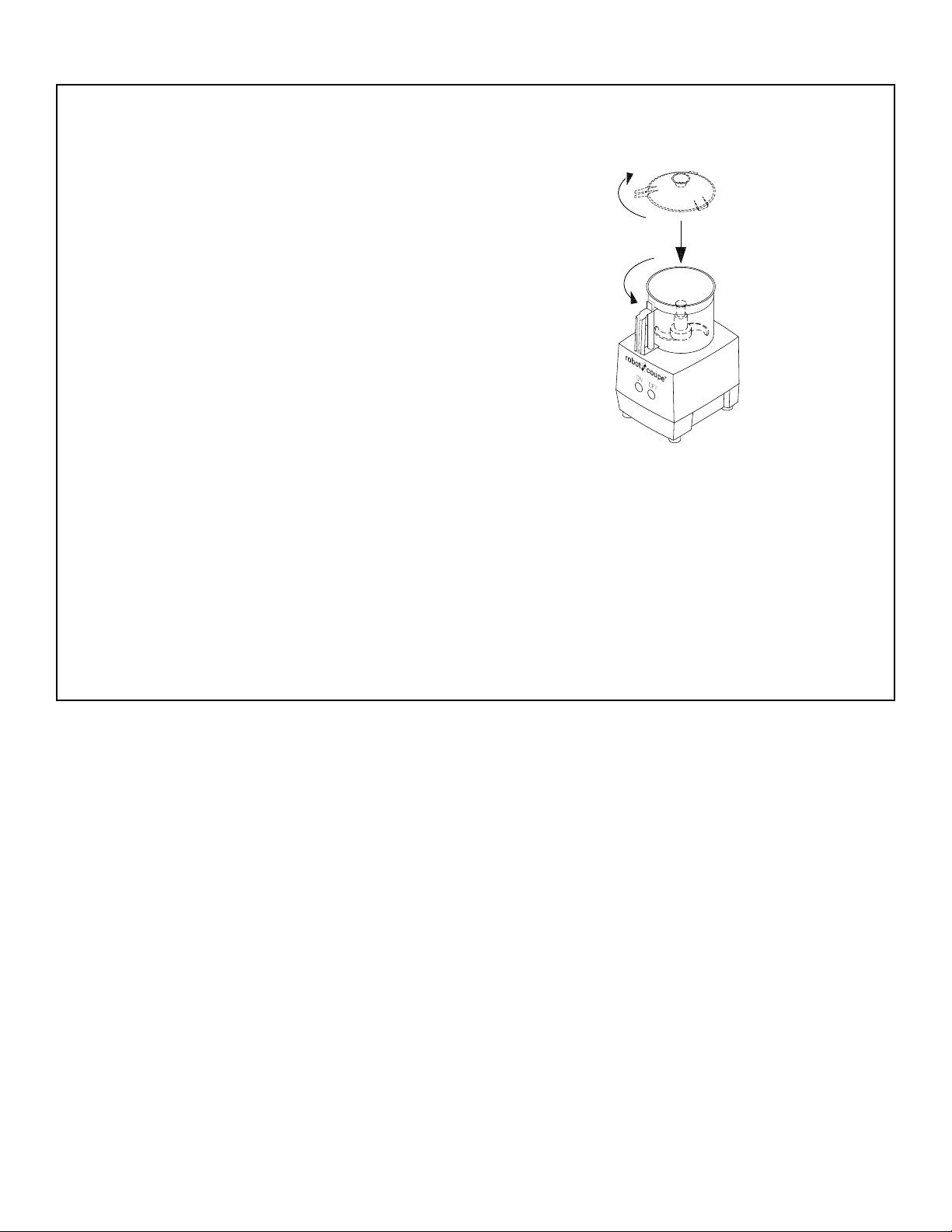

Illustration #4

5. Facing the front of the motor base assembly, place the lid

on the bowl with the long tab turned off-center and to the left.

6. Turn the lid back to the right (counterclockwise) until it

locks in place and the long tab is centered over the handle.

7. DO NOT OPERATE THE MACHINE UNLESS

IT IS PROPERLY ASSEMBLED WITH THE LID

CENTERED ON THE BOWL AND THE LONG

TAB LOCKED IN PLACE OVER THE BOWL

HANDLE!

NEVER ATTEMPT TO DEFEAT THE SAFETY

SWITCH MECHANISM.

ALWAYS USE THE OFF SWITCH TO TURN THE

MACHINE OFF.

The Food Processor is now assembled and ready to perform its desired function.

Illustration #4

5

6

BEFORE CONTINUING YOU SHOULD COMPLETELY READ THE INSTRUCTIONS CONTAINED IN THE REST OFF THIS MANUAL.

Page 5

R4Y and R6Y Series A

Operation Manual

B. CUTTER BOWL ATTACHMENT

DISASSEMBLY INSTRUCTIONS

STEP #1 Turn the machine OFF and UNPLUG the power

cord from the wall socket.

STEP #2 Rotate the bowl lid clockwise and lift off.

STEP #3 Firmly grasp the top of the blade assembly and lift

off of the motor shaft.

STEP #4 Locate the release trigger on the lower back portion

of the bowl handle. Pull the trigger, and at the same time, turn

the bowl clockwise and lift free.

C. BLADE DISASSEMBLY

INSTRUCTIONS

(6 Liter Models Only)

The blade assembly comes from the factory completely

assembled. To take the assembly apart, use the plastic bladestop and metal rod shipped with the machine.

Put the blade on the blade-stop, and insert the metal rod into

the hole near the top of the blade assembly. Then, turn the

blade assembly counterclockwise until it contacts the raised

tab on the blade stop. The blade assembly will come to a

stop when it hits the tab on the blade-stop. At this point,

continue to turn the rod in the counterclockwise direction, until

the top locking nut releases and unscrews.

Wear cut-resistant gloves when handling

the blade assembly.

Put the blade-stop on the machine as shown.

D. BLADE ASSEMBLY INSTRUCTIONS

(6 Liter Models Only)

Put the blade assembly together as shown. The blade turns

counterclockwise, so assemble the blades with the bevelled

side up. The blades should be spaced opposite each other at

180 degrees apart.

Page 6

R4Y and R6Y Series A

Operation Manual

III. OPERATING INSTRUCTIONS

THE UNIT SHOULD BE OFF EXCEPT WHEN PROCESSING IS UNDERWAY.

It is recommended that the machine be operated on a 50%

duty cycle. This is easily accomplished since the preparation

time (cleaning, coring, peeling, and loading) takes longer than

the processing time. This will yield the longest life for your

machine.

NOTE: Some models may be equipped with a manual reset

circuit breaker. If the machine is overloaded or run too long

under heavy load conditions, the breaker will trip. If this occurs, first remove the bowl and reduce the amount of food

being processed. The reset button is located on the bottom

left side of the motor base. Press the button in to reset the

overload protector. It may be necessary to allow the machine

to cool a few minutes before restarting.

DO NOT allow the machine to run unattended.

INSTRUCTIONS FOR USE OF THE CUTTER

BOWL

The cutter bowl attachment is used for grinding, pureeing,

blending, mixing, of ingredients. With the power switch off

and the bowl and blade secured in place (per previous instructions) you are now ready to add product to the bowl.

There are two ways to run your machine. Chopping using a

quick start/stop action, or running continuously for a fine chop

or puree.

3. TO CHOP HARD CHEESE: Place uniform 1” to 1 1/2”

cubes of chilled cheese up to 1 1/2 pounds into the bowl and

follow the instructions for chopping. For powdered cheese

chop until the cheese is about pea size then allow the motor

to run continuously until you have a fine powder.

4. TO CHOP ONIONS, CELERY, CABBAGE, ETC. Quarter onions, and cut other vegetables into 2 to 3 inch portions.

Place the product into the bowl up to 3/4 full and follow the

previous chopping instructions until you reach the desired consistency. CAUTION: If you overfill or allow the machine to run

continually, the product on the top may not be cut while that

on the bottom will be pureed.

5. TO PUREE OR MIX: To puree, make sauces, or to mix

and blend, place the ingredients into the bowl (do not overfill),

turn the unit on, and allow to run continuously.

6. TO MAKE MAYONNAISE: Place in the bowl 6 eggs, 3

tsp. of salt, 3 tsp. of sugar, 2/3 tsp of dry mustard, a pinch of

white pepper, and a pinch of red pepper. Turn the unit on.

Begin adding 2 qts. of oil pouring very slowly through the top

allowing the stream of oil to fall on the top of the cutter blade.

When you have added 1/2 of the oil, pour in 4 oz. of vinegar

and the balance of the oil. After all of the oil has been added

let the machine run for 20 seconds longer. The mayonnaise

is now homogenized.

7. TO MAKE BREAD CRUMBS: Place torn fresh or dried

bread in the bowl, and quickly start and stop the unit. Continue this process until you reach the desired consistency, or

allow the unit to run continuously for fine powered bread

crumbs as used in stuffing mix.

1. TO CHOP

To achieve a chopped consistency for vegetables, meats,

cheese, etc., fill the bowl 2/3 to 3/4 full with portions no larger

than 1 to 2 inches square. Quickly press the on and then the

off button alternately until the desired consistency is reached.

If the motor stalls, reduce the amount of product in the bowl.

2. TO PUREE OR FINE CHOP: For a fine puree, emulsification, or fine chop, fill the bowl 2/3 to 3/4 full with portions no

larger than 1 to 2 inches square. Begin as with the chopping

instructions to reduce the size, then press the on button, and

allow the machine to run until the product is finely chopped or

pureed. Some purees may require the addition of a liquid to

obtain the correct consistency.

DO NOT remove the bowl lid until the blades

have come to a complete stop.

DO NOT remove the bowl while the motor is

running.

DO NOT put nonfood objects into the bowl.

Page 7

R4Y and R6Y Series A

Operation Manual

Sharpening the “S” blade

The “S” blade will require sharpening on a periodic basis depending on use. The use of a dull blade will

sometimes give unsatisfactory results. Follow the directions shown to sharpen the blade, or have the

blades sharpened professionally if you prefer.

1. Put on your cut-resistant gloves

2. Use a Robot Coupe stone or any good sharpening

stone.

3. Hold or clamp the blade flat on the edge or corner of

a sturdy table.

4. With the other hand hold the stone at a 30 degree

angle against the top bevel of one blade.

5. Pull the stone into the blade edge moving from hub

to tip, several strokes, until the blade is sharp.

6. Turn the blade over and rub the stone flat against the

underside of the blade to remove the feather edge

formed at step 5.

7. Repeat the procedure for the other blade.

8. Wash the blades before use.

Page 8

R4Y and R6Y Series A

Operation Manual

IV. CLEANING/PREVENTIVE

MAINTENANCE

(1) CLEANING: Proper cleaning of the machine is one of the

most important preventive maintenance measures the user

can employ. The high acid content of food can cause harm to

the electrical parts contained within the housing. Although a

seal isolates these elements from the outside, food juices will

tend to seep. If food juices are allowed to collect on the machine over periods of use, erosion of the seal can occur. It is

recommended that the machine be cleaned after each operational use.

Correct cleaning procedures are required to assure that damage is not inflicted in the cleaning process. The motor base

assembly contains the motor and electrical components.

DO NOT IMMERSE THE MOTOR BASE ASSEMBLY IN WATER!

CLEANING INSTRUCTIONS

The machine should be cleaned per the following instructions

or as required by local health department regulations.

ATTACHMENTS: Remove and all attachments before cleaning. The bowl, blade, and lid are dishwasher safe. These

attachments can be washed in a dish machine or three tank

system pot sink. Pre-rinse the attachments before washing

to remove any bulk food. A stiff bristle brush or power sprayer

faucet attachment is effective in knocking the food out of the

crevices as a pre-rinse procedure. The washer should have

an industry standard wash, rinse and sanitization cycle. Allow the parts to air-dry after sanitizing and before reassembly.

NOTE: The high temperatures of dish machines

will tend to shorten the life of plastic and rubber parts. Hand washing using a three pot sink

will provide for the longest life of these parts.

MOTOR BASE: Cleaning of the motor base assembly must

be done with care. First unplug the unit. A sponging with a

cloth lightly soaked (not dripping) in a mild detergent is acceptable, making sure the water is not permitted to penetrate

the shaft seal or around the switches. Clean around the shaft

seal with a small brush, taking care to remove all food. Do

not forget to clean the motor shaft. Rinse the motor base first

using a cloth lightly dampened (not dripping) with water, then

with a sanitizing solution, and dry the machine with a soft cloth

removing all liquids from seal areas.

BLADE ASSEMBLY:

Wear cut-resistant gloves when cleaning the blade.

The blade assembly on the 6 liter models must be disassembled before cleaning. See the Assembly/Disassembly

section of this manual. After washing, allow the parts to airdry before reassembly.

(2) PREVENTIVE MAINTENANCE CHECKS

While your Robot Coupe is a ruggedly constructed machine,

overall handling should be accomplished with a sense of use

rather than abuse. Reasonable care should be exercised.

While the machine is reasonably portable, care should be taken

not to drop it. Equally, caution should be exercised in handling all the parts to assure they are not damaged.

An examination should be made periodically to assure that a

seal against liquids is being maintained around the motor shaft.

With proper care, and depending on use, the seal should last

for a year or more. However, it can and should be replaced

whenever wear or erosion is noted, or once every three to six

months. It is recommended that the seal be replaced by an

authorized repair agency.

Blades should be kept sharp. It is not necessary to have a

razor edge however, they will need sharpening periodically.

See the directions for sharpening within this manual. Replacement of the dull blades is recommended.

(3) CARE: Your Robot Coupe is a piece of kitchen equipment

and like all other kitchen equipment, care and caution should

be used when operating. Although training requirements are

minimal, only responsible individuals familiar with this operation manual should be allowed to operate your Robot Coupe.

In general, the best preventive measures that can be applied

are close adherence to the assembly, operation, cleaning,

and handling instructions, common sense and regular maintenance.

Page 9

R4Y and R6Y Series A

Operation Manual

TROUBLE SHOOTING AIDS: The following sections indicate potential problems and the correct solution which should

be implemented by the user. Problems which extend beyond

these will require an experienced serviceman. A list of the

authorized agencies is supplied.

V. TROUBLE SHOOTING AIDS

A. Unit does not start when assembled correctly

1. Pull plug and try another outlet

2. Make sure bowl lid is in the proper position with

the long tab centered at the front of the machine.

C. Unit stops during processing

1. Turn the machine off and unplug.

2. Reduce the amount of product in the bowl.

4. Reassemble the bowl attachment, plug in the

machine, and try to restart by pressing the on button.

D. If unit does not operate after following above:

1. Some models have a circuit breaker. Look for the

white button on the underside of the machine. If the

breaker has tripped, press the button back in. If the

machine doesn’t start after pressing the on button.

Allow the machine to cool, for several minutes and try

again.

2. Check outlet for current (Breaker or Fuse)

2. Try unit again

3. Call local authorized service agency.

VI. SERVICE INFORMATION /SERVICE

AGENCY LIST

Your Robot Coupe has a one year limited warranty against

defects in parts and workmanship. Should the unit require

service, check with your distributor to see where local service

is available. If not or if you wish your unit to be serviced at the

factory, call for a return merchandise authorization (RMA) number, and upon receipt of same, ship it PREPAID and insured

to our factory address.

Robot Coupe USA, Inc. Service Dept.

Phone: 1-800-824-1646

601-898-8411

E. Unit starts to spark or smoke

1. Turn unit off, unplug it, call local authorized service

agency.

Page 10

Page 11

PRICES AND OTHER INFORMATION SUBJECT TO CHANGE WITHOUT NOTICE

MODEL

R4Y

Series A Serial Numbers R4YxxxxxxA

Series A

Part # Description

Indexes

1

RA443

2

RA441

3

RA406

4

RA4933

5

RA418

6

RA419

7

Number NA

8

R664S

9

RA441.1

10

RA441.2

11

RA442

12

C420

13

RA4940

14

R611

15

RA489

16

RA467

17

RA455

18

R604S

19

R492A

20

Number NA

21

S193552

22

Number NA

23

Number NA

24

Number NA

25

Number NA

26

29620

27

BX658

28

RA490

29

R496

30

Number NA

31

117770

32

R694

33

R492A

34 RA604F No longer available

35

R662

36

R237

37

R4950

38

RA494

39

RA493

40

RA402

41

RA420

42

RA451

43

RA422

44

RA423

45

RA472

46

RA424

47

RA424.2

48

RA424.3

49

RA424.4

50

R199

Pad,Rear

Support/Pad,Front

Motor Support

Front Data Plate (R4Y)

Green "On" Switch Assy

Red "Stop" Switch Assy

Description NA

Relay DPST

Gasket

Metal Plate

Support,Magnetic Switch

Mag Swtch w/Hse (single)

R4Y Motor Base Assy

Motor Support Seal

O Ring, Seal Support

Seal Assembly (Seal Support)

Plate, Motor Mounting

Seal, Motor

Shaft Pin (new style)

Description NA

(D) Motor R4Y/R6Y Low Profile

Description NA

Description NA

Description NA

Description NA

(E) Plastic Base, Low Profile

Base Bolt W/Washer

Strain Relief

Cord W/Plug (R4X,S,P,Y)

Description NA

(D) Din Rail 2"L, R4/R6 'D"

Contactor R6Y-1

Shaft Pin (new style)

Bearing, Motor Top

6203 Bearing R2 Top/Btm

Capacitor (R4S R4Y)

Baffle

Base

Foot

Lid

Seal,Lid

* Blade Assy

* Serrated Blade Assy

* Bowl Assy (4 Qt)

Bowl

Pin, Bowl

Spring, Bowl Pin

Nut For Bowl Pin

* Robo-Cart

Page 12

PRICES AND OTHER INFORMATION SUBJECT TO CHANGE WITHOUT NOTICE

MODEL

R6Y

Series A

Series A

Serial Numbers

R6YxxxxxxA

Indexes

Part # Description

1

RA443

2

RA441

3

RA406

4

RA612Y

5

RA418

6

RA419

7

Number NA

8

R664S

9

RA441.1

10

RA441.2

11

RA442

12

C420

13

RA696

14

R611

15

RA489

16

RA467

17

RA455

18

R604S

19

R492A

20

Number NA

21

S193552

22

Number NA

23 CL5547 Switch/Relay

24

Number NA

25

Number NA

26

29620

27

BX658

28

RA490

29

R496

30

Number NA

31

117770

32

R694

33

R492A

34 RA604F No longer available

35

R662

36

R237

37

R4950

38

RA494

39

RA493

40

RA402

41

103903

42

RA645.2

43

RA424.3

44

RA424.4

45

RA451

46

RA653

47

RA657

48

RA654

49

RA654

50

RA655

51

RA656

52

RA617

53

RA658

54

RA659

55

102071

56

RA420

57

RA616

58

RA644

59

RA651

60

RA651A

61

RA645

62

R199

Pad,Rear

Support/Pad,Front

Motor Support

Front Data Plate (R6Y)

Green "On" Switch Assy

Red "Stop" Switch Assy

Description NA

Relay DPST

Gasket

Metal Plate

Support,Magnetic Switch

Mag Swtch w/Hse (single)

R6Y Motor Base Assy

Motor Support Seal

O Ring, Seal Support

Seal Assembly (Seal Support)

Plate, Motor Mounting

Seal, Motor

Shaft Pin (new style)

Description NA

(D) Motor R4Y/R6Y Low Profile

Description NA

Description NA

Description NA

(E) Plastic Base, Low Profile

Base Bolt W/Washer

Strain Relief

Cord W/Plug (R4X,S,P,Y)

Description NA

(D) Din Rail 2"L, R4/R6 'D"

Contactor R6Y-1

Shaft Pin (new style)

Bearing, Motor Top

6203 Bearing R2 Top/Btm

Capacitor (R4S R4Y)

Baffle

Base

Foot

(D) 10mm S.S. Spacer (R6N)

Pin, Bowl

Spring, Bowl Pin

Nut For Bowl Pin

Seal,Lid

Blade Locking Nut

Plastic Spacer(5mm)

SS Spacer(15mm)

SS Spacer(15mm)

Top Blade (Straight)

Top Blade(Serrated)

Spacer,Blade

Bottom Blade (Straight)

Bottom Blade(Serrated)

(D) Blade Support

Lid

Blade Tool Assy.

* Bowl Kit

*Smooth Blade Assembly

*Serrated Blade Assy

Bowl

* Robo-Cart

Page 13

U.S.A., Inc.U.S.A., Inc.

U.S.A., Inc.

U.S.A., Inc.U.S.A., Inc.

PP

.O. Box 16625, Jackson, MS 39236-6625.O. Box 16625, Jackson, MS 39236-6625

P

.O. Box 16625, Jackson, MS 39236-6625

PP

.O. Box 16625, Jackson, MS 39236-6625.O. Box 16625, Jackson, MS 39236-6625

280 South Perkins St., Ridgeland, MS 39157280 South Perkins St., Ridgeland, MS 39157

280 South Perkins St., Ridgeland, MS 39157

280 South Perkins St., Ridgeland, MS 39157280 South Perkins St., Ridgeland, MS 39157

email: robocoup@misnet.comemail: robocoup@misnet.com

email: robocoup@misnet.com

email: robocoup@misnet.comemail: robocoup@misnet.com

website: www.rwebsite: www.r

website: www.r

website: www.rwebsite: www.r

1-800-824-16461-800-824-1646

1-800-824-1646

1-800-824-16461-800-824-1646

obotcoupeusa.comobotcoupeusa.com

obotcoupeusa.com

obotcoupeusa.comobotcoupeusa.com

ROBOT COUPE U.S.A., INC. LIMITED WARRANTY

YOUR NEW ROBOT COUPE PRODUCT IS WARRANTED TO THE ORIGINAL PURCHASER

FOR A PERIOD OF ONE YEAR FROM THE DATE OF PURCHASE.

This LIMITED WARRANTY is against defects in the material and/or workmanship, and includes labor for

replacement of defective parts, provided repairs are performed by an authorized service agency (see attached

list). The

copy of the dated sales or delivery receipt BEFORE WARRANTY REPAIRS ARE BEGUN. Replacement parts

and accessories are warranted for ninety (90) days from the date of purchase when purchased separately and

will be verified by dated sales receipt OR packing slip which lists that item. All parts or accessories replaced

under warranty must be returned to the Service Agency.

CUSTOMER must inform the Service Agency of the possibility of warranty coverage and provide a

THE FOLLOWING ARE

1. Damage caused by abuse, misuse, dropping, or other similar incidental damage caused by or as

a result of failure to follow assembly, operating, cleaning, user maintenance, or storage

instructions.

2. Labor to sharpen and/or parts to replace knife assemblies or blades which have become dull,

chipped, or worn due to normal use.

3. Material or labor to renew or repair scratched, stained, chipped, dented or discolored surfaces,

blades, knives, attachments, or accessories.

4. Transportation charges to or from an authorized service agency for repairs of a machine designated

as “CARRY IN SERVICE” (table top models). NOTE: R4N/R6N are now field service units.

5. Labor charges to install or test attachments or accessories (i.e., bowls, cutting plates, blades,

attachments) which are replaced for any reason.

6. Charges to change Direction-of-Rotation of Three Phase electric motors (INSTALLER IS

RESPONSIBLE).

7. SHIPPING DAMAGE IS NOT COVERED BY WARRANTY. Visible and hidden damages are the

responsibility of the freight carrier. The consignee must file a damage claim promptly against the

carrier, or upon discovery in the case of hidden damage.

KEEP ALL ORIGINAL CONTAINERS AND PACKING MATERIALS FOR CARRIER INSPECTION.

Robot Coupe U.S.A., Inc., Robot Coupe S.A. or any of their affiliates, distributors, officers, directors, agents,

employees, or insurers will not be obligated for consequential or other damages, losses, or expenses in connection

with or by reason of the use of or inability to use the machine for any purpose.

“NOT” COVERED UNDER WARRANTY:

THIS WARRANTY IS GIVEN EXPRESSLY AND IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED

OR IMPLIED, FOR MERCHANTABILITY AND FOR FITNESS TOWARD A PARTICULAR PURPOSE

AND CONSTITUTES THE ONLY WARRANTY MADE BY ROBOT COUPE, U.S.A., Inc.

Loading...

Loading...